Sanyo PLV-HD2000N,PLV-HD2000E Service Manual

FILE NO.

SERVICE MANUAL

REFERENCE NO. SM 5110803-00

PRODUCT CODE :

PLV-HD2000N MA4A 1 122 323 00 U.S.A., Canada

PLV-HD2000E PA4A 1 122 332 00 Europe, Asia, Africa

PLV-HD2000E PA4C 1 122 332 02 U.K.

Multimedia Projector

Give complete “CHASSIS NO." for

parts order or servicing, it is shown on

the rating sheet on the cabinet of the

Projector.

Chassis No. MA4-HD2000N00

PA4-HD2000E00

NOTE: Match the Chassis No. on the rat-

ing sheet on the cabinet with the

Chassis No. in the Service

Manual.

If the Original Version Service

Manual Chassis No. does not

match the unites, additional

Service Literature is required.

You must refer to “Notices” to the

Original Service Manual prior to

servicing the unit.

MODEL NO. PLV-HD2000N

U.S.A., Canada

PLV-HD2000E

U.K., Europe

(Projection lens is optional.)

Original Version

RoHS

• This product does not contain any hazardous substances prohibited by the RoHS Directive. (You will

find “RSF” mark near the rating plate on the RoHS

compliant product.)

!

WARNING

• You are requested to use RoHS compliant parts for

maintenance or repair.

• You are requested to use lead-free solder.

■ Contents

- 2 -

■ Contents .................................................................................................................2

■ Safety Instructions..................................................................................................3

■ Technical Specifications.........................................................................................4

■ Circuit Protections ..................................................................................................5

■ Lamp Replacement ................................................................................................9

■ Maintenance and Cleaning ..................................................................................13

■ Mechanical disassemblies ...................................................................................15

■ Optical Unit disassemblies ...................................................................................40

● Optical Parts Location and Direction ..........................................................51

■ Troubleshooting....................................................................................................53

● No Picture ...................................................................................................53

● No Power ....................................................................................................58

● No Audio Output .........................................................................................62

● Temperature Abnormality ...........................................................................63

● Power Lens System Abnormality................................................................64

● Lamp Abnormality .......................................................................................65

■ Adjustments After Parts Replacement (Optical parts) .........................................66

■ Optical adjustments..............................................................................................67

■ Electrical Adjustments..........................................................................................78

● Adjustments after Parts Replacement (Electrical Parts).............................78

● Service Adjustment Menu Operation ..........................................................79

● Service Mode Adjustment Menu.................................................................80

● Circuit Adjustments .....................................................................................82

● Service Adjustment Data table (Factory Set Data List) ..............................88

● Special Menu ..............................................................................................97

■ Control Port Functions .........................................................................................98

■ Waveforms .........................................................................................................106

■ IC Block Diagrams .............................................................................................107

■ Mechanical and Optical Parts list.......................................................................113

■ Electrical Parts list..............................................................................................124

■ Diagrams and Drawings ......................................................................................A1

● Parts description and reading in schematic diagram .................................A2

● Block Diagrams ..........................................................................................A3

● Schematic Diagrams ..................................................................................A4

● Printed Wiring Board Diagrams................................................................A17

● Pins description of ICs, transistors, diodes ..............................................A29

WARNING:

The chassis of this projector is isolated (COLD) from AC line by using the converter transformer. Primary side of

the converter and lamp power supply unit circuit is connected to the AC line and it is hot, which hot circuit is identified with the line ( ) in the schematic diagram. For continued product safety and protection of personnel

injury, servicing should be made with qualified personnel.

The following precautions must be observed.

SAFETY PRECAUTIONS

1: An isolation transformer should be connected in the

power line between the projector and the AC line

before any service is performed on the projector.

2: Comply with all caution and safety-related notes pro-

vided on the cabinet back, cabinet bottom, inside the

cabinet or on the chassis.

3: When replacing a chassis in the cabinet, always be

certain that all the protective devices are installed

properly, such as, control knobs, adjustment covers

or shields, barriers, etc.

DO NOT OPERATE THIS PROJECTOR WITHOUT

THE PROTECTIVE SHIELD IN POSITION AND

PROPERLY SECURED.

4: Before replacing the cabinet cover, thoroughly

inspect the inside of the cabinet to see that no stray

parts or tools have been left inside.

Before returning any projector to the customer, the

service personnel must be sure it is completely safe to

operate without danger of electric shock.

SERVICE PERSONNEL WARNING

Eye damage may result from directly viewing the light produced by the Lamp used in this equipment. Always turn

off Lamp before opening cover. The Ultraviolet radiation eye protection required during this servicing.

Never turn the power on without the lamp to avoid electric-shock or damage of the devices since the stabilizer

generates high voltages(15kV - 20kV) at its starts.

Since the lamp is very high temperature during units operation replacement of the lamp should be done at least

45 minutes after the power has been turned off, to allow the lamp cool-off.

PRODUCT SAFETY NOTICE

Product safety should be considered when a component replacement is made in any area of the projector.

Components indicated by mark in the parts list and the schematic diagram designate components in which

safety can be of special significance. It is, therefore, particularly recommended that the replacement of there parts

must be made by exactly the same parts.

■ Safety Instructions

- 3 -

CAUTION

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE INSTRUCTIONS.

CAUTION

Not for use in a computer room as defined in the Standard for the Protection of Electronic Computer/Data

Processing Equipment, ANSI/NFPA 75.

Ne puet être utillisé dans une salle d’ordinateurs telle que définie dans la norme ANSI/NFPA 75 Standard for

Protection of Electronic Computer/Data Processing Equipment

Owner’s Manual

AC Power Cord

Wireless/Wired Remote Control Transmitter and Batteries

6 Types Light-Block Sheet (For option lens)

2 Types Lens Attachment (For option lens)

Real Color Manager Pro

1.64" TFT Active Matrix type, 3 panels

Multi-media Projector

82.0 lbs (37.2 kg)

22.9" x 10" x 30.9" (581 mm x 252 mm x 783 mm)

2048 x 1080 dots

6,635,520 (2048 x 1080 x 3 panels)

PAL, SECAM, NTSC, NTSC4.43, PAL-M and PAL-N (With option video board)

Up, Down, Left and Right

Projector Type

Net Weight

Dimensions

(W x H x D)

Panel Resolution

Number of Pixels

Color System

Scanning Frequency

LCD Panel System

300 watt type x 4

Projection Lamp

480i, 480p, 575i, 575p, 720p, 1035i, 1080i-50 and 1080i-60

Component Signal

H-sync. 15 ~ 120 KHz, V-sync. 24 ~ 120 Hz

Motorized Lens Shift

BNC Type x 4 (Dual-link SDI Input /Output A and B ) Y/Cb/Cr, RGB format compatible

Input 1 Jacks

BNC Type x 5 (R/Pr, G/Y, B/Pb, H/HV and V), RCA Type (Audio R and L)

and DIN 8-pin (Control port)

Input 2 Jacks

DVI-I Terminal (Digital/Analog), RCA Type (Audio R and L)

and DIN 8-pin (Control port)

Input 3 Jacks

Accessories

41 ˚F ~ 86 ˚F (5 ˚C ~ 30 ˚C)

14 ˚F ~ 140 ˚F (-10 ˚C ~ 60 ˚C)

Operating Temperature

Storage Temperature

0˚ to 5.7˚

Feet Adjustment

AC 120 V (16 A Max. Ampere), 50 / 60 Hz

(The U.S.A and Canada)

AC 200 ~ 240 V (9.0 A Max. Ampere), 50 / 60 Hz

(Continental Europe and The U.K.)

Voltage and

Power Consumption

Serial port in (DB 9), Serial port out (DB 9), USB port and

Audio out (RCA Type R and L)

Other Jacks

Power Source : AA or R06 Type x 2

Operating Range : 16.4’ (5m) / ±30˚

Dimensions : 2.0” x 1.1” x 7.1” (50mm x 29mm x 181mm)

Net Weight : 0.34 lbs (154 g) (including batteries)

Remote Control Transmitter

● Specifications are subject to change without notice.

● LCD panels are manufactured to the highest possible standards. At least 99.99% of the pixels are effective,

however a tiny fraction of the pixels (0.01% or less) may be ineffective by the characteristics of the LCD

panels.

● Each projector has its own characteristics.

When projecting with several projectors on the same screen or side by side, you may recognize different

white balance and color uniformity on each projector.

This symbol on the nameplate means the product is Listed by Underwriters Laboratories

Inc. It is designed and manufactured to meet rigid U.L. safety standards against risk of

fire, casualty and electrical hazards.

The CE Mark is a Directive conformity mark of the European Community (EC).

- 4 -

■ Technical Specifications

This projector provides the following circuit protections to operate in safety. If the abnormality occurs inside the projector, it will automatically turn off by operating one of the following protection circuits.

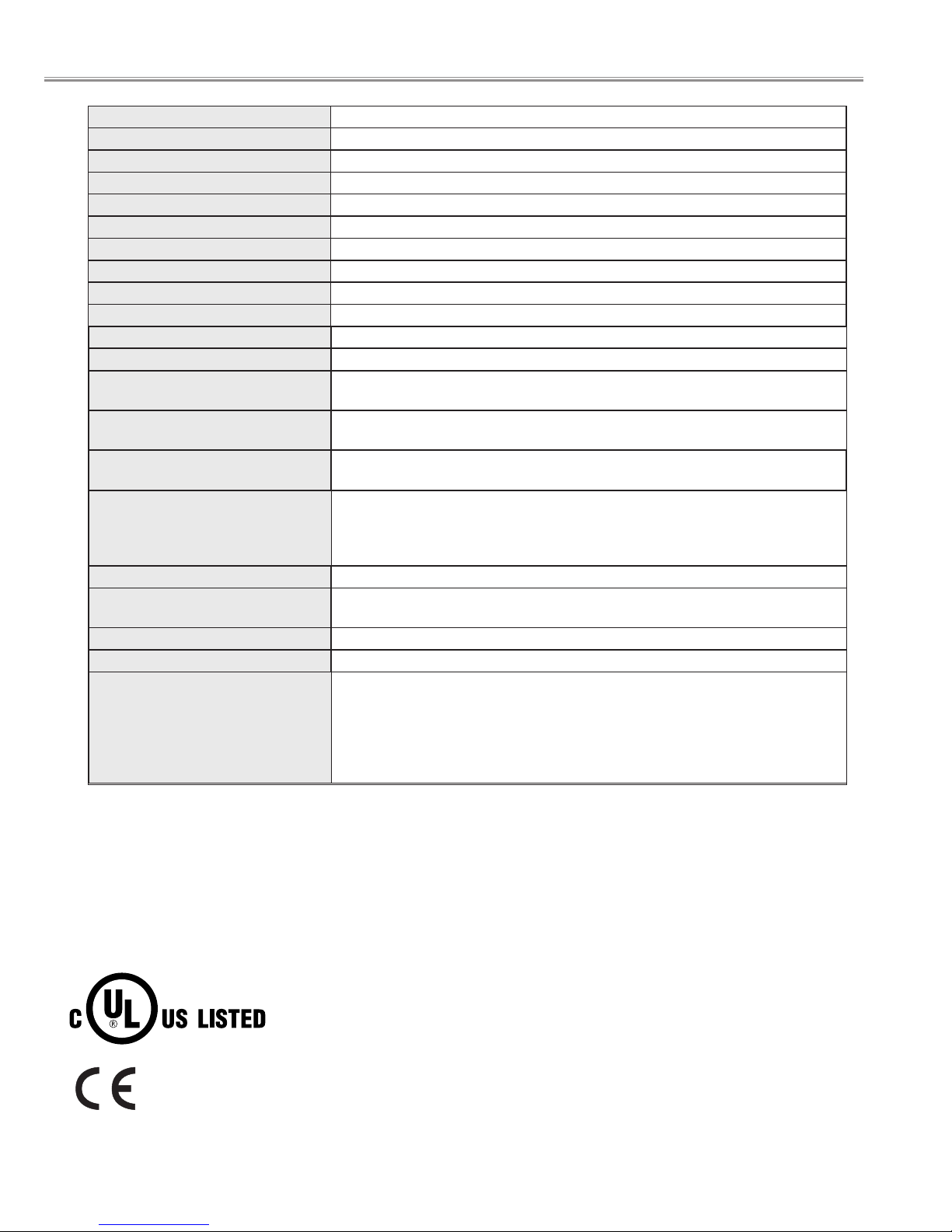

A fuse(F901) is located inside of the projector. When the

POWER indicator is not lighting, the fuse may be

opened. Check the fuse as following steps.

The fuse should be used with the following type;

● Fuse

How to replace the fuse

1. Remove the cabinet top following to "Mechanical

Disassemblies".

2. Remove the cover and the fuse from fuse holder.

To install the fuse, take reversed step in the above.

Fuse Part No.: 323 028 4202

TYPE 15.0A400V FUSE

SOC CORP. SHV14 15A N4

Fuse Part No.: 323 033 1807

TYPE 30.0A250V FUSE

SOC CORP. KST2 30A

PLV-HD2000E

PLV-HD2000N

Fuse (F901)

Fuse (F901)

Cover

Cover

Fuse

Fuse

Holder

Holder

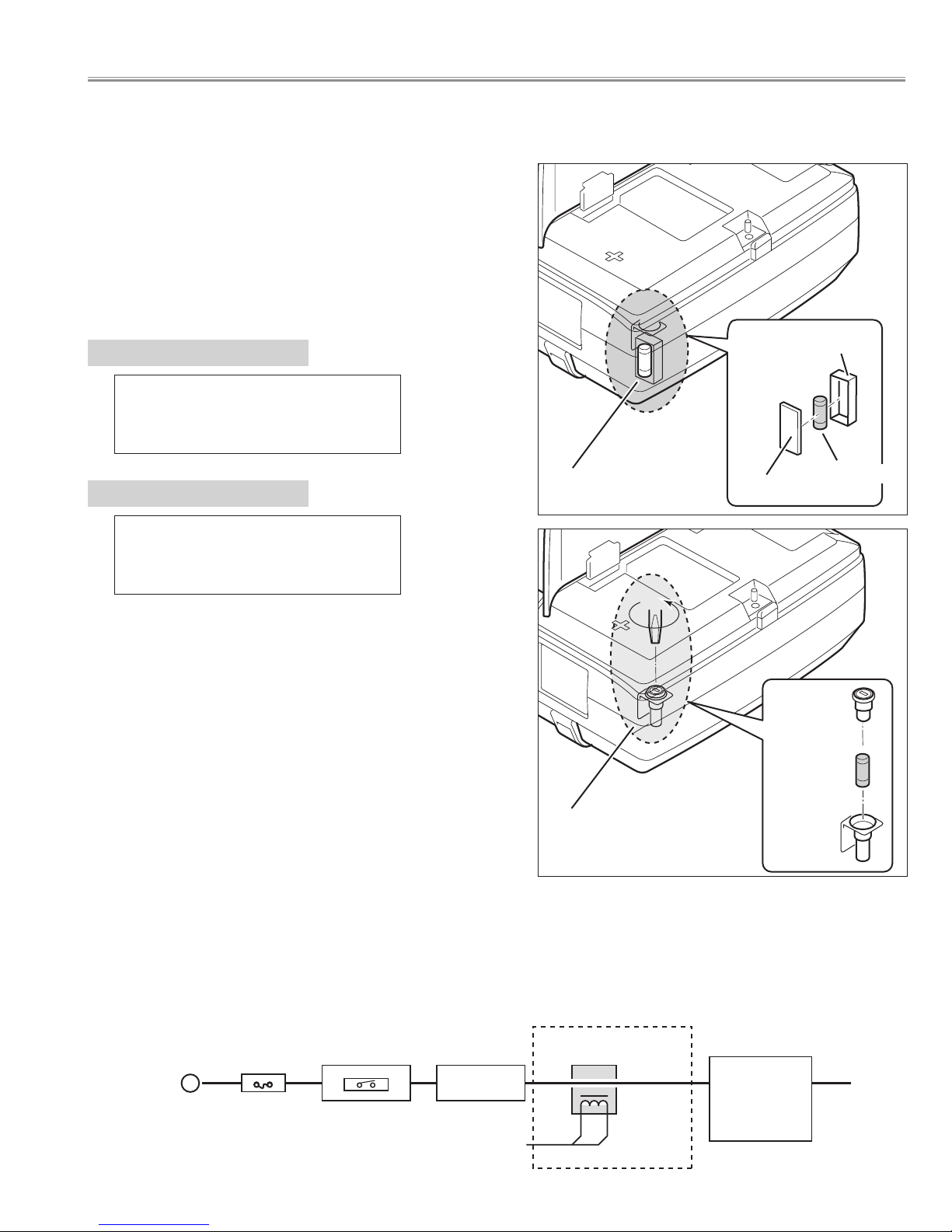

● AC Current Sensor

AC current sensor is used only for PLV-HD2000E.

The AC Current Sensor is provided to prevent damage to the power supply circuits.

When AC input voltage is under 108V at MAINS SW ON, the AC Current Sensor will be operated and the CPU

does not turn the projector on, and both of READY and WARNING TEMP. indicators start flashing.

Check that the AC current sensor signal is correct. L : Abnormality

K96W

- 5 -

■ Circuit Protections

Hot circuit

AC-INPUT

FUSE

F901

MAINS SW

SW901

NOISE FILTER

LF901

CURRENT SENSOR

A903

ASS'Y POWER

Circuit Protections

Lamp Cover switch

SW902

When the lamp cover is removed or no close completely, the lamp cover switch (SW902) cuts off

12V_PFC line to the PFC unit, and then a projector will

be shut down.

After opening the lamp cover for replacing the lamp

unit, place the lamp cover correctly, otherwise the projector can not be turned on.

Lamp Cover

● Lamp cover switch

● Power Failure Protection

Power failure protection diodes detect abnormal voltage on the power supply circuits or the fan operation stop.

When both of the WARNING TEMP. and READY Indicators are flashing:

When the projector detects an internal problem, it will shut down

automatically and both of the WARNING TEMP. and READY Indicators starts

flashing. In this condition, the projector cannot be turned on even if you press

the POWER ON-OFF button on the remote control unit or on the side control.

If this case happened, disconnect and reconnect the AC power cord, and

then turn on the projector again to check its operation. If the projector shuts

down again or fails to be turned on, the internal check and repair will be

required.

Check items listed below;

● Power Failure Protection

● AC Current Sensor (See the previous page.)

● Temperature Check of Lamps

● Lamp Cover Switch

READY

LAMP

LAMP

REPLACE

WARNING

TEMP.

FRONT INDICATORS

WARNING TEMP.

Indicator

READY

Indicator

WARN ING

TEMP.

READY

LAMP

REPLACE

LAMP

REAR INDICATORS

Temperature switches (SW 903~906)

are arranged near the four lamps.

Temperature switches will operate, if

temperature reaches 110 degrees.

Temperature switches

--- open at 110 degrees.

SW903 ---Lamp1

SW904 ---Lamp2

SW905 ---Lamp3

SW906 ---Lamp4

When temperature switches become

open, they cut off 12V_PFC line to

PFC(power factor control) unit, and

then a projector will be shut down.

● Temperature Check of Lamps

Temperature switch

SW906 (For Lamp4)

Temperature switch

SW905 (For Lamp3)

Temperature switch

SW903 (For Lamp1)

Temperature switch

SW904 (For Lamp2)

- 6 -

READY

LAMP

LAMP

REPLACE

WARNING

TEMP.

When the WARNING TEMP. Indicator is flashing:

The WARNING TEMP. Indicator flashes red to let you know the internal

temperature of the projector exceeds the normal level. If the temperature goes

up further, the projector will be turned off automatically and the Ready indicator

will go out. (The WARNING TEMP. Indicator continues flashing.) After the

cooling-off period, the READY Indicator lights on again and the projector can be

turned on by pressing the POWER ON-OFF button on the remote control unit or

on the side control. When you turn on the projector, the WARNING TEMP.

Indicator will go out.

If the WARNING TEMP. Indicator is still flashing, check the followings;

● Installation

● Air Filter

● Temperature Monitor System

FRONT INDICATORS

WARNING TEMP.

Indicator

WARNING

TEMP.

READY

LAMP

REPLACE

LAMP

REAR INDICATORS

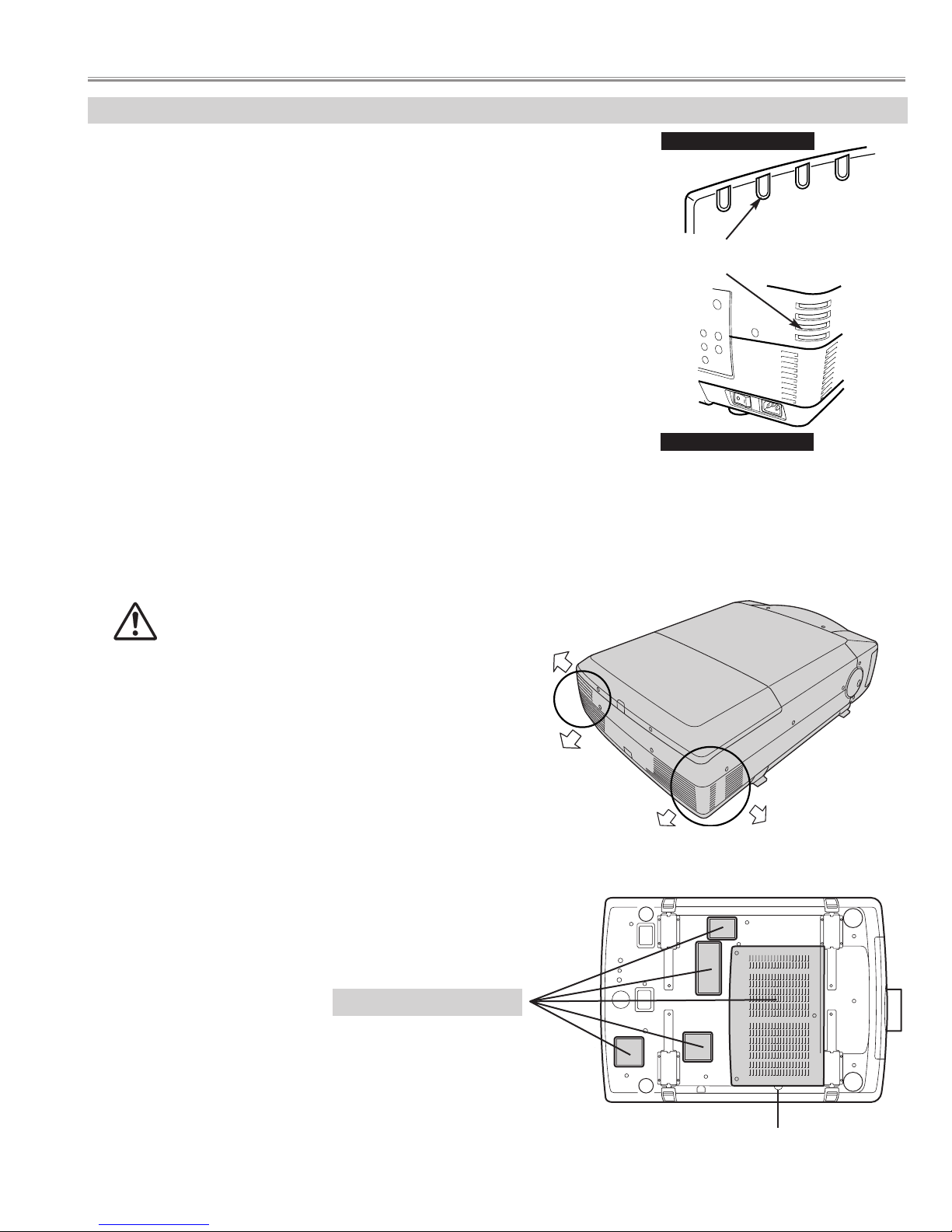

This projector is equipped with cooling fans for protection

from overheating. Pay attention to following to ensure proper ventilation and avoid a possible risk of fire and malfunction.

- Do not cover vent slots.

- Keep bottom clear any objects. Obstructions may block cooling air.

AIR INTAKE VENTS

EXHAUST VENTS

HOT AIR EXHAUSTED !

Air blown from exhaust vent is hot. When using

or installing a projector, following precautions

should be taken.

● Do not put flammable objects near these vents.

● Keep rear grills at least 3’ (1m) away from any object,

especially heat-sensitive object.

● Do not touch this area, especially screws and metallic

parts. This area will become hot while a projector is used.

HOT

● Installation

● Air Filter

- Air filter is clogged with dust particles. Remove dust from the air filter by following instruction in the "Air filter care

and cleaning".

- Ventilation slots of the projector are blocked. In such case, reposition the projector so that ventilation slots are not

obstructed.

- Check if projector is used at higher temperature place(Normal operate is 5 to 35°C or 41 to 95°F)

- 7 -

Circuit Protections

AIR FILTER

■ To control the driving power of the cooling fans.

This projector detects internal temperature and automatically controls operating power of cooling fans.

The CPU checks the temperature and atmospheric pressure inside a projector. It checks a temperature using

temperature sensor-IC5801and it checks an atmospheric pressure using pressure sensor-IC4849.

The CPU controls the driving power of the cooling fans so the temperature inside the projector is maintained to

normal temperature.

■ To shut down the projector.

The CPU checks temperature of Blue polarized glass (PTH901) and inhalation air(IC5801). If each part temperature reaches to abnormal temperature, the CPU will turn off a projector, and will blink WARNING TEMP. indicator at intervals of 0.5 seconds. Cooling fans operate until temperature returns to normal. WARNING TEMP.

indicator will stop blink, if temperature returns to normal.

● Temperature Monitor System

Main Board

A-side

Front side

B-side

Temp. Sensor

IC1519

Temp. Sensor

(Inhalation air)

IC5801

Pressure Sensor

IC4849

Temp. Sensor

(Blue polarized glass)

PTH901

Temperature sensors location

Blue polarizer unit

- 8 -

Circuit Protections

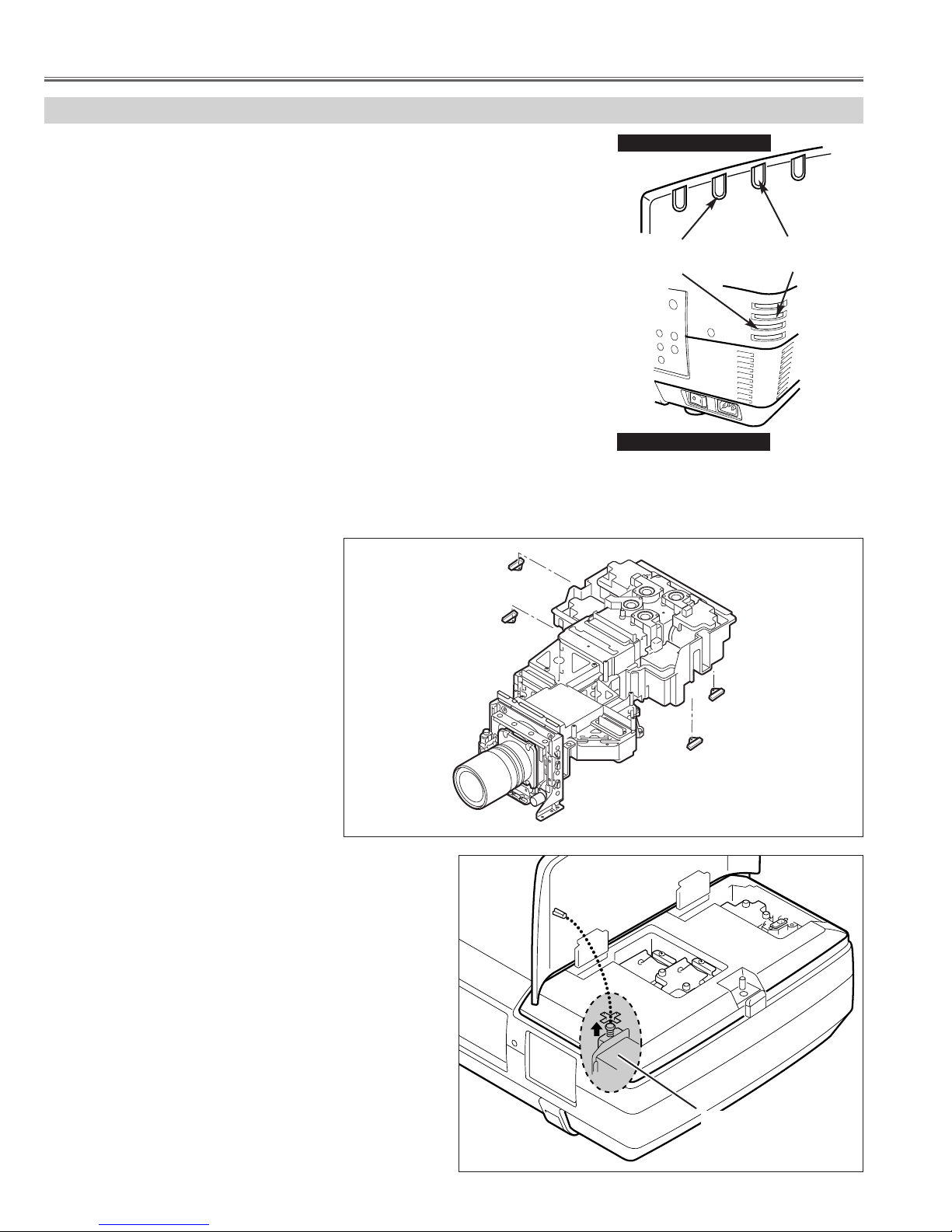

This Projector is equipped with 4 Projection Lamps to ensure brighter image and those lamps are controlled by Lamp

Management Function. Lamp Management Function detects status of all lamps and shows status on screen or on LAMP

REPLACE indicator. This function also automatically controls Lamp Mode when any of lamps is out for end of life or

malfunctions.

Projection Lamp lights normally.

Lamp Replace Indicator

This LAMP REPLACE indicator lights yellow when any of Projection Lamps is nearing its end, and flashes when any of them

becomes out. Check number of lamp on Lamp Status Display and replace lamp.

Yellow Lamp

Dim Lamp

X Mark on Lamp

Red Lamp

LAMP REPLACE

INDICATOR

Projection Lamp is turned off.

Projection Lamp is nearing its end. When image becomes

darker or color becomes unnatural, replace lamp. (LAMP

REPLACE indicator lights yellow.)

(LAMP REPLACE indicator flashes yellow.)

Projection lamp is defective or fails to be turned on. Restart

a projector on, and make sure lamp is on. If this mark still

appears, replace lamp corresponding with number marked

X.

LAMP STATUS

DISPLAY

Lamp Mode Changeover

Lamp Management Function automatically changes combination of lighting lamp (Lamp Mode) by detecting status of lamp.

When any of 4 lamps becomes out, Lamp Mode is changed over from 4 lamps to 2 lamps. And when any of 2 lamps are out,

a projector operates with 1 lamp. Lamp Mode can be switched to 4 lamps or 2 lamps manually.

4 LAMP MODE

2 LAMP MODE

(Example)

1 LAMP MODE

(Example)

Lamp Status Display

Lamp Status Display appears on screen when power switch is on or changed input position (input 1, input 2, Input 3 or input 4).

This shows status of each lamp as; ON, OFF, NEAR END, or OUT. Refer to following for each status.

20

INPUT AND LAMP STATUS

LAMP MANAGEMENT (before replacement)

- 9 -

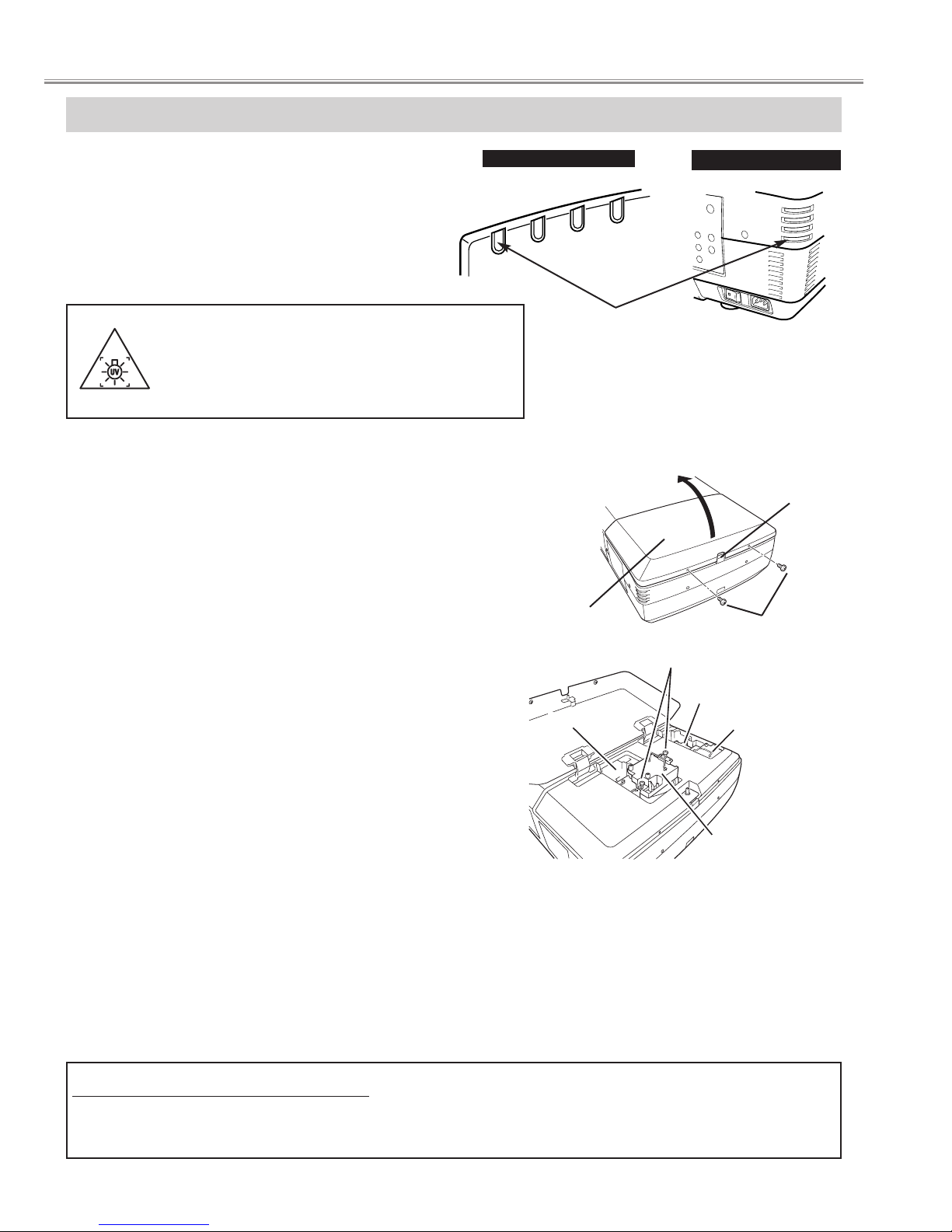

■ Lamp Replacement

LAMP REPLACEMENT

Check number of lamp to be replaced on Lamp Status

Display.

Remove two screws on Lamp Cover and press button to

open Lamp Cover. (See right figure.)

1

3

Loosen two screws and pull out Lamp Assembly to be

replaced by grasping handle.

4

Turn off a projector and disconnect AC Power Cord.

Allow a projector to cool down for at least 45 minutes.

2

Replace Lamp Assembly with a new one and tighten two

screws. Make sure Lamp is set properly.

6

Follow these steps to replace lamp assembly.

Replace Lamp Cover and tighten two screws.

5

7

8

Connect AC Power Cord to a projector and turn a

projector on.

Reset Lamp Replacement Counter. (Refer to section

"Lamp Replace Counter".)

NOTE : Do not reset LAMP REPLACEMENT COUNTER when

lamp is not replaced.

BUTTON

SCREWS

SCREWS

LAMP1

LAMP2

LAMP

COVER

Make sure which number of lamp needs to

be replaced on Lamp Status Display.

Figure shows case of replacing LAMP 2.

CAUTION : Do not operate a Projector while any of lamps removed.

It may result in malfunctions, fire hazard, or other accidents.

NOTES ON LAMP REPLACEMENT

To maintain quality of picture (better balance of color and brightness in entire screen), we recommend replacing all 4 lamps at a time.

CAUTION : High pressure lamp may explode if improperly handled.

Refer to lamp replacement instructions.

When the life of the projection lamp of this projector

draws to an end, the LAMP REPLACE indicator

lights yellow. If this indicator lights yellow, replace

the lamp with a new one promptly.

The time when the LAMP REPLACE indicator lights

is depending on the lamp mode.

LAMP3

LAMP4

WARNING :

TURN OFF THE UV LAMP BEFORE OPENING

THE LAMP COVER. USE UV RADIATION EYE

AND SKIN PROTECTION DURING SERVICING.

REAR INDICATORS

READY

LAMP

LAMP

REPLACE

WARNING

TEMP.

WARNING

TEMP.

READY

LAMP

REPLACE

LAMP

FRONT INDICATORS

LAMP REPLACE

INDICATOR

- 10 -

Lamp replacement

CAUTION

Do not drop a lamp assembly or touch a glass

bulb! Glass can shatter and may cause injury.

CAUTION

For continued safety, replace with a lamp

assembly of same type.

Allow a projector to cool for at least 45 minutes

before you open Lamp Cover. Inside of a

projector can become very hot.

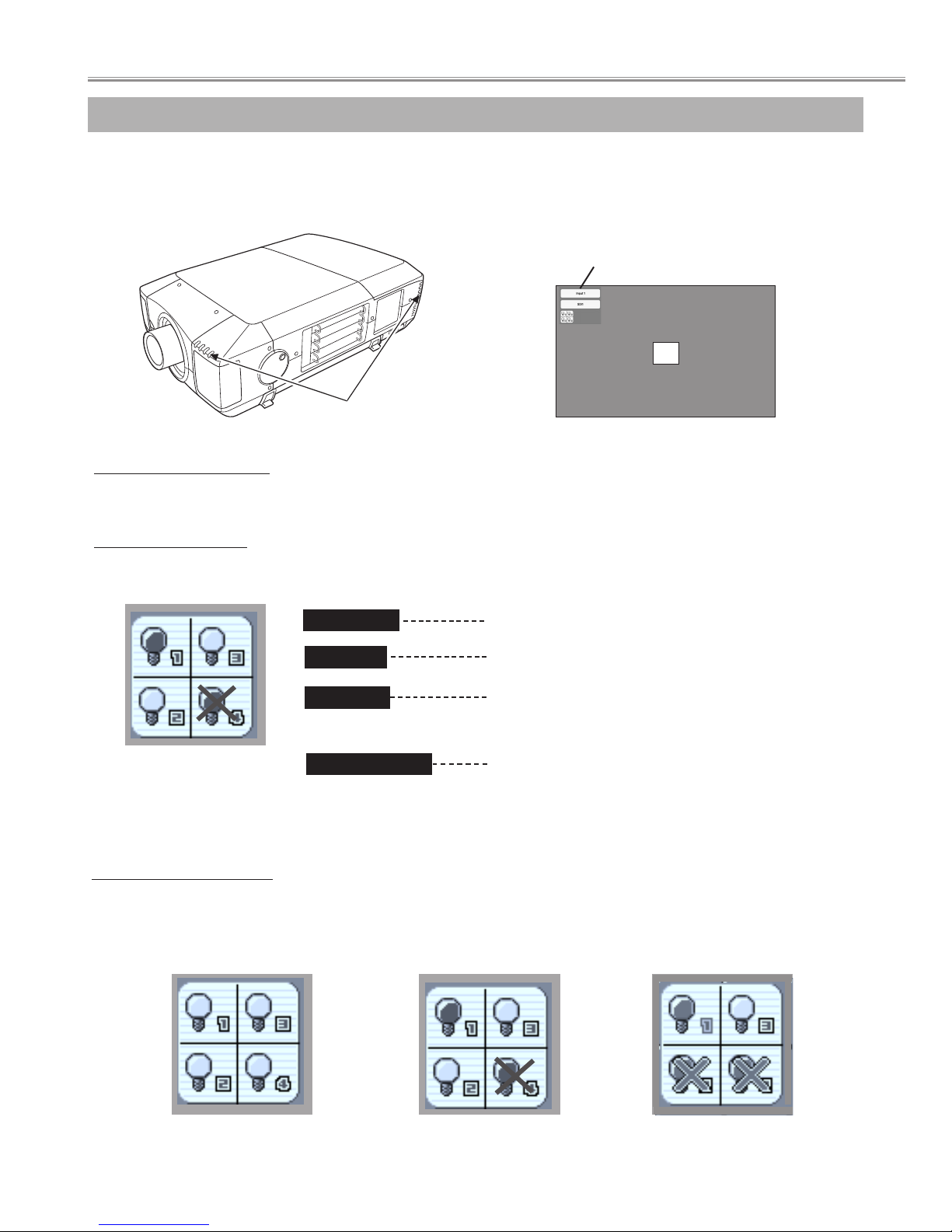

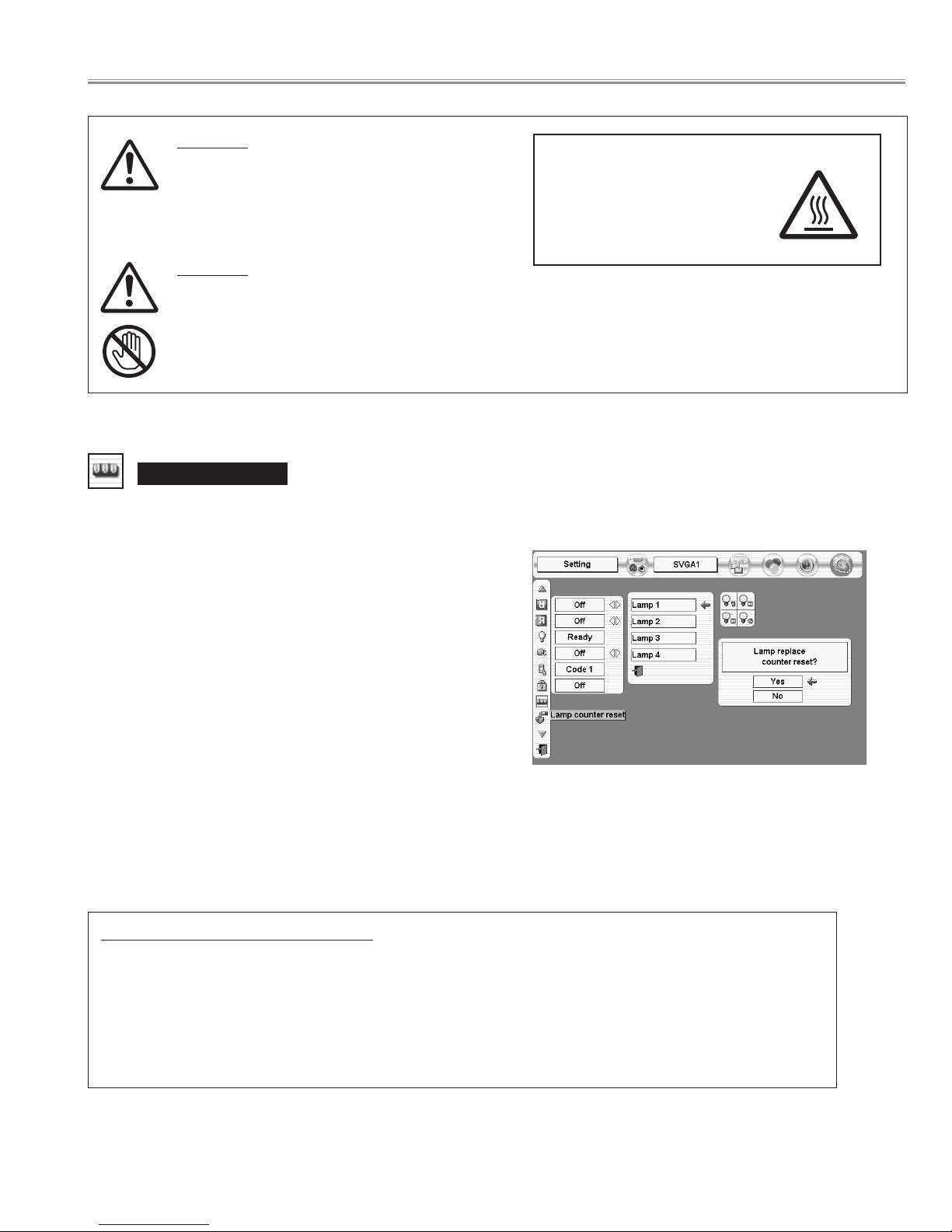

Lamp counter reset

Be sure to reset Lamp Counter when Lamp Assembly is replaced. When Lamp Replace Counter is reset, LAMP

REPLACE indicator stops lighting.

Turn projector on, press MENU button and ON-SCREEN

MENU will appear. Press POINT LEFT/RIGHT button(s) to

move a red frame pointer to SETTING Menu icon.

1

Press POINT DOWN button to move a red frame pointer to

“Lamp counter reset” and then press

SELECT button.

2

Do not reset Lamp Replace Counter except after Projection lamp is

replaced.

Another confirmation dialog box appears and select [Yes] to

reset Lamp Replace Counter.

4

Move arrow to replaced lamp number (Lamp 1, Lamp 2, Lamp 3

or Lamp 4) and then press

SELECT button. Message "Lamp

replace counter Reset?" is displayed. Move pointer to [Yes] and

then press SELECT button.

3

NOTE: Be sure to reset correct lamp number otherwise LAMP

REPLACE indicator continues lighting.

ORDER REPLACEMENT LAMP

Replacement Lamp can be ordered through your dealer. When ordering a Projection Lamp, give the

following information to the dealer.

●

Model No. of your projector : PLV-HD2000N / PLV-HD2000E

● Replacement Lamp Type No. : POA-LMP100

(Service Parts No. 610 327 4928)

- 11 -

Lamp replacement

CAUTION

HIGH VOLTAGE

HOT

This projector uses a high-pressure lamp which must be handled carefully and properly. Improper handling

may result in accidents, injury, or create a fire hazard.

● Lamp lifetime may differ from lamp to lamp and according to the environment of use. There is no

guarantee of the same lifetime for each lamp. Some lamps may fail or terminate their lifetime in a shorter

period of time than other similar lamps.

● If the projector indicates that the lamp should be replaced, i.e., if the LAMP REPLACE INDICATOR lights

up, replace the lamp with a new one IMMEDIATELY after the projector has cooled down.

( Follow carefully the instructions in the LAMP REPLACEMENT section of owner's manual. ) Continuous

use of the lamp with the LAMP REPLACE INDICATOR lighted may increase the risk of lamp explosion.

● A Lamp may explode as a result of vibration, shock or degradation as a result of hours of use as its

lifetime draws to an end. Risk of explosion may differ according to the environment or conditions in which

the projector and lamp are being used.

IF A LAMP EXPLODES, THE FOLLOWING SAFETY PRECAUTIONS SHOULD BE TAKEN.

If a lamp explodes, disconnect the projector’s AC plug from the AC outlet immediately. Contact an

authorized service station for a checkup of the unit and replacement of the lamp. Additionally, check

carefully to ensure that there are no broken shards or pieces of glass around the projector or coming out

from the cooling air circulation holes. Any broken shards found should be cleaned up carefully. No one

should check the inside of the projector except those who are authorized trained technicians and who are

familiar with projector service. Inappropriate attempts to service the unit by anyone, especially those who

are not appropriately trained to do so, may result in an accident or injury caused by pieces of broken glass.

LAMP HANDLING PRECAUTIONS

- 12 -

Lamp replacement

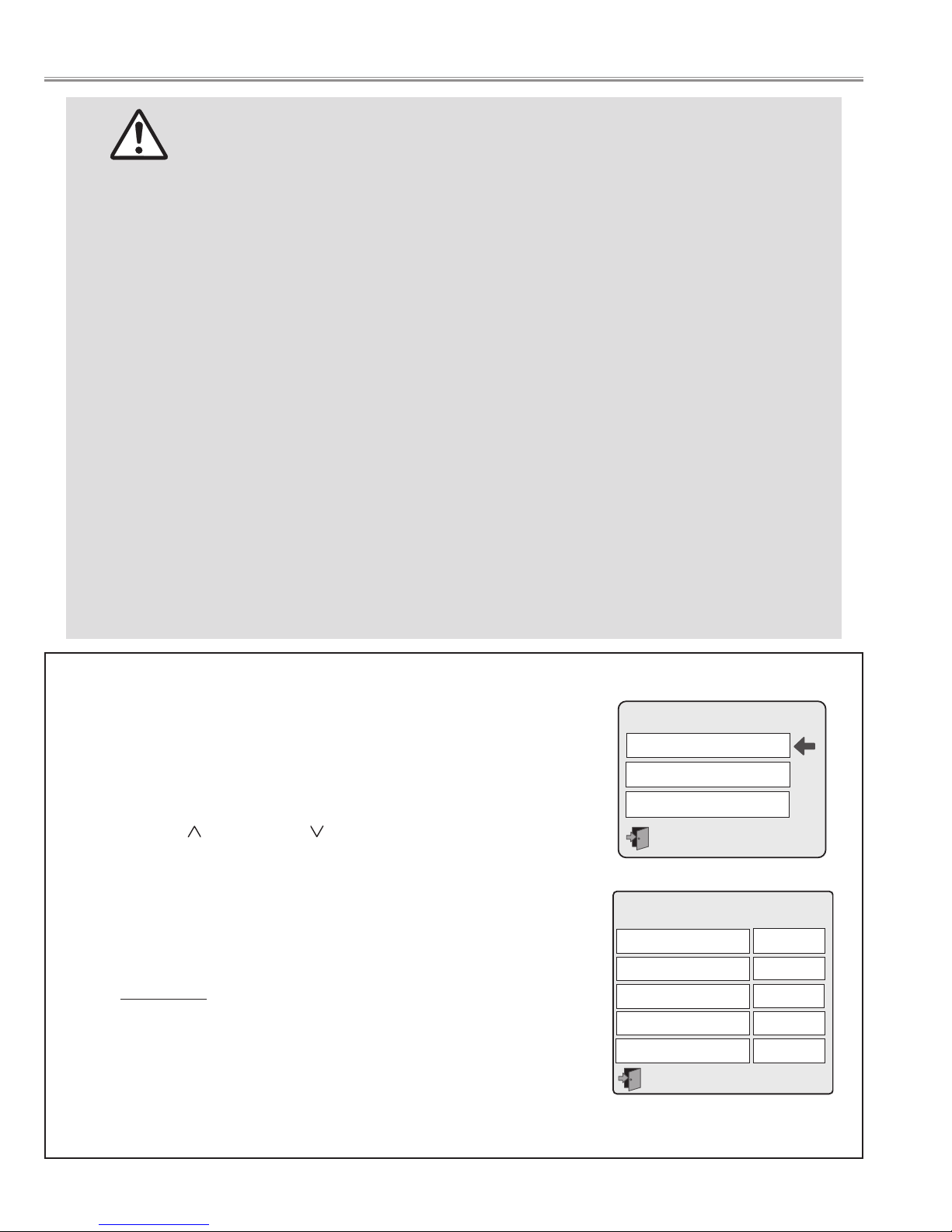

You can check the lamp used time and projector used time following to below

procedure.

1 Enter special menu mode.

Press and hold POWER ON-OFF button on the side control of the projector

or the remote control unit for more than 20 seconds.

Press point Up( ) and DOWN ( )buttons to select "Counter" and than

press "SELECT" button.

2 The projector used time and lamp used time will be displayed on the screen.

3 Press Power button "ON-OFF" once and close the special menu mode.

The LAMP REPLACE indicator will light yellow when the total lamp used time

reaches 2,000 hours - (✽). This is to indicate that lamp replacement is

required.

(✽) The specification is subject to change without notice.

● How to check Lamp Used Time

Special

Counter

Fan control

RS232C

Counter

Projector

Lamp 1

Lamp 2

Lamp 3

Lamp 4

123H

123H

123H

123H

123H

After long periods of use, dust and other particles will accumulate on the LCD panel, prism, mirror, polarized glass,

lens, etc., causing the picture to darken or color to blur. If this occurs, clean the inside of optical unit.

Remove dust and other particles using air spray. If dirt cannot be removed by air spray, disassemble and clean the

optical unit.

● Cleaning with air spray

1. Remove the cabinet top following to "Mechanical Disassemblies".

2. Clean up the LCD panel and polarized glass by using the air spray from the cabinet top opening.

Caution:

Use a commercial (inert gas) air spray designed for cleaning camera and computer equipment. Use a resin-based nozzle only. Be vary careful not to damage optical parts with the nozzle tip. Never use any kind of cleanser on the unit. Also,

never use abrasive materials on the unit as this may cause irreparable damage.

● Disassembly Cleaning

Disassembly cleaning method should only be performed when the unit is considerable dirty and cannot be sufficiently cleaned by air spraying alone.

Be sure to readjust the optical system after performing disassembly cleaning.

1. Remove the cabinet top and main units following to "Mechanical Disassemblies".

2. Remove the optical base top following to"Optical Unit Disassemblies". If the LCD panel needs cleaning, remove the

LCD panel unit following to "LCD panel/Prism ass'y replacement".

3. Clean the optical parts with a soft cloth. Clean extremely dirty areas using a cloth moistened with alcohol.

Caution:

The surface of the optical components consists of multiple dielectric layers with varying degrees of refraction.

Never use organic solvents (thinner, etc.) or any kind of cleanser on these components.

Since the LCD panel is equipped with an electronic circuit, never use any liquids (water, etc.) to clean the unit. Use of

liquid may cause the unit to malfunction.

Unplug the AC power cord before cleaning.

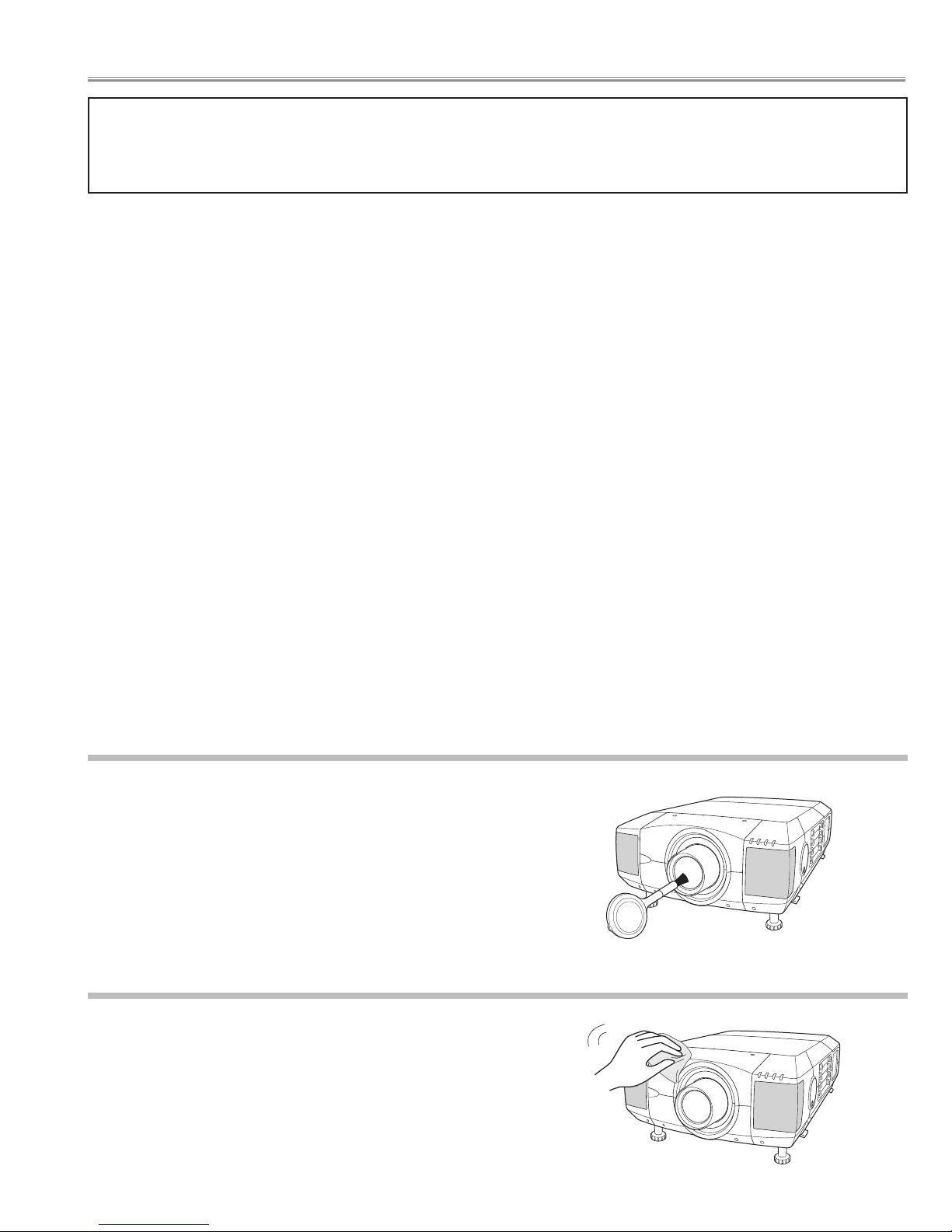

Gently wipe the projection lens with a cleaning cloth that contains

a small amount of non-abrasive camera lens cleaner, or use a

lens cleaning paper or a commercially available air blower to clean

the lens. Avoid using an excessive amount of cleaner. Abrasive

cleaners, solvents, or other harsh chemicals might scratch the

surface of the lens.

Cleaning the Projection Lens

Cleaning the Projector Cabinet

Unplug the AC power cord before cleaning.

Gently wipe the projector body with a dry soft cloth. When the

cabinet is heavily soiled, apply a small amount of mild detergent

and finish with a dry soft cloth. Avoid using an excessive amount

of cleaner. Abrasive cleaners, solvents, or other harsh chemicals

might scratch the surface of the cabinet.

- 13 -

■ Maintenance and Cleaning

AIR FILTER CARE AND CLEANING

Air Filter prevents dust from accumulating on surface of Projection Lens and Projection Mirror. Should Air Filter

become clogged with dust particles, it will reduce Cooling Fans' effectiveness and may result in internal heat build up

and adversely affect life of a projector.

Clean Air Filter following steps below:

1

Turn power off, and disconnect AC power cord from AC

outlet.

2

Pull out air filter unit from the projector.

3

Pulling up center frame of air filter top, separate air filter

top and sheet from air filter base.

4

Clean each parts with brush, vacuum cleaner dust and

particles.

5

Assemble sheet, air filter top and air filter base, and

replace air filter unit to a projector.

CAUTION

- Do not operate a projector with air filter removed.

Or dust may accumulate on LCD panel and

Mirror degrading picture quality.

- Do not put small parts into air Intake Vents. Or It

may result in malfunction of a projector.

- The filter be careful and handle. The effect of the

filter runs out in case of a leak and it being

broken off.

AIR FILTER UNIT

AIR FILTER TOP

AIR FILTER BASE

SHEET

Caution; Assembles sheet and filter base

- 14 -

Maintenance and Cleaning

NOTE: If the dust cannot be removed by cleaning, it is

probably time to replace the air filters with new

ones.

Air Filter Parts No. 610 301 4814

Before Disassemblies :

Turn off a projector and disconnect the AC power cord.

When remove the lens shift unit, shift to the position from which the attachment screws of a lens shift unit and an

optical base unit can be removed.

Disassemble should be made following procedures in numerical order.

Following steps show the basic procedures, therefore unnecessary step may be

ignored.

Caution:

The parts and screws should be placed exactly the same position as the original oth-

erwise it may cause lose of performance and product safety.

The wiring method of the leads and ferrite cores should be returned exactly the same

state as the original otherwise it may cause lose of performance and product safety.

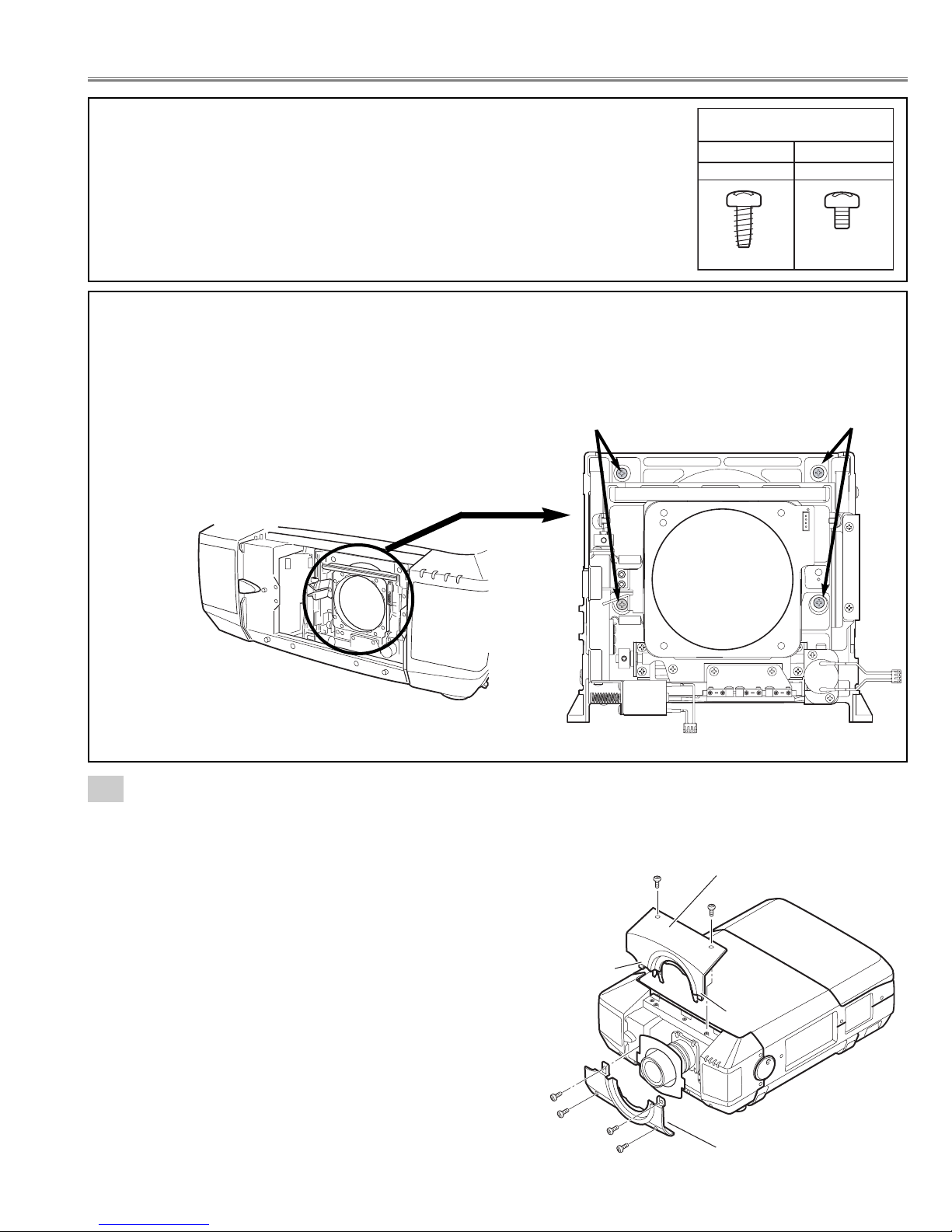

Screw

Screw

Lens shift unit is moved to the position

from which an attachment screws can

be removed, as shown in a figure.

Lens shift unit

- 15 -

Fig.1-1

1-1

Cabinet-front-top unit and Cabinet-front-bottom unit removal.

Note :Be careful not to damage Hook. The cabinet-front-top unit is being fixed with cabinet-front-bottom by hook.

1. Remove 2 screws-A.

Push part(a) and pull the Cabinet-front-top unit upward.

2. Remove 4 screws-B and remove the Cabinet-front-bottom unit.

(See Fig.1-1)

Refer to Lens replacement and installation manual.

■ Mechanical disassemblies

Screws Expression

(Type

Diameter x Length) mm

T type M Type

Ta pping screw Machine screw

A

Hook

(a)

B

B

B

B

Cabinet front top

unit

A

(a)

Cabinet front bottom unit

- 16 -

Fig.1-3

Fig.1-4

1-3

Cabinet front-top-unit disassemblies.

1. Remove 4 screws and remove the Mounting cover lens-A.

2. Remove 2 Spring coils and remove Cover lens-A.

(See Fig.1-3)

1-4

Cabinet front-bottom-unit disassemblies.

1. Remove 4 screws and remove the Mounting Cover lens-B.

2. Remove 2 Spring coils and remove Cover lens-A.

(See Fig.1-4)

Mechanical disassemblies

Fig.1-2

1-2

Cabinet-front unit removal.

1. Remove 11 screws and remove the Cabinet-front unit.

(See Fig.1-2)

A

A

A

A

A

Cabinet front unit

A

A

A

A

A

A

Cover lens-A

Spring coil-A

Cabinet front top

Mounting cover lens-A

Mounting cover lens-B

Cabinet front bottom

Spring

coil-B

Cover lens-A

- 17 -

Mechanical disassemblies

1-5

Speaker boxes and Front LED Board removal.

1. Remove 4 screws-A and remove the Speaker box-A.

2. Remove 4 screws-B and remove the Speaker box-B.

3. Remove 2 screws-C and remove the Front LED Board.

(See Fig.1-5)

Fig.1-5

1

-6

Decoration Inlays and R/C-1 Board removal.

1. Remove screw-A and remove the R/C-1 Board.

2. Remove 2 screws-B and remove the DEC Inlay R/C-F.

3. Remove 2 screws-C and remove the DEC Inlay-A.

(See Fig.1-6)

Fig.1-6

1

-7

Speaker Grills and Nets removal.

1. The bent portion is stretched and remove the Grille SP-L,

remove the Grille SP-R from cabinet front.

2. Remove the Nets.

(See Fig.1-7)

Mark the Grills as they are removed from the Cabinet front so that

they may be reassembled in the same location from which they

were removed. Be careful of the attached direction of Grills.

Fig.1-7

Speaker unit-A

A

A

C

A

A

Front LED Board

C

B

B

Speaker unit-B

B

B

Cabinet front

DEC Inlay R/C-F

Net

R/C 1 Board

B

B

A

C

C

DEC Inlay A

Cabinet front

Grill SP-L

Grill SP-R

Net

- 18 -

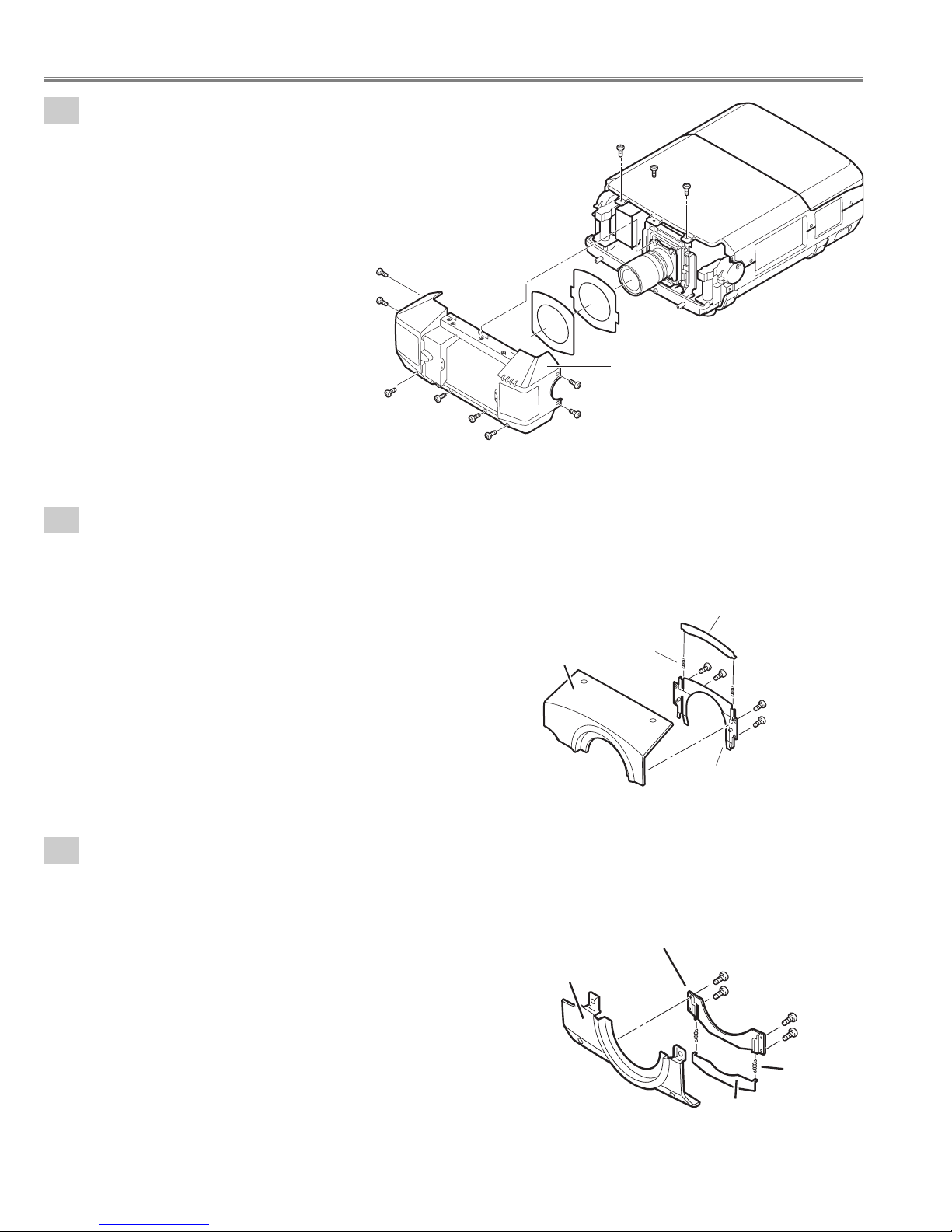

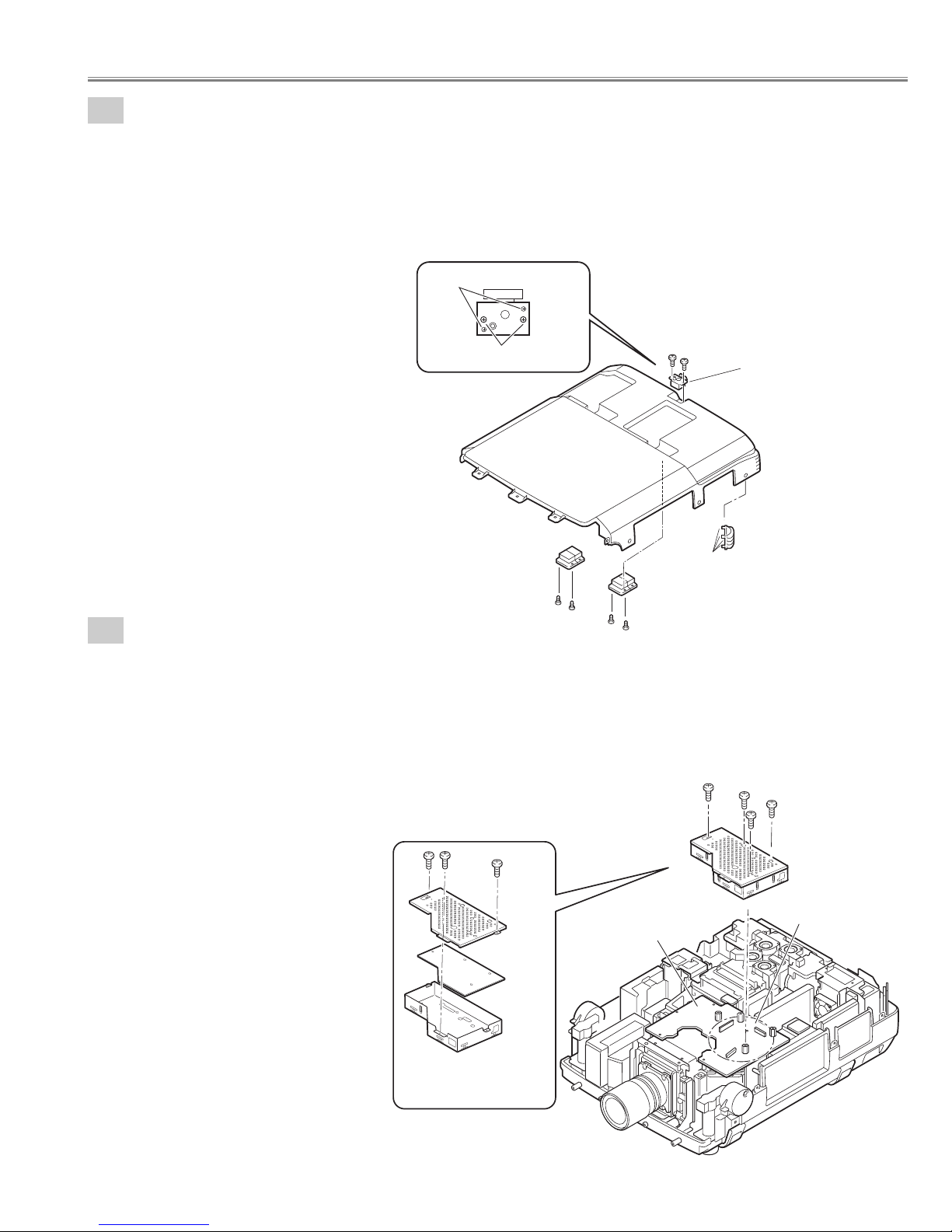

2-1

Cabinet-top unit removal.

1. Remove 8 screws and remove the Cabinet-top unit.

(See Fig.2-1)

2-2

Lamp cover and Push Latch-B removal.

1. Remove 2 screws-A and press button to open the Lamp cover.

2. Remove 4 screws-B and remove the Lamp cover.

3. Remove 2 screws-C and remove the Push Latch-B.

(See Fig.2-2, 2-2a)

Fig.2-1

Fig.2-1a

Fig.2-2

Fig.2-2a

Back View

Mechanical disassemblies

Cabinet top unit

Lamp cover

A

Press

Button

Push Latch-B

C

Lamp cover

Cabinet top

B

A

B

C

B

B

- 19 -

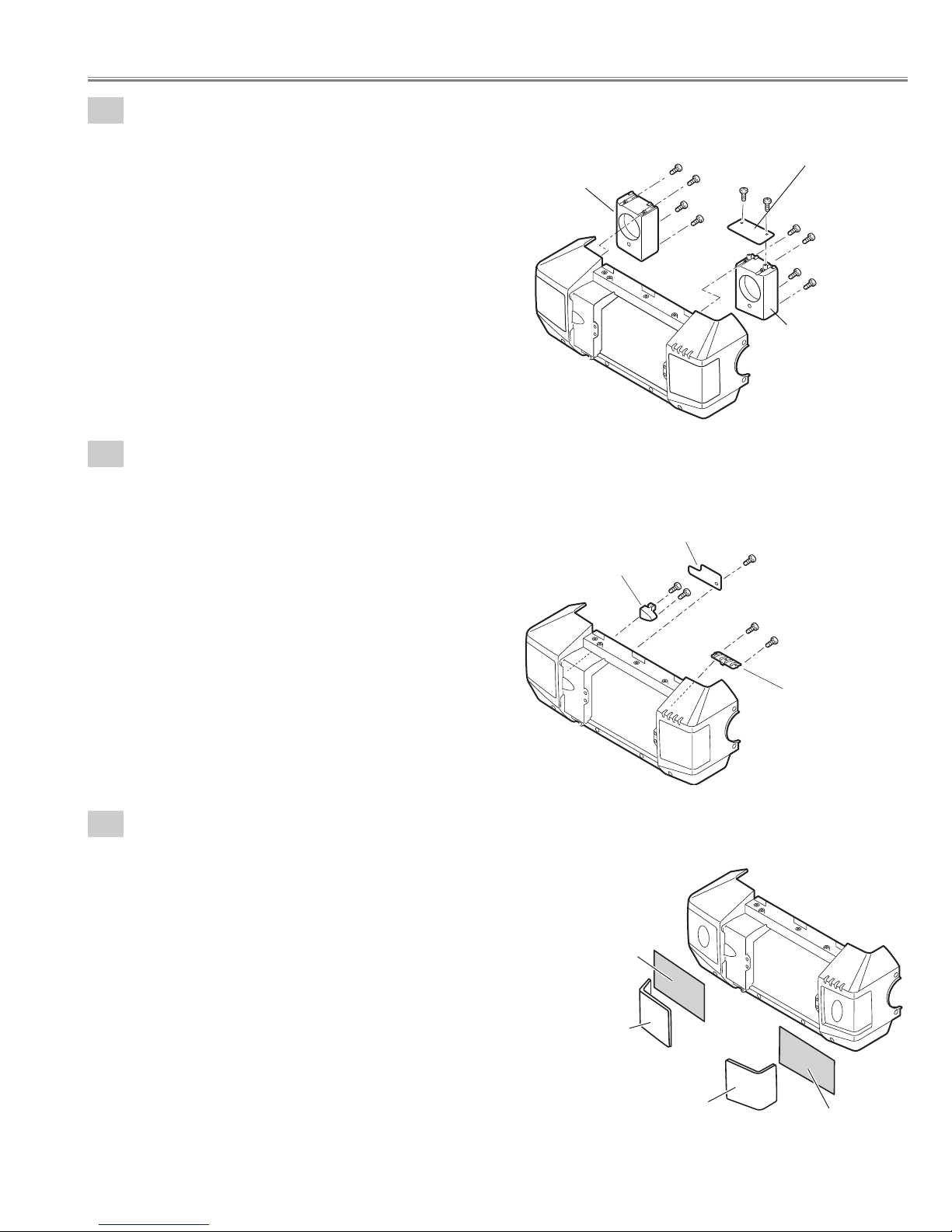

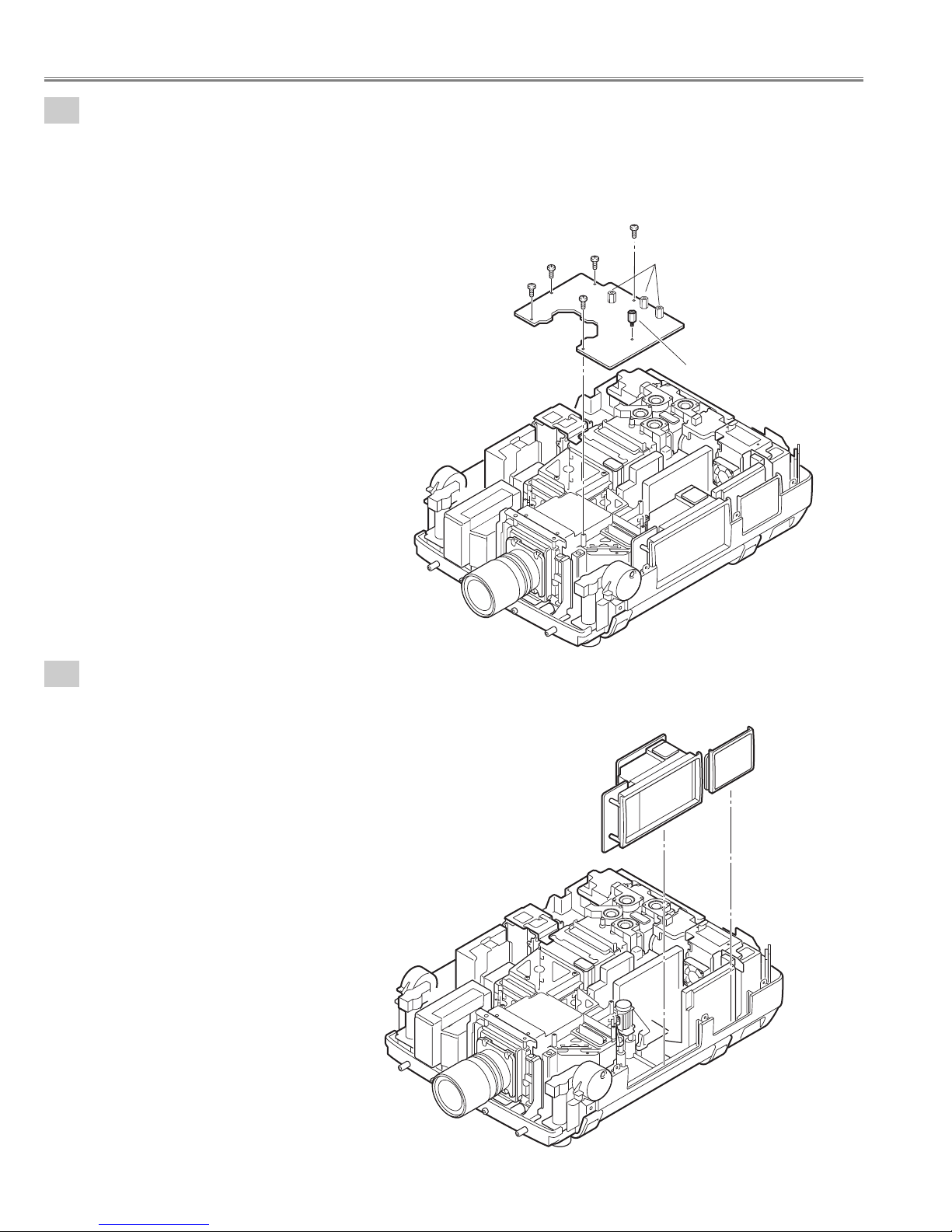

2-3

Decoration Inlay-B, Push Latch-A, and Hinges removal.

1. Remove 4 screws-A and remove the 2 Hinges.

2. Remove 2 screws-B and remove the push Latch-A.

3. Remove DEC Inlay-B. (Unhook the Cabinet top and take the DEC Inlay off inside.)

Push part(a) and pull the DEC Inlay inside.

(See Fig.2-3, 2-3a)

3

-1

BGA Board removal.

Fig.2-3

Fig.2-3a

Fig.3-1

Fig.3-1a

Mechanical disassemblies

1. Remove 4 screws-A and remove the BGA unit.

Be careful not to damage connector, Main Board and BGA Board are connected.

2. Remove 3 screws-B and disassemble the BGA unit.

(See Fig.3-1,3-1a)

Do not remove

Remove the screws

Cabinet top

B

B

Push Latch-A

Hook

Hinge

Hinge

A

A

A

A

B

B

B

Main Board

Shield BGA-B

(a)

A

DEC Inlay-B

A

A

A

BGA unit

Be careful connectors

BGA Board

Shield BGA-A

- 20 -

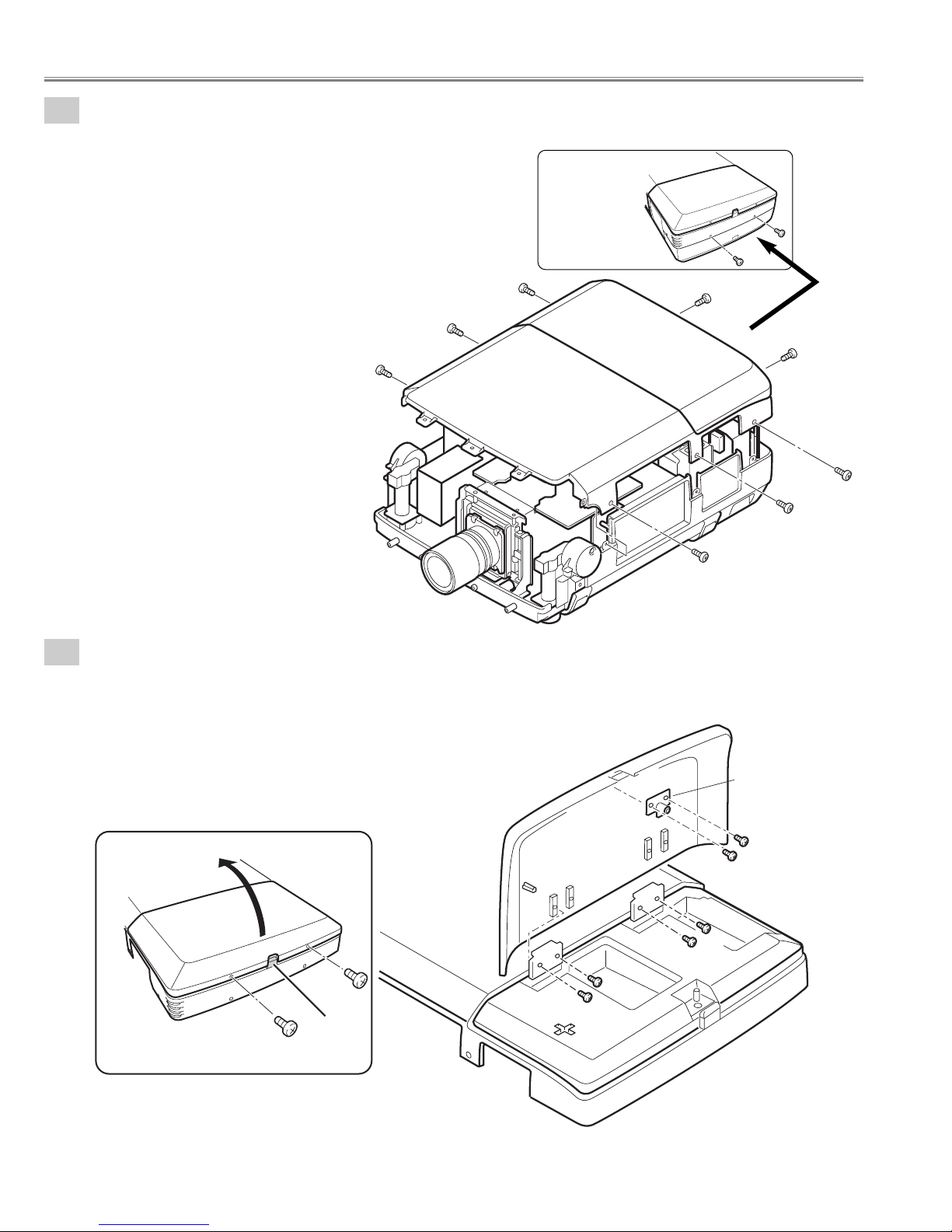

3-2

Main Board removal.

Remove the connectors and the flexible cables of the LCD panels from the Main Board.

(Never touch the electrode of flexible cables.)

1. Remove 5 screws-A.

2. Remove spacer-A and remove the Main Board.

(Do not remove the Spacer-B.)

(See Fig.3-2)

4-1

Control switch unit and Terminal slots unit removal.

1. Remove the Control switch unit upward.

2. Remove the Terminal slots unit upward.

(See Fig.4-1)

Fig.3-2

Fig.4-1

Mechanical disassemblies

A

MAIN Borad

A

A

A

A

Spacer-B

(Do not remove)

Spacer-A

Control-Switch

Unit

Terminal slots

Unit

- 21 -

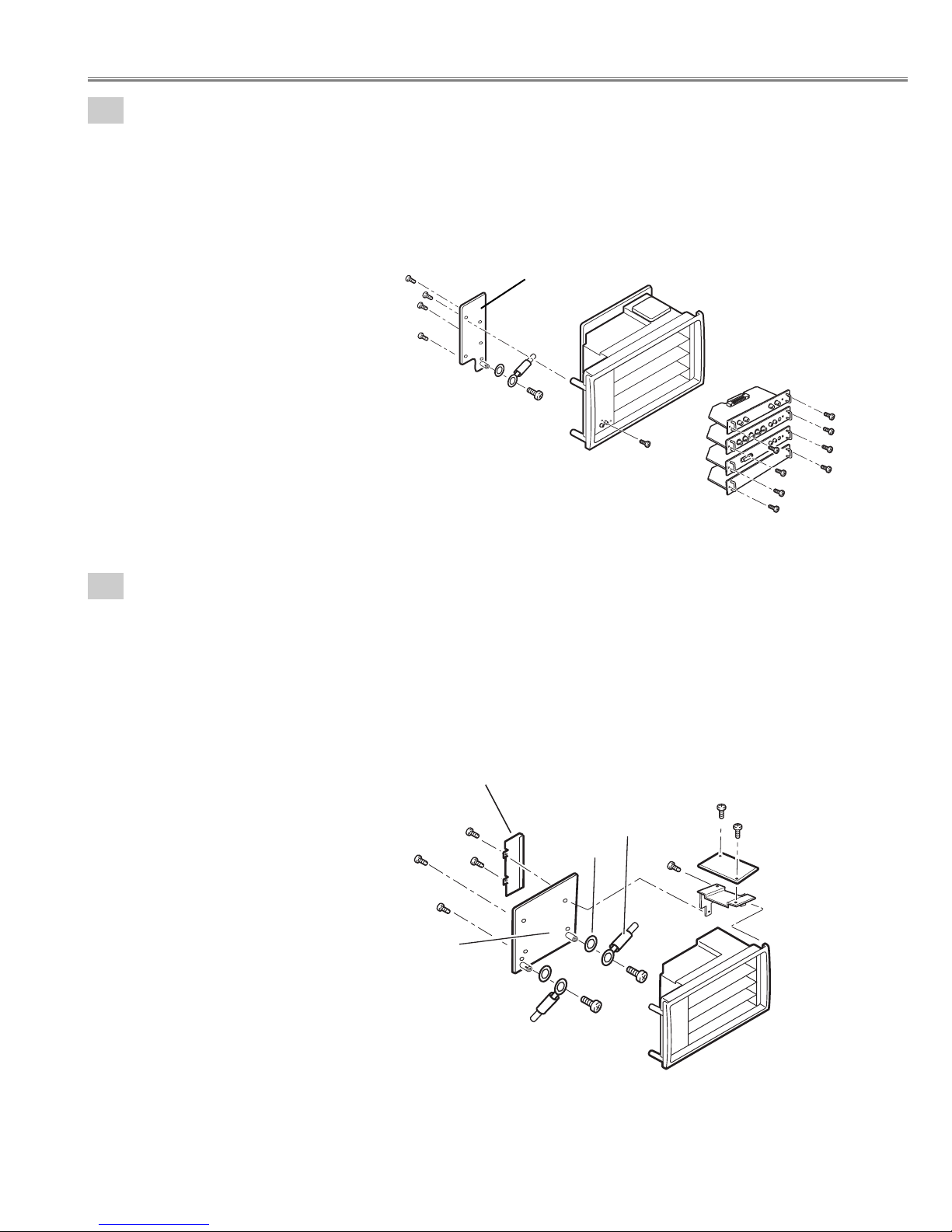

4-2

Terminal Board units and RS232C Board removal.

Fig.4-2

Fig.4-3

1. Remove 8 screws-A and remove the Terminal Board units 1-4.

2. Remove screw-B.

3. Remove 4 screws-C and remove the RS232C Board.

4. Remove screw-D and remove Grounding Lead from the RS232C Board.

(See Fig.4-2)

4

-3

Terminal Slot units disassemblies.

1. Remove 2 screws-A and remove the Lamp net Board.

2. Remove 2 screws-B and remove the Holder-A.

3. Remove 3 screws-C, remove the Holder-B and remove the Mother Board.

4. Remove 2 screws-D, remove 2 washers and remove Grounding Leads from the Mother Board.

(See Fig.4-3)

Mechanical disassemblies

RS232C Board

C

C

C

C

D

B

Terminal Board

units 1-4

A

A

A

A

A

A

A

A

CG Mother Board

C

Holder-B

B

B

C

Washer

Grounding Lead

Grounding Lead

Washer

D

D

A

A

C

Lamp net Board

Holder-A

Panel

- 22 -

Fig.4-5

Fig.4-4

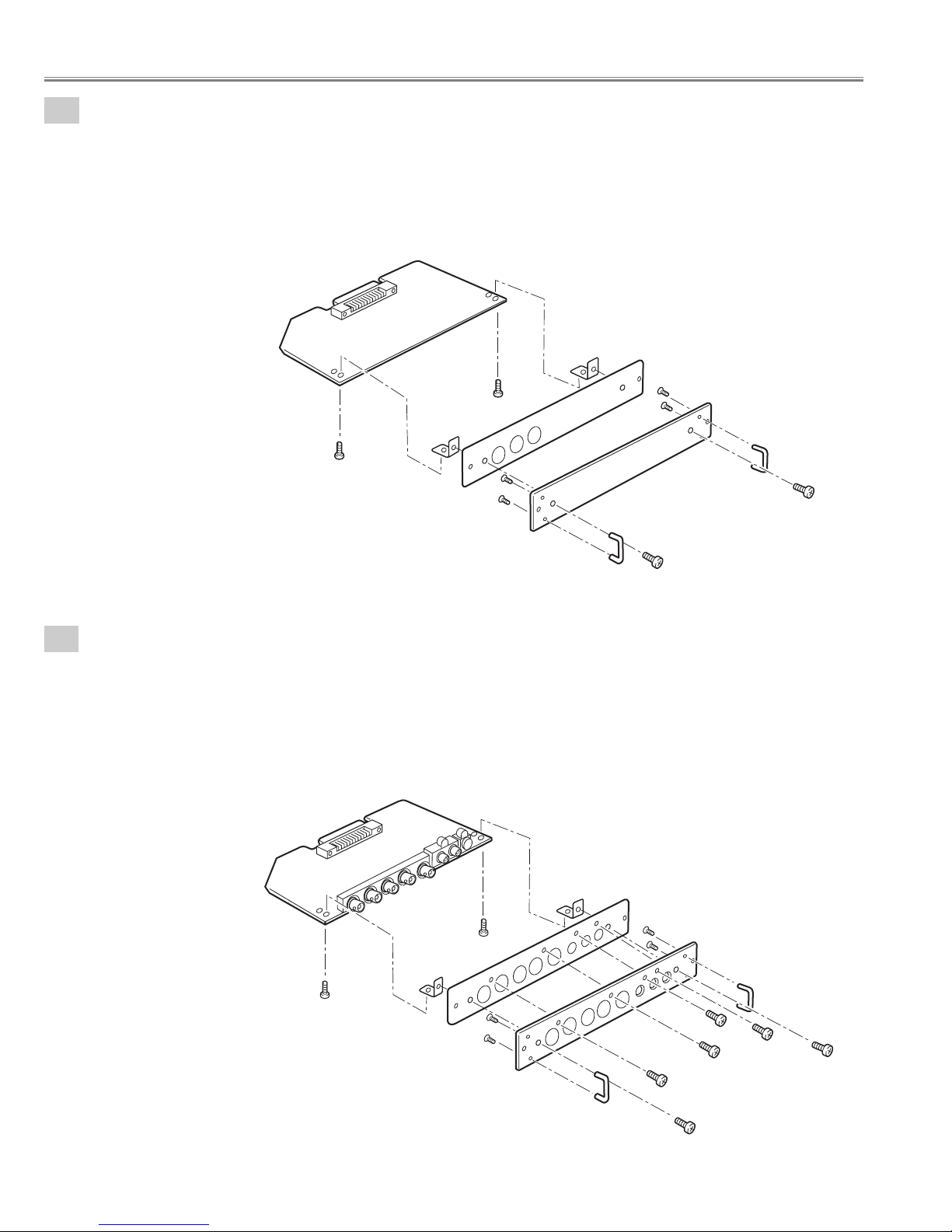

4-5

Terminal Board Component disassemblies.

1. Remove 2 screws-A ,remove 2 screws-B, remove screw-C,remove screw-D and remove the Terminal board

Component.

2. Remove 2 screws-E, remove the Holders and remove the Earth BRKT Slot.

3. Remove 4 screws-G and remove the Handles.

(See Fig.4-5)

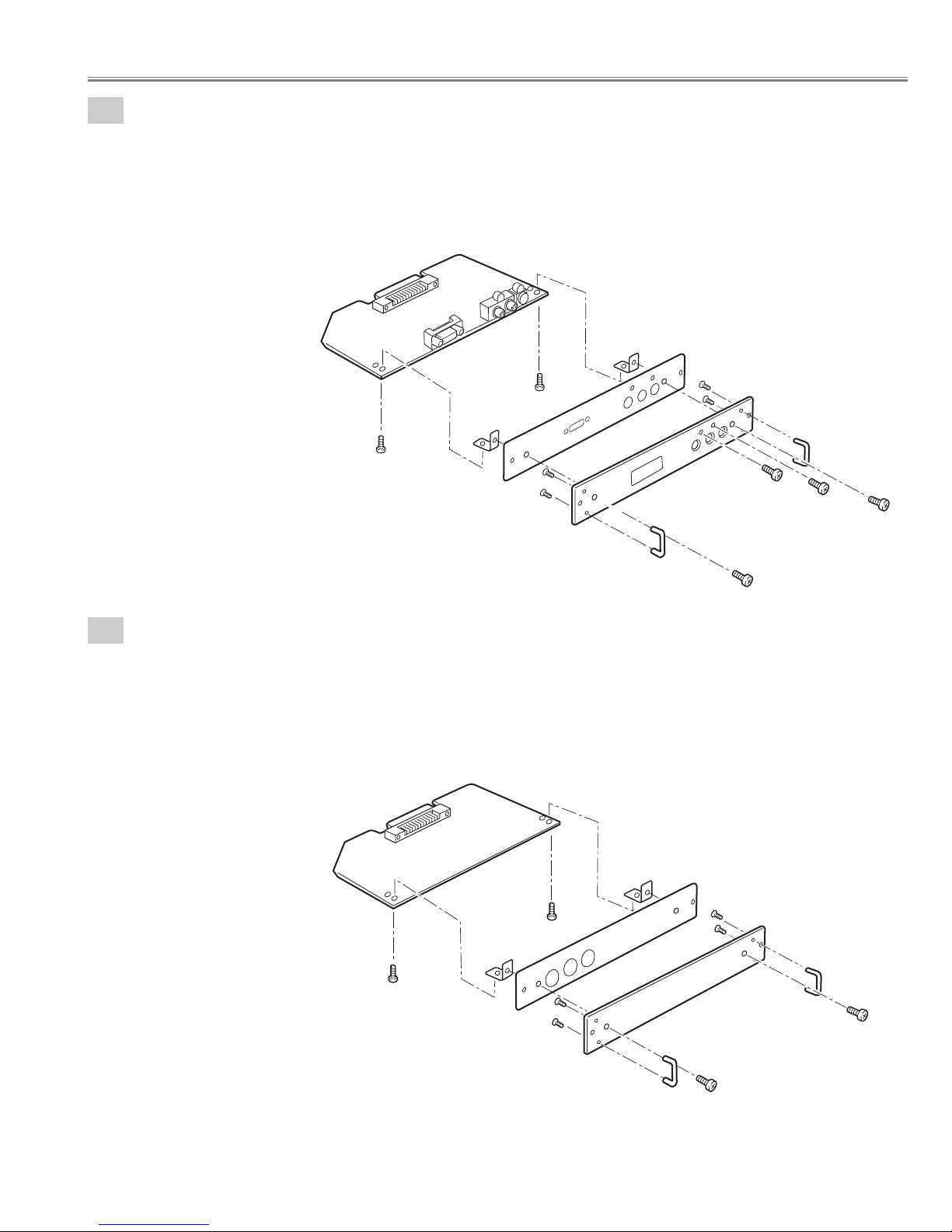

4-4

Terminal Board DL-SDI disassemblies.

1. Remove 2 screws-A, remove 4 nuts-B, remove 4 washers-C and remove the Terminal board DL-SDI.

2. Remove 2 screws-D, remove the Holders and remove the Earth BRKT Slot.

3. Remove 4 screws-E and remove the Handles.

(See Fig.4-4)

Mechanical disassemblies

Terminal board Earth

Holder

D

A

A

Holder

D

Earth BRKT Slot

Terminal board Component

D

Panel

Handle

D

Handle

B

B

A

Holder

Earth BRKT Slot

A

G

G

Panel

Holder

Handle

G

G

Handle

C

D

B

B

E

E

- 23 -

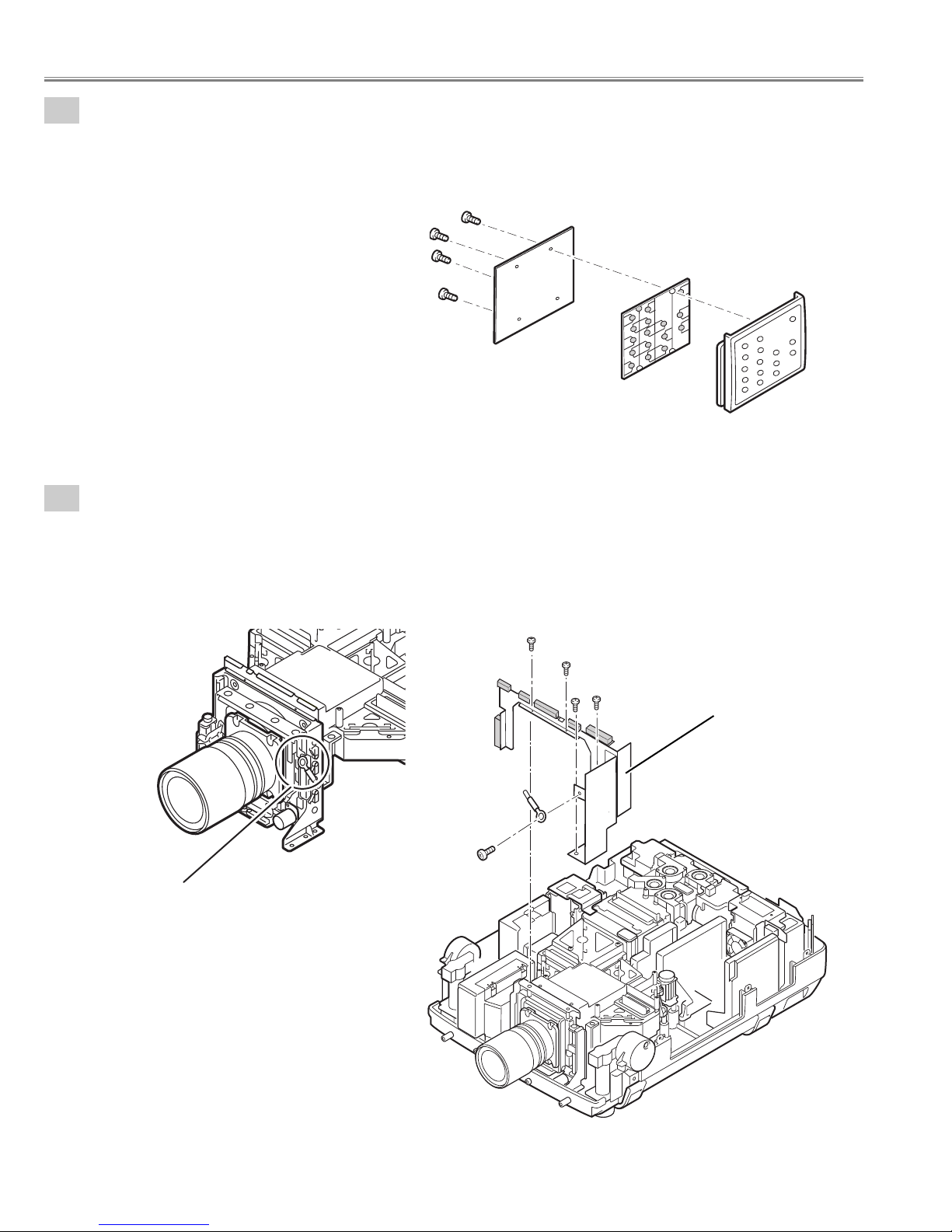

4-6

Terminal Board DVI disassemblies.

1. Remove 2 screws-A, remove screw-B, remove screw-C, and remove the Terminal board DVI.

2. Remove 2 screws-D, remove the Holders and remove the Earth BRKT Slot.

3. Remove 4 screws-F and remove the Handles.

(See Fig.4-6)

4

-7

Terminal Board Earth disassemblies.

1. Remove 2 screws-A and remove the Terminal board Earth.

2. Remove 2 screws-B, remove the Holders and remove the Earth BRKT Slot.

3. Remove 4 screws-D and remove the Handles.

(See Fig.4-7)

Fig.4-6

Fig.4-7

Mechanical disassemblies

Terminal board DVI

A

Holder

Holder

F

F

Handle

A

Earth BRKT Slot

Terminal board Earth

F

F

Panel

B

C

D

Handle

D

Holder

D

A

Holder

Earth BRKT Slot

A

D

D

Panel

Handle

D

Handle

B

B

- 24 -

Mechanical disassemblies

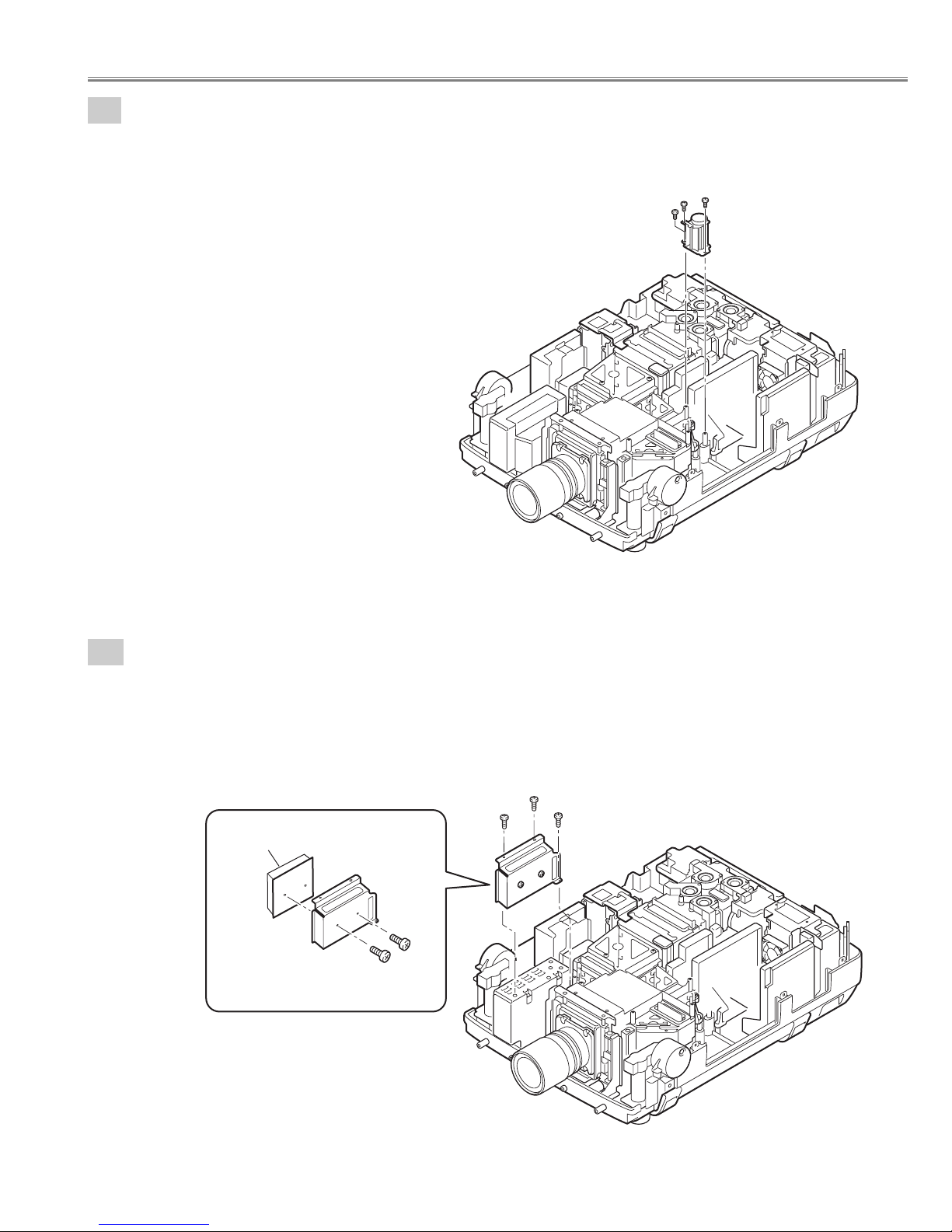

4-8

Control Switch unit disassemblies.

1. Remove 4 screws, remove the Control Button and remove the Control Board.

(See Fig.4-8)

Fig.4-8

5-1

Shield plates removal.

1. Remove screws-A, and remove the grounding lead.

2. Remove 2 screws-B, remove 2 screws-C and remove the shield plate.

( Do not remove the Lens shift unit screw. Otherwise the Lens shift mechanism is damaged.

Warning:

Do not remove the screw.

Shield plate

Fig.5-1

Fig.5-1a

Control Button

Control Board

Control Panel

Grounding Lead

A

B

B

C

C

- 25 -

Mechanical disassemblies

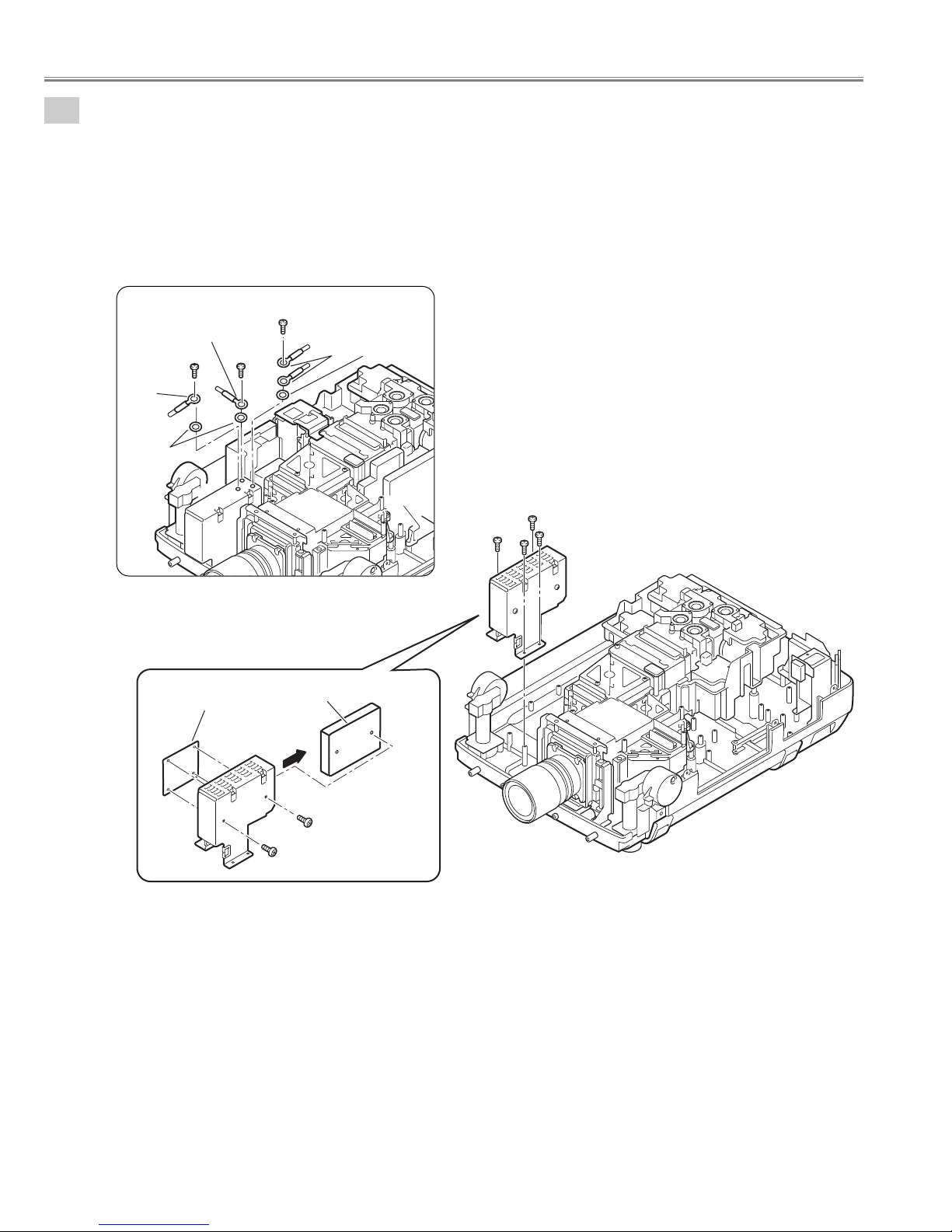

5-3

Switch Power Supply unit(5V) removal.

1. Remove 2 screws-A, remove screw-B and remove the Switch power supply(5V) unit .

2. Remove 2 screws-c and remove the Switch power supply(5V) Board.

(See Fig.5-31, 5-3a)

Fig.5-3

Fig.5-3a

5-2

Fan(FN901) removal.

1. Remove 3 screws-A and remove the Fan(FN901).

(See Fig.5-2)

Fig.5-2

A

A

A

Fan(FN901)

Switch Power Supply(5V) Board

Holder

C

A

A

C

B

Switch Power Supply(5V) unit

- 26 -

Mechanical disassemblies

A

A

A

Grounding

Lead

Grounding

Lead

Grounding Lead

Washer

Washer

5-4

Switch Power Supply(25V) unit removal.

Fig.5-4

Fig.5-4a

Fig.5-4b

1. Remove 3 screws-A, remove 3 washers and remove the grounding leads. (See Fig.5-4b)

2. Remove 4 screws-B, and remove the Switch power supply(25V) unit.

3. Remove 2 screws-C and remove the Switch power supply(25V)Board.

4. Unhook the 4 Fixer Clamps and remove the Motor &Audio Board.

(See Fig.5-4, 5-4a, 5-4b)

Motor and Audio

Board

The Motor and Audio Board is fixed with

holder by hook. (4places)

Switch Power Supply (25V)

Board

C

C

SW-Power supply unit(25V)

B

B

B

B

- 27 -

5-5

Lamp Ballast Units removal.

1. Remove screw-C and remove the grounding lead. (Lamp ballast 3-4 unit. See Fig.5-5)

Fig.5-5

Fig.5-5

Fig.5-5a

Fig.5-5b

Mechanical disassemblies

2. Remove screw-A and remove the grounding lead from the Holder. (Lamp ballast 1-2 units. See Fig.5-5a)

3. Remove 2 screws-B and remove the Holder-D.

4. Remove the Lamp Ballast Unit1 and Lamp Ballast Unit2.

5. Remove 3 screws-F and remove the Holder-F.

6. Remove 2 screws-D, remove screw-E and remove the Holder-E.

7. Remove the Lamp Ballast Unit3 and Lamp Ballast Unit4.

(See Fig.5-5, 5-5a, 5-5b,)

Grounding

Lead

Lamp ballast

3-4 unit

C

Washer

Holder -F

Holder -E

Ballast4

Lamp ballast 3-4

units

F

D

F

F

D

E

Ballast3

Ballast2

A

Grounding Lead

B

Washer

B

Ballast1

Lamp ballast 1-2

units

Holder -D

- 28 -

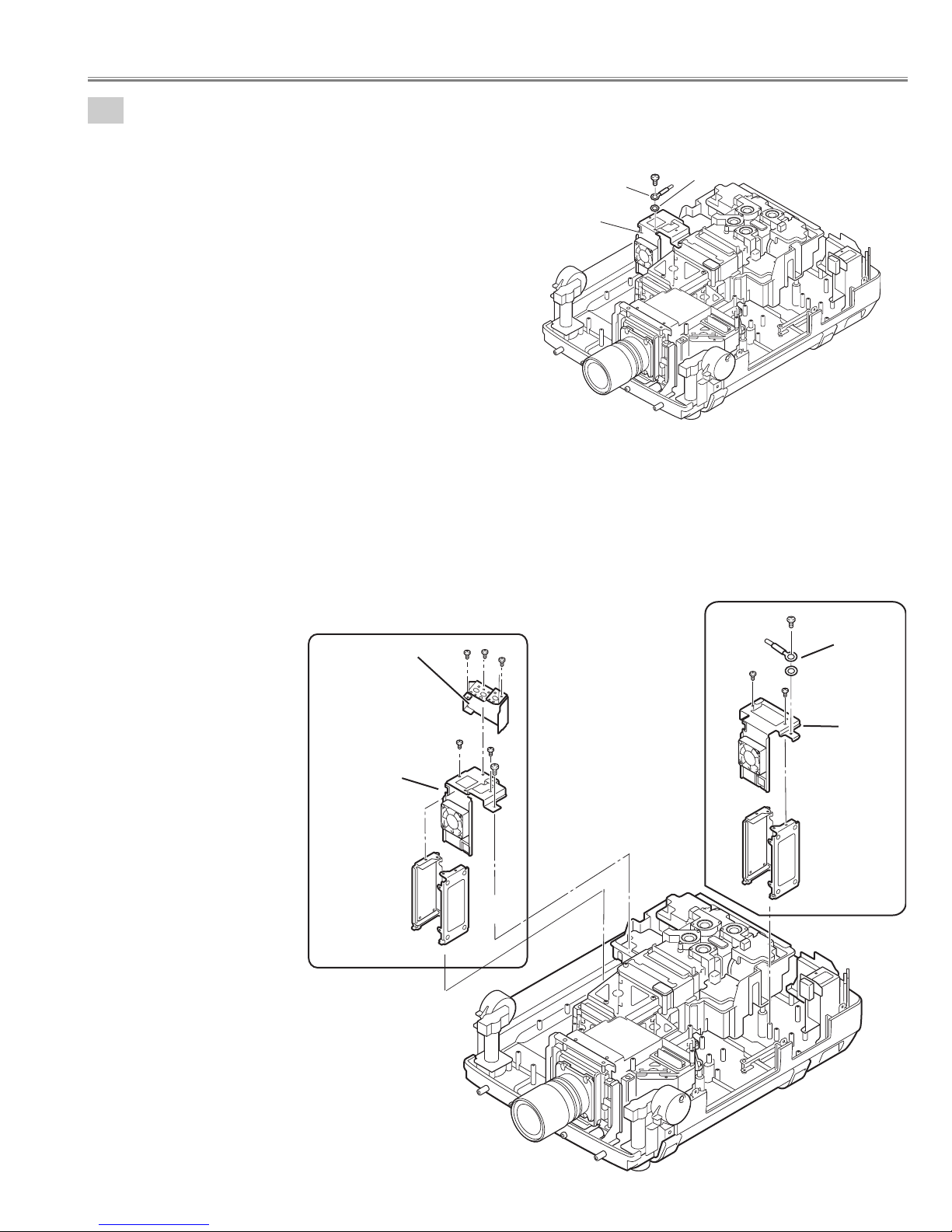

Note;

Mark the Fans as they are removed from the holder so that they may be reassembled in the same

location from which they were removed. Be careful of the attachment direction of Fans.

See arrow mark in a figure.

Ballast units may be reassembled in the same location and direction from which they were removed.

Be careful of the attached direction of Ballast units.

Lamp Ballast Units 1-2

1. Remove 2 screws-A, remove the Fan(FN908) and FAN Guard.

2. Remove Lamp Ballast unit 1 and remove the Spacer.

(Unhook the Fixer Clamp and remove the Lamp Ballast unit .)

3. Remove Lamp Ballast unit 2 and Spacer.

(Unhook the Fixer Clamp and remove the Lamp Ballast unit .)

(See Fig.5-6a)

Lamp Ballast Units 3-4

4. Remove 2 screws-B, remove the Fan(FN907) and FAN Guard.

5. Remove Lamp Ballast unit 3 and Spacer.

(Unhook the Fixer Clamp and remove the Lamp Ballast unit .)

6. Remove Lamp Ballast unit 4 and remove the Spacer.

(Unhook the Fixer Clamp and remove the Lamp Ballast unit .)

(See Fig.5-6b)

5-6

Lamp Ballast Units disassemblies.

Fig.5-6aFig.5-6b

Mechanical disassemblies

Holder -C

Spacer

The direction

of a wind.

(FN907)

B

Ballast 4

FN907

FAN GUARD

B

Spacer

Ballast 3

Holder

Holder -E

A

Holder-C

Spacer

The Ballast Board is being fixed with

Holder by hook. (4places)

The direction

of a wind.

(FN908)

A

Ballast 2

Holder-D

FN908

FAN GUARD

Ballast 1

Spacer

Holder-C

- 29 -

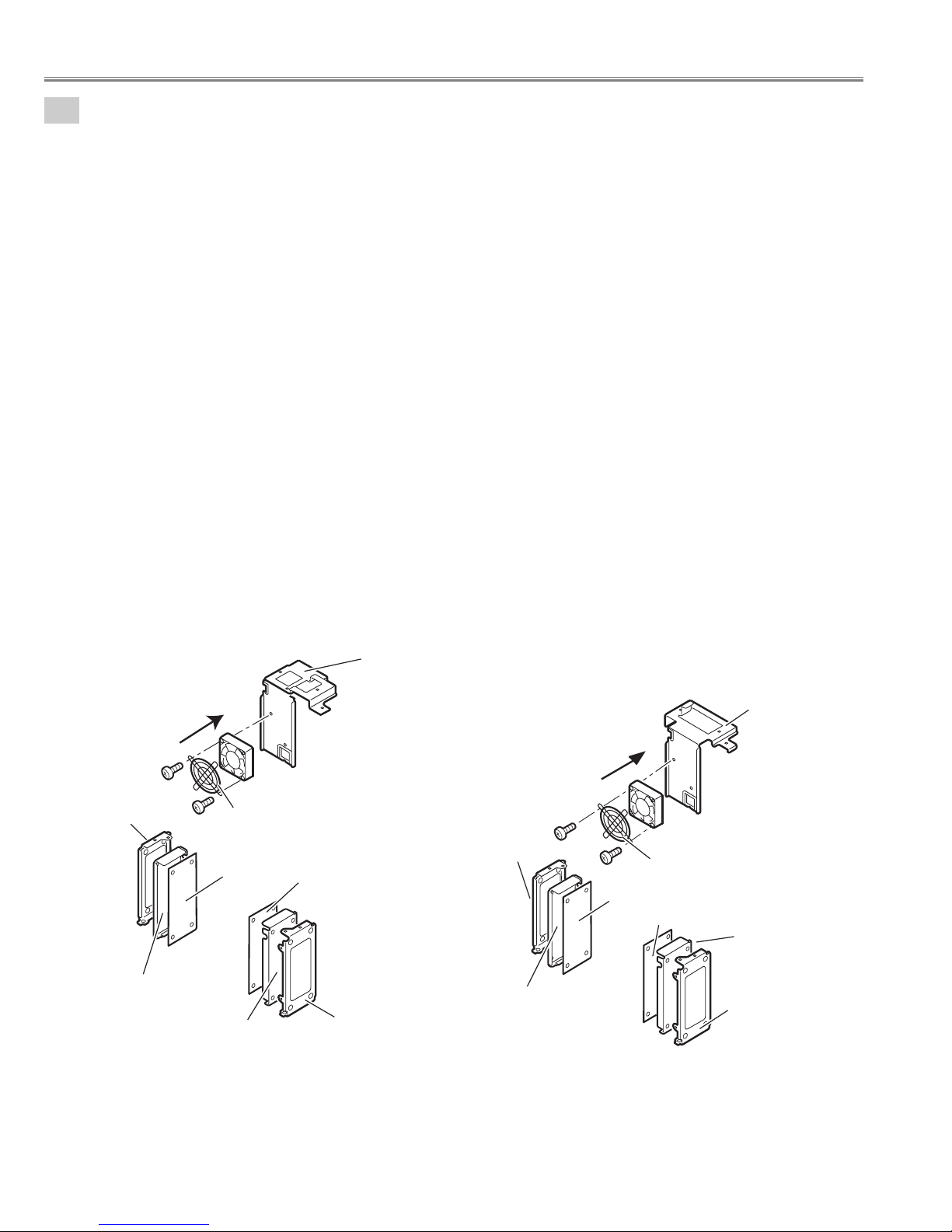

5-7

PFC Unit 3-4 and Power Unit removal.

PFC Unit 3-4 removal.

1. Remove 4 screws-A and remove the PFC 3-4 Unit.

2. Remove 4 screws-B and remove the Fan (FN914).

3. Remove 3 screws-C and remove the Holder FN.

4. Remove 4 screws-D and remove the PFC 3-4 Board.

5. Remove 2 screws-E and remove the AC4 net Board.

(See Fig.5-7, 5-7a)

Note;

Mark the Fans as they are removed from the holder so that they may be reassembled in the same location from

which they were removed. Be careful of the attached direction of Fan.

See arrow mark in a figure.

PWB units may be reassembled in the same location and direction from which they were removed. Be careful of

the attached direction of PWB units.

Fig.5-7

Fig.5-7a

Mechanical disassemblies

E

E

AC net Board

Holder PFC

PFC3-4 Board

D

D

D

D

Holder FN

C

C

The direction

of a wind.

(FN914)

C

B

B

A

A

B

A

A

PFC3-4 unit

B

- 30 -

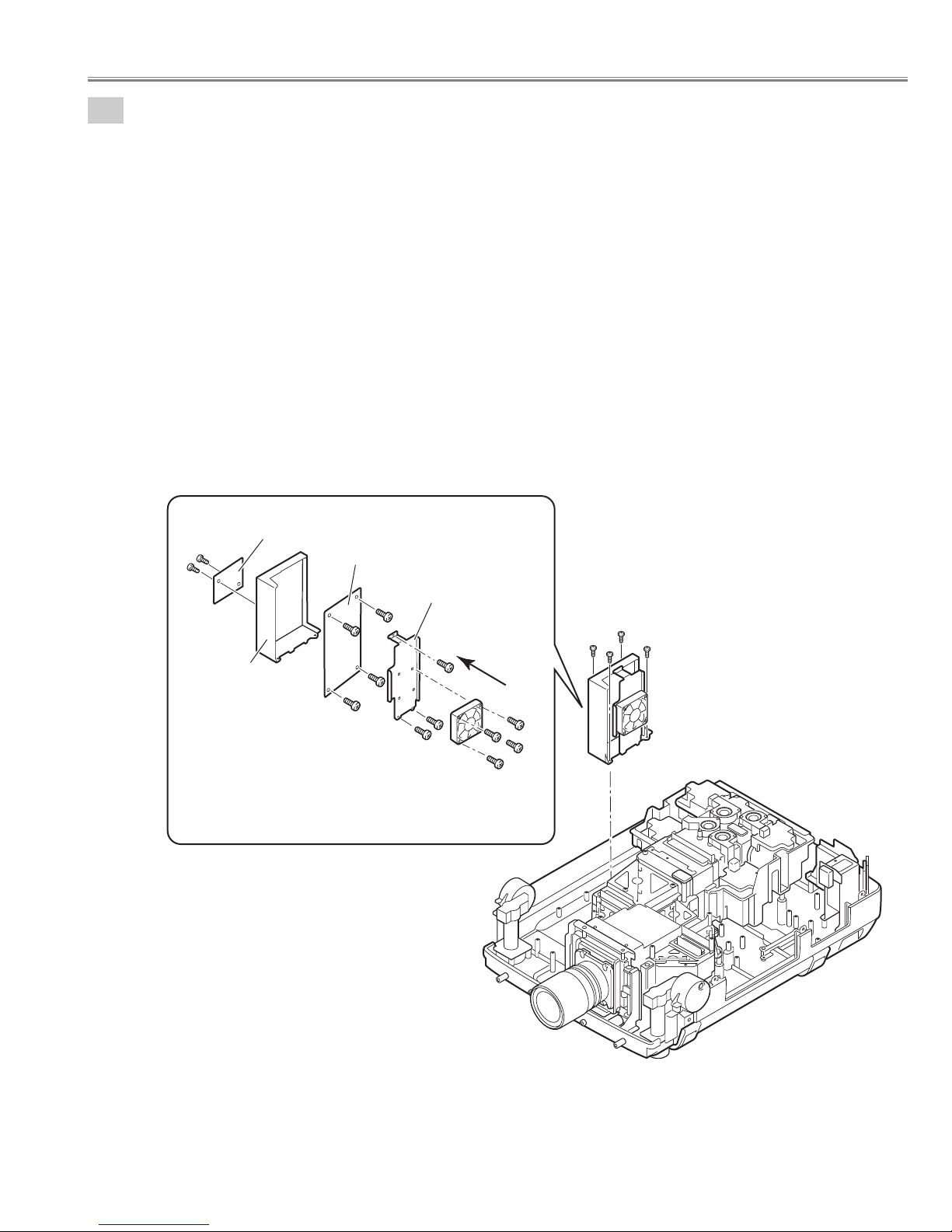

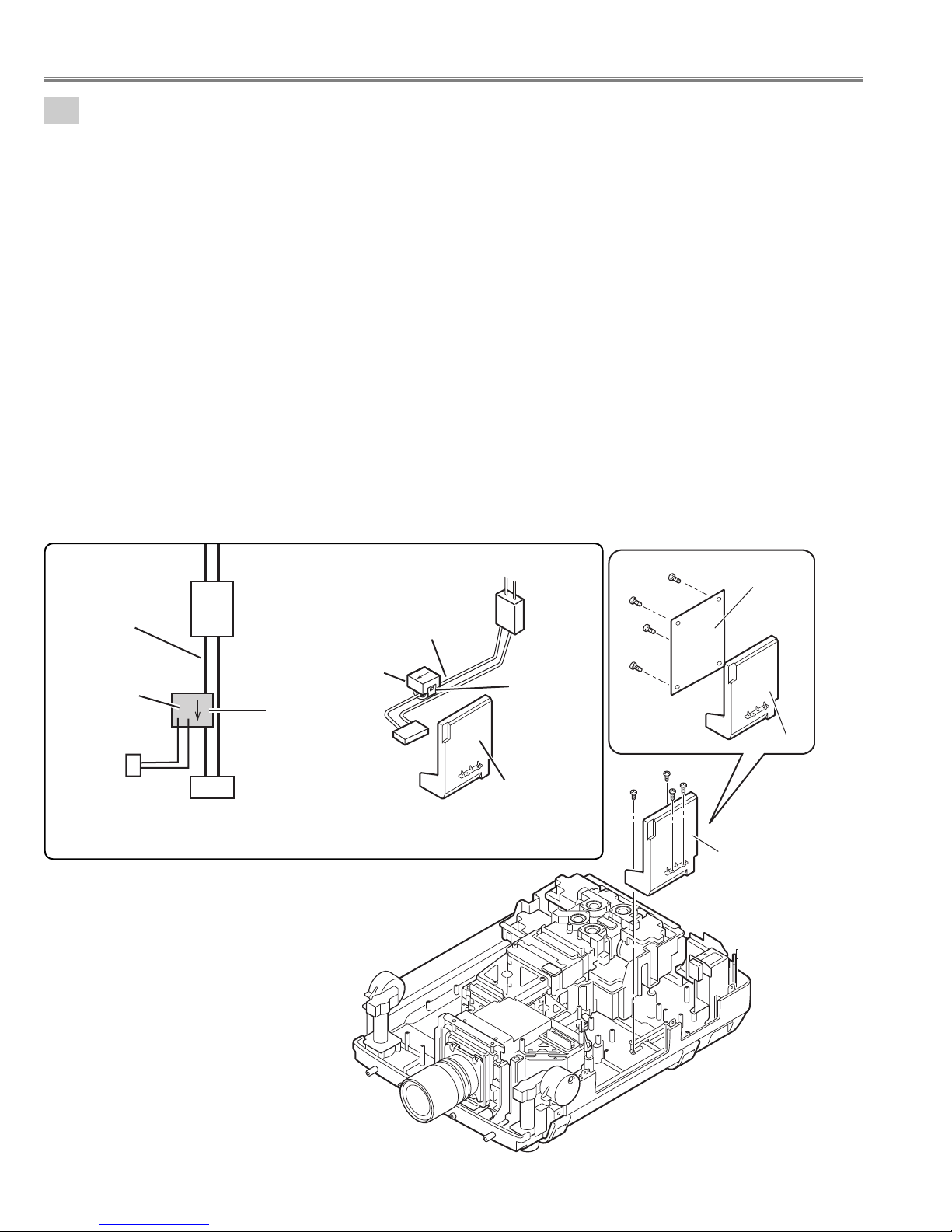

5-8

Current sensor removal and replacement.

(Current sensor is used only for PLV-HD2000E.)

Power unit

Ass'y Power unit

K6A

Current sensor

Current

sensor

K

L

K96W

Noise Filter

LF901

Blue lead wire

Blue lead wire

K6A

LF901

Printed mark

A903

(a)

1. Unhook the part(a) and remove the current sensor.

Note:The way of installing a current sensor is very important on the performance and the safety. Install in the

condition which is the same as the time of disassemble.

Replacement

1. The Current sensor is attached in the blue lead wire between an interlock switch (SW902) and power unit

(K6A).

2. The Current sensor (L) side is attached in the K6A side.

Refer to schematic diagrams (page-S1).

PWB units may be reassembled in the same location and direction from which they were removed. Be careful of the

attached direction of PWB units.

Power Unit removal.

Power Unit removal.

1. Remove 2 screws-A, remove 2 screws-B and remove the Power Unit.

2. Remove 4 screws-C and remove the Power Board.

(See Fig.5-8, 5-8a)

Fig.5-8b

Fig.5-8a

Fig.5-8

Mechanical disassemblies

C

C

C

C

Power Board

Holder Power

A

B

B

A

Power unit

Loading...

Loading...