Sanyo SBM-201 Service Manual

SERVICE MANUAL

Automatic Bread Maker

FILE NO.

SBM-201

PRODUCTIONCODENO.

343631822 (New Zealand)

343631829 (Malaysia)

REFERENCE NO. SM-680078

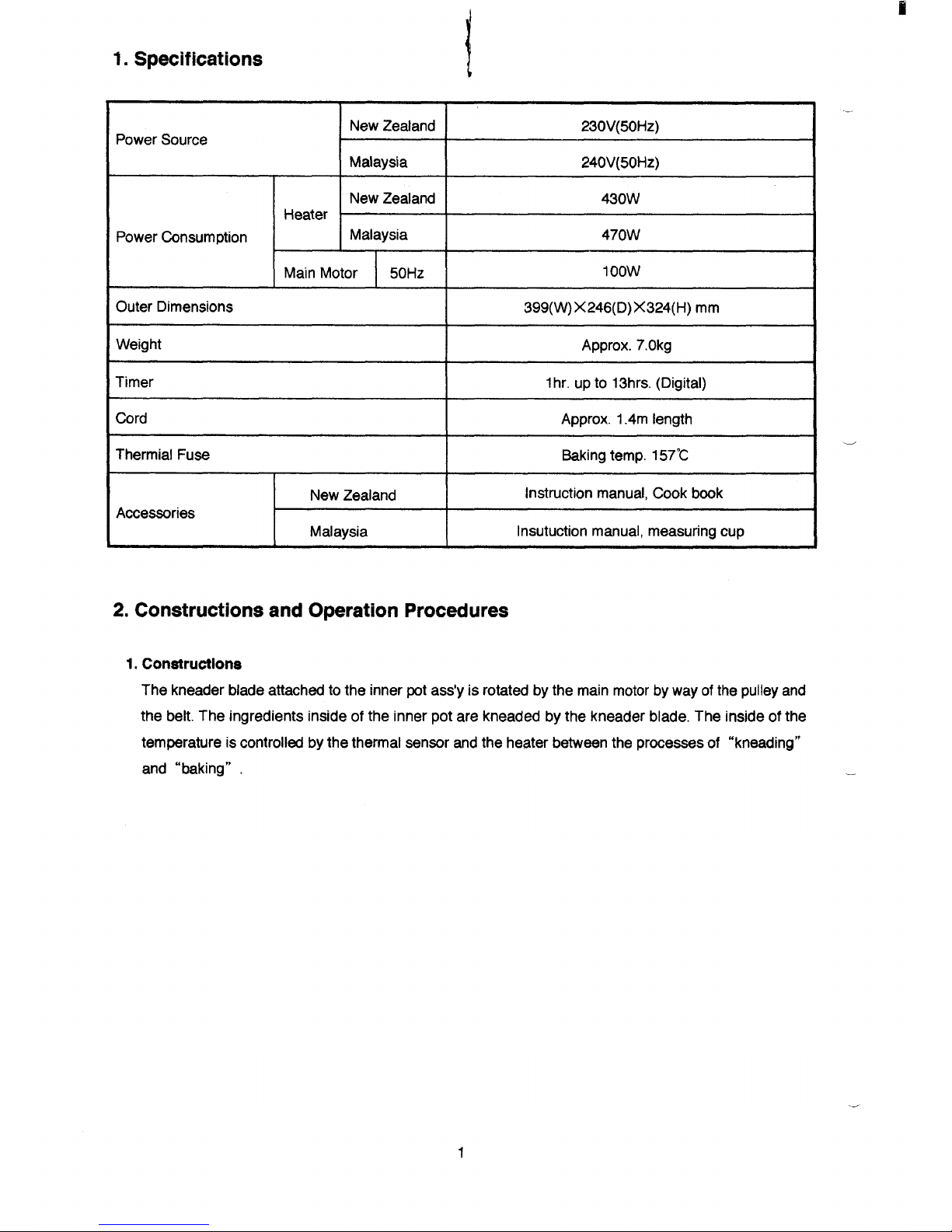

i. Specifications

b

New Zealand

230V(50HZ)

Power Source

Malaysia

240V(50HZ)

New Zealand

430W

Heater

Power Consumption

Malaysia

470W

Main Motor

50Hz

1

Oow

Outer Dimensions

399(W)X246( D)X324(H) mm

Weight

I

Approx. 7.Okg

Timer

I

1

hr. up to 13hrs. (Digital)

Cord

Approx. 1.4m length

Thermial Fuse

Baking temp. 157°C

New Zealand

Instruction manual, Cook book

Accessories

Malaysia

Insutuction manual, measuring cup

2. Constructions and Operation

1.

ConstructIons

The kneader blade attached to the inner pot ass’y is rotated by the main motor by way of the pulley and

the belt. The ingredients inside of the inner pot are kneaded by the kneader blade. The inside of the

temperature is controlled by the thermal sensor and the heater between the processes of “kneading”

and “baking” .

—

1

i

I

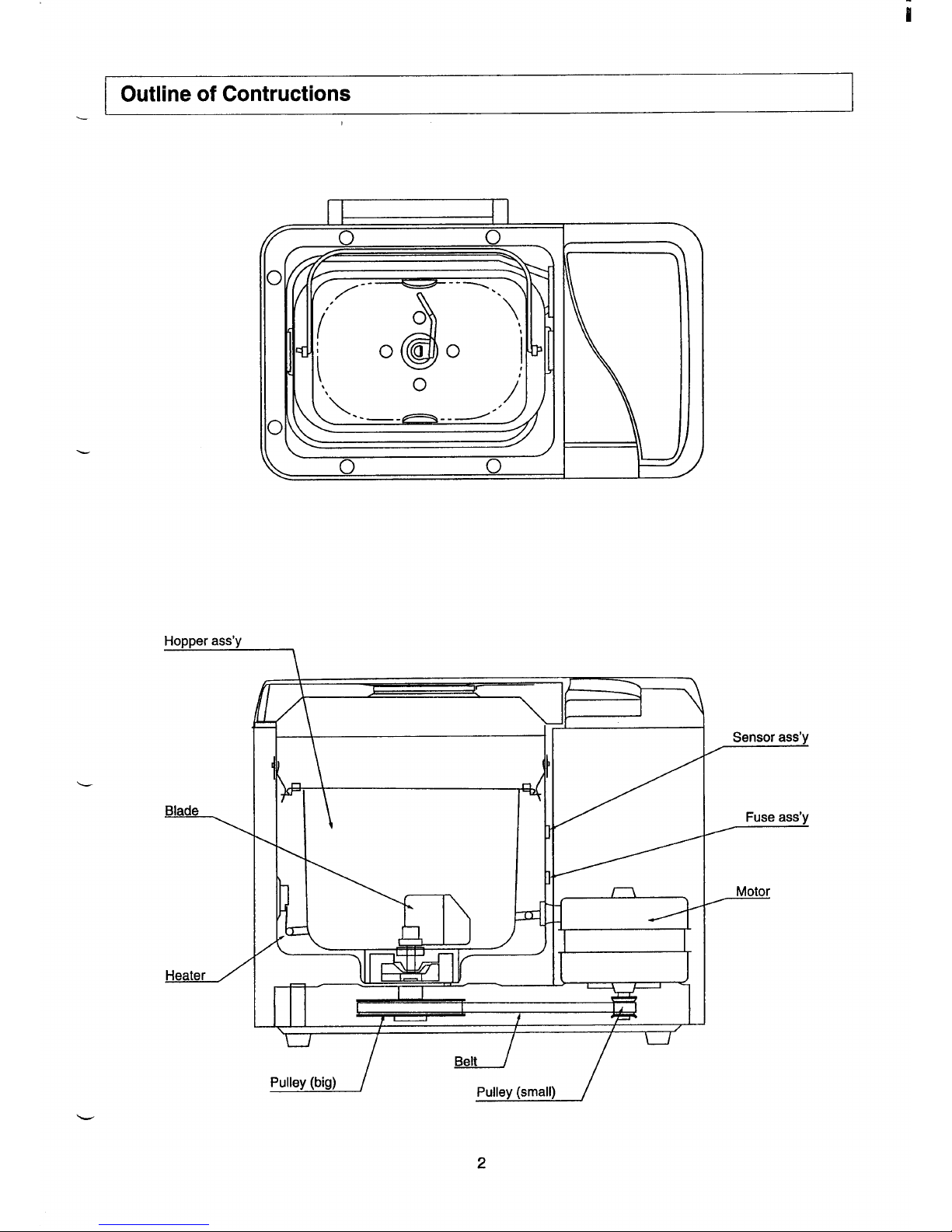

Outline of Constructions

I

I

I

[1 I

L

k..

u

w

Hopperass’y

\

Blade

d

,, ,,

—

\ \

lr

\ r

1

1

I

I 1.

r

f

I

I

f

/

—

/ /

/

d

“d

Sensor ass’y

/

Fuse ass’y

, Motor

I

2

i

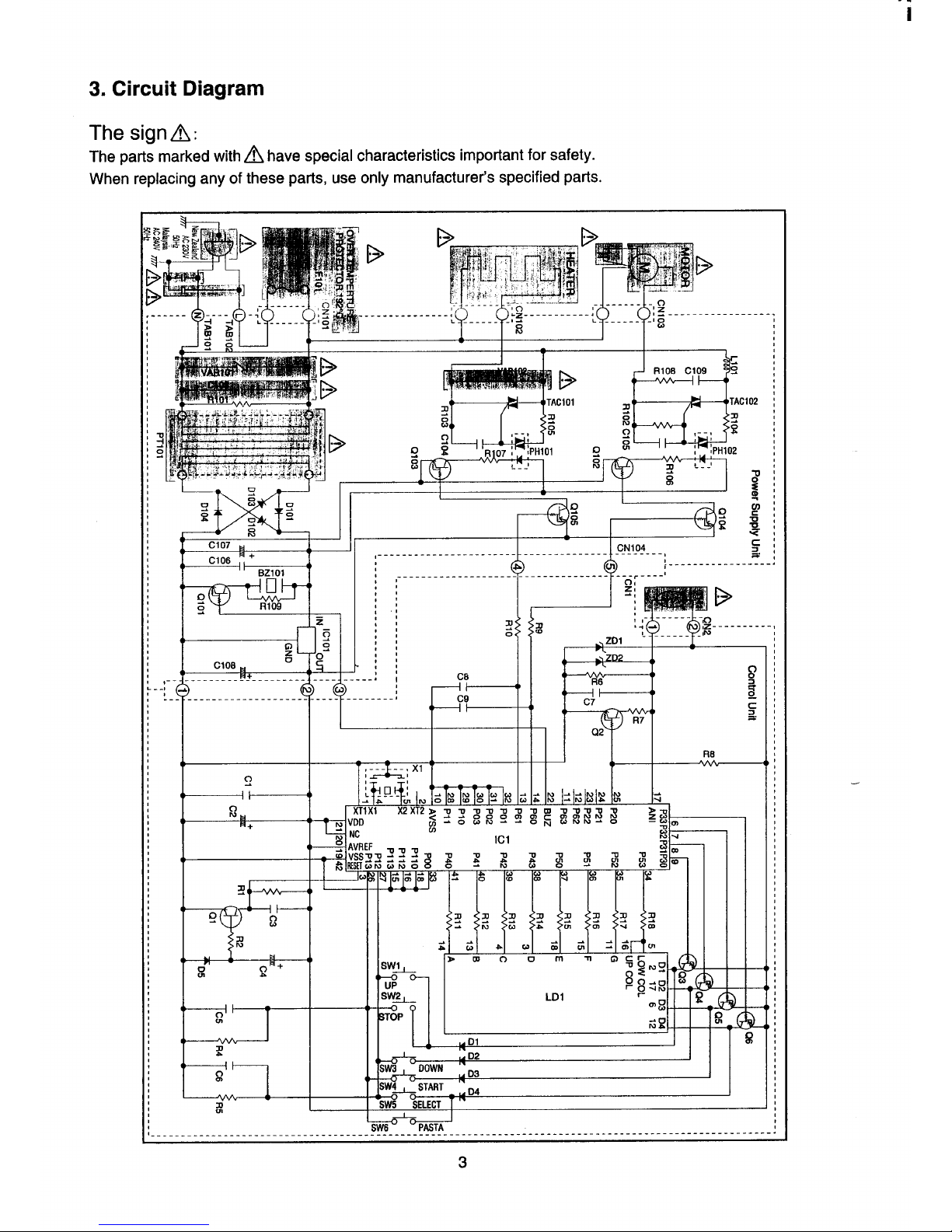

3. Circuit Diagram

The sign A:

The parts marked with ~ have special characteristics important for safety.

When replacing any of these parts, use only manufacturer’s specified parts.

-,

=

1

I

CJ

$L-.-J

t

A

I T I –r

m .HAC102

J1

.

L-.:–

!!

. .

l.At!- 11

Q-4’!kdir--------------T=-Ti-’

a’

0(

s

.,

z

,1

,1

q

,1

,1

C)s

,1

,1

5

0

,1

C108

,1

,1

+

,!

.---- ----.---- ii

B

11L&’F

-!, . .

------

n

g

1,-

-0

.+a

,= ---------

s

Zol L

-,N

D

03

.

g

@

------------------ -----

-------. ,

C9

I-YL_.l

Il.-e+

: D2 I

II

I

,

m

WC)

!-----------------------------------------------------------------------------------------------------

,

,

1

,

,

,

,

,

0

,

,

.-

3

ii

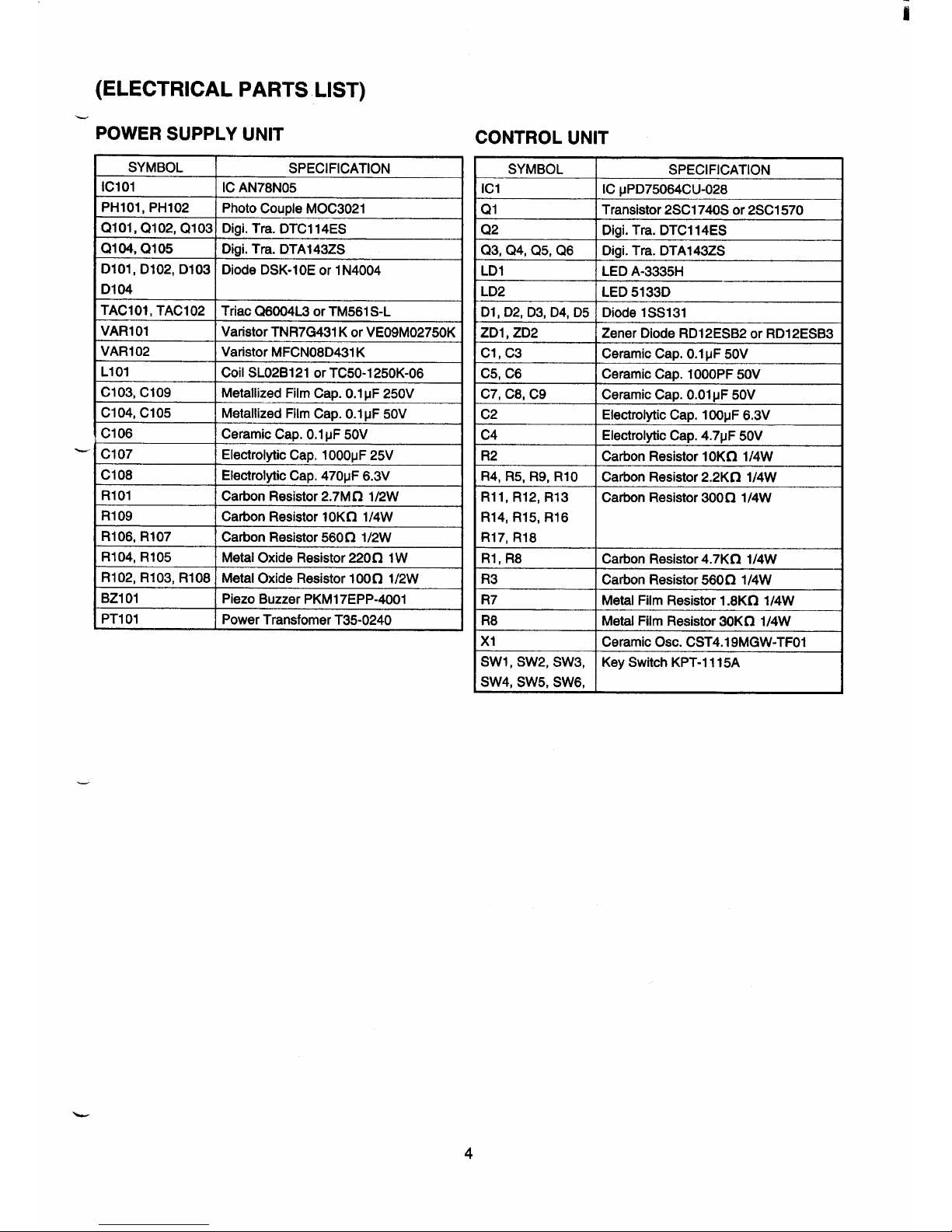

(ELECTRICAL PARTS LIST)

-

POWER SUPPLY UNIT

L

SYMBOL

SPECIFICATION

Iclol

IC AN78N05

PH101, PH102 Photo Couple MOC3021

Q101, Q102, Q103 Digi. Tra. DTC114ES

Q104,Q105

Diai. Tra. DTA143ZS

D101, D102, D103

Diode DSK-1OEor 1N4004

D104

TAC101 , TAC102 Triac Q6004L3 or TM561 S-L

VAR101

Varistor TNR7G431 K or VE09M02750K

VAR102

Varistor MFCN08D431 K

LI 01

Coil SL02B121 orTC50-1250K-06

C103, C109

] Metallized Film Ca~. 0.1UF250V

C104, C105 Metallized Film Cap. 0.1pF 50V

Cl 06 Ceramic Cap. 0.1uF 50V

C107

I Electrolytic Cam 10OOUF25V

.

,---r ——

C108 Electrolytic Cap. 470pF 6.3V

R101

Carbon Resistor 2.7Mfl l/2W

R109

I

CarbonResistor 10Kf2 l/4W

R106, R107

Carbon Resistor 560fl l/2W

R104, R105

Metal Oxide Resistor 220t2 1W

R102, RI 03, R108 I Metal Oxide Resistor 100(1 l/2W

BZ101 Piezo BuzzerPKM17EPP-4001

PT101 Power Transformer T35-0240

CONTROL UNIT

SYMBOL

SPECIFICATION

icl IC pPD75064CU-028

Q1

Transistor 2SC1740S or 2SC1570

Q2 Digi.Tra. DTC114ES

Q3,Q4,Q5, Q6

Digi. Tra. DTA143ZS

LD1 LEDA-3335H

LD2

LED5133D

D1, D2,D3,D4,

D5 Diode 1SS131

ZD1, ZD2 Zener Diode RD12ESB2 or RD12ESB3

cl, C3

Ceramic Cap. 0.1pF 50V

C5, C6 Ceramic Cap. 10OOPF50V

C7, C8, C9

Ceramic Cap. O.OlpF 50V

C2

Electrolytic Cap. 10OpF6.3V

C4

Electrolytic Cap. 4.7pF 50V

R2

Carbon Resistor 10KL2 l/4W

R4, R5, R9, R1O

Carbon Resistor 2.2Kt3 l/4W

Rll, R12, R13

Carbon Resistor 300C4 l/4W

R14, R15, R16

R17, R18

R1, R8 Carbon Resistor 4.7KCI l/4W

R3

Carbon Resistor 560S2 l/4W R7

Metal Film Resistor 1.8K(I l/4W

R8 Metal Film Resistor 30KLI l/4W

xl

Ceramic Osc.CST4.19MGW-TFO1

Swl , SW2, SW3,

Key Switch KPT-111 5A

SW4, SW5, SW6,

4

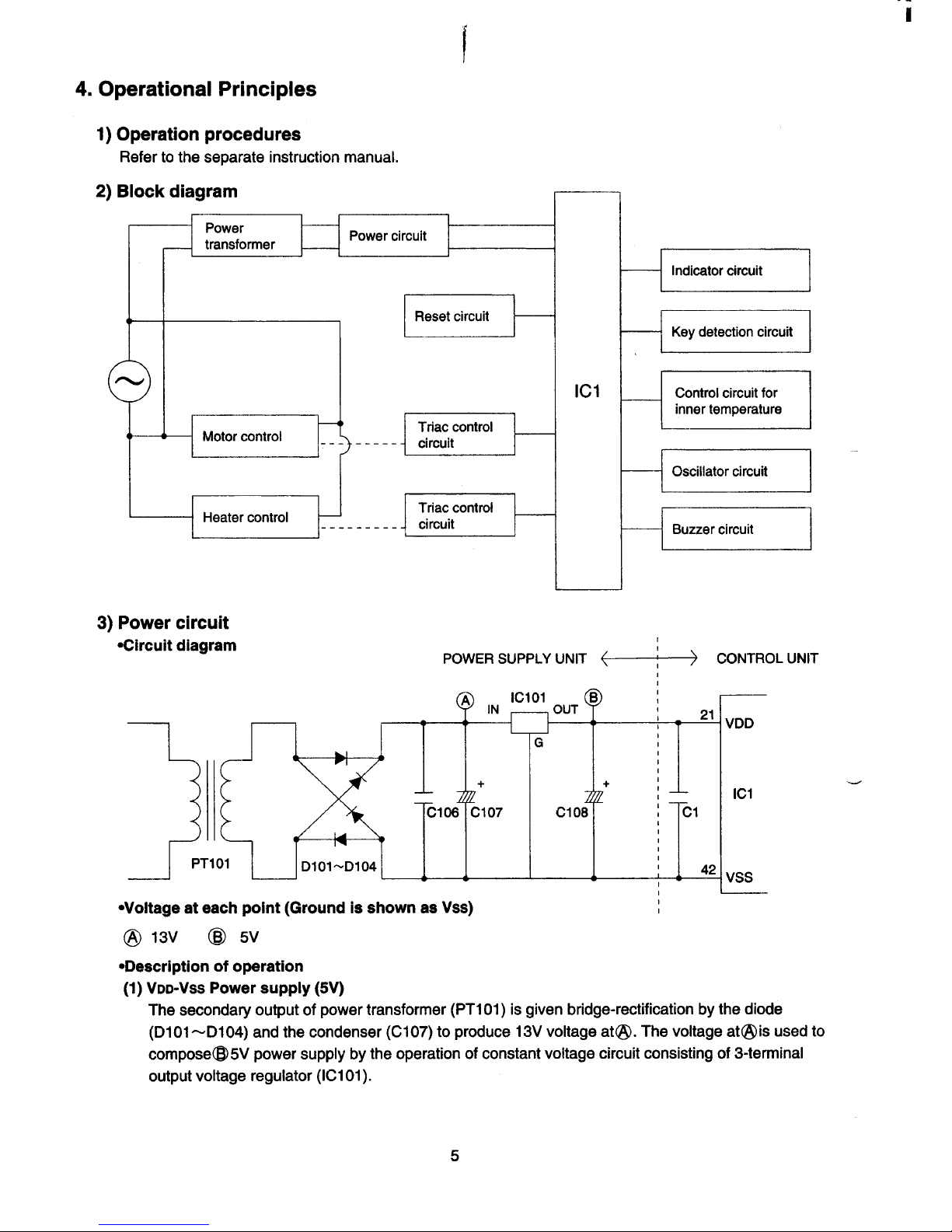

4. Operational Principles

1) Operation procedures

Refer to the separate instruction manual.

2) Block diagram

Power

transformer

Power circuit

m------

I I 7

+

Heater control

k!------] ::::i~’m’ I___

I

I

I

I

3) Power circuit

=ircuit diagram

----J

Icl

Indicator circuit

=

-

---EEcl

1

POWERSUPPLYUNIT

(

)

CONTROLUNIT

1

I

Iclol

IN

OUT

I 1

21 VDD

I

T T T

I

T

l-pi

G

+ +

T

C106 Clul

I

bl

I

I

I

Vllul 1 ]D101-D1o4,

L

1

I 1 t 1

f

“q Vss

I

I

+oltage at each point (Ground is shown as Vss)

I

I

@

13V @ 5V

●Description of operation

(1)

VDD-VSS Power supply (5V)

The secondary output of power transformer(PT101 ) is given bridge-rectification by the diode

(D101 -D104) and the condenser (C107) to produce 13V voltage at@. The voltage at@is used to

compose@ 5V power supply by the operation of constant voltage circuit consisting of 3-terminal

output voltage regulator (ICI 01).

5

ii

w

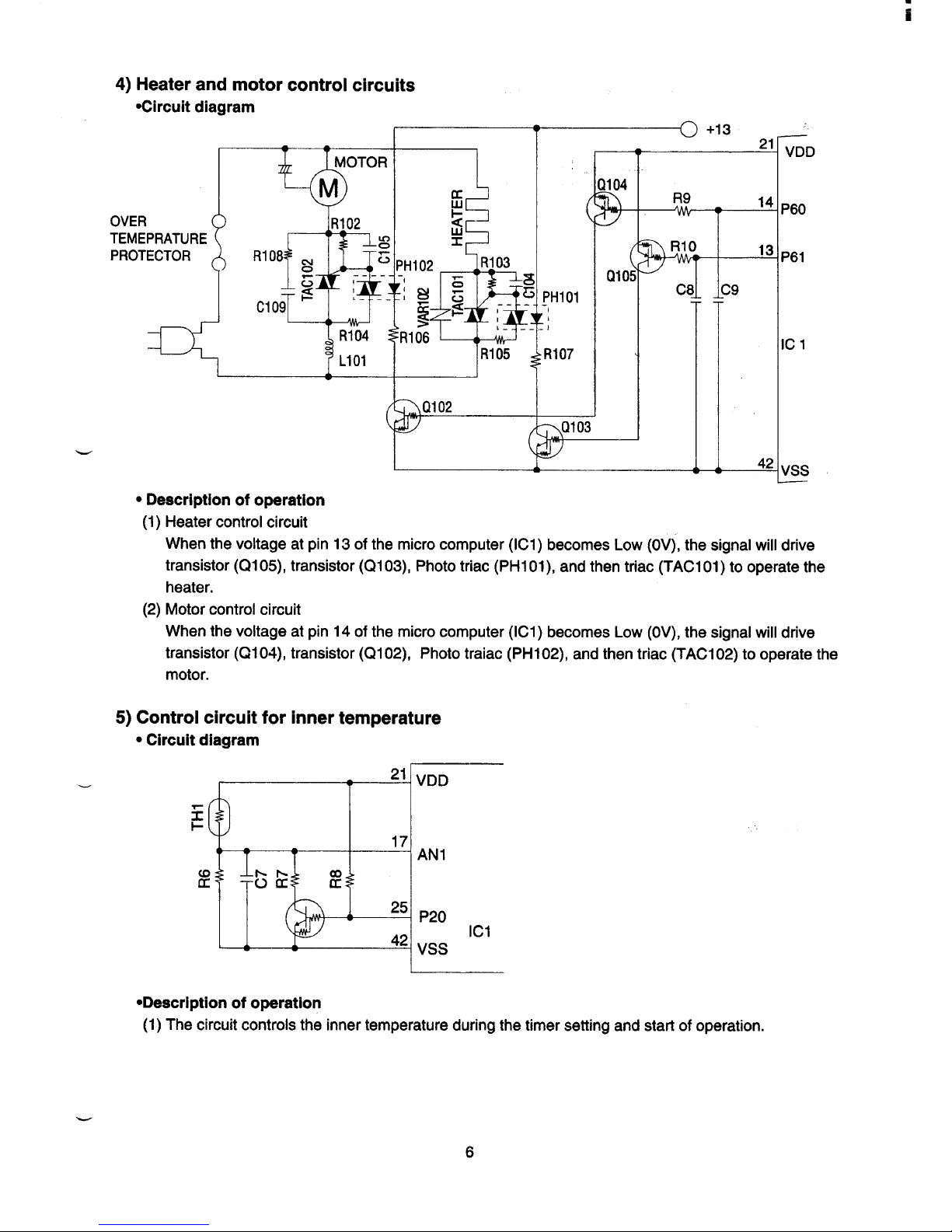

4) Heater and motor control circuits

●

Circuit diagram

m

‘F

(N04

010!

~ +13

21

.

I

A

I

(%

Q102

M

Rl(

Ca

-t---

1

C9

1-

VDD

P60

P61

Ic 1

Wss

● Description of operation

(1) Heater control circuit

When the voltage at pin 13 of

the micro computer (ICI) becomes Low (OV), the signal will drive

transistor (QI 05), transistor (Ql 03), Photo triac (PH101 ), and thentriac(TAC101 ) to operate the

heater,

(2) Motor control circuit

When the voltage at pin 14 of the micro computer (IC1) becomes Low (OV), the signal will drive

transistor (Q104), transistor (Ql 02), Photo traiac (PH1 02), and thentriac(TAC102) to operate the

motor.

5) Control circuit for inner temperature

● Circuit diagram

2’~VDD

z

1-

17

)

AN1

i?”“

- -G Ii

i?: ~

25 P20

Icl

42 Vss

.Description of operation

(1) The circuit controls the inner temperature during the timer setting and starl of operation.

w

6

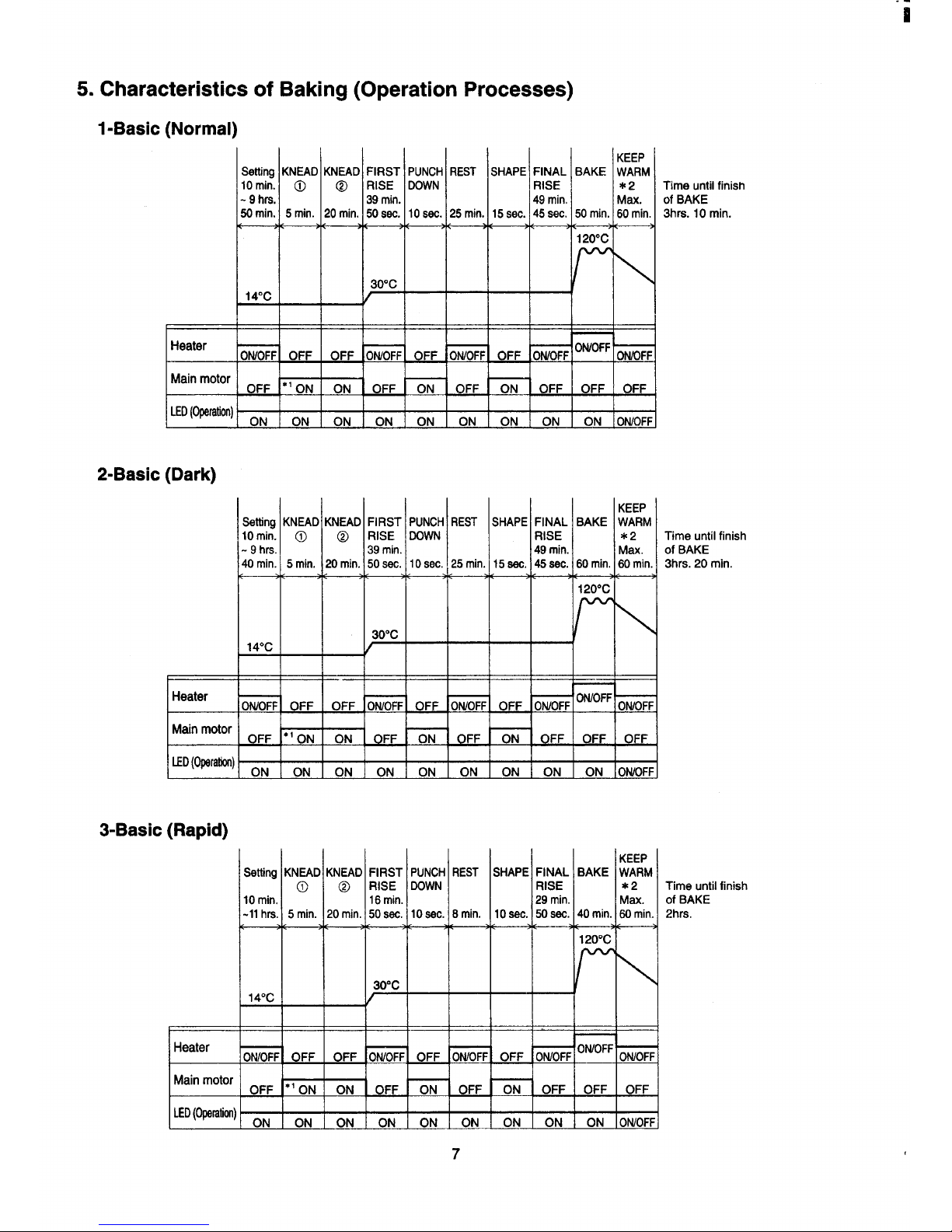

5. Characteristics of Baking (Operation Processes)

l-Basic (Normal)

KEEP

SettingKNEADKNEADFIRST

PUNCHREST SHAPEFINAL

BAKE

WARM

10min. @

@ RISE

DOWN

RISE

*2

-9 hre. 39min.

49rein,

Mex.

50min. 5 min. 20

min. 50sec.

10sec. 25

min. 15sec. 45sec.

50min. 60min.

<

>

120”C

30°c

14°C

r

Heater

ON/OFFOFF OFF ON/OFF

OFF ON/OFFOFF ON/OFF

OwOFF

ONK)FF

Mainmotor

OFF *’ON ON OFF

ON OFF

ON

OFF

OFF OFF

LED(Cpsrstbn)

ON ON ON ON

ON ON ON ON

ON OIWOFF

2-Basic (Dark)

L

Setting

10rein,

-9

hrs

40min

1-

14°C

I

I

3-Basic (Rapid)

Ml14_

KNEADKNEADFIRST PUNCHREST SHAPEFINAL BAKE

5

min. 20min. 50sec. 10sec. 25 min. 16W. 45sec. 60min

J4-u4-T

— —.

— .

OFF OFF ON/OFF

OFF OfVOFFOFF OFJOFF

‘ ON/OFF

*‘ON I ON OFF ON OFF ON

10

FF

OFF

I I

{

I

1 1

1

ON ION] ON\ ON ION ION\ ONION

i

KEEP

WARM

*2

Max.

60 min.

ON/DFF

FF

!2K?.E.

KEEP

SettingKNEADKNEADFIRST

PUNCHREST SHAPEFINAL

BAKE WARM

@

@ RISE

DOWN RISE

*2

10min. 16min.

29min.

Msx.

-11hre. 5min. 20min. 50sec.

loeec. 8min. 10sec. 50sec.

40min. 60min.

(

>

120”C

30”C

14°C

L

Heater

ONIOFFOFF OFF ON/OFF

OFF ON/OFFOFF ON/OFF

‘ON/OFFOWOFF

Mainmotor

OFF *’ ON ON OFF

ON OFF

ON OFF

OFF OFF

LED(Opsrstii)

ON ON ON ON

ON ON ON ON

ON

OfVOFF

7

Time until finish

of

BAKE

3hrs.10 min.

Time until finish

of BAKE

3hrs. 20 min.

Time until finish

of BAKE

2hrs.

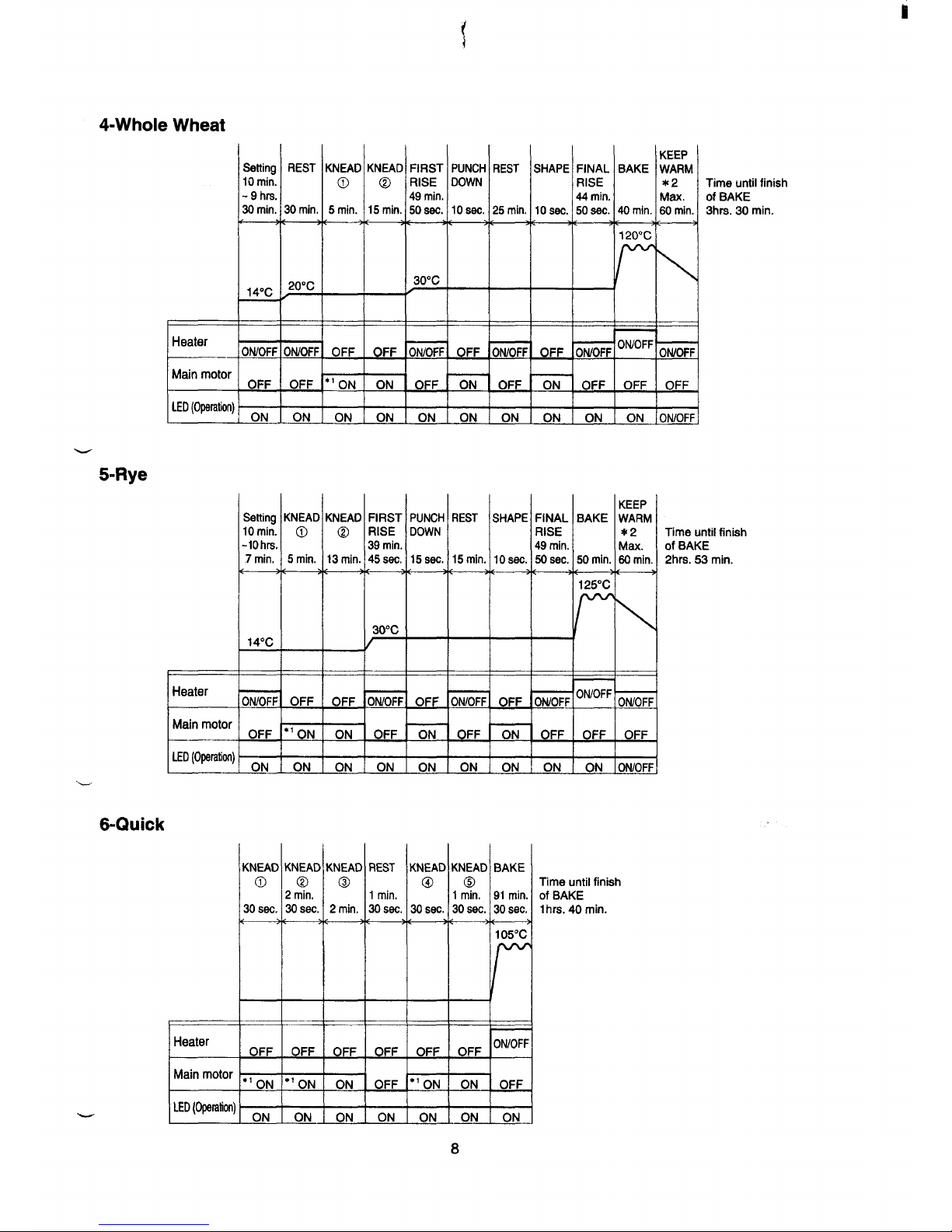

4-Whole Wheat

KEEP

Setting REST KNEADKNEAD FIRST PUNCHREST SHAPE FINAL BAKE WARM

10min.

@

@ RISE DOWN

RISE

*2

Time until finish

-9 hrs.

49min.

44 min.

Max. of BAKE

30min. 30 min. 5min. 15min. 50 sec. 10sec. 25 min. 10sec. 50Sec. 40 min. w min. 3hrs, 30 min.

<

>

120”C

30°c

Heater

OWOFFON/OFF OFF OFF ON/OFF

OFF ON/OFF

OFF “OtVOFFOwOFFON/OFF

Mainmotor

OFF OFF

*’ ON ON

OFF ON OFF

ON OFF OFF OFF

LED(Operation)ON ON ON ON ON ON ON

ON ON ON ON/OFF

w

5-Rye

KEEP

Setting KNEADKNEAD FIRST PUNCHREST SHAPE FINAL BAKE WARM

10min. @

@ RISE DOWN

RISE

*2

Time until finish

-lOhrs.

39min. 49min.

Max. of BAKE

7min. 5 min.

13min. 45 sec. 15sec. 15min. 10sac. 50 sec. 50 min. Ml min. 2hrs. 53 min.

6

>

125°C

30”C

14°C

L

Heater

ON/OFF OFF OFF ON/OFF OFF ONIOFF OFF ON/OFF

ON/OFF

ON/OFF

Main motor

OFF

●’ ON ON OFF ON OFF ON

OFF OFF OFF

LED(Operation)ON ON

ON ON ON ON ON ON

ON ON/OFF

L

6-Quick

KNEADKNEADKNEADREST KNEADKNEADBAKE

@ @ @

@ @

Timeuntilfinish

2min.

1min.

1min.

91 min.

of BAKE

30sac. 30sac. 2 min. 30sac. 30 sec. 30 sac. 30sec. lhrs. 40 min.

<

—

*

>

105°C

Heater

OFF

OFF OFF OFF OFF OFF

ON/OFF

Main motor

*’ ON *’ON ON OFF

*’ON ON OFF

LED(operation) ON ON ON ON ON ON ON ‘

8

Loading...

Loading...