Page 1

Ordering number : EN4850A

93098HA (OT) / 30895TH (OT) No. 4850-1/24

LA7265W

SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquarters

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

Single-Chip Black and White CCD Camera

Signal Processing IC

Monolithic Linear IC

Any and all SANYO products described or contained herein do not have specifications that can handle

applications that require extremely high levels of reliability, such as life-support systems, aircraft’s

control systems, or other applications whose failure can be reasonably expected to result in serious

physical and/or material damage. Consult with your SANYO representative nearest you before using

any SANYO products described or contained herein in such applications.

SANYO assumes no responsibility for equipment failures that result from using products at values that

exceed, even momentarily, rated values (such as maximum ratings, operating condition ranges, or other

parameters) listed in products specifications of any and all SANYO products described or contained

herein.

Overview

The LA7265W is a single-chip IC that provides the signal

processing required by black and white CCD cameras.

This IC is optimal for surveillance cameras, door intercom

cameras, and personal computer input cameras due to its

ultraminiature package, low current drain, wide dynamic

range, and high AGC gain.

Functions

• CCD clamping

• CDS (built-in S/H capacitor)

• IRIS amplifier

• AGC backlight correction

• S-curve gamma correction

• Aperture correction

• Variable setup

• Sync addition

• CCD clipping

• IRIS window

• AGC amplifier

• Gamma correction (0.45, 1.0 and variable)

• 1H interpolation switch

• Aperture low illumination suppression

• Variable W.C.

• 75 Ω drivers

Features

• CCD clamping used to provide a wide dynamic range:

The LA7265W can handle a 1.5 Vp-p CCD signal data

level.

• Reduced sampling noise provided by a built-in CDS

capacitor.

• Variable AGC gain: up to a maximum of 32 dB.

• Backlight correction provided by weighting the iris and

AGC levels.

• Three different gamma correction circuits, including Scurve gamma correction

• Knee characteristics are added to the gamma correction

to prevent incorrect white rendering in low light

situations.

• Automatic aperture adjustment according to the

brightness

• Reduced current drain (under 40 mA)

• Ultraminiature package (SQFP48)

• Reduced external component count (50% as compared

to the earlier Sanyo LA7261M)

• Reduced number of adjustment points (two points)

Page 2

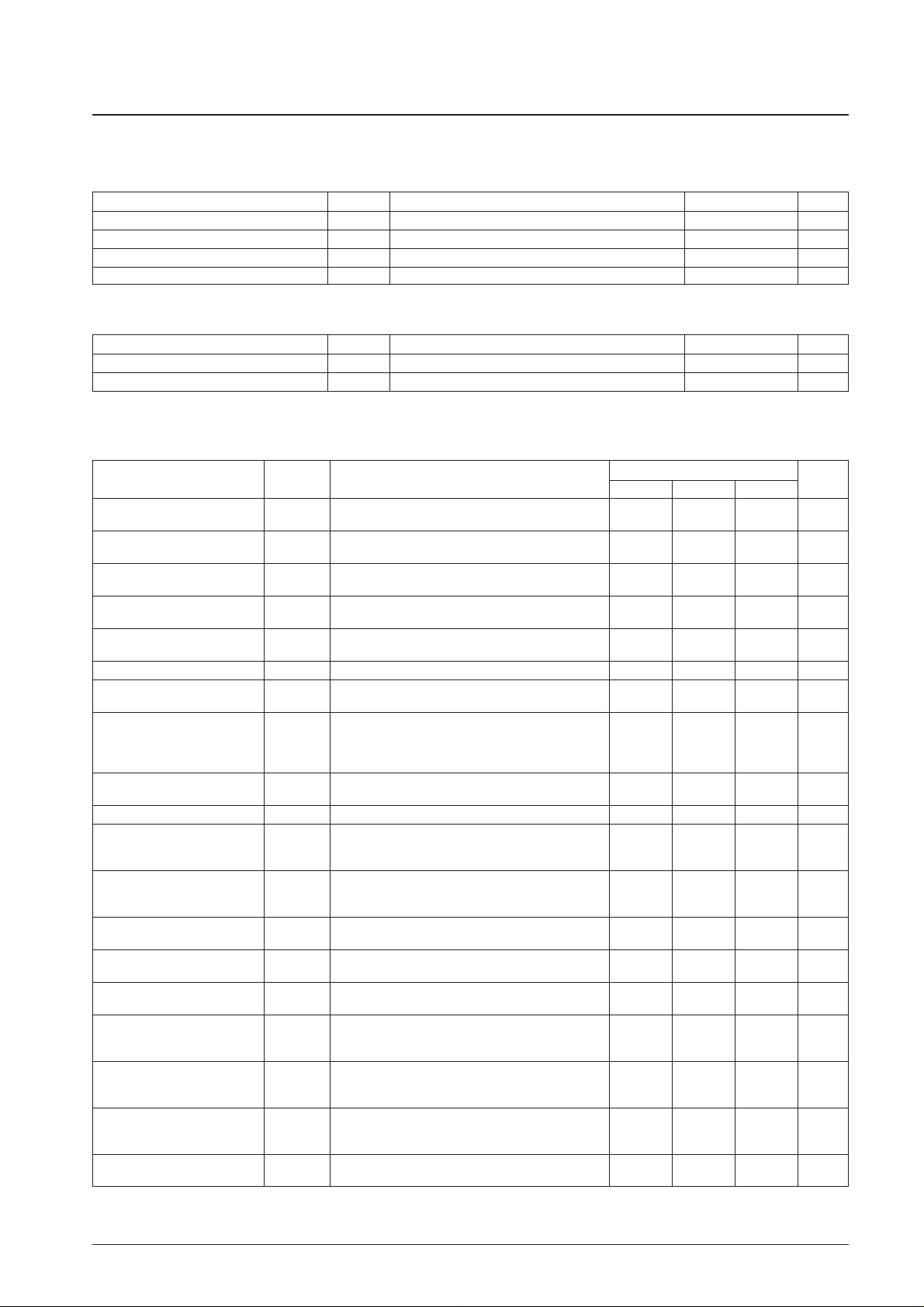

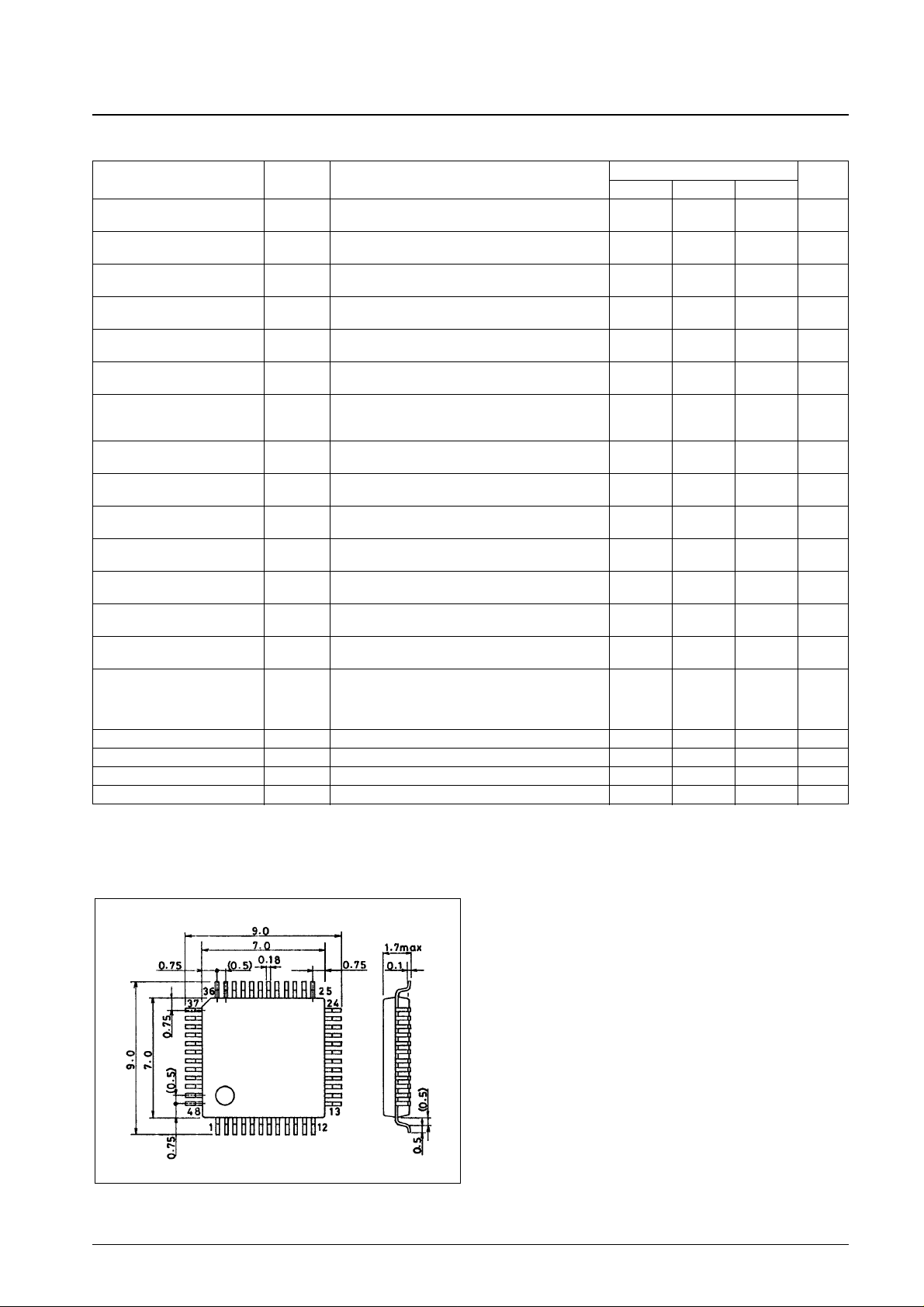

Specifications

Maximum Ratings at Ta = 25°C

Recommended Operating Conditions at Ta = 25°C

Note: Full IC immersion solder dip mounting techniques should be avoided.

Operating Characteristics at Ta = 25°C, VCC= 5 V

No. 4850-2/24

LA7265W

Parameter Symbol Conditions Ratings Unit

Maximum supply voltage V

CC

max 6.0 V

Allowable power dissipation Pd max Ta ≤ 65°C 270 mW

Operating temperature Topr –15 to +65 °C

Storage temperature Tstg –40 to +150 °C

Parameter Symbol Conditions Ratings Unit

Recommended supply voltage V

CC

5.00 V

Operating supply voltage range V

CC

op 4.75 to 5.25 V

Parameter Symbol Conditions

Ratings

Unit

min typ max

CCD clipping high level CCLIPH

Measure the output voltage difference for inputs of

1.11 1.22 1.33 V

0 Vp-p and 2 Vp-p. T1 output

CCD clipping middle level CCLIPM

Measure the output voltage difference for inputs of

0.60 0.91 1.22 V

0 Vp-p and 2 Vp-p. T1 output

CCD clipping low level CCLIPL

Measure the output voltage difference for inputs of

0.25 0.40 0.50 V

0 Vp-p and 2 Vp-p. T1 output

CDS dynamic range CDSD

Measure the output amplitude for a 2 Vp-p input.

1.20 1.47 V

T4 output

CDS hold ability CDSH

Measure the voltage drop during a 30/fsc hold

58 88 mV

for a 1 Vp-p input. T1 output

CDS offset CDSO Measure the output noise level. T1 output 11 mV

Sampling noise CDSN

Stipulated as the absorption remainder for the input

4 mV

dark current difference (200 mV). T1 output

Measure the output voltage for a 500 mVp-p input and

CDS linearity CDSL

the output voltage for a 1000 mVp-p input. Stipulates

100 %

the voltage difference of those two measurements

as a gain ratio. T1 output

IRIS.OUT DC level IRISDC

Measure the output voltage (OPB) with no input.

0.78 1.10 1.42 V

T2 output

IRIS.OUT pedestal level IRISP Measure the pedestal level with no input. T2 output –20 +300 +620 mV

Measure the output voltage for a 300 mVp-p input.

IRIS.OUT maximum W.C. level IRISWL Stipulated as the difference between that measurement –490 –230 +30 mV

and the IRISDC level. T2 output

Measure the output voltage difference for inputs of

IRIS.OUT gain IRISG 0 Vp-p and 300 mVp-p. Stipulated as the gain with 7.5 9.0 10.5 dB

respect to the input. T2 output

IRIS.OUT D range IRISD

Measure the output voltage difference for inputs of

2.05 2.40 V

0 Vp-p and 2 Vp-p. T2 output

IRIS.OUT W.C. level initial value IRISWT

Measure the output voltage difference for inputs of

1.25 1.60 1.95 V

0 Vp-p and 2 Vp-p. T2 output

AGC DC level (maximum) AGCDC1

Measure the output voltage (OPB) with no input.

0.85 2.10 3.50 V

T1 output

Measure the output voltage difference for inputs of

AGC maximum gain (maximum) AGCHG1 0 Vp-p and 30 mVp-p. Stipulated as the gain with 26.0 31.0 34.5 dB

respect to the input. T1 output

Measure the output voltage difference for inputs of

AGC maximum gain (typical) AGCHG2 0 Vp-p and 30 mVp-p. Stipulated as the gain with 19.5 24.0 27.5 dB

respect to the input. T1 output

Measure the output voltage difference for inputs of

AGC maximum gain (minimum) AGCHG3 0 Vp-p and 30 mVp-p. Stipulated as the gain with 13.5 15.5 17.5 dB

respect to the input. T1 output

AGC DC level (minimum) AGCDC2

Measure the output voltage (OPB) with no input.

2.30 2.50 2.70 V

T1 output

Continued on next page.

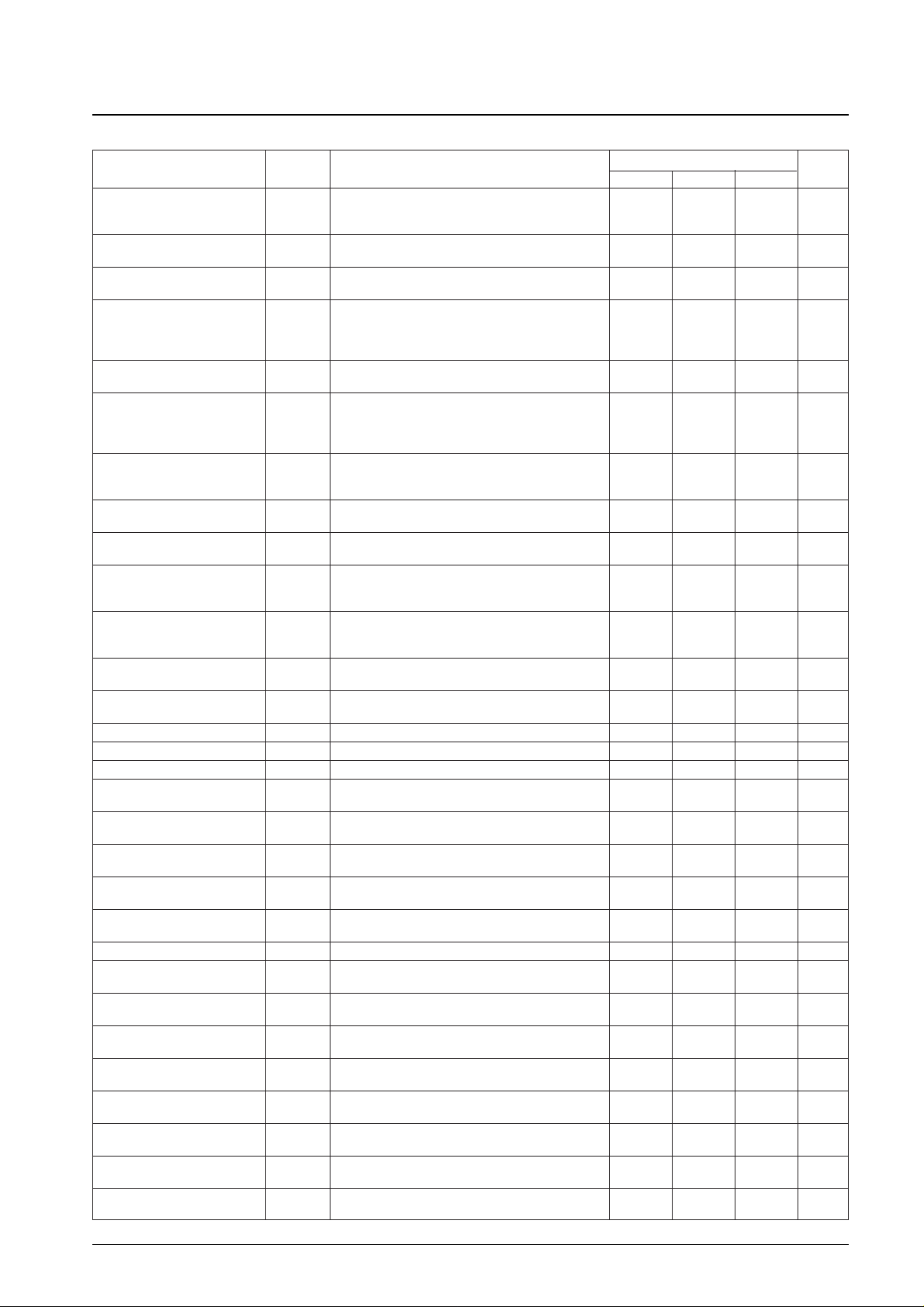

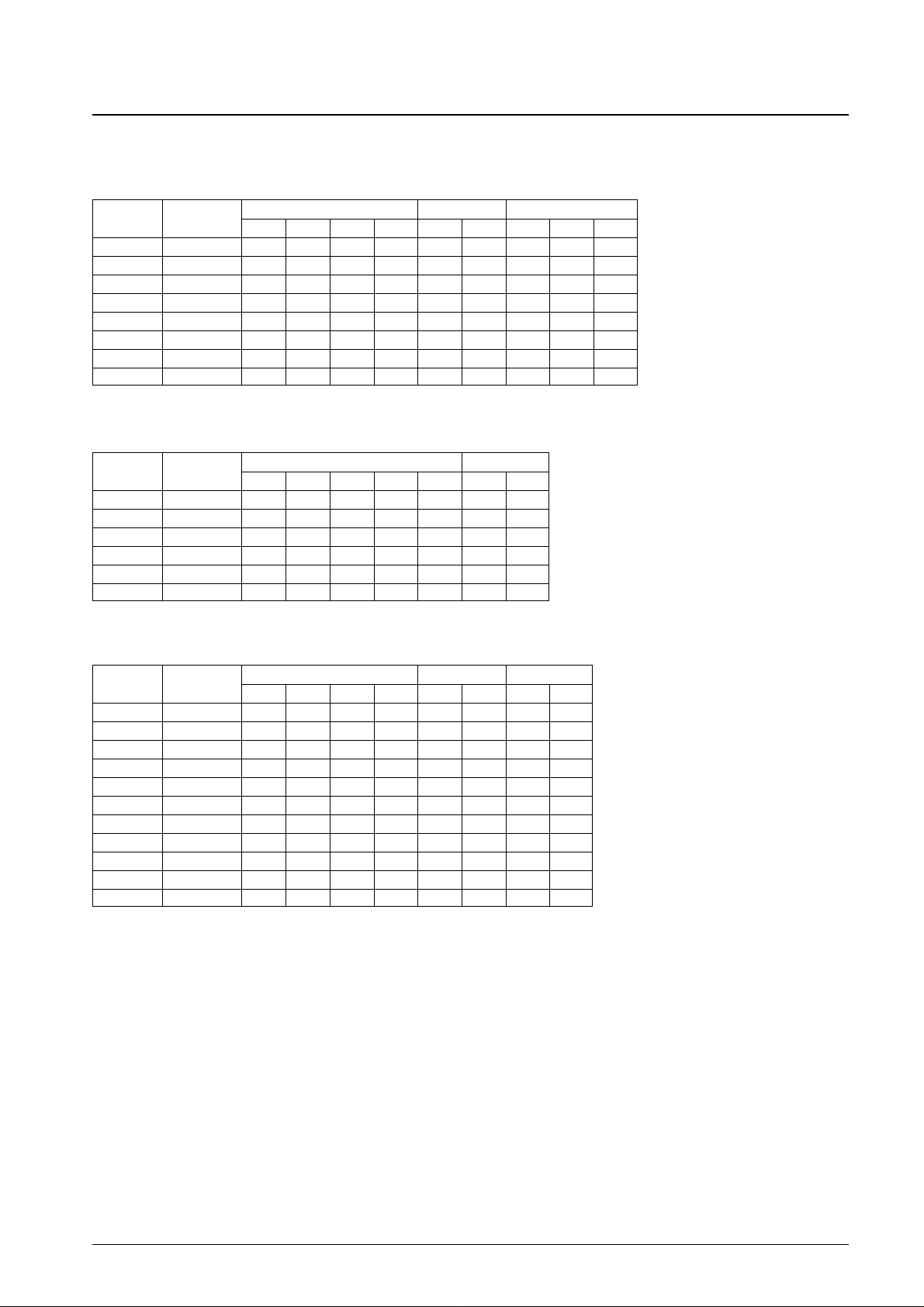

Page 3

Continued from preceding page.

No. 4850-3/24

LA7265W

Parameter Symbol Conditions

Ratings

Unit

min typ max

Measure the output voltage difference for inputs of

AGC minimum gain AGCLG 0 Vp-p and 300 mVp-p. Stipulated as the gain with –3.5 –2.0 –0.5 dB

respect to the input. T1 output

AGC minimum D range AGCLD

Measure the output voltage difference for inputs of

0.63 1.80 V

0 Vp-p and 300 mVp-p. T1 output

AGC W.C. level AGCWC

Measure the WC voltage for a 300 mVp-p input.

3.83 4.15 4.47 V

T1 output

Measure the output voltage difference for inputs of

AGC standard voltage AGCT

0 Vp-p and 100 mVp-p by adjusting VR4. Stipulated

2.07 2.13 2.19 V

as the VR4 voltage when that difference is 400 mVp-p.

T1 output

AGC frequency characteristics AGCF

Stipulated as the gain difference between f = 10 MHz

–6.0 –5.0 dB

and f = 500 kHz. T1 output

Measure the output voltage difference for inputs of

AGC linearity AGCL

0 mVp-p and 25 mVp-p and the output voltage difference

95 %

for inputs of 100 mVp-p and 125 mVp-p. Stipulated as

the ratio of those two gains. T1 output

Increase the lower side input pulse voltage and

Y1.IN clamping input low level CLP2L measure the input pulse level when the clamping level 1.26 1.40 V

begins to change. T9 output

AGC detector DC level DETDC

Measure the output voltage (OPB) with no input.

2.28 2.38 2.48 V

T3 output

AGC detector pedestal level DETP

Measure the pedestal level with no input.

58 70 82 mV

T3 output

Measure the output voltage for a 300 mVp-p input.

AGC detector maximum W.C. level DETWL Stipulated as the difference between that measurement –150 –110 –70 mV

and the detector DC level. T3 output

Measure the output voltage difference for inputs of

AGC detector gain DETG 0 Vp-p and 300 mVp-p. Stipulated as the gain with 8.4 8.8 9.2 dB

respect to the input. T3 output

AGC detector D range DETD

Measure the output voltage difference for inputs of

1.21 1.33 V

0 Vp-p and 1500 mVp-p. T3 output

AGC detector W.C. level

DETWT

Measure the output voltage difference for inputs of

0.70 0.90 1.10 V

initial value 0 Vp-p and 1500 mVp-p. T3 output

AGC control characteristics 1 CONT1 Measure the output DC voltage. T4 output 0.92 1.12 1.22 V

AGC control characteristics 2 CONT2 Measure the output DC voltage. T4 output 0.92 2.00 3.10 V

AGC control characteristics 3 CONT3 Measure the output DC voltage. T4 output 2.90 3.00 3.10 V

γ = 0.45 DC level γ1DC

Measure the output voltage (OPB) with no input.

0.94 1.52 2.10 V

T5 output

γ = 0.45 characteristics 1 γ11

Measure the output voltage difference for inputs of

80 140 185 mV

0 Vp-p and 50 mVp-p. T5 output

γ = 0.45 characteristics 2 γ12

Measure the output voltage difference for inputs of

180 335 490 mV

0 Vp-p and 200 mVp-p. T5 output

γ = 0.45 characteristics 3 γ13

Measure the output voltage difference for inputs of

320 500 625 mV

0 Vp-p and 500 mVp-p. T5 output

γ = 0.45 knee characteristics γ1K

Measure the output voltage difference for inputs of

550 735 880 mV

0 Vp-p and 1500 mVp-p. T5 output

γ = 0.45 pedestal level γ1P Measure the pedestal level with no input. T5 output –50 0 +50 mV

γ = 0.45 low clipping level γ1L

Measure the output voltage difference for inputs of

150 300 450 mV

0 Vp-p and -300 mVp-p. T5 output

γ = 0.6 DC level γ3DC

Measure the output voltage (OPB) with no input.

0.87 1.49 2.11 V

T5 output

γ = 0.6 characteristics 1 γ31

Measure the output voltage difference for inputs of

60 90 105 mV

0 Vp-p and 50 mVp-p. T5 output

γ = 0.6 characteristics 2 γ32

Measure the output voltage difference for inputs of

240 300 360 mV

0 Vp-p and 200 mVp-p. T5 output

γ = 0.6 characteristics 3 γ33

Measure the output voltage difference for inputs of

430 510 590 mV

0 Vp-p and 500 mVp-p. T5 output

γ = 0.6 knee characteristics γ3K

Measure the output voltage difference for inputs of

660 805 905 mV

0 Vp-p and 1500 mVp-p. T5 output

γ.max characteristics 1 γM1

Measure the output voltage difference for inputs of

60 160 260 mV

0 Vp-p and 50 mVp-p. T5 output

γ.max characteristics 2 γM2

Measure the output voltage difference for inputs of

120 335 465 mV

0 V p-p and 200 mV p-p. T5 output

Continued on next page.

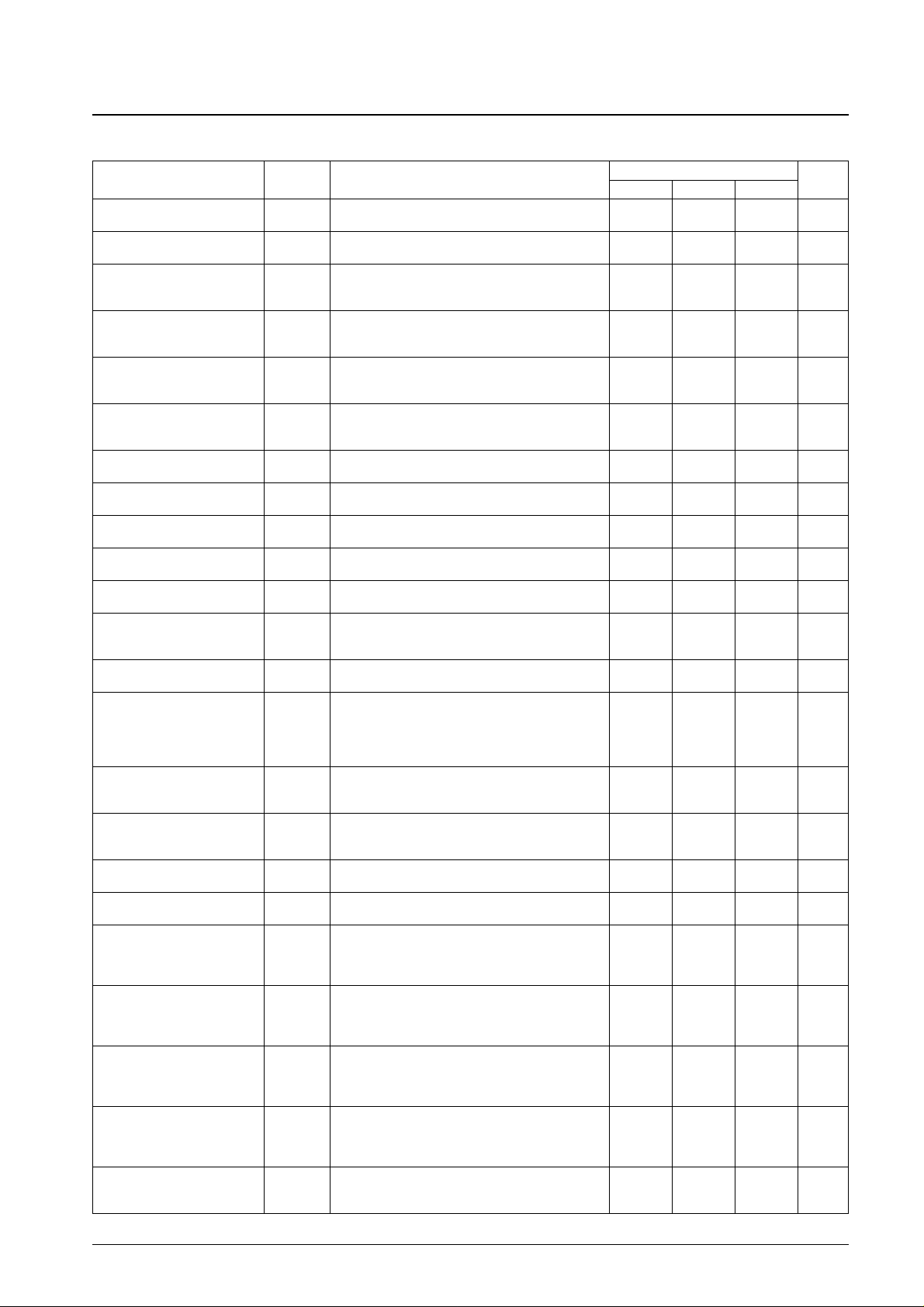

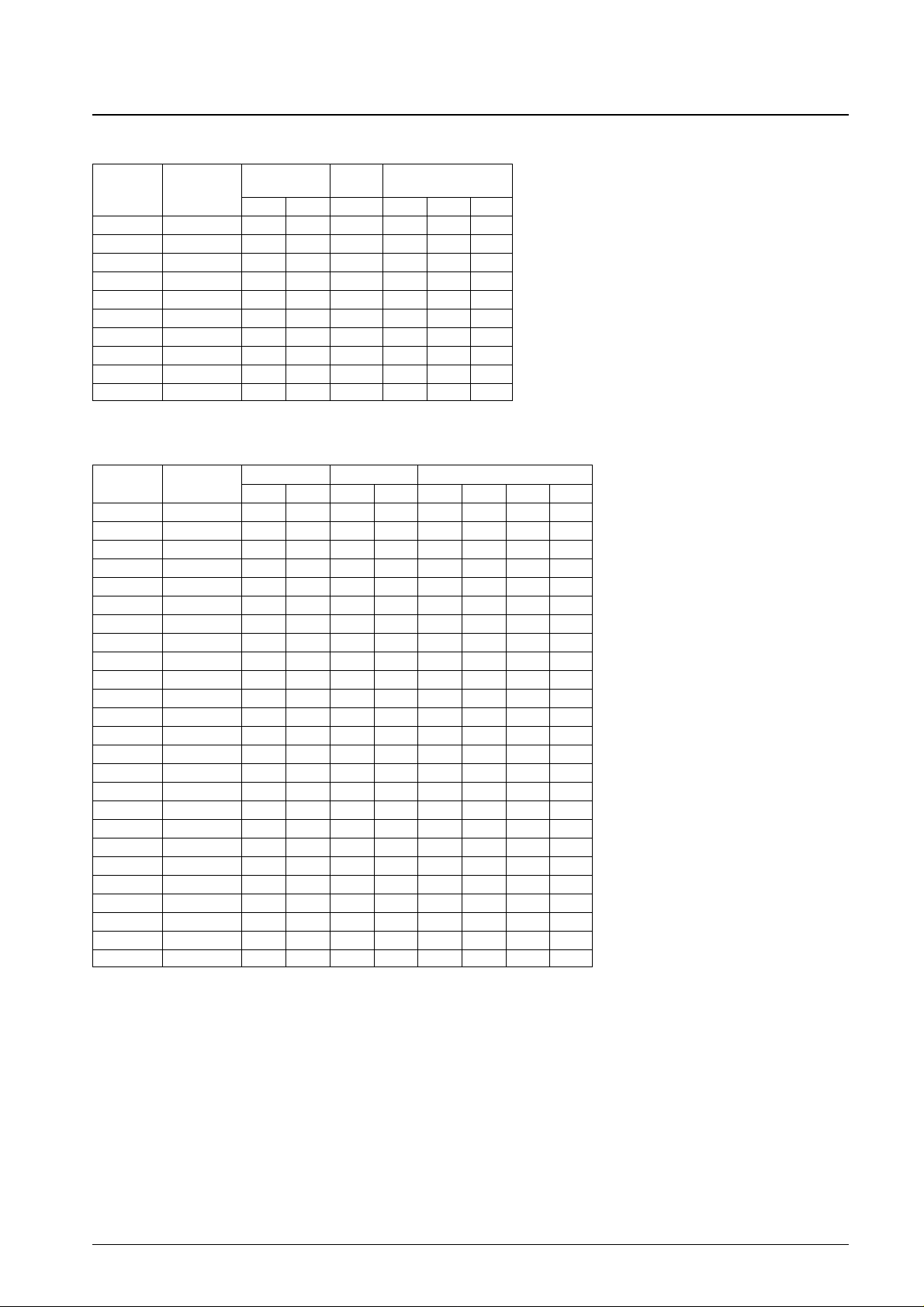

Page 4

Continued from preceding page.

No. 4850-4/24

LA7265W

Parameter Symbol Conditions

Ratings

Unit

min typ max

γ.max characteristics 3 γM3

Measure the output voltage difference for inputs of

200 515 675 mV

0 Vp-p and 500 mVp-p. T5 output

γ.max knee characteristics γMK

Measure the output voltage difference for inputs of

520 750 930 mV

0 Vp-p and 1500 mVp-p. T5 output

Measure the output voltage difference for inputs of

γ dark clipping characteristics γMC 0 Vp-p and 200 mVp-p. Stipulated as the difference 0 105 280 mV

between that measurement and γM2. T5 output

Measure the output voltage difference for inputs of

Y gain control minimum gain γ2L 0 Vp-p and 200 mVp-p. Stipulated as the gain with –24 –16 –8 dB

respect to the input. T5 output

Measure the output voltage difference for inputs of

Y gain control maximum gain γ2H 0 Vp-p and 200 mVp-p. Stipulated as the gain with 10 11 12 dB

respect to the input. T5 output

Measure the output voltage difference for inputs of

Y gain control typical gain γ2T 0 Vp-p and 200 mVp-p. Stipulated as the gain with 0.2 1.4 2.3 dB

respect to the input. T5 output

Y gain control D range γ2D

Measure the output voltage difference for inputs of

1.10 1.53 V

0 Vp-p and 1500 mVp-p. T5 output

γ = 1 DC level γ2DC

Measure the output voltage (OPB) with no input.

0.87 1.49 2.11 V

T5 output

γ = 0.45 frequency characteristics γ1F

Stipulated as the gain difference between 10 MHz

–5.0 –3.8 dB

and f = 500 kHz. T5 output

γ = 1 frequency characteristics γ2F

Stipulated as the gain difference between 10 MHz

–2.9 –1.9 dB

and f = 500 kHz. T5 output

γ = 0.6 frequency characteristics γ3F

Stipulated as the gain difference between 10 MHz

–4.7 –3.7 dB

and f = 500 kHz. T5 output

Stipulated as the output voltage difference between

LSP.SW DC offset LSPDO SW14 being set to the B and A positions for a 0 Vp-p –10 0 +10 mV

input. T6 output

DL.OUT DC level LSPDC

Measure the output voltage (OPB) with no input.

2.30 2.52 2.75 V

T6 output

With SW14 in the B position, measure the output voltage

difference for inputs of 0 Vp-p and 500 mVp-p. Perform

LSP.SW gain differential LSPGD the same measurement with SW14 in the A position. –20 0 +20 mV

Stipulated as the difference between the two voltage

differences. T6 output

Measure the output voltage difference for inputs of

DL.OUT gain LSPG 0 Vp-p and 500 mVp-p. Stipulated as the gain with –0.5 0 +0.5 dB

respect to the input. T6 output

Input a f = 2 MHz, 200 mVp-p signal and adjust VR1 so

Aperture clipping standard voltage APCT that the output amplitude becomes 44 mVp-p. 2.35 2.60 2.85 V

Determine the VR9 voltage at that time. T7 output

Aperture clipping level (maximum) APCH

Measure the output for an f = 2 MHz, 200 mVp-p input

36 mV

signal. T7 output

Aperture maximum level APH

Measure the output for an f = 2 MHz, 200 mVp-p input

100 320 500 mV

signal. T7 output

Measure the output amplitude for an f = 2 MHz,

Aperture dark point APDP

200 mVp-p input signal. Stipulated as the VR4 setting

1.90 2.06 2.22 V

where the output starts to decrease when VR4 is slowly

increased starting at 0 mV. T7 output

With VR4 set at 0 V and 2.4 V, measure the output

Aperture dark slope (typical) APDST

gain for an f = 2 MHz, 200 mVp-p input signal.

–1.0 dB

Stipulated as the difference between those two gains.

T7 output

With VR4 set at 0 V and 2.4 V, measure the output

Aperture dark slope (minimum) APDSL

gain for an f = 2 MHz, 200 mVp-p input signal.

0.5 dB

Stipulated as the difference between those two gains.

T7 output

With VR4 set at 0 V and 2.4 V, measure the output

Aperture dark slope (maximum) APDSH

gain for an f = 2 MHz, 200 mVp-p input signal.

–4.0 dB

Stipulated as the difference between those two gains.

T7 output

Measure the output voltage difference for inputs of

Aperture Y signal gain APYG 0 Vp-p and 300 mVp-p. Stipulated as the gain with –1.0 –0.5 0 dB

respect to the input. T7 output

Continued on next page.

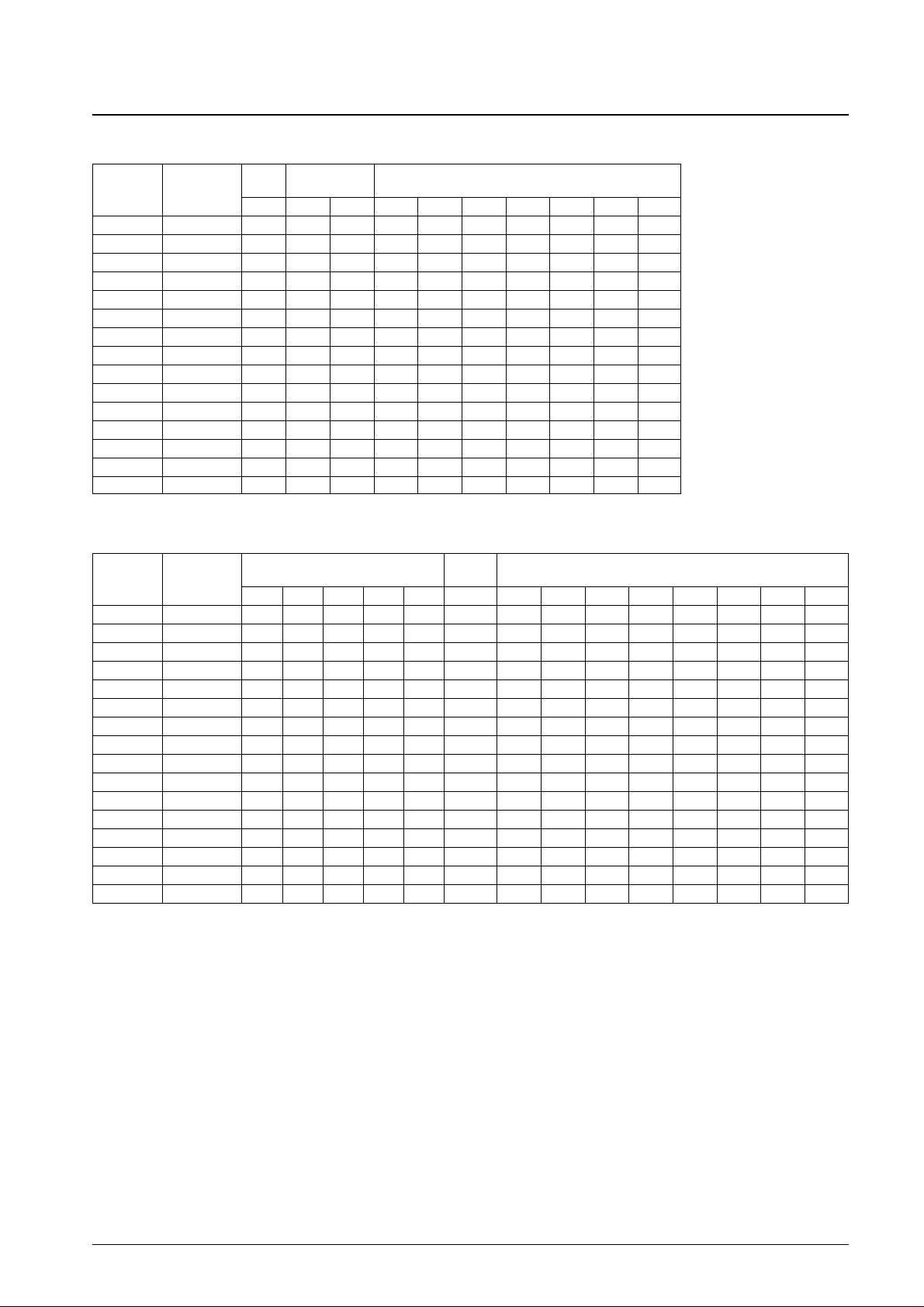

Page 5

Continued from preceding page.

No. 4850-5/24

LA7265W

Parameter Symbol Conditions

Ratings

Unit

min typ max

Aperture Y signal D range APYD

Measure the output voltage difference for inputs of

720 785 mV

0 Vp-p and 1200 mVp-p. T7 output

Aperture YOUT DC level APYDC

Measure the output voltage (OPB) with no input.

1.86 1.98 2.10 V

T7 output

Aperture YOUT frequency

APYF

Stipulated as the gain difference between 10 MHz

–7.2 –6.2 dB

characteristics and f = 500 kHz. T7 output

VIDEO-OUT DC level VODC

Measure (without setup) the pedestal voltage for

1.70 2.00 2.35 V

a 0 Vp-p input. T8 output

VIDEO-OUT sync level VOSY

Measure the pedestal and sink voltage difference for

500 550 630 mV

a 0 Vp-p input. T8 output

VIDEO-OUT typical pedestal level VOPT

Measure (without setup) the setup level for a 0 Vp-p

75 95 125 mV

input. T8 output

Measure the output voltage difference for inputs of

VIDEO-OUT gain VOG 0 Vp-p and 500 mVp-p. Stipulated as the gain with 7.30 7.75 8.20 dB

respect to the input. T8 output

VIDEO-OUT low clipping level VOLC

Measure the output voltage difference for inputs of

220 260 300 mV

0 Vp-p and –300 mVp-p. T8 output

VIDEO-OUT W.C. level (typical) VOWCT

Measure the output voltage difference for inputs of

1.42 1.50 1.58 V

0 Vp-p and 1200 mVp-p. T8 output

VIDEO-OUT minimum

VOPL Measure the setup level for a 0 Vp-p input. T8 output –180 –120 –80 mV

pedestal level

VIDEO-OUT maximum

VOPH Measure the setup level for a 0 Vp-p input. T8 output 180 240 280 mV

pedestal level

VIDEO-OUT W.C. level (maximum) VOWCH

Measure the output voltage difference for inputs of

0.85 0.93 1.00 V

0 Vp-p and 1200 mVp-p. T8 output

VIDEO-OUT D range VOD

Measure the output voltage difference for inputs of

1.80 2.03 V

0 Vp-p and 1200 mVp-p. T8 output

VIDEO-OUT frequency

VOF

Stipulated as the gain difference between f = 10 MHz

–3 –2 dB

characteristics and f = 500 kHz. T8 output

Measure the output voltage difference for inputs of

Aperture VIDEO-OUT linearity VOL

0 Vp-p and 100 mVp-p and the output voltage

98 %

difference for inputs of 400 mVp-p and 500 mVp-p.

Stipulated as the ratio of those two gains. T8 output

CDS current drain ICDS T10 output 5.50 7.85 10.20 mA

Video system current drain IVDO T11 and T15 outputs 16.5 23.5 30.5 mA

75 Ω driver current drain IDRI T12 output 4 6 8 mA

V

REF

reference voltage V

REF

T13 output 1.73 1.80 1.87 V

Package Dimensions

unit: mm

3163A-SQFP48

SANYO: SQFP48

[LA7265W]

Page 6

Switch Conditions

[CDS System]

[IRIS Amplifier System]

[AGC Amplifier System]

No. 4850-6/24

LA7265W

Symbol Input signal

Input pulse Trimmer voltage Switch

S2 S3 S4 S5 VR4 VR5 SW19 SW2 SW1

CCLIPH S1 = SIG.1 P1 P2 P3 P1 0 V 0 V B On On

CCLIPM S1 = SIG.1 P1 P2 P3 P1 0 V 0 V Off On On

CCLIPL S1 = SIG.1 P1 P2 P3 P1 0 V 0 V A On On

CDSD S1 = SIG.2 P1 P4 P5 5 V DC — — B — Off

CDSH S1 = SIG.1 P1 P6 P7 P1 0 V 0 V B On On

CDSO No signal P1 P2 P3 P1 0 V 0 V B On On

CDSN S1 = SIG.3 P1 P2 P3 P1 0 V 0 V B On On

CDSL S1 = SIG.1 P1 P2 P3 P1 0 V 0 V B On On

Symbol Input signal

Input pulse Trimmer voltage Switch

S2 S3 S4 S5 VR4 VR5 SW19 SW2

AGCDC1 No signal P1 P2 P3 P1 5 V 5 V B On

AGCHG1 S1 = SIG.1 P1 P2 P3 P1 5 V 5 V B On

AGCHG2 S1 = SIG.1 P1 P2 P3 P1 5 V — B Off

AGCHG3 S1 = SIG.1 P1 P2 P3 P1 5 V 0 V B On

AGCDC2 No signal P1 P2 P3 P1 0 V 0 V B On

AGCLG S1 = SIG.1 P1 P2 P3 P1 0 V 0 V B On

AGCLD S1 = SIG.1 P1 P2 P3 P1 5 V 5 V B On

AGCWC S1 = SIG.1 P1 P2 P3 P1 5 V 5 V B On

AGCT S1 = SIG.1 P1 P2 P3 P1 Scan — B Off

AGCF S1 = SIG.4 P1 P2 P8 P1 AGCT — B Off

AGCL S1 = SIG.1 P1 P2 P3 P1 AGCT — B Off

Symbol Input signal

Input pulse Switch

S2 S3 S4 S5 S6 SW19 SW3

IRISDC No signal P1 P2 P3 P1 P8 B Off

IRISP No signal P1 P2 P3 P1 P8 B Off

IRISWL S1 = SIG.1 P1 P2 P3 P1 P8 B B

IRISG S1 = SIG.1 P1 P2 P3 P1 P8 B A

IRISD S1 = SIG.1 P1 P2 P3 P1 P8 B A

IRSIWT S1 = SIG.1 P1 P2 P3 P1 P8 B Off

Page 7

[AGC Detector System]

[γ Correction System]

No. 4850-7/24

LA7265W

Input pulse

Trimmer

Switch

Symbol Input signal

voltage

S5 S6 VR6 SW5 SW4 SW6

CLP2L S8 = SIG.5 P1 P8 — — B, A Off

DETDC No signal P1 P8 — Off B Off

DETP No signal P1 P8 — Off B Off

DETWL S8 = SIG.5 P1 P8 — B A Off

DETG S8 = SIG.5 P1 P8 — A A Off

DETD S8 = SIG.5 P1 P8 — A A Off

DETWT S8 = SIG.5 P1 P8 — Off A Off

CONT1 No signal P1 5 V 1.4 V Off B On

CONT2 No signal P1 5 V 1.9 V Off B On

CONT3 No signal P1 5 V 2.4 V Off B On

Symbol Input signal

Input pulse Trimmer voltage Switch

S5 S6 VR2 VR3 SW4 SW7 SW8 SW9

γ1DC No signal P1 P8 0 V — B On Off Off

γ11 S8 = SIG.5 P1 P8 0 V — A On Off Off

γ12 S8 = SIG.5 P1 P8 0 V — A On Off Off

γ13 S8 = SIG.5 P1 P8 0 V — A On Off Off

γ1K S8 = SIG.5 P1 P8 0 V — A On Off Off

γ1P S8 = SIG.5 P1 P8 0 V — B On Off Off

γ1L S8 = SIG.5 P1 P8 0 V — A On Off Off

γ3DC No signal P1 P8 — 2.54 V B Off Off On

γ31 S8 = SIG.5 P1 P8 — 2.54 V A Off Off On

γ32 S8 = SIG.5 P1 P8 — 2.54 V A Off Off On

γ33 S8 = SIG.5 P1 P8 — 2.54 V A Off Off On

γ3K S8 = SIG.5 P1 P8 — 2.54 V A Off Off On

γM1 S8 = SIG.5 P1 P8 4 V 2.32 V A On Off On

γM2 S8 = SIG.5 P1 P8 4 V 2.32 V A On Off On

γM3 S8 = SIG.5 P1 P8 4 V 2.32 V A On Off On

γMK S8 = SIG.5 P1 P8 4 V 2.32 V A On Off On

γMC S8 = SIG.5 P1 P8 4 V 2.32 V A On On On

γ2L S8 = SIG.5 P1 P8 5 V 1.0 V A On Off On

γ2H S8 = SIG.5 P1 P8 5 V 5 V A On Off On

γ2T S8 = SIG.5 P1 P8 5 V — A On Off On

γ2D S8 = SIG.5 P1 P8 5 V 3.4 V A On Off On

γ2DC No signal P1 P8 5 V — B On Off Off

γ1F S8 = SIG.6 P1 P8 0 V — A On Off Off

γ2F S8 = SIG.6 P1 P8 5 V — A On Off Off

γ3F S8 = SIG.6 P1 P8 — 2.54 V A Off Off On

Page 8

[1H Interpolation: Aperture Correction System]

[Video Output System: Current Drain]

No. 4850-8/24

LA7265W

Input

Trimmer voltage Switch

Symbol Input signal

pulse

S7 VR4 VR1 SW10 SW11 SW12 SW14 SW15 SW16 SW13

LSPDO No signal P1 — — B Off — B, A — — —

LSPDC No signal P1 — — B Off — B — — —

LSPGD S10 = SIG.5 P1 — — A Off — B, A — — —

LSPG S10 = SIG.5 P1 — — A Off — B — — —

APCT S10 = SIG.6 P1 0 V Scan A A A B Off C Off

APCH S10 = SIG.6 P1 0 V — A A A B Off A Off

APH S10 = SIG.6 P1 0 V — A A A B Off B Off

APDP S10 = SIG.6 P1 Scan APCT A A A B A C Off

APDST S10 = SIG.6 P1 0, 2.4 V APCT A A A B Off C Off

APDSL S10 = SIG.6 P1 0, 2.4 V APCT A A A B B C Off

APDSH S10 = SIG.6 P1 0, 2.4 V APCT A A A B A C Off

APYG S10 = SIG.5 P1 — — A B B B — — Off

APYD S10 = SIG.5 P1 — — A B B B — — Off

APYDC No signal P1 — — B B B B — — Off

APYF S10 = SIG.6 P1 — — A B B B — — Off

Input pulse

Trimmer

Switch

Symbol Input signal

voltage

S2 S5 S7 S9 S11 VR12 SW6, 7 SW10 SW11 SW12 SW14 SW13 SW17 SW18

VODC S13 = SIG.5 — — P1 P9 P8 — — — — — — A Off Off

VOSY S13 = SIG.5 — — P1 P9 P8 — — — — — — A Off Off

VOPT S13 = SIG.5 — — P1 P9 P8 — — — — — — A Off Off

VOG S13 = SIG.5 — — P1 P9 P8 — — — — — — A Off Off

VOLC S13 = SIG.5 — — P1 P9 P8 — — — — — — A Off Off

VOWCT S13 = SIG.5 — — P1 P9 P8 — — — — — — A Off Off

VOPL S13 = SIG.5 — — P1 P9 P8 — — — — — — A B Off

VOPH S13 = SIG.5 — — P1 P9 P8 — — — — — — A A Off

VOWCH S13 = SIG.5 — — P1 P9 P8 — — — — — — A Off B

VOD S13 = SIG.5 — — P1 P9 P8 — — — — — — A Off A

VOF S13 = SIG.6 — — P1 P9 P8 — — — — — — A Off Off

VOL S13 = SIG.5 — — P1 P9 P8 — — A B B B B Off Off

ICDS No signal P1 — — — — — — — — — — — — —

IVDO No signal P1 P1 P1 — — 0 V On — B B — — — —

IDRI No signal — — — — — — — — — — — — — —

V

REF

No signal P1 P1 P1 — — — — — — — — — — —

Page 9

Pin Assignment and Equivalent Circuit Block Diagram

No. 4850-9/24

LA7265W

Page 10

Pin Functions

Unit (resistance: Ω), I: input, O: output, B: I/O, P: power supply

No. 4850-10/24

LA7265W

Pin No. Symbol I/O Equivalent circuit Function

1

2

3

4

5

6

CCD. IN

SH-GND

SH-D

VIDEO-V

CC

1

MAX. GAIN

CLP. C

I

P

I

P

I

B

CCD signal input. This pin can handle CCD signal reset levels up to

0.5 Vp-p. The data level is sliced at a maximum saturation output of

1.5 V.

CDS system ground. This line should be kept as short as possible

since the CDS system handles high frequencies.

This pin controls the charge and discharge speeds of the SH1 circuit.

Leave this pin open when a CCD element with 300,000 or fewer

pixels is used. Set this pin to 5 V when a CCD element with over

300,000 pixels is used.

AGC amplifier system V

CC

. Apply 5 V to this pin. Use pin 43 as the

corresponding ground. Either decouple (we recommend using a

power supply separate from the other V

CC

s for this voltage) or use a

DC-DC converter design so that signal component frequencies do

not leak into this V

CC

.

AGC maximum gain control.

The value of the maximum gain is:

About 15.5 dB when pin 5 is at 0 V,

About 24 dB when pin 5 is open, and

About 31 dB when pin 5 is at 5 V.

Charge/discharge capacitor used for post-CDS OPB clamping. We

recommend a value of 0.1 µF for this capacitor.

Continued on next page.

Page 11

Continued from preceding page.

Unit (resistance: Ω), I: input, O: output, B: I/O, P: power supply

No. 4850-11/24

LA7265W

Pin No. Symbol I/O Equivalent circuit Function

7

8

9

10

11

AGC. GAIN

AGC. CONT

DETECT. IN

DETECT. OUT

AGC. REF

I

O

I

O

I

AGC control signal input. The signal that was clamped by the postCDS OPB is split into two paths. The first path goes to the AGC

amplifier system. This pin is provided to adjust the AGC gain

according to the brightness, and it uses the smoothed AGC control

voltage output from pin 8. The AGC minimum gain is about –2 dB.

See the description of pin 39 for the second path from this pin.

AGC control signal output. This output is smoothed by an RC circuit

and then input to pin 7. The range over which the AGC control

voltage varies is about 1 to 3 V.

AGC detector circuit input. The pin 10 output is resistor divided,

smoothed and input to this pin.

AGC detector circuit output. A signal that has had pedestal added

and has been white clipped (see the pin 35 description) is amplified

by the AGC detector amplifier and output from this pin. An emitter

open circuit is used for this output. This output must be resistor

divided and smoothed by a capacitor.

AGC control amplifier reference input. The voltage input to pin 9 goes

to the AGC control amplifier. The state of this pin adjusts the AGC

control voltage. (This pin is normally left open.) If the image is too

bright, lower the AGC amplifier gain sensitivity by lowering this pin

(AGC.REF) to lower the AGC control voltage. If the image is too

dark, increase the AGC amplifier gain sensitivity by raising this pin

(AGC.REF) to increase the AGC control voltage.

Continued on next page.

Page 12

Continued from preceding page.

Unit (resistance: Ω), I: input, O: output, B: I/O, P: power supply

No. 4850-12/24

LA7265W

Pin No. Symbol I/O Equivalent circuit Function

12

13

14

15

V

REF

Y1. OUT

Y1. IN

GAMMA

O

O

I

I

1.8 V reference voltage. This pin outputs the OPB clamping

reference voltage used by pins 14, 23, 24 and 29. Insert a capacitor

between this pin and ground to stabilize this voltage.

Output for the signal amplified by the AGC circuit.

The signal that passed through the AGC amplifier is input to this pin

through a low-pass filter and a coupling capacitor. OPB clamping is

applied at the input stage. This clamping is applied with the timing of

the clamping pulse input to pin 41. The clamping level is about 1.8 V,

and when the OPB level is 1.8 V signals and noise with a level of

under about 0.5 V must not be input. If signals or noise at such levels

occur, or if pedestal displacement occurs at pin 23, (both of these

condition occur when the AGC maximum gain is at its maximum

level) first low clip the signal by inserting an NPN emitter follower at

pin 13, and then insert a low-pass filter. Use a low-pass filter with an

input impedance ratio of 1:10.

Gamma circuit selection and gamma variation control. The signal

OPB clamped at pin 14 is divided into two paths. The first path goes

to the gamma correction system. First, this signal is blanked with the

timing of the pre-blanking pulse input to pin 39 and pedestal is added

by a built-in DC source with a level essentially identical to the OPB

level. At that time, low clipping is applied at a level about 300 mV or

more below the OPB level. Next, the signal passes through the γ

correction circuit. However, there are three γ-correction circuits, one

with γ = 0.45, one with γ= 1, and one with a variable γ. The gamma

correction circuit is selected by this pin.

Pin 15 = 0 V:........................The γ= 0.45 circuit is used.

Pin 15 = 1 to 4 V:.................The variable γcircuit is used.

(When pin 15 is open:..........The variable γ circuit at γ = 0.6 is used.)

Pin 15 = 5 V:........................The γ= 1 circuit is used.

To select the maximum γ for the variable γ circuit, set the pin 15

voltage to 4 V. See the description of pin 35 for the second signal

path

Continued on next page.

Page 13

Continued from preceding page.

Unit (resistance: Ω), I: input, O: output, B: I/O, P: power supply

No. 4850-13/24

LA7265W

Continued on next page.

Pin No. Symbol I/O Equivalent circuit Function

16

17

18

19

20

PED. CLIP

Y. GAIN

VIDEO-V

CC

2

AP. DARK. SL

AP. CLIP

I

I

P

I

I

S-curve gamma control. This pin is normally left open when the

variable γ circuit is used. However, S-curve γ correction can be

enabled by clipping near the pedestal level by applying 5 V to this pin.

Y signal gain control. The signal that has passed through one of the

γ correction circuits goes to the Y gain control amplifier. This pin

adjusts the amount of amplification, which determines the amplitude

of the final output. This pin is normally left open when the γ = 0.45 or

the γ = 1 circuits are used. Gamma correction is applied when the

data level of the input CCD signal is under 500 mV, and the knee

characteristics apply when that level is over 500 mV. Set up pin 15

as follows to set the Y gain control output level for a 500 mV input

signal to be identical for all three gamma correction circuits.

When pin 15 is open (γ = 0.6): .......Pin 17 = 2.54 V

When pin 15 = 4 V (γ = max): ........Pin 17 = 2.32 V

Video system V

CC

. This VCCis used as the VCCfor all systems

except the CDS system, the AGC amplifier system and the 75 Ω

driver system. Apply 5 V and insert a 0.1 µF capacitor between this

pin and ground.

Aperture dark slope control. The aperture clipping level varies with

the AGC control voltage (pin 7). The clipping level is fixed for

relatively bright situations, i.e., when pin 7 is under 2 V. However, as

the image begins to get darker (i.e., as the pin 7 voltage moves from

about 2 V to the aperture dark point) the clipping level begins to

increase. When the AGC control voltage exceeds the aperture dark

point, the aperture is suppressed for low illumination and the clipping

level increases along with the AGC control voltage. It is this pin that

controls the coefficient for that increase.

Pin 19 = 0 V:........................Minimum coefficient value

Pin 19 = open: .....................Typical coefficient value

Pin 19 = 5 V:........................Maximum coefficient value

Aperture clipping control. The LA7265W clips the aperture whisker

components at the base. This pin adjusts the clipping level. Adjust

this pin if the IC internal slice level is inappropriate.

Page 14

Continued from preceding page.

Unit (resistance: Ω), I: input, O: output, B: I/O, P: power supply

No. 4850-14/24

LA7265W

Continued on next page.

Pin No. Symbol I/O Equivalent circuit Function

21

22

23

24

25

PED

W. CLIP

Y2. OUT

Y2. IN

Y2D. IN

I

I

O

I

I

Setup control. The setup level can be controlled by using this pin to

control the level of the pedestal that is added with the timing of the

blanking pulse input to pin 38.

Pin 21 = 0 V:........................Setup level = –120 mV

Pin 21 = open: .....................Setup level = 95 mV

Pin 21 = 5 V:........................Setup level = 240 mV

Saturation level control. The LA7265W white clips the signal to which

pedestal has been added at pin 21. This pin adjusts the white

clipping level.

Pin 22 = 0 V:........................Clipping at about 0.9 V

Pin 22 = open: .....................Clipping at about 1.5 V

Pin 22 = 5 V:........................Clipping at about 2.0 V

Outputs the signal that has passed through the Y gain control. (See

the description of pin 17.) Normally, this output is input to pin 24 (25)

through a coupling capacitor. However, it is input to pin 29 through a

coupling capacitor when aperture correction is not used.

Original signal input. Input the γ corrected signal through a coupling

capacitor. OPB clamping is applied at the input stage, clamping at

about 1.8 V. The clamping pulse signal is input to pin 40.

Input for the 1H delayed signal used for interpolation. When a low

resolution CCD device (e.g., about 60,000 pixels) is used and 1H

interpolation is desired, use a 1H delay line and input the 1H delayed

signal through a coupling capacitor. OPB clamping is applied at the

input stage, clamping at about 1.8 V. Leave this pin open when 1H

interpolation is not required. Input the clamping pulse signal to pin 40.

Page 15

Continued from preceding page.

Unit (resistance: Ω), I: input, O: output, B: I/O, P: power supply

No. 4850-15/24

LA7265W

Continued on next page.

Pin No. Symbol I/O Equivalent circuit Function

26

27

28

29

30

31

DL. OUT

DL. IN

Y3. OUT

Y3. IN

DRIVE-GND

VIDEO-OUT

B

I

O

I

P

O

Output to the delay line and input for the delay line reflected signal.

Outputs the signal that has passed through 1H interpolation. Aperture

correction is performed by inserting an aperture correction delay line

(with an impedance of about 1 kΩ) at this output. Since a 1 kΩ

resistor is built in to this pin's internal circuit, the DL reflected signal is

created at about 1/2 the level of the original signal. This signal is

combined with the original signal and the combination is input to the

aperture correction circuit.

Delay line delayed signal input. This pin inputs the signal that has

passed through the aperture correction delay line to the aperture

correction circuit. The combined signal consisting of the original

signal and the reflected signal is subtracted from the delay line signal

(pin 27), and the aperture whisker components are created by

amplifying that difference signal. See the description of pins 19 and

20 for details on whisker component control.

The aperture clipped whisker components are added to the original

signal at a fixed ratio and output from this pin. The original signal

gain is about 0 dB.

The aperture corrected signal is input to this pin through a coupling

capacitor. OPB clamping is applied at the input stage, clamping at

about 1.8 V with the timing of the clamp pulse signal input to pin 40.

Ground for the 75 Ω driver system.

Video signal output. A signal that has sync added at pin 37 and has

been amplified is output through the driver circuit. When output is to

a unit that has a 75 Ω load, the 140 IRE = about 1.9 V output signal

can be converted to a 140 IRE = about 1.0 V signal by inserting a

68 Ω resistor.

Page 16

Continued from preceding page.

Unit (resistance: Ω), I: input, O: output, B: I/O, P: power supply

No. 4850-16/24

LA7265W

Continued on next page.

Pin No. Symbol I/O Equivalent circuit Function

32

33

34

35

36

DRIVE-V

CC

IRIS-OUT

IRIS. WIN

AGC. WIN

LSP

P

O

I

I

I

75 Ω driver system V

CC

. Since the current variations in this system

are large, care must be taken to prevent this system from influencing

other power supplies. Apply a 5 V potential and insert a capacitor of

about 0.1 µF between this pin and ground.

Iris control signal output. The signal that had pedestal added and

was white clipped is amplified by about 10 dB by the iris amplifier and

output from this pin.

Iris window pulse input. White clipping is applied to the signal that

had pedestal added (see the pin 39 description). The clipping level

changes depending on this pin's input state. (0 V → maximum,

open → typical, 5 V → minimum clipping levels) Iris windowing is

possible by inputting an iris window pulse signal that has three

values: 0 V, floating, and 5 V.

AGC window pulse input. The other signal that had OPB clamping

applied at pin 14 goes to the AGC detector system. First a pedestal

on the order of a few tens of mV is added using the blanking pulse

input from pin 39. Next, white clipping is applied. However, the clipping

level changes according to the state of this pin. (0 V → maximum,

open → typical, 5 V → minimum clipping levels) AGC backlighting

correction is possible by inputting an AGC window pulse signal that

has three values: 0 V, floating, and 5 V.

1H interpolation control pulse input. When 1H interpolation is used,

input an LSP pulse ( ) that switches on each 1H to this pin. Pin

40 clamp pulse switching is performed by the LSP pulse. This circuit

also switches the OPB clamped original signal and the 1H delayed

signal. When 1H interpolation is not used, only the original signal is

OPB clamped and passed through this circuit.

Page 17

Continued from preceding page.

Unit (resistance: Ω), I: input, O: output, B: I/O, P: power supply

No. 4850-17/24

LA7265W

Continued on next page.

Pin No. Symbol I/O Equivalent circuit Function

37

38

39

40

41

C. CYNC

C. BLK

P. BLK

CLP2

CLP1

I

I

I

I

I

Composite synchronization signal pulse input. Sync is added to the

signal white clipped at pin 22 with the timing of the composite

synchronization pulse ( ) signal input to this pin. Also, the signal

including synchronization is amplified by about 7.7 dB. When the pin

29 input signal level is set to 500 mV (white average), the signal

level, including setup and sync, is amplified to be 140 IRE = about

1.9 V when pin 31 is unloaded. Therefore the pin 31 output will be:

White average: = about 1220 mV

Saturation level: = about 1700 mV (when the pin 29 input

saturation level is about 700 mV)

Sync level: = about 550 mV

Composite blanking pulse input. The signal OPB clamped at pin 24 is

blanked with the timing of the composite blanking pulse ( ) input

to this pin. Also, pedestal of the prescribed level is added with the

same timing and setup is also inserted. At that time, levels 250 mV or

more lower than the OPB level are low clipped.

Pre-blanking pulse input. The other path for the signal that was

clipped by the post-CDS OPB goes to the iris amplifier system. First,

pedestal is added using the pre-blanking pulse ( ) input to this

pin. In addition, this signal is also used by the AGC detector system

and the γ correction system.

Input for the output clamping pulse. This pin inputs the clamping

pulse ( ) for OPB clamping used by pins 24, 25 and 29. The

clamping pulse timing is delayed with respect to CLP1 to take into

account the amount the signal is delayed within the IC and by the

external LPF. When 1H interpolation is used, the clamping pulse is

turned on or off every 1H with the timing of the LSP pulse. This is

then used as the OPB clamp for pins 24 and 25.

OPB clamp pulse input. The dark current variations every 1H are

taken up by clamping, with the OPB timing, the signal that became a

continuous wave signal in the CDS system. This pin is the clamp

pulse ( ) input for that operation, and normally can be shared

with pin 42.

Page 18

Continued from preceding page.

Unit (resistance: Ω), I: input, O: output, B: I/O, P: power supply

No. 4850-18/24

LA7265W

Continued on next page.

Pin No. Symbol I/O Equivalent circuit Function

42

43

44

45

46

47

48

CLP0

VIDEO-GND

DS1

DS2

SH-V

CC

SH-P

SLICE

I

P

I

I

P

I

I

CCD signal clamp pulse input. The CCD signal input to pin 1 is

clamped to the prescribed voltage with the OPB timing. This pin inputs

that clamp pulse ( ), and normally can be shared with pin 41.

Ground for the video system.

Data timing sampling pulse input. This signal is divided into two paths

to perform CDS (correlation dual sampling) on the sliced CCD signal.

In the first path, the data level is sampled and held (SH1) with the

data timing. This pin is the sampling pulse ( ) input pin for that

function.

Pre-charge timing sampling pulse input. In the second sliced CCD

signal path, the precharge level is sampled and held (SH2) with the

precharge timing. This pin is the sampling pulse ( ) input pin for

that function. Next, this sampled and held signal is once again

sampled and held (SH3), here, by DS1 (the data timing sampling

pulse). Finally, the reset noise for each pixel is taken up by

subtracting these two sampled and held signals by a mixing amplifier.

CDS system VCC. Apply 5 V and insert a 0.1 µF capacitor between

this pin and ground.

This pin controls the charge/discharge speed of the SH2 and SH3

circuits. Pin usage is identical to that for pin 3.

CCD signal level control. Slices the saturation level of the CCD signal

that was OPB clamped. The possible slice levels are as follows:

Pin 48 = 0 V:........................about 1.5 V

Pin 48 = open: .....................about 1.1 V

Pin 48 = 5 V:........................about 0.5 V

Page 19

No. 4850-19/24

LA7265W

Page 20

Test Circuit

No. 4850-20/24

LA7265W

Page 21

Test Signals

No. 4850-21/24

LA7265W

Page 22

Test Input Pulse Signals

No. 4850-22/24

LA7265W

Page 23

No. 4850-23/24

LA7265W

Sample Application Circuit

Page 24

PS No. 4850-24/24

LA7265W

This catalog provides information as of September, 1998. Specifications and information herein are

subject to change without notice.

Specifications of any and all SANYO products described or contained herein stipulate the performance,

characteristics, and functions of the described products in the independent state, and are not guarantees

of the performance, characteristics, and functions of the described products as mounted in the customer’s

products or equipment. To verify symptoms and states that cannot be evaluated in an independent device,

the customer should always evaluate and test devices mounted in the customer’s products or equipment.

SANYO Electric Co., Ltd. strives to supply high-quality high-reliability products. However, any and all

semiconductor products fail with some probability. It is possible that these probabilistic failures could

give rise to accidents or events that could endanger human lives, that could give rise to smoke or fire,

or that could cause damage to other property. When designing equipment, adopt safety measures so

that these kinds of accidents or events cannot occur. Such measures include but are not limited to protective

circuits and error prevention circuits for safe design, redundant design, and structural design.

In the event that any or all SANYO products (including technical data, services) described or contained

herein are controlled under any of applicable local export control laws and regulations, such products must

not be exported without obtaining the export license from the authorities concerned in accordance with the

above law.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or any information storage or retrieval system,

or otherwise, without the prior written permission of SANYO Electric Co., Ltd.

Any and all information described or contained herein are subject to change without notice due to

product/technology improvement, etc. When designing equipment, refer to the “Delivery Specification”

for the SANYO product that you intend to use.

Information (including circuit diagrams and circuit parameters) herein is for example only; it is not

guaranteed for volume production. SANYO believes information herein is accurate and reliable, but

no guarantees are made or implied regarding its use or any infringements of intellectual property rights

or other rights of third parties.

Loading...

Loading...