Page 1

Ordering number : EN4874

N2894TH (OT) No. 4874-1/8

Overview

The STK6877 is an H bridge power pack reversible brushtype DC motor driver that uses Sanyo’s unique insulated

metal substrate technology (IMST) substrate. This

technology provides superlative thermal dissipation

characteristics. By adopting MOSFET devices as its

power elements, this hybrid IC realizes reduced loss and

increased current outputs as compared to our earlier

STK6860H series.

Applications

• Plain paper copier drum and scanner motors

• LBP drum motors

• Printer head carriage motors

• All types of DC motor application equipment

Features

• Increased margins with respect to rush currents due to

the adoption of MOSFET elements

• TTL level compatible inputs

• Support for both two pin control saturation operation

and three pin control PWM control

• A braking function is provided.

• Wide operating power supply voltage range (VCC1 = 12

to 42 V)

• Few required external components (Operation is

possible with only two external bootstrap capacitors.)

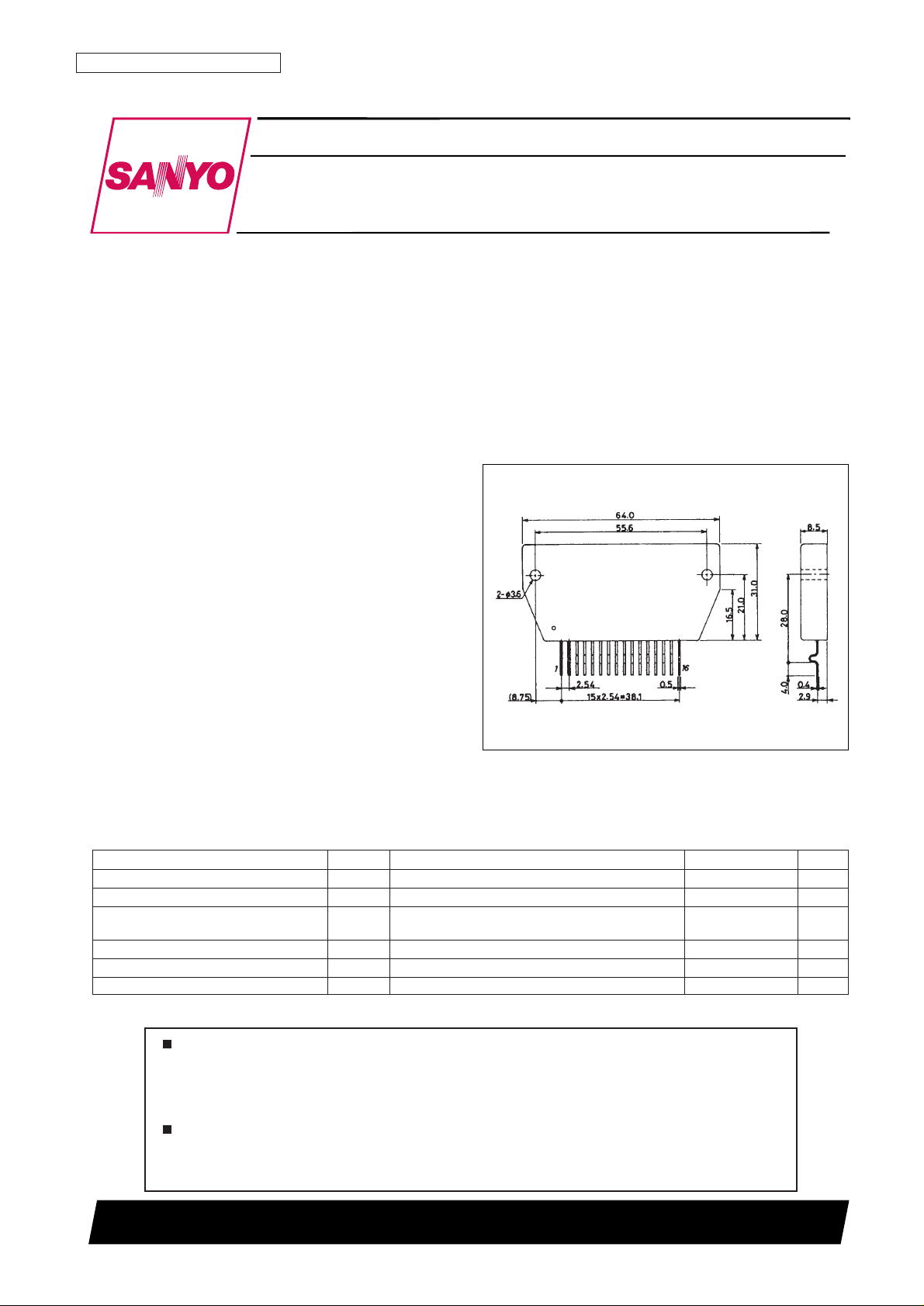

Package Dimensions

unit: mm

4148

[STK6877]

STK6877

SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquarters

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

Reversible Brush-Type DC Motor Driver

(output current: 8 A)

Thick Film Hybrid IC

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft’s

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges, or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

Specifications

Absolute Maximum Ratings at Ta = 25°C

Parameter Symbol Conditions Ratings Unit

Maximum supply voltage 1 V

CC

1 max No signal 50 V

Maximum supply voltage 2 V

CC

2 max No signal 7 V

Maximum motor rush current I

O

peak

Period = 100 ms, duty ≤ 1%

18 A

V

CC

2 = 5.0 V

Operating substrate temperature Tc max 105 °C

Junction temperature Tj max 150 °C

Storage temperature range Tstg –40 to +125 °C

Page 2

Operating Characteristics at Ta = 25°C, VCC1 = 24 V, VCC2 = 5.0 V

Note: Constant voltage power supplies must be used.

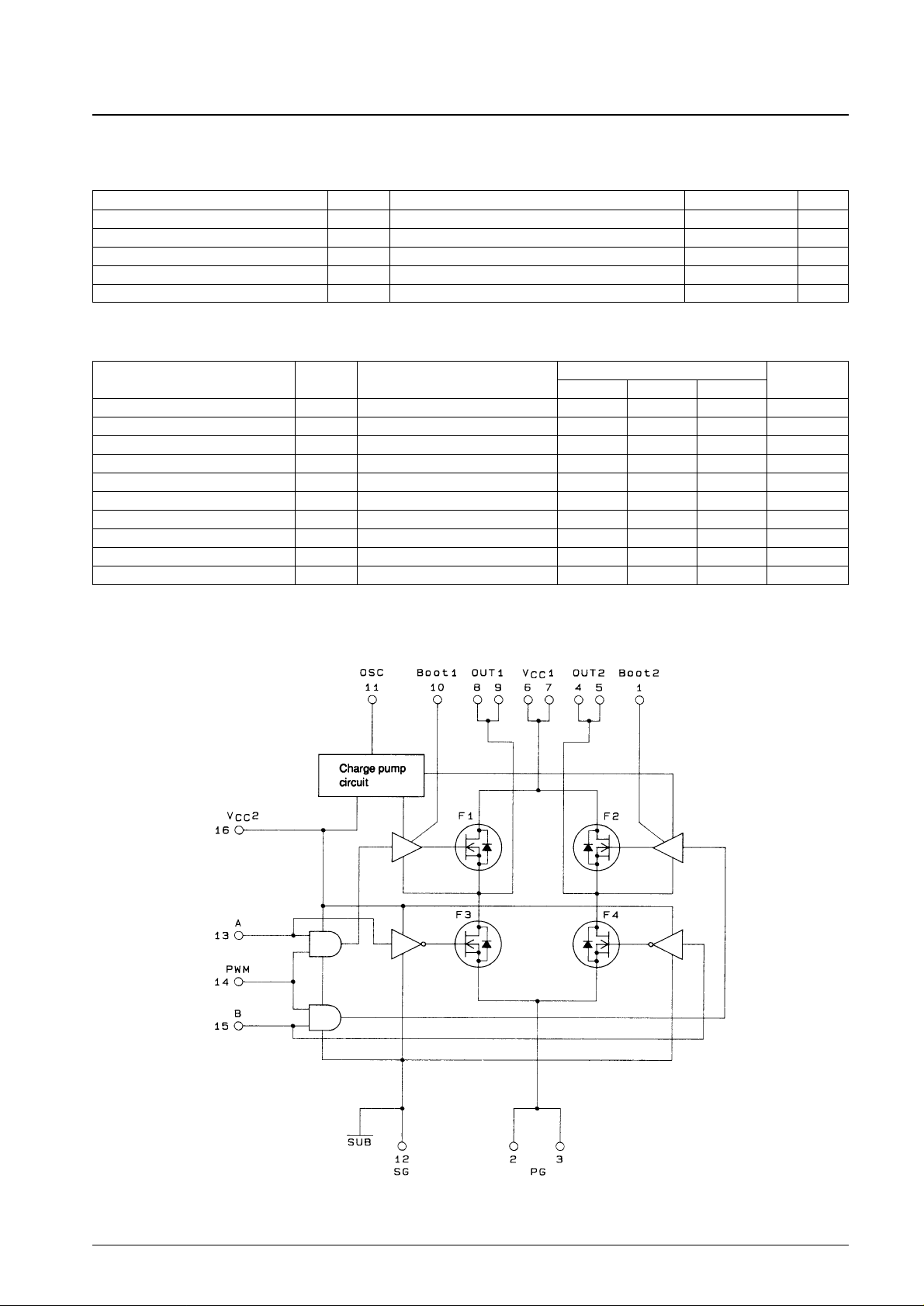

Equivalent Circuit

Note: 1. Boot is an abbreviation for bootstrap.

2. The OSC pin (pin 11) must be left open in operation.

No. 4874-2/8

STK6877

Ratings

Parameter Symbol Conditions

min typ max

Unit

Quiescent current I

CCO

RL= 2.8 Ω 30 40 50 mA

Output saturation voltage Vst R

L

= 2.8 Ω 0.90 1.20 V

Input on voltage V

IH

2.0 V

Input off voltage V

IL

0 0.8 V

Input on current 1 I

IH

1 VI= 2.7 V, pin 14 20 µA

Input on current 2 I

IH

2 VI= 2.7 V, pin 13 or pin 15 0.7 mA

Input off current 1 I

IL

1 VI= 0.4 V, pin 14 –0.4 mA

Input off current 2 I

IL

2 VI= 0.4 V, pin 13 or pin 15 –0.2 mA

Diode forward voltage Vdf Idf = 8 A, V

GS

= 0 1.6 2.0 V

Sensing voltage Vsens 0.5 V

Specifications

Allowable Operating Ranges at Ta = 25°C

Parameter Symbol Conditions Ratings Unit

Supply voltage 1 V

CC

1 Input active 12 to 42 V

Supply voltage 2 V

CC

2 Input active 5 ±5% V

Motor output current I

OH

max DC 8 A

PWM frequency fp 1 to 30 kHz

FET withstand voltage V

DSS

60 V

Page 3

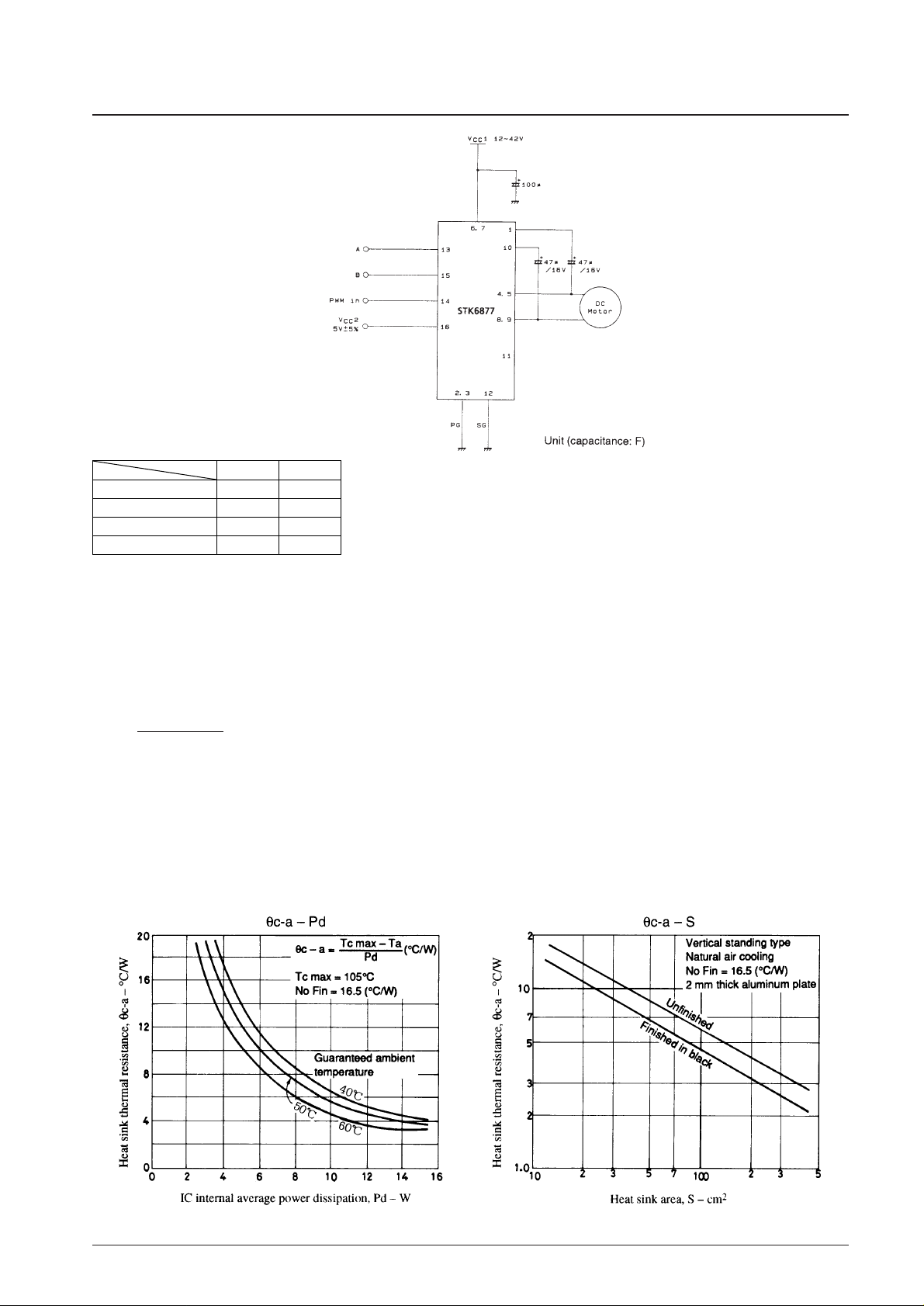

Sample Application Circuit

A B

Forward H L

Reverse L H

Standby 1(illegal) H H

Standby 2 L L

Thermal Design

1. Heat Sink Thermal Resistance (θc-a) Derivation

The size of the heat sink required for the hybrid IC is determined by the motor output current (IOH), the electrical

characteristics of the motor and the chopping frequency, and the frequency of current application.

The thermal resistance (θc-a) of the heat sink is derived from the following formula.

θc-a =

Tc max – Ta

(°C/W)

Pd

Tc max: Hybrid IC case temperature (°C)

Ta: Ambient temperature within the set (°C)

Pd: Average internal power dissipation within the hybrid IC (W)

As an example, Figure 2 can be used to derive the required area for a 2 mm aluminum plate heat sink. Since the ambient

temperature within a set varies greatly with the set internal air circulation conditions, the size of the heat sink must be

determined taking into account the constraint that the temperature of the back surface of the IC (the aluminum plate side)

must never under any conditions exceed 105°C.

No. 4874-3/8

STK6877

H: 5 V

L: 0 V

Note: 1. Input pin specifications

• TTL levels handled

• Maximum PWM input frequency: 30 kHz

• When used in two pin control mode, the PWM pin must be tied high.

2. Since the OSC pin (pin 11) is a monitor pin, it should be left open in normal operation.

Figure 1 θc-a vs. Pd Figure 2 θc-a vs. S

Page 4

2. Hybrid IC Internal Average Power Dissipation (Pd)

Of the power dissipations within the hybrid IC, the following components have large power dissipations: the FETs that

are the upper PWM elements in the H bridge structure, the lower FETs that form the motor direction reversing loop, and

the flywheel FET body diode. This can be expressed as shown below from experiment (from the output current

waveform in the figure below).

Pd = upper FETs + lower FETs + body diode losses

= Vst × IM× fp × tON+ Vst × IM+ Vdf × IM× fp × t

OFF

Vst: FET saturation voltage (V)

IM: Motor output current (A)

Vdf: FET body diode forward voltage (V)

fp: Chopping frequency (Hz)

Figures 5 and 6 show the IOvs. Vst and IOvs. Vdf characteristics.

3. Junction Temperature, Tj

The junction temperatures Tj (°C) for each element (F1, F2,

F3 and F4) can be derived from the formula below from the

power dissipation Pds (W) for each element and the

junction thermal resistances θj-c (°C/W).

Tj = Tc + θj-c × Pds (°C)

Pds: Loss per element

Note that the thermal resistances for the power elements are

as follows.

F1, F2, F3, F4 θj-c = 4 (°C/W)

No. 4874-4/8

STK6877

F1, F2, F3, F4, ASO

Ta = 25°C

1 pulse

Figure 3 IMWaveform Model

Figure 4 Model Circuit Diagram

Figure 5 IOvs. Vst Figure 6 IOvs. Vdf

Page 5

Usage Notes

1. Drive Circuit Start-up Procedure

Figure 7 Upper and Lower MOSFET Drive Circuits

When starting (applying power to) the driver circuit (STK6877), the external control signals must be set to standby

mode, i.e., pins A and B both set to low (setting both these pins high is an illegal mode). Then, after the specified power

supply voltages (VCC1 and VCC2) have been input to the driver circuit, the circuit can be driven by inputting external

control signals.

2. Illegal Input Mode with both the A and B Phase Signals (pins 13 and 15) High

Since the circuit operation problems described below occur when the input signal mode with both signals high is used,

this mode should be avoided.

2-1 If used in the standby state, the voltage (Vch) charged on the external bootstrap capacitor (47 µF/16 V) will drop to

an inadequate level. As a result, when the STK6877 driver circuit is switched to the start-up state, an insufficient

drive voltage state for the upper FETs (F1 and F2) will occur.

2-2 If the A and B phase input signals are both switched to the high level in the motor start-up state (CW or CCW

mode), a current loop (braking current) will be created in the upper side FETs due to the motor energy. At this

point, since the upper FET drive voltage (the VGSvoltage) drops, an insufficient drive state will occur in the upper

FETs, and they may be destroyed. However, if during this operation the charge voltages Vch across the two

terminals of the bootstrap capacitors (47 µF/16 V) are monitored at the following points:

①

The voltage between pin 10 and pin 8 (or 9)......................................Phase A

...................(1)

②

The voltage between pin 1 and pin 4 (or 5)........................................Phase B

and if both these voltages can be maintained at 4.0 V or higher, then the A and B phase pin input signals can both

set to high safely. In other words, if the A and B phase pin input signal mode with both signals high is used as a

motor stopping technique, care must be taken to assure that the charge voltages Vch on the external bootstrap

capacitors meet this condition.

3. Handling the Hybrid IC’s PG (pins 2 and 3) and SG Pins (pin 12)

Basically, the PCB pattern must be designed so that the PG and SG pins connect to a single grounding point. Also, if a

current detection resistor (RE) is inserted on the PG pin, handle the PG and SG pins as shown in Figure 8, i.e., connect

them to a single grounding point, and select a value of the resistor REso that the voltage drop VREmeets the following

condition.

VRE= (IOH× RE) ≤ 0.5 V ...................................................(2)

IOH: Motor output current (A)

RE: Current detection resistance(Ω)

VRE: Voltage drop across RE(V)

The condition specified by formula (2) is specified in the

specifications as the sensing voltage Vsens.

No. 4874-5/8

STK6877

Figure 8 Handling for the PG and SG Pins

Page 6

4. Braking Operation Procedures

There are three methods for applying braking to the motor.

(a) Setting both the A and B phase inputs to low. (This shorts the

motor pins.)

(b) Setting the PWM input low. (This effects motor flywheel

current regenerative braking.)

(c) After setting the PWM input low, setting both the A and B

phase inputs to low. (This is the combination of methods (a)

and (b).)

(a) When braking method (a) is used, damping is applied through

the lower MOSFETs. (This stops the motor quickly.) Since this

method is equivalent to shorting the motor, the braking flywheel

current rises radically, and the lower MOSFETs go to the

overload state. As shown in Figure 9, F3 and F4 go to the

overload state, and Figure 10 shows the flywheel current that

flows in this braking method. Thus if this method is to be used,

the user must confirm that, under the conditions of the actual

application circuit, the flywheel current that flows in the lower

FETs does not exceed the maximum rated current range for the

hybrid IC.

When brake method (b) is used, the motor drive current from

before braking is applied is released in the lower MOSFETS thus

resulting in a motor stopping operation. (This is a free running

motor stop method.) Although the MOSFETs will not be

overloaded, the braking is not as fast.

When brake method (c) is used, first the PWM input is set to

low, and the motor’s rotational energy is released to a certain

degree. Then full braking is applied by setting both the A and B

phase inputs to low. This method allows the flywheel current that

flows in the lower MOSFETs to be held to within the maximum

rated range by first applying method (b) braking, and then when

the motor’s rotational energy has been reduced, applying method

(a) braking to stop the motor.

No. 4874-6/8

STK6877

Note: (*) Braking applied during reverse motor rotation

Figure 9 Brake Method (a) Current Flow

Figure 10 Flywheel Current Flowing in the

Lower FET (F4)

Note: (*) Braking applied during reverse motor rotation

Figure 11 Current Path in Brake Method (a)

Page 7

The dead time (td) and the flywheel current must be checked

with the motor actually used, since the amount of dead time (td)

that must be inserted between setting the PWM input low and

setting the A and B phase inputs low to assure that the flywheel

current is held within the maximum rated range will vary with

the conditions under which the circuit operates. (See Figure 12.)

Method (c) allows the motor to be stopped in a much shorter

time than is possible with method (b). When releasing the brake

it does not matter if the phase input signals or the PWM input

signal is set high first.

Although we have presented three braking methods, we

recommend the use of method (c) due to the speed of braking

and the current levels flowing during the braking operation.

5. Upper and Lower MOSFET Shorting Currents

It is conceivable that both the upper and lower MOSFETs could

be in the on state at the same time during braking operations

(braking methods (a) and (c)) and release states. Taking this into

consideration, the STK6877 provides two dead times (td1 and

td2) of at least 1 µs with respect to the input signals in the upper

and lower MOSFET drive circuits as shown in the figure below.

As a result there is no need for concern about shorting currents in

the upper and lower MOSFETs.

No. 4874-7/8

STK6877

Note: (*) Braking applied during reverse motor rotation

Figure 12 Input Signal Timing Chart for

Braking Method (c)

Figure 13 Upper and Lower MOSFET

Equivalent Circuit

Note: td1: Dead time in the upper MOSFET drive circuit

td2: Dead time in the lower MOSFET drive circuit

(*) td1, td2 ≥ 1 µs

Figure 14 Upper and Lower MOSFET VGSVoltage Timing Chart

Page 8

No. 4874-8/8

STK6877

This catalog provides information as of August, 1998. Specifications and information herein are subject to

change without notice.

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer’s

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer’s products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

semiconductor products fail with some probability. It is possible that these probabilistic failures could

give rise to accidents or events that could endanger human lives, that could give rise to smoke or fire,

or that could cause damage to other property. When designing equipment, adopt safety measures so

that these kinds of accidents or events cannot occur. Such measures include but are not limited to protective

circuits and error prevention circuits for safe design, redundant design, and structural design.

In the event that any and all SANYO products described or contained herein fall under strategic

products (including services) controlled under the Foreign Exchange and Foreign Trade Control Law of

Japan, such products must not be exported without obtaining export license from the Ministry of

International Trade and Industry in accordance with the above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or any information storage or retrieval system,

or otherwise, without the prior written permission of SANYO Electric Co., Ltd.

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the “Delivery Specification”

for the SANYO product that you intend to use.

Information (including circuit diagrams and circuit parameters) herein is for example only; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but

no guarantees are made or implied regarding its use or any infringements of intellectual property rights

or other rights of third parties.

Loading...

Loading...