Page 1

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft’s

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges,or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

CMOS IC

Single-Chip 4-bit Microcontroller

(Low-Threshold Input, On-Chip FLT Driver)

Ordering number:ENN1802C

LC6514B

SANYO Electric Co.,Ltd. Semiconductor Company

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

Overview

The LC6514B is a microcontroller with FLT drivers. It is

identical with the LC6510C in the internal architecture and

instruction set. Since the normal/low-threshold lev el of input port A can be selected by option and the on-chip pulldown resistor can be bitwise connected to the FLT driver

by option, the number of external parts used in the user

equipment can be minimized, reducing the cost consider-

ably.

Features

• Low power dissipation.

• ROM capacity : 4096×8 bits.

• RAM capacity : 256×4 bits.

• Subroutine stack : 8 levels (common with interrupt).

• On-chip OSC circuit

CR OSC : 800kHz typ.

Ceramic OSC : 400kHz, 800kHz, 1000kHz

External iuput : 1290kHz max.

• Power-down by 2 standby modes

HAL T mode : Po wer dissipation sa ving by program stadby

during normal operation

HOLD mode : Power supply backup during power fail-

ure.

• Input/output ports

Input : 4 bits × 1 port

3 bits × 1 port

Input/output : 4 bits × 2 ports

Output : 4 bits × 4 ports

2 bits × 1 port

• Interrupt.

External interrupt : 1

Internal timer interrupt : 1

• On-chip 4-bit prescaler and 8-bit program timer.

• Instruction cycle time : 3.1µs (at 1290kHz)

• Supply voltage

Normal operation : 4.0 to 6.0 V

Memory hold : 1.8 to 6.0 V

• Instruction set common to the LC6502, LC6505 (BANK

instruction added)

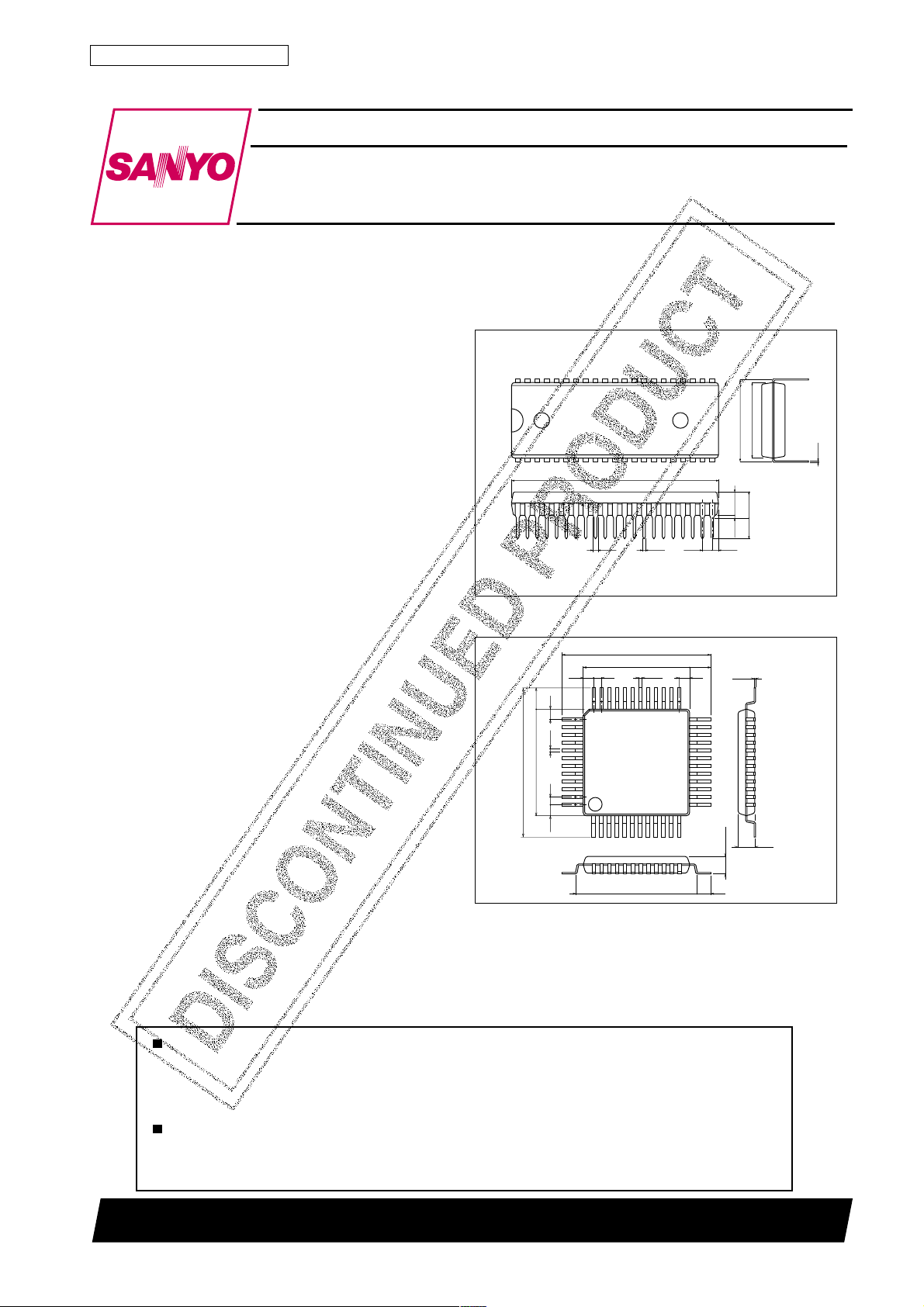

Package Dimensions

unit:mm

3025B-DIP42S

[LC6514B]

42

1

unit:mm

3052B-QIP48

3.0

1.5

0.35

20.0

14.0

1.0

1.5

37.9

20.0

14.0

0.48

0.35

16.6

0.95

1.5

1.0

36

37

48

1

22

13.8

15.24

21

4.25

5.1max

3.8

1.15

3.0

1.5

24

13

2.45max

1.7

0.51min

SANYO : DIP42S

0.15

2.15

SANYO : QIP48A

1.78

25

12

0.25

O1501TN (KT)/7209YT/3246KI/2265KI, TS No.1802–1/17

Page 2

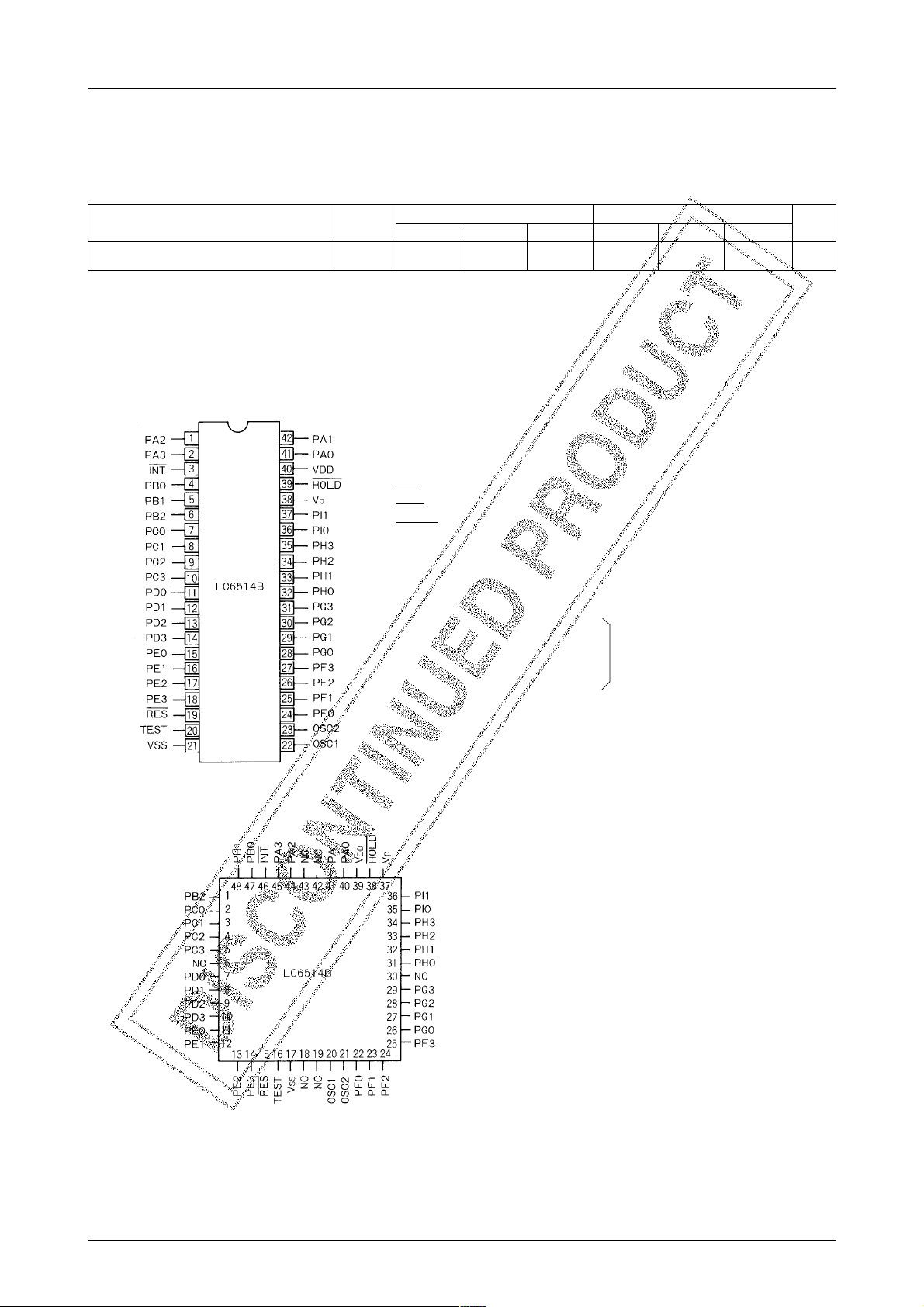

LC6514B

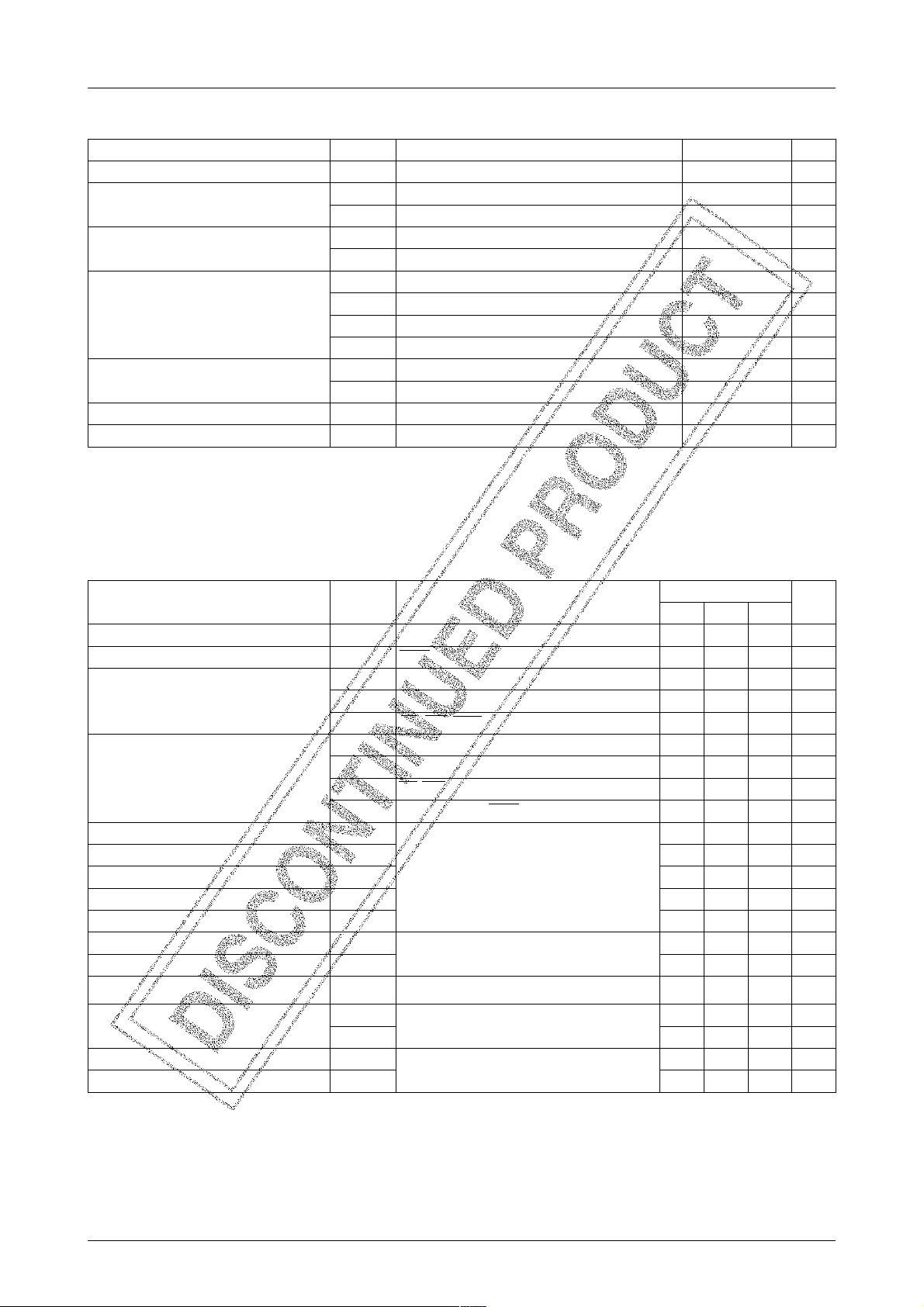

Note

The LC6514B heretofore in use has been improved by changing the value of the pull-down resistor to be contained in

FLT drivers as shown below. When using the LC6514B, fully check that the new resistor value meets your application

specifications.

tnerructuptuolevel-L

Pin Assignment

retemaraP

I

)ecnatsisernwod-lluptuptuO(

R(DP)

LO

nimpytxamnimpytxam

091.0

)002(

eulavrotsiserweNeulavrotsiserdlO

263.0

)501(

067.0

)05(

tinU

801.0

)053(

403.0

)521(

345.0

Am

)07(

k( Ω)

Pin name

OSC1, OSC2 : C, R or ceramic resonator for system OSC

INT : Interrupt

RES : Reset

HOLD :Hold

PA

PB

PC

PD

PE

PF

PG

PH

PI

: Input port A

0 to 3

: Input port B

0 to 2

: Input/output common port C

0 to 3

: Input/output common port D

0 to 3

: Output port E

0 to 3

: Output port F

0 to 3

: Output port G

0 to 3

: Output port H

0 to 3

: Output port I

0, 1

0 to 3

0 to 2

0 to 3

0 to 3

0 to 3

0 to 3

0, 1

0 to 3

0 to 3

With

High-voltage

driver

TEST : TEST

V

: Power supply for high-voltage port pull-down resistor

p

When mounting the QIP package

version on the board, do not dip it in

solder.

NC pin : No connection

No.1802–2/17

Page 3

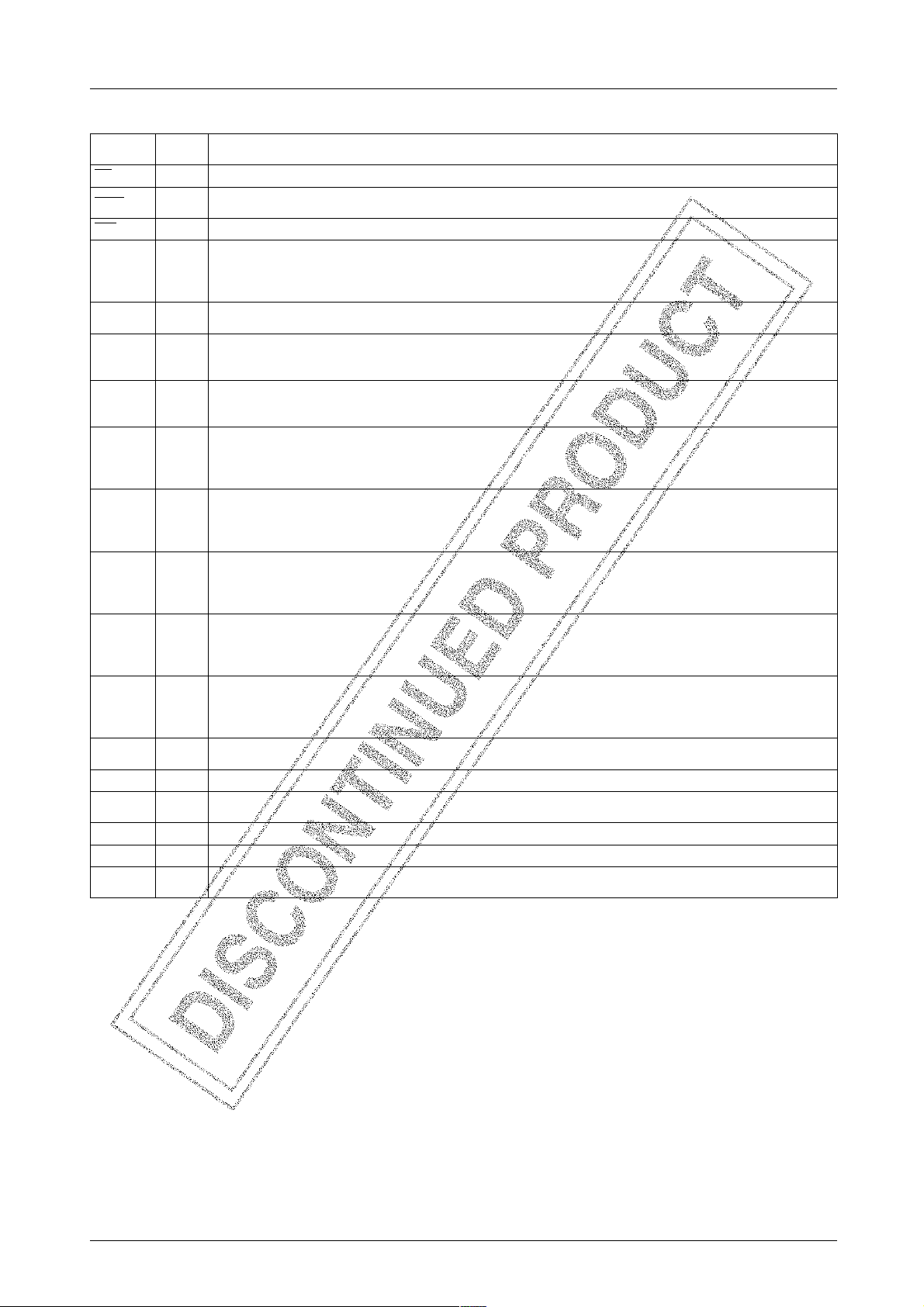

Pin Function

emaNniP

TNItupnI.niptupnitseuqertpurretnI

DLOHtupnI

SERtupnI.niptupniteseR

AP

3ot0

BP

2ot0

CP

3ot0

DP

3ot0

EP

3ot0

FP

3ot0

GP

3ot0

HP

3ot0

IP

1,0

1CSOtupnI

2CSOtuptuO .edomkcolclanretniehtroftiucricecnanoseragnitcennocyllanretxerofniP

V

DD

V

SS

PVtupnI.rotsisernwod-lluptropegatlov-hgihrofylppusrewoP

TSETtupnI

– .ylppusrewopV0otdetcennoC

LC6514B

/tupnI

tuptuO

AtroptupnI

Aot

0

3

tupnI

BtroptupnI

Bot

0

tupnI

/tupnI

tuptuO

/tupnI

tuptuO

tuptuO

tuptuO

tuptuO

tuptuO

tuptuO

tupnI

2

Ctropnommoctuptuo/tupnI

Dtropnommoctuptuo/tupnI

EtroptuptuO

Eot

0

3

FtroptuptuO

Fot

0

3

GtroptuptuO

Got

0

3

HtroptuptuO

Hot

0

3

ItroptuptuO

0I,1

.nipylppusrewoP

.niptsetCI

VdetcennocyllamroN

SS

.)egatlovlamroN(

.)egatlovlamroN(

Cot

0

3

Dot

0

3

.kcolclanretxegniylppusrofniP

.V5+otdetcennocyllamroN

.)V0(

.hcnarbrofnoisicedtib-elgnisdnatupnitib-4foelbapaC

.tupnitseuqeresaeleredomTLAHrofosladesU

.noitpoybelbatcelesstib4roftupnidlohserhtWOL

.hcnarbrofnoisicedtib-elgnisdnatupnitib-3foelbapaC

.)egatlovlamroN(

.)egatlovlamroN(

.)revirdtnemgesegatlov-hgihhtiw(

.teser/testib-elgnisdnatuptuotib-4foelbapaC

.)revirdtnemgesegatlov-hgihhtiw(

.teser/testib-elgnisdnatuptuotib-4foelbapaC

.)revirdtigidegatlov-hgihhtiw(

.teser/testib-elgnisdnatuptuotib-4foelbapaC

.)revirdtigidegatlov-hgihhtiw(

.teser/testib-elgnisdnatuptuotib-4foelbapaC

.)revirdtigidegatlov-hgihhtiw(

.teser/testib-elgnisdnatuptuotib-2foelbapaC

noitcnuF

).noitcnufni50/2056CLehtmorfsreffiD(niptupnitseuqeredomDLOH

.desusiedomybdnatsehtsselnutroptupnitib-elgnisesoprup-larenegsadesugniebfoelbapaC

.tupnignirudhcnarbrofnoisicedtib-elgnisdnatupnitib-4foelbapaC

.tuptuognirudteser/testib-elgnisdnatuptuotib-4foelbapaC

.tupnignirudhcnarbrofnoisicedtib-elgnisdnatupnitib-4foelbapaC

.tuptuognirudteser/testib-elgnisdnatuptuotib-4foelbapaC

.hcnarbrofhctaltuptuofonoisicedtib-elgnisdnastnetnochctaltuptuofotupnitib-4foelbapaC

.noitpoybelbatcelesesiwtibrotsisernwod-llupfoesunon/esU

.hcnarbrofhctaltuptuofonoisicedtib-elgnisdnastnetnochctaltuptuofotupnitib-4foelbapaC

.noitpoybelbatcelesesiwtibrotsisernwod-llupfoesunon/esU

.hcnarbrofhctaltuptuofonoisicedtib-elgnisdnastnetnochctaltuptuofotupnitib-4foelbapaC

.noitpoybelbatcelesesiwtibrotsisernwod-llupfoesunon/esU

.hcnarbrofhctaltuptuofonoisicedtib-elgnisdnastnetnochctaltuptuofotupnitib-4foelbapaC

.noitpoybelbatcelesesiwtibrotsisernwod-llupfoesunon/esU

.hcnarbrofhctaltuptuofonoisicedtib-elgnisdnastnetnochctaltuptuofotupnitib-2foelbapaC

.noitpoybelbatcelesesiwtibrotsisernwod-llupfoesunon/esU

.2CSOnipdnanipsihtotdetcennocsirotanosercimarecaroR,C,desusiedomkcolclanretniehtfI

No.1802–3/17

Page 4

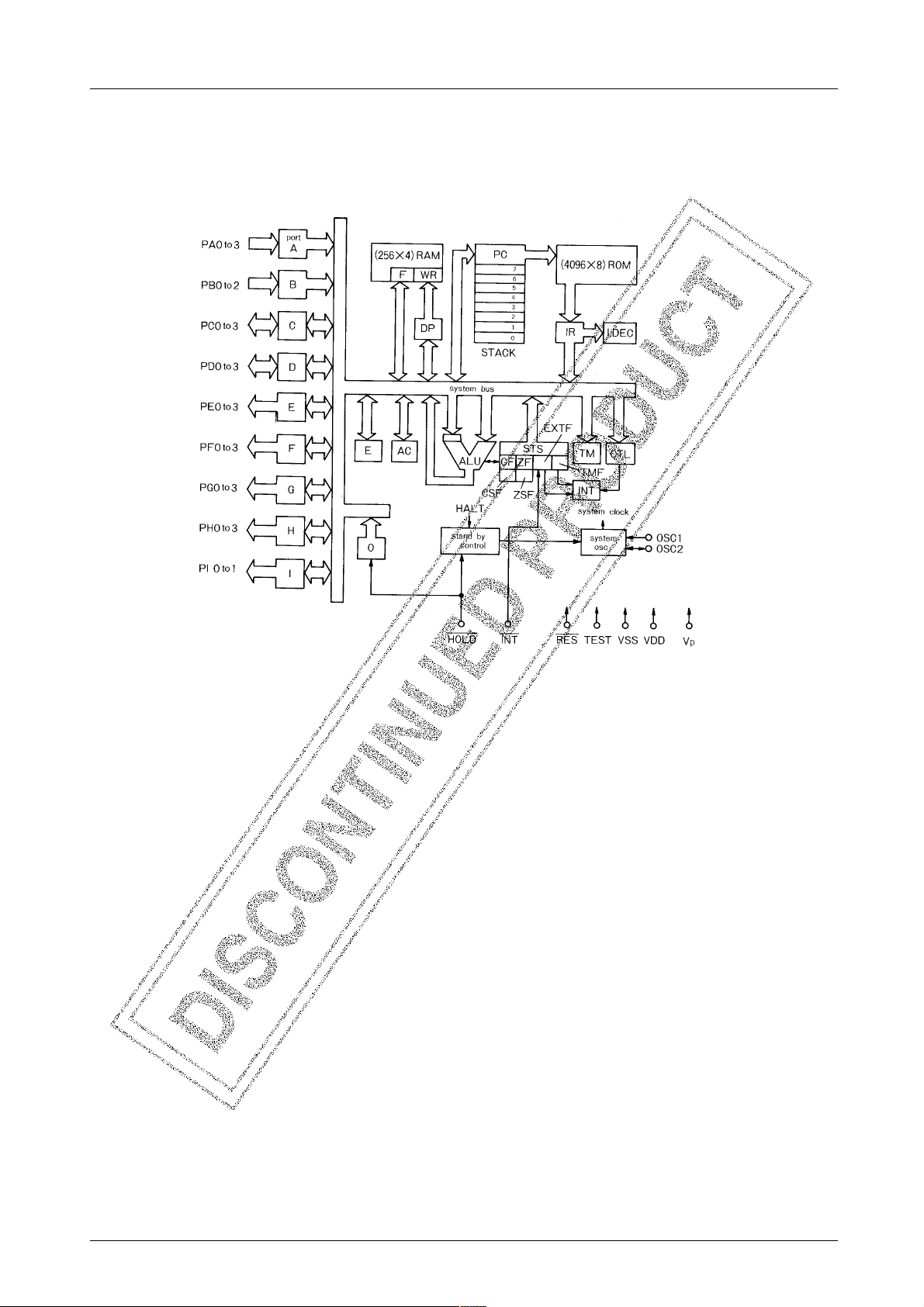

System Block Diagram

LC6514B

RAM : Data memory ROM : Program memory

F : Flag PC : Program counter

WR : Working register INT : Interrupt control

AC : Accumulator IR : Instruction resister

ALU : Arithmetic and logic unit I.DEC : Instruction decoder

DP : Data pointer CF, CSF : Carry flag

E : E register Carry save flag

CTL : Control register ZF, ZSF : Zero flag

OSC : Oscillator Zero save flag

TM : Timer EXTF : External interrupt request flag

STS : Status register TMF : Internal interrupt request flag

No.1802–4/17

Page 5

LC6514B

Absolute Maximum Ratings at Ta = 25˚C, VSS=0V (VDD=5V±20% unless otherwise specified)

retemaraPlobmySsnoitidnoCsgnitaRtinU

egatlovylppusmumixaMV

egatlovtupnI

egatlovtuptuO

tnerructuptuokaeP

noitapossidrewopelbawollA

erutarepmetgnitarepOrpoT 07+ot03–°C

erutarepmetegarotSgtsT 521+ot55–°C

Note 1: For pin OSC1, up to oscillation amplitude generated when internaly oscillated under the recommended

oscillation conditions in Fig. 3 is allowable.

xam 0.7+ot3.0– V

DD

V

1NI

V

V

V

I

I

I

I

V

2NI

P

1TUO

2TUO

1O

2O

3O

4O

1xamdP07+ot03–=aT,egakcappiD °C006Wm

2xamdP07+ot03–=aT,egakcaptalF °C004Wm

I,H,G,F,EstroPV

)1etoN(pVnahtrehtostupnIot3.0– V

V

I,H,G,F,EstropnahtrehtostuptuOot3.0– V

D,CstropfoniphcaE 0.2+ot0.2– Am

F,EstropfoniphcaE 0ot01– Am

I,H,GstropfoniphcaE 0ot51– Am

IotCstropfosnipllA 61+ot09– Am

ot54– V

DD

ot54– V

DD

DD

DD

DD

DD

3.0+V

3.0+V

3.0+V

3.0+V

Recommended Operating Conditions at T a = –30˚C to +70˚C, V

specified)

retemaraPlobmySsnoitidnoC

egatlovylppusgnitarepOV

egatlovylppusnwod-rewoPV

egatovtupnilevel-H

egatovtupnilevel-L

ycneuqerfkcolcgnitarepOf

htdiweslupkcolclevel-Ht

htdiweslupkcolclevel-Lt

emitesirtupnikcolCt

emitllaftupnikcolCt

CSORCrofecnaticapaclanretxEtxeC

CSORCrofecnatsiserlanretxEtxeR

CSOcimarecrofstnatsnoctiucriclanretxE

gnimitybdnatS

niyaledelbawollAt

tiucricnacsyeKt

DD

RM=DLOHV

DD

V

1HI

V

V

V

V

V

V

wφH

t

t

V

2HI

3HI

1LI

V

2LI

3LI

V

4LI

csotxe

wφL

R 2.0sµ

cso

F 2.0sµ

cso

2R,1R

2C,1C

RDDV

FDDV

LD

HD

4LI

DD

DD

DD

8.giFeeS

3.giFeeS

V,6.giFeeS

DD

.01,9.giFeeS

edomDLOH,8.10.6V

snip1CSO,SER,TNIV

= 0V(VDD = 4.0V to 6.0V unless otherwise

SS

gnitaR

nimpytxam

0.40.50.6V

"tupnidlohserhtlamron":Atrop,DotAstroP

"tupnidlohserhtwol":Atrop,V5.5ot5.4=9.1V

snip1CSO,DLOH,SER,TNI

"tupnidlohserhtlamron":Atrop,DotAstroPV

"tupnidlohserhtwol":Atrop,V5.5ot5.4=V

snipTSET,DLOH,V0.6ot8.1=V

1.giFeeS,tupnikcolclanretxetA

V0.6ot8.1=

V7.0

DD

V8.0

DD

SS

SS

SS

SS

2220921zHk

3.0sµ

3.0sµ

0sµ

0sµ

V

V

V3.0

V2.0

V2.0

tinU

V

DD

V

DD

V

DD

V

DD

5.0V

V

DD

V

DD

%5±022

Fp

%1±8.6

kΩ

cT·)3-n(

sµ

cT·)3-n(

sµ

No.1802–5/17

Page 6

LC6514B

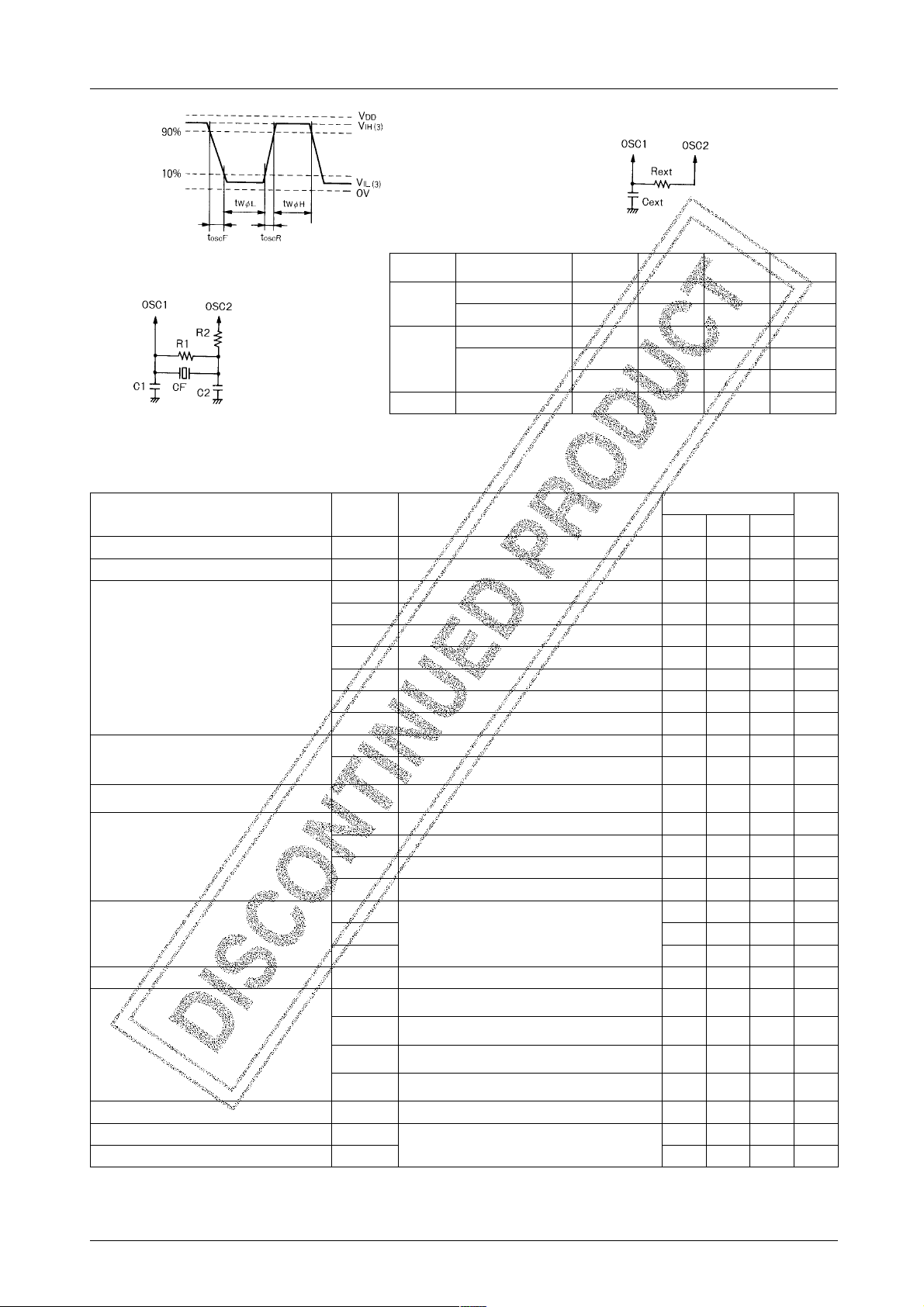

Fig. 2 Recommended Oscillator for CR OSC

Fig. 1 OSC1 Pin input waveform

CF : Ceramic resonator

CSB400P (Murata)

KBR400B (Kyocera)

CSB800K (Murata)

KBR800H (Kyocera)

CSB1000K (Murata)

Fig. 3 Recommended Oscillator for Ceramic OSC

retneC

ycneuqerF

zHk004

zHk008

zHk0001)ataruM(K0001BSC00100100015.1

FC)Fp(1C)Fp(2Ck(1R Ω)k(2R Ω)

)ataruM(P004BSC07407400015.1

)arecoyK(B004RBK07407400015.1

)ataruM(K008BSC02202200010.1

)arecoyK(H008RBK

C1, C2 : Tolerance ±10%

R1, R2 : Tolerance ±5%

Electrical Characteristics at Ta = –30 to +70˚C, VDD=5V±20%, VSS=0V

retemaraPlobmySsnoitidnoC

(Note 1) f

tnerructupuilevel-HI

tnerructupuilevel-LI

egatovtuptuolevel-H

egatovtuptuolevel-L

tnerructuptuoevel-L

)rotsisernwod-lluptuptuO(

tnerruckaelFFOtuptuO

CSOcimarecrofycneuqerfCSOkcolC

CSORCrofycneuqerfCSOkcolCf

niardtnerruC

ecnaticapactupnIC

ecnaticapactuptuOC

ecnaticapactuptuo/tupnIC

: Oscillatable frequency.

CFOSC

f

f

f

V

V

V

V

V

V

V

V

V

I

R(DP)

I

I

I

I

I

I

I

I

HI

LI

1HO

2HO

3HO

4HO

5HO

6HO

7HO

1LO

2LO

LO

1FFO

2FFO

3FFO

4FFO

1CSOFC

2CSOFC

3CSOFC

C

CSORC

txe

1DD

2DD

3DD

4DD

NI

TUO

OI

V,nip

NIV=DD

4

5

zHM1=f5Fp

VtpecxesniptupnillA

PV,NIV=DD

VtpecxesniptupnillA

PV,NIV=SS

I:D,CstroP

Am1–=

HO

I:D,CstroP

I:F,EstroP

I:F,EstroP

I:D,CstroP

LO

V:D,CstroP

V:D,CstroP

V:IotEstroP

V:IotEstroP

R,Fp022=

C,CSORCtA

V,edomTLAH

V,edomDLOH

Aµ001–=

HO

Am2–=

HO

HO

I:I,H,GstroP

I:I,H,GstroP

I:I,H,GstroP

Am01–=

HO

Am2–=

HO

HO

Am1=4.0V

V:I,H,G,F,EstroP

P

rotsisernwod-lluphtiw,nepo

txe

V,niptupni,nepo

DD

DD

V:I,H,G,F,EstroP

V=

TUO

V=

TUO

TUO

TUO

txe

NIV=DD

V,V53–=

P

rotsisernwod-lluphtiw

DD

SS

V=

DD

V=

DD

)1etoN(3.giFnitiucric

k8.6= Ω 2.giFnitiucricCSOta,0060080221zHk

R,Fp022=

txe

02202200010.1

05105100015.1

gnitaR

nimpytxam

1– Aµ

VDD0.2–

VDD5.0–

VDD0.1–

Istroplla,Am1–=

ecnadepmihgih:tuptuo,zHM1=f

Am1–=

HO

Istroplla,Am1–=

HO

V,V3=

LO

DD

tuptuoDO,03Aµ

tuptuoDO,V04– 03– Aµ

k8.6= Ω niptuptuo,

VDD5.0–

VDD8.1–

VDD0.1–

VDD5.0–

Am1–=

tuptuo,FFOrTtuptuo,V53–=

,V5=

CSOta,CSOcimarecrofsnoitidnocdednemmoceR

tupni,neponiptuptuo,)zHk008(CSOcimarectA

.giFnitiucrictsetta,V0.6ot0.4=

091.0

)002(

0.1– Aµ

483004614zHk

867008238zHk

06900010401zHk

.giFnitiucrictsetta,V0.6ot8.1=

263.0

)501(

0.10.2Am

0.10.2Am

01Fp

01Fp

1Aµ

33– V

067.0

)02(

0.1Aµ

01Aµ

01Aµ

V

V

V

V

V

V

V

k( Ω)

tinU

Am

No.1802–6/17

Page 7

Fig. 4 I

Test Circuit

DD3

LC6514B

Input/output common

port C, D : Output inhibit

The HALT instruction is

executed to csuse the

HALT mode to be

entered.

Fig. 5 I

Test Circuit

DD4

Fig. 6 Standby Mode Timing

(Note)

During the HALT instruction

execution cycle, no chattering

must be applied to the HOLD

pin and PA

0 to 3

pins.

No.1802–7/17

Page 8

LC6514B

τV

: Power supply rise time constant

DD

τRES : RES pin rise time constant

Fix C, R so that τV

yielded. (t

: OSC stabilized time)

OSC

≤τRES,t

DD

OSC

≥10ms is

Fig. 7 Initial Reset Timing

CR OSC characteristic of LC6514B

Fig. 8 shows the CR OSC characteristic of the LC6514B. For the variation range of CR OSC frequency of the

LC6514B, the following is guaranteed at external consatants of Cext=220pF, Rext=6.8kΩ only. The outgoing inspection is performed under this condition only.

Ta=–30°C to +70°C

600kHz≤f

If any other constants than specified above are used, the range of Rext=5k to 50kΩ, Cext=100p to 300pF must be

observed. (See Fig. 8.)

Fig. 8 f

CROSC.

CROSC

–Rext

≤1220kHz

(

VDD=4 to 6V

)

Note 1. The OSC frequency at VDD=5V, Ta=25°C

must be 800KHz or less.

Note 2. The OSC frequency at V

Ta=–30 to +70°C must be within the

operation clock frequency range

(222KHz to 1290 kHz).

=4 to 6V,

DD

No.1802–8/17

Page 9

LC6514B

Proper Cares in using the IC

[Digit drive signal-used key scan]

When key-scanning with the FLT digit drive signal in Fig. 9 and inputting the return signal to port A, the following

must be observed.

(a) Estimate voltage drop (V

teristic of the output port of the LC6514B.

(b) Estimate voltage drop (V

(c) Check to see that (V

ON

) in the output transistor using the current flowing in an FLT used and the V-1 charac-

ON

) in the switch circuit.

SW

+ VSW) meets the VIH/VIL requirement of the input port.

Fig. 9 Sample Key Scan Application

For the key scan application in Fig. 9, make the program considering the deley in the external circuit and the input

delay shown below.

N : Number of instruction cycles existing between instruction (OP, SPB, RPB) used to output data to output port and

insutruction (IP, BP, BNP) used to input data from input port. (Number of instruction cycles to be programmed

according to the length of t

, tDH : Delay in external circuit from output port to input port.

t

DL

DL

, tDH)

When the IP instruction is used to input the return signal as shown in Fig. 10, the input delay must be considered and

three instructions are placed between the IP instruction and the crossing of input port waveform and V

or V

VI

H1

Some instructions must be placed additionally according to the length of delay (t

respectively.

IH2,

, tDH) in the external circuit after

DL

IL1

or V

IL2

,

the digit drive signal is delivered with the execution of the OP instruction ( a and c ).

No.1802–9/17

Page 10

LC6514B

<Notes for Standby Fuction Application>

[Proper cares in using standby function]

The LC6514B provides the standby function called HALT, HOLD mode to minimize the current drain when the

program is in the wait state. The standby function is controlled by the HALT instruction, the HOLD pin, RES pin. A

peripheral circuit and program must be so designed as to provide precise control of the standby function. In most

applications where the standby function is performed, voltage regulation, instantaneous break of power, and external

noise are not negligible. When designing an application circuit and program, whether or not to take some measures

must be considered according to the extent to which these factors are allowed.

This section mainly describes power failure backup for which the satndby function is mostly used. A sample application circuit where the standby function is performed precisely is shown below and notes for circuit design and program design are also given below. When using the standby function, the application circuit shown below must be used

and the notes must be also fully observed. If any other method than shown in this section is applied, it is necessary to

fully check the environmental conditions such as power failure and the actual operation of an application equipment.

[Sample application and notes]

When using the HOLD mode, an appliacation circuit and program must be designed with the following in mind.

(1) The supply voltage at the standby state must not be less than specified.

(2) Input timing of each control signal (HOLD, RES port A, INT, etc.) at the standby initiate/release state.

(3) Release operation must not be overlapped at the time of execution of the HALT instruction.

A sample application where the standby function is used for power failure backup is shown below as a concrete

method to observe these notes. A sample application circuit, its operation, and notes for program design are given

below.

1. Sample application where the standby function is used for power failure backup.

Power failure backup is an application where power failure of the main power source is detected by the HOLD pin,

etc. to cause the HOLD mode to be entered so that the current drain is minimized and a backup capacitor is used to

retain the contents of the internal registers even during power failure.

1-1. Sample application circuit (CF OSC)

Fig. 11 shows a CF OSC-applied circuit where the standby function is used for power failure backup.

Unit (resistance : Ω, capacitance : F)

Fig. 11 Sample Application Circuit

No.1802–10/17

Page 11

LC6514B

1-2. Operating waveform

The operating waveform in the sample application circuit in Fig. 11 is shown below. The mode is roughly divided

as follows.

1 Initial application of power

2 Instantaneous break

3 Return from backup mode

1-3. Operation of sample application circuit

1 At the time of initial application of power

A reset occurs and the execution of the program starts at address 000H of the program counter (PC).

2 At the time of instantaneous break

(1) At the time of very short instantaneous break

The execution of the program continues.

(2) At the time of instantaneous break being a little longer than (1)

(When the RES input voltage meets V

and HOLD input voltage does not meet VIL)

IL

A reset occurs during the execution of the program and the execution of the program starts at address 000H of

the program counter (PC).

Since the HOLD request signal is not applied to the HOLD pin, the HOLD mode is not entered.

(3) At the time of long instantaneous break (When both of the RES input voltage and HOLD input voltage meet

)

V

IL

The HOLD request signal is applied to the HOLD pin and the HOLD mode is entered.

When V+ rises after instantaneous break, a reset occurs to release the HOLD mode and the execution of the

program starts at address 000H of the program counter (PC).

3 At the time of return from backup voltage

A reset occurs and the execution of the program starts at address 000H of the program counter (PC).

No.1802–11/17

Page 12

LC6514B

1-4. Notes for circuit design

1 How to fix C3, R6, C2, R2

Fix closed loop A dischar ge time constants C3, R6 and HOLD pin char ge time constants C2, R2 so that closed loop

A fully discharges before the HOLD input voltage gets lo wer than V

input voltage is sure to get lower than V

input voltage gets lower than V

.

IL

(a reset occurs) when V+ rises after instantaneous break where the HOLD

IL

2 How to fix C3, R7

Fix RES pin charge time constats C3, R7 so that when power is applied initially or the HOLD mode is released the CF

OSC oscillates normally and the RES input voltage exceeds V

IH

3 How to fix R4, R5

Fix Tr bias constants R4, R5 so that when V+ rises after instantaneous break the RES input voltage gets lower than

(brought to L-level) befor the HOLD input voltage exceeds V

V

IL

4 How to fix C2, R3

Fix HOLD pin charge time constants C2, R3 so that when the HOLD mode is released from the backup mode the

HOLD input voltage does not exceed V

(brought to L-level).

V

IL

(not brought to H-level) until the RES input voltage gets lower than

IH

Fix C3, R7 and C2, R3 so that the time interval from the moment the HOLD input voltage exceeds V

input voltage exceeds V

is longer than the CF OSC stabilizing time.

IH

5 When the load is heavy or the polling interval is long

Since C1 discharges largely, increase the capacity of C1 or separate B detection from V+ and use a power supply or

signal that rises faster than V+.

at the time of instantaneous break and the RES

IL

and the program starts running.

(brought to H-level).

IH

until the RES

IH

1-5. Notes for software design

When the HOLD request signal is detected, the HALT instruction is executed immediately. A concrete example is

shown below.

1 An interrupt is inhibited before polling the HOLD request pin (HOLD pin).

2 Polling of the HOLD pin and the HALT instruction are programmed consecutively.

[Concrete example]

RCTL 3 ; EXTEN, TMEN←0 (External, timer interrupt intibit)

BPO AAA ; Polling of the HOLD pin (If H-level, a branch occurs to AAA.)

HALT ; The HOLD mode is entered.

AAA :

No.1802–12/17

Page 13

LC6514B

Application development tools

Evaluation chip (LC6597), simulation chip (LC65PG97) and the dedicated equipment called “applicaction development tools” are available to facilitate application development of the LC6514B.

• SDS-410 system

This is combination of floppy disk-provided CPU, CRT, and priter. This system enables application deveropment

programs of microcomputers to be prepared (edited, assembled) very speedily and efficiently in assembly language. By connecting the EVA-410 to the CPU, programs can be debugged and assembled data can be written into

the EPROM (using EPROM WRITER function contained in the EVA-410).

• EVA-410

This is an evaluation kit having EPROM WRITER function, function of parallel/serial data communication with

external equipment (SDS-410, etc.). This kit enables application development programs to be corrected or debugged

on the machine language level.

• EVA-TB3B

This is board which is connected with the EVA-410 to develop programs dedicated to the LC6514B.

• EVA-97-14B

Simulation chip (LC65PG97) is identical with the LC6510C in the I/O port breakdown voltage and pin assignment.

Since the LC6514B has high-voltage output ports and differs partially in the pin assignment, conversion board

“EVA-97-14B” with high-voltage drivers is used to evaluate the LC6514B.

(Note) The threshold level of input port A of the LC6514B can be selected to be normal/low level by option. However,

since port A of the EVA-TB3B, EVA-97-14B is of normal threshold input type, they cannot be used to evaluate

the low threshold input version of the LC6514B.

No.1802–13/17

Page 14

LC6514B

APPENDIX LC6510 Series Instruction Set (by Function)

Symbols Meaning

AC : Accumulator

ACt : Accmulator bit t

CF : Carry flag

CTL : Control register

DP : Data pointer

E : E register

EXTF : External interrupt request flag

M : Memory

M (DP) : Memory addressed by DP

P (DP

) : Input/output port addressed by DP

L

L

PC : Program counter

STACK : Stack register

TM : Timer

TMF : Timer (internal) interrupt request flag

At, Ha, La :Working resister

Fn : Flag bit n

cinomenM

Instruc-

tions

ALCCAraelC0011000011CA ←0.deraelcerastnetnocCAehTFZ

CLCFCraelC0111100011FC ←0.tesersiFCehTFC

CTSFCteS1111100011FC ←1tessiFCehTFC

AMCCAtnemelpmoC0111110111CA ← )CA(detnemelpmocerastnetnocCAehT

CNICAtnemercnI0000011111CA ← 1+)CA(+detnemercnierastnetnocCAehT

CEDCAtnemerceD0000111111CA ← 1–)CA( –detnemercederastnetnocCAehT

LARtfelCAetatoR

EATEotCArefsnarT0000110011E← )CA(otderrefsnarterastnetnocCAehT

Accumulator manipulation instructions

EAXEhtiwCAegnahcxE0000101111CA ↔ )E(stnetnocEehtdnastnetnocCAehT

MNIMtnemercnI0100011111)PD(M ← 1+])PD(M[erastnetnoc)PD(MehT

MEDMtnemerceD0100111111)PD(M ← 1–])PD(M[erastnetnoc)PD(MehT

tibBMStibatadMteS0000B011B011 B,PD(M

Memory manipulation

tibBMRtibatadMteseR0100B011B011 B,)PD(M

instructions

DACAotMddA0110000011CA ← ])PD(M[+)CA()PD(MehtdnastnetnocCAehT

CDAFChtiwCAotMddA0100000011CA ← +])PD(M[+)CA(

AADniCAtsujdalamiceD

SADniCAtsujdalamiceD

LXECAotMroevisulcxE1111101011CA ← ])PD(M[V)CA()PD(MehtdnastnetnocCAehT

DNACAotMdnA0111111011CA ← ])PD(M[)CA()PD(MehtdnastnetnocCAehT

ROCAotMrO0111101011CA ← ])PD(M[V)CA()PD(MehtdnastnetnocCAehT

MCMhtiwCAerapmoC1111110111])PD(M[ + 1+)CA()PD(MehtdnastnetnocCAehT

Operation/comparison instructions

FChguorht

noitidda

noitcartbus

D7D6D5D4D3D2D1D

edocnoitcutsnI

0000100011CA0← 1+nCA,)FC( ←

0111011011CA ← 6+)CA(.stnetnocCAehtotdeddasi6FZ

0111010111CA ← 01+)CA(.stnetnocCAehtotdeddasi01FZ

setyBselcyCnoitcnuFnoitpircseD

0

FC,)nCA( ← CA(3)

)←1deificeps)PD(MehtfotibelgnisA

1B0

)←0deificeps)PD(MehtfotibelgnisA

1B0

)FC(

<

ZF : Zero flag

( ), [ ] : Contents

←: Transfer and direction

+ : Addition

– : Subtraction

: AND

: OR

: Exclusive OR

.)0emoceb

.1

.1

.FCehthguoht

.Eeht

.degnahcxeera

.1+detnemercni

.1–detnemerced

Byb1B,

Byb1B,

.tessi

0

.tessi

0

.CAehtni

.CAehtnidecalp

.CAehtnidecalp

])PD(M[ > )CA(00

)CA(=])PD(M[11

)CA(<])PD(M[10

stibeno,1emocebstiborez(

.CAehtnidecalpsitluser

.CAehtnidecalpsitlusereht

.teser/teseraFZdna

tlusernosirapmoCFCFZ

sutatS

galf

detceffa

FZ

FCFZ

FCFZ

tfeldetfihserastnetnocCAehT

ehtdnadedda-yraniberastnetnoc

erastnetnoc)PD(M,FC,CAehT

dnadeRO-evisulexeerastnetnoc

sitluserehtdnadeROerastnetnoc

FCehtdnaderapmocerastnetnoc

FCFZ

FCFZ

FCFZ

FZ

FCFZ

FCFZ

decalpsitluserehtdnadedda-yranib

FZ

FZ

sitluserehtdnadeDNAerastnetnoc

FZ

FCFZ

skrameR

1*

atadIChtiwCAerapmoC

atadILCPDerapmoC

atadetaidemmi

htiw

L

atadetaidemmi

0100

0010

0100

1010

I3I2I1I

I3I2I1I

0011

22I3I2I1I

0

0011

22PD(LIV)3I2I1I

0

1+)CA(+etaidemmidnastnetnocCAehT

0

0

Iatad3I2I1I

0

I3I2I1I0> )CA(00

I3I2I1I

I3I2I1I0)CA(<10

Iatad3I2I1I

tlusernosirapmoCFCFZ

)CA(=11

0

0

dnaderapmocera

.teser/teseraFCdnaFZeht

etaidemmidnastnetnocLPDehT

.derapmocera

Continued on next page

FCFZ

FZ

.

No.1802–14/17

Page 15

LC6514B

Continued from preceding page.

edocnoitcutsnI

setyBselcyCnoitcnuFnoitpircseD

0

0011I

3I2I1I0

0101M02M1M012 )CA( ↔ ])PD(M[

1111011112)CA( ↔ ])PD(M[

1111111112)CA( ↔ ])PD(M[

11CA ←I3I2I1I

PDH← PD(H)V––

M02M1M

PDL← PD(L1+)

PDL← PD(L1–)

0110110012E,CA ← MOR

0001I

3I2I1I0

0010I

3I2I1I0

11PDH←0

PDL←I3I2I1I

11PDH←I3I2I1I

0111011111PDL← PD(L1+)PDehT

0111111111PDL← PD(L1–)PDehT

1111111011PDL← )CA(ehtotderrefsnarterastnetnocCAehT

0100110011)CA( ↔ PD(H)PDehtdnastnetnocCAehT

0t1t

0000

1

1

0111

0111

0111

1111

1111

0110

4

a

a

3B2B1B0

3B2B1B0

P101P9P

P3P2P1P

0010

1

0001

1

0011

1

0001

1111PD(H)↔ )0H(

0011

0000

1111PD(L)↔ )0L(

0010

11nF ←1BybdeificepsgalfA

11nF ←0BybdeificepsgalfA

22CP ← CP

8

0

1111010111CP

1101P

3P2P1P0

0101

P101P9P

P3P2P1P

4

11 KCATS ← 1+)CP(

22 KCATS ← 2+)CP(

8

0

1

1

1

CP

CP

CP

P3P2P1P

CP

P001P9P

P7P6P4P3P2P1P

)CA( ↔ )0A(

)CA( ↔ )1A(

)CA( ↔ )2A(

)CA( ↔ )3A(

PD(H)↔ )1H(

PD(L)↔ )1L(

P01P9P8P7P

P5P4P3P2P1P

← )CA,E(ehtybdeifisepssserddanaotpmujA

0ot7

6ot11

←0

0ot1

←

2ot5

0ot11

0110010011CP ← )KCATS(.sruccoenituorbusamorfnruterA

0100010011CP ← )KCATS(

FZFC ← FSZ,FSC

Instruc-

tions

cinomenM

atadILhtiwCAdaoL

D7D6D5D4D3D2D1D

atadetaidemmi

SMotCAerotS0000010011)PD(M ← CAehtniderotserastnetnocCAehT

LMmorfCAdaoL0100100011CA ← ])PD(M[ehtnidedaolerastnetnoc)PD(MehT

atadMXhtiwCAegnahcxE

PDyfidomneht.M

H

atadetaidemmihtiw

XMhtiwCAegnahcxE0101000012)CA( ↔ ])PD(M[)PD(MehtdnastnetnocCAehT

IXhtiwCAegnahcxE

Load/store instructions

DXhtiwCAegnahcxE

LBTRmorfatadelbatdaeR

atadZDLPDdaoL

PD

L

PD

L

PDdna

atadIHLPDdaoL

DNIPDtnemercnI

DEDPDtnemerceD

LATPDotCArefsnarT

ALTPDrefsnarT

HAXhtiwCAegnahcxE

Data pointer manipulation instructions

tAX

instructions

aLX

Working register manipulation

PD

H

0AX

1AX

2AX

3AX

aHX

0HX

1HX

0LX

1LX

tnemercnineht.M

tnemercedneht.M

MORmargorp

oreZhtiw

H

htiw

L

atadetaidemmi

ylevitcepser

htiw

H

atadetaidemmi

L

L

L

otCA0111100111CA (← PDL)PDehT

L

htiwCAegnahcxE

tAretsigergnikrow0111

PDegnahcxE

htiw

H

aHretsigergnikrow1111

PDegnahcxE

htiw

L

aLretsigergnikrow1111

galfBFStibgalfteS1010B

galfBFRtibgalfteseR1000B

Flag manipulation intructions

rddaPMJtnerrucehtnipmaJ

knab

AEPJtnerrucehtnipmaJ

CAdna

rddaPZCnienituorbusllaC

rddaLACnienituorbusllaC

TRmorfnruteR

Jump/subroutine instructions

enituorbus

ITRmorfnruteR

egaporezeht

knaborezeht

P7P6P5P

Eybdeifidomegap

P7P6P5P

enituortpurrretni

KNABknabegnahC1111101111CP11← CP(11).degnahcsiknabehT

sutatS

galf

skrameR

detceffa

0

atadetaidemmII

.CAeht

3I2I1I0

nidedaolsi

1*

FZ

.)PD(M

PD(fostnetnocehthtiwdeifidomera

stnetnoc

V)

H

stnetnoc

stnetnoc

ehtybdesserddaMORfostnetnocehT

decalpererastib8redro-wolesohwCP

dedaolerastnetnocCAdnaEehthtiw

.ylevitcepser

atadetaidemmihtiwdedaolsi

.1+detnemercnierastnetnocFZ

.1–detnemercnierastnetnocFZ

FZ

stnetnoc)PD(MehtdnastnetnocCAehT

FZ

M02M1M0.

FZ

PD

H

stnetnoc)PD(MehtdnastnetnocCAehT

FZ

stnetnoc)PD(MehtdnastnetnocCAehT

FZ

teser/tessiFZehT

ehtotgnidrocca

PD(fotluser

)V––

H

teser/tessiFZehT

ehtotgnidrocca

ehttastnetnoc

noitcurtsnifoemit

.noitucexe

teser/tessiFZehT

ehtotgnidrocca

PD(fotluser

.)1+

L

teser/tessiFZehT

ehtotgnidrocca

PD(fotluser

.)1–

L

dna0htiwdedaolera

.CA

PDeht,nehT.degnahcxeera

0

M02M1M0.

H

.degnahcxeerastnetnoc

PDeht,nehT.degnahcxeera

L

.1+detnemercniera

PDeht,nehT.degnahcxeera

L

.1–detnemercedera

)CA,E,hCP(

.EdnaCAehtni

PDehT

PDdna

H

L

0

0

I3I2I1I0.

Iatadetaidemmi

3I2I1I0

PDehT

H

L

L

PDL.

ehtotderrefsnarterastnetnoc

L

.CA

.degnahcxeera

PDehT

H

H

3Aro,2A,1A,0Aretsigergnikrow

.degnahcxeera0t1tybdeificeps

.degnahcxeera

PDehT

L

.degnahcxeera

3B2B1B0

3B2B1B0

CPro(

)

11

11

CP

CPro(

6

Pot

0

0

)Patadetaidemmidna

11

11

.srucco

.srucco

,

0

←

8

.dellac

.dellacsi0knabnienituorbusA

0

.sruccoenituor

gnicivrestpurretninamorfnruterA

FZ

stnetnoc

fostnetnocehtdnastnetnocCAehT

fostnetnocehtdnastnetnoc

aybdeificeps1Hro0Hretsigergnikrow

fostnetnocehtdnastnetnoc

aybdeificeps1Lro0Lretsigergnikrow

.tessi

.tesersiFZ

ehtybdeifisepssserddanaotpmujA

B3B2B1B0.

01

stib8redro-wolesohwCPehtfostnetnoc

stnetnocCAdnaEehthtiwdecalperera

si0knabfo0egapnienituorbusA

FCFZ

Continued on next page

CP11→ CP

erasgalfehT

4otnidedivid

,3Fot0Ffospuorg

,11Fot8F,7Fot4F

.51Fot21F

teser/tessiFZehT

4ehtotgnidrocca

agnidulcnistib

deificepstibelgnis

atadetaidemmiyb

dnaKNABehtfI

snoitcurtsniPMJ

detucexeera

,ylevitucesnoc

11

nehwylnoevitceffE

yletaidemmidesu

PMJehterofeb

.noitcurtsni

.

No.1802–15/17

Page 16

LC6514B

Continued from preceding page.

1100

1100

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

edocnoitcutsnI

t001t

P3P2P1P

t001t

P3P2P1P

t101t

P3P2P1P

t101t

P3P2P1P

t011t

P3P2P1P

t011t

P3P2P1P

P3P2P1P

P3P2P1P

P3P2P1P

P3P2P1P

P3P2P1P

P3P2P1P

P3P2P1P

P3P2P1P

n3n2n1n

P3P2P1P

n3n2n1n

P3P2P1P

setyBselcyCnoitcnuFnoitpircseD

0

22CP

0

0

22CP

0

0

22CP

0

0

[fit,PD(M

22CP

0

0

[fit,PD(M

22CP

0

0

[fiPD(PLt,1t01=])

22CP

0

0

[fiPD(PLt,1t00=])

0011

22CP

0

0011

22CP

0

1011

22CP

0

1011

22CP

0

1111

22CP

0

1111

22CP

0

0111

22CP

0

0111

22CP

0

22CP

0

0

22CP

0

0

Instruc-

tions

rddatABtibCAnohcnarB1110

rddatANBtibCAonnohcnarB1100

rddatMBtibMnohcnarB1110

tMNB

rdda

rddatPBtibtroPnohcnarB1110

rddatPNBtroPonnohcnarB

tib

rddaMTBremitnohcnarB1110

MTNB

rdda

rddaIBtpurretninohcnarB1110

cinomenM

D7D6D5D4D3D2D1D

P7P6P5P

P7P6P5P

P7P6P5P

tibMonnohcnarB1100

P7P6P5P

P7P6P5P

P7P6P5P

P7P6P5P

remitonnohcnarB1100

P7P6P5P

P7P6P5P

Branch instructions

rddaINBonnohcnarB

rddaCBFCnohcnarB1110

rddaCNBFConnohcnarB1100

rddaZBFZnohcnarB1110

rddaZNBFZonnohcnarB1100

rddanFBtibgalfnohcnarB1011

nFNB

rdda

tpurretni

P7P6P5P

P7P6P5P

P7P6P5P

P7P6P5P

P7P6P5P

P7P6P5P

tibgalfonnohcnarB1001

P7P6P5P

PICAottroptupnI0000001111CA ← PD(P[

POtropotCAtuptuO0110100011PD(PL)← CAtropotdettuptuoerastntnocCAehT

tibBPStibtropteS000010B1B012 PD(PL,B1B0)←1atadetaidemmIB

tibBPRtibtropteseR010010B1B012 PD(PL,B1B0)←0atadetaidemmIB

Input/output instructions

←P7P6P

0ot7

1=tCAfi

←P7P6P

0ot7

0=tCAfi

←P7P6P

0ot7

←P7P6P

0ot7

←P7P6P

0ot7

←P7P6P

0ot7

←P7P6P

0ot7

1=FMTfi

FMTneht ←0

←P7P6P

0ot7

0=FMTfi

FMTneht ←0

←P7P6P

0ot7

1=FTXEfi

FTEXneht ←0

←P7P6P

0ot7

0=FTXEfi

FTEXneht ←0

←P7P6P

0ot7

1=FCfi

←P7P6P

0ot7

0=FCfi

←P7P6P

0ot7

1=FZfi

←P7P6P

0ot7

0=FZfi

←P7P6P

0ot7

1=nFfi

←P7P6P

0ot7

0=nFfi

P4P3P

P1P

0

P4P3P

P1P

0

P4P3P

P1P

0

1t0

P4P3P

P1P

0

1t0

P4P3P

P1P

0

P4P3P

P1P

0

P4P3P

P1P

0

P4P3P

P1P

0

P4P3P

P1P

0

P4P3P

P1P

0

P4P3P

P1P

0

P4P3P

P1P

0

P4P3P

P1P

0

P4P3P

P1P

0

P4P3P

P1P

0

P4P3P

P1P

0

])PD(PtropfostntnocehT

L

sutatS

galf

5

2

Pot

0

5

2

Pot

0

5

2

1=])

Pot

0

5

2

0=])

Pot

0

5

2

Pot

0

5

2

Pot

0

5

2

tatadetaidemmi

1t0

tatadetaidemmi

1t0

tatadetaidemmi

1t0

tatadetaidemmi

1t0

tatadetaidemmi

1t0

tatadetaidemmi

1t0

ybdeificepsCAehtfotibelgnisafI

naothcnarba,1si

Patadetaidemmiybdeificepssserdda

7

.sruccoegaptnerrucehtnihtiw

ybdeificepsCAehtfotibelgnisafI

naothcnarba0si

Patadetaidemmiybdeificepssserdda

7

.sruccoegaptnerrucehtnihtiw

ybdeificeps)PD(MehtfotibelgnisafI

naothcnarba,1si

Patadetaidemmiybdeificepssserdda

7

.sruccoegaptnerrucehtnihtiw

ybdeificeps)PD(MehtfotibelgnisafI

naothcnarba,0si

Patadetaidemmiybdeificepssserdda

7

PD(PtropfotibelgnisafI

PD(PtropfotibelgnisafI

.sruccoegaptnerrucehtnihtiw

L

L

naothcnarba,1si

Patadetaidemmiybdeificepssserdda

7

.sruccoegaptnerrucehtnihtiw

naothcnarba,0si

Patadetaidemmiybdeificepssserdda

7

.sruccoegaptnerrucehtnihtiw

sserddanaothcnarba,1siFMTehtfI

Patadetaidemmiybdeificeps

Pot

7

0

.tesersi

5

2

sserddanaothcnarba,0siFMTehtfI

Patadetaidemmiybdeificeps

Pot

7

0

.tesersi

5

2

.tesersiFTXE

5

2

.tesersiFTXE

5

2

5

2

5

2

5

2

5

2

5

2

natadetaidemmi

3n2n1n0

Patad

Pot

7

0

.srucco

natadetaidemmi

3n2n1n0

Patad

Pot

7

0

.srucco

.CAehtot

L

sserddanaothcnarba,1siFTXEehtfI

Patadetaidemmiybdeificeps

Pot

7

0

ehT.sruccoegaptnerrucehtnihtiw

sserddanaothcnarba,0siFTXEehtfI

Patadetaidemmiybdeificeps

Pot

7

0

ehT.sruccoegaptnerrucehtnihtiw

sserddanaothcnarba,1siFCehtfI

Patadetaidemmiybdeificeps

Pot

7

0

.sruccoegaptnerrucehtnihtiw

sserddanaothcnarba,0siFCehtfI

Patadetaidemmiybdeificeps

Pot

7

0

.sruccoegaptnerrucehtnihtiw

sserddanaothcnarba,1siFZehtfI

Patadetaidemmiybdeificeps

Pot

7

0

.sruccoegaptnerrucehtnihtiw

sserddanaothcnarba,0siFZehtfI

Patadetaidemmiybdeificeps

Pot

7

0

.sruccoegaptnerrucehtnihtiw

ybdeificepssgalf61ehtfotibgalfehtfI

etaidemmiybdeificepssserddanaot

egaptnerrucehtnihtiw

ybdeificepssgalf61ehtfotibgalfehtfI

etaidemmiybdeificepssserddanaot

egaptnerrucehtnihtiw

dettupniera)

detceffa

ybdeificeps)

ybdeificeps)

FMT

FMTehT.sruccoegaptnerrucehtnihtiw

FMT

FMTehT.sruccoegaptnerrucehtnihtiw

FTXE

FTXE

hcnarba,1si

hcnarba,0si

FZ

skrameR

ot0ABsicinomenM

otgnidrocca3AB

.tfoeulaveht

0ANBsicinomenM

gnidrocca3ANBot

.tfoeulavehtot

0MBsicinomenM

otgnidrocca3MBot

.tfoeulaveht

0MNBsicinomenM

gnidrocca3MNBot

.tfoeulavehtot

ot0PBsicinomenM

otgnidrocca3PB

.tfoeulaveht

0PNBsicinomenM

gnidrocca3PNBot

.tfoeulavehtot

ot0FBsicinomenM

otgnidrocca51FB

.nfoeulaveht

0FNBsicinomenM

gnidrocca51FNBot

.nfoeulavehtot

PD(PL.)

1B0

PD(Ptriop

tessi)

L

1B0

PD(Ptriop

tesersi)

L

nitibenodeificeps-

nitibenodeificeps-

FZ

Continued on next page

0FNBsicinomenM

gnidrocca51FNBot

.nfoeulavehtot

sihtnehW

sinoitcurtsni

Eeht,detucexe

stnetnocretsiger

.deyortsedera

.

No.1802–16/17

Page 17

LC6514B

Continued from preceding page.

0100

0001

0100

1001

edocnoitcutsnI

B3B2B1B

B3B2B1B

setyBselcyCnoitcnuFnoitpircseD

0

0011

22 LTC ← V)LTC(

0

0011

22 LTC ← )LTC(

0

as LI, LI, LI, -----, or CLA, CLA, CLA,-----, the first LI instruction or CLA

instruction only is effective and the following LI instructions or CLA instructions are changed to the NOP instructions.

Instruc-

tions

tibLTCSretsigerlortnocteS

tibLTCRlortnocteseR

MTTWremmitetirW1111100111MT ← )CA(,)E(

TLAHtlaH1111011011tlaH.deretnesiedomybdnatsehT

Other instructions

PONnoitarepooN0000000011 noitarepooN1tub,demrofrepsinoitarepooN

cinomenM

)S(tib

D7D6D5D4D3D2D1D

)S(tibretsiger

*1 If the L1 instruction or CLA instruction is used consecutively in such a manner

B3B2B1B

B3B2B1B

FMT ←0

sutatS

galf

atadetaidemmIB

3B2B1B0

0

<

0

atadetaidemmIB

3B2B1B0

.tesersiFMTehT.remit

.teseraretsigerlortnocehtni

.tesereraretsigerlortnocehtni

.demusnocsielcycenihcam

detceffa

stibdeificeps-

stibdeificeps-

FZ

ehtnidedaolerastnetnocCAdnaEehT

FMT

skrameR

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer's

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer's products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

semiconductor products fail with some probability. It is possible that these probabilistic failures could

give rise to accidents or events that could endanger human lives, that could give rise to smoke or fire,

or that could cause damage to other property. When designing equipment, adopt safety measures so

that these kinds of accidents or events cannot occur. Such measures include but are not limited to protective

circuits and error prevention circuits for safe design, redundant design, and structural design.

In the event that any or all SANYO products(including technical data,services) described or

contained herein are controlled under any of applicable local export control laws and regulations,

such products must not be exported without obtaining the export license from the authorities

concerned in accordance with the above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or any information storage or retrieval system,

or otherwise, without the prior written permission of SANYO Electric Co. , Ltd.

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the "Delivery Specification"

for the SANYO product that you intend to use.

Information (including circuit diagrams and circuit parameters) herein is for example only ; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but

no guarantees are made or implied regarding its use or any infringements of intellectual property rights

or other rights of third parties.

This catalog provides information as of October, 2001. Specifications and information herein are subject

to change without notice.

PS No.1802–17/17

Loading...

Loading...