Page 1

Ordering number: EN 6157

Overview

The LC7940YC and LC7941YC are segment driver ICs

for driving large, dot–matrix LCD displays. They read 4

bit parallel or serial input, display data from a controller

into an 80–bit latch, and then generate LCD drive signals

corresponding to that data.

The LC7940YC and LC7941YC feature mirror–image pin

assignments, allowing them to be used together to increase

component density. They are designed to be used with the

LC7942YC common driver to drive large LCD panels.

CMOS IC

LC7940YC,7941YC

Dot-matrix LCD Drivers

–

Features

• 80 built–in LCD display drive circuits

• 1/8 to l/128 display duty cycle

• Serial or 4–bit parallel data input

• Chip disable for low power dissipation for large–sized

panels

• Bias supply voltags can be supplied externally

• Operating supply voltage and ambient temperature

- 2.7 to 5.5 V logic supply ( VDD) at Ta = –20 to +85°C

- 8 to 20V LCD supply (V

–

VEE ) at Ta = –20 to

DD

+85 °C

• CMOS process

Specifications

The following electrical characteristics apply when sealed in a Sanyo standard QIC-100 package.

Absolute Maximum Ratings at Ta = 25 ± 2°C, V

Parameter Symbol Ratings Unit

Logic supply voltge VDD max –0.3 to +7.0

LCD supply voltage, See Note below. VDD – VEE max 0 to 22

Input voltage VI max –0.3 to VDD + 03

SS

= 0 V

V

V

°C

■ Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft’s

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

■ SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges, or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

SANYO Electric Co., Ltd. Semiconductor Company

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

63099RM (ID) No. 6157—1/13

Page 2

Parameter Symbol Ratings Unit

Operating temperature range

Storage temperature range

Note

V

≥ V1 > V3 > V4 > V

DD

EE

LC7940YC, LC7941YC

T

opr

T

stg

–20 to +85

–40 to +125

°C

°C

Recommended Operating Condltions at Ta =

Parameter Symbol Conditions

Logic supply voltage V

LCD supply voltage VDD – V

HIGH–level input voltage V

LOW–level inpvt voltage V

CP shift clock frequency f

CP pulsewidth t

LOAD pulsewidth t

DIn and SDI to CP setup time t

DIn and SDI to CP hold time t

CP to LOAD time

LOAD to CP time t

CP rise time t

CP fall time t

LOAD rise time t

LOAD fall time t

DD

IH

IL

CP

WC

WL

SETUP

HOLD

t

CL1

t

CL2

LC

R

F

RL

FL

EE

See Notes 1 and 2. 8 – 20

CP, CDl, DI1 to DI3, M,

SDl, P/S, DISPOFF and

LOAD

CP, CDI, Dl1 to DI3, M,

SDl, P/S,DISPOFF and

LOAD

–

20 to + 85°C, V

= 0V

SS

Ratings

min typ max

2.7 – 5.5

Unit

V

V

0.8V

DD

– – 0.2V

100––

100––

80––

80––

0––

100––

100––

––50

––50

––50

––50

––

DD

–3.3

V

V

MHz

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

Notes

1. V

≥ Vl > V3 > V4 > V

DD

EE

2. At turn ON, the LCD supply should be energized after or simultaneously with the logic supply. At turn OFF, the logic supply

should be cut after or simultaneously with the LCD supply.

Electrlcai Characterfstlcs at Ta = 25 ± 2°C,V

Parameter Symbol Conditions

HIGH–level input current I

LOW–level input current I

CDO HIGH–level output voltage V

CDO LOW–levef output voltage V

O1 to O80 driver ON resistance RON

IH

IL

OH

OL

= 0V, VDD = 2.7 to 5.5 V

SS

Ratings

min typ max

VIN =VDD; LOAD, CP, CDI,

P/S, DI1 to DI3, SDl, M,

––1

and DISPOFF

VIN = VSS; LOAD, CP,

CDl, P/S, DI1 to DI3, SDI,

–––1

M, and DISPOFF

IOH = –400 µA VDD – 0.4 – –

IOL = 400 µA – – 0.4

VDD – VEE = 18 V,

|VDE – VO|= 0.25 V.

–24

See note

Unit

µA

µA

V

V

kΩ

No. 6157—2/13

Page 3

LC7940YC, LC7941YC

Parameter Symbol Conditions

CDI = VDD,

VDD to VSS standby supply current I

ST

VDD – VEE = 18 V,

fCP = 3.3 MHz,

no output load ; V

SS

VDD – VEE = 18 V,

VDD to Vss operating supply current I

SS

fCP = 3.3 MHz,

I

= 5.156 kHz,

LOAD

fM = 52 Hz ;VSS

VDD – VEE = 18V,

VDD to VEE operating supply current I

CP input capacitance C

EE

I

fCP = 3.3 MHz,

f

= 5,156 kHz,

LOAD

= 52 Hz ; V

f

M

EE

fCP = 3.3 MHz ; CP – 5 –

Note

V

= V1 or V3, or V4 or VEE, V1 = VDD, V3 = 9/11 × (VDD – VEE), V4 = 2/11 × (VDD – VEE)

DE

Switching Characteristics at Ta = 25 ± 2°C,V

Parameter Symbol Conditions

CDO output delay time t

D

= 0V, VDD = 2.7 to 5.5 V

SS

CL = 30 pF – – 200

Ratings

min typ max

– – 200

––1.0

––0.1

Ratings

min typ max

Unit

µA

mA

mA

pF

Unit

ns

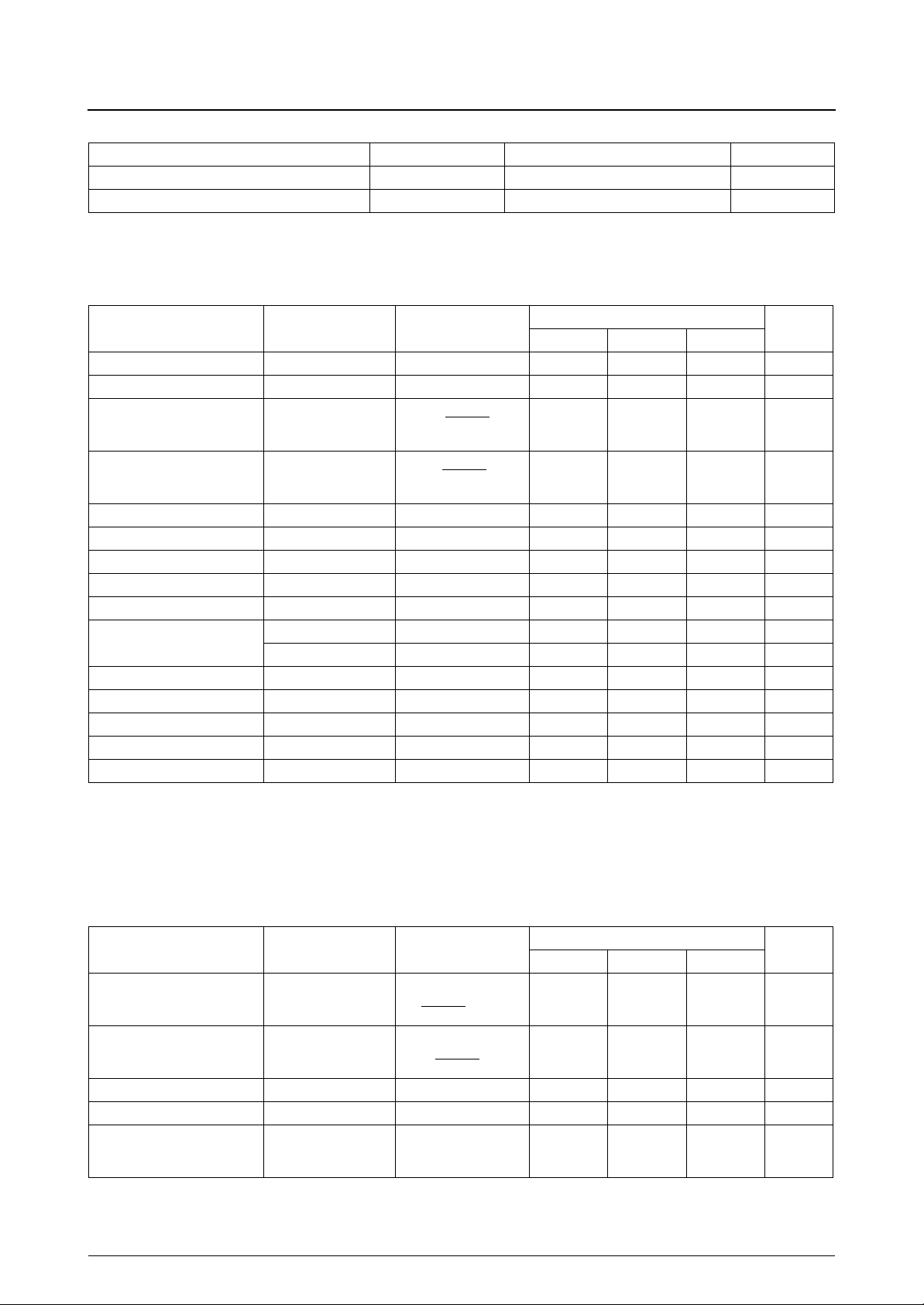

Switching Characteristics Waveform

t

t

CP

SDI

DI1 to 3

LOAD

CDO

WC

R

t

t

CL (1)

SET

UP

t

t

t

RL

WC

F

t

HOLD

t

CL (2)

t

WL

t

D

t

FL

0.8V

DD

0.2VDD

t

LC

t

D

No. 6157—3/13

Page 4

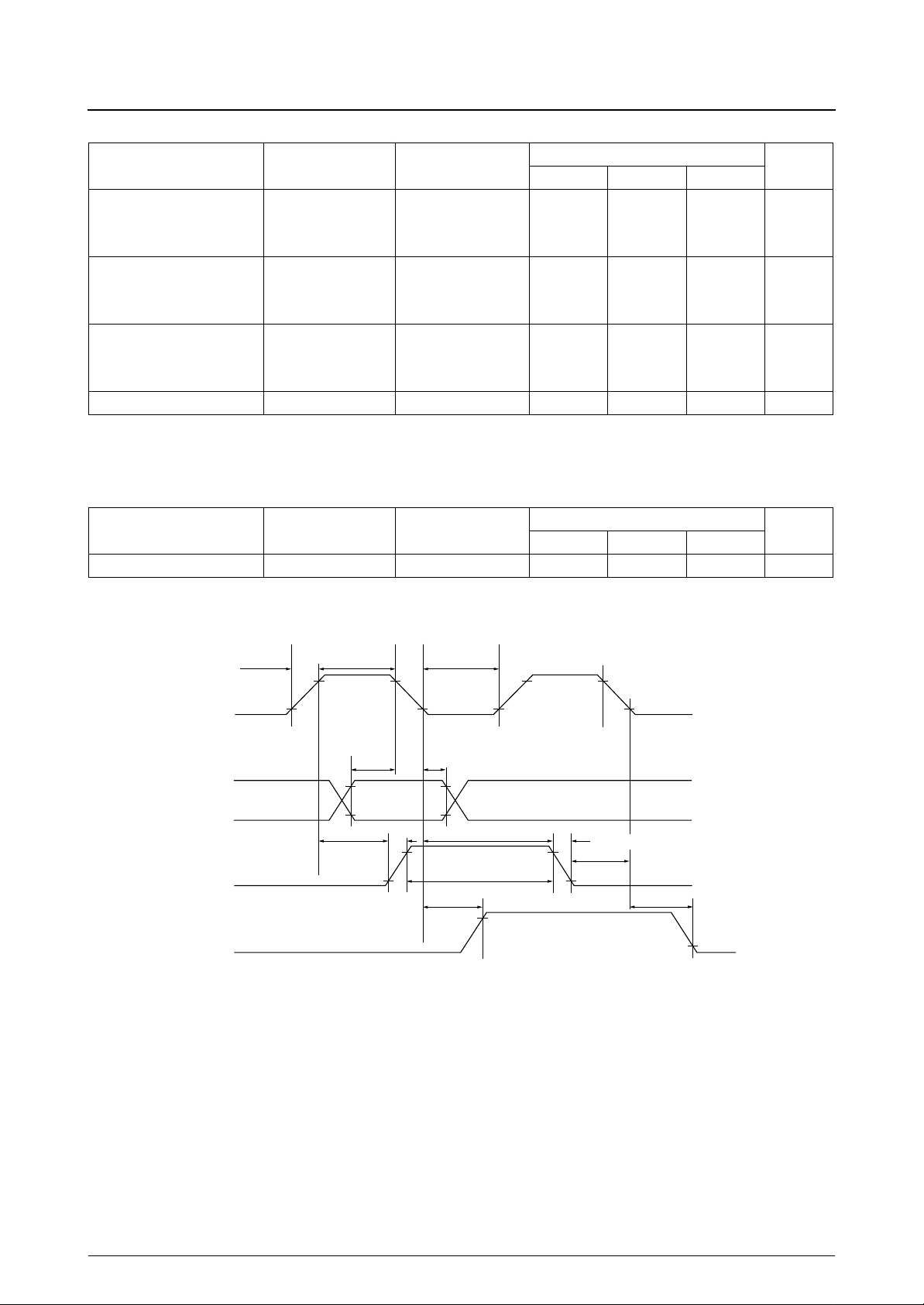

Pad Layout (Top view)

O1

O2

O3

O4

O5

O6

O7

O8

O9

O10

O11

O12

O13

O14

O15

O16

O17

O18

O19

O20

O21

O22

O23

O24

O25

O26

O27

O28

O29

O30

CP

O31

CDI

O32

LOAD

O33

LC7940YC, LC7941YC

SDI

DI3

DI2

DI1

M

V1

LC7940YC

O34

O35

O36

O37

O38

O39

O40

VDDV3V4

O41

O42

O43

O44

VEE

O45

VSS

O46

O47

P/S

DISPOFF

O48

O49

CDO

O50

O80

O79

O78

O77

O76

O75

O74

O73

O72

O71

O70

O69

O68

O67

O66

O65

O64

O63

O62

O61

O60

O59

O58

O57

O56

O55

O54

O53

O52

O51

O80

O79

O78

O77

O76

O75

O74

O73

O72

O71

O70

O69

O68

O67

O66

O65

O64

O63

O62

O61

O60

O59

O58

O57

O56

O55

O54

O53

O52

O51

CDO

DISPOFF

O50

O49

P/S

O48

O47

VSS

VEEV4V3

O46

O45

VDD

LC7941YC

O44

O43

O42

O41

V1

O40

O39

M

O38

DI1

O37

DI2

O36

DI3

O35

SDI

O34

LOAD

O33

CDI

O32

CP

O31

O1

O2

O3

O4

O5

O6

O7

O8

O9

O10

O11

O12

O13

O14

O15

O16

O17

O18

O19

O20

O21

O22

O23

O24

O25

O26

O27

O28

O29

O30

No. 6157—4/13

Page 5

LC7940YC, LC7941YC

LC7940YC Pad Location

chip size : 4.830 mm x 3.550 mm

Pin_No. Name X Y Pin_No. Name X Y

1 O1 -1600 2240 51 O51 1600 -2240

2 O2 -1600 2072 52 O52 1600 -2072

3 O3 -1600 1906 53 O53 1600 -1906

4 O4 -1600 1742 54 O54 1600 -1742

5 O5 -1600 1580 55 O55 1600 -1580

6 O6 -1600 1420 56 O56 1600 -1420

7 O7 -1600 1262 57 O57 1600 -1262

8 O8 -1600 1106 58 O58 1600 -1106

9 O9 -1600 952 59 O59 1600 -952

10 O10 -1600 800 60 O60 1600 -800

11 O11 -1600 650 61 O61 1600 -650

12 O12 -1600 502 62 O62 1600 -502

13 O13 -1600 356 63 O63 1600 -356

14 O14 -1600 212 64 O64 1600 -212

15 O15 -1600 70 65 O65 1600 -70

16 O16 -1600 -70 66 O66 1600 70

17 O17 -1600 -212 67 O67 1600 212

18 O18 -1600 -356 68 O68 1600 356

19 O19 -1600 -502 69 O69 1600 502

20 O20 -1600 -650 70 O70 1600 650

21 O21 -1600 -800 71 071 1600 800

22 O22 -1600 -952 72 O72 1600 952

23 O23 -1600 -1106 73 O73 1600 1106

24 O24 -1600 -1262 74 O74 1600 1262

25 O25 -1600 -1420 75 O75 1600 1420

26 O26 -1600 -1580 76 O76 1600 1580

27 O27 -1600 -1742 77 O77 1600 1742

28 O28 -1600 -1906 78 O78 1600 1906

29 O29 -1600 -2072 79 O79 1600 2072

30 O30 -1600 -2240 80 O80 1600 2240

31 O31 -1420 -2240 81 --- --- --32 O32 -1262 -2240 82 CDO 1415 2240

33 O33 -1106 -2240 83 --- --- --34 O34 -952 -2240 84 DISPOFF

35 O35 -800 -2240 85 P/S 1091 2240

36 O36 -650 -2240 86 V

37 O37 -502 -2240 87 V

38 O38 -356 -2240 88 V

39 O39 -212 -2240 89 V

SS

EE

4

3

40 O40 -70 -2240 90 --- --- --41 O41 70 -2240 91 V

42 O42 212 -2240 92 V

DD

1

43 O43 356 -2240 93 M -316 2240

44 O44 502 -2240 94 DI1 -467 2240

45 O45 650 -2240 95 DI2 -620 2240

46 O46 800 -2240 96 DI3 -775 2240

47 O47 952 -2240 97 SDI -932 2240

48 O48 1106 -2240 98 LOAD -1091 2240

49 O49 1262 -2240 99 CDI -1252 2240

50 O50 1420 -2240 100 CP -1415 2240

1252 2240

825 2179

629 2179

464 2179

299 2179

123 2179

-42 2179

No. 6157—5/13

Page 6

LC7940YC, LC7941YC

LC7941C Pad Location

chip size : 4.830 mm x 3.550 mm

Pin No. Name X Y Pin No. Name X Y

1 O80 -1600 2240 51 O30 1600 -2240

2 O79 -1600 2072 52 O29 1600 -2072

3 O78 -1600 1906 53 O28 1600 -1906

4 O77 -1600 1742 54 O27 1600 -1742

5 O76 -1600 1580 55 O26 1600 -1580

6 O75 -1600 1420 56 O25 1600 -1420

7 O74 -1600 1262 57 O24 1600 -1262

8 O73 -1600 1106 58 O23 1600 -1106

9 O72 -1600 952 59 O22 1600 -952

10 O71 -1600 800 60 O21 1600 -800

11 O70 -1600 650 61 O20 1600 -650

12 O69 -1600 502 62 O19 1600 -502

13 O68 -1600 356 63 O18 1600 -356

14 O67 -1600 212 64 O17 1600 -212

15 O66 -1600 70 65 O16 1600 -70

16 O65 -1600 -70 66 O15 1600 70

17 O64 -1600 -212 67 O14 1600 212

18 O63 -1600 -356 68 O13 1600 356

19 O62 -1600 -502 69 O12 1600 502

20 O61 -1600 -650 70 O11 1600 650

21 O60 -1600 -800 71 O10 1600 800

22 O59 -1600 -952 72 O9 1600 952

23 O58 -1600 -1106 73 O8 1600 1106

24 O57 -1600 -1262 74 O7 1600 1262

25 O56 -1600 -1420 75 O6 1600 1420

26 O55 -1600 -1580 76 O5 1600 1580

27 O54 -1600 -1742 77 O4 1600 1742

28 O53 -1600 -1906 78 O3 1600 1906

29 O52 -1600 -2072 79 O2 1600 2072

30 O51 -1600 -2240 80 O1 1600 2240

31 O50 -1420 -2240 81 CP 1415 2240

32 O49 -1262 -2240 82 CDI 1252 2240

33 O48 -1106 -2240 83 LOAD 1091 2240

34 O47 -952 -2240 84 SDI 932 2240

35 O46 -800 -2240 85 DI3 775 2240

36 O45 -650 -2240 86 DI2 620 2240

37 O44 -502 -2240 87 DI1 467 2240

38 O43 -356 -2240 88 M 316 2240

39 O42 -212 -2240 89 V

40 O41 -70 -2240 90 V

1

DD

41 O40 70 -2240 91 --- --- --42 O39 212 -2240 92 V

43 O38 356 -2240 93 V

44 O37 502 -2240 94 V

45 O36 650 -2240 95 V

3

4

EE

SS

46 O35 800 -2240 96 P/S -1091 2240

47 O34 952 -2240 97 DISPOFF -1252 2240

48 O33 1106 -2240 98 --- --- --49 O32 1262 -2240 99 CDO -1415 2240

50 O31 1420 -2240 100 --- --- ---

42 2179

-123 2179

-299 2179

-464 2179

-629 2179

-825 2179

No. 6157—6/13

Page 7

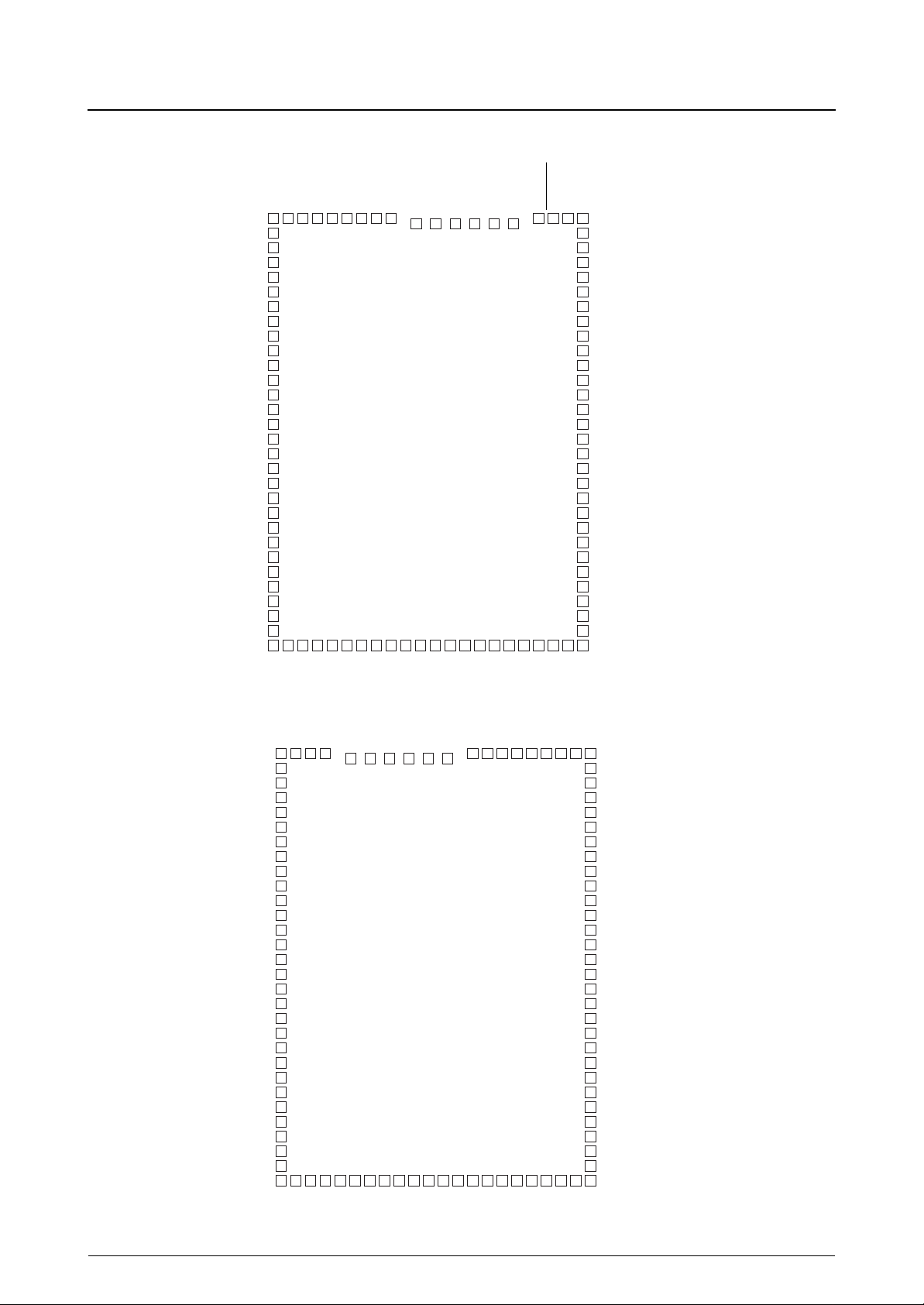

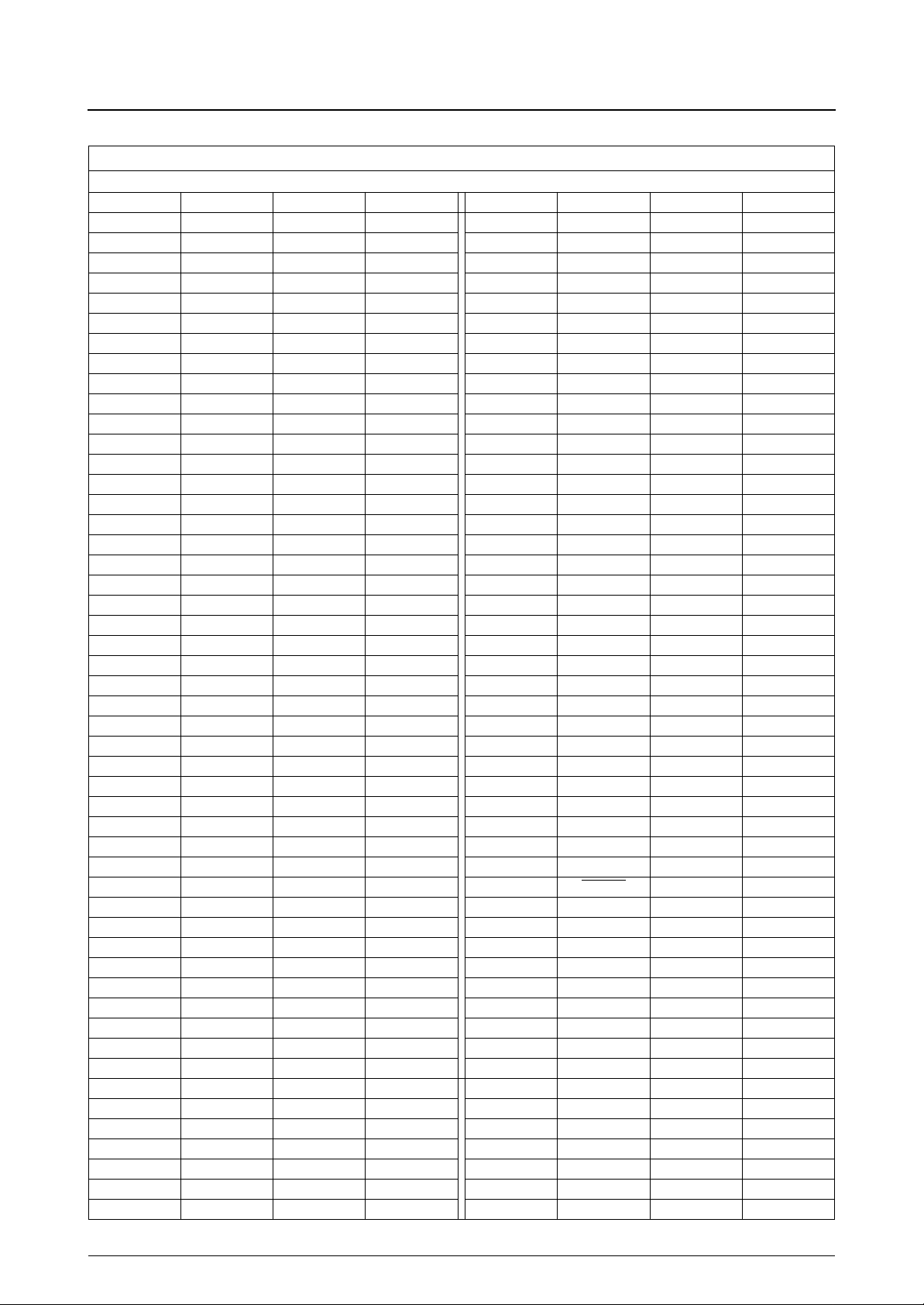

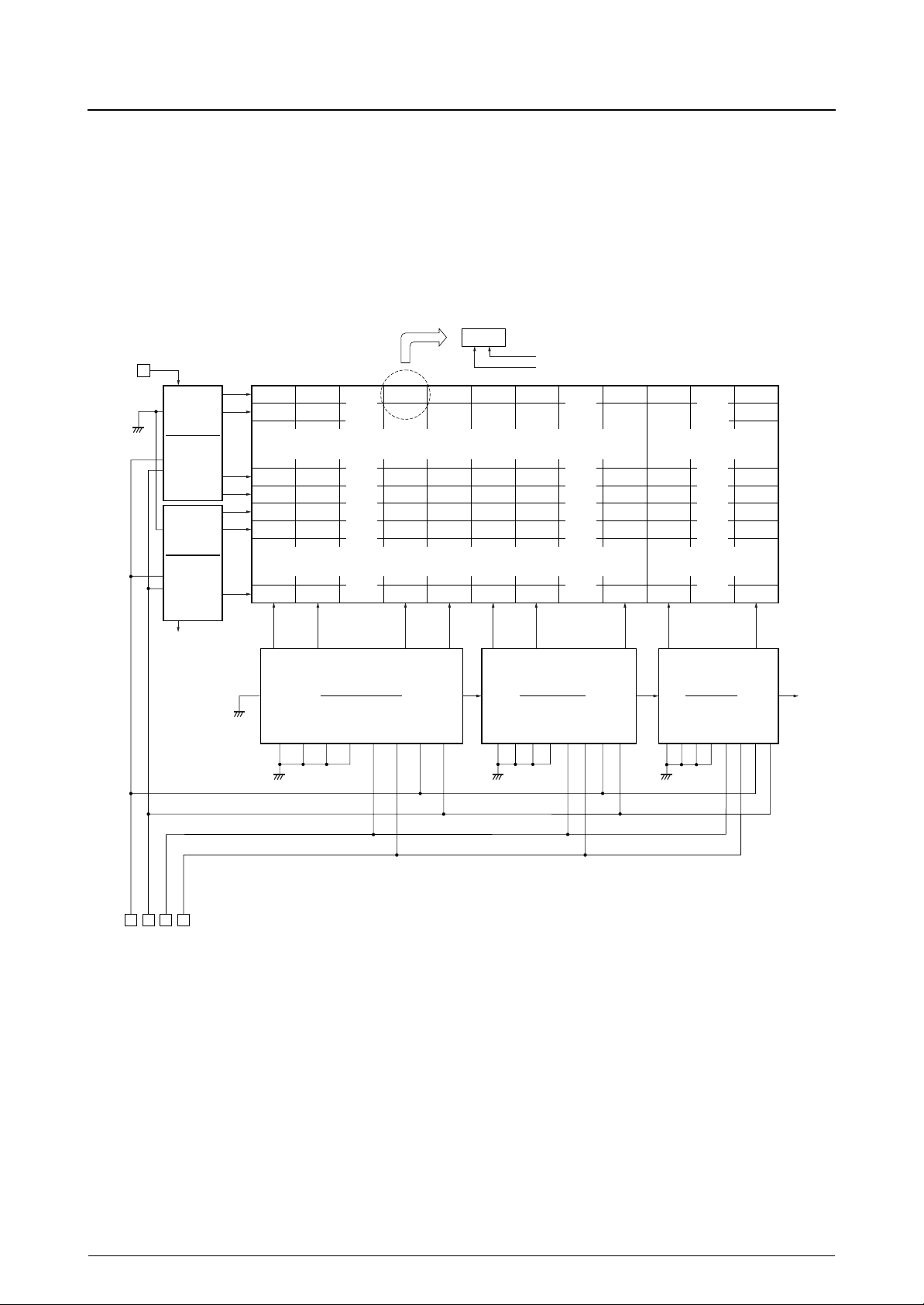

Block Diagram

LC7940YC, LC7941YC

01 02 03 079 080

V1

V3

V4

V

EE

M

4 Level LCD Drive Circuit

(80 bits)

80

Level Shifter (80 bits)

80

2nd Latch (80 bits)

80

1st Latch (80 bits)

VDD

SS

V

DISP OFF

SDI

DI3

DI2

DI1

P/S CDO

CDI

CP

LOAD

4 bits

Data Bus

Interface

SER/PAR

Control

CLK

204

Address Decoder

Address Counter

(7 bits)

Chip Disable &

Latch Control

Pin Functions

Pin No.

LC7940YC LC7941YC

91 90 V

86 95 V

87 94 V

92 89 V

89 92 V

88 93 V

l00 81 CP I Display data Input clock (falling–edge trigger).

99 82 CDI I

98 83 LOAD I

97 84 SDI I Serial data input.

96 85 DI3

95 86 DI2

94 87 D11

Symbol I/O Function

DD

SS

EE

Supply

1

3

4

Supply

V

– VSS is the logic supply.

DD

VDD – VEE is the LCD supply.

LCD panel drive voltage supplies

V1 and VEE are selected levels.

V3 and V4 are not–selected levels.

Chip disable.

Data is read in when LOW, and not road in when HIGH.

Display data latch clock (falling–edge trigger).

On the falling edge, the LCD drive signals set by the display data are output.

4–bit parallel data input pins.

Data input LCD driver outputs

SDI O4 O8

I

DI3 O3 O7 O79

DI2 O2 O6 O78

DI1 O1 O5 O77

O80

In serial data input mode, DI1 to DI3 should all be tied HIGH or LOW.

No. 6157—7/13

Page 8

LC7940YC, LC7941YC

Pin No.

LC7940YC LC7941YC

Symbol I/O Function

93 88 M I LCD panel drive voltage output alternation control signal.

85 96 P/S I Data input mode select. 4–bit parallel input when HIGH, and serial input when LOW

82 99 CDO O

Cascade connection pin for extension segment drivers. Data is read out when HIGH.

Goes LOW after data is read out. Connected to the CDI input of the next chip.

LCD drive outputs.

The output drive level is determined by the display data, M signal and DISP OFF

input as shown below.

M Q DISP OFF Output

LOW LOW HIGH V

1 to 80 80 to 1 Ol to O80 O

LOW HIGH HIGH V

HIGH LOW HIGH V

HIGH HIGH HIGH V

××

LOW V

Note

x = don’t care (tied HIGH or LOW)

84 97 DISPOFF

I

O1 to O80 output control input pin.

When LOW, V1 is output on the O1 to 080 outputs, See the truth table.

81 91 NC

– No connection.83 98 NC

90 100 NC

3

1

4

EE

1

No. 6157—8/13

Page 9

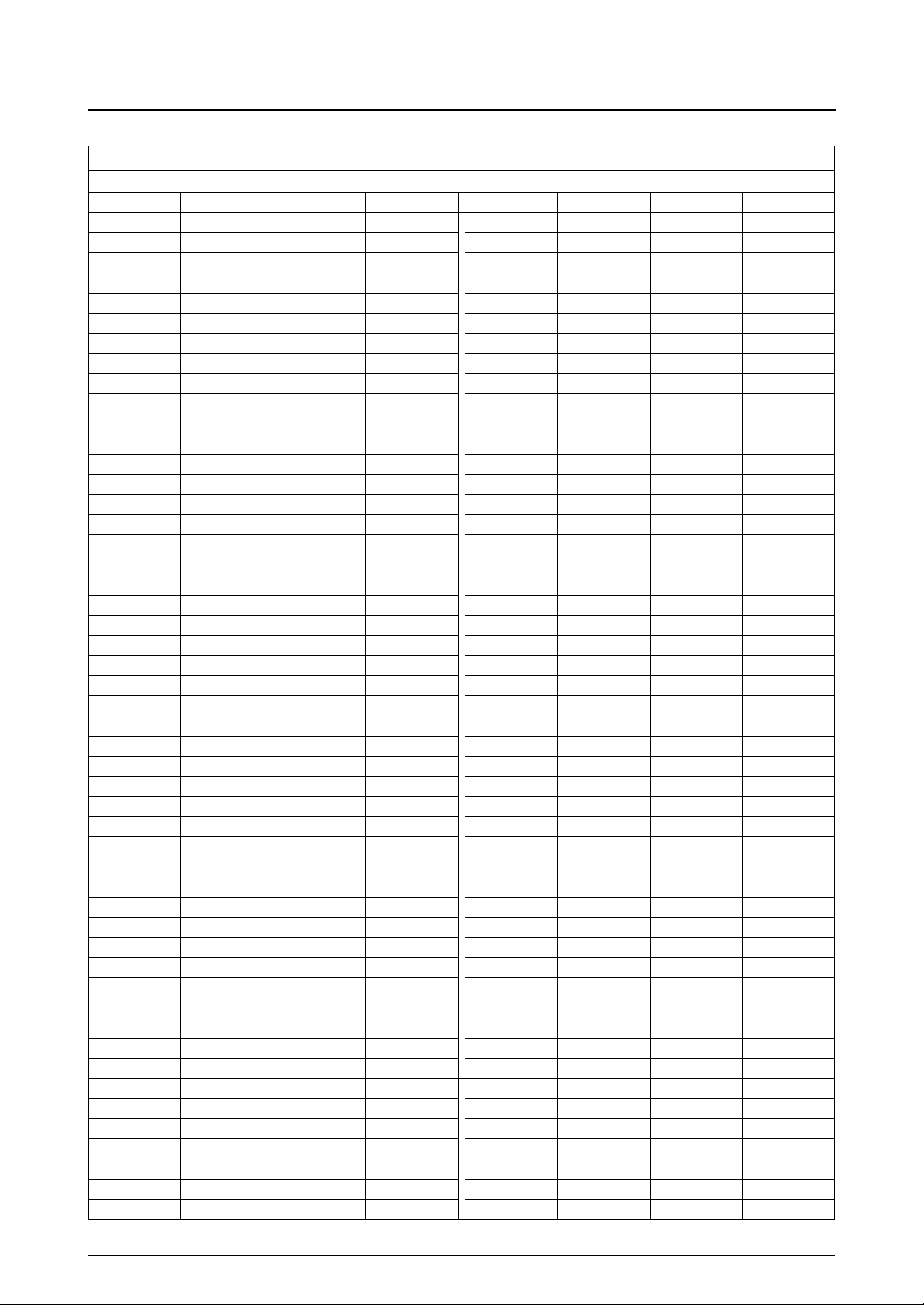

Application Notes

LCD Panel 1

4

CP

SDI

LOAD

V3V1M

CP

LOAD

OD1 ED1

2

CP

SDI

LOAD

V3V1M

CP

SDI

LOAD

V3V1M

CP

SDI

LOAD

V3V1M

LC7940YC, LC7941YC

CP

SDI

LOAD

CDI

EE

V

VEE

V3

V4

V1

V4

LC7941YC

VEE

V4

VEE

V4

VEE

V4

(LC7940YC)

CDOCDI

LC7941YC

(LC7940YC)

CDOCDI

LC7941YC

(LC7940YC)

CDOCDI

LC7941YC

(LC7940YC)

M

EE

V

V3

V4

V1

M

EE

V

V3

V4

V1

M

EE

V

V3

V4

V1

M

1

2

159

160

161

162

319

320

321

322

LCD panel (640 × 200 pixels)

479

480

481

482

639

640

100

641

642

799

800

801

802

959

960

961

962

1119

1120

1121

1122

1279

1280

LC7940YC

LC7940YC

LC7940YC

LC7940YC

(LC7941YC)

M

(LC7941YC)

M

(LC7941YC)

M

(LC7941YC)

M

EE

V3

V

V1

V4

LC7941YC

EE

V3

V

V1

V4

LC7941YC

EE

V3

V

V1

V4

LC7941YC

EE

V3

V

V1

V4

LC7941YC

4

CP

LOAD

OD2 ED2

M

EE

V

4

V1 V3

V4

OD1

ED1

FLM

01

DI01

M

M

controller

064CP

DI064

LC7942YC

CL1

V2

V1

CL2

01

036CP

DI01

EE

4

V

V5

ED2

OD2

LC7942YC

M

VDD

EE

V2

V

V1

V5

V146V2

LA5311M

R

4

V3

V4

V5

+

–

+

+

–

+

–

R

–

R7RR

VEE

–11 to –13V

No. 6157—9/13

Page 10

LCD Panel 2

LC7940YC, LC7941YC

42

4

2 4

EE

V4 V

M V1 V3

CP

LOAD

4bit Data

CDI

080 01

CDO

CDICDO

080 01

4bit Data

CP LOAD

LC7941YC-#1

EE

V3

V

V1

V4

M

24244

LC7941YC-#2 LC7941YC-#1

24

LC7941YC-#2

24

LCD panel (640 × 200 pixels)

2

LC7941YC-#8

24

LC7941YC-#8

4bit Data

100

DI01

01

M

036CP

LC7942YC-#2

VDD

EE

V2

V

V1

V5

V146V2

LA5311M

R

V3

–

–

+

+

R

100

01

064CP

4

4bit Data

FLM

DI01

M

M

controller

LC7942YC-#1

CP

LOAD

EE

4

V

V1 V3

V4

EE

V

4

–11 to –13V

4

V4

V5

–

–

+

+

R

R

7R

No. 6157—10/13

Page 11

LC7940YC, LC7941YC

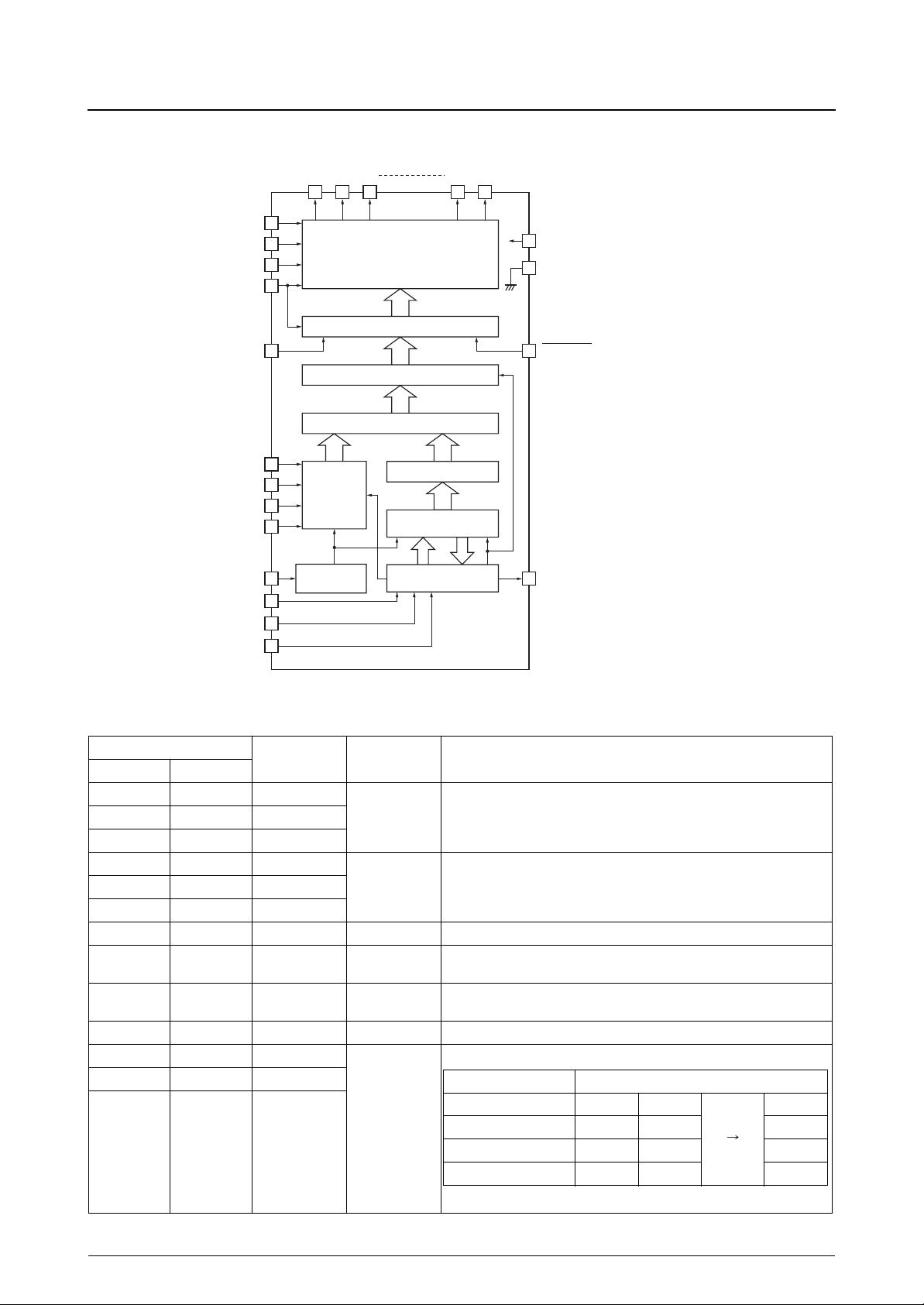

100 x 240-pixel LCD Panel Application

A 100 × 240

pixel LCD panel requires the following

–

drivers.

• 3 x LC7940YC (or LC7941YC) drivers

• 2 x LC7942YC drivers

An example using l/l00 duty cycle is shown below.

Frame Signal

1,2

DI01 01

RS/LS 02

LC7942YC

#1

CP

M

063

DI064 064

DI01 01

RS/LS 02

LC7942YC

#2

CP

M

036

DI064

O37 to O64

are open.

1,1

2,1

--- ---

63,2

63,1

64,2

64,1

65,2

65,1

66,2

66,1

100,2

100,1

01

---

2,2

--- ---

---

---

---

02

LCD Panel (100 × 240 pixels)

100,79

1,79

1,80

64,80

65,80

100,80

079#1080

1,79

1,81

64,81

65,81

100,81

01 02

(m,n) : pixel address

Segment line (n)

Common line (m)

1,82

---

---

---

100,82

---

1,160

64,160

65,160

100,160

080

1,

161

--- ---

64,161

65,161

1,240

---

2,240

--- ---

---

64,240

65,240

---

100,161

---

100,240

01

080

Data latch clock

Alternating signal

Serial Data

Data Shift

clock

P/S

LC7940YC

(LC7941YC)

DI1

DI2

DI3

SDICPLOAD

CDOCDI

1. The LC7942YC chips are cascaded by connecting

DIO64 on chip I to DIO1 on chip 2. For a 100

bit shift

–

register, O37 to O64 on chip 2 are left open.

2. The LC7940YC (or LC7941YC) chips are cascaded by

connecting CDO on chip I to CDI on chip 2, and CDO

on chip 2 to CDI on chip 3. CDI on chip I is tied to

GND, and CDO on chip 3 is not used. This

configuration allows the input of 240

bit serial data.

–

LC7940YC

(LC7941YC)

M

P/S

DI1

DI2

#2

DI3

SDICPLOAD

CDOCDI

M

LC7940YC

(LC7941YC)

P/S

DI1

DI2

#2

DI3

SDICPLOAD

CDOCDI

M

No. 6157—11/13

Page 12

LC7940YC, LC7941YC

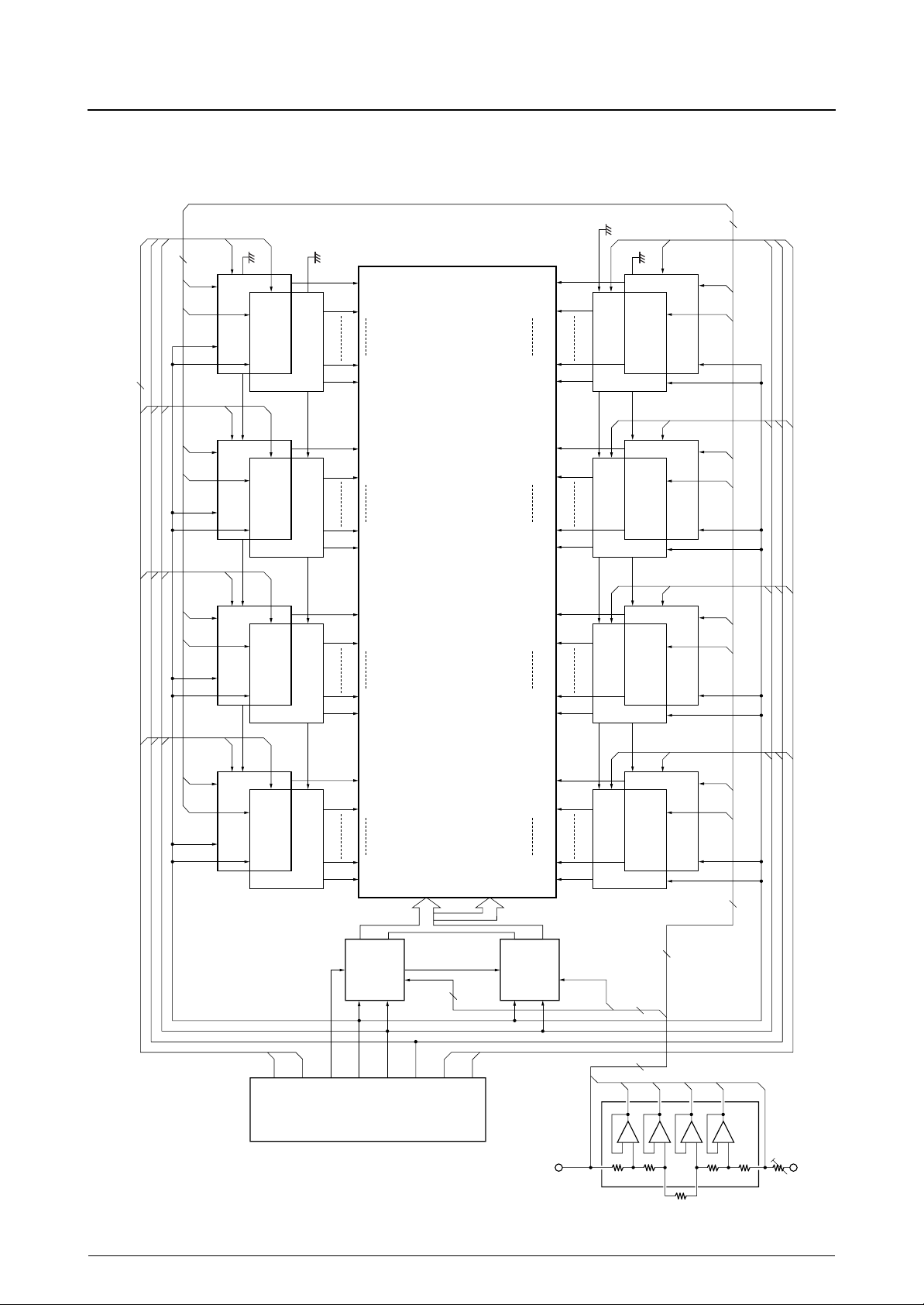

100 x 240-pixel LCD Panel Timing Diagram

M

LOAD

CP

SDO

SDI

LOAD

CP

SDI

1,1

#1

#2

#3

M

1,1

M

1,2 1,79 1,80 1,81 ------

Chip 1 data read

1 frame (240 bits)

1,2 1,239

1st line data read 2nd line data read

1frame (100 × 240 bits)

1,240 2,240 3,1 100,2402,1---

Chip 2 data read Chip 3 data read

--- ---

---1,160 1,161 1,240

#1 DIO1

LOAD

#1

080

#2

080

#3

080

98,1 99,1 99,1100,1 100,11,1

01

02

01

--- ---

01

1,1 2,1

1,2 2,2

1,80 2,80

1,81 2,81

1,160 2,160

1,161 2,161

1,240 2,240

--- ---

98,2 99,2 99,2100,2 100,21,2--- ---

98,80 99,80 99,80100,80 100,801,80--- ---

98,81 99,81 99,81100,81 100,811,81--- ---

98,160 99,160 99,160100,160 100,1601,160--- ---

98,161 99,161 99,161100,161 100,1611,161--- ---

98,240 99,240 99,240100,240 100,2401,240--- ---

LCD driver output data

No. 6157—12/13

Page 13

Segment Data Not Multiples of 4

Example.

LCD panel (100 × 230 pixels)

LC7940YC, LC7941YC

---

LOAD

SDI

01 080

LC7940YC

#1

m,1 m,2 ,228 m,229 m,230 m+1,1 m+1,2 m+1,229 m+1,230,228---

01 080

LC7940YC

#2

If this timing data is sent, data elements (m, 229), (m,

230), (m+1, 229), (m+1. 230)... will not appear in the

output (O69 and O70 on chip 3). This is because the

LC7940YC (or LC7941YC) converts serial/parallel data

LOAD

SDI

m,1 m,2 ,228 m,229 m,230 m,231 m,232

---

In this case, (m, 231) is output on O71 on chip 3, and (m,

232) on O72 on chip 3. However, these outputs are not

connected to the panel and are, therefore, invalid.

---

01 070

LC7940YC

#3

in 4–bit units, which also decreases power dissipation . For

data that is not a multiple of 4, like 230, the following

scheme is used.

Dummy dataValid display data

Multiple of 4

■

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer’s

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer’s products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

■

semiconductor products fail with some probability. It is possible that these probabilistic failures could give

rise to accidents or events that could endanger human lives, that could give rise to smoke or fire, or that

could cause damage to other property. When designing equipment, adopt safety measures so that these

kinds of accidents or events cannot occur. Such measures include but are not limited to protective circuits

and error prevention circuits for safe design, redundant design, and structural design.

■

In the event that any or all SANYO products(including technical data,services) described or contained

herein are controlled under any of applicable local export control laws and regulations, such products

must not be exported without obtaining the export license from the author ities concerned in accordance

with the above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

■

mechanical, including photocopying and recording, or any information storage or retrieval system, or

otherwise, without the prior written permission of SANYO Electric Co. , Ltd.

■

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the "Delivery Specification" for

the SANYO product that you intend to use.

■

Information (including circuit diagrams and circuit parameters) herein is for example only ; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but no

guarantees are made or implied regarding its use or any infringements of intellectual proper ty rights or

other rights of third parties.

This catalog provides information as of June, 1999. Specifications and information herein are subject to

change without notice.

No. 6157—13/13

Loading...

Loading...