Sanyo PLC-XW20,PLC-SW20 Service Manual

Multimedia Projector

SERVICE MANUAL

REFERENCE NO. SM5110302-00

CONTENTS

Pages

TECHNICAL SPECIFICATIONS --------------------------------------------------------- 2 - 3

SAFETY INSTRUCTIONS --------------------------------------------------------------------- 4

LAMP REPLACEMENT------------------------------------------------------------------------- 5

PROTECTIONS----------------------------------------------------------------------------------- 6

MECHANICAL DISASSEMBLIES------------------------------------------------------ 7 - 11

ADJUSTMENT ---------------------------------------------------------------------------- 12 - 15

PIN DESCRIPTION OF DIODE, TRANSISTOR AND IC----------------------------- 16

ELECTRICAL PARTS LIST ------------------------------------------------------------ 17 - 53

MECHANICAL PARTS LIST & ACCESSORIES --------------------------------- 54 - 55

SCHEMATIC DIAGRAMS------------------------------------------------------------ A1 - A12

PRINTED WIRING BOARD DIAGRAMS --------------------------------------- A13 - A14

FILE NO.

PRODUCT CODE

1 122 103 00 PLC-XW20 (MW6A)

1 122 104 00 PLC-XW20 (PW6A)

1 122 104 02 PLC-XW20 (PW6C)

1 122 112 00 PLC-SW20 (MZ6A)

1 122 113 00 PLC-SW20 (PZ6A)

1 122 113 02 PLC-SW20 (PZ6C)

ORIGINAL VERSION

Chassis No. MW6-XW2000

(PLC-XW20)

MZ6-SW2000

(PLC-SW20)

Model No. PLC-XW20

PLC-SW20

(U.S.A., Canada, Europe

Asia, Africa U.K.)

NOTE: Match the Chassis No. on the

unit’s back cover with the Chassis

No. in the Service Manual.

If the Original Version Service

Manual Chassis No. does not

match the unit’s, additional

Service Literature is required. You

must refer to “Notices” to the

Original Service Manual prior to

servicing the unit.

-2-

■ Technical Specifications

■ PLC-XW20

0.7" TFT Active Matrix type, 3 panels

Multi-media Projector

6.2lbs (2.8 kg)

10.12" x 2.98" x 9.02" (257mm x 75.8mm x 229mm)

(not including Adjustble Feet and Lens)

1024 x 768 dots

2,359,296 (1024 x 768 x 3 panels)

PAL, SECAM, NTSC, NTSC4.43, PAL-M and PAL-N

H-sync. 15 ~ 100 KHz, V-sync. 50 ~ 100 Hz

Adjustable from 34” to 200”

550 TV lines

1 speaker, ø1.1" (28mm)

41 ˚F ~ 95 ˚F (5 ˚C ~ 35 ˚C)

14 ˚F ~ 140 ˚F (-10 ˚C ~ 60 ˚C)

Owner’s Manual

AC Power Cord

Wireless Remote Control Transmitter and Battery

VGA Cable

Carrying Bag

Lens Cover

Projector Type

Net Weight

Dimensions

(W x H x D)

Panel Resolution

Number of Pixels

Color System

Scanning Frequency

Projection Image size

(Diagonal)

Horizontal Resolution

Built-in Speakers

Operating Temperature

Storage Temperature

Accessories

LCD Panel System

● The specifications are subject to change without notice.

F 1.6 ~ 1.78 lens with f 28.7 mm ~ 34.5 mm with manual zoom and focus

5.3’ ~ 26.6’ (1.6 m ~ 8.1 m)

150 W

RCA Type x 3 (Video/Y, Pb/Cb, Pr/Cr) and Mini DIN 4 pin x 1 (S-Video)

Projection Lens

Throw Distance

Projection Lamp

Video Input Jacks

Mini Jack (stereo) x 1

Audio Input Jacks

(VGA) HDB 15 Terminal x 1

Mini Jack (stereo) x 1

Mini DIN 8 pin x 1

Mini Jack (stereo) x 1

1.0 W RMS

Computer Input Terminals

Computer Audio Input Jack

Control Port Connector

Audio Output Jacks

Internal Audio Amp

0˚ to 10.6˚

Feet Adjustment

Power Source : Lithium Type (CR2025 / 3.0V)

Operating Range : 16.4’ (5m) / ±30˚

Dimensions : 2.1” x 0.28” x 5.3” (54mm x 7mm x 135mm)

Net Weight : 1.27oz (36 g) (including battery)

Remote Control Transmitter

480i, 480p, 575i, 575p, 720p, 1035i, and 1080i

High Definition TV Signal

USB Series B receptacle x 1

USB Connector

AC 100 ~ 120 V (2.8 A Max. Ampere), 50 / 60 Hz

(The U.S.A and Canada)

AC 200 ~ 240 V (1.4 A Max. Ampere), 50 / 60 Hz

(Continental Europe and The U.K.)

Voltage and

Power Consumption

-3-

■ Technical Specifications

■ PLC-SW20

0.7" TFT Active Matrix type, 3 panels

Multi-media Projector

6.2lbs (2.8 kg)

10.12" x 2.98" x 9.02" (257mm x 75.8mm x 229mm)

(not including Adjustable Feet and Lens)

800 x 600 dots

1,440,000 (800 x600 x 3 panels)

PAL, SECAM, NTSC, NTSC4.43, PAL-M and PAL-N

H-sync. 15 ~ 80 KHz, V-sync. 50 ~ 100 Hz

Adjustable from 34” to 200”

500 TV lines (S-Video)

1 speaker, ø1.1" (28mm)

41 ˚F ~ 95 ˚F (5 ˚C ~ 35 ˚C)

14 ˚F ~ 140 ˚F (-10 ˚C ~ 60 ˚C)

Owner’s Manual

AC Power Cord

Wireless Remote Control Transmitter and Battery

VGA Cable

Carrying Bag

Lens Cover

Projector Type

Net Weight

Dimensions

(W x H x D)

Panel Resolution

Number of Pixels

Color System

Scanning Frequency

Projection Image size

(Diagonal)

Horizontal Resolution

Built-in Speaker

Operating Temperature

Storage Temperature

Accessories

LCD Panel System

● The specifications are subject to change without notice.

F 1.6 ~ 1.78 lens with f 28.7 mm ~ 34.5 mm with manual zoom and focus

5.3’ ~ 26.6’ (1.6 m ~ 8.1 m)

150 W

RCA Type x 3 (Video/Y, Pb/Cb, Pr/Cr) and Mini DIN 4 pin x 1 (S-Video)

Projection Lens

Throw Distance

Projection Lamp

Video Input Jacks

Mini Jack (stereo) x 1

Audio Input Jacks

(VGA) HDB 15 Terminal x 1

Mini Jack (stereo) x 1

Mini DIN 8 pin x 1

Mini Jack (stereo) x 1

1.0 W RMS

Computer Input Terminals

Computer Audio Input Jack

Control Port Connector

Audio Output Jacks

Internal Audio Amp

0˚ to 10.6˚

Feet Adjustment

Power Source : Lithium Type (CR2025 / 3.0V)

Operating Range : 16.4’ (5m) / ±30˚

Dimensions : 2.1” x 0.28” x 5.3” (54mm x 7mm x 135mm)

Net Weight : 1.27oz (36 g) (including battery)

Remote Control Transmitter

480i, 480p, 575i, 575p, 720p, 1035i, and 1080i

High Definition TV Signal

USB Series B receptacle x 1

USB Connector

AC 100 ~ 120 V (2.8 A Max. Ampere), 50 / 60 Hz

(The U.S.A and Canada)

AC 200 ~ 240 V (1.4 A Max. Ampere), 50 / 60 Hz

(Continental Europe and The U.K.)

Voltage and

Power Consumption

-4-

■ Safety Instructions

WARNING:

The chassis of this projector is isolated (COLD) from AC line by using the converter transformer. Primary side of

the converter and lamp power supply unit circuit is connected to the AC line and it is hot, which hot circuit is iden-

tified with the line ( ) in the schematic diagram. For continued product safety and protection of personnel

injury, servicing should be made with qualified personnel.

The following precautions must be observed.

1: An isolation transformer should be connected in the power line between the projector and the AC line before any

service is performed on the projector.

2: Comply with all caution and safety-related notes provided on the cabinet back, cabinet bottom, inside the cabi-

net or on the chassis.

3: When replacing a chassis in the cabinet, always be certain that all the protective devices are installed proper-

ly, such as, control knobs, adjustment covers or shields, barriers, etc.

DO NOT OPERATE THIS PROJECTOR WITHOUT THE PROTECTIVE SHIELD IN POSITION AND PROPERLY SECURED.

4: Before replacing the cabinet cover, thoroughly inspect the inside of the cabinet to see that no stray parts or

tools have been left inside.

Before returning any projector to the customer, the service personnel must be sure it is completely safe to operate without danger of electric shock.

■ SAFETY PRECAUTIONS

■ PRODUCT SAFETY NOTICE

Product safety should be considered when a component replacement is made in any area of the projector.

Components indicated by mark in the parts list and the schematic diagram designate components in which

safety can be of special significance. It is, therefore, particularly recommended that the replacement of the parts

must be made by exactly the same parts.

Eye damage may result from directly viewing the light produced by the Lamp used in this equipment. Always turn

off Lamp before opening cover. The Ultraviolet radiation eye protection is required during this servicing.

Never turn the power on without the lamp to avoid electric-shock or damage of the devices since the stabilizer

generates high voltages(20~25kV) at its starts.

Since the lamp is very high temperature during units operation. Replacement of the lamp should be done at least

45 minutes after the power has been turned off, to allow the lamp cool-off.

■ SERVICE PERSONNEL WARNING

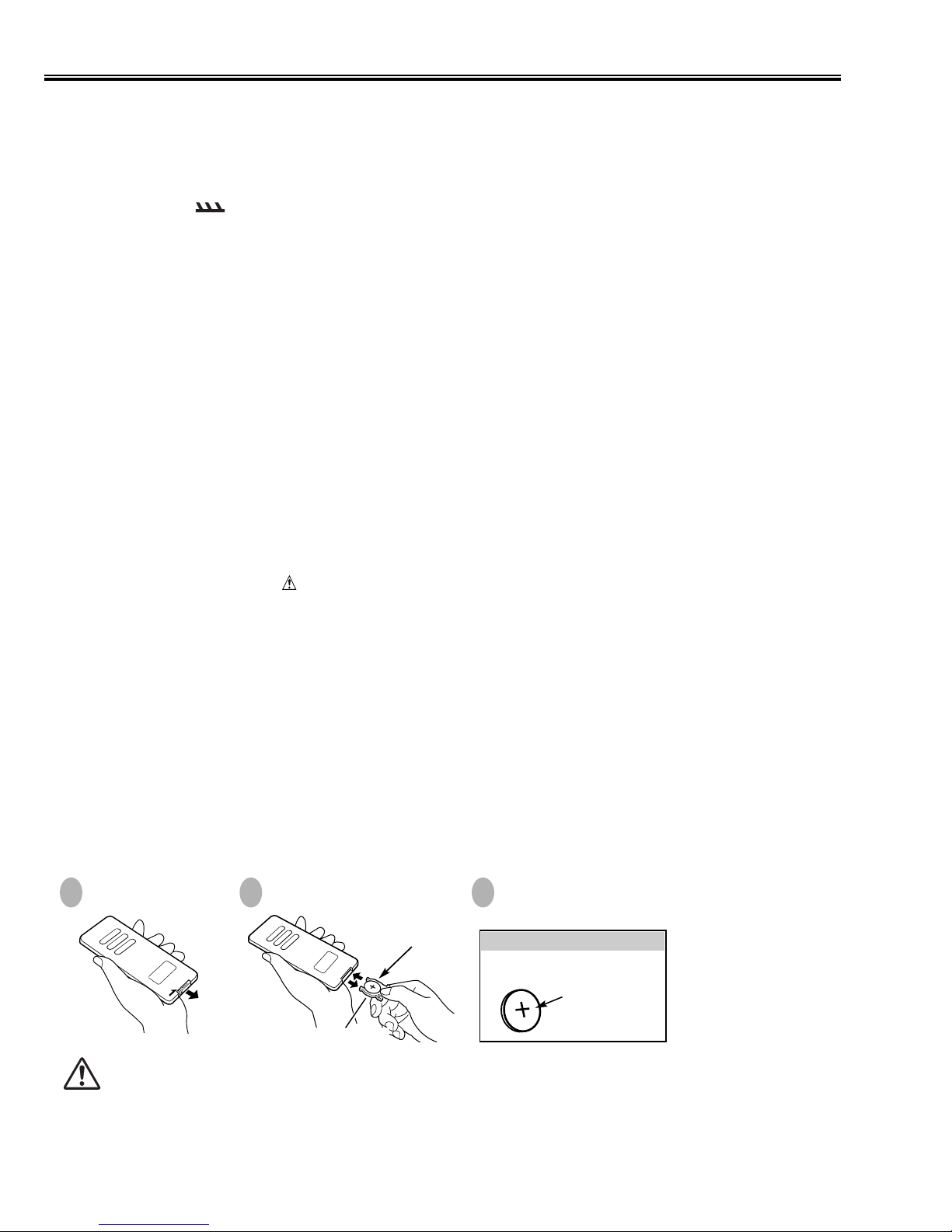

■ REMOTE CONTROL BATTERY INSTALLATION

Pull out Battery Holder.

1 2 3

To insure safe operation, please observe the following precautions :

● Use only specified battery. Improper battery may cause malfunction of Remote Control or a battery.

● Do not expose a battery to moisture or heat. Do not charge a battery.

● If a battery have leaked on Remote Cotrol Unit, carefully wipe the case clean and load a new battery.

● Be sure to install battery with correct polarity.

● Dispose used battery following local regulation.

● Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type

recommended by the manufacturer.

Replace with new battery. Install

with battery (+),(–) marks properly.

Put Battery + mark

as shown direction.

BATTERY HOLDER

Install battery and

Battery Holder into

Remote Control Unit.

BATTERY

LITHIUM BATTERY

CR2025 (3.0V)

(+) mark indicates

its (+) polarity.

-5-

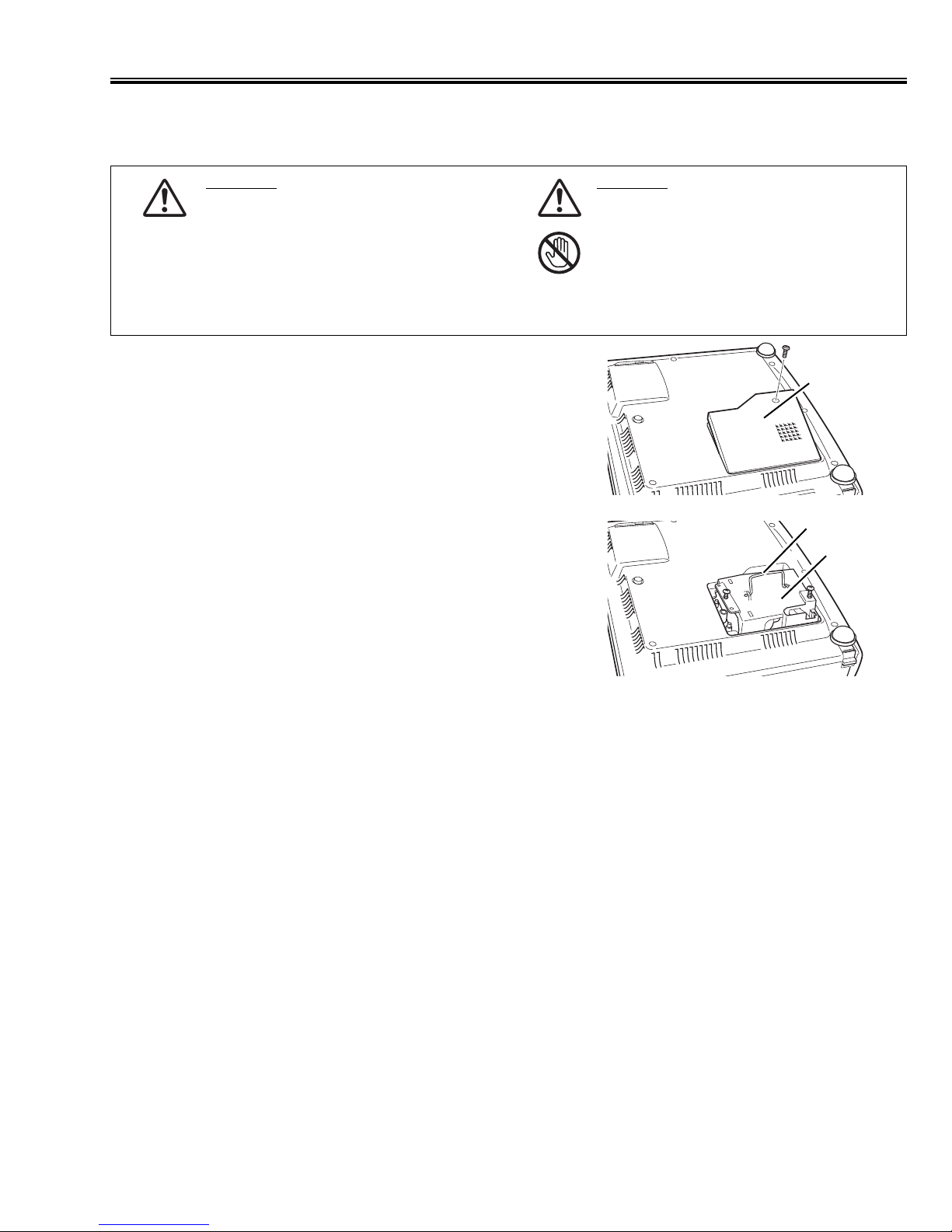

■ Lamp Replacemant

When the life of Projection Lamp of this projector draws to an end, LAMP REPLACEMENT indicator lights yellow.

When a projected image becomes dark or the color of an image becomes unnatural, replacement of Projection

Lamp is required.

CAUTION

Do not drop a lamp assembly or touch a

glass bulb! The glass can shatter and

may cause injury.

CAUTION

For continued safety, replace with a lamp

assembly of the same type.

Allow a projector to cool for at least 45

minutes before you open Lamp Cover.

The inside of a projector can become

very hot.

LAMP

ASSEMBLY

HANDLE

LAMP COVER

Follow these steps to replace the lamp assembly.

1. Turn off the projector and disconnect AC plug. Allow the projector

to cool for at least 45 minutes.

2. Remove a screw with a screwdriver to remove Lamp Cover.

3. Remove 2 screws with a screwdriver and pull out Lamp Assembly

by grasping Handle.

4. Replace Lamp Assembly with a new one and tighten 2 screws

back. Make sure that Lamp Assembly is set properly. Replace

Lamp Cover and tighten a screw.

5. Connect AC Power Cord to the projector and turn it on.

6. Reset Lamp Replace Counter (refer to the section “Lamp Replace

Counter” below).

Do not reset Lamp Replace Counter when Projection Lamp is

not replaced.

■

LAMP REPLACE COUNTER

Be sure to reset Lamp Replace Counter when Lamp Assembly is replaced. When Lamp Replace Counter is

reset, LAMP REPLACE Indicator stops lighting.

1. Turn projector on, press MENU button and ON-SCREEN MENU will appear. Press POINT LEFT/RIGHT

button(s) to move a red frame pointer to SETTING Menu icon.

2. Press POINT DOWN button to move a red frame pointer to “Lamp counter reset” and then press

SET button.

The message "Lamp replace counter reset?" is displayed. Move the pointer to [Yes] and then press SET button.

3.

Another confirmation dialog box appears and select [Yes] to reset Lamp Replace Counter.

Do not reset Lamp Replace Counter except after Projection Lamp is replaced.

-6-

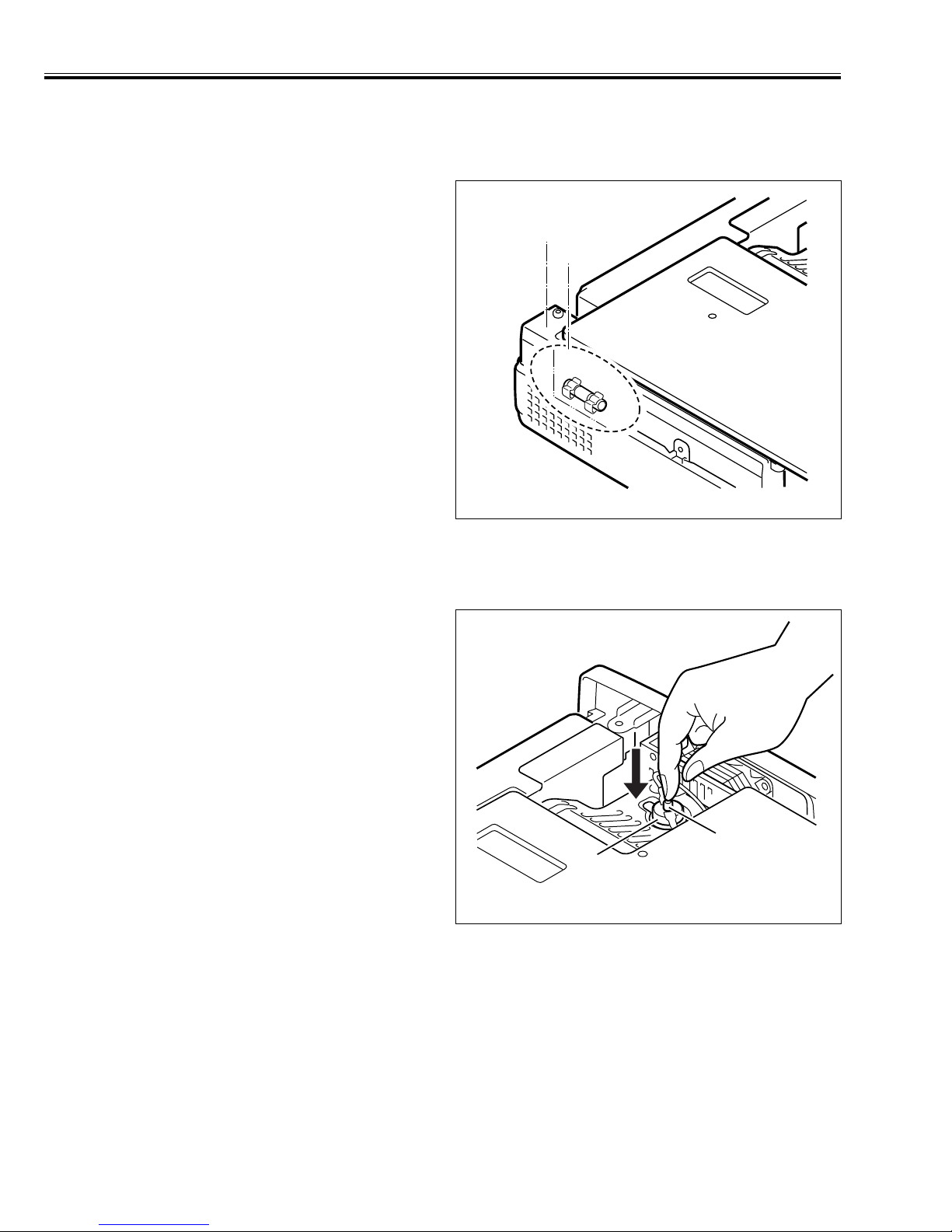

■ Protections

This projector is equipped with the following protections to operate in safety. If the abnormality occurs

inside the projector, it will turn off the projector by operating one of the following protections.

■

FUSE FOR CIRCUIT PROTECTION

The fuse is located on the ass'y-power. When either the

LAMP indicator or the READY indicator is not illuminated,

fuse may be opened. Check the fuse as following steps.

1. Remove the ass'y-power following to “Mechanical

Disassemblies”.

2. Remove the fuse from fuse holder.

3. Check the resistance of fuse by using the tester.

To install the fuse, take reversed step in the above.

It should be used the specified fuse as parts list.

■

OVERHEATING PROTECTION

(The temperature monitor system )

The temperature monitor system is provided to prevents damage of component parts inside the projector from overheat. Two protection systems are provided. Each system operating as follows.

■ Temperature monitor -1 :

When this function operates, warning-temperature-indicator flashes. And cooling fan continues operating until it

becomes a normal temperature. If it continue to flush and

flash does not stopped, disconnect the AC cord and investigate the cause of overheating.

■ Temperature monitor -2 :

(thermal switch SW902)

This function (thermal switch SW902) will not operate,

while the temperature monitor -1 is operating normally. If it

has operated, it needs to be reset manually. Disconnect

the AC cord first and investigate the cause of overheating.

After servicing, reset the thermal switch (SW902) as shown

in a figure.

Holder Power

Ass'y Power

Fuse

Thermal switch(sw902)

Press

Reset button

-7-

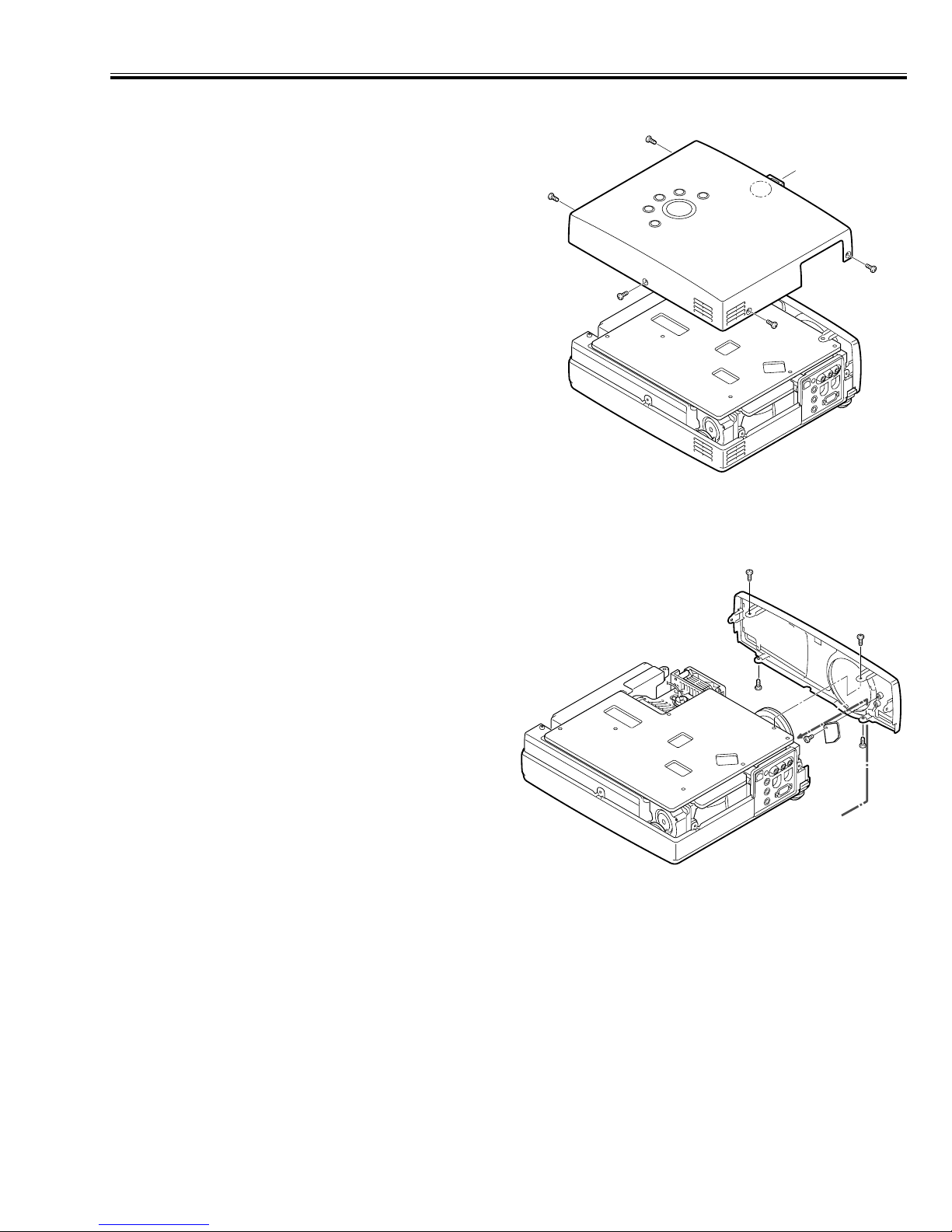

■ Mechanical disassemblies

1. CABINET - TOP REMOVAL

1. Remove five screws-A.

2. Grasp the rear both ends of Cabinet-front with both

hands, and slightly pull upward.

3. Release hook, by pressing down "C" portion lightly with

finger.

4. Grasp the rear both ends of Cabinet-front with both

hands, pull up and remove upwards.

Note:

Be careful not to damage Hook. Cabinet-top is being fixed

with cabinet-front by hook.

2.

CABINET - FRONT REMOVAL

1. Remove four screws A and B.

2. Turn the focus-ring of Projection lens fully clockwise.

3. Set zoom-lever of Projection lens to under lens.

4. Slightly pull the upper part of Cabinet-front forward with

both hands. (hook is released and cabinet front is

removed.)

5. Remove a screw and, next, remove Unit R/C.

Note:

Be careful not to damage Hook. There is hook which is fixing Cabinet-front and Cabinet-bottom under Projection

lens.

Screws-A and screws-B are used different kind screws.

Check the kind of screw, and proper screw should be

used.

A

Hook

A

A

C

Cabinet-top

A

Cabinet-front

A

A

Cabinet-front

A

B

R/C

B

Cabinet-bottom

Hook

-8-

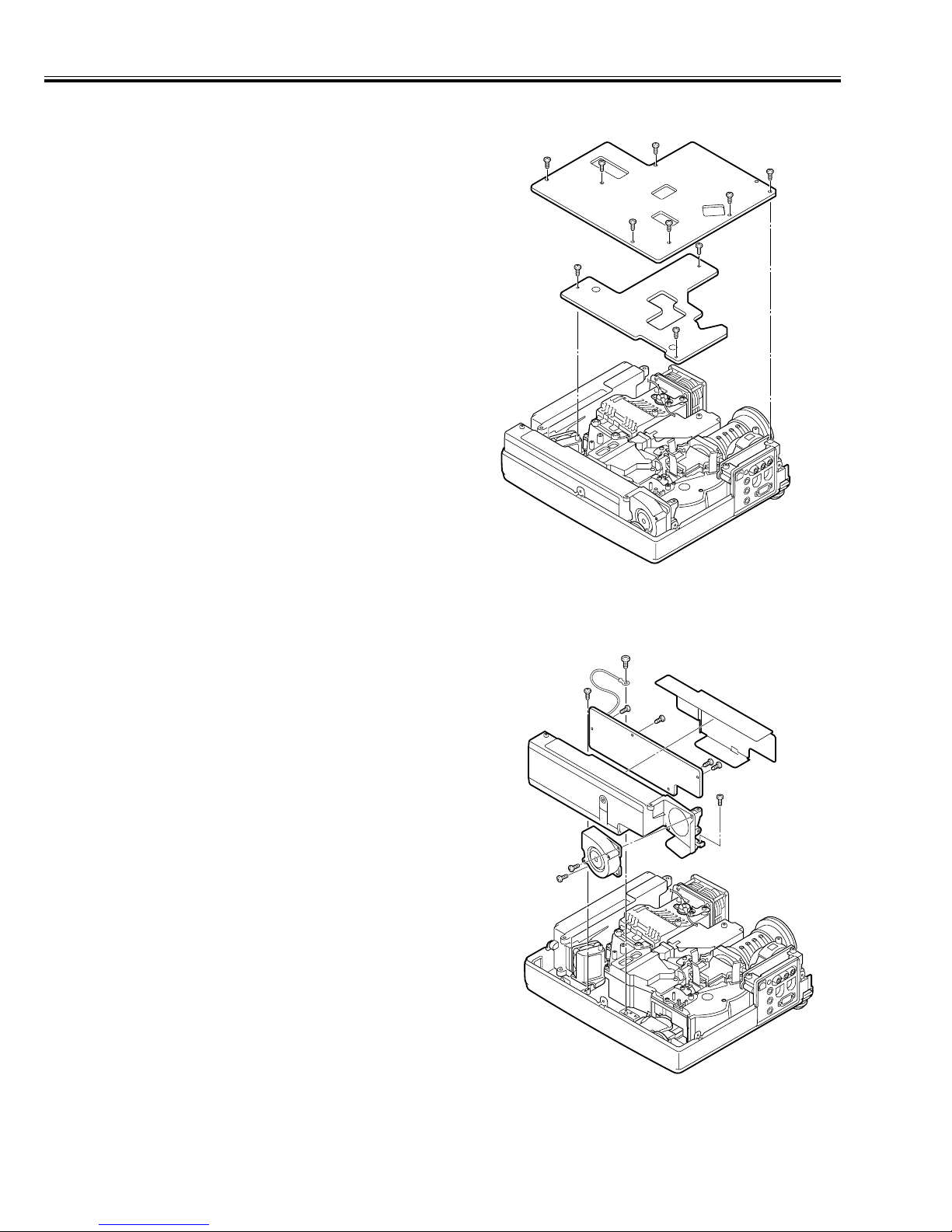

■ Mechanical disassemblies

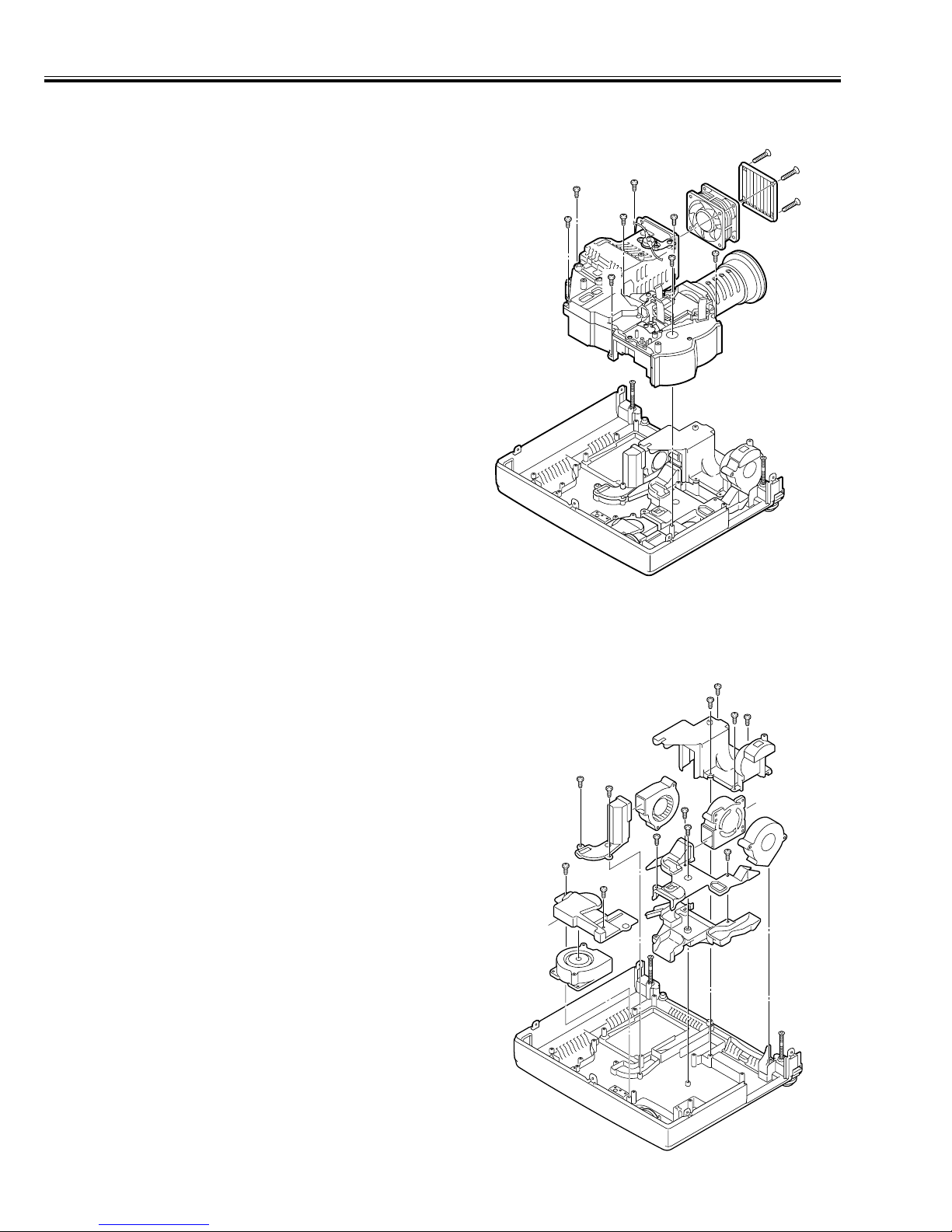

3. ASS'Y - MAIN AND ASS'Y - SUB REMOVAL

1. Remove seven screws and remove Ass'y Main.

2. Remove three screws and remove Ass'y-Sub.

See figure right.

4. ASS'Y - POWER AND FAN (FN903) REMOVAL

1. Remove seven screws and remove Ass'y Power.

2. Remove two screws and remove Fan (FN903).

See figure right..

M

ain

Sub

FN903

Po

wer

-9-

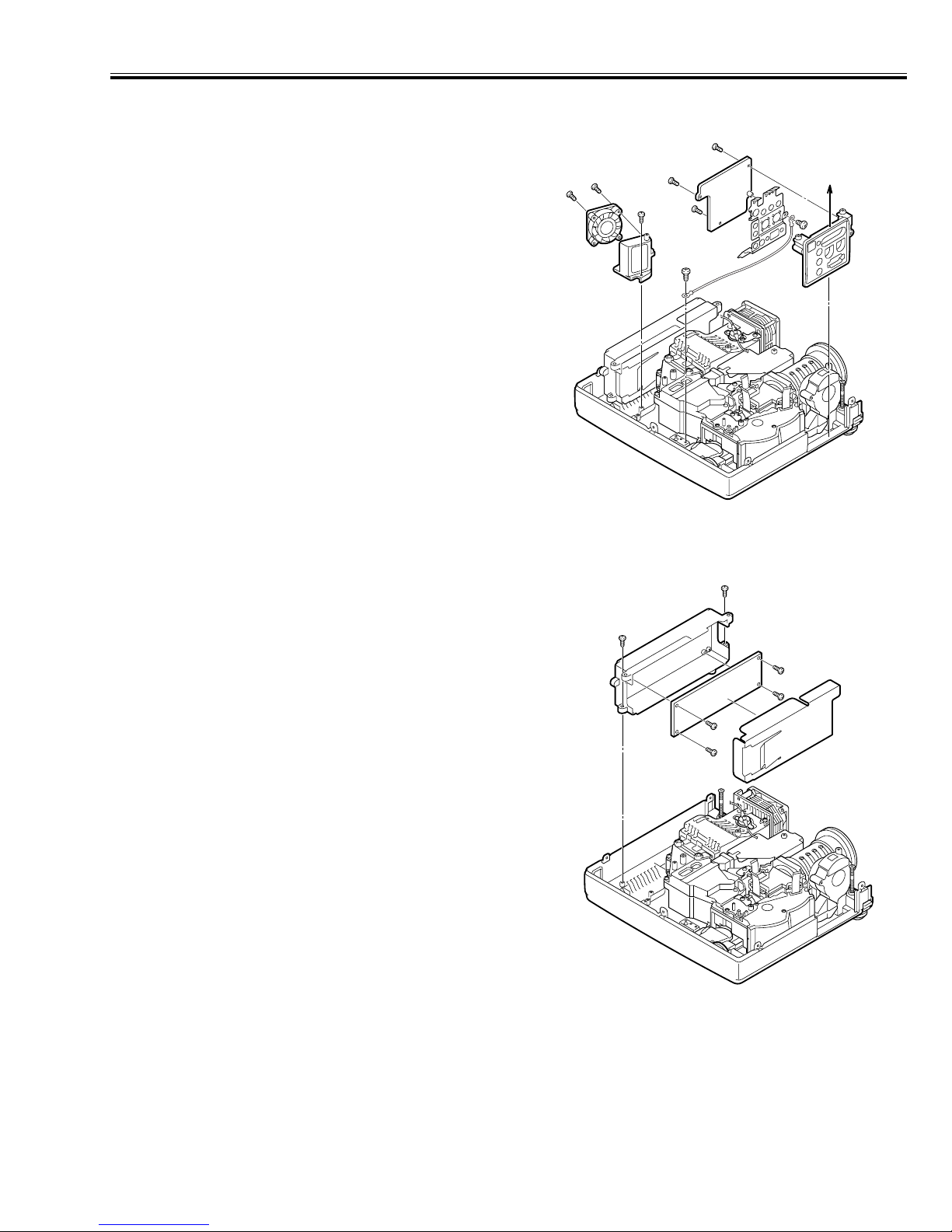

■ Mechanical disassemblies

5. ASS'Y - AV AND FAN (FN907) REMOVAL

1. Remove five screws and remove Ass'y AV.

2. Remove three screws and remove Fan (FN907).

See figure right.

6. ASS'Y - LAMP - BSALLAST REMOVAL

1. Remove six screws and remove Ass'y Lamp-ballast.

AV

FN907

Lam

p ballast

-10-

■ Mechanical disassemblies

7. OPTICAL UNIT, FAN (FN901) AND LOUVER REMOVAL

1. Remove eight screws and remove Optical unit.

2. Remove three screws and remove Fan(FN901) and

louver.

See figure right.

8. AIR DUCTS AND FANS REMOVAL

1. Remove four screws-A and remove Duct-FR and

FN905.

2. Remove two screws-B and remove Duct-PBS and

FN906.

3. Remove three screws-C and remove Duct-TOP and

FN902.

4. Remove two screws-D and remove Duct-TOP-Green

and FN904.

5. Remove screw-E and remove Duct-BTM.

See figure right.

FN901

Louver

Duct-top-Green

A

A

Dukt-FR

B

B

FN906

C

E

C

D

Duct-PBS

D

FN904

A

C

Duct-TOP

Duct-BTM

A

FN902

FN905

-11-

■ Mechanical disassemblies

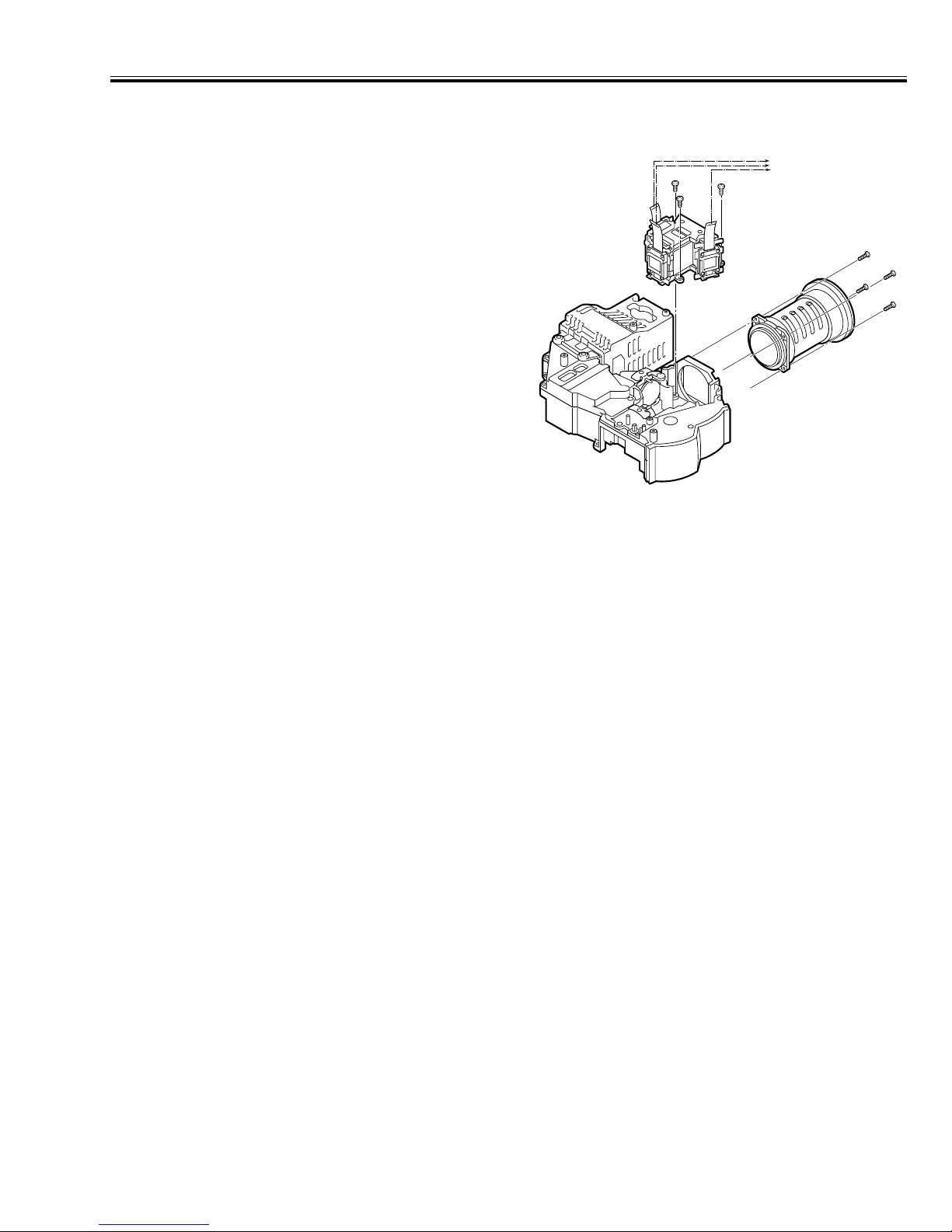

9. Projection lens and Assembly Panel-Prism removal

1. Remove four screws and remove projection lens.

2. Remove three screws and remove Assembly Panel-

Prism.

See figure right.

Caution :

Don't disassemble Assembly-Panel-Prism other wise

parts may damaged

Never touch the electrode

of flexible cables.

Ass'y P/Prism

Projection lens

-12-

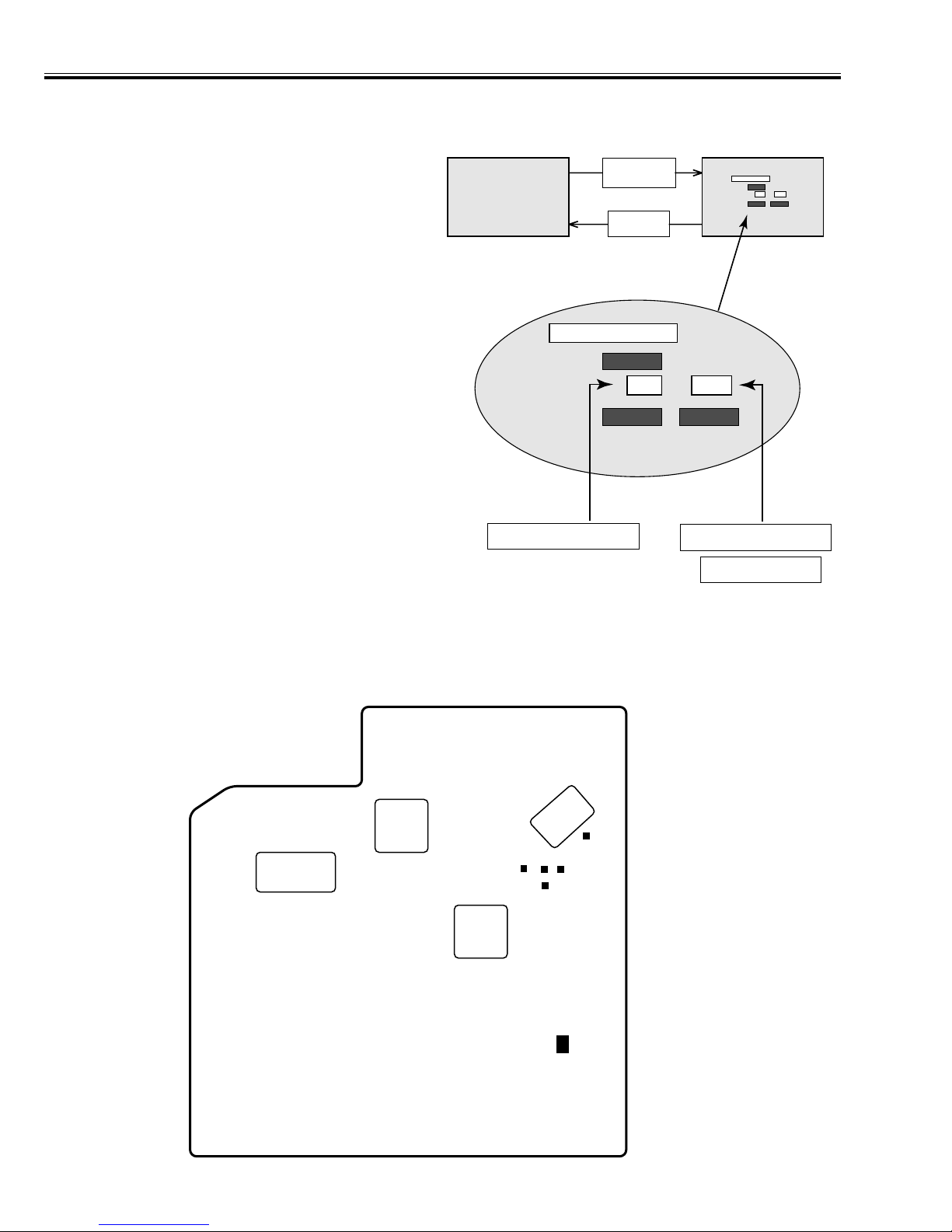

■ Adjustment

■ SERVICE ADJUSTMENT MENU OPERATION

■ To enter service mode

To enter service mode press the "MENU" and "IMAGE"

buttons on the projector simultaneously and hold for 2

seconds. As shown in a figure, a service mode display

appears on a screen.

■ Adjustment

Adjust service data using the following control buttons.

1. "POINT UP" ------- An item number increases.

2. "POINT DOWN" -- An item number decreases.

3. "POINT RIGHT" -- An adjustment value increases.

"VOLUME+"

4. "POINT LEFT" ---- An adjustment value decreases.

"VOLUME - "

■ To exit service mode

Press the "POWER on/off" button only once on the projec-

tor or remote control unit to quit the service mode.

■ LOCATION OF TEST POINT AND VR

Normal Mode Service Mode

"MENU"

"IMAGE"

"POWER

ON/OFF"

Service Mode

Computer

13710

Service Mode

Computer

13710

"Point Up / Down"

Adjustment item

"Point Left / Right"

"Volume + / -"

TEST POINTS LOCATION

TP-NRS1

TP-R1

TP-B1

Adjustment deta value

TP-66A

TP-G1

ASSY PWB MAIN

VR5601

-13-

■ Adjustment

Not designated PC AV Component

1 3. Signal center DC adjustment-Red ●

2 3. Signal center DC adjustment-Green ●

3 3. Signal center DC adjustment-Blue ●

7 4. Red contrast adjustment ●● ●

8 4. Green contrast adjustment. ●● ●

9 4. Blue contrast adjustment ●● ●

10 5. Signal amplitude adjustment-Red ●

11 5. Signal amplitude adjustment-Green ●

12 5. Signal amplitude adjustment-Blue ●

16 8. Contrast linearity adjustment ●●

17 7. White balance adjustment-Red ●●

18 7. White balance adjustment-Blue ●●

19 6. Flicker reduction -Red ●

20 6. Flicker reduction -Green ●

21 6. Flicker reduction -Blue ●

22 2. NRS adjustment ●

23 2. NRS adjustment ●

50 1. Fan driving voltage adjustment ●

67 1. Fan driving voltage adjustment ●

Caution :

Other adjustment items are not related to service and a maintenance. Don't press the VOLUME (+) and (-) but-

tons at the time of those adjustment items. Otherwise it may cause loss of product safety.

Item-no.

Adjustment Item

Adjustment Mode

■ SERVICE MODE ADJUSTMENT MENU

-14-

■ Adjustment

■ ELECTRICAL ADJUSTMENTS

1. Fan driving voltage adjustment

Equipment Digital voltmeter.

Test point TP66A

Enter the Service mode.

1. Set the item no. to [50] by pressing the Point up or down

button.

Set the data value to [1] by pressing the Volume + or -

button.

2. Set the item no. to [67]. Set the data value to [1].

3. Adjust the voltages of TP66A to 8.4 ± 0.1 V-DC by the

VR5601.

4. Set the item no. to [50]. Set the data value to [0].

5. Set the item no. to [67]. Set the data value to [1].

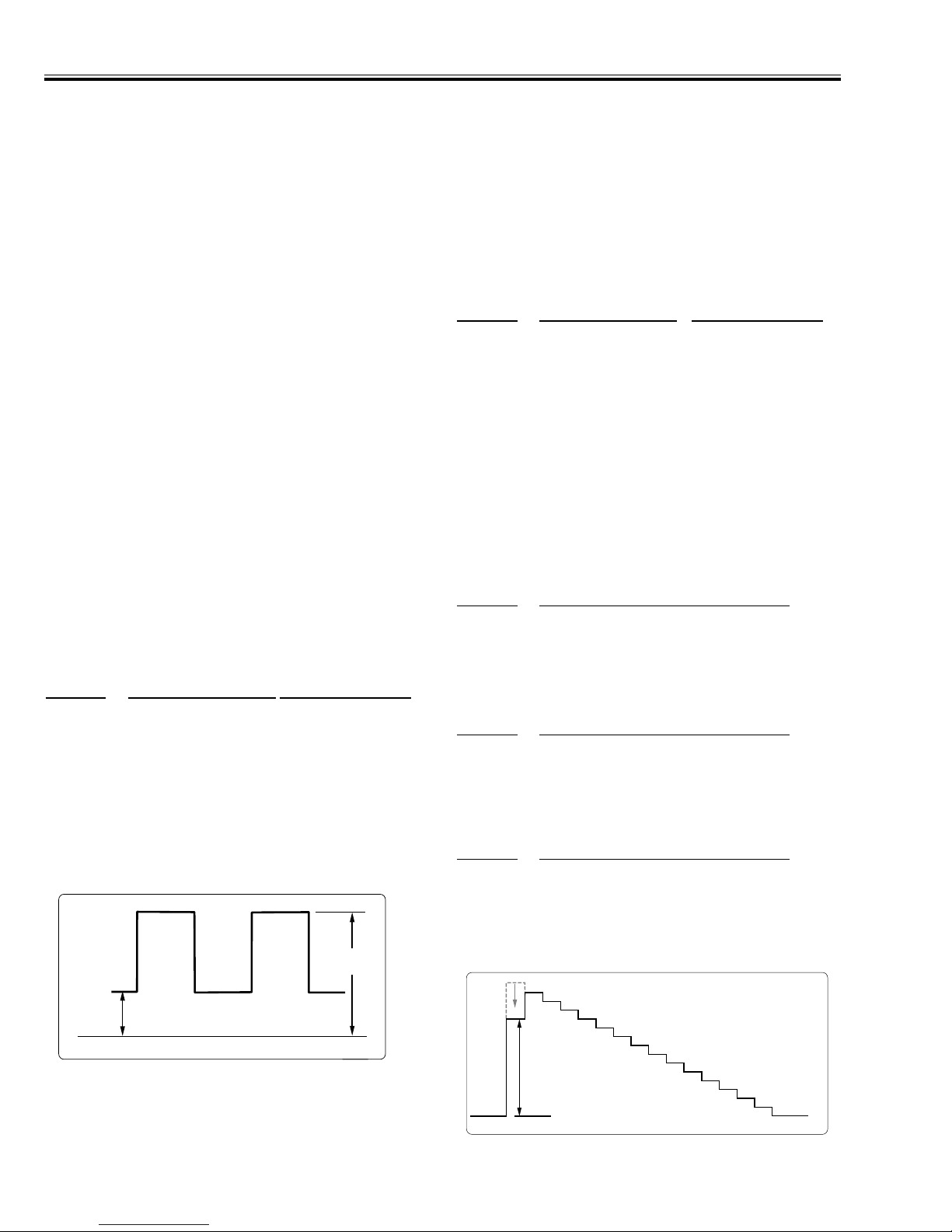

2. NRS adjustments

Equipment Oscilloscope

Test Point TP-NRS1

Input mode Computer

Input Signal 16 step gray scale signal

Enter the Service mode.

Adjust values of below items by the Volume + or - buttons.

Item no.

Adjustment part Adjustment value

22 DC level-A in a figure 2.1 ± 0.1 V-DC.

( for PLC-XW20 )

3.0 ± 0.1 V-DC.

( for PLC-SW20 )

23 DC level-B in a figure 12.0 ± 0.5 V-DC.

3. Signal center DC adjustments

Equipment Digital voltmeter.

Input mode Computer

Input Signal 16 step gray scale signal

Enter the Service mode.

Adjust each values of below test point to be minimum

amplitude by the Volume + or - buttons.

Item no. Test Point Adjustment value

1 TP-R1 7.3 ± 0.05 V-DC.

2 TP-G1 7.3 ± 0.05 V-DC.

3 TP-B1 7.3 ± 0.05 V-DC.

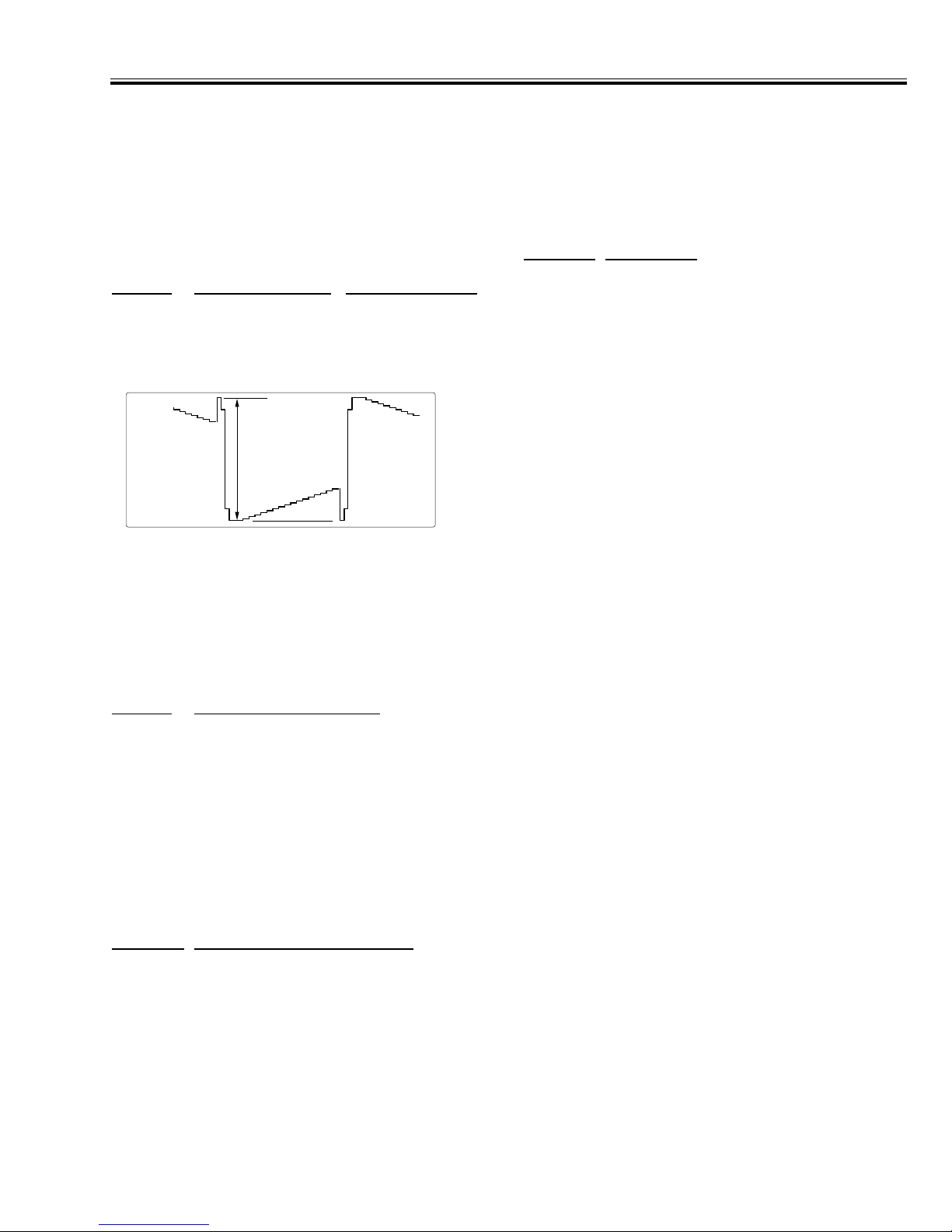

4. Contrast adjustments

Equipment Oscilloscope

Input Signal 16 step gray scale signal

Enter the Service mode.

Adjust each values of below test points in the figure (Part

A) by the Volume + or - buttons.

1-1 Input mode Computer

Item no. Test Point

7 TP-R1 (Red contrast of PC)

8 TP-G1 (Green contrast of PC)

9 TP-B1 (Blue contrast of PC)

1-2 Input mode AV (NTSC)

Item no.

Test Point

7 TP-R1 (Red contrast of AV)

8 TP-G1 (Green contrast of AV)

9 TP-B1 (Blue contrast of AV)

1-3 Input mode Component (480)

Item no. Test Point

7 TP-R1 (Red contrast of Component)

8 TP-G1 (Green contrast of Component)

9 TP-B1 (Blue contrast of Component)

A

GND

B

A

-15-

■ Adjustment

5. Signal Amplitude adjustments

Equipment Oscilloscope

Input mode Computer

Input Signal 16 step gray scale signal

Enter the Service mode.

Adjust the amplitude of part A to be below value for each

test point by the Volume + or - buttons.

Item no. Test Point Adjustment value

10 TP-R1 10.0 ± 0.1 Vp-p

11 TP-G1 10.0 ± 0.1 Vp-p

12 TP-B1 10.0 ± 0.1 Vp-p

6. Flicker Reduction

Input mode Computer

Input Signal 1dot computer signal

Enter the Service mode.

Adjust to be minimum flicker for each color by the Volume

+ or - buttons.

Item no.

Screen

19 Only red color picture

20 Only green color picture

21 Only blue color picture

7. White Balance Adjustments

Input Signal 16 step gray scale signal

Enter the Service mode.

Adjust each value of below item to be good white balance

by the Volume + or - buttons.

Item no. Imput Mode

17 and 18 Computer

17 and 18 AV (NTSC)

(17:Red, 18:Blue)

Note:

The white balance of Computer and AV pictures should be

same.

8. Contrast Linearity Adjustments

Input Signal 16 step gray scale signal

Enter the Service mode.

If the black or white saturated picture can be seen, adjust

the value of below item to be reduced it by the Volume + or

- buttons.

Item no. Imput Mode

16 Computer

16 AV (NTSC)

A

-16-

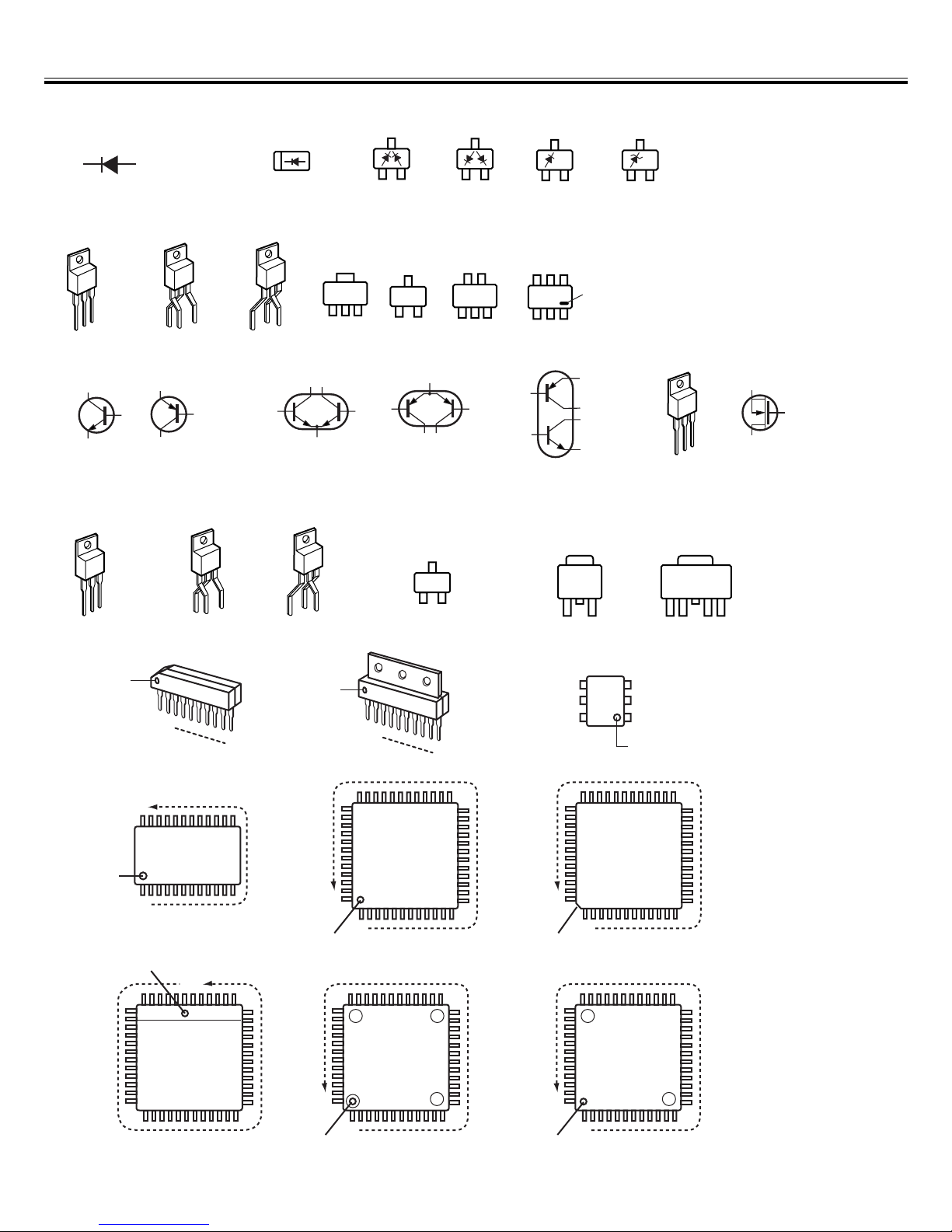

■ Pin Description of Diode, Transistor and IC

● Diode

K

A

● Transistor/FET

E

C

B

C

E

C

B

E

B

C

● IC

K

A

K

A

K

K

K: Cathode

A: Anode

AA

C

E

E

B

C

B

B1

C1

CBE

C2

B2

E

C

BE

B1

C1

E

C2

Vdd

2

KK

C1

C2

B1 B2

E

B2

C2

E2 C1

B1

B2

A

B1

E1

B2

(GND)

Index

E1

C1

C2

E2

2

A

C: Collector

B: Base

E: Emitter

D: Drain

G: Gate

S: Source

S

G

D

S

D

G

3

1

3

2

Index

Index

N

1

Index

1

3

2

Index

Index

1

3

N

GND

(IN)

Index

3

1

(OUT)

4

5

6

21

5

4

3

2

1

Index

N

1

RESET

1

2

N

1

2

1

2

1

3

1

N

N

N

Index

N

1

Index

1

-17-

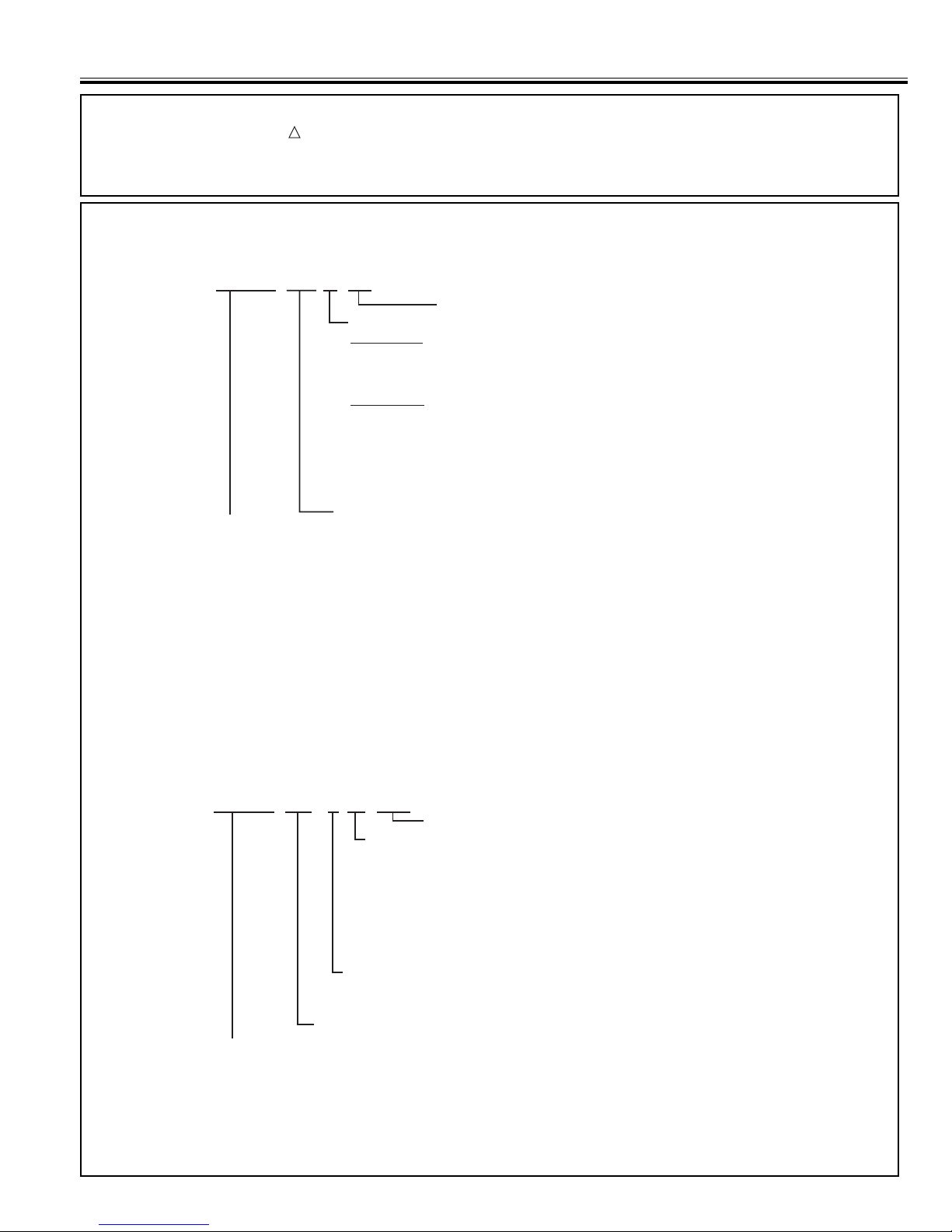

■ Electrical Parts List

Product safety should be considered when a component replacement is made in any area of a projector.

Components indicated by a mark in this parts list and the circuit diagram show components whose value have

special significance to product safety. It is particularly recommended that only parts specified on the following parts

list be used for components replacement pointed out by the mark.

!

● Read Description in the parts list

Read description in the Capacitor and Resistor as follows:

CAPACITOR

CERAMIC 100P K 50V

Rated Voltage

Tolerance Symbols:

Less than 10pF

A : Not specified B : ±0.1pF C : ±0.25pF

D : ±0.5pF E : +0 -1pF F : ±1PF

G : ±2pF H : +0.1 -0pF L : +0 -0.1pF

R : ±0.25 -0pF S : +0-0.25pF

More than 10pF

A : Not specified B : ±0.1% C : ±0.25%

D : ±0.5% F : ±1% G : ±2%

H : ±3% J : ±5% K : ±10%

L : ±15% M : ±20% N : ±30%

P : +100-0% Q : +30-10% T : +50-10%

U : +75-10% V : +20-10% W : +100-10%

X : +40-20% Y : +150-10% Z : +80-20%

Material:

CERAMIC........... Ceramic

MT-PAPER......... Metallized Paper

POLYESTER...... Polyester

MT-POLYEST.....Metallized Polyester

POLYPRO.......... Polypropylene

MT-POLYPRO....Metallized Polypropylene

COMPO FILM.....Composite film

MT-COMPO........Metallized Composite

STYRENE...........Styrene

TA-SOLID........... Tantalum Oxide Solid Electrolytic

AL-SOLID........... Aluminium Solid Electrolytic

ELECT................ Aluminum Foil Electrolytic

NP-ELECT..........Non-polarised Electrolytic

OS-SOLID.......... Aluminium Solid with Organic Semiconductive Electrolytic

POS-SOLID........ Polymerized Organic Semiconductive

DL-ELECT.......... Double Layered Electrolytic

PPS-FILM...........Polyphenylene Sulfide Film

MT-PPS-FILM.....Metalized Polyphenylene Sulfide Film

MT-PEN-FILM.....Metalized Polyethylenenaphthalate Film

CAPACITOR.......Other

Rated value: P=pico farad, U=micro farad

RESISTOR

CARBON 4.7K J A 1/4W

Rated value, ohms:

Material:

CARBON........... Carbon

MT-FILM............ Metal Film

OXIDE-MT......... Oxide Metal Film

SOLID................ Composition

MT-GLAZE......... Metal Glaze

WIRE WOUND...Wire Wound

CERAMIC RES.. Ceramic

FUSIBLE RES....Fusible

RESISTOR ........Other

K: 1,000, M: 1,000,000

Rated Wattage

Performance Symbols:

A: General B: Non flammable Z: Low noise

Other: Temperature coefficient

T: ±10ppm/°C U: ±25ppm/°C C: ±50ppm/°C

D: ±100ppm/°C E: ±200ppm/°C F: ±250ppm/°C

G: ±350ppm/°C H: ±1000ppm/°C±10% W: ±1200ppm/°C±10%

Y: ±1400ppm/°C±10% J: ±2000ppm/°C±10% K: ±2400ppm/°C±10%

L: ±2700ppm/°C±10% M: ±3000ppm/°C±10% N: ±3300ppm/°C±10%

P: ±3600ppm/°C±10% Q: ±3900ppm/°C±10% R: ±4200ppm/°C±10%

S: ±4300ppm/°C±10% V: ±4500ppm/°C±10% X: ±8000ppm/°C±10%

Tolerance Symbols:

A: ±0.05% B: ±0.1% C: ±0.25% D: ±0.5%

F: ±1% G: ±2% J: ±5% K: ±10%

M: ±20% P: +5-15% Z: 0 ohm

Loading...

Loading...