Page 1

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft’s

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges,or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

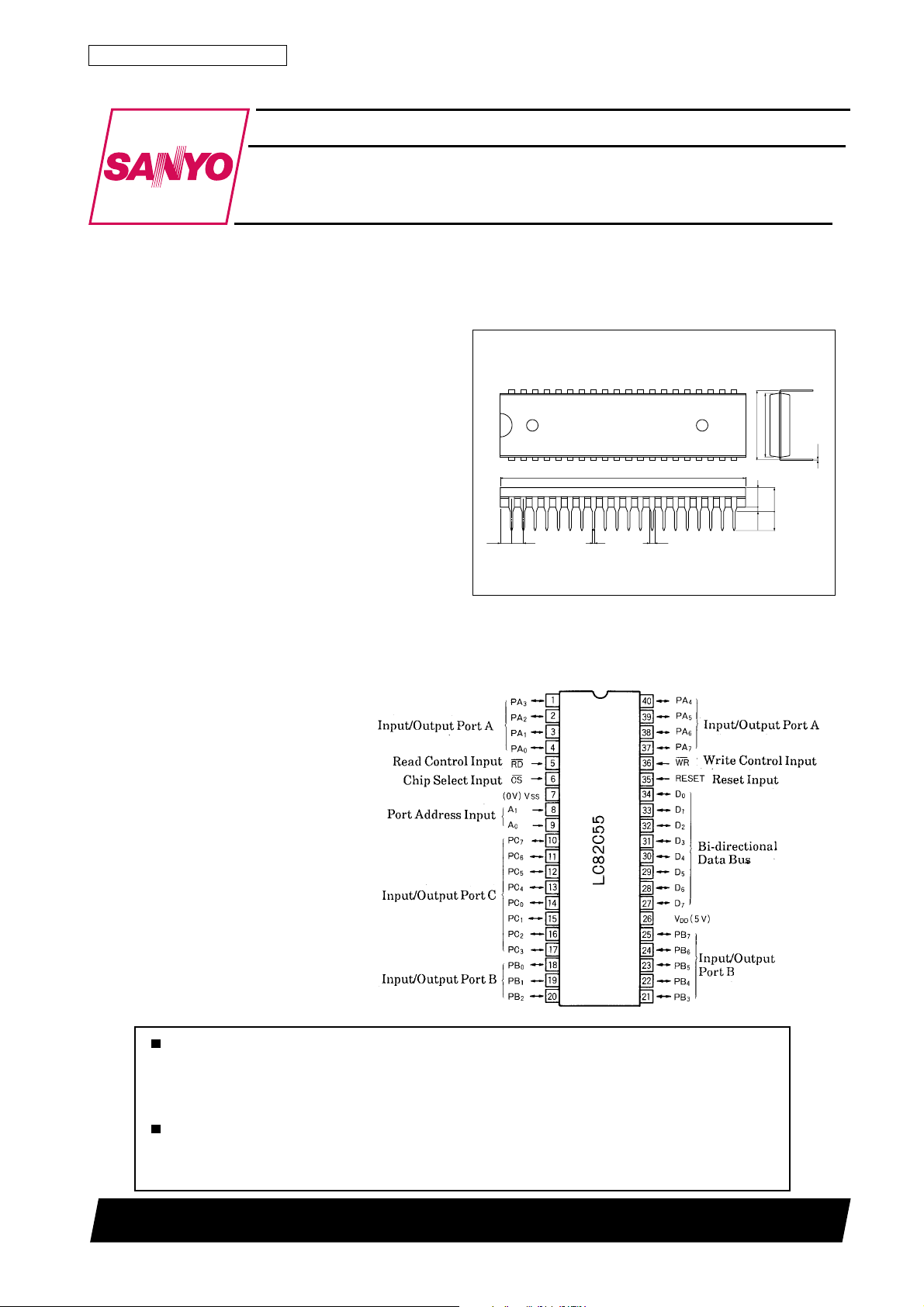

CMOS IC

Programmable Peripheral Interface

Ordering number:ENN2721

LC82C55

SANYO Electric Co.,Ltd. Semiconductor Company

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

Overview

The LC82C55 Programmable Peripheral Interface IC is a

pin-compatible CMOS version of the industry-standard

8255 device.

The 24 input/output pins may be programmed to operate in

3 different modes. Basic input/output, strobed input/output, and bi-directional input/output modes are available.

All inputs and outputs are fully TTL compatible, and the

device is easily interfaced to standard microprocessors.

The LC82C55 is fabricated using a Si-gate CMOS process

for low operating and standby power consumption.

The LC82C55 operates on a single 5V power supply and is

available in standard 40-pin plastic DIP packages.

Features

• 24 programmable input/output pins.

• Flexible input/output modes.

• Individual bit set/reset capability.

• Compatible with standard microprocessors.

• Zero wait-state operation with an 8MHz CPU. (TRD =

120ns)

• Fully TTL compatible IOL = 2.5mA.

• Low-power CMOS process.

• Single 5V power supply.

Package Dimensions

unit:mm

3013A-DIP40

[LC82C55]

40

1

2.47 2.54

Pin Assignment (Top view)

53.2

0.5

1.2

21

13.8

15.24

20

4.25

5.2max

4.1

0.51min

SANYO : DIP40

0.25

91001TN (KT)/4058TA,TS No.2721–1/16

Page 2

LC82C55

Specifications

Absolute Maximum Ratings at VSS = 0V

retemaraPlobmySsnoitidnoCsgnitaRtinU

egatlovylppusmumixaMV

egatlovtupnIV

noitapissidrewopelbawollAxamdP 1W

erutarepmetgnitarepOrpoT –57+ot02

erutarepmetegarotSgtsT –051+ot56

DC Recommended Operating Conditions at Ta = –20 to +75˚C, VSS = 0V

retemaraPlobmySsnoitidnoCsgnitaRtinU

egatlovylppuSV

egatlovlevel-woltupnIV

egatlovlevel-hgihtupnIV

Electrical Characteristics(1)

DC Characteristics at Ta = –20 to +75˚C, VDD = 5V ± 10%, VSS = 0V

retemaraPlobmySsnoitidnoC

egatlovlevel-woltuptuOV

egatlovlevel-hgihtuptuOV

tnerrucegakaeltupnII

tnerrucegakaeltaolftuptuOI

)noitarepolamroN(1niardtnerruCI

)edomyb-dnatS(2niardtnerruCI

ecnaticapactupnIC

ecnaticapacnipO/IC

xam –7+ot3.0V

DD

NI

DD

V

LI

V

HI

I

LO

LO

IHO=– Aµ0044.2V

HO

VNIV=

LI

V

LFO

1 01Am

DD

2 01Aµ

DD

NI

f

c

O/I

%01±V5=–8.0+ot3.0V

DD

%01±V5=ot0.2VDD3.0+V

DD

Am5.2= 54.0V

V0ot01±Aµ

DD

V=

TUO

V0ot01±Aµ

DD

–ot3.0VDD3.0+V

˚C

˚C

5.5ot5.4V

sgnitaR

nimpytxam

.V0tadlehsnipderusaemnu,zHM1=

tinU

01Fp

02Fp

Electrical Characteristics(2)

AC Characteristics at Ta = –20 to +75˚C, VDD = 5V ± 10%, VSS = 0V

retemaraPlobmySsnoitidnoC

])elcycdaer(gnimitsuB[

DRerofebelbatssserddA ↓ t

DRretfaelbatssserddA ↑ t

htdiweslupDRt

DRerofebdilavataD ↓ t

DRretfadilavataD ↑ t

evisseccusneewtebemiT

selcycetirw/daeR

])elcycetirw(gnimitsuB[

RWerofebelbatssserddA ↓ t

RWretfaelbatssserddA ↑ t

htdiweslupRWt

RWerofebdilavataD ↑ t

RWretfadilavataD ↑ t

evisseccusneewtebemiT

selcycetirw/daeR

]sgnimitsubrehtO[

RWretfatuptuO ↑ t

DRerofebdilavatadtroP ↓ t

DRretfadilavatadtroP ↑ t

htdiweslupKCAt

htdiweslupBTSt

BTSerofebdilavatadtroP ↓ t

BTSretfadilavatadtroP ↑ t

KCAretfatuptuO ↓ t

KCAretfataolftroP ↑ t

RA

AR

RR

C

DR

FD

t

VR

WA

AW

WW

WD

DW

t

VR

BW

RI

RH

KA

TS

SP

HP

DA

DK

Fp051= 021sn

L

C

C

C

C

R,Fp02=

L

L

L

L

k2= Ω 0158sn

L

Fp051= 053sn

Fp051= 003sn

R,Fp02=

k2= Ω 02052sn

L

sgnitaR

nimpytxam

0sn

0sn

061sn

002sn

0sn

0sn

021sn

001sn

0sn

002sn

0sn

0sn

003sn

053sn

0sn

051sn

Continued on next page.

tinU

No.2721–2/16

Page 3

Continued from preceding page.

retemaraPlobmySsnoitidnoC

RWretfa0=FBO ↑ t

KCAretfa1=FBO ↓ t

BTSretfa1=FBI ↓ t

DRretfa0=FBI ↑ t

DRretfa0=RTNI ↓ t

BTSretfa1=RTNI ↑ t

KCAretfa1=RTNI ↑ t

RWretfa0=RTNI ↓ t

AC Test Input Waveform

Input/Output Waveforms

Mode 0 (Basic Input Mode)

LC82C55

sgnitaR

nimpytxam

C

BOW

BOA

BIS

BIR

TIR

TIS

TIA

TIW

Fp051= 003sn

L

C

Fp051= 053sn

L

C

Fp051= 003sn

L

C

Fp051= 003sn

L

C

Fp051= 004sn

L

C

Fp051= 003sn

L

C

Fp051= 053sn

L

C

Fp051= 054sn

L

tinU

Mode 0 (Basic Output Mode)

Mode 1 (Strobed Input Mode)

No.2721–3/16

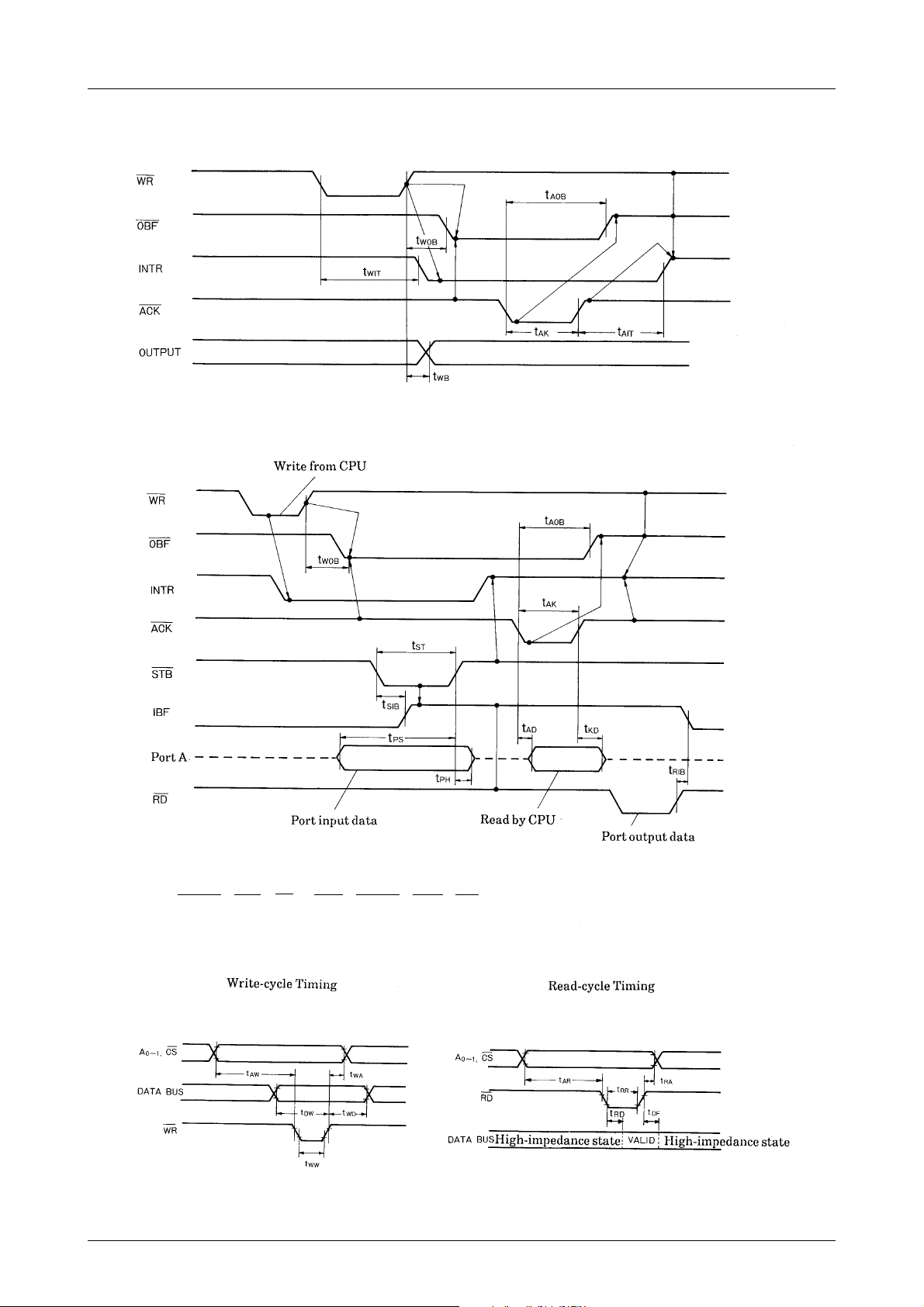

Page 4

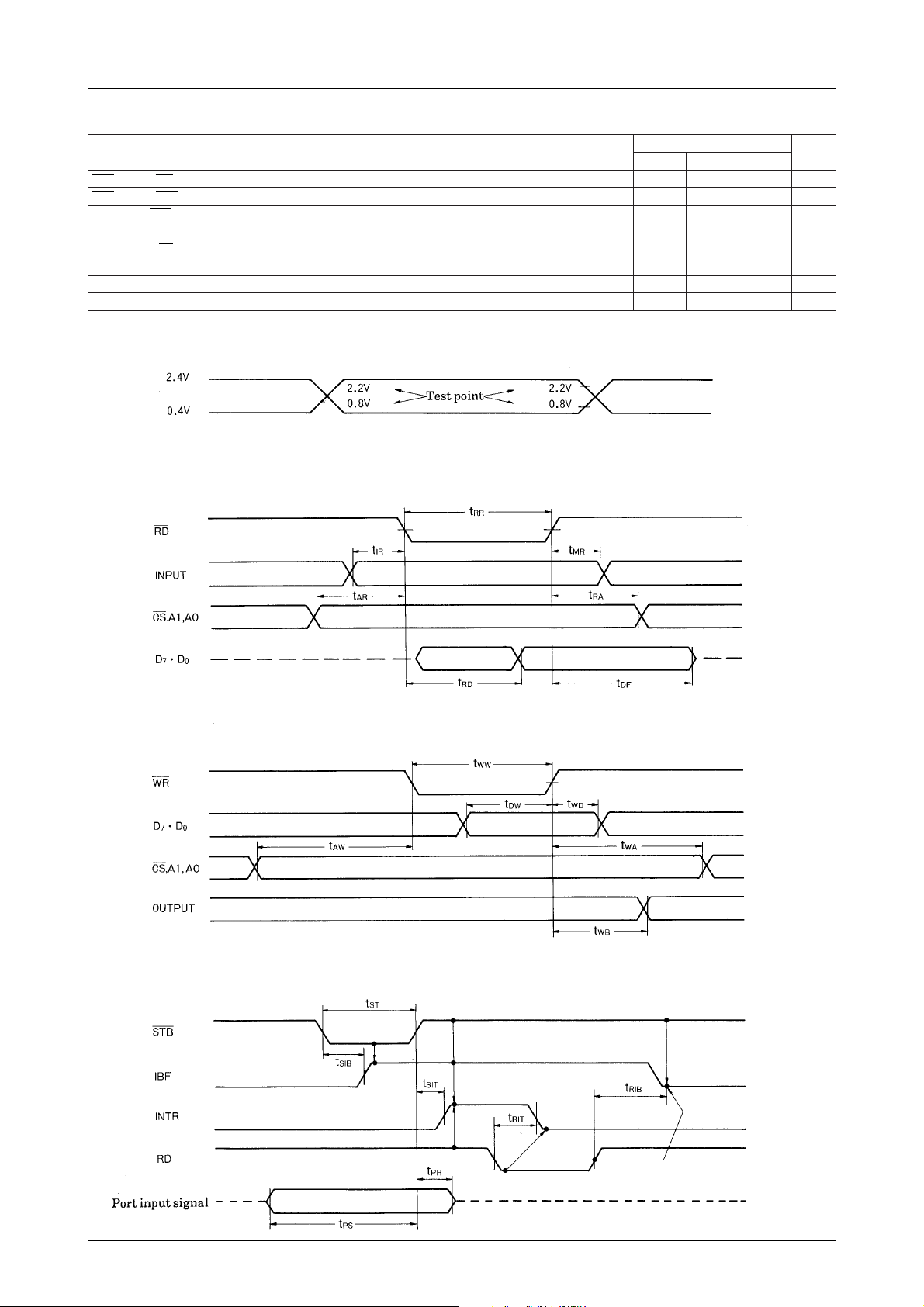

Mode 1 (Strobed Output Mode)

Mode 2 (Bi-directional Bus Mode)

LC82C55

Note

INTR = IBF · MASK · STB · RD + OBF · MASK · ACK · WR

No.2721–4/16

Page 5

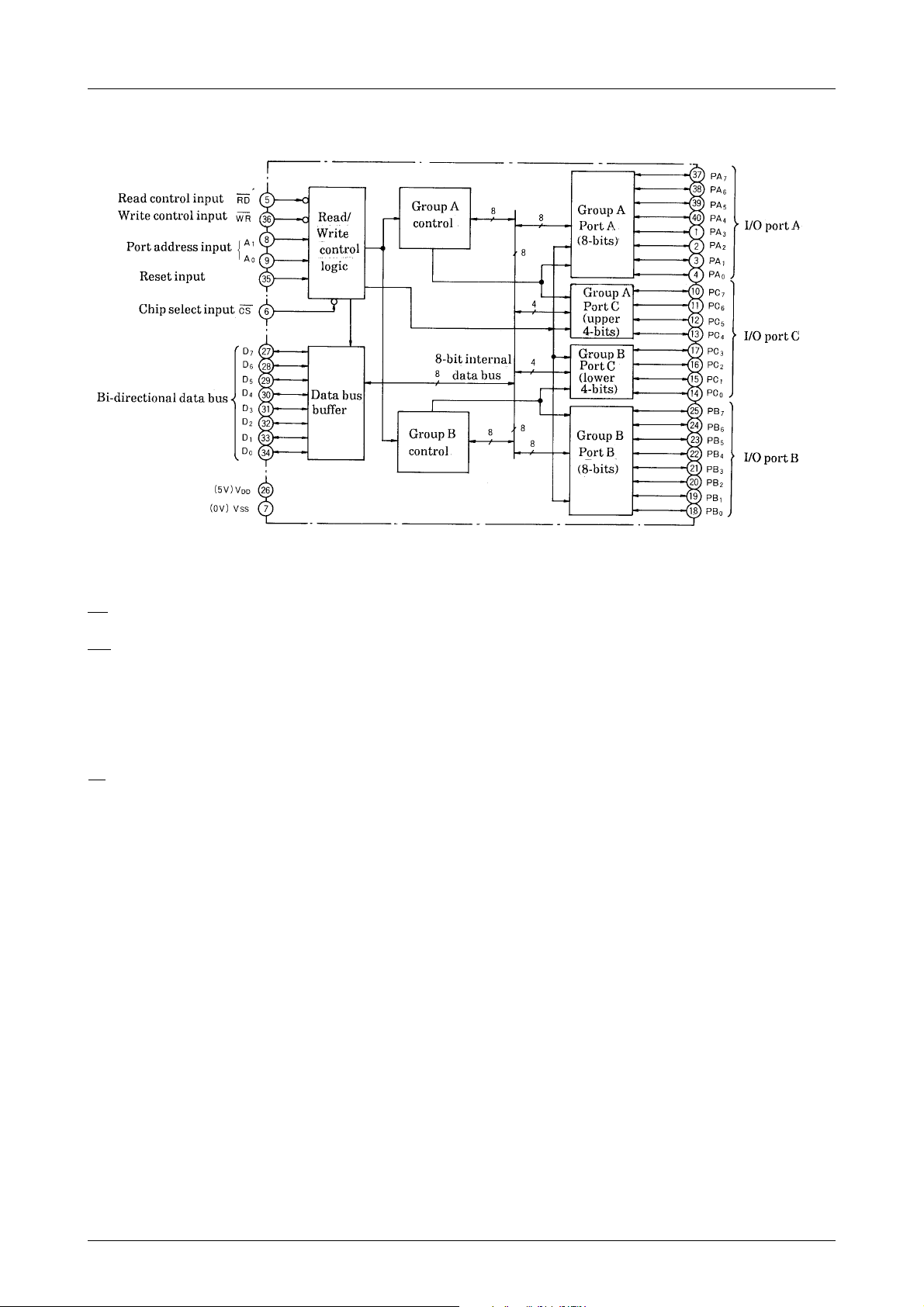

Block Diagram

LC82C55

Description of Operation

RD (read control input)

When Low, data or status word is transferred from the LC82C55 to the CPU via the data bus.

WR (write control input)

When Low, a data or control word is written from the CPU to the LC82C55.

A0, A1 (port address inputs)

Used to select Ports A, B and C, and the control register. Normally, the least significant 2 bits of the address bus are

connected to these pins.

RESET input

A High level on this input clears the control register. All ports are set to the input mode (high-impedance state).

CS (chip select input)

A Low level on this input enables communication between the LC82C55 and CPU . W hen High, the data b us remains in

the high-impedance state and control signals from the CPU are ignored.

Read/write control logic

This block performs the transfer of data and control words between the CPU and the internal circuitry. It receives data

via the CPU interface signals and data bus, and issues commands to the port control logic.

Data bus buffer

This 8-bit, tri-state, bi-directional bus buffer interfaces the external 8-bit data bus to the LC82C55. Data control, and

status information is transferred under the control of the CPU.

Group A/Group B control

Ports A, B and C are divided into the control Groups A and B, each with its own control circuitry. Group A consists of

Port A and the upper 4 bits of Port C; Group B consists of port B and the lower 4-bits of Port C.

The control register is write-only.

Ports A, B and C

The operating mode of each 8-bit port is set by the CPU system software. Port A has an output latch/b uffer and an input

latch.

Port B has an input/output latch/buffer and an input buffer.

Port C has an output latch buffer and input buffer, and can be divided into two 4-bit ports using mode control. Each 4bit port can be used as status and control signals for Ports A and B.

No.2721–5/16

Page 6

LC82C55

Table 1 Basic Operation

A

00001 subataD ← AtroP

01001 subataD ← BtroP

10001 subataD ← CtroP

00010 AtroP ← subataD

01010 BtroP ← subataD

10010 CtroP ← subataD

11010 retsigerlortnoC ← subataD

××

11001 noitarepolagellI

0 : Low-level

1 : High-level

Bit Set/Reset

When Port C is used as an output port, any individual bit can be set or reset with a single control word from the CPU.

This feature simplifies CPU control software in certain applications.

The bit/reset feature of Port C is also used to enable or disable the interrupt request signals from Ports A and B, when

these ports are operating in Modes 1 or 2.

A

1

0

SCDRRWnoitcnuF

1

××

etatsecnadepmi-hgihsisubataD

Figure 1. Port C Bit/Reset Control Word

Basic Operating Modes

The LC82C55 has three basic operating modes, selectable by control words from the CPU.

(1) Mode 0 : Basic input/output

(2) Mode 1 : Strobed input/output

(3) Mode 2 : Bi-directional bus

The operating modes for Groups A and B can be selected independently, however, Mode 2 operation can be selected

for Group A only.

Figure 2 shows the format of the mode selection control word.

No.2721–6/16

Page 7

LC82C55

Figure 2. Mode Set Control Word

1. Mode 0 (basic input/output mode)

Mode 0 is used for simple input/output operations for Ports A, B and C (Port C is used as two, 4-bit ports). There

are no control signals such as interrupt requests or handshaking.

Output data to a port is latched. Input data is not latched.

Each of the two, 8-bit ports and two, 4-bit ports can be used for either input or output.

The I/O configurations for Mode 0 are shown in Figure 3.

Figure 3. Mode 0 Port I/O Configurations

No.2721–7/16

Page 8

LC82C55

2. Mode 1 (strobed input/output mode)

Mode 1 can be selected independently for Groups A and B. Each group consists of an 8-bit data port and a 4-bit

control/data port.

Data is transferred to or from a Mode 1 port with strobes or handshaking signals. Ports A and B provide each

group’s I/O signals, and Port C provides these control signals. Both input and output data are latched.

Input Mode Control Signals

STB (strobe input)

When Low, the data present on the port input pins is loaded into the input latch, STB enables the data from a

peripheral device to be latched into the LC82C55 without CPU intervention.

IBF (input buffer full flag)

A High level on this output indicates that input data has been latched into the LC82C55. This flag is set on the

falling edge of STB and is reset on the rising edge of RD.

INTR (interrupt request output)

This active-high output can be used to interrupt the CPU when input data is strobed into the port. If the interrupt

enable flag, INTE is High, INTR is set on the rising edge of the STB input. INTR is reset on the falling edge of

the RD input.

INTEA and INTEB are set and reset using the bit set/reset capability of Port C. INTEA and INTEB correspond to

Bits 4 and 2, respectively (PC4 and PC2) for Mode 1 input.

Examples of Mode 1 input are shown in Figure 4. The timing waveforms are shown in Figure 5.

Figure 4. Mode 1 Input Configuration Figure 5. Mode 1 Input Timing

Output Mode Control Signals

OBF (output buffer full flag)

This active-low output indicates to a peripheral device that data is available in the port’s output buffer. It is set to

Low by the rising edge of the WR input, and is reset to High by the falling edge of the ACK input.

ACK (acknowledge input)

This active-low input indicates that the peripheral device has accepted data present on the port output.

INTR (interrupt request output)

This active-high output can be used to interrupt the processor when a peripheral devices accepts data from the

LC82C55.

INTR is set if INTE is High (active), and both OBF and ACK are High (inactive). It is reset on the falling edge of

WR.

INTEA and INTEB are set and reset using the bit set/reset capability of Port C. INTEA and INTEB correspond to

Bits 4 and 2, respectively (PC6 and PC2) for Mode 1 output.

Examples of the use of Port A and Port B for input/output in Mode 1 are shown in Figures 8 and 9.

No.2721–8/16

Page 9

LC82C55

Figure 6. Mode 1 Output Configuration Figure 7. Mode 1 Output Timing

Figure 8. Mode 1 Input/Output Example Figure 9. Mode 1 Input/Output Example

3. Mode 2 (strobed bi-directional bus)

Mode 2 provides a single 8-bit bi-directional bus. Handshaking and interrupt signals are available to control the

flow of data between the peripheral device and the LC82C55.

This mode can only be used for Group A. It uses an 8-bit bi-directional data port (Port A) and a 5-bit control port

(upper 5 bits of Port C). Inputs and outputs are both latched. The selection of Group B’s operating mode is independent of Group A’s operating mode.

Mode 2 Control Signals

OBF (output buffer full flag)

This active-low output signal indicates that the CPU has written data to the Port A output buffer.

ACK (acknowledge input)

The tri-state outputs are enabled while the ACK input is Low. When ACK is High, the output drivers are in the

high-impedance state.

STB (strobe input)

When Low, the data present on the Port A pins are loaded into the input latch.

IBF (input buffer full flag)

This active-high output indicates that data has been latched into the Port A input latch.

No.2721–9/16

Page 10

LC82C55

INTR (interrupt request output)

This active-high output signal can be used to interrupt the CPU on both input and output operations. Operation is

the same as in Mode 1.

There are two interrupt request control flags : INTE1 and INTE2.

INTE 1 is combined with OBF and ACKA, to generate an interrupt request on output data transfers. It is controlled

by bit set/reset of DC6.

INTE 2 is combined with IBF and STBA, to generate an interrupt request on input data transfers. It is controlled

by bit set/reset of DC4.

Figure 10. Mode 2 Timing Waveforms

Figure 11. Mode 2 Input/Output Configuration

4. Reading Control Signals

When any of the Port C pins are used as control signals, the CPU can read these signals from Port C. These signals

appear on the data bus as shown in Table 2. Note that the INTE flags are present in place of the STB and ACK

signals. Port C pins not used for control or status are used as normal input or output pins, in accordance with the

Port C input/output mode. Only those pins defined as Mode 0 outputs are affected by a write to Port C. Note that the

INTE flags can only be changed using the appropriate bit set/reset commands.

Table 2. Port Control Signals

ataD

D

edoM

tupni1edoMO/IO/IFBI

tuptuo1edoMFBO

2edoMFBO

7

A

A

D

6

ETNI

A

1ETNIFBI

D

5

A

O/IO/IRTNI

A

D

4

ETNI

A

2ETNIRTNI

D

3

RTNI

A

A

A

D

2

ETNI

B

ETNI

B

ETNI

B

D

FBI

FBO

1

B

B

etoNeeSRTNI

Note

IBFB for 1 input, OBFB for Mode 1 output.

D

0

RTNI

B

RTNI

B

B

No.2721–10/16

Page 11

LC82C55

5. Control Word Tables

Table 3, 4 and 5 summarize the mode definition control words for Modes 0, 1 and 2. Note that the operating modes

for both control groups can be set independently, however, these options have not been included in Tables 3 and 4.

Table 6 summarizes the bit set/reset control words.

Table 3. Mode 0 Control Words

droWlortnoCApuorGBpuorG

D7D6D5D4D3D2D1D

10000000 08TUOTUOTUOTUO

10000001 18TUOTUONITUO

10000010 28TUOTUOTUONI

10000011 38TUOTUONINI

10001000 88TUONITUOTUO

10001001 98TUONINITUO

10001010 A8TUONITUONI

10001011 B8TUONININI

10010000 09NITUOTUOTUO

10010001 19NITUONITUO

10010010 29NITUOTUONI

10010011 39NITUONINI

10011000 89NINITUOTUO

10011001 99NININITUO

10011010 A9NINITUONI

10011011 B9NINININI

0

-axeH

lamiced

AtroP

CtroP

)stib4reppU(

CtroP

)stib4rewoL(

BtroP

droWlortnoCApuorGBpuorG

D7D6D5D4D3D2D1D

10 100 10

10 100 11

10 10 110

10 10 111

10 110 10

10 110 11

1011110

1011111

droWlortnoCApuorGBpuorG

D7D6D5D4D3D2D1D

11

11

11

11

11

11

×××

×××

×××

×××

×××

×××

000 0C

001 1C

010 2C

011 3C

10

11

Table 4. Mode 1 Control Words

0

×

×

×

×

×

×

×

×

-axeH

lamiced

4A

5A

5A

7A

CA

DA

EA

FA

4B

5B

6B

7B

CB

DB

EB

FB

AtroP

CP

TUOFBO

TUOFBO

TUOFBO

TUOFBO

NITUOFBI

NITUOFBI

NINIFBI

NINIFBI

CP

7

6

KCA

A

KCA

A

KCA

A

KCA

A

CtroPCtroP

CP

CP

5

4

A

A

A

A

TUORTNI

TUORTNI

NIRTNI

NIRTNI

A

A

A

A

BTS

A

BTS

A

BTS

A

BTS

A

CP

CP

3

A

A

A

A

RTNI

A

RTNI

A

RTNI

A

RTNI

A

CP

2

KCA

B

BTS

B

KCA

B

BTS

B

KCA

B

BTS

B

KCA

B

BTS

B

CP

1

0

FBO

FBI

FBO

FBI

FBO

FBI

FBO

FBI

RTNI

B

RTNI

B

RTNI

B

RTNI

B

RTNI

B

RTNI

B

RTNI

B

RTNI

B

BtroP

TUO

B

NI

B

TUO

B

NI

B

TUO

B

NI

B

TUO

B

NI

B

Table 5. Mode 2 Control Words

0

×

×

-axeH

lamiced

4C

6C

AtroP

CP

CP

7

→←

→←

→←

→←

→←

→←

FBO

FBO

FBO

FBO

FBO

FBO

6

KCA

A

KCA

A

KCA

A

KCA

A

KCA

A

KCA

A

CtroPCtroP

CP

CP

5

FBI

A

FBI

A

FBI

A

FBI

A

FBI

A

FBI

A

4

BTS

A

A

A

A

A

A

A

BTS

A

BTS

A

BTS

A

BTS

A

BTS

A

CP

CP

CP

3

RTNI

RTNI

RTNI

RTNI

RTNI

RTNI

2

A

A

A

A

KCA

A

B

BTS

A

B

CP

1

NITUO

NINI

FBO

FBI

0

TUOTUO

TUONI

RTNI

B

RTNI

B

BtroP

TUO

B

NI

B

No.2721–11/16

Page 12

LC82C55

Table 6. Control Words for Port C Bit Set/Reset

droWlortnoCCtroP

D7D6D5D4D3D2D1D

×××

0

×××

0

×××

0

×××

0

×××

0

×××

0

×××

0

×××

0

×××

0

×××

0

×××

0

×××

0

×××

0

×××

0

×××

0

×××

0

0000 000

0001 101

0010 200

0011 301

0100 400

0101 501

0110 600

0111 701

1000 800

1001 901

10 10 A00

10 11 B01

1100 C00

1101 D01

1110 E00

1111 F01

0

-axeH

CP

7CP6CP5CP4CP3CP2CP1CP0

lamiced

Sample Application Circuit

1. Mode 0

A typical Mode 0 application circuit is shown in Figure 12. This circuit has 8 input pins and 16 output pins. The CPU

used is the 8085.

skrameR

ETNI:tupnI1edoM

B

ETNI:tuptuO1edoM

B

ETNI:tupnI1edoM

A

ETNI:2edoM

2

ETNI:2edoM

1

teser/tes

ETNI:tuptuO1edoM

A

teser/tes

teser/tes

teser/tes

teser/tes

teser/tes

Figure 12. Mode 0 Application Circuit

No.2721–12/16

Page 13

LC82C55

The control word for this particular input/output configuration is 10010000 (90H). The PPI is initialized by the

following 8085 instructions:

MVI A, 90H

OUT 03H

The instruction sequence for reading data from Port A and writing it to Ports B and C is as follows:

IN 00H Port

OUT 01H Register

OUT 02H Register

The following instruction sequence reads data from Port A, outputs it to Port B, and sets Bit 0 of Port C.

IN 00H Port

OUT 01H Register

MVI A, 01H Control

OUT 03H Output

2. Mode 1

A typical application circuit for Mode 1 is shown in Figure 13.

Figure 13. Mode 1 Application Circuit

The peripheral device can latch data into Port A using the input strobe signal STBA. The input buffer full flag IBFA is set

to High. If interrupt request generation has been enabled by setting the INTEA flag, an interrupt request is generated on

INTRA. For polled operation, the CPU can check the value of the IBFA flag by reading Port C of the LC82C55.

The following program examples demonstrate the use of the Mode 1 application circuit.

MVI A, B0H Control word 10110000. Port A set to input, Ports B and C set to output.

OUT 03H Output to control address

MVI A, 09H Set the INTE flag, 00001001.

OUT 03H Output to control address

EI Enable processor interrupts.

HALT Wait for input data.

When data is strobed into Port A by the STBA signal, the input data is latched into the Port A input buffer. The CPU

transfers control to the RST7.5 interrupt vector (003CH). A typical RST7.5 interrupt service routine is as follows:

ORG 003CH Location set to 003CH

003CH IN 00H Read Port A.

EI Enable Interrupts.

RET Return

No.2721–13/16

Page 14

LC82C55

3. Mode 2

A typical application circuit for Mode 2 is shown in Figure 14. This circuit demonstrates the use of a bi-directional

Mode 2 interface in a master/slave CPU system configuration.

Figure 14. Mode 2 Application Circuit

The LC82C55 is mapped into the I/O address space of the master CPU. The master CPU must initialize Group A to

Mode 2 operation.

The tri-state bi-direcitonal I/O pins of Port A are directly connected to the slave CPU data bus. Additional circuitry is

used to allow the slave CPU to read the LC82C55 IBFA (input buffer full) and OBFA (output buffer full) signals as

Bits 1 and 0 of I/O address 01H. Port A of the LC82C55 is located at I/O address 00H. A read by the slave CPU from

this address activates the ACKA input signal, and data is transferred from Port A to the slave CPU. A write activates

the STBA input signal, causing data from the slave CPU to be loaded into the input latch of Port A.

Both reads from and writes to the LC82C55 by the slave CPU can generate an interrupt to the master CPU via the

LC82C55 INTR output signal. These interrupts are enabled or disabled by setting the appropriate INTE1 and INTE2

flags using the Port C bit set/reset commands.

Data transfer from master CPU to slave CPU

• The slave CPU writes a byte of data to Port A of the LC82C55 (I/O address 00H). IBFA is set to High.

• The master CPU writes a byte of data to Port A of the LC82C55. The OBFA signal goes Low.

• The slave CPU polls the OBFA flag (Bit 0 of I/O address 01N). When OBFA is read as active, the slave CPU reads

the data byte from Port A (I/O address 00H). OBFA returns to High.

• The master CPU polls the status of the OBFA and IBFA flags by reading Port C of the LC82C55. It waits for a High

level on OBFA, indicating that the previous data byte has been read, before writing another byte. The IBFA flag

may also be checked at this time.

Data transfer from slave CPU to the master CPU

• The slave CPU writes a byte of data to Port A of the LC82C55 (I/O address 00H). IBFA is set to High.

• The master CPU checks the status of the IBFA flag by reading Port C of the LC82C55. If High, the master CPU

reads a byte of data from Port A. IBFA is reset to Low.

• The slave CPU polls the IBFA flag (Bit 1 of I/O address 01H). A Low level indicates that the previous data byte has

been read by the master CPU, and another byte can then be written.

The above data transfers operations have not used the INTR signal to interrupt the main CPU. If INTR is used,

polling of the OBFA and IBFA flags by the master CPU is not necessary.

Note that there are separate latches for input and output data. A complete data transfer in one direction does not have

to be completed before a transfer in the opposite direction is initiated.

No.2721–14/16

Page 15

Program examples for the master/slave CPU system.

LC82C55

(1) Master CPU program to transfer

data to the slave CPU.

(3) Slave CPU program to transfer

data to the master CPU.

(2) Master CPU program to receive

data from the slave CPU.

(4) Slave CPU program to receive

data from the master CPU.

4. PPI address decoding

Figures 15 and 16 give examples of address decoding for a system with multiple LC82C55s.

Figures 15 and 16 both perform the same function, since the 8-bit I/O address appears on both the upper and lower

halves of the 8085 address bus during an I/O operation. The example in Figure 15 de-multiplexes the lower half of

the address bus from the data bus, while the Figure 16 example uses the upper half of the address bus.

Figure 15. PPI Address Decoding (1)

Figure 16. PPI Address Decoding (2)

No.2721–15/16

Page 16

LC82C55

5. Initial state of PPI

The LC82C55 must be reset after power up, and the operating mode set. Figure 17 shows the power-up and initialization waveforms when the ports are set to output mode.

Figure 17. PPI Reset On Power-Up

Note

The power-up reset pulse must be at least 50µs long. Subsequent reset pulses must be at least 500ns long.

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer's

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer's products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

semiconductor products fail with some probability. It is possible that these probabilistic failures could

give rise to accidents or events that could endanger human lives, that could give rise to smoke or fire,

or that could cause damage to other property. When designing equipment, adopt safety measures so

that these kinds of accidents or events cannot occur. Such measures include but are not limited to protective

circuits and error prevention circuits for safe design, redundant design, and structural design.

In the event that any or all SANYO products(including technical data,services) described or

contained herein are controlled under any of applicable local export control laws and regulations,

such products must not be exported without obtaining the export license from the authorities

concerned in accordance with the above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or any information storage or retrieval system,

or otherwise, without the prior written permission of SANYO Electric Co. , Ltd.

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the "Delivery Specification"

for the SANYO product that you intend to use.

Information (including circuit diagrams and circuit parameters) herein is for example only ; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but

no guarantees are made or implied regarding its use or any infringements of intellectual property rights

or other rights of third parties.

This catalog provides information as of September, 2001. Specifications and information herein are

subject to change without notice.

PS No.2721–16/16

Loading...

Loading...