Page 1

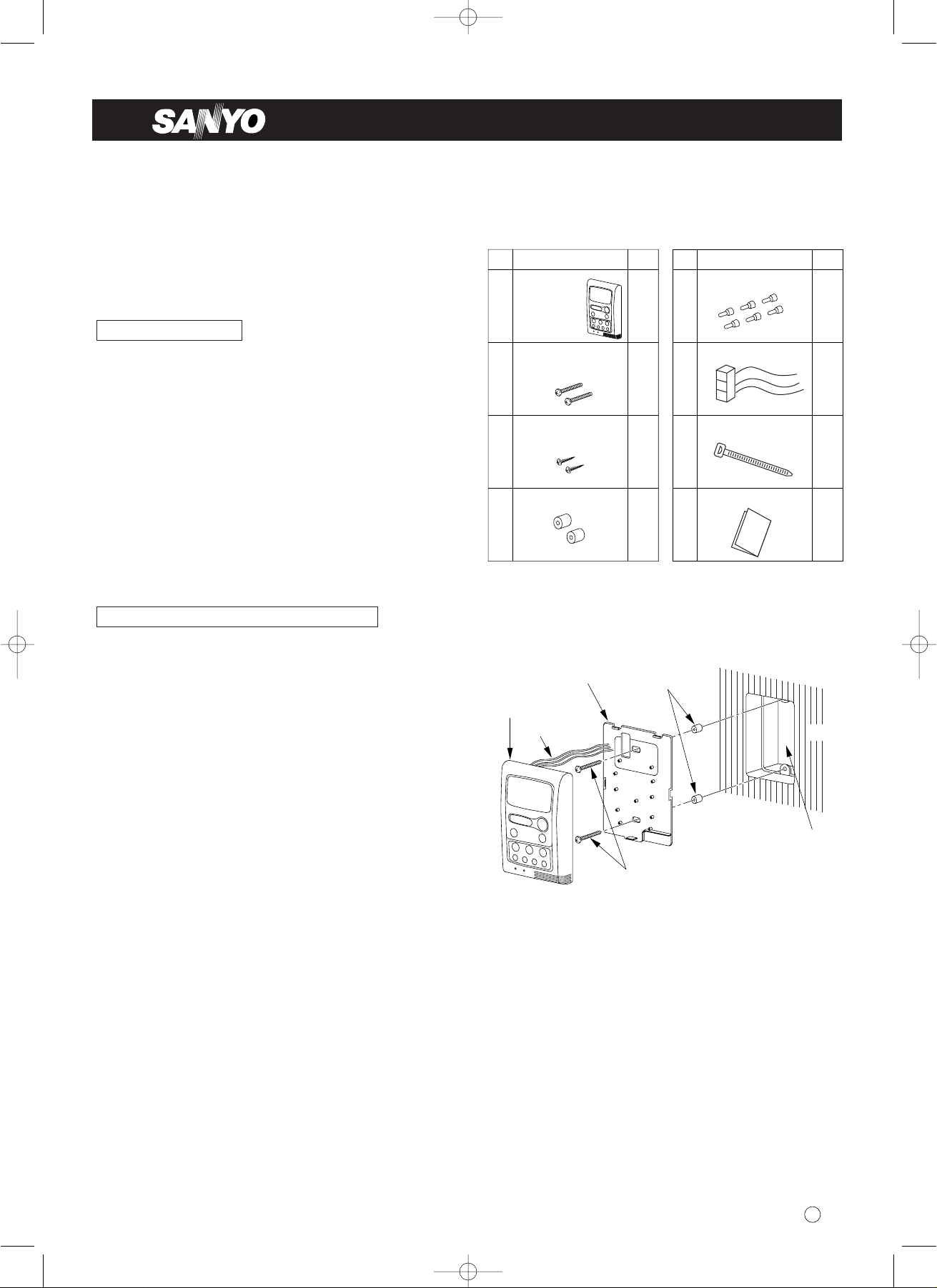

■ Parts supplied with remote controller

See Table 1.

■ Remote controller installation guidelines

• Mount the remote controller 1 to 1.5 meters off the

floor where it can sense the average temperature of

the room.

• Do not mount the remote controller in a place

exposed to direct sunlight or where it is exposed to

outside air such as near a window.

• Do not mount the remote controller behind a curtain

or other object so that it is separated from the air circulation of the room.

• Mount the remote controller inside the room being air

conditioned.

• The remote controller should be mounted on a wall or

other surface vertically.

Room temperature sensors are separately incorporated

in both the indoor unit and the remote controller. Either

sensor can be used to sense the room temperature. The

indoor unit sensor is usually used.

If you wish the remote controller to sense the room temperature, press the SENSOR button with a ballpoint pen

or tool with a small tip.

■ How to install the remote controller

<NOTE 1> Do not twist the remote controller wire

with the power cord, or run them in the

same metal conduit, because this may

cause a malfunction.

<NOTE 2> Install the remote controller away from all

sources of electrical noise.

<NOTE 3> Install a noise filter or take other appro-

priate action if electrical noise affects the

power supply circuit of the unit.

• Use an electric junction box (supplied locally) for

embedded mounting of the remote controller.

(See Fig. 1)

Switching the room temperature sensor

Installation location

Q’tyNo.

➀ 1

Supplied parts

Remote

controller

(comes with

200mm wire)

Machine screws

M4 × 25

Tapping screws

M4 × 25

2

2

➁

➂

Q’tyNo.

➃ 2

Supplied parts

Spacers

Wire joints

Harness

Clamper

Instruction manual

6

1

1

1

➄

➅

➆

➇

Ta bl e 1

85464359404000 © SANYO 2003

Note: Remote controller model name RCS-KS2432AWD

Code: 851-0-0054-590-00-0

W

INSTALLATION INSTRUCTIONS

Fig. 1

RCS-KS2432AWD

03-242.Sanyo.85464359404000 8/21/03 9:17 AM Page 1

Under-case (back case)

Remote controller

Lead wires (3)

Spacers

Wall

Electric junction box

(no cover)

Machine screws

M4 × 25 (2)

Page 2

2

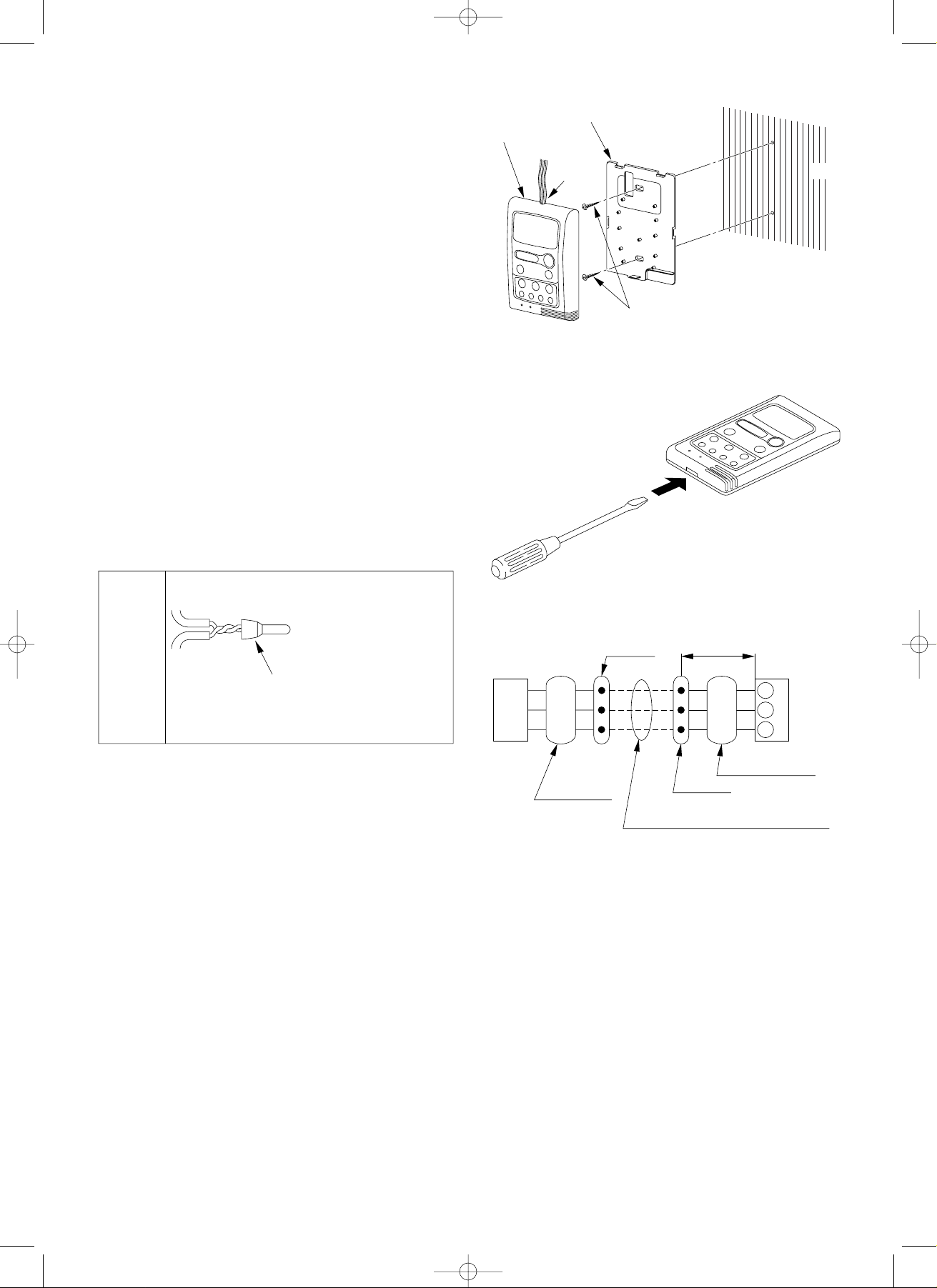

• For surface mounting on the wall, see Fig. 2.

1. Insert a screwdriver or the like in the groove on the

lower side of the remote controller to pry off the

back case. (See Fig. 3)

2. Use the 2 supplied M4 × 25 machine screws for

embeded mounting or M4 × 25 tapping screws for

surface mounting to secure the remote controller

back case. Prior to mounting, clear the cutouts in

the back case corresponding to the holes in the

wall box using a screwdriver or the like. Use the

spacers and take care not to tighten the screws

excessively. If the back case will not seat properly,

cut the spacers to a suitable thickness.

3. Connect locally supplied 3-core lead wires to the

lead wires from the remote controller. (See “How to

wire the remote controller.”)

(The remote controller will be damaged if

220/240V AC is applied.)

4. Hook the remote controller to the tabs of the back

case and mount it.

■ How to wire the remote controller

●

Connection diagram

See Fig. 4.

●

How to connect the harness (supplied parts)

1. Turn off the power, and remove the grille.

2. Remove the screws of the electrical box and

remove its cover.

3. Pull out the indoor unit controller (PCB ass’y).

(Fig. 6 on next page)

4. Pull out the lead wire that connects the remote con-

trol receiver to CN11 of the controller (PCB ass’y).

(Fig. 5 on next page)

5. Plug the socket of the supplied wire harness onto

CN11.

6. Bind the wire harness and the inter-unit lead wires

together, and route them. Fasten them under the

electrical box with the clamp. Then, pull them out

from the back of the indoor unit.

If required, connect the lead wire (field supply, max.

10 m). (Fig.4)

Use the supplied wire joints (6 pcs.) to connect the

lead wire. (See the connection diagram as shown at

right.)

Fig. 3

Fig. 4

Fig. 2

03-242.Sanyo.85464359404000 8/21/03 9:17 AM Page 2

Under-case (back case)

Remote controller

Lead

wires (3)

Wall

Tapping screws

M4 × 25 (2)

6 supplied

white wire

joints

Lead wire from

indoor unit

Lead wire

from

remote controller

1. Peel off 14mm of cable

sheathing on each wire.

2. Twist the 2 wires

together and crimp them

together with a wire joint.

3. When a crimping tool is

Wire

joint

not used, solder the

wires together and cover

the joint with insulating

tape.

Indoor

unit

*1: 0.5mm

Wire joint

RED

WHT

BLK

Wiring from

indoor unit

2

to 2.0mm2 wires are used for lead wires.

*1

Wiring for remote

controller (supplied locally), Max. 10m

Approx. 200mm

RED

WHT

BLK

Wiring from

remote controller

Wire joint

1

2

3

Remote

Controller

Page 3

3

Fig. 5

Fig. 6

03-242.Sanyo.85464359404000 8/21/03 9:17 AM Page 3

• Electric Wiring Diagram

FAN MOTOR

FMI

GRN / YEL

G

G

TERMINAL

PLATE

WHT

BLK

G

GRN

RED

1

2

G

4

FROM

OUTDOOR UNIT

BLK

VLT

YEL

ORG

87654321

87654321

CONNECTOR

[WHT]

FLP

PNK

BRN

GRY

WHT

CONNECTOR

[WHT]

CAPACITOR

PNK

BRN

GRY

WHT

VLT

ORG

YEL

BLK

[WHT] [WHT]

1

1

2

2

3

3

4

4

5

5

WHT

BLU

BLU

BLU

BLU

FLAP MOTOR [UPPER]

CONNECTOR

[WHT] [GRN] [BLK]

FLP

*

FLAP MOTOR [LOWER]

WHT

1

1

BLU

2

2

BLU

3

3

BLU

4

4

BLU

5

5

(RC1)

1

1

2

2

3

3

4

4

5

5

1

1

2

2

3

3

4

4

5

5

GRN

w

G

FM

w

w

HH

w

H

w

M

w

L

w

LL

FLAP1

5P [WHT]

CONTROLLER

FLAP2

5P [BLK]

135

135

SUP

5P [WHT]

PRY

3P [RED]

SEC

2P [WHT]

RECEIVER

3P [WHT]

LAMP

4P [WHT]

ROOM/COIL

4P [WHT]

WHT

1

1

WHT

3

3

121

3

2

1

1

2

3

4

BRN

BRN

2

3

WHT CN11

2

GRY

1

GRY

WHT

1

GRY

2

GRY

3

GRY

4

P

S

1

1

2

2

3

3

4

4

5

5

6

6

7

7

COIL THERMISTOR (TH1)

BLK

1

1

BLK

2

2

BLK

3

3

BLK

4

4

ROOM THERMISTOR (TH2)

8512-5253-714XX-1 (KS2432A)

POWER

TRANSFORMER (TR1)

IND LAMP ASSY

Indoor Electrical Component Box

TRANS

C

BP

1 2G4

Upper flap motor

*GREEN MARK on

lower flap motor

Lower flap motor*

Controller (PCB ass'y

Power transformer (TR1)

Fan motor capacitor (RC1)

Terminal plate

Room thermistor (TH2)

Coil thermistor (TH1)

Clamp lead wires.

Indicator lamp ass'y

)

Grille air outlet

(

Side View

)

Page 4

4

Fig. 7

■ How to test run the air conditioner

1. Switch on the power source.

2. Press the ON/OFF button on the remote control unit

once.

3. Set the operation selector switch of the indoor unit

to the TEST position. This starts the fan, producing

uncooled forced air. (Fig. 7)

4. After 3 minutes, the system shifts into cooling operation, and cool air will start to be felt. Cooling operation with the switch at the TEST position is unaffected by the room temperature.

5. After stopping the test run, turn the operation selector switch of the indoor unit to the OFF position

once, then move to ON position. (Fig. 7)

6. Press the ON/OFF button on the remote control unit

to stop the air conditioner.

If the unit does not operate and the OPERATION lamp

on the unit is blinking after going through the procedure, check the wiring between the units.

NOTE

03-242.Sanyo.85464359404000 8/21/03 9:17 AM Page 4

INDOOR UNIT

OPERATION lamp

OPERATION

TIMER lamp

TIMER

Remote control

receiver

ON

OFF

TEST

Operation selector

Loading...

Loading...