Page 1

Ordering number:ENN3945A

CMOS IC

LC83010N, 83010NE

Audio Digital Signal Processor

Overview

The LC83010N, 83010NE is a single-chip digital signal

processor (DSP). It is designed for use in the application

fields such as a digital processing of audio signals.

The LC83010N, 83010NE CMOS processor has various

on-chip filtering circuits such as a graphic equalizer for

reproduction of sound quality. It also has simulation circuit for reverberation (sound reflection and echo), so that

sound field with surround and delay can be created.

The LC83010N and LC83010NE are upgraded versions of

the LC83010 and the LC83010E. The LC83010N and

LC83010NE have a 64fs clock output that enables improved

interfacing with external A/D converters. TEST5 has been

renamed FS640/T5 and incorporates both the new clock

output and the original test output.

Features

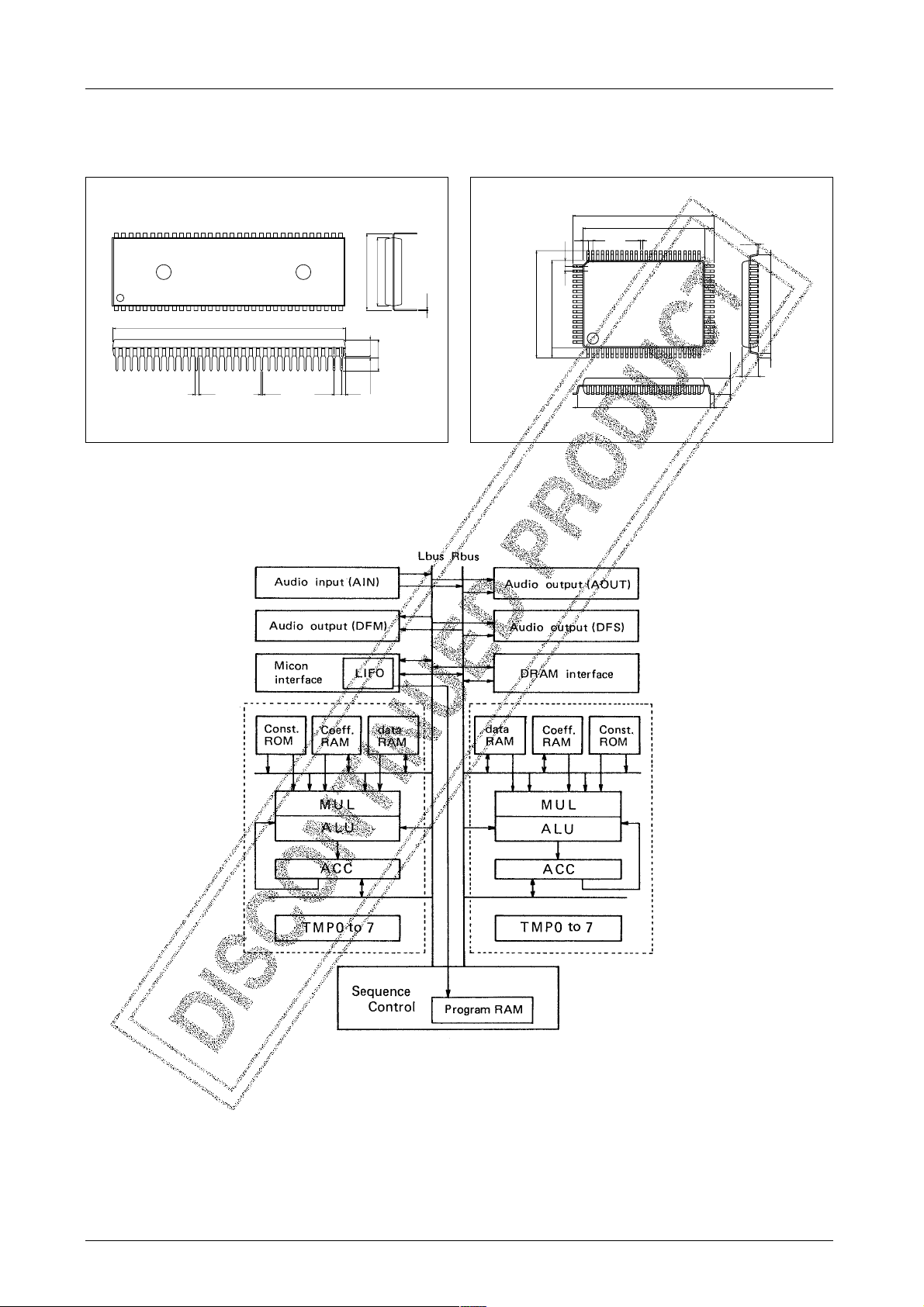

LSI functions

• Dual Harvard Architecture: Enables simultaneous processing (multiply and addition) of stereo signals in a single

instruction cycle.

The LC83010N, LC83010NE processor has the following two independent units:

· Multiplier : 24 bits × 16 bits (fixed-point decimal)

· ALU : 32-bit arithmetic calculation, 24-bit arithmetic

and logical operations.

· ACCumulator (ACC) : 32 bits

· Temporal Registers (TMP0 to TMP7) : 32-bit for each

· Internal Memory Data RAM 128 × 24 bits

Coefficient RAM 256 × 16 bits

Constant ROM 256 × 24 bits

• Program memory Capacity (RAM) : 320 × 32 bits

• A variety of I/O interfaces.

· Audio signal I/O :

1 channel for input (applicable to various formats)

3 channel for output (applicable to up to 4 types of data

format)

· Surround DRAM access signal :

16 accesses/CH Max. (within 1 fs)

Up to 2 256K (64K × 4 bits) DRAMs or 1M (256K × 4

bits) DRAMs can be directly connected to this chip.

· Uses external DRAMS with RAS access times of 120

ns or lower.

· Serial input/output interface with a microcomputer.

Synchronous 8-bit serial input : 1

[Mail box (16 bits × 8) function available]

Synchronous 8-bit serial output : 1

• Interrupt function (Vectored interrupt with the INT pin)

• Stack Nesting Levels : 4

• On-chip Interval Timer :

12 bits (timer clock = sampling frequency)

• Cycle time : 108ns (sampling frequency = 48kHz)

• Single 5V power supply.

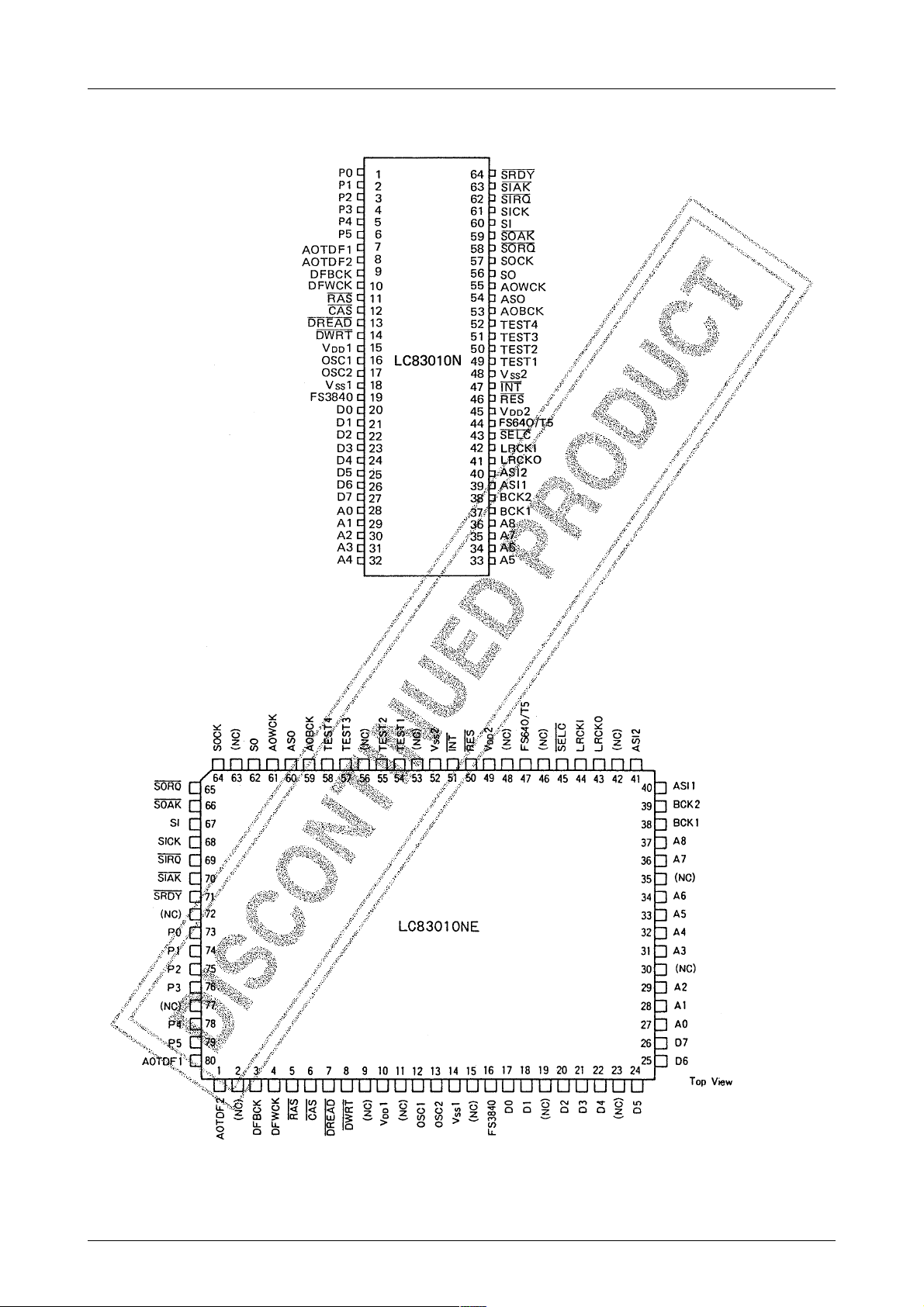

• Package : 64-pin DIPs (LC83010N).

80-pin QFPs (LC83010NE).

Note) When soldering QFP devices, do not use the solder

dip method.

• Evaluation chip : LC83EV010N (PGA100)

· Applications

· Graphic Equalizer

· Power calculation for spectrum analyzer display

· Sound field creation (using external DRAMs)

· 4 Speakers + REC output

Development Environment

• Software Tools

· Assembler

· Debugger with simulation

• Hardware Tools

· IBM PC-AT compatible machines or AX per sonal computers

· In Circuit Emulator (ICE)

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft’s

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges,or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

SANYO Electric Co.,Ltd. Semiconductor Company

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

O1001TN (KT)/N251JN KI No.3945–1/18

Page 2

Package Dimensions

unit:mm

3071-DIP64S

[LC83010N]

57.2

0.95 0.48 1.78 1.01

Block Diagram

LC83010N, 83010NE

unit:mm

3174-QIP80E

3364

16.8

19.05

5.0max

3.2

0.25

321

4.0

0.51min

SANYO : DIP64S

17.2

[LC83010NE]

23.2

0.8 0.8

1.0

64

65

0.8

14.0

80

1.6

124

0.35

20.0

21.6

1.6

0.15

41

40

25

3.0max

2.7

0.8

SANYO : QIP80E

15.6

0.8

No.3945–2/18

Page 3

Pin Assignments

(DIP64S)

LC83010N, 83010NE

(QIP80E)

Top view

No.3945–3/18

Page 4

Pin Function

emaNniPO/I noitpircseDlanoitcnuF

VDD2,1

VSS2,1

1ISA

2ISA

1KCB

2KCB

IKCRL

OKCRL

OSA

KCBOA

KCWOA

Audio I/F (Interface)

DRAM I/F

Microcomputer I/F

Control pins

1FDTOA

2FDTOA

KCBFD

KCWFD

SAR

SAC

DAERD

TRWD

8ot0A

7ot0D

IS

KCIS

QRIS

KAIS

YDRS

OS

KCOS

QROS

KAOS

5ot0PO/I)rotsiserpu-lluppihc-nohtiw(stroptuptuO/tupnIesoprup-lareneG

1CSO

2CSO

O483SFOniptuptuosf483

TNII )rotsiserpu-lluppihc-nohtiw(niptupnitseuqertpurretnI

SERI )rotsiserpu-lluppihc-nohtiw(niptupniteseR

CLESI

5T/O46SF

LC83010N, 83010NE

I

I

I

I

I

O/I

I

O

O

O

O

O

O

O

O

O

O

O

O

O

O/I

I

I

I

O

I

O

I

I

O

I

O

4ot1TSET

I

O

)tuptuo

1tupnilairesatadoiduA

2tupnilairesatadoiduA

atad1ISArofniptupnikcolctiB

)RCybelbatcelesO/I(atad2ISArofniptupnikcolctiB

tuptuolairesatadoiduA

)sf84dnasf23rof(atadOSArofniptuptuokcolctiB

atadOSArofniptuptuokcolcdroW

)1ecneserphgihrof(atadoiduarofniptuptuolaireS

)2ecneserphgihrof(atadoiduarofniptuptuolaireS

)sf84dnasf23rof(atad2FDTOAdna1FDTOArofniptuptuokcolctiB

atad2FDTOAdna1FDTOArofniptuptuokcolcdroW

sMARDlanretxeotlangisSARrofniptuptuO

sMARDlanretxeotlangisSACrofniptuptuO

sMARDlanretxeotlangisdaeratadrofniptuptuO

sMARDlanretxeotlangisetirwatadrofniptuptuO

K46(sMARDlanretxeotslangissserddarofsniptuptuO × K652,7Aot0A:stib4 × )8Aot0A:stib4

.desuera7Dot0Dsnip,edomnoitarugifnocMARDelbuodehtnI.desu

)atadlairestib-8(retupmocorcimlortnocmorfatadlairesrofniptupnI

atadISrofniptupnikcolclaireS

tupniatadlairesrofniptupnilangistseuqeR

)atadlairestib-8(retupmocorcimgnillortnocaotatadlairesrofniptuptuO

atadOSrofniptupnikcolclaireS

tuptuoatadlairesrofniptupnilangistseuqeR

.noitarepolamrongnirudsretrevnocD/Alanretxeroftuptuokcolc

).ecruosrewopevitisopehtotdetcennocebdluohssnipesehT(snipylppusrewopV5+

).leveldnuorgehtotdetcennocebdluohssnipesehT(snipylppusrewopDNG

)atadlennahcR:L;atadlennahcL:H(langishsiugnitsidlennahcR/LrofniptupnI

)atadlennahcR:L;atadlennahcL:H(langishsiugnitsidlennahcR/LrofniptupnI

era3Dot0Dsnip,edomnoitarugifnocMARDelgnisehtnI.sMARDlanretxehtiwrefsnartatadrofsniptuptuo/tupnI

retupmocorcimamorflangistseuqertupniehtotesnopseregdelwonkcArofniptuptuO

refsnartatadafodneehtgnitacidniretupmocorcimgnillortnocamorflangisydaeRarofniptupnI

retupmocorcimamorflangistseuqertuptuoehtotesnopseregdelwonkcArofniptuptuO

)sf483(.ecruoslanretxenamorftupnikcolcrofrorotallicsolatsyrcahtiwnoitcennocrofniP

)edomtupnikcolclanretxeninepotfelebdluohs(rotallicsolatsyrcahtiwnoitcennocrofniP

redividlanretni(lanretni:H,)IKCRL(lanretxe:L;rotsisernwod-lluppihc-nohtiwniptupnitceleslangislennahcR/L

.leveldnuorgehtotdetcennocebdluohssnipeseht,yllamroN.sniptupnilangistseT

sf46asadnaedomtsetnituptuotsetasasnoticnuf5T/O46SF.tuptuotset/tuptuokcolcsf46.sniptuptuolangistseT

No.3945–4/18

Page 5

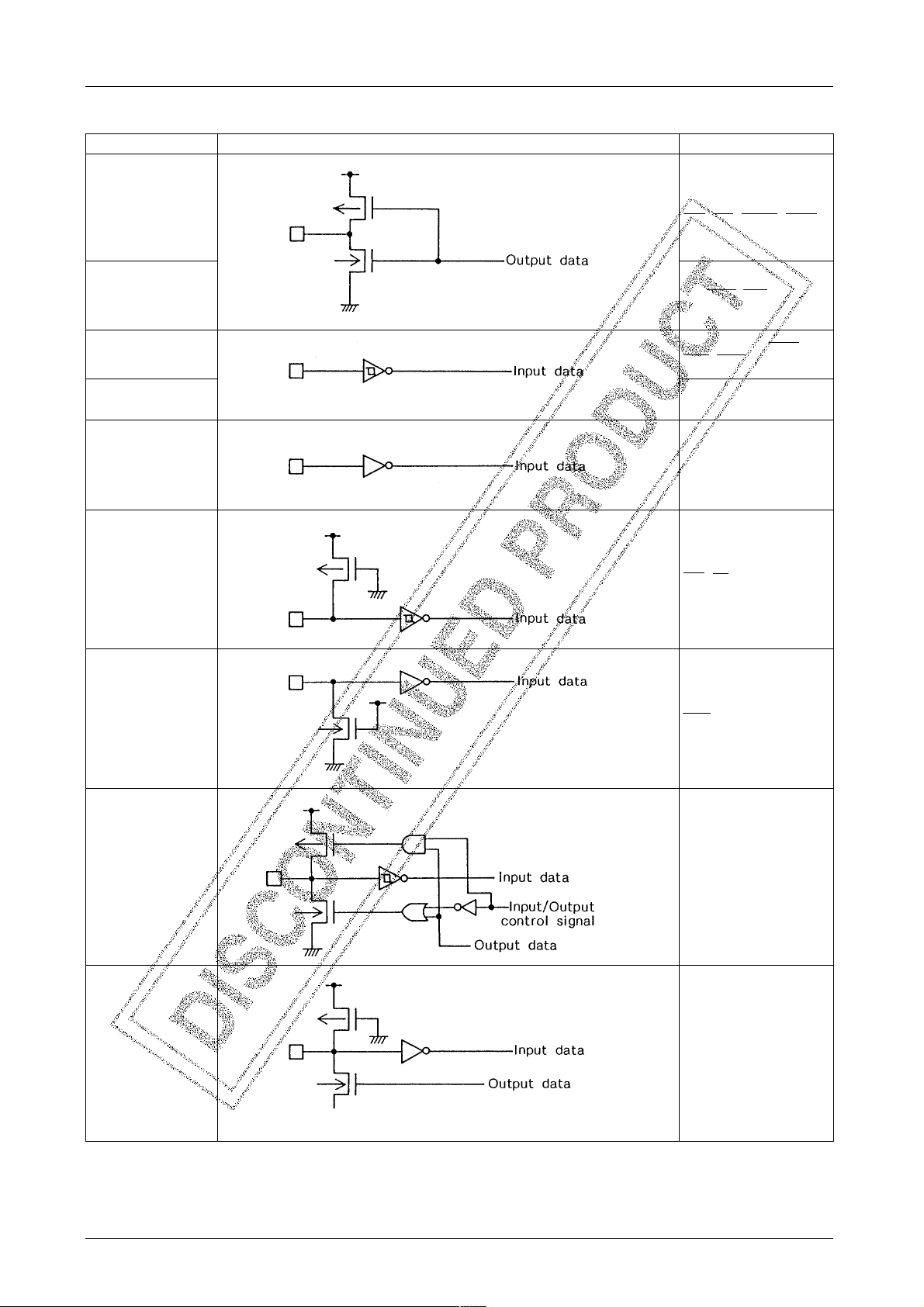

Pin Configuration Types

noitacificepsleveL epyttiucriCemaNniP

tuptuolevelLTT

LC83010N, 83010NE

,KCWOAKCBOA,OSA

,2FDTOA,1FDTOA,OKCRL

,O483SF,8Aot0A,KCWFD

5T/O46SF

,TRWD,DAERD,SAC,SAR

levelmuidemSOMC

tuptuotnerruc

tupnittimhcS

tupnittimhcSlevelL IKCRL,2ISA,1ISA,1KCB

tupnilamroN 4ot1TSET

rotsiser

rotsisernwod

pu-lluplanretnihtiwtupnI

-lluplanretnihtiwtupnI

KAIS,KAOS,OS

YDRS,QRIS

TNI,SER

CLES

,QROS,KCIS,IS,KCOS

tuptuolevelLTT

tupnittimhcSlevelwoL

tuptuo

tupnilamroN

tnerrucmuidemSOMuP

7Dot0D,2KCB

5Pot0P

No.3945–5/18

Page 6

LC83010N, 83010NE

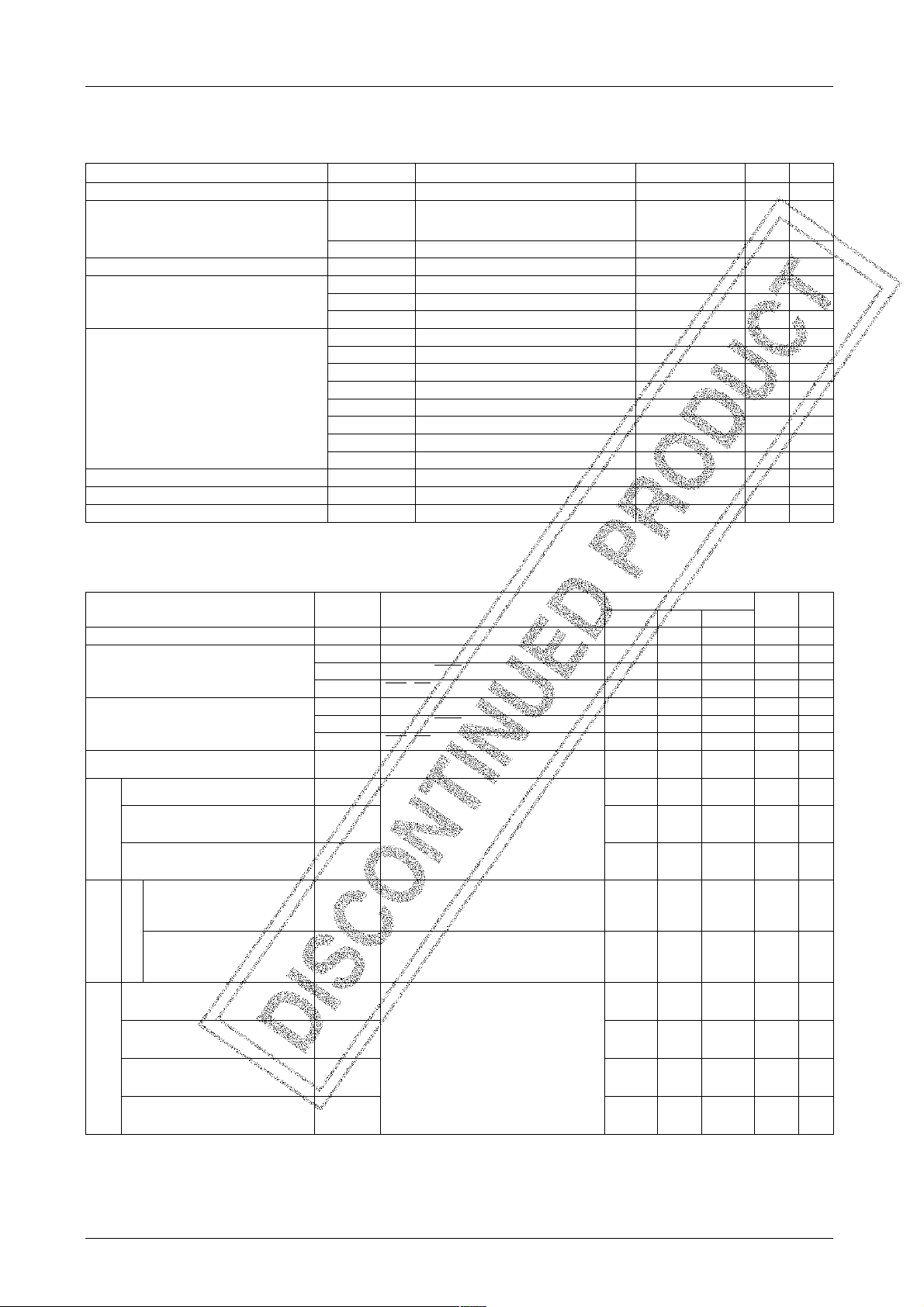

Specifications

Absolute Maximum Ratings at Ta = 25˚C, VSS = 0V

retemaraPlobmySsnoitidnoCsgnitaRtinUetoN

egatlovylppusmumixaMV

egatlovtuptuO

egatlovtupnIVNI– ot3.0VDD3.0+V

tnerructuptuokaeP

tnerructuptuoegarevA

noitapissidrewopelbawollAxamdP 006Wm

erutarepmetgnitarepOrpoT – 07+ot03

erutarepmetegarotSgtsT – 521+ot04

xam – 0.7+ot3.0V

DD

10Vtuptuo2CSO

20V2CSOehtroftpecxesniP – ot3.0VDD3.0+V

IPO1F/IMARD,F/IoiduA – 4+ot2Am1

IPO2F/IretupmocorciM – 01+ot2Am2

IPO35Pot0P – 01+ot5.0Am3

IAO1nipreP:F/IoiduA – 4+ot2Am4

IAO2nipreP:F/IMARD,F/IoiduA – 4+ot2Am5

IAO3nipreP:F/IretupmocorciM – 01+ot2Am2

IAO4nipreP:5Pot0P – 01+ot5.0Am3

∑IAO1

∑IAO2

∑IAO3

∑IAO4

Ta=–30 to +70˚C

egatlovehtotpU

ybdecudorp

noitallicso

latoT:F/IoiduA – 54+ot11Am4

latoT:F/IMARD,F/IoiduA – 51+ot4Am5

latoT:F/IretupmocorciM51+ot4Am2

latoT:5Pot0P – 03+ot3Am3

V

˚C

˚C

* When soldering QFP devices, do not use the solder dip method.

Allowable Operating Conditions at T a = –30 to +70˚C, V

retemaraPlobmySsnoitidnoC

External clock

input conditions

Self-oscillation

conditions

Crystal oscillation

egatlovylppusgnitarepOV

egatlovlevel-hgihtupnI

egatlovlevel-woltupnI

)emitelcycnoitcurtsnI(ycneuqerfgnitarepO

ycneuqerFf

htdiwesluP

emitesiR

emitllaF

ycneuqerfnoitallicsof

doirepgnizilbatsnoitallicsof

DD

VHI1F/IMARD,F/IoiduA4.2V6

VHI24ot1TSET,CLES,5Pot0PV7.0

VHI3F/IretupmocorciM,TNI,SER

VLI1F/IMARD,F/IoiduA 8.0V6

VLI24ot1TSET,CLES,5Pot0PV3.0

VLI3F/IretupmocorciM,TNI,SER

f

PO

)CYCT(

TXE

f

HTXE

f

LTXE

f

RTXE

f

FTXE

TXE

STXE

DD

zHk84:xam × 483 × 10.1

.1erugifeeS

.3erugifeeS sm

= 4.75V to 5.25V, VSS = 0V, unless otherwise noted

sgnitaR

nimpytxam

57.452.5V

DD

V57.0

DD

V52.0

.dewollasirorrenoitallicsoaltsyrc%1otpU

.nip1CSOehtotseilppA

)nepo:2CSO,tupni:1CSO(

.2erugifeeS,2CSO,1CSO 26.81zHM

71.21

)561(

71.2126.81zHM

02sn

V

V7

V

DD

V7

DD

26.81

sn)701(

01sn

tinUetoN

zHM

)sn(

emitputesataDt

Audio data input conditions

emitdlohataDt

elcyckcolctibrefsnarTt

htdiweslupkcolctibrefsnarTt

CYCB

WCB

.4erugifeeS

S

H

523sn

001sn

.snip2KCBdna1KCBehtotseilppA

57sn

57sn

Continued on next page.

No.3945–6/18

Page 7

Continued from preceding page.

retemaraPlobmySsnoitidnoC

elcyckcolclaireSt

LC83010N, 83010NE

CYCS

sgnitaR

nimpytxam

056sn

tinUetoN

Serial I/O clock conditions

DRAM input

conditions

htdiweslupkcolclaireSt

emitputesataDt

emitdlohataDt

emitputesataDt

emitdlohataDt

WCS

.5erugifeeS

SS

HS

SD

.6erugifeeS.MARD

HD

.ecafretniretupmocorcimehtotseilppA

).snipISdnaKCOS,KCISehtotseilppA(

lanretxemorftupniatadehtotseilppA

)7Dot0DdnaSAC,SARneewtebsgnimiT(

523sn

57sn

57sn

14sn8

0sn8

Electrical Characteristics at T a = –30 to +70˚C, VDD = 4.75V to 5.25 V, VSS = 0V, unless otherwise noted

sgnitaR

02sn

001sn

Audio data

output timing

retemaraPlobmySsnoitidnoC

tnerruclevel-woltupnI

tnerruclevel-hgihtupnIIHIrotsisernwod-lluphtiwniptupnI,CLES 052Aµ

egatlovlevel-hgihutptuO

egatlovlevel-woltuptuO

tnerrucegakaeltupnIV

tnerrucegakaelffo-tuptuOI

ecnaticapactuptuo/tupnI 01Fp

emitdlohatadtuptuOt

yaledatadtuptuOt

ILI1V,TNI,SER

ILI2V,5Pot0P

VHO1IHO=– Am4.00.4V1

VHO2IHO=– Aµ05

VLO1IHOAm2=4.0V 1

VLO2IHOAm01=5.1V 3,2

NI

VOV=

FFO

HO

DO

NIV=SS

NIV=SS

V=

V

otSS

DD

,SSVDD

.7erugifeeS

.tuptuoatadoiduaotseilppA

nimpytxam

– 052Aµ

–1Am

VDD– 2.1

– 0101+Aµ

– 0404+Aµ

tinUetoN

V3,2

.tuptuoatadlairesotseilppA

59sn8

051sn8

08sn8

101sn8

.MARDlanretxerofgnimittuptuoataD

wolebemitsseccaSARsahhcihwMARD

.desuebdluohssn021

kcolclanretxezHM26.81,2,105001Am

0sn8

02sn8

0sn8

04sn8

05sn8

0sn8

0sn8

05sn8

001sn

Microcomputer

I/F output delay

Access timings for external DRAM

niardtnerruCI

yaledatadtuptuOt

htdiweslupHSARt

htdiweslupLSARt

htdiweslupHSACt

htdiweslupLSACt

emitputessserddaSARt

emitdlohsserddaSARt

emitputessserddaSACt

emitdlohsserddaSACt

htdiweslupTRWDt

emitputesETIRW-erofeb-SACt

emitputesataDt

emitdlohataDt

noitallicsolatsyrC2C,1C.2erugifeeS,2CSO,1CSO02Fp

DS

PR

SAR

PC

SAC

SR

HR

SC

HC

W

CW

DS

DH

V

DD

.8erugifeeS

.9erugifeeS

)etoN(

DD

(Note 1) TTL level output pins: ASO, AOBCK, AOWCK, LRCK O, BCK2, AOTDF1, AOTDF2, DFBCK, DFWCK, D0 to

D7, A0 to A8, FS384O, RAS, CAS, DREAD, DWRT and FS64O/T5

(Note 2) CMOS medium current outputs: SO, SOAK, and SIAK

(Note 3) Pu MOS medium current outputs: P0 to P5

(Note 4) TTL level outputs (first group): ASO, AOBCK, AOWCK, LRCKO, A0 to A8, D0 to D7, FS384O and BCK2

(Note 5) TTL level outputs (second group): AOTDF1, AOTDF2, DFWCK, RAS, CAS, DREAD, DWRT, and DFBCK

(Note 6) L level Schmitt inputs pin: BCK1, BCK2, ASI1, ASI2, LRCKI, and D0 to D7

(Note 7) Schmitt input pins: RES, INT, SOCK, SI, SICK, SORQ, SIRQ, and SRDY

(Note 8) The maximum load capacitance of RAS, CAS, DREAD, DWRT, D0 to D7 and A0 to A8 is 50pF.

No.3945–7/18

Page 8

LC83010N, 83010NE

No.3945–8/18

Page 9

LC83010N, 83010NE

No.3945–9/18

Page 10

LC83010N, 83010NE

Program Load to The LC83010N

- Boot procedure -

2

Programs must be loaded (boot strap) into the LC83010N (D

its internal program memory consists of RAMs. The capacity of the program memory is 320 words × 32 bits.

The procedural flow to load a 320-word program into the D2SP from a controlling microcomputer is shown in Figure A-

1.

2

(1) Reset the entire system (microcomputer and D

SP) or reset the D2SP from the controlling microcomputer.

After the D2SP is reset, it then enters the Boot mode.

2

(2) Transfer the program to the D

SP from the microcomputer. The program is transferred to the D2SP in 8-bit synchro-

nous serial communication mode.

The program data of 8 bits × 16 data (equal to 4 instructions) is transferred to the D2SP continuously from the

microcomputer, and follo wed by the SRDY signal. The D2SP stores that program data of 4 instructions to the internal

mail box. The program data is then moved to the program RAM at the moment when the SRDY signal reaches the

2

SP.

D

(3) The operations discussed in (2) are repeated 80 times until the program data transfer of 320 instructions from the

2

microcomputer to the D

SP is complete.

(4) The D2SP automatically starts the program execution when the program loading of 320 instructions is complete.

The program is transferred to the D2SP from the microcomputer in that manner.

SP) from an external control unit (microcomputer) because

Figure A-1. Example Program Boot Flow (D2SP ← Microcomputer)

No.3945–10/18

Page 11

LC83010N, 83010NE

Figure A-2 gives the outline of an example program Boot system.

Figure A-2. Outline of an Example Program Boot System

Development Tool System

- Program development flow Development tools are provided to help the user to easily

2

develop application programs for the D

SP. These

development tools are divided into two groups: software

support tool group and hardware support tool group. The

software support tool group consists of an assembler,

debugger and simulator.

The hardware support tool group is realized as an InCircuit Emulator (ICE).

Figure A-3 shows the applications development flow for

2

SP system.

the D

(1) Write an application source program.

(2) Check the source program for syntax errors with the

assembler. If every syntax error is corrected, the

assembler generates a HEX program file.

(3) Check the HEX file for operational errors with the

simulator. If the desired operations are not successful,

start the debugger to find what caused logical errors.

(4) If program operations are checked successfully, use

the ICE to evaluate the audio signal output.

First, evaluate sound signals only with the ICE. In this

evaluation process, the delay memory and microcomputer of the ICE are used.

Second, start the total evaluation on an application

system. In this evaluation stage, the AD/DA converters, microcomputer, and delay memory on the user

application system are used.

Figure A-4 shows the entire program development

2

tool system for the D

SP.

The software tools such as the assembler, debugger,

simulator can be run on an IBM PC-AT compa tible

machine or an AX personal computer. The ICE is also

controlled by such a host personal computer.

Figure A-3. Applications Development Flow

No.3945–11/18

Page 12

LC83010N, 83010NE

Figure A-4. Entire Support Tool System for Microprogram Development

(1) Debugger

2

The debugger is a software support tool designed to realize virtual D

SP functional circuits. In this virtually

emulated D2SP environment, user application programs can be evaluated as if they were executed on the real chip.

The debugger is used mainly for logics analysis and detailed data analysis.

Major functions of the debugger are listed in the table below, with brief explanation for each.

· Display and Edit instructions

These instructions can be used to display the contents of memory and registers on a screen and to update them.

· Memory Fill instruction

This instruction is used to fill a specified memory address range with a desired value.

· Move instruction

This instruction is used to transfer the data in a specified memory address range to another range.

· Memory Load and Save instructions

These instructions are used to transfer data between memory and disk. The memory load instruction enables the

data transfer from a disk file to memory while the memory save instruction allows the data transfer from memory

to a disk file.

· Assemble and Unassemble instructions

The assemble instruction is used to convert mnemonics into machine codes.

The unassemble instruction is used to convert memory data back to mnemonics.

· Emulation instruction control instruction and Break point instruction

2

These instructions are used to execute the D

SP program and trace its operations. The break point instruction is

used to set a point where the program execution stops.

Table Major debugger functions

No.3945–12/18

Page 13

LC83010N, 83010NE

(2) Outline of the simulator functions

The application programs can be tested in the following sequence:

2

· Inputting digital audio signals to the D

· Executing a program,

· Converting the audio output into analog signals, and

· Measuring the analog signals with an oscilloscope or frequency characteristics meter (or sweep meter).

The simulator enables the above operations on a personal computer.

Figure A-5 shows the signal waveform measurement.

This simulator has the following three measurement functions:

1) Audio output waveforms (sine waves) with respect to audio input waveforms (sine waves)

2) Frequency characteristics of audio output (AOUT)

3) Impulse response characteristics of audio output

SP chip,

Figure A-5. Display of Various Waveforms

No.3945–13/18

Page 14

LC83010N, 83010NE

Figure A-6. Display of Frequency Characteristics

Figure A-7. Impulse Response Waveforms (Limit Cycle Characteristic)

No.3945–14/18

Page 15

LC83010N, 83010NE

(3) ICE outline

The In-Circuit Emulator (ICE) provides an operating environment where the application pr ogram already check ed by

the simulation debugger is executed and then outputs audio signals. T he ICE functions can be di vided into two: One is

the program evaluation by outputting audio signals only on the ICE. In this evaluation method, delay can be produced

by the DRAM in the ICE system. The other is the final program evaluation by connecting a user application board to

the ICE system. In this test method, the interfaces to the controlling microcomputer and other various peripheral ICs

on the application board can be evaluated. Figure A-8 shows the ICE system configuration for the entire evaluation

using a user application board.

Figure A-8. Final Evaluation System Configuration with an Application Board and ICE

ICE functions

· The ICE has debugging functions.

· The ICE consists of unique hardware functions specifically designed as the ICE for audio DSP.

(a) ICE debugging functions

(1) Execution command : Allows the program execution to continue until a break point is detected. It also enables

the program execution in the step mode or in the trace mode.

(2) Break function : Enables the user to set a desired break point.

(3) The edit dump command is useful in displaying the conditions of a specified memory area after the break of

program execution. The register edit command is used to convert the contents of a present specified register.

(4) The memory dump command is useful in displaying the contents of a specified memory area when the program

execution breaks. On the other hand, the edit command is used to edit the contents of a specified memory area

when the program execution breaks.

(5) Program modification and confirmation : Enables the user to modify part of the program and to check how it

works.

(6) Other functions : Memory management facility and so on. For details, refer the sections following section 8-3.

(b) Unique ICE hardware configuration

(1) Audio data input/output : Digital Interface Receiver (DIR).

This function allows direct input of audio digital data. Digital Interface Transmitter (DIT). This function allows

direct output of 3-channel digital audio data.

(2) DRAM : Delay DRAM for audio signal. 256k (64k × 4 bits) × 2. 1M (256k × 4 bits) × 2

(3) Evaluation function of serial input/output : Z80 microcomputer for evaluating serial input/output. This control

2

unit makes an access to the D

SP instead of any controlling microcomputer to adjust the serial input/output

operations.

No.3945–15/18

Page 16

Example Application System

LC83010N, 83010NE

No.3945–16/18

Page 17

Instruction Bit Map

The instruction bit map is shown below.

LC83010N, 83010NE

Instruction Bit Map Diagram

No.3945–17/18

Page 18

LC83010N, 83010NE

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer's

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer's products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

semiconductor products fail with some probability. It is possible that these probabilistic failures could

give rise to accidents or events that could endanger human lives, that could give rise to smoke or fire,

or that could cause damage to other property. When designing equipment, adopt safety measures so

that these kinds of accidents or events cannot occur. Such measures include but are not limited to protective

circuits and error prevention circuits for safe design, redundant design, and structural design.

In the event that any or all SANYO products(including technical data,services) described or

contained herein are controlled under any of applicable local export control laws and regulations,

such products must not be exported without obtaining the export license from the authorities

concerned in accordance with the above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or any information storage or retrieval system,

or otherwise, without the prior written permission of SANYO Electric Co. , Ltd.

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the "Delivery Specification"

for the SANYO product that you intend to use.

Information (including circuit diagrams and circuit parameters) herein is for example only ; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but

no guarantees are made or implied regarding its use or any infringements of intellectual property rights

or other rights of third parties.

This catalog provides information as of October, 2001. Specifications and information herein are subject

to change without notice.

PS No.3945–18/18

Loading...

Loading...