Page 1

OWNER’S MANUAL

W

W

PACKAGED TERMINAL AIR CONDITIONER

STW-2 Series

Operating Instructions

Contents

Page

Alert Symbols........................................................... 1

Installation Location ................................................ 2

Electrical Requirements .......................................... 2

Safety Instructions................................................... 2

Names of Parts......................................................... 2

Control Panel and Operation Functions................ 2

Installation Instructions

Front Grille................................................................ 3

Other Features .......................................................... 3

Care and Cleaning.................................................... 4

Tips for Energy Saving............................................ 5

Troubleshooting....................................................... 5

Cool / Heat Model

Contents

Page

IMPORTANT!

Please Read Before Starting................................... 6

1. NAMES OF PARTS............................................. 7

2. WALL CASE AND REAR GRILLE..................... 7

3. INSTALLATION................................................... 7

4. PERMANENT CONNECTION ............................. 8

4-1. For 230/208V Units...................................... 8

4-1-1. Preparation........................................ 8

4-1-2. Installation.......................................... 8

4-2. For 265V Units............................................. 8

4-2-1. Preparation........................................ 8

4-2-2. Installation.......................................... 8

5. AIR LOUVERS.................................................... 9

6. TEMPERATURE LIMITING................................. 9

7. REMOTE CONTROL ........................................ 10

8. FRONT DESK CONTROL ................................ 10

PRODUCT INFORMATION............................... 11

85164119653000 © SANYO 2001 SANYO Electric Co., Ltd.

Power Source:

60 Hz, single-phase, 230/208V & 265V

Alert Symbols

The following symbols used in this manual alert you to potentially dangerous conditions to users, service personnel or the appliance:

WARNING

CAUTION

Model No.

STW-2 Series

This symbol refers to a hazard or

unsafe practice which can result in

severe personal injury or death.

This symbol refers to a hazard or

unsafe practice which can result in

personal injury or product or property damage.

Osaka, Japan

Page 2

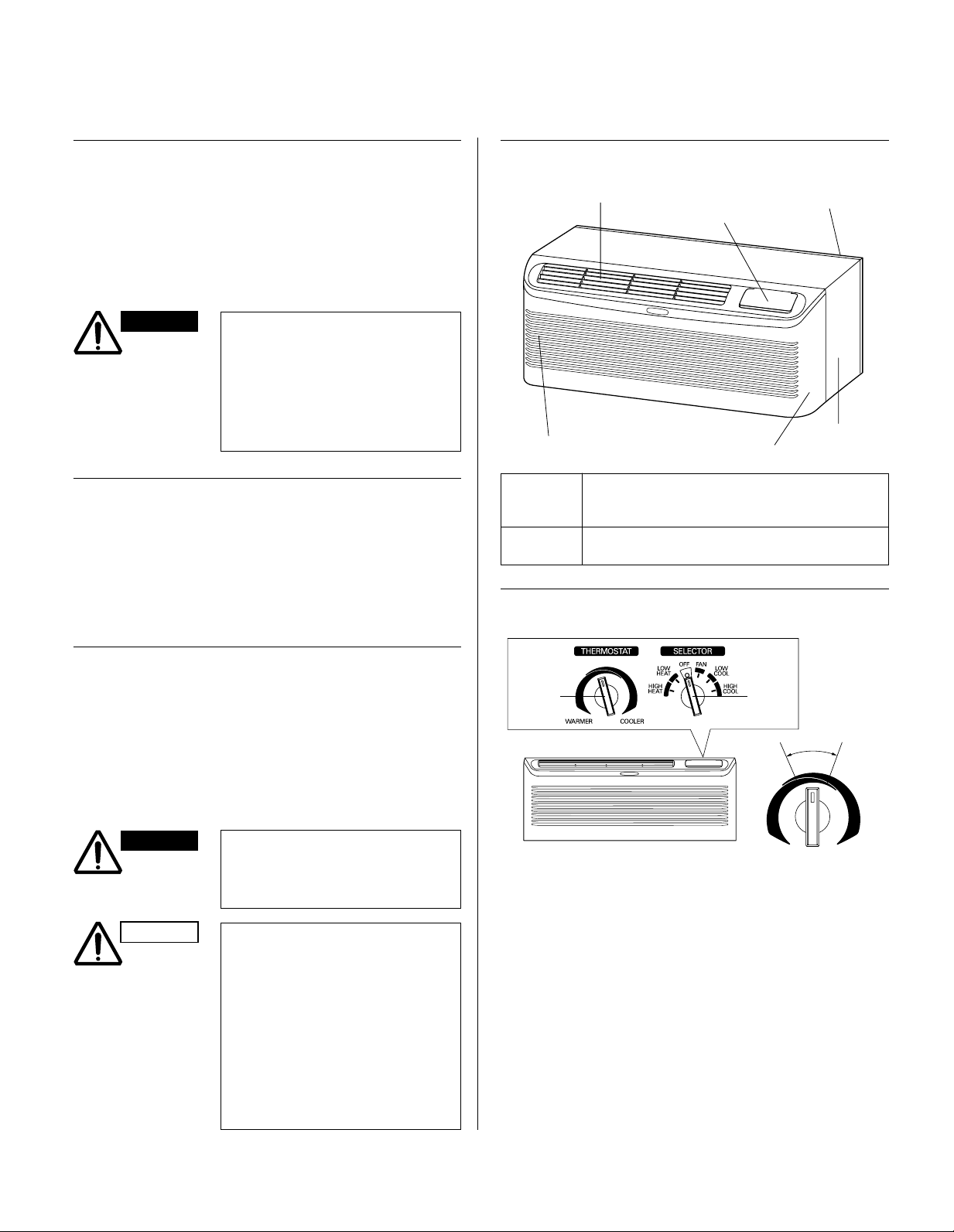

Air outlet

Wall case

Cover switch and

control panel

Air intake

Front grille

Rear grille

WARMER

COOLER

r

a

n

g

e

I

n

t

e

r

m

e

d

i

a

t

e

7

2

°

F

(88°F)

(55°F)

Thermostat

Mode

selector

OPERATING INSTRUCTIONS

Installation Location

• We recommend that this air conditioner be installed

properly by qualified installation technicians in accordance with the Installation Instructions provided with

the unit.

• Before installation, check that the voltage of the electric

supply in your home or office is the same as the voltage

shown on the nameplate.

WARNING

• Do not install this air conditioner

where there are fumes or flammable gases, or in an extremely

humid space such as a greenhouse.

• Do not install the air conditioner

where excessively high heatgenerating devices are placed.

Electrical Requirements

1. All wiring must conform to the local electrical codes.

Consult your dealer or a qualified electrician for details.

2. Each unit must be properly grounded with a ground (or

earth) wire or through the supply wiring.

3. Wiring must be done by a qualified electrician.

4. Never use an extention cord with this air conditioner.

Names of Parts

Air Intake Air from the room is drawn into this section

and passes through air filters which remove

dust.

Air Outlet Conditioned air is blown out of the air con-

ditioner through the air outlet.

Control Panel and Operation Functions

Safety Instructions

• Read this Instruction Manual carefully before using this

air conditioner. If you still have any difficulties or problems, consult your dealer for help.

• This air conditioner is designed to give you comfortable room conditions. Use this only for its intended

purpose as described in this Instruction Manual.

• Avoid letting cooled/heated air blow directly on your

body for a long time.

WARNING

CAUTION

• Never use or store gasoline or

other flammable vapor or liquid

near the air conditioner — it is

very dangerous.

• Do not turn the air conditioner

on and off from the power

mains switch. Use the mode

selector switch.

• Do not stick anything into the

air outlet of the unit. This is dangerous because the fan is rotating at high speed.

• Do not let children play with the

air conditioner.

• Do not cool or heat the room

too much if babies or invalids

are present.

Thermostat Control

The thermostat knob is used to control the room temperature. The unit automatically cycles on and off to maintain

room temperature. A comfortable temperature will be

maintained in most rooms when the control is set to

about intermediate range.

Mode Selector

HI HEAT provides heating with high fan speed operation.

LOW HEAT provides heating with low fan speed operation.

OFF setting stops heating or cooling operation.

FAN provides fan operation without cooling or heating.

LO COOL provides cooling with low fan speed operation.

HI COOL provides cooling with high fan speed operation.

∗ As long as power is connected to the unit, Freeze

Protection always functions at any position even at OFF

position.

2

Page 3

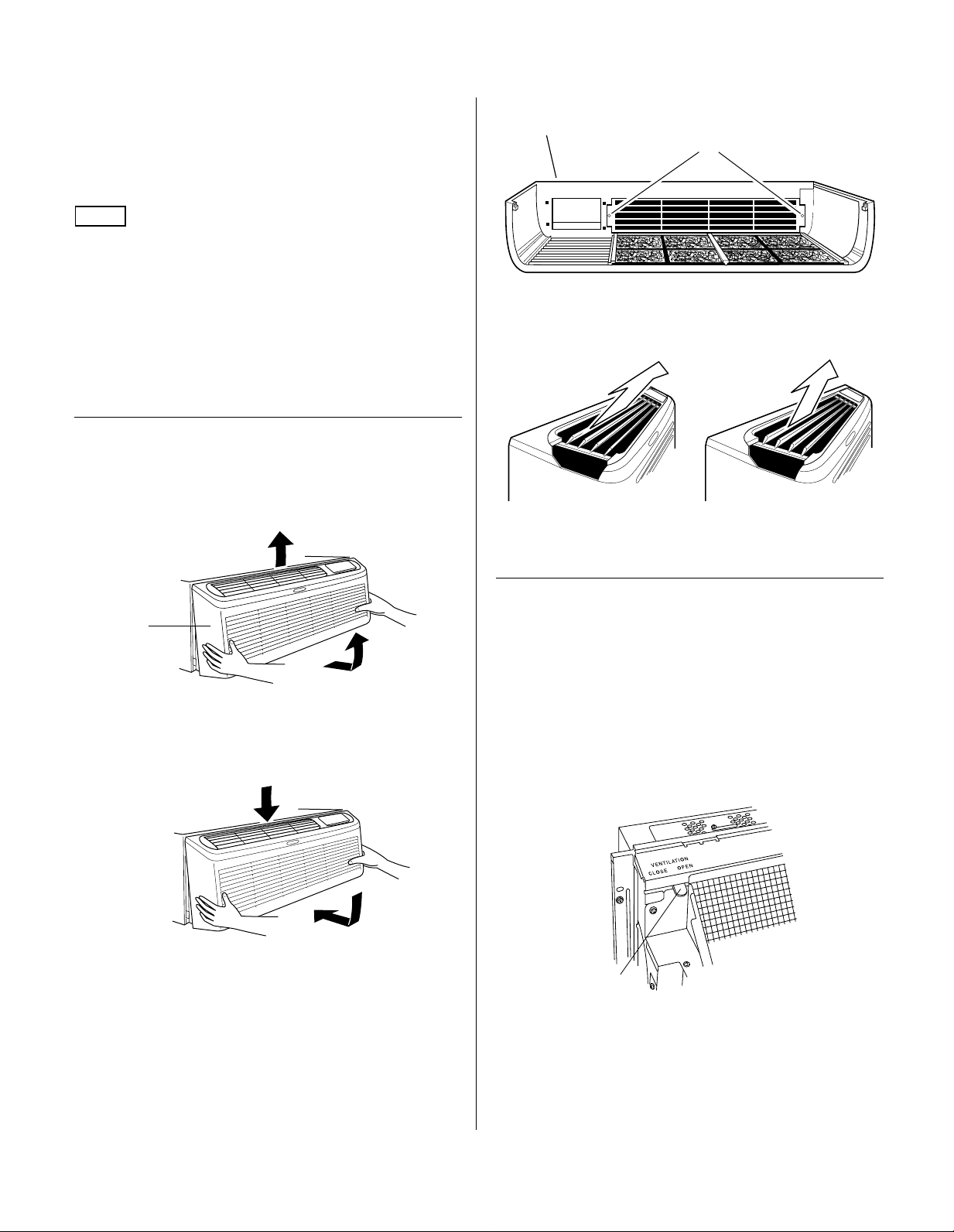

Operation:

NOTE

1

2

Front grille

1

2

Front grille

Louver screws

37° OFF VERTICAL 20° OFF VERTICAL

Ventilation control lever

1. Set the mode selector for fan, cooling or heating operation.

2. Set the thermostat to the desired position. (Refer to the

Setting Temperature Guide on page 2.)

The temperatures at the Setting Temperature Guide on

Page 2 are provided for reference only, and may differ

from the actual temperature of the room.

How to stop the air conditioner:

Set the mode selector to OFF position.

How to restart the air conditioner:

Set the mode selector to the desired position.

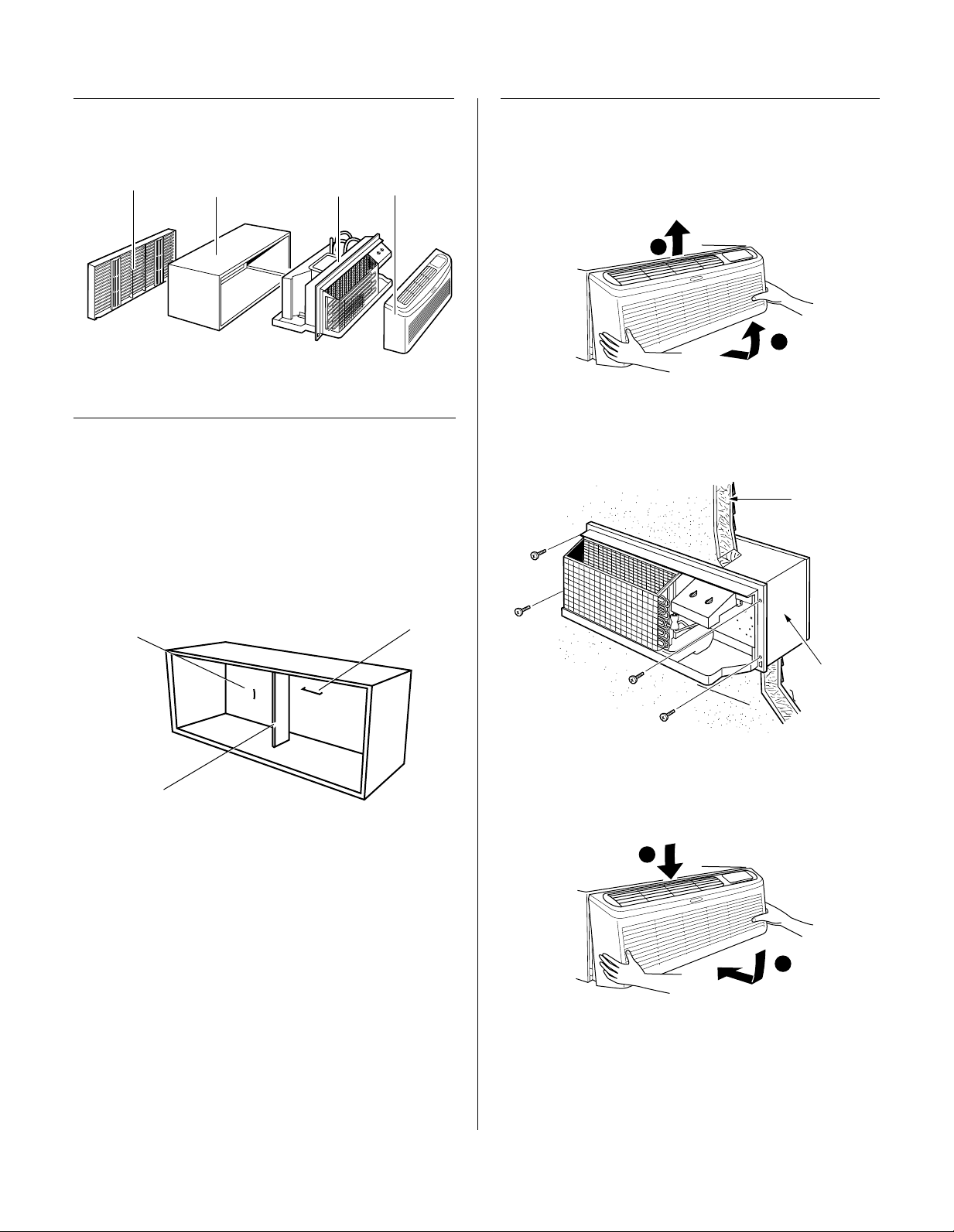

Front Grille

To remove:

Additional controls are located behind the front grille.

Pull out to release it from the tabs. Then lift up.

The direction of the heated or cooled air may be adjusted

by removing and turning the louvers around.

To reinstall:

Place the tabs over the top rail. Push inward until it snaps

into place.

Air Louvers

To change the louver direction, remove the front grille and

2 louver screws that hold the louvers in place. Turn the

louver section 180° (end for end), replace the screws and

replace the front grille. The textured face of the louver

section must be facing toward the room side.

Other Features

Ventilation Control

The ventilation control lever is located at the upper left

side of the unit, behind the front grille.

This knob is set to CLOSE at the factory. When in this

position, the vent door is closed and only indoor air is circulated by the air conditioner. Switching the knob to

OPEN opens the vent door to allow outdoor air to enter

the room. However, leaving the vent door at OPEN

reduces heating or cooling effectiveness and increases

operating costs.

Remote Control

Remote controlling is available with the optional Class 2

Remote Controller and Interface kit. See the Installation

Instructions.

3

Page 4

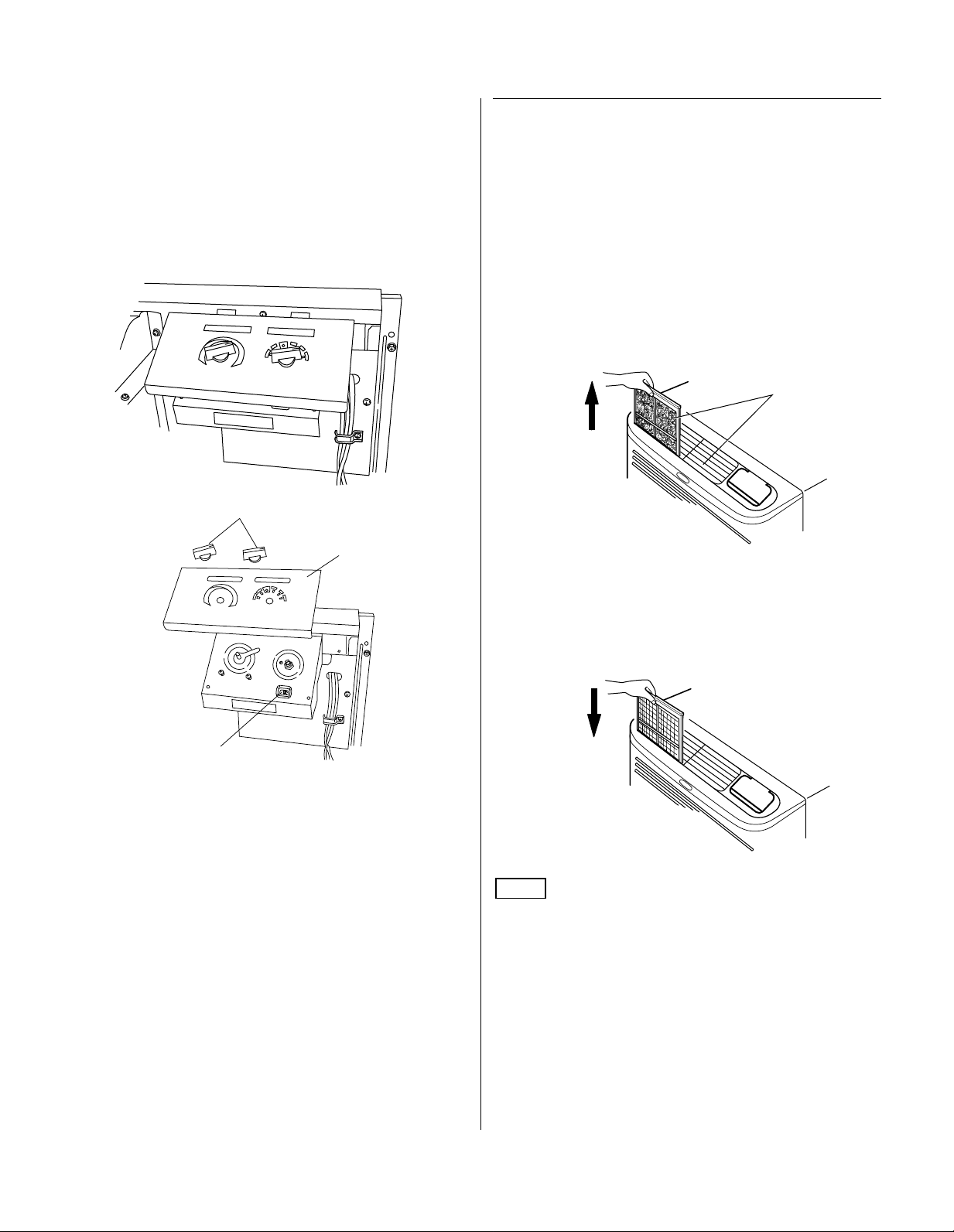

Fan Cycle Switch

THERM

O

STAT

WARMER COOLER

SELECTOR

OFF FAN

LOW

LOW

HEAT

COOL

COOL

HEAT

HIGH

HIGH

Pull up

2 air filters

Front

Push

down

NOTE

W

A

R

M

ER

COOLER

CONT

CYCLE

HEAT

HIGH

H

E

A

T

LO

W

OFF

F

A

N

LO

W

C

O

O

L

HIG

H

C

O

O

L

THERMOSTAT

SELECTOR

Knob

Control panel

Fan cycle switch

The Fan Cycle Switch is located under the control panel

behind the front grille. This switch is set to CONT at the

factory to provide continuous fan operation in cool or

heat modes. Leaving the switch at the CONT setting

allows continuous circulation of room air and will keep

the room temperature at stable condition. If you want the

fan to cycle on and off with the compressor or electrical

heater, set the switch to CYCLE.

Care and Cleaning

Turn off the air conditioner before cleaning.

Air Filters

The air filters should be cleaned at least once every two

weeks. Clogged filters reduce cooling, heating and air

flow.

Keeping these filters clean will:

• Decrease cost of operation.

• Save energy.

• Prevent clogged heat exchanger coils.

• Reduce costly compressor problems.

To remove the air filters:

Freeze Protection

Freeze Protection helps prevent plumbing damage due to

sub-freezing temperatures — even if you have turned the

mode selector switch to OFF. The unit automatically turns

on the heater and fan if the room temperature falls to

about 46°F.

You do not have to do anything to activate the Freeze

Protection. It will work as long as power to the unit has

not been interrupted.

To clean the air filters:

• Vacuum off heavy dirt.

• Run water through the filters.

• Dry thoroughly before replacing.

To reinstall the air filters:

Do not operate the air conditioner without the filters in

place. If a filter becomes torn or damaged it should be

replaced immediately. Operating the unit without the filters in place or with damaged filters will allow dirt and

dust to reach the indoor coil and reduce the efficiency of

the unit.

Replacement filters (STK01AF) are available from the dealer or installer.

Front Grille & Wall Case

Wash the front grille and wall case finish with mild soap

or detergent and lukewarm water.

4

Page 5

Control Panel

The control panel is shipped with a protective plastic

film. This film can be left on or removed. To clean, use a

damp cloth and mild detergent.

Outdoor Coil

The coil on the outdoor side of the unit should be

checked periodically and cleaned if clogged with dirt or

soot from the atmosphere. If extremely dirty, it may need

to be professionally steam cleaned.

Base Pan

In some installations, dirt or other foreign matter may be

blown into the unit from the outside and settle in the

base pan (the bottom of the unit). Check the base pan

periodically and clean it out, if necessary.

Tips for Energy Saving

Do not

• Block the air intake and outlet of the unit. If they are

obstructed, the unit will not work well, and may be

damaged.

• Let direct sunlight into the room. Use sunshades,

blinds or curtains. If the walls and ceiling of the room

are warmed by the sun, it will take longer to cool the

room.

Do

• Keep the air filter clean. (Refer to “Care and

Cleaning.”)

A clogged filter will impair the performance of the unit.

• To prevent conditioned air from escaping, keep windows, doors and any other openings closed.

• Keep the ventilator closed for economy and maximum

cooling.

Troubleshooting

PROBLEM POSSIBLE CAUSE

AIR CONDITIONER

DOES NOT

OPERATE

AIR CONDITIONER

“DOES NOT COOL

OR HEAT AS IT

SHOULD”

“BURNING” ODOR

AT START OF

HEATING

OPERATION

OPERATING

SOUNDS

AIR IS NOT

ALWAYS COOL

DURING COOLING

OPERATION

AIR IS NOT

ALWAYS HOT

DURING HEATING

OPERATION

• The power cord is not plugged in or

circuit breaker is tripped.

• The unit is waiting for the compressor

overload protector to reset.

• Curtains, blinds or furniture blocking

the front of the air conditioner are

restricting the air flow.

• Thermostat control may not be set

high/low enough. Turn the control to a

lower or higher position. (NOTE: In

some installations, the thermostat

control cannot be turned all the way to

the highest end or lowest end. This is

normal. Do not attempt to force the

control beyond its stopping points.)

• A dirty air filter is blocking air flow.

The filter should be cleaned at least

once every 2 weeks. See the instructions in the cleaning section.

• The room may have been very hot or

very cold when the air conditioner

was first turned on. Allow time for it

to cool down or warm up.

• The ventilation control may be set to

the OPEN position, allowing outside

air to enter the room.

• Dust on the surface of the electrical

heater can cause a “burning” odor at

the beginning of the heating operation. This odor should quickly fade.

• Relay clicks may be heard when the

compressor or fan cycles on and off.

This is normal.

• The fan runs continuously when the

unit is operating unless the Fan Cycle

Switch under the control panel is set

to CYCLE. In this case, the fan cycles

on and off with the electrical heater

or compressor.

• The Fan Cycle Switch may be set to

Fan Cont (continuous). This causes

the fan to blow room air even when

the compressor is off. The continuous

air flow provides better overall temperature control.

• The Fan Cycle Switch may be set to

Fan Cont (continuous). This causes

the fan to blow room air even when

the electrical heater is off. The continuous air flow provides better overall

temperature control.

5

Page 6

WARNING

CAUTION

CAUTION

INSTALLATION INSTRUCTIONS

IMPORTANT!

Please Read Before Starting

This air conditioner meets strict safety and operating standards. As the installer or service person, it is an important

part of your job to install or service the system so it operates safely and efficiently.

For safe installation and trouble-free operation, you

must:

• Carefully read this OWNER’S MANUAL before installation and service.

• Follow each installation or service step exactly as shown.

• Observe all local, state, and national electrical codes.

• Pay close attention to all warning and caution notices

given in this manual.

This symbol refers to a hazard or

unsafe practice which can result

in severe personal injury or death.

This symbol refers to a hazard or

unsafe practice which can result

in personal injury or product or

property damage.

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help for a

special problem, contact our sales/service outlet or your

certified dealer for additional instructions.

• DO NOT turn the air conditioner on and off by plugging

and unplugging. Use the Operation switch (SELECTOR).

• Follow National Electrical Code (NEC) and local codes,

ordinances and regulations. All wiring — including

installation of receptacles, must be in accordance with

these codes.

• The NEC requires permanent connection for installations over 250 volts.

• Protective devices (fuses or circuit breakers) acceptable for this air conditioner are specified on the nameplate of each unit.

• Aluminum building wiring may pose special problems

— consult a qualified electrician.

When Transporting

Be careful when picking up and moving the air conditioner.

Get a partner to help, and bend your knees when lifting to

reduce strain on your back. Sharp edges or thin aluminum

fins on the air conditioner can cut your fingers.

When Servicing

• Turn the power OFF at the main power box (mains)

before opening the unit to check or repair electrical

parts and wiring.

• Keep your fingers and clothing away from any moving parts.

• Clean up the site after you finish, remembering to

check that no metal scraps or bits of wiring have been

left inside the unit being serviced.

Tools Needed

SPECIAL PRECAUTIONS

When Wiring

ELECTRICAL SHOCK CAN CAUSE SEVERE PERSONAL INJURY OR DEATH. ONLY A QUALIFIED, EXPERIENCED ELECTRICIAN SHOULD ATTEMPT TO WIRE

THIS SYSTEM.

• All wiring must conform to local electrical codes.

• Each unit must be properly grounded with a ground (or

earth) wire or through the supply wiring.

• DO NOT, under any circumstances, cut or remove the

third (ground) prong from the power cord plug.

• Never use an extension cord with this air conditioner.

• DO NOT use a damaged power cord, plug, or wall outlet. Replace them immediately.

• DO NOT change the internal wiring or any part of the

system.

Phillips screwdriver

Flat blade screwdriver

Others

• Before starting the installation, the power to the direct

connect wiring should be set to OFF.

• Ventilate any enclosed areas when installing or testing the

refrigeration system. Escaped refrigerant gas, on contact

with fire or heat, can produce dangerously toxic gas.

• Confirm upon completing installation that no refrigerant

gas is leaking. If escaped gas comes in contact with a

stove, gas water heater, electric room heater or other

heat source, it can produce dangerously toxic gas.

6

Page 7

1. NAMES OF PARTS

Rear grille/louver**

Wall case**

Chassis

Front grille*

* Shipped with the chassis

** Check essential components list on chassis

Protective panel

Slit

Stiffener

1

2

Wall

Wall case

1

2

2. WALL CASE AND REAR GRILLE

1) The STK01WC wall case must be properly

installed according to the instructions packed with

the case.

2) Remove the corrugated stiffener and the outdoor

protective panel. Use the slit in the outdoor panel

as a grip and push out.

3) Install the rear grille from the room side according

to the instructions packed with the grille.

3. INSTALLATION

1) Remove the front grille by pulling out at the bottom to release it, then lift it up to clear the rail

along the chassis top.

2) Slide the chassis into the wall case and secure

with four screws through the chassis flange

holes.

3) Reinstall the front grille by hooking the top over

the rail along the chassis top, then pushing it in

at the bottom.

7

Page 8

4. PERMANENT CONNECTION

Approx. 6"

Cut

Power plug

Electrical junction box

Screws

Cover plate

Bottom plate

Screw A

Electrical

junction box

Bottom plate

Screw B

Screw A

Conduit

Cover plate

Power cord

4-1. For 230/208V Units

The 230/208V model is equipped for connection

with a power cord according to the unit capacity

at the time of shipment.

Should local codes or special requirements specify permanent connection of this unit, use optional

adapter kit (Cover plate and Bottom plate)

STK02JB.

A power cord is supplied with 230/208V units. For

direct-connect applications, the power cord is cut

and a wire nut connection is made to the building

power supply. The cover plate and bottom plate

are the junction box kit. The conduit and wire

nuts are supplied by the installer.

4-1-1. Preparation

1) The electrical rating marked on the previously

installed air conditioner must be the same as the

supply branch circuit.

2) The modification kit provides for connection of

1/2" trade size electrical conduit and connection to

a wiring system in accordance with the National

Electric Code, ANSI/NFPA No. 70-1999.

4-1-2. Installation

1) Remove the Front Grille from the chassis by lifting out and up.

2) Cut the power cord approximately 6" from the

Electrical Junction Box.

4-2. For 265V Units

All 265V units are direct connected and come

with the cover plate (junction box) and bottom

plate. The conduit is field-supplied by the

installer.

4-2-1. Preparation

1) The electrical rating marked on the previously

installed air conditioner must be the same as the

supply branch circuit.

2) The unit provides for connection of 1/2 trade size

electrical conduit and provision for connection to

a wiring system in accordance with the National

Electrical Code ANSI/NFPA No. 70-1993.

4-2-2. Installation

1) Remove the front grille from the chassis by lifting

out and up to clear mounting brackets. (See “Front

Grille” on page 3.)

2) Remove the “A” screw and cover plate from the

mounting plate.

3) Split and strip the wires as shown above.

4) Install the Bottom Plate using the provided field

supplied conduit and power supply conductors to

the unit with screw “B”.

5) Connect Power Supply wires to the stripped inner

wires with the wire nuts.

6) Dress the wiring inside the compartment and

attach the cover plate with screw “A”.

7) Reinstall the Front Grille.

8

Page 9

3) Attach the field-supplied conduit to the

Stop link

Tapped holes (10)

Thermostat

shaft

(Coldest)

(Warmest)

Temperature limiting screws (location at shipment)

Front grille

Louver screws

Terminal block

Grounding screw

Bottom plate

Conduit

Cover plate

bottom plate.

4) Connect the power supply conductors to

the Terminal block and the Grounding

screw.

5) Attach the cover plate.

6) Reinstall the front grille. (See “Front

Grille” on page 3.)

6. TEMPERATURE LIMITING

The normal range of the thermostat control is

approximately 55°F to 88°F. The control range may

be narrowed by the use of the Temperature Limiting

screws located behind the control panel.

Repositioning the screw on the left will limit the

maximum temperature about 3.7°F for each hole in

a clockwise rotation; the screw on the right will limit

the minimum temperature when moved counterclockwise. Limiting the maximum and minimum settings prevents users from turning the controls to

extreme positions. Restrictions to full rotation of the

thermostat knob may require explanation to the

room occupant that the unit will provide comfortable conditions at the settings allowed.

To access the limiting screws, remove the front

grille, the thermostat knob and the operation knob

by pulling each knob off its shaft and the control

panel. (See the illustration “Fan Cycle Switch” on

page 4.) Set the limiting screws to the desired setting, and replace the control panel and the control

knobs. If the settings do not allow sufficient room

temperature control, the limiting screws may have

to be repositioned.

5. AIR LOUVERS

The direction of the heated or cooled air may be

adjusted by removing and turning the louvers

around.

To change the louver direction, remove the front

grille and 2 louver screws that hold the louvers in

place. Turn the louver section 180° (end for end),

replace the screws and replace the front grille. The

textured face of the louver section must be facing

toward the room side.

When the limiting screws are relocated, it is recommended that the screws be set no higher than the

second hole from the original bottom position. This

provides an operating range between approximately

58°F and 80°F. In order to maximize the benefit of the

temperature limiting, it may be necessary to adjust

the limiting screws seasonally, maintained at moderate temperatures (i.e., heating season temperatures

limited between 60°F and 75°F; cooling season temperatures limited between 85°F and 65°F).

9

Page 10

Remote Control

Class 2 RemoteFDC

Low voltage

Terminals on Interface kit

7. REMOTE CONTROL

Interface kit

Terminals

(optional)

8. FRONT DESK CONTROL

The unit may be controlled either by the unit-mounted controls (Control Panel) or by optional Class 2 thermo controller (SC2001 for Cool/Heat Model and

SC2201 for Heat Pump Model) with optional Interface

kit (STK02LVC). Detailed instructions are included in

the kit.

The unit may be connected to a switch at the front

desk to control on and off operation of the compressor or heater from the front desk with the optional

interface kit. (See the picture below.) When the switch

is set to OPEN, the unit is operable. When the switch

is set to CLOSED, the unit is made inoperative.

Detailed hook-up instructions are in the interface kit.

Follow the recommended wire sizing in the table

below. Two wires must be used from each FDC switch

to each individual unit.

Good wiring practices (e.g. twisted pairs, SEPARATION FROM POWER CIRCUITS) must be followed to

minimize induced voltages which may harm the control system. Do not use a common line in the FDC

wiring.

A 24V A/C transformer is contained within the unit

and no external voltage should be applied to the unit

through the FDC switch. The Freeze Protection

remains in active mode to help protect against low

temperature damage even though the unit may be

OFF by FDC.

Recommended Wire Size for Front Desk Control

Installation

Wire Size #AWG Maximum Allowable Length

#22 600 ft.

#20 900 ft.

#18 1500 ft.

#16 2000 ft.

10

Page 11

Product Information

If you have problems or questions concerning your Air Conditioner, you will need the following information.

Model and serial numbers are on the nameplate of the cabinet.

Model No. Serial No.

Date of purchase

Dealer’s address

Phone number

11

Page 12

SANYO FISHER COMPANY

A DIVISION OF SANYO NORTH AMERICA CORPORATION

21605 plummer Street, Chatsworth, CA 91311 U.S.A.

In Canada

SANYO Canada Inc.

300 Applewood Crescent, Concord, Ontario, L4K 5C7, Canada

Loading...

Loading...