Page 1

FILE NO.

REFERENCE NO. TI5110LCD

Training Manual

Principle of LCD Display

CONTENTS

Pages

1. Construction of LCD Display ----------------------------------------------------------------------- 2 - 5

1-1 Principle of LCD Display ------------------------------------------------------------------------------- 2

1-2 Construction of LCD Display --------------------------------------------------------------------- 2 - 3

1-3 Main Component of LCD Display --------------------------------------------------------------- 4 - 5

2. Principle of Liquid Crystal --------------------------------------------------------------------------- 6 - 8

2-1 Liquid Crystal --------------------------------------------------------------------------------------------- 6

2-2 Rubbing-process------------------------------------------------------------------------------------- 6 - 7

2-3 Operation of Liquid Crystal ---------------------------------------------------------------------------- 8

3. Principle of LCD --------------------------------------------------------------------------------------- 9 - 11

3-1 Operation of Polarized Board for LCD Panel (Shutter)----------------------------------------- 9

3-2 Operation of Alignment Film------------------------------------------------------------------------- 10

3-3 Operation of LCD Panel ------------------------------------------------------------------------ 10 - 11

3-4 Transparent Electrode -------------------------------------------------------------------------------- 11

4. Type of LCD Display Construction ------------------------------------------------------------ 12 - 13

4-1 Twisted Nematic (TN) Type -------------------------------------------------------------------- 12- 13

4-2 Super TN (STN) Type---------------------------------------------------------------------------- 12- 13

4-3 Triple STN (TSTN) Type / Film STN (FSTN) Type --------------------------------------- 12- 13

5. System of LCD Display ---------------------------------------------------------------------------- 14 - 20

5-1 Dot-Matrix System ------------------------------------------------------------------------------------- 14

5-2 Colorization ---------------------------------------------------------------------------------------------- 15

5-3 Drive System -------------------------------------------------------------------------------------------- 16

5-4 Passive Matrix System-------------------------------------------------------------------------- 16 - 17

5-5 Active Matrix System---------------------------------------------------------------------------- 18 - 19

5-6 Drive of Active Matrix System----------------------------------------------------------------- 19 - 20

6. Improvement Technology of LCD Display -------------------------------------------------- 21 - 27

6-1 Subject of LCD Display ------------------------------------------------------------------------------- 21

6-1-1 Angle of View----------------------------------------------------------------------------------------- 21

6-1-2 Response Characteristic--------------------------------------------------------------------------- 21

6-2 Angle of View-------------------------------------------------------------------------------------------- 22

6-3 Multi-Domain System --------------------------------------------------------------------------------- 23

6-4 MVA (Multi-domain Vertical Alignment) System ----------------------------------------------- 24

6-5 IPS (In-Plain Switching) System ------------------------------------------------------------------- 25

6-6 Optically Compensated Film ------------------------------------------------------------------------ 26

6-7 OCB (Optically Compensated Birefringence) System ---------------------------------------- 26

6-8 Improvement of Response Speed ----------------------------------------------------------------- 27

6-8-1 Inpulse System--------------------------------------------------------------------------------------- 27

6-8-2 FFD (Feed Forward Driving) System----------------------------------------------------------- 27

7. Appendix ----------------------------------------------------------------------------------------------- 28 - 31

7-1 Backlight-------------------------------------------------------------------------------------------------- 28

7-2 LVDS Circuit--------------------------------------------------------------------------------------------- 29

7-3 Block Diagram Example------------------------------------------------------------------------ 30 - 31

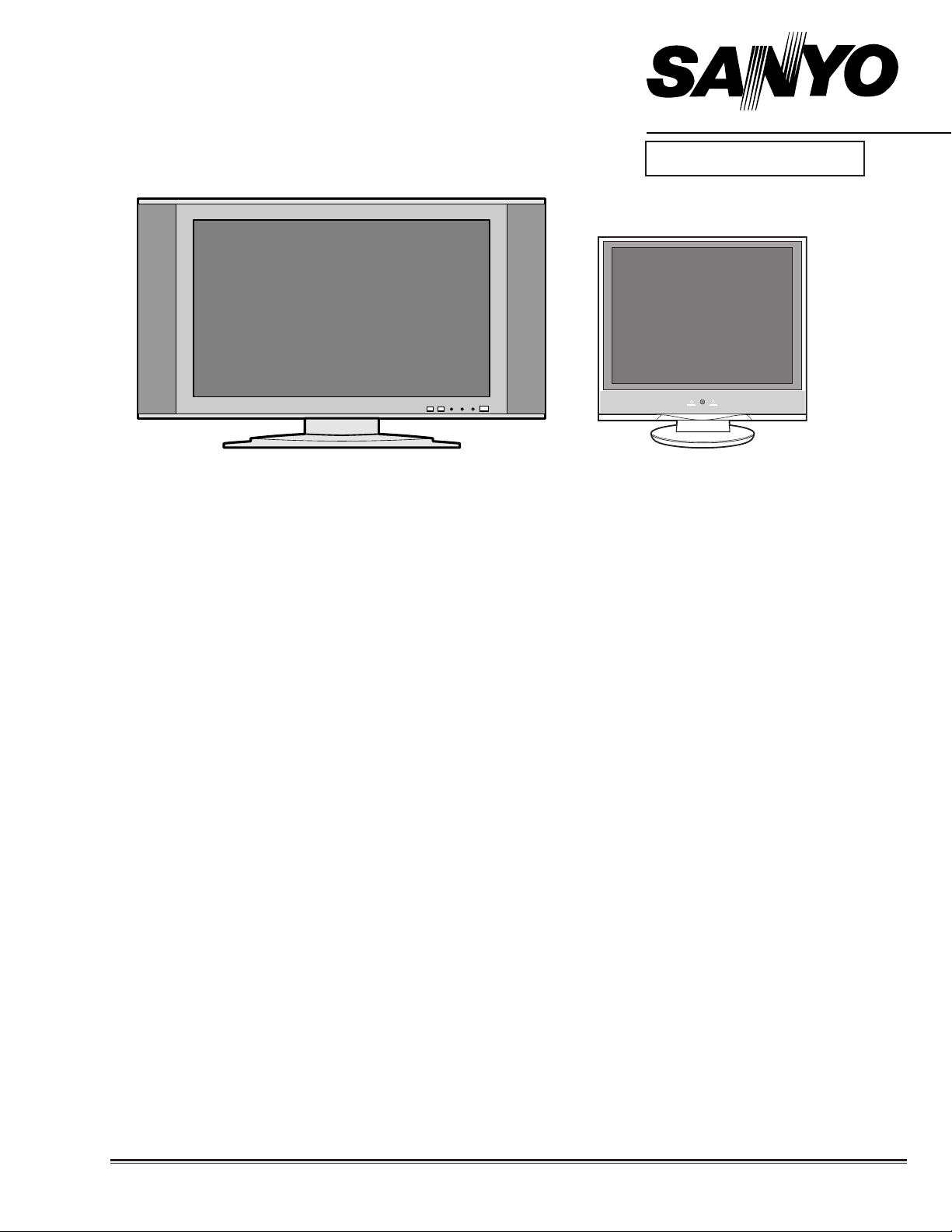

Page 2

-2-

Training Manual Principle of LCD

■ Construction of LCD Display

1. Construction of LCD Display

1-1 Principle of LCD Display

The LCD (Liquid Crystal Device) Display is used to display the electric signal, converted from picture

data similar to a CRT display. The transistor (TFT) switched by the electric signal changes the transmis-

sion to light in small picture elements (pixels) of the LCD. The LCD display makes the picture by grouping

these elements of each RGB color.

1-2 Construction of LCD Display

LCD Display

Liquid Crystal is packed between the board modules (TFT and Common) and the LCD panel (or LCD

shutter) is constructed. A back light is attached to the LCD panel for LCD Display.

Board Module (Common Electrode)

The Common Electrode consists of a polarized board, a color filter, and a transparent electrode on a

glass plate. An alignment film is formed on the transparent electrode.

Board Module (TFT Electrode)

The TFT Electrode consists of a polarized board and a transparent electrode (pixel electrode and drive

transistor) on a glass plate. An alignment film is formed on the transparent electrode.

Backlight

A fluorescent light is used for the Backlight.

✐ TFT:

Thin Film Transistor

✐ LCD Panel and LCD Shutter: They are the same things, but in the explanation LCD panel is used

for structure and LCD shutter is used for function.

Page 3

-3-

Training Manual Principle of LCD

Construction of LCD Display

Note: Alignment film is not

shown in this figure.

Fig. 1 Construction of LCD Display

(Transparent Type TFT LCD)

Backlight

Board

Module

(TFT side)

Polarized

Board

Glass

Plate

Pixel

(Picture Element)

Transparent

TFT

Electrode

(Pixel, TFT)

Transparent

Electrode

(Common)

Color Filter

Glass

Plate

Polarized

Board

LCD Layer

Board Module

(Common side)

The light of each picture element is transmitted

by switching the drive transistor (TFT) on and off.

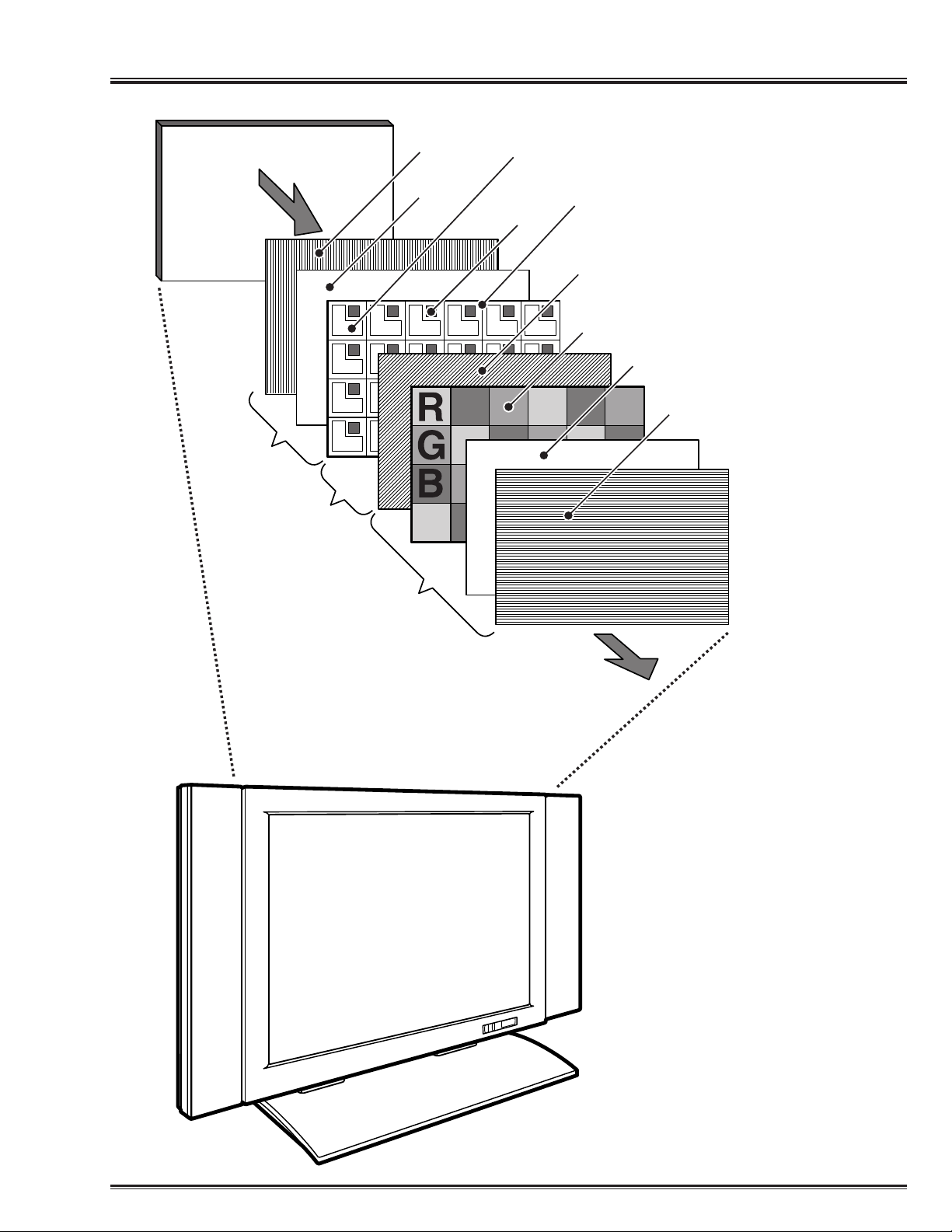

Page 4

-4-

Training Manual Principle of LCD

Construction of LCD Display

1-3 Main component of LCD Display

LCD Shutter

Supplying voltage to the transparent electrodes between the pixel and common sides changes the

arrangement of liquid crystal. By assembling two polarized boards, the transfer of light from the backlight

can be controlled by the transparent ratio of the LCD Shutter.

Liquid Crystal

Liquid Crystal is a material whose state is between a solid and a liquid. It has both characteristics of

solids and liquids, and generally it is a white turbid liquid. Its molecules are normally arranged compara-

tively opaque and change to transparent with the application of voltage or heat.

Transparent Electrode (Film)

An LCD shutter is operated by supplying voltage derived from the video signal. Transparent film is used

for its electrode.

Alignment Film

This is a film for arranging liquid crystal molecules and is made of Polymid resin.

Polarized Board

The light with a specified direction passes through a polarized board.

Drive Transistor

The thin film transistor (TFT) is used to drive the LCD shutter of each pixel.

Color Filter

It is a filter with three colors (R, G, B) arranged for each pixel.

Backlight

Liquid crystal does not emit light. A light source is needed for display. The light source placed on the

reverse side of the LCD panel is called “Backlight.”

Page 5

-5-

Training Manual Principle of LCD

Construction of LCD Display

Fig. 2 Construction of LCD Display

(Cross Section)

Fig. 3 Assembly of LCD Display

Backlight

LCD

Shutter

Module

(Back)

LCD Layer

Module

(Front)

Polarized

Board

Glass

Plate

Transparent Electrode

(Pixel, TFT)

Alignment Film

Liquid Crystal

Alignment Film

Transparent Electrode

(Common)

Color Filter

Glass Plate

Polarized

Board

LCD

Display

LCD

Module

Backlight

LCD Panel

(LCD Shutter)

TFT Display

Drive Circuit

(with IC)

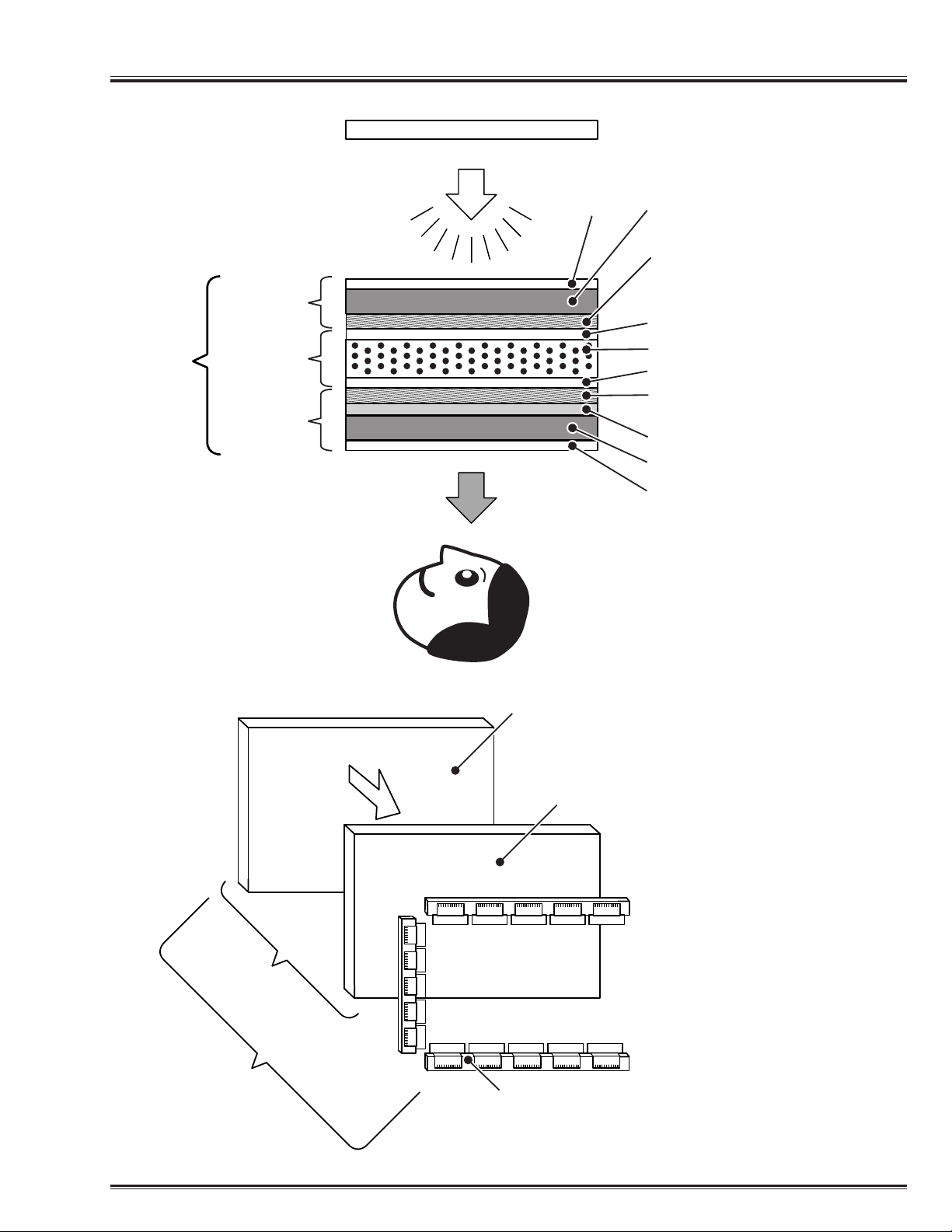

Page 6

-6-

Training Manual Principle of LCD

2. Principle of Liquid Crystal

2-1 Liquid Crystal

What is Liquid Crystal?

Liquid Crystal is a material whose state is between a solid and liquid. It has characteristics of both solids

and liquids, and generally is a white turbid liquid. Its molecules are normally arranged comparatively

opaque and change to transparent with the application of voltage or heat.

Almost all the materials consist of an organic compound taking the form of a slender stick or a flat plate.

There are three types of liquid crystal as shown in Fig. 4, and they depend on the construction and

arrangement of molecules.

Generally Nematic liquid crystal is used for the display apparatus.

(a) Smectic

Molecules are in layers and arranged parallel to each other. The center of gravity is arranged at random

in the layer.

(b) Nematic

Molecules are not in layers. They are arranged parallel. The center of gravity is able to move freely to the

major axis.

(c) Cholesteric

Molecules are in layers and arranged parallel. The arranging direction of the major axis for the neighbor-

ing layers is shifted gradually.

In order to use liquid crystal for display, it is necessary to regularly arrange the molecules of Nematic

(Rubbing-process).

2-2 Rubbing-process

After chemicals for arranging are put on the glass plate, they are hardened, and then the surface on the

plate is rubbed with a cloth to fix the direction of the gaps that are made. The arranging direction of mole-

cules is settled in the gaps.

This process is used to change the characteristics so the molecules that touch the rubbed surface are

arranged to the major axis of the rubbed direction.

This thin film on the glass plate is called “Alignment film.”

■ Principle of Liquid Crystal

Page 7

-7-

Training Manual Principle of LCD

Principle of Liquid Crystal

Fig. 4 Liquid Crystal

(a) Smectic

(c) Cholesteric

(b) Nematic

Fig. 5 Rubbing-Process

Natural Condition

Liquid Crystal Molecule

Arranging

Rubbing

Direction

Alignment Film

Page 8

-8-

Training Manual Principle of LCD

Principle of Liquid Crystal

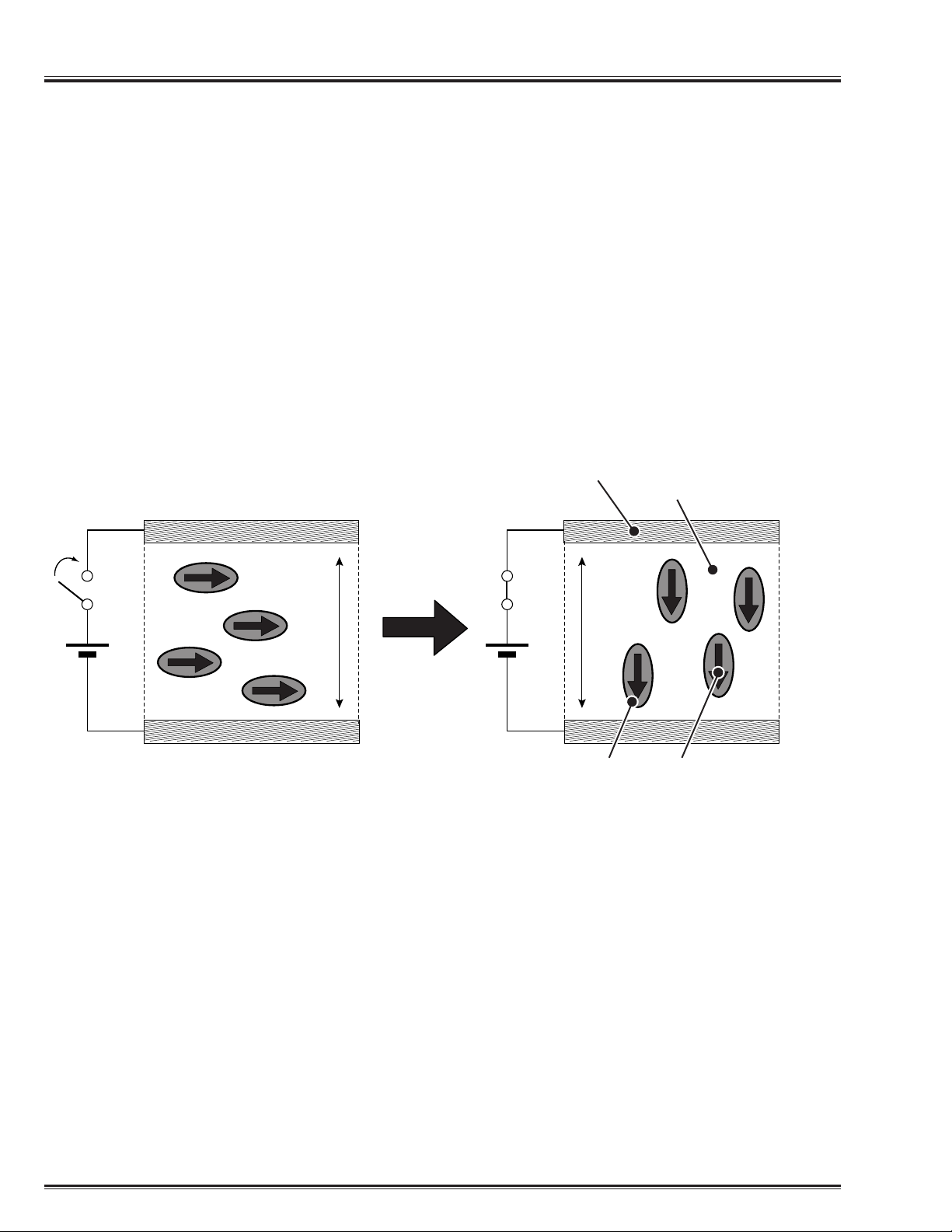

2-3 Operation of Liquid Crystal

The chemistry substance required for liquid crystal material is one that reacts so that the arrangement

direction is changed according to an applied electric field.

In the LCD display, a liquid crystal is placed between two electrodes. When the voltage is supplied

between them, an electric field is generated in the liquid crystal, and liquid crystal molecules are moved

and arranged. The Backlight applied to the liquid crystal is either passed or blocked according to the

arrangement of the molecules.

If an electric field from an external source is applied to liquid crystal, electric dipoles will be generated

that will react to the intensity and direction of the electric field. Through the operation of these electric

dipoles and the electric field, the power changing direction of liquid crystal molecules is generated.

Therefore, according to an external electric field, liquid crystal molecules move and change direction

from horizontal to vertical.

Fig. 6 Operation of Liquid Crystal

Electric

Field

Transparent

Electrode

Liquid Crystal

Electric

Field

Liquid Crystal

Molecule

Electric

Dipole

Page 9

-9-

Training Manual Principle of LCD

3. Principle of LCD

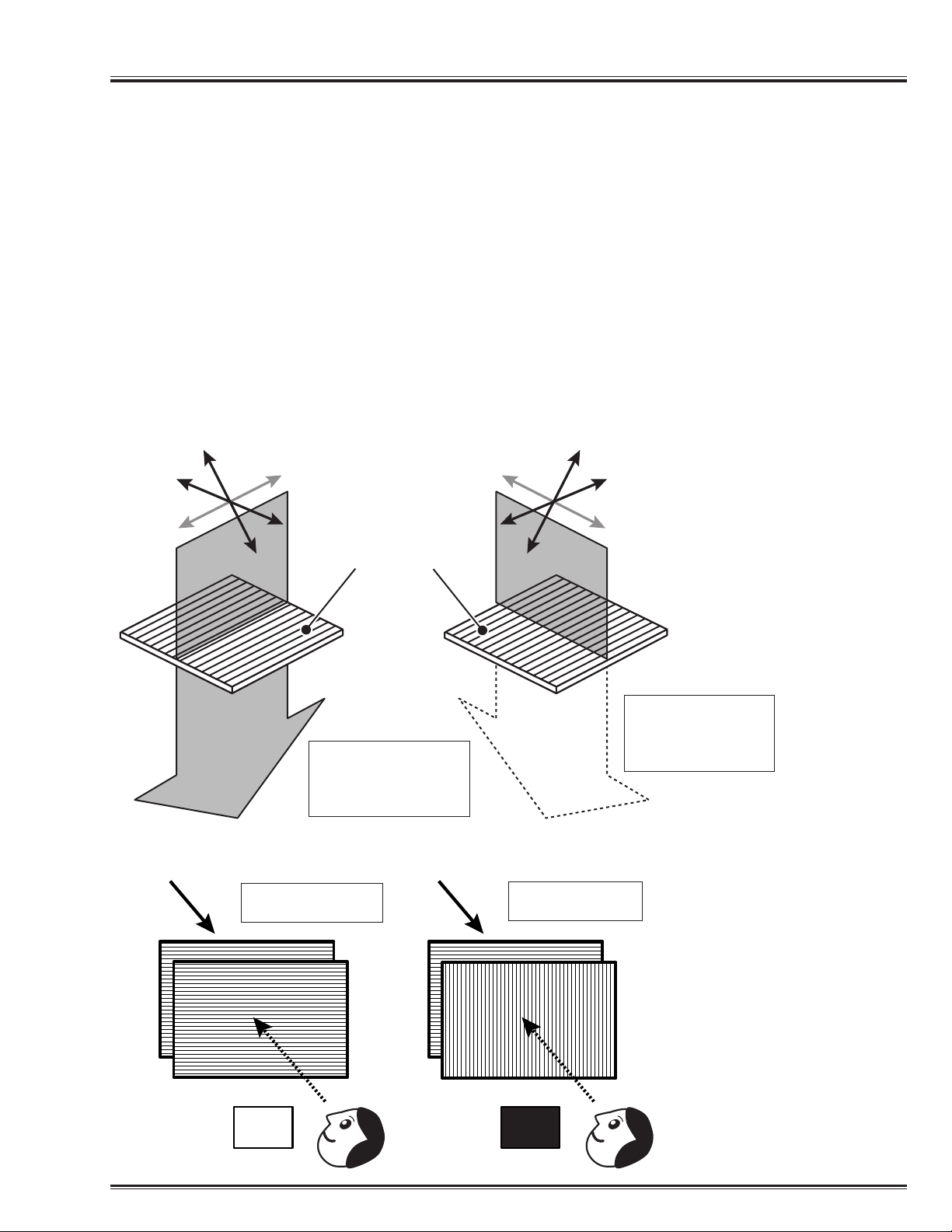

3-1 Operation of Polarized Board for LCD Panel (Shutter)

Light is an electromagnetic wave that is oscillating at right angles to the direction of advance. In fact, the

oscillating directions of all light is mixed. A polarized board can let only the light in the specific direction

pass from the light with which these various oscillating directions were mixed. Therefore, only the light of

the same direction as the polarization direction of a polarized board can be taken out by letting the light

pass through this polarized board. That is, if the oscillating direction of light and the direction of a polarized board are in agreement, the light will pass through a polarized board. Moreover, if the direction of a

polarized board differs from the oscillating direction of light, the light cannot pass through a polarized

board. When the oscillating direction of a polarized board and light are shifted 90º(right-angled), the light

is blocked completely. The light passes and looks bright if the two boards are in the same direction when

looking at two polarized boards in piles, however, if shifted at right-angles, the light is blocked and looks

dark.

■ Principle of LCD

Fig. 7 Operation of

Polarized Board

Fig. 8 Operation of

Polarized Board

Oscillating direction of light

Oscillating direction of light

The oscillating direction

of light and the direction

of a polarized board are

in agreement.

The direction of a

polarized board differs

from the oscillating

direction of light

Passage Interception

The two boards are

the same directions.

The two boards are

shifted right-angled.

Polarized

Board

Light

Light

White

Black

Page 10

-10-

Training Manual Principle of LCD

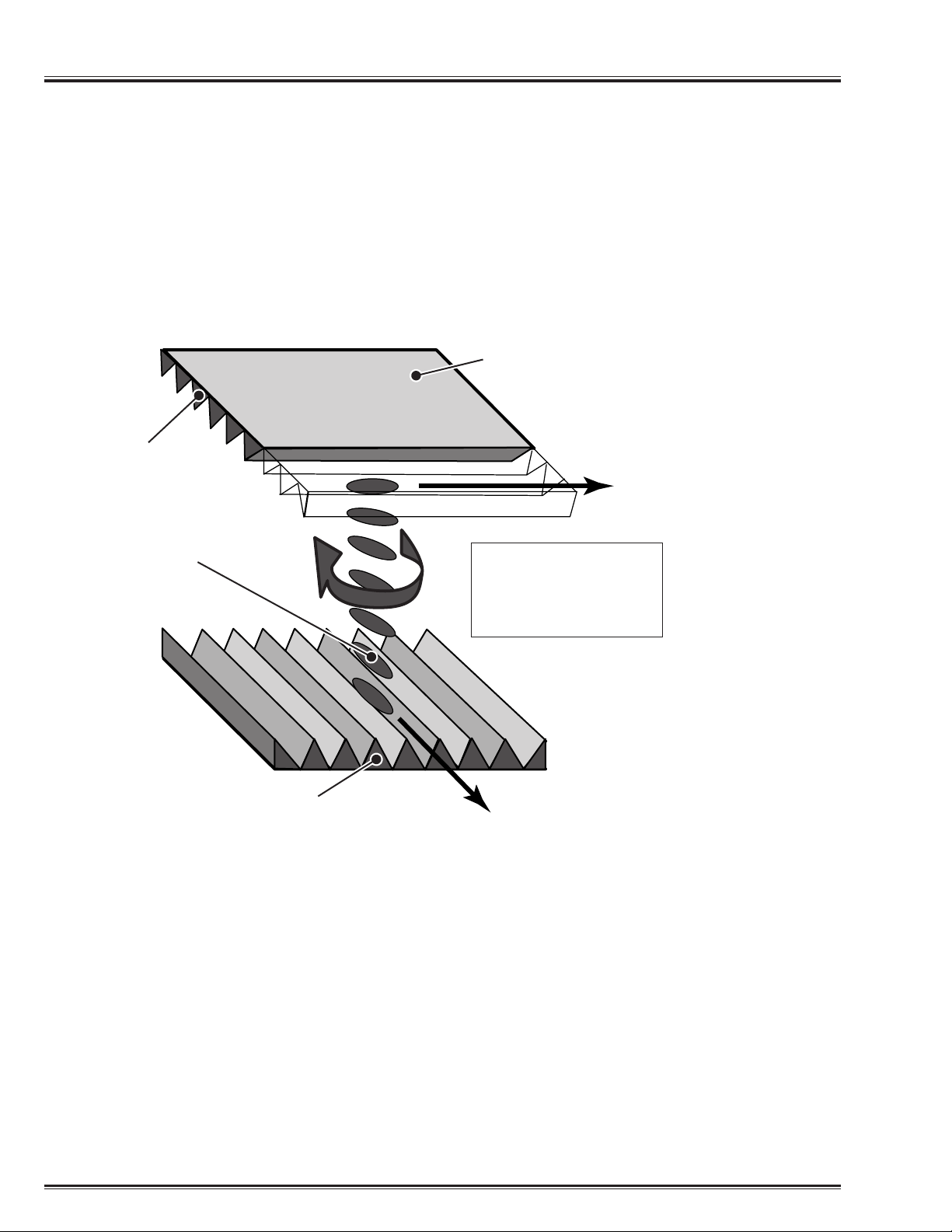

3-2 Operation of Alignment Film

Liquid crystal is inserted into alignment films of an upper and lower plate that have the direction of

grooves shifted by 90º on the LCD display. The liquid crystal molecules of upper alignment plate are

arranged along with the upper alignment film. The liquid crystal molecules of lower alignment plate are

arranged along with the lower alignment film. The liquid crystal layer between these alignment films is

twisted little by little and is arranged so that a spiral is formed. Light entering through the first alignment

plate will have its oscillating direction twisted 90º by the liquid crystal layer between the alignment films.

Now the direction of oscillation is aligned with the second alignment plate and the light will pass through.

Principle of Liquid Crystal

Fig. 9

Operation of

Alignment Film

By the upper-and-lower

alignment films, spirally, a

liquid crystal molecules are

twisted 90º and arranged.

3-3 Operation of LCD Panel

In the LCD panel, a liquid crystal is inserted and enclosed between two glass plates. The polarized

board, transparent electrode, and the alignment film are formed on these glass plates. The light can be

passed or blocked by supplying voltage or not to this LCD panel.

In the condition (Switch-Off) that the voltage is not supplied, the liquid crystal molecules are twisted 90º

sideways and arranged spirally. The oscillating direction of the light that passed the upper polarized

board is changed by the twisted liquid crystal molecule arrangement. Therefore, the direction of a polar-

ized board and the oscillating direction of the light which is shifted 90º and arranged become the same,

and this light can now pass through a polarized board. This is the liquid crystal shutter-on condition and

an LCD panel (LCD shutter) passes the light.

Alignment

Plate

Alignment

Film

Direction

of Groove

Liquid

Crystal

Molecule

Alignment

Film

Direction

of Groove

Page 11

-11-

Training Manual Principle of LCD

Principle of Liquid Crystal

Fig. 10 Operation of

LCD Panel

Passage

Interception

3-4 Transparent Electrode

In order to generate an electric field in liquid crystal, voltage is supplied to the upper-and-lower electrodes. If metal is used for these electrodes, the light is interrupted by this metal and cannot pass into the

liquid crystal. Therefore, a transparent electrode that passes light is used for the electrode of the LCD

shutter.

On the contrary, in the condition (Switch-On) that voltage is supplied, the liquid crystal molecules are

arranged in a line at right angles to a glass plate. Since vertical liquid crystal molecules do not affect the

oscillating direction of light, the light that passed the upper polarized board passes as it is without changing the oscillating direction. Since the oscillating direction of this light differs from direction of the lower

polarized board which is shifted 90º and arranged, the light collides with this polarized board and cannot

pass. This is the liquid crystal shutter-off condition and the LCD panel (LCD shutter) blocks the light.

This is the basic structure (On—Off of the light by the LCD shutter) of an LCD panel. It is a sandwich

structure of the upper and lower sides of transparent electrodes, alignment films, and polarized boards,

with an enclosed liquid crystal material between them.

The LCD panel shown in Fig. 10 is a type of panel that changes the light into a passage condition when

voltage is not supplied between the upper-and-lower polarized boards that are arranged at 90º. This type

of panel has the advantage that black contrast is improved, and it usually works well. This mode is called

“Normally White Mode.”

An LCD panel that passes light when voltage is not supplied is referred to as “Normally Black Mode.” In

practice, with this type (when the upper-and-lower polarized boards are arranged in the same direction),

displaying perfect black becomes difficult due to the leakage of light caused by variations in the arrangement of the liquid crystal molecules.

Polarized

Board

Transparent

Electrode

(Upper)

Alignment

Film

Liquid

Crystal

Alignment

Film

Transparent

Electrode

(Lower)

Polarized

Board

Light

Light

Polarized

Board

Transparent

Electrode

(Upper)

Alignment

Film

Liquid

Crystal

Alignment

Film

Transparent

Electrode

(Lower)

Polarized

Board

Page 12

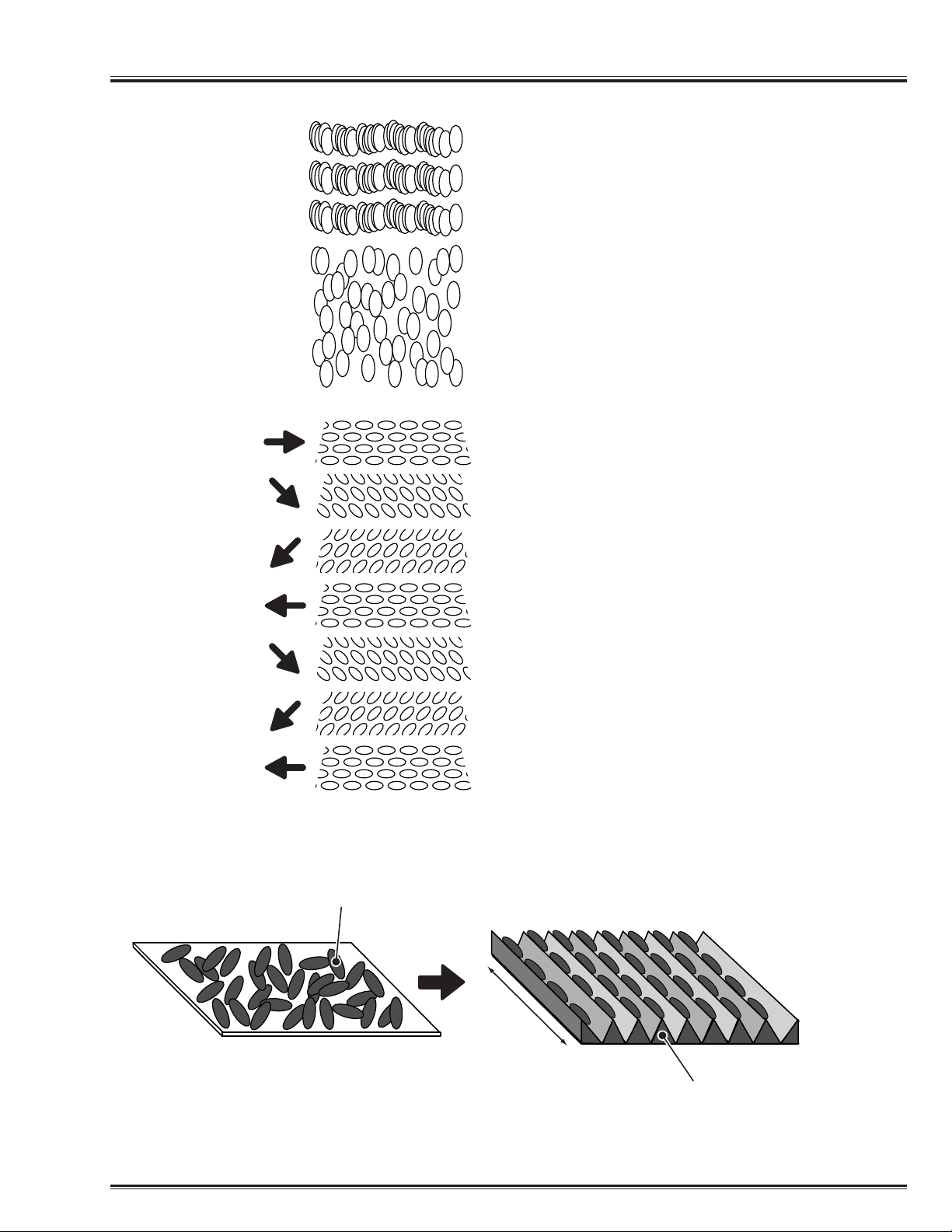

-12-

Training Manual Principle of LCD

■ Type of LCD Display Construction

4 Type of LCD Display Construction

4-1 Twisted Nematic (TN) Type

A Nematic type of LCD Display where the liquid crystal molecules are twisted 90º between upper and

lower boards is called a Twisted Nematic type (TN type) liquid crystal.

Most LCD displays are of this type and feature high contrast (ratio) under low voltage and power.

4-2 Super TN (STN) Type

Super TN type (STN type) LCD Displays are used for LCD televisions, personal computer monitors, cel-

lular phones, etc. A liquid crystal material developed to improve visual characteristics, such as contrast

ratio is used.

In this STN type liquid crystal molecules are twisted 180º to 270º and arranged between upper and lower

electrodes. By supplying voltage to this liquid crystal, the transparent ratio of light changes more steeply.

Therefore, with the STN type as compared to the TN type, contrast and rise characteristic of the voltage

(response of switch On and Off) are improved, and a clearer picture on larger screens becomes possible.

4-3 Triple STN (TSTN) Type / Film STN (FSTN) Type

A fault of the STN type is that the display colors during On and Off of the LCD shutter become yellowish

green and navy blue. (In TN type, they are white and black.) This is because light of a specific wave-

length is reflected and scattered by the thickness of the LCD panel. Therefore, even if a color filter of

RGB is attached to an STN type liquid crystal, bluish green is mixed with the colors from black, gray to

white, and a natural color picture cannot be displayed. The triple STN type (TSTN type) and the film STN

type (FSTN type) have been developed as an advanced type of STN.

In the TSTN type, optically compensated films (high polymer films) which sandwich the upper and lower

LCD panels are used. They compensate for the twist of the light crystal cell, and the display colors of yel-

lowish green and navy blue are changed to the correct white and black. The “FSTN” type uses a single

optically compensated film

Page 13

-13-

Training Manual Principle of LCD

Type of LCD Display Construction

Fig. 11 Type of LCD Display Construction

Twist of molecule

(90º)

Twist of molecule

(180º - 270º)

TSTN Type

STN Type

TN Type

Module

LCD Layer

Module

Module

LCD Layer

Module

Optically

Compensated

Film

Module

LCD Layer

Module

Optically

Compensated

Film

Page 14

-14-

Training Manual Principle of LCD

5 System of LCD Display

5-1 Dot-Matrix System

LCD displays have two drive systems, Segment and Dot-Matrix. The Dot-Matrix system is used for LCD

television displays.

The picture elements (pixels) of the display unit are arranged horizontally (X line) and vertically (Y row)

by this Dot-Matrix system, and various characteristics and figures can be displayed.

Fig. 12 shows a matrix of “X x Y = 10 (pixels)” with the character “Y” displayed. In this Dot-Matrix system,

by making the size of a pixel smaller and increasing the whole number of pixels, the big screen with fine

character or picture becomes possible.

With the present liquid crystal manufacture technology, the number of pixels per inch has reached

200ppi*, and very high definition screen display is possible. Moreover, the number of pixels of an LCD

display panel corresponding to bigger screen sizes can be specified and manufactured. For example, the

number of pixels of the SXGA* panel is about 1,300,000 (1,280 x 1,024 = 1,310,720 pixels).

✐ ppi: pixel per inch

✐ SXGA: Super eXtended Graphics Array

■ System of LCD Display

Fig. 12 Dot-Matrix System

In colorization of LCD panel,

one pixel consists of 3 RGB

dots (sub-pixels).

A character or a figure is

displayed by making the

pixel of each X and Y inter-

section turn on (or off).

X

Y

RGB

Page 15

-15-

Training Manual Principle of LCD

5-2 Colorization

Since an LCD shutter only passes or blocks light, in itself it cannot display a color picture. The color pic-

ture is made by mixing the three colors of RGB (three primary colors of light) respectively, like the CRT

color television. The color LCD panel has a color filter of RGB attached to the monochrome panel. See

Fig. 13. In this color LCD panel, by controlling the voltages and the waveforms that are supplied at each

RGB pixel, the transparent ratio is controlled and hue and brightness are adjusted. Therefore, smaller

pixels and more numbers of pixels are required for the color LCD Display. For example, although the

SXGA panel described before has about 1,300,000 pixels, in colorization, there are about 4 million dots

(sub-pixels).

System of LCD Display

Fig. 13 Colorization of LCD Display

Color Panel Monochrome Panel

R

Backlight

White

Color

G

White

Monochrome

B

Color Filter

LCD Shutter

Backlight

LCD Shutter

Page 16

-16-

Training Manual Principle of LCD

5-3 Drive System

The drive systems for LCD display are divided into the following classifications:

The Static Drive System, which is seldom used;

The Passive Matrix System, which is used for still pictures, such as calculators and notebook PCs;

The Active Matrix System, which is suitable for high definition and the high-speed response needed for

big screen LCD television.

System of LCD Display

Drive System Static Drive System

Dynamic Drive System Passive Matrix System

Active Matrix System

Classification of LCD Drive System

5-4 Passive Matrix System

In the structure of a passive matrix system, Y electrodes of the vertical direction (Y-direction) are formed

in upper glass plate, and X electrodes of the horizontal direction (X direction) are formed in lower glass

plate as a matrix. The liquid crystal molecules are sandwiched between these electrodes. By supplying

voltage between the Y electrode and the X electrode in sequence, at a certain time, an electric field is

generated in the liquid crystal where the selected Y electrode and X electrode cross. Therefore, the liquid

crystal molecules of this pixel address (X, Y electrode intersection) change arrangement and an LCD

shutter is turned On or Off.

Fig. 14 Passive Matrix System

These electrodes are

transparent electrodes.

Y Electrode

0 Y1 Y2 Y3 Y4

Y

Glass

Plate

Liquid

Crystal

Layer

Glass

Plate

X0

X1

X2

X Electrode

X3

X4

Page 17

-17-

Training Manual Principle of LCD

System of LCD Display

Fig. 15

Passive Matrix System

LCD shutter is turned on

or turned off in this

address (X2, Y1).

In the dynamic drive system, since the electric signal (voltage) is supplied to the Y electrode and the X

electrode in sequence, the number of pixels which makes all pixels (the total number of pixels are “X x

Y”) turn on or off becomes “X+Y”. Therefore, compared with the static drive system that has an indepen-

dent electrode for each pixel, the number of electrodes of the dynamic drive system is very few.

However, with this dynamic drive system, since the electrode itself is the wiring, it has resistance that

cannot be disregarded in the big screens. This resistance causes the speed of the shutter to become

slower. Therefore, when displaying moving pictures etc., an afterimage is generated.

This passive matrix system is not suitable for LCD televisions with big screens that require moving pic-

tures and high resolution.

The active matrix system was developed in order to overcome these faults.

Y1

Y0 Y1 Y2

X0

X1

Liquid

X2

Crystal

X3

X2

Page 18

-18-

Training Manual Principle of LCD

5-5 Active Matrix System

In the active matrix system, a switch element is attached for every pixel at the intersection of the X and Yelectrodes of a passive matrix system. Each pixel is now controlled by the switch element (active element). Since the switch for each pixel is turned On and Off independently, the response speed is

increased. Thin Film Transistor (TFT) is used for the switch element and is attached on the glass board.

The LCD display using this TFT is called “TFT LCD display”.

The upper electrode for the whole pattern is formed on the upper glass plate and is called the “Common

Electrode”. A pixel electrode (pixel pattern), TFT (switch element) which drives a pixel electrode, and X

electrode for gate input and Y electrode for source input of TFT are formed on the lower glass plate. In

this structure, the electric field is generated in the area between the pixel electrode and the common

electrode, and the LCD shutter for 1 pixel is operated.

When an electric signal (voltage) is supplied to the Y and X electrode of TFT, TFT is turned On, and the

liquid crystal molecules are operated as a light switch. Refer to Fig. 17 (Address X1 and Y0).

System of LCD Display

Fig. 16 Structure of Active

Matrix System

Fig. 17 Equivalent Circuit of

Active Matrix System

By TFT, the shutter of a pixel at the

address (X1, Y0) is turned On or Off.

Glass Plate

(Upper)

COMMON

Electrode

Liquid

Crystal

Liquid

Crystal

Layer

0

Y

TFT

Glass Plate

(Lower)

COMMON

Electrode

Y Electrode

Y1

X1

X Electrode

X2

Pixel Electrode

Y Electrode

COMMON

Electrode

Electrode

X1

Gate

TFT

(Switch Element)

Equivalent Circuit

(TFT)

COMMON

Pixel

Source

Y0

Pixel Electrode

(Pixel Pattern)

X Electrode

Liquid

Crystal

Drain

TFT

X1

Gate

Equivalent Circuit

(Switch)

COMMON

Source

Switch

0

Y

(On / Off)

Drain

Page 19

-19-

Training Manual Principle of LCD

System of LCD Display

Fig. 18 Structure of TFT Matrix

The LCD shutter is operated by

TFT at the address (X1, Y0).

The amplification operation of a transistor is used for the TFT switch in the active matrix system. In this

system, switching speed is unified over the whole display, increasing drive response speed as compared

with the passive matrix system. Therefore, TFT LCD display (active matrix system) is adopted for the

highly efficient display, which can provide the response speed required for big screens or quickly moving

pictures. However, further response speed is needed for high definition LCD television. This will be

described later.

5-6 Drive of Active Matrix System

The TFT LCD display consists of a matrix of n lines of X direction (X0 - Xn-1) and of n rows of Y direction

(Y0 - Yn-1). The line of X direction is called the “gate line” and the line (row) of Y direction is called the

“data line.”

First, the scan is started from the pixel address

(X0, Y0), and when the address (X0, Yn-1) is

selected the scan of X0 line is completed. Next, all

the pixels from X1 line to Xn-1 line are scanned in

sequence, and the final address is (Xn-1, Yn-1).

The operation of selected pixel address (X1, Y2)

is explained below.

First, (signal) voltage is supplied to X1 line (gate

of TFT), next voltage is supplied to Y2 row (source

of TFT), and the address of the intersection of X1

line and Y2 row is selected and its TFT is turned

On or Off. However, just switching the TFT on and

off will not change the brightness of the screen.

The brightness of a screen is changed by controlling the voltage of a data line (Y row). Fig. 19

shows the voltage characteristic of the matrix system.

Fig. 19 Voltage Characteristic of Matrix System

Since the time for the drive voltage to reach its

required value is shorter in the active matrix system,

the response time of the display becomes quicker.

Y0 Y1 Y2 Y3

X0

TFT (Switch)

Liquid Crystal

COMMON Electrode

X1

X2

X3

Active Matrix System

Passive Matrix System

Voltage to liquid crystal

Time

Page 20

-20-

Training Manual Principle of LCD

In Fig. 20, the voltage of the data line (Y2) is supplied in the positive direction to a common electrode

(DC drive). In practice a uniform AC voltage is supplied to the common electrode (AC drive) to prolong

the life of the liquid crystal.

Fig. 20 LCD Drive Circuit (Normally White Type)

In practice, driven by AC signal

to COMMON. (AC Drive)

System of LCD Display

Data Line Drive Circuit (Y row)

TFT

Pixel

Electrode

Glass Plate

(Common)

Liquid

Crystal

Glass Plate

(TFT)

Variable

Voltage

Y0

Video Data

Processor

Y1 Y2 Y3

X Direction

Y Direction

• • •

Timming Controller

(Scan Converter)

Yn-1

X0

X1

X2

X3

Xn-1

COMMON

Power

Circuit

• • •

Gate Line Drive Circuit (X line)

X1

Y2

TFT: On (X1, Y2)

Y2

Y2

Y2

Y2

COMMON

Brightness

of Screen

COMMON

TFT: On

TFT: Off

Page 21

-21-

Training Manual Principle of LCD

6 Improvement Technology of LCD Display

6-1 Subject of LCD Display

6-1-1 Angle of View

Angle of view means the normal visible range (angle) of a screen.

In an LCD display, the angle of view is narrow compared with a CRT or PDP (Plasma Display Panel). The

viewing angle of the typical TN type LCD display is about 100º. However with the new improved technolo-

gy that has been developed the angle of view for LCD display has increased to 160º or 170º. This

improved system will be described later. (The angle of view for a CRT or PDP is 180º.)

■ Improvement Technology of LCD Display

6-1-2 Response Characteristic

The response characteristic of the LCD display is the speed at which the display is refreshed by the input

signal (video data signal).

If this response characteristic is slow, an afterimage will appear on the screen. Therefore, in large screen

LCD television, improving this response characteristic becomes very important.

Fig. 21 Angle of View

Vertical

Angle of View

Horizontal

Angle of View

Page 22

-22-

Training Manual Principle of LCD

6-2 Angle of View (TN Type)

The principle of optical penetration and the interception of the LCD shutter by the arranged direction of

cylindrical liquid crystal molecules controls the direction of light. Therefore, brightness, hue, and contrast

depend on the direction of view of the LCD display. The range (angle) where these look normal is called

the “angle of view.” The fault of the TN LCD display is that this angle of view is narrow.

Fig. 22 shows that brightness changes depending on the angle the screen with a gray picture is viewed.

In this figure, the liquid crystal molecule leans diagonally. Therefore, the amount of optical penetration will

change depending on the angle when watching the screen from the front or the side.

Fig. 22 Angle of View (TN type)

Improvement Technology of LCD Display

The brightness becomes

different depending on the

angle of view.

Glass

Plate

Glass

Plate

Polarized

Board

Transparent Electrode

(Common)

Alignment Film

Liquid Crystal Molecule

Alignment Film

Transparent Electrode

(Pixel, TFT)

Polarized

Board

Page 23

-23-

Training Manual Principle of LCD

6-3 Multi-Domain System

The arrangement of the TN LCD display is one directional. In this Multi-Domain System, one pixel is

divided into two or more different arranged domains.

Fig. 23 shows the example of Multi-Domain System with two domains. The quantity of the light per pixel

from various angles is equalized by this system. Moreover, the angle of view becomes even wider by

increasing the number of divisions. However, manufacturing is difficult in the rubbing process*.

✐ Refer to 2-2 Rubbing-process.

Improvement Technology of LCD Display

Fig. 23

Multi-Domain System

The brightness of a screen

is equalized as macro view.

Polarized

Board

Glass

Plate

Transparent Electrode

(Common)

Alignment Film

Glass

Plate

Alignment Film

(Left)

Alignment Film

(Right)

Liquid Crystal Molecule

Transparent Electrode

(Pixel, TFT)

Polarized

Board

Page 24

-24-

Training Manual Principle of LCD

Improvement Technology of LCD Display

6-4 MVA (Multi-domain Vertical Alignment) System

In the MVA system, the (alignment) film is arranged so that the liquid crystal molecules are stood vertical-

ly. The MVA system combines vertical alignment with the Multi-domain system. By vertically aligning the

liquid crystal molecules, the influence of optical interception is lost, and the angle of view and contrast

are improved.

A type of material is used that causes the liquid crystal molecules to become vertical to the glass plate

without supplying voltage. (Nega-Nematic liquid crystal*)

In the MVA system, attaching the boss by resin and making the liquid crystal molecules stand diagonally

on the transparent electrode make multiple alignment domains. Therefore, since the rubbing process can

be skipped at the alignment film production, manufacturing becomes easier compared with the multi-

domain system.

✐ Generally, a Posi-Nematic system is used that aligns the liquid crystal molecules by supplying voltage.

Fig. 24 MVA (Multi-domain Vertical Alignment) System

Glass

Plate

(Left)

Glass

Plate

Polarized

Board

Transparent Electrode

(Common)

Alignment Film

Liquid Crystal Molecule

(Nega-Nematic)

Alignment Film

Boss

(Right)

Transparent Electrode

(Pixel, TFT)

Polarized

Board

Page 25

-25-

Training Manual Principle of LCD

Improvement Technology of LCD Display

6-5 IPS (In-Plain Switching) System

The structure of an IPS system is shown in Fig. 25. The pixel and common electrodes are mounted to

the transparent film (drive transistor) side and the electric field is generated horizontally to the glass

plate. With this electric field, the alignment direction of liquid crystal molecules is rotated 90º in parallel to

the glass plate.

In the IPS system, liquid crystal molecules rotate all at once in the horizontal direction. Since these liquid

crystal molecules do not lean like the TN type, there is little change in the picture characteristics (contrast, brightness, hue, etc.) and the angle of view becomes wider. However, there are a few problems.

The quantity of transparent light is reduced, slower response speed, and a white picture becomes a little

bluish or yellowish depending on the viewing direction. The S-IPS (Super-IPS) type was developed to

improve upon these problems. In the S-IPS type, the structure of the electrode for driving the liquid crystal molecules becomes a zigzag form, which reduces the change of color, increases the viewing angle to

about 160º and has high definition equivalent to a CRT.

Fig. 25 IPS (In-Plain Switching) System

Basic Structure of IPS System

Normally Black Mode

Polarized

Board

Transparent Electrode

(Pixel)

Liquid Crystal Molecule

(Vertical)

Electric

Field

Glass Plate

(Without Transparent Electrode)

Alignment Film

Alignment Film

Transparent Electrode

(Common)

Glass Plate

Polarized

Board

Polarized

Board

Alignment Film

Dark (Switch Off) Bright (Switch On)

Liquid Crystal

Molecule

(Vertical)

Page 26

-26-

Training Manual Principle of LCD

Improvement Technology of LCD Display

6-6 Optically Compensated Film

By using the optically compensated film, the phase shift of the STN type of LCD display is corrected, and

the angle of view and contrast are improved.

(Refer to 4-3 Triple STN Type.)

Three methods for attaching the optically compensated film are shown in Fig. 26.

Fig. 26

Optically Compensated Film

1 sheet / 1 side 2 sheets / 1 side 2 sheets / 2 sides

6-7 OCB (Optically Compensated Birefringence) System

The OCB system combines the bend-alignment system where the liquid crystal molecules are bent and

aligned between the upper and lower boards and optically compensation film. This system has the features of increased angle of view and quicker response speeds. However, bend-alignment is difficult to

make uniform and stable.

Fig. 27 OCB System

Polarized Board

Compensated

Film

Liquid Crystal

Polarized

Board

Polarized Board

Compensated Film 1

Compensated Film 2

Liquid Crystal

Polarized

Board

Polarized Board

Compensated

Film 1

Liquid Crystal

Polarized

Board

Compensated

Film 2

Polarized Board

Glass

Plate

Glass

Plate

Optically Compensated

Film

Transparent Electrode

(Common)

Alignment Film

Liquid Crystal Molecule

Alignment Film

Transparent Electrode

(Pixel, TFT)

Polarized

Board

Page 27

-27-

Training Manual Principle of LCD

6-8 Improvement of Response Speed

6-8-1 Inpulse System

In order to reduce afterimage and dim outline, there is the system that has the backlight blinked for every

writing of one picture or an all black picture in inserted in the fixed cycle. It is called the “Inpulse System.”

For example, with the system called “Super Inpulse System,” the black data is written in every 1/60 second, and the afterimage and the ghosts are reduced.

Improvement Technology of LCD Display

With the usual LCD panel, since the

picture is displayed continuously,

the front picture becomes dim as

the afterimage.

In the inpulse system, by inserting

black data between the picture

data, the afterimage is reduced and

the high-speed response is

improved.

Fig. 28 Inpulse System

6-8-2 FFD (Feed Forward Driving) System

The response speed of LCD brightness can be improved by adding over-shoot characteristic to the data

line voltage. Fig. 29 shows the actual overdrive circuit used in a digital drive system.

Fig. 29

Overdrive Circuit

Waveform (Normal)

Waveform with Over-Shoot

Drive Circuit (Normal)

Overdrive Circuit

Picture Data

Black Data

Over-Shoot

Time

Response Time

(By Overdrive Circuit)

Voltage

Brightness

Voltage

Time

Response

Time

Brightness

Voltage

Time

Time

Voltage

Time

Time

Page 28

-28-

Training Manual Principle of LCD

7 Appendix

7-1 Backlight

An LCD panel does not emit light itself. For the display, a light source is required, and normally fluores-

cent lights are used for the backlight of the LCD television.

The backlight consists of fluorescent lights, a reflective plate, and a diffusion sheet (or board). Fig. 30

shows the structure and photograph of 30V and 15V LCD televisions backlights.

Fig. 30

Backlight

30V Type

15V Type

■ Appendix

LCD Panel

Fluorescent Lights

(30V: 16pcs)

LCD Panel

Fluorescent Lights

(15V: 2pcs, 20V:3pcs)

Diffusion Sheet (Board)

Reflective Plate

Diffusion Sheet

Reflective Plate

Page 29

-29-

Training Manual Principle of LCD

7-2 LVDS Circuit

(1) LVDS Interface

For transmitting the video signal information, an interface circuit with an LVDS (Low Noise Differential

Signaling) standard is used, which has the merit of low noise, high speed operation by a small amplitude,

and low power consumption.

The LVDS cable connects the transmitter in the driving circuit and the receiver in the module.

(2) Driving Circuit

Fig. 32 shows the block diagrams of a panel driving circuit. The final video information (signal) from the

video processor (for example pixelworks) is transmitted to the LCD panel module through an LVDS cable.

1.2V

345/200mV

100Ω

Terminated

3.5mA

Receiver

(LCD Panel)

Transmitter

(Driving

Circuit)

LVDS Cable

Fig. 31

LVDS Interface

LVDS Transmitter

LVDS Receiver

Video Processor (pixelworks)

LCD Module

Part of (Panel) Driving Circuit Part of Panel Display (in the module)

Fig. 32

Block Diagrams of Panel Driving Circuit

Appendix

TxCLKIN

TxIN

8

R

8

G

8

B

VsyncVsync

Hsync

BLANK

PARITY

DCLK

TxOUT

DATA (LVDS)

CLOCK (LVDS)

LVDS

PDWN

RxOUTRxIN

8

R

8

G

8

B

VsyncVsync

Hsync

BLANK

PARITY

DCLK

RxCLKOUT

Page 30

-30-

Training Manual Principle of LCD

7-3 Block Diagram Example

(1) CLT-1583

Appendix

(2) CLT-2053

Fig. 33 Block Diagram: CLT-1583

Fig. 34

Block Diagram: CLT-2053

Tuner Board

Sub CPU

M37272M6

U101

+CONTROL

TU201

Tuner / IF

TMQJ8

47

+9V

34

CVBS_OUT

L_OUT

LVR

Monitor Output

IIC

V_TV

3033

R_OUT

R_TV

48 46

32

6717

L_TV

+12V

AV Switch U46

CXA2089Q

SY1

SC1

S1

S

AV1 Input

+9V

4

16

Audio Processor

CC_R

CC_G

CC_B

CVBS1

L1

L

V

Audio AMP

LA4263

108

L

R

238

NJW1138M

301

AUDIO_R

AUDIO_L

41

R1

R

U45

R

3

L

1

Headphone (J26)

U44

Main Board

S_CLK / SIN_OUT/ ENABLE_IN / ENABLE_OUT

V33D

Video Decoder

VPC3230D

717472 5 4 6

SELECTED_C

SELECTED_Y

CVBS

43

4539

9842735 1

11

L2

R2

R

L

AV2 Input

U19

INPUT_Y

INPUT_Cr/Pr

INPUT_Cb/Pb

18

16

YCbCr

Component

VY [0-7]

VUV [0-7]

R_PC

L_PC

3

2

1

40

CVBS2

V

R

L

U36

Main Scaler / (Main)CPU

PW113-10Q

PIXELWORKS

GRE [0-7]

GGE [0-7]

U6

Graphic A/D

AD9883

54

30 31

48 43

Red_PC

HS_PC

RHG

PC Input

GBE [0-7]

V33D

G_PC

VS_PC

V

Speaker (R)

Speaker (L)

VCPU 33/18

MENORY

DATA

Flash ROM

8Mbits

AVDD

PVDD

B_PC

B

D-SUB

LCD Panel

V33

RX CLK+/-

RX IN+/-[0-3]

IC1

DRO [0-7]

DGO [0-7]

DBO [0-7]

VCPU 33

37

LVDS

Interface

THC63LVDM83A

U30

Tuner Board

Sub CPU

M37272M6

U101

TU201

Tuner / IF

TMQJ8

+9V

34

CVBS_OUT

Monitor Output

IIC

+CONTROL

V_TV

47

48 46

3033

L_OUT

R_OUT

LVR

6717

R_TV

32

L_TV

S1

+14V

+9V

16

AV Switch U46

CXA2089Q

SY1

SC1

CVBS1

V

S

AV1 Input

Audio AMP

4

LA4263

Audio Processor

NJW1138M

CC_R

CC_G

CC_B

41

L1

R1

R

L

108

L

R

238

301

AUDIO_R

AUDIO_L

U45

R

3

L

1

Headphone (J26)

U44

Main Board

S_CLK / SIN_OUT/ ENABLE_IN / ENABLE_OUT

V33D

3

2

1

40

CVBS2

V

AV2 Input

U19

Video Decoder

VPC3230D

717472 5 4 6

SELECTED_C

SELECTED_Y

CVBS

43

4539

18

16

9842735 1

11

L2

R2

RLR

L

INPUT_Y

INPUT_Cr/Pr

INPUT_Cb/Pb

L3

Audio

Board

VY [0-7]

VUV [0-7]

R3

AV3 Input

R

L

Main Scaler / (Main)CPU

PW113-10Q

PIXELWORKS

U36

U30

YCbCr

Component

MENORY

DATA

Flash ROM

VCPU 33/18

8Mbits

Speaker (R)

Speaker (L)

DRO [0-7]

DGO [0-7]

DBO [0-7]

VCPU 33

37

LCD Panel

Page 31

-31-

Training Manual Principle of LCD

Appendix

(3) CLT1554 / CLT2054

Fig. 35 Block Diagram: CLT1554 / CLT2054

AV1

S Video

Composite Video

Audio

AV2

Composite Video

Audio

AV3

Component Video

Audio

TV (A201)

Tuner

IF

Sound Multiplex

3

AV1_Y

IC1001

1

AV1_CV

Video SW

5

TV_CV

AV1/TV_Y/CV

AV2_V

1

3

AV3_Y

90 85

AV1_C

92

AV3_Cr

Digital Decoder

94

AV3_Cb

AD_Cb

(480i)

AD_Y

AD_Cr

Y/C Separation

48

54

A/D Converter

43

(480p)

AD_HS

7

5

IC1002

Video SW

IC2001

with

IC4101

30

AD_VS

16

36 37

(For Caption)

SEL_Y/CV

7

DEC_Y/C (0-7)

AD_R/G (0-7)

38

31

AD_CLAMP

28

5V

3.3V

IIC Bus

(Y/UV)

IIC Bus

IIC Bus

IC1701

26

AD_Y

Sync Separation

R: 1

AV1_L/R

L: 30

R: 2

L: 29

R: 3

L: 28

R: 4

L: 27

IC001

Audio SW

Audio Control

Surround

AV2_L/R

AV3_L/R

TV_L/R

IIC Bus IIC Bus

15

10

21

SEL_R

SEL_L

IC801

CPU

22

OSD_HD

12 10

IC871

DD Converter

13 11

OSD_HD

154

SDRAM

13

IC101

Audio AMP

9

23 18

VD

VD

153

19G20B21Y16

R

OSD_CC

152R151G150B148Y149

IC301

IP Converter

Screen Controller

IC361

16

R-OUT (+)

15

R-OUT (-)

24

L-OUT (+)

25

L-OUT (-)

I

I

IIC Bus

R/G/B (0-7)

R/G/B (0-7)

SPEAKER

(Right)

SPEAKER

(Left)

(For 20V)

(For 15V)

IC781

LVDS

Transmitter

LCD PANEL

(20V)

LCD PANEL

(15V)

Page 32

SEP / 2004 Printed in Japan SANYO Electric Co., Ltd.

Loading...

Loading...