Page 1

INSTALLATION INSTRUCTIONS

— Split System Air Conditioner —

CONTENTS

IMPORTANT Page

Please Read Before Starting

1. GENERAL.............................................................3

1-1. Tools Required for Installation (not supplied)

1-2. Accessories Supplied with Unit

1-3. Optional Copper Tubing Kit

1-4. Type of Copper Tube and Insulation Material

1-5. Additional Materials Required for Installation

1-6. Operating Range

1-7. Tubing Length

2. SELECTING THE INSTALLATION SITE ............ 5

Indoor Unit

Outdoor Unit

2-1. Baffle Plates for the Outdoor Unit

3. HOW TO INSTALL THE INDOOR UNIT.............. 7

3-1. Suspending the Indoor Unit

3-2. Preparation for Suspending

3-3. Placing the Unit Inside the Ceiling

3-4. Installing the Drain Piping

3-5. Checking the Drainage

■ Ceiling Panel......................................................11

3-6. Before Installing the Ceiling Panel

3-7. Installing the Ceiling Panel

3-8. When Removing the Ceiling Panel for

Servicing

3-9. Duct for Fresh Air

4. HOW TO INSTALL THE REMOTE

CONTROL UNIT .................................................15

■ Wireless Remote Control Unit

4-1. Mounting on a Wall

■ Wired Remote Control Unit (Option)

4-2. Installing the Wired Remote Control Unit

Model Combinations

Combine indoor and outdoor units only as listed below.

Indoor units Outdoor units

XS1852 (PNR-XS2432) C1852, CL1852

Power Supply :

60Hz, single-phase, 208/230 V

Units should be installed by licensed contractor

according to local code requirements

7. HOW TO PROCESS TUBING ........................... 21

7-1. Use of the Flaring Method

7-2. Flaring Procedure with a Flare Tool

7-3. Precaution before Connecting Tubes Tightly

7-4. Precautions during Brazing

7-5. Connecting Tubing between Indoor and

Outdoor Units

7-6. Insulating the Refrigerant Tubing

7-7. Taping the Tubes

7-8. Finishing the Installation

8. AIR PURGING ....................................................24

■ Air Purging with a Vacuum Pump

(for Test Run)

9. TEST RUN ..........................................................26

9-1. Performing Test Run

9-2. Performing Test Run with Optional Wired

Remote Control Unit

9-3. Basic Function of the Service Valves

9-4. Pump Down

5. ADDRESS SWITCHES.......................................17

5-1. Finding the Address Switches

5-2. Switch Positions for 2 Units or 2 Groups of

Units

6. ELECTRICAL WIRING .......................................18

6-1. General Precautions on Wiring

6-2. Recommended Wire Length and Wire

Diameter for Power Supply System

6-3. Wiring Instructions for the Outdoor Unit

6-4. Examples of Incorrect Wiring

6-5. How to Connect Wiring to the Terminal

85464359128000 SANYO 2000

SANYO FISHER COMPANY

A DIVISION OF SANYO NORTH

AMERICA CORPORATION

21605 Plummer Street

1

S4359128

Chatsworth, CA91311

Page 2

Important

IMPORTANT!

Please Read Before Starting

This air conditioning system meets strict safety and

operating standards. As the installer or service person, it

is an important part of your job to install or service the

system so it operates safely and efficiently.

For safe installation and trouble-free operation,you

must:

ⓦ Carefully read this instruction booklet before beginning.

ⓦ Follow each installation or repair step exactly as shown.

ⓦ Observe all local, state, and national electrical codes.

ⓦ Pay close attention to all warning and caution notices

given in this manual.

This symbol refers to a hazard

or unsafe practice which can

result in severe personal injury

or death.

This symbol refers to a hazard

CAUTION

or unsafe practice which can

result in personal injury or

product or property damage.

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help for a

special problem, contact our sales/service outlet or your

certified dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for

improper installation or maintenance service, including

failure to follow the instructions in this document.

SPECIAL PRECAUTIONS

When Wiring

……………………………………………………………………

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

ONLY A QUALIFIED, EXPERIENCED

ELECTRICIAN SHOULD ATTEMPT TO

WIRE THIS SYSTEM.

• Do not supply power to the unit until all wiring and

tubing are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this

system. Carefully refer to the wiring diagram and these

instructions when wiring. Improper connections and

inadequate grounding can cause accidental injury or

death.

• Ground the unit following local electrical codes.

• Connect all wiring tightly. Loose wiring may cause

overheating at connection points and a possible fire

hazard.

When Transporting

……………………………………………………………………

Be careful when picking up and moving the indoor and

outdoor units. Get a partner to help, and bend your knees

when lifting to reduce strain on your back. Sharp edges or

thin aluminum fins on the air conditioner can cut your

fingers.

When Installing

……………………………………………………………………

…In a Room

Properly insulate any tubing run inside a room to prevent

“sweating” that can cause dripping and water damage to

walls and floors.

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide a

solid, level foundation for the outdoor unit. This prevents

water damage and abnormal vibration.

…In an area with High Winds

Securely anchor the outdoor unit down with bolts and a

metal frame. Provide a suitable air baffle.

…In a Snowy Area

(for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is higher

than drifting snow. Provide snow vents.

When Connecting Refrigerant Tubing

……………………………………………………………………

• Execute enough ventilation in case refrigerant gases

leak during operations. Be careful that the contact of the

refrigerant gases with the flare will cause the generation

of poisonous gases.

• Keep all tubing runs as short as possible.

• Use the flare method for connecting tubing.

• Apply refrigerant lubricant to the matching surfaces of

the flare and union tubes before connecting them, then

tighten the nut with a torque wrench for a leak-free

connection.

• Check carefully for leaks before starting the test run.

NOTE

Depending on the system type, liquid and gas lines may

be either narrow or wide. Therefore, to avoid confusion the

refrigerant tubing for your particular model is specified as

either “narrow” or “wide” rather than as “liquid” or “gas”.

When Servicing

……………………………………………………………………

• Turn the power OFF at the main power box (mains)

before opening the unit to check or repair electrical

parts and wiring.

• Keep your fingers and clothing away from any moving

parts.

• Clean up the site after you finish, remembering to check

that no metal scraps or bits of wiring have been left

inside the unit being serviced.

2

S4359128

Page 3

1. General

This booklet briefly outlines where and how to install

the air conditioning system. Please read over the

entire set of instructions for the indoor and outdoor

units and make sure all accessory parts listed are with

the system before beginning.

1-1. Tools Required for Installation (not supplied)

1. Standard screwdriver

2. Phillips head screwdriver

3. Knife or wire stripper

4. Tape measure

5. Level

6. Sabre saw or key hole saw

7. Hacksaw

8. Core bits

9. Hammer

10. Drill

11. Tube cutter

12. Tube flaring tool

13. Torque wrench

14. Adjustable wrench

15. Reamer (for deburring)

16. Service valve wrench

17. Wire cutter

1-2. Accessories Supplied with Unit

Table 1-1

Part Name Figure Q’ty Remarks

Full-scale

installation

diagram

Flare

insulator

Installation

gauge

For determining

suspension bolt

1

pitch

For wide tubes

1

For adjusting the

1

unit position

Part Name Figure Q’ty

Wireless

remote control unit

AAA alkaline

battery

Tapping screw

Tapping screw

Special

screw

4 ✕ 16 mm

TOTA 4 ✕ 16

1

2

1

1

1-3. Optional Copper Tubing Kit

Copper tubing for connecting the outdoor unit to the

indoor unit is available in kits which contain the narrow

and wide tubing, fittings and insulation. Consult your

nearest sales outlet or A/C workshop.

1-4. Type of Copper Tube and Insulation Material

If you wish to purchase these materials separately

from a local source, you will need:

1. Deoxidized annealed copper tube for refrigerant

tubing.

Cut each tube 12 in. to 16 in. longer than the

appropriate lengths to dampen vibration between

units.

2. Foamed polyethylene insulation for 5/8"

(15.88 mm) O.D. copper tubes as required to

precise length of tubing. Wall thickness of the

insulation should be not less than 0.3 inch

(8 mm).

Check local electrical codes

CAUTION

and regulations before

obtaining wire. Also, check

any specified instructions or

limitations.

Insulating

tape

(White for insulating)

Hose band

Packing

Drain

insulator

Drain hose

Drain hose

adapter

Owner’s

manual

Hexagonal

Wrench*

*Packed in the outdoor unit

For wide tube

1

flare nuts

For securing drain

2

hose

1

For drain joint

For drain joint

1

1

1

For drain outlet

1

To open and shut

the Narrow Tube

1

Service Valve

1-5. Additional Materials Required for Installation

1. Insulated staples or clamps for connecting wire

(See your local codes.)

2. Putty

3. Refrigeration tubing lubricant

4. Clamps or saddles to secure refrigerant tubing

5. Scale for weighing

1-6. Operating Range

Temperature Indoor Air Intake Outdoor Air Intake

Maximum 95°F DB, 71°F WB 115°F DB

Minimum 67°F DB, 57°F WB 67°F DB (0°F DB)*

*CL&&&& Models

3

Cooling

S4359128

Page 4

1-7. Tubing Length

● Refrigerant tubing between the indoor and outdoor

units should be kept as short as possible.

● Select and decide the installation location so that

the length of the refrigerant tubing will be within the

limits given in Table 1-2.

Elevation difference (H)

Table 1-2

Models C1852

Tubing Data

Tubing size

outer dia.

Narrow tube in. (mm) 1/4 (6.35): Thickness 0.0314" (0.8 mm)

Wide tube in. (mm) 5/8 (15.88): Thickness 0.0394" (1.0 mm)

CL1852

Limit of tubing length (ft.) 65

Limit of elevation

difference between

the 2 units

Outdoor unit is higher

than indoor unit (ft.)

Outdoor unit is lower

than indoor unit (ft.)

Max. allowable tubing length at shipment (ft.) 33

Required additional refrigerant *

1

(oz./ft.) 0.27

INDOOR

UNIT

23

23

Tubing length (L)

OUTDOOR

UNIT

0711_M_I

Fig. 1-1

No additional charge of compressor oil is necessary.

*1If total tubing length becomes 33 to 65 ft., charge additional refrigerant (R22) by 0.27 oz./ft..

4

S4359128

Page 5

2. Selecting the Installation Site

Indoor Unit

AVOID:

● areas where leakage of flammable gas may be

expected.

● places where large amount of oil mist exist.

● direct sunlight.

● locations near heat sources which may affect

performance of the unit.

● locations where external air may enter the room

directly. This may cause “sweating” on the air

discharge ports, causing them to spray or drip.

● locations where the remote control unit will be

splashed with water or affected by dampness or

humidity.

● installing the remote control unit behind curtains or

furniture.

● locations where the receiver in the indoor unit is

exposed to the inverter lamp light. Faulty operation

of the unit occurs.

DO:

● select an appropriate position from which every

corner of the room can be uniformly cooled.

● select a location where the ceiling is strong enough

to support the weight of the unit.

● select a location where tubing and drain pipe have

the shortest run to the outdoor unit.

● allow room for operation and maintenance as well

as unrestricted air flow around the unit. (Fig. 2-1)

● install the unit within the maximum elevation

difference above or below the outdoor unit and

within a total tubing length from the outdoor unit as

detailed in Table 1-2.

● allow room for mounting the remote control unit

about 3 ft. off the floor, in an area that is not in

direct sunlight nor in the flow of cool air from the

indoor unit.

3 ft.

3 ft.

3 ft.

3 ft.

3 ft.

1330_X_S

Fig. 2-1

NOTE

Air delivery will be degraded if the distance from the

floor to the ceiling is greater than 10 ft..

5

S4359128

Page 6

Air intake

Concrete

or equal

About 4" (10 cm)

Min. 4"

(10 cm)

Anchor bolts

(4 pcs)

About 16" (40 cm)

1820_M_I

Outdoor Unit

AVOID:

● heat sources, exhaust fans, etc. (Fig. 2-2)

● damp, humid or uneven locations.

Hot air

NO

Exhaust fan

Heat source

Outdoor

unit

DO:

● choose a place as cool as possible.

● choose a place that is well ventilated.

● allow enough room around the unit for air intake/

exhaust and possible maintenance. (Fig. 2-3)

● Install the outdoor unit above

CAUTION

snowfall line.

● Do not place objects on or sit

on the outdoor unit. Also, never

block the air intake/outlet or

exhaust. Distortion of the

outdoor unit or incomplete

combustion may result.

● Do not introduce foreign matter

into the air intake/outlet or

exhaust. Do not poke them with

such objects as a stick.

● provide a solid base (level concrete pad, concrete

block, 4 in. × 16 in. (10 × 40 cm) beams or equal), a

minimum of 4 in. (10 cm) above ground level to

reduce humidity and protect the unit against possible

water damage and decreased service life (Fig. 2-4).

Air intake

Min. 6"

(15 cm)

Min. 6" (15 cm)

Air discharge

Fig. 2-2

Valve side

Min. 10"

(25 cm)

Min. 12"

(30 cm)

Fig. 2-3

1818_M_I

1817_C_I

Obstacle above

Min.

7 ft.

(2 m)

Air discharge

Ground

Min. 6 in.

(15 cm)

Air intake

Min.

7 ft.

(2 m)

Obstacle

1819_M_I

● use lug bolts or equal to bolt down unit, reducing

vibration and noise.

2-1. Baffle Plates for the Outdoor Unit

(CL×× models only)

NOTE

It is recommended to use baffle plates for model

CL1852. The baffle plates are not normally required for

the other models.

When the outdoor unit is installed in a position exposed

to strong wind (like seasonal winds with low air

temperature in winter), baffle plates must be installed on

the outdoor unit. (Fig. 2-5)

This unit is designed so that the fan of the outdoor unit

runs at low speed when the air conditioner is operated at

low outdoor air temperatures. When the outdoor unit is

exposed to strong wind, the system pressure drops

because of the freeze protector.

6

6" min

Air discharge

S4359128

Baffle

plate

Fig. 2-4

Fig. 2-5

Air discharge

6" min

Baffle

plate

1821_M_I

Page 7

3. How to Install the Indoor Unit

3-1. Suspending the Indoor Unit

This unit uses a drain pump. Use a carpenter’s level to

check that the unit is level.

3-2. Preparation for Suspending

(1) Fix the suspension bolts securely in the ceiling

using the method shown in the diagrams (Figs.

3-1 and 3-2), by attaching them to the ceiling

support structure, or by any other method that

ensures that the unit will be securely and safely

suspended.

(2) Follow Fig. 3-2 and Table 3-1 to make the holes

in the ceiling.

Table 3-1 Unit : inch (mm)

Type

Length

AB

XS1852 (PNR-XS2432) 32-9/32 (820) 28-3/4 (730)

(3) Determine the pitch of the suspension bolts using

the supplied full-scale installation diagram. The

diagram and table (Fig. 3-3 and Table 3-2) show

the relationship between the positions of the

suspension fitting, the unit, and the panel.

Hole-in-anchor

Hole-in-plug

Suspension bolt (M10 or 3/8")

(field supply)

Fig. 3-1

A (ceiling opening dimension)

1/2"

1/2"1/2"

590 (suspension bolt pitch)

820 (ceiling opening dimension)

B (suspension bolt pitch)

Fig. 3-2

Concrete Insert

0038_T_I

1/2"

Refrigerant

tubing side

Drain hose

side

Unit: inch

0962_S_I

Refrigerant tubing joint (narrow tube side)

Refrigerant tubing joint (wide tube side)

Suspension lug

E

15/32" 15/32"

Power supply inlet

Table 3-2 Unit : inch

Type

Length

ABCDE

XS1852 (PNR-XS2432) 5-29/32 7-7/8 10-1/32 11-23/32 4-29/32

7

S4359128

Fig. 3-3

Drain inspection port

C

B

A

1019_X_I

D

Page 8

3-3. Placing the Unit Inside the Ceiling

I

(1) When placing the unit inside the ceiling, deter-

mine the pitch of the suspension bolts using the

supplied full-scale installation diagram. (Fig. 3-4)

The size of the opening for the indoor unit can be

confirmed by attaching the full-scale installation

diagram beneath the unit. (Fig. 3-4)

Tubing and wiring must be laid inside the ceiling

when suspending the unit. If the ceiling is already

constructed, lay the tubing and wiring into position for connection to the unit before placing the

unit inside the ceiling.

(2) The length of suspension bolt must be appropri-

ate for a distance between the bottom of the bolt

and the bottom of the ceiling of more than

2-3/8 in. as shown in Fig. 3-4.

(3) Thread the 2 hexagonal nuts and washers (field

supply) onto the 4 suspension bolts as shown in

Fig. 3-5.

Use 2 sets of nuts and washers (upper and

lower), so that the unit will not fall off the suspension lugs.

Full-scale installation diagram

(printed on a cardboard packing)

More than 2-3/8 inch

Nuts and washers

(2 sets)

1-7/8 inch

Full-scale installation

diagram

0963_X_I

Fig. 3-4

Suspension bolt

Suspension lug

Upper

Lower

(4) Remove the protective cardboard used to protect

the fan parts during transport.

(5) Adjust the distance between the unit and surface

of the ceiling (1-7/8 in.) using the supplied installation gauge. (Fig. 3-4)

0041_X_

Fig. 3-5

8

S4359128

Page 9

3-4. Installing the Drain Piping

I

I

(1) Prepare standard hard PVC pipe (O.D. 1-3/64 in.)

for the drain and use the supplied drain hose and

hose band to prevent water leaks.

The PVC pipe must be purchased separately.

The transparent part allows you to check drainage. (Fig. 3-6)

Tighten the hose clamps

CAUTION

so their locking nuts face

upward. (Fig. 3-6)

(2) After checking the drainage, wrap the supplied

packing and drain pipe insulator around the pipe.

(Fig. 3-7)

NOTE

Ensure the drain pipe has a downward gradient

(1/100 or more) and that there are no water traps.

Transparent part for

checking drainage

Packing

(supplied)

Drain hose

(supplied)

Drain insulator (supplied)

Hose band

(supplied)

Fig. 3-6

Fig. 3-7

Hard PVC pipe

(not supplied)

Drain hose

adapter

(supplied)

0964_X_I

0197_X_I

● Do not install an air

CAUTION

bleeder tubes, as this

may cause water to spray

from the drain tube outlet.

(Fig. 3-8)

● If it is necessary to increase the height

of the drain pipe, the section directly

after the connection port can be raised

a maximum of 10 in. Do not raise it any

higher than 10 in., as this could result

in water leaks.

(Fig. 3-9)

● Do not install the pipe with an upward

gradient from the connection port. It

will cause the drain water to flow

backwards and leak when the unit is

stopped. (Fig. 3-10)

● Do not apply force to the piping on the

unit side when connecting the drain

pipe. The pipe should not be allowed

to hang unsupported from its connection to the unit. Fasten the pipe to a

wall, frame, or other support as close

to the unit as possible. (Fig. 3-11)

Air bleeder

0047_X_I

Fig. 3-8

5 in. or less (as short as possible)

10 in. or less

0965_X_I

Fig. 3-9

Upward gradient

0049_X_

Fig. 3-10

● Provide insulation for any drain pipes

that are installed indoors.

Support

pieces

0050_X_

Fig. 3-11

9

S4359128

Page 10

3-5. Checking the Drainage

After wiring and piping are completed, use the following procedure to check that the water will drain

smoothly. For this, prepare a bucket and wiping cloth

ready to catch and wipe up spilled water.

Do not supply power to the

unit until the tubing and

wiring to the outdoor unit

are completed.

(1) Take off the tube cover and through the opening,

slowly pour about 43 oz. of water into the drain

pan to check drainage.

(2) Do Test Run to check the drainage after complet-

ing installation. When performing Test Run, be

sure to observe the Test Run procedure.

Refer to page 37.

CAUTION

start turning when checking

the drainage.

(3) After drain checking is finished, return the

Operation Selector switch to the RUN position

(ON position ) and remount the tube cover.

To mount the tube cover,

Be careful since the fan will

CAUTION

use 5/16" (4 × 8 mm) tapping

screws. Do not use long

screws as they may puncture the drain pan and cause

water leakage.

5/16"(4 × 8 mm)

tapping screw

Tube cover

Siphon

0966_X_I

Fig. 3-12

10

S4359128

Page 11

■ Ceiling Panel

Never touch or attempt to

CAUTION

move the air direction louver

by hand or you may damage

the unit. Instead, use the

remote control unit if you

want to change the direction

or air flow.

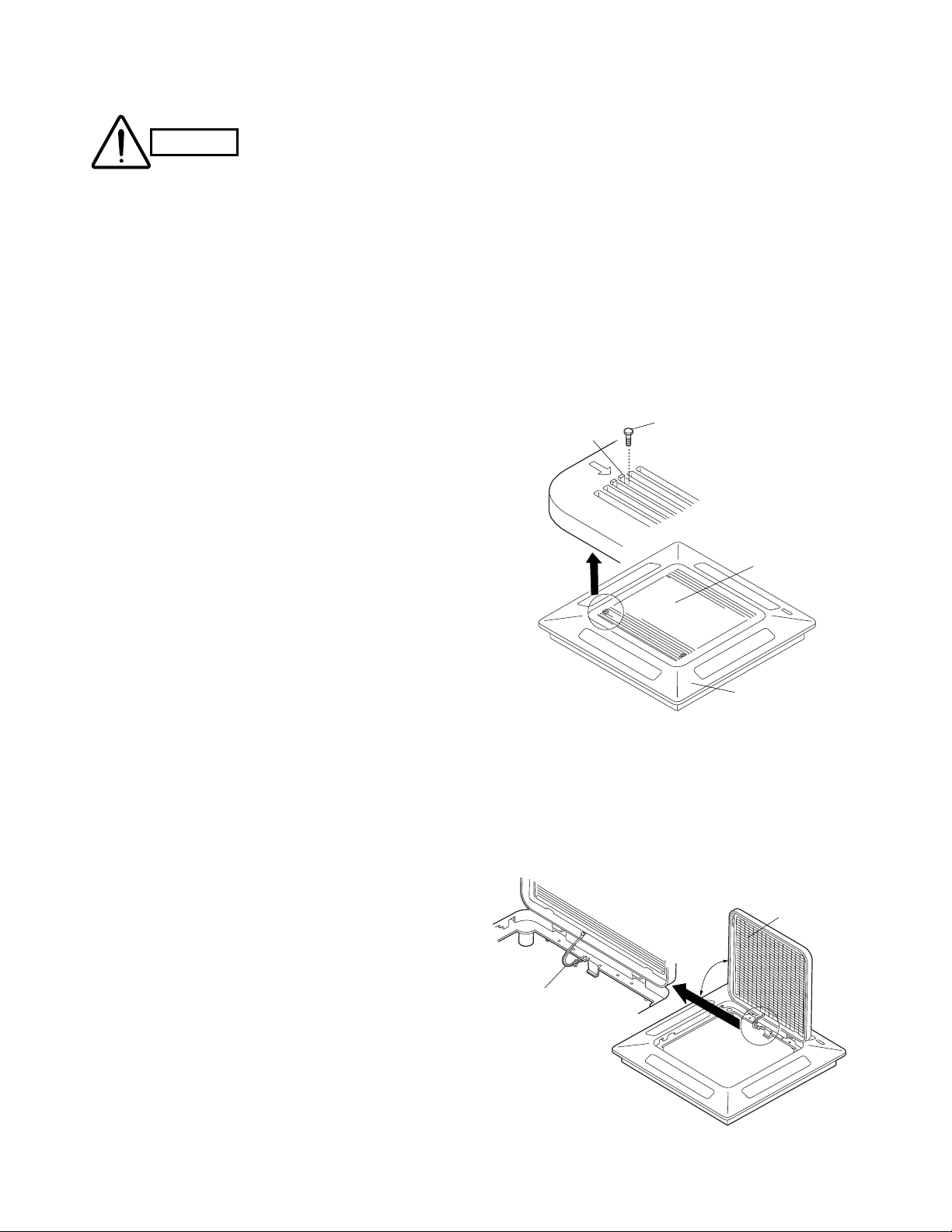

3-6. Before Installing the Ceiling Panel

(1) Remove the air-intake grille and air filter from the

ceiling panel. (Figs. 3-13 and 3-14)

(a) Remove the 2 screws on the latch of the air-

intake grille. (Fig. 3-13)

(b) Press on the 2 latches of the air-intake grille

with your thumb in the direction of the arrow

to open the grille. (Fig. 3-13)

(c) With the air-intake grille open about 45˚,

remove the safety string (hook on the grille

side). (Fig. 3-14)

(d) Pull the air-intake grille towards you to

remove it from the ceiling panel.

Latch

Screw

Air intake grille

(2) Pull down the two panel catches on the body of

the indoor unit body. (Fig. 3-15)

Ceiling panel

0149_X_I

Fig. 3-13

Air filter

45°

Safety string

11

Fig. 3-14

0150_X_I

S4359128

Page 12

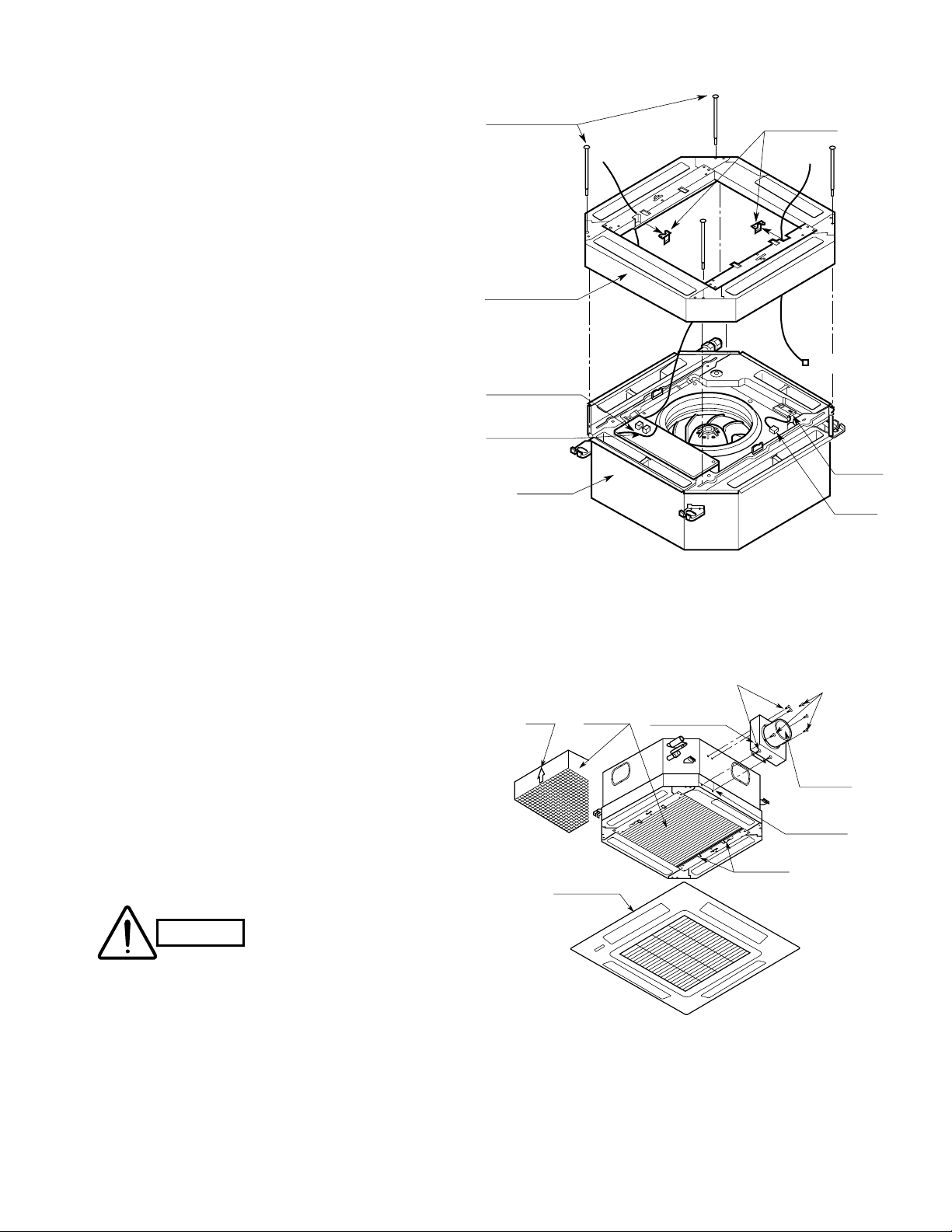

3-7. Installing the Ceiling Panel

(1) Lift the ceiling panel and position it to align the

(5) Install the air filter and air-intake grille by perform-

panel hook with the panel catch of the indoor unit.

NOTE NOTE

The ceiling panel must be mounted in the correct

direction. Note that the 2 catches of the panel differ in

Rehook the safety string before closing the air-intake

grille.

size.

Confirm that the catches are correctly matched be-

3-8. When Removing the Ceiling Panel for

tween the ceiling panel and the indoor unit body.

(2) Next, check to see that the ceiling panel is prop-

erly aligned with the seamline of the ceiling. If it is

not, remove the ceiling panel and slightly readjust

the indoor unit body to the proper suspension

When removing the ceiling panel for servicing, remove

the air-intake grille and air filter, disconnect the wiring

connector inside the electrical component box, and

then remove the 4 mounting screws.

point.

(3) When the ceiling panel has been properly

aligned, use the supplied 4 mounting screws (M5)

with washers to permanently fasten the ceiling

panel.

(4) Install the wiring connector from the ceiling panel

to the connector in the electrical component box

of the indoor unit. After installing the connector,

use the clamp on the body of the indoor unit to

secure the wiring.

Panel catch

(pull down)

ing the steps in section 3-6 in reverse.

Servicing

Connector on unit

(inside electrical component box)

Ceiling panel

Clamp

Ceiling panel wiring

connector

Electrical

component box

Electrical component box

Connector of ceiling panel

Unit body

Panel catch (pull down)

Ceiling panel

Screws M5 with washer

Mark

Air filter

Fig. 3-15

12

Air-intake grille

0967_X_I

S4359128

Page 13

3-9. Duct for Fresh Air

● Air-intake chamber (including Duct connection box and flange) are attached to the indoor unit when used to

take fresh outdoor air.

High-performance filter or Super long-life filter can be also installed in the air-intake chamber.

(1) SETUP PRIOR TO INSTALLATION

● When installing the high performance filter or super long-life filter, the parts and parts numbers of filters to be

assembled with the air-intake chamber are listed below. Please check that the correct part numbers are

present.

Air-intake

chamber

CMB-GSJ80T

(XS1852)

High performance

filter

AFT-MSJ80T

AFT-HSJ80T

Super long-life

filter

AFT-LSJ80T

(2) ACCESSORIES

● Check that the following parts are in the box when unpacking.

NAME QT’Y REMARKS

Cord with socket

(9P)

Screw

(M5 × L125) (for fastening)

Screw

(M4 × L12) (for fastening)

Duct connection box 1 (for fresh air)

Duct connection flange 1

Connecting line. Connect only when

1

high-performance filter is used

Air-intake filter

4

Duct connection flange/ box

4+4

(for connecting fresh air duct

)

(3) INSTALLATION

(a) Setup for the indoor unit

●

When assembling the high-performance filter, open the lid of the electrical component box, remove the socket

(9P) of the fan motor cable inside the electrical component box and connect the accessory cord with socket (9P).

Do not connect the “acces-

CAUTION

sory cord with socket” to

the electrical component box

when the unit is used to take

fresh air.

Do not connect the “accessory cord with socket” when

assembling the super longlife filter.

Always store the “accessory

cord with socket” inside the

electrical component box.

Installation steps (a) to (b) are the same for both

the CMB-GSJ80T and the GSJ140T. The drawing

illustrates installation of air-intake chamber to the

CMB-GSJ80T.

Cord with socket

(9P)

Electrical

component box

13

S4359128

1114_X_S

Fig. 3-16

Page 14

(b) INSTALLING THE AIR-INTAKE CHAMBER

● Set the air-intake chamber to the indoor unit taking

care not to set to the incorrect direction. (Fig. 3-17)

● Fasten the air-intake camber with the accessory

screws. (M5 × L125, 4pcs) (Fig. 3-17)

(c) INSTALLING THE DUCT CONNECTION BOX

● Fasten the duct connection flange to the duct

connection box with the accessory screws (M4 ×

L12, 4 pcs.). (Fig. 3-18)

● Put the duct connction box into the rectangular hole

of the air-intake chamber and fasten it to the both

sides of the indoor unit and chamber with the

accessory screws (M4 × L12, 4 pcs.). (Fig. 3-18)

(d) INSTALLING THE INDOOR UNIT

● Install the indoor unit to the ceiling.

(Install the indoor unit according to items 3-1 to 3-6.)

(e) INSTALLING THE CEILING PANEL

● Attach the ceiling panel to the chamber.

● Remove the socket cover of the air-intake chamber

and pass the 3P and 6P sockets through it. (Fig. 3-17)

● Connect the 3P socket to the 3P plug of the indoor

unit electrical component box.

● Connect the 6P socket to the 6P plug from the

operation selector.

● Reattach the socket cover.

Installation screws

Air-intake chamber

3P socket

(from ceiling panel)

3P plug

(electrical

component box)

Indoor unit

Socket cover

(6P socket)

Operation

selector

6P plug

1115_X_S

Fig. 3-17

(f) INSTALLING THE HIGH-PERFORMANCE FILTER

OR SUPER LONG-LIFE FILTER (Fig. 3-18)

● Turn the filter hooks of the air-intake chamber.

● Install high-performance or super long-life filter into

the chamber. (Install in the correct direction. Set the

filter so that the arrow on the side as shown in the

drawing on the right can be installed into the

air-intake chamber.

● Turn the filter hook (positioned so the filter frame is

aligned) and secure the air filter in place.

Take adequate precautions

CAUTION

when installing onto the

ceiling. The air-intake chamber is especially prone to

rupture if struck on it’s side.

Arrow

Air filter

Ceiling panel

Installation screws

(M4 × 12)

connection box

Duct

Fig. 3-18

Installation screws

(M4 × 12)

Duct

connection

flange

Rectangular

hole

Filter hook

1113_X_S

14

S4359128

Page 15

4. How to Install the Remote Control Unit

■ Wireless Remote Control Unit

The remote control unit can be operated from either a

non-fixed position or a wall-mounted position.

To ensure that the air conditioner operates correctly,

do not install the remote control unit in the following

places:

● In direct sunlight

● Behind a curtain or other place where it is covered

● More than 26 ft. away from the air conditioner

● In the path of the air conditioner’s airstream

● Where it may become extremely hot or cold

● Where it may be subject to electrical or magnetic

interference

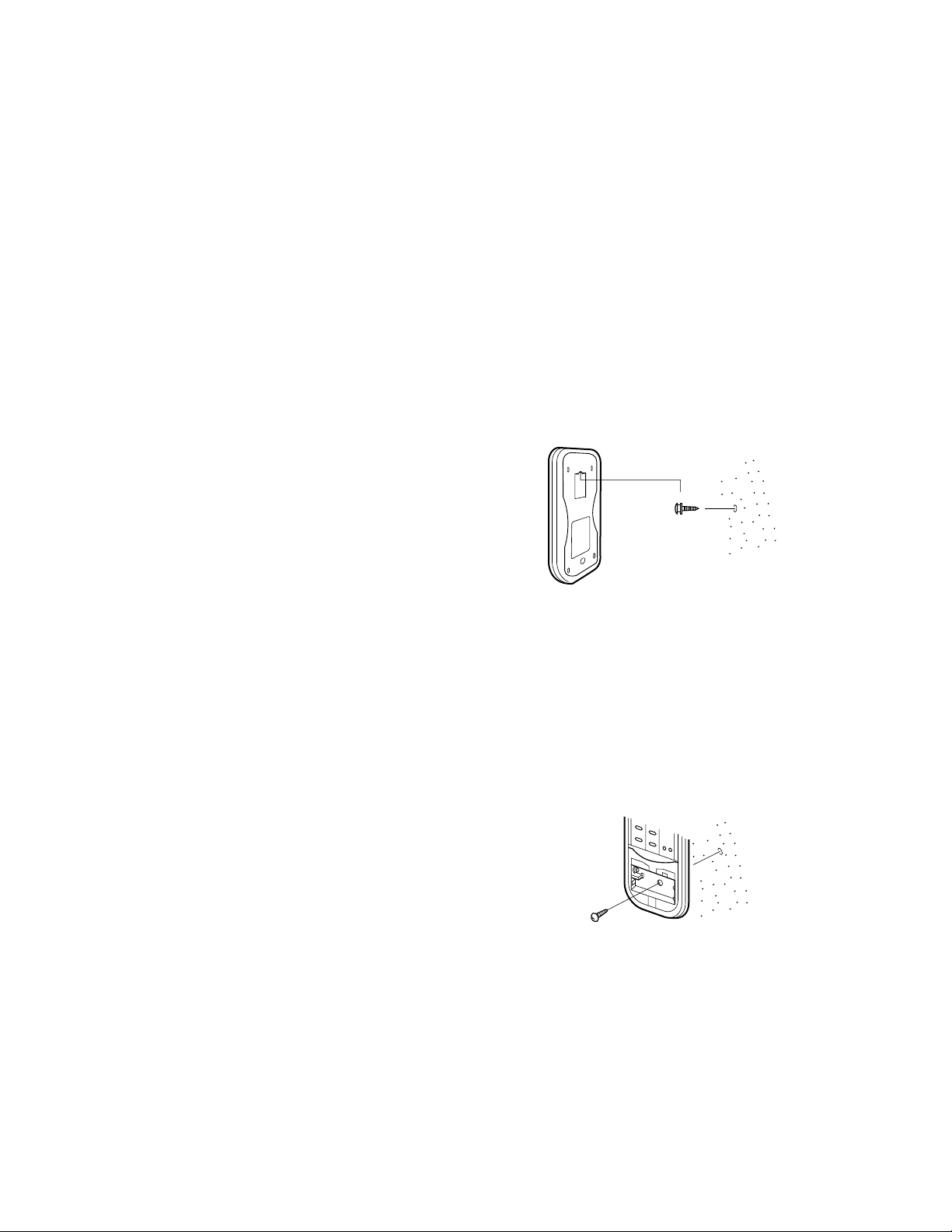

4-1. Mounting on a Wall

(1) Removable mounting

(a) Momentarily hold the remote control unit in

the desired mounting position.

(b) Confirm that the air conditioner responds

correctly when you press keys on the

remote control from that position.

(c) After confirming correct operation, use a

screwdriver to screw the supplied special

mounting screw into the wall. (Fig. 4-1)

(d) Hang the remote control unit from the

mounting screw.

Removable mounting

Wall

Special

mounting

screw

(Packed in indoor unit)

0532_M_I

Fig. 4-1

(2) Non-removable mounting

(a) Momentarily hold the remote control unit in

the desired mounting position.

(b) Confirm that the air conditioner responds

correctly when you press keys on the

remote control from that position.

(c) After confirming correct operation, use a

screwdriver to screw the mounting screw

into the wall. (Fig. 4-1)

(d) Remove the remote control cover by sliding

it downward.

(e) Remove the batteries of the remote control

unit.

(f) Hang the remote control unit from the

mounting screw, and use a screwdriver to

screw the remote control unit securing

screw into the wall through the hole in the

battery compartment. (Fig. 4-2)

(g) Replace the batteries.

(h) Again confirm that the remote control unit

operates correctly.

Non-removable mounting

Wall

Screw

(Packed in indoor unit)

0533_M_I

Fig. 4-2

15

S4359128

Page 16

■ Wired Remote Control Unit (Option)

(1) To access the printed circuit board, remove the

cover plate of the electrical component box.

(2) Attach the remote control connectors securely to

the mating connector pins on the printed circuit

board.

(3) Turn the R.C.U. switch from “WIRELESS” to

“WIRED”.

(4) Replace the cover plate.

Do not supply power to

the unit until the tubing and

wiring to the outdoor unit is

completed.

Electrical

component box

Cover plate

The mounting position for the remote control unit

should be located in an accessible place for control

and permit the average room temperature to be

detected. Never cover the unit or recess it into the wall.

4-2. Installing the Wired Remote Control Unit

(1) Use a ballpoint pen or similar pointed object to

remove the plastic bushing which is inserted in

the rear of the remote control unit. The bushing

can be discarded. (Fig. 4-4)

(2) Align the cord with the groove of the remote

control unit.

(3) Attach the mounting plate to the wall with the 2

supplied screws. Then align the rail on the rear of

the control unit with the slot of the mounting plate

and slide the unit down as far as it will go. (Fig. 4-4)

Fix the control unit cord to the wall.

(4) If local codes allow, the remote control unit cord

can be wired in the wall. (Fig. 4-5)

WIRED WIRELESS

R.C.U. Switch

Flat-head

tapping screw

25/64"(3 × 10 mm)

(SATA)

Cord clip

Remote

control

unit

Mounting

plate

Truss-head

tapping screw

5/8"(4 × 16 mm)

(TOTA)

Connector for the wired

remote control unit

Fig. 4-3

Cord

Rear

1006_M_I

Groove

Plastic

bushing

Ballpoint

pen

Remote

control

unit

Wall

16

S4359128

Fig. 4-4

1020_M_I

0531_M_I

Fig. 4-5

Page 17

5. Address Switches

If you are installing one indoor unit or one group of

indoor units in the same room, it is necessary for you

to assign each unit its own address so that each can

be operated by its own remote control unit. You assign

the addresses by matching the switch position of each

indoor unit with the switch position of its remote control

unit. The switch of the remote control unit is shown in

Fig. 5-1.

5-1. Finding the Address Switches

Remote Control Unit

Remove the lid by sliding it off. You can see the

switches inside the battery compartment. (Fig. 5-1)

Indoor Unit

(1) Turn off the Power Switch.

(2) Remove the Grille.

(3) Remove the cover of the Electrical Component

Box.

5-2.

Switch Positions for 2 Units or 2 Groups of Units

Table 5-1 shows the positions you can use for up to 2

units or 2 groups of indoor units installed in the same

room. Two remote control units are necessary to allow

the respective units or group to be controlled independently.

Table 5-1

Remote Control Indoor Unit

Unit No. Address switch Address switch

Address switch is in “A” position

at time of shipment.

Fig. 5-1

A

B

Address

1008_M_I

12

1 A OFF OFF

2 BONON

The indoor unit address switch is set at 1-OFF & 2-OFF

position at shipment.

NOTE

An indoor unit cannot be controlled if its remote control

unit is too far away (more than 26 ft.). If the remote

control unit does not work correctly, bring it closer to

the unit being operated and try again. There should be

no obstacles between the remote control unit and the

indoor unit. For this reason, if the remote control unit is

to be used from a fixed position, check the operation

before mounting.

17

P.C.B

S4359128

WIRED WIRELESS

R.C.U. Switch

Fig. 5-2

ON

2

1

Address Switch

(DSW1)

1321_M_I

Page 18

6. Electrical Wiring

6-1. General Precautions on Wiring

(1) Before wiring, confirm the rated voltage of the unit

as shown on its nameplate, then carry out the

wiring closely following the wiring diagram.

(2) Provide a power outlet to be used exclusively for

each unit, and a power supply disconnect and

circuit breaker for overcurrent protection should

be provided in the exclusive line.

(3) To prevent possible hazards from insulation

failure, the unit must be grounded.

(4) Each wiring connection must be done in accor-

dance with the wiring system diagram. Wrong

wiring may cause the unit to misoperate or

become damaged.

(5) Do not allow wiring to touch the refrigerant tubing,

compressor, or any moving parts of the fan.

(6) Unauthorized changes in the internal wiring can

be very dangerous. The manufacturer will accept

no responsibility for any damage or misoperation

that occurs as a result of such unauthorized

changes.

(7) Regulations on wire diameters differ from locality

to locality. For field wiring rules, please refer to

your LOCAL ELECTRICAL CODES (ex. National

Electric Code: ANSI/NFPA70) before beginning.

You must ensure that installation complies with all

relevant rules and regulations.

(8) To prevent malfunction of the air conditioner

caused by electrical noise, care must be taken

when wiring as follows:

● The inter-unit control wiring and the remote control

wiring (option) should be wired apart from the interunit power wiring.

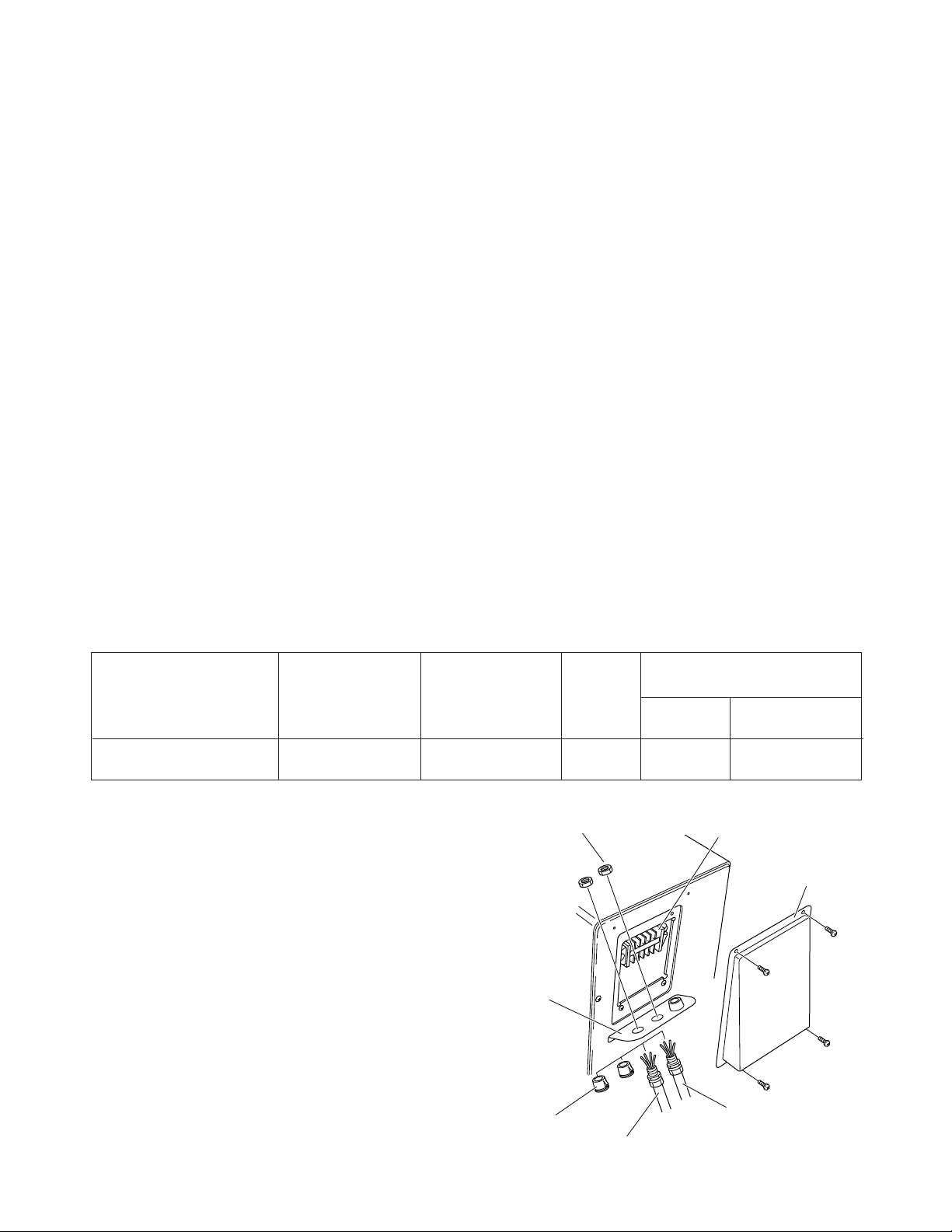

6-2. Recommended Wire Length and Wire Diameter for Power Supply System

Power Supply Terminal Base

(Outdoor Unit)

Capacity

Models

(A)*1 Power Supply

(B)*1 Inter-unit

AWG #12 AWG #12

Wiring

Time Delay

Fuse or

Circuit

Capacity

C1852, CL1852 75 ft. 65 ft. 15 A 20 A AWG #12

*1 Refer to the Wiring System Diagrams (See Fig. 6-3) for the meaning of “A”, “B”.

AWG = American Wire Gauge

Lock nut

Terminal

block

6-3. Wiring Instructions for the Outdoor Unit

(1) To take off the access panel, remove the 4

screws. (See Fig. 6-1)

(2) Dismount plugs on the conduit plate.

(3) Temporarily mount the conduits on the conduit

plate.

Conduit

plate

(4) Properly connect both the power supply and inter-

unit lines to the corresponding terminals on the

terminal block.

Refer to the wiring diagram in Fig. 6-2 (which also

appears on the access panel).

Plug

Power supply

Inter-unit line

Fig. 6-1

Max. Wire

Diameter

Access panel

1822_M_I

18

S4359128

Page 19

NOTE

● Conduit's trade size for this unit is 1/2". The

conduit can be purchased at a hardware store.

● The fuse located in the outdoor unit provides

power supply protection and may blow when

power is applied if the system has been

incorrectly wired.

(5) Ground the unit in accordance with local codes.

(6) Be sure to size each wire allowing several inches

longer than the required length for wiring.

(7) Use lock nuts to secure the conduit tubes.

● Be sure to comply with

local codes while running

the wire from the indoor

unit to the outdoor unit

(size of wire and wiring

method, etc.).

● Every wire must be

connected firmly.

● No wire should be

allowed to touch

refrigerant tubing, the

compressor or any

moving part.

INDOOR

INDOOR UNIT

1

2

3

G

Disconnect

switch

(Field supply)

CAUTION

(Inter-unit)

Power lines

230/208 V

230/208 V

230/208 V

Grounding

line

OUTDOOR UNIT

B

1

2

3

4

5

6

G

Fuse

A

L1

L2

Fig. 6-2

● To avoid the risk of

electric shock, each air

conditioner unit must be

grounded.

● Be sure to connect the

power supply line to the

outdoor unit as shown in

the wiring diagram. The

indoor unit draws its

power from the outdoor

unit.

Power supply line

Single-phase, 230/208 V

1823_M_I

6-4. Examples of Incorrect Wiring

The following are examples of improper wiring that result in system misoperation. You should confirm that you

have wired the units correctly before beginning the test run.

Problem 1

● Short circuit will occur after approx.

Problem 2

● Air conditioner will not operate.

3 minutes and the power circuit

fuse blows.

Disconnect

(A)

switch

1

2

3

G G

Grounding line

Indoor unit Outdoor unit

1

2

3

1301_C_I

Disconnect

(B)

switch

1

2

3

G G

Grounding line

Indoor unit Outdoor unit

1

2

3

1302_C_I

Disconnect

(C)

switch

1

2

3

G G

Grounding line

Indoor unit Outdoor unit

1

2

3

1303_C_I

Problem 3

● Compressor will not start; only indoor unit will operate.

Disconnect

(D)

switch

1

2

3

G G

Grounding line

Indoor unit

1

2

3

Outdoor unit

1304_C_I

Disconnect

(E)

switch

1

2

3

G G

Grounding line

Indoor unit

1

2

3

Outdoor unit

1305_C_I

19

S4359128

Page 20

Loose wiring may cause the

I

terminal to overheat or result

in unit malfunction. A fire

hazard may also exist.

Therefore, ensure that all

wiring is tightly connected.

When connecting each power wire to the corresponding terminal, follow the instructions on “How to connect

wiring to the terminal” and fasten the wire securely with

the fixing screw of the terminal plate.

6-5. How to Connect Wiring to the Terminal

■ For solid core wiring (or F-cable)

(1) Cut the wire end with a wire cutter or wire-cutting

pliers, then strip the insulation to expose the solid

wire about 1 in.. (Fig. 6-3)

(2) Using a screwdriver, remove the terminal

screw(s) on the terminal plate.

(3) Using the pliers, bend the solid wire to form a

loop suitable for the terminal screw.

(4) Shape the wire loop properly, position it on the

terminal plate and fix it securely with the terminal

screw using a screwdriver.

■ For stranded wiring

(1) Cut the wire end with a wire cutter or wire-cutting

pliers, then strip the insulation to expose the

stranded wiring about 3/8 in.. (Fig. 6-4)

(2) Using a Pillips head screwdriver, remove the

terminal screw(s) on the terminal plate.

(3) Using a ring connector fastener or pliers, securely

clamp each stripped wire end with a ring pressure

terminal. (Fig. 6-4)

(4) Place the ring pressure terminal, and replace and

tighten the removed terminal screw using a

screwdriver. (Fig. 6-5)

Special

washer

Wire

Solid wire

Strip 1 in.

Insulation

Stranded wire

Strip 3/8 in.

Screw

Ring pressure

terminal

Terminal plate

Fig. 6-3

Fig. 6-4

Wire

Fig. 6-5

Loop

1004_M_I

Ring

pressure

terminal

1106_M_I

Screw and

Special washer

Ring

connector

1308_M_

20

S4359128

Page 21

7. How to Process Tubing

I

Flare nut

Copper

tubing

Flare tool

0128_M_I

Apply refrigerant

lubricant here and here

0129_M_I

The narrow tubing side is connected by flare nut, and

the wide tubing side is connected by brazing.

7-1. Use of the Flaring Method

Many of the conventional split system air conditioners

employ the flaring method to connect refrigerant tubes

which run between indoor and outdoor units. In this

method, the copper tubes are flared at each end and

connected with flare nuts.

7-2. Flaring Procedure with a Flare Tool

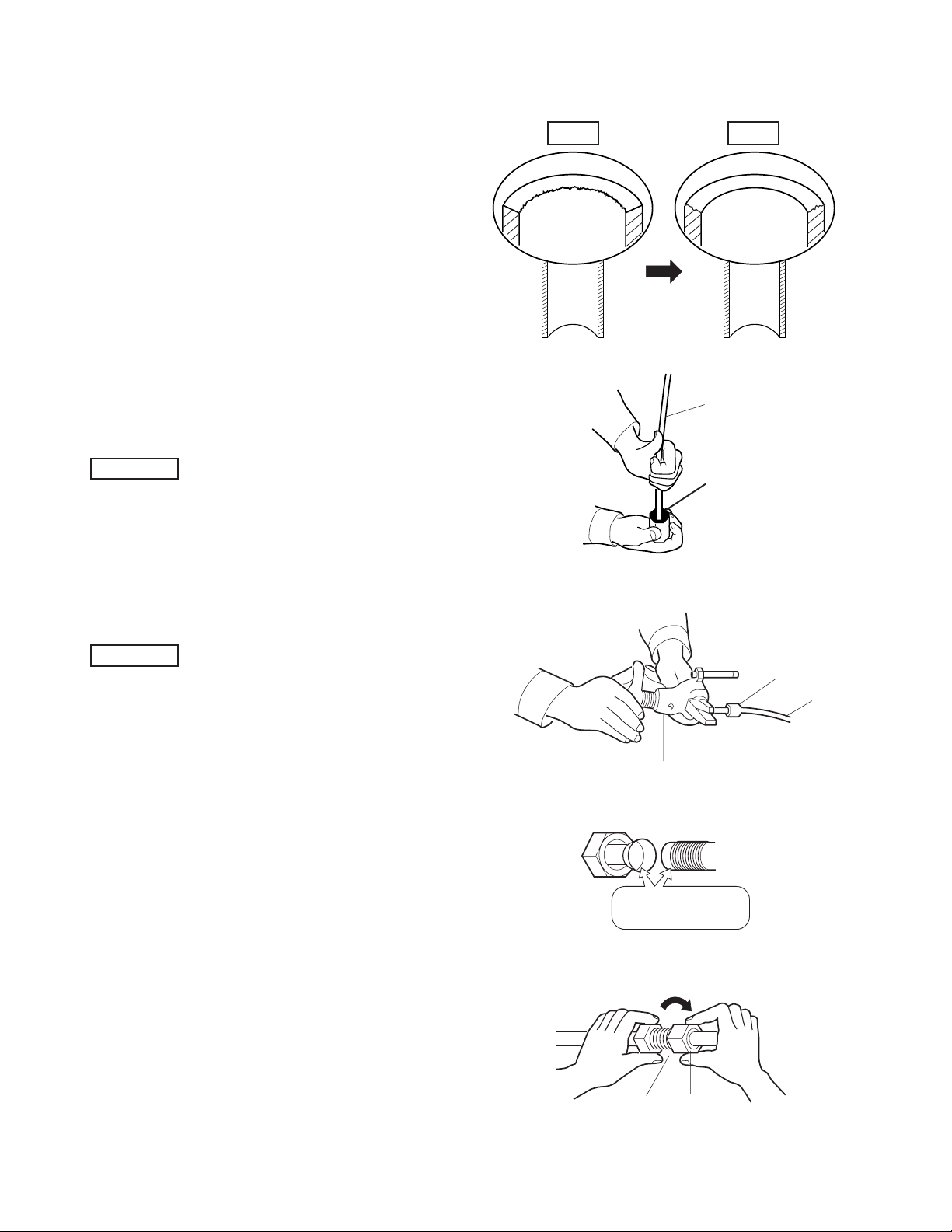

(1)

Cut the copper tube to the required length with a

tube cutter. It is recommended to cut about

12 – 20 in. longer than the estimated tubing length.

(2) Remove burrs at the end of the copper tube with

a tube reamer or file. This process is important

and should be done carefully to make a good

flare. (Fig. 7-1)

NOTE

When reaming, hold the tube end downward and be

sure that no copper scraps fall into the tube. (Fig. 7-2)

(3) Remove the flare nut from the unit and mount it

on the copper tube.

(4) Make a flare at the end of copper tube with a flare

tool.* (Fig. 7-3)

*Use “RIGID®” or equivalent.

Deburring

Before After

Fig. 7-1

Copper

tubing

Reamer

0127_M_I

Fig. 7-2

0126_M_

NOTE

A good flare should have the following characteristics:

● inside surface is glossy and smooth.

● edge is smooth.

● tapered sides are of uniform length.

7-3. Precaution before Connecting Tubes Tightly

(1) Apply a sealing cap or water-proof tape to pre-

vent dust or water from entering the tubes before

they are used.

(2) Apply refrigerant lubricant to the matching sur-

faces of the flare and union before connecting

them together. This helps to reduce gas leaks.

(Fig. 7-4)

(3) For proper connection, align the union tube and

flare tube with each other, then screw in the flare

nut lightly at first to obtain a smooth match.

(Fig. 7-5)

● Adjust the shape of the narrow and wide tubes

using a tube bender at the installation site and

connect them to the each tubing side valve using

a flare nut.

Fig. 7-3

Fig. 7-4

Union Flare nut

Fig. 7-5

0130_M_I

21

S4359128

Page 22

7-4. Precautions during Brazing

● Replace air inside the tube with nitrogen gas to

prevent copper oxide film from forming during the

brazing process.

● Do not allow the tubing to get too hot during the

brazing process.

The nitrogen gas inside the tubing may overheat,

causing refrigerant system valves to become

damaged. Therefore allow the tubing to cool between brazings.

Indoor unit

Torque wrench

Fig. 7-6

Spanner

Outdoor unit

0131_C_I

7-5. Connecting Tubing between Indoor and

Outdoor Units

(1) Tightly connect the indoor side refrigerant tubing

with the outdoor side tubing. (Fig. 7-6)

(2)

To fasten the flare nuts, apply specified torque as:

Table 7-1

Tube Dia.

1/4" (6.35 mm)

5/8" (15.88 mm)

Tightening Torque

Approx. 140 — 180 kg-cm

(120 — 160 Ibs-in.)

Approx. 680 — 820 kg-cm

(590 — 710 lbs-in.)

7-6. Insulating the Refrigerant Tubing

Always insulate tubes after

CAUTION

completing leak tests on all

connection points.

Important

To avoid condensation and water leaks, the wide and

narrow tubes must be insulated with the supplied

insulation materials.

Taping the flare nuts

Wind white insulation tape around the flare nuts at the

wide and narrow tube connections. Place the seal

(supplied) on the unit. Then cover up the tubing

connections with the flare nut insulator, and cover the

gap at the union with the supplied black insulation

tape. Finally, fix the insulator at both ends with vinyl

clamps. (Fig. 7-7)

Refrigerant tubing

Seal (supplied)

Unit side

insulator

Flare nut

Insulation tape (white)

(supplied)

Flare insulator (supplied)

Tube insulator

(not supplied)

Vinyl clamps (supplied)

Fig. 7-7

Refrigerant tubing and insulator

Drain insulator

and clamp.

Large

(supplied)

Packing

clamp.

Small

hose band

(supplied)

(not supplied)

Drain pipe and insulator

(not supplied)

Insulation

tape

Vinyl

Flare

clamp

insulator

Seal

0558_X_I

Never grasp the drain or refrigerant connecting

outlets when moving the unit.

1015_X_I

Insulation material

The material used for insulation must have good

insuIation characteristics, be easy to use, be age

resistant, and must not easily absorb moisture.

After a tube has been insu-

CAUTION

lated, never try to bend it

because it can cause the

tube to break or crack.

22

Fig. 7-8

S4359128

Page 23

Tubing

Apply putty here

0137_C_I

I

Important

Because capillary tubing is installed in the outdoor unit,

both the wide and narrow tubes of this air conditioner

become cold. Therefore, to prevent heat loss and wet

floors due to dripping of condensation water, both

tubes must be well insulated with proper insulation

material. The thickness of the insulation material

should be a min. 8 mm (5/16").

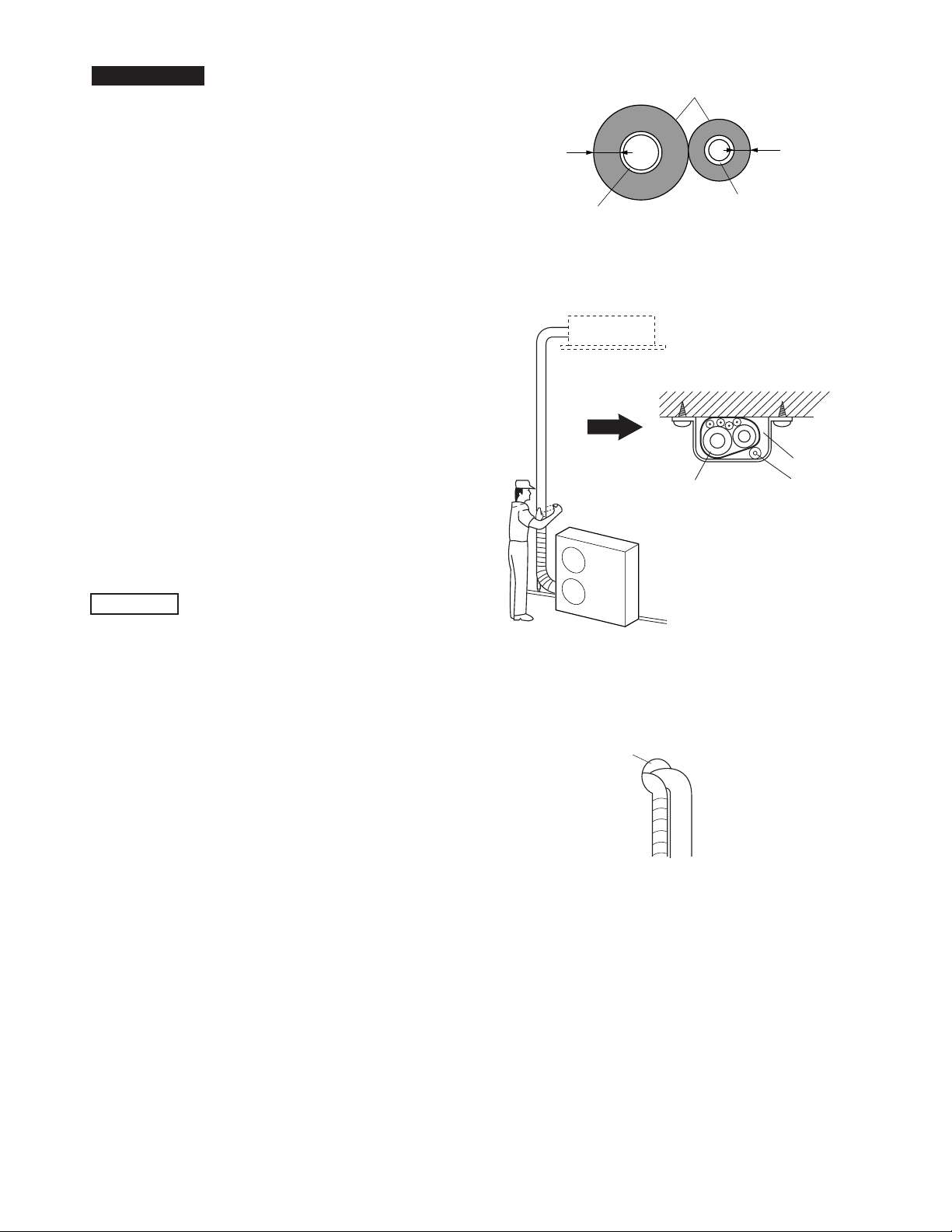

7-7. Taping the Tubes

(1) At this time, the refrigerant tubes (and electrical

wiring if local codes permit) should be taped with

armoring tape in 1 bundle. To prevent the condensation from overflowing the drain pan, keep

the drain hose separate from the refrigerant

tubing.

Thickness:

Min. 5/16 in.

Wide tube

Insulation

Thickness:

Min. 5/16 in.

Narrow tube

0999_C_I

(2) Wrap the armoring tape from the bottom of the

outdoor unit to the top of the tubing where it

enters the wall. As you wrap the tubing, overlap

half of each previous tape turn. (Fig. 7-9)

(3) Clamp the tubing bundle to the wall, using 1

clamp about every 3 feet.

NOTE

Do not wind the armoring tape too tightly since this will

decrease the heat insulation effect. Also ensure that

the condensation drain hose splits away from the

bundle and drips clear of the unit and the tubing.

7-8. Finishing the Installation

After finishing insulating and taping over the tubing,

use sealing putty to seal off the hole in the wall to

prevent rain and draft from entering. (Fig. 7-10)

Insulated tubes

Fig. 7-9

Clamp

Drain hose

0136_M_

Fig. 7-10

23

S4359128

Page 24

8. Air Purging

Air and moisture remaining in the refrigerant system have

undesirable effects as indicated below. Therefore, they

must be purged completely.

● pressure in the system rises

● operating current rises

● cooling (or heating) efficiency drops

● moisture in the air may freeze and block capillary tubing

● water may lead to corrosion of parts in the refrigerant

system

■ Air Purging with a Vacuum Pump (for Test Run)

(1) Check that each tube (both narrow and wide tubes)

between the indoor and outdoor units have been

properly connected and all wiring for the test run has

been completed.Note that both narrow and wide tube

service valves on the outdoor unit are kept closed at

this stage.

(2) Using an adjustable wrench or box wrench, remove

the valve caps from the service valve on both narrow

and wide tubes.

(3) Connect a vacuum pump and a manifold valve (with

pressure gauges) to the service port on the wide tube

service valve. (Fig. 8-1)

Pressure

gauge

Indoor unit

Outdoor unit

Manifold valve

HiLo

Be sure to use a manifold valve

CAUTION

for air purging. If it is not

available, use a stop valve for

this purpose. The “Hi” knob of

the manifold valve must always

be kept closed.

(4) With the “Lo” knob of the manifold valve open, run the

vacuum pump. The operation time for the vacuum

pump varies with tubing length and the capacity of the

pump. The following table shows the amount of time

for evacuation:

Required time for evacuation when capacity

of 100 liter/h vacuum pump is used

If tubing length is If tubing length is

less than 33 ft. (10 m) more than 33 ft. (10 m)

10 min. or more 15 min. or more

NOTE

The required time in the above table is calculated based on

the assumption that the ideal (or target) vacuum condition

is around 10 mmHg abs.

Vacuum pump

Fig. 8-1

1824_M_I

24

S4359128

Page 25

(5) With the vacuum pump still running, close the “Lo”

knob of the manifold valve. Then stop the vacuum

pump.

(6) With the accessory hex wrench, turn the valve stem

on the narrow tube service valve counter-clockwise by

90 degress (1/4 turn) for 10 seconds, and then turn

the stem clockwise to close it again. (Fig. 8-2)

Be sure to completely insert

CAUTION

the hex wrench before

attempting to turn the valve.

(7) Leak test all joints at the tubing (both indoor and

outdoors) with liquid soap. Bubbles indicate a leak. Be

sure to wipe off the soap with a clean cloth.

(8) With the hex wrench, turn the wide tube service valve

stem counter-clockwise to fully open the valve.

(9) Turn the narrow tube service valve stem counter-

clockwise to fully open the valve.

(10) Loosen the vacuum hose connected to the wide tube

service port slightly to release the pressure. Then,

remove the hose.

90° (1/4 turn)

Valve cap

Vacuum hose to manifold valve

Narrow tube

Fig. 8-2

Hex wrench

Wide tube

1825_M_I

(11) Replace the bonnet and flare nut on the wide tube

service port and fasten the flare nut securely with an

adjustable wrench or box wrench or box wrench.

Next, mount the valve cap and tighten it with a torque

wrench (the cap needs to be tightened with the torque

of 170 ibs.·in. (200 kg·cm)). This process is very

important to prevent gas from leaking from the

system.

(12) Test run the air conditioner. (See next page.)

(13) While the air conditioner is running, apply liquid soap

to check for any gas leaks around the service valves

or caps.

(14) If there is no leakage, stop the air conditioner.

(15) Wipe off the soap on the tubing.

This completes air purging with a vacuum pump and the air

conditioner is ready for actual operation.

25

S4359128

Page 26

9. Test Run

9-1. Performing Test Run

Be careful since the fan will

CAUTION

start when performing Test

Run.

(1) The Operation Selector is located on the electrical

component box inside the indoor unit. To access the

Operation Selector, press the two latches of the air

intake grille in the direction of the arrow to open the

grille. Open the air intake grille downward.

(Fig. 9-1)

(2) Set the Operation Selector to the “Test” position.

The air conditioner will start running.

(3) Let the unit run for about 30 minutes and check that

the unit operates normally.

(4) After the Test Run, be sure to reset the Operation

Selector to the “ON” position for normal operation.

The air conditioner continues to run .

(5) Referring to the Operating Instructions, select the

Cooling mode and press the ON / OFF operation

button on the remote control unit, to confirm remote

control unit operation.

Air filter

TESTOFF ON

Fig. 9-1

Operation

selector

Air intake grille

1323_M_I

Important

Set the Operation Selector at the “ON” position. Otherwise the unit will stop or will not run correctly.

9-2. Performing Test Run with Optional Wired

Remote Control Unit

(1) Service TEST RUN switch is located on the rear

side of the remote control unit. Set the switch to the

TEST RUN position. (Fig. 9-2)

(2) Referring to the Operating Instructions, select the

cooling mode and press the ON / OFF operation

button on the remote control unit.

(3) The air conditioner will start running 3 minutes after

the ON / OFF operation button is pressed.

(4) Let the unit run for about 30 minutes and check that

it operates normally.

(5) Press the ON / OFF operation button again to stop

the unit.

RUN

TEST

RUN

(Bottom)

Remote control unit

viewed from rear

Fig. 9-2

Service TEST RUN

switch

0543_M_I

Important

Set the Service Test RUN switch at “RUN” position,

otherwise the unit will not run correctly.

26

S4359128

Page 27

9-3. Basic Function of the Service Valves

Valve cap

Stem

O-ring

1827_M_I

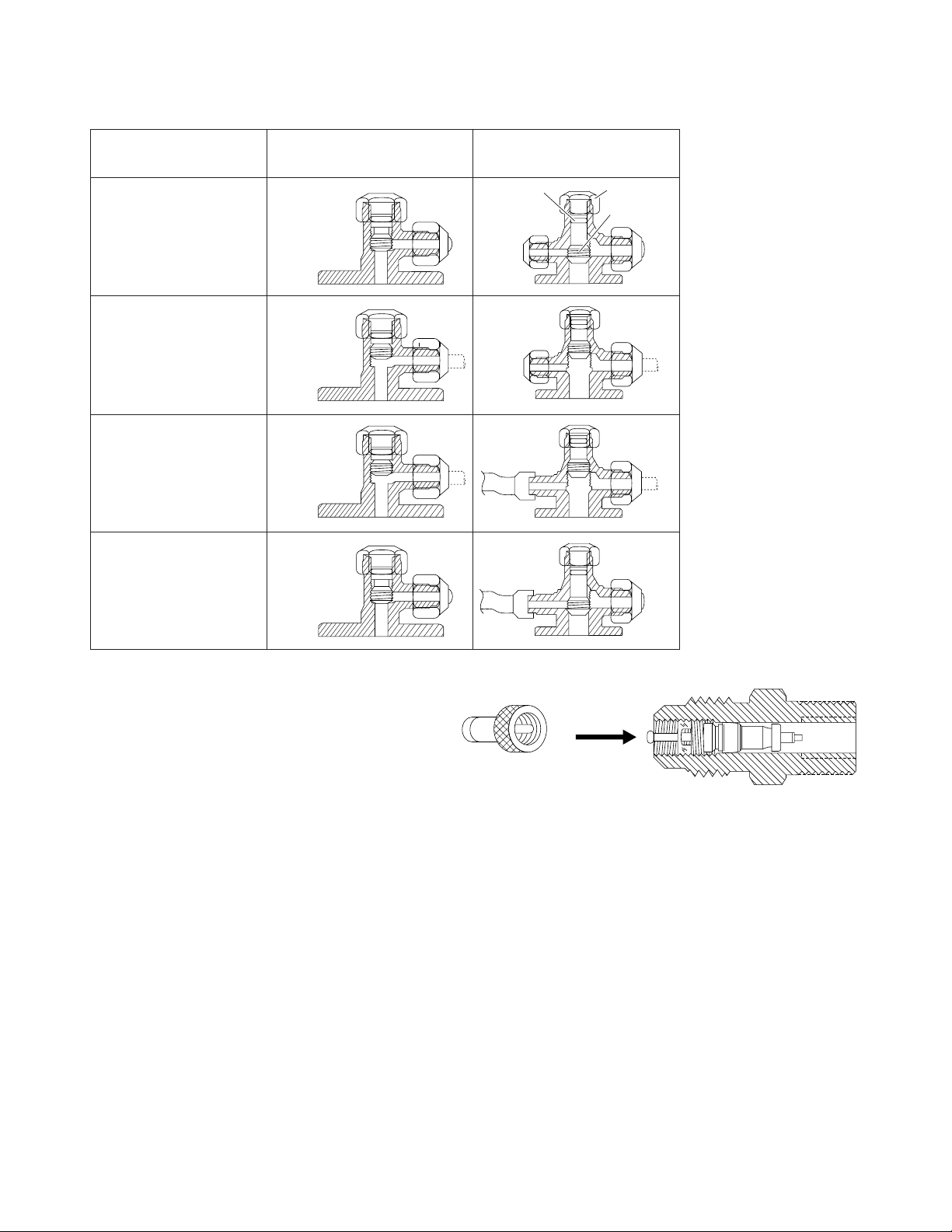

The basic function of the service valves are given in Table 7 below.

Action

Shipping

Operating and

test running the

air conditioner

Measuring

pressure

and gas charging

Air purging with a

vacuum pump

Narrow Tube Service Wide Tube Service

Valve (2-Way) Valve (3-Way)

1826_M_I

1828_M_I

1829_M_I

∗

1830_M_I

1831_M_I

∗

1832_M_I

∗ The service port on the wide tube service

valve uses a Schrader core valve to access

the refrigerant system. Therefore, be sure to

use a hose connector which has a push-pin

inside. (Fig. 9-3)

9-4. Pump Down

Pump down means collecting all refrigerant gas in the

system back into the outdoor unit without losing any of

the gas. Pump down is used when the unit is to be

moved or before servicing the refrigerant circuit

Pump Down Procedure

Be sure to carry out pump down with the unit in

cooling mode.

(1) Connect the Lo side charging hose of the manifold

valve to the service port on the wide tube service

valve.

(2) Using a hex wrench, turn the narrow tube service

1833_M_I

Service valve

Hose with push-pin

PUSH

1834_M_I

Fig. 9-3

valve clockwise all the way to close the service

valve. (Be sure to confirm that the wide tube

service valve is fully open.)

(3) Press the operation button and start cooling

operation.

(4) When the low pressure gauge reading falls to 1 to

0.5 kg/cm2 (14.2 to 7.1 PSI), fully close the wide

tube valve stem with a standard screwdriver. Then

quickly stop the unit.

(5) Disconnect all gauges and hose, and replace the

bonnets and the valve caps as they were before.

27

S4359128

Loading...

Loading...