Page 1

Ordering number : EN4844

73098HA (OT)/63094TH (OT) A8-8679 No. 4844-1/5

Overview

The LB1692 is a three-phase brushless motor driver IC. It

is optimal for use with DC fan motors in equipment such

as air conditioners or water heaters. The LB1692 is a highbreakdown voltage version of the LB1690.

Functions and Features

• Three-phase brushless motor driver

• 60 V breakdown voltage, 2.5 A output current

• Built-in current limiter

• Built-in low voltage protection circuit

• Built-in thermal protection circuit

• Built-in Hall amplifier with hysteresis

• FG output function

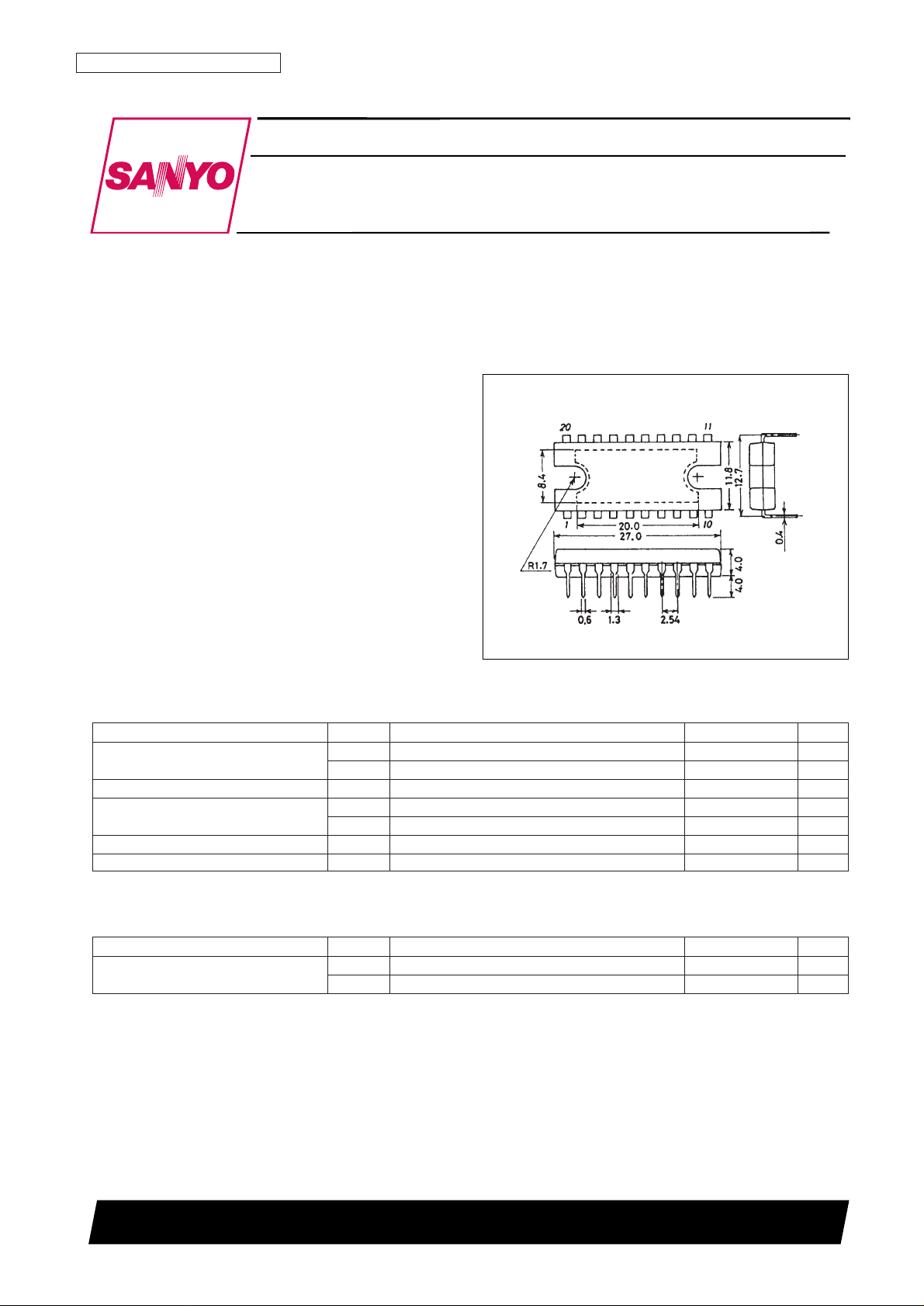

Package Dimensions

unit: mm

3037A-DIP20H

SANYO: DIP20H

[LB1692]

LB1692

SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquarters

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

Three-Phase Brushless Motor Driver

Monolithic Digital IC

Specifications

Absolute Maximum Ratings at Ta = 25°C

Allowable Operating Ranges at Ta = 25°C

Parameter Symbol Conditions Ratings Unit

Maximum supply voltage

V

CC

max 10 V

V

M

max 60 V

Output current I

O

2.5 A

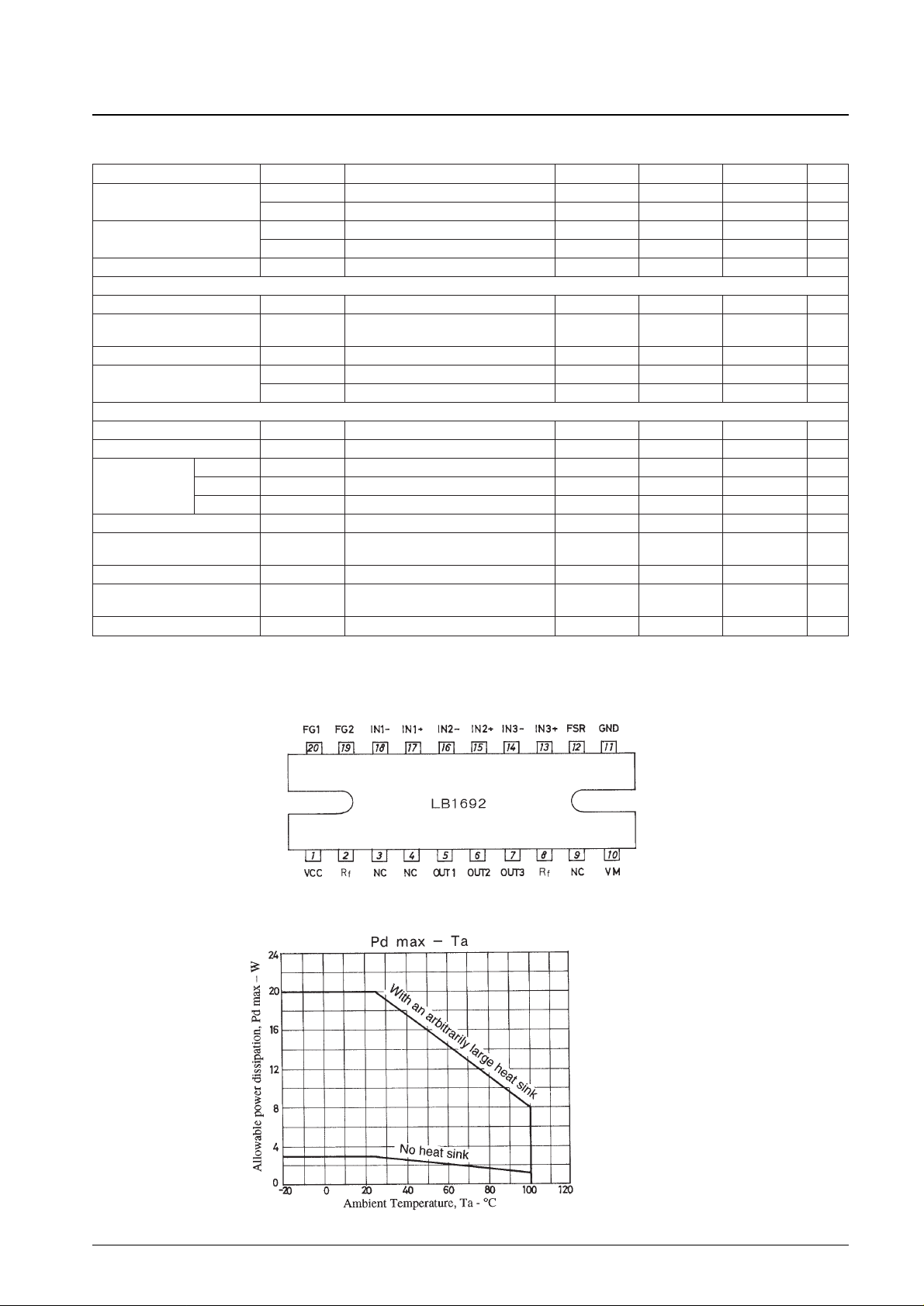

Allowable power dissipation

Pd max1 Independent IC 3 W

Pd max2 With an arbitrarily large heat sink 20 W

Operating temperature Topr –20 to +100 °C

Storage temperature Tstg –55 to +150 °C

Parameter Symbol Conditions Ratings Unit

Supply voltage range

V

CC

4.5 to 5.5 V

V

M

5 to 56 V

Page 2

Electrical Characteristics at Ta = 25°C, VCC= 5 V, VM= 45 V

Pin Assignment

No. 4844-2/5

LB1692

Parameter Symbol Conditions min typ max Unit

Current drain

I

CC1

When stopped 4 6 mA

I

CC2

10 15 mA

Output saturation voltage

V

O

sat1 IO= 1 A, VO(sink) + VO(source) 2.1 3.0 V

V

O

sat2 IO= 2 A, VO(sink) + VO(source) 3.0 4.2 V

Output leakage current I

O

leak 100 µA

[Hall amplifier]

Input bias current I

HB

1 4 µA

Common mode input voltage

1.5 3.2 V

range

Hysteresis ∆V

IN

23 30 37 mV

Input voltage

V

SLH

L → H 5 15 25 mV

V

SHL

H → L –25 –15 –5 mV

[FG pin] (Speed pulse output)

Output low level voltage V

FGL

IFG= 5 mA 0.16 0.4 V

Pull-up resistance R

FG

7.5 10 12.5 kΩ

Forward, reverse,

Forward V

FSR1

0 0.8 V

and stop Stop V

FSR2

2.1 2.5 2.9 V

operation

Reverse V

FSR3

4.2 5.0 V

Current control operation limiter V

Rf

0.42 0.5 0.6 V

Thermal cutoff operating

T

SD

Design target value 150 180 °C

temperature

Hysteresis ∆T

SD

25 °C

Low voltage protection

V

LVSD

3.5 3.8 4.1 V

operating voltage

Hysteresis ∆V

LVSD

0.2 0.3 0.4 V

(Top view)

Page 3

Truth Table

FSR

Forward: L (0 to 0.8 V)

Reverse: H (4.2 to 5.0 V)

FG Output

Block Diagram and Peripheral Circuits

No. 4844-3/5

LB1692

Item Source → Sink

Input

Forward/Reverse Control

IN1 IN2 IN3

FSR

1

OUT3 → OUT2

H H L

L

OUT2 → OUT3 H

2

OUT3 → OUT1

H L L

L

OUT1 → OUT3 H

3

OUT2 → OUT3

L L H

L

OUT3 → OUT2 H

4

OUT1 → OUT2

L H L

L

OUT2 → OUT1 H

5

OUT2 → OUT1

H L H

L

OUT1 → OUT2 H

6

OUT1 → OUT3

L H H

L

OUT3 → OUT1 H

Page 4

No. 4844-4/5

LB1692

Pin Functions

1. Position Detection Circuit (Hall device input circuit)

The position detection circuit is a differential amplifier with hysteresis (typically 30 mV).

Voltages within the common mode input voltage range (1.5 V to VCC– 1.8 V) should be used as the operating DC level.

We recommend using an input level that is more than three times the hysteresis, i.e., on the order of 120 to 160 mVp-p.

2. Current Control Circuit

Current control is performed by switching the sink side transistor from the saturated to the unsaturated range.

Therefore, it is possible for ASO to be a problem.

I = (A)

Therefore, if at all possible, applications should be designed so that the current limiter does not operate. Also, be

especially careful to design applications so that the maximum output current (2.5 A) is not exceeded when the

current limiter operates. Note that a current limiter must be added to the VMpower supply. (We recommend a current

limiter with a short delay time and with a design current that is about 60 to 70% of the current control circuit's

current value.)

3. Protection Circuits

• Low voltage protection circuit

The sink side output drivers are turned off if the VCCpin voltage falls below the stipulated range. This circuit is

provided to prevent incorrect operation.

• Thermal cutoff protection circuit

If the junction temperature exceeds the stipulated temperature range, the sink side output drivers are turned off.

This is identical to the operation of the circuit described in 3-1 above.

4. VMpower supply minimum voltage

The VMpower supply voltage should be greater than or equal to the VCCvoltage.

VM≥ V

CC

5. FG Output Circuit

The position detection inputs IN1, IN2, and IN3 are combined and the output is generated using waveform shaping.

The frequencies of those outputs are proportional to the rotational speed signal, and, as seen from the position

detectors, are equal to the input frequency itself (FG1) and three times the input frequency (FG2).

V

Rf

Rf

Pin Pin No. Function

IN1+, IN1– 17, 18 OUT1: A logic high level indicates that the Hall device input pins are in the state IN+ > IN-.

IN2+, IN2– 15, 16 OUT2: A logic high level indicates that the Hall device input pins are in the state IN+ > IN-.

IN3+, IN3– 13, 14 OUT3: A logic high level indicates that the Hall device input pins are in the state IN+ > IN-.

OUT1 5 Output pin 1

OUT2 6 Output pin 2

OUT3 7 Output pin 3

V

CC

1 Power supply for all sections other than the output block

V

M

10 Power supply that provides the output power

Rf 2, 8

Output current detection pin. The output current is converted to a voltage for detection by a resistor connected

between this pin and GND.

GND 11

Ground for all sections other than the output block

The Rf pin voltage will be the lowest output transistor potential.

Forward/stop/reverse control pin

The voltage on this pin controls the IC forward, stop, or reverse operation.

FSR 12 Forward: 0 to 0.8 V

Stop: 2.1 to 2.9 V

Reverse: 4.2 to 5.0 V

FG1 20 Speed pulse output pin 1. A pull-up resistor is built in.

FG2 19 Speed pulse output pin 2. A pull-up resistor is built in.

Page 5

PS No. 4844-5/5

LB1692

This catalog provides information as of July, 1998. Specifications and information herein are subject to change

without notice.

■ No products described or contained herein are intended for use in surgical implants, life-support systems, aerospace

equipment, nuclear power control systems, vehicles, disaster/crime-prevention equipment and the like, the failure of

which may directly or indirectly cause injury, death or property loss.

■ Anyone purchasing any products described or contained herein for an above-mentioned use shall:

➀ Accept full responsibility and indemnify and defend SANYO ELECTRIC CO., LTD., its affiliates, subsidiaries and

distributors and all their officers and employees, jointly and severally, against any and all claims and litigation and all

damages, cost and expenses associated with such use:

➁ Not impose any responsibility for any fault or negligence which may be cited in any such claim or litigation on

SANYO ELECTRIC CO., LTD., its affiliates, subsidiaries and distributors or any of their officers and employees

jointly or severally.

■ Information (including circuit diagrams and circuit parameters) herein is for example only; it is not guaranteed for

volume production. SANYO believes information herein is accurate and reliable, but no guarantees are made or implied

regarding its use or any infringements of intellectual property rights or other rights of third parties.

Loading...

Loading...