Page 1

FILE NO

SERVICE MANUAL

LCD TV

LCD-40E40F

PRODUCT CODE No.: 168234974 (3P AC Plug)

: 168234975 (2P AC Plug)

CHASSIS No.::::SSB40SM-00

CHASSIS No.::::SSB40SM-01

CHASSIS No.::::SSB40SA-00

CHASSIS No.::::SSB40SA-01

1

REFERENCE No.:

SM0945004-02

Page 2

CONTENTS

1. Safety precautions .................................................................................................

2. Alignment instructions and method of software upgrading.....................................

3. Working principle analysis of the unit ...................................................................

4. Block diagram ......................................................................................................

5. IC block diagram..................................................................................................

6. Wiring diagram ...................................................................................................

7. Troubleshooting guide..........................................................................................

8. Schematic diagram ..............................................................................................35

APPENDIX-A: Assembly list

APPENDIX-B: Exploded View

Removing or Installing the Stand

Wall mounting instructions

1

5

19

20

22

28

31

2

Page 3

Attention:

please read the following points carefully.

Safety precautions

This service manual is only for service personnel to take reference with. Before

servicing

1. Instructions

Be sure to switch off

inserting/plugging in connection wire Anti static measures to be taken (throughout the entire production

process!):

a) Do not touch here and there by hand at will;

b) Be sure to use anti static electric iron;

c) It’s a must for the welder to wear anti static gloves.

Please refer to the detailed list before replacing components that have special safety requirements.

Do not change the specs and type at will.

the power supply before

replacing or welding any components or

2. Points for attention in servicing of LCD

2.1 Screens are different from one model to another and therefore not interchangeable. Be sure to

Use the screen of the original model for replacement.

2.2 The operation voltage of LCD screen is

protecting yourself and the machine when testing the system in the course of normal operation or

right after the power is switched off. Please do not touch the circuit or the metal part of the module

high voltage. Be

sure to take proper measures in

That is in operation mode. Relevant operation is possible only one minute after the power is switched

off.

2.3 Do not use any adapter that is not identical with the TV set. Otherwise it will cause fire or damage

to the set.

2.4 Never operate the set or do any installation work in bad environment such as wet bathroom,

laundry, kitchen, or nearby fire source, heating equipment and devices or exposure to sunlight etc.

Otherwise bad effect will result.

2.5 If any foreign substance such as water, liquid, metal slices or other matters happens to fall into the

module, be sure to cut the power off immediately and do not move anything on the module lest it should

cause fire or electric shock due to contact with the high voltage or short circuit.

2.6 Should there be smoke, abnormal smell or sound from the module, please shut the power off at

once. Likewise, if the screen is not working after the power is on or in the course of operation, the

power must be cut off immediately and no more operation is allowed under the same condition.

2.7 Do not pull out or plug in the connection wire when the module is in operation or just after the

power is off because in this case relatively high voltage still remains in the capacitor of the driving

circuit. Please wait at least one minute before the pulling out or plugging in the connection wire.

2.8 When operating or installing LCD please don’t subject the LCD components to bending, twisting or

extrusion, collision lest mishap should result.

2.9 As most of the circuitry in LCD TV set is composed of CMOS integrated circuits, it’s necessary to

pay attention to anti statics. Before servicing LCD TV make sure to take anti static measure and

ensure full grounding for all the parts that have to be grounded.

2.10 There are lots of connection wires between parts behind the LCD screen. When servicing or

moving the set please take care not to touch or scratch them. Once they are damaged the screen

would be unable to work and no way to get it repaired.

If the connection wires, connections or components fixed by the thermo tropic glue need to disengage

when service, please soak the thermo tropic glue into the alcohol and then pull them out in case of

damage.

3

Page 4

2.11 Special care must be taken in transporting or handling it. Exquisite shock vibration may lead to

breakage of screen glass or damage to driving circuit. Therefore it must be packed in a strong case

before the transportation or handling.

2.12 For the storage make sure to put it in a place where the environment can be controlled so as to

prevent the temperature and humidity from exceeding the limits as specified in the manual. For

prolonged storage, it is necessary to house it in an anti-moisture bag and put them altogether in one

place.

The ambient conditions are tabulated as follows:

Temperature

Scope for operation

5

~+ 35

oC

Humidity

2.13

Display of a fixed picture for a long time may result in appearance of picture residue on the

screen, as commonly called “ghost shadow”. The extent of the residual picture varies with the maker

of LCD screen. This phenomenon doesn’t represent failure. This “ghost shadow” may remain

in the picture for a period of time (several minutes). But when operating it please avoid displaying still

picture in high brightness for a long time.

Scope for storage

Scope for operation

Scope for storage

0 ~

+ 40oC

0% ~

90

0% ~ 90%

%

3. Points for attention during installation

3.1 The front panel of LCD screen is of glass. When installing it please make sure to put it in place.

3.2 For service or installation it’s necessary to use specified screw lest it should damage the screen.

3.3 Be sure to take anti dust measures. Any foreign substance that happens to fall down between the

screen and the glass will affect the receiving and viewing effect

3.4 When dismantling or mounting the protective partition plate that is used for anti vibration and

insulation please take care to keep it in intactness so as to avoid hidden trouble.

3.5 Be sure to protect the cabinet from damage or scratch during service, dismantling or mounting.

4

Page 5

Alignment instructions

1. Test equipment

VG-848 (YPbPr, VGA signal generator)

VG-849 (HDMI signal generator)

FLUKE 54200(TV signal generator)

CA210

2. Power test

(white balancer)

Connect main board, power board and IR board according the wiring diagram, connect

the power and press power key (Remote controller or Keypad) button to turn on the TV.

a) Test the pin voltage of P802/power board , the data is shown in table1:

Table1 voltage data of P802

P802 Pin1,2

Voltage

Pin3,4 Pin5,6,7

GND 22.8-25.2V

For 40”

Pin8,9 Pin10,11,12

GND 11.4-12.6V 4.75-5.25V

On:2V-5.5V

Off: 0-0.5V

b) Test the pin voltage of P803/power board, the data is shown in table2:

Table2 voltage data of P803

P803 Pin1,2,3,4,5 Pin6,7,8,9,10

Voltage

22.8-25.2V GND NC 2.5V-5V 2.5-5V PWM NC

For 40”

Pin11 Pin12 Pin13 Pin14

Pin13 Pin14

<0.6V 2.5-5V PWM 2-5V

Pin15 Pin16

5

Page 6

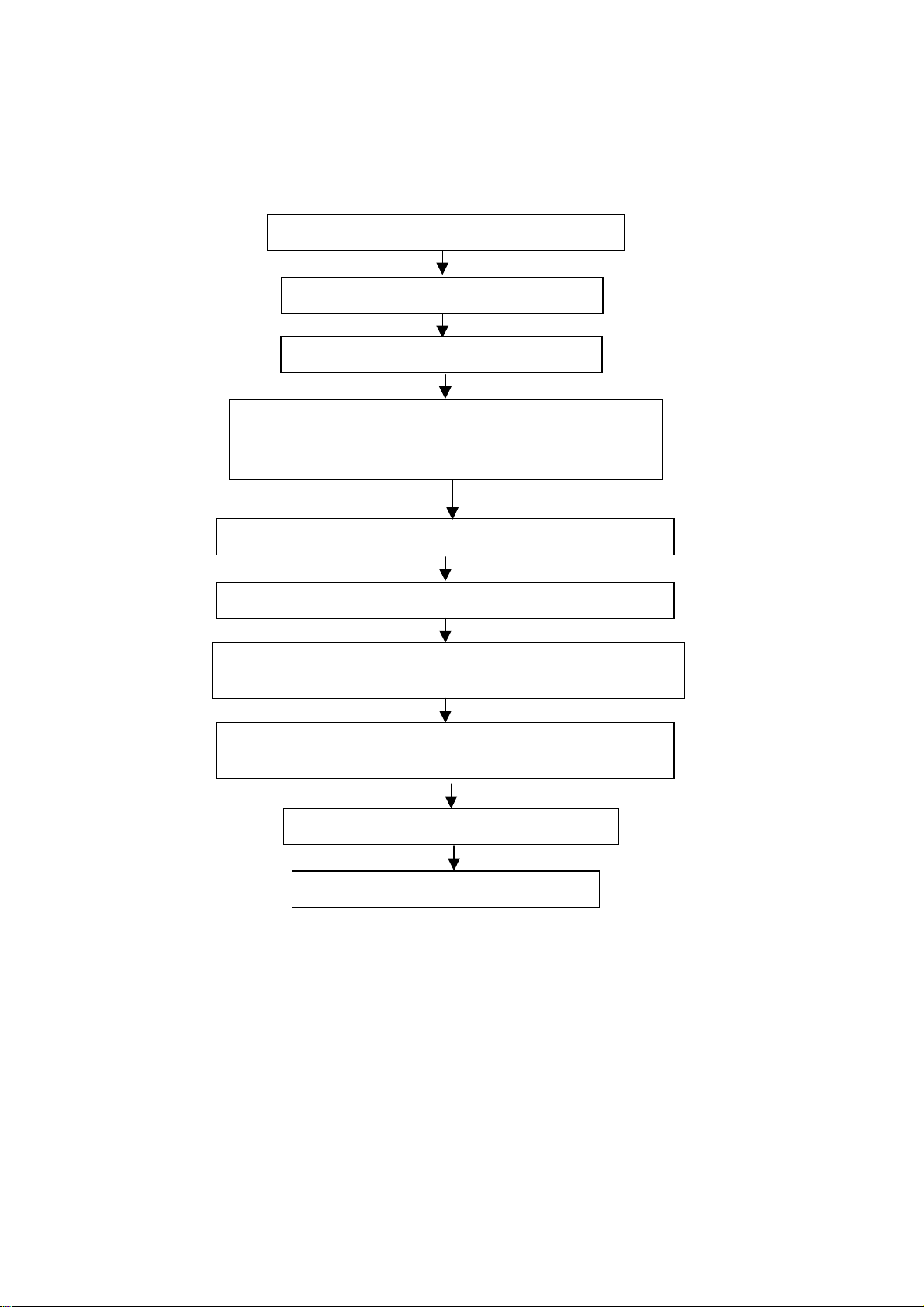

3. Alignment flow-chart

The alignment flow-chart is shown as fig-1

Connect to the center signal source and check each

Function of TV (station leaking, analog control, etc.)

Check the output of earphone and speaker.

Check if DDC, HDCP KEY, FLASH are written

Combined test for general assembly

White balance adjustment

Input AV/SVIDEO signal and check the function

Input HD signal and check the function of YPbPr

Input VGA signal and check if the display is normal, check

the function (analog control), horizontal/vertical center, etc.

Input HDMI signal and check if the display is normal, check

the function (analog control), horizontal/vertical center, etc.

Preset ex-factory

Check the accessories and packing

Fig-1 adjustment flow-chart

6

Page 7

4. Adjustment instruction

At any input source then press the “Mute” and “ Menu (key pad) to enter factory mode

During Factory menu, if “MENU” key is pushed, system will exit factory mode.

4-1. Source Calibration

4-1.1. Set the signal generator to input sources Video3 (Component) on LCD-TV; ASTRO-859 signal setting

to720P/60

(PG2 mode Timing 940 and Pattern 924 100% Color Bar.)

4-1.2. Entering into factory Mode: Press up or down key of remote control to select “Auto Calibration”, Press

「RIGHT」 key to enter the item.

-> Source calibration performed automatically when finished that will show OK.

7

Page 8

Repeat step 2 to do VGA input sources,

ASTRO-859 signal setting to1024X768 60Hz. (PG2 mode: Timing 963 and Pattern 924 100% color bar.)

4-2. Color Temperature Adjustment & Check

4-2.1. Set the signal generator to RGB, 1024*768, 60HZ(ASTRO-859: PG1 856), Level:0.56V(80%). Full

white pattern.

4-2.2. Press up or down key of remote control to select “Cool”, Press 「ENTER」 key to enter the item.

RGAIN, GGAIN, BGAIN, ROFFSET, GOFFSET, BOFFSET, drive values are set for COOL, NORMAL, and

WARM independently.

4-2.3. Select 「Cool 」

Step 1.First Turning Gain parts of RGB.

(1) Cool spec.:

x= 0.267±0.030

y= 0.271±0.030

(2) If the x and y value are larger than specification,

Decrease R GAIN drive from default value.

Increase B GAIN drive from default value.

(3) If the x or y or both x and y value is/are smaller than specification.

Decrease B GAIN drive from default value

(4) According to a x and y value, please following adjustment of (4)-1 or (4)-2.

(4)-1 If x value is higher than spec

Decrease R GAIN drive from default value.

8

Page 9

Increase B GAIN drive from default value.

(4)-2 If y value is higher than spec,

Decrease B GAIN drive from default value

Step 2.When finsh Gain parts, then turning OFFSET parts

Set the signal generator to RGB, 1024*768, 60HZ(ASTRO-859: PG2 963), Level:0.217V(31%).

Full white pattern.

(1) Cool spec.: (Same as the Gain session )

x= 0.267±0.030

y= 0.271±0.030

(2) If the x and y value are larger than specification,

Decrease R OFFSET drive from default value.

Increase B OFFSET drive from default value.

(3) If the x or y or both x and y value is/are smaller than specification.

Decrease B OFFSET drive from default value

(4) According to a x and y value, please following adjustment of (4)-1 or (4)-2.

(4)-1 If x value is higher than spec

Decrease R OFFSET drive from default value.

Increase B OFFSET drive from default value.

(4)-2 If y value is higher than spec,

Decrease B OFFSET drive from default value

Step 3.When finsh OFFSET parts, then recheck Gain parts .unitl Both of them meet the

target specification

4-2.4. Select [NORMAL]

NORMAL spec.:

x=0.281±0.030

y=0.288±0.030

Adjust R drive (RED) or B drive (BLUE) to set x and y above.

4-2.5. Select [WARM]

WARM spec.:

x=0.301±0.030

y=0.31±0.030

Adjust R drive (RED) or B drive (BLUE) to set x and y above.

4-2.6. Exit Factory Mode:

After finish adjusting color temperature,press [MENU] to exit factory mode.

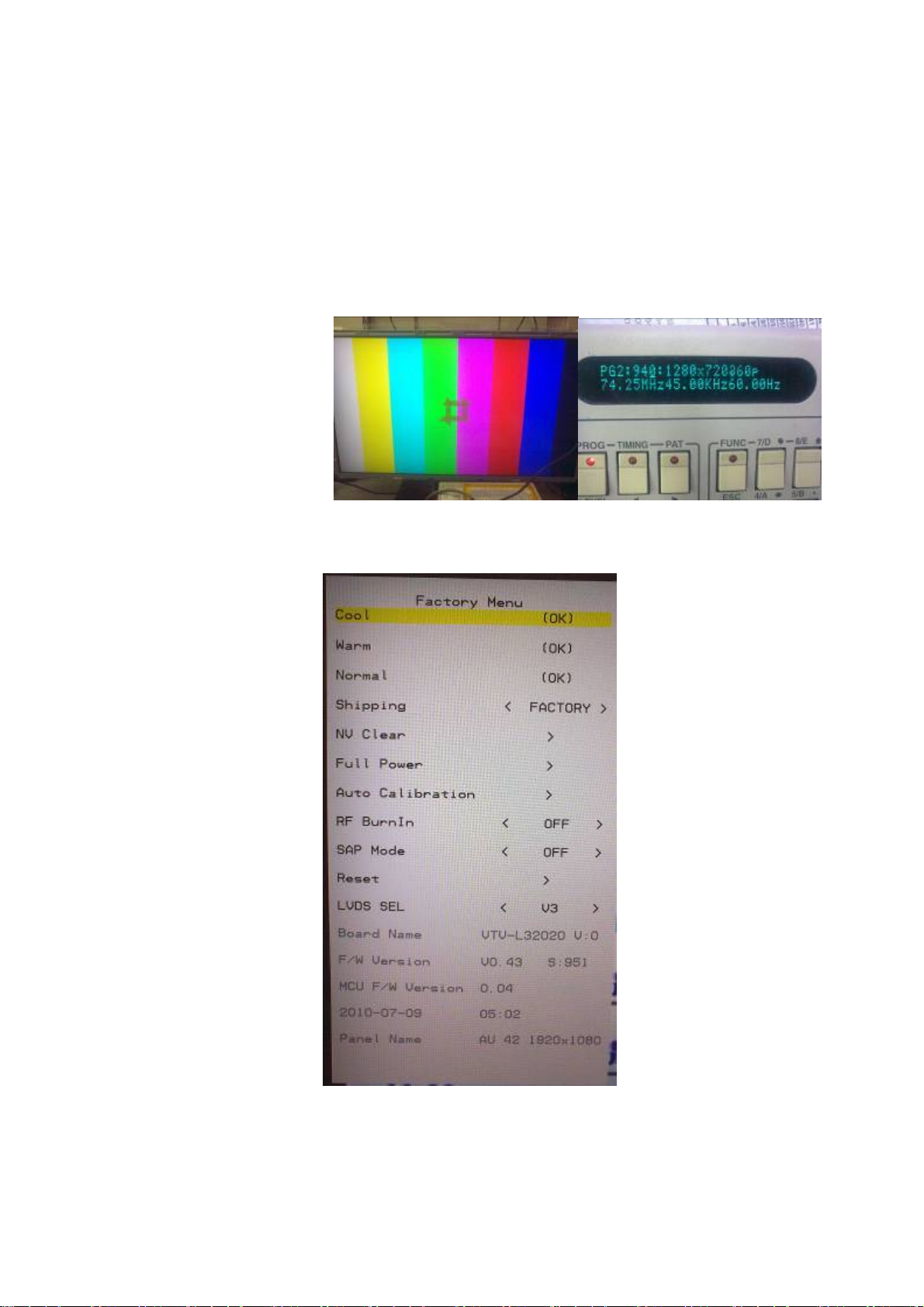

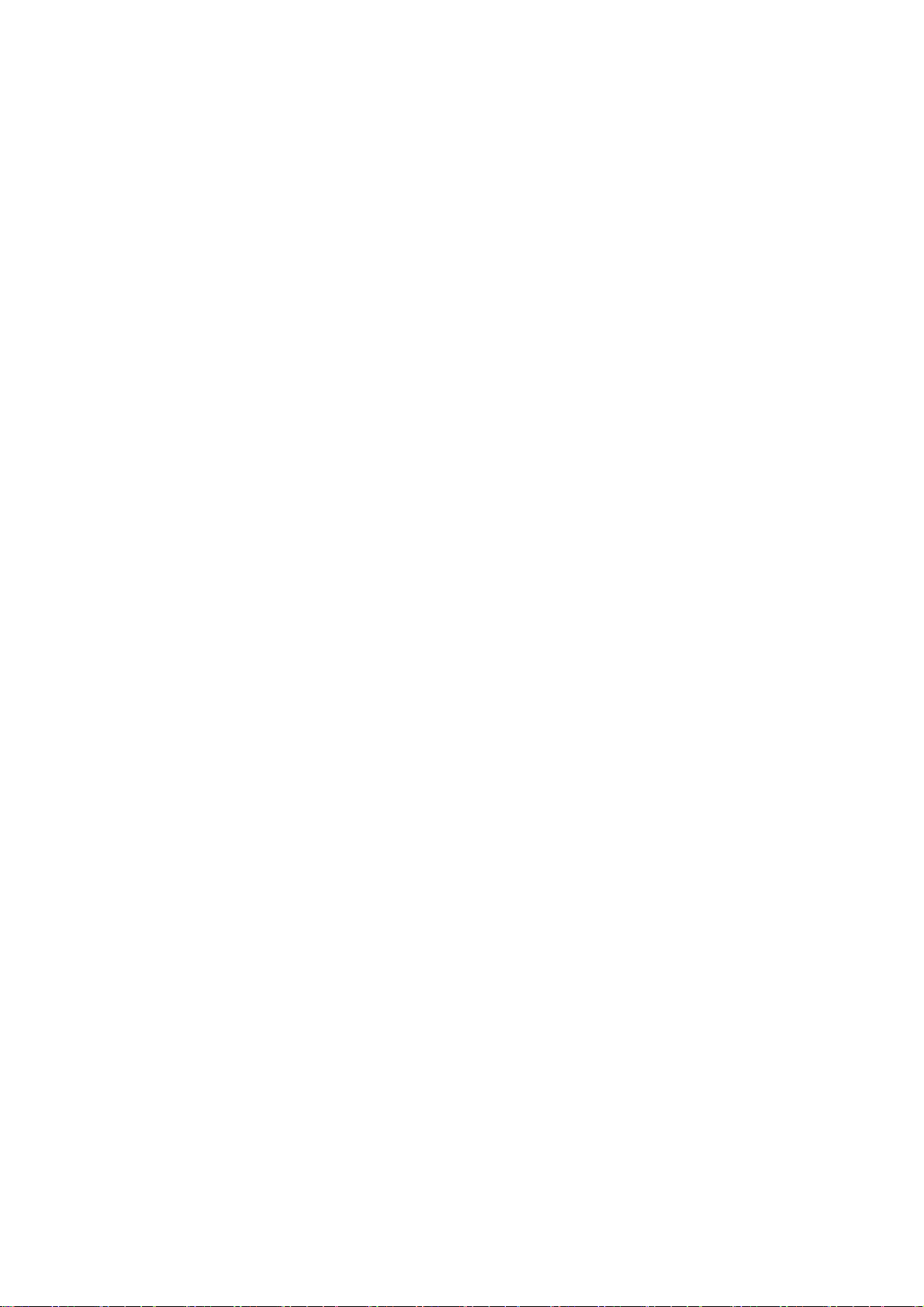

5. Items of Factory menu

Vendor may customize design and add adjustment items Factory menu as far as all required items are

included.

Press up and down key can move high light item from Cool ->Warm -> Normal ->Shipping-> NV clear-> Full

Power -> Auto Calibration -> RF Burn In -> SAP mode->Reset.

The NVRAM Clear and Reset to Default items will have a check dialog “yes or no” to do or not.

Push “OK” key can select high light item function. (Press right key can adjust value)

Display Board name, firmware version, Panel name and released date on bottom.

9

Page 10

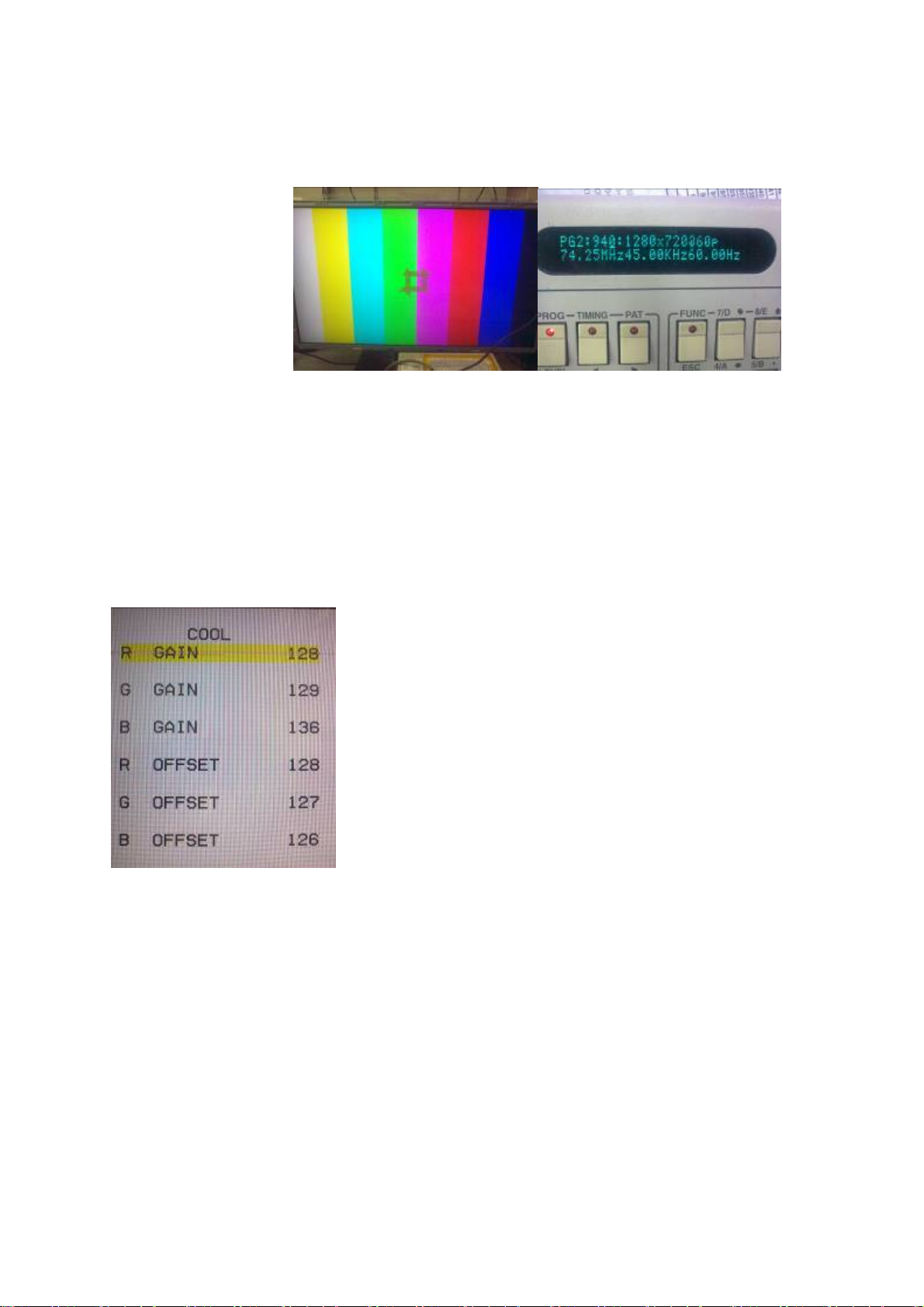

5-1) Cool

Press up or down key can select high light item function.

Press OK key to enter the item.

Following data for color temp shall be edited manually.

-R, G, B data for each preset.

-Press “Up” or “Down” key to select “R”, “G”, “B” Gain and Offset item

-Press “Left” or “Right” key to set the “R”, “G”, “B” Gain and Offset value.

- Press “MENU” or “BACK” item to exit to factory mode

5-2) Warm

Press up or down key can select high light item function.

Press OK key to enter the item.

Following data for color temp shall be edited manually.

-R, G, B data for each preset.

-Press “Up” or “Down” key to select “R”, “G”, “B” Gain and Offset item

-Press “Left” or “Right” key to set the “R”, “G”, “B” Gain and Offset value.

- Press “MENU” or “BACK” item to exit to factory mode

5-3) Normal

Press up or down key can select high light item function.

Press OK key to enter the item.

Following data for color temp shall be edited manually.

-R, G, B data for each preset.

-Press “Up” or “Down” key to select “R”, “G”, “B” Gain and Offset item

-Press “Left” or “Right” key to set the “R”, “G”, “B” Gain and Offset value.

10

Page 11

-Press “MENU” or “BACK” item to exit to factory mode

5-4)Shipping

Press up or down key can select high light item function

Press “Left” & “Right” key to select the item. Default set in Factory mode

Following shipping area to select the item(ME)

5-5) NVRAM Clear

Initialize program’s default values to NVRAM for following adjustment items accuracy.

In factory mode it is the first and important step to make sure all values are default value and correct.

- Reset settings: Gamma table, Channel table (Favorite channel, Channel label etc.), Model table

(H/V Position, Clock, Phase), Source dependent setting (Contrast, Brightness etc.), Common

setting (Volume, Language etc.), Parental Control (Rating, Password etc).

To avoid a mistake initial process after factory setting is done. This item will have a check dialog “yes or no”

to do the initial or not.

NOTICE:

This item just enabled in PC input and after this item is processed then the DUT needs to be powered off

then AC powered off.

5-6) Full power

This is for power consumption testing.

To measure the maximum power consumption of TV set, we adjust the value of following items to maximum.

- Contrast

- Brightness

- Audio output

5-7) Auto Calibration

Auto Calibration (gain/offset) must be adjusted color by firmware automatic adjustment in PC and

Video3(Component) input source.

5-8) RF Burn In

Use “snow” pattern for burn in. Selected items are “On” and “Off”.

While turn on burn in mode, firmware will automatically turn off “Auto power off” function.

If there is no power supply suddenly, firmware will re-enter burn in mode automatically when power supply is back.

Selected RF Burn In items to Off or Reset Items to reset TV , firmware will turn off burn in mode

Burn in mode: Source is “ANT”, Input Configuration is “Antenna” and channel is NTSC channel 2.

5-9) SAP Mode.

N/A

5-10) Reset

Reset all settings of OSD menu to default value and will go to standby mode.

- Reset settings: Channel table, Model table (H/V Position, Clock, Phase), Source dependent setting

(Contrast, Brightness etc.), Common setting (Volume, Language etc.)

11

Page 12

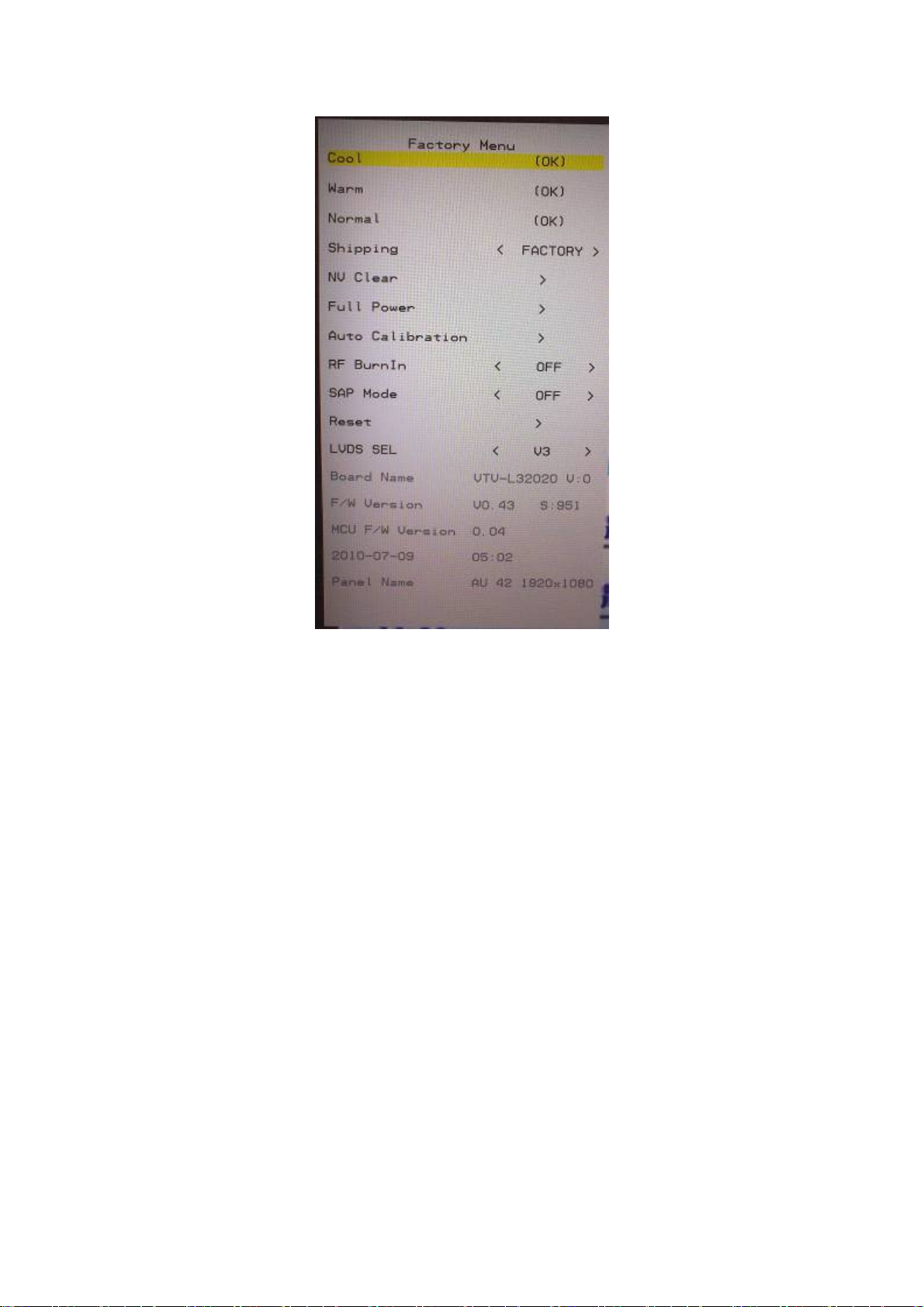

6. Dealer Mode Function

7. Performance check

7-1 TV function

Connect RF to the center signal source, enter Channel menu → auto tuning, check if there are channels be

skipped, check if the picture and speaker are normal.

7-2 AV/S-Video terminals

Input AV/S-Video signal, check if the picture and sound are normal.

7-3 YPbPr/YCbCr terminal

Input YUV signal (VG848 signal generator), separately input the YUV signals listed in table4 and check if the

display and sound are normal at any situation (power on, channel switch and format convert, etc.)

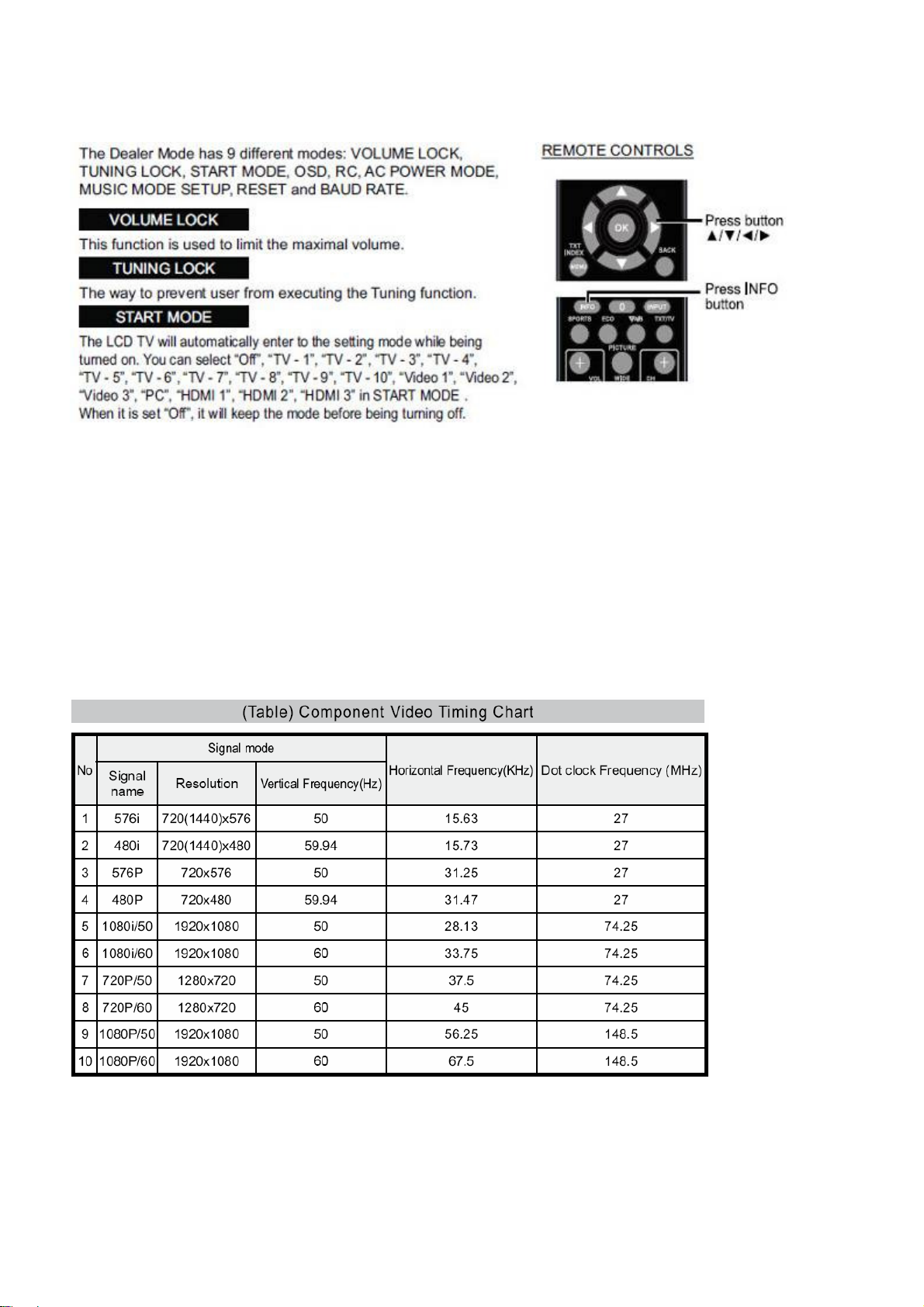

7-4 VGA terminal

Input VGA signal (VG848 signal generator), separately input the signals listed in table5 and check the display and

sound. If the image is deflection of the Horizontal and vertical, select Menu->Setup->Auto Adjust to perform autocorrect.

Table4 YUV signal format

Table5 VGA signal format

12

Page 13

7-5 HDMI terminal

Input HDMI signal (VG849 signal generator), separately input the signals listed in table4 and table5 and check the

display and sound (32 KHz, 44.1 KHz, 48 KHz) at any situation (power on, channel switch and format convert,

etc.)

7-6 other functions check

a) Check the turn on/turn off timer, sleep timer, picture/sound mode, OSD, stereo and analog TV Teletext, etc.

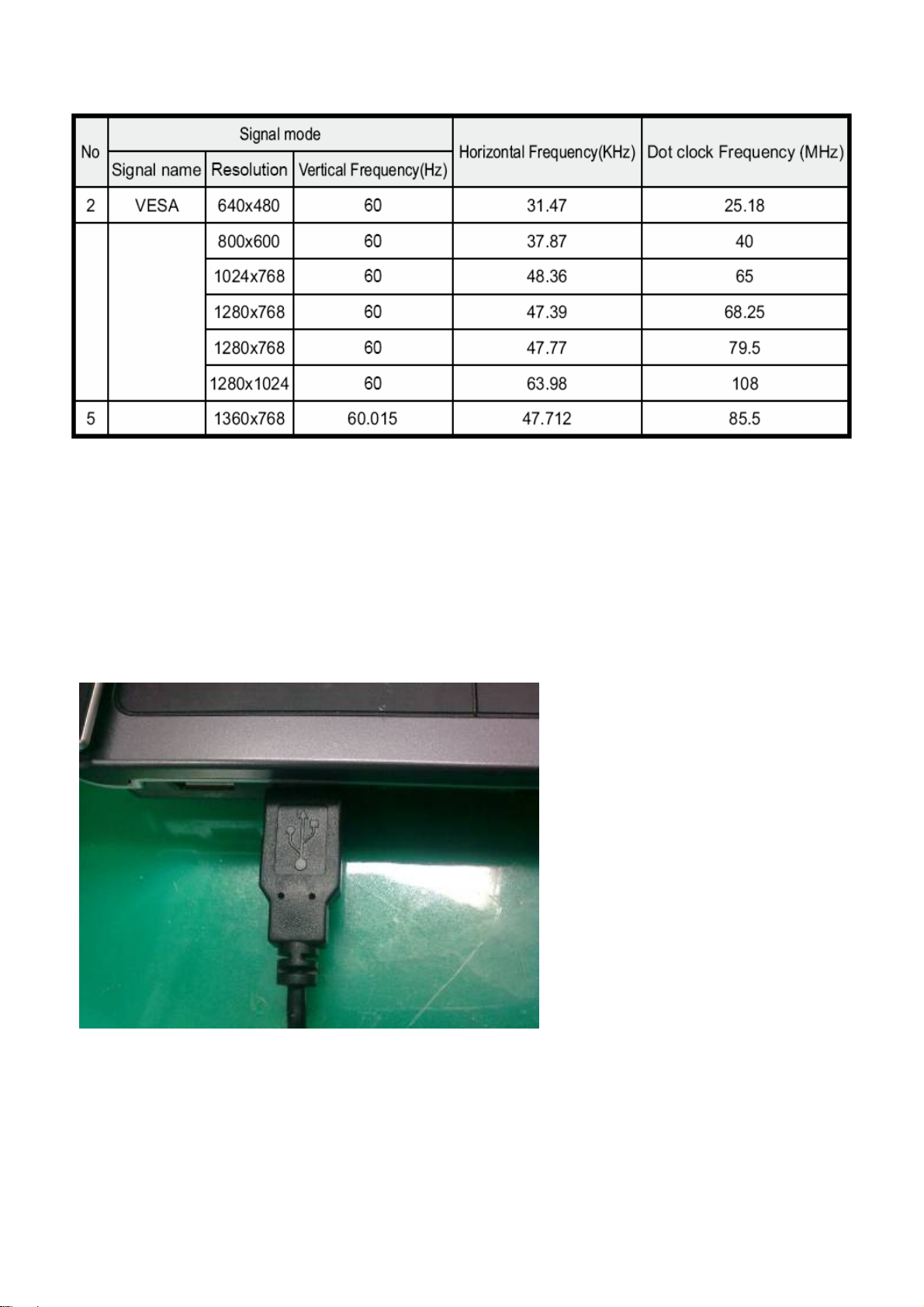

8. Software instruction

Update S/W tool

Tools setting.

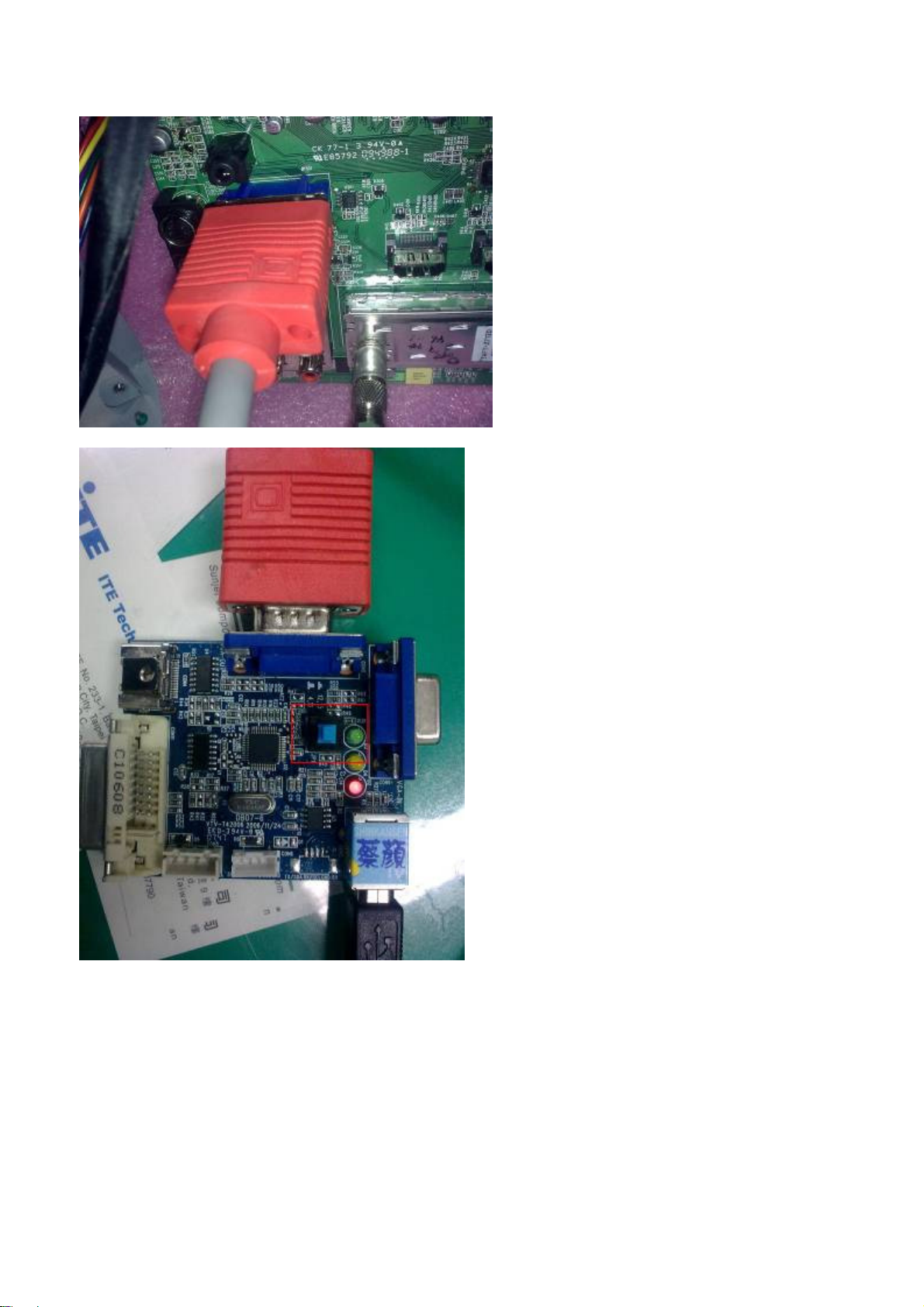

Connector to PC and VTV_T42006 use USB cable

Connect VTV_L32020 and VTV_T42006 use special VGA cable.

13

Page 14

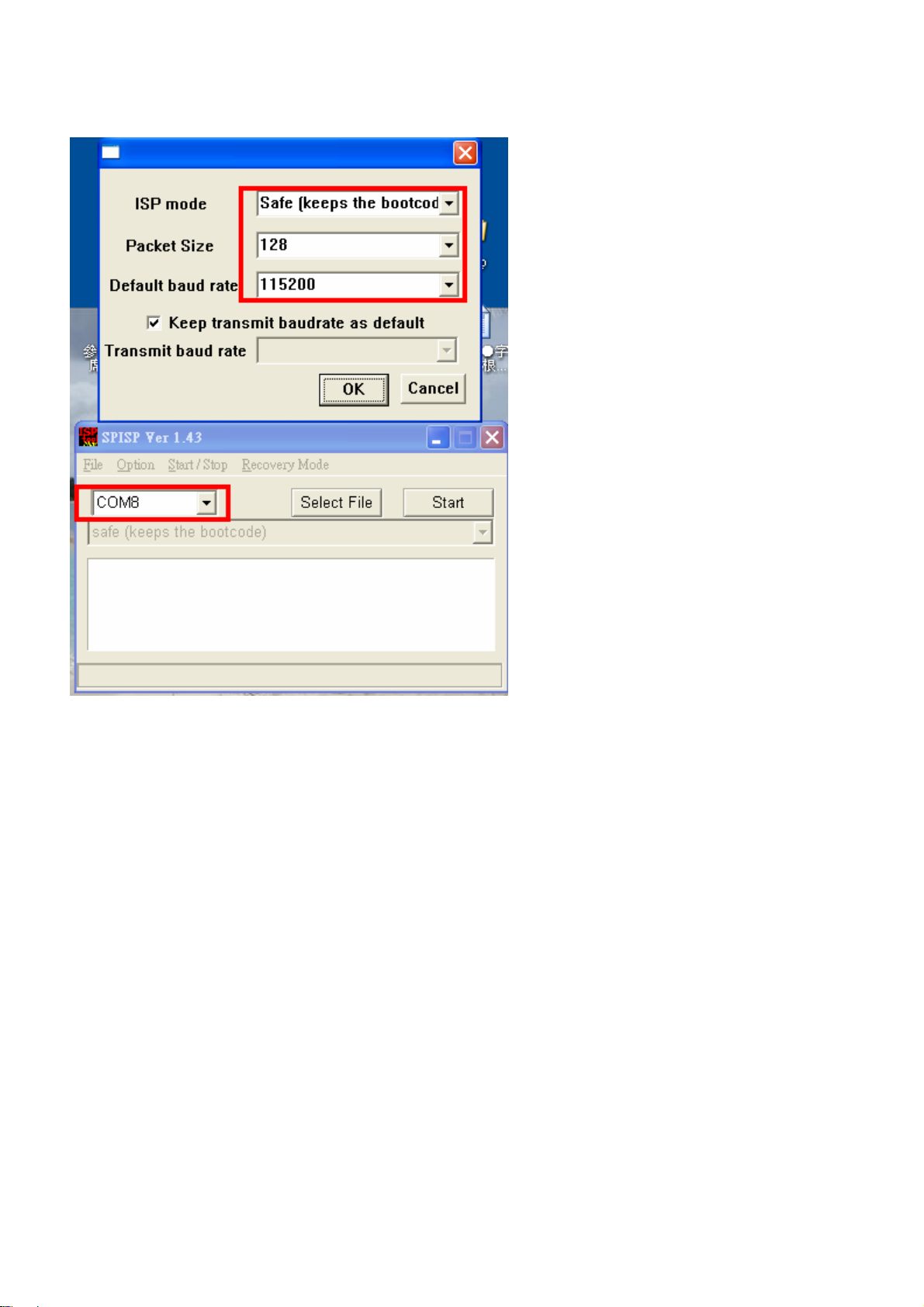

Don’t push blue Key.

SoftWare seeting.

1. press Option to check ISP mode, Packet size and Default baud rate then press OK

2. select communication COM port.

14

Page 15

15

Page 16

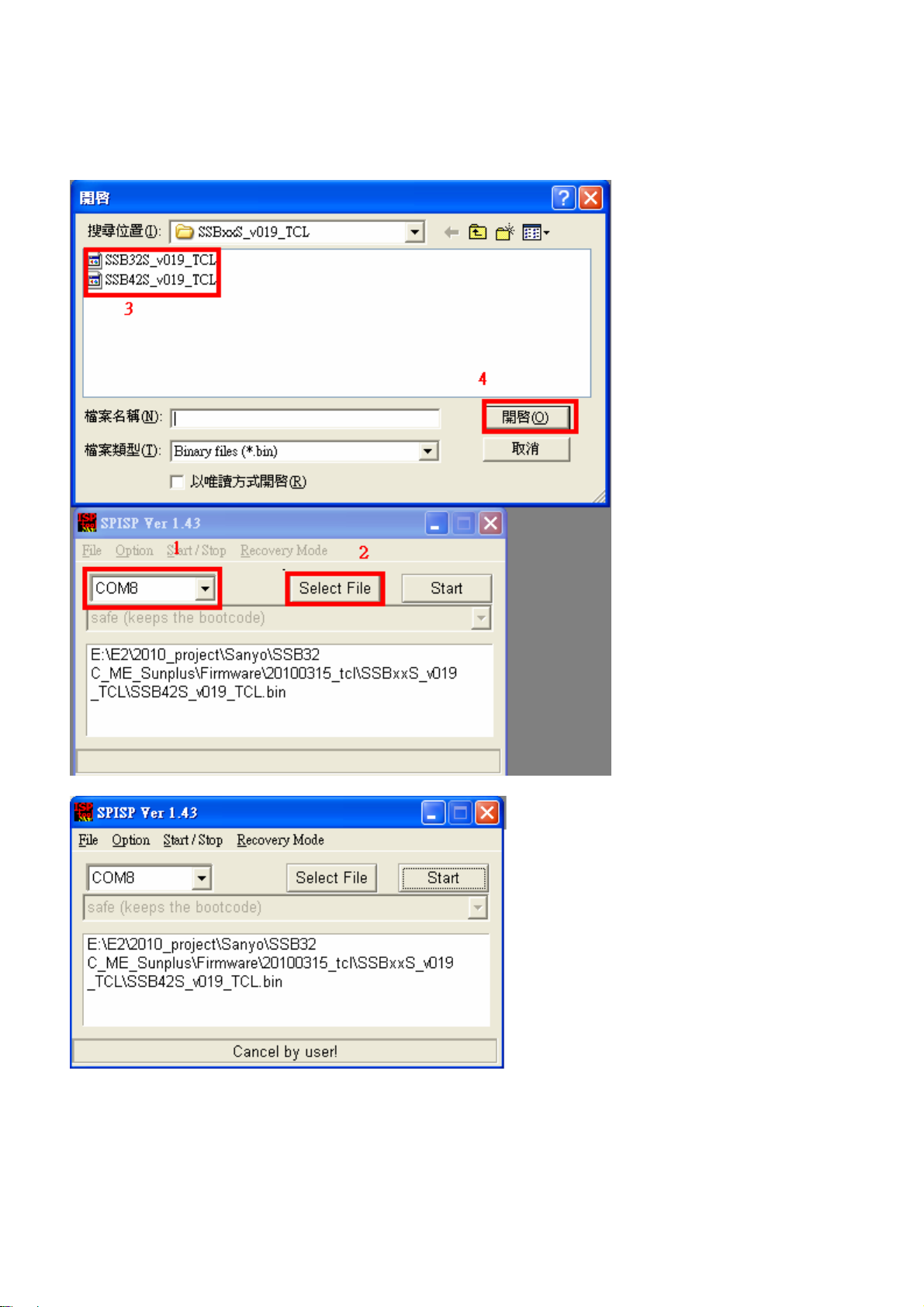

3. press Select File then select update F/W file.

4. press Start

16

Page 17

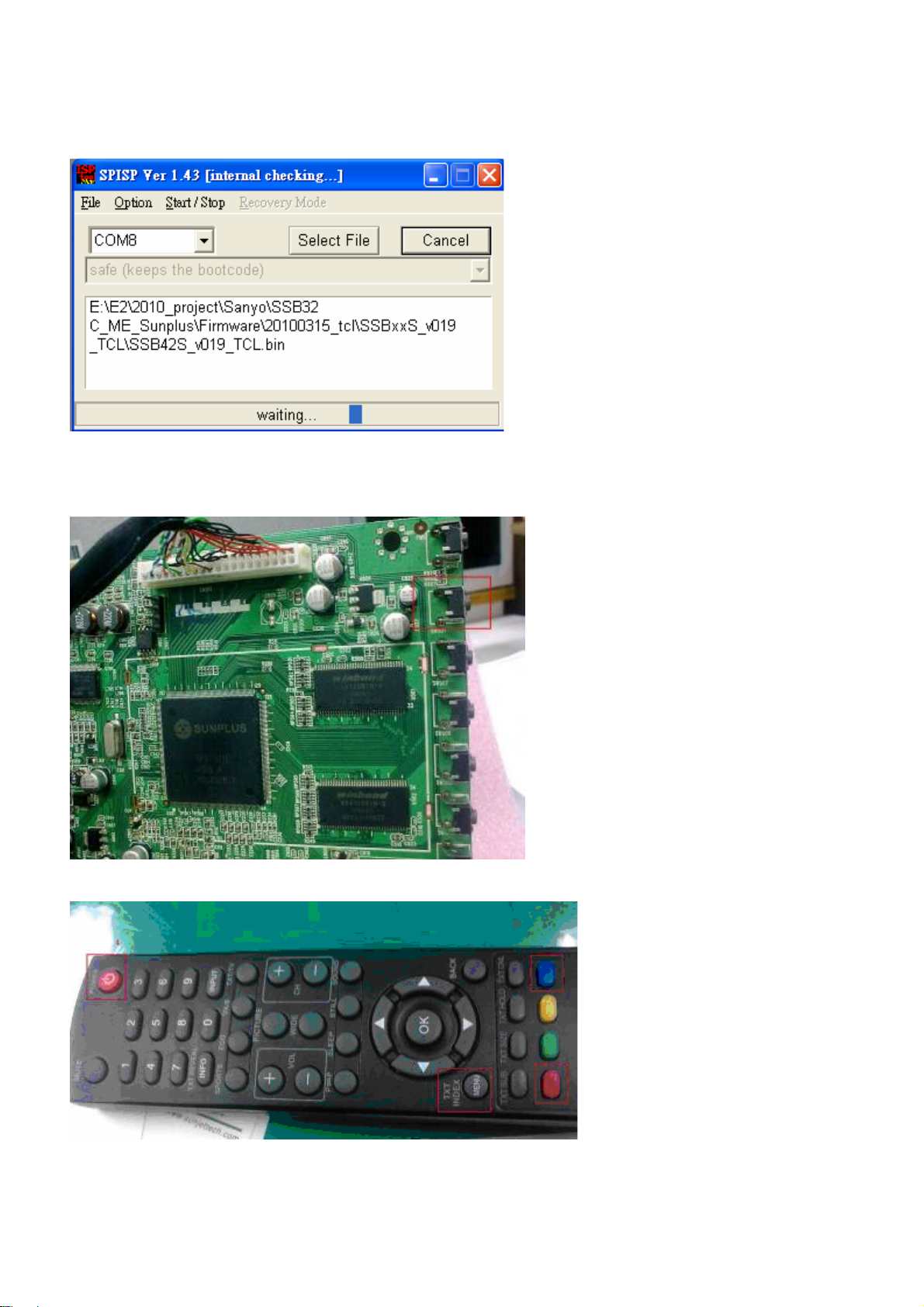

5.start update F/W, there has two method to start update F/W

(1)keep push Channel up key and turn on the power.

(2)press Menu key then red key then blue key then Power key to update F/W.

17

Page 18

6.Erasing EE PROM

7.Build in F/W on the EE PROM.

8. update success.

18

Page 19

Working principle analysis of the unit

1. PAL/SECAM

Antenna reception, B/G, I, D/K, signal will be send to tuner M40CPT-2PNB-E,

demodulating and output standard video signal TV-CVBS, and sound SIF signal

and NTSC

signals flow:

t he n T u n er w i l l b e

.

TV-CVBS will send to the master control IC SPV7101P to video decode, de-interlace and scaler, then

output

LVDS level drive for panel display.

The

sound IF (SIF) will be fed into SPV7101P, after demodulating, pre-amplifying, bass adjusting

and volume control, the sound signal will

tr a n sf o rm into d ig i ta l I2S s ig n al

speaker, another will be sent analog sound signal to

2. Composite/S-Video signal flow

Composite signal and S-Video signal path AV signal switch

be ou t p ut t wo w a y s , o n e w a y w i ll b e

and sent to digital amplifier STA335BW,

earphone amplifier TPA6132.

then sent to

by menu “Setup”->“Video1 Input”

via

terminal socket to Video switch IC NC7SB3157, then signal and the Video2 path AV signal will be

fed to SPV7101P to perform video decode, de-interlace and scaler, then output LVDS drive level for

panel display.

Audio signal from Composite/S-Video

adjust and volume control, the sound signal will

tr a n sf o rm in t o d i gi t al I 2 S si g na l

speaker, another will be sent analog sound signal to

3. PC/Video3 signal flow

PC and the Video3 path

via terminal

to back end module to Video decode,

drive

for panel display.

Sound signal of PC/YPrPb

adjust

and volume control, the sound signal will

tr a n sf o rm in t o d i gi t al I 2 S si g na l

speaker, another will be sent analog sound signal to

4. HDMI signal flow

socket

terminal

via matched resistance is fed to SPV7101P to bass

b e o u t p u t t w o w a y s , o n e w a y w il l b e

and sent to digital amplifier STA335BW,

earphone amplifier TPA6132.

Composite/

YPbPr signal

switch by menu”SET UP”->”Video3 Input”

sent to SPV7101P A/D conversion(YPbPr),

de- interlace and

image scale, then send to LVDS level

t e r m i n a l

via matched resistance

b e o u t p u t t w o w a y s , o n e w a y w il l b e

and sent to digital amplifier STA335BW,

earphone amplifier TPA6132.

PC/YP b Pr

a n d

sent to SPV7101P to bass

then sent to

output R/G/B of 24 bit

then sent to

Three HDMI video signals via switcher IT6633P are directly fed to the master control IC SPV7101P to

digital

decode, image scale, then output LVDS drive level for panel display. HDMI audio signal via

decoder built-in SPV7101P to bass adjust and volume control, the sound signal will

wa y s , o ne wa y w i l l b e t r an s f o r m i n to di g it a l I 2 S s ig n a l

STA335BW,

TPA6132.

then sent to speaker, another will be sent analog sound signal to

and sent to digital amplifier

b e o u tp u t t w o

earphone amplifier

19

Page 20

I. Block Diagram

Sanyo 40” Block Diagram

20

Page 21

Block diagram-POWER-40”

21

Page 22

IC block diagram

1.SUNPLUS SPV7101P

Feature:

Graphics and Video Input Port

Integrate 150MHz 10-bit ADC/PLL

Dual CCIR656 digital video ports to support 2 input or 1 input/1output

Support SDTV at 480i/576i and 480p 576p

Support HDTV at 720p,1080i and 1080p

Support PC graphics VGA, SVGA, XGA, WXGA, SXGA@75Hz(135M)

Built-in sync. Processor for separate, composite or sync onY/G

Image Format Detection/Auto Image Positioning/Auto Phase Detection

Full SCART support including RGB fast blank

HDMI

HDMI1.2 compliant and DVI 1.0 compliant receiver

HDCP 1.1 compliant receiver

HDMI 1.3 CEC protocol compliant

Support 480i/576i/480p576p/720p/1080i/1080p resolutions

S/PDIF output supports PCM, Dolby Digital, DTS digital audio with bypass

mode

Four I2S audio outputs to SSD(Stereo Sound Decoder) with bypass mode

Auto audio error detection with programmable soft mute

Built-in OTP for HDCP key

3D Video Decoder

Enhanced NTSC/PAL/SECAM video decoder

3D comb filter for NTSC, PAL I(B,G,H,D,N), PAL-M, PAL-N

Enhanced NTSC/PAL/SECAM auto detection

4 analog input and one analog video output

Enhanced Cross-color reduction for NTSC by 3-line comb filtering

Enhanced Cross-color reduction for PAL by 5-line comb filtering

Enhanced Motion adaptive 3D Y/C separation comb filter for NTSC/PAL system

Enhanced Multi-standard VBI data decoder, Teletext 2.5, WSS,VPS,

Closed-caption and V-chip

Macrovision detection

VBI data(C.CTTX2.5, V-chip)overlay display

High Quality Video Processing

Enhanced pixel-based SDTV/HDTV 3D motion adaptive de-interlacing

Enhanced 2:2/3:2 film mode detection

Support Graphics mode frame rate conversion

Support Video mode frame rate conversion

2D Edge enhancement

Enhanced Dynamic Peaking Filter

Enhanced Digital Luma Transient Improvement(DLTI)

Enhanced Digital Chroma Transient Improvement(DCTI)

Black/White Level Expansion and Dynamic Contrast

Enhanced RGBYMC color adjustment

Dark and Gray area UV suppression

Enhanced 3D motion adaptive noise reduction

De-blocking and de-mosquito filters

Enhanced color management/color temperature adjustment

Brightness/Contrast/Hue/Saturation adjustment

Support RGB color correction

Built-in three 256-point gamma tables with 10 bits resolution

Color space conversion, both YCbCr to RGB and RGB toYCbCr

Built-in temporal/spatial color dithering

10-bit video/image processing

22

Page 23

High Quality Video Scaling Engine

Advanced fourth-generation scaling engine

Support 4:3 /16:9 with non-linear scaling

Support moiré Canceling

Multi-standard TV Sound Decoder

Fidel proven TV sound decoder

Support BTSC, A2/Zweiton, NICAM, EIAJ, SECAM, and FM stereo

Automatic TV-standard detection(ADS)

Non-standard carrier compatible

SAP decoding where applicable

Auto fallback from NICAM where applicable

Embedded OSD and VBI controller

Built-in programmable OSD engine for two OSD windows(bitmap OSD)

1,2,4 and 8-bit per pixel(bitmap OSD)

Support hardware cursor

Support programmable 512 font-based OSD and Graphics-based OSD

Support VBI decoder(CC, V-Chip and Teletext)

Support VBI CC/TTX/Menu with more than 1000 char-fonts

Embedded SDR/DDR SDRM Controller

Integrated SDR/DDR SDRAM controller with DLL(DDR)

Support 32-bit DRAM bus with memory size from 16Mb(limited functions) to

256Mb

Programmable Digital Output for LCD

Support output sequence mapping for TI and Thine

Built-in dual-channel 8-bit LVDS Transmitter or single channel 10-bit LVDS

Transmitter

Support display output up to 1920X1200 @60Hz WUXGA reduced blanking

mode(Supported by SPV7101Px only)

Support Power Down Sequence

4-channel PWM backlight intensity control

Note Dolby Surround is the Trade Mark of Dolby Laboratories SRS TurSurround is

the Trademark of SRS

CPU

Powerful 32-bit RISC CPU

Simple memory management stub(SMMU)

MIPS-I instruction with DSP instruction set extension

2K byte 2-way instruction cache

4K bytes direct-mapped data cache

8K byes data memory for DMA operation

EJTAG interface

One UART up to 115200 baud rate

Four 24-bit up/down timers

3K byes IMEM for power saving mode.

Audio Processor

Support S/PDIF input

Support S/PDIF output(signal could come from S/PDIF input or SSD)

Support up to 8 channels I2S I/O

4channels audio DAC output

4channels audio ADC input

Channel: L,R,C,S,Sub, Aux1,2 and 3 @ 32KHz

5-band equalizer

3D surround sound

Bass management

Volume control

Support sub-woofer output

Sample rate converter

23

Page 24

SSD could output up to 3 sources

Dolby Surround (VDSII 422 and 423)(Supported by SPV7101PD only)

SRS TruSurround(XT, WOW,3D sound)(Supported by SPV7101PS only)

Miscellaneous

Built-in TV remote control via infra-red receiver interface

2-channel 6-bit ADC for key scan function

Built-in pattern generator for auto testing

256-pin LQFP(SPV7100P pin-to-pin compatible)

2. M40CTP-2PNB-E

Analog terrestrial video module

3. STA335BW

20-W Stereo Digital Audio Power Amplifier with EQ and DRC

24

Page 25

4. IT6633E-P

3-to-1 HDMI 1.3 Active Switch with EDID RAM

25

Page 26

5. TPA6132A2

25-mW DIRECTPATH STEREO HEADPHONE AMPLIFIER WITH POP

SUPPRESSION

26

Page 27

6. WT6702F

The WT6702F is a microcontroller for system power manager with 1)Turbo 8051

compatible(3T) CPU2) 8K bytes flash memory, 3)256 bytes SRAM, 4) 2

PWMs,5)DPMS detector, 6)8051 2 timers and UART,7)Three Slave IIC interface,

8) 4 Channel 8-bit A/D converter, 9) Real Time Clock, 10) watch-dog timer, 11)

Embedded ISP, 12)Power down mode, 12) Embedded ICE mode.

27

Page 28

I. BLOCK

Sanyo 40-inch Wiring Diagram

28

Page 29

II. Wiring Connection

CMO panel

29

Page 30

Samsung panel

30

Page 31

Trouble shooting

1. Fault clearance

31

Page 32

Change to new power board.

Check

Check L21

OK

NG

H

L

Power LED no

Change MAIN

Change LED

NG

2. Troubleshooting guide

The flow chart shown below will help you to troubleshoot your Televison set with it doesn’t display

normally. Each procedure offers a simple way to check for system errors. Before starting, ensure

that there is a signal in and that the Televison is turned on.

2-1 Power LED no light

Light

+5V_IN

CN2

Pin 2

Check

LED

P/N:

PK101V1110I or PK101V2070I

PCB

PCB

32

Page 33

Change to new power board.

2-2 Has audio but no video out

P/N: PK101V1110I or

PK101V2070I

33

Page 34

Change to new power board.

2-3 Has video but no audio out step 1

2-4 Has video but no audio out step 2

P/N:

PK101V1110I or

PK101V2070I

34

Page 35

8.SCHEMATIC DIAGRAM

ELECTRON (LCD-40E40F)

Page 36

5

C823

C823

82pF

C803

C803

R801 10KR801 10K

C811

C811

22pF/50V

22pF/50V

82pF

1uF/50V/0805

1uF/50V/0805

3.3nF/50V

3.3nF/50V

R804

R804

6.2K/1%

6.2K/1%

APW7085

APW7085

C809

C809

D D

C C

scaler

1.8V digital- 0.75A

1.8V analog - 0.34A

3.3V digital- 45mA MAX

3.3V analog- 55mA MAX

100k ----> 10k

SPV7100 Power (1.8V/2.5V/3.3V)

4

L802

L802

BLM21PG300SN1D

C802

C802

SE22uF/16V

SE22uF/16V

U801

U801

4

2

6

BLM21PG300SN1D

1

VIN

VCC

EN

COMP

below current measure timming

1080P 60

full white pattern

UGND

LX

FB

GND

8

THERMAL

9

3

5

7

+5V_SW

C804

C804

1uF/50V/0805

1uF/50V/0805

R806

R806

10K/1%

10K/1%

3

Vout=0.8(1+R1/R2)

C808 D801close U801

L804

L804

SMTDR43-3.3uH/1.44A

SMTDR43-3.3uH/1.44A

D801

D801

SM540B

SM540B

1 2

1 2

R805

R805

13K/1%

13K/1%

C812

C812

270pF/50V

270pF/50V

Del C813 1/13

HDMI 690mA

PC 620mA

L801

L801

BLM21PG300SN1D

BLM21PG300SN1D

+

+

C808

C808

SE100uF/16V

SE100uF/16V

1.85V~1.88V

+1V8

VCC3_3

C844

C844

82pF

82pF

2

U802

U802

LD1117AL-ADJ-223-1 A

LD1117AL-ADJ-223-1 A

3

VIN

1

C807

C807

0.1uF

0.1uF

C0603D

C0603D

C810

C810

SE10uF/16V

SE10uF/16V

ADJ

VOUT

TAB

2

4

R802

R802

121/1%/

121/1%/

R803

R803

54.9/1%

54.9/1%

C805

C805

0.1uF

0.1uF

C0603D

C0603D

G_PWR

C806

C806

SE100uF/16V

SE100uF/16V

L803

L803

L1206D

L1206D

1

HDMI 1.mA

Analog 74.2 mA

pc 163mA

+1V8_ADCA

+5V_SW

U803 UTC1084-3.3V-252U803 UTC1084-3.3V-252

GND

OUT

TAB

1

2

4

R807

R807

910/1%/

910/1%/

R808

R808

1K/1%

1K/1%

2

C820

C820

SE100uF/16V

SE100uF/16V

G_PWR

DDR

C826

C826

0.1uF

0.1uF

C0603D

C0603D

G_PWR

C816

C816

100nF

100nF

HDMI 160mA

KC PBMA-L11-321611-300LMA60T

KC PBMA-L11-321611-300LMA60T

C827

C827

SE100uF/16V

SE100uF/16V

VIN3VOUT

C818

C818

SE100uF/16V/NC

SE100uF/16V/NC

B B

+5V_SW

A A

del C825 7/27

C821

C821

82pF

82pF

C822

C822

82pF

82pF

SE10uF/16V

SE10uF/16V

C819

C819

100nF

100nF

U806

U806

LD1117AL-ADJ-223-1 A

LD1117AL-ADJ-223-1 A

3

VIN

GND

1

C828

C828

0.1uF

0.1uF

C0603D

C0603D

C829

C829

Ypbpr/PC 340mA AV 90mA

L807

L807

KC PBMA-L11-321611-300LMA60T

KC PBMA-L11-321611-300LMA60T

KC PBMA-L11-321611-300LMA60T

KC PBMA-L11-321611-300LMA60T

KC PBMA-L11-321611-300LMA60T

KC PBMA-L11-321611-300LMA60T

KC PBMA-L11-321611-300LMA60T

KC PBMA-L11-321611-300LMA60T

All source 190mA

L812

L812

71mA

L808

L808

L809

L809

L810

L810

HDMI/other 170mA ATV 220mA

切切

other source 仍仍160mA, 不仍HDMI source

+2V5

VCC3_3

+3V3

+3.3V_HD

+3V3_STBC

應應應應

10mA

C824

C824

82pF

82pF

MCU

+5V_S

Power & Ground 4

5

4

3

U804

U804

LD1117-3.3V-223-1A

LD1117-3.3V-223-1A

3

VIN

C814

C814

100nF

100nF

TP801TP801

2

OUT

4

TAB

GND

1

C815

C815

100nF

100nF

2

C817

C817

SE100uF/16V

SE100uF/16V

G_PWR

L806

L806

KC PBMA-L11-321611-300LMA60T

KC PBMA-L11-321611-300LMA60T

Title

Title

Title

Size Docum ent Number Rev

Size Docum ent Number Rev

Size Docum ent Number Rev

B

B

B

Date: Sheet of

Date: Sheet of

Date: Sheet of

3V3_MCU

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

SCHEMATIC, M/B VTV-L32020, SSB32S

SCHEMATIC, M/B VTV-L32020, SSB32S

SCHEMATIC, M/B VTV-L32020, SSB32S

401C2M

401C2M

401C2M

2 15Tuesday, July 27, 2010

2 15Tuesday, July 27, 2010

2 15Tuesday, July 27, 2010

1

0A

0A

0A

Page 37

5

D D

4

3

2

1

R306

R306

RX

TX

B_IN

R_IN

SOG_IN

B_IN <6>

G_IN <6>

R_IN <6>

SOG_IN <6>

R307

R307

R308

R308

R302 100R /0402R302 100R /0402

R303 100R /0402R303 100R /0402

R304 100R /0402R304 100R /0402

R305 100R /0402R305 100R /0402

C302 0.01uF /0402/50VC302 0.01uF /0402/50V

C303 0.01uF /0402/50VC303 0.01uF /0402/50V

C304 0.01uF /0402/50VC304 0.01uF /0402/50V

C301 1nF/04 02/50VC301 1nF/04 02/50V

Close to SCALER IC

R361

D314

D314

R361

R362

R362

D315

D315

D302

D302

0R/0402

0R/0402

0R/0402

0R/0402

D303

D303

D-SUB INPUT

C C

VSI

HSI

DSUB-15P/FEMALE/V

DSUB-15P/FEMALE/V

JP301

JP301

15

14

13

12

11

5

10

4

9

3

8

2

7

1

1611

1611

6

16 17

+5V_PC

VGA_B+

VGA_G+ G_IN

VGA_R+

TXD <6,8>

RXD <6 ,8>

D304

D304

D305

D305

These components close to SPV7100

75R/0402/1%

75R/0402/1%

75R/0402/1%

75R/0402/1%

QV1AA10P-R05/NC

QV1AA10P-R05/NC

QV1AA10P-R05/NC

QV1AA10P-R05/NC

QV1AA10P-R05/NC

QV1AA10P-R05/NC

HSI HS_VGA

B B

D301

C305

C305

D301

QV1AA10P-R05/NC

QV1AA10P-R05/NC

D308

D308

QV1AA10P-R05/NC

QV1AA10P-R05/NC

0.1uF/0402/16V

0.1uF/0402/16V

U301

U301

1

NC

2

NC

3

NC

GND4SDA

24C02/SOP8

24C02/SOP8

4

R315

R315

4.7K/0402

4.7K/0402

VCC

VCLK

SCL

8

7

6

5

D306

D306

QV1AA10P-R05/NC

QV1AA10P-R05/NC

D307

D307

QV1AA10P-R05/NC

QV1AA10P-R05/NC

A A

5

+5V_SW

TP301TP301

+5V_PC

1

2

D309 BAT54C/SOT -23D309 BAT 54C/SOT-23

3

QV1AA10P-R05/NC

QV1AA10P-R05/NC

R316

R316

4.7K/0402

4.7K/0402

R318

R318

10K/0402

10K/0402

QV1AA10P-R05/NC

QV1AA10P-R05/NC

R317

R317

100R/0402

100R/0402

PC_WP

QV1AA10P-R05/NC

QV1AA10P-R05/NC

100R/0402

100R/0402

R301

R301

75R/0402/1%

SCL_VGA

SDA_VGA

75R/0402/1%

PC_WP <6>

SCL_VGA <8>

SDA_VGA <8>

3

Change1

R309 1K/0402R309 1K/0402

R310 10K/0402R310 10K/0402

R311 1K/0402R311 1K/0402

R312 10K/0402R312 10K/0402

HS_VGA <6>

VS_VGAVSI

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

Title

Title

Title

SCHEMATIC, M/B VTV-L32020, SSB32S

SCHEMATIC, M/B VTV-L32020, SSB32S

SCHEMATIC, M/B VTV-L32020, SSB32S

ize Docum ent Number Rev

Size Docum ent Number Rev

Size Docum ent Number Rev

S

B

B

B

Date: Sheet of

Date: Sheet of

2

Date: Sheet of

401C2M

401C2M

401C2M

VS_VGA <6>

1

0A

0A

0A

3 15Monday, September 20, 2010

3 15Monday, September 20, 2010

3 15Monday, September 20, 2010

Page 38

5

CVBS & Ypbpr AV input

JP302B

JP302B

D D

MKC21-029PV

MKC21-029PV

Ypbpr_G

T5

S5

SC1_AU_LOUT

CVBS_TU_OUT1

C327 2.2uFC327 2.2uF

C330 2.2uFC330 2.2uF

R347

R347

47K

47K

AOUT0L

AOUT0R

R348

R348

47K

47K

T6

S6

T7

S7

T8

B8

S8

Side AV input

R343

C C

270pF/25V/0402

JP304

JP304

FRON-AV-KYOYAKU

FRON-AV-KYOYAKU

R_S

R_S

3

2

R

GND

R

GND

1

L_S

L_S

6

5

L

GND

L

GND

4

V_S

V_S

9

8

CVBS

GND

CVBS

GND

7

Video Output

+5V_SW

L301

L301

FBMA-300LMT

FBMA-300LMT

C334

CVBSO

C334

10uF/0805/10V

10uF/0805/10V

GNDV

C336

C336

10uF/0805/10V

10uF/0805/10V

B B

CVBSO<6>

270pF/25V/0402

270pF/25V/0402

270pF/25V/0402

100pF/25V/0402/NC

100pF/25V/0402/NC

C335

C335

0.1uF

0.1uF C314

R351

R351

R352

R352

220R

220R

10K

10K

C

Q302

Q302

B

PMBT3904

PMBT3904

E

R357

R357

R356

R356

75R

75R

12K

12K

GNDV

R343

10K

10K

C328

C328

C331

C331

C333

C333

R3530RR353

0R

R344

R344

6.8K

6.8K

R345

R345

10K

10K

R346

R346

6.8K

6.8K

L312

L312

1.8uH

1.8uH

C348

C348

C347

C347

220pF

220pF

220pF

220pF

EC

Q301

Q301

B

PMBT3906

PMBT3906

R354

R354

75R

75R

C363 SE10uF/16VC363 SE10uF/16V

CVBS0_IN_A

C362 SE10uF/16VC362 SE10uF/16V

AOUT0L <6>

AOUT0R <6>

SC1_AU_ROUT

MMBT3904L

MMBT3904L

Add Q303 Q304 R364 R365 for Fix DC/ON Po noise 7/23

C329

C329

560pF/25V/0402

560pF/25V/0402

C332

C332

560pF/25V/0402

560pF/25V/0402

R35075R350

75

C364

C364

+

+

CVBS_TU_OUT1

220uF 6.3V

220uF 6.3V

VGA audio input

L307

2

1

L307

KHB0805Q300SA

KHB0805Q300SA

L308

L308

KHB0805Q300SA

KHB0805Q300SA

270pF/25V/0402

270pF/25V/0402

270pF/25V/0402

270pF/25V/0402

JP305

JP305

R

T

3

S

PhoneJack-SHI-BLU 3P

PhoneJack-SHI-BLU 3P

A A

PC Audio

Input

5

R355

R355

10K

10K

C337

C337

C339

C339

R358

R358

6.8K

6.8K

R359

R359

10K

10K

R360

R360

6.8K

6.8K

AIN3R

C338

C338

560pF/25V/0402

560pF/25V/0402

AIN3L

C340

C340

560pF/25V/0402

560pF/25V/0402

Y/CVBS SWITCH

R387

R387

4.7K/0402

4.7K/0402

R385

R385

4.7K/0402

4.7K/0402

+5V_SW

R364

R364

C

Q304

Q304

E

AIN1L

R349

R349

CVBS2_IN

100/1%/0402

100/1%/0402

AIN3R <6>

AIN3L <6>

4

+5V_SW

GND

SC1_AU_LOUT

MMBT3904L

MMBT3904L

4.7K

4.7K

AVout_Mute

AVout_Mute

B

AIN1R

JP306

JP306

1

EARPHONE/SW/KYOYAKU

EARPHONE/SW/KYOYAKU

4

SW_CON Output

0 CVBS1

1 S_Video

R388

R388

4.7K/0402

4.7K/0402

1

2

3

NC7SB3157P6X

GND

+5V_SW

R365

R365

4.7K

4.7K

C

B

E

AVout_Mute <6>

AIN1L <6>

AIN1R <6>

CVBS2_IN <6>

NC7SB3157P6X

Close SPV7101

AVout_Mute

JP303

JP303

JALCO / AV SV-IN_V

JALCO / AV SV-IN_V

R386

R386

4.7K/0402

4.7K/0402

Q303

Q303

EARPHONE

678

2L3R

4L5R

91011

B1

GND

B0

U302

U302

Vcc

5

CVBS

CVBS

Audio L

Audio L

Audio R

Audio R

6

S

5

4

A

6

S_SWS_GND

S_SWS_GND

TOP_C

TOP_C

TOP_Y

TOP_Y

GND

GND

GND

GND

GND

GND

+5V_SW

R3840R384

0

R331

R331

100/1%/0402

100/1%/0402

C345

C345

0.1uF/25V/0402

0.1uF/25V/0402

GND

JP302A

JP302A

MKC21-029PV

MKC21-029PV

T1

S1

T2

S2

T3

S3

T4

B4

S4

S-AV Input

4

3

GND

GND

2

GND

GND

1

YT

100pF/25V/0402/NC

YS

WT

WS

RT

RB

RS

D316

D316

QV1AA10P-R05/NC

QV1AA10P-R05/NC

100pF/25V/0402/NC

D317

D317

D318

D318

QV1AA10P-R05/NC

QV1AA10P-R05/NC

QV1AA10P-R05/NC

QV1AA10P-R05/NC

L314

L314

3

SW_CONSV_Y_IN

CVBS0_IN <6>

GND_IO

100pF/25V/0402/NC

100pF/25V/0402/NC

100pF/25V/0402/NC

100pF/25V/0402/NC

270pF/25V/0402

270pF/25V/0402

270pF/25V/0402

270pF/25V/0402

C350

C350

L313

L313

430pF/0603/50V/NC

430pF/0603/50V/NC

3.3uH/KSI0603

3.3uH/KSI0603

3.3uH/KSI0603

3.3uH/KSI0603

3

SW_CON <6>

C311

C311

C314

C344

C344

C358

C358

C343

C343

C352

C352

470pF/0603/50V

470pF/0603/50V

L317

L317

KHB0805Q300SA

KHB0805Q300SA

L0805D

C308

430pF/NC

430pF/NC

C312

C312

C316

C316

C323

C323

L309

L309

1.8uH

1.8uH

L310

L310

1.8uH

1.8uH

L316

L316

1.8uH

1.8uH

220pF

220pF

R368

R368

6.8K

6.8K

430pF/0603/50V/NC

430pF/0603/50V/NC

L315

L315

3.3uH/KSI0603

3.3uH/KSI0603

C342

C342

220pF

220pF

C359

C359

220pF

220pF

C355

C355

L0805D

KHB0805Q300SA

KHB0805Q300SA

KHB0805Q300SA

KHB0805Q300SA

R369

R369

6.8K

6.8K

C353

C353

KHB0805Q300SA

KHB0805Q300SA

KHB0805Q300SA

KHB0805Q300SA

KHB0805Q300SA

KHB0805Q300SA

AIN2R

Ypbpr_G HD1Y

430pF/NC

430pF/NC

430pF/NC

430pF/NC

C320

C320

270pF/25V/0402

270pF/25V/0402

270pF/25V/0402

270pF/25V/0402

C361

C361

220pF

220pF

C360

C360

220pF

220pF

C356

C356

220pF

220pF

R367

R367

10K

10K

R371

R371

10K

10K

C351

C351

L302

L302

L0805D

L0805D

L303

L303

L0805D

L0805D

L304

L304

L0805D

L0805D

L305

L305

L0805D

L0805D

L306

L306

L0805D

L0805D

R32275R322

75

R32875R328

75

0/1%/0402

0/1%/0402

R33675R336

75

AIN2L

C357

C357

560pF/25V/0402

560pF/25V/0402

C341

C341

560pF/25V/0402

560pF/25V/0402

470pF/0603/50V

470pF/0603/50V

R321

R321

100/1%/0402

100/1%/0402

R370

R370

+3.3V_SW

C354

C354

R363

R363

CVBS1_IN <6>

100

100

C309

C309

10pF/NC

10pF/NC

R319

R319

C313

C313

75/1%

75/1%

10pF/NC

10pF/NC

GND_IOGND_IOGND_IO

R330

R330

C317

C317

75/1%

75/1%

10pF/NC

10pF/NC

R333

R333

10K

10K

R334

R334

R335

R335

47K/NC

47K/NC

6.8K

6.8K

GND_IO

R338

R338

10K

10K

R339

R339

R340

R340

47K/NC

47K/NC

6.8K

6.8K

GND_IO

C1_IN

R327

R327

SV_Y_IN

0/1%/0402

0/1%/0402

CVBS0_IN_A

(1)When plug in the earphone cable,

"HP_DET" connects to GND.

(2)If plug out the earphone cable,

"HP_DET" was floating.

R382

R382

4.7K

4.7K

0.1uF/0603/16V

0.1uF/0603/16V

HP_OUTR <11>

HP_DET <6>

HP_OUTL <11>

2

D311

D311

QV1AA10P-R05/NC

QV1AA10P-R05/NC

GND_IOGND_IO GND_IOGND_IO

HD1CBSC1_AU_ROUT

D312

D312

QV1AA10P-R05/NC

QV1AA10P-R05/NC

GND_IO

HD1CR

D313

D313

QV1AA10P-R05/NC

QV1AA10P-R05/NC

GND_IOGND_IOGND_IOGND_IO

C319

C319

560pF/25V/0402

560pF/25V/0402

GND_IOGND_IOGND_IO

C325

C325

560pF/25V/0402

560pF/25V/0402

GND_IOGND_IOGND_IO

C1_IN <6>

AIN2L <6>

AIN2R <6>

2

1

R320

R320

100

100

R3240R324

R323

R323

75/1%

75/1%

R326

R326

100

100

R329

R329

100

100

0

C349

C349

0.01uF/0402/50V

0.01uF/0402/50V

C315

C315

0.01uF/0402/50V

0.01uF/0402/50V

PB1_IN

PR1_IN

C306

C306

10pF/NC

10pF/NC

C307

C307

0.01uF/0402/50V

0.01uF/0402/50VC308

C310

C310

1000pF

1000pF

GND_IO

PB1_IN <6>

PR1_IN <6>

SOY1_IN

R3251MR325

1M

10M modify to 1M

9/29

Y1_IN <6>

SOY1_IN <6>

These components close to SPV7100

AIN0L

AIN0R

AIN0L <6>

AIN0R <6>

GND_IO

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

Title

Title

Title

SCHEMATIC, M/B VTV-L32020,SSB32S

SCHEMATIC, M/B VTV-L32020,SSB32S

SCHEMATIC, M/B VTV-L32020,SSB32S

ize Document Number Rev

Size Document Number Rev

Size Document Number Rev

S

C

C

C

401C2M

401C2M

401C2M

Date: Sheet of

Date: Sheet of

Date: Sheet of

1

4 15Monday, September 20, 2010

4 15Monday, September 20, 2010

4 15Monday, September 20, 2010

0A

0A

0A

Page 39

5

HD5V_0

HDMI-1

JP402

JP402

HDMI-19PV-SMD-JALCO

HDMI-19PV-SMD-JALCO

R404

22

H0_SCL

H0_SDA

QV1AA10P-R05/NC

QV1AA10P-R05/NC

QV1AA10P-R05/NC

QV1AA10P-R05/NC

QV1AA10P-R05/NC

QV1AA10P-R05/NC

HD5V_1

HD5V_1

22

H1_SCL

H1_SDA

R404

CEC/DDC GND

DDC SCL

D D

C C

B B

A A

DDC SDA

Dat2 shield

Dat1 shield

Dat0 shield

clk shield

DAT0-

DAT0+

DAT1-

DAT1+

DAT2-

DAT2+

GND20GND21GND22GND23GND24GND

HDMI-2

JP403

JP403

HDMI-19PV-SMD-JALCO

HDMI-19PV-SMD-JALCO

CEC/DDC GND

DDC SCL

DDC SDA

Dat2 shield

Dat1 shield

Dat0 shield

clk shield

GND20GND21GND22GND23GND24GND

CEC

HPD

clk-

clk+

25

DAT0-

DAT0+

DAT1-

DAT1+

DAT2-

DAT2+

+5V

CEC

HPD

clk-

clk+

25

R43722R437

15

R436 22R436 22

16

13

19

2

5

8

D403

D403

11

D404

D404

D405

D405

D401 QV1AA10P-R05/NCD401 QV1AA10P-R05/NC

12

10

9

7

6

4

3

1

18

17

R43822R438

15

R439 22R439 22

16

13

19

2

5

8

11

D409 QV1AA10P-R05/NCD409 QV1AA10P-R05/NC

D410 QV1AA10P-R05/NCD410 QV1AA10P-R05/NC

D411 QV1AA10P-R05/NCD411 QV1AA10P-R05/NC

D412 QV1AA10P-R05/NCD412 QV1AA10P-R05/NC

12

10

9

7

6

4

3

1

5

CEC

CHPD

CEC

BHPD

HD5V_0

18

+5V

17

R405

R405

10K/0402

10K/0402

R403

R403

10K/0402

10K/0402

C401

C401

10K/0402

10K/0402

0.1uF/0402/16V

0.1uF/0402/16V

R413

R413

20K/0402/NC

20K/0402/NC

D406

D406

QV4AA20P-0R1/NC

QV4AA20P-0R1/NC

2

3

4

5

D407

D407

QV4AA20P-0R1/NC

QV4AA20P-0R1/NC

2

3

4

5

R409

R409

10K/0402

10K/0402

R414

R414

D413

D413

QV4AA20P-0R1/NC

QV4AA20P-0R1/NC

2

3

4

5

D414

D414

QV4AA20P-0R1/NC

QV4AA20P-0R1/NC

2

3

4

5

1

6

1

6

C403

C403

0.1uF/0402/16V

0.1uF/0402/16V

20K/0402/NC

20K/0402/NC

1

6

1

6

D402

D402

BAT54C/SOT-23

BAT54C/SOT-23

3

R416

R416

100K/0402

100K/0402

L401

L401

QTC28CG900/1012D

QTC28CG900/1012D

10

1

9

2

8

3

7

4

1

10

2

9

3

8

4

7

L402

L402

QTC28CG900/1012D

QTC28CG900/1012D

R415

R415

100K/0402

100K/0402

L403

L403

QTC28CG900/1012D

QTC28CG900/1012D

1

10

2

9

3

8

4

7

10

1

9

2

8

3

7

4

L404

L404

QTC28CG900/1012D

QTC28CG900/1012D

2

1

5

6

7

8

5

6

7

8

D408

D408

BAT54C/SOT-23

BAT54C/SOT-23

3

4

Change5

+5V_SW

HD5V_0

CRXCM

CRXCP

CRX0M

CRX0P

CRX1M

CRX1P

CRX2M

CRX2P

2

+5V_SW

1

HD5V_1

5

6

7

8

5

6

7

8

4

BRXCM

BRXCP

BRX0M

BRX0P

BRX1M

BRX1P

BRX2M

BRX2P

H1_SDA

H1_SCL

3

Side HDMI

HDMI-3

JP401

JP401

HDMI-19PV-SMD-JALCO

HDMI-19PV-SMD-JALCO

18

+5V

17

CEC/DDC GND

15

DDC SCL

16

DDC SDA

13

CEC

19

HPD

2

Dat2 shield

5

Dat1 shield

8

Dat0 shield

11

clk shield

DAT0-

DAT0+

DAT1-

DAT1+

DAT2-

DAT2+

GND20GND21GND22GND23GND24GND

+3V3_HDMI_SW +5V_SW

HD5V_0

CRX0P

CRX2M

CRX1P

CRX0M

CRX2P

CRX1M

C405

C405

82pF

BHPD

HD5V_1

HD5V_2

AHPD

BRXCM

BRXCP

BRX0M

BRX0P

BRX1M

BRX1P

BRX2M

BRX2P

10uF/0805/10V

10uF/0805/10V

82pF

+3V3_HDMI_SW

C420

C420

C0805D

C0805D

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

R442

R442

10K

10K

U401

U401

BHPD

BSDA

BSCL

BRXCM

BRXCP

BRPWR5V

BRX0M

BRX0P

VSS

BRX1M

BRX1P

VCC

BRX2M

BRX2P

APWR5V

AHPD

64

58

59

62

61

60

63

NC

VCC

CRX1P

CRX2P

CRX1M

CRX2M

IT6633P

IT6633P

ASDA18ASCL

ARXCM20ARXCP21VCC22ARX0M23ARX0P24VSS25ARX1M26ARX1P27NC28ARX2M29ARX2P30REXT

RESET

19

17

ARX0M

ARXCP

ARXCM

H2_SDA

H2_SCL

R434 0R/0402R434 0R/0402

3

55

56

57

VSS

CRX0P

CRX0M

ARX1M

ARX0P

clk-

clk+

25

CRXCM

CRXCP

53

54

CRXCP

CPWR5V

ARX1P

CRXCM

H0_SCL

52

CSCL

ARX2M

12

10

9

7

6

4

3

1

TP401TP401

CHPD

H0_SDA

51

50

CSDA

31

ARX2P

HDMI_5V_DET

100K/0402

100K/0402

49

CHPD

32

R433

R433

510

510

Reset

High Active

D416 QV1AA10P-R05/NCD416 QV1AA10P-R05/NC

D417 QV1AA10P-R05/NCD417 QV1AA10P-R05/NC

D418 QV1AA10P-R05/NCD418 QV1AA10P-R05/NC

D419 QV1AA10P-R05/NCD419 QV1AA10P-R05/NC

R435

R435

TXPWR5V

TXSDA

TXHPD

PCADR0

PCSCL

PCSDA

NC

RESETN_HDMI <6>

HD5V_2

R410

R410

R411

R411

HD5V_2

22

H2_SCL

R44022R440

R441 22R441 22

CEC

AHPD

6633 DDC bus is 5v / 3v tolerant

depend on Scaler requirement

48

47

TXSCL

46

TXCM

45

TXCP

44

43

TX0M

42

TX0P

41

VSS

40

TX1M

39

TX1P

38

VCC

37

TX2M

36

TX2P

35

34

33

H2_SDA

HDMI_5V_DET <6>

R421

R421

0R/0402/NC

0R/0402/NC

R423

R423

R429

R429

0R/0402

0R/0402

+3V3_HDMI_SW

10K/0402

10K/0402

10K/0402

10K/0402

2

3

4

5

2

3

4

5

+3V3_HDMI_SW

R424

R424

47K/0402

47K/0402

47K/0402

47K/0402

RXCM

RXCP

TXHPD_HDMI

RXM0

RXP0

RXM1

RXP1

RXM2

RXP2

R430

R430

10K/0402/NC

10K/0402/NC

R412

R412

D420

D420

QV4AA20P-0R1/NC

QV4AA20P-0R1/NC

D421

D421

QV4AA20P-0R1/NC

QV4AA20P-0R1/NC

BAT54C/SOT-23

BAT54C/SOT-23

3

R417

R417

C402

C402

0.1uF/0402/16V

0.1uF/0402/16V

100K/0402

100K/0402

20K/0402/NC

20K/0402/NC

10

9

8

7

1

6

10

9

8

7

1

6

R422

R422

0R/0402

0R/0402

R426 22R426 22

R427 22R427 22

C404

C404

NC / 220pF

NC / 220pF

L409

L409

FBMA-L11-321611-102LMA10T

FBMA-L11-321611-102LMA10T

10uF/0805/10V

10uF/0805/10V

2

D415

D415

2

1

L405

L405

QTC28CG900/1012D

QTC28CG900/1012D

1

2

3

4

1

2

3

4

L406

L406

QTC28CG900/1012D

QTC28CG900/1012D

R428 0R/0402R428 0R/0402

C406

C406

NC / 220pF

NC / 220pF

4.7K/0402/NC

4.7K/0402/NC

+3V3_HDMI_SW+3.3V_HD

C415

C415

C0805D

C0805D

2

+5V_SW

HD5V_2

ARXCM

5

ARXCP

6

ARX0M

7

ARX0P

8

ARX1M

5

ARX1P

6

ARX2M

7

ARX2P

8

From Scaler to reply HPD signal

R443

R443

0/NC

0/NC

R425

R425

100

100

SDA_HDMI <6>

SCL_HDMI <6>

RXCM <6>

RXCP <6>

RXM0 <6>

RXP0 <6>

RXM1 <6>

RXP1 <6>

RXM2 <6>

RXP2 <6>

PCSCL, PCSDA control IT6633 by

R432

R432

R431

R431

+3V3_HDMI_SW

TP402TP402

C416

C416

0.1uF/0402/16V

0.1uF/0402/16V

4.7K/0402/NC

4.7K/0402/NC

C417

C417

0.1uF/0402/16V

0.1uF/0402/16V

C418

C418

software mode

C419

C419

0.1uF/0402/16V

0.1uF/0402/16V

0.1uF/0402/16V

0.1uF/0402/16V

Title

Title

Title

ize Document Number Rev

Size Document Number Rev

Size Document Number Rev

S

C

C

C

Date: Sheet of

Date: Sheet of

Date: Sheet of

1

HPD_HDMI <6>

DDC bus connect to

Scaler RX DDC bus

TMDS bus connect to

Scaler HDMI TMDS

input

SCL_M <6,8,11>

SDA_M <6,8,11>

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

SCHEMATIC, M/B VTV-L32020,SSB32S

SCHEMATIC, M/B VTV-L32020,SSB32S

SCHEMATIC, M/B VTV-L32020,SSB32S

401C2M

401C2M

401C2M

1

5 15Monday, September 20, 2010

5 15Monday, September 20, 2010

5 15Monday, September 20, 2010

0A

0A

0A

Page 40

5

SDRAM Data Bus

MA[0..11]<6>

D D

C C

B B

A A

RASN<6>

BA0<6>

BA1<6>

WEN<6>

CASN<6>

CKE<6>

SDCLKP<6>

SDCLKN<6>

DQS0L<6>

DQM0L<6>

DQS0H<6>

DQM0H<6>

DQS1L<6>

DQM1L<6>

DQS1H<6>

DQM1H<6>

MA0 MA0_0

MA3 MA3_0

MA6 MA6_0

MA10 MA10_0

MA11 MA11_0

MA5 MA5_1

MA6 MA6_1

MA7 MA7_1

MA10 MA10_1

MA11 MA11_1

MD[0..15]<6>

MA[0..11]

RASN

BA0

BA1

WEN

CASN

CKE

SDCLKP

SDCLKN

DQS0L

DQM0L

DQS0H

DQM0H

DQS1L

DQM1L

DQS1H

DQM1H

MD[16..31]<6>

5

MA1_0MA1

MA2_0MA2

MA4_0MA4

MA5_0MA5

MA7_0MA7

MA8_0MA8

MA9_0MA9

MA0_1MA0

MA1_1MA1

MA2_1MA2

MA3_1MA3

MA4_1MA4

MA8_1MA8

MA9_1MA9

MD[0..15]

MD[16..31]

MD0

MD1

MD2

MD3

MD4

MD5

MD6

MD7

MD8

MD9

MD10

MD11

MD12

MD13

MD14

MD15

DQM0L

DQS0L

MD16

MD17

MD18

MD19

MD20

MD21

MD22 DDR_MD22

MD23

MD24

MD25

MD26

MD27

MD28

MD29

MD30

MD31

DQM1L

DQS1L

1 8

2

3

4 5

47R/0804

1 8

2

3

4 5

1 8

2

3

4 5

1 8

2

3

4 5

R510

R510

47R

47R

R511

R511

47R

47R

1 8

2

3

4 5

1 8

2

3

4 5

1 8

2

3

4 5

1 8

2

3

4 5

R512

R512

47R

47R

R513

R513

47R

47R

47R/0804

47R/0804

47R/0804

47R/0804

47R/0804

RP501

RP501

RP502 47R /0804RP502 47R /0804

RP503 47R/0804RP503 47R/0804

RP504

RP504

RP505 47R/0804R P505 47R /0804

RP506 47R/0804R P506 47R /0804

RP507 47R/0804R P507 47R /0804

RP508

RP508

7

6

7

6

7

6

7

6

7

6

7

6

7

6

7

6

4

DDR_MD0

DDR_MD1

DDR_MD2

DDR_MD3

DDR_MD4

DDR_MD5

DDR_MD6

DDR_MD7

DDR_MD8

DDR_MD9

DDR_MD10

DDR_MD11

DDR_MD12

DDR_MD13

DDR_MD14

DDR_MD15

DDR_DQM0L

DDR_DQS0L

DDR_MD16

DDR_MD17

DDR_MD18

DDR_MD19

DDR_MD20

DDR_MD21

DDR_MD23

DDR_MD24

DDR_MD25

DDR_MD26

DDR_MD27

DDR_MD28

DDR_MD29

DDR_MD30

DDR_MD31

DDR_DQM1L

DDR_DQS1L

4

GNDM

GNDM

U501

U501

+2V5

DDR_MD15

+2V5

DDR_MD14

DDR_MD13

DDR_MD12

DDR_MD11

+2V5

DDR_MD10

DDR_MD9

DDR_MD8

+2V5

DQS0H

+2V5

DQM0H

WEN

CASN

RASN

CSN

BA0

BA1

MA10

MA0_0

MA1_0

MA2_0

MA3_0 MA4_0

+2V5

DDR data bus & clk

signal end trace impedance

differential impedance = 100 ohm.

+2V5

DDR_MD31

+2V5

DDR_MD30

DDR_MD29

DDR_MD28

DDR_MD27

+2V5

DDR_MD26

DDR_MD25

DDR_MD24

+2V5

DQS1H

+2V5

DQM1H

WEN

CASN

RASN

CSN

BA0

BA1

MA10_1

MA0_1

MA1_1

MA2_1

MA3_1 MA4_1

+2V5

1

VDD

2

DQ0

3

VDDQ

4

DQ1

5

DQ2

6

VSSQ

7

DQ3

8

DQ4

9

VDDQ

10

DQ5

11

DQ6

12

VSSQ

13

DQ7

14

NC

15

VDDQ

16

LDQS

17

NC

18

VDD

19

NC

20

LDM

21

WE

22

CAS

23

RAS

24

CS

25

NC

26

BA0

27

BA1

28

AP/A10

29

A0

30

A1

31

A2

32

A3

33

VDD

W9412G6JH-5

W9412G6JH-5

GNDM GNDM

All traces must have the same length

W9412G6JH-5(128Mb/2Mx16x4B)

建建建建建建, 同同建同同(可可可可可

U502

U502

1

VDD

2

DQ0

3

VDDQ

4

DQ1

5

DQ2

6

VSSQ

7

DQ3

8

DQ4

9

VDDQ

10

DQ5

11

DQ6

12

VSSQ

13

DQ7

14

NC

15

VDDQ

16

LDQS

17

NC

18

VDD

19

NC

20

LDM

21

WE

22

CAS

23

RAS

24

CS

25

NC

26

BA0

27

BA1

28

AP/A10

29

A0

30

A1

31

A2

32

A3

33

VDD

W9412G6JH-5

W9412G6JH-5

GNDM GNDM

All traces must have the same length

W9412G6JH-5(128Mb/2Mx16x4B)

VSS

DQ15

VSSQ

DQ14

DQ13

VDDQ

DQ12

DQ11

VSSQ

DQ10

DQ9

VDDQ

DQ8

NC

VSSQ

UDQS

NC

VREF

VSS

UDM

CK

CK

CKE

NC

NC/A12

A11

A9

A8

A7

A6

A5

A4

VSS

盡可盡盡盡

VSS

DQ15

VSSQ

DQ14

DQ13

VDDQ

DQ12

DQ11

VSSQ

DQ10

DQ9

VDDQ

DQ8

NC

VSSQ

UDQS

NC

VREF

VSS

UDM

CK

CK

CKE

NC

NC/A12

A11

A9

A8

A7

A6

A5

A4

VSS

3

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

50 ohm.

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

3

DDR_MD0

DDR_MD1

DDR_MD2

DDR_MD3

DDR_MD4

DDR_MD5

DDR_MD6

DDR_MD7

DDR_DQS0L

DDR_DQM0L

MCLKN_0

MCLKP_0

CKER_0

MA11_0

MA9_0

MA8_0

MA7_0

MA6_0

MA5_0

).

DDR_MD16

DDR_MD17

DDR_MD18

DDR_MD19

DDR_MD20

DDR_MD21

DDR_MD22

DDR_MD23

DDR_DQS1L

DDR_DQM1L

MCLKN_1

MCLKP_1

CKER_1

MA11_1

MA9_1

MA8_1

MA7_1

MA6_1

MA5_1

+2V5

+2V5

+2V5

+2V5

+1.25V

+1.25V

+2V5

GNDM

+2V5

GNDM

R502

R502

120R_1%

120R_1%

R503

R503

120R_1%

120R_1%

R516

R516

120R_1%

120R_1%

R518

R518

120R_1%

120R_1%

C502

C502

0.1uF

0.1uF

C503

C503

0.1uF

0.1uF

C512

C512

0.1uF

0.1uF

C513

C513

0.1uF

0.1uF

These components close to DDR

These components close to DDR

GNDM

2

SDRAM CONTROLLER

SIGNAL

R506 10RR506 10R

R507 10RR507 10R

R509 10RR509 10R

SOURCE POWER/GND (2.5V)

C508

C508

C525

C525

C507

C504

C504

0.1uF

0.1uF

C522

C522

0.1uF

0.1uF

C523

C523

C505

C505

0.1uF

0.1uF

82pF

82pF

C528

C528

C521

C521

82pF

82pF

0.1uF

0.1uF

*Short these ground planes on PCB

2

C507

C506

C506

0.1uF

0.1uF

82pF

0.1uF

0.1uF

C518

C518

0.1uF

0.1uF

Title

Title

Title

Size Docum ent Number Rev

Size Docum ent Number Rev

Size Docum ent Number Rev

B

B

B

Date: Sheet of

Date: Sheet of

Date: Sheet of

82pF

0.1uF

0.1uF

C516

C516

C519

C519

0.1uF

0.1uF

0.1uF

0.1uF

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

COMPAL OPTOELECTRONICS CO., LTD

SCHEMATIC, M/B VTV-L32020,SSB32S

SCHEMATIC, M/B VTV-L32020,SSB32S

SCHEMATIC, M/B VTV-L32020,SSB32S

401C2M

401C2M

401C2M

+2V5

R501

R501

22K

22K

+2V5 +1.25V

+2V5

C509

C509

GNDMGNDM

10uF/0805/10V

10uF/0805/10V

+2V5

C527

C527

C517

C517

82pF

82pF

GNDMGNDM

10uF/0805/10V

10uF/0805/10V

R504

R504

R519

R519

22K

22K

C510

C510

1uF

1uF

C515

C515

1uF

1uF

47R

47R

1

1

+1.25V

R521

R521

47R

47R

C524

C524

82pF

82pF

C514

C514

1000pF

1000pF

R505

R505

47R

47R

R508

R508

NC/220R

NC/220R

R522

R522

47R

47R

R520

R520

NC/220R

NC/220R

C501

C501

1000pF

1000pF

C526

C526

82pF

82pF

6 15Friday, September 10, 2010

6 15Friday, September 10, 2010

6 15Friday, September 10, 2010

CKER_0CKE

MCLKP_0SDCLKP

MCLKN_0SDCLKN

CKER_1

MCLKP_1

MCLKN_1

C511

C511

0.1uF

0.1uF

C520

C520

0.1uF

0.1uF

0A

0A

0A

Page 41

5

Crystal Circuit

Y201

Y201

27MHz

27MHz

CRYSTAL\SMD\4MA

CRYSTAL\SMD\4MA

R2071MR207

1M

C203

C203

D D

15pF

15pF

C204

C204

15pF

15pF

These components close to SPV7100

RESET<11>

RESETN

RESETN<8>

RXD

RXD<2,8>

TXD

TXD<2,8>

IR_DAT

IR_DAT<8>

SD1_FLASH

SD1_FLASH<8>

SD0_FLASH

SD0_FLASH<8>

WP#<8>

MCU_INT High Keep current staus.

MCU_INT Low TV turn off

Add R255 for Fix AV out PO noise

MCU_INT<8>

C C

SDA_HDMI<4>

SCL_HDMI<4>

B B

CVBS0_IN<3>

CVBS1_IN<3>

CVBS2_IN<3>

CVBS3_IN<10>

A A

CEN_FLASH

SCK_FLASH

BL_ON

AVout_Mute<8>

MCU_INT

SDA_HDMI

SCL_HDMI

RXCM

RXCM<4>

RXCP

RXCP<4>

RXM0

RXM0<4>

RXP0

RXP0<4>

RXM1

RXM1<4>

RXP1

RXP1<4>

RXM2

RXM2<4>

RXP2

RXP2<4>

HS_VGA

HS_VGA<2>

VS_VGA

VS_VGA<2>

B_IN

B_IN<2>

G_IN

G_IN<2>

SOG_IN

SOG_IN<2>

R_IN

R_IN<2>

Y1_IN

Y1_IN<3>

SOY1_IN

SOY1_IN<3>

PB1_IN

PB1_IN<3>

PR1_IN

PR1_IN<3>

CVBS0_IN

CVBS1_IN

CVBS2_IN

CVBS3_IN

C1_IN

C1_IN<3>

SARIN0

SARIN0<8>

Light_SEN

Light_SEN<8>

AIN0L

AIN0L<3>

AIN0R

AIN0R<3>

AIN1L

AIN1L<3>

AIN1R

AIN1R<3>

AIN2L

AIN2L<3>

AIN2R

AIN2R<3>

AIN3L

AIN3L<3>

AIN3R

AIN3R<3>

SIFAIN0R

SIFAIN0R<10>

CVBSO

CVBSO<3>

PC_WP

PC_WP<2>

CLKIN

CLKOUT

C202

C202

NC/10pF

NC/10pF

C205

C205

22pF

22pF

IR_DAT

CEN_FLASH <8>

SCK_FLASH <8>

+DVDD

AUSD3

+CVDD

MCU_INT

BL_ADJ

Del LED_PWM_C 3/10

*change value

+3V3_ADCP

C212

C212

8200pF

8200pF

+3V3

R205 10K/0402R205 10K/0402

R206 10K/0402R206 10K/0402

R211 10K/0402/NCR211 10K/0402/NC

R246 10K/0402R246 10K/0402

C206

C206

22pF

22pF

WP#

R243 33RR243 33R

PANEL_ON

PC_WP

AUBCK

AUWS

R225 0/0402R225 0/0402

C209

C209

22pF

22pF

+3V3_TMDS

C211 390pFC211 390pF

R230

R230

5.6K

5.6K

R203

R203

22R

22R

RESET

C208

C208

22pF

22pF

R255 0/0402R255 0/0402

R224 0/0402/NCR224 0/0402/NC

Chnage MCU_INT from pin 219 to pin72 2/8

dd LED_PWM_C 2/8

A

These components close to SPV7100

VCM_AUI

RXD

TXD

RESETN

RESET

SD1_FLASH

R213 33RR213 33R

SD0_FLASH

R214 33RR214 33R

CEN_FLASH

SCK_FLASH

R215 33RR215 33R

HOLD_FLASH

AUMCK

R218 0/0402R218 0/0402

R221 0/0402R221 0/0402

R220 0/0402R220 0/0402

R222 0/0402R222 0/0402

R223 0/0402R223 0/0402

+3V3_XTAL

+1V8_AUD

+CVDD

FILT

MCU_7100<8>

C213

C213

1uF

1uF

GND_ADC GND_ADC

C231

C231

C232

C232

0.1uF

0.1uF

10uF/0805/10V

10uF/0805/10V

RXD

TXD

Del R244 R245 12/16

IR_DAT

MCU_INT

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

213

HPD_HDMI

SDA_HDMI

SCL_HDMI

CLKIN

CLKOUT

GND_TMDS

GND_ADC

C201

C201

1uF

1uF

C233

C233

0.1uF

0.1uF

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

246

247

248

249

250

251

252

253

254

255

256

GND_AUO

MSDA_MCU_A

MSCL_MCU_A

RXCM

RXCP

RXM0

RXP0

RXM1

RXP1

RXM2

RXP2

HS_VGA

VS_VGA

MIDSCV

+1V8_ADCA_A

MIDSCV VCM

VCM_AUO

U201A

U201A

4

LVDS Output

+3V3_LVDS

GNDP

TX0M0

TX0P0

TX0M1

TX0P1

TX0M2

TX0P2

TXCLK0M

TXCLK0P

TX0M3

191

189

187

185

190

192

UART_RX

UART_TX

RESETN

AVSS33_LVDS

AVDD33_LVDS

PWM3/EXINT1

PWM2/WP_FLASH

IR_DAT

SD1_FLASH

SD0_FLASH

CEN_FLASH

SCK_FLASH

HOLD_FLASH

TESTMODE

DVSS33

I2SDA3/SPDIFO

I2SDA2/SPDIFI

I2SMCLKA/JCLK

I2SDA1/JTMS

I2SDA0/JTDO

DVDD33

I2SCLKA/JTDI

I2SWSA/JRSTN

DVDD18

HPD_HDMI

SDA_VGA

SCL_VGA

SDA_HDMI

SCL_HDMI

PWM1//EXINT2

PWM0

DPLLVSS33

DPLLVDD33

AVDD33_REG

AVDD33_XTL

XTALI

XTALO

PVSS18_AUD

PVDD18_AUD

PVSS33_TMDS

PVDD33_TMDS

AVDD33_TMDS

RXCM

RXCP

AVSS33_TMDS

AVDD33_TMDS

RXM[0]

RXP[0]

AVSS33_TMDS

AVDD33_TMDS

RXM[1]

RXP[1]

AVSS33_TMDS

AVDD33_TMDS

RXM[2]

RXP[2]

AVSS33_TMDS

DVSS18_TMDS

DVDD18_TMDS

PVDD33_ADC

FILT

PVSS33_ADC

HSYNC1

VSYNC1

HSYNC0

VSYNC0

MIDSCV

BIN2GIN3SOG4RIN5Y18SOY19PB110PR111Y215SOY216PB217PR218CVBS023CVBS125CVBS227CVBS328C124C2

AVDD18_ADC

1

B_IN

G_IN

SOG_IN

C234

C234

10uF/0805/10V

10uF/0805/10V

181

188

186

184

183

182

TX0P[0]

TX0P[1]

TX0P[2]

TX0M[0]

TX0M[1]

TX0M[2]

TXCLK0P

TXCLK0M

AVDD18_ADC

AVSS18_ADC

7

6

12

R_IN

Y1_IN

SOY1_IN

PB1_IN

PR1_IN

VGA/YUV Input

TX1M0

TX0P3

179

177

178

180

TX0P[3]

TX0M[3]

TX1M[0]

AVSS33_LVDS

AVDD33_LVDS

VCM

AVDD18_ADC

AVSS18_ADC

13

14

TP205TP205

TP207TP207

VCM

TP206TP206