Page 1

Ordering number : EN*4434

O3098HA (OT)/42194TH (OT) No. 4434-1/17

LC58E76

SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquarters

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

On-Chip EPROM Microcomputer

4-Bit Single Chip Microprocessor with LCD Driver,

12 Kbytes of EPROM and 1 Kbit of RAM On-Chip

CMOS IC

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft’s

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges, or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

Overview

The LC58E76 is an on-chip EPROM microcontroller in

the LC587X series of CMOS 4-bit single chip

microcontrollers.

The LC58E76 provides the same functionality as the

LC5876 mask ROM version, and has the same pin layout.

The LC58E76 has a 16-kbyte EPROM capacity, and

corresponds to the LC5872, LC5873, LC58E74 and

LC5876.

The LC58E76 is provided in an 80-pin ceramic window

package, and programs can be written and erased

repeatedly. Thus it is optimal for use during program

development.

Applications

The LC58E76 can be used for program and function

evaluation in the following applications.

• System control of consumer products that use LCD

displays, such as cameras, CD players and tuners

• Remote controllers for products such as VCRs or tuners

• System control of instruments that use LCD displays,

such as miniature test equipment and medical

equipment.

• The LC58E76 is optimal for products that use LCD

displays, in particular, battery operated products.

Features

• Optional functions can be switched by EPROM data

settings.

The LC58E76 includes both program and option

selection EPROM on-chip. The option selection

EPROM can be used to specify almost all of the

LC587X options, including crystal/ceramic oscillator

specifications, port hold transistor selection and segment

PLA specifications. These option specifications allow

functional and operational testing in the actual PC board

used in the mass-produced end product.

• On-chip 16 kbyte program EPROM

The on-chip 16 kbyte program EPROM allows the

LC58E76 to be used to evaluate all four members of the

LC587X series. (See the series structure table on the

next page.)

• Program and option data read/write

The program and option data can be read and written

with a standard commercial EPROM writer by using a

dedicated EPROM writing board. (256K equivalent)

(Either a Sanyo or an Advanced EPROM writer should

be used.)

• Pin correspondence

The LC58E76 is pin compatible with the mask ROM

versions. (There is no chip correspondence.)

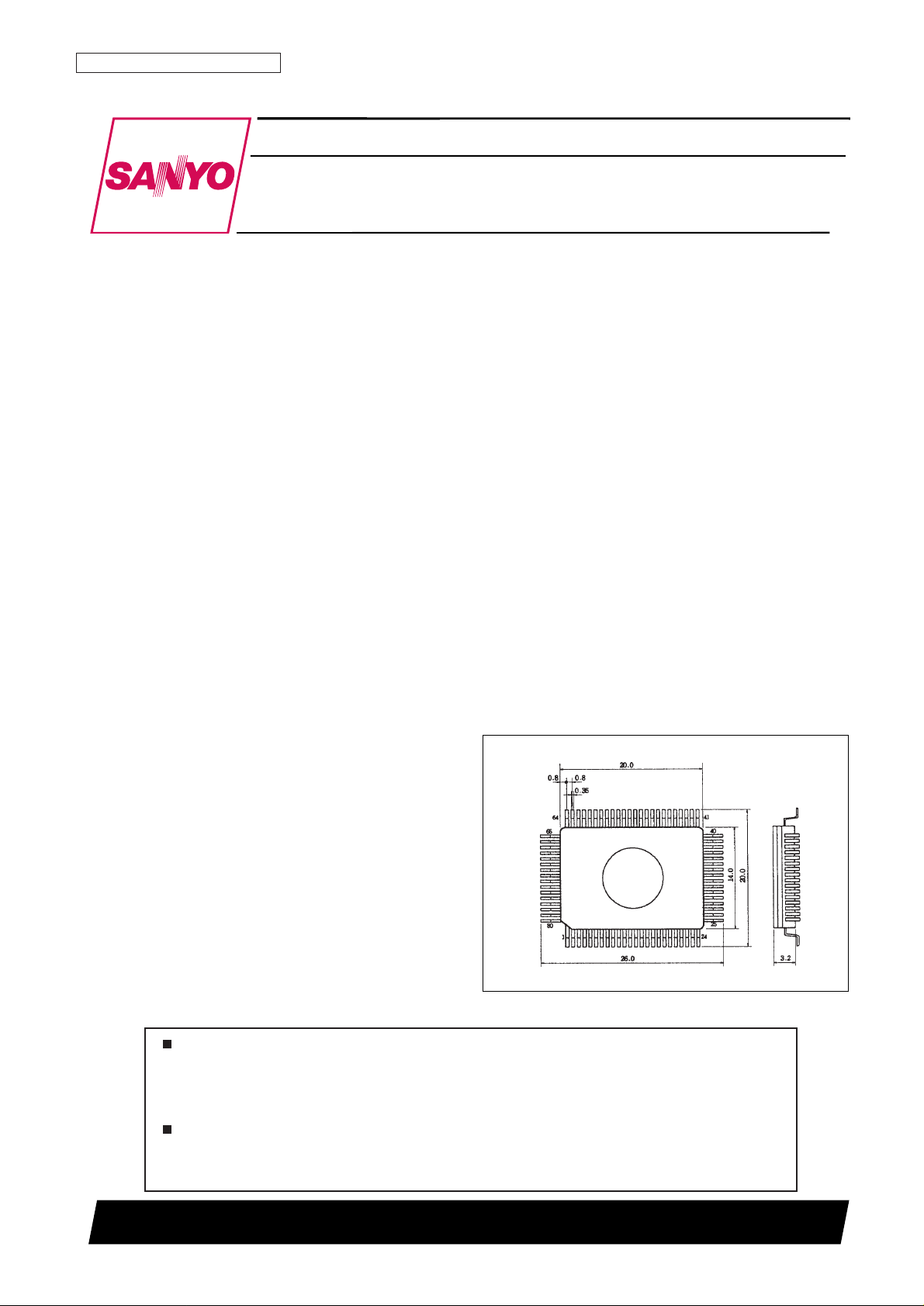

Package Dimensions

unit: mm

3152A-QFC80

[LC58E76]

SANYO: QFC80

Page 2

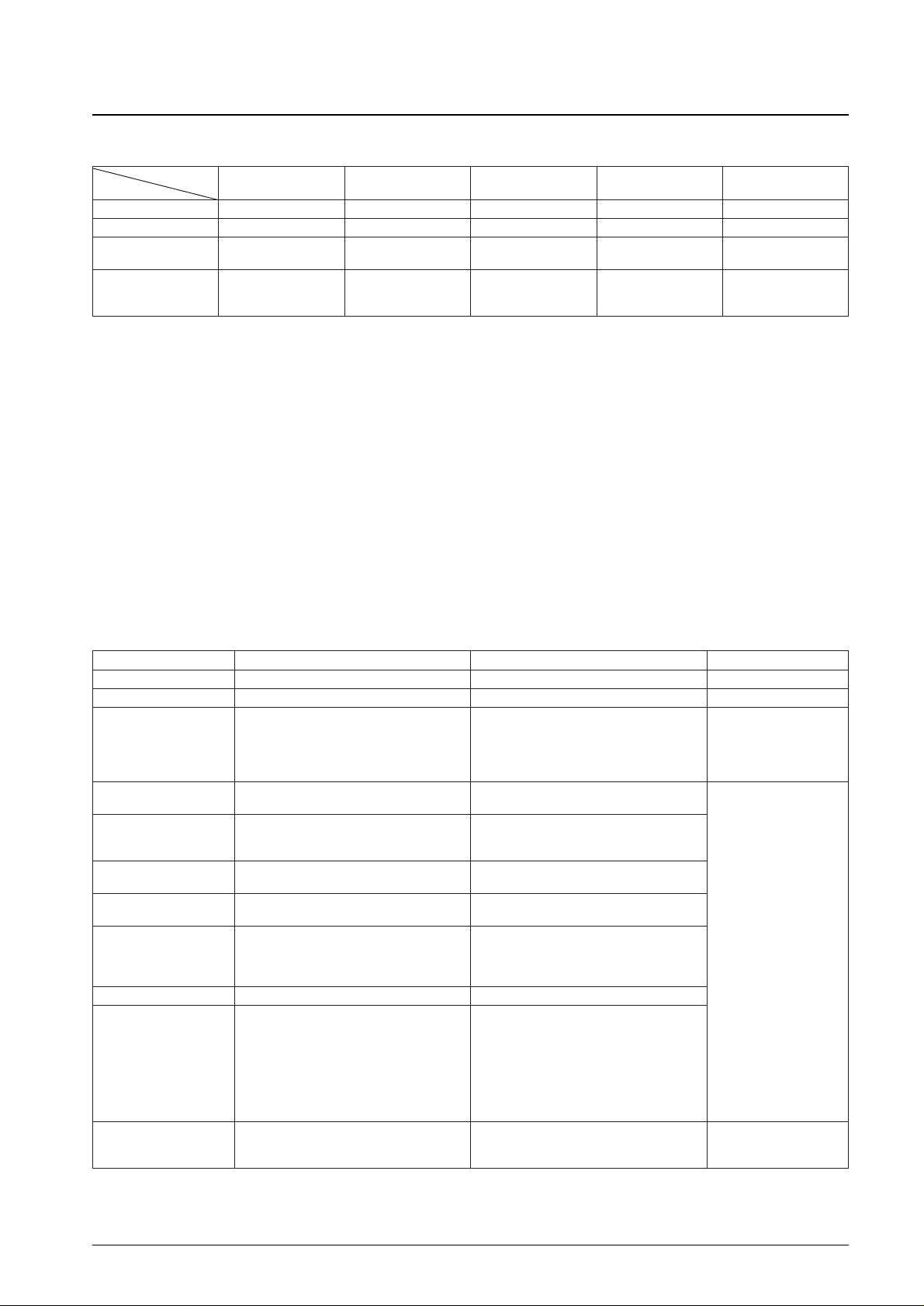

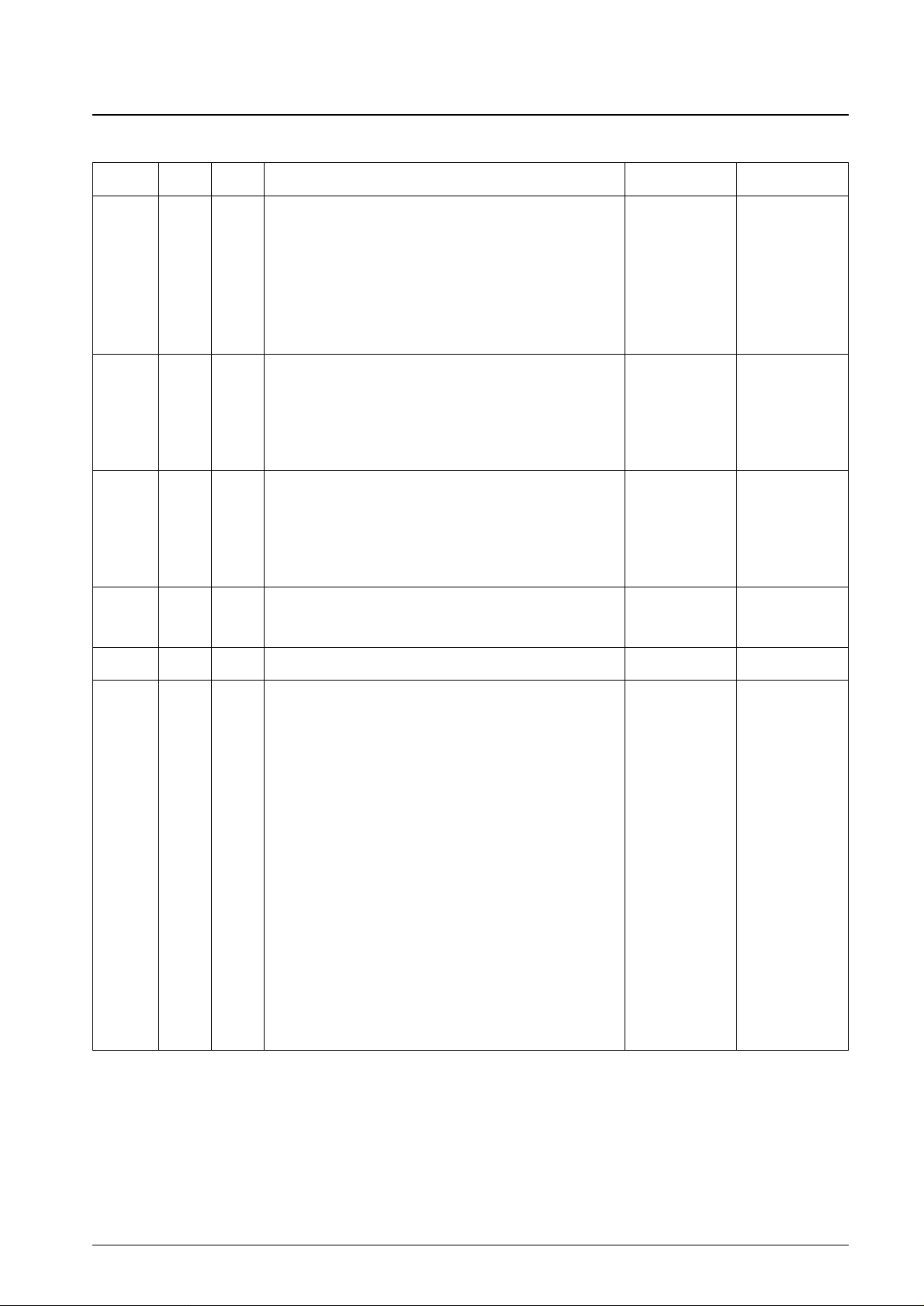

Series Structure

Usage Notes

The LC58E76 is designed for use in developing and evaluating programs for the microprocessors in the

LC587X series. However, there are differences between the LC58E76 and the mask ROM versions. Keep the

following points in mind when using the LC58E76.

1. Notes on Reset

When the RES pin input changes from high to low, the reset state is cleared after the prescribed oscillator

stabilization period has elapsed. The options and the segment PLA are set up during the first 256 cycles following the

clearing of the reset state. Instructions are executed starting at location 0 after this setup phase has completed. (The

options are undefined and the segment outputs are held at the VSSlevel when the RES pin is high and during the first

256 cycles following the clearing of the reset state.)

2. Cover the LC58E76’s window with an opaque seal when writing data to EPROM.

3. The LC58E76 and the mask ROM versions differ in the following points.

Note: Although the strobes number 00 to 1E can be used with CF 2 MHz and lower specifications, strobes number 0E, 0F and 1E cannot be used with the

CF 4 MHz specifications.

No. 4434-2/17

LC58E76

Type No.

LC5872 LC5873 LC5874 LC5876 LC58E76

Item

ROM capacity 2 k

× 16 bits 3 k × 16 bits 4 k × 16 bits 6 k × 16 bits EPROM: 16 kbytes

RAM capacity 256 × 4 bits 256 × 4 bits 256× 4 bits 256 × 4 bits 256 × 4 bits

Package QIP80 QIP80 QIP80 QIP80

QFC80 ceramic window

package

The on-chip EPROM

Notes Available in quantity Available in quantity Available in quantity Available in quantity window version will be

available shortly.

Item LC58E76 Mask ROM versions (LC587X) Note

Operating temperature 10 to 40°C –30 to 70°C

Operating supply voltage 2.8 to 5.5 V 2.0 to 6.0 V

5 µA typ. (3 V, 32 kHz crystal) 4 µA typ. (3 V, 32 kHz crystal)

20 µA typ. (5 V, 32 kHz crystal) 15 µA typ. (5 V, 32 kHz crystal)

Operating supply currents 400 µA typ. (5 V, 400 kHz ceramic) 400 µA typ. (5 V, 400 kHz ceramic) Hold mode

500 µA typ. (5 V, 2 MHz ceramic) 500 µA typ. (5 V, 2 MHz ceramic)

700 µA typ. (5 V, 4 MHz ceramic) 700 µA typ. (5 V, 4 MHz ceramic)

Common segment output Segment pins: VSS level (CMOS output) Static operation

states at reset Common pins: N-channel open drain (LCD drive output)

Segment output states

after the reset state is Off state Off state/lit state

cleared

Oscillator circuit

CF/Xtal/CF + Xtal

CF/Xtal/CF + Xtal

specifications RC/RC+Xtal/EXT/EXT+Xtal

Crystal oscillator circuit

32K/38K/65K (Note that this is 65K in the

32K/38K/65K

reset state)

Open (reset on high)

RES pin specifications Open (reset on high)

Open (reset on low)

Pull-up (reset on low)

Pull-down (reset on high)

N ports Open drain output Open drain output/CMOS output

Static Static

1/2 bias, 1/2 duty 1/2 bias, 1/2 duty

1/2 bias, 1/3 duty 1/2 bias, 1/3 duty

LCD drive specifications

1/2 bias, 1/4 duty 1/2 bias, 1/4 duty

1/3 bias, 1/3 duty 1/3 bias, 1/3 duty

1/3 bias, 1/4 duty 1/3 bias, 1/4 duty

(Substitute static when the LCD driver is not (Substitute static when the LCD driver is not

used.) used.)

Number of specifiable

00 – 1E 00 – 1E

However, 0E and 0F cannot be used with However, 0E and 0F cannot be used with

strobes

the 4 MHz specifications. the 4 MHz specifications.

• Option switching in the

EPROM version is

performed by writing

data to the option

EPROM.

• Option switching in

mask ROM versions is

performed by

specifying mask

options.

Page 3

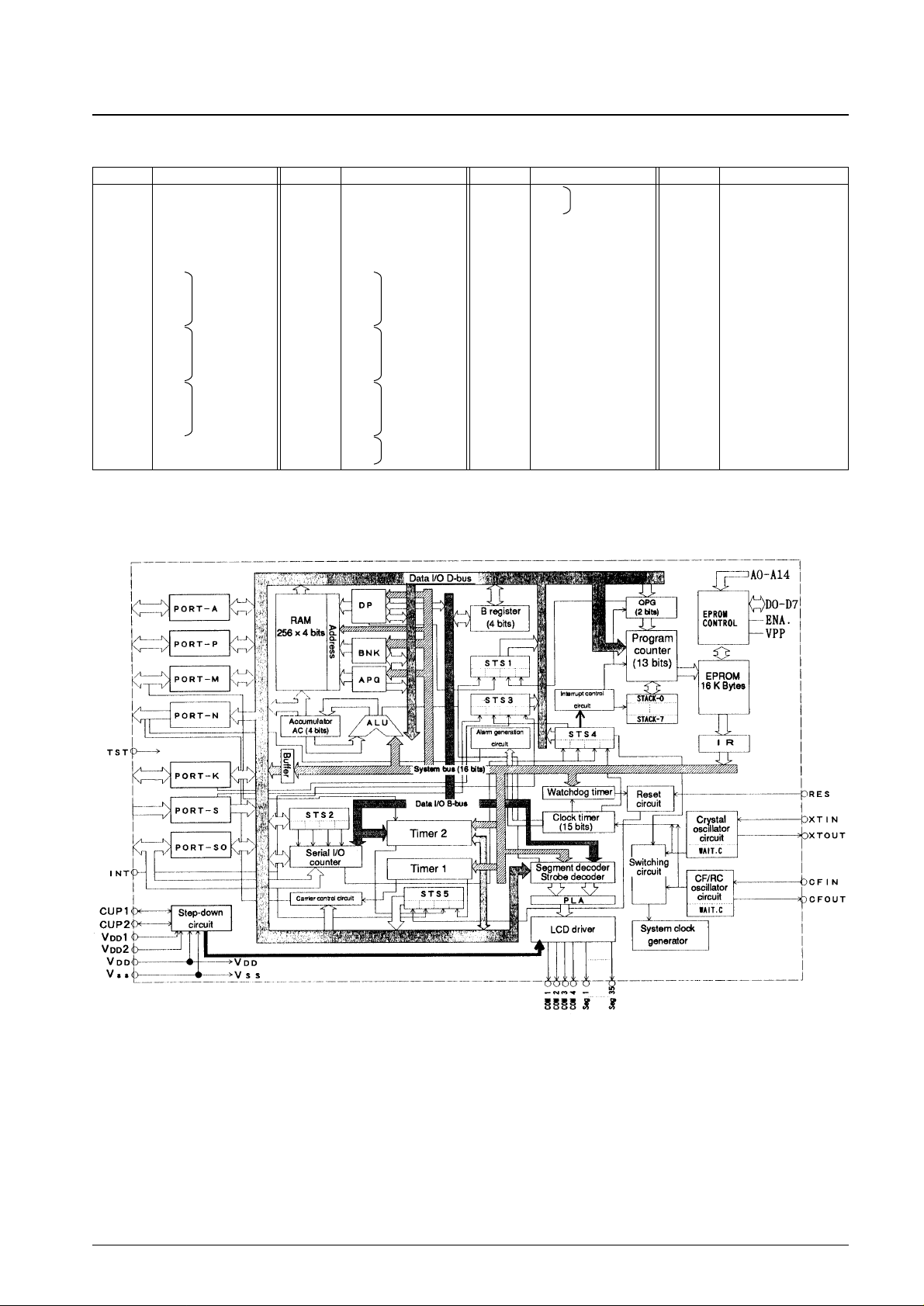

Pin Assignments

Note: 1. The TST pin must be connected to VSSin normal operation.

2. When mounting the LC58E76, do not use solder dip techniques.

System Block Diagram

LC58E76 System Block Diagram

No. 4434-3/17

LC58E76

PIn No. Symbol PIn No. Symbol PIn No. Symbol PIn No. Symbol

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

COM2

COM1

CUP1

CUP2

RES

INT

SO1

SO2

SO3

SO4

A1

A2

A3

A4

P1

P2

P3

P4

XTOUT

XTIN

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

V

DD

2

V

DD

1

V

SS

V

DD

CFIN

CFOUT

S1

S2

S3

S4

K1

K2

K3

K4

M1

M2

M3

M4

N1

N2

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

N3

N4

TST

Seg1

Seg2

Seg3

Seg4

Seg5

Seg6

Seg7

Seg8

Seg9

Seg10

Seg11

Seg12

Seg13

Seg14

Seg15

Seg16

Seg17

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Seg18

Seg19

Seg20

Seg21

Seg22

Seg23

Seg24

Seg25

Seg26

Seg27

Seg28

Seg29

Seg30

Seg31

Seg32

Seg33

Seg34

Seg35

COM4

COM3

I/O, serial I/O

ports

Input ports

Output ports

I/O ports

I/O ports

I/O ports

I/O ports

Output ports

RAM : Data memory

ROM : Program memory

DP : Data pointer register

BNK : Bank register

APG : RAM page flag

AC : Accumulator

ALU : Arithmetic and logic unit

B : B register

OPG : ROM page flag

PC : Program counter

IR : Instruction register

STS1 : Status register 1

STS2 : Status register 2

STS3 : Status register 3

STS4 : Status register 4

STS5 : Status register 5

PLA : Program logic for

segment data and strobes

WAIT.C : Wait time counter

Page 4

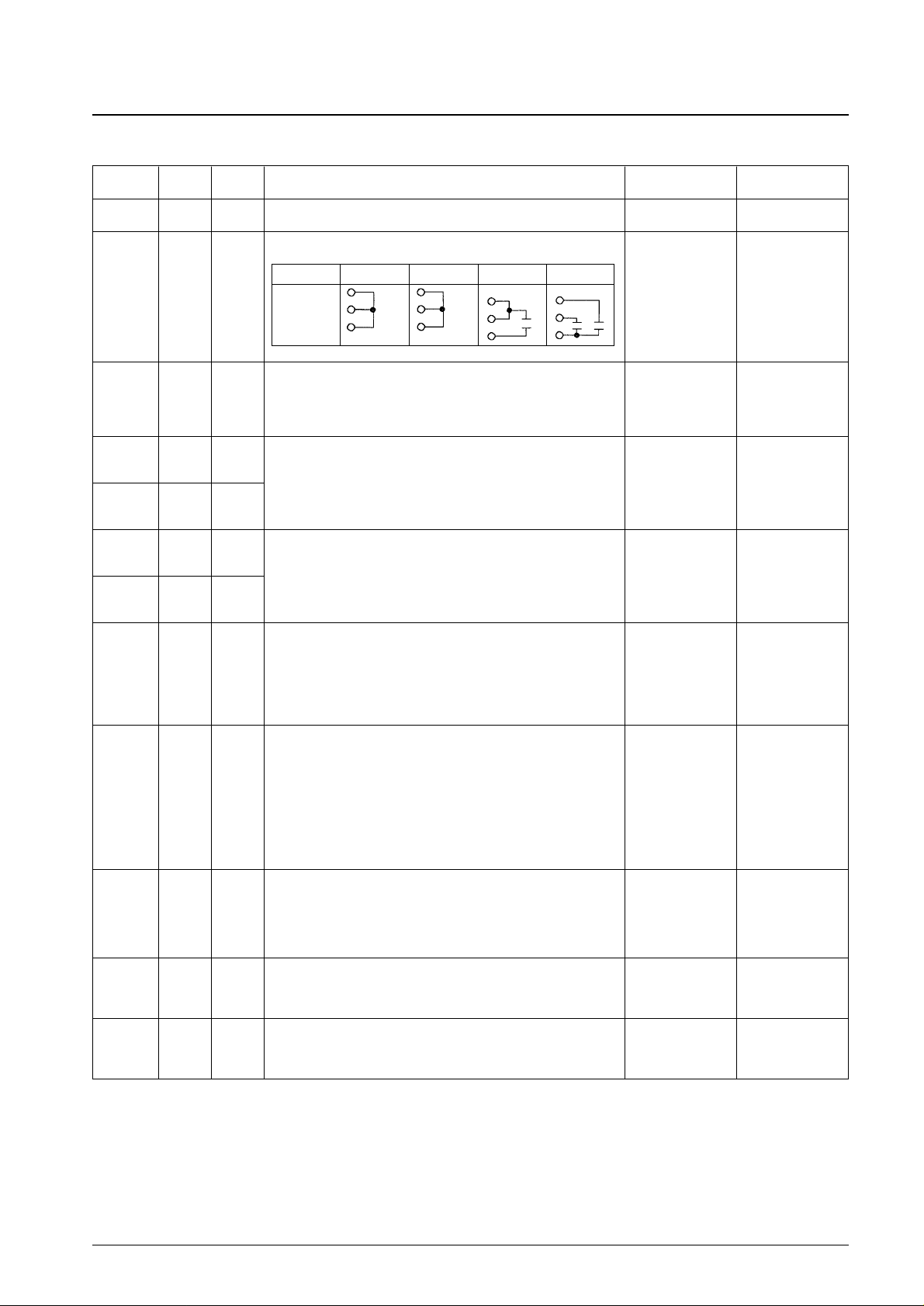

Pin Functions

No. 4434-4/17

LC58E76

Pin I/O

QFC-80

Function Option At reset

Pin No.

V

DD

— 24

V

SS

— 23

VDD1 — 22

V

DD

2 — 21

CUP1 — 3

CUP2 — 4

CFIN Input 25

CFOUT Output 26

XTIN Input 20

XTOUT Output 19

S1 27

S2 28

S3

Input

29

S4 30

K1 31

K2 32

K3

I/O

33

K4 34

M1 35

M2

I/O

36

M3 37

M4 38

A1 11

A2

I/O

12

A3 13

A4 14

P1 15

P2

I/O

16

P3 17

P4 18

Power supply

LCD drive power supply

Switching pin used to supply the LCD drive voltage to the VDD1 and

VDD2 pins

• Connect a nonpolar capacitor between CUP1 and CUP2 when 1/2 or

1/3 bias is used.

• Leave open when a bias other than 1/2 or 1/3 is used.

• CF specifications

• Not used

• The pull-up or pulldown resistors are

on.

Note: These pins go

to the floating

state when

reset is cleared.

• The pull-up or pulldown resistors are

on.

Note: These pins go

to the floating

state when

reset is cleared.

• Input mode

• Output latch data is

set high.

NON 1/1 bias 1/2 bias 1/3 bias

V

DD

VDD1

V

DD

2

V

SS

• 32k specifications

• 65k specifications

• 38k specifications

• Not used

• Transistors to hold

a low or high level

• Selection of either

pull-up or pulldown resistors

• Transistors to hold

a low or high level

• Selection of either

pull-up or pulldown resistors

The same as K1 toK4The same as K1 to

K4

The same as K1 to

K4

The same as K1 to

K4

The same as K1 to

K4

The same as K1 to

K4

System clock oscillator connections

• Ceramic resonator connection (CF specifications)

• RC component connection (RC specifications)

• External signal input pin (CFOUT is left open)

This oscillator is stopped by the execution of a STOP or SLOW

instruction.

Reference calculation (clock specifications, LCD alternation frequency),

system clock oscillator

• 32 kHz crystal resonator connection

• 65 kHz crystal resonator connection

This oscillator is stopped by the execution of a STOP instruction.

Input-only ports

• Input pins used to read data into RAM

• Built-in 7.8 ms and 1.95 ms chatter exclusion circuits

• Built-in pull-up/pull-down resistors

Note: The 7.8 ms and 1.95 ms times are the times when ø0 is

32.768 kHz.

I/O ports

• Input pins used to read data into RAM

• Output pins used to output data from RAM

• Built-in 7.8 ms and 1.95 ms input-mode chatter exclusion circuits. The

selection of 7.8 or 1.95 ms is linked to that for the S ports.

Note: The 7.8 ms and 1.95 ms times are the times when ø0 is

32.768 kHz.

I/O ports

• Input pins used to read data into RAM

• Output pins used to output data from RAM

• M4 is used as the external clock input pin in TM2 mode 3.

* The minimum period for the external clock is twice the cycle time.

• Built-in pull-up/pull-down resistors

I/O ports

• Input pins used to read data into RAM

• Output pins used to output data from RAM

• Built-in pull-up/pull-down resistors

I/O ports

Function: The same as pins A1 to A4

Continued on next page.

Page 5

Continued from preceding page.

No. 4434-5/17

LC58E76

Pin I/O

QFC-80

Function Option At reset

Pin No.

SO1 7

SO2

I/O

8

SO3 9

SO4 10

N1 39

N2

Output

40

N3 41

N4 42

INT Input 6

RES Input 5

TST Input 43

I/O ports

Function: The same as pins A1 to A4

Pins SO1 to SO3 area also used for the serial interface.

• Use of these pins in serial mode can be selected under program

control.

• Pin functions: SO1: Serial input pin

SO2: Serial output pin

SO3: Serial clock pin

The serial clock pin can be switched between internal and external,

and between rising edge output and falling edge output.

• Transistors to hold

a low or high level

• Selection of either

pull-up or pulldown resistors

• Internal serial clock

divisor selection

I 1/1

II 1/2

III 1/4

The same as K1 to

K4

The output levels on

pins N1 to N4 can be

specified as an option.

• Pin N1 to N4

output circuit type:

I N-channel

open drain

• Pin N1 to N4

output level

I High level

II Low level

• Transistors to hold

a low or high level

• Selection of either

pull-up or pulldown resistors

• Signal conversion

(rising/falling)

selection

* Only when the

input resistor open

specification is

selected

• LCD driver/

general-purpose

output switching

• LCD drive type

switching

— STATIC

— 1/2 bias – 1/2

duty

— 1/2 bias – 1/3

duty

— 1/2 bias – 1/4

duty

— 1/3 bias – 1/3

duty

— 1/3 bias – 1/4

duty

• General-purpose

output circuit

switching

— CMOS

— P-channel

open drain

— N-channel

open drain

• Output latch control

in standby modes

• LCD drive

All segments off

• General-purpose

outputs

Low level

Note: When a

combination of

LCD drive and

general- purpose outputs,

the output

state is either

all segments

off or low level.

• These pins go to

the V

SS

level

during the reset

period.

Output-only ports

• Output pins used to output data from RAM

• An alarm signal can be output from pin N4. (Note that this is only

when the N4 output latch is low.)

• An alarm signal modulated at 1, 2 or 4 kHz can be output. (These

frequencies are output when ø0 is 32.768 kHz.)

• A carrier signal can be output from N3. (Note that this is only when

the N3 output latch is low.)

Input ports

• External interrupt request inputs

• Input pins used to read data into RAM

• Input detection can be performed on either rising or falling edges.

• Built-in pull-up/pull-down resistors

LSI reset input

• The LC58E7008 resets on a high level input

Note: • An external resistor is required.

• The reset pulse must be at least 200 µs.

Test input

Connect to V

SS

in normal operation.

• LCD panel drive/general-purpose output

— LCD panel drive

I STATIC

II 1/2 bias – 1/2 duty

III 1/2 bias – 1/3 duty

IV 1/2 bias – 1/4 duty

V 1/3 bias – 1/3 duty

VI 1/3 bias – 1/4 duty

Types I to V can be specified as mask options.

— General-purpose output mode

I CMOS

II P-channel open drain

III N-channel open drain

Types I to III can be specified as mask options.

• LCD/general-purpose output control is handled by the segment PLA,

and thus program control is not required.

• These pins support output latch control on reset and in standby

states when the oscillators are stopped.

• Arbitrary combinations of LCD drive and general-purpose outputs can

be used.

Seg1,

Seg2 to

Seg35

Output

44,

45 to

78

Continued on next page.

Page 6

Continued from preceding page.

Usage Notes

The following tools and software are required when the LC58E76 is used.

The LC5870 Series Software Development Tools: For creating programs and option data.

Note that only MS-DOS machines are supported as the development host machine. See the LC5870 Series Software

Development Tools manuals for details on the use of these tools.

EC5876.EXE: This is a program that converts and merges program and option data for the LC5870 series so that it can

be written to the LC58E76 EPROM.

EPROM writing board (adapter socket: W58E68Q): This is a socket adapter that allows a general-purpose PROM writer

to be used to write program data to the LC58E76.

General-purpose PROM writer: The EVA-520 programmer that comes with the LC5870 Series Software Development

Tools cannot be used. A general-purpose PROM writer must be used.

This section describes the procedures used with the LC58E76 and the EC5876.EXE program, which is one of the tools

mentioned above. More details on LC5870 Series program development are available in LC5870 Series Users Manual

and the manuals for the LC5870 Series Development Tools and the general-purpose PROM writer.

No. 4434-6/17

LC58E76

Pin I/O

QFC-80

Function Option At reset

Pin No.

COM1 2

COM2 1

COM3

Output

80

COM4 79

These pins are nchannel open-drain

outputs during the

reset period.

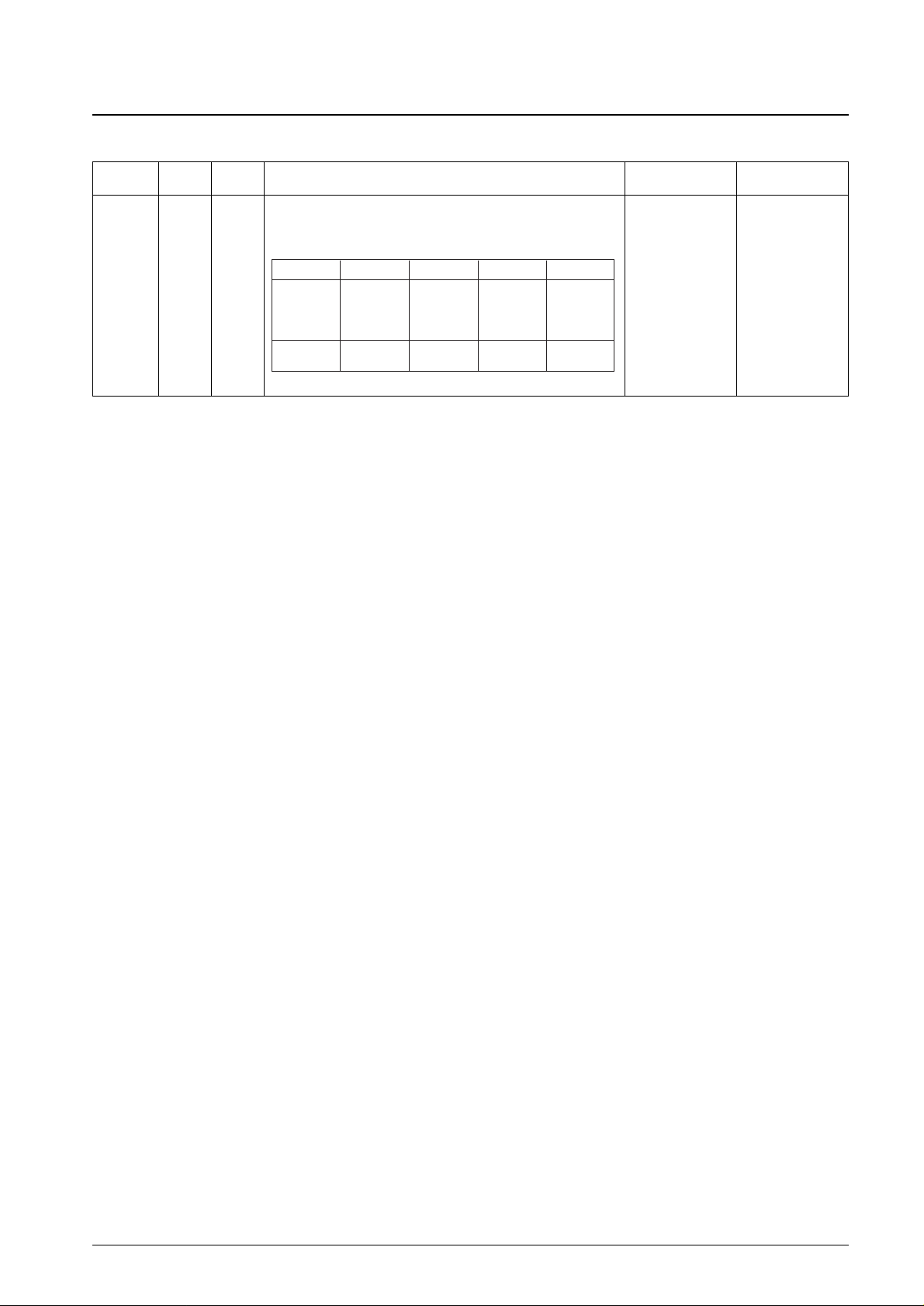

LCD panel drive common polarity outputs

The table below shows how these pins are used depending on the duty

used. (Values for alternation frequency reflect a typical specification of

32.768 MHz for ø0)

Note: A cross ( × ) indicates that the pin is not used with that duty type.

Static duty 1/2 duty 1/3 duty 1/4 duty

COM1

❍ ❍ ❍ ❍

COM2

× ❍ ❍ ❍

COM3

× × ❍ ❍

COM4

× × × ❍

Alternation

32 Hz 32 Hz 42.7 Hz 32 Hz

frequency

Page 7

1. Procedure (This flowchart describes the procedure used.)

Note: There are differences in function and characteristics between the LC58E76 and the LC5870 series mask ROM

versions. Be sure to take these differences into account when testing the programmed LC58E76. See the “Usage

Notes” section for details on the differences.

2. Using the EC5876.EXE Program (Operation)

As shown in the figures below, the data to be written to the LC58E76 consists of a program data area (instruction

code area) and an option data area. The EC5876.EXE program applies a special conversion process to the option

specification data to create the option data area data.

The EC5876.EXE program converts and merges program data and option data to create the data to be written to the

LC58E76.

• Start-up procedure

A:>EC5876 ROMSAMP.HEX PLASAMP.HEX EP-SAMP.HEX<ENT>

Or:

A:>EC5876<ENT>

*******************************************************

* LC58E76 PROGRAM & MASK OPTION CONVERSION Ver XXXXXX *

*******************************************************

ROM PROGRAM NAME : ROMSAMP.HEX<ENT>

PLA PROGRAM NAME : PLASAMP.HEX<ENT>

EP ROM WRITE NAME: EP–SAMP.HEX<ENT>

Program complete...........Program termination message

No. 4434-7/17

LC58E76

Specification

determination

Mask option

specification

Program creation and

debugging

Data conversion and

merging for the

LC58E76

PROM writer setup

Write data transfer

EPROM writing

board setup

Write

Mounted configuration

program testing

Use the SU5870.EXE program to create the option specification data.

Use the LC5870S.EXE cross assembler to create the program. Use the dedicated development tools

for debugging.

Use the EC5876.EXE program to convert and merge the program and option data. This creates the

data to be written to the LC58E76 EPROM. (See “Using the EC5876.EXE Program”.)

Setup the PROM writer ROM type, the start and stop addresses, and other states.

(See “Use of the EPROM Writing Board”.)

Transfer the LC58E76 EPROM data created with the EC5876.EXE program to the PROM writer.

Mount the PROM writer in the LC58E76 EPROM writing board.

Mount the LC58E76 in the EPROM writing board, and write the data.

Apply an opaque seal to the LC58E76 window at the point that the data is written.

Mount the LC58E76 in the socket in the application circuit, and check that the program functions

correctly.

Page 8

• Error messages

Error ON filename.HEX, FILE NOT FOUND...............The file “filename.HEX” was not found.

The filename “filename.HEX” was incorrect.

Error ON MAKE LC5876, 5874, 5873, 5872.............The ROM data and the option data object

microprocessor type did not agree. The ROM data

must be created with a cross assembler and option

specification software designed for the same

microprocessor type.

Error ON filename.HEX, EOF NOT DETECTED..........A hexadecimal record end marker was not found

in the file “filename.HEX”.

Error ON filename.HEX, ILLEGAL CHARACTER........A character other than 0 to 9 or A to F was found

in a hexadecimal context while reading the file

“filename.HEX”.

Error ON filename.HEX, ADDRESS OVER....................An address in the file “filename.HEX” exceeded

the allowed range.

Error ON filename.HEX, ILLEGAL FILEHDR.............The header in the file “filename.HEX” is not for

the LC5870 series.

There was an error in the hexadecimal file

specification.

Error ON command line input,

INVALID NUMBER OF PARAMETERS...............The number of parameters in the command line

was inappropriate.

Error ON ILLEGAL, MASK OPTION DATA......................There was an error in the mask option data.

• EPROM data structure

Cross assembler and mask option data EPROM Data

(1) Cross assembler data

(2) Mask option data

No. 4434-8/17

LC58E76

Page 9

3. Use of the W58E68Q EPROM Writing Board (Board used with both the LC58E68 and the LC58E76)

The EPROM writing board is a socket adapter that fits the LC58E76 to the device socket in a general-purpose

PROM writer.

• EPROM Writing Board Appearance

• PROM writer settings

— ROM type: 256 K, VPP = 21 V mode

— Start and stop addresses: Set these to 0000H and 40FFH.

4. Erasing LC58E76 EPROM Data

Use a general-purpose EPROM eraser to erase data written to an LC58E76.

5. Notes On Order Mask ROM

• The following methods cannot be used to order LC5870 Series mask ROM products.

— Use of “.HEX” files that were converted and merged for use in an LC58E76

— Use of an LC58E76 itself

• Ordering mask ROM

— Use the program hexadecimal data generated by the cross assembler.

— Use the option hexadecimal data generated by the option specification software.

— Provide three EPROMs to which the program hexadecimal data has been written using a general-purpose

EPROM writer.

— Provide three EPROMs to which the option hexadecimal data has been written using a general-purpose

EPROM writer.

No. 4434-9/17

LC58E76

Page 10

Specifications

The electrical characteristics listed here are provisional values and are subject to change.

Absolute Maximum Ratings at VSS= 0 V, TA = 25°C

No. 4434-10/17

LC58E76

Parameter Symbol Conditions/Pin

Ratings

Unit

min typ max

V

DD

–0.3 +6.0 V

Maximum supply voltage V

DD

1 –0.3 V

DD

V

V

DD

2 –0.3 V

DD

V

V

I

(1)

As allowed in the specified circuit (Figure 1)

Allowed up to the voltage that appears

XTIN, CFIN

Maximum input voltage S1 – 4, K1 – 4, P1 – 4, SO1 – 4, A1 – 4, RES,

V

DD

VI(2) INT, TST –0.3

+0.3

V

(K, P, M, SO and A ports in input mode)

V

O

(1)

As allowed in the specified circuit (Figure 1)

Allowed up to the voltage that appears

XTOUT, CFOUT

K1 –4, P1 – 4, SO1 – 4, A1 – 4, N1 – 4,

V

DD

Maximum output voltage VO(2) CUP1, CUP2, Seg1 – 35, COM1 – 4, –0.3

+0.3

V

(K, P, M, SO and A ports in output mode)

V

O

(3) Open drain specifications

N1 to N4

–0.3 +13 V

(n-channel)

I

O

(1) Per pin

N1 – 4

0 15 mA

I

O

(2) Per pin –10 0 mA

I

O

(3) Per pin

K1 – 4, P1 – 4, M1 – 4, SO1 – 4, 0 5 mA

Output pin current

I

O

(4) Per pin

A1 – 4 –5 0 mA

Σ I

O

(1)

Total (summed)

K1 – 4, P1 – 4, M1 – 4, 70 mA

pin current

SO1 – 4, A1 –4, N1 – 4,

Σ IO(2)

Total (summed)

Seg1 – 35

–70 mA

pin current

Allowable power dissipation Pdmax For the QFC80 window ceramic flat package 500 mW

Operating temperature Topr 10 40 °C

Storage temperature Tstg –55 +125 °C

Page 11

Allowable Operating Ranges at VSS= 0 V, Ta = 25°C

Note: * In a state with the CF/RC oscillator and the crystal oscillator completely stopped, and all internal circuits stopped

Electrical Characteristics at VDD= 2.8 to 3.2 V, VSS= 0 V, Ta = 25°C

Note: * The 24 pins S1 to S4, K1 to K4, P1 to P4, M1 to M4, SO1 to SO4 and A1 to A4.

No. 4434-11/17

LC58E76

Parameter Symbol Conditions/Pin

Ratings

Unit

min typ max

No LCD specifications: V

DD

1 = VDD2 = V

DD

2.8 5.5 V

Static drive specifications: V

DD

1 = VDD2 = V

DD

2.8 5.5 V

Supply voltage V

DD

1/2 bias specifications: VDD1 = VDD2 ≅ 1/2V

DD

2.8 5.5 V

1/3 bias specifications: V

DD

1 ≅ 2 × 1/3V

DD

2.8 5.5 V

V

DD

2 ≅ 1/3V

DD

Data retention supply voltage V

HD

RAM and register contents retention voltage* 2.8 V

DD

V

S1 – 4, K1 – 4, P1 – 4, M1 – 4, SO1 – 4,

Input high-level voltage VIH1

A1 – 4, INT

0.7 V

DD

V

DD

V

(K, P, M, SO and A ports in input mode)

Input low-level voltage VIL1 0 0.3 V

DD

V

Input high-level voltage V

IH

2

RES pin

0.75 V

DD

V

DD

V

Input low-level voltage V

IL

2 0 0.25 V

DD

V

Input high-level voltage V

IH

3

CFIN pin

0.75 V

DD

V

DD

V

Input low-level voltage V

IL

3 0 0.25 V

DD

V

Operating frequency 1 fopg1 V

DD

= 2.8 to 5.5 V, 32 kHz

XTIN/XTOUT

32 33 kHz

Operating frequency 2 fopg2 V

DD

= 2.8 to 5.5 V, 38 kHz crystal 37 39 kHz

Operating frequency 3 fopg3 V

DD

= 2.8 to 5.5 V, 65 kHz

oscillator

60 70 kHz

Operating frequency 4 fopg4 V

DD

= 2.8 to 5.5 V

CFIN/CFOUT CF

190 1200 kHz

Operating frequency 5 fopg5 V

DD

= 3.0 to 5.5 V 190 2300 kHz

Operating frequency 6 fopg6 V

DD

= 4.5 to 5.5 V

specifications

190 4200 kHz

Pins SO1 and SO3

(in serial mode)

Operating frequency 7 fopg7 V

DD

= 3.0 to 5.5 V

The rising and falling

DC 200 kHz

edges of input signal

and clock waveforms

must be ≤ 10 µs.

Parameter Symbol Conditions/Pin

Ratings

Unit

min typ max

R

IN

1 A

VIN = 0.2 V

DD

,

60 300 1200 kΩ

Low-level hold transistor *, Figure 2

RIN1 B VIN = VDD, Pull-down resistor *, Figure 2 30 150 500 kΩ

R

IN

1 C

VIN = 0.8 V

DD

,

60 300 1200 kΩ

High-level hold transistor *, Figure 2

Input resistance

RIN1 D VIN = VSS, Pull-up resistor *, Figure 2 30 150 500 kΩ

R

IN

2 A VIN = 0.2 VDD, INT low-level hold transistor 60 300 1200 kΩ

R

IN

2 B VIN = VDD, INT pull-down resistor 300 1500 5000 kΩ

R

IN

2 C VIN = 0.8 VDD, INT high-level hold transistor 60 300 1200 kΩ

R

IN

2 D VIN = VSS, INT pull-up resistor 300 1500 5000 kΩ

R

IN

3

VIN = V

DD

,

20 70 300 kΩ

With a pull-down resistor on the TST pin

Output low-level voltage VOL(1) IOL = 1.0 mA N1 – 4 0.5 V

Output high-level voltage V

OH

(2) IOH = –400 µA

K1 – 4, P1 – 4, M1 – 4,

V

DD

– 0.5 V

SO1 – 4, A1 – 4

Output low-level voltage V

OL

(2) IOL = 400 µA

(K, P, M, SO and A ports

0.5 V

in output mode)

Output off leakage current | I

OFF

| VOH = 10.5 V N1 – 4, Figure 10 1.0 µA

Segment port output impedance

• When CMOS output ports are used

Output high-level voltage V

OH

(3) IOH = –100 µA

Seg 1 to 35

VDD– 0.5 V

Output low-level voltage V

OL

(3) IOL = 100 µA 0.5 V

Continued on next page.

Page 12

Continued from preceding page.

No. 4434-12/17

LC58E76

Parameter Symbol Conditions/Pin

Ratings

Unit

min typ max

• When p-channel open-drain output ports are used (See Figure 11.)

Output high-level voltage V

OH

(3) IOH= –100 µA

Seg 1 to 35

VDD– 0.5 V

Output off leakage current | I

OFF

| VOL= V

SS

1.0 µA

• When n-channel open-drain output ports are used (See Figure 11.)

Output low-level voltage V

OL

(3) IOL= 100 µA

Seg 1 to 35

0.5 V

Output off leakage current | I

OFF

| VOH= V

DD

1.0 µA

• Static drive

Output high-level voltage V

OH

(4) IOH= –20 µA Seg 1 to 35 VDD– 0.2 V

Output low-level voltage V

OL

(4) IOL= 20 µA 0.2 V

Output high-level voltage V

OH

(5) IOH= –100 µA COM1 VDD– 0.2 V

Output low-level voltage V

OL

(5) IOL= 100 µA 0.2 V

• 1/2 bias

Output high-level voltage V

OH

(4) IOH= –20 µA

Seg 1 to 35

VDD– 0.2 V

Output low-level voltage V

OL

(4) IOL= 20 µA 0.2 V

Output high-level voltage V

OH

(6) IOH= –100 µA VDD– 0.2 V

Output middle-level voltage V

OM

2–1

I

OH

= –100 µA

COM1 – 4 V

DD

/2 – 0.2 VDD/2 + 0.2 V

I

OL

= 100 µA

Output low-level voltage V

OL

(6) IOL= 100 µA 0.2 V

• 1/3 bias

Output high-level voltage V

OH

(4) IOH= –20 µA VDD– 0.2 V

Output middle-level voltage

V

OM

1–1

I

OH

= –20 µA

Seg 1 to 35

2V

DD

/3 – 0.2 2VDD/3 + 0.2 V

V

OM

1–2

I

OL

= 20 µA

V

DD

/3 – 0.2 VDD/3 + 0.2 V

Output low-level voltage V

OL

(4) IOL= 20 µA 0.2 V

Supply leakage current I

LEK

(1) VDD= 3.0 V

Ta = 25°C, STOP mode,

1.0 µA

Figure 3

VDD= 3.0 V

Input leakage current I

OFF

VIN= V

DD

1.0 µA

V

IN

= V

SS

–1.0 µA

VDD= 3.0 V, C1 = C2 = 0.1 µF

Output voltage 1 V

DD

1–(1) 1/2 bias, fopg = 32.768 kHz, VDD1 = V0 1.5 V

Figure 4

V

DD

2–(1)

V

DD

= 3.0 V, C1 = C2 = 0.1 µF

V

DD

1 = V0

2.0 V

Output voltage 2

V

DD

2–(2)

1/3 bias, fopg = 32.768 kHz,

V

DD

2 = V0

1.0 V

Figure 4

Ta = 25°C, Crystal oscillator

specifications, Crystal: 32 kHz,

Supply current 1 | I

DD

| 1 V

DD

DD

= 3.0 V Cg = 20 pF, CI = 25 kΩ 5.0 µA

Halt mode, LCD at 1/3 bias,

Figure 6

Ta = 25°C, Crystal oscillator

specifications, Crystal: 38 kHz

Supply current 2 | I

DD

| 2 VDD= 3.0 V or 65 kHz, Cg = 10 pF, 10.0 µA

CI = 25 kΩ, Halt mode,

LCD at 1/3 bias, Figure 6

Ta = 25°C, CF oscillator

specifications, CF: 400 kHz,

Supply current 3 | I

DD

| 3 VDD= 3.0 V Ccg = Ccd = 330 pF 150 µA

Halt mode, LCD at 1/3 bias,

Figure 8

Ta = 25°C, CF oscillator

Supply current 4 | I

DD

| 4 VDD= 3.0 V

specifications, CF: 1 MHz,

200 µA

Ccg = Ccd = 100 pF, Halt mode,

LCD at 1/3 bias, Figure 8

S1 – 4, K1 – 4, P1 – 4,

M1 – 4, SO1 – 4, A1 – 4,

INT, RES (K, P, M, SO

and A ports in input

mode, INT and RES pin

open specifications)

Continued on next page.

Page 13

Continued from preceding page.

Electrical Characteristics at VDD= 4.5 to 5.5 V, VSS= 0 V, Ta = 25°C

Note: * The 24 pins S1 to S4, K1 to K4, P1 to P4, M1 to M4, SO1 to SO4 and A1 to A4.

No. 4434-13/17

LC58E76

Parameter Symbol Conditions/Pin

Ratings

Unit

min typ max

V

DD

= 2.8 V Crystal oscillator specifications,

Oscillator start time | TSTT | with a 32 kHz crystal 5 s

CI ≤ 25 kΩ, Cg = 20 pF

Oscillator stabilization degree ∆f

V

DD

= 2.95

Figure 6 3 ppm

to 3.05 V

Crystal oscillator specifications,

Oscillator start time | TSTT | V

DD

= 2.8 V

with a 38 or 65 kHz crystal

5 s

XCg = 10 pF, CI ≤ 25 kΩ

Figure 6

CF oscillator specifications,

Oscillator start time | TSTT | V

DD

= 2.8 V with a 400 kHz CF used 30 ms

Ccg = Ccd = 330 pF, Figure 7

CF oscillator specifications,

Oscillator start time | TSTT | V

DD

= 2.8 V

with an 800 kHz CF used

30 ms

Ccg = Ccd = 220 pF or 100 pF

Figure 7

Oscillator compensation

Cd V

DD

= 3.0 V XTOUT pin (built-in) 20 pF

capacitance

Parameter Symbol Conditions/Pin

Ratings

Unit

min typ max

R

IN

1 A

VIN = 0.2 V

DD

,

30 120 500 kΩ

Low-level hold transistor *, Figure 2

RIN1 B VIN = VDD, Pull-down resistor *, Figure 2 10 50 200 kΩ

R

IN

1 C

VIN = 0.8 V

DD

,

30 120 500 kΩ

High-level hold transistor *, Figure 2

Input resistance

RIN1 D VIN = VSS, Pull-up resistor *, Figure 2 10 50 200 kΩ

R

IN

2 A VIN = 0.2 VDD, INT low-level hold transistor 30 120 500 kΩ

R

IN

2 B VIN = VDD, INT pull-down resistor 100 500 2000 kΩ

R

IN

2 C VIN = 0.8 VDD, INT high-level hold transistor 30 120 500 kΩ

R

IN

2 D VIN = VSS, INT pull-up resistor 100 500 2000 kΩ

R

IN

3

VIN = V

DD

,

20 70 300 kΩ

With a pull-down resistor on the TST pin

Output low-level voltage VOL(1) IOL = 10.0 mA N1 – 4 0.5 V

Output high-level voltage V

OH

(2) IOH = –1.0 mA

K1 – 4, P1 – 4, M1 – 4,

V

DD

– 0.5 VDD– 0.2 V

SO1 – 4, A1 – 4

Output low-level voltage V

OL

(2) IOL = 2.0 mA

(K, P, M, SO and A ports

0.2

0.5 V

in output mode)

Output off leakage current | I

OFF

| VOH = 10.5 V N1 – 4, Figure 10 1.0 µA

Segment port output impedance

• When CMOS output ports are used

Output high-level voltage V

OH

(3) IOH = –500 µA

Seg 1 to 35

VDD– 0.5 VDD– 0.2 V

Output low-level voltage V

OL

(3) IOL = 500 µA 0.5 V

• When p-channel open drain output ports are used (See Figure 11.)

Output high-level voltage V

OH

(4) IOH = –500 µA

Seg 1 to 35

VDD– 0.5 VDD– 0.2 V

Output off leakage current | I

OFF

| VOL = V

SS

1.0 µA

• When n-channel open-drain output ports are used (See Figure 11.)

Output low-level voltage V

OL

(4) IOL = 500 µA

Seg 1 to 35

0.2 0.5 V

Output off leakage current | I

OFF

| VOH = V

DD

1.0 µA

• Static drive

Output high-level voltage V

OH

(4) IOH = –40 µA

Seg 1 to 35

VDD– 0.2 V

Output low-level voltage V

OL

(4) IOL = 40 µA 0.2 V

Output high-level voltage V

OH

(6) IOH = –400 µA

COM1

VDD– 0.2 V

Output low-level voltage V

OL

(6) IOL = 400 µA 0.2 V

Continued on next page.

Page 14

Continued from preceding page.

No. 4434-14/17

LC58E76

Parameter Symbol Conditions/Pin

Ratings

Unit

min typ max

• 1/2 bias

Output high-level voltage V

OH

(4) IOH= –40 µA

Seg 1 to 35

VDD– 0.2 V

Output low-level voltage V

OL

(4) IOL= 40 µA 0.2 V

Output high-level voltage V

OH

(6) IOH= –400 µA VDD– 0.2 V

Output middle-level voltage V

OM

2–1

I

OH

= –400 µA

COM1 – 4 V

DD

/2 – 0.2 VDD/2 + 0.2 V

I

OL

= 400 µA

Output low-level voltage V

OL

(6) IOL= 400 µA 0.2 V

• 1/3 bias

Output high-level voltage V

OH

(4) IOH= –40 µA VDD– 0.2 V

Output middle-level voltage

V

OM

1–1 IOH= –40 µA

Seg 1 to 35

2VDD/3 – 0.2 2VDD/3 + 0.2 V

V

OM

1–2

I

OL

= 40 µA

V

DD

/3 – 0.2 VDD/3 + 0.2 V

Output low-level voltage V

OL

(4)

I

OL

= 40 µA

0.2 V

Output high-level voltage V

OH

(6) IOH= –400 µA VDD– 0.2 V

Output middle-level voltage

V

OM

2–1

I

OH

= –400 µA

COM1 – 4

2V

DD

/3 – 0.2 2VDD/3 + 0.2 V

V

OM

2–2

I

OL

= 400 µA

V

DD

/3 – 0.2 VDD/3 + 0.2 V

Output low-level voltage V

OL

(6) IOL= 400 µA 0.2 V

Supply leakage current I

LEK

(1) VDD= 5.5 V

Ta = 25°C, Stop mode,

1.0 µA

Figure 3

VDD= 5.5 V

Input leakage current I

OFF

VIN= V

DD

1.0 µA

V

IN

= V

SS

–1.0 µA

Output voltage 1 V

DD

1–(1)

V

DD

= 5.0 V, C1 = C2 = 0.1 µF, VDD1 = V0

2.5 V

1/2 bias, fopg = 32.768 kHz Figure 4

V

DD

2–(1)

V

DD

= 5.0 V, C1 = C2 = 0.1 µF,

V

DD

1 = V0

3.33 V

Output voltage 2

V

DD

2–(2)

1/3 bias, fopg = 32.768 kHz

V

DD

2 = V0

1.67 V

Figure 4

Ta = 25°C, Crystal oscillator

specifications, Crystal: 32 kHz,

Supply current 1 | I

DD

| 1 V

DD

DD

= 5.0 V Cg = 20 pF, CI = 25 kΩ 20 µA

Halt mode, LCD at 1/3 bias,

Figure 6

Ta = 25°C, Crystal oscillator

specifications, Crystal: 38 kHz

Supply current 2 | I

DD

| 2 VDD= 5.0 V or 65 kHz, Cg = 10 pF, 30 µA

CI = 25 kΩ, Halt mode, LCD

at 1/3 bias, Figure 6

Ta = 25°C, CF oscillator

specifications, CF: 400 kHz,

Supply current 3 | I

DD

| 3 VDD= 5.0 V Ccg = Ccd = 330 pF 400 µA

Halt mode, LCD at 1/3 bias,

Figure 7

Ta = 25°C, CF oscillator

Supply current 4 | I

DD

| 4 VDD= 5.0 V

specifications, CF: 1 MHz,

450 µA

Ccg = Ccd = 100 pF, Halt mode,

LCD at 1/3 bias, Figure 8

Ta = 25°C, CF oscillator

Supply current 5 | I

DD

| 5-1 VDD= 5.0 V

specifications, CF: 2 MHZ,

500 µA

Ccg = Ccd = 33 pF, Halt mode,

LCD at 1/3 bias, Figure 8

Ta = 25°C, CF oscillator

Supply current 6 | I

DD

| 6-1 VDD= 5.0 V

specifications, CF: 4 MHz,

700 µA

Ccg = Ccd = 33 pF, Halt mode,

LCD at 1/3 bias, Figure 8

Oscillator compensation

Cd V

DD

= 5.0 V XTOUT pin (built-in) 20 pF

capacitance

S1 – 4, K1 – 4, M1 – 4,

SO1 – 4, A1 – 4, INT,

RES (K, P, M, SO and A

ports in input mode, INT

and RES pin open

specifications)

Page 15

Figure 1-(1) Specified Oscillator Circuit (XT pin) Figure 1-(2) Specified Oscillator Circuit (CF pin)

Figure 2 S, K, P, M, SO and A Port Input Circuit

(Reference)

Recommended Ceramic Resonators for Mask ROM Versions

No. 4434-15/17

LC58E76

Xtal

32 k: 32.768 kHz

65 k: 65.536 kHz

38 k: 38.2293 kHz

Manufacturer Murata Mfg. Co., Ltd. Kyocera Corporation

Item

Type No. Ccg (pF) Ccd (pF) Type No. Ccg (pF) Ccd (pF)

Frequency

400 kHz CSB400P 330 330 KBR-400B 330 330

800 kHZ CSB800J 220 220 KBR-800H 100 100

1 MHz CSB1000J 220 220 KBR-1000H 100 100

2 MHz CSA2.00MG, CST2.00MG 33 33 KBR-2.00MS 33 33

4 MHz CSA4.00MG, CST4.00MG 33 33 KBR-4.00MS 33 33

Figure 13 Serial I/O Timing

(in external clock mode)

Figure 14 Timer 2 External Clock Input Timing

(in external clock mode: pin M4)

Page 16

Figure 3 Supply Leakage Current Test Circuit

Figure 4 Output Voltage Test Circuit

Figure 6: Supply Current Test Circuit

Figure 8 Supply Current Test Circuit

Figure 3

• In the stop state

• With the S-port input resistors on

• With the I/O ports in output mode with high-level data

values

• With the INT pin built-in resistor connected and in the

open state

• With an external pull-down resistor on the RES pin

• The LCD-port values do not include the external

component currents.

• With a crystal frequency between 32 and 65 kHz

• With CF between 200 kHz and 4 MHz

Figures 4 and 5

• With a crystal frequency of 32 kHz

• C1, C2, and C3 are 0.1 µF capacitors.

• With the LCD ports open

• With CD between 200 kHz and 4 MHz

Figure 5 Output Voltage Test Circuit

Figure 7: Supply Current Test Circuit

Figure 10 Pin N1 to Pin N4 Circuits

No. 4434-16/17

LC58E76

Page 17

PS No. 4434-17/17

LC58E76

This catalog provides information as of December, 1998. Specifications and information herein are

subject to change without notice.

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer’s

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer’s products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

semiconductor products fail with some probability. It is possible that these probabilistic failures could

give rise to accidents or events that could endanger human lives, that could give rise to smoke or fire,

or that could cause damage to other property. When designing equipment, adopt safety measures so

that these kinds of accidents or events cannot occur. Such measures include but are not limited to protective

circuits and error prevention circuits for safe design, redundant design, and structural design.

In the event that any or all SANYO products (including technical data, services) described or contained

herein are controlled under any of applicable local export control laws and regulations, such products must

not be exported without obtaining the export license from the authorities concerned in accordance with the

above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or any information storage or retrieval system,

or otherwise, without the prior written permission of SANYO Electric Co., Ltd.

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the “Delivery Specification”

for the SANYO product that you intend to use.

Information (including circuit diagrams and circuit parameters) herein is for example only; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but

no guarantees are made or implied regarding its use or any infringements of intellectual property rights

or other rights of third parties.

Figure 11: Segment Pin Open-Drain Circuits

Loading...

Loading...