Sanyo PW-UMR184EXH56, SPW-UMR94EXH56, SPW-UMR74EXH56, SPW-UMR224EXH56, SPW-UMR124EXH56 User Manual

...Page 1

– ECO-i System Air Conditioner –

INSTALLATION AND OPERATION MANUAL

■ R410A Models

Indoor Units

Outdoor Units

SPW-UMR74EXH56

SPW-UMR94EXH56

SPW-UMR124EXH56

SPW-UMR164EXH56

SPW-UMR184EXH56

SPW-UMR224EXH56

* Refrigerant R410A is used in the outdoor units.

C

DC Inverter Main Unit SPW-CR604GDXH8, SPW-CR704GDXH8, SPW-CR904GDXH8, SPW-CR1154GDXH8

Constant Speed (Sub) Unit SPW-CR704GDCH8, SPW-CR904GDCH8, SPW-CR1154GDCH8

Optional Controllers

Remote Controller RCS-SH80AG

RC Wireless Remote Controller RCS-BH80AG.WL

Simplified Remote Controller RCS-KR1AG

for Refrigerant R410A

SANYO Airconditioners Europe S.r.l.

Via Bisceglie, No. 76

20152 Milano, Italy

37.4196.054.0 ©SANYO 2005

Page 2

2

IMPORTANT!

Please Read Before Starting

This air conditioning system meets strict safety and operating standards. As the installer or service person, it is an

important part of your job to install or service the system so it

operates safely and efficiently.

For safe installation and trouble-free operation, you must:

●

Carefully read this instruction booklet before beginning.

●

Follow each installation or repair step exactly as shown.

●

Observe all local, state, and national electrical codes.

●

This product is intended for professional use.

Permission from the power supplier is required when

installing an outdoor unit that is connected to a 16 A

distribution network.

●

Pay close attention to all warning and caution notices

given in this manual.

This symbol refers to a hazard or

unsafe practice which can result

in severe personal injury or death.

This symbol refers to a hazard or

unsafe practice which can result

in personal injury or product or

property damage.

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help for a

special problem, contact our sales/service outlet or your

certified dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for

improper installation or maintenance service, including failure to follow the instructions in this document.

SPECIAL PRECAUTIONS

When Wiring

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

ONLY A QUALIFIED, EXPERIENCED

ELECTRICIAN SHOULD ATTEMPT TO

WIRE THIS SYSTEM.

• Do not supply power to the unit until all wiring and tubing

are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this system. Carefully refer to the wiring diagram and these

instructions when wiring. Improper connections and inadequate grounding can cause accidental injury or death.

• Ground the unit following local electrical codes.

• Connect all wiring tightly. Loose wiring may cause overheating at connection points and a possible fire hazard.

When Transporting

Be careful when picking up and moving the indoor and outdoor

units. Get a partner to help, and bend your knees when lifting

to reduce strain on your back. Sharp edges or thin aluminum

fins on the air conditioner can cut your fingers.

When Installing…

…In a Room

Properly insulate any tubing run inside a room to prevent

“sweating” that can cause dripping and water damage to

walls and floors.

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide a

solid, level foundation for the outdoor unit. This prevents

water damage and abnormal vibration.

…In an area with High Winds

Securely anchor the outdoor unit down with bolts and a

metal frame. Provide a suitable air baffle.

…In a Snowy Area (for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is higher

than drifting snow. Provide snow vents.

When Connecting Refrigerant Tubing

• Ventilate the room well, in the event that is refrigerant

gas leaks during the installation. Be careful not to allow

contact of the refrigerant gas with a flame as this will

cause the generation of poisonous gas.

• Keep all tubing runs as short as possible.

• Use the flare method for connecting tubing.

• Apply refrigerant lubricant to the matching surfaces of

the flare and union tubes before connecting them, then

tighten the nut with a torque wrench for a leak-free connection.

• Check carefully for leaks before starting the test run.

Depending on the system type, liquid and gas lines may

be either narrow or wide. Therefore, to avoid confusion

the refrigerant tubing for your particular model is specified as either “narrow” or “wide” than as “liquid” or “gas.”

When Servicing

• Turn the power OFF at the main power box (mains)

before opening the unit to check or repair electrical parts

and wiring.

• Keep your fingers and clothing away from any moving

parts.

• Clean up the site after you finish, remembering to check

that no metal scraps or bits of wiring have been left

inside the unit being serviced.

• Ventilate any enclosed areas when installing or testing the

refrigeration system. Escaped refrigerant gas, on contact

with fire or heat, can produce dangerously toxic gas.

• Confirm after installation that no refrigerant gas is leaking. If the gas comes in contact with a burning stove, gas

water heater, electric room heater or other heat source, it

can cause the generation of poisonous gas.

NOTE

WARNING

CAUTION

WARNING

CAUTION

Page 3

3

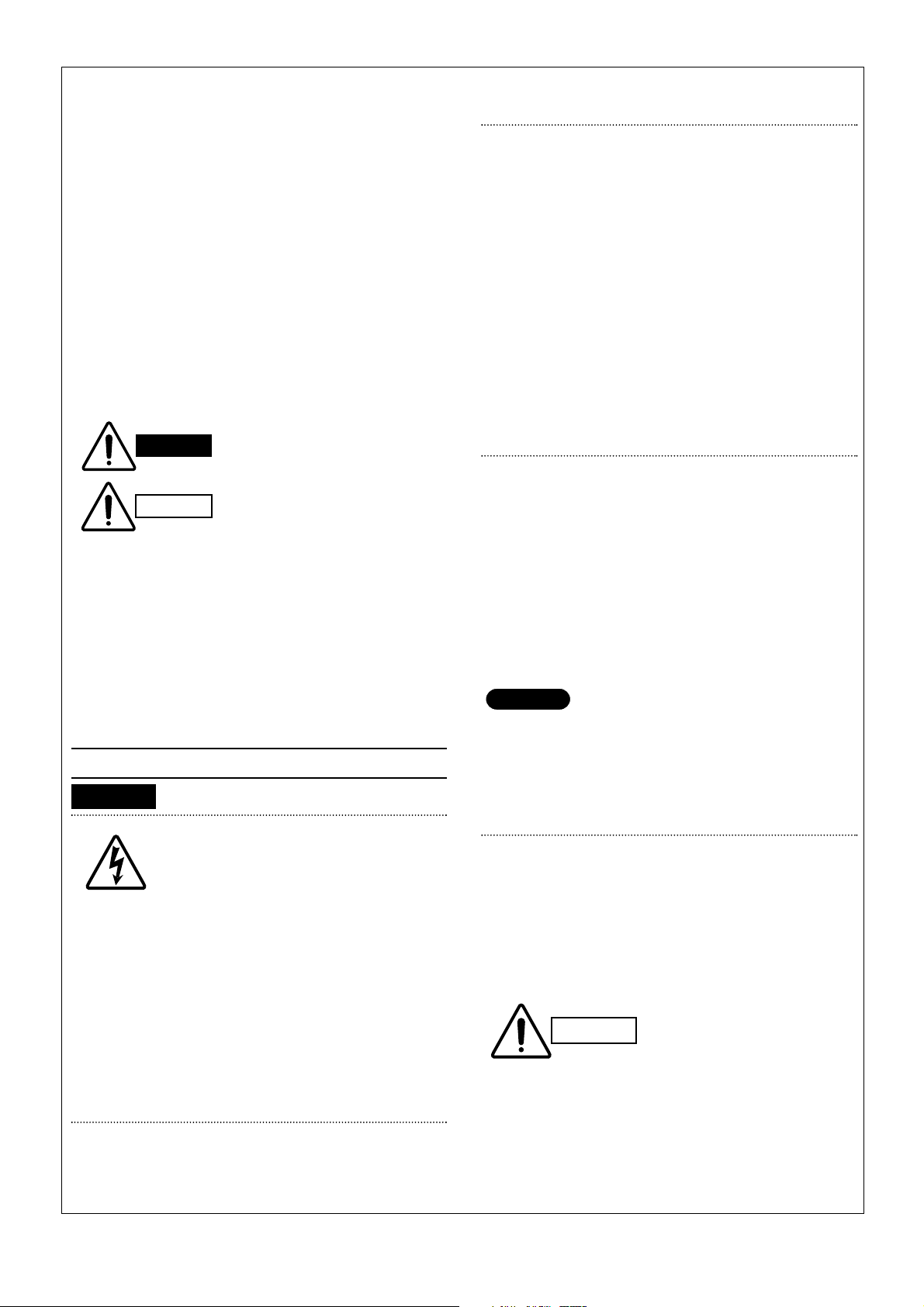

2. The standards for minimum room volume are as

follows.

(1) No partition (shaded portion)

(2) When there is an effective opening with the adja-

cent room for ventilation of leaking refrigerant gas

(opening without a door, or an opening 0.15% or

larger than the respective floor spaces at the top

or bottom of the door).

(3) If an indoor unit is installed in each partitioned

room and the refrigerant tubing is interconnected,

the smallest room of course becomes the object.

But when mechanical ventilation is installed interlocked with a gas leakage detector in the smallest

room where the density limit is exceeded, the volume of the next smallest room becomes the object.

3. The minimum indoor floor space compared with the

amount of refrigerant is roughly as follows: (When

the ceiling is 2.7 m high)

Check of Density Limit

The room in which the air conditioner is to be

installed requires a design that in the event of

refrigerant gas leaking out, its density will not

exceed a set limit.

The refrigerant (R410A), which is used in the air conditioner, is safe, without the toxicity or combustibility of

ammonia, and is not restricted by laws imposed to protect the ozone layer. However, since it contains more

than air, it poses the risk of suffocation if its density

should rise excessively. Suffocation from leakage of

refrigerant is almost non-existent. With the recent

increase in the number of high density buildings, however, the installation of multi air conditioner systems is

on the increase because of the need for effective use

of floor space, individual control, energy conservation

by curtailing heat and carrying power, etc.

Most importantly, the multi air conditioner system is

able to replenish a large amount of refrigerant compared to conventional individual air conditioners. If a

single unit of the multi air conditioner system is to be

installed in a small room, select a suitable model and

installation procedure so that if the refrigerant accidentally leaks out, its density does not reach the limit

(and in the event of an emergency, measures can be

made before injury can occur).

In a room where the density may exceed the limit,

create an opening with adjacent rooms, or install

mechanical ventilation combined with a gas leak

detection device. The density is as given below.

Total amount of refrigerant (kg)

Min. volume of the indoor unit installed room (m3)

≤ Density limit (kg/m

3

)

The density limit of refrigerant which is used in multi air conditioners is 0.3 kg/m

3

(ISO 5149).

1. If there are 2 or more refrigerating systems in a single refrigerating device, the amount of refrigerant

should be as charged in each independent device.

For the amount of charge in this example:

The possible amount of leaked refrigerant gas in rooms

A, B and C is 10 kg.

The possible amount of leaked refrigerant gas in rooms

D, E and F is 15 kg.

Outdoor unit

Refrigerant tubing

Indoor unit

Refrigerant tubing

NOTE

e.g., charged

amount (10 kg)

Indoor unit

Room A Room B Room C Room D Room E Room F

Outdoor unit

e.g., charged

amount (15 kg)

Outdoor unit

Very

small

room

Small

room

Mechanical ventilation device – Gas leak detector

Medium

room

Large room

Indoor unit

40

Range below the

2

35

m

density limit

of 0.3 kg/m

30

(countermeasures

not needed)

25

20

15

10

5

Min. indoor floor space

0

3

10 20 30

Total amount of refrigerant

Range above

the density limit

of 0.3 kg/m

(countermeasures

needed)

3

kg

Page 4

1. GENERAL

This booklet briefly outlines where and how to install the air conditioning system. Please read over the entire set of

instructions for the indoor unit and make sure all accessory parts listed are with the system before beginning.

1-2. Type of Copper Tube and Insulation Material

If you wish to purchase these materials separately

from a local source, you will need:

1. Deoxidized annealed copper tube for refrigerant

tubing.

2. Foamed polyethylene insulation for copper tubes as

required to precise length of tubing. Wall thickness

of the insulation should be not less than 8 mm.

3. Use insulated copper wire for field wiring. Wire

size varies with the total length of wiring. Refer to

4. Electrical Wiring for details.

1-3. Additional Materials Required for Installation

1. Refrigeration (armored) tape

2. Insulated staples or clamps for connecting wire

(See your local codes.)

3. Putty

4. Refrigeration tubing lubricant

5. Clamps or saddles to secure refrigerant tubing

6. Scale for weighing

Check local electrical codes

and regulations before

obtaining wire. Also, check

any specified instructions

or limitations.

4

IMPORTANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Please Read Before Starting

Check of Density Limit

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-1. Tools Required for Installation (not supplied)

1-2. Type of Copper Tube and Insulation Material

1-3. Additional Materials Required for Installation

2. HOW TO INSTALL THE UNIT . . . . . . . . . . . . . .5

2-1. Duct for fresh air

3. TEST OF THE SYSTEM AND CONTROL OF THE

AIR VOLUME TO THE OUTLET GRILLES . . . .7

CONTENTS

Page

Page

1-1. Tools Required for Installation (not supplied)

1. Standard screwdriver

2. Phillips head screwdriver

3. Knife or wire stripper

4. Tape measure

5. Carpenter’s level

6. Sabre saw or key hole saw

7. Hacksaw

8. Core bits

9. Hammer

10. Drill

11. Tube cutter

12. Tube flaring tool

13. Torque wrench

14. Adjustable wrench

15. Reamer (for deburring)

4. ELECTRICAL WIRING . . . . . . . . . . . . . . . . . . . .8

4-1. General Precautions on Wiring

4-2. Recommended Wire Length and Wire Diame-

ter for Power Supply System

4-3. Wiring System Diagrams

5. HOW TO PROCESS TUBING . . . . . . . . . . . . . .12

5-1. Connecting the Refrigerant Tubing

5-2. Connecting Tubing between Indoor and Out-

door Units

5-3. Insulating the Refrigerant Tubing

5-4. Taping the Tubes

5-5. Finishing the Installation

6 APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

CAUTION

Page 5

5

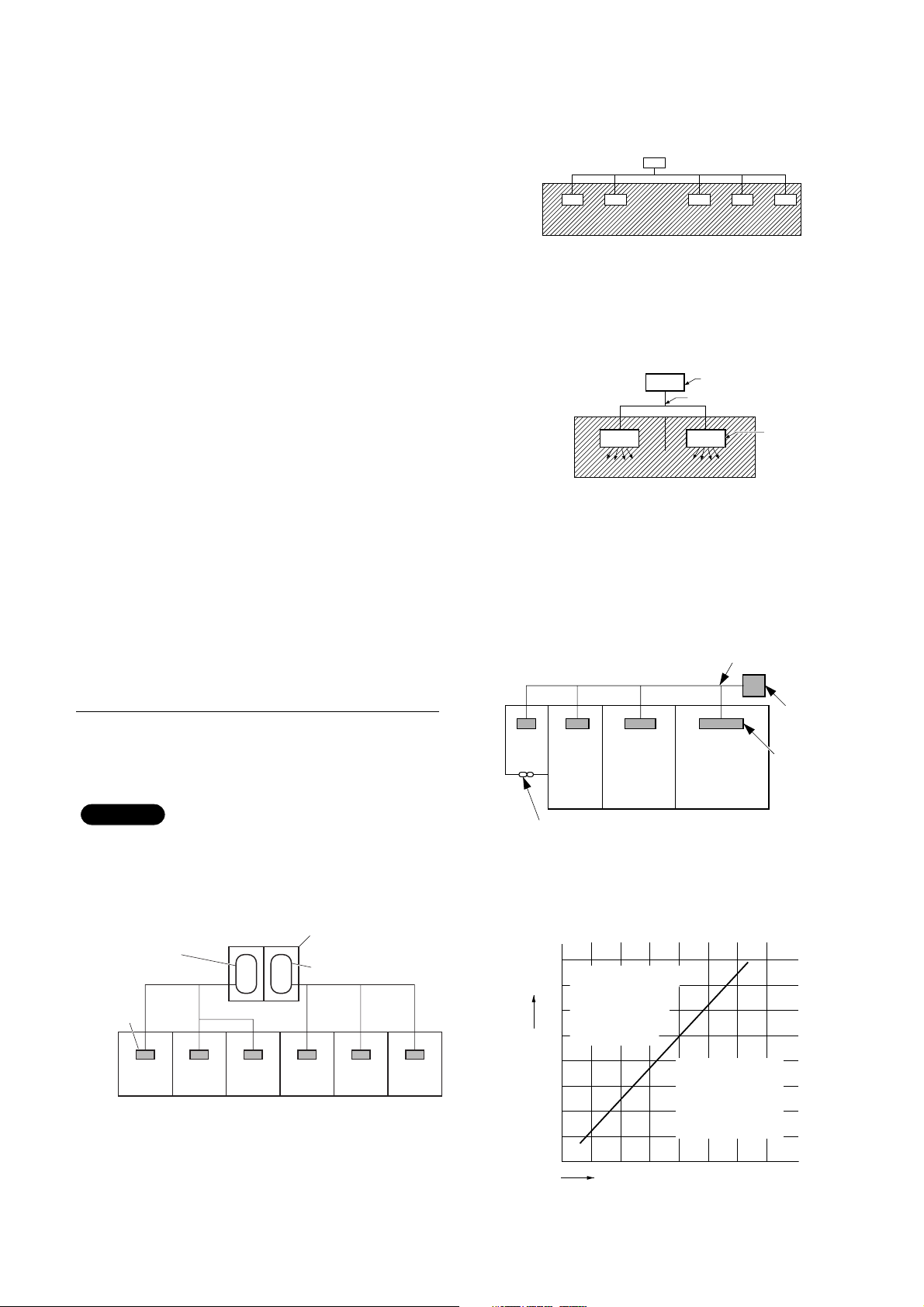

2. HOW TO INSTALL THE UNIT

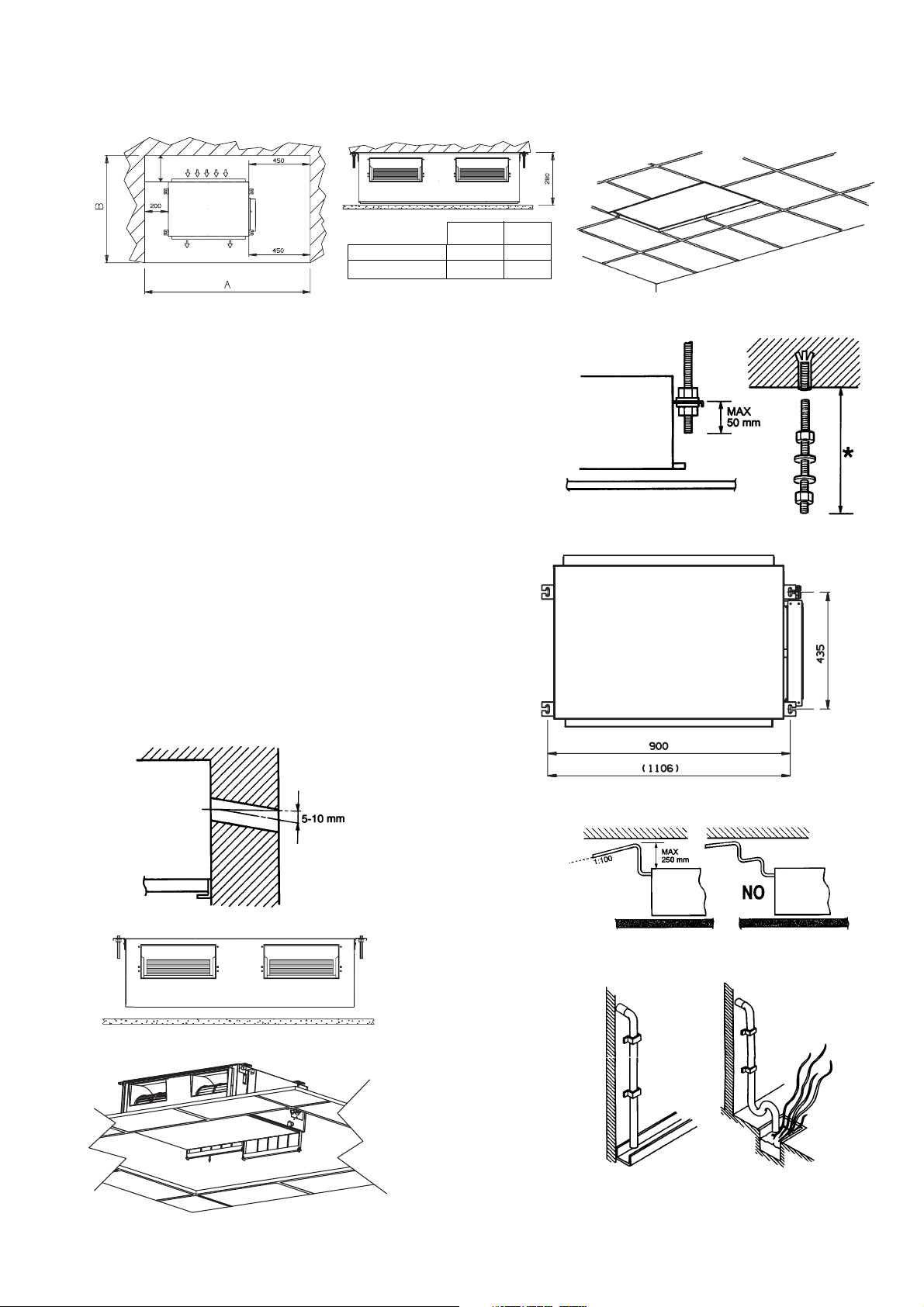

Fig. 2-1

Minimum operation and maintenance area. (fig. 2-1)

Fig. 2-2

Fig. 2-4

Find the space for the installation of the return air grille and

mark the opening to do. Cut the falseceiling. (fig. 2-2)

Use rawl plug suitable to the ceiling consistence and four

M10 threaded bars of suitable length (not supplied). (fig. 2-

3)

Mark on the ceiling the holes for the hanging rods, verify the

distance of the centres. The value included in the brackets

is referred to the model X18. (fig. 2-4)

Drill a 80 mm diameter hole, for the passage of refrigeration

pipework, condensate pipework and electrical cable. Insert

a PVC pipe in the wall. (fig. 2-5)

Secure the unit in position with locknuts and washers, level

the unit, keeping the right distance from the falseceiling for

the installation of return air grille. (fig. 2-6)

Foresee a removable panel of the falseceiling for servicing.

(fig. 2-7)

The unit is supplied with PVC hose from the condensate

pump. Maximum pump lift is 250 mm over the unit. Convoy

the condensate with a positive slope (min. 1:100) to the outside. The highest point in the condensate pipework should

be as close to the unit as possible. This prevents a large

volume of water draining back into the unit when it is

switched off. (fig. 2-8)

Convoy the condensate to the outside with a positive slope,

from a trap at the end if necessary. (fig. 2-9)

300

Fig. 2-3

Fig. 2-5

Fig. 2-6

Fig. 2-7

Fig. 2-8

Fig. 2-9

7/9/12 1500 1100

16/18/22 1700 1100

AB

Page 6

6

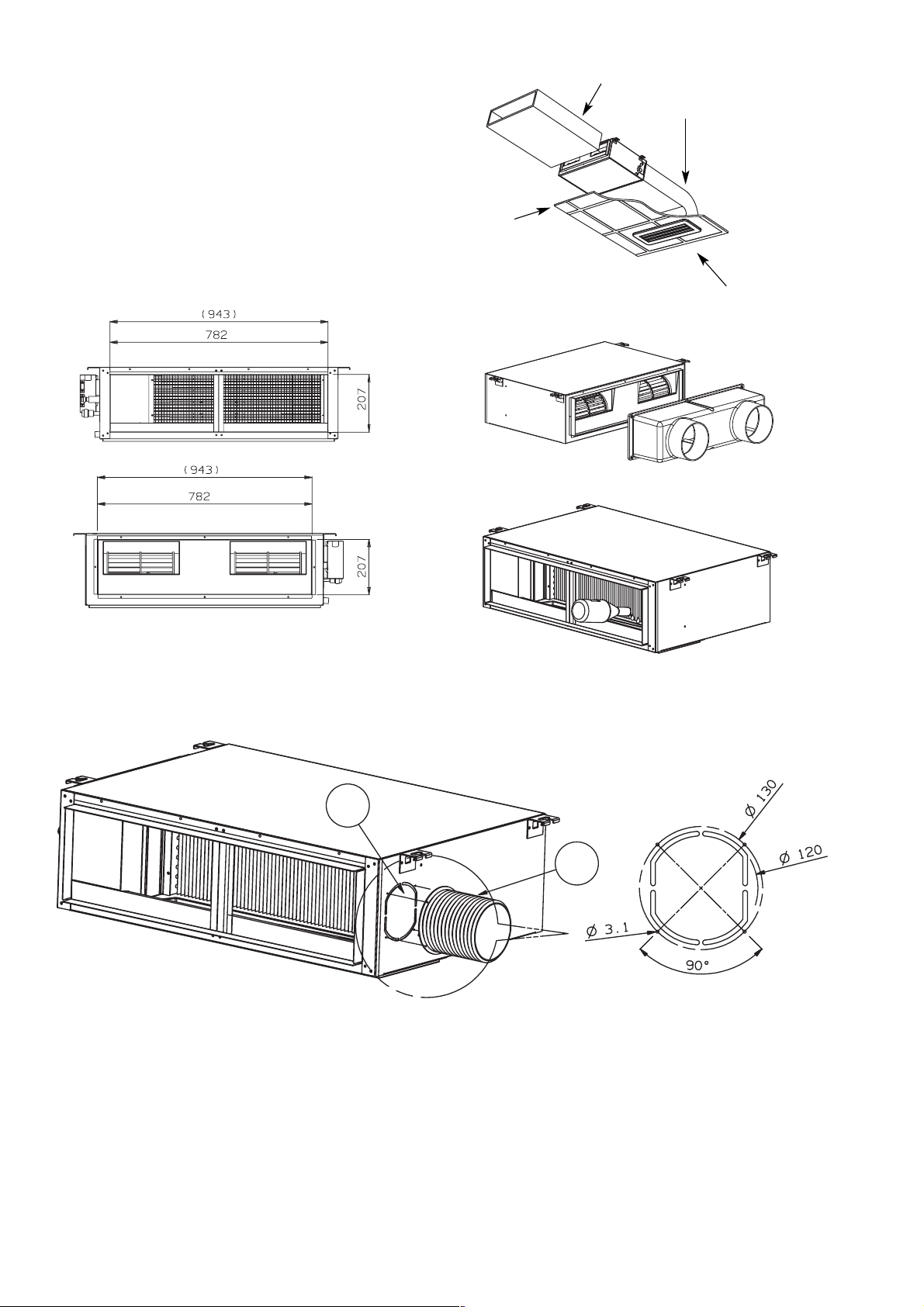

Intake coduct

False ceiling

Air intake

Outlet conduct

On the front and rear side of the unit a rectangular port

(with flange) helps during duct mounting. (fig. 2-10)

Rear and front flange for the air intake. The value included

in the brackets is referred to the model X18. (fig. 2-11)

Discarge air duct (optional accessory).

Contact the After Sale Service. (fig. 2-12)

Remove the filter and pour, inside the condensate drain

pan, 0.5 liter of water. Start the unit checking for proper

drain pump operation. (fig. 2-13)

Fig. 2-10

Fig. 2-11

Fig. 2-12

Fig. 2-13

2

1

There is a duct connection port for drawing in fresh air.

The supplementary fan motor for outside air intake has to be supplied separately and controlled by a bipolar ON-OFF switch

with safety fuses.

Fresh air flow must be about 10% of the total air flow to avoid operating problems and noise.

•

Open the knock-out hole , fix a 120 mm flange on the unit and connect the thermically insulated duct.

•

Install an outside grille with filter inspection port to prevent dust and leaves from entering and fouling the indoor unit heat

exchanger.

2-1 Duct for fresh air

Page 7

7

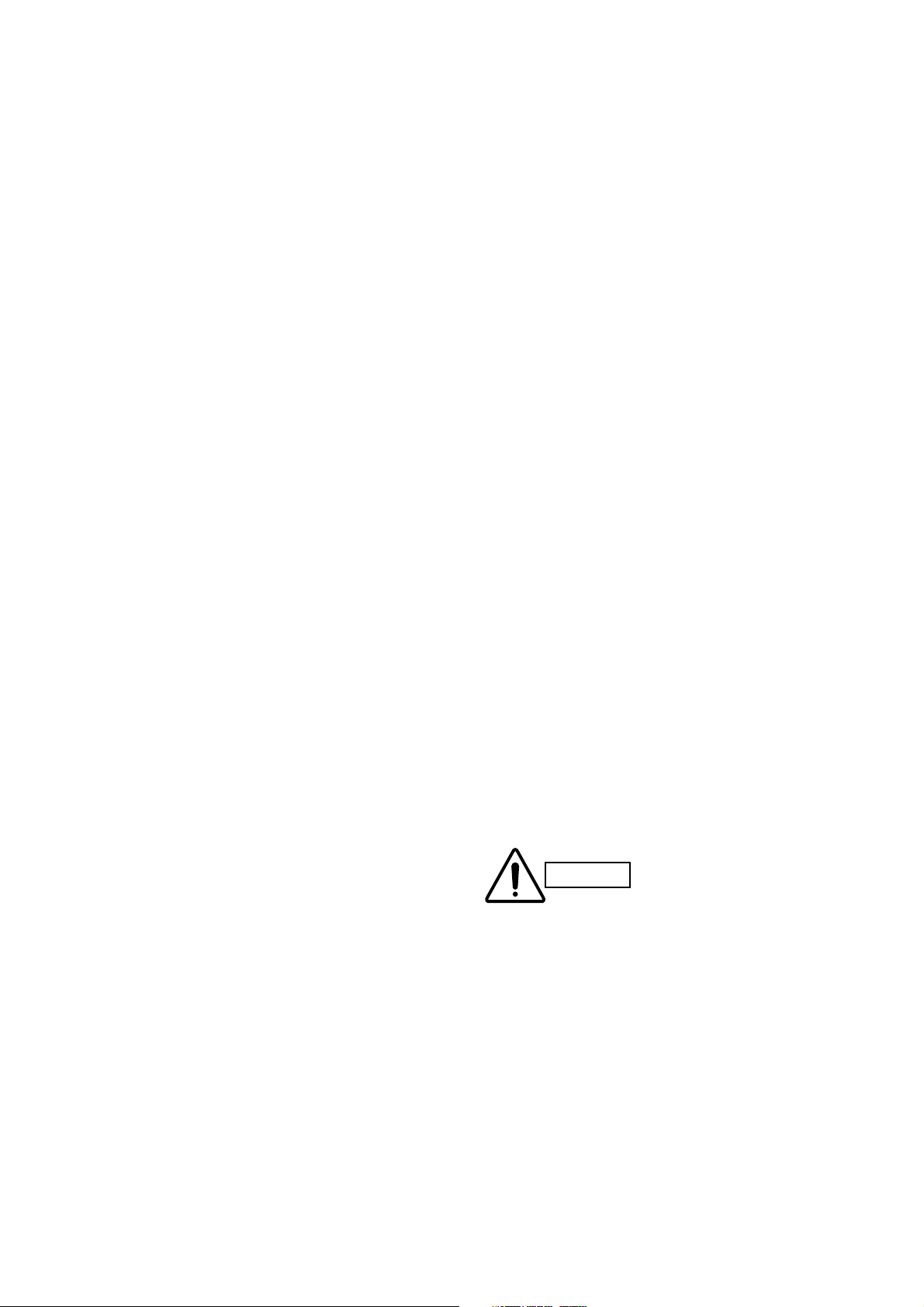

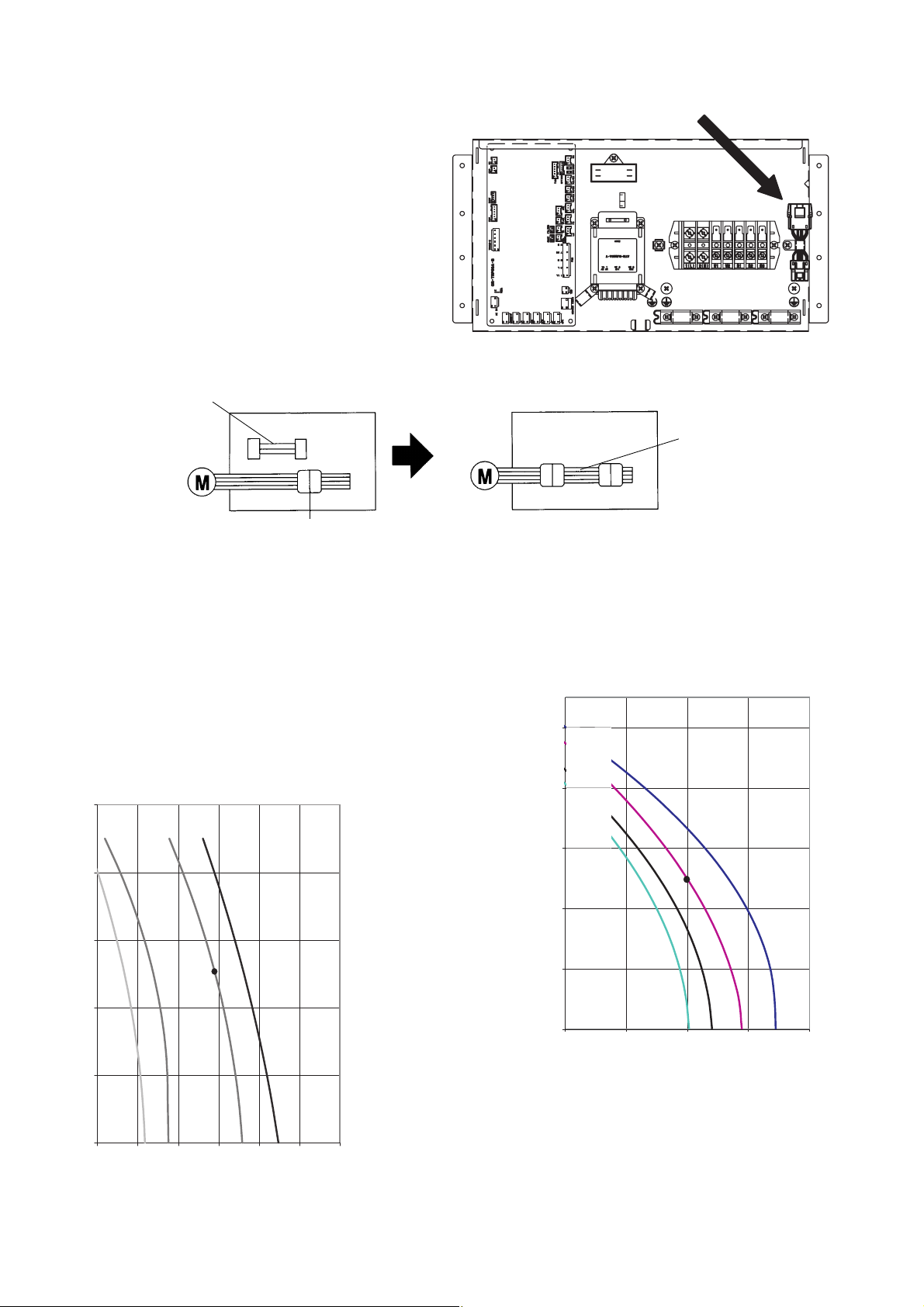

3. TEST OF THE SYSTEM AND CONTROL OF THE AIR VOLUME TO THE OUTLET GRILLES

The unit is prearranged to supply an external static pressure

of about 5 mm. Too high resistances in the air distribution

system can cause an exceedingly small air volume to the

outlet grilles.

This trouble can be solved by increasing the fan speed as

follows:

Open the cover of the electrical junction box. Take out the

booster cable clamped in the box. (fig. 3-1)

Disconnect the fan motor plug in the electrical box and insert

the booster cable as a cable extension between the motor

plug and the socket from the PCB. The external static pressure will increase to 7 mm w.g. Check static pressure and air

flow rate on the fan performance graph. (fig. 3-2)

Fan motor

Fan motor

Booster cable

Booster cable

Connector motor cable (at the supply)

Fig. 3-1

Fig. 3-2

0

2

4

6

8

10

200 400 600 800 1000

H

HH

M

L

7/9/12

16/18/22

m3/h

m

3

/h

EXTERNAL STATIC PRESSURE (mmW.G.)

EXTERNAL STATIC PRESSURE (mmW.G.)

H = High fan speed

L = Low fan speed

HH = Very high fan speed

M = Middle fan speed

H: Standard supplied unit. Available fan speeds: Low-Midd-

le-High (L - M - H). Max. static pressure: about 5 mm

HH: Unit with cable extension of the fan motor (booster

cable). Available fan speeds: Middle-High-Very high (M H - HH). Max. static pressure: about 7 mm

10

8

6

4

2

0

300 500 700 900 1100 1300 1500

M

L

HH

H

Page 8

8

4. ELECTRICAL WIRING

4-1. General Precautions on Wiring

(1) Before wiring, confirm the rated voltage of the unit

as shown on its nameplate, then carry out the

wiring closely following the wiring diagram.

(2) Provide a power outlet to be used exclusively for

each unit, and a power supply disconnect and circuit breaker for overcurrent protection should be

provided in the exclusive line.

(3) To prevent possible hazards from insulation fail-

ure, the unit must be grounded.

(4) Each wiring connection must be done in accor-

dance with the wiring system diagram. Wrong

wiring may cause the unit to misoperate or

become damaged.

(5) Do not allow wiring to touch the refrigerant tubing,

compressor, or any moving parts of the fan.

(6) Unauthorized changes in the internal wiring can be

very dangerous. The manufacturer will accept no

responsibility for any damage or misoperation that

occurs as a result of such unauthorized changes.

(7) Regulations on wire diameters differ from locality

to locality. For field wiring rules, please refer to

your LOCAL ELECTRICAL CODES before beginning.

You must ensure that installation complies with all

relevant rules and regulations.

(8) To prevent malfunction of the air conditioner

caused by electrical noise, care must be taken

when wiring as follows:

● The remote control wiring and the inter-unit control

wiring should be wired apart from the inter-unit

power wiring.

● Use shielded wires for inter-unit control wiring

between units and ground the shield on both sides.

(9) If the power supply cord of this appliance is dam-

aged, it must be replaced by a repair shop

appointed by the manufacture, because special

purpose tools are required.

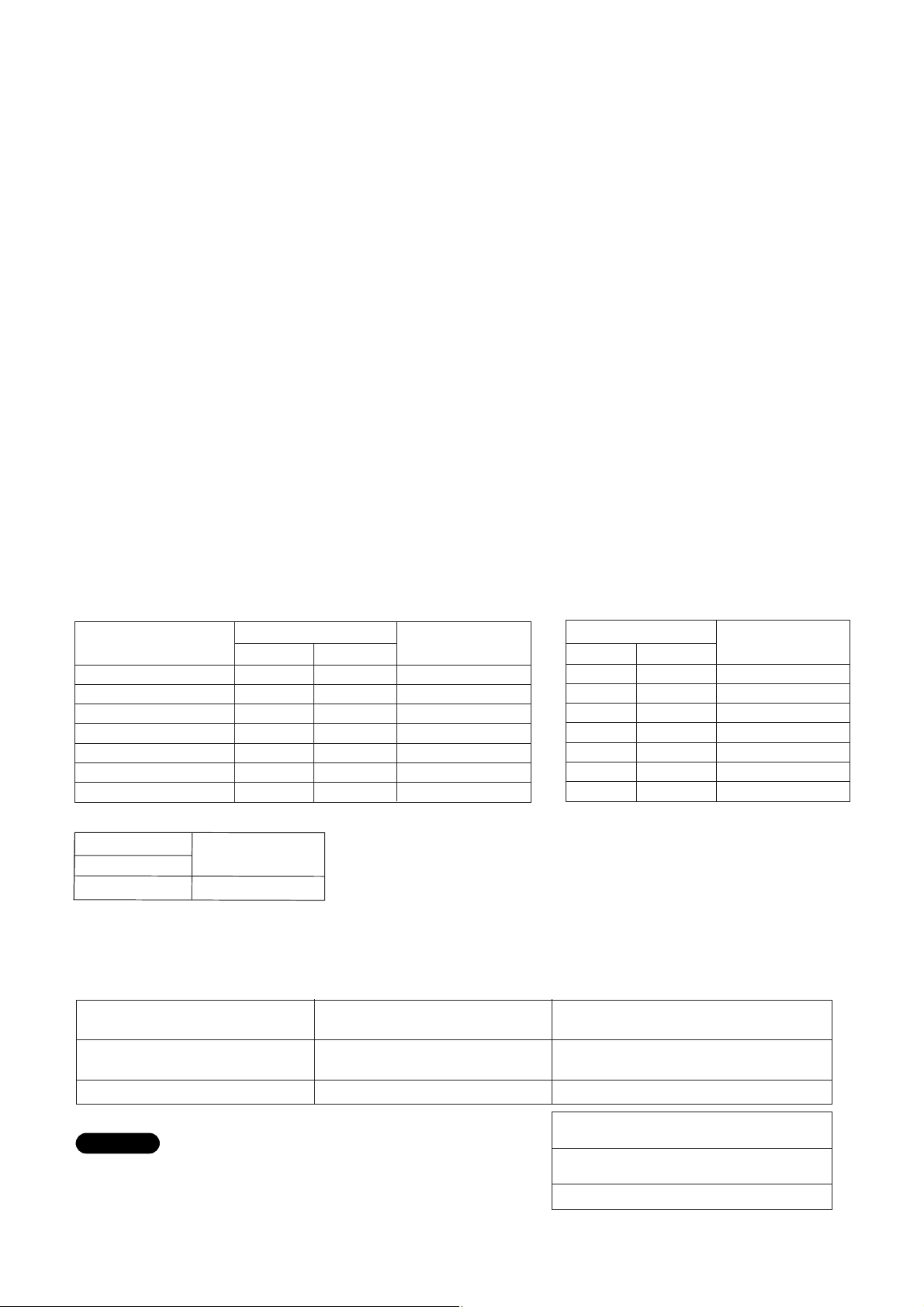

4-2. Recommended Wire Length and Wire Diameter for Power Supply System

* With ring-type wire terminal.

Outdoor unit

(A) Power supply

Wire size Max. length

2

SPW-CR604GDXH8 113 m 15 A

SPW-CR704GDXH8 74 m 30 A

SPW-CR904GDXH8 60 m 35 A

SPW-CR1154GDXH8 55 m 40 A

SPW-CR704GDCH8 47 m 35 A

SPW-CR904GDCH8 46 m 40 A

SPW-CR1154GDCH8

4 mm

6 mm

6 mm

6 mm

6 mm

6 mm

6 mm

2

2

2

2

2

2

39 m 50 A

Time delay fuse or

circuit capacity

Indoor unit

(B) Power supply

2.5 mm

Max. 130 m

Time delay fuse or

2

circuit capacity

10 ~ 16A

Control wiring

(C) Inter-unit (between outdoor and

(D) Remote control wiring (E) Control wiring for group control

indoor units) control wiring

0.75 mm

2

(AWG #18)

0.75 mm

2

(AWG #18)

Use shielded wiring* Use shielded wiring Use shielded wiring

Max. 1,000 m

Max. 500 m

or

(A) Power supply

Wire size Max. length

2.5 mm

6 mm

6 mm

10 mm

6 mm

10 mm

10 mm

2

70 m

2

74 m

2

60 m

2

91 m

2

47 m

2

77 m

2

65 m

0.75 mm

2

(AWG #18)

Max. 500 m (Total)

Time delay fuse or

circuit capacity

16A

35A

35A

50A

35A

50A

50A

NOTE

(F) Inter-outdoor unit control wiring

2

0.75 mm

(AWG #18)

Use shielded wiring

Max. 500 m

Page 9

9

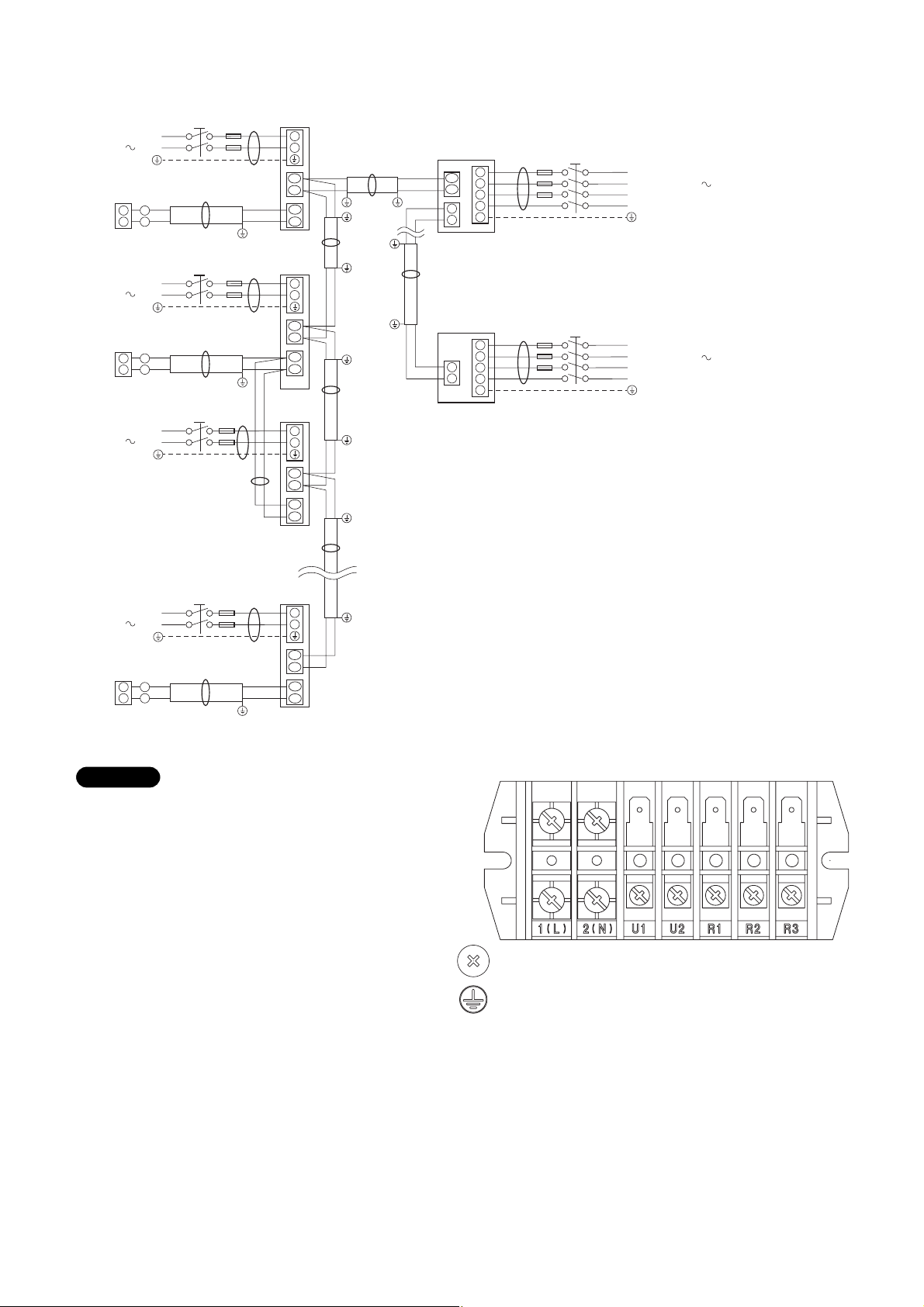

4-3. Wiring System Diagrams

(1) Refer to Section 5-2. “Recommended Wire Length

and Wire Diameter for Power Supply System” for

the explanation of “A,” “B,” “C,” “D,” and “E,” in the

above diagrams.

(2) The basic connection diagram of the indoor unit

shows the 7P terminal board, so the terminal

boards in your equipment may differ from the diagram.

(3) Refrigerant Circuit (R.C.) address should be set

before turning the power on.

7P terminal board

1(L)

power

supply

2(N) U1 U2

Inter-unit

control

wiring

R1 R2

Remote

controller

Power supply

220-240V 50Hz

Remote

controller

WHT

BLK

Power supply

220-240V 50Hz

Remote

controller

WHT

BLK

Group control:

Power supply

220-240V 50Hz

L

N

Ground

B

D

1

1

2

2

L

N

Ground

B

D

1

1

2

2

L

N

Ground

B

E

Indoor

unit (No. 1)

1

2

U1

U2

R1

R2

Indoor

unit (No. 2)

1

2

U1

U2

R1

R2

Indoor

unit (No. 3)

1

2

U1

U2

R1

R2

Outdoor unit

C

Ground

Ground

C

U1

U2

3

4

INV unit

A

1

2

3

4

5

L1

L2

L3

N

Ground

Power supply

380-415V-3N 50Hz

Ground

F

Inter-outdoor-unit control wiring

Outdoor unit

CS unit

Ground

C

3

4

A

1

2

3

4

5

L1

L2

L3

N

Ground

Power supply

380-415V-3N 50Hz

Ground

C

Indoor

Power supply

220-240V 50Hz

Remote

controller

1

WHT

BLK

1

2

2

L

N

Ground

D

unit (No. n)

B

1

2

U1

U2

R1

R2

Ground

NOTE

Page 10

10

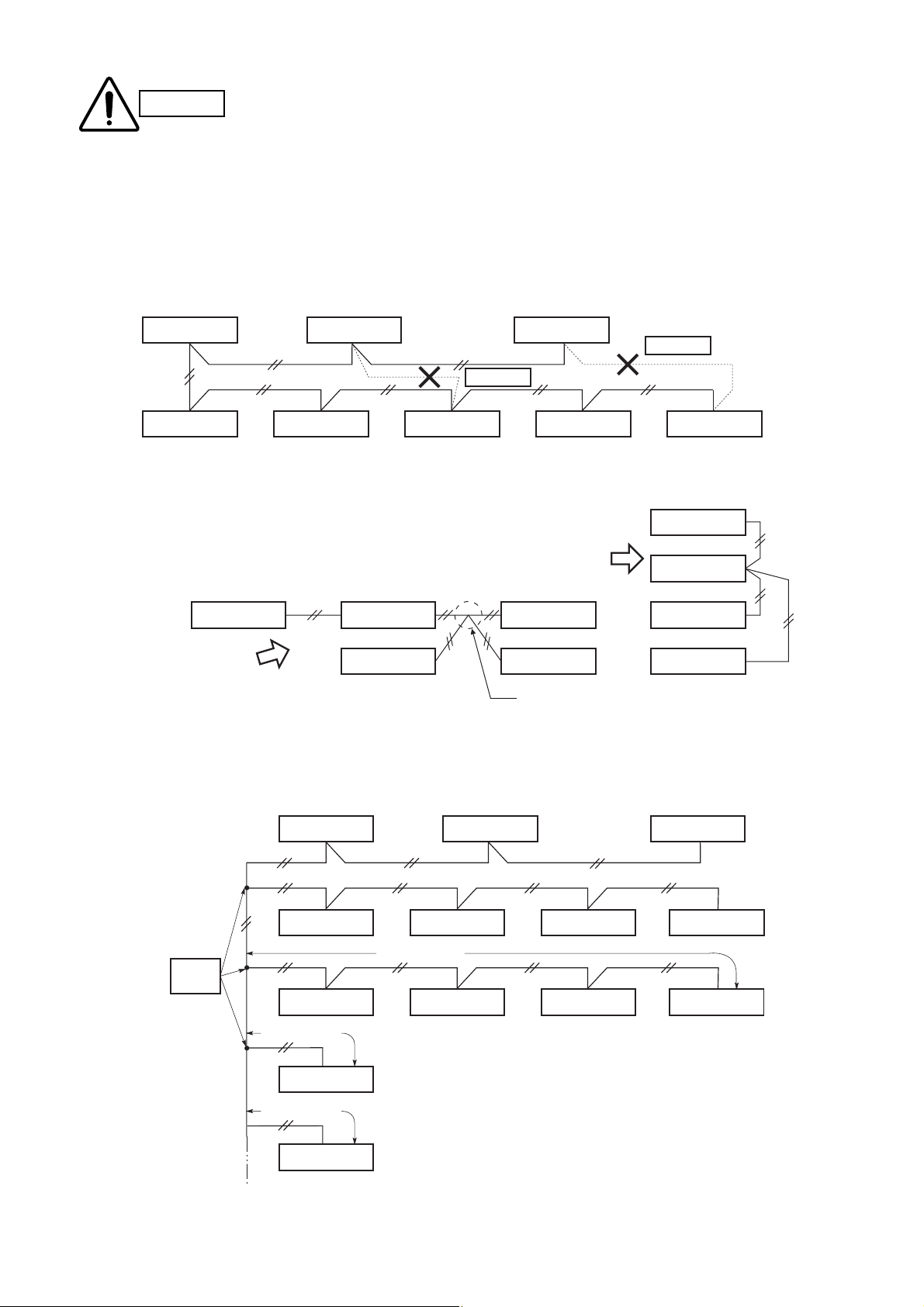

(1) When linking outdoor units in a network (S-net link system), disconnect the terminal extended from the

short plug (CN003, 2P Black, location: right bottom on the outdoor main control PCB) from all outdoor

units except any one of the outdoor units.

(When shipping: In shorted condition.)

Otherwise the communication of S-net link system is not performed. For a system without link (no connection wiring between outdoor units), do not remove the short plug.

(2) Do not install the inter-unit control wiring in a way that forms a loop. (Fig. 4-1)

Fig. 4-1

Fig. 4-2

Fig. 4-3

CAUTION

(3) Do not install inter-unit control wiring such as star

branch wiring. Star branch wiring causes mis-address

setting.

(4) If branching the inter-unit control wiring, the number of branch points should be 16 or fewer.

(Branches less than 1 m are not included in the total branch number.) (Fig. 4-3)

Outdoor unit Outdoor unit Outdoor unit

Prohibited

Indoor unit Indoor unit Indoor unit Indoor unit Indoor unit

NO

Outdoor unit Indoor unit Indoor unit Indoor unit

NO

Indoor unit Indoor unit Indoor unit

Branch point

Prohibited

Outdoor unit

Indoor unit

Branch

point

16 or fewer

Outdoor unit Outdoor unit Outdoor unit

Indoor unit Indoor unit Indoor unit Indoor unit

more than 1 m

Indoor unit

more than 1 m

Indoor unit

less than 1 m

Indoor unit

Indoor unit Indoor unit Indoor unit

Page 11

11

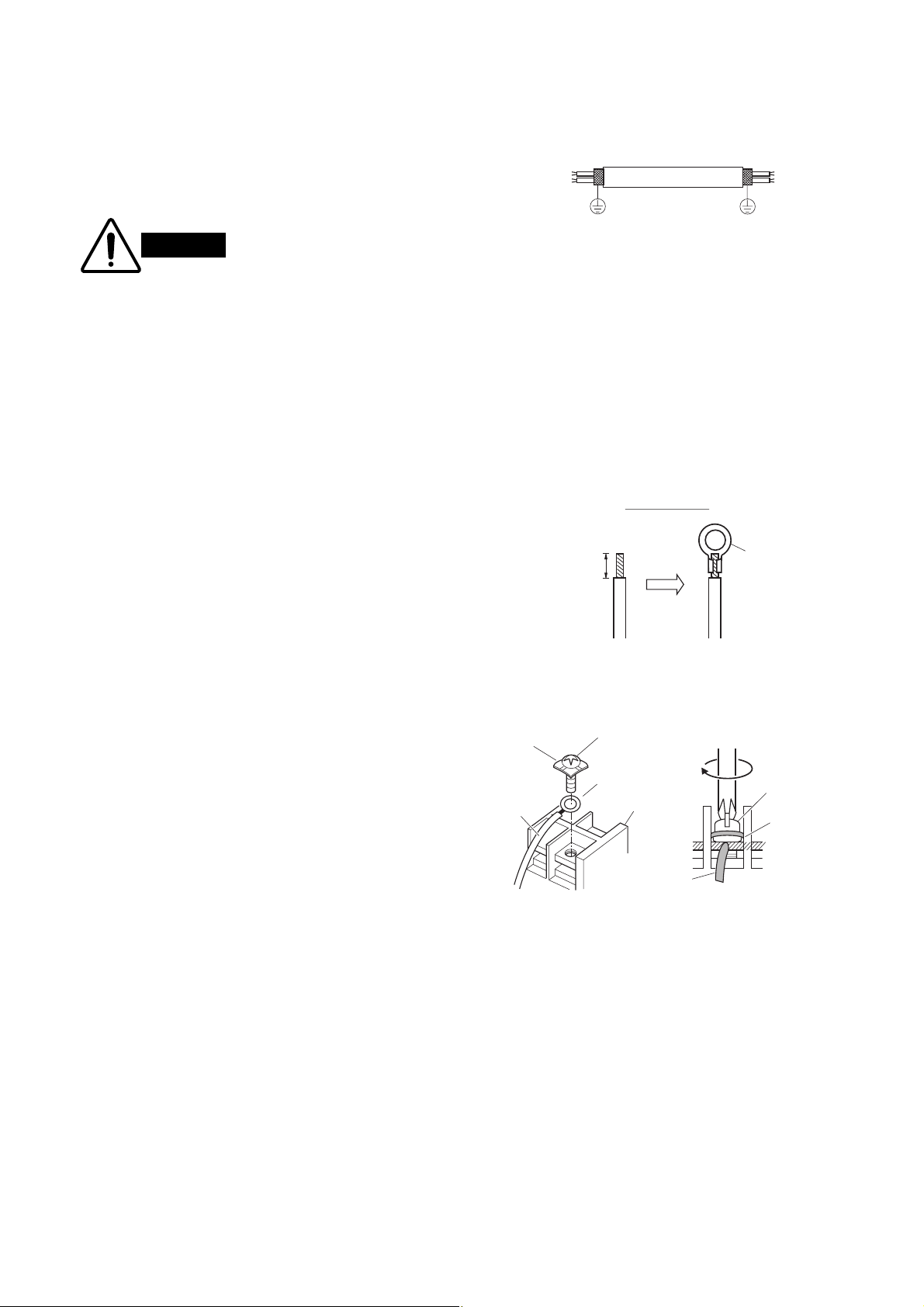

Fig. 4-4

Fig. 4-5

Fig. 4-6

(5) Use shielded wires for inter-unit control wiring

(c) and ground the shield on both sides, otherwise misoperation from noise may occur.

(Fig. 4-4)

Connect wiring as shown in Section “4-3.

Wiring System Diagrams.”

Loose wiring may cause

the terminal to overheat or

result in unit malfunction.

A fire hazard may also

exist. Therefore, ensure

that all wiring is tightly

connected.

When connecting each power wire to the terminal, follow the instructions on “How to connect wiring to the

terminal” and fasten the wire securely with the fixing

screw of the terminal plate.

How to connect wiring to the terminal

■ For stranded wiring

(1) Cut the wire end with cutting pliers, then strip the

insulation to expose the stranded wiring about 10

mm and tightly twist the wire ends. (Fig. 4-5)

(2) Using a Phillips head screwdriver, remove the ter-

minal screw(s) on the terminal plate.

(3) Using a ring connector fastener or pliers, securely

clamp each stripped wire end with a ring pressure

terminal.

(4) Place the ring pressure terminal, and replace and

tighten the removed terminal screw using a screwdriver. (Fig. 4-6)

WARNING

Special

washer

Wire

Ground

Strip 10 mm

Screw

Ring pressure

terminal

Terminal plate

Shielded wire

Ground

Stranded wire

Ring

pressure

terminal

Screw and

Special washer

Ring

pressure

terminal

Wire

Page 12

12

5. HOW TO PROCESS TUBING

The narrow tubing side is connected by a flare nut,

and the wide tubing side is connected by brazing.

5-1. Connecting the Refrigerant Tubing

Use of the Flaring Method

Many of conventional split system air conditioners

employ the flaring method to connect refrigerant tubes

which run between indoor and outdoor units. In this

method, the copper tubes are flared at each end and

connected with flare nuts.

Flaring Procedure with a Flare Tool

(1) Cut the copper tube to the required length with a

tube cutter. It is recommended to cut approx. 30

– 50 cm longer than the tubing length you estimate.

(2) Remove burrs at the end of the copper tube with a

tube reamer or file. This process is important and

should be done carefully to make a good flare.

(Fig. 5-1)

When reaming, hold the tube end downward and be

sure that no copper scraps fall into the tube. (Fig. 5-2)

(3) Remove the flare nut from the unit and be sure to

mount it on the copper tube.

(4) Make a flare at the end of copper tube with a

flare tool.* (Fig. 5-3)

(*Use “RIGID

®

” or equivalent.)

A good flare should have the following characteristics:

● inside surface is glossy and smooth

● edge is smooth

● tapered sides are of uniform length

NOTE

NOTE

Fig. 5-1

Fig. 5-2

Fig. 5-3

Before

Deburring

After

Copper

tubing

Reamer

Flare nut

Copper

tubing

Flare tool

Page 13

13

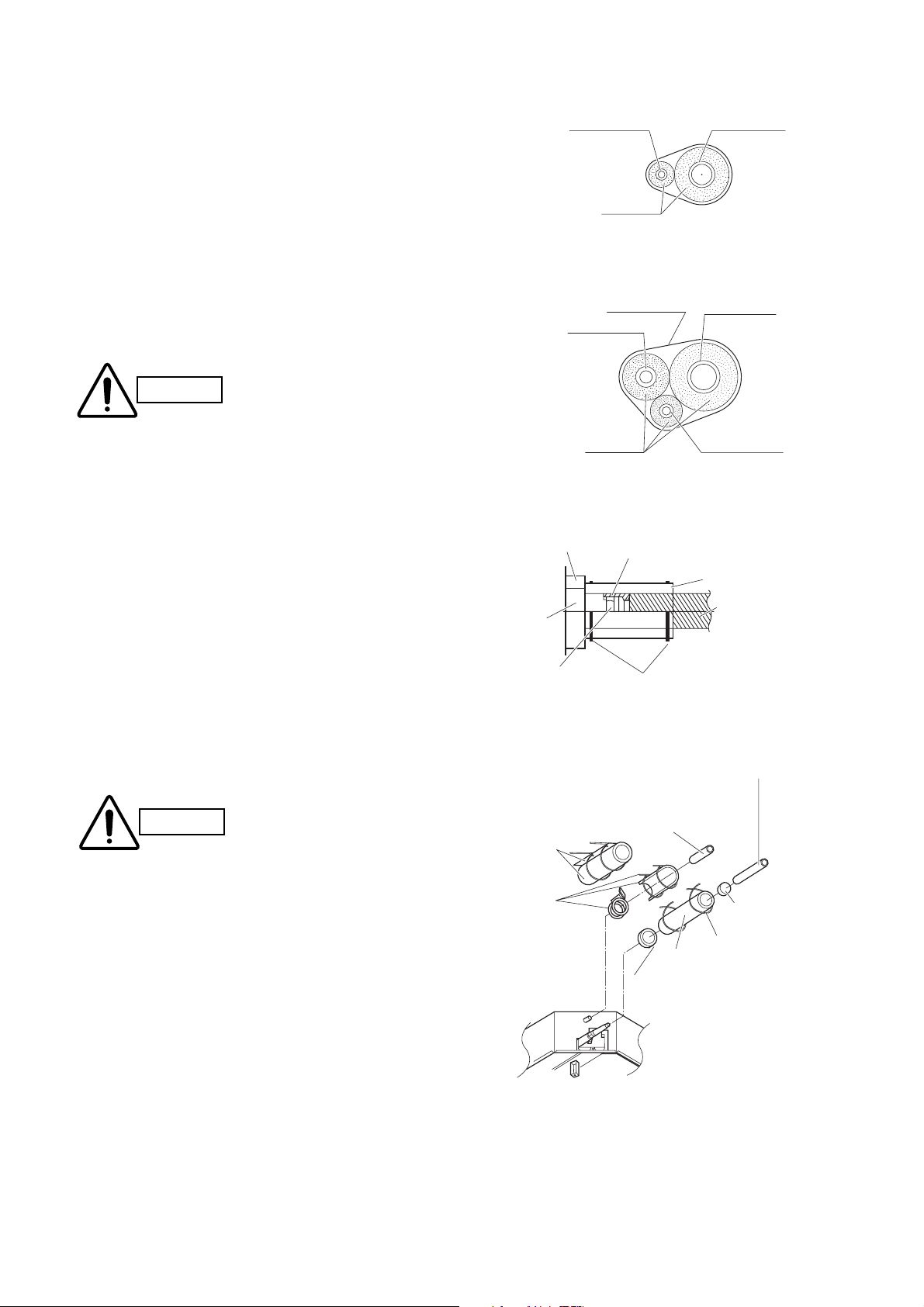

Caution Before Connecting Tubes Tightly

(1) Apply a sealing cap or water-proof tape to prevent

dust or water from entering the tubes before they

are used.

(2) Be sure to apply refrigerant lubricant to the match-

ing surfaces of the flare and union before connecting them together. This is effective for reducing

gas leaks. (Fig. 5-4)

(3) For proper connection, align the union tube and

flare tube straight with each other, then screw in

the flare nut lightly at first to obtain a smooth

match. (Fig. 5-5)

● Adjust the shape of the narrow tube (liquid tube)

using a tube bender at the installation site and

connect it to the narrow tubing side (liquid tubing

side) valve using a flare.

Cautions During Brazing

● Replace air inside the tube with nitrogen gas to

prevent copper oxide film from forming during

the brazing process. (Oxygen, carbon dioxide

and Freon are not acceptable.)

● Do not allow the tubing to get too hot during

brazing. The nitrogen gas inside the tubing

may overheat, causing refrigerant system

valves to become damaged. Therefore allow

the tubing to cool when brazing.

● Use a reducing valve for the nitrogen cylinder.

● Do not use agents intended to prevent the for-

mation of oxide film. These agents adversely

affect the refrigerant and refrigerant oil, and

may cause damage or malfunctions.

5-2. Connecting Tubing Between Indoor and Out-

door Units

(1) Tightly connect the indoor-side refrigerant tubing

extended from the wall with the outdoor-side tubing.

(2) To fasten the flare nuts, apply specified torque as

at right:

● When removing the flare nuts from the tubing con-

nections, or when tightening them after connecting

the tubing, be sure to use 2 monkey wrenches or

spanners as shown. (Fig. 5-6)

If the flare nuts are over-tightened, the flare may be

damaged, which could result refrigerant leakage

and cause in injury or asphyxiation to room occupants.

● For the flare nuts at tubing connections, be sure to

use the flare nuts that were supplied with the unit,

or else flare nuts for R410A (type 2). The refrigerant tubing that is used must be of the correct wall

thickness as shown in the table at right.

Fig. 5-4

Fig. 5-5

Fig. 5-6

Because the pressure is approximately 1.6 times

higher than conventional refrigerant pressure, the

use of ordinary flare nuts (type 1) or thin-walled

tubes may result in tube rupture, injury, or asphyxiation caused by refrigerant leakage.

● In order to prevent damage to the flare caused by

over-tightening of the flare nuts, use the table

above as a guide when tightening.

● When tightening the flare nut on the narrow tube,

use a monkey wrench with a nominal handle length

of 200 mm.

Indoor unit

Tube diameter

φ

6.35 (1/4")

φ

9.52 (3/8")

φ

12.7 (1/2")

φ

15.88 (5/8")

Apply refrigerant

lubricant here and here

Union

Flare nut

Torque wrench

Outdoor unit

Tightening torque,

approximate

14 – 18 N

(140 – 180 kgf

34 – 42 N

(340 – 420 kgf

49 – 61 N

(490 – 610 kgf

68 – 82 N

(680 – 820 kgf

m

·

cm)

·

m

·

cm)

·

m

·

cm)

·

m

·

cm)

·

Spanner

Tube thickness

0.8 mm

0.8 mm

0.8 mm

1.0 mm

Page 14

14

Fig. 5-8

Fig. 5-7

Fig. 5-9

5-3. Insulating the Refrigerant Tubing

Tubing Insulation

● Thermal insulation must be applied to all unit tub-

ing, including distribution joint (purchased separately).

* For gas tubing, the insulation material must be

heat resistant to 120°C or above. For other tubing,

it must be heat resistant to 80°C or above.

Insulation material thickness must be 10 mm or

greater.

If the conditions inside the ceiling exceed DB 30°C

and RH 70%, increase the thickness of the gas

tubing insulation material by 1 step.

Taping the flare nuts

Wind the white insulation tape around the flare nuts at

the wide tube connections. Then cover up the tubing

connections with the flare insulator, and fill the gap at

the union with the supplied black insulation tape.

Finally, fasten the insulator at both ends with the supplied vinyl clamps. (Fig. 5-8)

Insulation material

The material used for insulation must have good insulation characteristics, be easy to use, be age resistant, and must not easily absorb moisture.

After a tube has been insulated, never try to bend it

into a narrow curve

because it can cause the

tube to break or crack.

Never grasp the drain or refrigerant connecting

outlets when moving the unit.

y

Three tubes arranged together

Two tubes arranged together

If the exterior of the outdoor

unit valves has been finished

with a square duct covering,

make sure you allow sufficient space to use the valves

and to allow the panels to be

attached and removed.

CAUTION

Narrow tubing

Sealer (supplied)

Unit side

insulator

Flare nut

Narrow tubing

Insulation

Cosmetic

(finishing) tape

Insulation

Insulation tape (white)

(supplied)

Vin

Wide tubing

Wide tubing

Balance tubing

Flare insulator (supplied)

Tube insulator

(not supplied)

Heat resistant

120°C or above

l clamps (supplied)

CAUTION

Refrigerant tubing and insulator

Drain insulator

and clamp.

Large

(supplied)

Packing

clamp.

Small

hose band

(supplied)

(not supplied)

Drain pipe and insulator

(not supplied)

Insulation

tape

Vinyl

Flare

clamp

insulator

Seal

The procedure used for

installing the insulator for

both wide and narrow

tubes is the same.

Page 15

15

Fig. 5-10

Fig. 5-11

5-4. Taping the Tubes

(1) At this time, the refrigerant tubes (and electrical

wiring if local codes permit) should be taped

together with armoring tape in 1 bundle. To prevent the condensation from overflowing the drain

pan, keep the drain hose separate from the

refrigerant tubing.

(2) Wrap the armoring tape from the bottom of the

outdoor unit to the top of the tubing where it

enters the wall. As you wrap the tubing, overlap

half of each previous tape turn.

(3) Clamp the tubing bundle to the wall, using 1

clamp approx. each meter. (Fig. 5-10)

Do not wind the armoring tape too tightly since this

will decrease the heat insulation effect. Also ensure

that the condensation drain hose splits away from the

bundle and drips clear of the unit and the tubing.

5-5. Finishing the Installation

After finishing insulating and taping over the tubing,

use sealing putty to seal off the hole in the wall to prevent rain and draft from entering. (Fig. 5-11)

NOTE

g

Insulated tubes

Clamp

Drain hose

Apply putty here

Tubin

Page 16

6. APPENDIX

1. 2.

■ Name of Parts (Indoor Unit)

Air outlet

Water drain

Air filter

■ Care and Cleaning

1. For safety, be sure to turn the air conditioner off and also to disconnect the power before

WARNING

Air intake and outlet side Clean the air intake and outlet side of the indoor unit with a vacuum cleaner brush, or wipe them

(Indoor unit) with a clean, soft cloth.

cleaning.

2. Do not pour water on the indoor unit to clean it. This will damage the internal components and cause an electric shock hazard.

1. Never use solvents or harsh chemicals when cleaning the indoor unit. Do not wipe plastic

CAUTION

parts using very hot water.

2. Some metal edges and the fins are sharp and may cause injury if handled improperly; be

especially careful when you clean these parts.

3. The internal coil and other components of the outdoor unit must be cleaned every year.

Consult your dealer or service center.

Air filter

The air filter collects dust and other particles from the air and should be cleaned at regular intervals

as indicated in the table below or when the filter indication ( ) on the display of the remote control

unit (wired type) shows that the filter needs cleaning. If the filter gets blocked, the efficiency of the air

conditioner drops greatly.

Type Period

UMR Six months

NOTE

The frequency with which the filter should be cleaned depends on the environment in which the

unit is used.

<How to clean the filter>

1. Remove the air filter from the air intake grille.

2. Use a vacuum cleaner to remove light dust. If there is sticky dust on the filter, wash the

filter in lukewarm, soapy water, rinse it in clean water, and dry it.

16

Page 17

Care: After a prolonged idle period

Care: Before a prolonged idle period

Check the indoor and outdoor unit air intakes and outlets for blockage; if there is a

blockage, remove it.

• Operate the fan for half a day to dry out the inside.

• Disconnect the power supply and also turn off the circuit breaker.

• Clean the air filter and replace it in its original position.

• Outdoor unit internal components must be checked and cleaned periodically. Con-

tact your local dealer for this service.

CAUTION

1. Certain metal edges and the condenser fins are sharp and may cause injury if handled

improperly; special care should be taken when you clean these parts.

2. Periodically check the outdoor unit to see if the air outlet or air intake is clogged with dirt

or soot.

3. The internal coil and other components of the outdoor unit must also be cleaned periodically. Consult your dealer or service center.

■ Troubleshooting

If your air conditioner does not work properly, first check the following points before requesting service. If it still does not work

properly, contact your dealer or a service center.

■ Tips for Energy Saving

Avoid

Do

• Do not block the air intake and outlet of the unit. If either is obstructed, the unit

will not work well, and may be damaged.

• Do not let direct sunlight into the room. Use sunshades, blinds or curtains. If the walls

and ceiling of the room are warmed by the sun, it will take longer to cool the room.

• Always try to keep the air filter clean. (Refer to “Care and Cleaning.”) A clogged filter

will impair the performance of the unit.

• To prevent conditioned air from escaping, keep windows, doors and any other openings closed.

Should the power fail while the unit is running

If the power supply for this unit is temporarily cut off, the unit will automatically resume operation once power is

restored using the same settings before the power was interrupted.

Trouble

Air conditioner does not run at all

1. Power failure.

2. Leakage circuit breaker has

3. Line voltage is too low.

4. Operation button is turned off.

5. The wired remote control unit or

Compressor runs but soon stops

Poor cooling (or heating)

performance

1. Obstr uction in front of condenser

1. Dirty or clogged air filter.

2. Heat source or many people in

3. Doors and/or windows are open.

4. Obstacle near air intake or air

5. Thermostat is set too high for

6. (Defrosting system does not work.)

Possible Cause

tripped.

malfunctioning.

(

The inspection mark and the

H, L, P in

on

(or too low for heating).

combination with numbers

the LCD of the wired

heat pump is

letters E, F,

appear

remote control unit.)

coil

room.

discharge port.

cooling

After a power outage, press ON/

1.

on the

2. Contact service center.

3. Consult your electrician or dealer.

4. Press the button again.

5. Consult your dealer.

1. Remove obstruction

1. Clean air filter to improve the

2. Eliminate heat source if possible.

3. Shut them to keep the heat (or

4. Remove it to ensure good airflow.

5. Set the temperature lower (or

6. (Consult your dealer.)

wired remote control unit.

Remedy

OFF operation

airflow.

cold) out.

higher).

button

NOTE

17

Page 18

■ Nom des pièces (unité intérieure)

1. 2.

Sortie díair

Drain

■ Entretien et nettoyage

1. Pour toute sécurité, éteignez le climatiseur et débranchez-le de la prise secteur.

AVERTISSEMENT

2. Ne versez pas d’eau sur l’unité intérieure pour la nettoyer. Cela pourrait abîmer les composants internes et provoquer des décharges électriques.

Filtre à air

L’arrivée d’air et la sortie d’air

(unité intérieure)

1. Ne utilisez jamais de dissolvants ni de produits chimiques puissants lorsque l’unité

ATTENTION

2. Certains bords métalliques et les ailettes étant coupants, ils doivent être manipulés avec

3. La bobine interne et les autres composants de l’unité extérieure doivent être nettoyés

Filtre à air

Le filtre à air recueille la poussière et les particules se trouvant dans l’air et doit être nettoyé à intervalles réguliers comme indiqué dans le tableau cidessous ou lorsque le symbole du filtre ( )

affiché sur la télécommande (avec fil) indique que le filtre doit être nettoyé. Si le filtre est bloqué,

l’efficacité du climatiseur diminue nettement.

Type Période

UMR Six mois

Nettoyez l’arrivée d’air et la sortie de l’unité intérieure avec la brosse d’un aspirateur ou les

essuyer avec un chiffon propre et doux.

intérieure est nettoyée. N’essuyez pas les pièces en plastique avec de l’eau très chaude.

précaution lors du nettoyage sous peine de provoquer des blessures.

tous les ans. Consultez le concessionnaire ou un service après-vente.

REMARQUE

La fréquence de nettoyage du filtre dépend de l’environnement dans lequel l’unité est utilisée.

<Comment nettoyer le filtre>

1. Retirez le filtre à air de la grille de l’arrivée d’air.

2. Se servir d’un aspirateur pour enlever la poussière légère. Si de la poussière adhère au

filtre, lavez celui-ci dans de l’eau tiède et savonneuse, puis rincez-le dans de l’eau propre

et séchez-le.

18

Page 19

Entretien : après une période d’inactivité

prolongée

Entretien : avant une période d’inactivité

prolongée

Vérifiez l’arrivée d’air et la sortie d’air des unités intérieure et extérieure et

assurez-vous qu’elles ne sont pas obstruées ; si elles sont obstruées, remédiez

à ce problème.

• Faites fonctionner le ventilateur pendant une demi-journée pour faire sécher

l’intérieur de l’unité.

• Débranchez l’alimentation et mettez le disjoncteur en position arrêt.

• Nettoyez le filtre à air et remettez-le dans sa position initiale.

• Les éléments internes de l’unité extérieur doivent être vérifiés et nettoyés

régulièrement. Contactez votre distributeur le plus proche pour effectuer ces

opérations.

ATTENTION

1. Certains bords métalliques et les ailettes du condensateur étant coupants, ils doivent être

manipulés avec précaution lors du nettoyage sous peine de provoquer des blessures.

2. Vérifiez régulièrement que la sortie et l’arrivée d’air ne soient pas obstruées par de la

poussière ou de la suie.

3. La bobine interne et les autres composants de l’unité extérieure doivent être nettoyés

régulièrement. Consultez le concessionnaire ou un service après-vente.

19

Page 20

■ Guide de dépannage

Si le climatiseur ne fonctionne pas correctement, effectuez les vérifications suivantes avant de faire appel à un réparateur. Si le

problème persiste, prenez contact avec votre concessionnaire ou avec un service après-vente.

Panne Cause possible Remède

Le climatiseur ne fonctionne pas du

tout.

Le compresseur se met en marche

mais il s’arrÍte aussitôt.

Refroidissement (ou chauffage)

insuffisant.

1. Coupure de courant. 1. Après une panne de courant,

2. Le disjoncteur a fonctionné. 2. Prenez contact avec un service

3. Tension de ligne trop basse. 3. Consultez un électricien ou le

4. Le bouton de fonctionnement est en

position Off.

5. La télécommande avec fil ou la

pompe thermique ne fonctionne pas

correctement.

(La marque díinspection et les

lettres E, F, H, L, P ainsi que des

numéros apparaissent sur l’affichage

à cristaux liquides de la

télécommande avec fil.)

1. Il y a un obstacle dev ant la bobine du

condensateur.

1. Filtre à air sale ou obstrué. 1. Nettoyez le filtre à air afin

2. Source de chaleur ou trop de monde

dans la pièce.

3. Portes et/ou fenÍtres ouv ertes. 3. Fermez-les pour empÍcher la

4. Obstacle devant l’arrivée ou la sortie

d’air.

5. Le thermostat est réglé sur une

température trop élevée pour le

refroidissement (ou trop basse pour

le chauffage).

6. (Le dégivrage du système ne

fonctionne pas.)

appuyez sur le bouton de marche/

arrêt de fonctionnement de la

télécommande avec fil.

après-vente.

concessionnaire.

4. Appuyez à nouveau sur le bouton.

5. Consultez le concessionnaire.

1. Retirez ce qui fait obstruction.

díaméliorer la circulation díair.

2. Si possible, éliminez la source de

chaleur.

pénétration d’air chaud (ou froid).

4. Retirez líobstacle pour assurer une

bonne circulation d’air.

5. Réglez la température plus bas (ou

plus haut).

6. (Consultez le concessionnaire

.)

■ Conseils pour économiser l’énergie

• Obstruer les arrivées et les sorties d’air de l’appareil. Si elles sont bouchées,

l’appareil ne fonctionnera pas de façon satisfaisante et il risque d’être endommagé.

• Laisser le soleil pénétrer directement dans la pièce. Utiliser des persiennes ou des

rideaux. Si les murs et le plafond de la pièce sont chauds sous l’action du soleil, il faudra

plus longtemps pour refroidir la pièce.

• Toujours maintenir le filtre à air propre. (Voir “Entretien et nettoyage”) Un filtre obstrué

risque d’affecter le fonctionnement de l’unité.

• Pour éviter que l’air refroidi ne s’échappe, maintenir toutes les fenêtres, portes et autres

ouvertures fermées.

REMARQUE

À éviter

Choses à faire

Si une panne de courant se produit lorsque l’unité fonctionne

Si l’alimentation de cette unité est temporairement arrêtée, l’unité se remettra en marche, après rétablissement

de l’alimentation, avec les mêmes réglages qu’avant la panne de courant.

20

Page 21

■ Bezeichnungen der Teile

Luftauslass

■ Care and Cleaning

■ Pflege und Reinigung

1. Aus Sicherheitsgründen darauf achten, das Gerät vor dem Reinigen auszuschalten und

WARNUNG

es außerdem vom Netz zu trennen.

2. Kein Wasser auf die Inneneinheit schütten, um diese zu reinigen. Dadurch werden die

inneren Bauteile beschädigt, und es besteht Stromschlaggefahr.

Wasserablass

Luftfilter

Lufteinlass- und -auslassseite

(Inneneinheit)

1. Verwenden Sie niemals Lösungsmittel oder starke Chemikalien, um die Inneneinheit zu

VORSICHT

2. Gewisse Metallkanten und die Kondensatorrippen sind scharf und können Verletzungen

3. Die innere Wärmeaustauscherschlange und andere Bauteile der Außeneinheit müssen

Luftfilter

Der Luftfilter sammelt Staub und andere Teilchen aus der Luft und sollte in regelmäßigen Abständen

gereinigt werden, wie in der Tabelle unten angezeigt, bzw. wenn die Filteranzeige ( ) auf dem Dis-

play der (verdrahteten) Fernbedienung anzeigt, dass der Filter gereinigt werden sollt. Falls der Filter

verstopft ist, nimmt der Wirkungsgrad des Klimageräts stark sb.

Typ Zeitraum

UMR Sechs Monate

Reinigen Sie die Lufteinlass- und -auslassseite der Inneneinheit mit einer Staubsaugerbürste bzw. wischen Sie sie mit einem sauberen weichen Tuch ab.

reinigen. Wischen Sie die Plastikteile nicht mehr sehr heißem Wasser ab.

verursachen, wenn sie nicht richtig gehandhabt werden; beim Reinigen dieser Teile

besonders vorsichtig sein.

einmal im Jahr gereinigt werden. Wenden Sie sich dazu bitte an Ihren Fachhändler oder

an eine Kundendienststelle.

ZUR BEACHTUNG

Die Häufigkeit der Luftfilterreinigung hängt von der Umgebung, in der der Luftfilter verwendet

wird, ab.

<Reinigen des Luftfilters>

1. Nehmen Sie den Luftfilter aus dem Lufteinlassgitter.

2. Einen Staubsauger verwenden, um leichten Staub zu entfernen. Wenn klebriger Staub

am Filter anhaftet, diesen in lauwarmer Seifenlauge auswaschen, mit sauberem Wasser

abspülen und trocknen lassen.

21

Page 22

Pflege: Wenn das Gerät über längere

Zeit nicht verwendet wurde

Pflege: Wenn das Gerät über längere

Zeit nicht verwendet werden soll

Überprüfen Sie Lufteinlässe und -auslässe der Innen- und der Außeneinheit auf

Verstopfung; ist eine Verstopfung vorhanden, entfernen Sie sie.

• Lassen Sie das Getriebe einen halben Tag lang laufen, um das Innere des

Geräts zu trocknen.

• Schalten Sie die Stromversorgung des Geräts aus; schalten Sie dann auch

den Trennschalter aus.

• Reinigen Sie den Luftfilter und setzen Sie ihn dann erneut an seiner Ausgangsposition ein.

• Die Innenbauteile der Außeneinheit müssen regelmäßig überprüft und gereinigt werden. Lassen Sie diese Arbeiten von Ihrem Fachhändler durchführen.

1. Gewisse Metallkanten und die Kondensatorrippen sind scharf und können Verletzungen

verursachen, wenn Sie nicht richtig gehandhabt werden. Seien Sie daher beim Reinigen

dieser Teile besonders vorsichtig.

2. Überprüfen Sie die Außeneinheit regelmäßig, um zu sehen, ob Luftauslass oder Lufteinlass mit Staub oder Ruß verstopft sind.

3. Die innere Wärmeaustauscherschlange und andere Bauteile der Außeneinheit müssen

ebenfalls regelmäßig gereinigt werden. Wenden Sie sich dazu bitte an Ihren Fachhändler

oder an eine Kundendienststelle.

VORSICHT

1. 2.

22

Page 23

■ Fehlersuche

Wenn Ihr Klimagerät nicht richtig funktioniert, zuerst die folgenden Punkte überprüfen, bevor ein Kundendiensttechniker angefordert wird. Läßt sich die Störung nicht beheben, so wenden Sie sich bitte an Ihren Fachhändler oder an eine Kundendienststelle.

Störung Mögliche Ursache Abhilfe

Das Klimagerät läuft überhaupt

nicht.

1. Keine Stromzufuhr. 1.

2. Der Fehlerstromschutzschalter

wurde ausgelöst.

3. Netzspannung ist zu niedrig. 3. Lassen Sie sich von Ihrem Elektriker

4. Die Betriebstaste ist ausgeschaltet. 4. Die Taste erneut drücken.

5. Fehlfunktion der verdrahtete

Fernbedienung oder der Wärmepumpe.

(

Das Überprüfungszeichen und

die Buchstaben E, F , H, L, P

zusammen mit Zahlen werden auf

der LCD-Anzeige der verdrahtete

Fernbedienung angezeigt.)

Kompressor läuft, kommt jedoch

bald zum Stillstand.

Schlechte Kühl- oder Heizleistung 1. Luftfilter ist schmutzig oder

1. Ein Hindernis befindet sich vor der

Kondensatorschlange.

zugesetzt.

2. Eine Wärmequelle oder viele Leute

befinden sich im Raum.

3. Türen und/oder Fenster sind

geöffnet.

4.

Ein Hindernis befindet sich in der

Nähe von Lufteinlass oder

Luftauslass.

5. Der Thermostat ist zu hoch zum

Kühlen eingestellt (bzw. zu niedrig

zum Heizen).

6. (Abtausystem funktioniert nicht.) 6. (Lassen Sie sich von Ihrem

Drücken Sie nach einem Stromausfall

die Betriebstaste (ON/OFF) auf der

verdrahteten Fernbedienung.

2. Wenden Sie sich an eine

Kundendienststelle.

oder Fachhändler beraten.

5. Lassen Sie sich von Ihrem

Fachhändler beraten.

1. Hindernis entfernen.

1. Luftfilter reinigen, um den Luftstrom

zu verbessern.

2. Die Wärmequelle möglichst

abschalten.

3. Diese schlieflen, damit keine Wärme

(bzw. Kälte) von auflen eindringt.

4. Hindernis entfernen, um einen

unbehinderten Luftstrom zu

gewährleisten.

5. Temperatur niedriger (bzw. höher)

einstellen.

Fac

hhändler beraten.)

■ Nützliche Hinweise für Energieeinsparung

Zu vermeiden

ZUR BEACHTUNG

Bei einem Stromausfall während des Betriebs des Geräts

Wird die Stromversorgung dieses Geräts vorübergehend unterbrochen, setzt das Gerät den Betrieb nach

erneuter Stromversorgung automatisch mit denselben Einstellungen wie vor der Unterbrechung der

Stromversorgung fort.

• Blockieren Sie den Lufteinlass und -auslass des Gerätes nicht. Falls der Ein- oder

Auslass blockiert wird, funktioniert das Gerät nicht richtig und kann sogar

beschädigt werden.

• Setzen Sie den Raum nicht direkter Sonnenbestrahlung aus. Markisen, Jalousien oder

Vorhänge verwenden. Wenn die Wände und Decke des Raumes Strahlungswärme von der

Sonne aufnehmen, dauert es länger, den Raum zu kühlen.

Ja

• Den Luftfilter stets sauber halten. (Siehe den Abschnitt „Pflege und Reinigung“.) Ein verstopfter Filter beeinträchtigt die Leistung des Gerätes.

• Um zu verhindern, dass klimatisierte Luft entweicht, Fenster, Türen und andere Öffnungen

außer für Lüftungszwecke geschlossen halten.

23

Page 24

■ Nome delle parti (Unità interna)

1. 2.

Uscita d’aria

Scarico dell’acqua

■ Cura e manutenzione

1. Per motivi di sicurezza, accertare che il condizionatore d’aria sia spento e che la spina

AVVERTIMENTO

del cavo di alimentazione sia staccata dalla presa di corrente prima di procedere con le

operazioni di pulizia.

2. Non versare acqua sull’unità interna per pulirla. Ciò può danneggiare i componenti interni

e causare il pericolo di scosse.

Filtro aria

Lato presa d’aria e uscita

d’aria (unità interna)

1. Per pulire l’unità interna, non si devono usare solventi o sostanze chimiche aggressive.

PRECAUZIONE

2. Alcuni bordi metallici e le alette sono taglienti e possono causare ferite se maneggiati in

3. La serpentina interna e gli altri componenti dell’unità esterna devono essere puliti una

Filtro dell’aria

Il filtro dell’aria raccoglie le particelle di polvere e sporco dall’aria e dovrebbe essere pulito a intervalli

regolari, come indicato nella tabella seguente, oppure quando l’indicazione del filtro ( ) sul display

del telecomando (tipo cablato) non segnala che occorre pulire il filtro. Se il filtro si ostruisce, l’efficienza del condizionatore d’aria ne risulta notevolmente compromessa.

Tipo Periodo

UMR Sei mesi

Pulire il lato della presa d’aria e dell’uscita d’aria dell’unità interna con una spazzola aspirapolvere o con un panno pulito e morbido.

Non pulire i componenti in plastica con acqua molto calda.

modo incorretto. Prestare perciò la dovuta attenzione nel pulire tali parti.

volta all’anno. Rivolgersi al proprio rivenditore o centro di assistenza.

NOTA

La frequenza alla quale occorre pulire il filtro dipende dall’ambiente in cui viene utilizzata l’unità.

<Pulizia del filtro>

1. Rimuovere il filtro dell’aria dalla griglia della presa d’aria.

2. Rimuovere la polvere leggera servendosi di un aspirapolvere. Se la polvere resta attaccata al fil-

tro, lavarlo con acqua saponata tiepida, sciacquarlo con acqua pulita ed asciugarlo.

24

Page 25

Cura: dopo un periodo di

inattività prolungato

Cura: prima di periodo di

inattività prolungato

Controllare le prese d’aria e le uscite d’aria delle unità interna ed esterna, verificando che non

siano ostruite; eliminare eventuali ostruzioni.

• Azionare la ventola per mezza giornata per far asciugare l’interno.

• Scollegare l’alimentazione elettrica e disinserire l’interruttore automatico.

• Pulire il filtro dell’aria e rimetterlo nella sua posizione originale.

• I componenti interni dell’unità esterna vanno controllati e puliti periodicamente. A questo

scopo rivolgersi al proprio rivenditore locale.

1. Alcuni bordi metallici e le alette del condensatore sono taglienti e possono causare ferite

se maneggiati in modo incorretto; occorre pertanto prestare particolare attenzione nel

pulire tali componenti.

2. Controllare periodicamente l’unità esterna, accertando che l’uscita d’aria e la presa d’aria

non siano ostruite da sporco o fuliggine.

3. Anche la bobina interna e altri componenti dell’unità esterna richiedono una pulizia periodica. Rivolgersi al proprio rivenditore o centro di assistenza.

PRECAUZIONE

25

Page 26

■ Prima di chiamare il tecnico

Se il condizionatore d’aria non funziona correttamente, prima di chiamare il tecnico per la riparazione controllare quanto segue.

Se ciò non consente di eliminare il problema, rivolgersi al proprio rivenditore o centro di assistenza.

Problema Causa probabile Rimedio

Il condizionatore d’aria non

funziona.

Il compressore funziona, ma si

arresta subito.

Le prestazioni di raffreddamento

(o di riscaldamento) sono

scarse.

1. Si è verificata una mancanza di corrente. 1.

2. Il salvavita è scattato. 2. Rivolgersi al centro di assistenza.

3. La tensione di rete è insufficiente. 3. Rivolgersi ad un elettricista o al

4. Il pulsante di accensione/spegnimento è

spento.

5. Il telecomando cablato o la pompa di

calore non funziona correttamente.

(Sullo schermo LCD del telecomando

cablato vengono visualizzati il segno di

ispezione e le lettere E, F, H, L, P, in

combinazione con dei numeri).

1. Presenza di un’ostruzione davanti alla

serpentina del condensatore.

1. Il filtro dellíaria è sporco o intasato. 1. Pulire il filtro dell’aria per

2. Nella stanza ci sono una fonte di calore o

molte persone.

3. Ci sono porte o finestre aperte. 3. Chiuderle per mantenere il caldo

4. C’è un ostacolo vicino alla presa d’aria o

all’uscita dell’aria.

5. Il termostato è impostato ad un valore

troppo alto per il raffreddamento (o

troppo basso per il riscaldamento).

6. (Il sistema di sbrinamento non funziona). 6. (Rivolgersi al proprio rivenditore

Dopo una mancanza di

corrente, premere il pulsante di

accensione/spegnimento (ON/

OFF) del telecomando cablato.

proprio rivenditore.

4. Premere nuovamente il pulsante.

5. Rivolgersi al proprio rivenditore.

1. Rimuovere l’ostruzione.

migliorare il getto dell’aria.

2. Se possibile, eliminate la fonte di

calore.

(o il freddo) all’esterno.

4. Rimuoverlo in modo da assicurare

un buon getto d’aria.

5. Impostare la temperatura a un

livello più basso (o più alto).

.)

■ Suggerimenti per risparmiare energia

• Non ostruire la presa d’aria e l’uscita d’aria dell’unità. In caso di ostruzione,

l’unità non funziona correttamente e può subire dei danni.

• Non lasciar entrare la luce solare diretta nella stanza. A tale scopo utilizzare parasole,

tende o persiane. Se le pareti e il soffitto vengono riscaldati dal sole, il raffreddamento

della stanza richiede più tempo.

• Mantenete sempre pulito il filtro dell’aria (fare riferimento a “Cura e manutenzione”). Un

filtro ostruito compromette il rendimento dell’unità.

• Per evitare fughe d’aria condizionata, tenete chiuse finestre, porte ed altre aperture.

NOTA

Da evitare

Cose da fare

Mancanza di corrente durante il funzionamento dell’unità

In caso di una temporanea mancanza di corrente, l’unità riprende automaticamente a funzionare, al ripristino

della corrente, con le stesse impostazioni che aveva prima dell’interruzione.

26

Page 27

■ Nomenclatura das peças (unidade interior)

Saída de ar

Drenagem de água

■ Cuidados e limpeza

1. Por motivos de segurança desligue o aparelho de ar condicionado e desligue-o também

ADVERTÊNCIA

da rede antes de proceder à sua limpeza.

2. Não verta água sobre a unidade interior para a limpar. Poderá danificar os componentes

internos e causar descargas eléctricas.

Filtro de ar

Lado de entrada e saída de ar

(unidade interior)

1. Nunca utilize solventes ou produtos químicos fortes para limpar a unidade interior. Não

PRECAUÇÃO

2. Algumas bordas metálicas e as pás do condensador são pontiagudas e podem causar

3. A serpentina interna e outros componentes da unidade exterior devem ser limpos todos

Filtro de ar

O filtro de ar recolhe a poeira e outras partículas do ar. Deve ser limpo em intervalos regulares como

indicado na tabela abaixo ou quando a indicação de filtro ( ) aparece no visor da unidade de controlo remoto (com fios) indicando que o filtro deve ser limpo. Se o filtro ficar bloqueado, a eficiência

do ar condicionado diminui bastante.

Tipo Período

UMR Seis meses

Limpe o lado de entrada e saída de ar da unidade interior com um aspirador ou com um

pano macio e limpo.

limpe as peças plásticas com água muito quente.

ferimentos se não forem manuseadas com cuidado; tenha especial cuidado ao limpar

estas partes.

os anos. Contacte o seu concessionário ou centro de reparações.

NOTA

A frequência de limpeza do filtro depende do ambiente de utilização da unidade.

<Como limpar o filtro>

1. Remova o filtro de ar da grelha de entrada de ar.

2. Utilize um aspirador para retirar poeira ligeira. Se houver poeira peganhosa no filtro, lave o filtro

com água morna com sabão, passe-o por água limpa e seque-o.

27

Page 28

Atenção: após um período de

inactividade prolongado

Atenção: antes de um período de

inactividade prolongado

Verifique se as entradas e saídas de ar da unidade exterior estão bloqueadas.

Se estiverem bloqueadas, limpe-as.

• Utilize o ventilador durante meio dia para secar o interior da unidade.

• Desligue a unidade da corrente eléctrica e do disjuntor.

• Limpe o filtro de ar e volte a colocá-lo na posição original.

• Os componentes internos da unidade exterior devem ser verificados e limpos

periodicamente. Contacte o revendedor local para efectuar esta operação.

1. Algumas bordas metálicas e as pás do condensador são pontiagudas e podem causar

ferimentos se não forem manuseadas com cuidado; tenha especial cuidado ao limpar

estas peças.

2. Inspeccione periodicamente a unidade exterior para verificar se a entrada ou a saída de ar

estão bloqueadas com sujidade ou fuligem.

3. A serpentina interna e outros componentes da unidade exterior também devem ser

limpos periodicamente. Contacte o seu concessionário ou centro de reparações.

PRECAUÇÃO

1. 2.

28

Page 29

■ Resolução de problemas

Se o seu aparelho de ar condicionado não funciona correctamente, verifique primeiro os seguintes pontos antes de solicitar

assistência. Se não conseguir solucionar o problema, contacte o seu concessionário ou o serviço de assistência.

Avaria Causa possível Solução

O aparelho de ar condicionado não

funciona de maneira nenhuma.

O compressor começa a funcionar

mas pára pouco depois.

Rendimento de arrefecimento (ou

aquecimento) deficiente.

1. Falha de alimentação. 1.

Após uma falha de corrente

eléctrica, pressione o bot

operaç

ão ON/OFF na unidade

ão de

de controlo remoto com fios.

2. O disjuntor de fugas foi activado. 2. Contacte o serviço de assistência.

3. Tensão de rede demasiado baixa. 3. Consulte um electricista ou o seu

4. O botão de operação está

desactivado.

5. A unidade de controlo remoto com

fios ou a bomba de calor não está

a funcionar correctamente.

(A marca de inspecção e as

letras E, F, H, L, P associadas a

n˙meros aparecem no LCD da

unidade de controlo remoto com

fios.)

1. Obstrução em frente da serpentina

do compressor.

1. Filtro de ar sujo ou obstr uído. 1. Limpe o filtro de ar para melhorar a

2. Fonte de calor ou demasiadas

pessoas na habitação.

3. Portas e/ou janelas abertas. 3. Feche-as para evitar a entrada de

4. Obstáculos perto da entrada ou

saída de ar.

5. O termóstato est·á ajustado muito

alto para arrefecimento (ou muito

baixo para aquecimento).

6. (O sistema de descongelação não

funciona.)

concessionário.

4. Pressione novamente o botão.

5. Consulte o seu concessionário.

1. Retire a obstrução.

circulação do ar.

2. Elimine a fonte de calor se for

possível.

calor (ou frio).

4. Retire os obstáculos para

assegurar uma boa circulação de

ar.

5. Coloque a temperatura mais baixa

(ou mais alta).

6. (Consulte o seu concessionário

.)

■ Sugestões para poupar energia

• Bloquear a entrada e saída de ar do aparelho. Se estiverem obstruídas, o aparelho

não funcionará adequadamente e poderá ficar danificado.

• SDeixar a luz solar incidir directamente na sala. Use cortinas, venezianas, etc. Se as

paredes e o tecto da habitação forem aquecidos pelo sol levará mais tempo para arrefecer a habitação.

• Procure manter o filtro de ar sempre limpo. (Consulte “Cuidados e limpeza”.) Um filtro

obstruído prejudica o rendimento do aparelho.

• Para evitar a saída do ar condicionado, mantenha janelas, portas e outras aberturas

fechadas.

NOTA

Evite

Faça

Se ocorrer uma falha de energia com a unidade a funcionar

Se a corrente eléctrica for cortada temporariamente, a unidade retoma a operação automaticamente após a

reposição da corrente eléctrica utilizando os mesmos ajustes programados.

29

Page 30

■

UMR

■

Air outlet

Water drain

Air filter

30

Page 31

1. 2.

31

Page 32

■

■

32

Page 33

■ Nombres de las partes (unidad interior)

1. 2.

Salida de aire

Drenaje de agua

■ Cuidados y limpieza

1. Por motivos de seguridad, asegúrese de apagar el acondicionador de aire, y desconec-

ADVERTENCIA

tarlo también de la red eléctrica antes de realizar su limpieza.

2. No vierta agua sobre la unidad interior para limpiarla. El agua podría estropear los componentes internos y producir una descarga eléctrica.

Filtro de aire

Lados de entrada y salida de

aire (Unidad interior)

1. No utilice nunca disolventes o productos químicos ásperos cuando limpie la unidad interi-

PRECAUCIÓN

or. No limpie las partes de plástico con agua muy caliente.

2. Algunos bordes metálicos y las aletas, al ser puntiagudos, pueden causar heridas si no se

manejan con cuidado. Tenga mucho cuidado al limpiar estas piezas.

3. El serpentín interno y otros componentes de la unidad exterior deberán limpiarse todos

los años. Póngase en contacto con su concesionario o centro de reparaciones.

Filtro de aire

El filtro de aire recoge polvo y otras partículas del aire y deberá ser limpiado a intervalos regulares

como se indica en la tabla de abajo o cuando la indicación de filtro ( ) del visualizador de la

unidad del mando a distancia (tipo alámbrica) muestre que el filtro necesita ser limpiado. Si se bloquea el filtro, la eficacia del acondicionador de aire disminuirá enormemente.

Tipo Periodo

UMR Seis meses

Limpie los lados de entrada y salida de aire de la unidad interior con el cepillo de una aspiradora, o límpielos con un paño limpio y suave.

NOTA

La frecuencia con que deberá ser limpiado el filtro de aire dependerá del entorno en el que se

utilice la unidad.

<Cómo limpiar el filtro>

1. Extraiga el filtro de aire de la rejilla de entrada de aire.

2. Utilice una aspiradora para quitar el polvo ligero. Si en el filtro hay polvo pegado, lave el filtro con

agua enjabonada templada, enjuáguelo en agua limpia y séquelo.

33

Page 34

Cuidado: después de un

periodo de inactividad

prolongado

Cuidado: antes de un

periodo de inactividad

prolongado

Compruebe las entradas y salidas de aire de la unidad exterior para ver si están obstruidas; si

hay una obstrucción, quítela.

• Haga funcionar el ventilador durante medio día para secar el interior.

• Desconecte el suministro eléctrico y desactive también el disyuntor.

• Limpie el filtro de aire y vuelva a ponerlo en su posición original.

• Los componentes internos de la unidad exterior deberán ser comprobados y limpiados per-

iódicamente. Póngase en contacto con su distribuidor local para este servicio.

1. Algunos bordes metálicos y las aletas del condensador son agudos y podrán ocasionar

heridas si se manejan incorrectamente; cuando limpie estas partes deberá tener cuidado

especial.

2. Compruebe periódicamente la unidad exterior para ver si la salida de aire o enterada de

aire está obstruida con suciedad u hollín.

3. El serpentín interno y otros componentes de la unidad exterior deberán también ser

limpiados periódicamente. Póngase en contacto con su concesionario o centro de

reparaciones.

PRECAUCIÓN

34

Page 35

■ Localización de averías

Si su acondicionador de aire no funciona correctamente, compruebe primero la lista de abajo antes de llamar al servicio de

reparaciones. Si no puede solucionar el problema, póngase en contacto con su concesionario o centro de reparaciones.

Avería Causa posible Remedio

El acondicionador de aire no funciona

en absoluto.

El compresor se pone en

funcionamiento pero se para pronto.

Mal enfriamiento (o calefacción). 1. Filtro de aire sucio u obstruido. 1. Limpie el filtro de aire para mejorar

1. Corte de alimentación eléctrica. 1.

Después de una interrupción del

suministro eléctrico, pulse el

bot

ón de operación ON/OFF en

la unidad de mando a distancia

alámbrica.

2. Ha saltado el ruptor de fugas. 2. Póngase en contacto con el centro

3. La tensión de la línea es

demasiado baja.

4. El botón de operación está

desactivado.

5. La unidad de mando a distancia

alámbrica o la bomba de calor está

funcionando mal.

(En el LCD de la unidad de mando

a distancia alámbrica aparece la

marca de inspección y las

letras E, F, H, L, P en combinación

con números.)

1. Obstrucción delante del serpentín

del condensador.

2. Fuente de calor o muchas

personas en la sala.

3. Puertas y/o ventanas abiertas. 3. Ciérrelas para que no entre el calor

4. Obstáculos cerca de la entrada o

salida de aire.

5. El termostato está ajustado

demasiado alto para enfriamiento

(o demasiado bajo para

calefacción).

6. (El sistema de descongelación no

funciona.)

de reparaciones.

3. Póngase en contacto con un

electricista o con su concesionario.

4. Pulse el botón otra vez.

5. Consulte a su distribuidor.

1. Retire la obstrucción.

la circulación del aire.

2. Elimine la fuente de calor si fuese

posible.

(o el frío).

4. Quite los obstáculos para asegurar

una buena circulación del aire.

5. Fije una temperatura m·s baja (o

más alta).

6. (Consulte a su distribuidor

.)

■ Sugerencias para ahorrar energía

• No bloquee la entrada y salida de aire de la unidad. Si cualquiera de ellas está

obstruida, la unidad no funcionará bien, y podrá dañarse.

• No deje que entre luz solar directa en la habitación. Utilice parasoles, persianas o cortinas. Si el sol calienta las paredes y el techo de la sala, se tardará más tiempo en enfriarla.

Sí

• Mantenga siempre limpio el filtro de aire. (Refer to “Cuidados y limpieza”.) Un filtro

obstruido reducirá el rendimiento de la unidad..

• Para evitar que escape el aire acondicionado, cierre las ventanas, las puertas y otras

aberturas.

NOTA

Evite

Si ocurre un corte del suministro eléctrico mientras está funcionando la unidad

Si el suministro eléctrico de esta unidad se interrumpe temporalmente, la unidad reanudará automáticamente

la operación una vez restablecido el suministro utilizando los mismos ajustes que los de antes de cortarse el

suministro eléctrico.

35

Page 36

Loading...

Loading...