Page 1

FILE NO.

SERVICE MANUAL

LCD Projection TV

REFERENCE NO. SM5110797-00

PRODUCT CODE :

PLV-55WHD1 M8LA 1 122 293 00

PLV-65WHD1 M8PA 1 122 364 00

Original Version

MODEL NO. PLV-55WHD1

PLV-65WHD1

U.S.A.

Chassis No. M8L-55WHD100

M8P-65WHD100

NOTE: Match the Chassis No. on the rating

sheet on the cabinet with the

Chassis No. in the Service Manual.

If the Original Version Service

Manual Chassis No. does not

match the unites, additional

Service Literature is required. You

must refer to “Notices” to the

Original Service Manual prior to

servicing the unit.

Give complete “CHASSIS NO." for parts order

or servicing, it is shown on the rating sheet on

the cabinet of the LCD Projection TV.

Page 2

■ Contents .................................................................................................................2

■ Safety Instructions..................................................................................................3

■ Specifications .........................................................................................................4

■ Circuit Protections ..................................................................................................5

■ Installation ..............................................................................................................7

■ Cleaning ...............................................................................................................10

■ Lamp Replacement ..............................................................................................12

■ Mechanical Disassemblies...................................................................................15

■ Optical Parts Location and Direction....................................................................54

■ Adjustments after Parts Replacement .................................................................58

■ Optical Adjustments .............................................................................................59

■ Electrical Adjustments..........................................................................................72

● Service Adjustment Menu Operation ..........................................................72

● Circuit Adjustments .....................................................................................73

● Service Adjustment Data Table...................................................................77

● Test Points Location ...................................................................................84

■ Chassis Block Diagrams ......................................................................................85

■ Power Supply Lines..............................................................................................94

■ Troubleshooting ....................................................................................................95

■ Control Port Functions .........................................................................................98

■ Waveforms..........................................................................................................100

■ IC Block Diagrams .............................................................................................101

■ Service Parts List ...............................................................................................106

■ Mechanical and Optical Parts List ............................................................106

■ Electrical Parts List ...................................................................................123

■ Appendix ............................................................................................................148

● Quick Reference of Chassis Disassemblies .............................................148

--------------------------------------------------------------------------------------------------------------------

Drawings & Diagrams .......................................................................... A1 - A15

■ Parts description and reading in schematic diagram .......................................... A2

■ Schematic Diagrams ....................................................................................A3 - A8

■ Printed Wiring Board Diagrams ................................................................ A9 - A14

■ Pins description of ICs, transistors, diodes ...................................................... A15

Note: "PTV" may be used as an abbreviation for LCD Projection TV in this manual.

- 2 -

■ Contents

Page 3

WARNING:

The chassis of this LCD projection TV is isolated (COLD) from AC line by using the converter transformer. Primary

side of the converter and lamp power supply unit circuit is connected to the AC line and it is hot, which hot circuit

is identified with the line ( ) in the schematic diagram. For continued product safety and protection of per-

sonnel injury, servicing should be made with qualified personnel.

The following precautions must be observed.

SAFETY PRECAUTIONS

1: An isolation transformer should be connected in the power line between the LCD projection TV and the

AC line before any service is performed on the LCD projection TV.

2: Comply with all caution and safety-related notes provided on the cabinet top, cabinet bottom, inside the

cabinet or on the chassis.

3: When replacing a chassis in the cabinet, always be certain that all the protective devices are installed

properly, such as, control knobs, adjustment covers or shields, barriers, etc.

DO NOT OPERATE THIS LCD projection TV WITHOUT THE PROTECTIVE SHIELD IN POSITION AND

PROPERLY SECURED.

4: Before replacing the cabinet, thoroughly inspect the inside of the cabinet to see that no stray parts or

tools have been left inside.

Before returning any LCD projection TV to the customer, the service personnel must be sure it is completely

safe to operate without danger of electric shock.

PRODUCT SAFETY NOTICE

Product safety should be considered when a component replacement is made in any area of the LCD projec-

tion TV. Components indicated by mark in the parts list and the schematic diagram designate components

in which safety can be of special significance. It is, therefore, particularly recommended that the replacement of

the parts must be made by exactly the same parts.

Caution:

The parts and screws should be placed exactly the same position as the original otherwise it may cause lose of

performance and product safety.

The wiring method of the leads should be returned exactly the same state as the original otherwise it may cause

lose of performance and product safety.

SERVICE PERSONNEL WARNING

Eye damage may result from directly viewing the light produced by the Lamp used in this equipment. Always

turn off Lamp before opening cover. The Ultraviolet radiation eye protection is required during this servicing.

Never turn the power on without the lamp to avoid electric-shock or damage of the devices since the stabilizer

generates high voltages at its starts.

Since the lamp is very high temperature during units operation. Replacement of the lamp should be done at

least 30 minutes after the power has been turned off, to allow the lamp cool-off.

CAUTION

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE INSTRUCTIONS.

- 3 -

■ Safety Instructions

Page 4

● LCD panels are manufactured to the highest possible standards. Even though 99.99% of the pixels are effective, a tiny

fraction of the pixels (0.01% or less) may be ineffective by the characteristics of the LCD panels.

Technical Specifications

- 4 -

Screen Size (Measured Diagonally):

PLV-55WHD1: 55-inches/PLV-65WHD1: 65-inches

LCD Panel System:

0.7” wide TFT Active Matrix type, 3 panels

Panel Resolution:

1280 x 720 dots

Number of Pixels:

2,764,800 (1280 x 720 x 3 panels)

Signal Compatibility:

NTSC; 480i, 480p, 1080i, 720p

Scanning Format:

720p (All Signals are Converted to 720p)

RF Antenna Input:

Analog—UHF/VHF/CATV 75 ohm

Digital—75 ohm

Jacks and Connectors:

Video 1 Input: Composite Video/S-Video

and Audio L/R

Video 2 Input: Component (Y/Pb/Pr) with

Audio L/R Input

Video 3 Input: Component (Y/Pb/Pr) with

Audio L/R Input

Digital Audio Output: Dolby® Digital (Optical)

Analog Audio Output:Audio L/R (Fixed)

HDMI Input: 19-pin connector

(Picture/Sound with HDCP)

Woofer Output: RCA Type

Service Jack: D-Sub (HDB 9)

Sound:

Two Speakers, size: 5.0” x 3.0” (128 x 77 mm)

Amplifier:

Built-in with 15.0 W/ch

Power Requirement:

Source: AC 120 V, 60 Hz

AC Power Consumption (average):

PLV-55WHD1: 120 V, 2.8 A

PLV-65WHD1: 120 V, 2.8 A

Size and Weight (approximately):

PLV-55WHD1

Width: 50.9” (1294 mm)

Height: 34.0” (864 mm)

Depth: 15.6” (397 mm)

Weight: 86.4 lbs (39.2 kg)

PLV-65WHD1

Width: 60.6” (1538 mm)

Height: 40.0” (1016 mm)

Depth: 18.4” (468 mm)

Weight: 106.0 lbs (48.1 kg)

Environmental Considerations:

Operating Temperature: 41˚F–95˚F (5˚C–35˚C)

Storage Temperature: 14˚F–140˚F (-10˚C–60˚C)

Remote Control:

Battery : 1.5 V AAA Alkaline type x 2

Operating Range:16.4’ (5 m)/±30

Dimensions: 7.72” (L) x2.15” (W) x 0.83” (H)

(196 mm x 54.7 mm x 21.0 mm)

Net Weight: 2.96 oz (84 g)

(without batteries)

Accessories:

Owner’s Manual

AC Power Cord

Remote Control

Specifications are subject to change without notice.

■ Specifications

Page 5

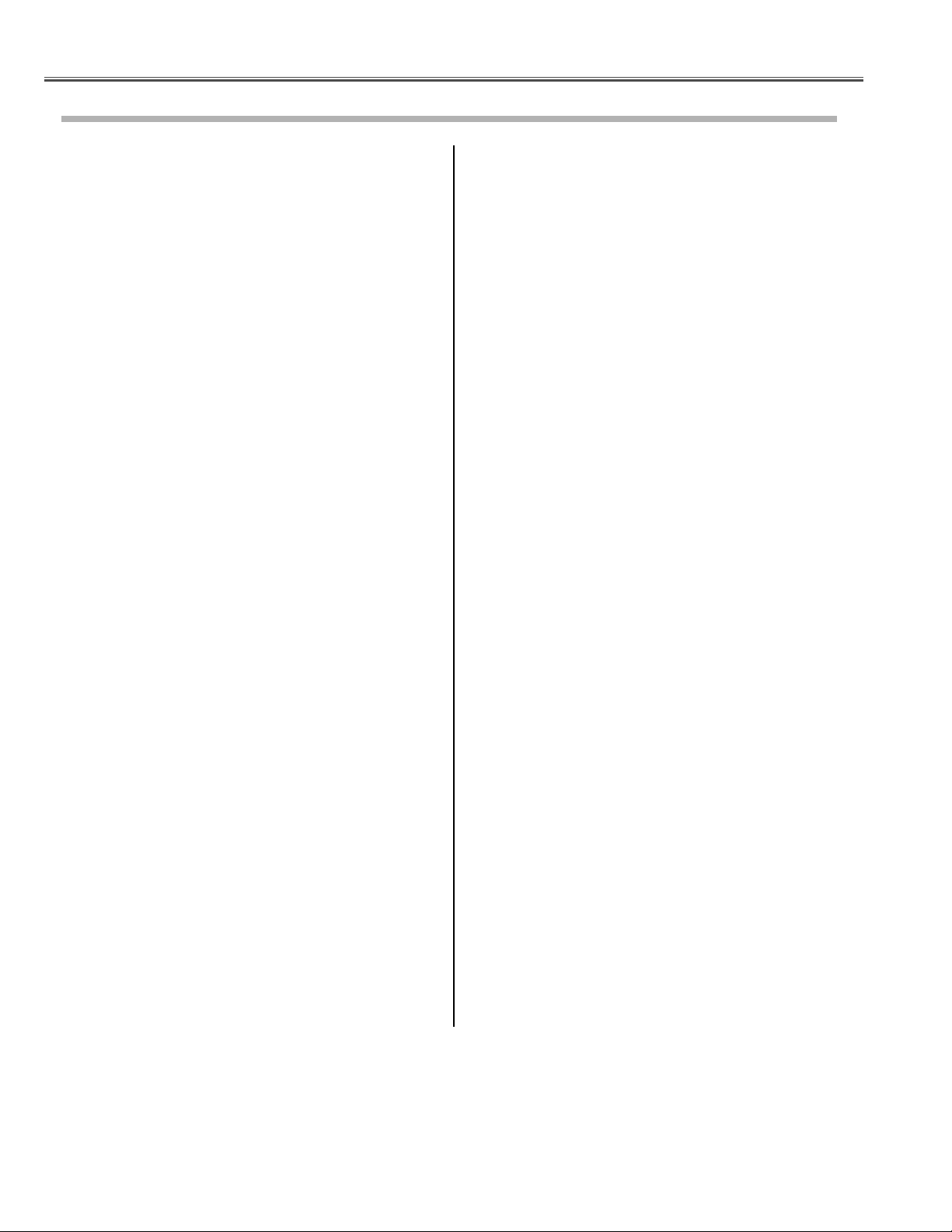

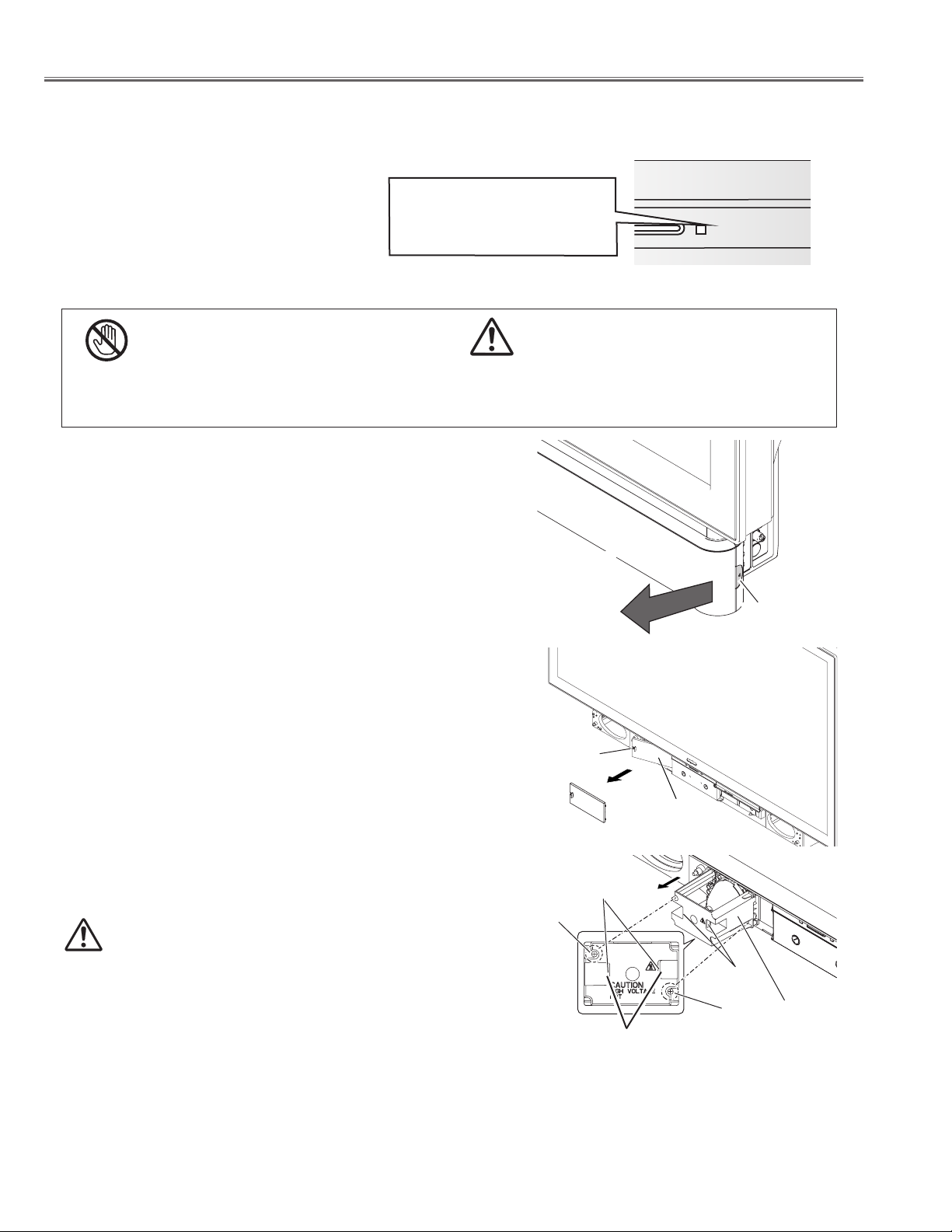

This LCD Projection TV provides the following circuit protections to operate in safety. If the abnormality occurs

inside the LCD Projection TV, it will automatically turn off by operating one of the following protection circuits.

A fuse(F601) is located inside of the LCD Projection TV.

When the POWER indicator is not lightning, the fuse may

be opened. Check the fuse as following steps.

The fuse should be used with the following type;

● Fuse

● Thermal switch

Fuse Part No. : 323 022 2105

TYPE T4.0AH 250V FUSE

LITTEL FUSE INC. TYPE 215004

How to replace the fuse

1. Unplug the AC power cord.

2. Remove the cabinet bottom cover following to

"Mechanical Disassemblies".

3. Remove the fuse from fuse holder on the Power Board.

To install the fuse, take reversed step in the above.

There is the thermal switch (SW902) inside of the LCD

Projection TV to prevent the internal temperature rising

abnormally. When the internal temperature reaches near

95°C, the thermal switch cuts off the drive signal to the

lamp circuit automatically.

The thermal switch is not reset to normal automatically

even if the internal temperature becomes normal. Reset

the thermal switch following procedure.

Check the resistance between terminals of thermal switch

by using a tester. If it has high impedance, thermal switch

may be in open.

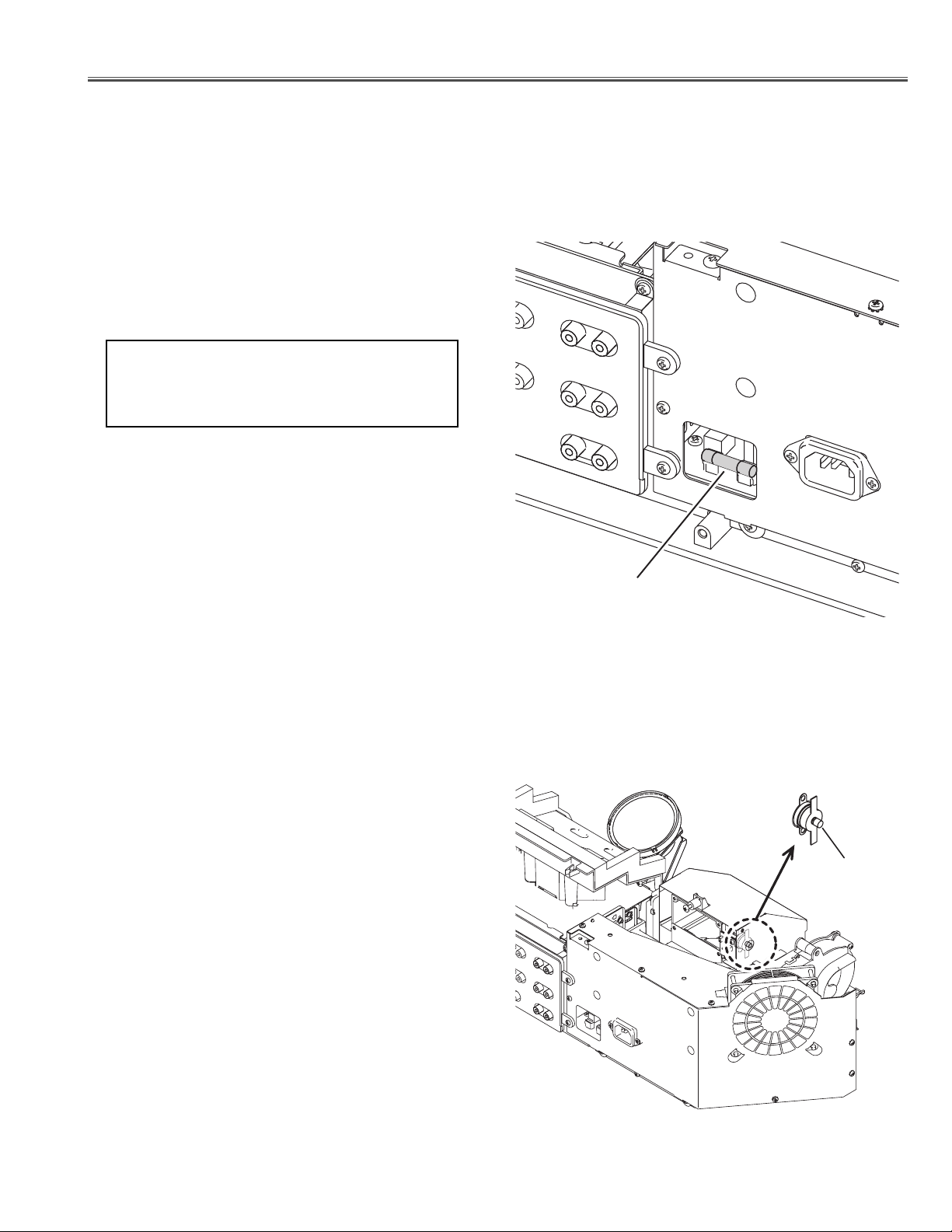

How to reset the thermal switch

1. Remove the optical / chassis unit following to

"Mechanical Disassemblies".

2. Press the reset button on the thermal switch.

CAUTION:

Before press the reset button, make sure that the AC cord

must be disconnected from the AC outlet.

- 5 -

■ Circuit Protections

Fuse

(F601)

Thermal switch

(SW902)

Press

Page 6

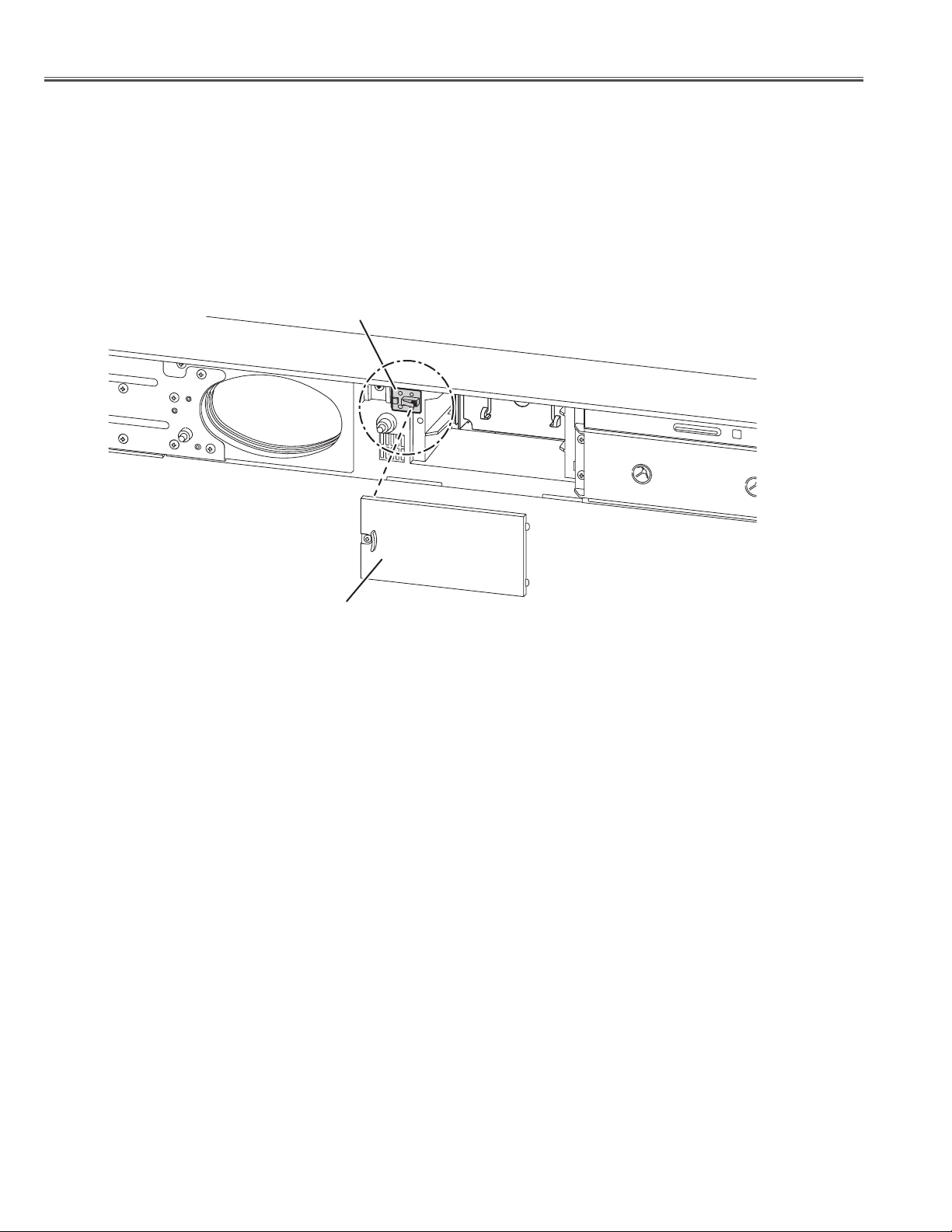

● Lamp cover switch

The lamp cover switch (SW1861) cuts off the drive signal to the lamp circuit when the lamp cover is removed or no

close completely.

After opening the lamp cover for replacing the lamp unit, place the lamp cover correctly otherwise the LCD

Projection TV can not be turned on.

● Warning indicator

The LCD Projection TV is shut down and the WARNING indicator is flashing red

When the temperature inside the LCD Projection TV exceeds the normal temperature, it is automatically shut down

to protect the LCD Projection TV. The POWER indicator flashes red and the LCD Projection TV is being cooled

down. When the temperature inside the LCD Projection TV returns to normal, the POWER indicator is turned off

and the LCD Projection TV can be turned on. When the LCD Projection TV is turned on again, the WARNING indi-

cator stops flashing.

Check the items listed below;

> Installation and air circulation

> Temperature abnormality with temperature sensors

The LCD Projection TV is shut down and the WARNING indicator lights red

When the LCD Projection TV detects an abnormal condition, it is automatically shut down to protect the LCD

Projection TV and the WARNING indicator lights red. In this case, unplug the AC power cord and plug it, and then

turn the LCD Projection TV on again to verify operation. If the LCD Projection TV is turned off again or fails to be

turned on, the internal check and repair will be required.

Check the items listed below;

> Power failure protection circuit

> Temperature abnormality with temperature sensors and thermal switch

> Lamp cover switch

Circuit Protections

- 6 -

LAMP COVER SWITCH

(SW1861)

LAMP COVER

Page 7

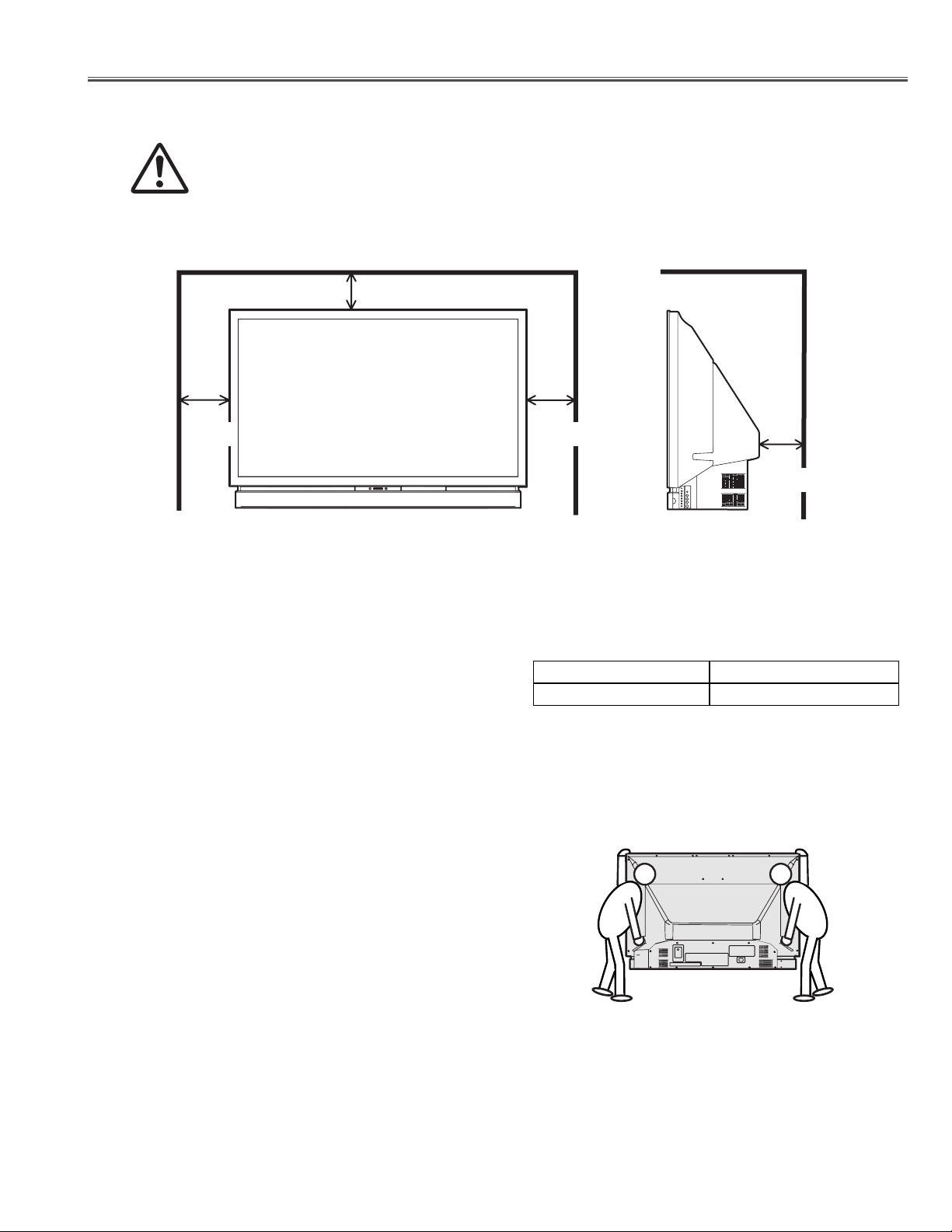

The openings in the cabinet are provided for ventilation. To

ensure reliable operation of the product and protect it from

overheating, these openings must not be blocked or

covered.

● Ta ke appropriate space on the top, sides and rear of the

LCD Projection TV

cabinet for allowing air circulation and

cooling the

LCD Projection TV

. Minimum distance should

be taken. If the

LCD Projection TV

is to be built into a

compartment or similarly enclosed, the minimum

distances must be maintained. Do not cover the

ventilation slot on the

LCD Projection TV

. Heat build-up

can reduce the service life of your

LCD Projection TV

, and

can also be dangerous.

Air Circulation

Throughout the installation process, handling by more

than two people is recommended.

RECOMMENDATION

BE SURE TO USE OR PLACE THE LCD

PROJECTION TV IN THE TEMPERATURE

INDICATED BELOW:

Place the LCD Projection TV on flat places or with an exclusive

LCD Projection TV stand. Placing on uneven places may cause

picture tilt or distortion.

Do not place the LCD Projection TV under direct sunlight. This may

have a damaging effect on picture quality and the screen surface

of the LCD Projection TV.

41°F ~ 95°F (5°C ~ 35°C)

14°F ~ 140°F (-10°C ~ 60°C)

Operating Temperature

Storage Temperature

Placing and Settling the LCD Projection TV

CAUTION;

When placing the LCD Projection TV, the spaces

for ventilation must be maintained.

SIDE and TOP REAR

- 7 -

■ Installation

4" (10cm)

8"

(20cm)

8"

(20cm)

4"

(10cm)

Page 8

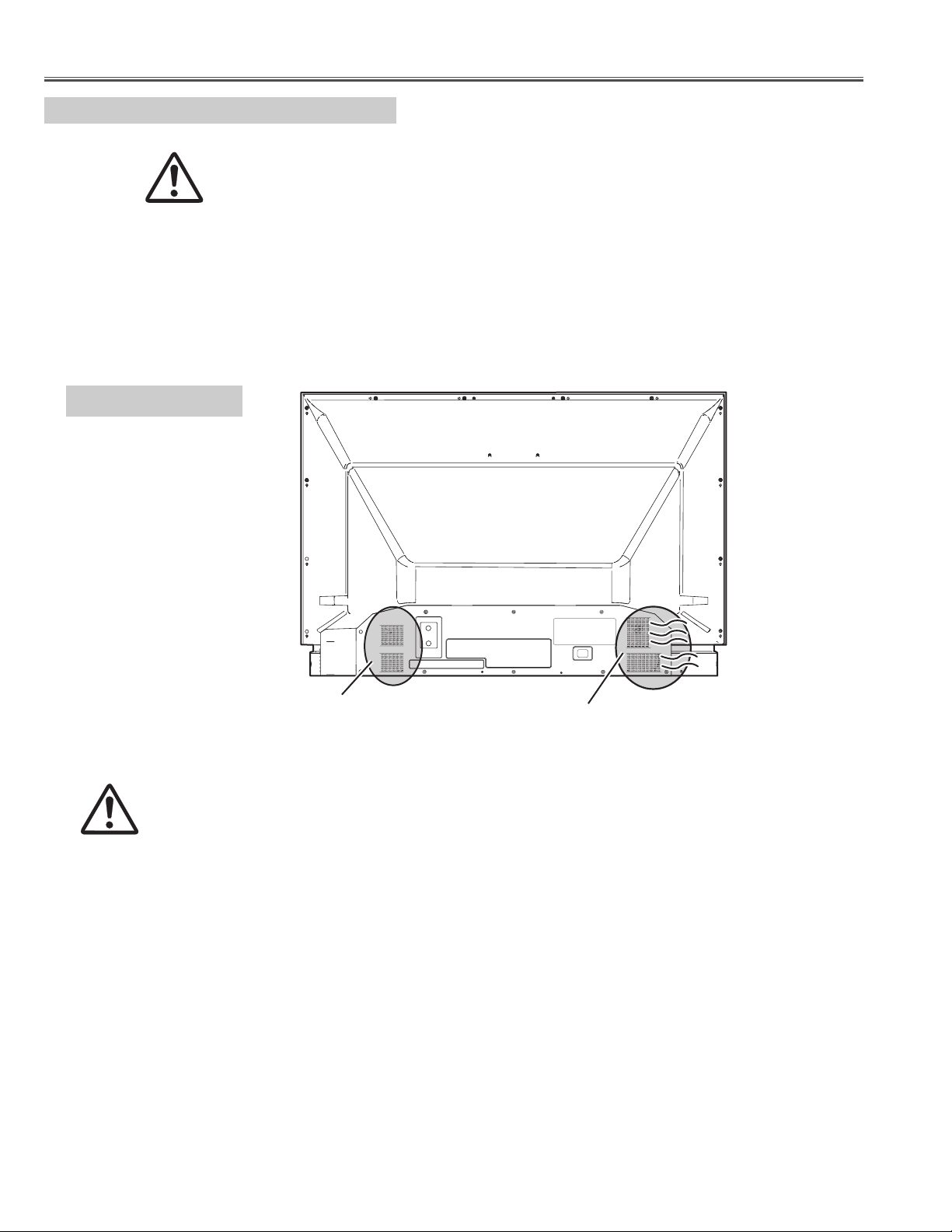

This LCD Projection TV is equipped with cooling fans for protec-

tion from overheating. Pay attention to following to ensure proper

ventilation and avoid a possible risk of fire and malfunction.

- Do not cover vent slots.

Obstructions may block cooling air.

Hot air is exhausted from the exhaust vent.

When using or installing the LCD Projection TV, the following pre-

cautions should be taken.

– Do not put any flammable objects near the vent.

– Do not touch a peripheral part of the exhaust vent, especially

screws and metallic part. This area will become hot while the

LCD Projection TV is being used.

COOLING FANS

Cooling fans are provided to cool the LCD Projection TV. The fans'

running speed is changed according to the temperature inside the

LCD Projection TV. When the LCD Projection TV is cooled down

enough, the fans will stop running.

Caution;

Caution;

Air intake vents and exhaust vents

BACK OF CABINET

Installation

- 8 -

Air intake vents

Exhaust vents (Hot air exhaust)

Page 9

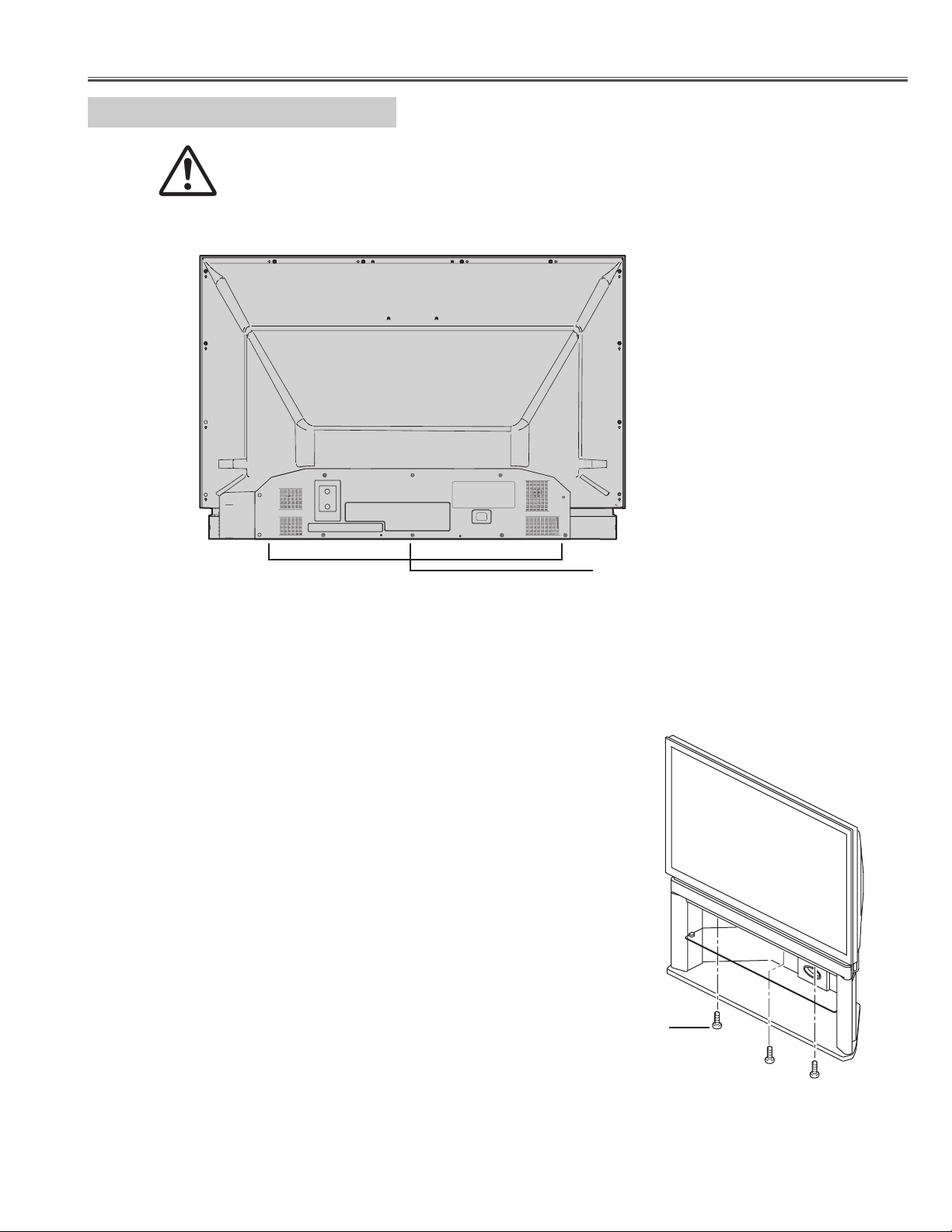

Caution;

When placing on a LCD Projection TV stand, take the measures against

prevention of fall for safety.

Placing on the TV stand

Attach the LCD Projection TV stand.

Stand attachment hole

(3 holes at bottom of cabinet)

Note; Follow to installation manual of a LCD Projection TV stand.

(PLV-5565STD)

Installing the LCD Projection TV for safety.

When Installing the LCD Projection TV, secure the LCD

Projection TV on the stand. If not, the LCD Projection TV may

fall down and accident can result.

Place the LCD Projection TV on the proper position of the

stand. There are 3 holes on the top panel of the stand. Use

the 3 screws (included with the stand) to fix the LCD

Projection TV.

Installation

- 9 -

Screw

Page 10

- 10 -

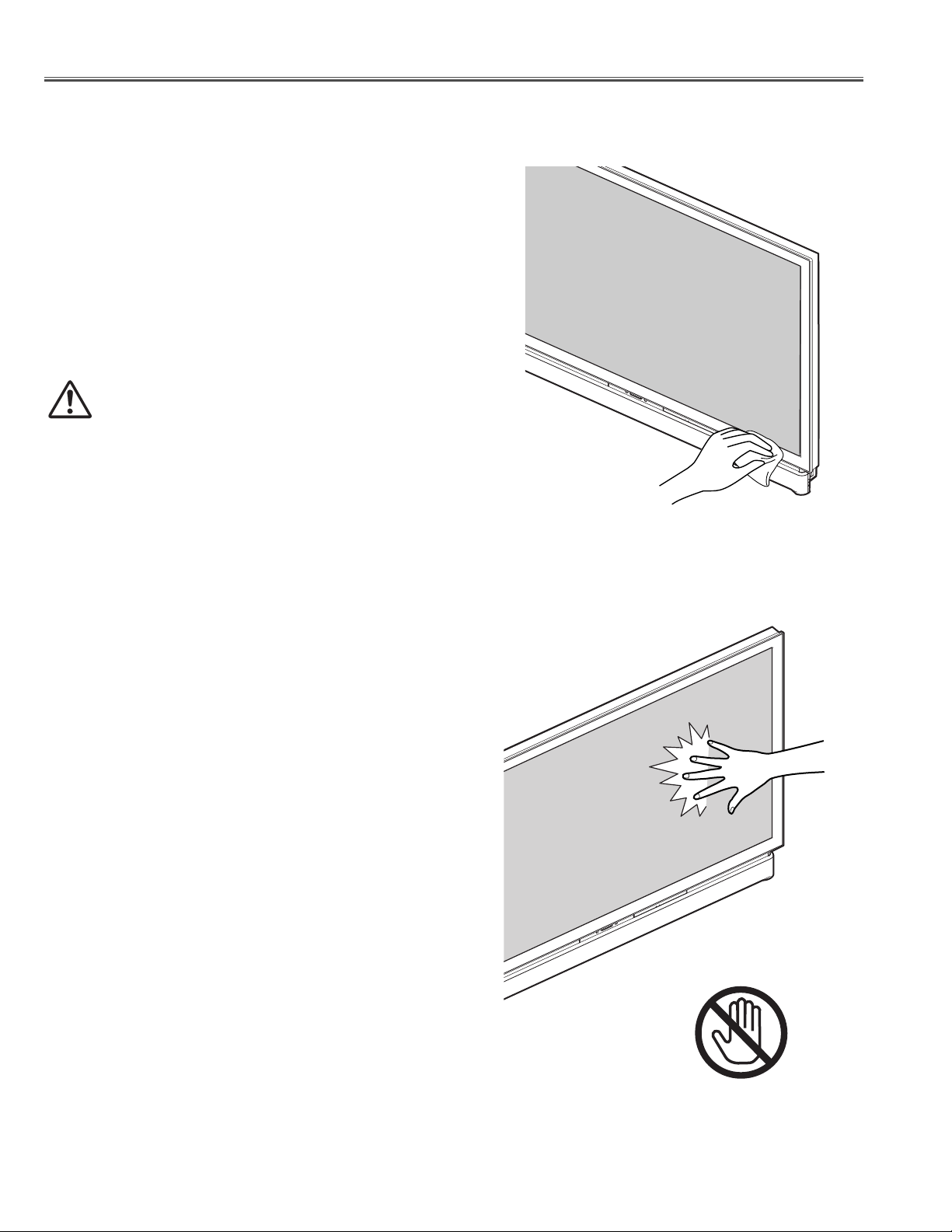

Care for Using the LCD Projection TV

When using the LCD Projection TV, the following

precautions should be taken. Otherwise, the screen can

be damaged:

●

Do not push or hit the screen surface.

●

Do not write, paint, or affix anything on the screen.

●

Do not put anything on the LCD Projection TV.

●

Never touch the projection screen directly with hands.

NOTE:

Black dots or bright points of light (red, green, or blue) may appear

on the screen. This is a characteristic of the LCD panels, not a

malfunction of the LCD Projection TV.

Do not push or hit

the screen.

Be sure to disconnect the AC Power cord from the AC outlet

before cleaning the LCD Projection TV.

●

Gently wipe the screen and the cabinet with a soft dry clean

cloth.

●

When it is heavily soiled, wipe the screen and the cabinet

with a soft cloth dampened with warm water and finish with a

soft, dry clean cloth.

CAUTION;

Do not use benzene, thinner, or any volatile

substances to clean the LCD Projection TV. These

chemicals may cause damage to the product.

● Cleaning the LCD Projection TV

■ Cleaning

Page 11

Cleaning

- 11 -

Cleaning Procedure

(When no good, progress to next step.)

1. Clean surface of optical parts using air spray.

2. Wipe the dry cleaning with wiping cloth and the wiper.

3. Soak a few medicines in the cloth as follows and wipe up them lightly. After that, always wipe the dry cleaning

cloth.

Disassembly Cleaning

Disassembly cleaning method should only be performed when the unit is considerable dirty and cannot be sufficient-

ly cleaned by air spraying alone.

Be sure to readjust the optical system after performing disassembly cleaning.

The surface of the optical components consists of multiple dielectric layers with varying degrees of refraction.

Never use organic solvents (thinner, etc.) or any kind of cleanser on these components.

Since the LCD panel is equipped with an electronic circuit, never use any liquid (water,etc.) to clean the unit.

Use of liquid may cause the unit to malfunction.

After long periods of use, dust and other particles will accumulate on the LCD panel, prism, mirror, polarized glass,

lens, etc., causing the picture to darken or color to blur. If this occurs,clean inside of the optical unit.

Remove dust or other particles using air spray. If dirt cannot be removed by air spray, disassemble and clean the opti-

cal unit.

Caution:

Use a commercial (inert gas) air spray designed for cleaning camera and computer equipment.

Use a resin-based nozzle only. Be very careful not to damage optical parts with the nozzle tip. Never use any kind

of cleanser on the unit. Also, never use abrasive materials on the unit as this may cause irreparable damage.

● Optical parts care and cleaning

Screen handling precaution;

1. Wear gloves when handling the screen to prevent fingerprints (also, protection of hand).

2. Do not use force when handling the screen so that edges will not brake or crack.

3. Be careful in handling at the process of disassemblies, because scratch or scrub wound makes transparency

decrease easily.

4. Keep the screen in a dust free environment, because dust may accumurate on the screen by static electricity.

5. Do not stand a screen obliquely for long time.

6. Use thinned synthetic detergent for cleaning, because of the weakness against solvent. Wipe gently with soft

cloth.

7. The screen has laminated Lenticular lens and the Fresnel lens. As scrubbed wound on lens is occured by vibra-

tion, so avoid too much vibration after lamination of Lenticular lens and Fresnel lens.

Page 12

- 12 -

When the life of the projection lamp of this LCD Projection TV

draws to an end, the LAMP REPLACE indicator will become

yellow. If this indicator turns to yellow, replace the lamp with a

new one promptly.

G

This indicator becomes yellow

when the life of the projection

lamp draws to an end.

Front Panel

Tu rn off the LCD Projection TV and disconnect the AC plug. Allow

the LCD Projection TV to cool for at least 30 minutes.

Loosen a screw that secure the Lamp Cover with a screwdriver

and remove the Lamp Cover.

1

3

Loosen 2 screws that secure the lamp with a screwdriver and

pull out the Lamp by holding the holes on both sides.

4

Replace the Lamp with a new one and put it back and tighten 2

screws. Make sure that the Lamp is correctly secured into the

Lamp compartment.

5

Press the latches on both side of the front cover and pull the front

cover forward to remove.

2

Connect the AC Power Cord to the Power Cord Connector and

turn on the LCD Projection TV.

Follow these steps to replace the lamp assembly.

Put the Lamp Cover back and tighten the screw, and then replace

the front cover.

6

Reset the Lamp replace counter.

See “Lamp Replace Counter” on the next page .

For continued safety, replace with a lamp of the same

type. Do not drop a lamp or touch a glass bulb! The

glass can shatter and may cause injury.

Allow a LCD Projection TV to cool, for at least 30

minutes before you open the Lamp cover. The inside of

the LCD Projection TV can become very hot.

CAUTIONCAUTION

Loosen the screw

Lamp Cover

CAUTION

When installing the new Lamp into the Lamp compartment, make sure

the Lamp socket is securely plugged into the compartment socket.

Improper or loosen socket connection may cause arc discharge resulting fire hazard.

7

8

Part (a)

Part (a)

Loosen the screw

Loosen the screw

LAMP

With pressing

the button, pull

the front cover

forward.

Press the latch

on both side.

Hold here and pull out the lamp.

(There are holes inside)

■ Lamp Replacement

LAMP

REPLACE

WARNIN

Page 13

Lamp Replacement

- 13 -

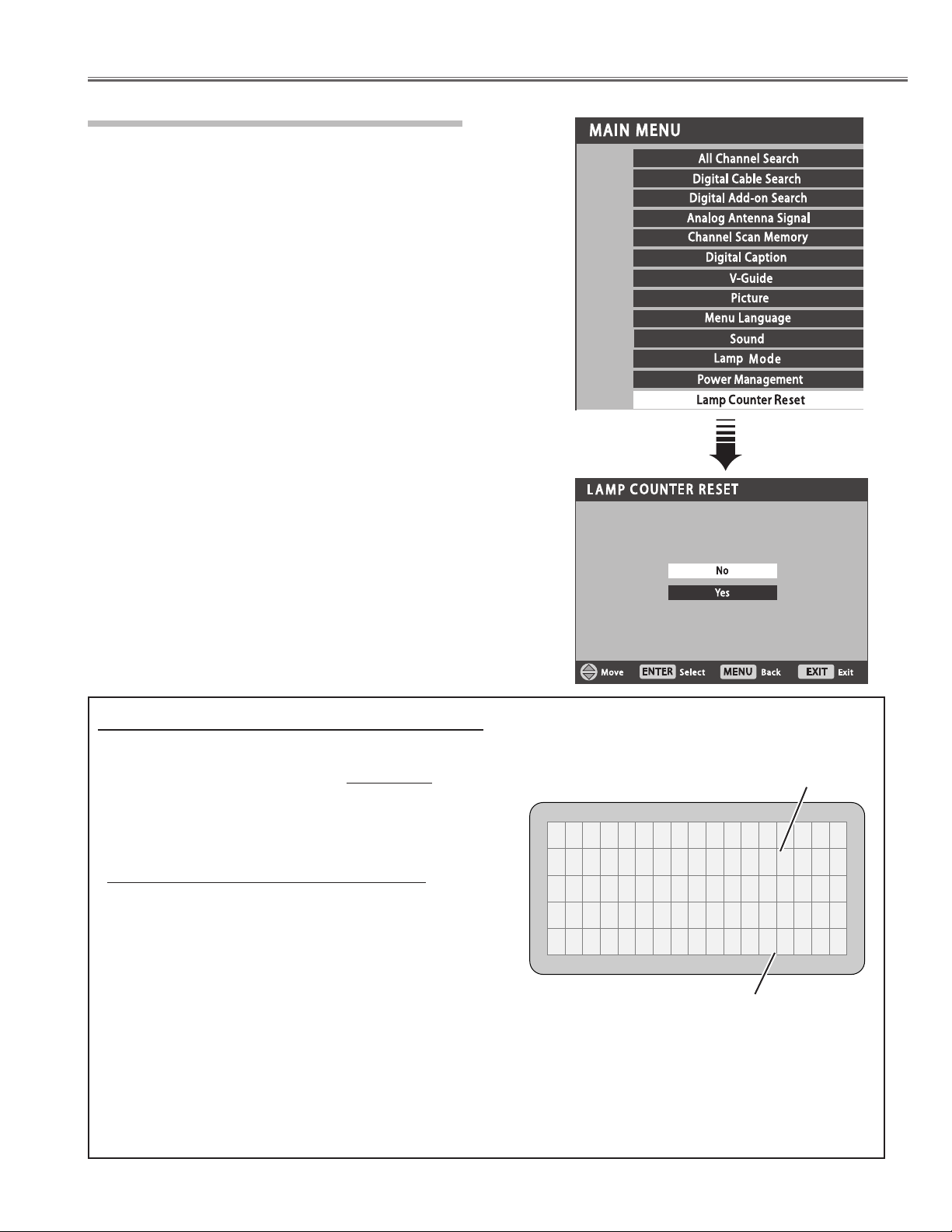

The LAMP REPLACE indicator will light yellow when

the total lamp used time reaches 7,980 hours -(✽).

This is to indicate that lamp replacement is required.

The total lamp used time is calculated by using the

below expression;

Total lamp used time = Teco + Tnormal x 1.14 -(✽)

T

eco : used time in LAMP MODE "Low"

Tnormal : used time in LAMP MODE "High" & "Mid"

You can check the lamp replace counter following to

below procedure.

1 Press and hold INFO button on the remote control

and then press CH(+) button on the side control.

2 The LCD Projection TV used time and lamp used

time will be displayed on the screen briefly.

Total lamp used time

● How to check Lamp Used Time

LCD Projection TV used time

(✽) The specifications are subject to change without

notice.

Be sure to reset the lamp counter after the lamp is

replaced. When the lamp counter is reset, the LAMP

REPLACE indicator will be turned off.

1

Press the MENU key to display the Main menu.

2

Use the CURSOR ed keys to highlight (green)

Lamp Counter Reset. Press ENTER.

3

Use the CURSOR d key to select Ye s . Press

ENTER.

4

Press the EXIT key to return to normal TV viewing.

Lamp Replace Counter

NOTE:

● Do not reset Lamp replace counter without implementation of

lamp replacement. Be sure to reset the Lamp replace counter only after replacing the lamp.

● The lamp counter cannot be reset even if you press the

RESET key on the remote control.

Lamp counter reset?

Use this feature only after replacing the lamp in your PTV.

Coun t e r

To t a lTime 0022

No rma l A 00 10

Eco B 0012

Ak+B 0023

3

H

0

H

3

H

7

H

Page 14

Lamp Replacement

- 14 -

This LCD Projection TV uses a high-pressure lamp which must be handled carefully and properly. Improper handling

may result in accidents, injury, or create a fire hazard.

● Lamp lifetime may differ from lamp to lamp and according to the environment of use. There is no guarantee of the

same lifetime for each lamp. Some lamps may fail or terminate their lifetime in a shorter period of time than other

similar lamps.

● If the LCD Projection TV indicates that the lamp should be replaced, i.e., if the LAMP REPLACE indicator lights up,

replace the lamp with a new one IMMEDIATELY after the LCD Projection TV has cooled down.

( Follow carefully the instructions in the Lamp Replacement section of this manual.) Continuous use of the lamp

with the LAMP REPLACE indicator lighted may increase the risk of lamp explosion.

● A Lamp may explode as a result of vibration, shock or degradation as a result of hours of use as its lifetime draws

to an end. Risk of explosion may differ according to the environment or conditions in which the LCD Projection TV

and lamp are being used.

IF A LAMP EXPLODES, THE FOLLOWING SAFETY PRECAUTIONS SHOULD BE TAKEN.

If a lamp explodes, disconnect the LCD Projection TV’s AC plug from the AC outlet immediately. Contact an authorized service station for a checkup of the unit and replacement of the lamp. Additionally, check carefully to ensure that

there are no broken shards or pieces of glass around the LCD Projection TV or coming out from the cooling air circulation holes. Any broken shards found should be cleaned up carefully. No one should check the inside of the LCD

Projection TV except those who are authorized trained technicians and who are familiar with LCD Projection TV service. Inappropriate attempts to service the unit by anyone, especially those who are not appropriately trained to do so,

may result in an accident or injury caused by pieces of broken glass.

ORDER REPLACEMENT LAMP

Replacement lamp can be ordered through your dealer. When ordering a projection lamp, give the following

information to the dealer.

● Model No. of your LCD Projection TV : PLV-55WHD1 / PLV-65WHD1

● Replacement Lamp Type No. : POA-LMP96

(Service Parts No. 610 322 7382)

Page 15

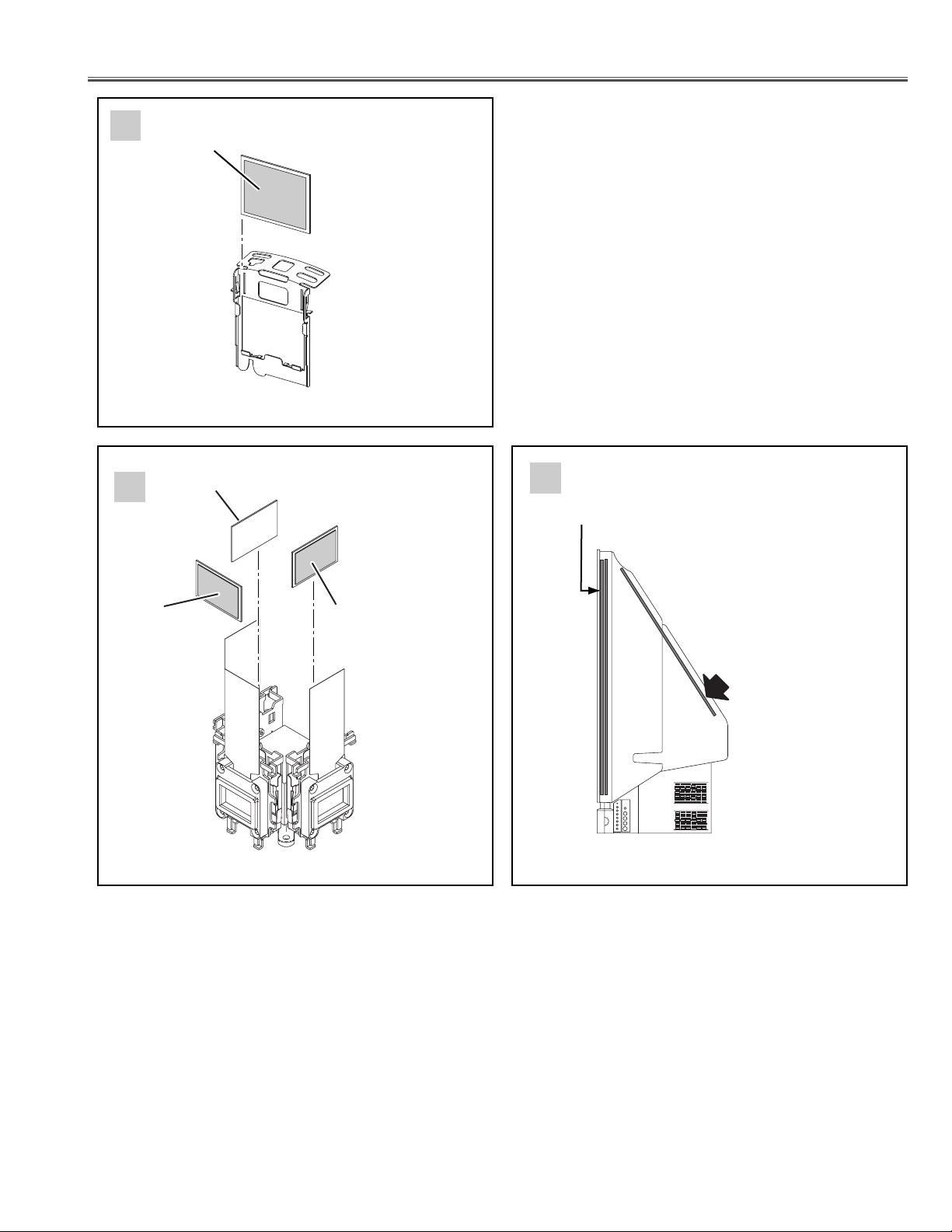

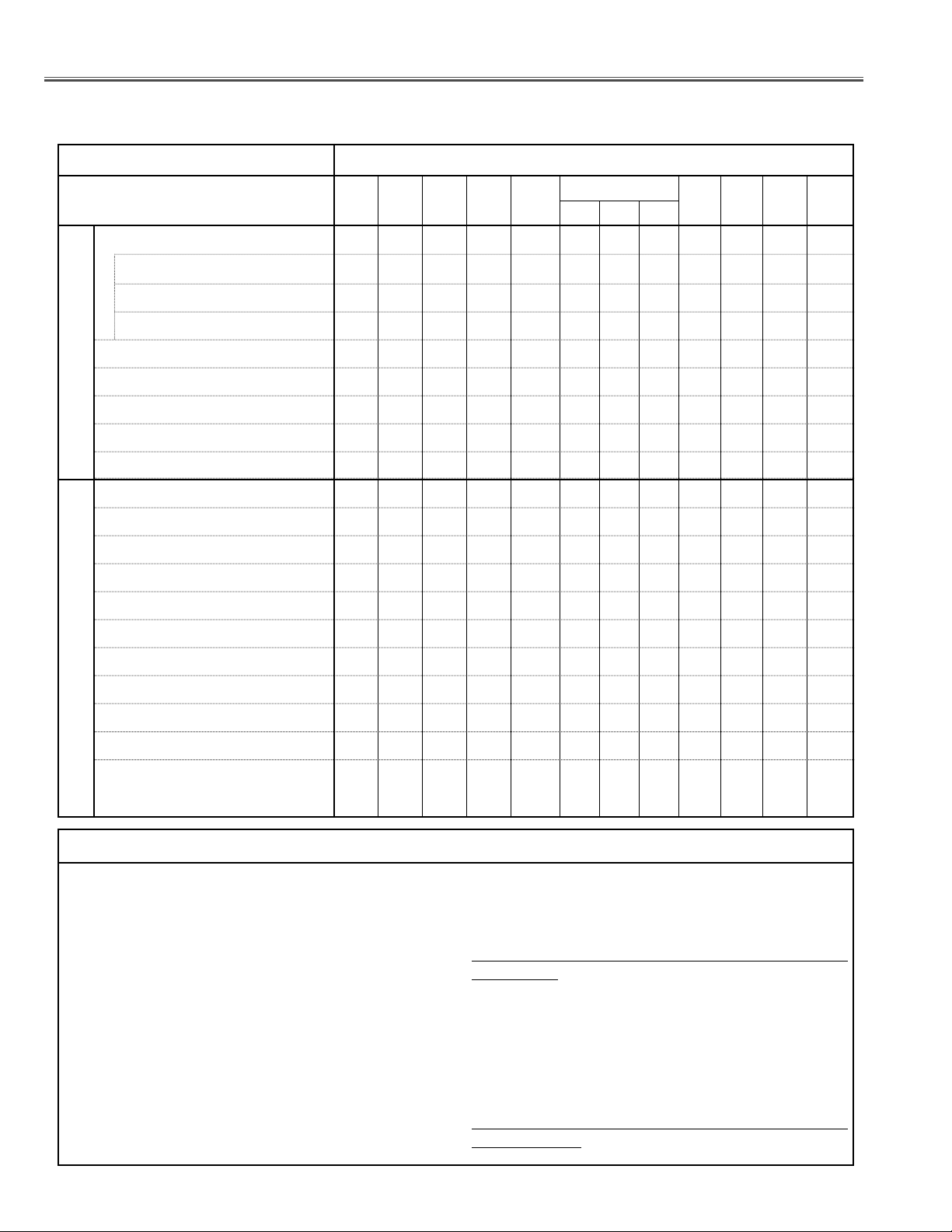

Film attached side

H

I

J

- 57 -

Optical parts location and direction

comes this side.

POLARIZED GLASS(IN)

Film side

Film side

Polarized glass

Film attached side

comes this side

(LCD panel side)

Optical filter (LENTI) comes this side.

(Black surface screen comes this side.)

Printed marker comes

this side.

Page 16

- 58 -

IC836 on the main board stores the data for the service

adjustments, and should not be replaced except for the

case of defective device.

If replaced, it should be performed the re-adjustments

following to the “Electrical Adjustments”.

The data of lamp replacement monitor timer is stored in

the IC836.

Please note that the lamp replace counter is reset

when the memory IC (IC836) is replaced.

(Lamp replace counter can not be set to the previous

value.)

● Caution to memory IC replacement

When IC836 is replaced with new one, the CPU writes

down the default data of the service adjustments to the

replaced IC, refer to the service adjustment table. As

these data are not the same data as factory shipped

data, it should be required to perform the re-adjustments following to the “Electrical Adjustments”.

Please note that in this case the lamp replace counter

will be reset.

● Caution of Main Board replacement (in the case

IC836 is not defective)

When the main board is replaced, IC836 should be

replaced with the one on previous main board. After

replacement, it should be required to perform the readjustments following to the “Electrical Adjustments”.

In this case, the lamp replace counter can be kept the

value as before.

● Memory IC Replacement

Contrast Adjustment

R-Contrast adjustment ●❍ ●

G-Contrast Adjustment ●❍ ●

B-Contrast adjustment ●❍ ●

Condenser lens adjustment ❍❍

Relay lens adjustment ❍❍

Picture image adjustment ❍❍ ●●

Picture focus adjustment ❍❍ ●●

Output voltage adjustment ❍

Fan minimum voltage adjustment ●

TV sound level adjustment ●

TV stereo separation adjustment ●

TV video level adjustment ●

Common center adjustment ●●

Panel luminance adjustment ❍❍

White balance adjustment ❍❍

Color shading correction ❍❍

● : Adjustment necessary ❍ : Check necessary

Disassembly / Replaced Parts

LCD/

Prism

unit

Opti-

cal

unit

Polarized glass

RGB

Optical Adjustments

Electrical Adjustments

Main

Board

Screen

and

mirror

Powe r

Board

Digital

Board

Projec

-tion

lens

After replacing electrical parts and optical parts, electrical adjustments and optical adjustments are required.

■ Adjustments after Parts Replacement

Page 17

- 59 -

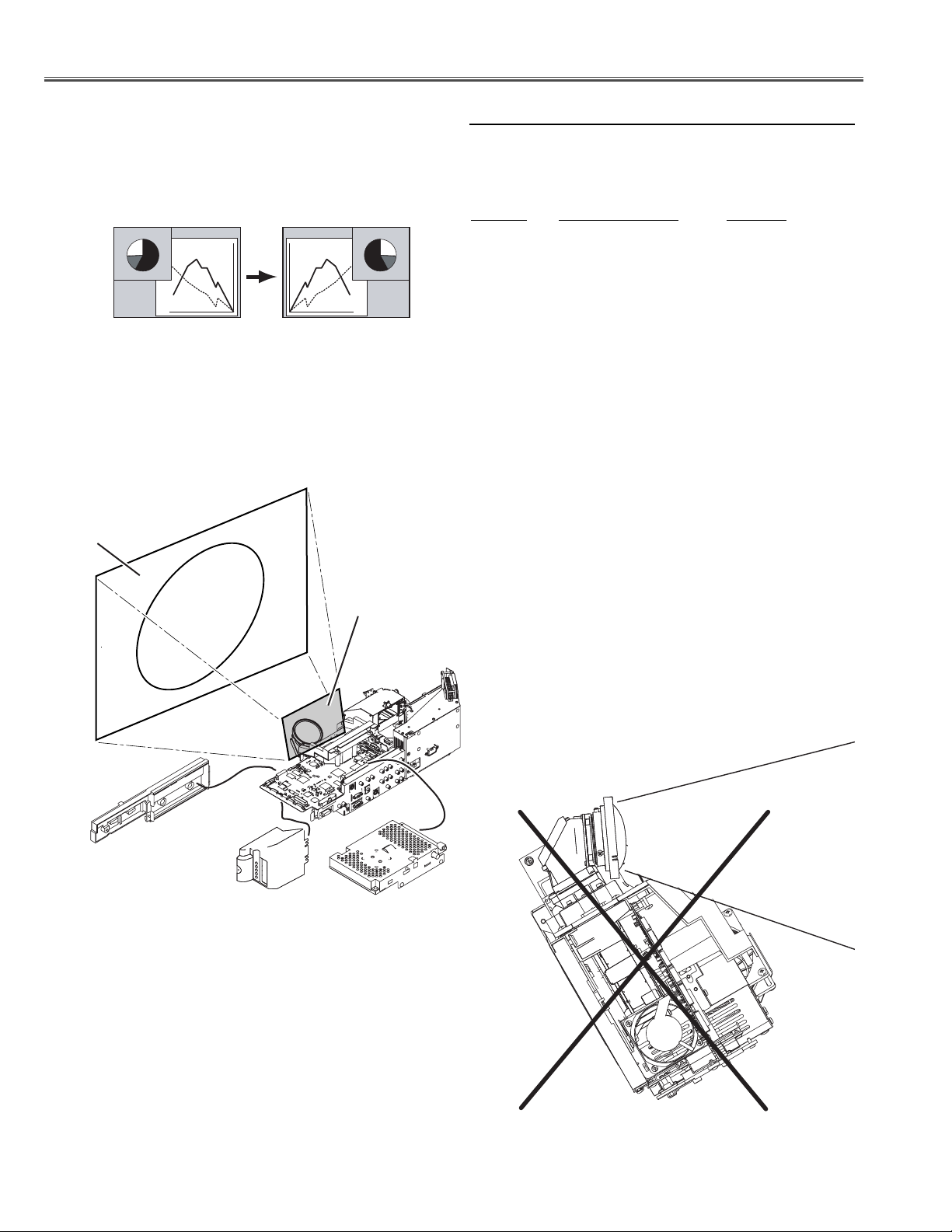

Note: The connector K18U is for the lamp cover switch, so you should short SW1861 on the Cover SW board.

Or you should short between 1 pin and 3 pin of K18U.

Before taking optical adjustments, remove the optical / chassis unit, front panel unit, key unit, digital unit following to

the “Mechanical Disassemblies”

Note: Do not disconnect connectors on the main board, except for K01L, K01R, K35R, K35G, or K35B, because

the LCD Projection TV can not be turned on due to operate the power failure protection.

OPTICAL / CHASSIS UNIT

● Preparation for Adjustments

LAMP COVER SWITCH

(SW1861)

Joint Board " K18U

Joint Board

Main Board " K8S "

Cover SW Board

Cover SW Board " K18S "

K18U

■ Optical Adjustments

Page 18

- 60 -

Optical adjustments

Note:

If the picture is left / right reversed on a screen, you can

select front or rear projection for your convenience.

Rear function

1. Enter the service mode.

2. Select item no. "400" and change data value to select

a direction of projection.

Item no. Adjustment value Function

400 0 Front projection

1 Rear projection

3. Exit the service mode.

---

4. After servicing, this item should be set to default

value = 1.

Note: Service mode is refer to "Service Adjustment

Menu Operation".

Front function

Overview for Servicing (an example)

● Rear - Front Project SW

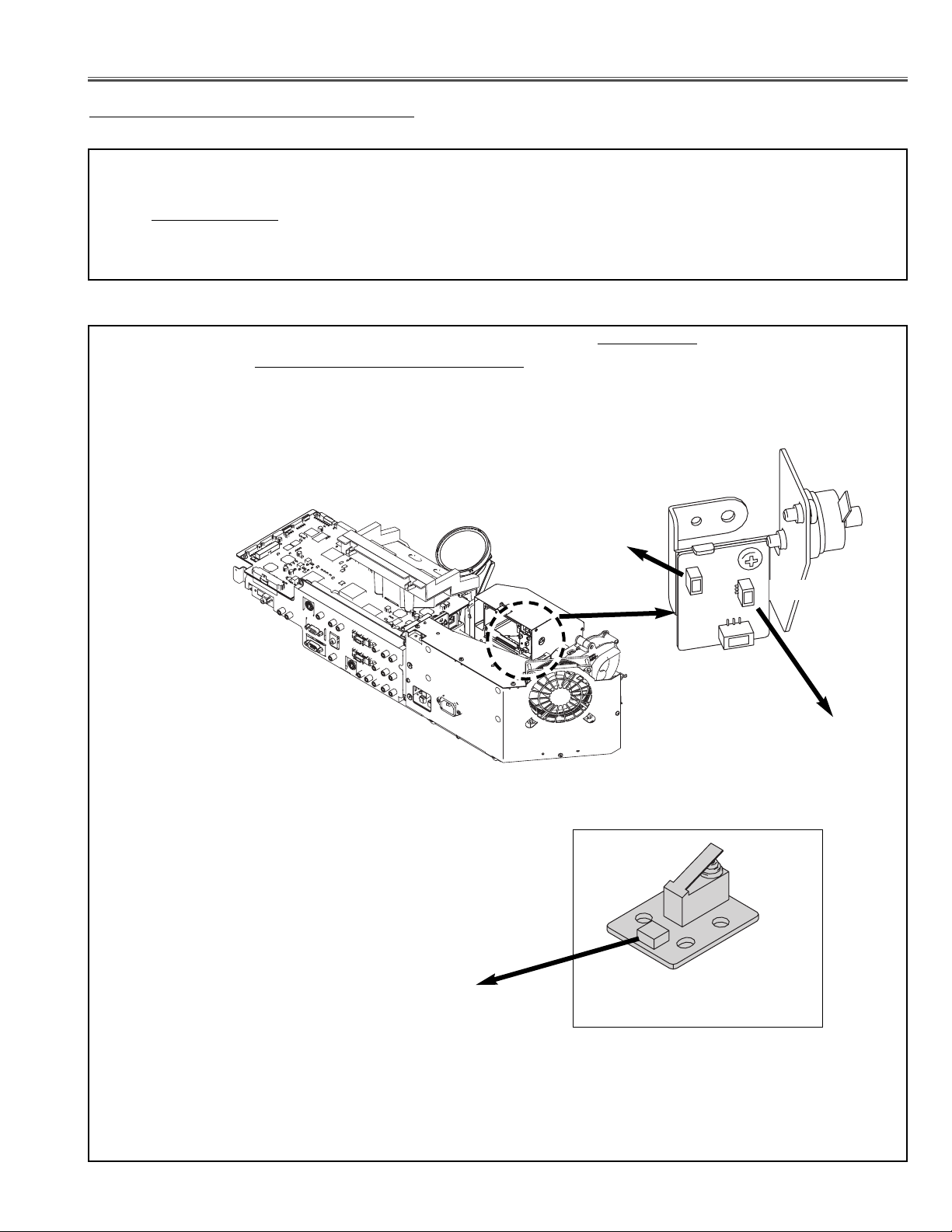

Warning!

Do not use Optical/chassis unit with inclining.

It may result in malfunction of the LCD Projection TV

Screen

Mirror

Page 19

- 61 -

Optical adjustments

Adjustment of optical components location

Blue mirror, Condenser lens, Relay lens and contrast adjustment operate it from a back side.(Item1-1~1-3)

(Remove the Optical/Chassis unit from the Cabinet)

Picture image and focus adjustment operate it from a front side.(Item 2-1~2-3)

(An optical unit must be fixed.)

(Install the cabinet bottom cover.)

Projection lens

FRONT VIEW

(2-2) Vertical centering

adjustment

(2-1) Horizontal centering

adjustment

(2-3) Picture focus adjustment

Picture image and focus

adjustment

(1-3) Contrast adjustment

(1-1) Relay lens adjustment

(b)

(a),(c)

(1-2) Condenser lens

adjustment

Page 20

- 62 -

Optical adjustments

Optical components adjustments procedure

When adjusting optical components, adjust each adjustment item in numerical order.

Incorrect adjustment steps may produce improper adjustment. The items adjusted correctly can

be omitted from the steps.

Pre-adjustment

(a) Condenser lens setting

(b) Relay lens adjustment

(c) Condenser lens adjustment

1. Optical system adjustment (Optical axis adjustment)

(1-1) Relay lens adjustment

(1-2) Condenser lens adjustment

(1-3) Contrast adjustment (Polarized glass adjustment) R,G,B

2. Picture image and focus adjustment

(2-1) Horizontal centering adjustment

(2-2) Vertical centering adjustment

(2-3) Picture focus adjustment

When the Optical unit is disassembled, the pre-adjustment is necessary.

The pre-adjustment can be omitted usually.

Page 21

- 63 -

Optical adjustments

(b) Relay lens pre-adjustment

Loosen the 2 screws I and screw K.

Adjust the slot J to make shading(Cyan) appears on the right of the

screen as shown in figure. (The same amount as red is appeared on

the other side.)

Adjust the slot L to make shading(Cyan) appears on the bottom of the

screen as shown in figure. (The same amount as red is appeared on

the other side.)

Tighten 2 screws I and screw K.

Optical Pre-adjustment

Tu rn the LCD projection TV on by a state of without FPC cables.

(a) Condenser lens pre-adjustment

Loosen the 2 screws A and 2 screws C.

Adjust the slot B to make shading(Red) appears on the right of the

screen as shown in figure.

Adjust the slot D to make shading(Red) appears on the bottom of the

screen as shown in figure.

(The screws are tightened later. The screws are tightened in step-d)

White

Shade (Red)

Screw A

Slot D

Screw C

Slot B

Shade (Cyan)

White

Shade (Red)

Screw I

Slot J

Screw K

Slot L

Page 22

- 64 -

Optical adjustments

(c) Condenser lens pre-adjustment

Adjust the slot B to make color uniformity in white.

(Shading disappears on the right of the screen. Red and Cyan)

Adjust the slot D to make color uniformity in white.

(Shading disappears on the bottom of the screen. Red and Cyan)

Tighten 2 screws A and 2 screws C.

Shade (Cyan)

White

White

Slot D

Screw A

Screw C

Shade (Red)

Slot B

Page 23

- 65 -

Optical adjustments

1-1. Relay lens adjustment

1. Turn the LCD projection TV on by a state of without FPC

cables.

2. Adjust the adjustment base of Relay lens unit to make

color uniformity in white.

a) If the shading appears on the left or right of the screen

as shown in figure, loosen 2 screws A with the ball allen

wrench, and adjust the slot B to make color uniformity in

white by using a slot screwdriver.

b) If the shading appears on the top or bottom of the

screen as shown in figure, loosen screw C with the ball

allen wrench, and adjust the slot D to make color uniformity

in white by using a slot screwdriver.

3. Tighten 2 screws A and screw C to fix the condenser lens

unit.

Shade

White

White

Shade

White

White

Screw A

Slot D

Screw C

Slot D

Page 24

- 66 -

Optical adjustments

1-2. Condenser lens adjustment

1. Turn the LCD projection TV on by a state of without FPC

cables.

2. Adjust the adjustment base of Condenser lens unit to make

color uniformity in white.

a) If the shading appears on the left or right of the screen

as shown in figure, loosen 2 screws A with the ball allen

wrench, and adjust the slot B to make color uniformity in

white by using a slot screwdriver.

b) If the shading appears on the top or bottom of the

screen as shown in figure, loosen 2 screws C with the

ball allen wrench, and adjust the slot D to make color unifor-

mity in white by using a slot screwdriver.

3. Tighten 2 screws A and 2 screws C to fix the condenser

lens unit.

Shade

White

White

Shade

White

White

Screw A

Slot D

Screw C

Slot B

Page 25

- 67 -

Optical adjustments

1-3. Contrast adjustment (R,G,B, polarized glass)

Screw-A

Slot-B

R, G and B Contrast adjustment :

1. Tu rn the LCD projection TV on and input a 100% of black raster

signal (0% of white raster signal).

2. Loosen screw A on the polarizer unit which you intend to adjust

using ball allen wrench.

3. Turn the polarized glass mounting base (slot B) by using a slot

screwdriver and adjust the brightness on the screen to the low-

est level of black.

4. Tighten the screw A to fix the polarizer unit.

5. Adjust the polarizer unit of other colors.

(Repeat steps 2 to 4.)

R-Polarized glass

mounting base

Slot B

Screw-A

Slot-B

Screw A

Screw A

G-Polarized glass

mounting base

Slot B

Screw A

Slot B

B-Polarized glass

mounting base

Page 26

- 68 -

Optical adjustments

2

Picture Image and focus adjustment (Projection lens adjustment)

Screw-A

Focus ring-E

Adjustment Cam-B

Adjustment Cam-C

Screw-D

Screw-A

Projection lens

Remove the Front cover unit, remove the Front

panel unit and remove the Optical cover.

Adjustment area

Install all parts on a back side.

Before adjustment

1. Turn the LCD projection TV on and display grid

pattern or circular pattern on the screen.

2. Be sure to fixed the Optical / Chassis unit with 3

screws to the cabinet.

Install all parts on a back side, otherwise it may

cause lose of performance of Optical

Adjustment.

(Refer to mechanical disassemblies.)

3. Remove the Front Cover unit from the cabinet

bottom.

4. Remove the 3 screws F and remove the Front

panel unit.

5. Remove the Optical Cover.

(Refer to mechanical disassemblies.)

6. When adjust the picture image (horizontal centering and vertical centering) , loosen the 4 screws

A of the lens shift unit.

7. When adjust the picture focus, loosen the focus

fixed screw D of the projection lens.

Front cover

F

F

F

Optical cover

Front panel

Page 27

- 69 -

Optical adjustments

2-1. Horizontal centering adjustment

When the picture is shifted to right or left, adjust the picture horizontally.

1. Loosen the 4 screws A from the lens shift unit.

2. Project the circular pattern on screen.

3. Turn the adjustment cam B to right or left and adjust the position to

project the picture on just center of the screen.

4. Tighten the 4 screws A.

Picture image movement

Horizontal centering

Screw-A

Screw-A

Adjustment cam-B

Page 28

- 70 -

Optical adjustments

2-2. Vertical centering adjustment

When the picture is shifted to right or left, adjust the picture vertically.

1. Loosen the 4 screws A from the lens shift unit.

2. Project the circular pattern on screen.

3. Turn the adjustment cam C to right or left and adjust the position to

project the picture on just center of the screen.

4. Tighten the 4 screws A.

Picture image movement Vertical centering

Screw-A

Screw-A

Adjustment cam-C

Page 29

- 71 -

Optical adjustments

2-3. Picture focus adjustment

When the picture is off focused, adjust the picture focus.

1. Loosen the Projection lens focus lock screw D and turn the focus ring

E for best focus.

Be sure to tighten the Projection lens focus lock screw D and fix the

Projection lens after adjustment.

Adjust center part and four corners on

the grid pattern to sharp focus.

1

4

5

2

3

Focus ring-E

Turn the Focus ring-E

Focus lock screw-D

Page 30

-72-

● Service Adjustment Menu Operation

Remote Control

Side Control

◆ To enter service mode

To enter service mode, press and hold the "INFO" button on the remote control, then press the "VOL(–)" button on the side control. As shown in a figure,

the service mode display appears on the screen.

◆ To adjust service data

Adjust service data using the following control buttons on the LCD projection

TV or the remote control.

– "CHANNEL UP" ..........................................An item number increases.

– "CHANNEL DOWN" ..................................An item number decreases.

– "POINT RIGHT" or "VOLUME (+)" ............An adjustment value increases.

– "POINT LEFT" or "VOLUME (–)" ..............An adjustment value decreases.

◆ To exit service mode

To quit the service mode, press the "POWER ON/OFF" button only once on

the LCD projection TV or the remote control.

Data value

Item No.

Temperature

Fan rotation speed

Note :

This part of display is available at the service mode No.600s.

■ Electrical Adjustments

w

q

e

VOL(-)

Normal Mode

+

INFO

Service Mode

Service Mode

INPUT

VOLUME

CHANNEL

VOL(-)

w

INFO

q

POWER

e

Service Mode Display

NO 0 Data 105

TA TB TC

2662 3237 3050

F1 F2 F3 F4

80 100 100 100

Page 31

-73-

● Circuit Adjustments

CAUTION: The each circuit has been made by the fine adjustment at factory. Do not attempt to adjust the follow-

ing adjustments except requiring the readjustments in servicing otherwise it may cause loss of performance and product safety.

Note: Please refer to “Service Adjustment Menu Operation” for entering to the service mode and adjusting

the service data.

Equipment Digital voltmeter

1. Enter the service mode.

2. Change data values of each test points to adjust the

fan minimum output voltage.

Item no

. Fan Location Test Point Adjustment value

0 FN905/6 TPFAN1 8.0 ±0.05Vdc

1 FN901 TPFAN2 8.0 ±0.05Vdc

2 FN903/4 TPFAN3 8.0 ±0.05Vdc

3 FN902 TPFAN4 8.0 ±0.05Vdc

Note:

The location of each fan is refer to P.90.

x Fan minimum voltage adjustment

Equipment Digital voltmeter

1. Adjust the voltage by using VR621 on the power

board as following.

Test Point AC Input Reading

(+) 1pin of K6A 120V . . . . . .355V ±2Vdc

(–) 3pin of K6A (or 230V . . . . .370V ±2Vdc)

Caution:

Be sure to connect the lamp when taking this adjustment.

"K6A" is in the primary circuit. HO

T CIRCUIT!

Note:

The Power Board for replacing is already adjusted in a

factory, so it is not required to perform this readjustment.

z Output voltage adjustment

Electrical Adjustments

[Adjustment Condition]

● Input signal

Video signal .......................... 1.0Vp-p/75Ω terminated, color bar pat-

tern, 16 steps gray scale pattern, and

100%/50% white pattern (Composite

video signal)

Component video signal ...... 0.7Vp-p/75Ω terminated, color bar pat-

tern (480i format)

RF Audio signal .................... 1KHz 100% modulation signal and

multi stereo signal

● Picture setup menu .................. Before the electrical adjustments from step [ 6 ] to step [ 11 ], the picture

setup menu should be set as follows;

Main menu > Picture setup menu >

Picture --- Auto

16 steps gray scale pattern

White 100%

Black 100%

Page 32

-74-

Electrical Adjustments

Equipment Oscilloscope

Input mode Analog TV mode

Input signal Color bar pattern

1. Adjust the amplitude "a" by using VR101 on the

tuner board.

Test Point

Adjustment value

(+) TPTV 1.0 ±0.03Vdc

(–) TUNER_GND

b TV video level adjustment

Equipment Oscilloscope

Input mode Analog TV mode

Audio mode Stereo mode

Input audio signal Multi sound program

1. Enter the service mode.

2. Adjust the amplitude of 4KHz at Audio output-(L) terminal to become minimum level.

Item no. Test Point Adjustment value

751 (+) L audio output Minimum at 4KHz

(–) GND

3. Adjust the amplitude of 300Hz at Audio output-(R)

terminal to become minimum level.

Item no. Test Point Adjustment value

752 (+) R audio output Minimum at 300Hz

(–) GND

v TV stereo separation adjustment

Equipment Digital voltmeter

Input mode Analog TV mode

Input audio signal 1KHz 100% modulation

1. Enter the service mode.

2. Adjust the audio output amplitude at Audio output-(L)

terminal to become 400 ±10 mVac.

Item no. T

est Point Adjustment value

750 (+) L audio output 500 ±10 mVac

(–) GND

Note:

At the case with using an oscilloscope, adjust the

audio output amplitude at Audio output-(L) terminal to

become 1.41 ±0.02 Vp-p.

c TV sound level adjustment

(a)

Minimum leakage

4KHz

Minimum leakage

300Hz

Page 33

-75-

Electrical Adjustments

Input mode Not designated

Input signal 50% whole green, blue or red signal

Picture Auto

Lamp mode High

1. Enter the service mode.

2. Select item no. "308", and change data value from

"0" to "2". (Flicker adjustment mode ...see Note)

3. Receive 50% whole green, blue or red signal and project only one color component to the screen.

4. Change data value to obtain the minimum flicker for

each color on the screen.

5. After this adjustment, select item no. "308", and

change data value from "2" to "0" for normal operation. (Or turn off the projection TV, then this data value

will be reset to "0".)

Item no. Screen

4 Only green color picture

5 Only blue color picture

6 Only red color picture

Note:

The FRP signal (common electrode reverse signal)

works at 120Hz, so flicker is invisible for human eyes.

The service mode no. "308" can change the FRP signal from 120Hz to 60Hz, and flicker can be seen.

n Common center adjustment

Input signal 16-step gray scale signal

Input mode VIDEO_1 [Video] mode

Picture Auto

Lamp mode High

1. Enter the service mode.

2. Select group/item no. “8”(Blue) or “9”(Red), and

change data values respectively to make a proper

white balance.

Note:

If the luminance meter is not equipped, you can take

another method instead as follows;

1. When the main board is replaced, the data value at

"7/8/9" of the previous main board should be copied

manually.

2. If the main board is not replaced, you need not readjust these items.

, White balance adjustment [High]

Equipment luminance meter

Input mode VIDEO_1 [Video] mode

Picture Auto

Lamp mode High

1. Receive the 100% whole-white signal.

2. Enter the service mode.

3. Measure luminance on the screen with the luminance

meter. It is A for the reading of luminance meter.

4. Change the signal source to the 50% whole-white

signal.

5. Select item no. “7” and change data value to make the

reading of luminance meter to be A x 22±1%.

Item no. Screen Ajustment value

100% white A (reading value)

7 50% white A x 22 ±1%

m Panel luminance adjustment [High]

Page 34

-76-

Electrical Adjustments

If you find the color shading on the screen, please adjust

the white uniformity by using the proper computer and

“Color Shading Correction” software supplied separately. The software can be ordered as follows;

COLOR SHADING CORRECTION ver.. 4.00

Service Parts No. 645 075 9611

Note on WHITE UNIFORMITY Adjustment

Input mode VIDEO_1 [Video] mode

Picture Auto

Lamp mode Mid

1. Enter the service mode.

2. Receive the 100% whole-white signal.

3. Select item no. “13”(Green), “14”(Blue) or “15”

(Red), and change data values respectively to make

a proper white balance.

4. Receive the 50% whole-white signal.

5. Select item no. “17”(Blue) or “18”(Red), and change

data values respectively to make a proper white balance.

Note:

Confirm that the same white balance is obtained in

100% white and 50% white signals.

⁄0 White balance adjustment [Mid]

Equipment luminance meter

Input mode VIDEO_1 [Video] mode

Picture Auto

Lamp mode Mid

1. Enter the service mode.

2. Receive the 100% whole-white signal, and select

item no. “10”, the screen image will be whole-green.

3. Measure luminance on the screen with the luminance

meter. It is B for the reading of luminance meter.

4. Change the signal source to the 50% whole-white

signal.

5. Change data value to make the reading of luminance

meter to be B x 22±1%.

6. Receive the 100% whole-white signal, and select

item no. “11”, the screen image will be whole-blue.

7. Measure luminance on the screen with the luminance

meter. It is C for the reading of luminance meter.

8. Change the signal source to the 50% whole-white

signal.

9. Change data value to make the reading of luminance

meter to be C x 22±1%.

10. Receive the 100% whole-white signal, and select

item no. “12”, the screen image will be whole-red.

11. Measure luminance on the screen with the luminance meter. It is D for the reading of luminance

meter.

12. Change the signal source to the 50% whole-white

signal.

13. Change data value to make the reading of luminance meter to be D x 22±1%.

Item no. Screen Ajustment value

10 100% green B (reading value)

50% green B x 22±1%

11 100% blue C (reading value)

50% blue C x 22±1%

12 100% red D (reading value)

50% red D x 22±1%

Note:

If the luminance meter is not equipped, you can take

another method instead as follows;

1. When the main board is replaced, the data value at

"10/11/12" of the previous main board should be

copied manually.

2. If the main board is not replaced, you need not readjust these items.

. Panel luminance adjustment [Mid]

Page 35

FACTORY ADJUSTMENT

0Fan1 Min Adjust 0 ~ 255 105 ✻ FAN1 minimum voltage adjustment

1Fan2 Min Adjust 0 ~ 255 105 ✻ FAN2 minimum voltage adjustment

2Fan3 Min Adjust 0 ~ 255 105 ✻ FAN3 minimum voltage adjustment

3Fan4 Min Adjust 0 ~ 255 105 ✻ FAN4 minimum voltage adjustment

4 G_LCCOM 0 ~ 511 280 ✻ Common center adjustment [G]

5 B_LCCOM 0 ~ 511 280 ✻ Common center adjustment [B]

6 R_LCCOM 0 ~ 511 280 ✻ Common center adjustment [R]

7 G-GammaShift (Lamp mode=High) 0 ~ 1023 512 ✻ Panel luminance adjustment [High]

8 B-GammaShift(Lamp mode=High) 0 ~ 1023 512 ✻ White balance adjustment B [High]

9R-GammaShift (Lamp mode=High) 0 ~ 1023 512 ✻ White balance adjustment R [High]

10 G-GammaShift (Lamp mode=Mid or Low) 0 ~ 1023 512 ✻ Panel luminance adjustment G [Mid]

11 B-GammaShift (Lamp mode=Mid or Low) 0 ~ 1023 512 ✻ Panel luminance adjustment B [Mid]

12 R-GammaShift (Lamp mode=Mid or Low) 0 ~ 1023 512 ✻ Panel luminance adjustment R [Mid]

13 G-SubGain factor (Lamp=Mid or Low) 0 ~ 255 255 ✻ White balance adjustment 100% G [Mid]

14 B-SubGain factor (Lamp=Mid or Low) 0 ~ 255 255 ✻ White balance adjustment 100% B [Mid]

15 R-SubGain factor (Lamp=Mid or Low) 0 ~ 255 255 ✻ White balance adjustment 100% R [Mid]

16 G-GammaShift (Lamp mode=Mid or Low) 0 ~ 1023 512

17 B-GammaShift (Lamp mode=Mid or Low) 0 ~ 1023 512 ✻ White balance adjustment 50% B [Mid]

18 R-GammaShift (Lamp mode=Mid or Low) 0 ~ 1023 512 ✻ White balance adjustment 50% R [Mid]

19 G_V_CENTER 0 ~ 255 18

20 B_V_CENTER 0 ~ 255 18

21 R_V_CENTER 0 ~ 255 18

22 REF_G 0 ~ 255 191

23 REF_B 0 ~ 255 191

24 REF_R 0 ~ 255 191

25 GAIN_G (Lamp mode=Mid or Low) 360 ~ 535 512

26 GAIN_B (Lamp mode=Mid or Low) 360 ~ 535 512

27 GAIN_R (Lamp mode=Mid or Low) 360 ~ 535 512

PANEL DRIVER (L3E07110, L3E06150, L3E01060)

100 G-SubGain (Lamp mode=High) 360 ~ 535 512

101 B-SubGain (Lamp mode=High) 360 ~ 535 512

102 R-SubGain (Lamp mode=High) 360 ~ 535 512

103 G_OFFSET 0 ~ 255 0

104 B_OFFSET 0 ~ 255 0

105 R_OFFSET 0 ~ 255 0

106 G_ENBX1 ~ 4 Pulse Width 0 ~ 127 11

107 B_ENBX1 ~ 4 Pulse Width 0 ~ 127 11

108 R_ENBX1 ~ 4 Pulse Width 0 ~ 127 11

109 G_DXIN Delay 0 ~ 255 20

110 B_DXIN Delay 0 ~ 255 20

111 R_DXIN Delay 0 ~ 255 20

112 G_CLXIN Delay 0 ~ 255 20

113 B_CLXIN Delay 0 ~ 255 20

114 R_CLXIN Delay 0 ~ 255 20

115 G_ENBX Delay 0 ~ 255 14

116 B_ENBX Delay 0 ~ 255 14

117 R_ENBX Delay 0 ~ 255 14

118 G-SubBright 0 ~ 1023 0

119 B-SubBright 0 ~ 1023 0

120 R-SubBright 0 ~ 1023 0

121 G_ReferH (NRS Level) 0 ~ 1023 1020

122 B_ReferH (NRS Level) 0 ~ 1023 1020

123 R_ReferH (NRS Level) 0 ~ 1023 1020

124 G_ReferL (NRS Level) 0 ~ 1023 256

125 B_ReferL (NRS Level) 0 ~ 1023 256

126 R_ReferL (NRS Level) 0 ~ 1023 256

127 G V-Line Correction (-) Tilt 0 ~ 255 0

128 G V-Line Correction (-) 1 dot 0 ~ 511 503

129 G V-Line Correction (-) 2 dot 0 ~ 511 0

130 G V-Line Correction (-) 3 dot 0 ~ 511 0

-77-

● Service Adjustment Data Table

These initial values are the reference data written from the CPU

ROM to memory IC when replaced new memory IC. The adjustment items indicated with “✻” are required to readjust following

to the “Electrical adjustments”. Other items should be used with

the initial data value.

Electrical Adjustments

Item No. Adjustment Item Range Initial Value Description

Page 36

-78-

Electrical Adjustments

131 G V-Line Correction (-) 4 dot 0 ~ 511 0

132 G V-Line Correction (-) 5 dot 0 ~ 511 0

133 G V-Line Correction (-) 6 dot 0 ~ 511 0

134 G V-Line Correction (-) 7 dot 0 ~ 511 0

135 G V-Line Correction (-) 8 dot 0 ~ 511 0

136 G V-Line Correction (-) 9 dot 0 ~ 511 0

137 G V-Line Correction (-) 10 dot 0 ~ 511 0

138 G V-Line Correction (-) 11 dot 0 ~ 511 503

139 G V-Line Correction (-) 12 dot 0 ~ 511 503

140 B V-Line Correction (-) Tilt 0 ~ 255 0

141 B V-Line Correction (-) 1 dot 0 ~ 511 503

142 B V-Line Correction (-) 2 dot 0 ~ 511 0

143 B V-Line Correction (-) 3 dot 0 ~ 511 0

144 B V-Line Correction (-) 4 dot 0 ~ 511 0

145 B V-Line Correction (-) 5 dot 0 ~ 511 0

146 B V-Line Correction (-) 6 dot 0 ~ 511 0

147 B V-Line Correction (-) 7 dot 0 ~ 511 0

148 B V-Line Correction (-) 8 dot 0 ~ 511 0

149 B V-Line Correction (-) 9 dot 0 ~ 511 0

150 B V-Line Correction (-) 10 dot 0 ~ 511 0

151 B V-Line Correction (-) 11 dot 0 ~ 511 503

152 B V-Line Correction (-) 12 dot 0 ~ 511 503

153 R V-Line Correction (-) Tilt 0 ~ 255 0

154 R V-Line Correction (-) 1 dot 0 ~ 511 503

155 R V-Line Correction (-) 2 dot 0 ~ 511 0

156 R V-Line Correction (-) 3 dot 0 ~ 511 0

157 R V-Line Correction (-) 4 dot 0 ~ 511 0

158 R V-Line Correction (-) 5 dot 0 ~ 511 0

159 R V-Line Correction (-) 6 dot 0 ~ 511 0

160 R V-Line Correction (-) 7 dot 0 ~ 511 0

161 R V-Line Correction (-) 8 dot 0 ~ 511 0

162 R V-Line Correction (-) 9 dot 0 ~ 511 0

163 R V-Line Correction (-) 10 dot 0 ~ 511 0

164 R V-Line Correction (-) 11 dot 0 ~ 511 503

165 R V-Line Correction (-) 12 dot 0 ~ 511 503

166 G V-Line Correction (+) Tilt 0 ~ 255 0

167 G V-Line Correction (+) 1 dot 0 ~ 511 10

168 G V-Line Correction (+) 2 dot 0 ~ 511 0

169 G V-Line Correction (+) 3 dot 0 ~ 511 0

170 G V-Line Correction (+) 4 dot 0 ~ 511 0

171 G V-Line Correction (+) 5 dot 0 ~ 511 0

172 G V-Line Correction (+) 6 dot 0 ~ 511 0

173 G V-Line Correction (+) 7 dot 0 ~ 511 0

174 G V-Line Correction (+) 8 dot 0 ~ 511 0

175 G V-Line Correction (+) 9 dot 0 ~ 511 0

176 G V-Line Correction (+) 10 dot 0 ~ 511 0

177 G V-Line Correction (+) 11 dot 0 ~ 511 10

178 G V-Line Correction (+) 12 dot 0 ~ 511 10

179 B V-Line Correction (+) Tilt 0 ~ 255 0

180 B V-Line Correction (+) 1 dot 0 ~ 511 10

181 B V-Line Correction (+) 2 dot 0 ~ 511 5

182 B V-Line Correction (+) 3 dot 0 ~ 511 0

183 B V-Line Correction (+) 4 dot 0 ~ 511 0

184 B V-Line Correction (+) 5 dot 0 ~ 511 0

185 B V-Line Correction (+) 6 dot 0 ~ 511 0

186 B V-Line Correction (+) 7 dot 0 ~ 511 0

187 B V-Line Correction (+) 8 dot 0 ~ 511 0

188 B V-Line Correction (+) 9 dot 0 ~ 511 0

189 B V-Line Correction (+) 10 dot 0 ~ 511 0

190 B V-Line Correction (+) 11 dot 0 ~ 511 10

191 B V-Line Correction (+) 12 dot 0 ~ 511 10

192 R V-Line Correction (+) Tilt 0 ~ 255 0

193 R V-Line Correction (+) 1 dot 0 ~ 511 10

194 R V-Line Correction (+) 2 dot 0 ~ 511 5

195 R V-Line Correction (+) 3 dot 0 ~ 511 0

196 R V-Line Correction (+) 4 dot 0 ~ 511 0

197 R V-Line Correction (+) 5 dot 0 ~ 511 0

198 R V-Line Correction (+) 6 dot 0 ~ 511 0

Item No. Adjustment Item Range Initial Value Description

Page 37

Electrical Adjustments

-79-

199 R V-Line Correction (+) 7 dot 0 ~ 511 0

200 R V-Line Correction (+) 8 dot 0 ~ 511 0

201 R V-Line Correction (+) 9 dot 0 ~ 511 0

202 R V-Line Correction (+) 10 dot 0 ~ 511 0

203 R V-Line Correction (+) 11 dot 0 ~ 511 10

204 R V-Line Correction (+) 12 dot 0 ~ 511 10

205 DXOUTG 0 ~ 1023 214

206 DXOUTB 0 ~ 1023 214

207 DXOUTR 0 ~ 1023 214

208 h_change_pos 0 ~ 255 22

209 sh_base_pos_b 0 ~ 4096 2730

210 NRG Position 0 ~ 127 34

211 NRG Width 0 ~ 255 45

212 OSD 0 ~ 3 2

213 OSD 0 ~ 7 0

214 GAMMA (ON/OFF) 0-1 1

215 ref_gate_pos (NRS Position) 0 ~ 1023 1

216 ref_gate_dur (NR Width) 0 ~ 1023 157

217 gray_on 0 ~ 7 7

218 Correction 0 ~ 1 0

219 V Line Correction DC Offset EN 0 ~ 1 1

220 V Line Correction Offset EN 0 ~ 1 1

221 V Line Correction BLSP_EN 0 ~ 1 1

222 Sequential Ghost Correction EN 0 ~ 1 1

223 Block Ghost Correction EN 0 ~ 1 1

224 Reversal Ghost Correction EN 0 ~ 1 1

225 Rear Crosstalk Correction EN 0 ~ 1 1

226 G_base_pos 0 ~ 15 6

227 B_base_pos 0 ~ 15 6

228 R_base_pos 0 ~ 15 6

229 RGB_adjust 0 ~ 7 0

230 RGB_level 0 ~ 1023 0 5 Step Setting [0,256,512,768,1023]

231 V Line Correction <G0> 0 ~ 255 8

232 V Line Correction <G1> 0 ~ 255 6

233 V Line Correction <G2> 0 ~ 255 2

234 V Line Correction <G3> 0 ~ 255 254

235 V Line Correction <G4> 0 ~ 255 253

236 V Line Correction <B0> 0 ~ 255 8

237 V Line Correction <B1> 0 ~ 255 6

238 V Line Correction <B2> 0 ~ 255 2

239 V Line Correction <B3> 0 ~ 255 254

240 V Line Correction <B4> 0 ~ 255 253

241 V Line Correction <R0> 0 ~ 255 8

242 V Line Correction <R1> 0 ~ 255 6

243 V Line Correction <R2> 0 ~ 255 2

244 V Line Correction <R3> 0 ~ 255 254

245 V Line Correction <R4> 0 ~ 255 253

246 Ghost_G_pos (Sequential) 0 ~ 15 6

247 Ghost_B_pos (Sequential) 0 ~ 15 6

248 Ghost_R_pos (Sequential) 0 ~ 15 6

249 Ghost_G_center 0 ~ 2047 0

250 Ghost_G_start 0 ~ 255 128

251 Ghost_G_end 0 ~ 255 128

252 Ghost_B_center 0 ~ 2047 0

253 Ghost_B_start 0 ~ 255 128

254 Ghost_B_end 0 ~ 255 128

255 Ghost_R_center 0 ~ 2047 0

256 Ghost_R_start 0 ~ 255 128

257 Ghost_R_end 0 ~ 255 128

258 G-Block Ghost 0 ~ 2047 0

259 B-Block Ghost 0 ~ 2047 0

260 R-Block Ghost 0 ~ 2047 0

261 G_base_level (Block) 0 ~ 2047 0

262 B_base_level (Block) 0 ~ 2047 0

263 R_base_level (Block) 0 ~ 2047 0

264 Ghost_G_pos (Reverse) 0 ~ 2047 0

265 Ghost_B_pos (Reverse) 0 ~ 2047 0

266 Ghost_R_pos (Reverse) 0 ~ 2047 0

Item No. Adjustment Item Range Initial Value Description

Page 38

-80-

Electrical Adjustments

267 C_TALK G_CENT 0 ~ 2047 0

268 C_TALK G_START 0 ~ 255 128

269 C_TALK G_END 0 ~ 255 128

270 C_TALK B_CENT 0 ~ 2047 0

271 C_TALK B_START 0 ~ 255 128

272 C_TALK B_END 0 ~ 255 128

273 C_TALK R_CENT 0 ~ 2047 0

274 C_TALK R_START 0 ~ 255 128

275 C_TALK R_END 0 ~ 255 128

276 lccom_correct_select 0 ~ 1 0

277 iromura_correct_select 0 ~ 1 1

278 Hori Start 0 ~ 2047 266

279 Vert Start 0 ~ 2047 8

280 Hori End 0 ~ 2047 1545

281 Vert End 0 ~ 2047 728

282 G MIN 0 ~ 1023 594

283 G_MID2 0 ~ 1023 664

284 G_MID1 0 ~ 1023 736

285 G_MAX 0 ~ 1023 780

286 B MIN 0 ~ 1023 594

287 B_MID2 0 ~ 1023 664

288 B_MID1 0 ~ 1023 736

289 B_MAX 0 ~ 1023 780

290 R MIN 0 ~ 1023 594

291 R_MID2 0 ~ 1023 664

292 R_MID1 0 ~ 1023 736

293 R_MAX 0 ~ 1023 780

294 G MIN (8 Stair) 0 ~ 1023 705

295 G_MID2 (8 Stair) 0 ~ 1023 730

296 G_MID1 (8 Stair) 0 ~ 1023 757

297 G_MAX (8 Stair) 0 ~ 1023 787

298 B MIN (8 Stair) 0 ~ 1023 705

299 B_MID2 (8 Stair) 0 ~ 1023 730

300 B_MID1 (8 Stair) 0 ~ 1023 757

301 B_MAX (8 Stair) 0 ~ 1023 787

302 R MIN( (8 Stair) 0 ~ 1023 705

303 R_MID2 (8 Stair) 0 ~ 1023 730

304 R_MID1 (8 Stair) 0 ~ 1023 757

305 R_MAX (8 Stair) 0 ~ 1023 787

306 H_OUT_START 0 ~ 2047 102

307 Stair Output out of effective field 0 ~ 1023 0

308 Flicker Adjustment Mode 0 ~ 3 0 0: Off, 1: Flicker adj. mode 1, 2: Flicker adj. mode 2

309 Frame Modulation Step 0 ~ 3 2

310 H Crosstalk Correction 2 G center 0 ~ 2047 0

311 H Crosstalk Correction 2 G start 0 ~ 255 126

312 H Crosstalk Correction 2 G end 0 ~ 255 128

313 H Crosstalk Correction 2 B center 0 ~ 2047 0

314 H Crosstalk Correction 2 B start 0 ~ 255 126

315 H Crosstalk Correction 2 B end 0 ~ 255 128

316 H Crosstalk Correction 2 R center 0 ~ 2047 0

317 H Crosstalk Correction 2 R start 0 ~ 255 126

318 H Crosstalk Correction 2 R end 0 ~ 255 128

319 R_hosei point 0 0-3FF 0

320 R_hosei point 24 0-3FF 200

321 R_hosei point 48 0-3FF 420

322 R_hosei point 88 0-3FF 565

323 R_hosei point 140 0-3FF 615

324 R_hosei point 200 0-3FF 645

325 R_hosei point 300 0-3FF 685

326 R_hosei point 400 0-3FF 712

327 R_hosei point 500 0-3FF 738

328 R_hosei point 600 0-3FF 758

329 R_hosei point 700 0-3FF 782

330 R_hosei point 800 0-3FF 807

331 R_hosei point 900 0-3FF 841

332 R_hosei point 948 0-3FF 878

333 R_hosei point 980 0-3FF 950

334 R_hosei point 1024 0-3FF 1023

Item No. Adjustment Item Range Initial Value Description

Page 39

Electrical Adjustments

-81-

335 G_hosei point 0 0 ~ 3FF 0

336 G_hosei point 24 0 ~ 3FF 200

337 G_hosei point 48 0 ~ 3FF 420

338 G_hosei point 88 0 ~ 3FF 565

339 G_hosei point 140 0 ~ 3FF 615

340 G_hosei point 200 0 ~ 3FF 645

341 G_hosei point 300 0 ~ 3FF 685

342 G_hosei point 400 0 ~ 3FF 712

343 G_hosei point 500 0 ~ 3FF 738

344 G_hosei point 600 0 ~ 3FF 758

345 G_hosei point 700 0 ~ 3FF 782

346 G_hosei point 800 0 ~ 3FF 807

347 G_hosei point 900 0 ~ 3FF 841

348 G_hosei point 948 0 ~ 3FF 878

349 G_hosei point 980 0 ~ 3FF 950

350 G_hosei point 1024 0 ~ 3FF 1023

351 B_hosei point 0 0 ~ 3FF 0

352 B_hosei point 24 0 ~ 3FF 200

353 B_hosei point 48 0 ~ 3FF 420

354 B_hosei point 88 0 ~ 3FF 565

355 B_hosei point 140 0 ~ 3FF 615

356 B_hosei point 200 0 ~ 3FF 645

357 B_hosei point 300 0 ~ 3FF 685

358 B_hosei point 400 0 ~ 3FF 712

359 B_hosei point 500 0 ~ 3FF 738

360 B_hosei point 600 0 ~ 3FF 758

361 B_hosei point 700 0 ~ 3FF 782

362 B_hosei point 800 0 ~ 3FF 807

363 B_hosei point 900 0 ~ 3FF 841

364 B_hosei point 948 0 ~ 3FF 878

365 B_hosei point 980 0 ~ 3FF 950

366 B_hosei point 1024 0 ~ 3FF 1023

367 Color Shading Correction 4/8 Layer SW 3 3: 4 Layer, 7: 8 Layer

Option

400 Rear Projection On/Off 0 ~ 1 1 0: Front Projection, 1: Rear Projection

401 PANEL R/B Reversal 0 ~ 1 1 0: Normal, 1: Reverse (Bin - Rout, Rin - Bout)

402 OnTimer/OffTimer Flag 0 ~ 1 0 0: Normal, 1: Acceleration

LPS mode < 55 inch > < 65 inch >

500 LPS1_Wat 1 ~ 75 30 30

501 LPS2_Wat 1 ~ 75 30 30

502 LPS3_Wat 1 ~ 75 30 30

503 LPS1_Time 2 ~ 120 45 45

504 LPS2_Time 2 ~ 120 60 60

505 LPS3_Time 2 ~ 120 15 15

506 INITIAL_Time 0 ~ 255 120 120

507 INIT_CURRENT 20 ~ 80 75 75

508 STARTUP_TIME 2 ~ 10 6 6

509 PULSE_ON_OFF 0 ~ 1 1 1

510 PowerUP_Time 0 ~ 120 30 30

511 PowerUP_LEVEL 50 ~ 110 100 100

512 ECO_Power 50 ~ 100 77 77

513 START_Power 50 ~ 110 100 100

514 COLD Start Time 0 ~ 255 10 10

515 HOT Start Time 0 ~ 255 1 1

516 NORMAL_Power 50 ~ 110 94 94

Dimmer (Lamp Mode:Auto) < 55 inch > < 65 inch >

517 Not used - - -

518 Not used - - -

519 Not used - - -

520 Not used - - -

521 Not used - - -

522 Not used - - -

523 Not used - - -

524 Not used - - -

525 Not used - - -

526 Not used - - -

527 Not used - - -

528 Not used - - -

Item No. Adjustment Item Range Initial Value Description

Page 40

-82-

Electrical Adjustments

529 Not used - - -

530 Not used - - -

531 Not used - - -

532 Not used - - -

Fan Control

600 Fan1 Max Adjust 0 ~ 255 135

601 Fan2 Max Adjust 0 ~ 255 135

602 Fan3 Max Adjust 0 ~ 255 135

603 Fan4 Max Adjust 0 ~ 255 135

604 Fan Control Mode 0 ~ 1 0

605 Fan Max Min SW 0 ~ 3 0

< 55 inch > < 65 inch >

Normal Highland Normal Highland

606 Manual Fan1 Voltage 40 ~ 138 100 100 100 100

607 Manual Fan2 Voltage 40 ~ 138 100 100 100 100

608 Manual Fan3 Voltage 40 ~ 138 100 100 100 100

609 Manual Fan4 Voltage 40 ~ 138 100 100 100 100

610 Normal Fan1 Min 40 ~ 138 67 95 67 95

611 Normal Fan2 Min 40 ~ 138 73 90 73 90

612 Normal Fan3 Min 40 ~ 138 65 95 65 95

613 Normal Fan4 Min 40 ~ 138 80 90 80 90

614 Normal Fan1 Max 40 ~ 138 135 135 135 135

615 Normal Fan2 Max 40 ~ 138 95 116 95 116

616 Normal Fan3 Max 40 ~ 138 135 135 135 135

617 Normal Fan4 Max 40 ~ 138 135 135 135 135

618 Normal TempA Low 10 ~ 100 30 30 30 30

619 Normal TempA High 10 ~ 100 37 37 37 37

620 Normal TempA Error 10 ~ 100 43 43 43 43

621 Normal TempB Low 10 ~ 100 60 60 60 60

622 Normal TempB High 10 ~ 100 65 65 65 65

623 Normal TempB Error 10 ~ 100 73 73 73 73

624 Normal TempC Low 10 ~ 100 80 80 80 80

625 Normal TempC High 10 ~ 100 80 80 80 80

626 Normal TempC Error 10 ~ 100 73 73 73 73

627 Normal TempB-A Error 10 ~ 100 42 42 42 42

628 Normal TempC-A Error 10 ~ 100 80 80 80 80

629 Eco Fan1 Min 40 ~ 138 55 85 55 85

630 Eco Fan2 Min 40 ~ 138 50 56 50 56

631 Eco Fan3 Min 40 ~ 138 55 80 55 80

632 Eco Fan4 Min 40 ~ 138 55 60 55 60

633 Eco Fan1 Max 40 ~ 138 135 135 135 135

634 Eco Fan2 Max 40 ~ 138 50 56 50 56

635 Eco Fan3 Max 40 ~ 138 135 135 135 135

636 Eco Fan4 Max 40 ~ 138 55 60 55 60

637 Eco TempA Low 10 ~ 100 30 30 30 30

638 Eco TempA High 10 ~ 100 37 37 37 37

639 Eco TempA Error 10 ~ 100 43 43 43 43

640 Eco TempB Low 10 ~ 100 60 60 60 60

641 Eco TempB High 10 ~ 100 65 65 65 65

642 Eco TempB Error 10 ~ 100 73 73 73 73

643 Eco TempC Low 10 ~ 100 80 80 80 80

644 Eco TempC High 10 ~ 100 80 80 80 80

645 Eco TempC Error 10 ~ 100 73 73 73 73

646 Eco TempB-A Error 10 ~ 100 42 42 42 42

647 Eco TempC-A Error 10 ~ 100 80 80 80 80

648 Not used - -

649 LPS Fan1 Min 40 ~ 138 55 55

650 LPS Fan2 Min 40 ~ 138 55 55

651 LPS Fan3 Min 40 ~ 138 55 55

652 LPS Fan4 Min 40 ~ 138 55 55

653 Not used - - -

654 Not used - - -

655 Not used - - -

656 Not used - - -

657 LPS Fan Stop ON/OFF 0 ~ 1 0

658 Not used - -

659 Not used - -

660 Not used - -

Item No. Adjustment Item Range Initial Value Description

Page 41

Electrical Adjustments

-83-

661 Not used - -

662 Ignore Time 0 ~ 5 1

NJW1180

700 AGC 0 ~ 7 3 bit2(AGC) 0:OFF,1:ON, bit1-0 (AGC-FLAT): LEVEL 0 ~ 3

701 FOCUS 0 ~ 4 2 0:OFF, 1 ~ 4:FOCUS LEVEL 1 ~ 4

702 SRS Surround 0 ~ 5 3 0:OFF, 1 ~ 5:SRS SURROUND LEVEL 1 ~ 5

703 TruBass_Low 0 ~ 4 1 0:OFF, 1 ~ 4:TruBass LEVEL 1 ~ 4 (Low)

704 TruBass_Mid 0 ~ 4 2 0:OFF, 1 ~ 4:TruBass LEVEL 1 ~ 4 (Mid)

705 TruBass_High 0 ~ 4 3 0:OFF, 1 ~ 4:TruBass LEVEL 1 ~ 4 (High)

706 Woofer_Level_Low 0 ~ 4 1 0:OFF, 1 ~ 4:Woofer LEVEL 1 ~ 4 (Low)

707 Woofer_Level_Mid 0 ~ 4 2 0:OFF, 1 ~ 4:Woofer LEVEL 1 ~ 4 (Mid)

708 Woofer_Level_High 0 ~ 4 3 0:OFF, 1 ~ 4:Woofer LEVEL 1 ~ 4 (High)

CXA2234

750 ATT 0 ~ 15 8 ✻ TV sound level adjustment

751 SPECTRAL 0 ~ 63 31 ✻ TV stereo separation adjustment at 4KHz

752 WIDEBAND 0 ~ 63 31 ✻ TV stereo separation adjustment at 300Hz

Lamp Replace

800 Lamp Replace Time 0 ~ 7FFFh 7980

801 ECO Corresponding Factor 0 ~ 300 114 100=Equal, Step=10

802 NORMAL LAMP TIME 0 ~ 7FFFh 0

803 ECO LAMP TIME 0 ~ 7FFFh 0

804 PROJECTOR TIME 0 ~ 7FFFh 0

JEPICO

805 Through Mode 0 ~ 1 0 0: Normal, 1: Through

806 Outer Control Mode 0 ~ 1 0 0: Normal, 1: Outer Control Mode

Version

900 DM Version - Read Only

901 TVCPU Version - Read Only

Item No. Adjustment Item Range Initial Value Description

NOTE:

The items and values of this service adjustment

data table are subject to change without notice.

Page 42

-84-

Electrical Adjustments

● MAIN BOARD

● Test Points Location

B10C55000 Side_A

K01R

IC5101

IC4801

K01L

IC5001

TPDCLK

K8T

TPFAN1

K8K

TPFAN2

K8F

TPTV

TPFAN3

VR101

K8G

K78B

TPFAN4

K78D

K78E

TP_OSDI0

TP_OSDI1

TP_OSDI2

TP_OSDE

TP_OHSB

TP_OVSB

TPDECLK

TPDEDE

TPDEHS

TPDEVS

TP_OACT

IC9401

TP_WAITB

TPDHS

TPHS_GAM

TPDVS

TPVS_GAM

TE401

TP_OCK

K8C

TE501

K8P

K8L

IC4861

IC4761

K8S

IC801

IC1801

IC501

IC401

TPRLCCOM

1

K35R

TPPANELR

TPPANELG

IC1501

K35G

TPGLCCOM

TPPANELB

TE1501

IC2501

K78A

K78C

K78F

K78G

3

K35B

TPBLCCOM

TE2501

Page 43

-85-

■ Chassis Block Diagrams

● Chassis Overview

IC5700,20

TERRESTRIAL

DIGITAL ANT

HDMI

DIGITAL

AUD IO

RF

ANT

VIDEO1

VIDEO

Y/C

DTV

A6120

ATSC

TUNER

DIGITAL RGB

SPDIF

TV

A101

ANALOG

TUNER

TV_CV

CV

DEMODULATOR

TU_AUDIO

Y

C

IC6100

TS

HDMI

Digital Audio

Video,Y/C

IC4001

VIDEO

SW

DDR MEMORY

PROCESSOR

CONVERTER

CV/Y

C

IC5500

DTV

&

SCAN

RECEIVER

IC5201

LVDS

IC5750

FLASH ROM

IC401

DIGITAL

GAMMA

IC9401

COLOR

MANAGER

GREEN

IC836

EEPROM

IC501

S&H

RED

IC1501

S&H

IC2501

S&H

BLUE

IC561

LEVEL

SHIFT

IC1561

LEVEL

SHIFT

IC2561

LEVEL

SHIFT

R

R-LCD PANEL G-LCD PANEL B-LCD PANEL

G

B

Y

Pb

Pr

VIDEO3VIDEO2HDMI

Y

Pb

Pr

AV1

AUDIO INPUT AUDIO OUTPUT

AV2

AV3

L/R

WOOFER

Y/Cb/Cr

Y/Cb/Cr

IC6200

Component

TU_AUDIO

IC5001

L/R

TV_L/R

DIGITAL_L/R

L/R

L/R

CONTROL

L/R

MONITOR OUTPUT L/R

WOOFER

DECODER

IC5101

AUDIO

IC5181

AMP.

A/D

MTS

Audio-L/R

Y/Cb/Cr

IC6300

AMP.

L/R

IC001

AUD IO

AMP.

SPEAKER

UART

POWER

FA IL

DC POWER

SUPPLY LINES

CONVERTER

DC-DC

STANDBY 5V

IC801

TV CPU

IC651,T651

SWITCHING

POWER SUPPLY

IC641,T641

SWITCHING

POWER SUPPLY

IC8801,11,61

TEMP.

SENSOR

IC1801

DAC

IC3811

RS-232C IN/OUT

IC601

P. F.

CONTROL

IC7801,21,41,61

FAN CONTROL

LAMP COVER SWTHERMAL SW

LAMP

BALLAST

LINE

FILTER

FA N

LED

R/C

POWER

KEY

SIDE

KEY SW

SERVICE

PORT

LAMP

AC

100~240V

Page 44

Chassis Block Diagrams

● Video signal processing stage

-86-

ANT

DIGITAL

ANTENNA IN

HDMI

HDMI

A6120

ATSC

TUNER

HDMI_HPD

DDC_CLK/DATA

IF OUT

IF AGC

IC6100

DEMODULATOR

<CAS-220>

TS

VIDEO3_Y/U/V

VIDEO2_Y/U/V

VIDEO1_C

VIDEO1_CV_Y

TE6207

(Y)

LPF

LPF

IC6200

A/D CONVERTER

<ISL98001>

TE5802

TE5801

VFE_CIN

VFE_YIN

VFE_CVBS

TPDATA

TPCLK

HDMI

HS_IN

VS_IN

DTCLK

RED

GREEN

BLUE

IC5500

DTV

PROCESSOR

&

SCAN

CONVERTER,

<ZR39660>

LV D S LV D S

DIGITAL BOARD

IC5700, 20

DDR MEMORY

<EDD2516>

IC5750

FLASH ROM

<S29JL064>

VIDEO 3 (RCA)

Y

Pb

Pr

VIDEO 2 (RCA)

Y

Pb

Pr

VIDEO 1 (DIN)

S-VIDEO

VIDEO

VIDEO 1 (RCA)

ANT

UHF/VHF/CATV

K6MA

K20P

S_SW

S_C

S_Y

CV1

AV BOARD

A101

ANALOG

TUNER

VIF/SIF

AV2_Y/CB/CR

AV3_Y/CB/CR

K20M

TPTV

TV_CV

AFT

MAIN BOARD

AV1_ C

IC4001

VIDEO SW.

<4052>

512

K8M

4446

3

59-60

CVBS

AV_SW1

AV_SW2

13

IC2561

LEVEL

SHIFT

<L3E01060>

K5LV

K8C

IC5201

LVDS RECEIVER

<THC63LVDF84B>

DGE

DRE

IC801

TV CPU

DBE

IC9401

COLOR

MANAGER

<J-L003>

DG

DR

DB

DEHS,DVES,DECLK,DEDE

DHS,DVS,DCLK

IC401

BOUT ROUT

IC2501

S&H

BLUE

<L3E06150>

DIGITAL

GAMMA

<L3E07110>

GOUT

IC1501

S&H

GREEN

<L3E06150>

IC1561

LEVEL

SHIFT

TPPANELB

<L3E01060>

K35B K35G K35R

TPPANELG

<L3E01060>

IC561

LEVEL

SHIFT

IC501

S&H

RED

<L3E06150>

TPPANELR

B-LCD

PA N E L

G-LCD

PA N E L

R-LCD

PA N E L

Page 45

-87-

● Description of video signal processing stage

Input signal selecting stage:

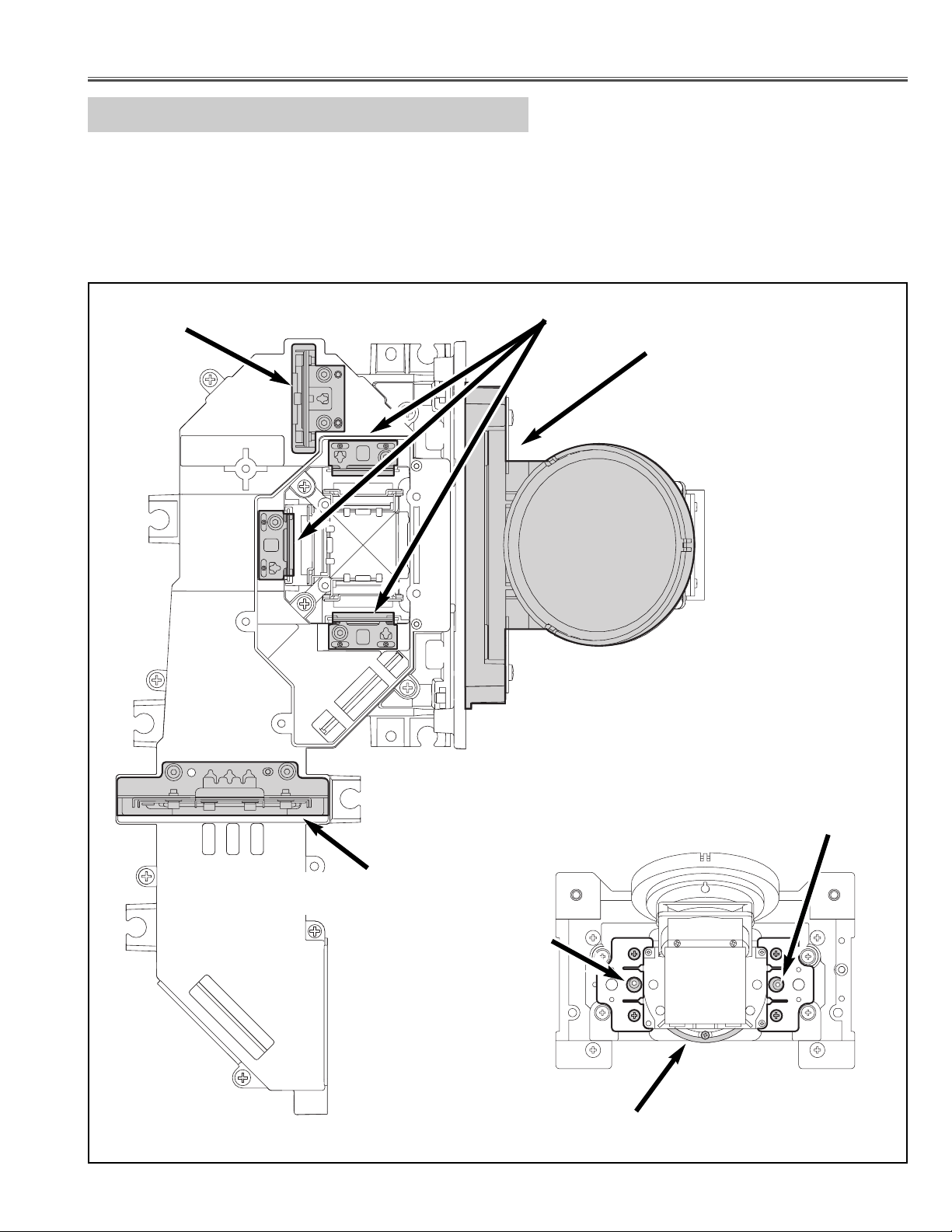

TV input; RF signal is converted to TV_CV signal in A101(Analog Tuner) and sent to IC4001.