Page 1

Monolithic Digital IC

Ordering number : ENN5340A

N3099TH (OT)/93096HA (OT) No. 5340-1/10

SANYO Electric Co.,Ltd. Semiconductor Company

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

Three-Phase Brushless Sensorless Motor Driver

LB1950V

Overview

The LB1950V is a 3-phase brushless sensorless motor

driver IC that is particularly well-suited to driving

camcorder drum motors.

Features

• Drives 3-phase full-wave brushless sensorless motors

• Soft switching drive

• Speed control using motor power-supply voltage control

for reduced power

• Allows operation from a 3-V power supply.

• The residual output voltage can be set to one of four

values.

• Supports bidirectional rotation.

• Standby function (only the FG and PG amplifiers

operate)

• Brake circuit

• Thermal shutdown circuit

• FG and PG amplifiers

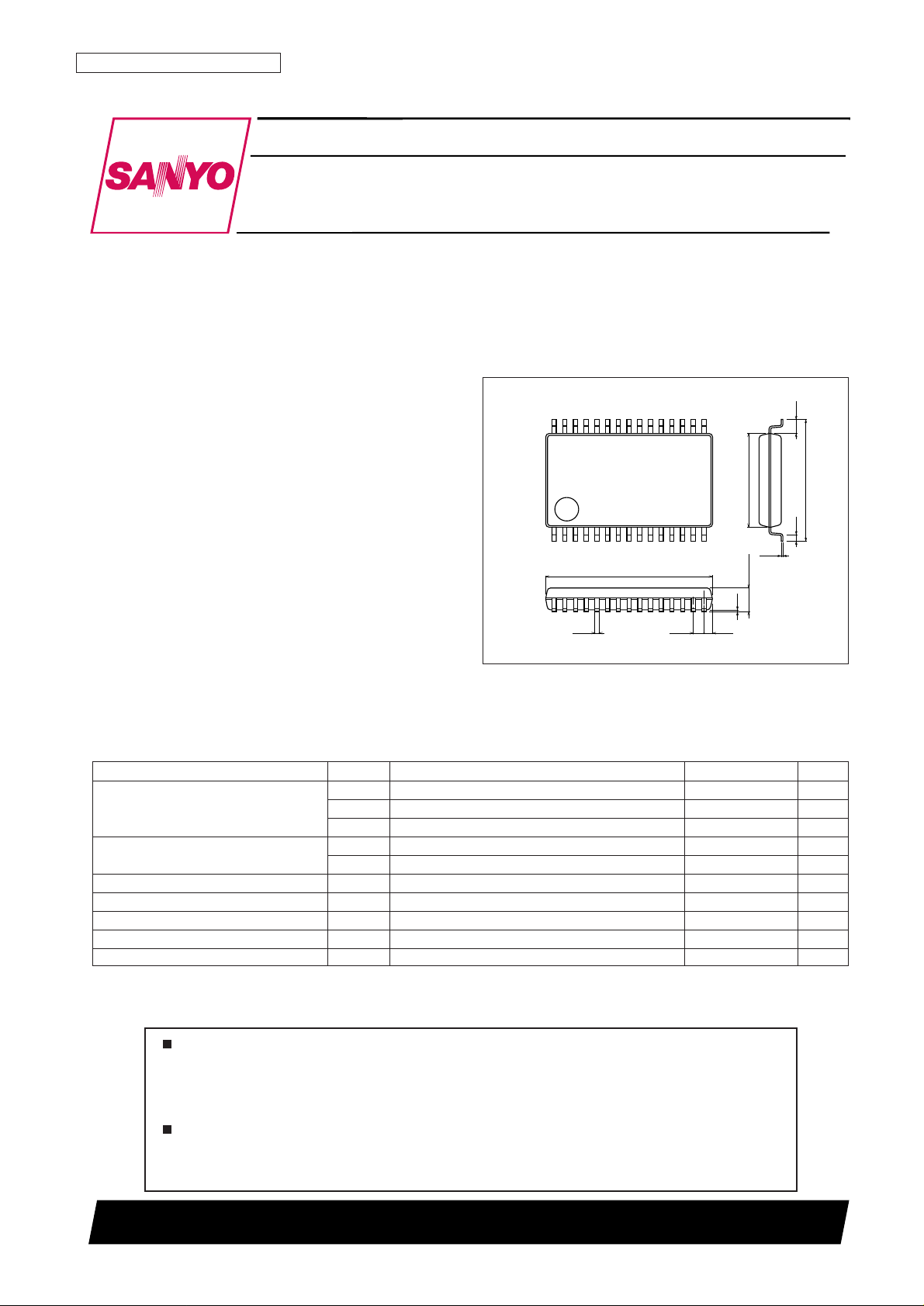

Package Dimensions

unit: mm

3191-SSOP30

115

16

7.6

0.65

9.95

0.5

5.6

0.1

1.6max

1.0

30

0.22

0.43

0.15

[LB1950V]

SANYO: SSOP30

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft’s

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges, or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

Specifications

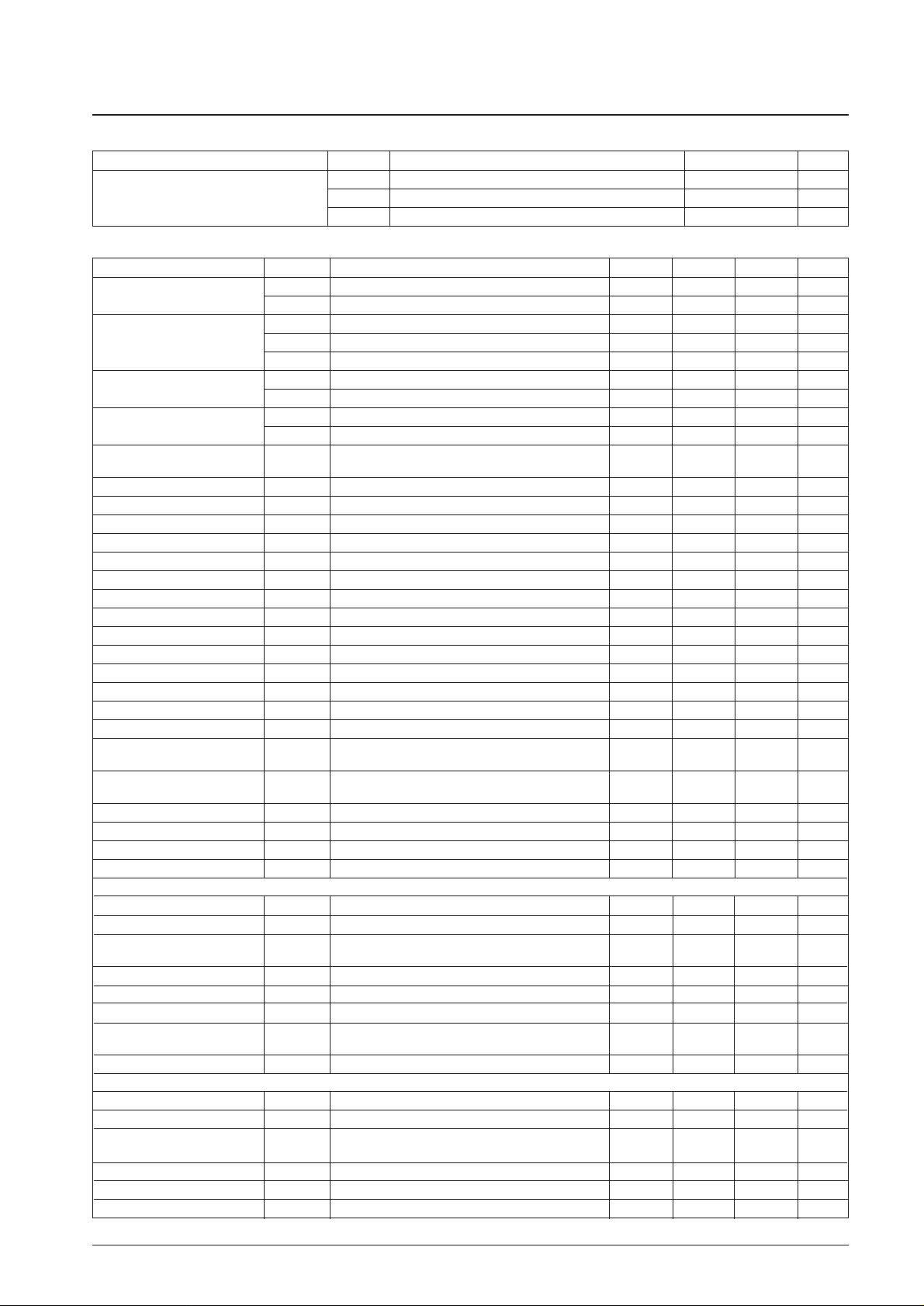

Absolute Maximum Ratings at Ta = 25°C

Parameter Symbol Conditions Ratings Unit

V

CC

1 max 7V

Maximum supply voltage V

CC

2 max 12 V

V

S

max VCC2V

Output voltage

V

O

max VS+ 2 V

V

I

1 max Control system –0.3 to VCC1 + 0.3 V

Input voltage V

I

2 max U, V, W, COM VS+ 2 V

Output current I

O

max 1.0 A

Allowable power dissipation Pd max 0.5 W

Operating temperature Topr –20 to +75 °C

Storage temperature Tstg –55 to +150 °C

Page 2

Allowable Operating Ranges at Ta = 25°C

Electrical Characteristics at Ta = 25°C, VCC1 = 3 V, VCC2 = 4.75 V, VS= 1 V

No. 5340-2/10

LB1950V

Parameter Symbol Conditions Ratings Unit

V

CC

1 2.7 to 6.0 V

Supply voltage V

CC

2 2.7 to 10.0 V

V

S

0 to VCC2V

Parameter Symbol Conditions min typ max Unit

Current drain

I

CC

1IO= 100 mA, RSAT1 = RSAT2 = GND 4.5 7 mA

I

CC

2IO= 100 mA, RSAT1 = RSAT2 = GND 1.2 2.5 mA

I

CC10QVSTBY

= 0 V 1 1.5 mA

Output quiescent current I

CC20QVSTBY

= 0 V 10 µA

I

S30Q

V

STBY

= 0 V 10 µA

Lower side output saturation

V

OU

1IO= 0.1 A, RSAT1 = RSAT2 = open 0.11 V

voltage

V

OU

2IO= 0.4 A, VS= 3 V, RSAT1 = RSAT2 = open 0.33 V

Upper side output saturation

V

OD

1IO= 0.1 A, RSAT1 = RSAT2 = open 0.11 V

voltage

V

OD

2IO= 0.4 A, VS= 3 V, RSAT1 = RSAT2 = open 0.33 V

COM pin common-mode input

V

IC

0.3 VCC2 – 0.9 V

voltage range

Standby pin high-level voltage V

STBYH

2V

CC

1V

Standby pin low-level voltage V

STBYL

–0.2 +0.7 V

Standby pin input current I

STBYIVSTBY

= 3 V 50 µA

Standby pin leakage current I

STBYLVSTBY

= 0 V –10 µA

Brake pin high-level voltage V

BRH

2V

CC

1V

Brake pin low-level voltage V

BRL

–0.2 +0.7 V

Brake pin input current I

BRI

VBR= 3 V 50 µA

Brake pin leakage current I

BRL

VBR= 0 V –10 µA

FRC pin high-level voltage V

FRCH

2V

CC

1V

FRC pin low-level voltage V

FRCL

–0.2 +0.7 V

FRC pin input current I

FRCI

V

FRC

= 3 V 50 µA

FRC pin leakage current I

FRCL

V

FRC

= 0 V –10 µA

Slope pin source current ratio R

SOURCE

ICSLP1SOURCE/ICSLP2SOURCE –12 +12 %

Slope pin sink current ratio R

SINK

ICSLP1SINK/ICSLP2SINK –12 +12 %

CSLP1 source and sink current

R

CSLP1

ICSLP1SOURCE/ICSLP1SINK –35 +15 %

ratios

CSLP2 source and sink current

R

CSLP2

ICSLP2SOURCE/ICSLP2SINK –35 +15 %

ratios

Startup frequency Freq C

OSC

= 0.1 µF, OSC frequency: * 11.5 Hz

Phase delay width Dwidth * 30 deg

Thermal shutdown temperature T

TSD

* 150 180 210 °C

Thermal shutdown hysteresis ∆T

TSD

* 15 °C

[FG Amplifier]

Input offset voltage V

IO

* ±1 ±5 mV

Input bias current I

B

* 250 nA

Common-mode input voltage

V

ICOM

* 12V

range

Output on voltage V

OL

When IO= 10 µA 0.4 V

Output off voltage V

OH

When IO= 10 µA VCC1 – 0.5 V

Schmitt amplifier hysteresis V

SHIS

* 50 mV

Output duty Duty

When the input signal level = 20 mVp-p and the input

30 70 %

frequency = 720 Hz.

Reference voltage V

REF

1.15 1.30 1.45 V

[PG Amplifier]

Input offset voltage V

IO

* ±1 ±5 mV

Input bias current I

B

* 500 nA

Common-mode input voltage

V

ICOM

* 12V

range

Output on voltage V

OL

When IO= 10 µA 0.4 V

Output off voltage V

OH

When IO= 10 µA VCC1 – 0.5 V

Schmitt amplifier hysteresis V

SHIS

* 20 mV

Note: * Items marked with an asterisk are design target values and are not tested.

Page 3

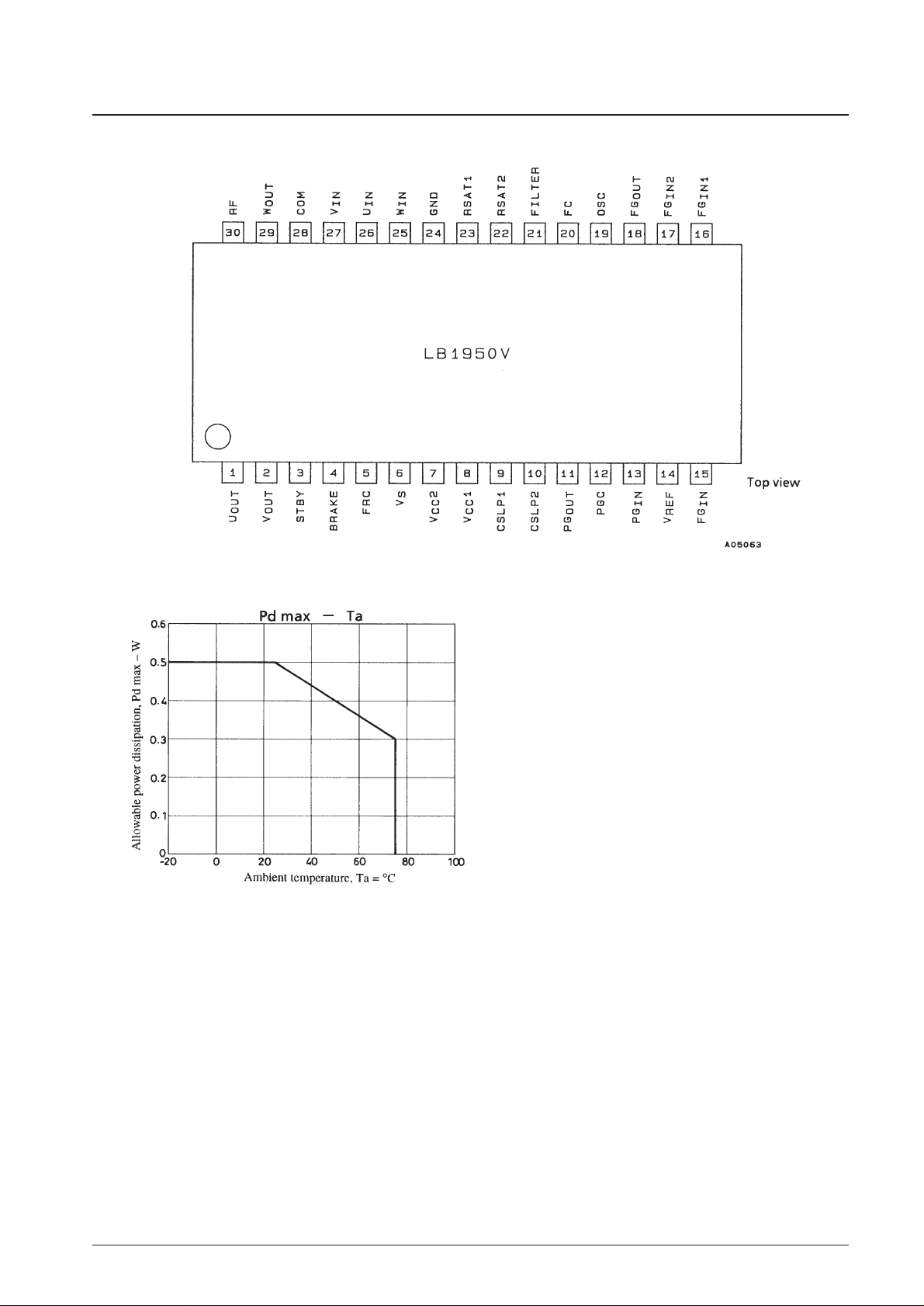

Pin Assignment

No. 5340-3/10

LB1950V

Page 4

Pin Functions

No. 5340-4/10

LB1950V

Pin No. Symbol Pin voltage Equivalent circuit Function

Connection for the triangular wave generator. The coil

output waveform is made to operate in a soft switching

manner by this triangular wave.

CSLP1

CSLP2

9

10

Power supply that provides the voltages other than the

motor voltage, the source side predrive voltage, and the

coil waveform detection comparator voltage.

2.7 to 6 V

V

CC

1

8

Power supply that provides the source side pre-drive

voltage and the coil waveform detection comparator

voltage.

2.7 to 10 V

V

CC

2

7

• Power supply that provides the motor voltage and

determines the output amplitude.

• This voltage must be lower than V

CC

2.

0 V to V

CC

2V

S

6

• Motor forward/reverse switching input

• Low level: forward

(–0.2 to 0.7 V or open)

• High level: reverse

(2 V to V

CC

1)

V

CC

1 max –

0.2 V min

FRC5

• Braking is applied to the motor if a voltage 2.0 V or

higher is applied to this pin.

• This pin must be open or set to a voltage 0.7 V or

lower to set the LB1950V to the motor drive state.

V

CC

1 max –

0.2 V min

BR4

• The LB1950V is set to a mode in which only the FG

and PG amplifiers operate when this pin is open or set

to a voltage 0.7 V or lower.

• This pin must be set to a voltage 2.0 V or higher in the

motor drive state.

V

CC

1 max –

0.2 V min

STBY3

Continued on next page.

Page 5

Continued from preceding page.

No. 5340-5/10

LB1950V

Pin No. Symbol Pin voltage Equivalent circuit Function

Connection for an FG amplifier input signal noise filter

capacitor

FG

IN

2

17

Connection for an FG amplifier input signal noise filter

capacitor

2.0 V max

1.0 V min

(when V

CC

1 =

3 V)

FGIN1

16

FG amplifier input

Connect the FG coil between this pin and V

REF

.

FG

IN

15

• Internal 1.3-V reference voltage

• This voltage is used as the FG and PG amplifier

reference voltage.

V

REF

14

• PG amplifier input

• Connect the PG coil between this pin and V

REF

.

2.0 V max

1.0 V min

(when V

CC

1 =

3 V)

PG

IN

13

Connection for the PG amplifier peak-hold capacitorPGC12

PG amplifier output

PG

OUT

11

Continued on next page.

Page 6

Continued from preceding page.

No. 5340-6/10

LB1950V

Pin No. Symbol Pin voltage Equivalent circuit Function

Ground for all systems other than the output system.GND

24

The residual output voltage setting can be increased by

connecting one, the other, or both of these pins to

ground.

RSAT1

RSAT2

22

23

Connecting a capacitor between this pin and ground

causes the coil output saturation prevention function to

operate. In this state, the motor voltage is controlled by

controlling the VS pin. Also, the torque ripple correction

can be adjusted by changing the value of the external

capacitor.

FILTER21

• Frequency characteristics determination

• Current control system closed loop oscillation can be

stopped by connecting a capacitor between this pin

and ground.

FC20

Connection for the triangular wave oscillator capacitor

that is used to forcibly generate the motor startup

waveform at startup.

OSC19

FG amplifier output

FG

OUT

18

Continued on next page.

Page 7

Continued from preceding page.

No. 5340-7/10

LB1950V

Pin No. Symbol Pin voltage Equivalent circuit Function

• Output transistor ground

• The LB1950V implements fixed-current drive by

detecting the voltage on this pin.

RF30

• W-phase coil output

• U-phase coil output

• V-phase coil output

W

OUT

U

OUT

V

OUT

29

1

2

• Motor coil center tap input

• The LB1950V detects the coil voltage waveform taking

this voltage as the reference.

COM28

Coil waveform detector comparator input

W

IN

U

IN

V

IN

25

26

27

Page 8

Block Diagram

Note: (The values of external components vary depending on the motor used.)

The FG

IN

and PGINpins must be connected to the V

REF

pin if the FG and PG amplifiers are not used.

No. 5340-8/10

LB1950V

Page 9

No. 5340-9/10

LB1950V

Control System Operation

The LB1950V is a current-linear drive motor driver. It implements motor power-supply voltage based speed control by

continually preventing coil output saturation and maintaining the output saturation voltage at the value set by the circuit.

1. The LB1950V detects the sum of the coil output voltage lower side envelope and the diode threshold voltage.

2. The low-pass filter formed by the internal 30-kΩ resistance and the capacitor connected between the FILTER and

GND pins cuts the high-frequency components of the envelope waveform. (The cutoff frequency is 1/2πCR.)

3. The FILTER pin voltage is input to the control amplifier + pin. The reference voltage is input to the control amplifier

– pin, and the control amplifier operates to force the FILTER pin voltage to the same potential as the reference

voltage. The coil output operates in the unsaturated region if this reference voltage is higher than the output transistor

saturation voltage.

4. Also, since the second control amplifier stage controls the RF voltage to a fixed level, the output current (i.e., the RF

current) becomes a fixed current drive.

Supplement: The low-frequency components that are not filtered out by the RC filter on the FILTER pin function to

correct motor torque ripple.

Control System Signals

Page 10

PS No. 5340-10/10

LB1950V

This catalog provides information as of November, 1999. Specifications and information herein are

subject to change without notice.

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer’s

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer’s products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

semiconductor products fail with some probability. It is possible that these probabilistic failures could

give rise to accidents or events that could endanger human lives, that could give rise to smoke or fire,

or that could cause damage to other property. When designing equipment, adopt safety measures so

that these kinds of accidents or events cannot occur. Such measures include but are not limited to protective

circuits and error prevention circuits for safe design, redundant design, and structural design.

In the event that any or all SANYO products (including technical data, services) described or contained

herein are controlled under any of applicable local export control laws and regulations, such products must

not be exported without obtaining the export license from the authorities concerned in accordance with the

above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or any information storage or retrieval system,

or otherwise, without the prior written permission of SANYO Electric Co., Ltd.

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the “Delivery Specification”

for the SANYO product that you intend to use.

Information (including circuit diagrams and circuit parameters) herein is for example only; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but

no guarantees are made or implied regarding its use or any infringements of intellectual property rights

or other rights of third parties.

Loading...

Loading...