Page 1

Ordering number : EN6205

LB1695D

Monolithic Digital IC

LB1695D

Three-Phase Brushless Motor Driver for DC Fan

Overview

The LB1695D is a driver IC for 3-phase brushless DC fan

motors such as used in water heaters and other domestic

electrical appliances.

Package Dimensions

unit: mm

3037A-DIP20H

[LB1695D]

20

11

Features

• Three-phase brushless motor driver

• Withstand voltage 45V, output current 2A

• Built-in current limiter

• Built-in low-voltage protection circuit

• Built-in thermal shutdown circuit

• Built-in Hall amplifier with hysteresis

• FG output function

8.4

R1.7

1

2.07 2.54 1.3

0.6

20.0

27.0

12.7

10

4.04.0

11.2

SANYO : DIP20H

Specifications

Absolute Maximum Ratings at Ta = 25˚C

Parameter Symbol Conditions Ratings Unit

Maximum supply voltage

Maximum output current IO max 2.0 A

Allowable power dissipation

Operating temperature Topr –20 to +100 °C

Storage temperature Tstg –55 to +150 °C

VCC max 10 V

VM max 45 V

Pd max1 IC only 3 W

Pd max2 With an arbitrary large heat sink 20 W

0.4

Allowable Operating Ranges at Ta = 25˚C

Parameter Symbol Conditions Ratings Unit

V

Power supply voltage range

Power supply startup voltage slew ∆VCC/∆tVCC = V

rate ∆VM/∆tVM = 0V point *1 Up to 0.16 V / µs

*1 After power-on, if the power supply voltage rise is fast, there may be some feedthrough current in the output.

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft's

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges, or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

CC

V

M

(OFF) point *1 Up to 0.04 V / µs

LVSD

4.5 to 9.0 V

5 to 42 V

SANYO Electric Co.,Ltd. Semiconductor Company

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

63099RM(KI)

No. 6205-1/10

Page 2

LB1695D

Electrical Characteristics at Ta = 25°C, VCC = 5V, VM = 30V

Parameter Symbol Conditions

Power supply current I

Output saturation voltage

VOsat1 IO = 0.5A VO (sink) + VO (source) 1.8 2.4 V

VOsat2 IO = 1.0A VO (sink) + VO (source) 2.1 2.8 V

Forward 13 19 mA

CC

Output leakage current IO leak 100 µA

[Hall amplifier]

Input bias current I HB 1 4 µA

Common mode input voltage range V

Hysteresis width ∆V

Input voltage L -> H V

Input voltage H -> L V

ICM

IN

SLH

SHL

[FG pin (Speed pulse output)]

Output Low level voltage V

Pull-up resistor value R

FGLIFG

FG

= 5 mA 0.4 V

[Forward/reverse operation]

Forward V

Reverse V

FR1

FR2

[Current limiter operation]

Limiter V

RF

[Thermal shutdown operation]

Operating temperature TSD Design target value 150 180 °C

Hysteresis width ∆TSD Design target value 40 °C

[Low-voltage protection circuit operation]

Operating voltage V

Release voltage

Hysteresis width ∆V

V

LVSD

LVSD

(OFF)

LVSD

[C pin]

Charge current I

Discharge current I

Charge start voltage V

Discharge start voltage V

R = 33 kΩ 30 40 50 µA

CL

R = 33 kΩ 90 120 150 µA

CH

R = 33 kΩ 0.3 0.4 0.5 V

CL

R = 33 kΩ 1.5 2.0 2.5 V

CH

Output current ignore time t sm R = 33 kΩ, C = 4700 pF 58 68 78 µs

Output off time t so R = 33 kΩ, C = 4700 pF 164 193 222 µs

Ratings

min typ max

1.5

VCC–1.8

21 30 37 mV

51525mV

–25 –15 –5 mV

7.5 10 12.5 kΩ

0 0.8 V

4.2 V

CC

0.42 0.5 0.6 V

3.5 3.8 4.1 V

4.3 4.5 V

0.4 0.5 0.6 V

Unit

V

V

No. 6205-2/10

Page 3

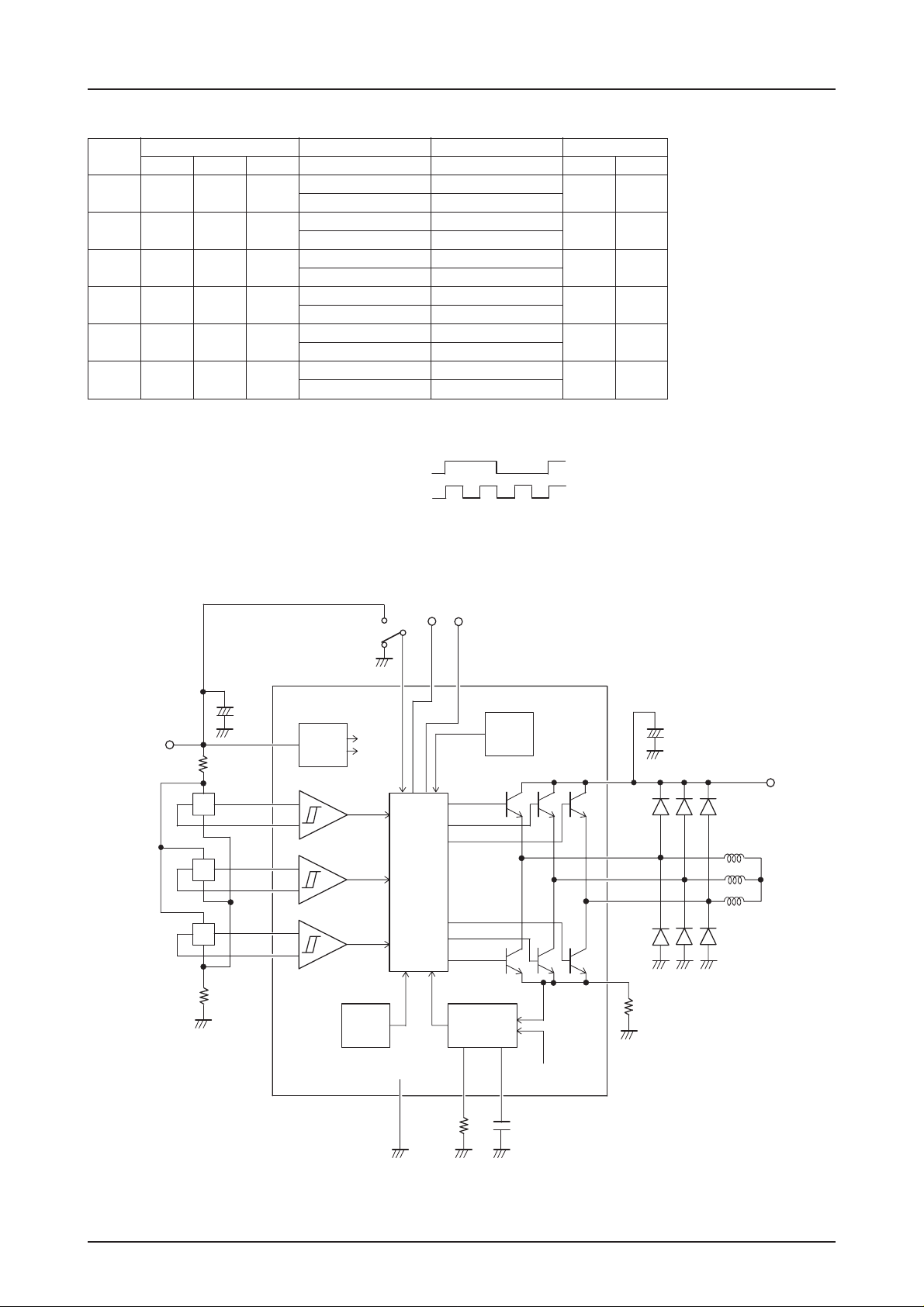

Truth Table

Input

IN1 IN2 IN3 F/R Source -> Sink FG1 FG2

1HLH

2HLL

3HHL

4LHL

5LHH

6LLH

F/R FG output

Forward L 0.0 to 0.8V FG1

Reverse H 4.2 to 5.0V FG2

LB1695D

Forward/reverse control

L OUT2 -> OUT1

H OUT1 -> OUT2

L OUT3 -> OUT1

H OUT1 -> OUT3

L OUT3 -> OUT2

H OUT2 -> OUT3

L OUT1 -> OUT2

H OUT2 -> OUT1

L OUT1 -> OUT3

H OUT3 -> OUT1

L OUT2 -> OUT3

H OUT3 -> OUT2

Output FG output

LL

LH

LL

HH

HL

HH

Block Diagram and Peripheral Circuitry

+

V

CC

Reg

Hys.Amp

+

IN1

–

+

IN2

–

+

IN3

–

1.3V

2.3V

TSD

Logic

FG2FG1F/R

Current

Limiter

LVSD

VM

OUT1

OUT2

OUT3

RF

+

VM

Rf

GND

0.5V

CR

No. 6205-3/10

Page 4

LB1695D

Pin Description

Pin name Pin number Function

VCC 1 Power supply pin for blocks except output

R 2 C pin charge/discharge current set pin

C 3 Setting pin for current limiter output off time and output current ignore time

NC 4, 9 May be used for wiring

OUT1 5 Output pin 1

OUT2 6 Output pin 2

OUT3 7 Output pin 3

RF 8

VM 10 Power supply pin for output

GND 11

F/R 12 Forward/reverse control pin

IN1+, IN1– 17, 18 Hall input pin Logic High refers to IN+ > IN–

IN2+, IN2– 15, 16 Hall input pin Logic High refers to IN+ > IN–

IN3+, IN3– 13, 14 Hall input pin Logic High refers to IN+ > IN–

FG1 20 Speed pulse output pin 1 with built-in pull-up resistor

FG2 19 Speed pulse output pin 2 with built-in pull-up resistor

Output current detection pin. Insert a resistor (Rf) between this pin and ground.

The output current will be limited to the value determined by VRF/Rf (output current limiter).

Ground for blocks except output

Lowest electrical potential of output transistors is voltage at RF pin.

Pin Assignment

24

20

16

VCC

FG2FG1

IN2– IN2+ IN3– IN3+ F/R GND

IN1+IN1–

11121317181920 141516

LB1695D

Top view

10654329871

R

C

Pdmax – Ta

OUT3OUT1OUT2

With an arbitrary large heat sink

VMRF NCNC

12

8

4

3

Allowable power dissipation, Pdmax – W

0

–20 0 20 40 60 80 100 120

Ambient temperature, Ta – °C

Without heat sink

8.0W

1.2W

No. 6205-4/10

Page 5

Pin Equivalent Circuit

Pin number

3

2

Pin name

C

R

Pin voltage

LB1695D

Equivalent circuit

Vcc

10

2.0V

2

Vcc

2.0V

0.4V

5

6

7

8

OUT1

OUT2

OUT3

RF

VM

Vcc

0.5V

200Ω

×4

200Ω

200Ω

3

10

6

5

7

12

F/R

0.0V min

VCC max

Vcc

10 kΩ

10 kΩ

10 kΩ

20 kΩ

8

12

Continued on next page

No. 6205-5/10

Page 6

Continued from preceding page

Pin number

17

18

15

16

13

14

Pin name

IN1+

IN1–

IN2+

IN2–

IN3+

IN3–

1.5V min

VCC–1.8V max

LB1695D

Vcc

13

15

17

200Ω

Equivalent circuitPin voltage

200Ω

14

16

18

20

19

FG1

FG2

Vcc

10kΩ

19

20

No. 6205-6/10

Page 7

LB1695D

Description of the LB1695D

1. Hall input circuit

The Hall input circuit is a differential amplifier with a hysteresis of 30 mV (typ.). The operating DC level must be

within the common mode input voltage range (1.5V to VCC – 1.8V). To prevent noise and other adverse influences,

the input level should be at least 3 times the hysteresis (120 to 160 mVp-p). If noise evaluation at the Hall input

shows a problem, a noise-canceling capacitor (about 0.01 µF) should be connected across the Hall input IN+ and

IN– pins.

2. Protection circuits

2-1. Low voltage protection circuit

When the VCC voltage falls below a certain level (V

sink-side output transistors to prevent malfunction caused by a VCC voltage drop.

2-2. Thermal shutdown circuit

When the junction temperature rises above a certain value (TSD), the thermal shutdown circuit cuts off the

sink-side output transistors to prevent IC damage due to overheating. Design the application heat

characteristics so that the protection circuit will not be triggered under normal circumstances.

), the low voltage protection circuit cuts off the

LVSD

3. FG output circuit

The Hall input signal at IN1, IN2, and IN3 is synthesized and subject to waveform shaping before appearing at this

output. The signal at FG1 has the same frequency as the Hall input, and the signal at FG2 has a frequency that is

three times higher than the Hall input.

4. Forward/Reverse control circuit

This IC is designed under the assumption that forward/reverse (F/R) switching will not be carried out while the

motor is running. If switching is carried out while the motor is running, a feedthrough current flows in the output

and a problem will be caused regarding ASO. F/R switching should be carried out while the VM power supply is

off (motor is stopped).

5. VCC, VM power supply

When the power supply voltage (VCC, VM) rises very quickly at power-on, a feedthrough current may flow in the

output and a problem will be caused regarding ASO. The power supply rise speed should be kept below ∆VCC/∆t =

0.04V/µS and ∆VM/∆t = 0.16V/µS. For the power-up sequence, VCC should be turned on before VM.

The sequence at power-down should be VM first, and then motor stop, and then VCC. With some motors, if VCC is

switched off immediately after VM, while the motor is still rotating due to inertia, the VM voltage may rise and

exceed the withstand voltage.

6. Power supply stabilizing capacitors

If the VCC line fluctuates drastically, the low-voltage protection circuit may be activated by mistake, or other

malfunctions may occur. The VCC line should therefore be stabilized by connecting a capacitor of at least several

µF between VCC and ground. Because a large switching current flows in the VM line, wiring inductance and other

factors can lead to VM voltage fluctuations. As the GND line also fluctuates, the VM line must be stabilized by

connecting a capacitor of at least several µF between VM and ground, to prevent malfunction or exceeding the

withstand voltage. Especially when long wiring runs (VM, VCC, GND) are used, sufficient capacitance should be

provided to ensure power supply stability.

Continued on next page

No. 6205-7/10

Page 8

LB1695D

Continued from preceding page

7. Current limiter circuit

The current limiter circuit cuts off the sink-side output transistors when the output current reaches a preset value

(limiter value). This limits the output current peak value.

For detection of output current, the RF pin is used. By connecting the resistance Rf between the RF pin and

ground, the output current can be detected as a voltage. When the RF pin voltage reaches 0.5V (typ.), the current

limiter is activated. This limits the output current to the value determined by 0.5/Rf.

7-1. Output off time

When the current limiter circuit was triggered and has switched off the sink-side output transistors, it will

turn them on again after a preset interval (power off time). By switching the output in this way, the current

limiter circuit of the LB1695D reduces the likelihood of ASO problems as compared to current limiters using

the non-saturation output principle.

The output off time is determined by the charge time for the capacitance C connected to the C pin. When the

limiter is triggered, C starts to charge, and the time required for the C voltage to reach 2V (typ.) is the output

off time. When C was charged to 2V, the sink-side output is turned on again. The charge current for C is

constant-current and is determined by the resistance R connected to the R pin. The C charge current ICL and

the output off time toff are calculated according to the following equations.

.

I

= 1.3/R (R should be between 13 kΩ to 100 kΩ)

.

CL

.

toff = C/ICL × 2.0

.

.

= 1.53 × R × C

.

7-2. Output current ignore time

While the sink-side output is turned off by the current limiter, a regenerative current flows in the upper side

regenerative current absorption diode connected externally. When the output off time has elapsed and the

sink-side output is turned on again, a momentary reverse current flows in the external diode (due to the

reverse recovery time of the diode), which causes a limiter-value current to flow momentarily in the output.

If this triggers the current limiter again, the output will be turned off, which lowers the average current and

causes a reduction in motor torque for example during startup. To prevent this, the circuit is designed not to

monitor the output current for a certain period after the sink-side output were turned off and on again. This is

called the output current ignore time.

The output current ignore time is determined by the discharge time of the capacitance C connected to the C

pin. After the current limiter was triggered and C was charged to 2V, the discharge process starts. The time

required to discharge to a voltage of 0.4V (typ.) is the output ignore time. The discharge current for C is

constant-current and is about 3 times the charge current (ICL). Therefore the output current ignore time is

about 1/3 of the output off time.

The C discharge current ICH and the output current ignore time tsm are calculated according to the following

equations.

.

I

= 1.3/R × 3

.

CH

.

tsm = C/ICH × 1.6

.

.

= 0.41 × R × C

.

Continued on next page

No. 6205-8/10

Page 9

Continued from preceding page

Because the current limiter circuit is slanted towards the ON time for turning the sink-side output on again,

the reverse current will not be so large even if a rectifying diode (without a short reverse recovery time) is

used as regenerative current absorption diode connected externally.

7-3. Output off time setting

The output off time must be optimized for the type of motor that is being controlled. The output off time

setting is controlled by the external resistance connected to the R pin and the external capacitance connected

to the C pin. Figure 1 shows the current limiter operating waveform.

(1) Short output off time setting

Because the IC is designed internally to give a ratio of about 3:1 for the output off time and output

current ignore time, the two values cannot be set independently. If the output off time is set to a very

small value, the output current ignore time may be too short. In such a case, the external regenerative

current absorption diode acts to limit current flow by its reverse current (see section 7-2). If the output

off time is small, the diode reverse current will increase, which can lead to ASO problems.

LB1695D

(2) Long output off time setting

If the output off time is set to a very high value, the average current will be reduced, resulting in lower

motor startup torque. Depending on the motor type, the circuit may not change from the current limiter

operating state to the normal rotation state.

tsmtso

2.0V

0.4V

0.0V

0.5V

0.0V

toff

C pin voltage

RF pin voltage

Figure. 1 Current limiter operating waveform

Continued on next page

No. 6205-9/10

Page 10

LB1695D

Continued from preceding page

8. Internal power dissipation calculation

Pd = (VCC × ICC) + (VM × IM) – (motor coil power dissipation)

9. IC temperature rise measurement

Because the chip temperature of the IC cannot be measured directly, measurement should be carried out according

to one of the following procedures.

9-1. Thermocouple measurement method

A thermocouple element is mounted to the IC heat dissipation fin. This measurement method is easy to

implement, but it will be subject to measurement errors if the temperature is not stable.

9-2. Measurement using internal diode characteristics of IC

This is the recommended measurement method. It makes use of the parasitic diode incorporated in the IC

between FG1 and GND. Set FG1 to High (off) and measure the voltage VF of the parasitic diode to calculate

the temperature.

(Sanyo data: for IF = –1 mA, VF temperature characteristics are about –2 mV/°C)

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer's

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer's products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

semiconductor products fail with some probability. It is possible that these probabilistic failures could

give rise to accidents or events that could endanger human lives, that could give rise to smoke or fire,

or that could cause damage to other property. When designing equipment, adopt safety measures so

that these kinds of accidents or events cannot occur. Such measures include but are not limited to protective

circuits and error prevention circuits for safe design, redundant design, and structural design.

In the event that any or all SANYO products(including technical data,services) described or

contained herein are controlled under any of applicable local export control laws and regulations,

such products must not be exported without obtaining the export license from the authorities

concerned in accordance with the above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or any information storage or retrieval system,

or otherwise, without the prior written permission of SANYO Electric Co. , Ltd.

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the "Delivery Specification"

for the SANYO product that you intend to use.

Information (including circuit diagrams and circuit parameters) herein is for example only ; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but

no guarantees are made or implied regarding its use or any infringements of intellectual property rights

or other rights of third parties.

This catalog provides information as of June, 1999. Specifications and information herein are subject to change

without notice.

No. 6205-10/10

PS

Loading...

Loading...