Page 1

FILE NO.

SERVICE MANUAL

LCD TV

LCD-32XR9K

PRODUCT CODE No.

PRODUCT CODE No.

1 682 348 51: PAL/SECAM

NTSC(AV)

REFERENCE No.:SM0915077

Page 2

CONTENTS

Safety precautions…………………………………………………………………1

Alignment instructions……………………………………………………………..3

Software upgrade method…………………………………………………………8

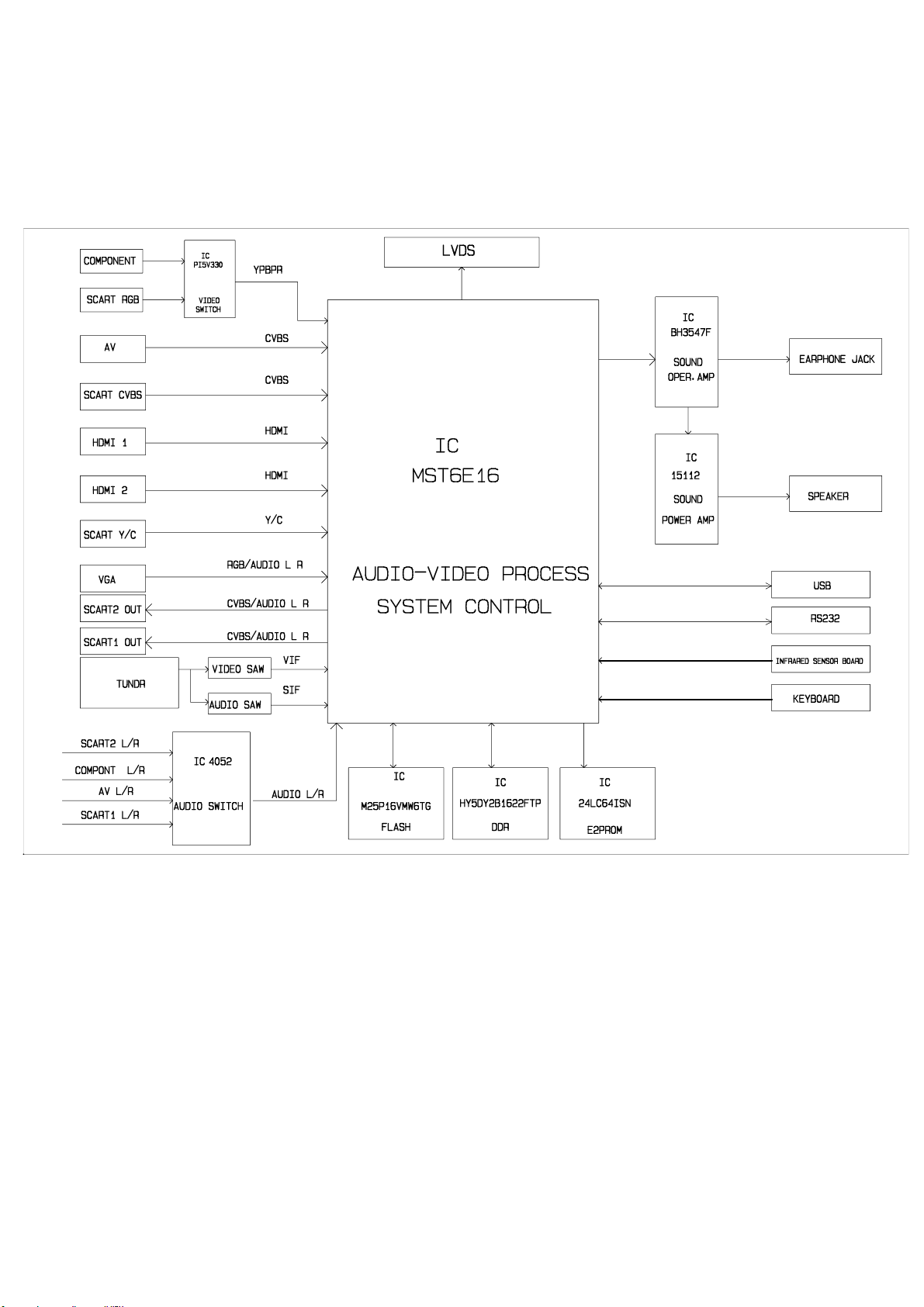

Block diagram………………………………………………………………………10

IC block diagram……………………………………………………………………11

Troubleshooting guide……………………………………………………………..12

Schematic diagram………………………………………………………………...20

APPENDIX-A: Assembly list

APPENDIX-B: Exploded view

Page 3

Attention: This service manual is only for service personnel to take reference with. Before

servicing please read the following points carefully.

Safety precautions

1. Instructions

Be sure to switch off the power supply before replacing or welding any components or

inserting/plugging in connection wire Anti static measures to be taken (throughout the entire

production process!):

a) Do not touch here and there by hand at will;

b) Be sure to use anti static electric iron;

c) It’s a must for the welder to wear anti static gloves.

Please refer to the detailed list before replacing components that have special safety

requirements. Do not change the specs and type at will.

2. Points for attention in servicing of LCD

2.1 Screens are different from one model to another and therefore not interchangeable. Be sure to

use the screen of the original model for replacement.

2.2 The operation voltage of LCD screen is 700-825V. Be sure to take proper measures in

protecting yourself and the machine when testing the system in the course of normal operation or

right after the power is switched off. Please do not touch the circuit or the metal part of the module

that is in operation mode. Relevant operation is possible only one minute after the power is

switched off.

2.3 Do not use any adapter that is not identical with the TV set. Otherwise it will cause fire or

damage to the set.

2.4 Never operate the set or do any installation work in bad environment such as wet bathroom,

laundry, kitchen, or nearby fire source, heating equipment and devices or exposure to sunlight etc.

Otherwise bad effect will result.

2.5 If any foreign substance such as water, liquid, metal slices or other matters happens to fall into

the module, be sure to cut the power off immediately and do not move anything on the module lest

it should cause fire or electric shock due to contact with the high voltage or short circuit.

2.6 Should there be smoke, abnormal smell or sound from the module, please shut the power off

at once. Likewise, if the screen is not working after the power is on or in the course of operation,

the power must be cut off immediately and no more operation is allowed under the same

condition.

2.7 Do not pull out or plug in the connection wire when the module is in operation or just after the

power is off because in this case relatively high voltage still remains in the capacitor of the driving

circuit. Please wait at least one minute before the pulling out or plugging in the connection wire.

2.8 When operating or installing LCD please don’t subject the LCD components to bending,

twisting or extrusion, collision lest mishap should result.

2.9 As most of the circuitry in LCD TV set is composed of CMOS integrated circuits, it’s necessary

to pay attention to anti statics. Before servicing LCD TV make sure to take anti static measure and

ensure full grounding for all the parts that have to be grounded.

2.10 There are lots of connection wires between parts behind the LCD screen. When servicing or

moving the set please take care not to touch or scratch them. Once they are damaged the screen

1

Page 4

would be unable to work and no way to get it repaired.

If the connection wires, connections or components fixed by the thermotropic glue need to

disengage when service, please soak the thermotropic glue into the alcohol and then pull them

out in case of dagmage.

2.11 Special care must be taken in transporting or handling it. Exquisite shock vibration may lead

to breakage of screen glass or damage to driving circuit. Therefore it must be packed in a strong

case before the transportation or handling.

2.12 For the storage make sure to put it in a place where the environment can be controlled so as

to prevent the temperature and humidity from exceeding the limits as specified in the manual. For

prolonged storage, it is necessary to house it in an anti-moisture bag and put them altogether in

one place. The ambient conditions are tabulated as follows:

Temperature Scope for operation 0 ~ +50 oC

Scope for storage -20 ~ +60 oC

Humidity Scope for operation 20% ~ 85%

Scope for storage 10% ~ 90%

2.13 Display of a fixed picture for a long time may result in appearance of picture residue on the

screen, as commonly called “ghost shadow”. The extent of the residual picture varies with the

maker of LCD screen. This phenomenon doesn’t represent failure. This “ghost shadow” may

remain in the picture for a period of time (several minutes). But when operating it please avoid

displaying still picture in high brightness for a long time.

3. Points for attention during installation

3.1 The front panel of LCD screen is of glass. When installing it please make sure to put it in

place.

3.2 For service or installation it’s necessary to use specified screw lest it should damage the

screen.

3.3 Be sure to take anti dust measures. Any foreign substance that happens to fall down between

the screen and the glass will affect the receiving and viewing effect

3.4 When dismantling or mounting the protective partition plate that is used for anti vibration and

insulation please take care to keep it in intactness so as to avoid hidden trouble.

3.5 Be sure to protect the cabinet from damage or scratch during service, dismantling or

mounting.

2

Page 5

Alignment Instructions

1. Alignment equipments

Digital Multimeter

Signal Generator (54200)

Personal Computer (FLASH writing tool pre-installed)

VG848 & VG849 (VGA, YPbPr, HDMI signal generator)

DVD player with HDMI jack

CA210 (white balancer)

Monitor

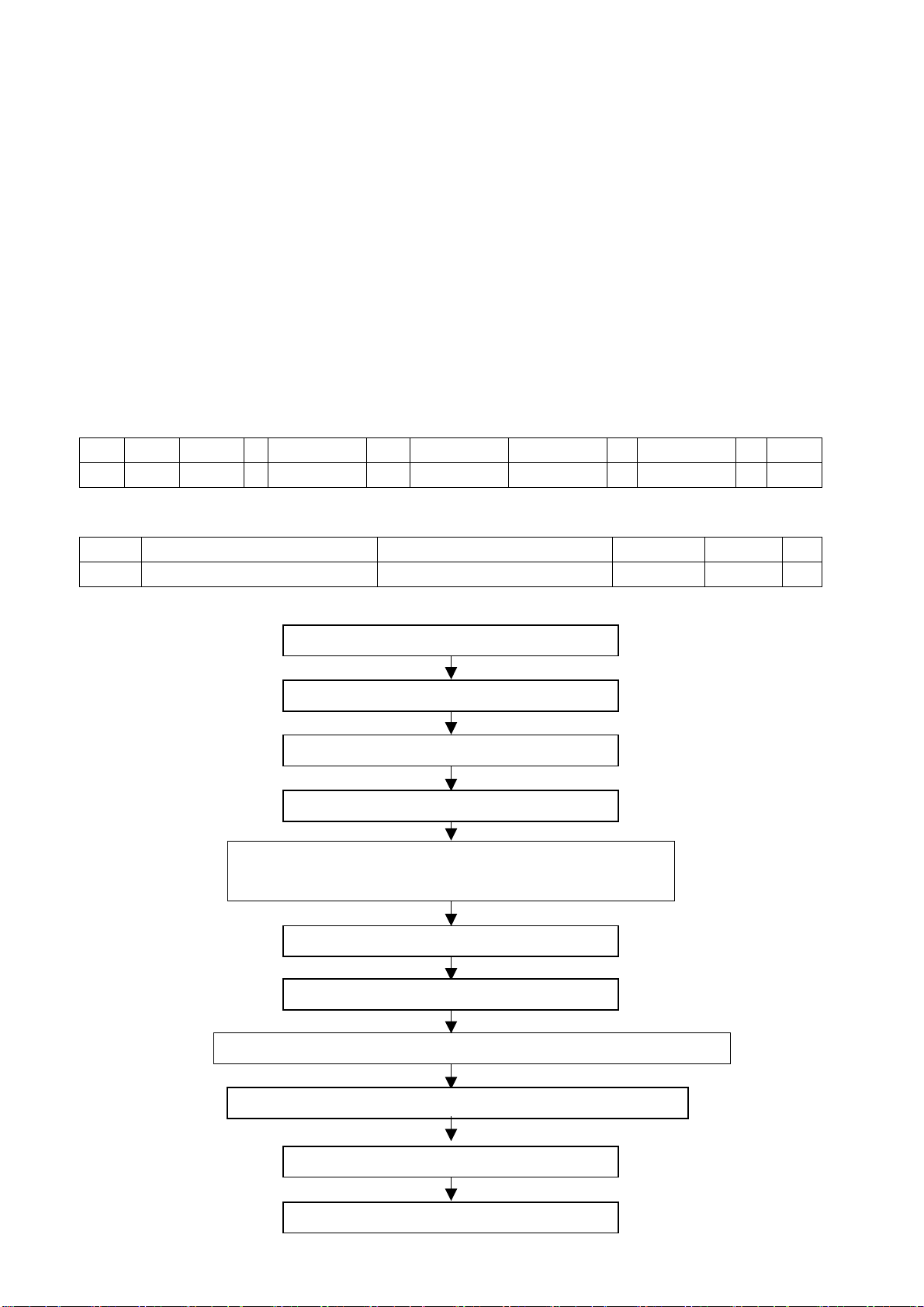

2. Power voltage test and alignment flow chart

2.1 Power voltage test

According to wiring diagram connect all boards correctly. Connect power and press POWER button

to turn on the TV.

a) In turn measure XJ01 all pin voltage. The data is shown below (Table 1).

Table 1: XJ01 all pin voltage

XJ01 Pin1 2 3

Voltage >2.5 V 0~3.3 V 0 11.4 V~12.6 V 0 31.4 V~32.6 V 4.75 V~5.25 V 0 4.75 V~5.25 V 0 >2.5 V

b) In turn measure XV04 all pin voltage, the data is shown below (Table 2).

XV04 Pin1 2 3 4 5

Voltage

22.8 V~25.2 V 22.8 V~25.2 V

4、5 6、7

Table 2 XV04 all pin voltage

8 9 10 11 12 13

0 0 0

2.2 Alignment flow chart (Fig.1)

Check if DDC, FLASH, KEYis written

Data process board making

Complete set alignment

White balance alignment

Input signal and check all TV function (no lost program, analog

control be normal). Check earphone and speaker output is normal.

Check if AV/SVIDEO/SCART input is normal

Check if YPbPrinput is normal

Check if VGA input is normal. Check VGA mode analog control, H/V-center, etc.

Check if HDMI input is normal. Check all the function at this mode.

Defaults preset

Check accessory, then pack the TV

3

Page 6

3. Alignment instructions

3.1 Complete set alignment

3.1.1 According to wiring diagram connect all boards correct ly. Power on the TV, check if the display

is normal.

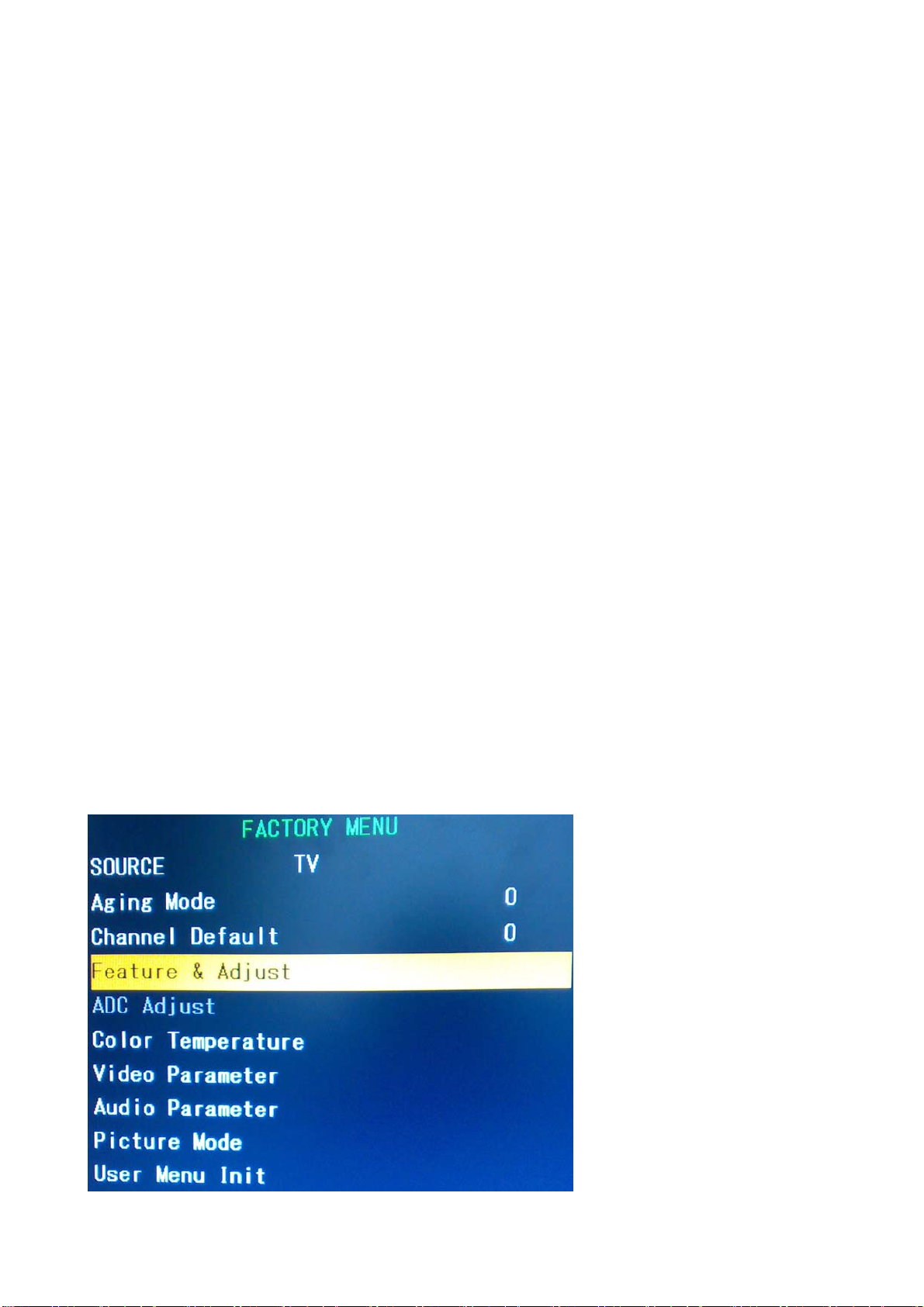

3.1.2 Factory menu usage

a) First press “INPUT” button, then in turn press “2、5、8、0” to access factory main menu.

b) Press “” and “” to select item, then press “” to access.

c) Press “” and “” to move upward or downward and select item.

d) Press “” and “” to adjust.

e) Press “MENU” to return to the previous screen.

3.2 White balance adjustment

3.2.1 Preparations before adjustment

Before white balance adjustment, let the TV work for more than 30 minutes so the TV will be in

stable status. Then use white balancer CA210 to adjust.

a) When adjusting in VGA mode, input VESA800×600/60Hz (for VG848 Timing, input 854) format

signal with crosshatch pattern. Go to user menu, select VGA Settings from Setup menu, then select

Auto to perform auto correction so that the picture can be displayed wholly. Then input signal from

VG848 with PATTERN of 914, go to factory menu and select ADC ADJUST to perform AUTO ADC

until “Complete” appears.

b) When adjusting in YPbPr mode, first input 480i/60 Hz format signal with 75% color bar plus gray

scale (VG848 Timing, input 968, PAT 918). Go to factory menu, select ADC ADJUST to perform

AUTO ADC until “Complete” appears.

c) In this chassis only perform NORMAL color temperature alignment. During alignment please

guarantee that bright step’s color temperature to be △X≤±5, △ Y≤±5, dark step color

temperature to be △X≤±10, △Y≤±10. Depending on different LCD panel type (non-TN panel

& TN panel), the color temperature requirement is different. See below table 3.

Panel type Cool Normal Warm

Non-TN panel 12000K(272、278) 9300K(285、293) 6500K(313、329)

TN panel 10000K(280、288) 8000K(295、305) 6500K(313、329)

Table 3: Color temperature requirements

4

Page 7

3.2.2 Four channels white balance adjustment

3.2.2.1 For AV channel (TV/S-VIDEO/SCART is the same)

Through AV channel, input 8-step gray scale signal (VG848 Timing, input 969, PAT 920), go to

factory menu and access Color Temperature menu page, fix G-GAIN, adjust R-GAIN and B-GAIN to

th

make the 7

B-OFFSET to make the 2

adjust R-GAIN, B-GAIN and R-OFFSET, B-OFFSET until both the first and second steps’

chromaticity coordinates be (285, 293).

3.2.2.2 For DVI channel (HDMI is the same)

Through DVI channel, input 8-step gray scale signal (VG848 Timing input 854, PAT 920), go to

factory menu and access color temperature menu page, fix G-GAIN, adjust R-GAIN and B-GAIN to

make the 7

B-OFFSET to make the 2

step chromaticity coordinates be (285, 293). Fix G-OFFSET, adjust R-OFFSET and

nd

step chromaticity coordinates be (285, 293). In this way repeatedly

th

step chromaticity coordinates be (285, 293). Fix G-OFFSET, adjust R-OFFSET and

nd

step chromaticity coordinates be (285, 293). In this way repeatedly

adjust R-GAIN, B-GAIN and R-OFFSET, B-OFFSET until both the first and second steps’

chromaticity coordinates be (285, 293).

3.2.2.3 For YPbPr channel

Through YPbPr channel input 8-step gray scale signal (VG848 Timing, input 968, PAT 920), go to

factory menu and access color temperature menu page, fix G-GAIN, adjust R-GAIN and B-GAIN to

th

make the 7

B-OFFSET to make the 2

step chromaticity coordinates be (285, 293). Fix G-OFFSET, adjust R-OFFSET and

nd

step chromaticity coordinates be (285, 293). In this way repeatedly

adjust R-GAIN, B-GAIN and R-OFFSET, B-OFFSET until both the first and second steps’

chromaticity coordinates be (285, 293).

3.2.2.4 For VGA channel

Through VGA channel input 8-step gray scale signal (VG848 Timing, input 854, PAT 920), go to

factory menu and access color temperature menu page, fix G-GAIN, adjust R-GAIN and B-GAIN to

th

make the 7

B-OFFSET to make the 2

step chromaticity coordinates be (285, 293). Fix G-OFFSET, adjust R-OFFSET and

nd

step chromaticity coordinates be (285, 293). In this way repeatedly

adjust R-GAIN, B-GAIN and R-OFFSET, B-OFFSET until both the first and second steps’

chromaticity coordinates be (285, 293).

5

Page 8

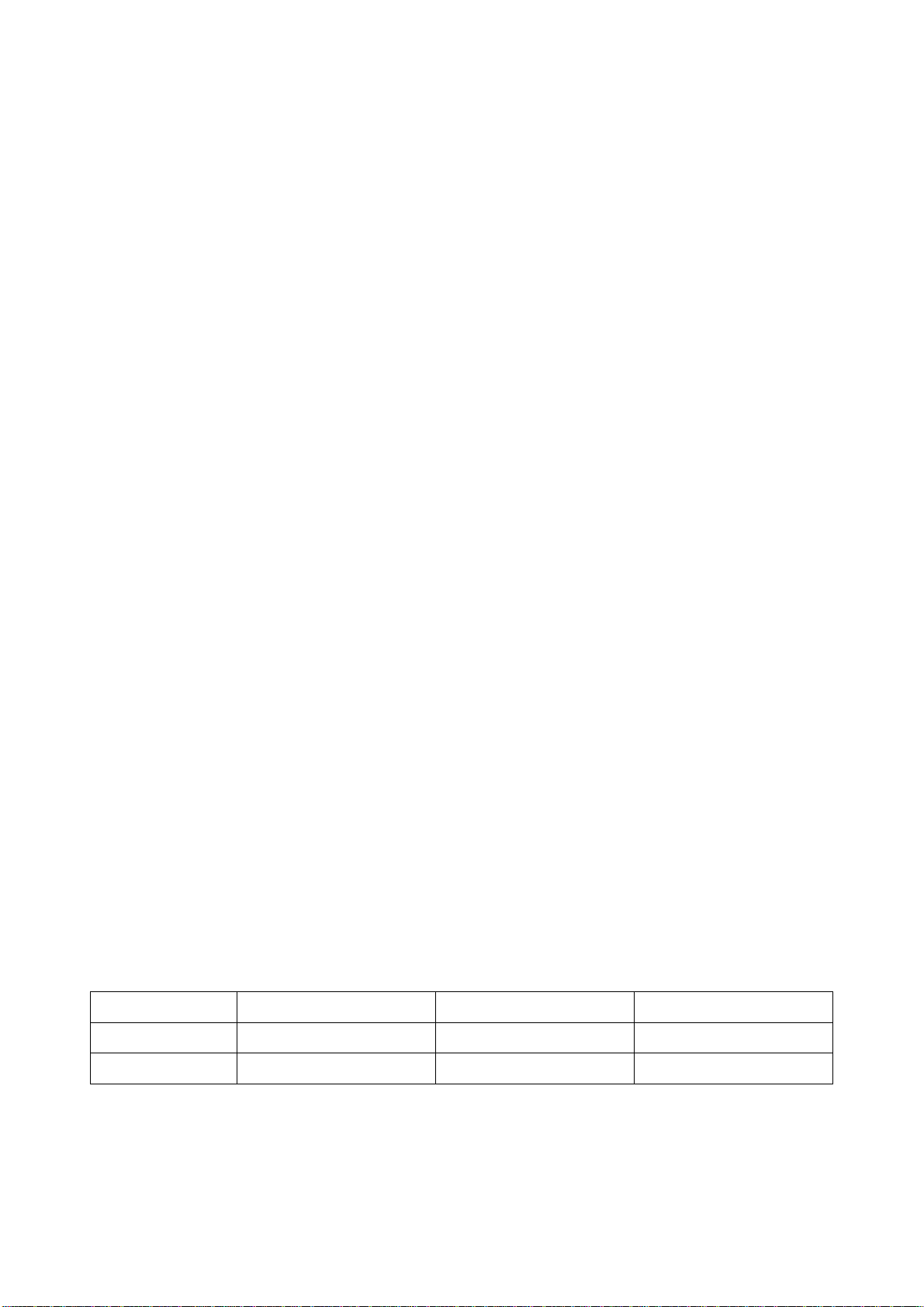

4. Performance check

4.1 TV function check

Input RF signal. Open the user menu and first go to Channel menu, perform auto scan to check if

there is any program lost. Check speaker output normally and picture is displayed normally.

4.2 AV/SVIDEO/SCART input check

Respectively input signal through AV/SVIDEO/SCART, check if picture and sound are normal.

4.3 YPbPr/YCbCr input check

Respectively input all format YUV signal (shown at below table 4) by VG848 signal generator and

check picture display and sound are normal.

Table 4: Component (YUV) signal format

# Resolution

712×484@59.94/60 Hz

1

702×574@50Hz

2

720×483p@59.94/60 Hz

3

720×576p@50 Hz

4

1280×720@50 Hz

5

1280×720p@59.94/60 Hz

6

H-freq.

kHz

15.734 59.94/60 13.50 480i(59.94/60p)

15.625 50 13.50 576i/50

31.469 59.94/60 27.00 480p(59.94/60p)

31.25 50 27.00 576p/50

37.50 50 74.25 720p/50

44.96 59.94 74.18 720p(59.94/60p)

V-freq.

Hz

Dot-clock freq.

MHz

Remarks

7

1920×1080i@50Hz

1920×1080i@59.94/60 Hz

8

1920×1080p@23.98/24 Hz

9

1920×1080p@50Hz

10

1920×1080p@59.94/60 Hz

11

28.125 50 74.25 1080i/50

33.75 59.94 74.25 1080i(59.94/60i)

27.00 23.98/24 74.25 1080p(23.98/24p)

56.25 50 148.50 1080p/50

67.50 60.00 148.50 1080p(59.94/60p)

4.4 VGA input check

Respectively input all format VGA signal (shown at below table 5) by VG848 signal generator.

Check if the display and sound are normal. If picture has deviation in horizontal and vertical

direction, perform auto correction by making use of Setup menu/VGA Settings/Auto item.

Table 5: PC signal format

# Resolution

1

720×400@70 Hz

2

640×480@60 Hz

3

640×480@72 Hz

4

640×480@75 Hz

5

800×600@60 Hz

6

800×600@70 Hz

7

800×600@75 Hz

31.47 70.08 28.32 DOS

31.50 60.00 25.18 VESA

37.90 72.00 31.50 VESA

37.50 75.00 31.50 VESA

37.90 60.00 40.00 VESA

46.90 72.19 49.50 VESA

48.08 75.00 50.00 VESA

H-freq.

kHz

V-freq.

Hz

Dot-clock freq.

MHz

Remarks

6

Page 9

8

1024×768@60 Hz

9

1024×768@70 Hz

10

1024×768@75 Hz

11

1360×768@60 Hz

48.40 60.00 65.00 VESA

56.50 70.00 75.00 VESA

60.00 75.00 78.75 VESA

47.71 60.01 85.50 VESA

4.5 HDMI input check

Respectively input all format HDMI signal (shown at below table 6) by VG849 signal generator,

check if picture display and sound are normal.

Table 6: HDMI signal format

# Resolution H-freq. (kHz) V-freq. (Hz)

712×484@59.94/60 Hz

1

2

3

4

5

6

7

8

9

10

11

702×574@50Hz

720×483p@59.94/60 Hz

720×576p@50 Hz

1280×720@50 Hz

1280×720p@59.94/60 Hz

1920×1080i@50Hz

1920×1080i@59.94/60 Hz

1920×1080p@23.98/24 Hz

1920×1080p@50Hz

1920×1080p@59.94/60 Hz

15.734 59.94/60 13.50 480i(59.94/60p)

15.625 50 13.50 576i/50

31.469 59.94/60 27.00 480p(59.94/60p)

31.25 50 27.00 576p/50

37.50 50 74.25 720p/50

44.96 59.94 74.18 720p(59.94/60p)

28.125 50 74.25 1080i/50

33.75 59.94 74.25 1080i(59.94/60i)

27.00 23.98/24 74.25 1080p(23.98/24p)

56.25 50 148.50 1080p/50

67.50 60.00 148.50 1080p(59.94/60p)

Note: A DVI device also can be connected to the HDMI jack by using a DVI to HDMI adapter cable.

About supported DVI signal format, please refer to table 5 PC signal format and table 6.

Dot-clock freq.

MHz)

Remarks

4.6 HDMI sound supporting format

HDMI sound only supports PCM format, its sample rate supports 32 KHz, 44 KHz and 48 KHz.

5. Default setting for user menu

Go to factory menu “User Menu Init” item, press ENTER button on the remote control, then the TV

will preset all settings to default. After factory alignment, this step must be done surely.

6. Packing

Check accessory then pack the TV.

7

Page 10

Software upgrade method

1 Using USB port to upgrade (it is suggested to use this method in preference)

1.1 Precautions

The upgrade file must be saved under root category of USB device, and the file name must be

changed to “KU19P.BIN” or “ku19p.bin”.

1.2 Upgrade steps:

a) Copy the provided “KU*.bin” file to USB device root category. Then change the file name to

“ku19p.bin” or “KU19P.BIN”.

b) Completely cut off the TV power by unplug the power cord from the power outlet. (Be sure to use

buttons on the remote control or on the TV to completely discharge the TV after power off).

c) Insert the USB device into the USB port. Keep holding any button (except POWER button) on the

TV and then plug the power cord into the power outlet, after about 2-3s release the button, the

software begins to upgrade automatically. Note that during upgrade the USB device can not be

removed and the TV can not be power off.

d) During the process operate according to hints provided on the screen. When complete, remove

the USB device, unplug the power cord and then plug it again, then press POWER to turn on the

TV.

e) After software upgrade the TV must be performed initialization and ADC correction and white

balance alignment again. Below are steps for initialization:

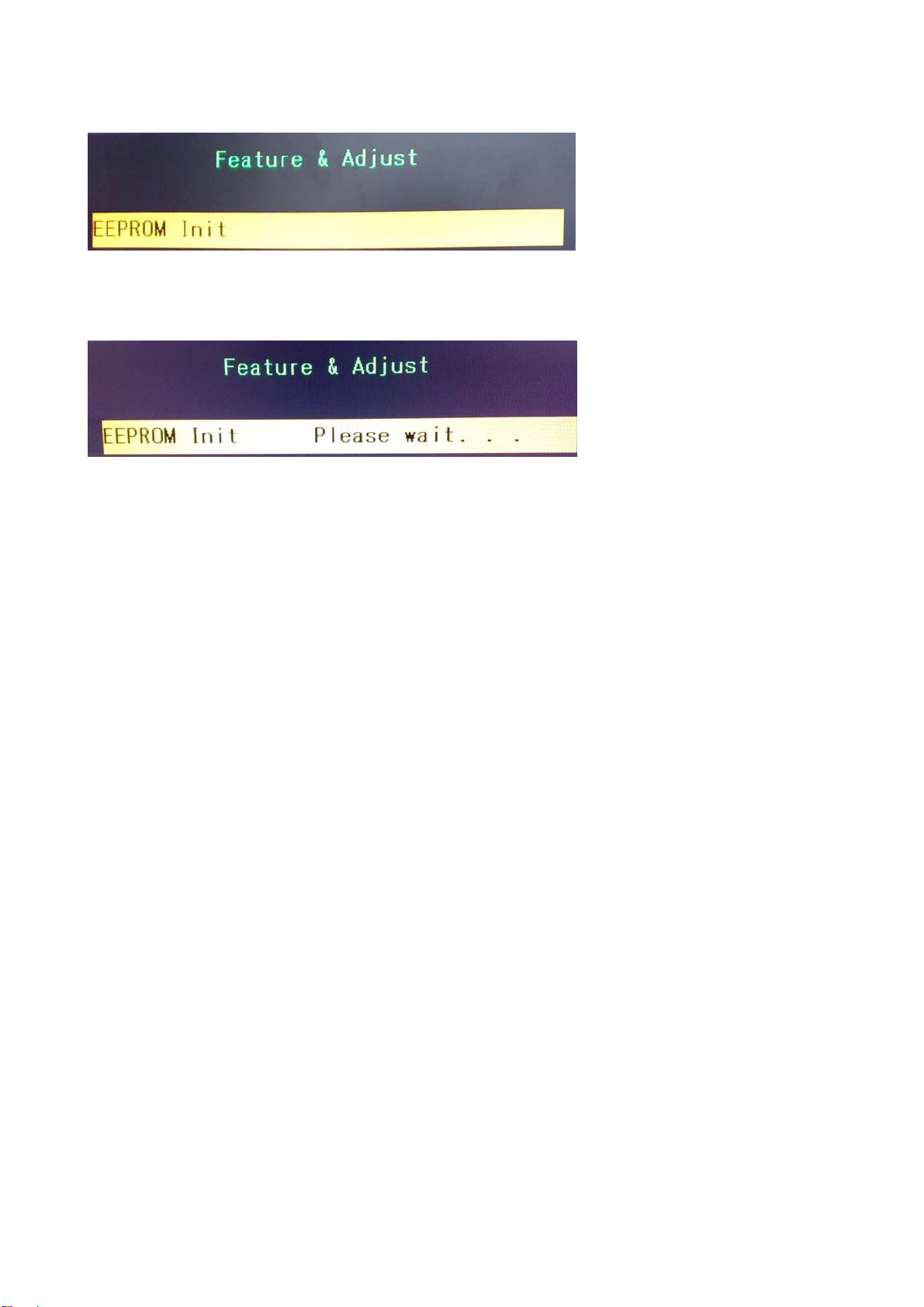

ⅰ. Go to factory menu, select the third item “Feature & Adjust”.

8

Page 11

ⅱ. Go to “Feature & Adjust” sub-menu, select “EEPROM Init” at the first line.

ⅲ. Press “” (RIGHT arrow button) to perform initialization. During the process the message

“Please Wait” will be displayed. When complete, “OK” is displayed.

9

Page 12

Block Diagram

10

Page 13

IC block diagram

GENERAL DESCRIPTION

The MST6E16GS is a high performance and fully integrated IC for multi-function LCD monitor/TV

with resolutions up to full HD (1920x1080). It is configured with an integrated triple-ADC/PLL, an

integrated DVI/HDCP/HDMI receiver, a multi-standard TV video and audio decoder, a video

de-interlacer, a scaling engine, the MStarACE-3 color engine, an on-screen display controller, an

8-bit MCU and a built-in output panel interface. By use of external frame buffer, PIP/POP is

provided for multimedia applications. Furthermore, 3-D video decoding and processing are

fulfilled for high-quality TV applications. To further reduce system costs, the MST6E16GS also

integrates intelligent power management control capability for green-mode requirements and

spread-spectrum support for EMI management.

11

Page 14

Troubleshooting Guide

Common-trouble judging flow chart

Connect the power.

Check if power supply or

infrared sensor board has trouble,

Check if the indicator

lights red.

Yes, then press

POWER button.

Check if the indicator

lights blue.

Yes

Check if the screen

lights up.

No

or power cord problem.

Check if main chip (MST6E16)

pin44 waveform is sine wave,

FLASH pin6 waveform is square-

No

wave. Check main chip peripheral

circuit and FLASH/EEPROM

peripheral circuit.

Check backlight board, then

No

check main chip pin81 backlight

control status.

Yes

Check if every source

video display is normal.

Check if every source

sound is normal.

Check if signal from its

input to IC pin is normal. If

No

normal, then check IC and

its periphery, and LVDS

output.

No

Check if signal from its

input to IC pin is normal.

If normal, then check IC

and its periphery

12

Page 15

1. No raster (screen is not lit), no picture, no sound

No raster,

no picture & sound

Check if indicator lights up.

Check if indicator

lights blue.

No

Check main chip

pin 156 LED

control status.

Check main chip and

FLASH periphery.

Check NS01 pin 44 waveform

is sine wave or not.

Yes

Check main chip

(NS01), FLASH

(NS02) power.

NormalAbnormal

Check if main chip pin169

(reset receiving signal) is of

low level.

Yes No

Check NS01, confirm NS01

has reset correctly.

NoYes

Check circuit of

infrared sensor board.

Check Standby _ 5V

Normal Abnormal

Disconnect power

board and Data

process board, then

test Standby _ 5V

again.

Normal

Abnormal

Power board

exists

problem.

No

Check NS01 crystal

oscillator circuit.

Yes

Check NS01, NS02, NS04,

NS05 and its periphery.

Note: If detect NS01 (main chip) pin 169 is of high level, you may remove RS14, detect VS01

emitter if first output high level after power on, then output low level continuously. If not, the reset

circuit may have problem. First detect if NS01 (main chip) pin 44 waveform is sine wave, if not,

check NS01 crystal oscillator circuit. When checking periphery of NS01, NS02 and NS05, check

relative component’s welding, then use oscilloscope to detect the joint resistor pin between NS01

and NS05. If the waveform is not regular square-wave, that means either NS01 or NS05 work

abnormally and therefore cause address line and data line be in error. NS05 error probability is

greater. In addition, if joint resistor between NS01 and NS05 is in error, it will also cause no raster,

no picture and no sound.

13

Page 16

2. Sound normal, but no picture

(blue screen and OSD can be displayed.)

Sound is OK,

but no picture.

Check backlight

is lit.

Yes No

Try other source, to

check the picture

display.

Yes No

Check NS01

and its

periphery.

Note: HDMI channel is excluded. For HDMI channel picture and sound check, please refer to procedure

of 5.

Check according to

steps of 4. Picture

OK, but no sound.

Check backlight

board, main chip pin

81 backlight control

status.

3. Sound OK, but no picture (only backlight lights up)

Sound is ok, but

only raster appears.

Check LVDS power

supply is normal.

Check signal from NS01

to XS01 is normal.

Normal Abnormal

Panel LVDS

reception board

has problem.

Check N402 circuit.

Normal Abnormal

Check NJ05 pin 2 is

low level or not.

Check NS01 power

supply and its

peripheral circuit.

Yes No

Check NS01 pin 162

and its inverter circuit.

14

Page 17

4. Picture normal, but no sound

No

Picture is OK,

but no sound.

Check main

board XV05 has

signal output.

Yes

Check power amplifier

relative pins have squarewave signal output.

Check power

amplifier rear

stage peripheral

circuit.

Check NV06

corresponding

channel has signal

input.

Speaker problem

NoYes

Check CV18,

CV22 have signal

input amplification.

YesNo

Check power

amplifier’s peripheral

circuit, the power

supply and MUTE pin

circuit.

Yes No

Check NV06

peripheral circuit

and its power

supply.

Check every stage

circuit along the

audio input channel

15

Page 18

4. Some source channel work abnormally.

a) AV1 channel has no picture

Check CS30 has

signal input.

Yes

Check NS01 peripheral

circuit, crystal oscillator

and its power supply.

b) channel has no picture

SCART CVBS

Check CS28 has

signal input.

Yes No

Check NS01 peripheral

circuit, crystal oscillator

and the power supply.

No

The route from AV 1

socket to NS01 exists

problem.

The route from SCART

CVBS socket to NS01

exists problem.

c)

SCART Y/C

Check NS01 peripheral

circuit, crystal oscillator

and the power supply.

channel has no picture

Check CS25, CS26

has signal input.

Yes No

The route from SCART

Y/C socket to NS01

exists problem.

16

Page 19

d) TV channel has no picture

Check LJ31 has

signal input.

Check NS01

peripheral circuit,

crystal oscillator and

the power supply.

e)

YPbPr/SCART RGB

Yes

Check circuit

between

TUNER1 and

NS01.

channel has no picture

No

Check TUNER1 pin

11 has signal output.

NoYes

Check TUNER1

peripheral

circuit, power

supply and bus.

Check NS01 peripheral

circuit, crystal oscillator

and the power supply.

Check NB06 pin 2,

pin 5, pin 11/3, pin 6,

pin 10 have signal

input.

No Yes

The route between

YPbPr/SCART RGB

socket and

NB06 exists problem.

Check CS21, CS22, CS23,

CS24 have signal input.

Yes No

Check NB06 pin 4, pin 7,

pin 9 have signal output.

No Yes

Check channel

between NB06

output and NS01

input.

Check NB06

peripheral circuit,

the power supply.

17

Page 20

e) VGA channel has no picture

Check NS01 pin 29,

pin 30 have

synchronous signal

input.

Yes

Check CS17, CS18, CS19,

CS20 have signal input.

Yes No

Check NS01

circuit.

Check circuit

between VGA

socket and NS01.

f) HDMI channel has no picture

Check NS01 has digital

signal input.

No

Check circuit

between VGA

socket and NS01.

Yes No

Check NS01 peripheral

circuit, crystal oscillator

and the power supply.

Check circuit between

HDMI socket and

NS01.

Note: To get normal HDMI picture, especially when connect to DVD player with HDCP

information, it must be guaranteed that NV04 and NV05 (HDMI port DDC chip) writing

is correct, and especially bus between NV04, NV05 and HDMI jack must be smooth

and unhindered. Secondly HOTPLUG circuit must be guaranteed (it is of high level at

normal broadcast), otherwise the picture playback can not be normal.

18

Page 21

g) HDMI channel has no sound

Check NS01 has

digital signal input.

Yes

Check NS01 peripheral

circuit, crystal oscillator

and the power supply.

No

Check circuit between

HDMI socket and NS01.

Note: To get normal HDMI sound , especially when connect to DVD player

with HDCP information, it must be guaranteed that NV04 and NV05 (HDMI

port DDC chip) writing is correct, and bus between NV04, NV05 and HDMI

jack must be smooth and unhindered, otherwise the sound playback can

not go

.

19

Page 22

Power Switch

Wiring diagram

Page 23

100n

CB16

5

BC847AW

VB03

RB84

47

RB86

8.2K

10K

2.2u

SC2_R

BC847AW

RB102

VB08

47

RB110

8.2K

SC2_L

HD2_Y

HD2_Pb

HD2_Pr

YPbPr_SOUND 1/2

HJR-413/PB-1

XB02

R1

L1

3

1

330p

CB15

PESD5V0L5UY

NB07

RB60

10K

12K

RB62

560p

CB23

HD1_RIN

SCART2_R

4.7K

CB39

SCART2_L

4.7K

RB109

330p

RB61

12K

CB22

560p

RB83

+12V

100n

RB101

+12V

CB46

100n

1234

6

RB85

47K

RB87

CB40

47K

RB111

10K

2.2u

CB47

11

12 13 14

67

1

234

RB24

RB2547RB23

47

VGA_R

VGA_G

R2

NB09

RB146

100

2.2u

CB60

RB1670RB168

0

SCART2_L

SCART2_VOUT

VGA AUDIO

JY-3541L-01-030

XB06

RB105

10K

12K

RB114

RB113

560p

CB51

PC_LIN

VGA

89

47

SOG

VGA_B

B2

CB29

RB157

0

RB92

150

27K

RB95

BC847AW

VB05

BC847AW

R

G

L

RB104

10K

GND-H

12K

560p

CB50

PC_RIN

15

10

RB27

470

SCART2_VOUT

RB69

470u

BC857AW

VB11

RB96

100

27K

RB97

VB06

4.7K

RB98

GAIN_SW

1

3

4

5

GND-H

5

RB22

2.2K

2.2K

RB26

DDC_SDA

G2

75

16V

BC857AW

VB01

RB70

200

RB71

270

BC847AW

VB04

10u

CB43

CVBSOUT2

PESD5V0L4UG

NB11

100n

CB48

CB49

100n

HC1038-15F-3.08

XB07

RB14

100

HS_RGB

DDC_SCL

R1

RB49

0

RB63

RB64

12K

560p

CB24

100n

CB27

470

RB156

330

RB88

100K

RB89

2

PESD5V0L4UG

2

RB154

47

SV1_YIN

SV1_CIN

5

6

1

3

4

5

RB13

100

VS_RGB

AV IN

B1

RB48

0

AV1_R

10K

+12V

RB68

12K

560p

CB28

AV1_RIN

S1_VIDEO

HJK-3.5-401

G

XB05

G

G

RB103

75

RB112

75

NB12

1

3

4

5

NB17

2

CB55

100n

RB153

47

PESD5V0L5UY

NB01

PESD5V0L4UG

NB04

2

100n

CB03

G1

RB47

0

AV1_L

CB25

330p

RB65

75

RB67

10K

47

AV1_VIN-

AV1_LIN

I2C_UPDATE

C

Y

S

1

3

4

5

TX0

RX0

34

2

1

RB148

G

NC

RB66

R

RB129

100

RXD0

100n

CB01

RB46

0

47

AV1_VIN+

L

RB128

100

TXD0

AV13-06-526

XB03

YPBPRIN

HJR-613/PB-1

R2

B2

G2

RB09

RB10

0

RB11

RB12

75

75

CB09

CB10

2.2u

2.2u

1

4

3

5

PESD5V0L4UG

2

100n

CB11

R2

4

CB14

HD1_LIN

6

2

CB13

330p

RB59

RB54

10K

10K

RB58

12K

560p

CB21

HD2_R

HD2_RIN

BC847AW

VB02

RB79

47

RB81

8.2K

SC1_R

BC847AW

RB100

VB07

47

RB107

8.2K

SC1_L

25V

NB05

47K

RB44

47K

RB45

L2

5

CB12

330p

RB56

10K

RB57

12K

CB20

560p

HD2_L

HD2_LIN

SCART1_R

RB80

47K

RB82

10K

2.2u

CB38

SCART1_L

RB106

47K

RB108

10K

2.2u

CB45

AU_SW1

RB78

4.7K

+12V

CB37

100n

RB99

4.7K

+12V

CB44

100n

0

25V

8

GND

IN

1

1K

RB1620RB163

0

europe

china

AU_SW0

RB04

0

RB08

75

CB08

10V

47u

RB41

47K

RB43

47K

13

15

S2D14S1D

EN

DD

12

RB55

11

12

B1

R1

HD1_Pb

HD1_Pr

RB07

75

RB06

75

CB07

CB06

2.2u

2.2u

25V

25V

47K

RB42

47K

10

5

S1B6S2B

S2C11S1C

PI5V330

NB06

DB

DC

7

9

RB53

RB52

47

PR+

SCART2 (CVBS+YC)IN/MONITOROUT

10

470

47

SOY

PB+

RB40

RB51

RS232

470n

CB63

470n

CB64

100n

CB65

1

C1+2V+3C1-4C2+5C2-6V-7T2OUT8R2IN

MAX3232CSE

NB18

R1OUT

T1OUT

R1IN

GND16Vcc

12

13

14

15

+5V_STB

RB159

RB158

100

100

CB70

10u

SCART2_ROUT

SCART2_LOUT

0

HD2_L

CB67

100n

30p

CB68

30p

CB69

TX0

RX0

RB144

HD2_R

8.2K

RB127

RB141

1.5K

RB155

RB145

0

SC2_FS

SCART2_VOUT

TXD0

R2OUT

RB161

0

T2IN11T1IN

9

RB160

RXD0

CB66

470n

10

0

G1

75

CB05

S1A3S2A

DA

Y+

0

RB05

47u

2

4

47

3456789

47

RB150

VCC

RB50

HD1_Y

10V

16

100n

25V

10u

CB19

CB36

100n

PESD5V0L4UG

NB10

AV2_L

1

2

0

RB125

RB126

SV1_CIN

SV1_YIN

XB01

RB38

47K

CB18

STPB3216-310PT

RCA-302A-01

2

AV2_R

XB09

TJC10-12A

0

RB133

0

1

4

3

5

CB04

100n

RB32

47K

LB01

NB03

PESD5V0L4UG

2

RB34

RB36

RB35

RB37

47K

47K

47K

47K

+5V

R

XB04

5

4

3

RB152

1

0

AV2_R

RB72

RB73

10K

RB75

RB74

12K

12K

560p

560p

CB35

CB34

AV2_RIN

HJ-2105F

XB08

6

PESD5V0L5UY

NB14

SCART1

2

1

1R_OUT31L_OUT5GND-D71B_IN9GND-D111G_IN13GND-D151RED_IN

1R_IN4GND-D61L_IN81FUN_SEL10@pinCo12@pinCo14GND-D161RGB_SW17GND-D191TV_OUT18GND-D201TV_IN21GND-D

5

1234

100n

CB52

0

RB135

1n

1n

CB31

10K

RB91

100

2.2u

SCART1_R

0

CB30

RB132

10K

RB90

RB94

RB93

100

2.2u

CB42

CB41

AV2_L

SCART1_L

0

RB29

RB31

DDC_SDA

AV2

W

@pinCo

RB151

0

AV2_L

CB32

330p

10K

RB76

RB149

47

AV2_LIN

AV2_VIN-

R168,R169 CONNECT CHINA

RB122

8.2K

RB130

1.5K

0

RB131

SC_FS

AV2_R

SC_FS

MMBD1204

1AO2A13A24

GND

SDA6SCL

5

100

75

R167,R166 CONNECT EUROPE

24C02N-10SI27

NB02

Vcc

7WP8

100n

CB02

RB28

10K

10K

RB15

10K

RB17

RB30

100

RB33

100

RB39

100

TXD0

DDC_SCL

47

AV2_VIN+

RXD0

Y

YWR

@pinCo

CB17

100n

PESD5V0L4UG

2

NB08

CB33

100n

AV2_V

SCART2_LOUT

SCART2_ROUT

2

1n

CB72

10K

RB165

RB169

0

SCART1_R

5

6

RB77

1234

RB118

0

RB115

75

RB1200

HD2_Y

HD2_Y

HD2_Pr

0

RB119

HD2_Pr

RB134

75

CB56

100n

470u

CB62

16V

RB170

VB12

BC857AW

150

BC857AW

VB09

RB136

BC847AW

330

RB138

VB10

47

220

RB137

47K

16K

CB57

10u

RB139

RB140

CVBSOUT

0

RB121

HD2_Pb

HD2_Pb

5

4

3

1

RB147

100

2.2u

CB61

RB166

0

SCART2_R

PESD5V0L5UY

NB13

5V_TUNNER

SC_FB

5

4

3

1

0

RB116

AV2_V

75

RB16

75

RB18

75

RB21

PESD5V0L4UG

1n

CB71

10K

RB164

AV OUT

SCART1_L

+5V

DB01

Page 24

POWER IN

XJ01

TJC3-13A

1

BL_ON/OFF

2

PWM

3

GND

4

12V

5

12V

6

GND

7

GND

8

32V

9

5V

10

GND

11

5V_STB

12

GND

13

ON/OFF

RJ08

12K

10n

CJ09

RJ07

CJ10

6.8n

6.8K

ON_USB1

ON_PANEL

+12V

+5V_STB

RJ03

10K

+32V

CJ06

3.9n

RJ04

+5V

RJ05

30K

CJ11

470p

RJ01

+5V

DJ01

SK34A

DJ08

D1FS4

RJ06

1K

20K

CJ07

1u

LJ02

STPB3216-380PT

CJ126

100n

8

7

6

5

2K

RJ103

5V_ALL

1K

CJ01

100n

STPB3216-380PT

BC847AW

8

7

6

5

CJ08

470p

HP-MUTE

100n

SS

EN

COMP

FB

+5V_STB

RJ09

1K

VJ01

BC847AW

CJ12

2.2u

LJ03

STPB3216-380PT

LJ04

+5V_STB

RJ16

4.7K

RJ17

4.7K

VJ04

NJ03

MP1410-C019

N/C

EN

COMP

FB

CJ05

CJ04

10V

220u

NJ04

MP1484

GND_4

RJ13

1K

CJ13

100u

16V

CJ15

100u

16V

AP1117-ADJ

BS

IN

SW

CJ27

100u

25V

1

2

3

4

RJ102

GND

RJ111

27K

IN

GND-H

CJ14

100n

CJ16

100n

0

BC847AW

BS

IN

SW

+12V

+5V_STB

RJ14

220

VJ03

BC847AW

AZ1084S-3.3

Vin

RJ100

4.7K

VJ17

5V_ALL

1

2

3

4

CJ22

100u

10V

10K

RJ112

NJ02

OUT

LJ06

STPB3216-380PT

CJ29

10n

CJ28

100n

5V_TUNNER

NJ01

Vout

ADJ/GND

GND-H

RJ101

4.7K

LJ05

STPB3216-380PT

CJ25

10n

SLF7032T-100M1R4-PF

1

CJ24

DJ03

MBRS130T3

10u

CJ23

100n

RJ110

10u

CJ123

RJ22

10K

LJ08

SLF12575T-220M4R0

1

CJ30

DJ04

470u

MBRS130T3

25V

LJ07

+5V

10K

VJ19

BC847AW

RJ19

470

RJ20

510

2

CJ17

100n

RJ21

20K

2

CJ26

470u

10V

CJ31

100n

RJ97

RJ12

4.7K

RJ24

4.7K

CJ19

100u

16V

PW_CTL

GND-H

CJ35

100n

VJ20

BC857AW

1K

RJ109

CJ21

220u

10V

RJ23

45.3K

STPB3216-380PT

STPB3216-380PT

4.7K

RJ98

4.7K

ON_PBACK

PWM2

LJ09

STPB3216-380PT

10u

CJ33

RJ25

820

VCC_1.26

CJ36

10u

+5V_EOP

+2.6VM

LJ10

STPB3216-380PT

CJ34

100n

LJ12

LJ13

+5V

RJ99

10K

+3.3V_STB

+5V_USB

+5V_PANEL

VJ16

BC847AW

AGC

SAS

SCL

SDA

TUNJ01

BP_+5V

NC7

VT_33V

NC9

NC10

TDQ-10A/126D

RJ26

1K

CJ59

100n

CJ71

100n

CJ70

10V

100uF

RJ40

560

+5V_USB1

+2.6VM

VCC_1.26

CJ60

100n

CJ72

100n

RJ108

0

BG2012D151T

STPB3216-380PT

5V_TUNNER

RJ38

10K

CJ74

RJ41

10n

10K

5V_TUNNER

RJ42

10K

CJ75

RJ43

10n

10K

LJ28

LJ29

GND-H

CJ61

100n

CJ73

1u

CJ76

1u

+2.6MVDD

CJ62

100n

VDDC

CJ63

2.2u

5V_TUNNER

RJ44

6.8K

LJ31

0.56uH

CJ64

100n

CJ65

100n

CJ84

CJ80

CJ78

CJ82

100n

100n

100n

100n

CJ85

CJ81

CJ79

CJ83

100n

100n

100n

100n

ZJ01

K9656

12345

RJ45

0

DJ06

MA859

VJ09

BC847AW

RJ49

0

12345

ZJ02

K3953

10p

CJ107

10p

CJ108

RJ50

10K

BC847AW

DJ07

+5V_USB1

RJ69

CJ120

12345

ZJ06

K9656

D3502H

EQ_AMP_F/B

IF_AGC2

IF_AGC1

VIF_in2

VIF_in1

GND

QIF_in

RF_AGC

AFT

Lofic_Vcc

Ref_Signal

Audio_Level_Cont.

Logic_GND

RJ64

100K

10n

NJ10

M61111FP

Video_det_out

51K

KEY&IR

Video_out

TV/FM_SW

Video_in

Vcc

APC

VCOF/B

SIF_in

Vreg

SIF_out

Audio_out

USB1_OC_DET

USB1_D+

USB1_D-

IR_IN

LED

5V_TUNNER

RJ104

2.7K

CJ116

10n

RJ106

2.7K

10n

CJ117

0

RJ47

CJ86

1200p

27p

GJ01

CJ87

RJ48

5V_TUNNER

4MHz

CJ88

150p

SIFP

SIFM

SIF_CTL

LJ32

STPB3216-310PT

CJ89

100n

5V_TUNNER

RJ59

2.2K

RJ60

2.2K

VIFM

VIFP

GND-H

GND-H

VJ12

BC847AW

RJ61

2.2K

CJ90

10V

47u

CJ96

100n

0

SIF_CTL

RJ51

10K

RJ52

10K

NC

RJ53

10K

5V_TUNNER

VJ10

RJ54

10K

RJ57

2.2K

VJ11

BC847AW

RJ58

4.3K

1u

RJ105

2.7K

5V_TUNNER

1u

CJ119

RJ107

GND-H

2.7K

GND-H

10n

CJ97

RJ66

4.7K

RJ65

100

ZJ05

12345

CJ118

GND-H

CJ92

10n

220n

CJ93

CJ94

10n

CJ95

100n

100n

CJ91

GND-H

GND-H

M9370M30

24

23

22

21

20

19

18

17

16

15

14

13

GND-H

VJ13

BC847AW

RJ67

10K

RJ68

30K

FUJ01

SMD1206P075TF

750mA

10V

100u

CJ114

XJ02

USB3112

100n

CJ115

4

3

USB

2

1

NJ07

NJ06

RJ76

+5V_STB

4.7K

XJ03

+5V_STB

+3.3V_STB

RJ74

330

RJ72

4.7K

VJ14

BC847AW

RJ73

CJ98

4.7K

100n

+3.3V_STB

KEY0_IN

NJ08

ICVL1018100Y500FR

5V_TUNNER

RJ79

100

VJ15

BC847AW

RJ80

100n

CJ101

10n

CJ102

470n

CJ103

1000p

470

200

RJ81

0

LJ33

22uH

RJ82

CJ104

CJ105

10n

5V_TUNNER

1

2

3

4

5

6

7

8

9

10

11

12

IR_IN

RJ77

1

0

2

3

4

RJ85

75

RJ86

47K

BG2012D151T

CJ106

RJ91

10

RJ92

220

240

RJ90

47

RJ93

0

TUNER_AFT

XJ04

1

2

5V_TUNNER

LJ34

10V

47u

AV3_VIN+

4.7uH

LJ35

RJ87

ZJ04

XT4M5

CJ111

SIFP

100n

CJ112

SIFM

100n

TUNER_AFT

RJ75

4.7K

CJ99

CJ100

1u

100n

RJ83

20

RJ84

0

ZJ03

LT4.5M

RJ88

100

RJ89

10K

AVDD_MemPLL

CJ37

100n

AVDD_AU

CJ38

100n

AVDD_USB

CJ40

100n

AVDD_RXS

CJ41

100n

AVDD_RXV

CJ44

100n

TPJ01

RJ29

CJ49

100n

LJ25

0.56uH

LJ14

100

22

CJ113

CJ47

10u

470u

CJ48

100n

CJ50

47u

+5V

RJ70

0

1

2

3

4

2

3

RJ31 22

4

CJ121

22p

RJ32

5

CJ122

6

22p

CJ46

7

100n

8

9

10

11

RJ33

IF

51

+12V

STPB3216-380PT

CJ53

RJ27

100n

10K

RJ28

1K

VJ07

BC847AW

LJ15

BG2012D151T

CJ39

2.2u

LJ16

BG2012D151T

LJ20

BG2012D151T

LJ21

BG2012D151T

CJ42

2.2u

LJ19

BG2012D151T

CJ43

2.2u

CD4148WP

CJ45

I2C_SCL

5V_TUNNER

I2C_SDA

LJ24

LJ26

NLC453232T-220K

RJ114

100K

CJ02

25V

100u

+5V_USB

RJ71

0

NJ05

AO4803A

S2

G2

S1

G1

+3.3V_STB

DJ05

RJ30

12K

100n

STBH3216-301PT

+32V

CJ52

2.2u

CJ51

10n

CJ124

100n

CJ125

47n

D2_8

D2_7

D1_6

D1_5

+12V

LJ27

RJ34

CJ109

VDDP_PM

LJ17

BG2012D151T

CJ56

100n

VDDP

LJ18

BG2012D151T

CJ57

CJ55

CJ58

100n

100n

100n

AVDD_33_PM

LJ22

STPB3216-380PT

CJ68

CJ66

CJ69

100n

100n

100n

AVDD_MPLL_PM

LJ23

BG2012D151T

CJ67

2.2u

POWER FOR MST6M16

TAGC

330

10n

8

7

6

5

RJ35

5.1K

CJ110

10n

RJ36

2K

CJ77

CJ54

47u

100n

25V

LJ36

STPB3216-380PT

0.56uH

RJ95

1.2K

RJ39

47

RJ37

0

VCC_PANEL

LJ30

VJ08

2SC4215

+5V_USB1

Page 25

MUX_LIN

MUX_RIN

AU_SW1

AU_SW0

HD1_LIN

HD1_RIN

HD2_LIN

HD2_RIN

AV2_LIN

AV2_RIN

AV1_LIN

AV1_RIN

HDMIA_HPDCTRL

CV40

2.2u

CV41

2.2u

2.2u

CV42

2.2u

CV43

2.2u

CV44

CV45 2.2u

CV46 2.2u

2.2u

CV47

RV05

0

1K

RV06

5V_HDMI-1_IN

RV07

VV01

BC847AW

GND-H

+5V

1K

18

16

14

12

10

8

6

4

2

XV01

HDMI-FIX

RV03

100K

+5V

19

177

15

13

11

9

5

3

1

4.7K

RV23

4.7K

RV24

5V_HDMI-1_IN

RV08

100K

GND-H

RV02

X-COM

47K

16

VDD

15

2X

14

1X

13

12

0X

11

3X

10

A

9

B

RV28

RV27

10K

10K

RV45

100K

RV19

RV17

100K

RV47

10K

100

RV32

100

RV33

100

RV29

RV30

100

RV31

10

RV34

10

NV01

HEF4052BT

100K

100K

RV13

RV04

100K

RV14

1

OY

2

2Y

3

Y-COM

4

3Y

5

1Y

6

INH

7

VEE

8

VSS

+5V

DV01

MMBD1204

0

RV26

RV25

3.6K

1

4

3

5

2

GND-H

PESD5V0L4UG

NV02

RV01

STBH2012-201PT

47K

10u

16V

CV38

CV02

CV01

10u

100n

RV21

100K

100K

SDA

5

SCL

6

WP

7

Vcc

8

CV03

100n

NV04

24C02N-10SI27

16V

CV11

47u

16V

5

6

CV05

RV49

RV51

4.7u

CV06

4.7u

DV06

CD4148WP

DV07

CD4148WP

HP-MUTE

4.7K

RV50

4.7K

AMP_R

AMP_L

RV81

SC2_FS

GND

4

A2

3

A1

2

AO

1

0

RV82

0

MUTE

HDMIA_DDC_SDA

HDMIA_DDC_SCL

HDMIA_RXCHDMIA_RXC+

HDMIA_RX0HDMIA_RX0+

HDMIA_RX1HDMIA_RX1+

HDMIA_RX2HDMIA_RX2+

RV53

4.7K

4.7K

CV09

CV07

22p

22p

RV54

RV52

4.7K

4.7K

CV10

CV08

22p

22p

HP-MUTE

RV73

1K

VV06

BC847AW

RV75

47K

AMP_MUTE

7

IN2

VCC

BIAS

OUT2

GND

IN1

MUTE

OUT1

4

3

2

CV15

1u

+12V

5V_TUNNER

RV55

0

RV56

4.7K

DV03

LL4148

CV17

470u

25V

CV13

CV12

100u

100n

8

NV06

BH3547F

+5V_STB

1

RV60

100K

RV61

0

DV04

LL4148

BC857AW

VV04

DV05

LL4148

10V

LV02

BG2012D151T

100u

CV14

16V

100u

CV16

16V

+5V_EOP

RV80

1K

+5V_STB

VV05

BC847AW

1

4

3

5

RV66

RV67

1.1K

1.1K

RV65

910

RV70

33K

CV21

10u

50V

CV19

100n

RV69

0

CV23

10u

16V

CV22

1u

RV64

4.7K

1u

RV68

CV18

910

+24V_AMP

CV27

RV71

0

10

12

IN1

CV20

16V

10u

CBIAS

13

ROSC

14

AVCC

15

GND16

16

NC17

17

NC18

18

NC19

19

NC20

20

NC21

21

CLOCK

22

VREF

23

PROT

24

1u

CV24

16V

CV25

100n

STBYL11GAIN1

IN226GAIN227MUTEL28NC2829NC2930NC3031NC3132VD2_3233VD2_3334NC3435OUT2_3536OUT2_36

25

RV72

0

100n

6

NC67NC78NC89NC9

GND49

R2A15112FP

NV08

+24V_AMP

2

NV07

100n

CV26

1

3

4

NC3

VD1_45VD1_5

OUT1_12OUT1_2

CV30

100n

VS1_47

VS1_46

VS2_39

VS2_38

CV28

100n

NC48

48

47

46

NC45

45

HB1

44

NC43

10u

43

DVDD

50V

42

CV29

HB2

41

NC40

40

39

38

NC37

37

CV31

100n

+5V

LV01

+3.3V_STB

RV74

4.7K

LV04

A7503AY-150M

LV05

A7503AY-150M

XV03

ST-113

G5

R

HP

G2

L

HP_DET

+24V_AMP

CV32

100n

CV33

1000u

35V

XV04

TJC3-05A

LV03

1

RV76

2

100K

3

4

5

CV35

1000u

35V

CV34

470n

XV05

1

2

3

CV36

1000u

35V

CV37

470n

4

RV79

0

HDMIB_HPDCTRL

DV02

+5V

5V_HDMI-2_IN

5V_HDMI-2_IN

RV11

1K

RV09

0

VV02

RV12

BC847AW

RV10

1K

GND-H

GND-H

100K

18

16

14

12

10

8

6

4

2

XV02

HDMI-FIX

19

177

15

13

11

9

5

3

1

GND-H

MMBD1204

RV38

RV36

RV37

10K

10K

3.6K

0

GND-H

RV35

4

6

5

NV03

1

3

2

RV48

RV41

10K

100

RV42

100

100

RV39

RV40

100

RV43

10

RV44

10

SDA

5

SCL

6

WP

7

Vcc

8

NV05

24C02N-10SI27

CV04

100n

GND

4

A2

3

A1

2

AO

1

HDMIB_DDC_SDA

HDMIB_DDC_SCL

HDMIB_RXC-

HDMIB_RXC+

HDMIB_RX0HDMIB_RX0+

HDMIB_RX1-

HDMIB_RX1+

HDMIB_RX2-

HDMIB_RX2+

RV58

+3.3V_STB

+5V_STB

RV57

VV03

2N7000

100

27K

G

D

S

RV59

200

HDMI_CEC

Page 26

SC2_L

SC2_R

SC1_L

SC1_R

AMP_L

AMP_R

I2C_SDA

I2C_SCL

FOR DEBUG

XS02

KEY0_IN

TUNER_AFT

SC_FS

IR_IN

GAIN_SW

SC2_FS

TAGC

PWM2

TXD0

RXD0

LED

HDMIB_RXCHDMIB_RXC+

HDMIB_RX0HDMIB_RX0+

HDMIB_RX1HDMIB_RX1+

HDMIB_RX2-

HDMIB_RX2+

HDMIB_HPDCTRL

HDMIB_DDC_SDA

HDMIB_DDC_SCL

HDMIA_RXCHDMIA_RXC+

HDMIA_RX0HDMIA_RX0+

HDMIA_RX1HDMIA_RX1+

HDMIA_RX2HDMIA_RX2+

HDMIA_HPDCTRL

HDMIA_DDC_SDA

HDMIA_DDC_SCL

HS_RGB

VS_RGB

VGA_B

SOG

VGA_G

VGA_R

PB+

SOY

Y+

PR+

SC_FB

SV1_YIN

SV1_CIN

AV3_VIN+

AV2_VIN+

AV2_VINAV1_VIN+

AV1_VINCVBSOUT

CVBSOUT2

PC_LIN

PC_RIN

MUX_LIN

MUX_RIN

RS02

22K

1

2

3

4

RS89

4.7K

8

7

6

5

22p

22p

CS64

CS62

+5V_STB

8

7

6

5

22p

22p

CS66

CS67

AR9

AR11

0

RS107

41

A9

A1142A12

NC2526BA027BA128A10/AP

25

BA1

BA0

+5V_STB

100n

GND-H

RS90

47

RS91

47

100n

CS63

RS93

47

RS94

47

AR8

AR7

29A030A131A232

AR0

AR10

CS65

0

RS92

+3.3V_STB

RS110

4.7K

10K

RS95

0

RS96

AR6

37A638A739A840

AR1

XS03

nGª [ª

5

4

3

2

1

WP_EEP

I2C_SCL

I2C_SDA

+3.3V_STB

10K

10K

10K

RS98

RS102

RS100

0

0

0

RS99

RS101

RS103

AR5

AR4

34

35A436

A5

VSS34

VDD33

A3

33

AR3

AR2

+5V_STB

10u

BC857AW

VS01

22K

RS13

AVDD_33_PM

CS32

CS33

RS18

0

RS19

RS20 100

RS21

RS22

RS23

RS24

VIFP

VIFM

SIFM

CS42

100p

RS17

390

CS38

100n

AVDD_RXS

CS44

100p

RS36

100

CS12

RS14

1K

CS13

RS15

27p

220

1M

GS01

CS14

27p

14.31818MHz

203

RXBCKN

204

RXBCKP

206

RXB0N

207

RXB0P

209

RXB1N

210

RXB1P

212

RXB2N

213

RXB2P

214

HOTPLUGB

215

DDCDB_SDA

216

DDCDB_SCL

1

RXACKN

2

RXACKP

3

RXA0N

4

RXA0P

6

RXA1N

7

RXA1P

8

RXA2N

9

RXA2P

10

HOTPLUGA

12

DDCDA_SDA

13

DDCDA_SCL

11

REXT

14

VCLAMP

15

REFP

16

REFM

29

HSYNC0

30

VSYNC0

22

BIN0P

25

SOGIN0

24

GIN0P

26

RIN0P

21

100n

BIN0M

23

100n

GIN0M

17

BIN1P

18

SOGIN1

19

GIN1P

20

RIN1P

31

VSYNC2

32

CVBS4

33

CVBS3

34

CVBS2

35

CVBS1

36

VCOM1

37

CVBS0

38

VCOM0

40

CVBSOUT1

41

CVBSOUT0

60

AUVAG

59

AUVRP

58

AUVRM

62

LINE_IN_0L

63

LINE_IN_0R

64

LINE_IN_1L

65

LINE_IN_1R

66

AUCOM

100

67

LINE_OUT_3L

68

LINE_OUT_3R

100

69

LINE_OUT_2L

100

70

LINE_OUT_2R

100

71

LINE_OUT_1L

100

72

LINE_OUT_1R

53

VIFP

52

VIFM

51

SIFM

50

SIFP

55

TAGC

47

VR27

158

DDCR_SDA

159

DDCR_SCL

160

DDCA_SDA

161

DDCA_SCL

SAR0

SAR1

SAR2

SAR3

152

153

154

155

100p

CS46

RS16

44

XIN

146

43

XOUT

SPI_SCK

SPI_SDI

147

169

SPI_SCZ

148

149

AVDD_AU

HWRESET

SPI_SDO

RS37

1n

61

163

33

CS47

AVDD_AU

IRIN

AVDD_33_PM

205

AVDD_33205

PWM0

156

100

RS38

56

39

AVDD_3356

AVDD_3339

PWM1

PWM2

165

166

157

5

27

AVDD_335

AVDD_3327

PWM3

RS39

33K

10K

RS108

+2.6MVDD

122

128

AVDD_MI122

AVDD_MI128

AVDD_MI133

GND208

GND211

211

VCC

SI

AVDD_MemPLL

111

117

107

AVDD_MI111

AVDD_MI117

8

7

6

5

AVDD_MPLL_PM

108

91

AVDD_MI91

AVDD_MI107

+3.3V_STB

CS50

CS49

10p

45

AVDD_MPLL

AVDD_MIPLL

100n

AVDD_RXV

AVDD_USB

54

48

AVDD_RXV

AVDD_RXS

GPIOT[1]/USB_DRVVBUS

INT

162

168

141

AVDD_USB

USB20_DP

USB20_DM

USB2_REXT

GPIOM[1]/HDMI_CEC

GPIOM[0]

LVB0M

LVB0P

LVB1M

LVB1P

LVB2M

LVB2P

LVBCKM

LVBCKP

LVB3M

LVB3P

LVB4M

LVB4P

LVA0M

LVA0P

LVA1M

LVA1P

LVA2M

LVA2P

LVACKM

LVACKP

LVA3M

LVA3P

LA4M

LVA4P

MVREF

MCLKE

MCLK

MCLKZ

DQM1

DQS[1]

MDATA[15]

MDATA[14]

MDATA[13]

MDATA[12]

MDATA[11]

MDATA[10]

MDATA[9]

MDATA[8]

MDATA[7]

MDATA[6]

MDATA[5]

MDATA[4]

MDATA[3]

MDATA[2]

MDATA[1]

MDATA[0]

DQS[0]

DQM0

MADR[0]

MADR[1]

MADR[2]

MADR[3]

MADR[4]

MADR[5]

MADR[6]

MADR[7]

MADR[8]

MADR[9]

MADR[10]

MADR[11]

CASZ

RASZ

BADR[0]

BADR[1]

ALE/SOFTWARESDA

RDZ//SOFTWARESCL

WRZ/SPDIFO

AD[3]/SPDIFIN

AD[2]

AD[1]

AD[0]

GPIOD[2]

GPIOD1/TXD1

GPIOD0/RXD1

GND

217

5.1

143

142

140

201

200

197

196

195

194

193

192

191

190

189

188

187

186

183

182

181

180

179

178

177

176

175

174

173

172

139

138

137

136

135

134

132

131

130

129

127

126

124

123

121

120

119

118

116

115

113

112

110

109

105

104

103

102

101

100

99

98

97

96

95

94

93

WEZ

92

88

87

86

85

84

83

82

81

80

79

75

74

73

5.1

910

RS109

RS43

RS47

RS48

RS53

RS57

RS58

RS59 100

RS54

RS55

RS60

RS61

RS62

RS56

RS63

RS64

100

100

100

100

RS40

RS41

RS42

100

100

RS44

RS45

RS46

RS49

RS50

RS51

33

RS52

100

100

100

100

100

100

100

22

22

22

22

22

22

RS65

RS66100

4.7K

RS72

RS67

RS68

RS69

100

RS75

RS76

100

GND-H

22

RXO0RXO0+

RXO1RXO1+

RXO2-

22

RXO2+

RXOCRXOC+

22

RXO3RXO3+

RXO4RXO4+

22

RXE0RXE0+

RXE1RXE1+

22

RXE2RXE2+

RXECRXEC+

RXE3-

22

RXE3+

RXE4RXE4+

CKE

MCLK+

GND-H

MCLK-

UDQM

DQS1

DATA15

DATA14

DATA13

DATA12

DATA11

DATA10

DATA9

DATA8

DATA0

DATA1

DATA2

DATA3

DATA4

DATA5

DATA6

DATA7

DQS0

LDQM

AR0

AR1

AR2

AR3

AR4

AR5

AR6

AR7

AR8

AR9

AR10

AR11

WEZ

CASZ

RASZ

BA0

BA1

4.7K

4.7K

4.7K

RS71

RS73

RS79

4.7K

4.7K

RS74

RS80

CS51

1n

+2.6V_DMQ

AU_SW1

AU_SW0

MUTE

ON_PBACK

PW_CTL

WP_EEP

+3.3V_STB

AMP_MUTE

SIF_CTL

HP_DET

+3.3V_STB

ON_USB1

ON_PANEL

RS09

10K

CS52

100n

+2.6V_DMC

KS01

USB1_D+

USB1_D-

HDMI_CEC

USB1_OC_DET

+2.6MVDD

RS77

10K

RS78

10K

66

NS05

HY5DU281622ET

1

VSS66

VDD1

65

2

DATA7

+2.6VM

39

40

DATA15

DQ15

DQ0

37

39

40

38

64

VSSQ64

VDDQ3

3

BG2012D151T

37

38

35

36

DATA14

63

DQ14

DQ1

4

DATA6

LS01

35

36

RXE4-

33

33

34

34

RXE4+

DATA13

62

DQ13

DQ2

5

DATA5

+2.6V_DMC

CS53

61

6

RXE3-

31

32

RXE3+

VDDQ61

VSSQ6

100n

31

32

RXEC-

29

30

RXEC+

DATA12

60

DQ12

DQ3

7

DATA4

CS54

29

30

100n

RXE2-

282826

RXE2+

DATA11

59

DQ11

DQ4

8

DATA3

RXE1-

RXE0-

21

23

252527

21

23

27

22

24

26

22

24

RXE1+

RXE0+

DATA9

DATA10

55

58

56

57

DQ9

DQ10

VSSQ58

DQ6

VDDQ9

DQ5

9

11

10

12

DATA1

DATA2

CS56

100n

151

89

VDDC171

VDDC151

78

VDDC78

VDDC89

VDDP

198

VDDP198

VDDP_PM

167

184

VDDP184

VDDP167

164

VDDP164

145

VDDP145

76

133

VDDP76

202

VDDC

171

VDDC202

NS01

MST6M16JS

GND49

GND28

GND42

GND46

GND57

GND77

GND90

57

77

49

28

42

46

90

106

10u

CS43

CS45

100n

1

2

3

4

CS48

100n

GND170

GND114

GND125

GND106

GND144

GND150

170

144

150

114

125

NS02

MX25L1605AM2C-12G

CS#

SO

WP#

GND

185

SIFP

GND185

199

HOLD#

GND199

208

GND-H

SCLK

19

19

20

20

DATA8

54

VDDQ55

VSSQ12

13

DATA0

+2.6V_DMQ

CS57

100n

RXO3-

RXO4-

151511

17

17

18

18

16

RXO3+

RXO4+

53

DQ8

DQ714NC14

CS58

RS81

RS82

16

NC53

100n

RS83

4.7K

RS84

4.7K

RS85

RS86

RXOC-

13139

14

14

RXOC+

52

VSSQ52

VDDQ15

15

CS59

51

16

DQS0

4.7K

4.7K

4.7K

4.7K

RXO2+

DQS1

100n

RXO2-

12

RS88

10K

UDQS

LDQS

11

12

RXO1-

9

10

10

RXO1+

RS87

10K

CS55

100n

50

NC50

NC1718VDD18

17

CS60

100n

DS01

BAV99

RS12

RS11

100K

4.7K

CD4148WP

DS02

2.2u

CS11

+5V_STB

10K

10K

RS01

RS10

RS34

RS25

22K

4.7K

1K

CS16

100n

CS39

10n

RS08

+3.3V_STB

CS17

CS18

CS19

CS20

CS21

CS22

CS23

CS24

CS25

CS26

CS27 47n

CS28

CS29

CS30 47n

CS31

CS34

CS35

CS36 2.2u

CS37 2.2u

RS27

22K

5V_TUNNER

4.7K

RS26

100

100

100

RS28

RS35 1K

CS15

100n

47n

1n

47n

47n

47n

1n

47n

47n

47n

47n

47n

47n

47n

2.2u

2.2u

CS40

10n

RS33

4.7K

CS41

100n

RS29

RS30100

RS31

RS32

1K

CS01

100n

CS02

100n

1u

10u

CS04

CS05

RS105

CS08

10n

+5V_STB

CS06

100n

CS10

RS07

CS09

RS05

10n

10n

22K

22K

2.7K

2.7K

RS04

RS06

100

RS106

CS03

4.7u

CS07

10n

RS03

22K

100

1

2

3

4

1

2

3

4

RXO0-

7

7

8

8

RXO0+

+2.6V_DMQ

CS68

49

48

VREF

19

CS61

AT24C04N-10SI-2.7

AO

A1

A2

GND

24LC64ISN

A0

A1

A2

Vss

1

5

3

5

3

4

6

4

6

2

UDQM

MCLK-

1n

47

CK

UDM

VSS48

WE

NC1920LDM

21

WEZ

LDQM

LS02

BG2012D151T

100n

NS03

NS04

1

2

+2.6VM

MCLK+CASZ

45CK46

CAS

22

Vcc

WP

SCL

SDA

Vcc

WP

SCL

SDA

XS01

VCC_PANEL

PHB-2x20-2.0

CKE

150

RS97

44

43

CKE

NC43

RAS24CS

23

RASZ

Page 27

Page 28

32" Power Board

Page 29

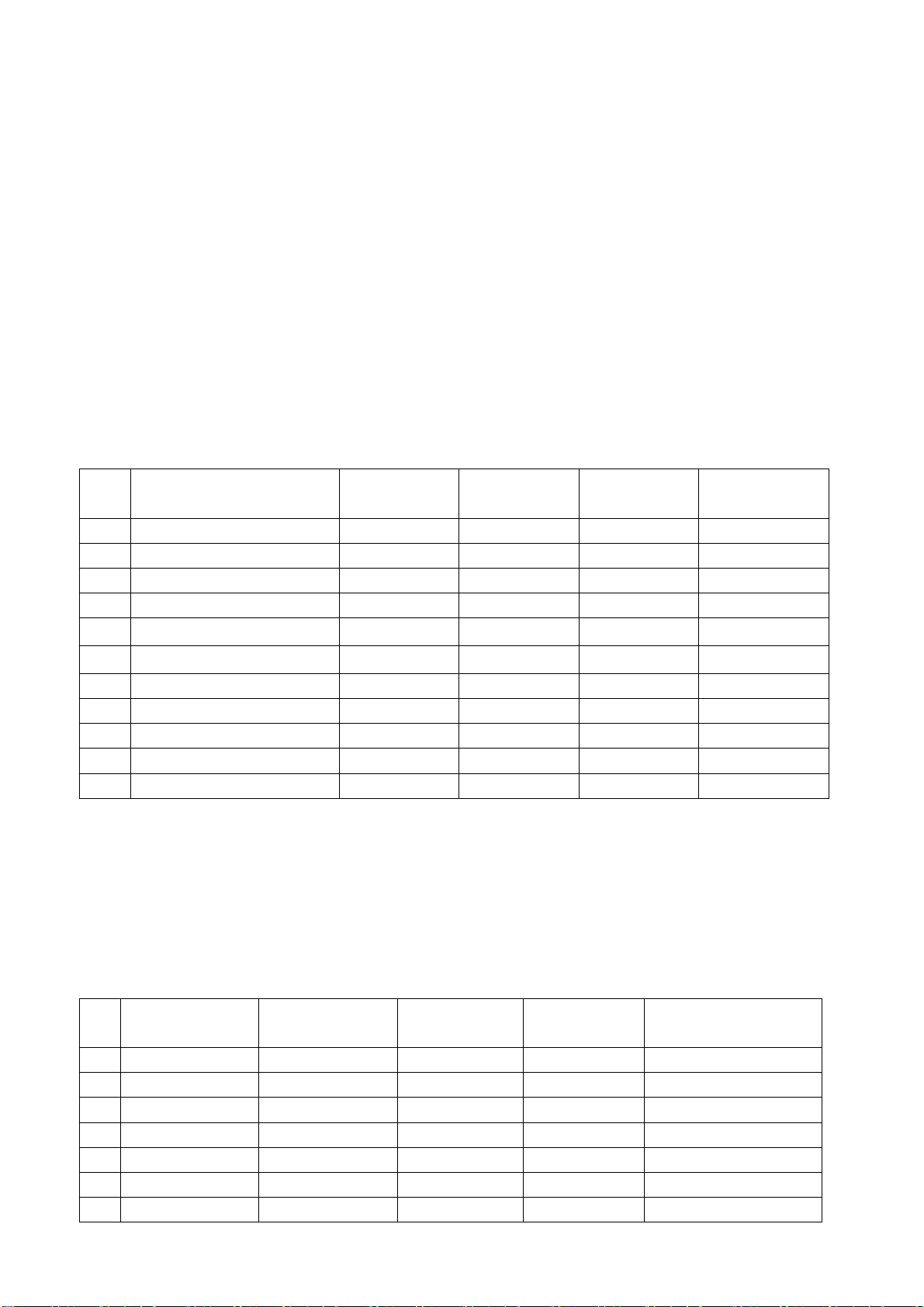

APPENDIX-A: Main assembly LCD-32XR9K 9232KU4212

NAME NO.

MAIN COMPONENT AND IT'S NO.

Main board

XI6KU01101F0

IR board XI635KU00303

Key board XI635HE00102

Power board

XI6HE0332010

Remote control XI6010200901

Panel

XI5203325512

NS01

NS05

NV01

TUNJ01

RC-209-0A

V315B6-L02

MST6E16G (5270616001)

HY5DU561 (5275616222)

HEF4052B (5274052001)

FTDC3S20 (5524050023)

Page 30

APPENDIX-B: Exploded view (LCD-32XR9K)

Page 31

PART LIST OF EXPLODED VIEW

REF.No. DESCRIPION

1 Front cabinet

2

3 IR board

4

5

6

7

8

9 Interface baffel (right)

10 nterface baffel (down)

11 Speaker

12

13

14

15 Wall-mounting holder

16

17

18

19

20

Panel

Conective bracket

Key board

Frame

Pedestal connection

Power board connection

Back cover

Pedestal

Standing pole

Power switch

Power board

Main board

SCART connection

Panel connection (up)

Page 32

PART LIST

LCD-32XR9K ver.1.0

REF.No. PARTS No. DESCRIPION Q'TY REMARK

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

XI6632420020

XI5203325512

XI6KU0090910

XI58A0A78000

XI6HE0330510

XI6153253000

XI58A0082700

XI58A0082600

XI5810D67620

XI5810M67700

XI6170806000

XI5H3263K010

XI6151192000

XI58D0028300

XI58A0083000

XI5293000042

XI6HE0332010

XI6KU01501E0

XI6KU0114610

XI58A0082500

Front cabinet 1

Panel

IR board 1

Conective bracket

Key board

Frame

Pedestal connection

Power board connection

Interface baffel (right) 1

nterface baffel (down) 1

Speaker 2

Back cover

Pedestal

Standing pole

Wall-mounting holder 2

Power switch

Power board

Main board

SCART connection

Panel connection (up)

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Only the parts in above list are used for repairing.

Other parts except the above parts can't be supplied.

Page 33

Assembly list of panel

Components No. Panel model

CMO Backlight board 60Z0000653 27-D029403(V315B6-L02)

Note: Specifications are subject to change without notice.

Page 34

Assemble & Disassemble the Pedestal Base (Option)-for 32x42

If the stand is provided, please read these instructions thoroughly before attempting this installation.

Safety Precautions:

1. Please read these instructions thoroughly prior to attempting this installation.

2. Be sure to handle this product very carefully when attempting assembly. If you are unsure of

your capability, or the use of tools necessary to complete this activity, refer to a professional

installer or service personnel. The manufacturer is not responsible for any damages or

injuries that occur due to mishandling or improper assembly/installation.

3. When using a table or bench as an aid to assembly, be sure to put a soft cushion or covering to

prevent accidental scratching or damage to the unit's finish.

4. The speaker is not intended to support the weight of this display. Do not move or handle this

product from the speaker; which can cause damage to the display not covered under the

manufacturer's warranty.

To install the stand:

1. Remove the stand from the box and place it on a table or bench.

You must pay attention to the direction of the stand. The wide portion of the stand should go towards

the front of the TV.

2. Lay your TV flat (screen down) on the edge of a table or bench. Make sure that you put down a soft

cushion or cloth so that your TV is not scratched.

3. Insert the stand column into the stand socket, move the column steadily until the Locators on the

column align with the locating grooves on the stand. And align the holes in the stand with the holes in

the stand column, then secure the stand to the column with four M5 screws(provided).

Locators

Locating grooves

Stand

M5 screws

To remove the stand from the TV, perform these steps in reverse order.

Page 35

Assemble & Disassemble the Pedestal Base (Option)-for 32x42

To remove the stand column:

1. Lay your TV flat (screen down) on a table or bench. Make sure that you put down a soft cushion or cloth

so that your TV is not scratched.

2. Remove the four screws holding the stand column to your TV, then remove the stand column.

Stand column

Note

The appearance of this product in these illustrations may differ from your actual product, and is for

comparative purposes only.

Remove four screws

Page 36

WALL MOUNTING INSTRUCTIONS-for 32x42

Safety Precautions:

1. Be sure to ask an authorized service personnel to carry out setup.

2. Thoroughly read this instruction before setup and follow the steps below precisely.

3.The wall to be mounted should be made from solid materials. Only use accessories supplied by the manufacturer.

4.Very carefully handle the unit during setup. We are not liable for any damage or injury caused by mishandling or improper installation.

5.Be sure to place the unit on a stable and soft platform which is strong enough to support the unit.

6.Do not uplift the speaker when moving the display. The appearance of the unit may different from the actual ones.

7.Design and specifications are subject to change without notice.

8. Retain these instructions for future reference.

Note: All the wall mounting parts are optional and may be unavailable in your model.

Below we will show you how to mount the Display on the wall using our company’s wall mounting components.

11

Take out these parts from the box.

Wall Mounting

Component

(including bracket

and connector)

Expansion Bolt

Wood Screw

M4 Screw

Fig. 1

Fully insert the two insertions on the wall mounting connector into the

44

locating grooves on the wall mounting bracket from top to bottom end.

22

Screw 4pcs expansion bolts to fix

the wall mounting bracket on the

wall.

Wall

Wall Mounting Bracket

Fig. 2a

If your wall is a wooden structure, please

fix the wall mounting bracket on the wall

with 8 pcs wood screws.

Wall

Wall Mounting Bracket

Fig. 2b

55

Use screwdriver to revolve the Clasper to the Positioner

following the direction of the arrow.

33

Use the 4pcs M4 screws to fix the wall

mounting connector to the rear of the

display unit.

Wall Mounting Connector

Fig. 3

Clasper

Positioner

Fig. 4

Fig. 5

Page 37

OCT/2009

Loading...

Loading...