Page 1

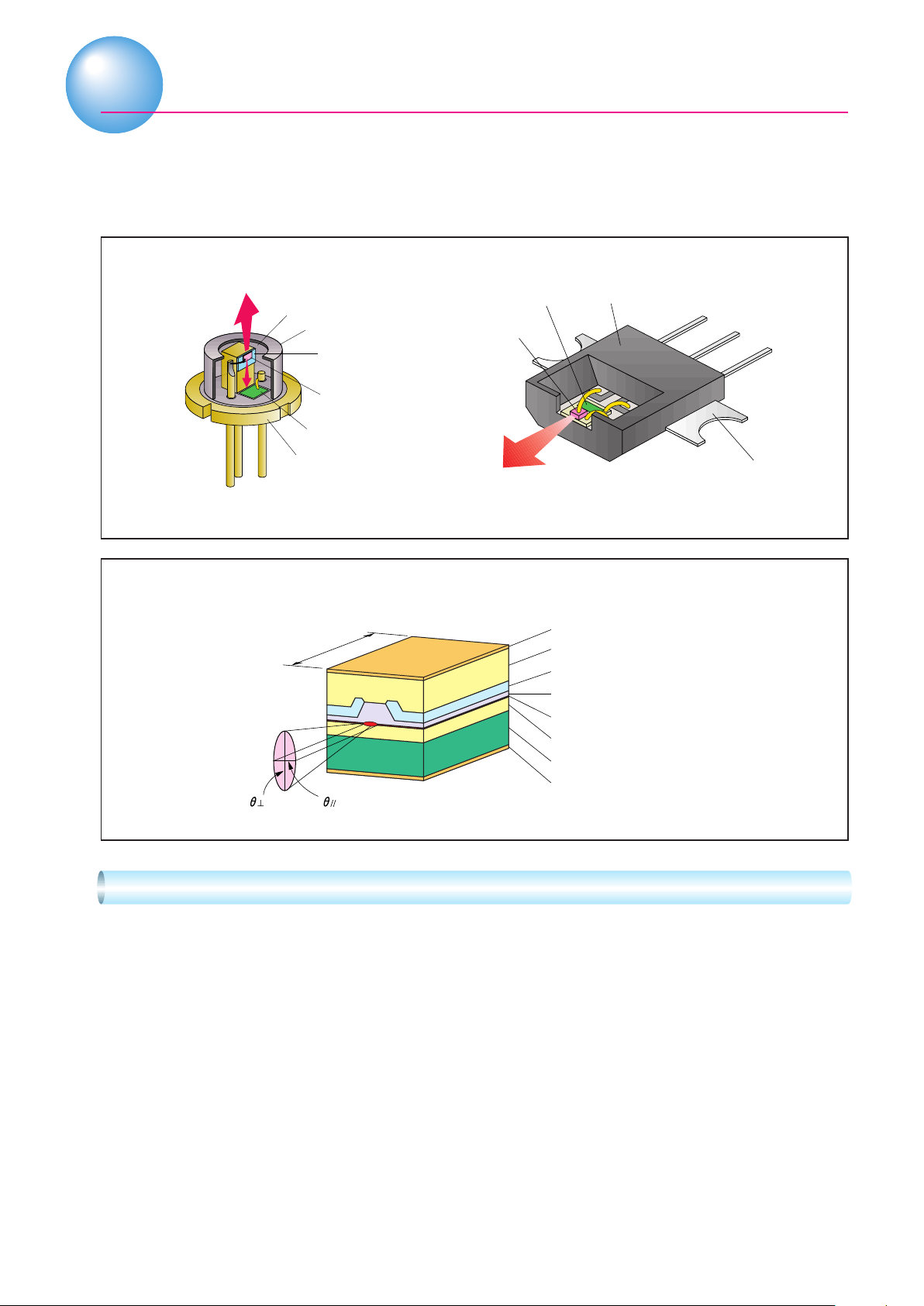

What is Laser Diode

The term laser is an acronym that stands for "Light Amplification by Stimulated Emission of

Radiation".

SANYO laser diode structure and basic element structure are listed below.

Laser diode structure

Can type

Cavity length

Window

Cap

Heatsink

Laser chip

PIN photodiode

Stem

PIN photodiode

Laser chip

Element structure

Electrode

Cap layer

Current blocking layer

Cladding layer

Active layer(MQW structure) *

Cladding layer

Substrate(Misoriented substrate)

Electrode

plastics

Heat radiation fin

Frame type

*MQW : Multiple Quantum Well

SANYO Laser Diodes Support Advanced Information Society

SANYO currently markets AlGaAs infrared laser diodes in the 780 – 830 nm wavelength, as well

as AlGaInP based red laser diodes in the 635 – 675 nm wavelength. SANYO realized 635 nm

AlGaInP laser diode for the first time in the world. The low operating current and high operating

temperature are realized by using misoriented substrate and MQW (Strain compensated) active

layer. With unique structures developed by SANYO, providing the following features, these laser

diodes are highly rated in a broad range of applications including compact discs, CD-R/RW, DVD

systems, bar code scanners, laser pointers and printers. SANYO laser diodes are also compatible

with multimedia and other new optical equipment on which advanced information societies in

future depend.

• A full line-up includes index guided short-wavelength, low-noise, high output power

• Long life and high reliability

• A stabilized fundamental transverse mode

• 9 mm, 5.6 mm diameter packages and frame type

• Pin connections compatible with various power supply systems

1

Page 2

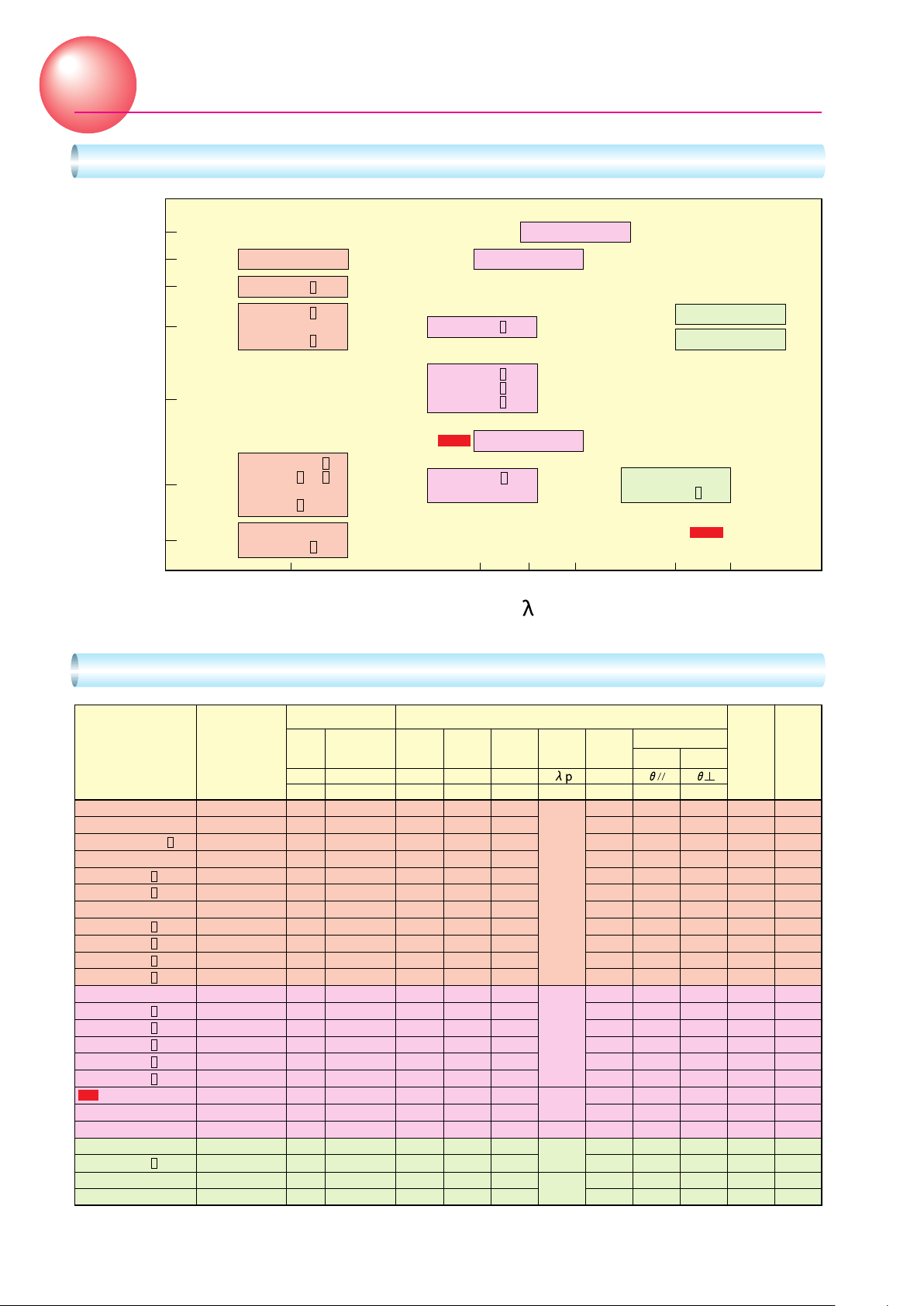

Red Laser Diode

SANYO Red laser diode line-up

70

30

20

10

7

5

Output Power Po (mW)

3

DL-LS1035

*

DL-4038-

26

DL-4038- 31

DL-4038-021

DL-4148- 21

DL-3038-033/ 34

DL-3148- 33/ 34

DL-3038-013

DL-3148- 13

DL-3038-023

DL-3148- 23

635 650 670

DL-5147-041

DL-4147- 61

DVD-P/ROM

DL-3147- 65

DL-3147- 85

DL-3247- 65

DVD Frame Laser

NEW

DL-3107-165

DL-3147- 31

DL-3147-021

DVD-R/RW

DL-LS1027

*

655 675660

2 Beam (LBP)

DL-LS1018

*

DL-4039-011

DL-3039-011

DL-3149- 57

NEW

New product

Under development

*

Lasing Wavelength p (nm)

Summary of Features (Typ.

Absolute

Maximum Ratings

Light

Po

mW

7

3

5

10

10

25

35

7

12

3

5

5

7

7

7

7

12

7

30

50

5

7

10

Operating

Temperature

Topr

°C

–

+40

10 to

–

+40

10 to

–

+50

10 to

–

+40

10 to

–

+50

10 to

–

+40

10 to

–

+40

10 to

–

+40

10 to

–

+40

10 to

–

+40

10 to

–

+50

10 to

–

+40

10 to

–

+50

10 to

–

+70

10 to

–

+80

10 to

–

+70

10 to

–

+70

10 to

–

+70

10 to

–

+60

10 to

–

+70

10 to

–

+60

10 to

–

+60

10 to

–

+50

10 to

–

+60

10 to

Part No. Main Feature

DL-3038-013

DL-3038-023

DL-3038-033/ 34

DL-4038-021

DL-4038- 31

DL-4038- 26

DL-LS1035

*

DL-3148- 13

DL-4148- 21

DL-3148- 23

DL-3148- 33/ 34

DL-3147-021

DL-3147- 31

DL-3147- 65

DL-3147- 85

DL-3247- 65

DL-4147- 61

NEW

DL-3107-165

DL-5147-041

DL-LS1027

*

DL-3039-011

DL-3149- 57

DL-4039-011

DL-LS1018

*

Under development

*

5mW at 40°C

3mW at 40°C

5mW at 50°C

10mW at 40°C

10mW at 50°C

20mW at 40°C

30mW at 40°C

5mW at 40°C

10mW at 40°C

3mW at 40°C

5mW at 50°C

5mW at 40°C

5mW at 50°C

5mW at 70°C

5mW at 80°C

5mW at 70°C

10mW at 70°C

5mW at 70°C

30mW at 60°C

70mW at 70°C

5mW at 60°C

5mW at 60°C

10mW at 50°C

10mW ,2Beam

Output

10x2

)

Ratings

Po

5

3

5

10

10

20

30

5

10

3

5

5

5

5

5

5

10

5

30

50

5

5

10

10

Electro-Optical Characteristics

Threshold

Current

Ith

mA

30

20

30

35

35

40

50

30

40

20

40

30

25

25

25

25

30

20

45

45

30

25

40

40

Operating

Current

lop

mA nm ° °mW

45

25

40

55

55

70

90

45

60

25

55

45

35

35

35

35

50

30

80

110

45

40

60

60

Lasing

Wavelength

635

650

655

660

670

675

Monitor

Current

lm

mA

0.20

0.20

0.20

0.15

0.15

0.20

0.30

0.20

0.15

0.15

0.20

0.40

0.20

0.20

0.20

0.20

0.30

0.10

0.03

–

1.20

1.50

0.15

0.15

Beam Divergence

Parallel

***

Perpendicular

8.0

8.0

8.0

8.0

8.0

7.0

7.0

8.0

8.0

8.0

8.0

7.5

8.0

8.0

8.0

8.0

8.0

8.0

7.0

8.5

8.0

8.0

8.0

8.0

30

30

30

30

30

28

30

30

30

30

30

30

30

30

30

30

28

30

23

17

33

30

30

30

Tc = 25°C

Package

Dimension

Type

B

B

B

B

B

B

B

C

C

C

C

C

C

C

C

D

C

I

C

C

B

C

C

E

Pin

Connection

Type

I

I

I, III

I

I, III

I, III

I

I, III

I, III

I, III

I, III

I

I, III

I, II, III

I, II, III

I, II, III

I, II, III

II

I

IV

I

I, III

I

V

2

Page 3

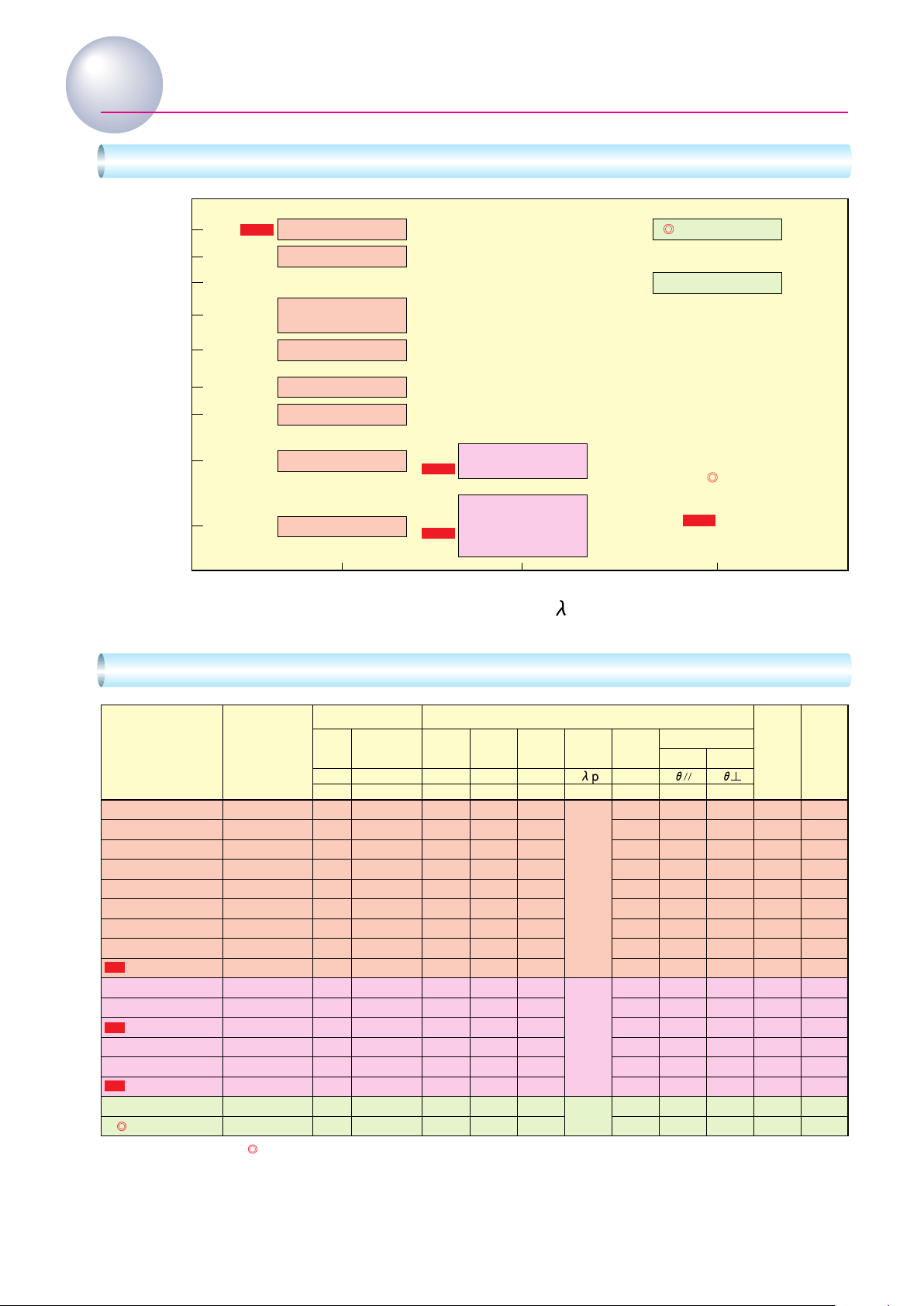

Infrared Laser Diode

SANYO Infrared laser diode line-up

CD-R/RW

150

120

100

80

20

15

NEW

DL-7140-201K

*

DL-7140-201H

*

DL-7140-201S

*

DL-7240-201S

*

DL-4140-001S

2 Beam (LBP)

DL-LS2003

DL-8032-001

DL-7032-001

10

5

Output Power Po (mW)

DL-4034-154S

DL-3144-005S

Frame laser (CD-P/ROM)

DL-LS3004

NEW

DL-3150-133

*

Frame laser (CD-P/ROM)

DL-3150-103/105

3

DL-3144-007S

DL-3150-106/107

NEW

DL-3180-121

DL-LS3007

*

785 790 830

Lasing Wavelength p (nm)

Summary of Features (Typ.

Absolute

Maximum Ratings

Light

Po

mW

8

5

15

15x2

25

80

80

80

80

5

5

5

5

7

7

100

150

Operating

Temperature

Topr

°C

–

10 to +60

–

10 to +60

–

10 to +60

–

10 to +60

–

10 to +60

–

10 to +60

–

10 to +60

–

10 to +60

–

10 to +60

–

10 to +70

–

10 to +60

–

10 to +60

–

10 to +60

–

10 to +70

–

10 to +70

–

10 to +50

–

10 to +50

Part No. Main Feature

DL-3144-005S

DL-3144-007S

DL-4034-154S

DL-LS2003

*

DL-4140-001S

DL-7140-201S

DL-7240-201S

DL-7140-201H

NEW

DL-7140-201K

DL-3150-103/105

DL-3150-106/107

DL-3180-121

NEW

DL-LS3007

*

DL-LS3004

*

NEW

DL-3150-133

DL-7032-001

DL-8032-001

at the power of ratings Export control-regulations products Under development

*

Low droop

Low droop

10mW at 60°C

15mW 2Beam

20mW at 60°C

85mW(Pulse)

85mW(Pulse)

120mW(Pulse)

150mW(Pulse)

Frame Laser

Frame Laser

Frame Laser, Low current

Frame Laser, Low current

Frame Laser, 5mW

Frame Laser, 5mW

100mW at 50

150mW at 50

Output

°C

°C

)

Ratings

Po

5

3

10

15

20

70

70

70

70

3

3

3

3

5

5

100

150

Electro-Optical Characteristics

Current

Ith

mA

25

25

30

30

25

30

30

30

30

35

35

20

20

20

20

50

50

Operating

Current

lop

mA nm ° °mW

45

35

60

55

60

100

100

100

100

45

45

25

25

30

30

140

185

Threshold

*

Lasing

Wavelength

Monitor

Current

785

790

830

lm

mA

4.50

0.60

0.40

0.40

0.75

0.25

—

—

—

0.20

0.20

0.20

0.20

0.30

0.30

0.20

0.50

***

Parallel

Export control-regulations

products

Under development

*

New product

NEW

Pulse condition

*

Beam Divergence

Perpendicular

9.0

25

9.0

27

9.0

28

8.0

25

9.0

25

8.0

17

8.0

17

8.5

17

8.5

17

10.5

10.5

11.0

11.0

10.5

10.5

7.0

7.0

35

35

35

35

35

35

18

18

Tc = 25°C

Package

Dimension

Type

C

C

A

E

C

C

D

C

C

G/F

F/G

H

G

H

G

A

A

Pin

Connection

Type

I

I

II

V

I

III

IV

IV

IV

II

II

II

II

II

II

I

I

3

Page 4

Photograph

Can Type Laser Diodes

A

DL-8032

DL-7032

DL-4034

B C D E

DL-4039

DL-4038

DL-3039

DL-3038

DL-7140

DL-5147

DL-4148

DL-4147

DL-4140

DL-3149

DL-3148

DL-3147

DL-3144

DL-3247

DL-7240

DL-LS2003

*

DL-LS1018

*

ø9.0mm (Infrared) ø9.0mm (Red) D-shaped stem ø5.6mm (2 Beam)

ø5.6mm

Under development

*

Frame Type Laser Diodes

F G H I

DL-3150-103

DL-3150-107

DL-3150-105

DL-3150-106

DL-3150-133

*

DL-LS3007

DL-LS3004

*

DL-3180-121

DL-3107-165

*

Frame type (CD) Frame type (CD) Small frame type (CD) Frame type (DVD)

Under development

*

4

Page 5

Application

Application

Examples of Applied Systems

Applications Products

Laser Pointer

Point of guide

(Meeting, Exhibition

Sightseeing etc.)

Line Marker, Leveler

Reference for

construction

(For Parallel line,

For measurement

distance)

Bar-code Scanner

Merchandise control

DL-3038-013

DL-3038-023

DL-3147-021

DL-3148- 13

DL-3148- 23

DL-4038-021

DL-4038- 26

DL-3038- 33/-034

DL-3038- 33/-034

DL-3039-011

DL-3147- 31

DL-3148- 33/- 34

DL-3149- 57

DL-4038- 31

DL-4038- 31

DL-4148- 21

DL-LS1035

DL-4039-011

DL-4147- 61

DL-5147-041

DL-LS1035

DVD, DVD-R/RW

DVD

Laser

Beam

Printer

CD, CD-ROM, CD-R/RW

CD-R/RW

Optical Communication

Digital Versatile Disc

(DVD)-ROM, R/RW

Drive

Image printing

Word printing

Compact Disc(CD),

-ROM,R/RW Drive

Optical Communication

DVD DVD-R/RW

DL-3107-165

DL-3147- 65

DL-3147- 85

DL-3247- 65

DL-4147- 61

Red Laser Infrarde Laser

DL-3039-011

DL-3149- 57

DL-4039-011

DL-LS1018

CD, CD-ROM CD-R/RW

DL-3150-103/105

DL-3150-106/107

DL-3180-121

DL-3150-133

DL-LS3004

DL-LS3007

DL-7140-201S

DL-8032-001

DL-LS1027

DL-3144-005S

DL-3144-007S

DL-4034-154S

DL-LS2003

DL-4140-001S

DL-7140-201S

DL-7240-201S

DL-7140-201H

DL-7140-201K

DL-7032-001

5

Page 6

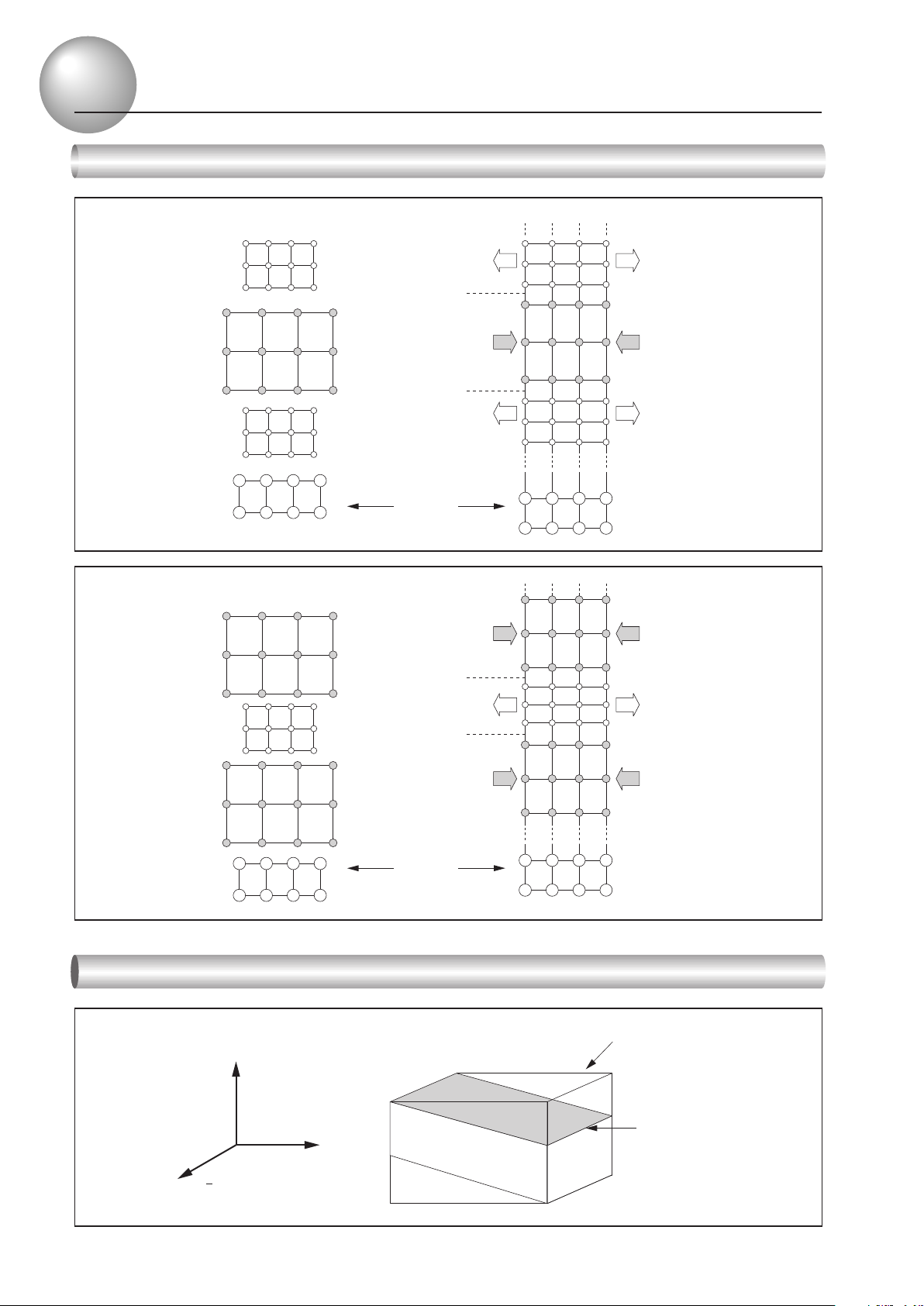

Key Technology

Strain compensated - MQW active layer

650~670nm Laser Diode

*

635nm Laser Diode (except DL-LS1035)

*

Quantum-barrier

Quantum-well

Quantum-barrier

Substrate

Quantum-well Tensile strain

Tensile strain

Compressive strain

Tensile strain

Compressive strainQuantum-barrier

Misoriented Substrate

[100]

[011]

[011]

Compressive strainQuantum-barrier

Substrate

Conventional Substrate

Misoriented Substrate

6

Page 7

Part Number Coding and Pin connection

Part Number Coding

DL-3 03 8-0 13

Laser diode series

Light output

Max.(mW)

3 :

4 :

5 :

6 :

7 :

8 :

7

20

40

50

100

150

Package dimension (mm)

03 : ø9.0

10 : Frame type(DVD)

14 : ø5.6

15 : Frame type(CD)

18 :

Small frame type(CD)

24 : D-shaped stem

Lasing wavelength (nm)

0 : 785–790

1 : 810

2 : 830

3 : 870

4 : 780

7 : 650–655

8 : 635

9 : 670–675

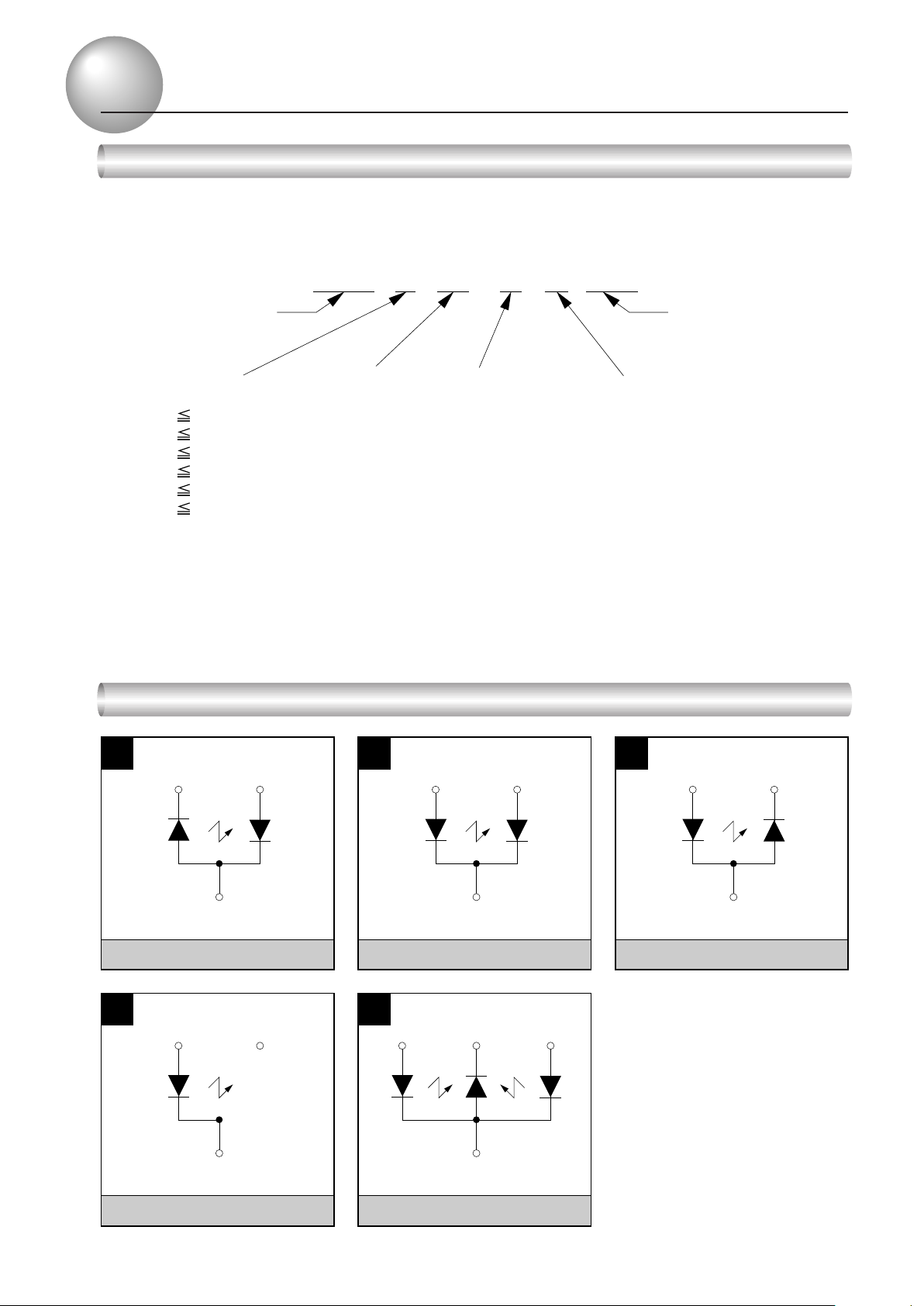

Pin connection

I II III

1 3

1 3

Suffix No.

Pin connection

0 : P-side down

(– power supply system)

1 : N-side down

(2 power supply systems)

2 : N-side down

(+ power supply system)

1 3

LD PD

2

– power supply system

IV

1 3 (NC)

LD

2

+ power supply system

no PD

LD PD

2

2 power supply system

V

1 3

LD1 LD2PD

2 beam + power supply system

2

4

LD PD

2

+ power supply system

7

Page 8

External appearance

External appearance dimensions

A CB

0

ø9.0–0.03

ø5.35

ø4.75±0.15

Effective window diameter 2.0min.

ø3.0

Effective window diameter 1.0min.

0

ø9.0–0.03

ø5.35

ø4.75±0.15

ø2.1

Tolerance : ±0.2

Unit : mm

0

ø5.6–0.025

ø4.4

ø3.55±0.1

Effective window diameter 1.0min.

ø1.6

1

3

1.0±0.1

LD facet

ø1.4max.

3–ø0.45±0.1

ø2.54

Top view

0.45±0.1

1.5±0.1

5.0±0.3

10±1.0

2.45±0.150.5max.

Pin No.

2

0.3

1 2 3

D E

0

ø5.6–0.025

ø4.4

ø3.55

Effective window diameter 0.6min.

ø1.6

2.45±0.150.5max.

Pin No.

1 3

2

0.3

1 2 3

Top view

1.0±0.1

0.45±0.1

LD facet

1.5±0.1

ø1.4max.

3–ø0.45±0.1

ø2.54

ø9.0mm stem (Red)

0

ø5.6–0.025

ø4.4

ø3.55±0.1

Effective window diameter 1.0min.

ø1.6

5.0±0.3

10±1.0

1.27±0.08

0.5max.

Pin No.

5.6mm ø stemø9.0mm stem (Infrared)

1 3

0.25

1 2 3

2

1.0±0.1

Top view

LD facet

ø1.4max.

3–ø0.45±0.1

ø2.0

0.4±0.1

1.2±0.1

3.5±0.5

6.5±1.0

2

1.270.5max.

Pin No.

1 3

4

1.0±0.1

1 4 3

Top view

LD facet

ø1.4max.

3–ø0.45±0.1

ø2.0

0.4±0.1

1.2±0.1

3.5±0.5

6.5±1.0

1.7±0.05

1.2

1.27±0.08

0.5max.

Pin No.

0.25

1 2 3

1.0±0.1

ø1.4max.

3–ø0.45±0.1

ø2.0

Top view

LD facet

0.4±0.1

1.2±0.1

3.5±0.5

6.5±1.0

D-shaped stem ø5.6mm stem (2 Beam)

8

Page 9

External appearance dimensions

F G

Tolerance : ±0.2

Unit : mm

1.9

3.4 1.85.0±0.5

0.7

0.7±0.12

R0.7

+0.1

0

1.4±0.12

3.0±0.1

6.4

2–0.4

3– 0.4±0.1

(

)

1.6

Pin No.

3.2

1.6

0

8.0

–0.1

4.0±0.12

3.7±0.15 3.0±0.15

4.2

3 2 1

2–C0.5

LD facet

2–R0.5

1.0

0.7

0.7±0.12

1.9

2–R0.7

3.4±0.12

3.7±0.15

+

0

1.4±0.12

3.4 1.85.0±0.5

3.0±0.1

6.4

2–0.4

3– 0.4±0.1

(

1.6

Pin No.

0.1

)

3 2 1

+0.1

0

0

+0.1

1.4

2

–

5

±

1

°

Frame type (CD) Frame type (CD)

6.8

1.6

4.2

3.2

0

–0.1

2–C0.5

LD facet

2

–

3

0

°

1.0

2

–

5

±

1

°

H I

0.21

1.41

0.2

2-0.3

2.0±0.15

0.5

1.75

1.37

1.75

4.0±0.1

2.87

3 2 1

ø3.3

0.6±0.15

LD facet

2-30

°

3.0

2.55

3.505.0±0.5

1.0

3-0.3

2-1.0 0.3

0.8

2.8

0.75±0.15

Pin No.

0.40.6

6.5 0.6

4.3

2-0.6

3.2

3-0.6

4.2

3.2

1.6

4.0

4.6

6.8±0.1

2.8

2 13

2-30

LD facet

0.9

°±

1°

2.4

0.8

2-5

°±

1°

1.4

5.5

1.0

2.9

0.6

Frame type (CD) Frame type (DVD)

9

Page 10

Definition of Feature

Absolute maximum ratings

Absolute maximum ratings are levels that can not be exceeded even momentarily

under any external conditions. The levels are stipulated in terms of case tempera

ture Tc = 25°C.

1. Light output power (PO)

This is maximum allowable output during

continuous operation. In the drive current

light output characteristics shown in the

figure on the right, there are no kinks or

bends under this light output power.

2. Reverse voltage (VR)

This is maximum allowable voltage with a

Output power P

reverse bias applied to the element. The

level is stipulated separately for a laser

diode and a photodiode.

3. Ambient operating temperature (Topr)

This is the maximum ambient temperature

in which the element can operate. The level is defined by case temperature of the

element.

Max. rating power

PO

Kink power

Forward current IF

Output power vs. Forward current (P–IF)

Non-linear

Kink

4. Ambient storage temperature (Tstg)

This is the maximum ambient temperature for element storage.

Electric optical characteristics

1. Threshold current (Ith)

Although P–IF curve distinguishes the LED

light emitting region A from the laser

oscillating region B, the current level that

triggers laser oscillating is the threshold

current. In actuality, Ith is defined as the

point where the straight line in B intersects

the X axis.

2. Rated light output power (Po)

This is recommended light output power

during continuous operation.

3. Operating current (Iop)

This is a current in the forward direction

that is required to generate rated light output power.

PO

Output power P

Output power vs. Forward current (P–IF)

LED

emitting region

B

A

Forward current IF

Laser

oscillating

region

lopIth

4. Monitor current (Im)

This is an output current of the photodiode at rated light output power.

10

Page 11

5. Differential efficiency (dP/dIop)

This is the increase in light output power per

unit of drive current. The amount is given by

the angle of the straight light output power

line with respect to forward current in the

laser oscillating range.

Definition of Feature

dP/dlop

dP

6. Lasing wavelength ( p)

This is peak lasing wavelength at rated

light output power. The lasing spectrum is

broadly classified as either a single mode

or a multi-mode as shown in the figure on

the right, and peak lasing wavelength is

defined by the maximum spectral intensity

in either mode.

Output power P

Forward current IF

Output power vs. Forward current (P–IF)

Single mode

Lasing spectrum

dlop

Multi mode

7. Beam divergence angle : Parallel ( ), Perpendicular( )

Light radiating from laser chip diverges as shown in the figure on the lower left. When the

light distribution is measured in the parallel (X axis) and perpendicular (Y axis) directions

with respect to the surface of the PN-junction on laser chip, (a) and (b) are shown in the

figure on the lower right. The beam divergence angle at 1/2 of the peak intensity of the light

distribution (full angle at half maximum) is defined as and .

Rear

PN-junction

Laser chip

Beam divergence

Front

1.0

Light

output power

0.5

Angle Angle

(a) (b)

Beam divergence ( , )

1.0

0.5

11

Page 12

Definition of Feature

8. Light axis off angle : Parallel ( ), Perpendicular ( )

This is expressed by a light axis shift with

respect to a reference surface. In a beam

divergent distribution of the parallel and

perpendicular directions as shown in the

figure on the right, shifts in both directions are

defined by (a - b)/2.

9. Light emission off center point (∆ X, ∆ Y, ∆ Z)

This is expressed by a shift in

the position of the light emitting

area. ∆ X and ∆ Y represent the

shift from the center of the

package, while ∆ Z represents a

shift with respect to stipulated

positions (a) from a reference

surface to the edge of a laser

diode (LD).

Top view

Light emission off center point (∆ X, ∆ Y, ∆ Z)

Light

output power

a

0

ZY

Side view

(a–b)/2

Light axis

off angle

Angle

LD facet

a

Reference plane

1.0

0.5

b

Light axis off angle ( , )

X

10. Astigmatism (As)

An astigmatism refers to a shift in focus position seen in the perpendicular and parallel

directions on the PN-junction surface of laser chip as shown in the figure on lower left.

11. Droop (∆ P)

This is the rate of light output power attenuation when a laser is driven by pulsed constant

current. The rate is defined by (A - B)/B x 100 % as shown in the figure on the lower right.

∆ P=(A–B)/Bx100%

A

Droop (∆ P)

600Hz

Duty : 10%

Duty : 90%

B

Time T

Laser chip

Astigmatism As

Focus position seen

in the parallel direction

Focus position seen

in the perpendicular

direction

Output power P

Laser beam

Astigmatism (As)

12

Page 13

Precautions for Use

Precautions for use

1. Temperature characteristics

Laser characteristics (wavelength, operating

current) vary with temperature, and variation

is more extreme at shorter wavelength. We

recommend installing an APC circuit to main

tain a constant output because operating

current varies significantly with temperature.

By the same token, laser reliability can be im

proved by designing products based on their

heat release characteristics. Since laser reli

ability falls off steeply at a higher tempera

ture, never allow the case to exceed the op

erating temperature range given in specifica

tions while a laser is in use.

25°C 50°C 70°C

Output power P

Forward current IF

Temperature characteristics of I-L curves

2. Thermal radiation

Make sure that a thermal radiating plate (W 30 x L 30 x t 5 mm) made of aluminum or

some other high thermal conducting materials is mounted to laser diode. The reliability

of laser diode is closely linked to junction temperature, so reliability rapidly declines at

a higher temperature. Do not overlook thermal radiation.

Thermal radiating plate

(Al or Cu)

3. Measuring light output power

Use a light power meter to measure light output

power of laser diodes. When measuring with APC

drive, set a power meter at an angle as shown in

the right figure so that a photodiode in a laser

diode is not exposed to reflected light from the

power meter.

Laser diode

Power meter

20°

13

Page 14

Precautions for Use

4. Absolute maximum ratings

Do not exceed, even momentarily, the maximum ratings.

When laser diode is driven in excess of the maximum ratings, it causes not only instant

breakdown or deterioration but also considerable reduction in reliability.

(1)

Laser diode may be damaged by surge current generated at power on-off operation.

Check on the transient characteristics of power supply to make sure that such surge

current does not exceed the maximum ratings.

(2)

The maximum ratings are specified by case temperature at 25˚C. Design should be

made well to work with temperature. As temperature goes up, power dissipation as

well as maximum light output power is reduced.

5. Soldering conditions

Maximum temperature is set at 260˚C and soldering time is within 3.0 seconds and

minimum clearance of 1.6 mm from the root of a lead is necessary.

6. Prevention of breakdown due to static electricity or surge current

Laser diode may be adversely affected by static electricity and surge current and,

consequently causes breakdown of element and reduction of reliability unless the

following cares are taken :

(1)

Power supply, installation and measuring equipment should be grounded. A noise

filter or noise-cut transformer is to be provided to power supply input utilized.

(2)

During operation, working clothes, hats and shoes should be static-protected when in

use.

Also, a workman body should be static-protected by use of an earth-band or the like

and grounded through high resistance (500 kΩ - 1MΩ ).

(3)

A soldering iron should be grounded to protect laser diodes from voltage leak.

(4)

Any container for carriage and storage should be static-protected.

(5)

Avoid using laser diodes at a place where high frequent surge current may be

generated as an inductive electric field gives breakdown or deterioration. (Avoid being

placed around fluorescent grow lamp, for example).

14

Soldering iron with surge protection

Static protected clothes

Conductive table mat

Grounded band

190

Humidifier

Conductive floor mat

1MΩ

Page 15

7. COD (Catastrophic Optical Damage) level

If current is flowing into the forward direction

and output continues to rise following a kink or

other deviation, then the laser eventually

reaches facet breakdown (COD) level where

the crystal at the facet melts due to the high

optical density. Special care must be taken in

the handling of red lasers because they may

continue to oscillate with a low power of 2 to 3

mW even after occuring facet breakdown.

There are several ways to tell whether an ele

ment is damaged or destroyed, such as

through a far field pattern or an increase in the

operating current. The life of a laser is signifi

cantly curtailed once the element is damaged,

so special care must be taken to avoid not

only excessing current when adjusting the out

put, but surge like static electricity as well.

Precautions for Use

COD level

Kink level

Output power P

Forward current IF

Output power vs. Forward current (P–IF)

Near field pattern

(A) Nomal laser

Near field pattern

(B) Damaged laser due to COD

Normal laser

Damaged laser

∆ lop

Po

Far field pattern

Damaged laser due to COD Output power vs. Forward current

Output Power (mW)

Forward current (mA)

lop1

lop2

15

Page 16

Precautions for Use

ESD data

(1) Measurement circuit

R=2MΩ

(2) Example of ESD data

100

80

60

40

Alive rate (%)

20

C=200pFV

AlGaInP Red laser diode

LD

(Machine model)

Judgment : ∆ lop 1.5mA

0

0

100

80

60

40

Alive rate (%)

20

0

0 20 40

20 40

60 80 100

Supplied voltage (V)

AlGaAs Infrared laser diode

60 80 100 120

Supplied voltage (V)

16

Page 17

8. Polarizing characteristics

Precautions for Use

Polarizing characteristics of red lasers vary

with distortions in the active layer. Conven

Y

635nm polarizing direction

tional infrared lasers as well as 650 to 675nm

lasers oscillate in the TE mode (polarizing di

rection parallel to the junction plane). As

such, special care must be taken when using

650–675nm, 780nm

X

polarizing direction

polarized optical parts with 635nm laser (ex

cept DL-LS1035) because it oscillates in the

TM mode (polarizing direction parpendicular

Top view of the stem

to the junction plane).

9. Package handling

(1)

Package must not be cut off, reworked nor deformed. Do not hold the cap of laser

diode tight, otherwise it may bring about cracks onto the window glass.

(2)

Do not touch the surface of the window glass. Any scratch or contamination may result

in reduction of optical characteristics.

(3)

Remove small contaminations on the surface softly using a cotton stick with a small

amount of methyl alcohol.

17

Page 18

Packaging

Packaging

192mm

43mm

1

Internal box

ESD

protective bag

(2tray / bag)

51mm

192mm

235mm

235mm

150

tray

Stem type Laser (300P)

100

Internal box

ESD

protective bag

(10tray / bag)

1

tray

18

Frame type Laser (1000P)

Page 19

Laser Drive System

Drive Circuit Recommendations

1. APC Circuit

GND

Im

R3

50k

V1

R4

4.7k

1/2 LA6358N

+

OP1

–

10µ

1k

2.2k

2.2k

+

5V

2.2k

V1

V2

1/2 LA6358N

–

OP2

+

47k5k

100k

470

1µ

2SD600

+

33µ

This APC drive circuit is used for type I pin connecting diagram.

When a laser diode (LD) emits light, light current (Im) proportionated to light output

power flows to a monitoring photodiode (PD) and a voltage V1 = Im (R3+R4) generates.

This voltage is sent by the op amp OP1 through a buffer to the op amp OP2.

Reference voltage V2 obtained from constant-voltage diode and volume switch is also

sent to the op amp OP2.

The op amp OP2 compares two voltages and then varies base current of output

transistor while controlling the current flowing to laser diode so that V1 = V2 is constantly

maintained. This is how constant light output power is obtained.

LDPD

R1

47µ

+

39

R2

10

Unit (Resistance : Ω Capacitance : F)

0.1µ

–

12V

Adjustment

Turn volume switch R3 as high as it will go, and set 5 kΩ volume switch so that V2 = 0.

(1)

Mount laser diode with power turned off.

(2)

Turn power on, and turn 5 kΩ volume switch to the center point while measuring light

(3)

output power with a light power meter. Here, light output power should be 1/2 of the

setting level. If difference from the setting level is significant, then turn off power and

adjust R3 and R4.

Turn volume switch R3 until light output power matches the setting level.

(4)

R1 – R4 setting procedure

Set light output range based on the data for laser diode characteristics and then use

(1)

the table below to determine proper operating current and monitoring output current

for light output power.

Light

output power

Pmax

Pmin

Operating

current

Imax

Imin

Monitoring

output current

Im max

Im min

19

Page 20

Laser Drive System

(2)

Set power resistance R1 and R2 for Imax based on table 1 used with the ACC circuit.

(3) After adjustments on the previous page, V2 will be about 1.7 volts.

Determine resistance R4 so that Immax x R4 = 1.7.

(4) Determine resistance R3 so that Immax x (R3 + R4) = 1.7. (Pmax = 4 mW and

Pmin = 1 mW when using 3 mW.)

2.APC Circuit

1/2 LA6358N

Im

PD

R3

1k

R4

100

+

–

OP1

10µ

1k

2.2k

+

2V

5k

5.6k

V1

V2

2k

–

OP2

+

1/2 LA6358N

33µ

+

470

100k

2SD600

1µ

+

47µ

R1

39

LD

Unit (Resistance : Ω Capacitance : F)

12V

0.1µ

GND

This drive circuit is used for type II pin connecting diagram. Operating principle

and adjustment procedure is exactly the same as that for APC circuit 1, except

that the resistance R3 and R4 settings are different.

R1 – R4 setting procedure

(1)

V2 in the circuit is about 0.26 volt, so determine resistance R4 so that Immax x R4 = 0.26.

(2)

Determine resistance R3 so that Immin x (R3 + R4) = 0.26. (Be sure to set R3 so that

voltage V1 is less than 0.5 volt because reverse bias is not applied to a photodiode).

3.APC Circuit

5V

1k

5k

2.2k

+

47k

2.2k2.2k

V2

V1

1/2 LA6358N

+

OP2

–

470

100k LD

33µ

2SB631

1µ

R2

10

47µ

+

0.1µ

R1

39

Unit (Resistance : Ω Capacitance : F)

R3

50k

Im

R4

4.7k

PD

–

OP1

+

1/2 LA6358N

+

10µ

This drive circuit is used for type III pin connecting diagram. The circuit is a version

of APC circuit 1 altered for reverse polarity characteristics and has the same

operating principle, adjustment procedure and resistance settings as APC circuit 1.

20

12V

GND

Page 21

Laser Drive System

4. APC Circuit

GND

+

C2

10µF

C1=1µ

TR1

2SC3383

0.6V

PD

R3

15kΩ

R4

5kΩ

LD

10kΩ

1kΩ

20µF

–

3V

(50Ω )

TR2

2SC3383

+

This is an example of an APC circuit for battery-powered Type I pin connection

circuits. It is ideally suited for a low-current DL-3148-023 The reference voltage

here is the voltage between the base and emitter of transistor TR1, and is normally

0.6 volts.

Since the absolute maximum rated power of the DL-3148-023 is 3 mW, the power

adjustment range for the circuit is between 0.5 and 2 mW. Resistors R3 and R4

used for adjusting power are set as outlined below.

Since Im is 0.12 mA at a maximum power of 2 mW, then R4 = VBE / Im = 0.6 / 0.12

= 5kΩ .

Then since R3 determines minimum optical output and Im is 0.03 mA with 0.5mW

of power, then R3 + R4 = VBE / Im = 0.6 / 0.03 = 20kΩ and R3 =15kΩ .

21

Page 22

Safety

The output light from laser diode is visible or invisible, and harmful to a human eye. Avoid looking at the output light of

laser diode directly or even indirectly through a lens while oscillating. When an optical axis is to be adjusted to a laser

beam and outer optical systems, a laser beam should be observed through an infrared TV camera or other equipment.

Particularly when the light is collimated or focused through a lens, safety glasses should be worn and care should be

taken to absolutely protect human eyes from the directly entering beam.

CAUTION – THE USE OF OPTICAL INSTRUMENTS WITH THIS PRODUCT WILL INCREASE EYE HAZARD.

Refer to IEC 825-1 and 21 CFR 1040.10 - 1040.11 as a radiation safety standard as to laser products.

LASER DIODE

Type :

Manufactured :

LASER DIODE

I S O

VISIBLE LASER RADIATIONAVOIDE DIRECT EXPOSURE TO BEAM

PEAK POWER 50 mW

WAVELENGTH 635-685 nm

CLASS IIIb LASER PRODUCT

AVOID EXPOSURE

-Visible laser radiation

is emitted from this aperture

INVISIBLE LASER RADIATIONAVOIDE DIRECT EXPOSURE TO BEAM

PEAK POWER 200 mW

WAVELENGTH 780-830 nm

CLASS IIIb LASER PRODUCT

This product complies with 21 CFR 1040.10

and 1040.11.

TOTTORI SANYO ELECTRIC CO., LTD.

LED DIVISION

5-318, Tachikawa, Tottori 680-8634 Japan

LASER DIODE

AVOID EXPOSURE

-Invisible laser radiation

is emitted from this aperture

Quality assurance system

LED Division of Tottori SANYO Electric Co., Ltd. takes pride in providing its customers

with the highest quality LED products possible. We are especially proud of the fact that all

LED products of our company have already obtained the verification of ISO 9001 in ac

cordance with IECQ (IEC Quality Assessment for Electronic Components). The produc

tion system is carried out in one continuous operation, including such processes as syn

thesis of compound semiconductors, single crystal growth and final display assembly. It

is our goal that, by making the best use of such production system, we develop quality

control activities which are supported by the verification of ISO, and offer the products in

100% conformance with our customers specifications.

Our quality assurance activities

for release of continually improving

new products are carried out re

flecting customers desires which

are constantly fed back into our

production lines. Our mass-pro

duction is controlled by standar

dized processes such as massproduction trial approval, a quality

control method to confirm the trial

products being made identical.

The guarantee shall be applied

only to the products delivered by

our company.

Environmental management system

Electronic Device Business Headquarters LED Division of Tottori Sanyo Electric Co.,

Ltd. has already obtained the verification of ISO 14001 in accordance with the assess

ment approval system of Environmental management system. The sphere of ISO 14001

are the development, design, manufacture and sales on the Optoelectoronic device.

45

Loading...

Loading...