Sanyo SUPER BL P5,SUPER BL PY2,SUPER BL PY User Manual

M0001584J

AC SERVO SYSTEM

BL Super Series

PY2

PY2 Servo Amplifier Instruction Manual

Released September 1999

Revision F April 2001

Revision J August 2003

SANYO DENKI CO.,LTD English

E

This product does not qualify as strategic goods as specified by the Foreign Exchange

and Foreign Trade Control Law. Accordingly, applying for an export permit from the

Ministry of Economy, Trade & Industry is not required. For customs purposes, however,

an explanation may be required. So, please ask us for the material explaining that this

product is not applicable. In addition, when this product is incorporated into other

equipment, the applicable regulations must be complied with.

i

PREFACE

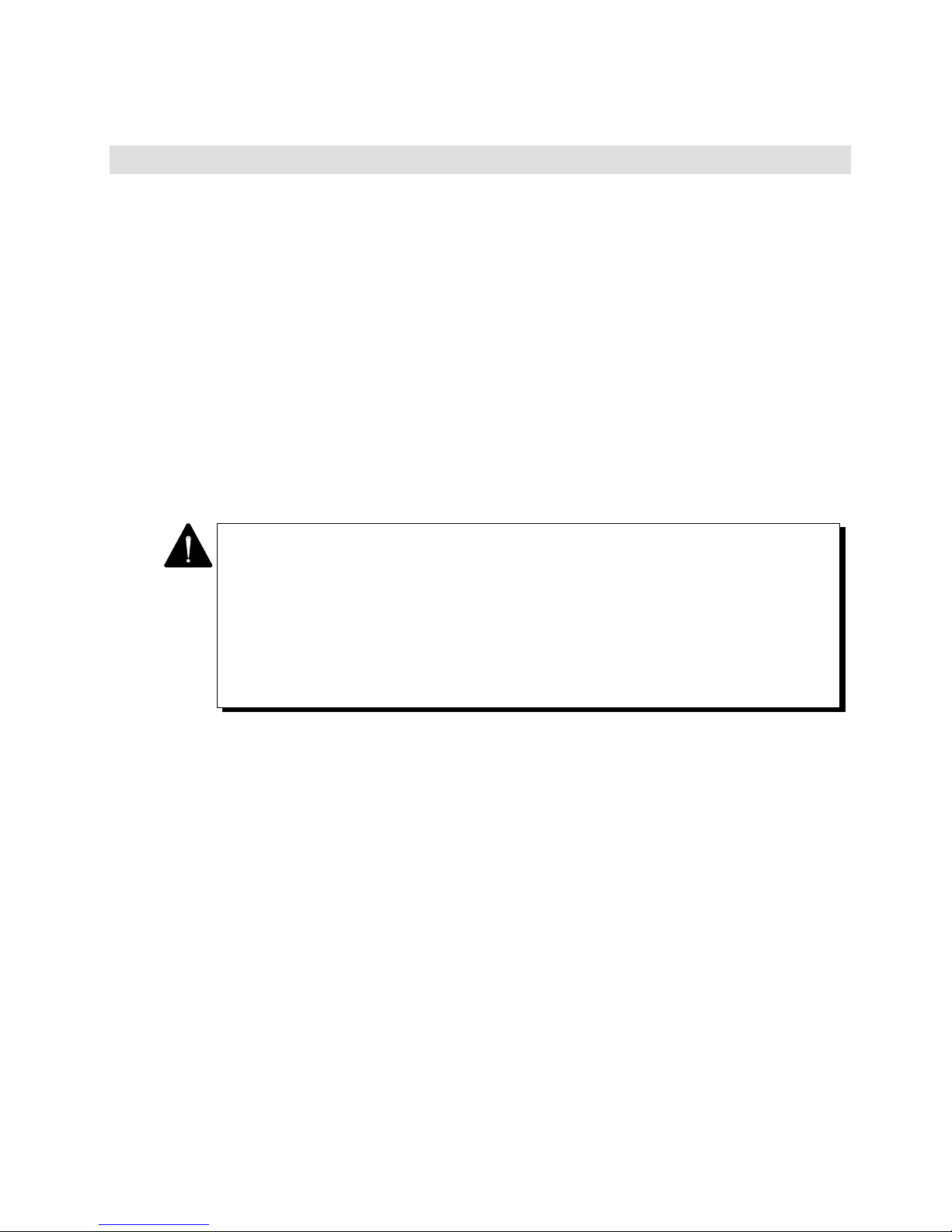

The "PY" series Servo Amplifier is applicable to a wide range of applications from small to medium

capacity thanks to its multiple functions, high performance, downsizing and high cost performance.

The "PY2" was developed as an upgraded version of this "PY" series to satisfy customer needs for

further downsizing.

The "PY2" Servo Amplifier features the same performance as the "PY" series, on which it is based,

with only the size reduced. The small and high performance "PY2" Servo Amplifier is useful for a

large number of customers in applications requiring space saving.

This User's Manual explains the functions, wiring, installation, operation, maintenance and

specifications of the "PY2" Servo Amplifies and our Servomotors.

To completely utilize all functions of the "PY2" series, read this manual carefully before use to

ensure proper operation.

After reading this manual, keep it handy so that it can be referred to by anyone at anytime.

In this manual,

"AC Servomotor" is sometimes abbreviated to "Servomotor" or "Motor".

"AC Servo Amplifiers" to "Servo Amps." or "Amps.".

Also, "Wiring-saved incremental encoders" and "Request signal-unavailable

absolute encoders" are sometimes abbreviated to "Encoders" and "Wiring-saved

incremental encoders", "Request signal-unavailable absolute encoders" and

"Request-available absolute sensors" to "Sensors".

i

International Standard Compliance

The “PY2” Servo Amplifier complies with the following International standards.

International standard Standard No.

TÜV EN50178

UL UL508C

CUL UL508C

Low Voltage Directive EN50178

EMC Directive EN55011

Working Environment

Since the working environment for the “PY2” Servo Amplifiers must be pollution level 2 or above (i.e. level 1

or 2) as specified in EN50178, be sure to use them in a pollution level 1 or 2 environment.

Power Supply

The “PY2” Servo Amplifiers must be used under the conditions specified in overvoltage category II, EN

50178. Use a reinforced insulation transformer conforming to the EN Standard for power supply input.

For the interface, use a DC power supply whose input and output sections have reinforced-insulation.

i

CE Marking

At Sanyo Denki, we are executing tests on the “PY2” Servo Amplifier for compliance with the CE marking at

qualifying institutions. The CE mark is required to be attached all end products sold in EU countries.

Only products conforming to the safety standards are permitted to have them. Accordingly, customers are

requested to perform the final conformity test on their machines or systems incorporating our amplifiers.

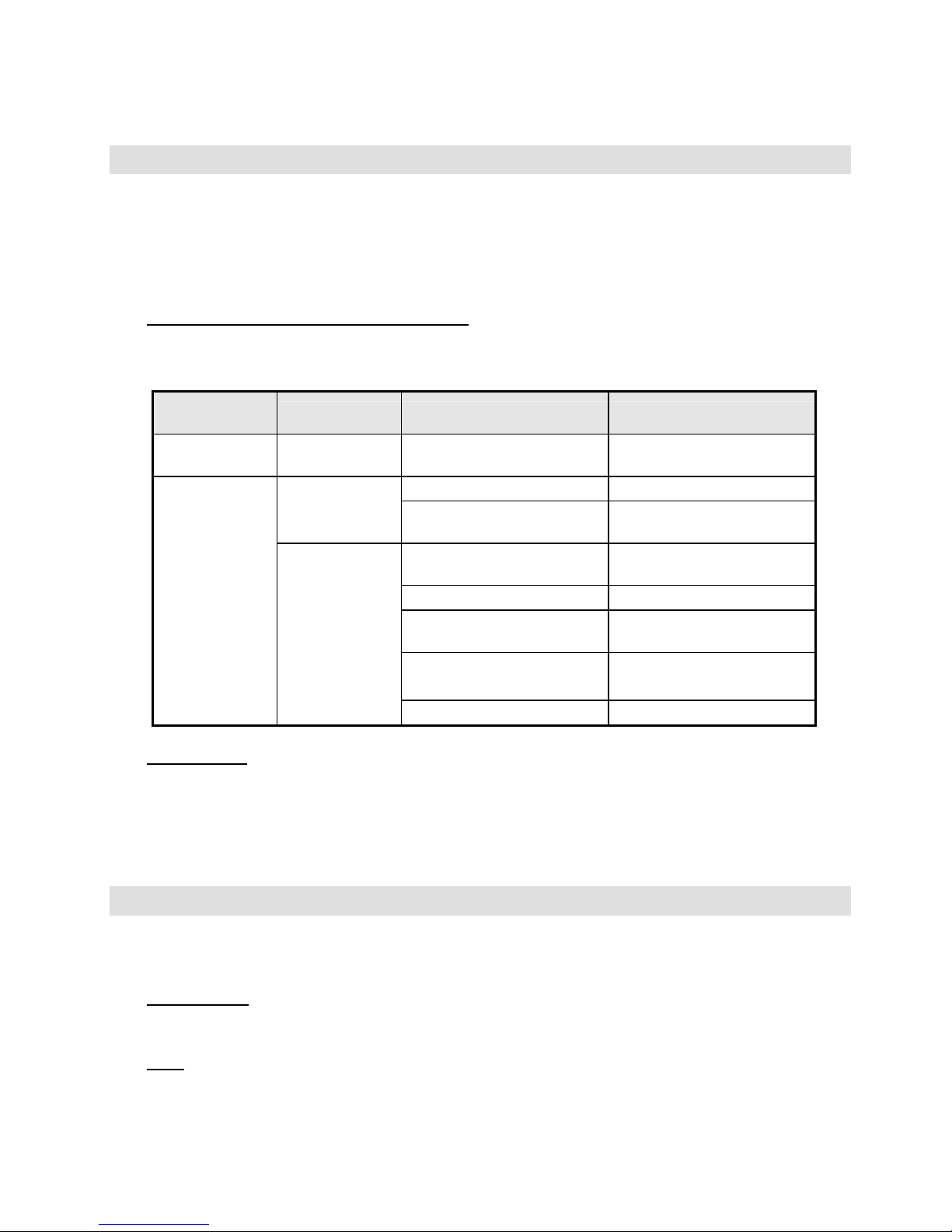

The CE Marking Conformity Standards

We execute conformity tests for the following standards on the “PY2” Servo Amplifier at qualifying

institutions.

Classification of

directive

Classification Test Test standard

Low Voltage

Directive

- - EN50178

Terminal interference voltage EN55011

Emission

Electromagnetic radiation

interference

EN55011

Radiation field immunity

EN61000-4-3 / 1996

ENV50204 / 1995

Conductivity immunity EN61000-4-6 / 1996

Electrostatic immunity

EN61000-4-2

EN61000-4-2 : A1 / 1998

Electrostatic immunity

EN61000-4-2

EN61000-4-2 : A1 / 1998

EMC Directive

Immunity

Burst immunity EN61000-4-4 / 1995

File numbers

Low Voltage Directive, Declaration : File No. C0002827C

Low Voltage Directive, Certification : File No. B 01 05 21206 040 (Messrs. TÜV PRODUCT SERVICE)

EMC Directive, Declaration : File No. C0004056

EMC Directive, Certification : File No. E9 99 05 30982 005 (Messrs. TÜV PRODUCT SERVICE)

UL Marking

The “PY2” series products are qualified to have the UL (U.S. version) and cUL (Canada version) marks of

the Underwriters Laboratories attached.

File Numbers

File No.: E179775 Power Conversion Equipment (CCN: NMMS, NMMS7)

Fuse

The “PY2” Servo Amplifiers are not equipped with fuses. Customers are requested to prepare a

UL-approved fast-blown fuse and install it in the input section of the main circuit power supply.

iv

CONTENTS

0. SAFETY PRECAUTIONS

0.1 Introduction ..................................................................................................................... 0-2

0.2 "Warning Label" Location on Product ............................................................................. 0-2

0.3 Meaning of Warning Indication ....................................................................................... 0-3

0.3.1 Details of Indications ........................................................................................... 0-3

0.3.2 Rank of Cautions on Safety................................................................................. 0-3

0.3.3 Symbolic Indication.............................................................................................. 0-4

0.4 Cautions on Safety .........................................................................................................0-5

1. BEFORE OPERATION

1.1 Precaution on Unpacking ................................................................................................. 1-2

1.2 Confirmation of the Product.............................................................................................. 1-2

1.3 Precautions on Operation................................................................................................. 1-2

1.4 How to Read Model Numbers .......................................................................................... 1-6

1.4.1 Model Number of Servomotor ............................................................................. 1-6

1.4.2 Model Number of Servo Amplifier ....................................................................... 1-7

1.5 "PY2" Servo Amplifier Standard Combination.................................................................. 1-8

1.6 Flowchart for Determining Servomotor

Model Number .................................................................................................................. 1-9

2. FUNCTION, CHARACTERISTICS AND CONFIGURATION

2.1 "PY2" Servo Amplifier Built-in Functions.......................................................................... 2-2

2.2 Characteristics of "PY2" Servo Amplifier.......................................................................... 2-6

2.3 Characteristics of Servomotor .......................................................................................... 2-11

3. SERVO SYSTEM CONFIGURATION

3.1 Block Diagram .................................................................................................................. 3-2

3.2 External Mounting and Wiring Diagram............................................................................ 3-2

3.3 Names of Servo Amplifier Parts ....................................................................................... 3-3

3.3.1 PY2A015/030 ...................................................................................................... 3-3

3.3.2 PY2E015/030 ...................................................................................................... 3-4

3.3.3 PY2A050 ............................................................................................................. 3-5

3.4 Optional Peripheral Equipment List.................................................................................. 3-6

4. WIRING

4.1 Applicable Wire Sizes.......................................................................................................4-2

4.2 Specifications of Sensor Cable ........................................................................................ 4-3

4.3 External Wiring Diagram................................................................................................... 4-4

4.3.1 External Wiring Diagram (200 VAC Input Type) ................................................. 4-4

4.3.2 External Wiring Diagram (100 VAC Input Type) ................................................. 4-6

v

4.3.3 Sensor Connection Diagram (INC-E).................................................................. 4-8

4.3.4 Sensor Connection Diagram (ABS-E) ................................................................. 4-9

4.3.5 Sensor Connection Diagram (ABS-RII) .............................................................. 4-10

4.3.6 Sensor Connection Diagram (ABS-E.S1) ........................................................... 4-11

4.4 Connector Terminal Arrangement Input/Output Signal Diagram..................................... 4-12

4.4.1 CN1: Interface Connector.................................................................................... 4-12

4.4.2 CN2: Sensor Connector ...................................................................................... 4-13

4.5 Wiring Procedure.............................................................................................................. 4-15

4.6 Precautions on Wiring ...................................................................................................... 4-16

4.6.1 Recommended Surge Protector.......................................................................... 4-17

4.6.2 CN1 & CN2 Shielding Procedure ........................................................................ 4-18

4.6.3 Typical CN2 Compression Insert Application...................................................... 4-20

5. INSTALLATION

5.1 Servo Amplifier Installation............................................................................................... 5-2

5.1.1 Installation Place ................................................................................................. 5-2

5.1.2 Installation Procedure.......................................................................................... 5-3

5.2 Servomotor Installation.....................................................................................................5-4

5.2.1 Installation Place ................................................................................................. 5-4

5.2.2 Installation Procedure.......................................................................................... 5-4

5.3 Cable Installation .............................................................................................................. 5-9

6. OPERATION

6.1 Operation Sequence......................................................................................................... 6-2

6.1.1 Power ON Sequence........................................................................................... 6-2

6.1.2 Stop Sequence .................................................................................................... 6-3

6.1.3 Servo OFF Sequence.......................................................................................... 6-5

6.1.4 Alarm Reset Sequence ....................................................................................... 6-6

6.1.5 Overtravel Sequence........................................................................................... 6-7

6.2 Display.............................................................................................................................. 6-8

6.2.1 Status Display...................................................................................................... 6-8

6.2.2 Alarm Display ...................................................................................................... 6-8

6.3 Be Sure to Check the Functioning at First ....................................................................... 6-9

6.3.1 Minimum Wiring................................................................................................... 6-9

6.3.2 Jog Operation ...................................................................................................... 6-10

6.3.3 Resetting and Turning the Power Off.................................................................. 6-12

6.4. Encoder Clear Using Remote Operator

(When Absolute Encoder is Used) ................................................................................... 6-13

7. EXPLANATION OF PARAMETERS

7.1 Remote Operator (Optional)............................................................................................. 7-2

7.1.1 Outline of Remote Operator ................................................................................ 7-2

7.1.2 Function Table..................................................................................................... 7-3

7.1.3 Basic Operation Procedure ................................................................................. 7-4

vi

7.1.4 Parameter Setting Mode

(Screen Mode 0 to 2 and 8)................................................................................. 7-5

7.1.5 Parameter Increment/Decrement Mode

(Screen Mode 3).................................................................................................. 7-8

7.1.6 Parameter Select Mode (Screen Mode 4)........................................................... 7-10

7.1.7 Monitor Mode (Screen Mode 5)........................................................................... 7-12

7.1.8 Alarm Trace Mode (Screen Mode 6)................................................................... 7-14

7.1.9 Test Mode (Screen Mode 7)................................................................................ 7-19

7.1.9.1 JOG Operation.................................................................................................. 7-18

7.1.9.2 Off Line Auto-tuning Function........................................................................... 7-20

7.1.9.3

7.2 Description of Parameters................................................................................................ 7-25

7.2.1 Block Diagram of Position, Velocity and

Torque Control Type Parameters........................................................................ 7-25

7.2.2 Parameter Summary Table ................................................................................. 7-26

7.2.3 Parameter List ..................................................................................................... 7-29

8. MAINTENANCE

8.1 Troubleshooting (Alarm)................................................................................................... 8-2

8.2 Troubleshooting (Non-Alarm) ........................................................................................... 8-20

8.3 Switching of Velocity Loop Proportional Gain Using Rotary Switch................................. 8-23

8.3.1 Overview.............................................................................................................. 8-23

8.3.2 Setting Procedure................................................................................................ 8-23

8.4 Maintenance ..................................................................................................................... 8-24

8.5 Overhaul Parts.................................................................................................................. 8-25

9. SPECIFICATIONS

9.1 Servo Amplifier ................................................................................................................. 9-3

9.1.1 Common Specifications....................................................................................... 9-3

9.1.2 Acceleration and Deceleration Time ................................................................... 9-5

9.1.3 Allowable Repetition Frequency.......................................................................... 9-6

9.1.4 Precautions on Load ........................................................................................... 9-9

9.1.5 CN1 Input/Output Interface Circuit Configuration................................................ 9-10

9.1.6 Position Signal Output ......................................................................................... 9-13

9.1.7 Monitor Output..................................................................................................... 9-17

9.1.8 Position Control Type Specifications................................................................... 9-20

9.1.9 Velocity/Torque Control Type Specifications ...................................................... 9-28

9.1.10 Switching of the Control Mode ............................................................................ 9-35

9.1.11 Internal Velocity Command ................................................................................. 9-36

9.1.12 Power Supply Capacity ....................................................................................... 9-37

9.1.13 Servo Amplifier/Servomotor Leakage Current .................................................... 9-39

9.1.14 Calorific Value ..................................................................................................... 9-40

9.1.15 Dynamic Brake .................................................................................................... 9-42

9.1.16 Regenerative Processing .................................................................................... 9-45

9.2 Servomotor ....................................................................................................................... 9-48

vii

9.2.1 Common Specifications....................................................................................... 9-48

9.2.2 Revolution Direction Specifications ................................................................... 9-49

9.2.3 Motor Mechanical Specifications......................................................................... 9-50

9.2.4 Holding Brake Specifications............................................................................... 9-53

9.2.5 Motor Data Sheet ................................................................................................ 9-55

9.3 External Views.................................................................................................................. 9-125

9.3.1 Servo Amplifier .................................................................................................... 9-125

9.3.2 Servomotor .......................................................................................................... 9-126

9.3.3 Remote Operator (Option)................................................................................... 9-140

9.4 External Regenerative Resistor (Optional) ..................................................................... 9-141

9.4.1 How to Connect and Set External Regenerative Resistor (Optional) ................. 9-141

9.4.2 External Regenerative Resistor Combination Table ......................................... 9-144

9.4.3 External Regenerative Resistor List.................................................................... 9-147

9.4.4 Detailed Connecting Methods of External Regenerative Resistor...................... 9-148

9.4.5 External Regenerative Resistor Outline Drawings.............................................. 9-149

9.5 Full Close Function (Option)............................................................................................. 9-151

9.5.1 Rough Diagram of Full Close Function (Option).................................................. 9-151

9.5.2 Hardware of Full Close Function (Option)............................................................ 9-152

9.5.3 Parameter of Full Close Function (Option) .......................................................... 9-153

10. INTERNATIONAL STANDARDS

10.1 International Standard Conformity.................................................................................... 10-2

10.1.1 Outline................................................................................................................. 10-2

10.1.2 International Standard Conformity for PYR Servo System ................................. 10-2

10.2 Cautions for International Standard Conformity ............................................................... 10-3

10.2.1 Cautions Common to UL/TUV Conformity .......................................................... 10-3

10.3 UL/cUL/TUV Standard Conformity ................................................................................... 10-4

10.3.1 UL/cUL Conformity and File Numbers ................................................................ 10-4

10.3.2 TUV Conformity and File Numbers ..................................................................... 10-5

10.4 Conformity with EC Directives.......................................................................................... 10-5

10.4.1 Outline................................................................................................................. 10-5

10.4.2 Conformity with EC Directives ............................................................................ 10-5

10.4.3 CE Marking Conformity Standard....................................................................... 10-6

10.4.4 Cautions for EMC Directive Conformity.............................................................. 10-7

11. PY PC INTERFACE

11.1 Outline of Servo Function ................................................................................................. 11-2

11.2 Control Mode Switch ........................................................................................................ 11-3

11.3 Gain Switch ...................................................................................................................... 11-4

11.4 Real Time Automatic Tuning............................................................................................ 11-5

11.5 Additional Function of Velocity Loop Proportional Gain................................................... 11-9

11.6 P-PI Control Automatic Switch ......................................................................................... 11-9

11.7 Full Close Function........................................................................................................... 11-10

0. SAFETY PRECAUTIONS

0-1

SAFETY PRECAUTIONS

0.1 Introduction ................................................................................ 0-2

0.2 "Warning Label" Location on Product ......................................... 0-2

0.3 Meaning of Warning Indication ................................................... 0-3

0.3.1 Details of Indications ......................................................... 0-3

0.3.2 Rank of Cautions on Safety............................................... 0-3

0.3.3 Symbolic Indication ........................................................... 0-4

0.4 Cautions on Safety ..................................................................... 0-5

This chapter summarizes the precautions to ensure safe operation of

the PY2 Servo Amplifier.

Be sure to read this chapter before operation.

0. SAFETY PRECAUTIONS

0-2

0.1 Introduction

The “PY2” Servo Amplifier is designed to be used for general industrial equipment. So, note the following

precautions.

• To ensure proper operation, thoroughly read the Instruction Manual before installation, wiring and

operation.

• Do not modify the product.

• For installation or maintenance, consult our dealer or authorized agency.

• When using the product for the following purposes, special measures, such as system multiplication or

emergency power generator installation, should be taken regarding operation, maintenance and

management of the product. In this case, consult us.

① Use in medical equipment affecting people's lives.

② Use in equipment that may be lead to physical injury, for example, trains or elevators.

③ Use in a computer system that may be socially or publicly influential.

④ Use in other equipment related to physical safety or equipment that may affect the functions of

public facilities.

• For use in an environment subject to vibration, for example, on-vehicle use, consult us.

Be sure to read all parts of this manual before use (installation, operation, maintenance, inspection, etc.) to

properly use the equipment and only start using it after completely understanding all aspects, safety

information and precautions relating to the equipment.

Keep this manual handy after reading it.

0.2 "Warning Label" Location on Product

The warning label is on the front upper left of the Servo Amplifier.

0. SAFETY PRECAUTIONS

0-3

0.3 Meaning of Warning Indication

This chapter explains how warnings are indicated.

Please understand the details of indications before reading 0.4 Cautions on Safety.

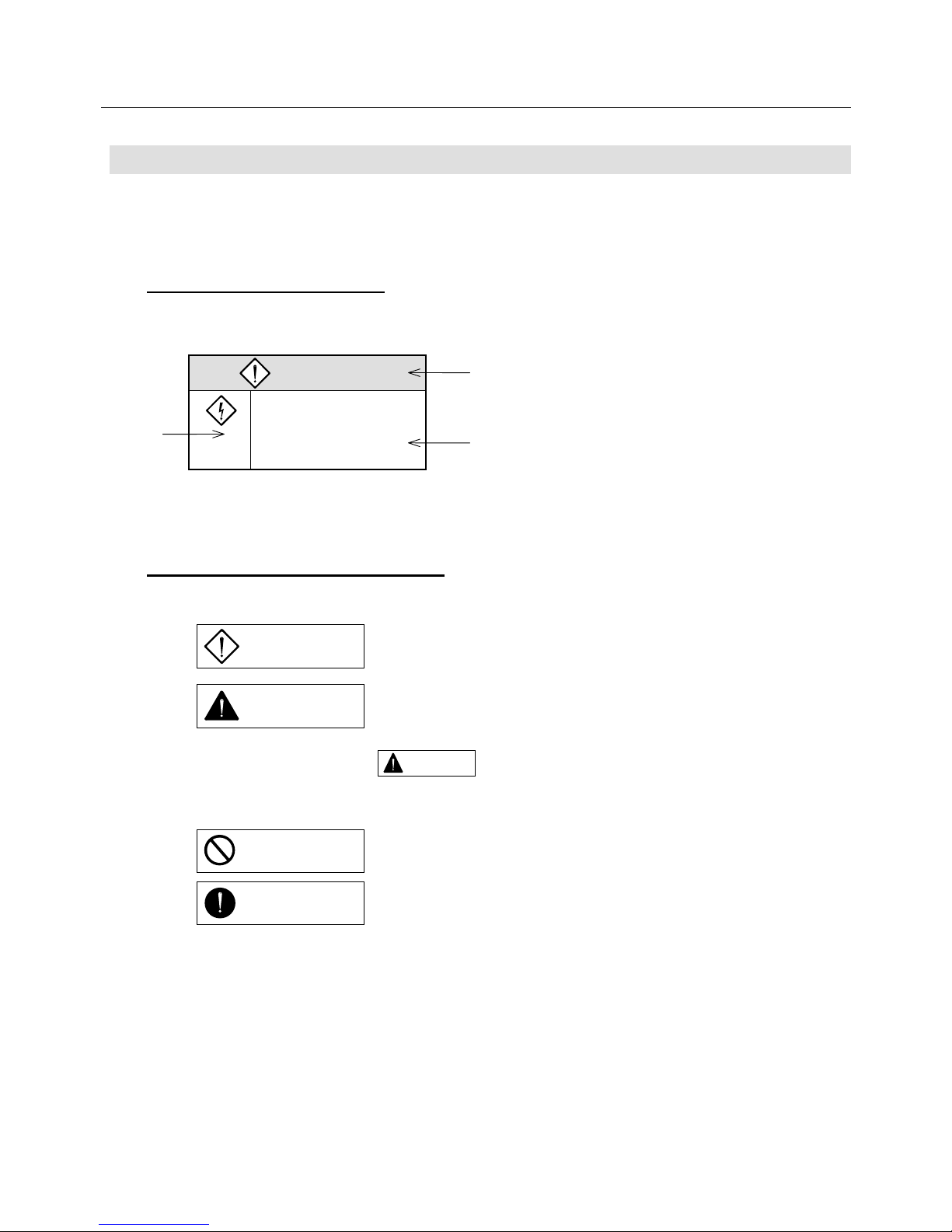

0.3.1 Details of Indications

Section 0.4 describes as follow s:

① : Rank of cautions on safety

② : Symbolic indication

③ : Meaning of each symbolic indication

0.3.2 Rank of Cautions on Safety

Cautions are divided into the following four ranks:

①

Incorrect operation may result in such a dangerous situation as

death or serious injury.

②

Incorrect operation may result in such a dangerous situation as

medium or slight injury or may result in only physical damage.

Note that some indications with may lead to serious results depending on situations.

Since any indications are important, be sure to observe them.

③ What should not be done are indicated.

④ What should be done by all means are indicated.

DANGER

1. The amplifier inside

①

②

③

DANGER

CAUTION

PROHIBITION

COMPULSION

CAUTION

0. SAFETY PRECAUTIONS

0-4

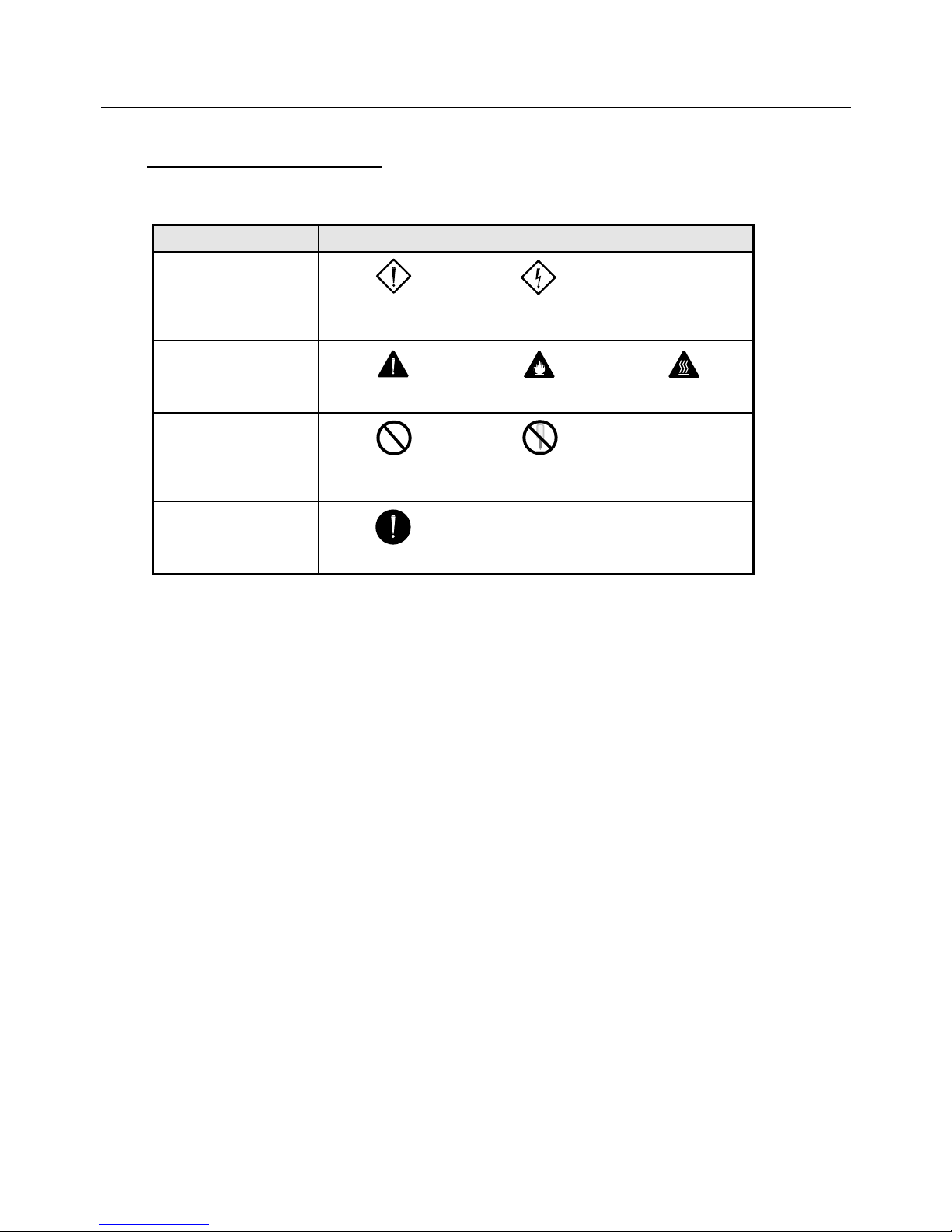

0.3.3 Symbolic Indication

Symbolic indications are divided into the following eight kinds:

Kinds of symbols Example of symbols

Symbolic indications of

danger

DANGER,

INJURY

ELECTRIC

SHOCK

Symbolic indications

calling attention

CAUTION

FIRE

BURN

Symbolic indications

prohibiting actions

PROHIBITION

PROHIBITION OF

DISASSEMBLING

Symbolic indication

urging actions

MANDATORY

0. SAFETY PRECAUTIONS

0-5

0.4 Cautions on Safety

DANGER

<General>

1. Don't operate the system in explosive environment, or you may be injured or fire

may occur.

2. Never touch any inside part of the amplifier, or you may be struck by electricity.

3. Don't arrange wires nor conduct maintenance work and inspection under a

hot-line condition.

Be sure to turn the power off more than 5 minutes in advance.

Otherwise, you may be struck by electricity.

4. Ask experts in respective fields for transportation, installation, wiring, operation,

maintenance and inspection.

Persons without expertise may receive electric shocks, be injured or fire may

occur.

<Wiring>

5. Be sure to ground the PE (protective earth) terminal of the amplifier.

The grounding terminal of the motor must be connected to the PE (protective

earth) terminal of the amplifier. Otherwise, an electric shock may occur.

6. Don't damage cable, stress them abnormally, place heavy items on them nor get

them caught between other parts or devices.

Otherwise, an electric shock may occur.

7. Be sure to connect the power cable in accordance with the connection diagram

or the User's Manual.

Otherwise, you may be struck by electricity, or fire may occur.

8. Since no fuse is built into the main power supply input terminals (R, S and T) of

the amplifier, be sure to insert a UL-approved circuit breaker or fast-blown fuse to

the amplifier power supply input wiring to protect it and its peripherals.

0. SAFETY PRECAUTIONS

0-6

DANGER

<Operation>

9. During operation, never touch the motor rotator, or you may be injured.

10. While the power is supplied, never approach nor touch terminals, or you may be

struck by electricity.

11. While the power is supplied, never remove any terminal cover, or you may be

struck by electricity.

0. SAFETY PRECAUTIONS

0-7

CAUTION

<General>

1. Before installation, operation, maintenance and inspection, be sure to read the

User's Manual and follow instructions detailed in the manual.

Otherwise, you may be struck by electricity or be injured, or fire may occur.

2. Don't use the amplifier and the motor in any situations where the specifications

are not fully satisfied.

Otherwise, you may be struck by electricity or injured, or they may be damaged.

3. Don't use the amplifier and the motor if they are damaged.

Otherwise, you may be injured or fire may occur.

4. Use the amplifier and the motor only in the combination specified, or fire or a

trouble may occur.

5. Note that the amplifier, the motor and their peripheral equipment are heated to

high temperatures.

Don't touch them, or you may be burnt.

<Unpacking>

6. Check which side is up before unpacking, or you may be injured.

7. Check if what you have received are as per your order.

Installation of an incorrect product may result in injury to you or breakage of the

product.

8. Don't apply static electricity to the motor sensor terminal, or the motor may get

out of order.

0. SAFETY PRECAUTIONS

0-8

CAUTION

<Wiring>

9. Don't measure insulation resistance and dielectric strength, or these units may

be damaged.

When you have to measure them, please contact us.

10. Arrange cables in accordance with the Technical Standard for Electric Facilities

and the Extension Rules.

Otherwise, cables may be burnt and fire may occur.

11. Arrange cables correctly and securely, or the motor may run away and you may

be injured.

12. Don't apply static electricity or high voltage to the motor sensor terminal, or the

motor may get out of order.

<Installation>

13. Don't climb up these units nor place heavy substance on them, or you may be

injured.

14. Don't stop the air inlets and outlets nor put foreign matters in them, or fire may

occur.

15. Be sure to observe the direction of installation, or a trouble will occur.

16. Decide the distances between the amplifier, the inside surface of the control

panel and other equipment in accordance with the User's Manual.

Otherwise, troubles may occur.

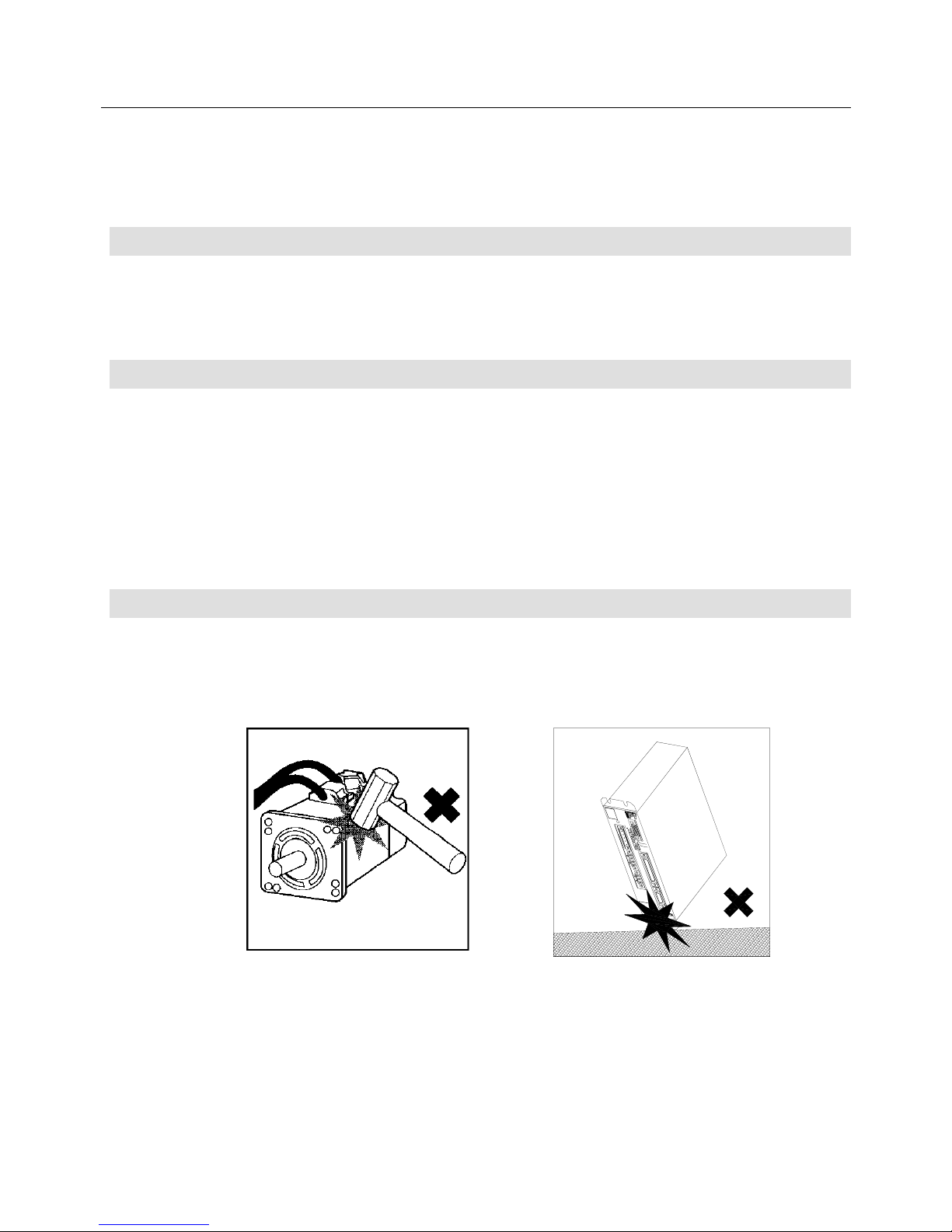

17. Don't shock these units badly, or they may be get out of order.

18. During installation, take an extreme care not to drop nor overturn these units, or

you may face serious dangers.

When raising the motor, use the lifting bolt if it is fitted.

19. Never install these units where they are exposed to splash of water, in corrosive

or inflammable gas atmosphere or near combustibles.

Otherwise, fire may occur or they may get out of order.

20. Install them to any of nonflammables like metal, or fire may occur.

0. SAFETY PRECAUTIONS

0-9

CAUTION

<Operation>

21. This motor is not equipped with any protective device.

So, protect it with an overcurrent device, an earth leakage breaker, a thermal

cutout or an emergency stop device.

Otherwise, you may be injured or fire may occur.

22. During the power is supplied or for a while after the power is turned off, don't

touch the amplifier radiator, the regenerative resistor and the motor because they

are or have been heated to high temperatures.

Otherwise, you may be burnt.

23. When any trouble has occurred, stop operating the system immediately, or you

may be struck by electricity or injured, or fire may occur.

24. An extreme adjustment change will make the system operate unstably. Never

make such a change, or you may be injured.

25. To check operation of the system in a trial run, fix the motor and separate it from

the mechanical system.

Otherwise, you may be injured.

After the trial run, mount it on the system.

26. The holding brake is not a stopping device to operate the system safely.

So, install a stopping device to the system for the purpose, or you may be

injured.

27. When an alarm occurs, remove the cause and check that the system is in safety.

Then, reset the alarm and resume the operation.

Otherwise, you may be injured.

28. When the power is restored after momentary interruption, don't approach the

system because it may suddenly start again.

(Design the system so that the operator can remain safe even if it may start

again.)

Otherwise, you may be injured.

29. Check that the power supply specification is normal.

Otherwise, troubles may occur.

0. SAFETY PRECAUTIONS

0-10

CAUTION

<Maintenance>

30. Since the amplifier frame is heated to high temperature, beware of it at the time

of maintenance and inspection, or you may be burnt.

31. The electrolytic capacitor inside the amplifier is recommended to be replaced

with a new one every five years for preventive maintenance providing that the

yearly ambient temperature is 40°C.

The expected life of the cooling fan motor is 10 years at the yearly ambient

temperature of 40°C. Regular replacement is recommended.

32. In case of repair, please contact us.

If these units are disassembled by yourself, they may malfunction.

<Transportation>

33. During transportation, take an extreme care not to drop nor overturn these units,

or you may face serious dangers.

34. During transportation, don't catch cables and the motor shaft, or these unit may

get out of order or you may be injured.

<Disposal>

35. Dispose of the amplifier and the motor as general industrial wastes.

0. SAFETY PRECAUTIONS

0-11

PROHIBITION

<Storage>

1. Don't store these units where they are exposed to water, rain drops, hazardous

gas or liquid.

Otherwise, they will get out of order.

<Operation>

2. The built-in brake of the motor is for holding and should not be used for braking

in general.

If used for braking, the brake will be broken.

<Maintenance>

3. Don't overhaul the system, or fire will occur and you will be struck by electricity.

<General>

4. Do not remove the nameplate.

0. SAFETY PRECAUTIONS

0-12

MANDATORY

<Storage>

1. Store these units where they are not exposed to direct sunlight and in the

specified ranges of temperature and humidity {–20°C to +65°C, below 90%RH

(without dew condensation)}.

2. When the amplifier was stored for a long period (over 3 years as a guide), please

contact us for how to treat it.

When it is stored for a long time, the electrolytic capacitor capacity will decrease

and any trouble may occur.

<Operation>

3. Install an emergency stop circuit outside the system so that operation can be

stopped immediately and that the power supply can be shut off.

4. When the alarm generates, assemble the safety circuit outside of the amplifier.

Running away, injury, burning, fire, and secondary damage may be caused.

5. Operate the system within the specified ranges of the temperature and humidity

(see below).

Amplifier: Temperature = 0 to 55°C, Humidity = 90% RH or lower (no dew

condensation)

Motor: Temperature = 0 to 40°C, Humidity = 90% RH or lower (no dew

condensation)

<Transportation>

6. Overloaded products will collapse.

So, load them in accordance with the indication on the outer cases.

7. Use the lifting bolts on motors for carrying motors only and don't use them for

carrying machines.

1. BEFORE OPERATION

1-1

BEFORE OPERATION

1.1 Precaution on Unpacking ............................................................. 1-2

1.2 Confirmation of the Product .........................................................1-2

1.3 Precautions on Operation ............................................................ 1-2

1.4 How to Read Model Numbers...................................................... 1-6

1.4.1 Model Number of Servomotor ........................................... 1-6

1.4.2 Model Number of Servo Amplifier ..................................... 1-7

1.5 PY2 Servo Amplifier Standard Combination ................................ 1-8

1.6 Flowchart for Determining Servomotor

Model Number ............................................................................. 1-9

1. BEFORE OPERATION

1-2

Please operate this system taking the contents of the following description into consideration.

A misoperation will lead to an unexpected accident or damage.

1.1 Precaution on Unpacking

When unpacking this product after purchasing, care is needed to the following.

• When unpacking the Servo Amplifier, don't touch its printed circuit boards in any case.

1.2 Confirmation of the Product

Check the following after receiving the product. Contact us if any abnormality is detected.

• Check if the model numbers of the Servomotor and the Servo Amplifier match those of the ordered ones

(the numbers are described after "MODEL" on the main nameplate).

• Check the appearance of the Servomotor and the Servo Amplifier to confirm that they are free from any

abnormality such as breakage or lack of parts.

• Check that all screws on the Servomotor and the Servo Amplifier are tightened properly.

1.3 Precautions on Operation

Take care the following during operation.

• At installation, don't give shocks to the Servomotor and the Servo Amplifier, or they may break.

In particular, handle the Servomotor carefully since it is provided with a sensor.

1. BEFORE OPERATION

1-3

• Be sure to use a power supply within the specified range.

200 VAC input type: PY2A…, PY2B…

200 VAC to 230 VAC (+10%, −15%) 50/60 Hz

100 VAC input type: PY2E…, PY2F…

100 VAC to 115 VAC (+10%, −15%) 50/60 Hz

If a power supply other than the above is used, an accident may result.

• When a surge voltage is produced in the power supply, connect a surge absorber or others between the

powers to absorb the voltage before operation.

Otherwise malfunction or breakage may result.

• Turn the power on and off during maintenance and inspection after safety (such as the situation of the

load) is completely checked. If the power is turned on or off during the load is applied, an accident or

breakage may result.

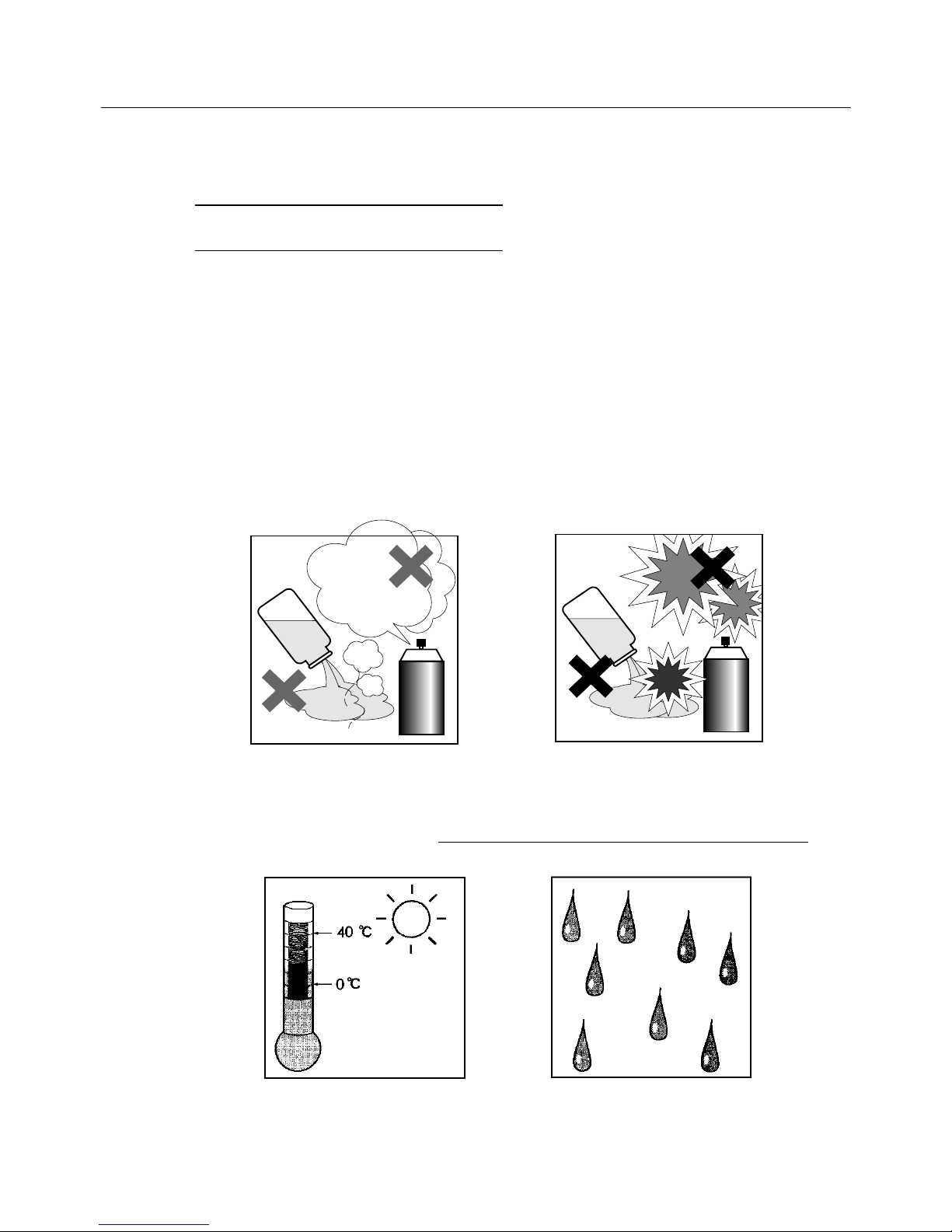

• Never use this product where corrosive (acid, alkali, etc.), flammable or explosive liquid or gas exists to

prevent it from deforming or breaking.

• Never use this product where flammable or explosive liquid or gas exists since the liquid or the gas may

be ignited, causing great danger.

Corrosives

Gas

Acid/Alkali

Flammables

Explosives

• Use this product within the ambient temperature range from 0°C to 40°C (0°C to 55°C for the Servo

Amplifier) and below the relative humidity limit of 90%.

• The Servomotor and the Servo Amplifier should be kept away from water, cutting fluid or rainwater

.

Otherwise electric leakage or and electric shock may result.

1. BEFORE OPERATION

1-4

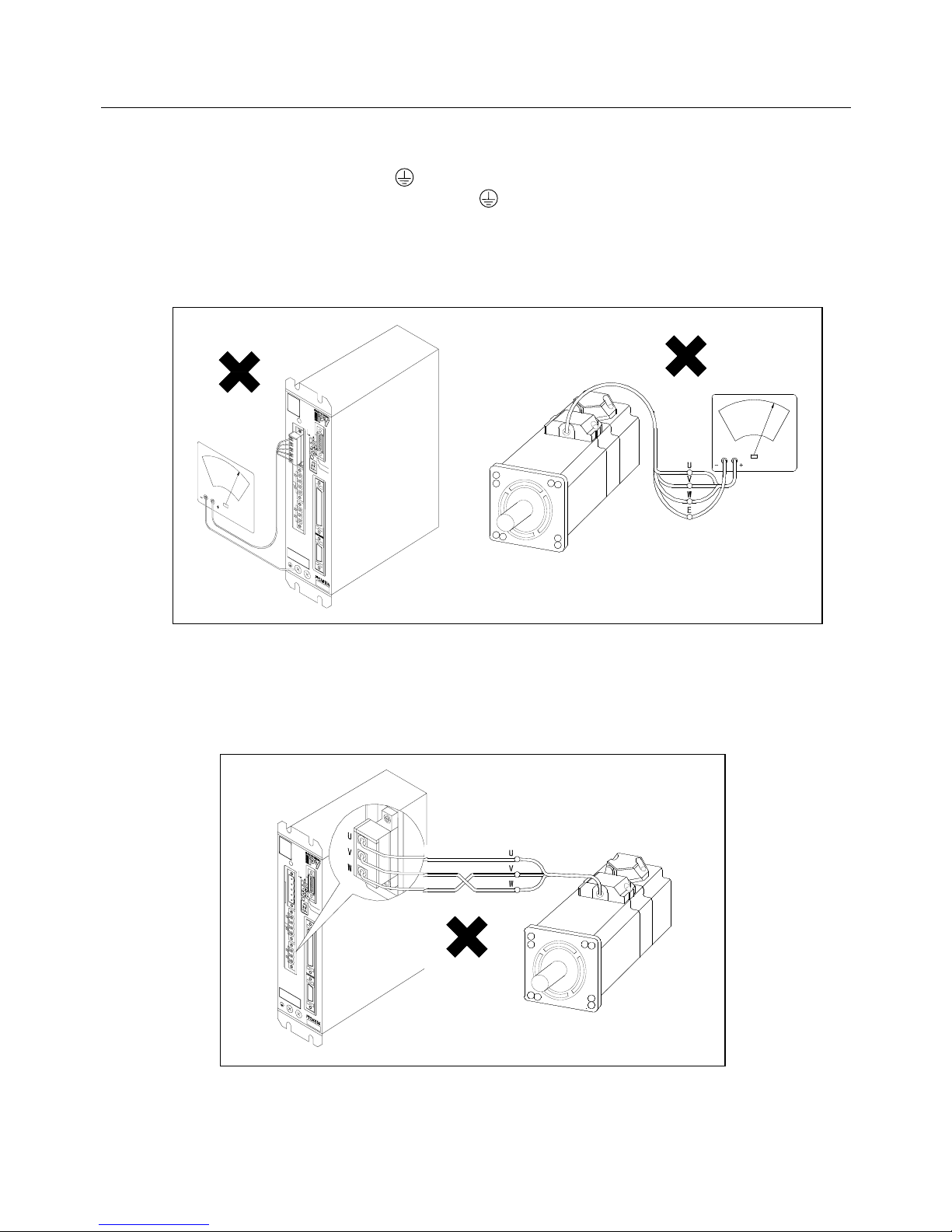

• For operating safety, check that the Servo Amplifier is grounded by at least a class 3 (less than 100Ω) of

the PE (protective earth) terminal . In addition, the grounding terminal of the Servomotor must be

connected to the PE (protective earth) terminal .

• Never perform a withstand voltage or a megger test of the Servomotor or the Servo Amplifier.

In this product, 0V and the main body is earthed by the capacitor.

If such test is necessary, consult with us.

• Perform correct wiring by referring to the chapter "4. Wiring".

Wrong wiring may cause Servomotor's or amplifier's breakage.

• Since the "P" series Servomotor is not an induction motor, the direction of revolution cannot be changed

by swapping the phases.

To change the direction, use the remote operator.

• For safety operation, be sure to install a surge absorber on the relay, electromagnetic contactor,

induction motor and brake solenoid coils.

1. BEFORE OPERATION

1-5

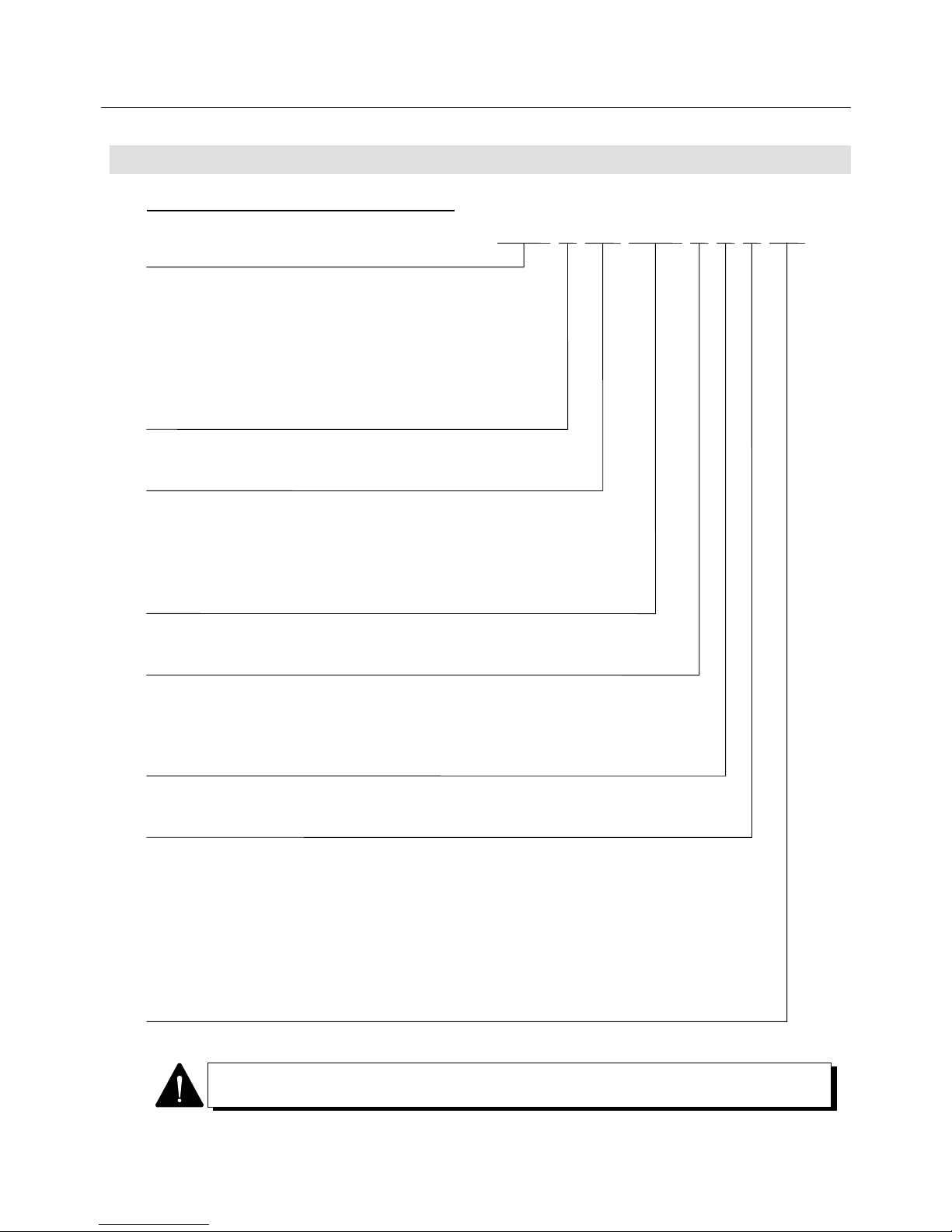

• Connect a power supply within the specified range to the Servo Amplifier’s R, S, T terminals respectively.

When a power supply out of the specified range is used, install a transformer.

If a commercial power supply is applied to the U, V or W terminal, the amplifier will break.

Commercial

power supply

1. BEFORE OPERATION

1-6

1.4 How to Read Model Numbers

1.4.1 Model Number of Servomotor

1. BL series

P10...P1 series

P20...P2 series

P30...P3 series

P50...P5 series

P60...P6 series

P80...P8 series

2. Indicates the BL motor

3. Indicates flange square size

03…35 mm 04…40 or 42 mm 05…54 mm

06…60 mm 07…76 mm 08…80 or 86 mm

13…130 mm 15…150 mm 18…180 mm

22…220 mm

4. Indicates rated output

○○○ = ○○○ × 10 w

5. Maximum revolution speed

S…1000 min

−

1

M…1500 min

−

1

B…2000 min

−

1

R…2500 min

−

1

H…3000 min

−

1

D…4500 min

−

1

P…4500 min

−

1

6. Equipping of holding brake

X…Not equipped. B…Equipped. (90V) C…Equipped. (24V)

7. Type of detector

S… Wiring-saved incremental encoder

J… Absolute encoder with the motor flange square of 60 mm or less;

Request signal-unavailable type.

A… Absolute encoder with the motor flange square of 76 mm or more;

Request signal-unavailable type.

N... ABS-RII; Super-capacitor-unavailable, request signal-available type.

V... ABS-RII; Super-capacitor-built-in, request signal-available type.

8. Specification identification

00… Standard motor

B

○○○ ○○○ △ □ ◇○○ ▽▽

The design revision order is indicated by an alphabet at the end of Lot No. on the

nameplate.

1. BEFORE OPERATION

1-7

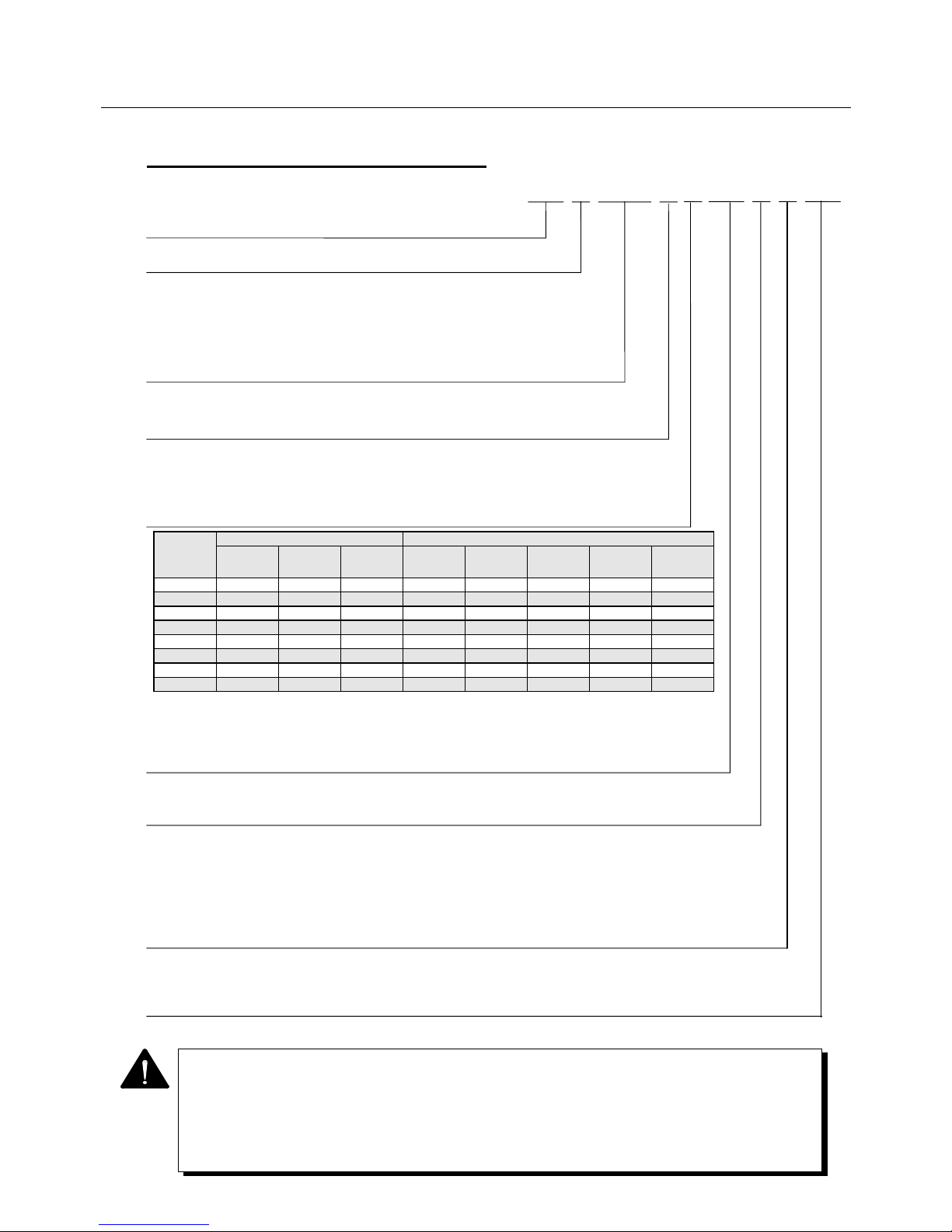

1.4.2 Model Number of Servo Amplifier

1. Indicates a PY2 servo amplifier

2. Type of power unit

A… For 200 VAC input, with dynamic brake

B… For 200 VAC input, without dynamic brake

E… For 100 VAC input, with dynamic brake

F… For 100 VAC input, without dynamic brake

3. Amplifier capacity

015… 15A 030… 30A 050...50A

4. Hardware type of control unit

A... Wiring-saved incremental encoder (INC-E) or request

signal-unavailable absolute encoder (ABS-E)

H... Request signal-available absolute sensor (ABS-RII)

P… Wiring-saved absolute sensor (ABS-E.S1)

5. Optional specifications of power supply input and power sections

6. Applicable motor

(For details, refer to the standard combination table on the next page. )

Example M1…P50B03003D□□□□ PA…P60B13050H□□□□

7. Type of applicable sensor

1... Wiring-saved incremental encoder (2000P/R)

2... Wiring-saved incremental encoder (6000P/R)

3... Request signal-unavailable absolute encoder (ABS-E, 2048P/R)

6... Request signal-available absolute encoder (ABS-RII, 8192P/R)

W…Wiring-saved absolute sensor (ABS-E.S1, 32768 dividing)

8. Interface specification

S…Speed control type. T…Torque control type. P…Position control type.

X…S-T switch type Y…P-T switch type U…P-S switch type V…Internal Speed control type

9. Discrete specification

00… Standard product

00

▽△

XX 0

PY2

○○○□

A

• The design revision order is indicated by an alphabet at the end of Lot No. on the

nameplate.

• In some Servo Amplifiers, the items 6 to 9 above are not specified. Servo Amplifiers

having the following model numbers can be used after specifying the parameters such as

motor, sensor and interface.

PY2A015A2 PY2A030A2 PY2A050A6 PY2E015A3 PY2E030A3

Model code Contents of specifications Support by power section type and amplifier capacity *3

Built-in

regenerative

resistor *1

RDY output

*2

Main circuit

power supply

type

PY2A015 PY2A030 PY2A050 PY2E015 PY2E030

0 × ○ 3-phase ○ ○ × × ×

1 × ○ Single phase ○ ○ × ○ ○

2 × × 3-phase ○ ○ × × ×

3 × × Single phase ○ ○ × ○ ○

4 ○ ○ 3-phase △ *4 ○ ○ × ×

5 ○ ○ Single phase △ *4 ○ ○ △*4 ○

6 ○ × 3-phase △ *4 ○ ○ × ×

7 ○ × Single phase △ *4 ○ ○ △*4 ○

*1: Built-in regenerative resistor: ○= with built-in regenerative resistor, ×= without built-in regenerative resistor

*2: RDY output: ○= with RDY output, ×= without RDY output

*3: Support by power section type and amplifier capacity ○= supportive, ×= not supportive

*4: For 15A regenerative resistor built-in type, configuration (dimension) of Amp. partially differs from standard.

1. BEFORE OPERATION

1-8

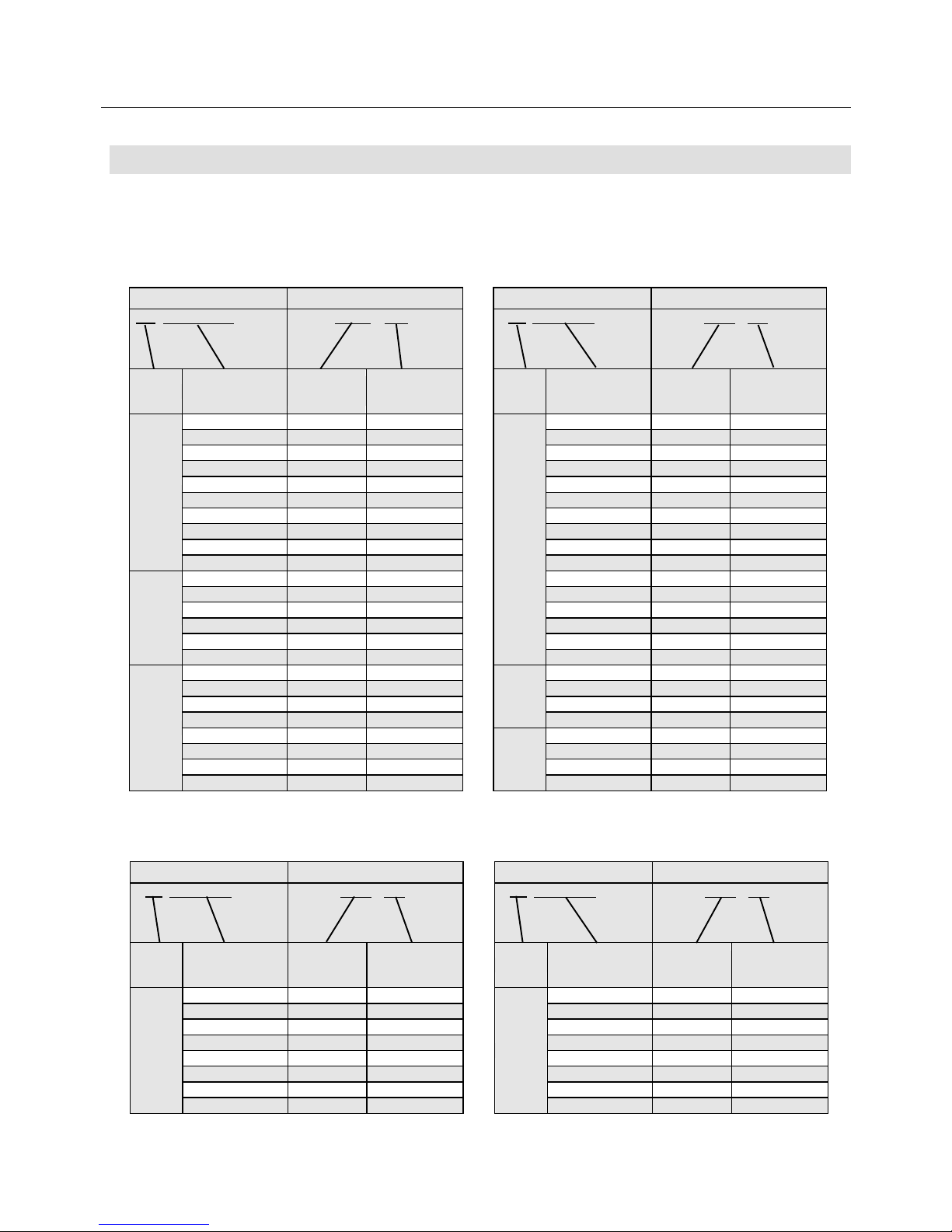

1.5 "PY2" Servo Amplifier Standard Combination

Check the model numbers of the motor and the amplifier on the combination table below.

If the combination is different, the system will not function properly.

Table1-1 "PY2" Servo Amplifier Standard Combination Table (200 VAC input type)

Table1-2 "PY2" Servo Amplifier Standard Combination Table (100 VAC input type)

Servomotor Servo Amplifier

P☆B○○○○○○□◇▽▽

PY2A○○○A2XX△▽00

Series

Flange square

Rated output

Maximum speed

Amplifier

capacity

Motor type

03003D 015 M1

04006D 015 M2

04010D 015 M3

05005D 015 M4

05010D 015 M5

05020D 015 M6

07020D 015 M8

07030D 015 M9

07040D 030 MA

08040D 030 MB

08050D 030 MC

08075D 050 MD

08100D 050 ME

08075H 030 MF

08100H 030 MG

P50

13050H 030 PA

13100H 050 P1

13150H 050 P2

P60

15075H 030 R2

18120H 050 R3

P80

Servomotor Servo Amplifier

P☆B○○○○○○□◇▽▽

PY2A○○○A2XX△▽00

Series

Flange square

Rated output

Maximum speed

Amplifier

capacity

Motor type

10030H 030 11

10075H 030 12

13050H 030 13

13100H 050 14

13150H 050 15

13050B 030 1A

13100B 030 1B

13150B 050 1C

18200B 050 1D

P10

10100D 050 21

10150D 050 22

10100H 030 28

10150H 050 29

10200H 050 2A

P20

04003D 015 N1

04005D 015 N2

04010D 015 N3

06020D 015 N4

06040D 030 N5

08075D 030 N6

P30

Servomotor Servo Amplifier

P☆B○○○○○○□◇▽▽

PY2E○○○A3XX△▽00

Series

Flange square

Rated output

Maximum speed

Amplifier

capacity

Motor type

03003P 015 MH

04006P 015 MJ

04010P 015 MK

05005P 015 ML

05010P 015 MM

05020P 030 MN

07020P 030 MR

P50

07030P 030 MS

Servomotor Servo Amplifier

P☆B○○○○○○□◇▽▽

PY2E○○○A3XX△▽00

Series

Flange square

Rated output

Maximum speed

Amplifier

capacity

Motor type

04003P 015 NA

04005P 015 NB

04010P 015 NC

06020P 030 ND

P30

1. BEFORE OPERATION

1-9

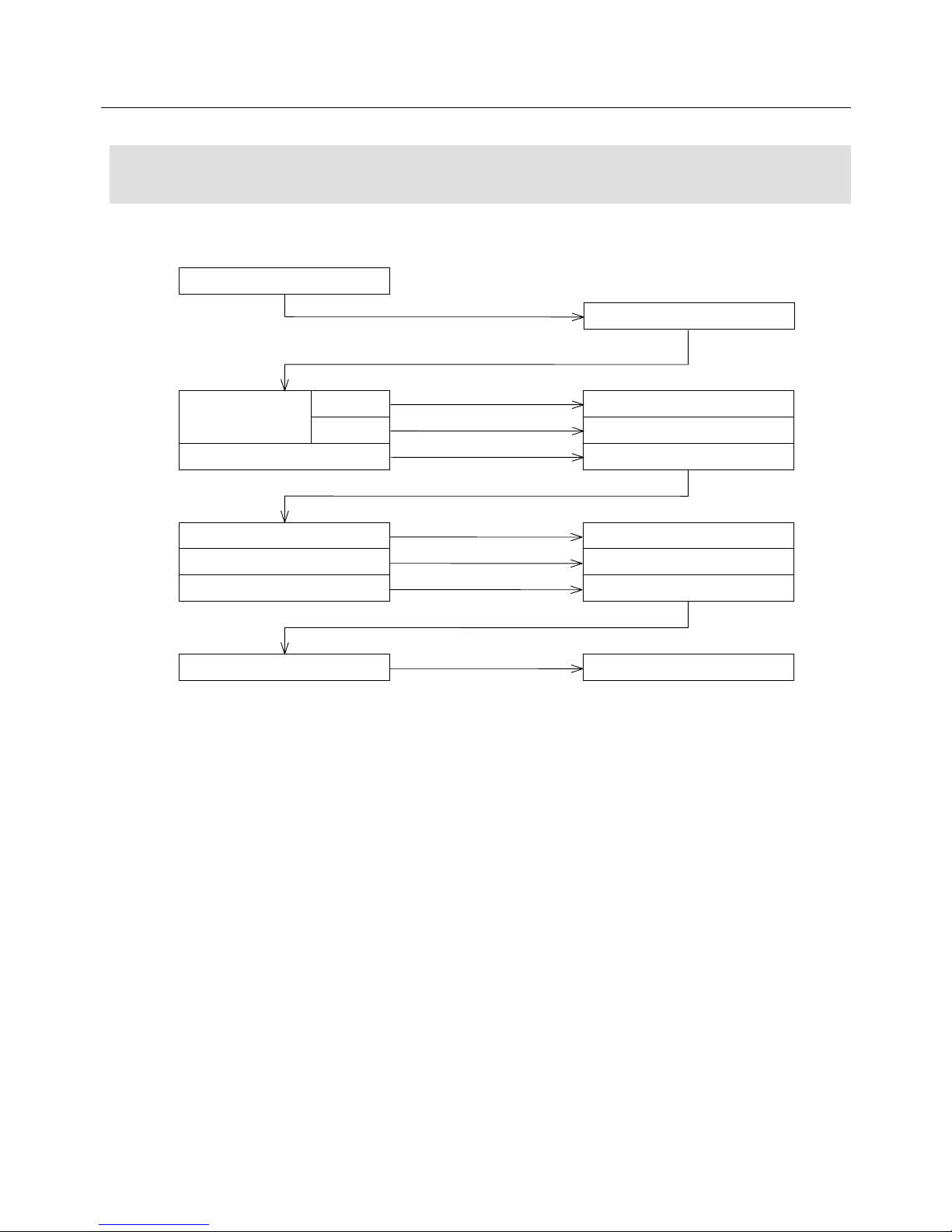

1.6 Flowchart for Determining Servomotor

Model Number

Refer to the following flowchart to determine the Servomotor model number.

Select Servomotor capacity.

With brake

90 V

24 V

Without brake

Determine capacity and

maximum speed.

Add B to the end.

Add C to the end.

Add X to the end.

P50B08100D

P50B08100DB

P50B08100DC

P50B08100DX

P50B08100DXS

P50B08100DXA

P50B08100DXS00

P50B08100DXN

Incre. 2000P/R

Standard specifications

Absol. 2048 divisions

ABS-RII 8192 divisions

Ex.

Ex. Sensor type

Add S to the end.

Add 00 to the end.

Consult with us for special

requirements.

Add A to the end.

Add N to the end.

Loading...

Loading...