Sanyo SAP–KM97AHA,SAP–CM1821AHA,SAP–K97AHA,SAP–CM1821AHA–S,SAP–CM1827AHA,SAP–KM97AHA–S Technical & Service Manual

TECHNICAL & SERVICE MANUAL

SAP–KM97AHA (✕2) + SAP–CM1827AHA

FILE NO.

REFERENCE NO. SM700505

Indoor Unit

Outdoor Unit

MULTI-SPLIT SYSTEM AIR CONDITIONER

SAP–CM1821AHA

SAP–KM97AHA (✕2)

Destination: Australia

Indoor Model No Product Code No.

SAP–KM97AHA–S 1 852 079 45

Outdoor Model No. Product Code No.

SAP–CM1821AHA–S 1 852 079 46

i

IMPORTANT!

Please Read Before Starting

This air conditioning system meets strict safety and operating standards. As the installer or service person, it is an

important part of your job to install or service the system

so it operates safely and efficiently.

For safe installation and trouble-free operation, you

must:

●

Carefully read this instruction booklet before beginning.

●

Follow each installation or repair step exactly as

shown.

●

Observe all local, state, and national electrical codes.

●

Pay close attention to all warning and caution notices

given in this manual.

This symbol refers to a hazard

or unsafe practice which can

result in severe personal injury

or death.

This symbol refers to a hazard

or unsafe practice which can

result in personal injury or

product or property damage.

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help for

a special problem, contact our sales/service outlet or

your certified dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for

improper installation or maintenance service, including

failure to follow the instructions in this document.

SPECIAL PRECAUTIONS

When Wiring

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

ONLY A QUALIFIED, EXPERIENCED

ELECTRICIAN SHOULD ATTEMPT TO

WIRE THIS SYSTEM.

• Do not supply power to the unit until all wiring and tubing are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this

system. Carefully refer to the wiring diagram and

these instructions when wiring. Improper connections

and inadequate grounding can cause

accidental

injury or death.

• Ground the unit

following local electrical codes.

• Connect all wiring tightly. Loose wiring may cause

overheating at connection points and a possible fire

hazard.

When Transporting

Be careful when picking up and moving the indoor and

outdoor units. Get a partner to help, and bend your

knees when lifting to reduce strain on your back. Sharp

edges or thin aluminum fins on the air conditioner can cut

your fingers.

When Installing…

…In a Ceiling or Wall

Make sure the ceiling/wall is strong enough to hold the

unit’s weight. It may be necessary to construct a strong

wood or metal frame to provide added support.

…In a Room

Properly insulate any tubing run inside a room to prevent

“sweating” that can cause dripping and water damage to

walls and floors.

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide

a solid, level foundation for the outdoor unit. This prevents water damage and abnormal vibration.

…In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a

metal frame. Provide a suitable air baffle.

…In a Snowy Area (for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is higher

than drifting snow. Provide snow vents.

When Connecting Refrigerant Tubing

• Use the flare method for connecting tubing.

• Apply refrigerant lubricant to the matching surfaces of

the flare and union tubes before connecting them,

then tighten the nut with a torque wrench for a leakfree connection.

• Check carefully for leaks before starting the test run.

When Servicing

• Turn the power OFF at the main power box (mains)

before opening the unit to check or repair electrical

parts and wiring.

• Keep your fingers and clothing away from any moving

parts.

• Clean up the site after you finish, remembering to

check that no metal scraps or bits of wiring have been

left inside the unit being serviced.

Others

• Ventilate any enclosed areas when installing or testing

the refrigeration system. Escaped refrigerant gas, on

contact with fire or heat, can produce dangerously

toxic gas.

• Confirm upon completing installation that no refrigerant gas is leaking. If escaped gas comes in contact

with a stove, gas water heater, electric room heater or

other heat source, it can produce dangerously toxic

gas.

WARNING

WARNING

CAUTION

CAUTION

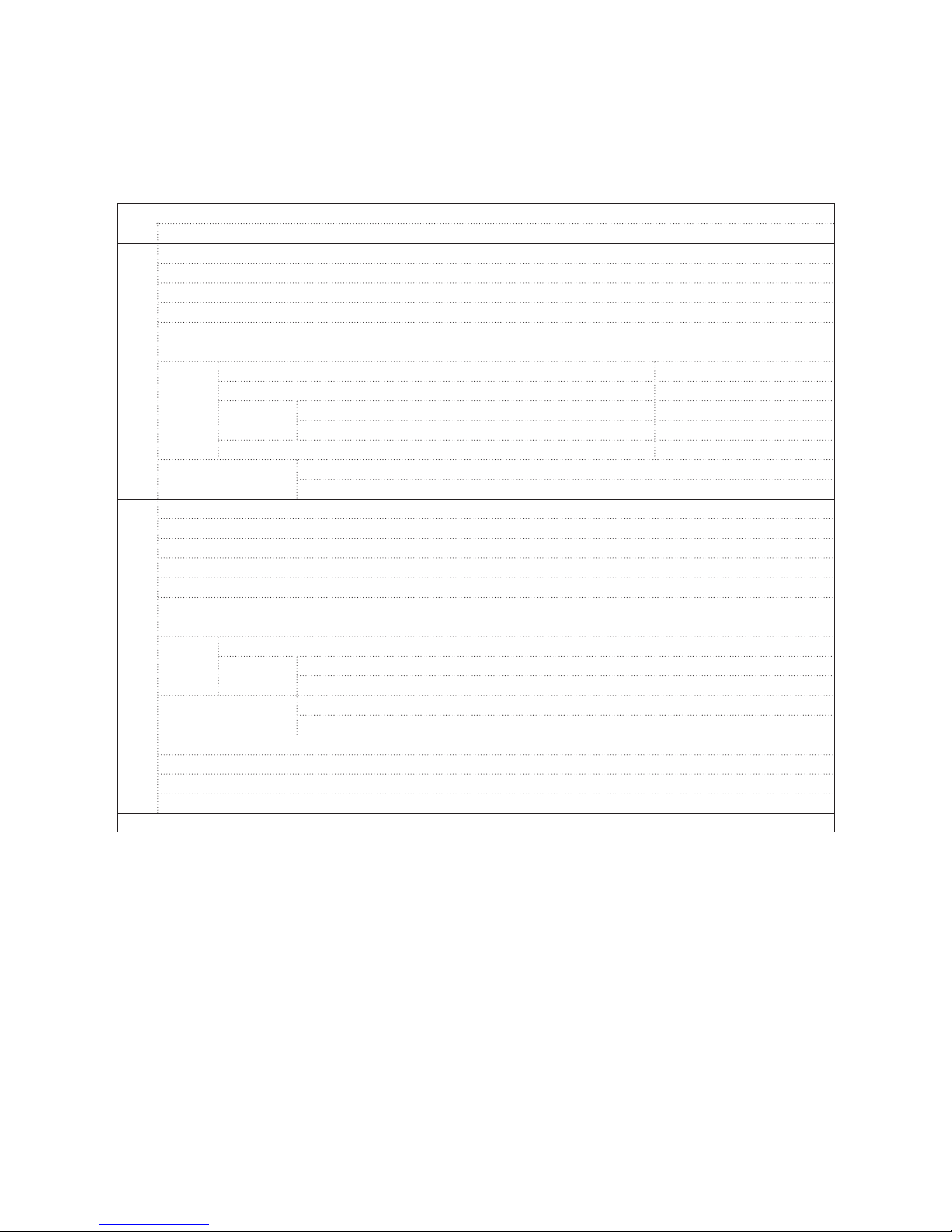

Table of Contents

Page

■ Unit Combination.................................................................................................................................... iii

1. OPERATING RANGE .............................................................................................................................. 1

2. SPECIFICATIONS

2-1. Unit Specifications.......................................................................................................................... 2

2-2. Major Component Specifications.................................................................................................... 3

2-3. Other Component Specifications.................................................................................................... 5

3. DIMENSIONAL DATA.............................................................................................................................. 6

4. COOLING CAPACITY ............................................................................................................................. 8

5. HEATING CAPACITY ............................................................................................................................. 10

6. AIR THROW DISTANCE CHART ........................................................................................................... 11

7. REFRIGERANT FLOW DIAGRAM ......................................................................................................... 12

8. ELECTRICAL DATA

8-1. Electrical Characteristics................................................................................................................ 14

8-2. Electric Wiring Diagrams................................................................................................................ 16

9. INSTALLATION INSTRUCTIONS

9-1. Installation Site Selection ............................................................................................................... 18

9-2. Remote Control Unit Installation Position....................................................................................... 20

9-3. Recommended Wire Length and Diameter ................................................................................... 21

10. FUNCTION

10-1. Room Temperature Control ........................................................................................................... 22

10-2. Dry Operation ................................................................................................................................ 24

10-3. Freeze Prevention ......................................................................................................................... 25

10-4. Overload Prevention ...................................................................................................................... 25

10-5. Cold draft Prevention ..................................................................................................................... 26

10-6. Defrosting Operation ..................................................................................................................... 27

11. TROUBLESHOOTING

11-1. Check before and after troubleshooting ........................................................................................ 29

11-2. Air conditioner does not operate .................................................................................................... 30

11-3. Some part of air conditioner does not operate .............................................................................. 34

11-4. Air conditioner operates, but abnormalities are observed ............................................................. 36

11-5. If a sensor is defective ................................................................................................................... 38

12. ARRANGEMENT OF ELECTRICAL COMPONENT .............................................................................. 39

13. CHECKING ELECTRICAL COMPONENTS

13-1. Measurement of Insulation Resistance .......................................................................................... 41

13-2. Checking Continuity of Fuse on PCB Ass'y.................................................................................... 42

13-3. Checking Motor Capacitor ............................................................................................................. 42

14.MAINTENANCE

14-1. Changing Address of Remote Control Unit in Indoor Unit ............................................................. 43

................................................................................................................................................. 44

APPENDIX

ii

iii

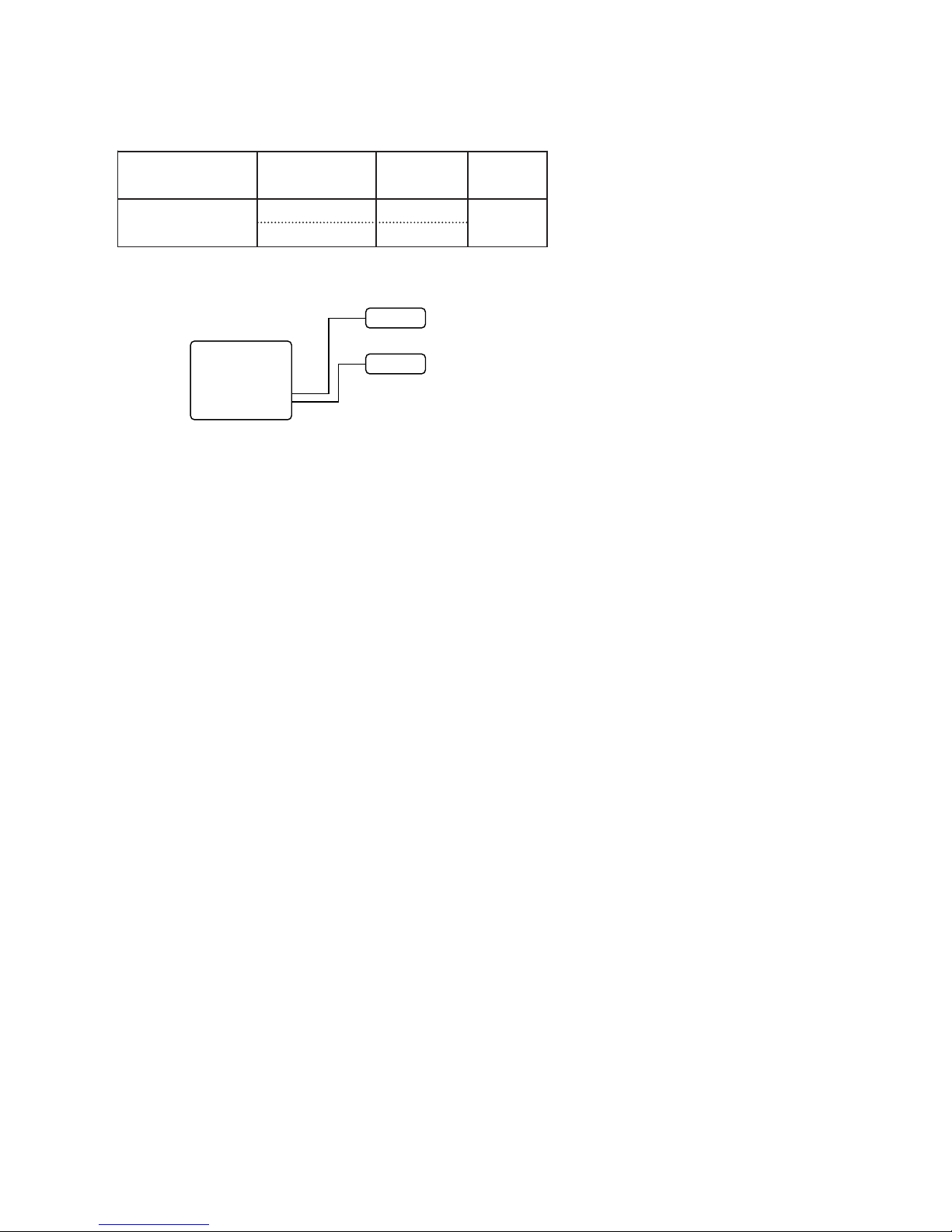

■

Unit Combination

Combine indoor and outdoor units only as listed below.

Indoor Unit

Outdoor Unit

A

B

Fig.1

Outdoor Unit Indoor Unit

Symbol of

Indoor Unit

Refer to

SAP–CM1827AHA

KM97 A

Fig.1

KM97 B

1

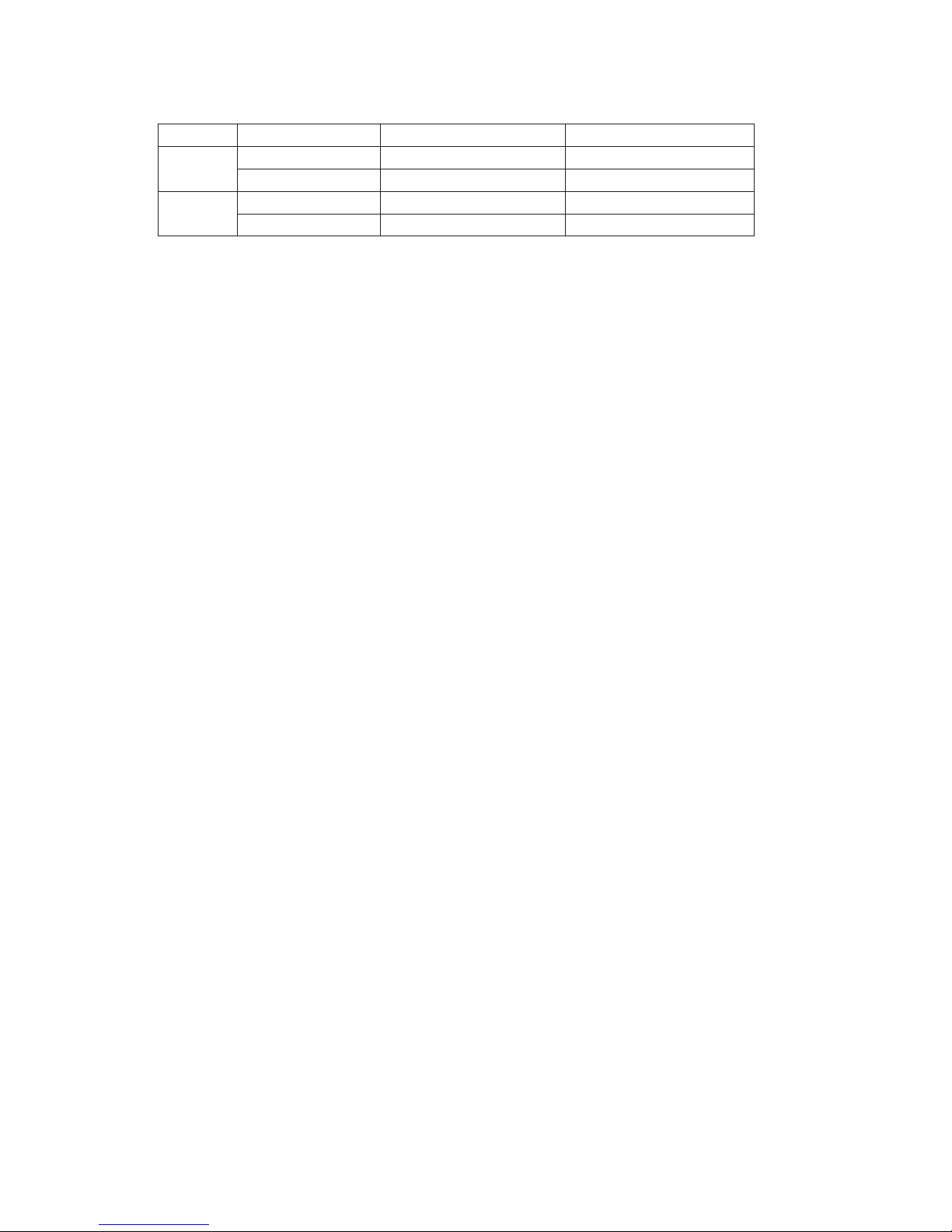

1. OPERATING RANGE

Temperature Indoor Air Intake Temp. Outdoor Air Intake Temp.

Cooling

Maximum 32°C D.B. / 23°C W.B. 43°C D.B.

Minimum 19°C D.B. / 14°C W.B. 19°C D.B.

Heating

Maximum 27°C D.B. 24°C D.B. / 18°C W.B.

Minimum 16°C D.B. –8°C D.B. / –9°C W.B.

2. SPECIFICATIONS

2-1. Unit Specifications

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

Remarks: Rating conditions are:

Cooling: Indoor air temperature 27°C DB/19°C WB

Outdoor air temperature 35°C DB/24°C WB

Heating: Indoor air temperature 20°C DB

Outdoor air temperature 7°C DB/6°C WB

2

No. of indoor units. 1-unit 2-unit

Power Source 240 V 1-phase 50 Hz 240 V 1-phase 50 Hz

Cooling Heating Cooling Heating

Capacity

kW 2.65 3.30 5.10 6.35

BTU/h 9,000 11,300 17,400 21,700

Air circulation (High) m

3

/h 450 450 x 2

Moisture removal (High) Liters/h 1.1 — 1.1 x 2 —

Voltage rating V 240 240

Available voltage range V 216 to 264 216 to 264

Running amperes A 4.6 4.9 9.1 8.9

Power input W 1,040 1,090 2,120 2,000

Power factor % 94 93 97 94

C.O.P. W/W 2.5 3.0 2.4 3.2

Compressor locked rotor amperes A 25 50

Controls / Temperature control Microprocessor / I.C. thermostat

Control unit Wireless remote control unit

Timer 1-hour OFF / 12-hour ON or OFF

Fan speeds Indoor / Outdoor 3 and Auto / 1

Airflow direction (Indoor)

Horizontal Manual

Vertical Auto

Air filter Washable, Anti–Mold

Compressor Rotary (Hermetic)

Refrigerant / Amount charged at shipment g R22 / 1,200

Refrigerant control Capillary tube

Operation sound

Indoor – Hi / Me / Lo dB-A 40 / 34 / 31

Outdoor – Hi dB-A 53

Refrigerant tubing connections Flare type

Max. allowable tubing length at shipment m 7.5

Refrigerant tube

Narrow tube mm (in.) 6.35 (1/4)

diameter

Wide tube mm (in.) 9.52 (3/8)

Refrigerant tube kit / Accessories Optional / Hanging wall bracket

Indoor Unit Outdoor Unit

Unit dimensions Height mm 265 630

Width mm 805 830

Depth mm 145 305

package dimensions Height mm 208 713

Width mm 855 994

Depth mm 326 413

Weight

Net kg 7.5 61.0

Shipping kg 10.0 66.0

Shipping volume m

3

0.06 0.29

Dimensions & Weight Features Electrical Rating Performance

Indoor Unit SAP–KM97AHA

Outdoor Unit SAP–CM1827AHA

2-2. Major Component Specifications

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

Part No. POW–KM97GHS

Controls Microprocessor

Control circuit fuse 250 V – 3.15 A

Remote Control Unit RCS–2MHS4E–G

Type Cross–flow

Number ... Dia. and length mm 1 ... ø70 / L598

Fan motor model ... Q´ty KFV2Q–11B5P ... 1

No. of poles ... rpm (240 V, High) 2 ... 1,960

Nominal output W 10

Coil resistance (Ambient temp. 20°C) Ω WHT – BRN : 385.3

WHT – VLT : 113.6

VLT – ORG : 37.4

ORG – YEL : 87.8

YEL – PNK : 95.8

Safety

Type Internal thermal fuse

devices

Operating temp.

Open °C 145 ± 2

Close —

Run capacitor

µF 1.0

VAC 440

Type Stepping motor

Model MP24GA1

Rating DC 12 V

Coil resistance (Ambient temp. 25°C) Ω WHT – BLU (respectively 4 wires) : 380 ± 7%

Coil Aluminum plate fin / Copper tube

Rows 2

Fin pitch mm 1.4

Face area m

2

0.126

Heat

Exch. Coil

Flap Motor Fan & Fan Motor

Controller

PCB

3

Indoor Unit SAP–KM97AHA

4

Controller PCB POW–C186CMH

Control circuit fuse 250 V– 3 A

Type Rotary (Hermetic)

Compressor model ... Q´ty C–R95H5K ... 2 / 80696745–S ... 2

Nominal output W 950 x 2

Compressor oil ... Amount cc SUNISO 4GSD–T ... 650 x 2

Coil resistance (Ambient temp. 25°C) Ω C – R : 2.88

C – S : 6.87

Type External (OLR 1, 3) External (OLR 2, 4)

Overload relay ... Number MRA99089–9201 ... 2 CS–7C115 ... 2

Safety

Operating

Open °C 145 ± 5 115 ± 3

devices

temp.

Close °C 69 ± 11 95 ± 5

Operating amp.(Ambient temp. 25°C) Trip in 6 to 16 sec. at 16.5 A —

Run capacitor µF 22.5 ... 2

... Q´ty VAC 400 ... 2

Type Propeller

Number ... Dia. mm 1 ... ø400

Fan motor model ... Q´ty SG6–51B5P ... 1

No. of poles ... rpm (240 V,High) 6 ... 920

Nominal output W 50

Coil resistance (Ambient temp. 20°C) Ω WHT – BRN : 92.1

WHT – PNK: 196.4

Safety Type Internal protector

devices

Operating

Open °C 130 ± 8

temp.

Close Automatic reclosing

Run capacitor

µF 2.0

VAC 480

Coil Aluminum plate fin / Copper tube

Rows 2

Fin pitch mm 1.6

Face area m

2

0.453

External Finish Acrylic baked-on enamel finish

Heat

Exch. Coil

CompressorFan & Fan Motor

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

Outdoor Unit SAP–CM1827AHA

5

2-3. Other Component Specifications

Indoor Unit SAP–KM97AHA

Transformer (TR) ATR-J125

Rating Primary AC 230V, 50Hz

Secondary 19V, 0.631A

Capacity 12VA

Coil resistance Ω (at 21°C) Primary (WHT – WHT): 205 ± 10%

Secondary (BRN – BRN): 1.5 ± 10%

Thermal cut-off temp. 150°C

Thermistor (Coil sensor TH1) PBC-41E-S4

Resistance kΩ –20°C 40.1 ± 5% 20°C 6.5 ± 5%

–10°C 24.4 ± 5% 30°C 4.4 ± 5%

0°C 15.3 ± 5% 40°C 3.0 ± 5%

10°C 9.9 ± 5% 50°C 2.1 ± 5%

Thermistor (Room sensor TH2) DTN-TKS106E

Resistance kΩ 25°C 5.0 ± 3%

Outdoor Unit SAP–CM1827AHA

Power Relay (PRA, PRB) DFU24D1-F (M)

Coil rating DC 24V

Coil resistance Ω (at 20°C) 650 ±10%

Contact rating AC 250V, 20A

Termistor (Coil sensor) PBC-41E-S15

Resistance kΩ –10°C 23.7 ± 5% 25°C 5.3 ± 5%

0°C 15.0 ± 5% 30°C 4.4 ± 5%

10°C 9.7 ± 5% 40°C 3.1 ± 5%

20°C 6.5 ± 5%

Solenoid Coil (4-way Valve SCA, SCB) CHV-01Ai038A1 (Coil), CHV-0101 (Valve)

Coil rating AC 230V, 50Hz, 5W

Coil resistance Ω (at 20°C) 1,408 ± 7%

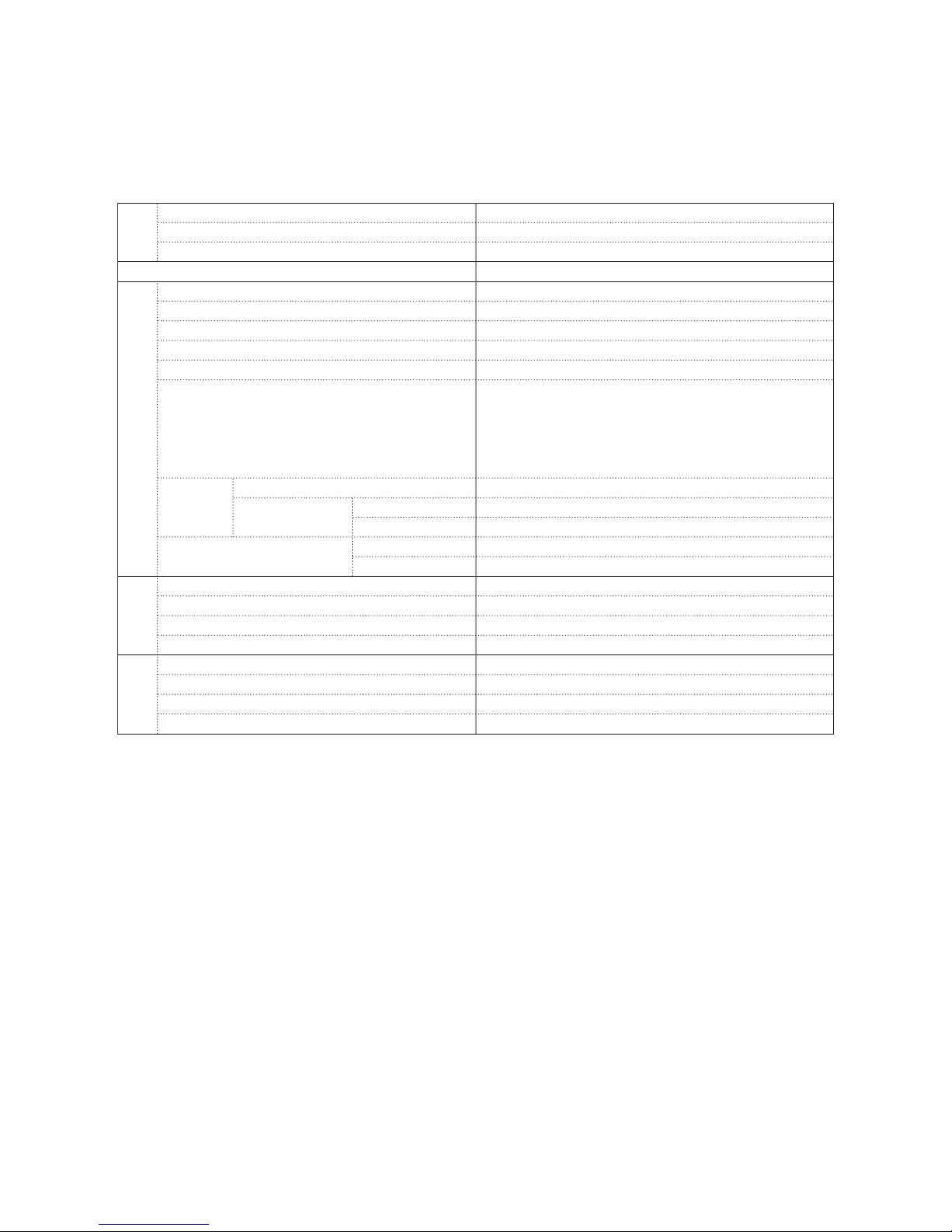

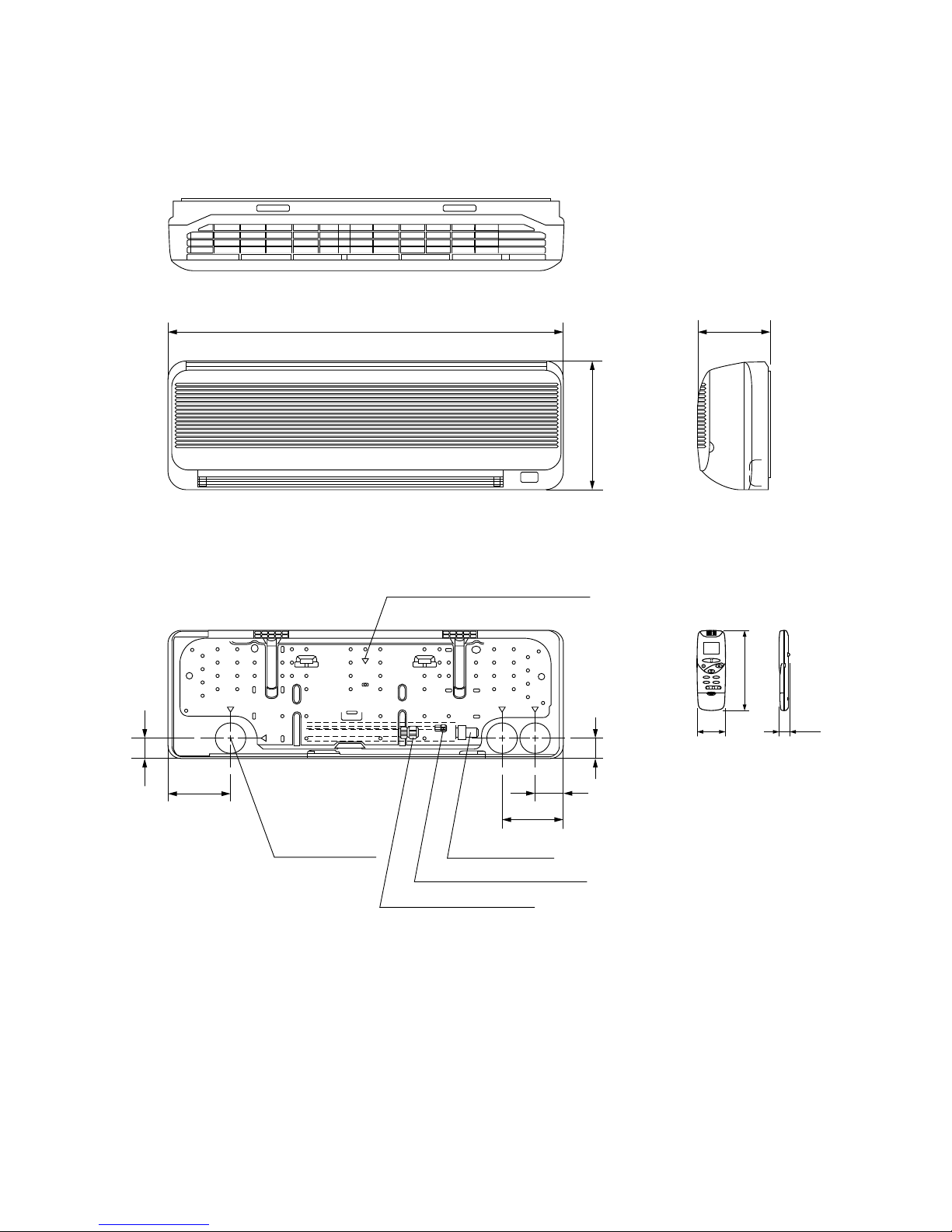

6

3. DIMENSIONAL DATA

Indoor Unit SAP–KM97AHA

805 145

130

Center of tubing

hole (3 places)

Drain hose ø18

Narrow tube ø6.35 (1/4")

Rear panel (center point of gravity)

Wide tube ø9.52 (3/8")

124

58

42

42

265

Remote control unit

172

61 23

Unit : mm

7

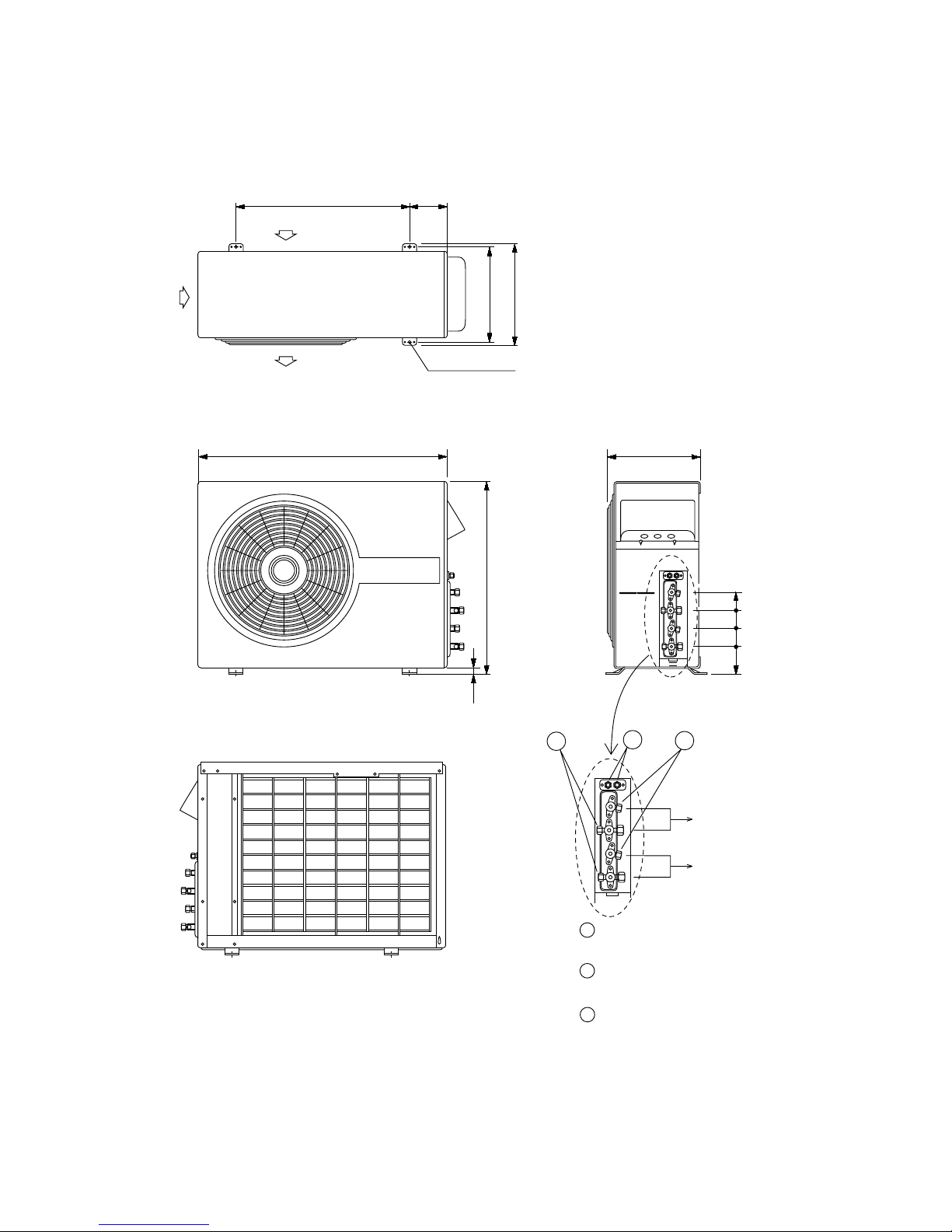

Outdoor Unit SAP–CM1827AHA

5858

95 58

337

307

630

19

Narrow tube service valve

ø6.35(1/4")

1

Wide tube service valve

ø9.52(3/8")

2

305

830

4 – ø12 holes

Air discharge

Air intake

538 146

2

Magnified illustration

3

1

To Indoor Unit B

To Indoor Unit A

3

Check Port

Unit : mm

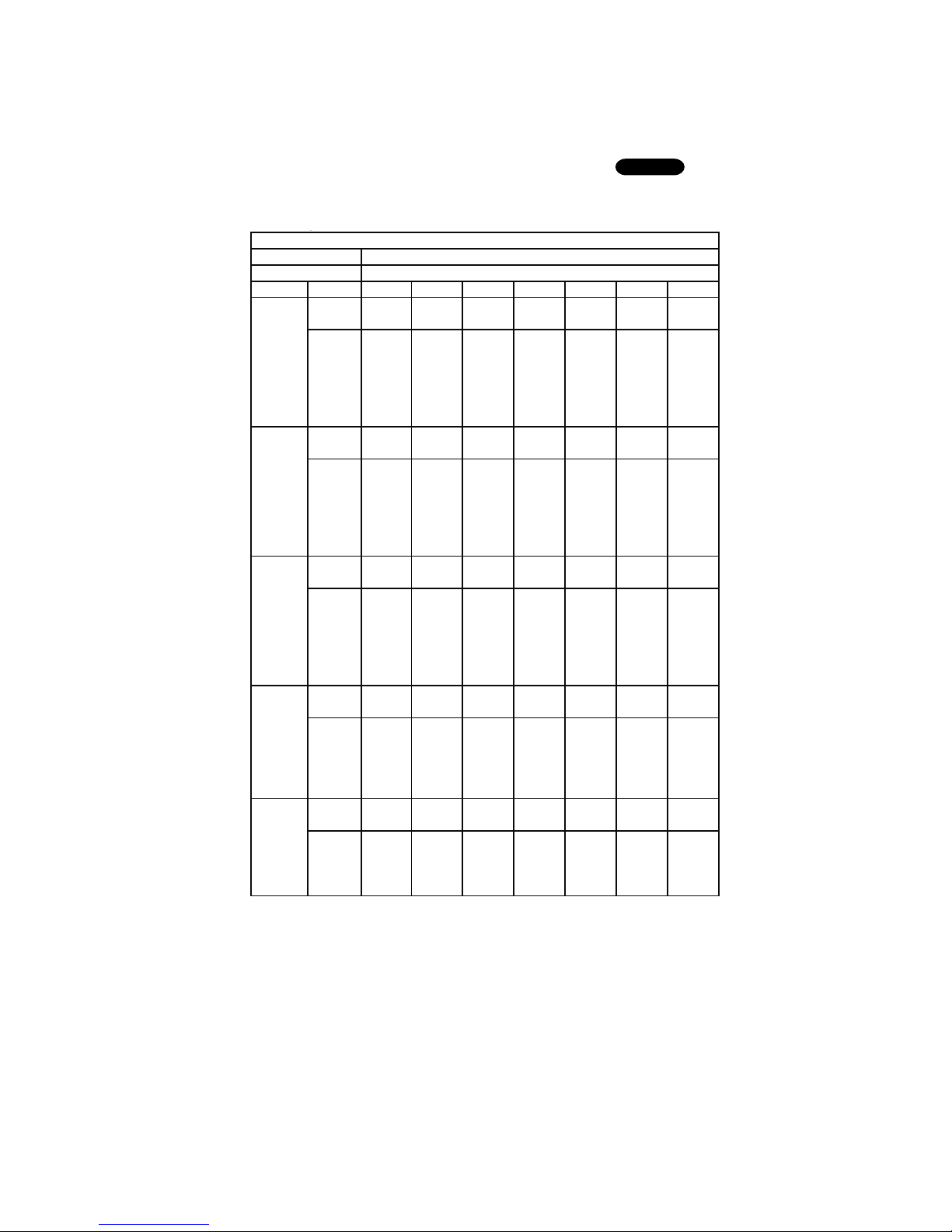

4. COOLING CAPACITY

■

1 - indoor unit in operation A(or B)

Indoor Unit SAP–K97AHA (✕ 1)

Outdoor Unit SAP–CM1827AHA

240 V Single phase 50 Hz

g

RATING CAPACITY 2.65 kW

EVAPORATOR CONDENSER

ENT. TEMP. °C OUTDOOR AMBIENT TEMP. °C

W.B. D.B. 20 25 30 35 40 43

TC 2.67 2.55 2.44 2.32 2.18 2.01

CM 0.69 0.75 0.80 0.86 0.98 1.10

21 SHC 1.81 1.75 1.70 1.64 1.57 1.49

15 23 SHC 2.04 1.98 1.92 1.86 1.79 1.71

25 SHC 2.26 2.20 2.14 2.09 2.02 1.93

27 SHC 2.48 2.43 2.37 2.31 2.18 2.01

29 SHC 2.67 2.55 2.44 2.32 2.18 2.01

31 SHC 2.67 2.55 2.44 2.32 2.18 2.01

TC 2.86 2.74 2.62 2.49 2.34 2.15

CM 0.71 0.77 0.83 0.89 1.01 1.13

21 SHC 1.59 1.53 1.47 1.41 1.34 1.26

17 23 SHC 1.81 1.75 1.69 1.63 1.56 1.48

25 SHC 2.03 1.97 1.91 1.86 1.79 1.70

27 SHC 2.26 2.20 2.14 2.08 2.01 1.93

29 SHC 2.48 2.42 2.36 2.30 2.23 2.15

31 SHC 2.70 2.64 2.58 2.49 2.34 2.15

TC 3.05 2.92 2.78 # 2.65 2.49 2.29

CM 0.73 0.79 0.85 0.91 1.03 1.16

21 SHC 1.34 1.28 1.23 1.17 1.10 1.02

19 23 SHC 1.57 1.51 1.45 1.39 1.32 1.24

25 SHC 1.79 1.73 1.67 1.62 1.55 1.47

27 SHC 2.01 1.96 1.90 1.84 1.77 1.69

29 SHC 2.24 2.18 2.12 2.06 2.00 1.91

31 SHC 2.46 2.40 2.34 2.29 2.22 2.14

TC 3.23 3.09 2.95 2.81 2.64 2.43

CM 0.76 0.82 0.87 0.94 1.06 1.19

23 SHC 1.32 1.26 1.21 1.15 1.08 1.00

21 25 SHC 1.55 1.49 1.43 1.37 1.31 1.23

27 SHC 1.77 1.71 1.65 1.60 1.53 1.45

29 SHC 1.99 1.93 1.88 1.82 1.75 1.67

31 SHC 2.22 2.16 2.10 2.04 1.98 1.90

TC 3.43 3.28 3.12 2.95 2.76 2.57

CM 0.77 0.84 0.90 0.96 1.09 1.21

23 25 SHC 1.29 1.23 1.17 1.11 1.04 0.97

27 SHC 1.51 1.45 1.40 1.33 1.26 1.20

29 SHC 1.74 1.68 1.62 1.56 1.49 1.42

31 SHC 1.96 1.90 1.84 1.78 1.71 1.64

TC : Total Cooling Capacity (kW)

SHC : Sensible Heat Capacity (kW)

CM : Compressor Input (kW)

Rating conditions (#Mark) are

Outdoor Ambient Temp. 35°C D.B.

Indoor Unit Entering Air Temp. 27°C D.B. / 19°C W.B.

8

NOTE

A : SAP–K97AHA

B : SAP–K97AHA

9

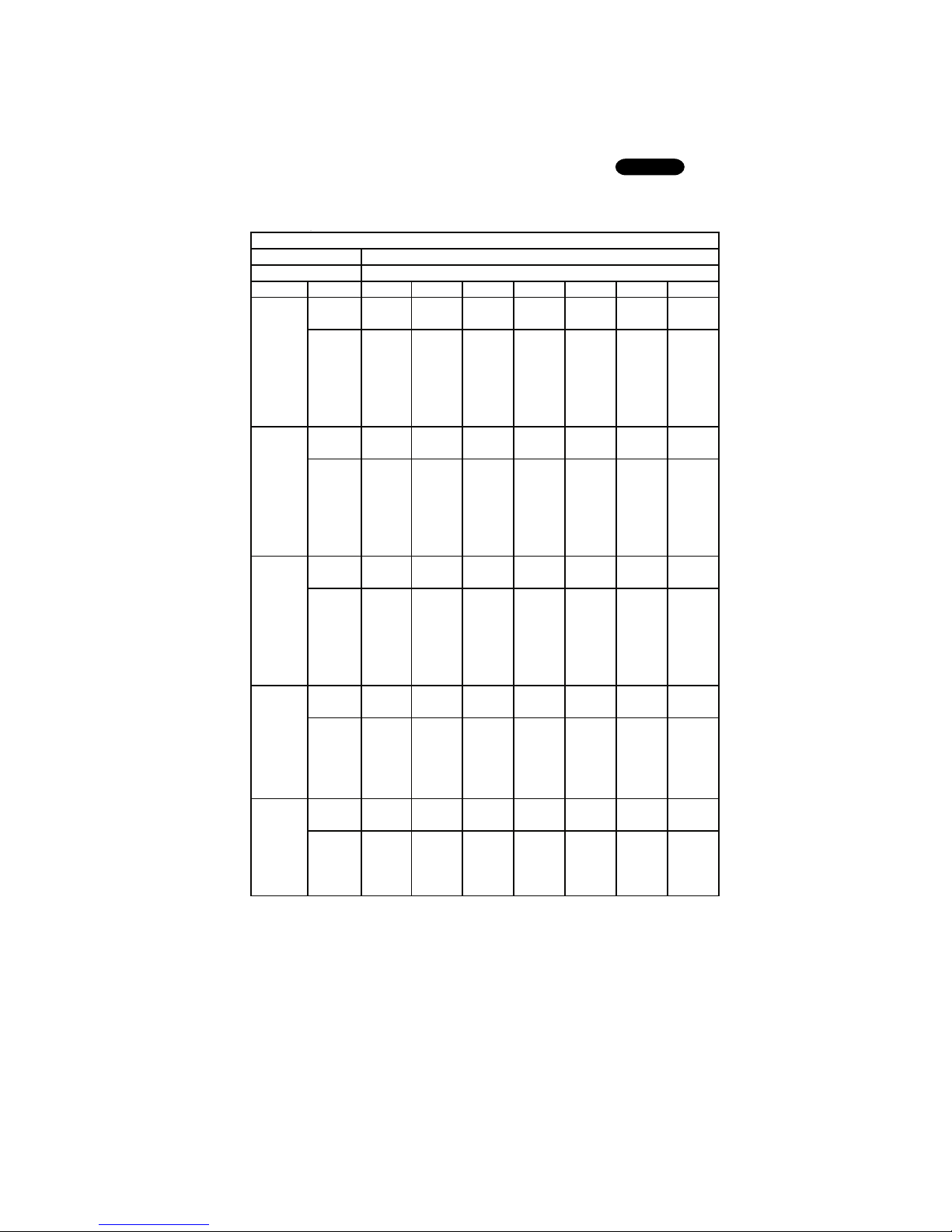

■

2 - indoor units in operation A + B

Indoor Unit SAP–K97AHA (✕ 2)

Outdoor Unit SAP–CM1827AHA

240 V Single phase 50 Hz

g

RATING CAPACITY 5.10 kW

EVAPORATOR CONDENSER

ENT. TEMP. °C OUTDOOR AMBIENT TEMP. °C

W.B. D.B. 20 25 30 35 40 43

TC 5.14 4.92 4.69 4.47 4.20 3.86

CM 1.49 1.61 1.72 1.85 2.09 2.35

21 SHC 3.52 3.41 3.30 3.19 3.06 2.90

15 23 SHC 3.97 3.86 3.75 3.64 3.51 3.35

25 SHC 4.42 4.31 4.19 4.08 3.95 3.80

27 SHC 4.87 4.75 4.64 4.47 4.20 3.86

29 SHC 5.14 4.92 4.69 4.47 4.20 3.86

31 SHC 5.14 4.92 4.69 4.47 4.20 3.86

TC 5.51 5.27 5.03 4.79 4.51 4.15

CM 1.53 1.65 1.77 1.90 2.15 2.40

21 SHC 3.07 2.95 2.84 2.73 2.60 2.44

17 23 SHC 3.51 3.40 3.29 3.18 3.05 2.89

25 SHC 3.96 3.85 3.74 3.63 3.50 3.34

27 SHC 4.41 4.29 4.18 4.07 3.94 3.78

29 SHC 4.85 4.74 4.63 4.52 4.39 4.15

31 SHC 5.30 5.19 5.03 4.79 4.51 4.15

TC 5.87 5.61 5.36 # 5.10 4.79 4.41

CM 1.58 1.70 1.82 1.96 2.21 2.47

21 SHC 2.59 2.47 2.36 2.25 2.12 1.97

19 23 SHC 3.03 2.92 2.81 2.70 2.57 2.41

25 SHC 3.48 3.37 3.26 3.15 3.02 2.86

27 SHC 3.93 3.81 3.70 3.59 3.47 3.31

29 SHC 4.37 4.26 4.15 4.04 3.91 3.76

31 SHC 4.82 4.71 4.60 4.49 4.36 4.20

TC 6.22 5.95 5.68 5.41 5.08 4.68

CM 1.62 1.75 1.88 2.01 2.27 2.53

23 SHC 2.54 2.43 2.32 2.22 2.09 1.94

21 25 SHC 2.99 2.88 2.77 2.66 2.54 2.38

27 SHC 3.44 3.33 3.22 3.11 2.99 2.83

29 SHC 3.88 3.77 3.67 3.56 3.43 3.28

31 SHC 4.33 4.22 4.11 4.00 3.88 3.72

TC 6.60 6.31 6.01 5.68 5.31 4.94

CM 1.65 1.80 1.92 2.07 2.33 2.59

23 25 SHC 2.48 2.37 2.26 2.14 2.01 1.88

27 SHC 2.92 2.82 2.71 2.58 2.45 2.32

29 SHC 3.37 3.26 3.15 3.03 2.90 2.77

31 SHC 3.82 3.71 3.60 3.48 3.35 3.22

TC : Total Cooling Capacity (kW)

SHC : Sensible Heat Capacity (kW)

CM : Compressor Input (kW)

Rating conditions (#Mark) are

Outdoor Ambient Temp. 35°C D.B.

Indoor Unit Entering Air Temp. 27°C D.B. / 19°C W.B.

NOTE

A : SAP–K97AHA

B : SAP–K97AHA

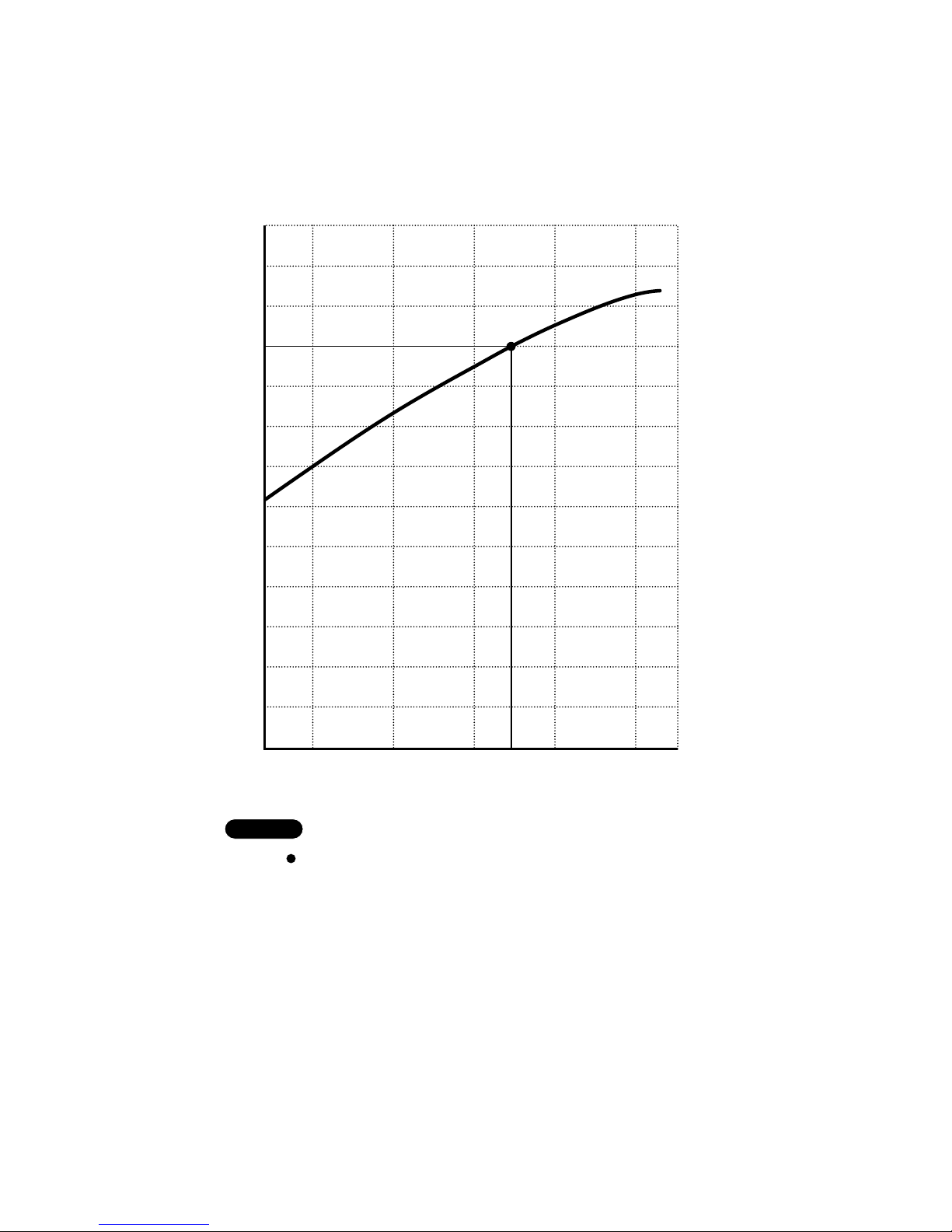

5. HEATING CAPACITY

10

Indoor Unit SAP–K97AHA

Outdoor Unit SAP–CM1827AHA

–5 0 5

7

10 15

Outdoor temperature (°C DB)

0

10

20

30

40

50

60

70

80

90

100

110

120

Heating capacity ratio (%)

NOTE

1) … Point of Rating condition

Black dot in the chart indicate the following rating condition.

Indoor : 20°C DB

Outdoor : 7°C DB / 6°C WB

2) Above characteristics indicate instantaneous operation, which does not take into

consideration defrost operation.

3) Fan speed : High

–8

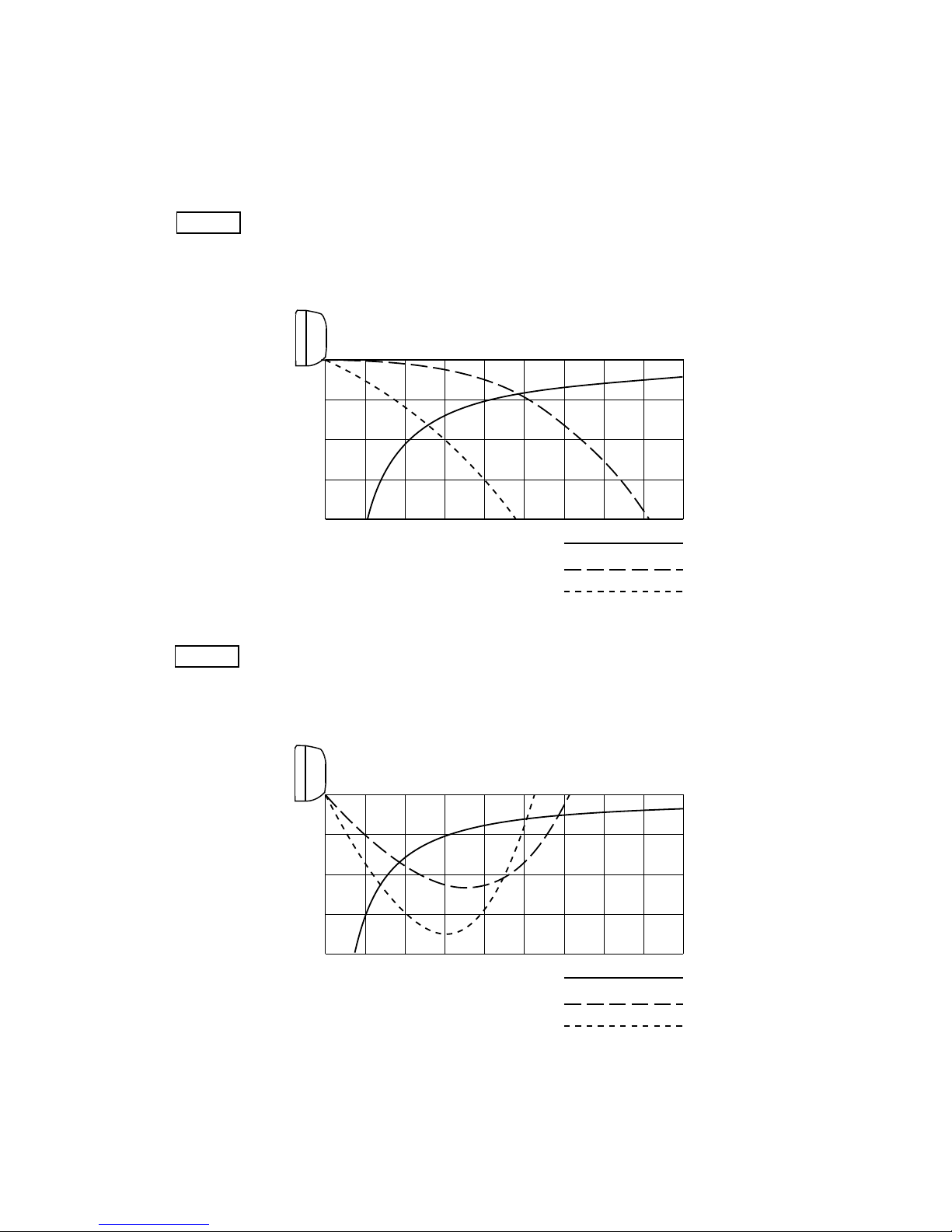

6. AIR THROW DISTANCE CHART

11

Indoor Unit SAP–KM97AHA

1 2 3 4 5 6 7 8 9

0

1

2

3

4

Horizontal distance (m)

Vertical distance (m)

Axis air velocity (m/s)

Room air temp.

Fan speed

27°C

High

:

:

Axis air velocity

Flap angle

0°

30°

1 2 3 4 5 6 7 8 9

0

1

2

3

4

Horizontal distance (m)

Vertical distance (m)

Axis air velocity (m/s)

Room air temp.

Fan speed

20°C

High

:

:

Axis air velocity

Flap angle

45°

60°

Heating

Cooling

Loading...

Loading...