Sanyo STERISONIC GXP User Manual

Sterisonic™ GxP

Series Cell Culture

Incubators

CO2 Incubators

MCO-19AIC(UVH)

MCO-19AIC(UV)

MCO-19AIC

CO

/ O2 Incubators

2

MCO-19M(UVH)

MCO-19M(UV)

MCO-19M

Features:

• The industry’s most complete cell culture

solution for highly regulated applications or

conventional incubation.

• Safe, effective and documented two-hour in situ

sterilization for fastest decontamination.

H

2O2

www.sanyobiomedical.com

My Life. My Work. My Choice.

MCO-19AIC

MCO-19M

MCO-19AIC(UV)

MCO-19AIC(UVH)

MCO-19M(UV)

MCO-19M(UVH)

Sterisonic™GxP Series Cell Culture CO2 and CO2 / O2 Incubators

The industry’s most complete cell culture solution for highly regulated applications or conventional

incubation. Now with safe, effective and documented two-hour in situ H

decontamination turn-around and maximum availability.

Sterisonic™ GxP Selection

Feature

Vapor Sterilization Standard Optional Optional Standard Optional Optional

H

2O2

™

SafeCell

UV Decontamination Standard Standard Optional Standard Standard Optional

Single Beam, Dual Detector IR CO

Oxygen Concentration Control, Zirconia Control N/A N/A N/A Standard Standard Standard

Sensor Standard Standard Standard Standard Standard Standard

2

MCO-

19AIC(UVH)

CO2 Incubators CO2/O2 Incubators

MCO-

19AIC(UV)

MCO19AIC

sterilization for fastest

2O2

MCO-

19M(UVH)

MCO-

19M(UV)

MCO-

19M

Product Applications

The combination of Sterisonic™ GxP

incubator performance functions permit

use with condence in high-value cell

protocols among hard-to-grow cell lines,

cells highly sensitive to contamination,

ultra-sensitive media and reagents, or

protocols that require a strict isolation

and sterilization between processes.

These include but are not limited to:

Stem cell research•

Autologous tissue regeneration •

and regenerative medicine

• In vitro fertilization

1

Genomic and proteomic expression•

Esoteric plant and amphibian •

cell culture

Hypersensitive and transgenic •

cell culture

Low media volume microplate work•

1

501(k) clearance applied for. Contact SANYO for status. MCO-19AIC

and MCO-20AIC CO2 incubators have received U.S. Food and Drug

Administration 510(k) clearance for in vitro fertilization applications in

accordance with the FDA Safe Medical Devices Act of 1990 and the Medical

Device Amendments of 1992. Reference: Number K013703. Regulation

Number: 21 CFR 884-6120, Assisted Reproduction Accessories, Regulatory

Class II, Product Code 85MOG, October 30, 2001

Designed for use with a variety

of standard cell culture vessels

and protocols.

Interior components and adjustable •

shelves are congured for easy access,

in situ sterilization and exible arrangement for a variety of applications.

Four adjustable shelves are included, •

standard; maximum shelf capacity

is 15 shelves.

MCO-19AIC(UVH)

MC O-19M

Multi-Gas Incubator, Oxygen

and CO2 Control

Ideal for • in vitro fertilization (IVF), genetic

research, regenerative medicine and

other protocols that require CO

sub-ambient (hypoxic) or above-ambient

oxygen control.

Cabinet based on MCO-19 platform •

with inCu safe

stainless steel chamber, continuous

contamination control, patented D.H.A.

multi-point, air-jacketed temperature

control system, elevated relative humidity

with integral water-level sensor.

™

copper-enriched

and

2

2 Sterisonic™ GxP Series Cell Culture Incubators

Sterisonc™ GxP Features and Benefits

The SANYO Sterisonic™ GxP is designed for a wide array of demanding and highly regulated applications in the biomedical, pharmaceutical,

medical research and clinical laboratory. Representing years of research, development and component testing, the Sterisonic™ GxP incorporates a

collective of mutually functional systems and design attributes to offer a holistic solution to cell culture protocols, from the most sophisticated to

more familiar and conventional processes.

Sterilization and Decontamination

The unique Sterisonic•

sterilization system limits downtime

to less than three hours when total

chamber sterilization with verication

is desired.

All interior components and CO•

sampling loop are sterilized in situ;

no need for removal and autoclaving.

Active Background Contamination •

™

Control

ghts contamination while

cell culture protocols are in process.

The patented SafeCell

system scrubs interior airow

to destroy airborne and humidity pan

contaminants.

Exclusive inCu saFe

enriched stainless steel interior

surfaces assure constant germicidal

protection.

™

GxP H2O2

2

™

UV

™

copper-

Shelf brackets are formed

with an exaggerated angle

to minimize surface contact

with flat shelves*.

Control and Monitoring

The Sterisonic•

information center includes an intuitive

pop-up menu, high resolution LCD

for inputs, outputs and performance

at-a-glance.

Multi-point data logging offers •

push-button graphical display. An

optional PC interface permits remote

transmission for GMP/GLP protocols

as required.

Precise PID logic controls and •

adjusts to all temperature, CO

points and alarm parameters.

™

GxP control and

set-

2

CO2 Control

SANYO proprietary single-beam,

dual detector infrared (IR2) CO

sensor delivers precise CO

control,

2

quick recovery following door openings,

and auto sampling with no moving parts.

Continuous zero calibration is standard.•

An optional semi-automatic, one-point •

calibration system is available. Catalog

No. MCO-SG; see Accessories.

2

Zirconia O2 Control System,

MCO-19M Series

A zirconia oxygen sensor main-

tains sub-ambient O

1% to 18%. Additionally, enriched O

levels from 22% to 80% are enabled

with proper safety precautions.

Concurrently the MCO-19M permits •

a CO

range 0% to 20% via infrared

2

sensor.

Nitrogen gas bubbler accelerates •

recovery of chamber humidity levels

following door openings.

An electronic P.I.D. control maintains •

accurate temperature and gas setpoints over the entire system range.

The MCO-19M includes an automatic •

gas switchover system that changes

from the primary to a secondary gas

cylinder for either oxygen or nitrogen;

an optional second gas switchover

system is available for CO

Cabinet based on MCO-19 platform •

with inCu saFe

™

copper-enriched

stainless steel chamber, continuous

contamination control, patented D.H.A.

multi-point, air-jacketed temperature

control system, elevated relative humidity with integral water-level sensor.

levels from

2

.

2

2

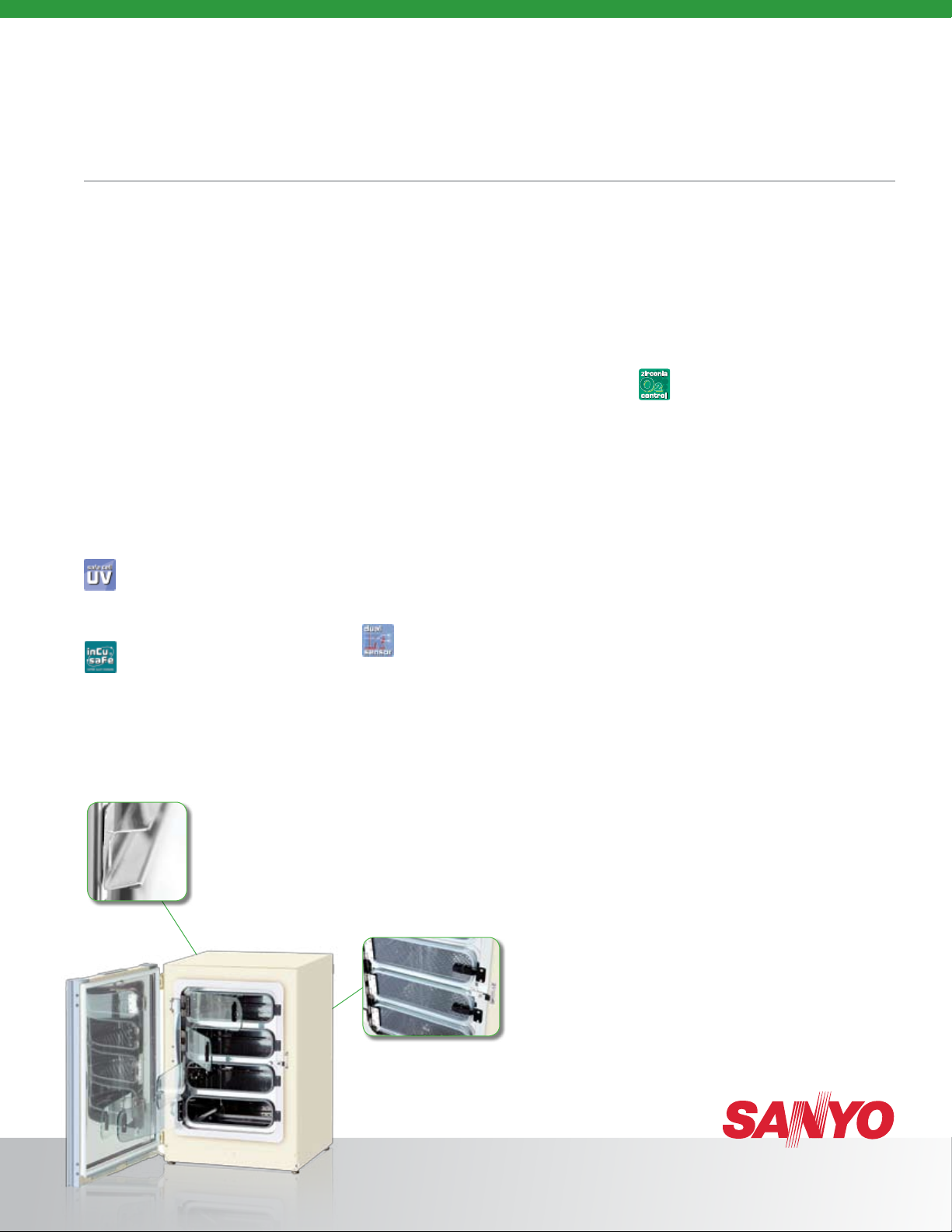

MC O-19M

MCO-19M shown with

four separate inner

doors with gaskets.

3

Sterisonc™ GxP Features and Benefits

Temperature

and Humidity Control

The patented Direct Heat and Air•

™

conditioning system manages setpoint

temperature through multiple, variable

warming points under microprocessor

control.

The humidity pan is easy to ll, easy •

to clean; the automatic optical sensor

advises of low water level.

H2O2 Sterilization

The use of H2O2 sterilization in

biological safety cabinets and barrier isolators is a popular alternative to ethylene

oxide (EtO) as a safer, more efcient

decontamination method. H

been widely used in the pharmaceutical

industry. In aerospace research, H

used to sterilize satellites.

The FDA has recently granted 510(k)

clearance to use H

in individual medi-

2O2

cal device manufacturing applications.

EtO criteria outlined in ANSI/AAMI/ISO

has long

2O2

2O2

is

14937 may be used as a validation guideline. For references online visit

www.sanyobiomedical.com/sterisonic.

Unlike conventional incubators, unique

features of the SANYO Sterisonic

GxP incubator permit use of the H

process in situ with complete safety,

zero impact on adjacent equipment or

the environment, and speed to return

the incubator to service.

The • H

tions with the patented SANYO

SafeCell

sterilization process func-

2O2

™

UV system. Following a

seven-minute H

circulation and dwell cycle, vaporization

is stopped and the SafeCell

turned ON for up to ninety minutes.

When exposed to UV light, the • H

vapor breaks down into water and

oxygen, leaving only traces of water

droplets. These droplets automatically condense onto a naturally cooler

section of the interior oor for easy

wipe-up.

Throughout the entire cycle the •

Sterisonic

™

GxP airow system continues to gently circulate interior air

assuring 100% vapor contact with all

interior surfaces, ultimately creating

a serial dilution of H

over the UV lamp.

vaporization,

2O2

as it passes

2O2

™

2O2

™

UV lamp

2O2

Orientation of interior sample ports •

of the single beam, dual detector IR

CO

sensor creates a slight Venturi

2

ow through the sample chamber,

permitting total sterilization of the

CO

system at the same time.

2

Shape and location of interior compo-•

nents such as shelves, shelf brackets,

plenum covers and the humidity pan

permit the components to remain

in the chamber during the sterilization

process, conveniently bypassing the

need for a separate autoclave cycle.

Once the cycle is complete, the door •

locking system is released; the inner

door can be opened, interior components repositioned and the incubator

is returned to service.

Ergonomic Cabinet Design

With reversible inner and outer doors,

a single SANYO incubator offers the

industry's most exible installation

options available.

Low prole cabinet with door-mounted •

control panel permits easy access and

viewing.

The outer door latch and door heater •

cable is easily switched if a reverse

opening is required.

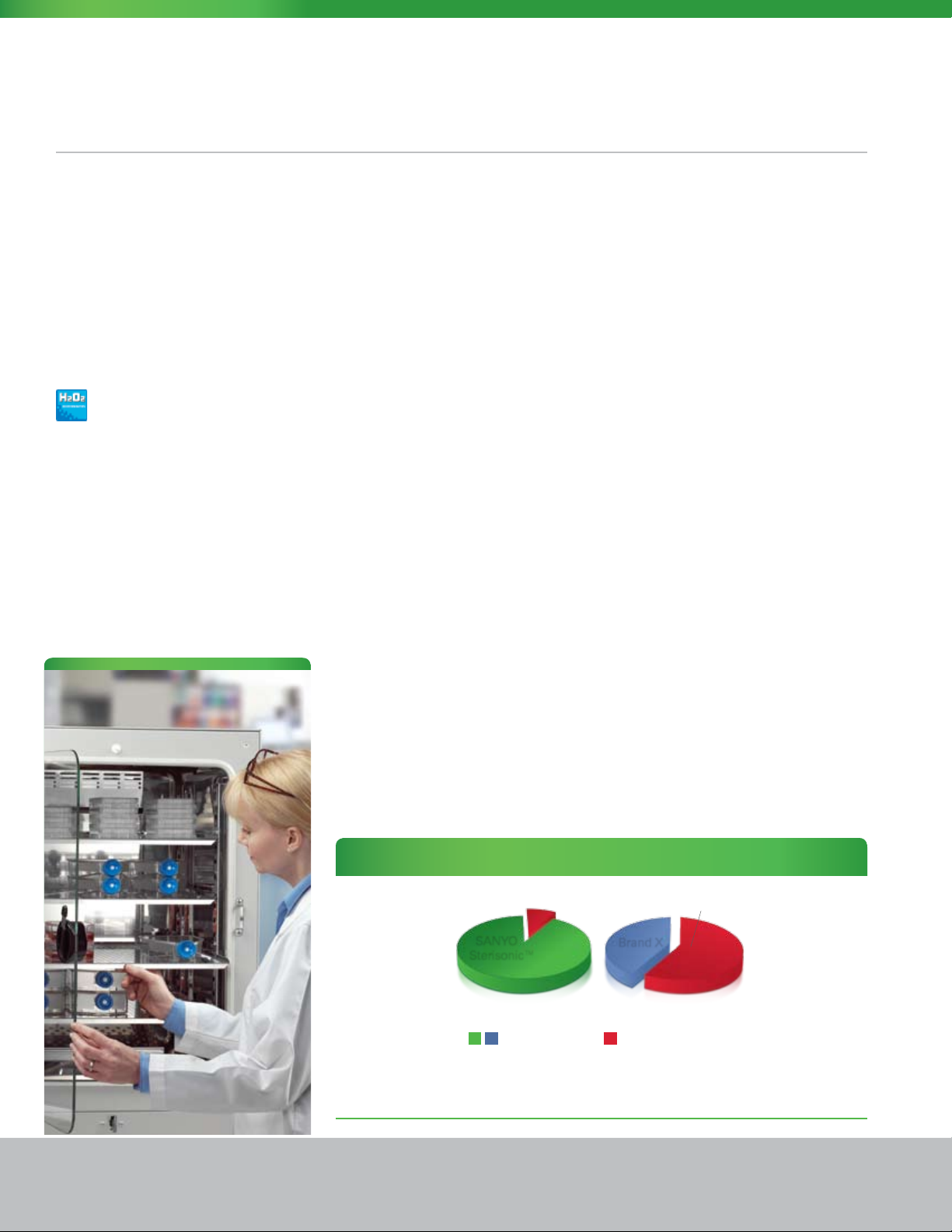

Sterisonic™ GxP Series H2O2 Sterilization Performance Value

2 Hours

SANYO

Sterisonic™

H2O

sterilization vs. high heat sterilization

2

= Uptime (Hours)

The documented two-hour in situ H2O2 sequence puts the fully sterilized Sterisonic™ GxP available and

ready for use quicker than any other incubator worldwide.

4 Sterisonic™ GxP Series Cell Culture Incubators www.sanyobiomedical.com

Brand X

=

Downtime (Hours)

14 Hours

Sterisonc™ GxP Features and Benefits

Cabinet knock-outs are pre-drilled •

and tapped to eliminate drilling and to

simplify re-mounting of door hardware.

The outer door closes against a •

soft, easily cleaned magnetic gasket

designed to eliminate ambient air

shear across the glass inner door,

minimizing condensation.

A door ajar alarm provides an audible •

and visual warning if the outer door

is left open.

A center-mounted key lock is located •

beneath the door for added security;

model MCO-19AIC(UVH) only.

Shelves and Inventory

Management

Convenient space efcient inventory

management is simplied through a system of adjustable, extendable shelves.

Inventory shelves and brackets are •

formed from polished copper-enriched

stainless steel, removable without

tools, and can remain inside the incubator during the H

or autoclaved separately if desired.

sterilization cycle

2O2

Shelves are perforated to permit natu-•

ral vertical air convection through and

around labware.

Shelf brackets are formed with an •

exaggerated angle to minimize surface

contact with at shelves (patent pending). Brackets slip easily into vertical

supports that attach to interior chamber walls with clearance sufcient to

permit proper air circulation.

Inner Door and Gasket

The inner design is critical to successful

contamination control technique.

The inner gasket body forms an •

effective thermal transition between

the ambient air and warm, humidied

incubator atmosphere, minimizing

condensation and eliminating moisture

traps which can harbor contaminants.

The inner door gasket is a dual •

durometer extrusion (two levels of

softness) from closed-cell silicone

to inhibit contamination.

The gasket feather-edge allows •

the inner glass door to close gently

against the chamber opening for

a tight peripheral seal.

The entire inner door gasket is remov-•

able for cleaning and/or replacement

if required.

Radiant heat from the outer door, •

apportioned by the microprocessor

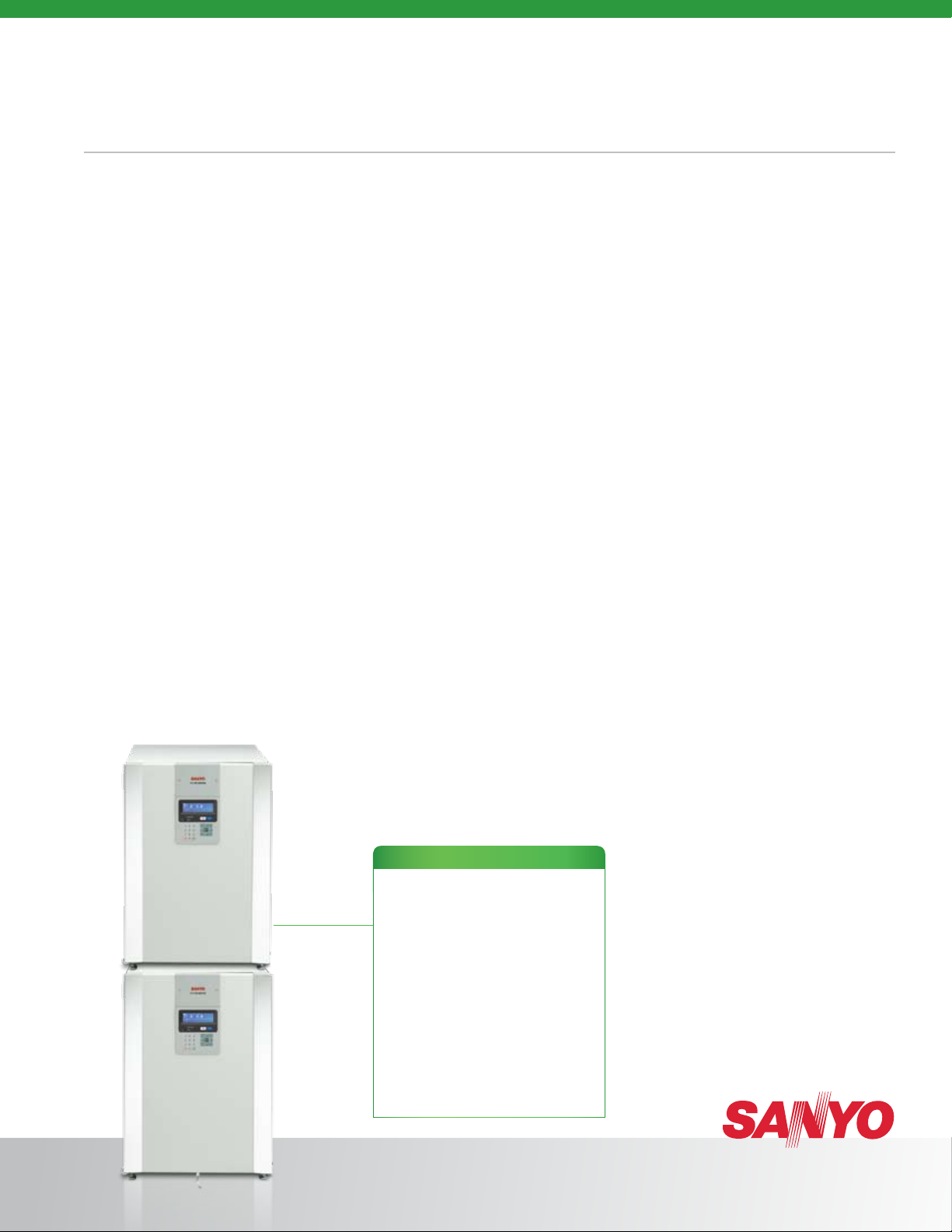

MCO-38AIC(UVH)

Stacking Doubles Capacity

in Same Footprint.

The Sterisonic•

designed for stacking, allowing one

unit to be positioned on top of

another, doubling interior volume

without additional oor space.

The combination of stacking and •

reversible doors offers the most

installation options possible.

An optional roller base is recom- •

mended for stacked installations

to permit mobility if required;

see Accessories.

™

GxP cabinet is

control as a function of the patented

Direct Heat and Air Jacket

™

, automatically warms the inner door glass

in proportion to total heat demand

and condensation control.

Field Reversible Door

The eld-reversible door allows

universal installation using the left-hand

hinge (standard) or a right-hand hinge

modication

The outer door includes a universal •

nger grip at each side.

Mounting holes for hinge hardware •

are pre-drilled and capped with easily

removable trim plugs.

The door heater cable plugs into the •

alternate connection to complete

the change.

Elevated Humidity,

Low Water Level Warning

To avoid cell culture desiccation, the

SANYO Sterisonic

maintains ~95% RH at 37°C.

Humidication is achieved by a com-•

bined forced-air and natural evaporation method enhanced by the Direct

Heat and Air Jacket

protected by an optical water level

indicator to warn of low water in the

removable humidity pan.

The humidity pan removes easily for •

regular cleaning and rell.

When lled, the pan slides into place. •

The optical sensor returns to position

and the SafeCell

any contaminants introduced during

the process.

For the H•

the humidity pan is repositioned

against the chamber wall to eliminate

the need for separate autoclaving.

™

GxP CO2 incubator

™

base heater, and

™

UV lamp destroys

in situ sterilization cycle

2O2

5

Loading...

Loading...