Page 1

General Installation Manual

© 2009 January, Sanyo Electric Co., Ltd. All Rights Reserved 1/1/09

General Installation Manual for SANYO

HIT© Double Photovoltaic Modules.

Please read this manual completely

before installation or use of HIT Double

modules. This manual applies to the

following products:

HIT Double 200 (HIP-200DA3)

HIT Double 195 (HIP-195DA3)

HIT Double 190 (HIP-190DA3)

HIT Double 186 (HIP-186DA3)

HIT Double 180 (HIP-180DA3)

INTRODUCTION

Thank you for choosing SANYO HIT©

Double PV modules. With proper operation

and maintenance, SANYO modules will

provide you with clean, renewable solar

electricity for many years. This manual

contains important installation, maintenance

and safety information. The word “module”

as used in this manual refers to one or

more PV modules. Retain this manual for

future reference.

Disclaimer of Liability

SANYO does not assume responsibility and

expressly disclaims liability for loss,

damage, or expense arising out of, or in

any way connected with installation,

operation, use, or maintenance by using

this manual.

SANYO assumes no responsibility for any

infringement of patents or other rights of

third parties, which may result from use of

modules.

No license is granted by implication or

under any patent or patent rights. The

information in this manual is believed to be

reliable, but does not constitute an

expressed and/or implied warranty.

SANYO reserves the right to make changes

to the product, specifications, or this

manual without prior notice.

The return of any modules will not be

accepted by SANYO unless prior written

authorization has been given by SANYO.

General Information

The installation of solar modules requires a

great degree of skill and should only be

performed by qualified licensed

professionals, including, without limitation,

licensed contractors and electricians.

WARNING

All instructions should be read and

understood before attempting to install,

wire, operate, and/or maintain the

photovoltaic module. PV modules

generate DC electrical energy when

exposed to sunlight or other light

sources. Contact with electrically active

parts of the module such as terminals

1

can result in burns, sparks, and lethal

shock whether the module is connected

or disconnected.

The shock hazard increases as modules

are connected in parallel, producing

higher current, and as modules are

connected in series, producing higher

voltage.

The installer assumes the risk of all

personal injury or property damage that

might occur during installation and

handling of modules.

To avoid injury or damage:

• Cover the entire front and back

surface of the bifacial modules with

a dense, opaque material such as a

cardboard box or heavy cloth.

• Work only in dry conditions, with

dry modules and tools.

• Do not stand or step on a module.

• Do not drop a module.

• Do not break the glass surfaces of a

module.

• Do not allow children and

unauthorized persons near the

installation site or storage area of

modules.

• Completely ground all modules

according to applicable electric

codes.

• Do not disassemble the module, or

remove any part installed by the

manufacturer.

• Do not open the cover of the

junction box.

• Wear suitable protection (gloves,

clothes, etc.) to prevent direct

contact with 30V DC or greater.

• Carry a module by its’ frame with

two or more people.

• Do not carry a module by its wires

or junction box.

• Wear non-slip gloves.

• Do not drop or place heavy items on

the surfaces of a module (such as

tools).

• Check that all other system

components (inverters, wires, racks,

balance of system materials, etc.)

are mechanically and electrically

compatible.

• Do not install the module where

flammable gases or vapors are

present.

• Never leave a module unsupported

or unsecured.

• Do not use or install broken

modules.

• Do not artificially concentrate

sunlight on a module by mirror,

Fresnel lens, magnification, etc.

• Do not touch the junction box

terminals.

• Do not change the wiring of bypass

diodes.

CAUTIONS

• Use a module for its intended

purpose only.

• Do not treat any portion of the

module with paint or adhesives, to

avoid damage to the module,

inoperable conditions, or reducing

the module’s functionality.

• HIT Double modules have bifacial

performance. These modules

produce power from both surfaces

of the module at the same time and

may generate up to 30% more

output power than its’ STC rated

value. Refer to Figure 5 for these

output electrical characteristics.

• This additional power depends upon

the level of incident light irradiance

(albedo) available to the back side of

the module, and can be increased or

decreased depending upon site

characteristics, installation design,

weather, etc.

• Treat the back side of the module

the same as the front side and avoid

objects that directly shade the solar

cells. Refer to “Notes on

installation” section.

GENERAL SAFETY

Follow all permission, installation and

inspection requirements.

• Before installing modules, contact the

appropriate authorities to determine

permissions, installation and inspection

requirements that apply to your site

and installation.

• Electrically ground modules for all

systems of any voltage. If not

otherwise specified, it is recommended

that requirements of the latest National

Electrical Code (USA) or Canadian

Electric Code (Canada) or other

national or international electrical

standards be followed. Refer to “Earth

Ground Wiring” section.

• Check applicable building codes to

ensure that the construction or

structure (roof, facade, support, etc.)

where the modules are being installed

has enough strength.

• For modules mounted on roofs, special

construction or structures may be

required to help provide proper

installation support.

• Both roof construction and module

installation design have an effect on

the fire resistance of a building.

Improper installation may contribute to

fire hazards. Additional devices such

Page 2

General Installation Manual

14

27

27

φ8

Installation (refe

rence)

(4

)

© 2009 January, Sanyo Electric Co., Ltd. All Rights Reserved 1/1/09

as ground faults, fuses, and

disconnects may be required.

• Do not use modules of different

specifications in the same series string.

• Do not use modules of different

specifications in parallel.

• Check and follow all safety precautions

of other system components used.

UL Listing Information

To satisfy UL standard 1703 requirements,

when installing modules, be sure to:

• Use only stranded or solid copper

single–conductor type UF cable or

USE cable, rated sunlight resistant, for

modules and interconnect wiring that is

exposed to weather.

• Observe the requirements described in

sections labeled INSTALLTION and

SPECIFICATIONS.

INSTALLATION

General

Please read this guide completely before

installation or use of the modules. This

section contains electrical and mechanical

specifications needed before using your

SANYO PV modules.

• Modules should be firmly fixed in place

in a manner suitable to withstand all

expected loads, including wind and

snow loads.

• Metals used in locations that are

exposed to moisture shall not be

employed alone or in combinations that

could result in deterioration.

• Install modules where they are not

shaded by obstacles like buildings and

trees. Especially pay attention to avoid

partially shading modules by objects

during the daytime.

• Modules are water resistant, but not

waterproof. Moisture may leak through

where the frame and glass connect.

• Please contact your SANYO

Authorized Representative with

questions regarding mounting profiles

for modules if needed.

Notes on Installation

• Clearance between the roof surface

and module frame is required to allow

cooling air to circulate under the back

side of the module. This also allows

any condensation or moisture to

dissipate. Install modules so that air

can circulate between the roof and the

module as freely as possible.

• Leave 4 inches of clearance between

the roof and the module frame.

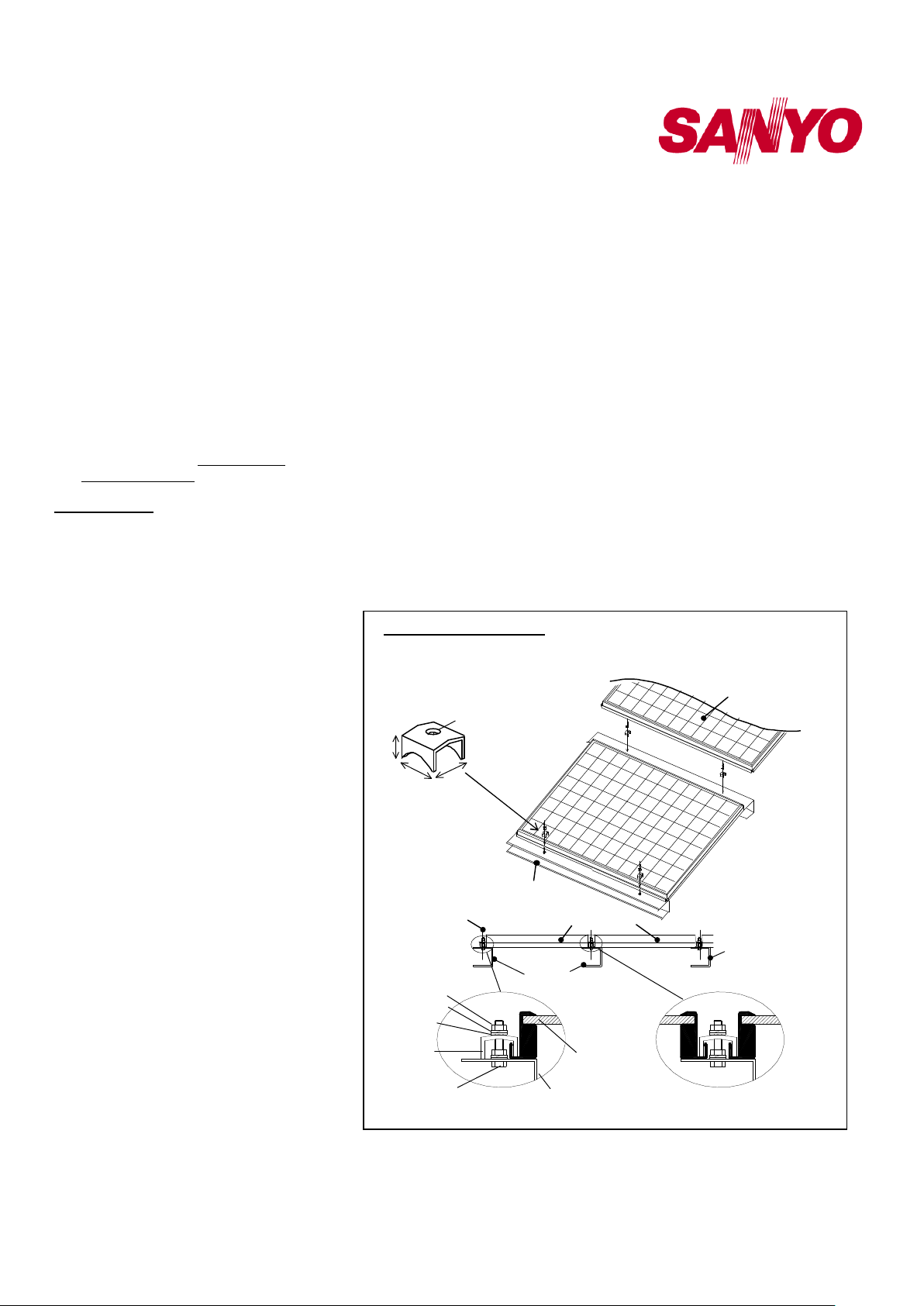

• SANYO recommends (but does not

require) the installation method and

mounting profile shown in Figure 1.

• A module should be attached on a

mount or support structure rail by metal

fittings (Size: 27x27x14mm, Material;

SUS304 or NSSC180). The metal

fitting must meet the following

specifications. Size: not less than 1.06’’

(27mm) width

Thickness: not less than 0.12’’ (3 mm)

Material: Stainless steel

• Bolting torque must be more than 8N.m.

The following information is provided to

help customers obtain good performance

without exceeding a module’s operating

conditions or warranty parameters.

• Do not artificially concentrate sunlight

on a module by mirror, Fresnel lens,

magnification, etc.

• The surface upon which modules are

installed is recommended to be flat, to

prevent artificially concentrated

sunlight.

• Additional output power from the back

face of the panel can be increased or

decreased depending upon angles of

installation, height from surfaces,

shade from structures or rails, and the

This referential figure is for HIT Double

(HIP-xxxDA3) modules

Metal fitting

Metal fitting

M6 Nut

Spring washer

Flat washer

Metal fitting

M6 Bolt/setscrew

places

Mounting

Structure Rail

End of Module

albedo of surrounding surfaces.

• Please see Figure 5 for the effect of

angles of installation on output power.

• The height of a module above a

surface affects the power potential of

the module’s back face.

• When possible, maximize the height of

modules above surfaces in order to

maximize ambient light beneath the

modules.

• Always position support structures and

rails along the edges of a module, or

between modules, and do not allow

rails to shade a module’s back surface.

• Light colored surfaces reflect more light

than dark colored surfaces. Installing

HIT Double modules over light colored

surfaces will increase the output power

potential from the back side.

Operating Conditions

SANYO requires that modules be operated

within the following conditions:

1) Terrestrial applications only—no outer

space use.

2) The ambient temperature must be

within –20°C (-4°F) to 46°C (115°F).

Solar Module

Solar Module

Mounting

Structure Rail

Mounting Structure Rail

Module

Mounting Structure Rail

Between Modules

Figure 1. Installation

2

Page 3

General Installation Manual

Module Ground Position

© 2009 January, Sanyo Electric Co., Ltd. All Rights Reserved 1/1/09

The temperature limits are defined as

the monthly average low and high of

the installation site.

3) The wind pressure load of the

installation site should be less than

1,440Pa (30PSF)*.

*Note: HIT Double modules were

tested at 30PSF at UL’s testing lab.

Modules of exactly the same structure

successfully achieved 50PSF load

ratings at JET’s (Japan Electrical

Safety & Environment Technology

Laboratories) testing lab, and are

certified as fully compliant at 50PSF.

4) Modules must not be installed nor

operated in areas where, salt, hail,

snow, sand, dust, air pollution,

chemically active vapors, acid rain,

soot, etc., are excessive.

SPECIFICATIONS

• Rated electrical characteristics are

within –5% to +10% of the values

measured at STC. STC Conditions are;

Irradiance of 1000W/m2, 25oC cell

temperature, and solar spectral

irradiance per IEC 60904-3.

• Under normal conditions, a

photovoltaic module may experience

conditions that produce more current

and/or voltage than reported at

Standard Test Conditions. Accordingly,

the values of Isc and Voc marked on

modules should be multiplied by a

factor of 1.25 when determining

voltage ratings, conductor capacities,

fuse sizes, and size of controls

connected to the module output.

Refer to Section 690 of the National

Electrical Code (NEC) for an

additional multiplying factor of 1.25,

which may be applicable.

• The current output for the modules

shown in the SPECIFICATIONS

section is measured at Standard Test

Conditions. These conditions may not

be frequently observed in actual

practice.

Mechanical Loading

• HIT Double modules should be

mounted at four (4) symmetrical

quarter points within the shaded areas

(Range A) shown in Figure 4, or any

mounting method with a continuous

attachment, by which those four points

are included in each side.

• The four symmetrical quarter point

method offers a maximum loading of

1,440Pa (30PSF) in a static state on

the module surface.

Note: This mechanical loading value

was tested using the following

mounting device:

3

Provider: AKATSUKI Industries, Ltd.

Part number: PVK-AJ4B

Note: HIT Double modules were tested

at 30PSF at UL’s testing lab. Modules

of exactly the same structure

successfully achieved 50PSF load

ratings at JET’s (Japan Electrical

Safety & Environment Technology

Laboratories) testing lab, and are

certified as fully compliant at 50PSF.

WIRING

• All wiring should be done in

accordance with applicable electrical

codes.

• Wiring methods should be in

accordance with the NEC in the USA

or the CEC in Canada.

• A qualified, licensed professional

should do all wiring.

• Wiring should be protected to help

ensure personal safety and to prevent

its damage.

• All modules connected in series should

be of the same model number and/or

type.

• Do not connect modules in parallel

without using a connection box.

• Use caution and design the system in

consideration of the increased output

power (Pmax) and current (Isc) from

the bifacial effect (see Table 1).

• Additional electrical values are

provided up to 30% beyond the STC

values for accurate system sizing

including the bifacial effect.

• If in doubt about the expected power

potential from the bifacial effect for

your particular site, please use the

values stated under the 30%

column.

Module Wiring

• The number of modules that can be

wired in series is recommended at

seven (7) or fewer. If connecting

eight (8) modules in series, check

local temperature conditions and

follow the National Electric Code

(690.7) to ensure compliance with

maximum voltage limitations. Also,

be sure to calculate and account for

the bifacial effect of the modules.

• HIT Double modules are not

designed for “off-grid” or battery

charging systems, because of their

operating voltage. Therefore, it is

not recommended to use them to

charge batteries.

• These modules contain factory

installed bypass diodes. If these

modules are incorrectly connected

to each other, the bypass diodes,

cable, or junction box may be damaged.

Array Wiring

• The term “array” is used to describe

the assembly of several modules on a

support structure with associated

wiring.

• Use copper wire that is sunlight

resistant and is insulated to withstand

the maximum possible system open

circuit voltage.

• Check local codes for requirements.

Earth Ground Wiring

• Grounding should be carried out by

attachment to the module or array

frame, to avoid the hazards of electric

shock or fire.

• The array frame shall be grounded in

accordance with NEC Article 250

(USA) or CEC in Canada.

• Each framed module has a 0.16”

diameter (4 mm) hole marked “G” in

the shorter side frame rail (see Figure

2), to connect a grounding conductor to

the module’s metal frame.

• Bonding shall be by a positive means,

such as clamping, riveting, bolting,

screwed connectors, welding, soldering,

or brazing.

• The bolt and nut size must be M3

(0.12” diameter (3 mm)).

• Washers are required as part of the

grounding connection. A star-washer is

required in order to penetrate the

coating of the frame in order to ensure

a good ground connection between the

grounding hardware, lead, and frame.

Ground Location (1 place)

Junction Box

Backside

The ground hole is

on the inside of the

module frame.

Figure 2.

Page 4

General Installation Manual

© 2009 January, Sanyo Electric Co., Ltd. All Rights Reserved 1/1/09

The star-washer’s material shall be

made of stainless steel in order to

avoid corrosion when in contact with

other metal types. The size of the starwasher as well as the size of any other

washers used will be M3 (0.12”

diameter (3mm)). The star-washer

shall be placed between the module’s

metal frame and the grounding

conductor.

• The grounding lead size must be

greater than 6mm2 (No.10 AWG), and

its type shall be sunlight-resistant UF

cable or USE-2 cable.

• Maximum torque value for the

connection must be 2.7 N.m (24 in-lb).

Module Terminations

• A junction box as a terminal enclosure

is equipped for electrical connections.

• Modules are equipped with MC3TM

plugs as a terminal enclosure. Use

these MC3TM plugs for electrical

connections.

Junction Box and Terminals

• Modules equipped with one junction

box and contain terminals for both

positive and negative polarity, and

bypass diodes.

• One terminal is dedicated to each

polarity; with the polarity symbols

engraved onto the body of the junction

box (see Figure 3).

Conduit

• For applications where wire conduits

are used, follow the applicable codes

for outdoor installation of wires in

conduits.

• Verify that all fittings are properly

installed to protect wires against

damage and prevent moisture intrusion.

Bypass Diodes

• When modules in series strings are

partially shaded, it may cause reverse

voltage across the cells or modules,

because the current from other cells in

the same series is forced to flow

through the shaded area. This may

cause undesirable heating to occur.

• The use of a diode to bypass the

shaded area can minimize both heating

and array current reduction.

• Modules are equipped with four (4)

factory installed bypass diodes. The

factory-installed diodes provide proper

circuit protection for the systems within

the specified system voltage, so that

you do not need any other additional

bypass diodes.

MAINTENANCE

• Some maintenance is recommended to

maintain optimal output performance of

the HIT Double solar modules.

• When a module’s front or back surface

becomes dirty, power output is reduced.

• It is recommended to clean the front

surface of the module with water and a

soft cloth or sponge, twice or more per

year. It is recommended to clean the

back surface as needed.

• A mild non-abrasive detergent may be

applied for persistent dirt.

• It is also recommended to inspect the

electrical and mechanical connections

annually.

• If you need electrical or mechanical

inspection or maintenance, it is

recommended to have a licensed

authorized professional carry out the

inspection or maintenance to avoid the

hazards of electric shock or injury.

For further information, please visit

www.sanyo.com/solar or contact your

SANYO Authorized Representative.

Connector

MCTM Plug

negative ( - )

Cable

Cable

Connector

MCTM Plug

positive ( + )

Figure 3. Configuration of Junction Box

4

Page 5

General Installation Manual

Dimensions

© 2009 January, Sanyo Electric Co., Ltd. All Rights Reserved 1/1/09

SPECIFICATIONS

HIT Double Series (HIP-xxxDA3)

Specifications

Cell Number in Series [Pieces]

Cell Type

Maximu m System Voltage [V]

Bypass Diodes

Panel Area

Panel We ight

Panel Dimensions LxWxH

Cable Lengths

Cable Size / Connector Type

Static Wind / Snow L oad

Pallet Dimensions LxWxH

Full Pallet Quantity / Full Pallet W eight

Quantity per 20', 40', 53' Container

HIT Double Series (HIP-xxxDA3)

Dimensions in mm

898

HIT* (hybrid of amorphous and monocrystalline silicon)

60

(107)

96

600

4 Bypass Di odes

2

13.06 f t

(1.21m2)

50.7 lbs. (23kg)

53.2x35.35x2.36in (1351x898x60mm)

39.4in each (1000mm )

No.12 A WG / MC3TM Connectors

50PSF (2400Pa) / 39PSF (1876Pa)

54.3x36x70.1in (1379x912x1781mm)

20pcs / 1 014Lbs (460kg)

200pcs / 420pcs / 54 0pcs

Ground (1 place)

Junction Box

(449)

(620)

1351

(620)

392

Front

392

Mount Locations

Side

Note: A module should be installed on support structure rails in

Note: A module should be installed on a support structure rail

accordance with the following: Use four symmetrical mounting

points within set range A.

using four (4) symmetrical attachment points within Range A.

Range A

Negative (-)

Connector (MC™ Plug)

Backside

1

Section A-A’

Positive (+)

60

7

7

19.3

5

Figure 4. Dimensions

Page 6

General Installation Manual

Electrical

S

pecifications

I

ncluding

B

ifacial

Effect

P mono

facial

Figure

5.

Installation angles and output changes

.

10

40 50 60 70 80 90

°

))))

Normalized

[

bifacial /

°

]

P bifacial

UP

’

10

40 50 60 70 80 90

o

)

bifacial

UP

Table 1

.

Specifications Including Bifacial Effect

© 2009 January, Sanyo Electric Co., Ltd. All Rights Reserved 1/1/09

Model

HIT Double 200

HIT Double 195

HIT Double 190

HIT Double 186

HIT Double 180

Maxim um Pow e r (Pmax)

Maxim um Pow e r V oltage (V pm )

Maxim um Pow e r Curr ent (Ipm )

Open Cir cuit Voltage (Voc)

(HIP-200DA3)

Short Circuit Curr ent (Is c)

Maxim um Pow e r (Pmax)

Maxim um Pow e r V oltage (V pm )

Maxim um Pow e r Curr ent (Ipm )

Open Cir cuit Voltage (Voc)

(HIP-195DA3)

Short Circuit Curr ent (Is c)

Maxim um Pow e r (Pmax)

Maxim um Pow e r V oltage (V pm )

Maxim um Pow e r Curr ent (Ipm )

Open Cir cuit Voltage (Voc)

(HIP-190DA3)

Short Circuit Curr ent (Is c)

Maxim um Pow e r (Pmax)

Maxim um Pow e r V oltage (V pm )

Maxim um Pow e r Curr ent (Ipm )

Open Cir cuit Voltage (Voc)

(HIP-186DA3)

Short Circuit Curr ent (Is c)

Maxim um Pow e r (Pmax)

Maxim um Pow e r V oltage (V pm )

Maxim um Pow e r Curr ent (Ipm )

Open Cir cuit Voltage (Voc)

(HIP-180DA3)

Short Circuit Curr ent (Is c)

Rated

STC

1

Specif ications Including Backside Irradiat ion Contribution

in Isc as a Percen t of STC

5% 10% 15% 20% 25% 30%

W 200 209 219 228 237 246 256

V 56.2 56.3 56.3 56.4 56.4 56.5 56.5

A 3.56 3.72 3.88 4.04 4.20 4.36 4.52

V 68.8 69.0 69.1 69.2 69.4 69.3 69.6

A 3.75 3.94 4.13 4.31 4.50 4.69 4.88

W 195 204 213 222 231 240 249

V 55.8 55.8 55.8 55.9 56.0 56.0 56.1

A 3.50 3.66 3.82 3.97 4.13 4.29 4.45

V 68.7 68.9 69.0 69.1 69.2 69.2 69.5

A 3.73 3.92 4.10 4.29 4.48 4.66 4.85

W 190 199 208 216 225 234 243

V 55.3 55.3 55.4 55.4 55.5 55.5 55.6

A 3.44 3.60 3.75 3.91 4.06 4.22 4.37

V 68.1 68.3 68.4 68.5 68.6 68.6 68.8

A 3.70 3.89 4.07 4.26 4.44 4.63 4.81

W 186 195 203 212 220 229 238

V 54.8 54.8 54.8 54.9 54.9 55.0 55.1

A 3.40 3.55 3.71 3.86 4.01 4.16 4.32

V 67.5 67.7 67.8 67.9 68.0 68.0 68.2

A 3.68 3.86 4.05 4.23 4.42 4.60 4.78

W 180 188 197 205 213 222 230

V 54.4 54.4 54.5 54.5 54.6 54.6 54.6

A 3.31 3.46 3.61 3.76 3.91 4.06 4.21

V 67.0 67.2 67.3 67.4 67.5 67.5 67.7

A 3.62 3.80 3.98 4.16 4.34 4.53 4.71

1

STC: Cell Temp. 25oC, AM1.5, 1000W/m

2

Pmax is normalized to that of a monofacial module at an inclination angle of 30°

1.6

1.6

30

rated

1.4

1.4

1.2

1.2

Pmax

Normalized Pmax

1.0

1.0

0.8

0.8

Pmax

0.6

0.6

Pmax

0.4

0.4

0.2

0.2

0.0

0.0

Horizontal installation

Horizontal installation

Albedo of ground (Concrete) : 55%

Albedo of ground (Concrete): 55%

Installation height : 1m

Installation height: 1m

15%

5

1111

HIT solar cell

Front incident light

Front incident light

Tempered glass

Tempered glass

0

0

20 30

20 30

HIT solar cell

Angle of Inclination (Degrees

6

Albedo =

P rated

monofacial

Rear incident light

Rear incident light

Angle of inclination (

EVA

EVA

Surface

concrete

Concrete Surface

<As an example>

Vertical installation

Vertical installation

Loading...

Loading...