Page 1

Ordering number : ENN6208A

LB1862

Monolithic Digital IC

LB1862

Fan Motor Single-Phase Full-Wave Driver

Overview

Single-phase full-wave drive design and a compact package

make this IC optimal for small fans (especially CPU

cooling fans). Low switching noise and effective motor

drive are further advantages.

Features

• Support for 5V/12V dual power supply voltage

• Built-in regenerative circuit allows use of reverseconnection protection diode

• Built-in Hall amplifier with hysteresis (supports core

without auxiliary electrode)

• Built-in lockup protection and automatic recovery circuits

• Latch-type lockup detection output (RD) is Low during

rotation and High during stop

• Hall bias pin and start/stop pin allow reduced current drain

in standby mode

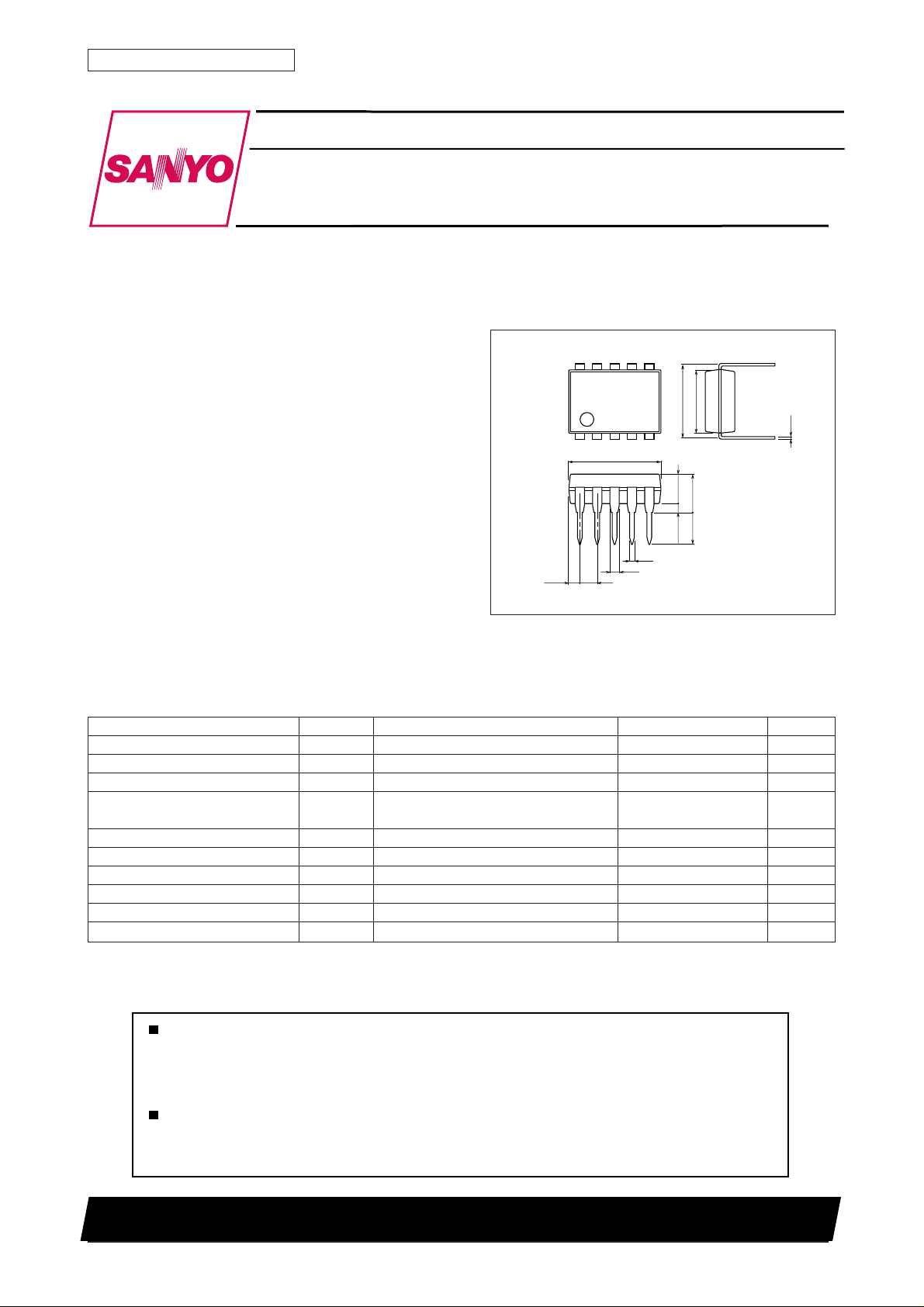

Package Dimensions

unit: mm

3098B-DIP10S

[LB1862]

10

1

1.14 1.78

9.4

0.95

6

5

0.48

6.4

7.62

3.0

3.9max

3.2

0.51min

0.25

SANYO : DIP10S

• Built-in thermal protection circuit

Specifications

Absolute Maximum Ratings at Ta = 25˚C

Parameter Symbol Conditions Ratings Unit

Maximum supply voltage VCC max 17 V

Maximum output current I

Maximum output withstand voltage V

RD maximum output withstand

voltage

RD maximum output current IR max 5mA

HB maximum output current IB max 10 mA

ST maximum input voltage VST max 15 V

Allowable power dissipation Pd max 1.0 W

Operating temperature Topr –30 to +85 °C

Storage temperature Tstg –55 to +150 °C

max 0.8 A

OUT

max 17 V

OUT

VR max

17 V

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft's

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges, or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

SANYO Electric Co.,Ltd. Semiconductor Company

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

O2599RM(KI)

No. 6208-1/7

Page 2

LB1862

Allowable Operating Ranges at Ta = 25˚C

Parameter Symbol Conditions Ratings Unit

Power supply voltage V

ST input High level voltage ST

ST input Low level voltage ST

Hall input common mode input

voltage range

CC

H

L

V

ICM

Electrical Characteristics at Ta = 25˚C, VCC = 5V

Parameter Symbol Conditions

Circuit current I

In drive mode (CT = [L], ST = [L]) 6.5 9.1 mA

CC

In lockup protection mode (CT = [H], ST = [L])

In standby mode (ST = [H]) 110 150 µA

Lockup detection ICT1 1.9 2.8 3.7 µA

capacitor charge current

Capacitor discharge current ICT2 0.32 0.46 0.60 µA

Capacitor charge/discharge current ratio

R

RCT = ICT1/ICT2 5.0 6.0 7.0

CT

CT charge voltage VCT1 2.55 2.75 2.95 V

CT discharge voltage VCT2 1.6 1.8 2.0 V

Output Low level voltage V

Output High level voltage V

Hall input sensitivity V

IO = 200 mA 0.2 0.3 V

OL

OHIO

HN

= 200 mA 3.9 4.1 V

Zero peak value 7 15 mV

(Including offset and hysteresis)

RD output pin Low voltage V

RD output pin leakage current I

HB output Low voltage V

ST pin input current I

RDL

IRD = 5 mA 0.1 0.3 V

RD

VRD = 15V 30 µA

HBLIHB

ST

= 5 mA 1.0 1.3 V

VST = 5V 75 100 µA

min typ max

3.8 to 16.8 V

3 to 14 V

–0.3 to +0.4 V

0.2 to VCC–1.5 V

Ratings

2.2 3.1 mA

Unit

1.2

1.0

0.8

0.6

0.4

0.2

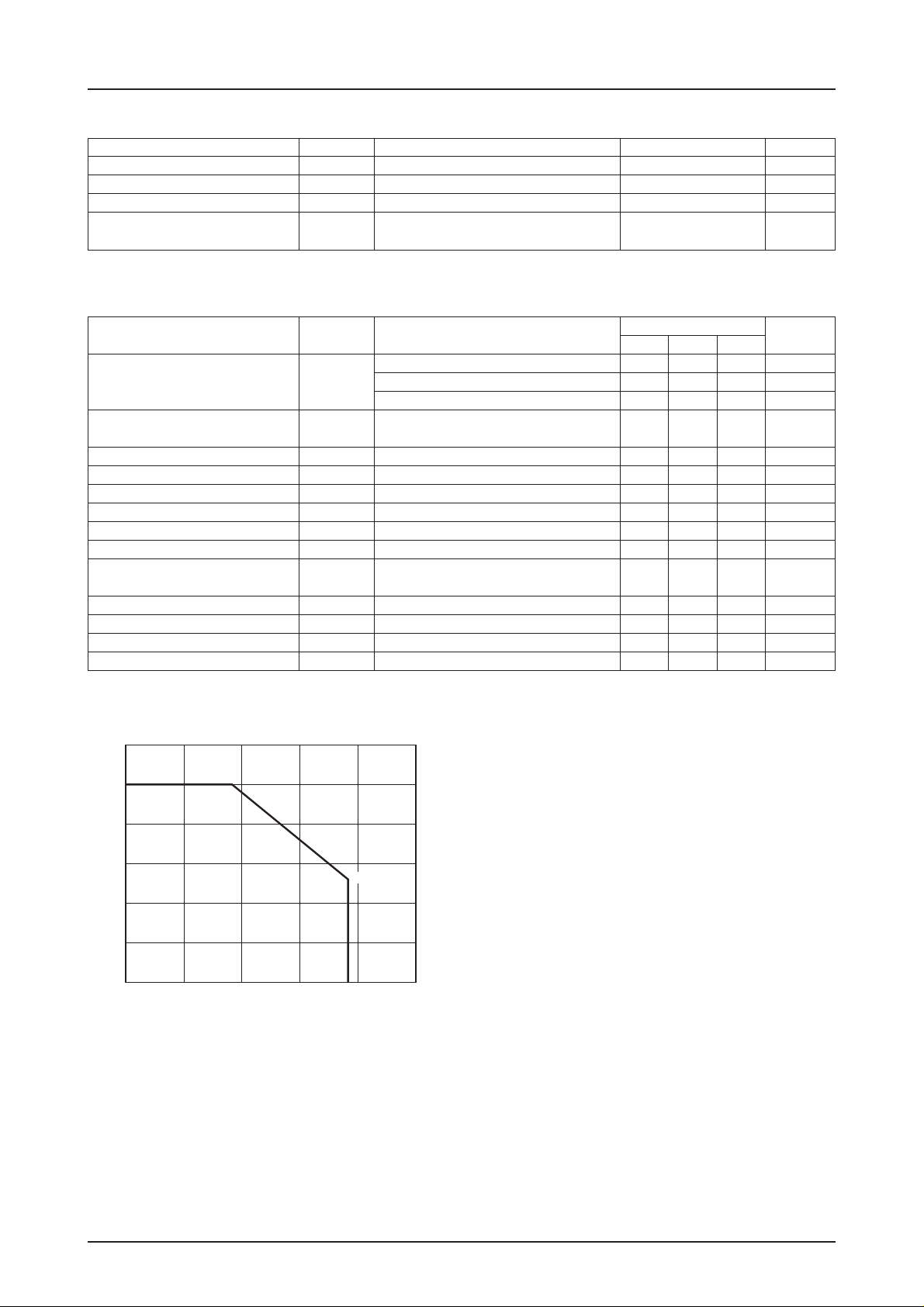

Pd max – Ta

0.52

Allowable power dissipation, Pd max – W

0

–30 0 30 60 90 120

Ambient temperature, Ta – °C

No. 6208-2/7

Page 3

LB1862

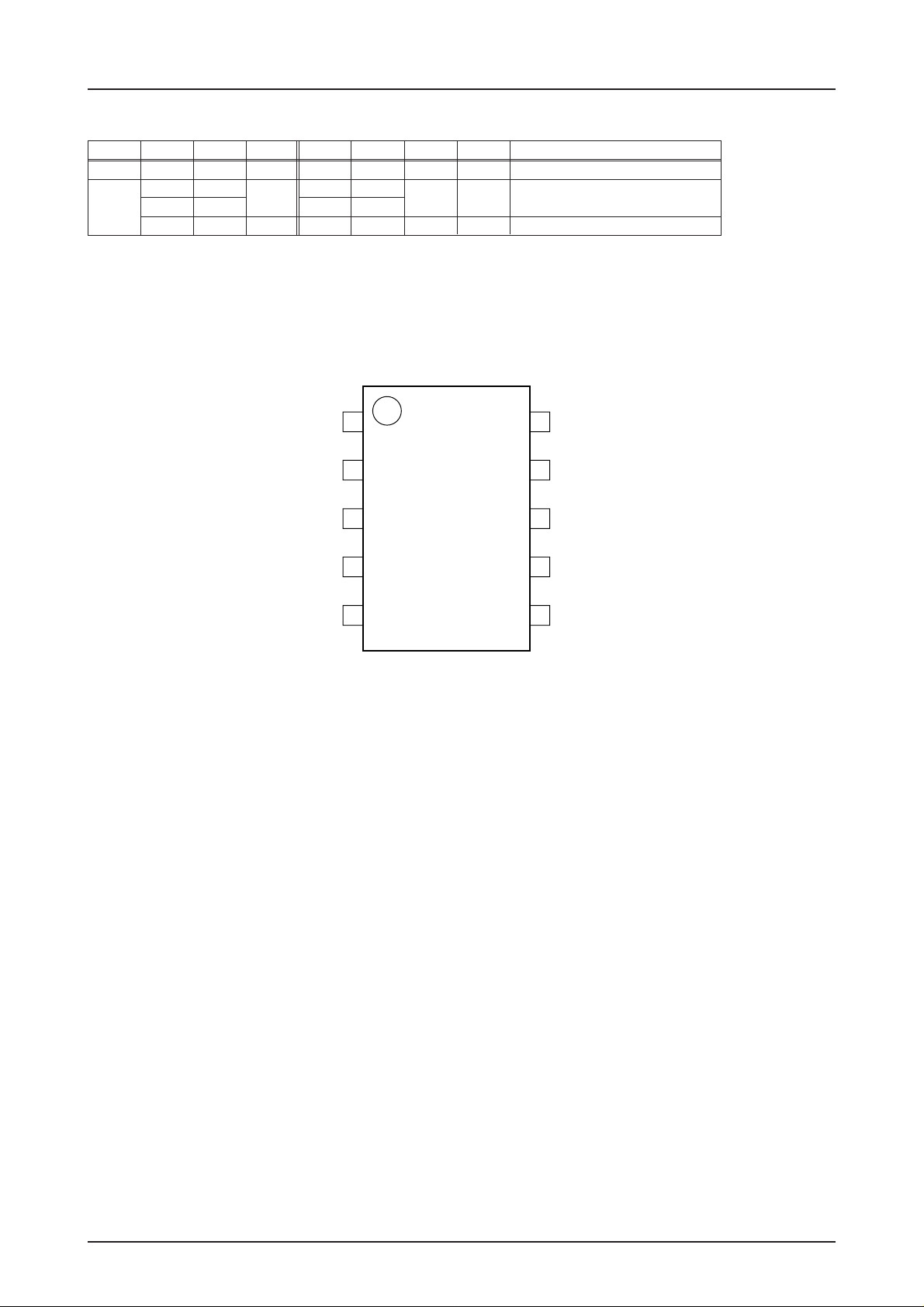

Truth Table

ST IN

H – – – off off off off Standby

LLH LH

–

HL

Pin Assignment

+

IN

CT OUT1 OUT2 RD HB Mode

L

H off off off L Lockup protection activated

HL

Latch-type RD output is Low during rotation and High during stop.

L L Rotating

IN

IN

CT

OUT1

GND

–

1

+

2

3

4

5

LB1862

10

RD

9

HB

8

ST

7

V

CC

6

OUT2

Top view

A12476

No. 6208-3/7

Page 4

Block Diagram

LB1862

0.47 to 1µF

HALL

CT

Discharge

V

CC

+

IN

–

IN

HB

pulse

Hysteresis amplifier

Thermal protection

circuit

Control

circuit

Charge/discharge

circuit

Delay circuit

Delay circuit

START/STOP

ST GND

RD

OUT2

M

OUT1

A12478

Sample Application Circuit

C2

C1=0.47 to 1µF

D1

V

CC

H

–

IN

RD

+

IN

OUT1

HB

OUT2

ST

CT

GND

A12477

(1) D1 is used to prevent IC destruction caused by reverse-connection. It can be omitted if no problems are expected.

(2) C2 would not be required for the internal fan PCB but required for the power supply line in order to reduce the

power line inpedance and pass the regenerative current because a motor is basically an inductive load and it has a

possibility of large current when the power is first applied or in other cases.

(3) When CT is not used, it should be connected to ground.

(4) When RD, ST, and HB are not used, they should be left open or connected to ground.

No. 6208-4/7

Page 5

Startup

LB1862

Startup

V

CC

OUT

CT

RD

Power-on

Lockup protection/automatic recovery

A12479

Start/stop

OUT

RD

CT

ST

OUT

Locked Released

Output OFF

Output OFF

Output ON

Output OFF

RD

A12480

No. 6208-5/7

Page 6

LB1862

Design reference

(1) VCC pin

Power supply pin for control block and motor drive.

Accepts a wide operation voltage range from 3.8 to 16.8V, for 5V/12V dual power supply support.

(2) OUT1, OUT2 pins

Single-phase coil output pins.

Bipolar drive output with upper side inverted and lower side single output. Built-in regenerative circuit regenerates

kickback current between lower side NPN outputs when a diode is used for protection against IC destruction caused

by reverse connection.

(3) IN–, IN+ pins

Hall input signal pins

The Hall signal is amplified into a square wave by the Hall amplifier with hysteresis characteristics of ±3.5 mV

(typ.). The Hall input signal amplitude should be 70 mV or more.

(4) CT pin

This pin serves for connecting a capacitor between CT and GND.

The capacitor determines the characteristics of the built-in lockup protection circuit for preventing coil burnout in

the case of motor restraint. Once normal motor load is restored, the automatic recovery circuit resets itself.

Changing the capacitance alters the lockup detection time.

When a 0.47 µF capacitor is connected between CT and GND

Lockup detection time : approx. 0.5s

Lockup protection time/automatic recovery time : approx. 0.16s (output ON)

approx. 1s (output OFF)

When not using lockup protection function, this pin should be connected to ground.

(5) RD pin

Open-collector output pin that is Low during rotation and OFF when lockup is detected.

The output is a latch type which stays OFF also when the automatic recovery circuit has restored drive mode, unless

the rotation actually resumes.

(6) ST pin and HB pin

ST pin : When input to this pin is High, motor drive is stopped (OUT is high impedance).

At this time, RD output indicates lockup protection mode OFF.

HB pin : Hall bias switching pin. At ST pin High input, Hall bias is cut off to reduce current drain in fan standby

mode.

If not used, both pins should be open.

(7) Thermal protection circuit

When internal temperature Tj of IC reaches 180°C, output current limiter is activated to protect against damage.

No. 6208-6/7

Page 7

LB1862

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer's

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer's products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

semiconductor products fail with some probability. It is possible that these probabilistic failures could

give rise to accidents or events that could endanger human lives, that could give rise to smoke or fire,

or that could cause damage to other property. When designing equipment, adopt safety measures so

that these kinds of accidents or events cannot occur. Such measures include but are not limited to protective

circuits and error prevention circuits for safe design, redundant design, and structural design.

In the event that any or all SANYO products(including technical data,services) described or

contained herein are controlled under any of applicable local export control laws and regulations,

such products must not be exported without obtaining the export license from the authorities

concerned in accordance with the above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or any information storage or retrieval system,

or otherwise, without the prior written permission of SANYO Electric Co. , Ltd.

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the "Delivery Specification"

for the SANYO product that you intend to use.

Information (including circuit diagrams and circuit parameters) herein is for example only ; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but

no guarantees are made or implied regarding its use or any infringements of intellectual property rights

or other rights of third parties.

This catalog provides information as of October, 1999. Specifications and information herein are subject to change

without notice.

No. 6208-7/7

PS

Loading...

Loading...