Page 1

Ordering number : ENN6656A

42001RM (OT) No. 6656-1/7

Applications

Refrigerator fan motors

Features

• No Hall sensors required.

• No FG sensors required.

• Lock detection circuit (Can be set to operate in either

automatic recovery or latching mode.)

• Thermal shutdown circuit

• Current limiter circuit

• Low-voltage shutdown circuit

• Forward/reverse switching

• Supports both single- and dual-power supply circuits.

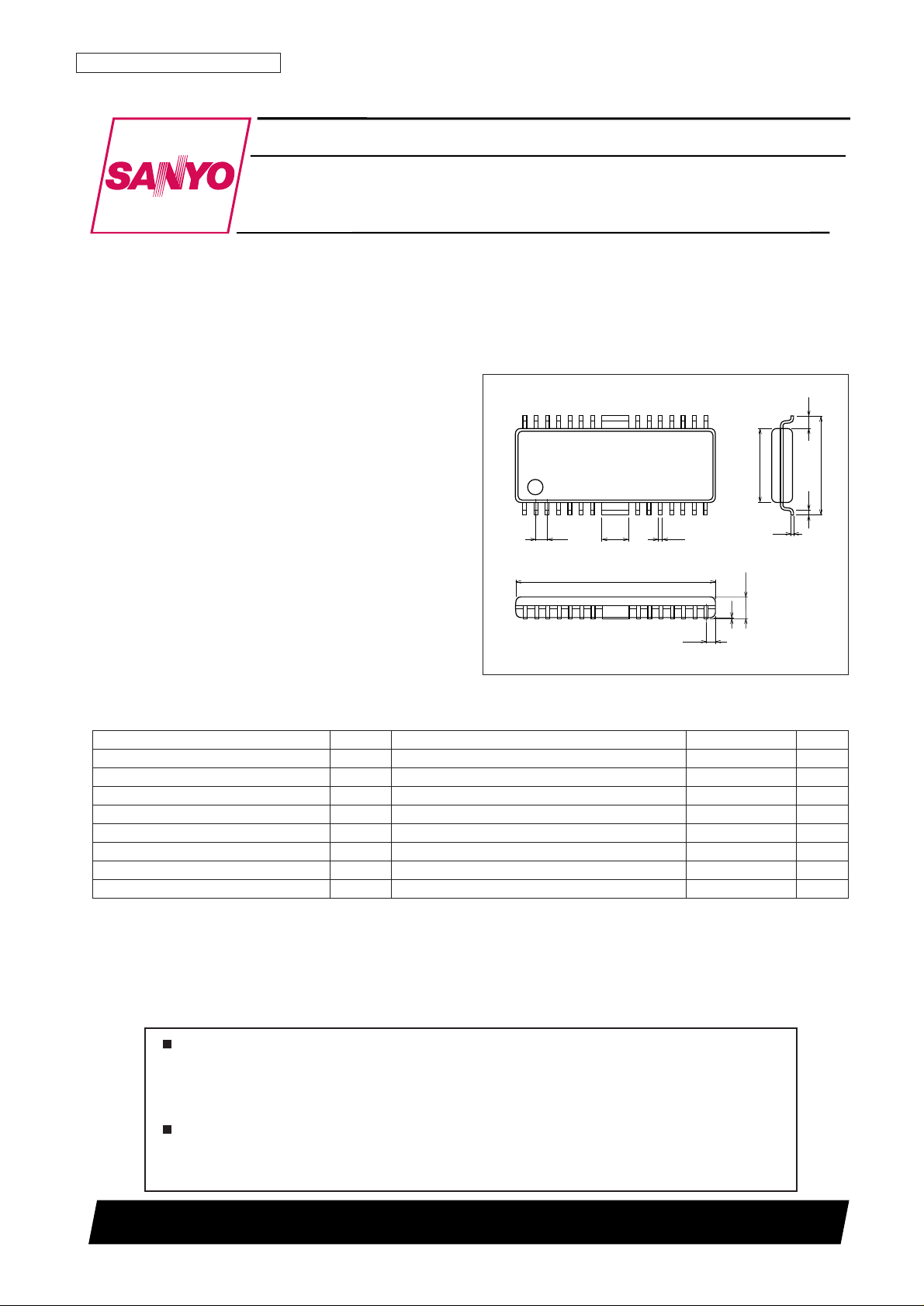

Package Dimensions

unit: mm

3222-HSOP28 (275 mil)

0.1

1.8max

7.6

1.0

114

0.3

0.8

1528

2.7

15.2

0.8

5.6

0.5

0.2

SANYO: HSOP28 (275 mil)

[LB11981]

LB11981

SANYO Electric Co.,Ltd. Semiconductor Company

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

Three-Phase Sensorless Motor Driver

Monolithic Digital IC

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft’s

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges, or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

Parameter Symbol Conditions Ratings Unit

Supply voltage 1 V

CC

max 30 V

Supply voltage 2 V

CC

max Power supply for output stage 30 V

Applied output voltage V

O

max 30 V

Applied input voltage V

I

max –0.3 to VCC+ 0.3 V

Maximum output current I

O

max 1.0 A

Allowable power dissipation Pdmax Independent IC 0.5 W

Operating temperature Topr –20 to +75 °C

Storage temperature Tstg –55 to +150 °C

Specifications

Maximum Ratings at Ta = 25°C

Page 2

No. 6656-2/7

LB11981

Parameter Symbol Conditions Ratings Unit

Supply voltage 1 V

CC

*8 (5) to 28 V

Supply voltage 2 V

CC

M 8 to 28 V

Operating Conditions at Ta = 25°C

Note: * This device should normally be used with VCC≥ 8 V. If used with 5 V ≤ VCC< 8 V, short the VCCand V

REG

pins together. Note that in this case the

electrical characteristics of the device become more easily influenced by fluctuations in the V

CC

supply voltage.

Parameter Symbol Conditions

Ratings

Unit

min typ max

Supply current 1 ICC 8.8 11 13.2 mA

Supply current 2 I

CCM

LKC = 5 V 480 600 720 µA

Internal power supply V

REF

4.75 5.0 5.25 V

Internal supply load regulation ∆V

REF

ILOAD = –5 mA 30 50 mV

Output saturation voltage 1 V

OSAT

1 IO = 0.4 A, Source + Sink 1.4 1.7 V

Output saturation voltage 2 V

OSAT

2 IO = 0.8 A, Source + Sink 2.0 2.4 V

MCOM pin common-mode input voltage range V

IC

0 VCC– 2 V

PCOUT pin output current 1 IPCOU Source side –120 –100 –80 µA

PCOUT pin output current 2 IPCOD Sink side 80 100 120 µA

VCOIN pin input current IVCOIN VCOIN = 4 V 1 2 µA

Minimum VCO frequency fVCOmin VCOIN = open 0.85 1 1.15 kHz

Maximum VCO frequency fVCOmax VCOIN = 5 V 36 42 48 kHz

Maximum CX pin charge/discharge current Icxmax VCOIN = 5 V 550 650 750 µA

Minimum CX pin charge/discharge current Icxmin VCOIN = open 11 14 17 µA

Thermal shutdown circuit operating temperature TTSD Design target value * 150 180 210 °C

Thermal shutdown circuit hysteresis ∆TTSD Design target value * 15 °C

BFGO pin output saturation voltage VsatFG ILOAD = 1 mA 0.2 0.4 V

[Lock Detection Circuit]

LKC pin voltage threshold Vth 3.7 4 4.3 V

Threshold level hysteresis ∆Vth 1.8 2 2.2 V

LKC pin charge current Ichg V (LKC) = 0 V 0.8 1 1.2 µA

LKC pin discharge current Idis V (LKC) = 4.2 V 0.52 0.65 0.78 µA

LAT pin input current ILAT V (LAT) = 0 V, V (LKC)= 4.2 V 3.2 4 4.8 µA

LKO pin saturation voltage VsatLKO ILOAD = 1 mA, V(LKC) = 4.2 V 0.2 0.4 V

[Low-Voltage Cutoff Circuit]

Low-voltage detection voltage VT VREG pin detection 38 4 4.2 V

Hysteresis ∆VF 150 180 210 mV

[Forward/Reverse Circuit]

INFR pin input current IINFR V (INFR) = 5 V 38 43 48 µA

INFR pin high-level input threshold voltage VINH 3.0 V

INFR pin low-level input threshold voltage VINL 1.0 V

Electrical Characteristics at Ta = 25°C, VCC= V

CCM

= 18 V

Note: * Design target values are not tested.

Page 3

No. 6656-3/7

LB11981

Pin Functions

Pin No. Pin Function

1 VCOIN VCO circuit voltage input. Inputs the PCOUT pin voltage filtered by an RC circuit.

2 CX

The value of the capacitor between this pin and ground determines the operating frequency range and the minimum operating

frequency of the VCO circuit.

3 LKC

Connection for the lock detection circuit capacitor. The value of the capacitor between this pin and ground determines the lock

state monitoring period. The lock detection circuit can be disabled by connecting this pin to ground.

4 LAT Lock detection circuit mode switching input

5 INFR Forward/reverse switching input

6 LKO Lock state detection signal. (A pull-up resistor is required.)

7 GND Ground

8 BFGO Motor back electromotive force detection FG output (3 phases combined). (A pull-up resistor is required.)

9 R

FS

Current limit sensing. The output current can be detected and current limiting applied by connecting this pin to the RF pin.

10 R

F

Lowest potential of the motor driver output transistor. The value of the resistor between this pin and ground determines the

current that flows in the output transistor.

11, 12, 14 N.C Not connected

13 U

OUT

15 V

OUT

Motor driver output

16 W

OUT

17 N.C Not connected

18 MCOM Motor coil midpoint input. The coil voltage waveform is detected using this voltage as the reference level.

19 FC

Frequency characteristics correction. Closed loop oscillation in the current control system can be stopped by inserting a

capacitor between this pin and ground.

20 V

CCM

Motor drive output stage power supply

21 U

IN

Coil waveform detection comparator input

22 V

IN

These are connected to the outputs for each phase through internal 10 kΩ resistors.

23 W

IN

24 V

CC

Power supply

25 V

REG

Internal 5 V regulator output

26, 27 TEST Test pin. This pin must be left open during normal operation.

28 PC

OUTVCO

circuit PLL output

Page 4

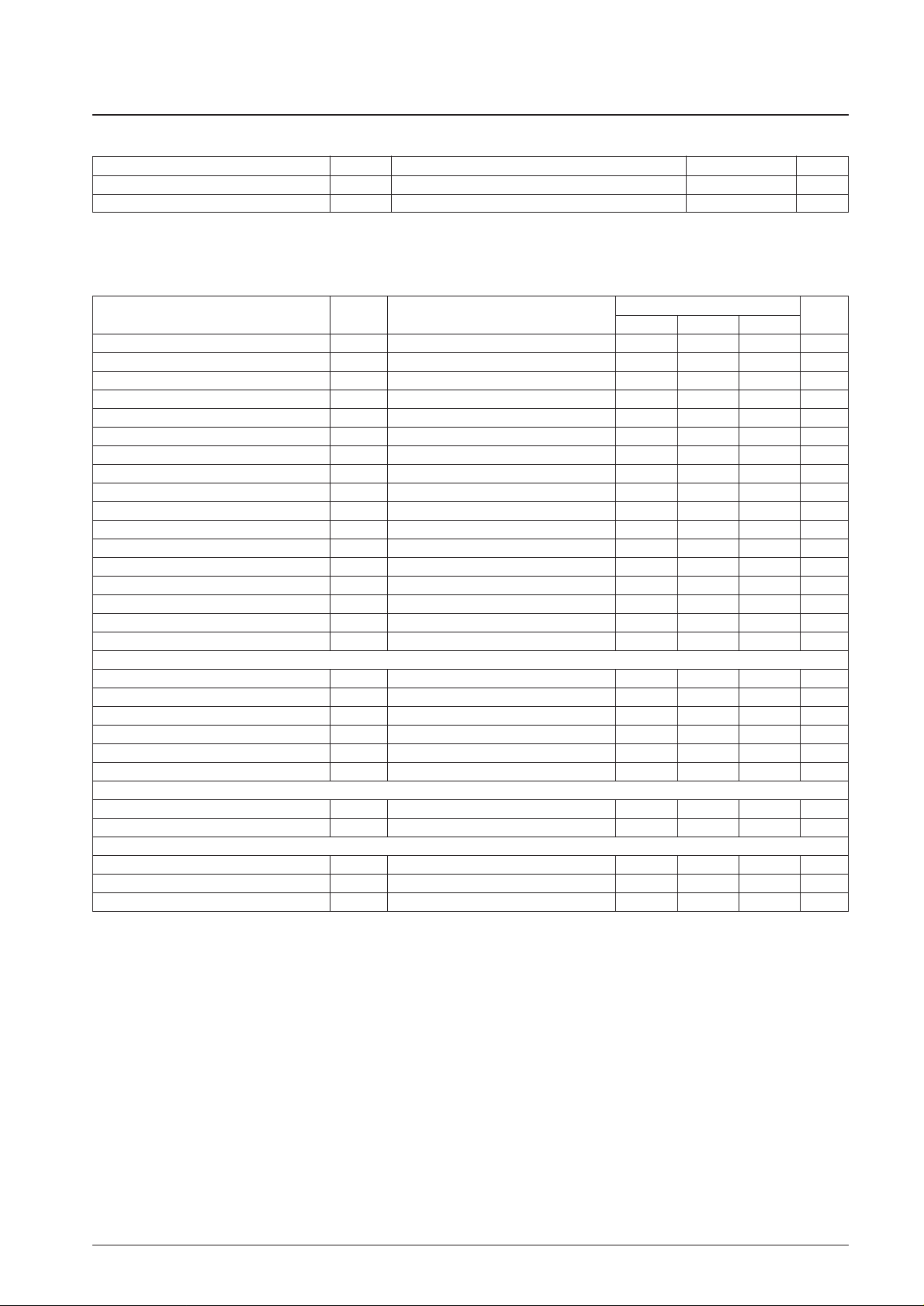

Pin Assignment

No. 6656-4/7

LB11981

ILB00049

1

2

3

4

5

6

7

8

9

10

11

12

13

14 15

16

17

18

19

20

21

22

23

24

25

26

27

28VCOIN

CX

LKC

LAT

INFR

LKO

GND

PC

OUT

TEST2

TEST1

VREG

V

CC

W

IN

V

IN

BFGO

R

FS

R

F

N.C

N.C

U

OUT

N.C

U

IN

VCCM

FC

MCOM

N.C

W

OUT

V

OUT

Top view

LB11981

Page 5

Truth Tables

Lock Detection Time Setting (automatic recovery mode)

No. 6656-5/7

LB11981

Pin 4 (LAT): Lock detection circuit mode switching

LAT Mode

OPEN Automatic recovery mode

“L” Output latched in the off state when lock detected.

Pin 5 (INFR): Motor rotation direction switching

INFR Mode

OPEN or “L” Forward

“H” Reverse

Pin 3 (LKC): Lock detection time setting capacitor connection

LKC Mode

GND Disabled

Capacitor inserted Enabled

Pin 6 (LKO): Lock state detection signal (A pull-up resistor is required.)

[LKC pin]

The following formula gives the time, t1, from the point the motor speed is locked until the output is turned off.

t1[s] = C [µF] × 4 [V] / 1 [µA]

The output off time, t2, is as follows.

t2[s] = C [µF] × 2 [V] / 0.65 [µA]

The time, t3, following the output off state until the motor speed locked state is monitored, is as follows.

t3[s] = C [µF] × 2 [V] / 1 [µA]

When pin 4 (LAT) is low (output off latching mode), after the t1 period lock state monitoring, the output is turned off

and the output is held in the off state until either the VCCor VCCM power supply is switched.

LKO State

“H” Lock not detected

“L” Lock detected

4 V

2 V

t1

Start of lock detection

t2 t3

Output off period

ILB00050

Page 6

No. 6656-6/7

LB11981

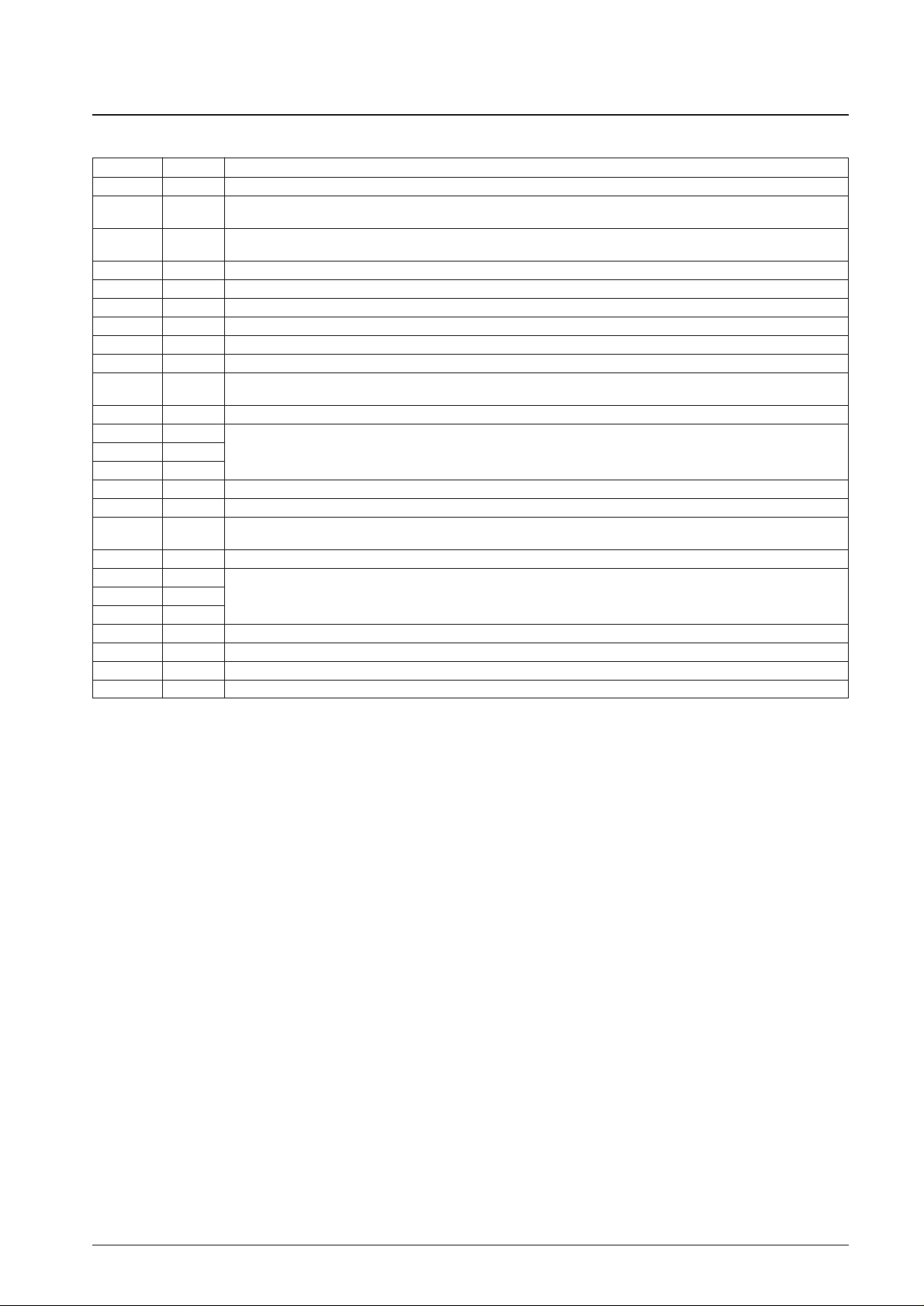

+

--

50 kΩ

V

REG

BFGO

TEST1

TEST2

PCOUT

VCOIN

CX

FC

LKC LAT

PLL

560 kΩ

50 kΩ

0.47 µF

0.01 µF

0.1 µF

V

CO

1 µF

LKO

INFR

V

REG

0.1 µF

0.5 Ω

200 Ω

GND

V

CC

R

FS

R

F

0.1 µF

5 V

REG

W

OUT

0.022 µF

V

OUT

U

OUT

W

INVIN

U

IN

MCOM

V

CCM

ILB00051

Thermal shutdown circuit

Startup control

circuit

Timing control

circuit

Lock detection

circuit

Switching drive

circuit

Upper saturation prevention circuit

Output drive circuit

Mask circuit

Divide-by-8

circuit

Low-voltage

cutoff circuit

Rotor position

detection circuit

Sample Application Circuit (Note that the values of the external components depend on the motor used.)

Page 7

PS No. 6656-7/7

LB11981

This catalog provides information as of April, 2001. Specifications and information herein are subject to

change without notice.

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer’s

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer’s products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

semiconductor products fail with some probability. It is possible that these probabilistic failures could

give rise to accidents or events that could endanger human lives, that could give rise to smoke or fire,

or that could cause damage to other property. When designing equipment, adopt safety measures so

that these kinds of accidents or events cannot occur. Such measures include but are not limited to protective

circuits and error prevention circuits for safe design, redundant design, and structural design.

In the event that any or all SANYO products (including technical data, services) described or contained

herein are controlled under any of applicable local export control laws and regulations, such products must

not be exported without obtaining the export license from the authorities concerned in accordance with the

above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or any information storage or retrieval system,

or otherwise, without the prior written permission of SANYO Electric Co., Ltd.

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the “Delivery Specification”

for the SANYO product that you intend to use.

Information (including circuit diagrams and circuit parameters) herein is for example only; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but

no guarantees are made or implied regarding its use or any infringements of intellectual property rights

or other rights of third parties.

Loading...

Loading...