Page 1

Ordering number : ENN4421

92099RM (OT)/31293YO 5-3108 No. 4421-1/9

Overview

These days, the variety of horizontal frequencies output

from personal computers (PCs) include 15 kHz, 24 kHz,

31 kHz and even 33 kHz. These differences are dependent

on the device and maker, and the market itself contains

many PCs and a wide array of frequencies; in other word,

the need to remain compatible is stronger then ever. As

the number of video signal formats created with newmedia devices becomes more diversified, the search for

circuit technology capable of supporting such a wide

range of scanning frequencies (multiscan support)

becomes even harder.

The STK750-010 is a chopper regulator using MOS FET

with multi-scan support. This IC is also designed for

output voltage variable control supporting a wide range of

horizontal frequencies. For these reasons, the STK750010 helps reduce streamlined power supply designs,

shorten overall development time, and reduce total costs

while providing high-precision CRT display performance

with the highest quality.

Applications

• Multi-scan supporting CRT displays (secondary voltage

variable regulator)

Features

• High efficiency (97%) provided by power MOS FET.

Compared with bi-polar chopper regulators used until

now, power dissipation is less than half while supporting

compact heat sink and lighter weight design.

• Multi-scan support (output voltage variability).

Supports horizontal frequency external control.

• Wider output voltage control range (50 to 130 V),

compared with dropper type ICs used until now. The

resonance condenser changeover circuit and the vertical

dummy coil changeover circuit of horizontal deflection

coil are eliminated within the horizontal autoscan

circuit.

• IC operating frequency supports horizontal frequency

synchronization.

• Standard chopper type eliminates need for complicated

transformers and supports choke coil applications.

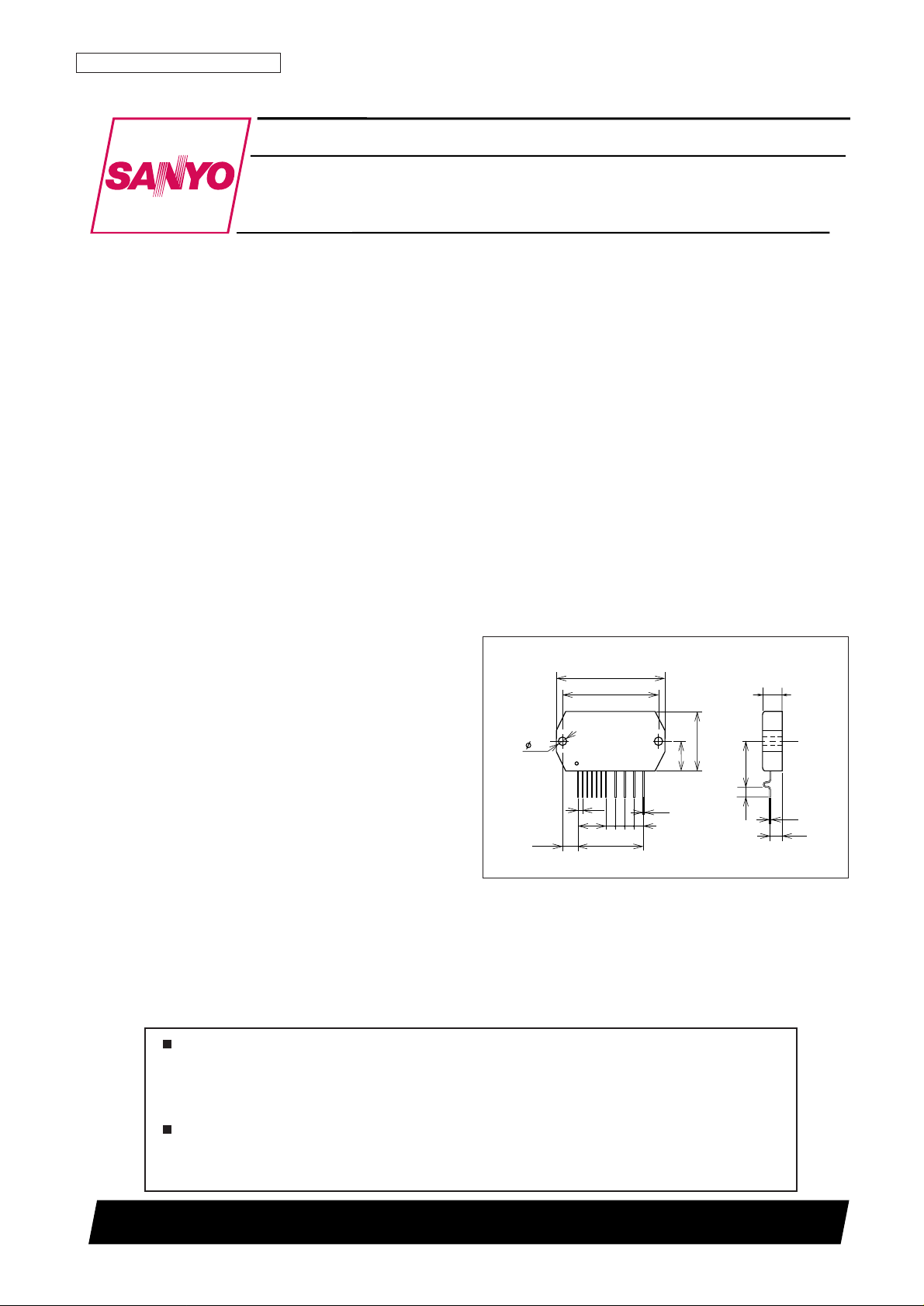

Package Dimensions

unit: mm

4136

115

46.6

41.2

12.7

25.5

(6.6)

2.0

×

14 = 28.0

0.5

2.0

12.0

8.5

0.4

5.2

4.0 20.0

AAAA

A = 4.0

3.6

[STK750-010]

STK750-010

SANYO Electric Co.,Ltd. Semiconductor Company

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

Chopper Regulator using MOS FET with Multi-Scan

Support (1 A Output Current)

Thick Film Hybrid IC

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft’s

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges, or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

Page 2

No. 4421-2/9

STK750-010

Parameter Symbol Conditions Ratings Unit

Maximum DC input voltage Vin (DC) max 190 V

Maximum output current Io max 1 A

Thermal resistance θj-c 2.5 °C/W

Junction temperature Tj max 150 °C

Operating substrate temperature Tc max 105 °C

Storage temperature Tstg –30 to +105 °C

Specifications

Maximum Ratings at Ta = 25°C

Parameter Symbol Conditions Ratings Unit

V

IN

voltage Vin 165 to 175 V

V

CC

voltage V

CC

11 to 13 V

Error amplifier input voltage Vamp 7 pin –0.3 to V

CC

–2 V

Timing condenser G

T

4 pin 0.47 to 10000 nF

Timing resistor R

T

3 pin 1.8 to 500 kΩ

Oscillation frequency f

OSC

20 to 100 kHz

Maximum duty D max 90 %

Recommended Operating Conditions at Ta = 25°C

Parameter Symbol Conditions

Ratings

Unit

min typ max

Output voltage Vo Vin (DC) = 170V, Io = 0.5A 130±1.5 V

Input regulaton Reg-IN Vin (DC) = 160 to 180V, Io = 0.5A 0.05 V/V

Load regulation Reg-L Vin (DC) = 170V, Io = 0.2 to 1A 0.5 V/A

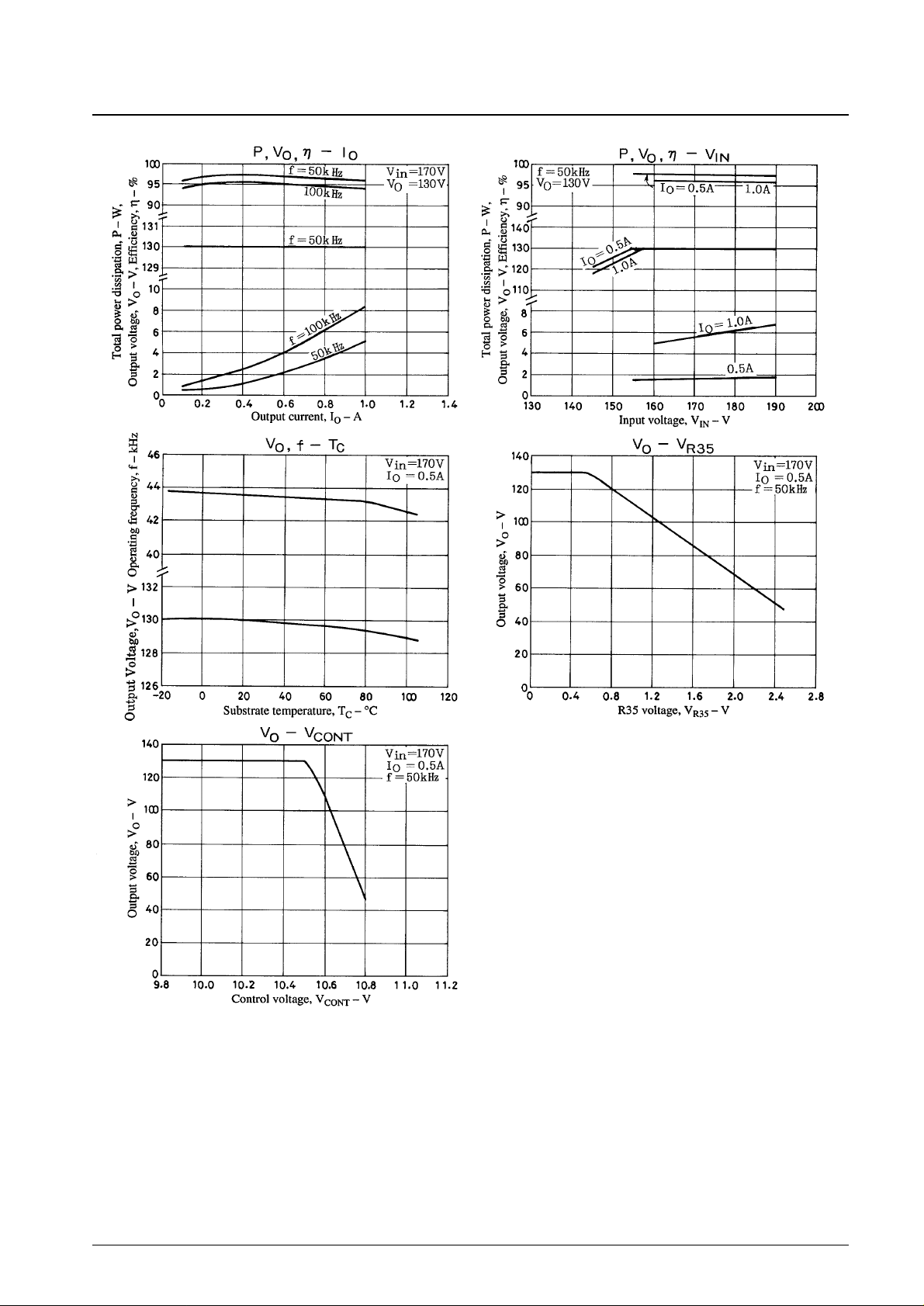

Efficiency η Vin (DC) = 170V, Io = 0.5A 97 %

Output voltage temperature coefficient T

CVO

Vin (DC) = 170V, Io = 0.5A 17 mV/°C

Operating Characteristics at Ta = 25°C, see specified Test Circuit, f = 50kHz

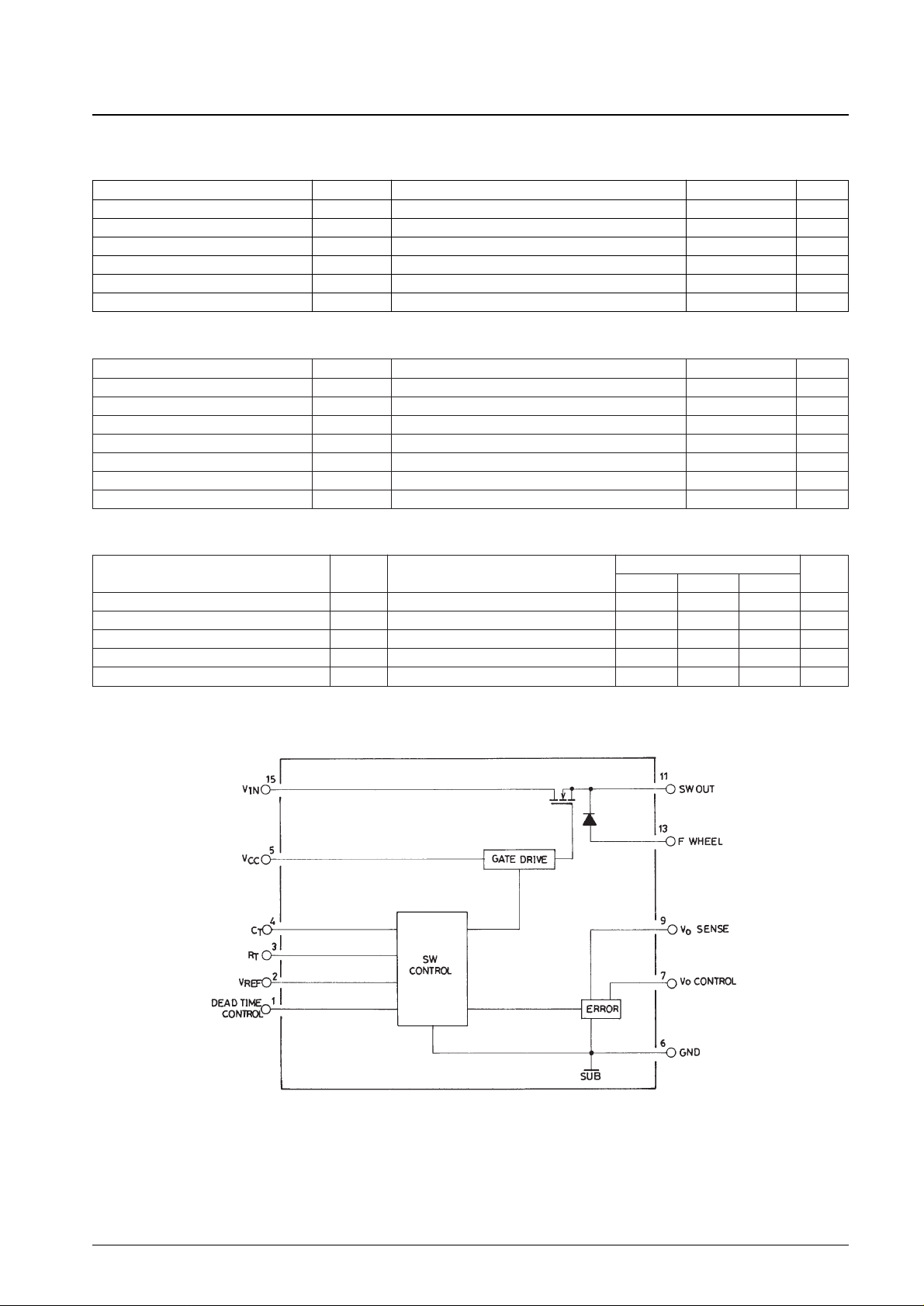

Block Diagram

Page 3

No. 4421-3/9

STK750-010

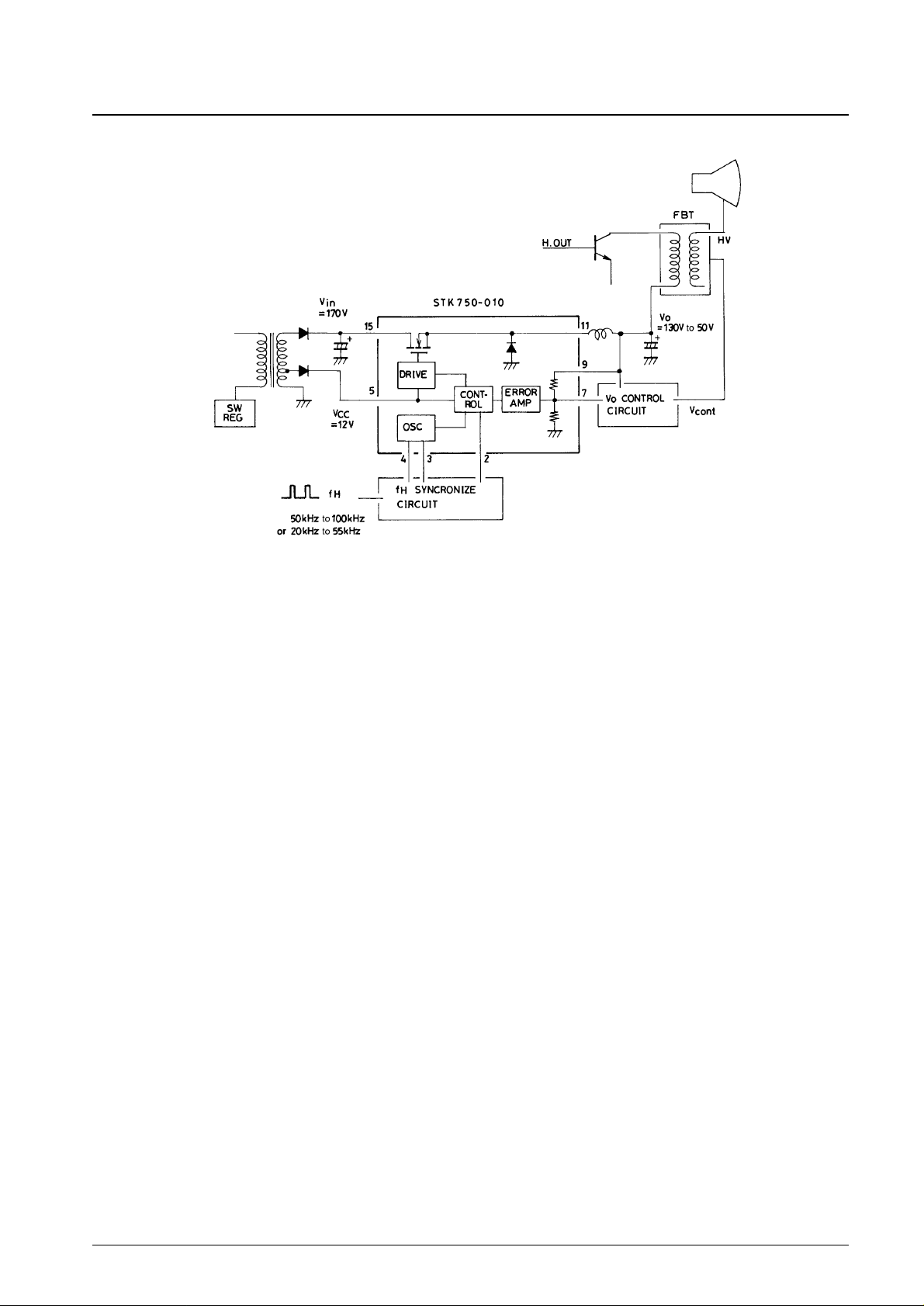

Application Circuit Block Diagram

Page 4

Test Circuit

C1 220µF / 200V R11 130KΩ TR11 2SC2274F L1 4.8mH

C2 220µF / 200V R12 8.2kΩ TR21 2SA984F

C3 10µF / 25V R13 470kΩ TR22 2SC2274F

C4 0.047µF / 250V R14 10kΩ TR31 2SA1209S

C11 22µF / 25V R21 2.0kΩ TR32 2SC2911S

C21 2200pF R22 47kΩ

C22 4700pF R23 30kΩ

C31 22µF / 25V R24 1kΩ IC31 LA6358

C32 10µF / 50V (N. P.) R25 100kΩ

C33 10µF / 25V R31 56kΩ

R32 100kΩ D21 GMA01

R33 3.9kΩ D31 GMA01

R34 10kΩ

R35 1kΩ

R36 100kΩ ZD31 GZA5.6X

R37 4.7kΩ

R38 4.7kΩ

R39 100Ω

R40 330kΩ

R41 10kΩ

VR31 500kΩ

No. 4421-4/9

STK750-010

Page 5

Description of Circuit Operations

1. Reference Voltage Circuit (REF REG.)

Reference voltage outputs at 5 V with built-in oscillator and protection circuits.

2. Oscillator (OSC)

When C and R are externally connected, self-oscillation of saw-tooth-wave forms begins. Charge current flows

from the CT pin (pin 4) to the condenser and when the CT pin reaches approximately 3 V, the discharge transistor

switches on and CT pin voltage drops to zero and one cycle ends. Charge current is determined by the current

flowing to the external resistor connected to the RT pin (pin 3).

Oscillation frequency is determined approximately according to the following equation:

f =

1.2

[kHz]

CT·R

T

CT: µF

RT: kΩ

3. Error Amplifier

Because the power supply error amplifier is supplied directly from VCC, the common mode input voltage range is

between –0.3 V and VCC–2 V. Figure 1 illustrates the equivalent circuit.

When output voltage is set to Vo, approximations are determined using the following equation:

Vo = V

REF’

x

R11 + R12

V

REF’

= 2.5V

R12

No. 4421-5/9

STK750-010

Oscillation frequency, f

OSC

– kHz

Figure 1

Page 6

Supported Functions

1. Oscillation Circuit

When all devices are synchronized to the clock cycle, a circuit diagram similar to that shown in figure 2 can be

synchronized.

2. Dead-time Adjustment Circuit (DT Pin)

Soft Start Circuit

R11 and R12 are dead-time setting resistors and vary DC input voltage. By modifying the slice level of the sawtooth wave, output maximum duty (on time) can be set. Maximum duty value should be set for approximately 90%.

If IC output pulse is operated at maximum duty when the power is turned on, a rush current flows to the output

transistor. Therefore, the duty cycle should be slowly increased from 0 (this is generally referred to as a “soft

start”). As shown in figure 3, configuration with the addition of a decay time constant circuit is possible using a

condenser connected to the dead-time control pin (1 pin).

Item R21 R22 f

OSC

External Synchronization Support Range f

H

EX1 2.4k 39k 45kHz 48k to 100kHz

EX2 3.3k 47k 37kHz 39k to 81kHz

EX3 4.3k 68k 28kHz 29k to 65kHz

EX4 5.1k 120k 18kHz 19k to 56kHz

No. 4421-6/9

STK750-010

Figure 2

Unit (resistance: Ω, capacitance: F)

Figure 3

Page 7

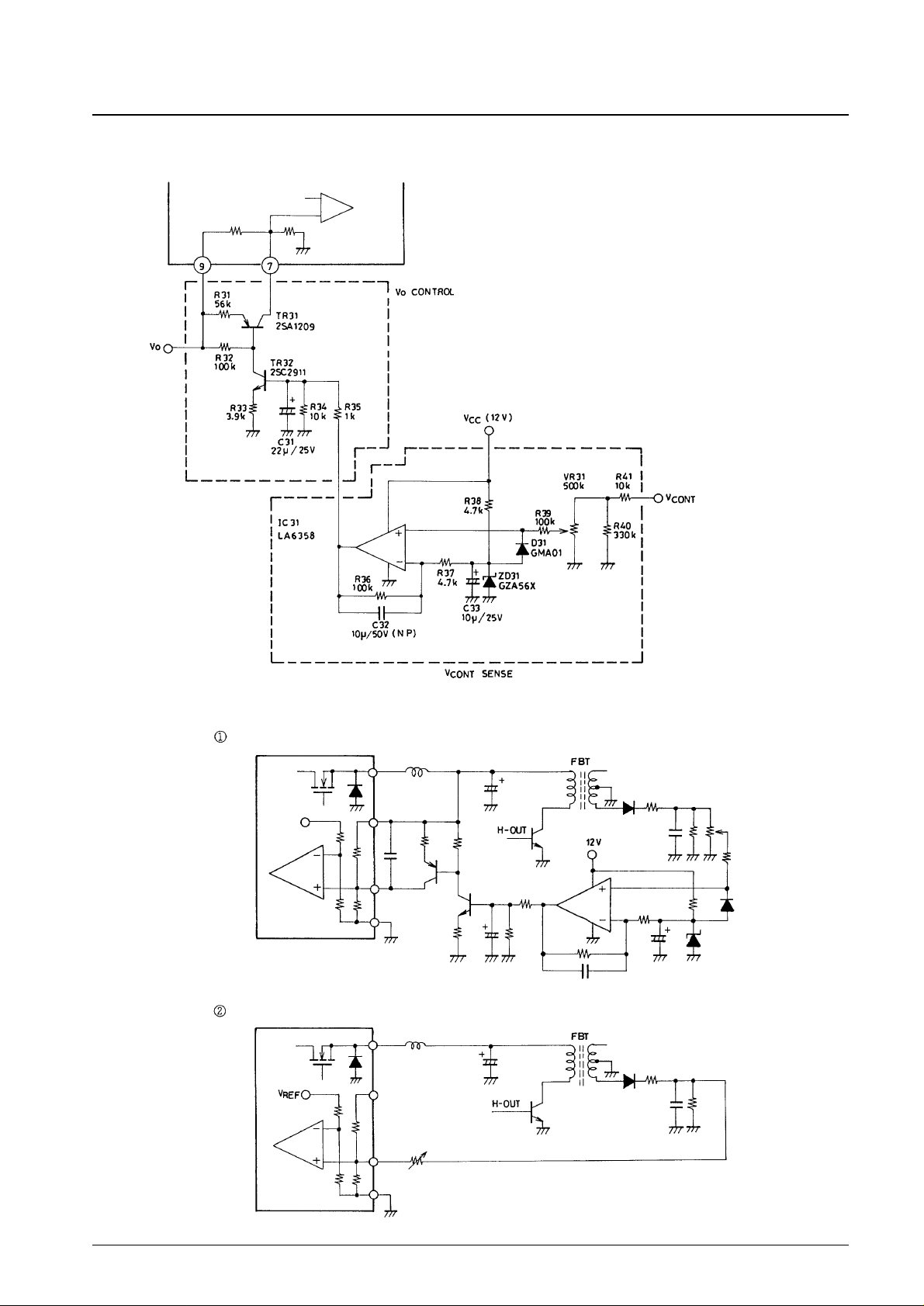

3. Output Voltage Vo Control Circuit

By supporting control voltage changes externally, output voltage Vo can be modified.

No. 4421-7/9

STK750-010

Unit (resistance: Ω, capacitance: F)

4. Support for Multi-Scan Applications

Page 8

No. 4421-8/9

STK750-010

Page 9

PS No. 4421-9/9

STK750-010

This catalog provides information as of September, 1999. Specifications and information herein are

subject to change without notice.

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer’s

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer’s products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

semiconductor products fail with some probability. It is possible that these probabilistic failures could

give rise to accidents or events that could endanger human lives, that could give rise to smoke or fire,

or that could cause damage to other property. When designing equipment, adopt safety measures so

that these kinds of accidents or events cannot occur. Such measures include but are not limited to protective

circuits and error prevention circuits for safe design, redundant design, and structural design.

In the event that any or all SANYO products (including technical data, services) described or contained

herein are controlled under any of applicable local export control laws and regulations, such products must

not be exported without obtaining the export license from the authorities concerned in accordance with the

above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or any information storage or retrieval system,

or otherwise, without the prior written permission of SANYO Electric Co., Ltd.

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the “Delivery Specification”

for the SANYO product that you intend to use.

Information (including circuit diagrams and circuit parameters) herein is for example only; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but

no guarantees are made or implied regarding its use or any infringements of intellectual property rights

or other rights of third parties.

Loading...

Loading...