Page 1

l?

r-

I FILE NO.

I

Service Manual

Specifications

Tuner section

Frequency range . . . . . .

Tuner section

L..._

Drive system . . . . . . . . .

Cassette deck section

Track system . . . . . . . . .

Frequency response . . . .

Signal to noise ratio . . . .

Wow and fiutter . . . . . . .

Tape speed . . . . . . . . . .

Fast forward /

rewind time . . . .

CD piayer section

Channels . . . . . . . . . . . .

Sampling frequency . . . .

D / A conversion . . . . . . .

Pickup . . . . . . . . . . . . . .

Frequency response . . . .

Signaito noise ratio . . . .

Total Harmonic Distortion

Wowandfluiter . . . . . . .

CD Stereo Sound

System

GCD 1500 (AU)

PRODUCT CODE No.

129 395 03

FM :87.5- 108MHz

AM :530-1,700 kHz

Beit Drive

AC bias, 4-track 2-channel stereo

100-12,500 Hz

50 dB

0.1 5% (WRMS)

1-7/8 i.p.s. (4.75 cmLsec..)

Approx. 120 sec.. (C-60)

2-channei stereo

44.1 kHz

Duai 16-bit linear D/A converters

Optical 3-beam semiconductor

iaser

20-20,000 Hz

94 dB

0.04% (1 kHz)

Undetectable

Ampiifier section

Output power . . . . . . . .

Graphic equaiizer . . . . .

Bass expander . . . . . . .

Output impedance . . . .

Generai section

Power requirements . . .

Power consumption . . .

Dimensions (approx.) . .

Weight(approx.) . . . . . .

Max. 5W x 2 (at 8 ohms, 10%

distortion)

~ 6 dB (300 Hz,

1 kHz, 10 kHz)

+ 6 dB (1OO Hz)

SPEAKERS : 8 ohms

PHONES : 8 ohms

AC : 230- 240V, 50HZ

28 W

14.2” (W) X 12.3” (H) X 8.9” (D)

(360 x 365 x 355 mm)

16.8 Ibs (7.6 Kg)

- ._

Specification subject to change without notice.

r“

REFERENCE No. Sh&580038

Page 2

LASER BEAM SAFETY PRECAUTIONS (CD)

Do not look straight at the laser beam from the pickup and do not

Structural Safety Interlock

point the beam at your fingers or any other part of your body.

This model has a disc chuck lever and top lid. This disc chuck lever

Note: The laser beam must never be allowed to enter the eyes since

and top lid prevent to expose the laser beam for users.

this

may damage the eyes.

Power must never be supplied to a pickup with a damaged laser

output part (objective lens, etc.).

INVISIBLE LASER RADIATION EXPOSURE TO BEAM

IS DANGEROUS CLASS 1 LASER PRODUCT

OUTPUT POWER : 0.6 mW MAX WAVELENGTH : 790 nm

1,

a.

b.

c.

d.

2,

a.

b.

c.

CAUTION-INVISIBI.ELASER

---I

t

RAOIATIONWHENPANEL

.--4

OPENANOINTERLOCK

OVERRIOOEN.

H

EE!

1 I %dl-

W

Precautions for handling the pickup and

semiconductors (particularly the ICS)

The pickup and semiconductors (particularly the ICS) may

be damaged if they come into contact with a source of

high voltage static electricity. Do not bring them,

therefore, into contact with or into the vicinity of anything

which has been charged with high voltage static.

The pickup consists of a large number of optical and

precision parts. Do not store or repair it, therefore, in any

location with a high temperature, high humidity, high

magnetic fields or high dust concentration. (Since the

pickup contains a powerful magnet, it must not be brought

near any magnetized objects.)

Do not apply strong external pressure to the pickup or

subject it to impact. Actions like these can cause the

printed circuit board to crack or malfunctioning to occur.

The pickup is a single integrated part which has been

very precisely adjusted. Therefore, its adjustment points

and set screws must not be touched.

How to prevent static during handling

When replacing any of the parts, disconnect the power

plug from the unit being repaired.

All measuring instruments, tools and repair equipment

must be grounded.

Cover the work bench where the

repair work will be done with a grounded electrically

conductive sheet.

Ground the metal part of the soldering iron in order to

safeguard against leakage of electricity from the heater.

,,,

r

d

[F,]

Repair personnel must wear grounding bands around their

wrists to discharge static picked up by their bodies. These

bands are grounded through a resistor (with a 1Mf2

resistance).

Note: Under no circumstances must be the grounding bands

e.

3.

a.

b.

be grounded without a resistor (with a 1ML? resistance)

since doing so involves the risk of electric shocks.

Since static in the clothes of the repair personnel will not

be discharged by wearing grounding bands, every care

must be taken not to allow the clothes to touch the pickup

and semiconductors (particularly the ICS).

>’” “

The pickup, which is a single integrated part, is kept in a

conductive bag. Use this bag to convey the pickup from

one place to another. In order to avoid damage resulting

from static which may occur when the pickup is removed

from the bag, make sure that it is not placed on top of the

bag.

Cleaning the lens surface

Blow off dust on the lens using the kind of air brush which

is used for cameras.

Remove stubborn dirt with a cotton swab dipped in

isopropyl alcohol. Do not use any other type of cleaning

fluid since it may mark the plastic lens.

Notes:

●Do not use too much isopropyl alcohol: the excess

may seep inside the pickup.

● The lens is held in place by a very feeble support

spring. Therefore, when cleaning the lens, avoid

applying any more force by the cotton swab than is

necessary since this may bend the support spring --._out of shape.

-1-

Page 3

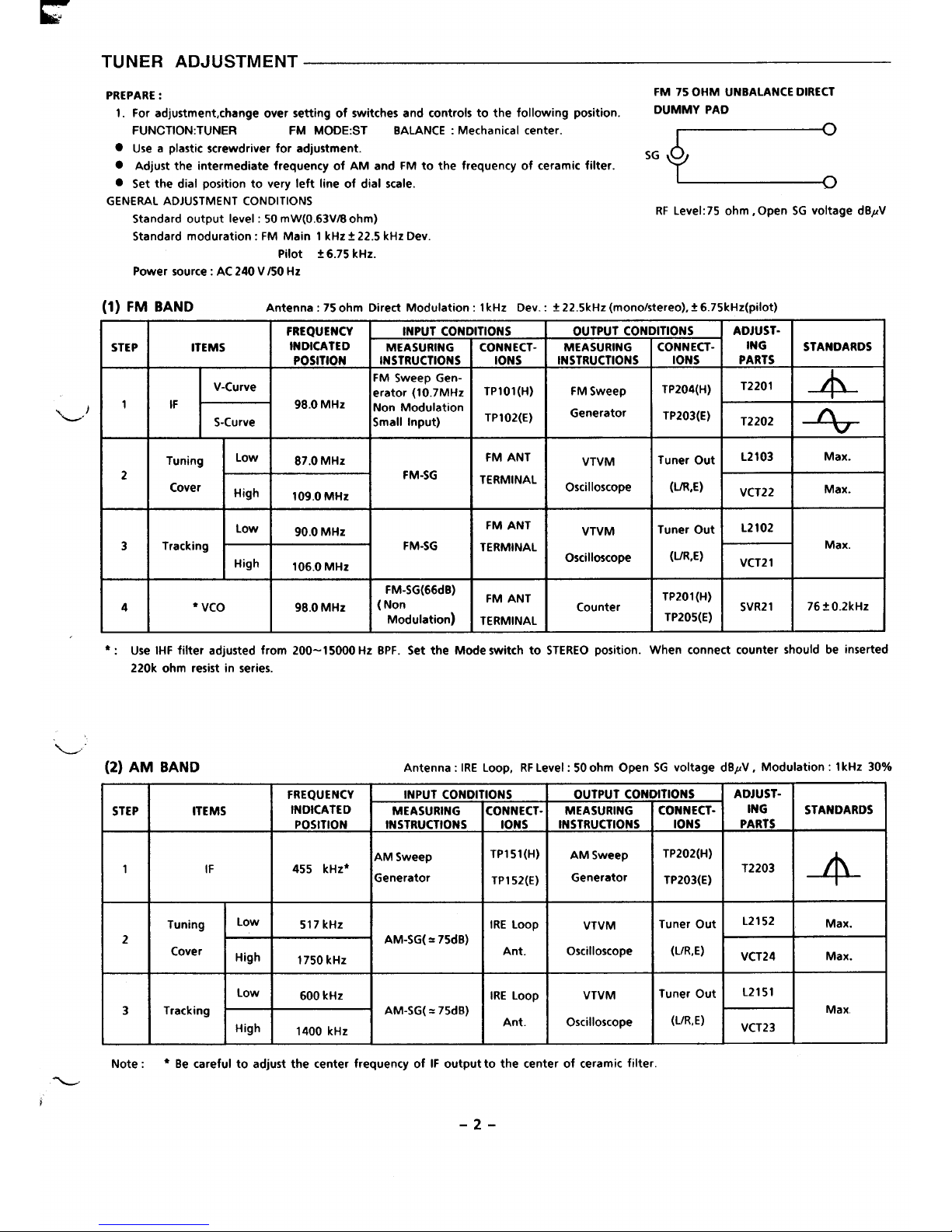

TUNER ADJUSTMENT

PREPARE :

FM 750HM UNBALANCE DIRECT

1. For adjustment, change oversetting of switches and controls to the following position.

DUMMY PAD

FUNCTION: TUNER

FM MODE:ST

BALANCE : Mechanical center.

● Use a plastic screwdriver for adjustment.

S.Y$O

●

Adjust the intermediate frequency of AM and FM to the frequency of ceramic filter.

● Set the dial position to very left line of dial scale.

GENERAL ADJUSTMENT CONDITIONS

Standard output level :50 mW(O.63V/8 ohm)

RF Level:75 ohm, Open SG voltage dB,uV

Standard moderation: FM Main 1 kHz * 22.5 kHz Dev.

Pilot * 6.75 kHz.

Power source: AC 240 V 150 Hz

(1)Fft

F

STEP

‘w) ‘

BAND Antenna :75 ohm Direct Modulation: 1kHz Dev.: t 22.5kHz (mono/stereo), f 6.7 Sk Hz(pilot)

FREQUENCY INPUT CONDITIONS OUTPUT CONI

ITEMS

INDICATED

MEASURING

CONNECT- MEASURING

POSITION INSTRUCTIONS

IONS INSTRUCTIONS

FM Sweep Gen-

V-Curve

erator (10.7 MHz

TP101(H)

FM Sweep

IF

98.0 MHz

Non Modulation

S-Curve Small Input)

TP102(E)

Generator

u--

Tuning

2

Cover

E

3

4

Tracking

FM-SG(66dB)

● Vco 98.0 MHz

( Non

FM ANT

Counter

Modulation)

TERMINAL

TP204(H)

I-=!!&&

TP203(E)

I

T2202

1+

‘“~’3=-l-

Tuner Out

H

L2 102

Max.

(UR,E)

VCT21

TP201(H)

SVR21

76~0.2kHz

TP205(E)

● : Use IHF filter adjusted from 200-15000 Hz BPF. Set the Mode switch to STEREO position. When connect counter should be inserted

220k ohm resist in series.

L,:

(2) AM BAND

Antenna : IRE Loop, RF Level: 50 ohm Open SG voltage d8,dJ, Modulation :1 kHz 30%

F

1

I

IF

Tuning

Low

2

Cover

High

Low

3

Tracking

High

I

AM Sweep

4S5 kHz*

Generator

=2-=

+ ‘“-sG(=75dB)

1400 kHz

I

IONS

OUTPUT CONDITIONS

ADJUST-

CONNECT-

MEASURING

CONNECT-

ING

STANDARDS

IONS

INSTRUCTIONS

IONS PARTS

IRE

LOOP

VTVM

Ant.

Oscilloscope

IRE

LOOfl

VTVM

Tuner Out

H

L2151

Max

Ant. Oscilloscope

(UR,E)

VCT23

Note:

● 8e careful to adjust the center frequency of IF output to the center of ceramic filter.

L

i

-2-

Page 4

Fii

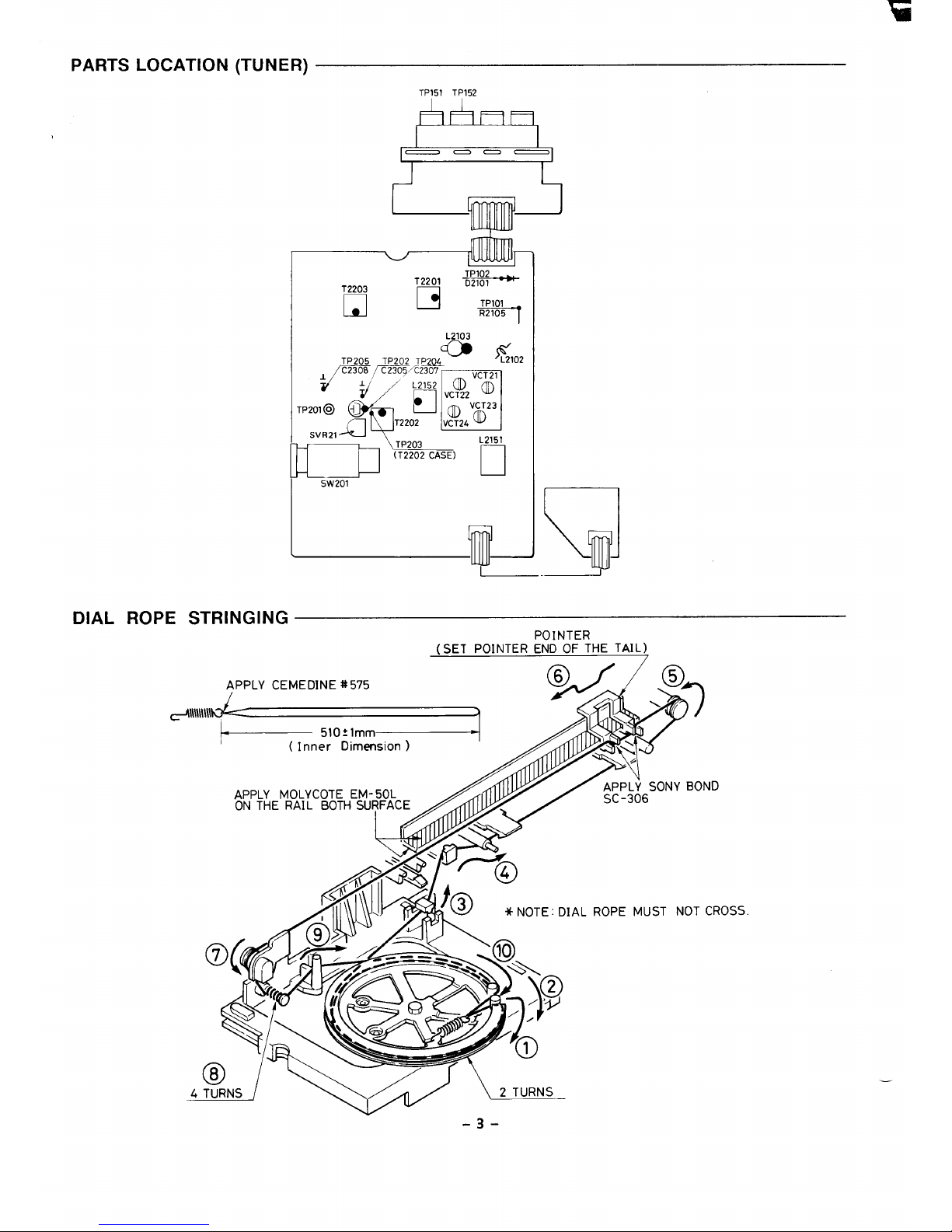

PARTS LOCATION (TUNER)

DIAL ROPE

TP151 TP152

e==+

—00—

r- ‘7

w

TP102

T2201

T2203

❑

mm-+

❑

+%

L2103

0 ,g,02

~<.d ,

‘ C23;P’= vc!!2vc~

TP201 @ i

,(2,vg3

T2202

SVR21

m “’2CASE) 0

SW201

lip

I

\

.-!F-

STRINGING

POINTER

(SET POINTER END OF THE TAIL)

APPLY CEMEDINE #575

3 Ah”

0/’

6

@

/

\

. Yl\

— 51021mm

I

( Inner Dimension )

-1

/A~+

BOND

+&@

-k NOTE : DIAL ROPE MUST NOT CROSS.

4 %NS / ~ \ 2 TURNS

-3-

Page 5

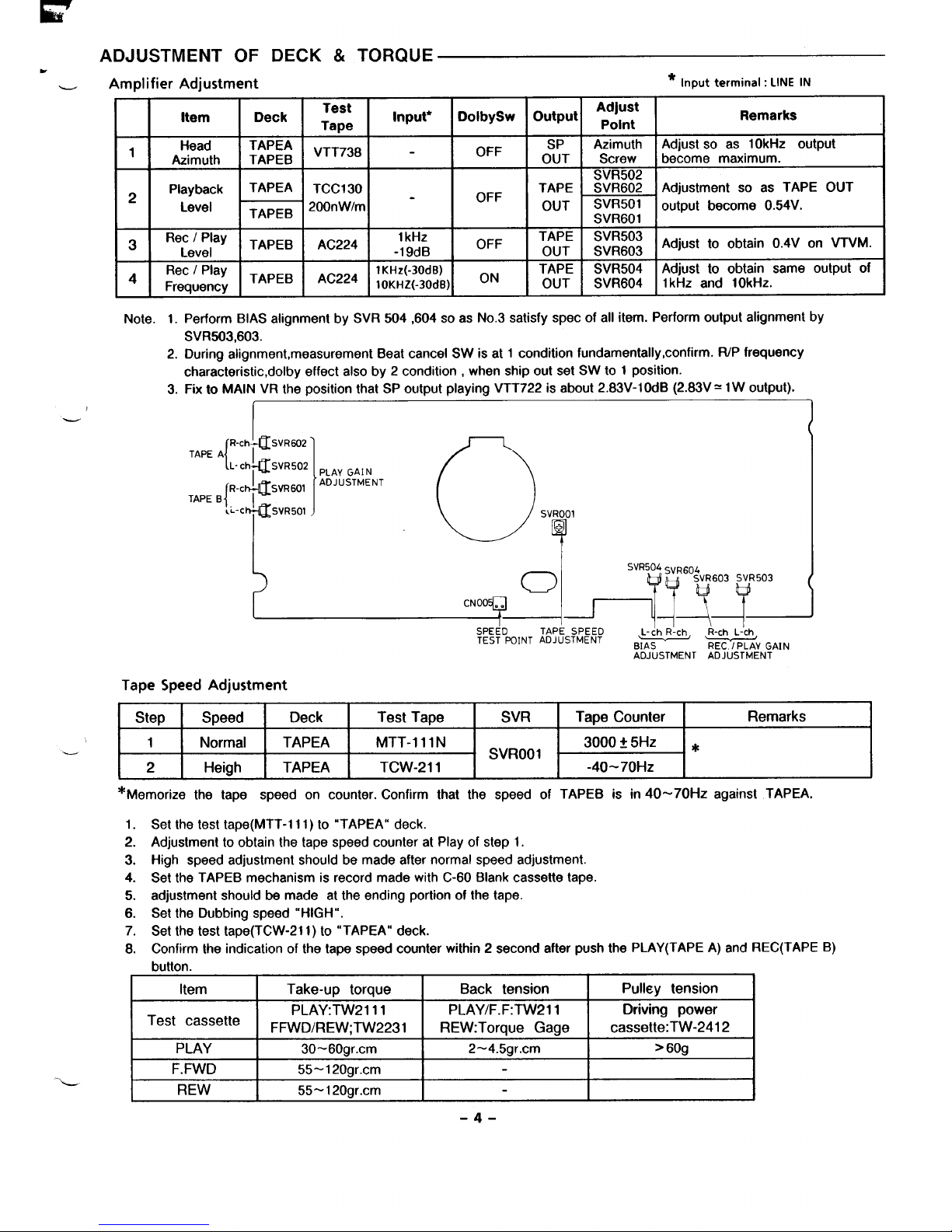

ADJUSTMENT OF DECK & TORQUE

Amplifier Adjustment

* lnputterminal: LINEIN

Item

Deck

Test

Input’

DolbySw output

Adjust

Tape

Point

Remarks

1

Head

TAPEA

VTT738 -

OFF

Azimuth

Adjust so as 10kHz output

Azimuth

TAPEB

OS(T

Screw

become maximum.

TAPEA TCC130

SVR502

2

Playback

OFF

TAPE

SVR602

Adjustment so as TAPE OUT

Level

TAPEB

200rrW/m -

OUT

SVR501

output become 0.54V.

SVR601

3

Rec / Play

TAPEB AC224

1kHz

Level

-19dB

OFF

y:; g:::; Adjust to obtain 0.4V on VTVM.

4

Rec I Play

TAPEB

lKHz(-30dB)

TAPE SVR504

Adjust to obtain same output of

Frequency

AC224 10KHZ(-30dB) ON OUT

SVR604

1kHz and 10kHz.

Note. 1.

2.

3.

Perform BIAS alignment by SVR 504,604 so as No.3 satisfy spec of all item. Perform output alignment by

SVR503,603.

During alignment, measurement Beat cancel SW is at 1 condition fundamentally,confirm. fUP frequency

characteristic, dolby effect also by 2 condition , when ship out set SW to 1 position.

Fix to MAIN VR the position that SP output playing VTT722 is about 2.83V-1 OdB (2.83V = 1W output).

[

R-ch ~SVR64)2 -

TAPE A

L- ch~SVR502

[1

R-ct4fsvR601

TAPE B

tiL-c~SVR501 ,

I

PLAY GA1 N

ADJUSTMENT

.0

SVROO1

?

+

I

a

CNOO

Q,

nfT0T03Y5

~~’

SPEED

TAPE SPEED

~-!~-~!~ch,

TEST POINT ADJUSTMENT

BIAS

REC /PLAY GAIN

ADJUSTMENT ADJUSTMENT

Tape Speed Adjustment

Step Speed

Deck

Test Tape

SVR

Tape Counter

Remarks

1 Normal TAPEA MTT-lll N 3000 ? 5Hz *

2 Heigh TAPEA

SVROO1

TCW-211

-40-70Hz

*Memorize the tape speed on counter. Confirm that the speed of TAPEB is in 40-70Hz against TAPEA.

1.

Set the test tape(MTT-111 ) to “TAPEA” deck.

2. Adjustment to obtain the tape speed counter at Play of step 1.

3. High speed adjustment should be made after normal speed adjustment.

4. Set the TAPEB mechanism is record made with C-60 Blank cassette tape.

5. adjustment should be made at the ending portion of the tape.

6. Set the Dubbing speed “HIGH”.

7. Set the testtape(TCW-211 ) to “TAPEA” deck.

8. Confirm the indication of the tape speed counter within 2 second after push the PLAY(TAPE A) and REC(TAPE B)

button.

Item Take-up torque Back tension

Pulley tension

Test cassette

PLAYTW211 1

PLAYIF.F:TW211

Driving power

FFWD/REW;TW2231

REW:Torque Gage cassette: TW-2412

PLAY

30-60gr.cm

2-4.5gr.cm

>

6(Jg

F.FWD 55-120gr.cm

REW

55-120gr.cm

-4-

Page 6

REPLACEMENT

OF HEADS

TAPE “B”

TAPE “A”

BROWN

WHITE

RE13

‘lN\K\ YELLOW \ /

FROM 6P CONNECTOR

BRO’WN

(FROM9P CONNECTOR)

RED

WHITE

FROM 9’P CONNECTOR BLACK

APPLVCEMEDINE TO FIX

APPLY CEMEDINETO FIX

SCHEMATIC DIAGRAM (TURN TABLE)

LG .

---------- ,

,

_________ .

RG’‘

(

L

I

CARTRIDGE

I

,1 ,

I ,1 ,

ADJ

USTM

33 RPM HOLE

FOR ADJUSTMENT

0

(a) 0

LEAF

SWITCH

MOTOR : MMI -6S2RWA0

Ii: 11:

kAA

lK(B)

45 Ipm

blw

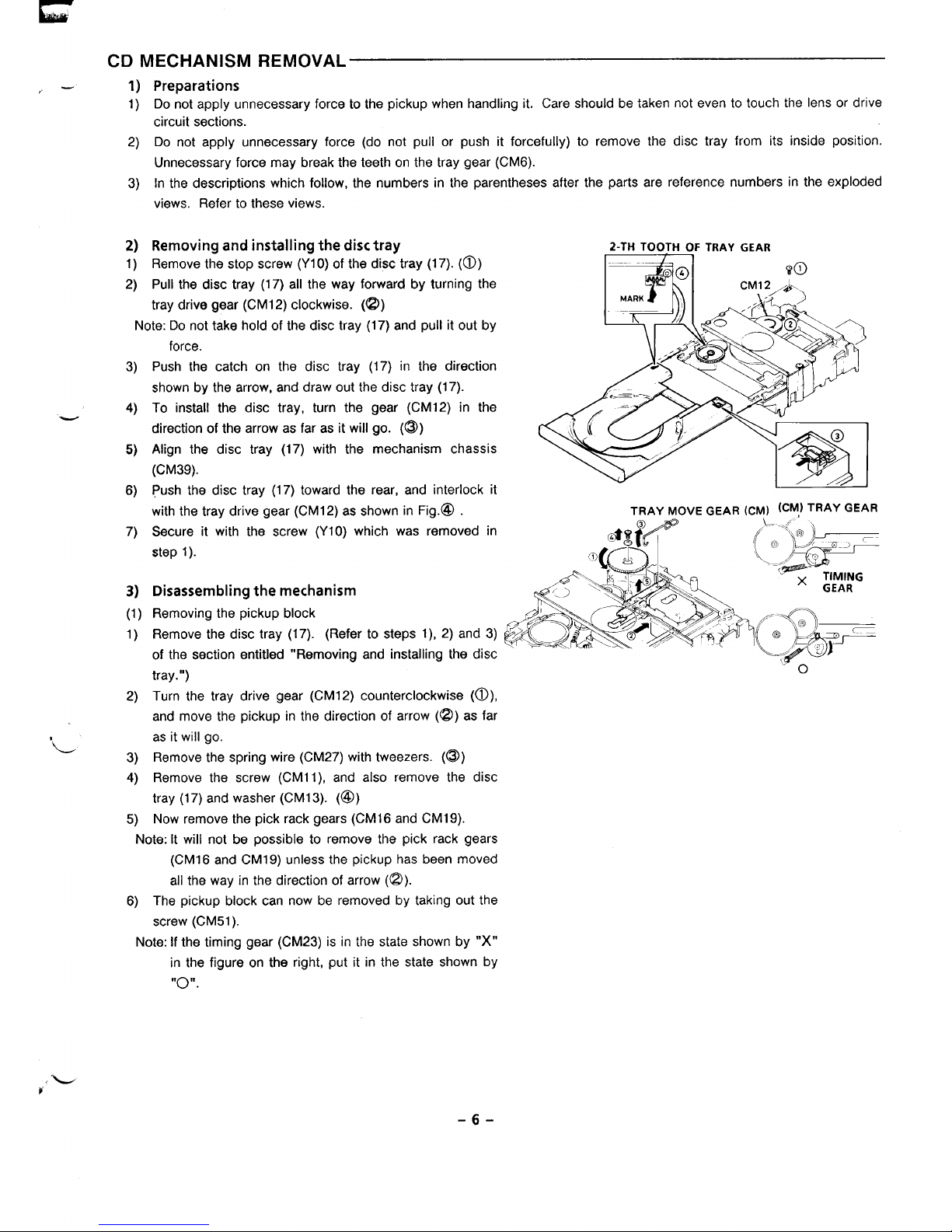

CD MECHANISM

,. —

1)

1)

2)

3)

2)

1)

2)

3)

4)

‘-

5)

REMOVAL

Preparations

Do not apply unnecessary force to the pickup when handling it. Care should be taken not even to touch the lens or drive

circuit sections.

Do not apply unnecessary force (do not pull or push it forcefully) to remove the disc tray from its inside position.

Unnecessary force may break the teeth on the tray gear (CM6).

In the descriptions which follow, the numbers in the parentheses after the parts are reference numbers in the exploded

views. Refer to these views.

Removing and installing the disc tray

2-TH TOOTH

OF TRAY GEAR

Remove the stop screw (YI O) of the disc tray (17). (~)

Pull the disc tray (17) all the way forward by turning the

tray drive gear (CM12) clockwise. (~)

Note: Do not take hold of the disc tray (17) and pull it out by

force.

Push the catch on the disc tray (17) in the direction

shown by the arrow, and draw out the disc tray (17).

To install the disc tray, turn the gear (CM12) in the

direction of the arrow as far as it will go. (@)

Align the disc tray (17) with the mechanism chassis

(CM39).

6) Push the disc tray (17) toward the rear, and interlock it

L

/

///

7)

3)

(1)

1)

2)

‘L

3)

4)

5)

with the tray drive gear (CM I 2) as shown in Fig.@ .

Secure it with the screw (Yl O) which was removed in

step 1).

Disassemblingthe mechanism

Removing the pickup block

Remove the disc tray (17). (Refer to steps 1), 2) and 3)

of the section entitled “Removing and installing the disc

TRAY MOVE GEAR (CM) (CM,) TRAY GEAR

tray.”)

u

Turn the tray drive gear (CM12) counterclockwise (~),

and move the pickup in the direction of arrow (@) as far

as it will go.

Remove the spring wire (CM27) with tweezers. (@)

Remove the screw (CM11 ), and also remove the disc

tray (17) and washer (CM1 3). (@)

Now remove the pick rack gears (CM I 6 and CM1 9).

Note: It will not be possible to remove the pick rack gears

(CM16 and CM19) unless the pickup has been moved

all the way in the direction of arrow (@).

6) The pickup block can now be removed by taking out the

screw (CM51).

Note: If the timing gear (CM23) is in the state shown by “X”

in the figure on the right, put it in the state shown by

“o”.

‘L

F’

-6-

Page 8

‘mm! -

‘“

- --’”

Iii

—

MECHANISM REMOVAL (CD)

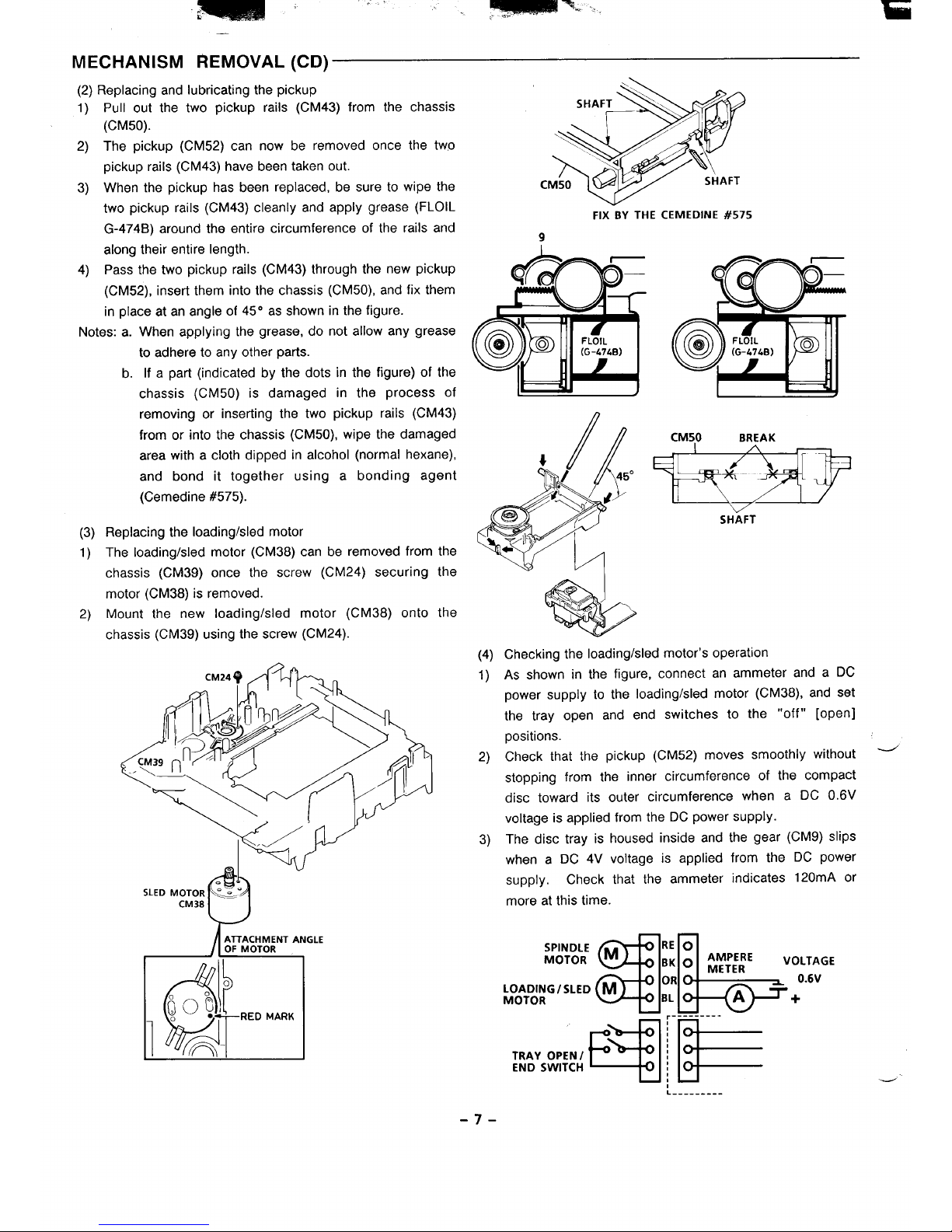

(2) Replacing and lubricating the pickup

‘<q

‘\

1) Pull out the two pickup rails (CM43) from the chassis

SHAFT ~

(CM50).

,/

@

2) The pickup (CM52) can now be removed once the tw,o

pickup rails (CM43) have been taken out.

3) When the pickup has been replaced, be sure to wipe the

crvl,rl & /

SHAFT

two pickup rails (CM43) cleanly and apply grease (FLOIL

G-474B) around the entire circumference of the rails and

FIX BY THE CEMEDINE #575

a

along their entire length.

4) Pass the two pickup rails (CM43) through the new pickup

@&e_

~c

(CM52), inserf them into the chassis (CM50), and fix them

in place at an angle of 45” as shown in the figure.

Notes: a. When applying the grease, do not allow any grease

m

o

@ o ,G-,,h,)

FLOIL

to adhere to any other parts.

b. If a part (indicated by the dots in the figure) of the

chassis (CM50) is damaged in the process of

removing or inserting the two pickup rails (CM43)

from or into the chassis (CM50), wipe the damaged

area with a cloth dipped in alcohol (normal hexane),

IL

and bond it together using a bonding agent

L/ 45°

(3)

1)

2)

(Cemedine #575).

e

,,.

#

/ #k

@?J >P-

Replacing the loading/sled motor

* [>

The loading/sled motor (CM38) can be removed from the

7 A

chassis (CM39) once the screw (CM24) securing the

motor (CM38) is removed.

Mount the new loading/sled motor (CM38) onto the

chassis (CM39) using the screw (CM24).

CM24 ?

CM38

In

ATTACHMENT ANGLE

OF MOTOR

.

~~

o

0 0.

O*

RED MARK

1 ‘% m-

(4)

1)

2)

3)

VI

SHAFT

Checking the loading/sled motor’s operation

As shown in the figure, connect an ammeter and a DC

power supply to the loading/sled motor (CM38), and set

the tray open and end switches to the “off” [open]

positions.

Check that the pickup (CM52) moves smoothly without stopping from the inner circumference of the compact

disc toward its outer circumference when a DC 0.6V

voltage is applied from the DC power supply.

The disc tray is housed inside and the gear (CM9) slips

when a DC 4V voltage is applied from the DC power

supply.

Check that the ammeter indicates 120mA or

more at this time.

——

-“

L---------

-7-

Page 9

m

MECHANISM REMOVAL (CD)

.—

4)

(1)

1)

2)

Check points for CD mechanism assembly and

lubrication

Lubricating and mounting the tray slide

Apply grease (FLOIL G-4748) to the area indicated by the

diagonal

in the figure.

When inserting the tray slide (CM1 5), set the position

where it is installed vis-a-vis the base/tray timing gear

(CM20) as shown in the figure.

y

P

BASE / TRAY

v I TIMING GEAR (CM20)

(3)

1)

2)

3)

4)

(2)

1)

2)

3)

Installing the tray gear

Move the tray slide (CM I 5) in the direction of the arrow

0.

Engage the gear section of the tray slide (CM15) with the

inner gear of the tray gear (CM6) at the center line, as

shown in the figure.

Align the tray move gear (CM3) with the position

(0) of

the hole in the outer gear of the tray gear (CM6), and

engage the tray move gear (CM3), as shown in the figure.

TRAY

SLIDE

CM6

Installing the base up/down slide and timing gear

Move the base up/down slide (CM14) in the direction of

the arrow @, and set the gears at the positions shown in

the figure.

Insert the timing gear (CM23), and mount it using the

screw (CM21 ).

Turn the timing gear (CM23) counterclockwise.

TIMING GEAR

BASE UP/ DOWN

@JF~:~4

\

v SCREW (CM21)

@

Hook the gear tension spring (CM22) onto the timing gear

(CM23).

msH’oN

-8-

Page 10

.

MECHANISM REMOVAL (CD)

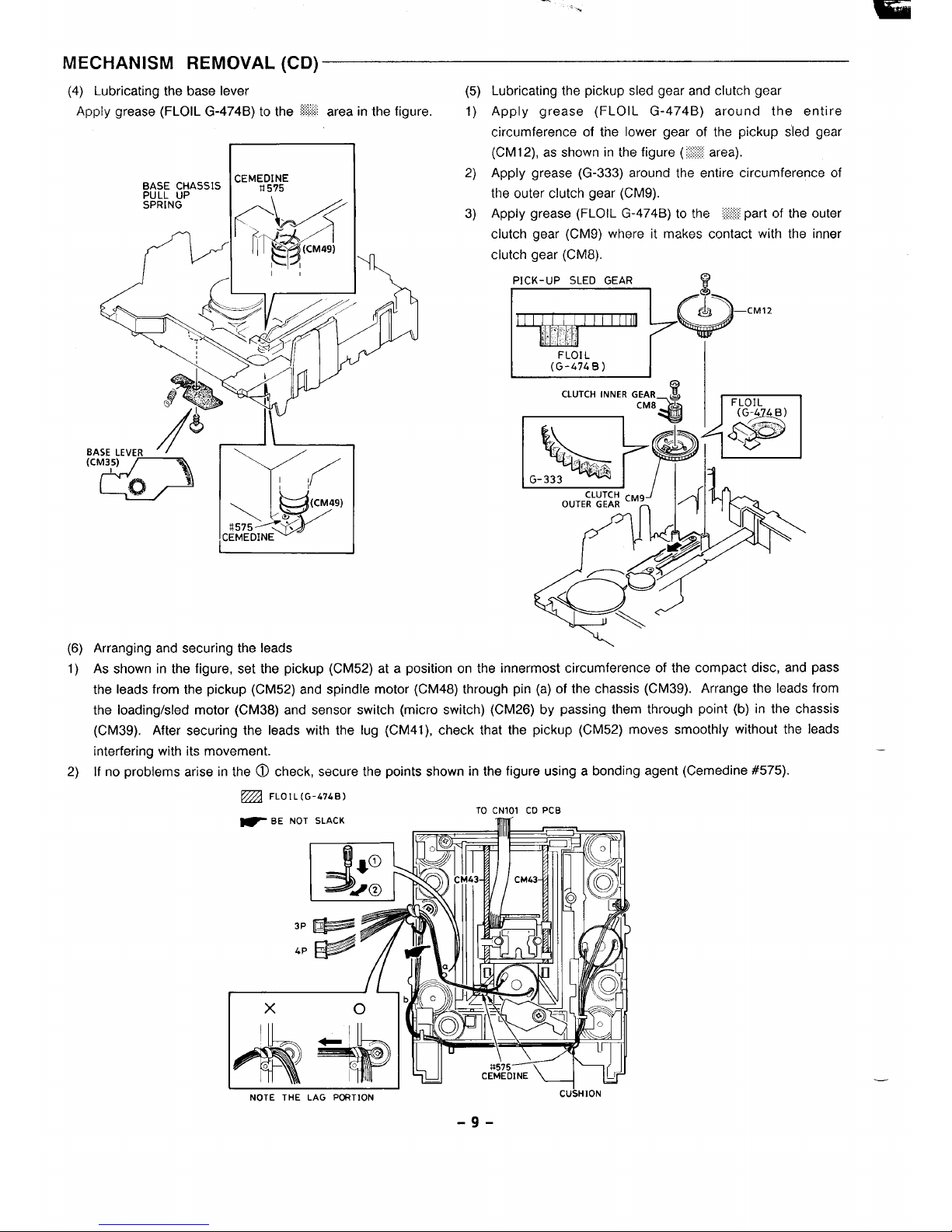

(4) Lubricating the base lever

(5)

Apply grease (FLOIL G-474B) to the ~~ area in the figure. 1)

2)

3)

1

I

(6) Arranging and securing the leads

Lubricating the pickup sled gear and clutch gear

Apply grease (FLOIL G-474B) around the entire

circumference of the lower gear of the pickup sled gear

(CM1 2), as shown in the figure (w area).

Apply grease (G-333) around the entire circumference of

the outer clutch gear (CM9).

Apply grease (FLOIL G-474B) to the ~ part of the outer

clutch gear (CM9) where it makes contact with the inner

clutch gear (CM8).

-CM12

L&h-l

I

CLUTCH INNER GEAR ~

~ ‘“84 w

pJ@._Jp,

p!??d

CLUTCH cM9~

OUTER GEAR n

k-w-oca

1) As shown in the figure, set the pickup (CM52) at a position on the innermost circumference of the compact disc, and pass

the leads from the pickup (CM52) and spindle motor (CM48) through pin (a) of the chassis (CM39). Arrange the leads from

the loading/sled motor (CM38) and sensor switch (micro switch) (CM26) by passing them through point (b) in the chassis

(CM39). After securing the leads with the lug (CM41 ), check that the pickup (CM52) moves smoothly without the

interfering with its movement.

2) If no problems arise in the @ check, secure the points shown in the figure using a bonding agent (Cemedine #575).

~ FLOIL(G-L7LB)

TO CN101 CO PCB

BE NO1

3P

4P

~L

o

+

lx

-3

1°

leads

.

.

CUkHION

NOTE THE LAG PORTION

-9-

Page 11

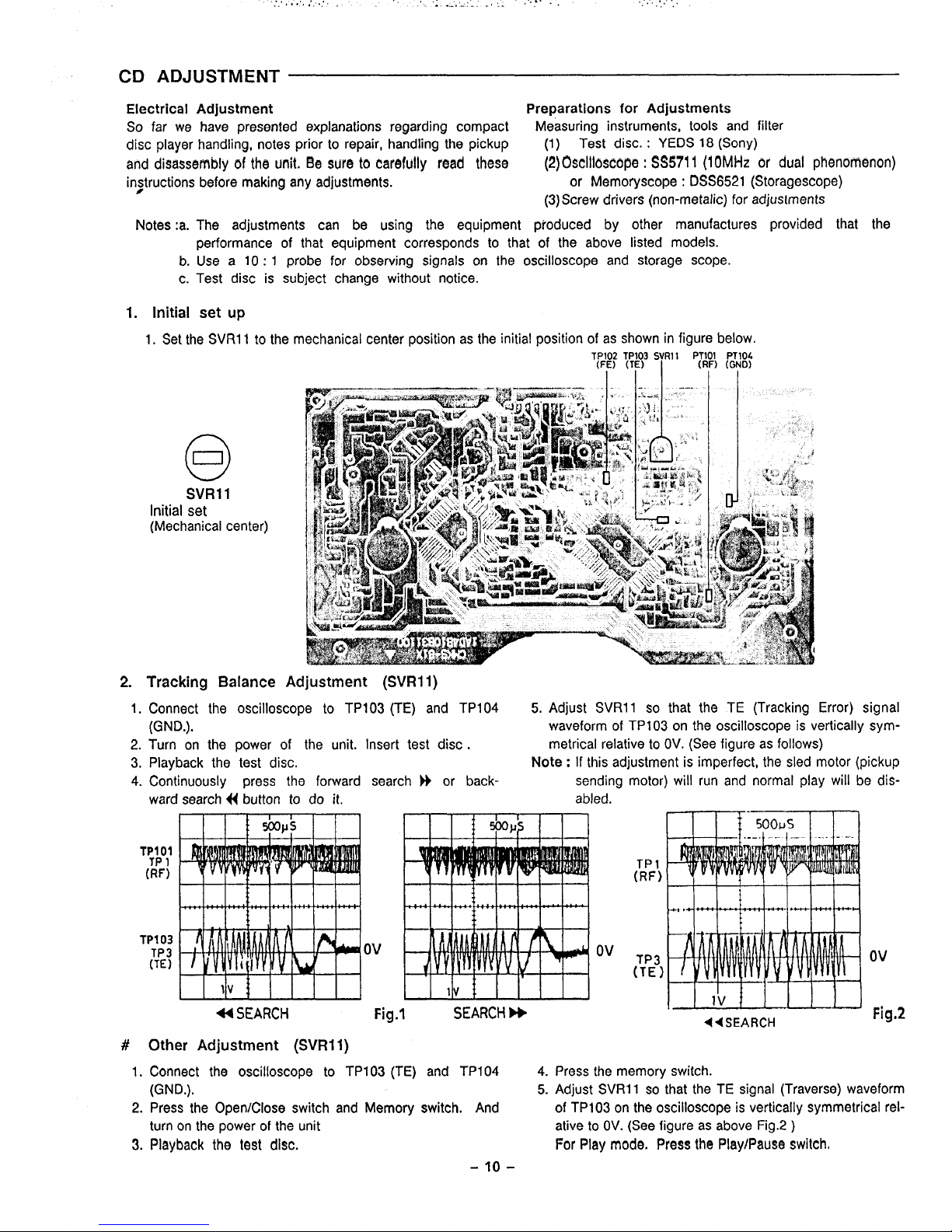

CD ADJUSTMENT

Electrical Adjustment

Preparations for Adjustments

So far we have presented explanations regarding compact

Measuring instruments, tools and filter

disc player handling, notes prior to repair, handling the pickup

(1)

Test disc. : YEDS 18 (Sony)

and disassembly of fhe unit. Be $w’e to carefully read these

(2)0sclllIwMpt3:SS5711 (1OMHZ or dua[ phenomenon)

instructions before making any adjustments.

or Memoryscope: DSS6521 (Storagescope)

r

Notes :a.

b.

c.

1.

Initial

(3) Screw drivers (non-metalic) for adjustments

The adjustments can be using the equipment produced by other manufactures provided that the

performance of that equipment corresponds to that of the above listed models.

Use a 10:1 probe for observing signals on the

oscilloscopeand storage scope.

Test disc is subject change without notice.

set up

1. Set the SVR11 to the I

e

SVR1l

Initial set

(Mechanical center)

2. Tracking Balance Adjustment (SVR11)

1. Connect the oscilloscope to

TPI 03 (TE) and TP104

5. Adjust SVR11 so that the

TE (Tracking Error) signal

(GND.).

waveform of

TP103 on the oscilloscope is vertically sym-

2. Turn

on the power of the unit. Insert test disc .

metrical relative to OV. (See figure as follows)

3. Playback the test disc.

4. Continuously

press the forward

ward search ~ button to do it,

TP103

TP3

(TE)

Ov

Note: If this adjustment is imperfect, the sled motor (pickup

search N or back-

sending motor)

willrun and normal play will be dis-

abled.

44 SEARCH

Fig.1 SEARCH W

# Other Adjustment (SVR11)

Ov

TP1

(RF)

TP3

(TE)

44 SEARCH

Ov

F!g.2

1.

2.

3.

Connect the oscilloscope to TP103 (TE) and TP104

4.

Press the memory switch,

(GND.). 5. Adjust

SVR11 so that the TE signal (Traverse) waveform

Press the Open/Close switch and Memory switch. And of TP103 on the oscilloscope is vertically symmetrical relturn on the power of the unit ative to OV. (See figure as above Fig.2 )

Playback the test disc.

For Play mode. Press the Play/Pause switch,

-1o-

Page 12

i

,.

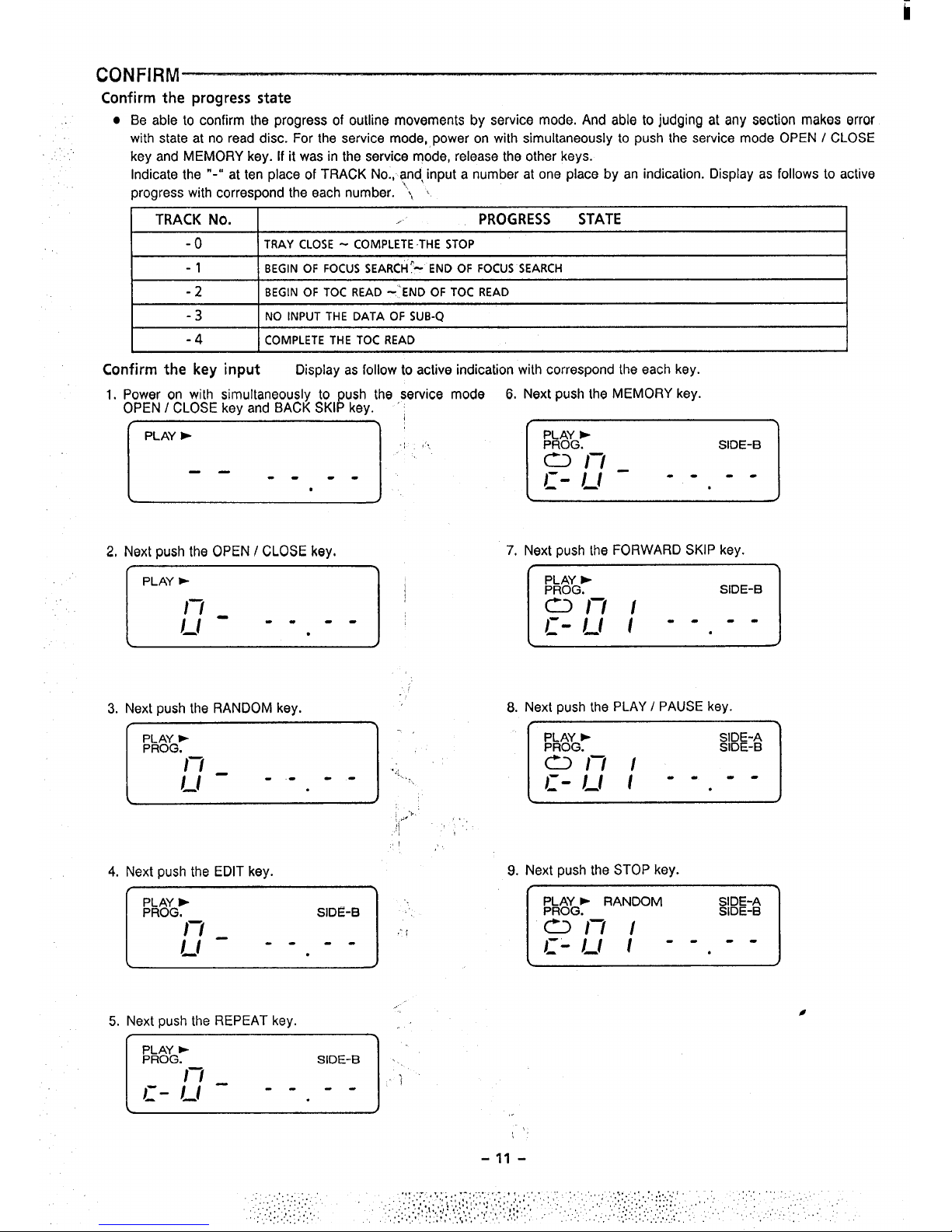

CONFiRM—--–

Confirm the progress state

. Be able to confirm the progress of outline movements by

service mode, And able to judging at any section makes error

with state at no read disc. For the service

mode, ,power on with simultaneously to push the service mode OPEN / CLOSE

key

and MEMORY key. If it was in the service mode, release the other keys.

Indicate the “-”

at ten place of TRACK No., and, input a number at one place by an indication. Display as follows to active

progress with correspond the each number. “i, \

TRACK

hlo.

.,

PROGRESS

STATE

I

-o

TRAY CLOSE- COMPLETETHE STOP

-1

BEGINOF FOCUSSEARCH!- END OF FOCUSSEARCH

i

J

-2

BEGIN OF TOC READ -“END OF TOC READ

-3 NO INPUT THE DATA OF SUB-Q

I

-4

COMPLETE THE TOC READ

I

Confirm the key input Display as follow to active indication with correspond the each key.

1.

2,

3.

4

Power on with simultaneously to ush the ,service mode

P

6. Next push the

MEMORY key.

OPEN / CLOSE key and BACK SKI key.

PLAY ●

--

---,

Next push the OPEN /

CLOSE key.

PLAY >

17 . . . . .

)_/

●

Next push the RANDOM key.

E

Next push the EDIT key.

I

.1 ,’.

1

.,

“...,.

,.,

,,

PLAY ➤

PROG,

SIDE-B

‘“

/–l ----- - I

)_l

●

5. Next push the REPEAT key.

PLAY *

PROG.

SIDE-B

I–l -----

c - I_!

.

7,

8.

PLAY >

PROG.

SIDE-B

es/-l_ -- .~- /_/

.

Next push the FORWARD SKIP key.

PLAY >

PROG.

SIDE-B

O//;l (....

~- _

.

Next push the PLAY I PAUSE key.

PLAY ➤

PROG.

SIDE-A

SIDE-B

y; /

~-_-.*--

9.

Next push the STOP key.

c

,.

-11-

Page 13

,.,

-,,,-,,,. ... . .,.,... .,

“,.:. ,’..:,,.,:’,., ..... .“, .

.: ..,..,

... , ,,, . . .

,.

., .,,.,. .

..’.. ,’.,’ ,’, .

,.:,’: . ....

., ...,

.,,

..... .....

..’.... .,. . . . . .

,.

. :.,.,....

EXPLODED VIEW (CABINET )

Uwl

/l!v

Y4

H

/“ ‘4

.

Y1

%)-Y1

-7

%-Yl

-12-

Page 14

ii

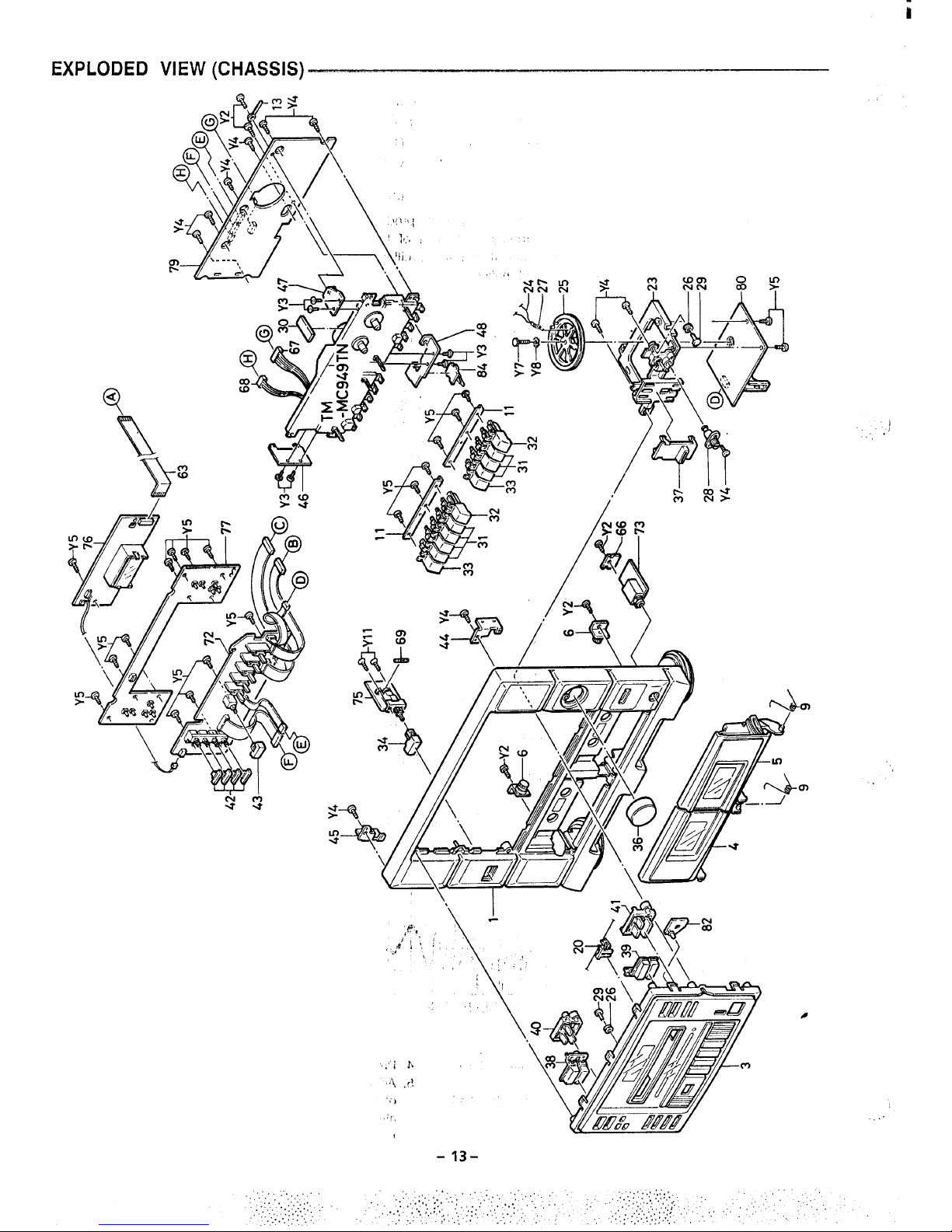

EXPLODED VIEW (CHASSIS) ~~

am

CyCy

-/1 /

-13-

“)

.,,,

m

..

Page 15

PARTS LIST

PRODUCT SAFETY NOTICE

Each precaution in this manual should be followed during servicing. Components identified with the IEC symbol ~ in the parts list

and the schematic diagram designate components in which safety can be of special significance. When replacing a component identified ~, use only the replacement parts designated, or parts with the same ratings of resistance, wattage or voltage that are designated in the parts list in this manual. Leakage-current or resistance measurements must be made to determine that exposed parts

are acceptably insulated from the supply circuit before returning the product to the customer.

CAUTION: Regular type resistors and capacitors are not list. To know those values, refer to the schematic diagram.

~BINET

Ref. No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

or

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

k ACCESSORIES

Part No.

614 246 1198

614 246 1204

614 240 6656

614 240 6663

614 176 7024

614 246 1211

614 231 6832

614 224 3480

614 245 9348

614 234 5511

614 232 6671

i CHASSIS

Part No.

614 246 1112

614 230 5096

614 246 1129

614 241 5504

614 241 5528

614 069 0385

614 239 4403

614 239 4410

614 216 0051

614 239 4281

614 194 9239

614 216 7083

614 130 0382

614 243 4109

614 246 1136

614 129 1901

614 240 2726

614 238 1694

614 242 2403

614 195 6976

614 240 2665

614 240 2702

614 240 2719

614 240 2771

614 118 5590

614 132 2773

614 135 5702

614 146 8778

614 068 7972

614 240 7716

614 208 0986

614 216 9063

614 216 9117

614 216 9124

Description

INNER CARTON “SINGAPORE”

INNER CARTON “MALAYSIA”

PAD,BOTTOM

PAD,TOP

INNER POLYE COVER,SET

INSTRUCTION MANUAL

LABEL,SAFETY,LASER CLASS

INDICATE

LABEL,NEEDLE(ST-707J)

SHEET,CD TRAY

LOOP ANTENNA,AM ANT

ANTENNA,FM ANT

Description

!SSY,PANEL,FRONT

?ANEL,Tf)p,TIJR$J TABLE

V3SY,PANEL

4SSY,LID,CASSETTE,TAPE B

USSY,LID,CASSETTE,TAPE A

2EAR ASSY

PANEL,SIDE,R

PANEL,SIDE,L

5PRING,WIRE,LID CASSETTE

CABINET,BOTTOM

BRACKET,MECHA KNOB

4SSY,FOOT

LUG,DECK PCB(DRESS LEAD)

PANEL,REAR “SINGAPORE”

PANEL,REAR “MALAYSIA”

FIXER,AC CORD

BRACKET-M,CD MECHA

TABLE,LOADING,CD TRAY

ESCUTCHEON,CD TRAY

RUBBER CUSHION,CD MECHA

POINTER

BRACKET-M,CD MECHA

(R)

BRACKET-M,CD MECHA

(L)

MOUNT-M,TUNER PCB

ROPE O.3X11OOMM

DRUM

PULLEY

SPRING COIL,ROPE

TUNING SHAFT ASSY

PIN,PULLEY

CUSHION,MECHA LEAD

BUTTON,MCHA BUTTON

(STOP,ETC)

BRACKET

BRACKET

FIX

BUTTON,MECHA (PAusE)

BUTTON,MECHA (REC,ETC)

Ref. No.

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

,1

,2

br

13

14

Part No.

614 239 4519

614 228 0218

614 240 2634

614 240 2641

614 242 0430

614 242 0423

614 240 2351

614 239 4557

614 240 236B

614 240 2656

614 239 4618

614 240 6926

614 216 9230

614 216 9247

614 216 9254

614 212 6343

614 219 6223

614 234 1056

614 234 3692

614 112 3479

614 112 3486

‘IXING PARTS

Ref. No.

Y1

Y2

Y3

Y4

Y5

Y6

Y7

Y6

Y9

Ylo

Yll

Y12

Y13

Part No.

411 021 6603

411 021 3503

411 028 2905

411 021 6405

411 021 1806

411 001 3905

411 011 4503

411 085 1200

411 021 1202

411 022 6406

411 022 2802

412 032 6408

412 004 5705

Description

BUTTON,POWER

BUTTON,DUBBING,BEAT CCL

KNOB,ROTARY,TUNER

KNOB,SLIDE,BAND

BUTTON,REPEAT.MEMORY

BUTTON,PLAY/STOP

BUTTON,EDIT.RANDOM INTRO

BUTTON,SKIP.OPEN.CLOSE

BUTTON,CD/TU/TAPE/PHONO

BUTTON,BASSXPANDER

BRACKET-E,FRONT-SIDE (R)

BRACKET-E,FRONT-SIDE (L)

BRACKET-E,DECK PCB

BRACKET-E,OECK PCB

BRACKET-E,DECK PCB

LABEL,SAFETY,LASER

ASSY,COVER,OUST

ASSY SHEET TURNTABLE

ASSY SHEET TURNTABLE

HINGE,R

HINGE,L

Description

SCR S-TPG BIN

3X8,PANEL,SIDE & TOP

SCR S-TPG BIN 3X1O

SCR S-TPG PAN 2X4,DECK

BRACKET-E

SCR S-TPG

BIN 3X6

SCR S-TPG BIN 2.6X1O

SCR S-TPG BIN 4X6,TRANS

BOLT HEX C-SCT 2.6X16,DRUM

WASHER OUT TW 2.6,DRUM

SCR S-TPG BIN 2X8,TRAY

ESCUTCHEON

SCR S-TPG PAN 2X8,CD TRAY

STOPPER

SCR S-TPG FLT 3X1O,POWER SW

SPECIAL SCREW,PLAYER

SPECIAL SCREW,CD MECHA

FIX

ELECTRICAL PARTS

Ref. No. Part No. Description

61

~614 023 2912

POWER

CORD

62

~614 241 6365

POWER TRANS

63 614 240 8391

CORD,MECHA-MICON 14P

-14-

Page 16

Iiiz

PARTS LIST

Ref. No.

Part No.

64 614 243 9548

65

66

67

68

69

MAIN P.

Ref. No.

71

C4703

C4803

CN107

CN901

CN902

CN905

CN906

CN907

CN924

Dill

or

D112

or

D113

or

D114

or

D115

D4900

or

D4901

or

D4903

or

D4904

or

D4905

or

D4906

or

D4907

or

D4908

or

IC107

IC900

or

or

or

IC901

or

or

or

IC903

IC904

Q106

R4706

R4806

S4403

/h614 242 3844

h614 242 3851

614 218 6442

614 218 6459

~423 016 9308

BOARD ASSY

Part No.

614 242 3424

403 057 3800

403 057 3800

614 017 2591

614 020 6579

614 020 6555

614 017 2591

614 017 2607

614 020 6593

614 020 1246

Lh407 004 9105

A407 012 3300

A407 004 9105

A407 012 3300

A407 004 9105

A407 012 3300

A407 004 9105

A407 012 3300

407 007 9904

A407 004 9105

A407 012 3300

A407 004 9105

A407 012 3300

A407 004 9105

A407 012 3300

A407 004 9105

A407 012 3300

A407 004 9105

A407 012 3300

A407 004 9105

A407 012 3300

A407 004 9105

A407 012 3300

A407 004 9105

A407 012 3300

409 018 5500

h409 001 7603

h409 078 2402

h409 122 6202

~409 168 2107

d409 001 7603

h409 078 2402

h409 122 6202

~409 168 2107

409 017 7505

409 016 7902

405 082 4609

A401 015 6108

A401 015 6108

614 240 8759

Description

ASSY,CONNECTOR-S,MECHA-DG

8P

PCB,PT 1

PCB,HEADPHONE STOPPER

ASSY,CONNECTOR-S,6P

ASSY,CONNECTOR-S,3P

FUSE 250V 0.2A

Description

ASSY,PCB,MAIN

POLYESTER

O.lu M 50V

POLYESTER

O.lU M 50V

PLUG,TO CD MECHA,3P

SOCKET,HP,5P

SOCKET,3P

PLUG,PRI,8P

PLUG,PRI,9P

SOCKET,AC,7P

SOCKET,5P

DIODE DSF1OC

DIODE 1SR35-200A

DIODE DSF1OC

DIODE 1SR35-200A

DIODE DSF1OC

DIODE 1SR35-200A

DIODE DSF1OC

DIODE 1SR35-200A

DIODE GMAO1

DIODE DSF1OC

DIODE 1SR35-200A

DIODE DSF1OC

DIODE 1SR35-200A

DIODE DSF1OC

DIOOE 1SR35-200A

DIODE DSF1OC

DIODE 1SR35-200A

DIODE DSF1OC

DIOOE 1SR35-200A

DIODE DSF1OC

DIODE 1SR35-200A

DIODE DSF1OC

DIODE 1SR35-200A

DIODE DSF1OC

DIODE 1SR35-200A

IC LA651O

IC AN7812F

IC L7812ML

IC NJM7812FA

IC UPC7812HF

IC AN7812F

IC L7812ML

IC NJM7812FA

IC UPC7812HF

IC LA4270

IC LA3161

TR DTA123YS

CARBON 2.2 JB l/4W,FLAME

PROOF

CARBON 2.2 JB l/4W,FLAME

PROOF

SWITCH,PUSH, DUB/BEAT SW

Ref. No.

iRAPHIC

Ref. No.

12

;N911

:N912

:N914

:N915

:N916

:N917

)4402

)4501

j4502

]4601

?4602

?4406

?4407

34400

$4401

JR900

JR901

JR902

JR903

L/R904

Part No. Description

614 203 7362 HEAT SINK, l.5T

614 241 5863 HEAT SINK,2T

614 244 9639 ASSY,CONNECTOR-S,5P 300MM

411 021 6405 SCR S-TPG BIN 3X8,1C-HEAT

SINK

411 021 6405 SCR S-TPG BIN 3X8,AMP PCB-

HEAT SINK

EQUALIZER P.C.9

Part No.

614 242 3431

614 020 6579

614 020 6616

614 035 4980

614 035 4973

614 020 6562

614 017 3819

407 007 9904

405 012 2002

405 012 2002

405 012 2002

405 012 2002

401 058 3201

401 063 0608

614 240 8773

614 240 8780

614 240 9893

614 240 9893

614 240 9893

614 240 9909

614 240 9916

614 244 0155

614 244 1947

614 211 3202

614 245 7771

614 245 7788

HEADPHONE P.C.BOARDASSY

IARD ASSY

Descrir)tion

ASSY,PCB,GEQ

SOCKET,5P

SOCKET,9P

SOCKET,9P

SOCKET,8P

SOCKET,4P

PLUG,2P

DIODE GMAO1

TR 2SC1815-GR

TR 2SC1815-GR

TR 2SC1815-GR

TR 2SC1815-GR

OXIDE-MT

100

JA

OXIDE-MT

68 JA

SWITCH,PUSH,FUNCTION

SWITCH, PUSH,BASS.EXP .

VR,SLIDE,GEQ

VR,SLIDE

VR,SLIDE

VR,SLIDE,BALANCE

VR,SLIDE,MAIN

lW

lW

SOCKET,TO DECK,9P(CN912CN718)

SOCKET,TO TUNER,4P(CN916CN203)

SOCKET,TO DECK,5P(CN911CN717)

ASSY,CONNECTOR-S ,TO

MAIN,CN915

ASSY,CONNECTOR-S,TO

MAIN,CN914

Ref. No.

73

CN920

CN921

Part No.

614 242 3448

614 020 6579

614 035 1712

Descri~tion

ASSY, PCB,HEADPHONE

SOCKET,TO MAIN,5P

SOCKET,H.P W/SW

PT SECONDARY P.C.BOARDASSY

Ref. No. Part No.

Description

74

614 242 3455

ASSY,PCB,PT SECONDARY

CN918

614 020 6593 SOCKET,C0,7P

614 129 9099 LUG

J’

.-.-’-

.15-

Page 17

PARTS LIST

POWER SWITCH P.C. BOARD ASSY

! Ref. No. I

Part No.

I

De$crbtion

75

C4922

or

S4404

614 242 3516

lh404 033 3401

h404 000 1607

~614 018 8967

Lh614 208 4540

h614 123 2089

LfJ614017 8203

ASSY, PC8, POWER Sw

CERAMIC O,OIU Z CERAMIC O,OIU F 400V

SWITCH

FUSE HOLDER

TERMINAL

TERMINAL BOARD

;D MICO

Ref. No.

76

CN106

CN108

CN132

D103

or

D104

or

IC108

LCDO1

PL101

Q103

Q104

Q11O

X102

or

:D SWIT

Ref. No.

77

CN109

Slol

S102

S103

S104

S105

S106

S107

S109

Silo

S1ll

I

P.C.BOARDASS

Part No.

614 242 3493

614 227 7942

614 243 9845

614 243 9555

407 007 9904

407 012 4406

407 007 9904

407 012 4406

410 147 9109

614 240 8193

614 045 9647

405 011 8609

405 000 4407

405

011 8609

614 215 5523

614 215 5561

614 240 8292

614 230 7359

614 232 0242

H P.C.BOARD A!

Part No.

614 242 3509

614 221 9041

614 220 5655

614 220 5655

614 220 5655

614 220 5655

614 220 5655

614 220 5655

614 220 5655

614 220 5655

614 220 5655

614 220 5655

I

Description

ASSY,PCB,CD-MICOM

SOCKET,14P

PLUG,TO SW

ASSY,CONNECTOR-S,2P

DIODE GMAO1

DIODE 1SS133

DIODE GMAO1

DIODE 1SS133

IC CXP5078H-523Q

LCD

LAMP,12V lOOMA

TR 2SC1740S-S

TR DTC124ES

TR 2SC1740S-S

RESONATOR,CERAM,4, 19MHZ

RESONATOR,CERAM

SHEET,ORANGE

MOUNT-E

SHEET

;Y

Description

ASSY,PCB,CD-SW

SOCKET,FROM

MICON

SWITCH,TACT,MEMORY

SWITCH,TACT,BACK

SWITCH,TACT,FWD

SWITCH,TACT,PLAYiPAUSE

SWITCH,TACT,STOP

SWITCH,TACT,OPENiCLOSE

SWITCH,TACT,RANOOM

SWITCH,TACT,EDIT

SWITCH,TACT,REPEAT

SWITCH,TACT,INTRO

;PEAKER TERMINAL P.C.BOARD ASSY

m

Descrir)tion

ASSY,PCB,SP TERMINAL

SOCKET,3P

TERMINAL,SP,4P W/SHIELD

DECK P.C.BOARD ASSY

Ref. No.

Part No.

Description

79

614 242 48m

lAssy,PcB,DEcK

C985

403 081 1209 POLYPRO

0.018U J 100V

CNOO1

614 017 2102

PLUG,AUTO TAPE,3P

Ref. No.

Part No. Description

;NO02 614 017 2133 PLUG,MECHA,6P

;NO05 614 016 4084 PLUG,HIGH SPEED,2P

:NO06 614 020 8849 SOCKET,TAPE 0UT,3P

;NO07 614 020 6562 SOCKET,MOTOR,4P

:NO08 614 020 6548 SOCKET,STOP SW,2P

;NO09 614 223 0329

ASSY,CONNECTOR-S,A MECHA,4P

W/LEAD

:NO1O 614 223 0336 ASSY,CONNECTOR-S,B MECHA,7P

W/LEAD

;N717

614 017 2126

PLUG,AMP1,5P

;N718 614 017 2164

PLUG,AMP2,9P

)001

407 007 9904 DIODE GMAO1

>r

407 012 4406 DIODE 1SS133

)002 407 007 9904 DIODE GMAO1

)r

407 012 4406 DIODE 1SS133

)003 407 007 9904

DIODE GMAO1

or

407 01? 4406 DIODE 1SS133

)004

407 007 9904 DIODE GMAOI

>r

407 012 4406 DIODE 1SS133

1005

407 007 9904

DIODE GMAO1

>r

407 012 4406 OIODE 1SS133

)006

407 007 9904 DIODE GMAO1

~r

407 012 4406

DIOOE 1SS133

JO07

407 007 9904

DIODE GMAO1

Dr

407 012 4406 DIODE 1SS133

DO08

407 007 9904 DIODE GMAO1

c)r

407 012 4406 DIODE 1SS133

DO09

407 007 9904 DIODE GMAO1

or

407 012 4406 DIODE 1SS133

DOlO

407 007 9904

DIODE GMAO1

or

407 012 4406 DIODE 1SS133

DO1l

407 007 9904

DIODE GMAO1

or

407 012 4406 DIODE 1SS133

D012

407 007 9904 DIODE GMAO1

or

407 012 4406 DIODE 1SS133

D013

407 007 9904

DIODE GMAO1

or

407 012 4406 DIODE 1SS133

D014

407 007 9904

DIODE GMAO1

or

407 012 4406 DIODE 1SS133

D015

407 005 4505 DIODE DS442X

or

407 013 7109 DIODE 1S2473

D016

407 007 9904

DIODE GMAO1

or

407 012 4406

DIODE 1SS133

D017

407 007 9904

DIODE GMAO1

or

407 012 4406

DIODE 1SS133

D018

407 007 9904

DIODE GMAO1

or

407 012 4406 DIODE 1SS133

D019

407 007 9904

DIODE GMAO1.

or

407 012 4406

DIODE 1SS133

D099

407 007 9904

DIODE GMAO1

or

407 012 4406

DIODE 1SS133

D501

407 007 9904

DIODE GMAO1

or

407 012 4406

DIODE 1SS133

D502

407 007 9904

DIODE GMAO1

or

407 012 4406

DIODE 1SS133

D601

407 007 9904

DIODE GMAO1

or

407 012 4406

DIODE 1SS133

D602

407 007 9904

DIODE GMAO1

or

407 012 4406

DIODE 1SS133

0

ICOO1

409 020 9107 IC LC4069UB

or

409 051 3907 IC TC4069UBP

or

409 059 3206 IC UPD4069UBC

IC501

409 121 8702

IC LA3246

IC502

409 145 8405

IC UPC1330HA

IC521

409 016 870 1 IC LA3220

IC551

409 119 980

3 IC CXA1101P

Page 18

PARTS LIST

Ref. No.

L501

L502

or

L511

L512

L601

L602

or

L611

L612

L981

QOO1

;;02

;:03

or

;:04

;;05

or

$06

;;08

or

;:09

or

;:10

or

::01

or

:;02

or

::04

or

:;05

or

;;06

or

;;07

or

;;08

or

:;09

or

;;10

or

;:01

or

or

Part No.

614 029 3807

614 027 8546

014 210 3685

614 202 8865

614 029 3142

614 029 3807

614 027 8545

614 210 3685

614 202 8865

614 029 3142

614 212 0804

405 001 7001

405 005 2002

405 001 7001

405 005 2002

405

011 8609

405 012 2002

405 020 7204

405 001 7001

405 005 2002

405

011 8609

405 012 2002

405 020 7204

405 012 7403

405 013 1301

405 011 8609

405 012 2002

405 020 7204

405 011 8609

405 012 2002

405 020 7204

405 011 8609

405 012 2002

405 020 7204

405 011 8609

405 012 2002

405 020 7204

405 011 8609

405 012 2002

405 020 7204

405 011 8609

405 012 2002

405 020 7204

405 011 8609

405 012 2002

405 020 7204

405 011 8609

405 012 2002

405 020 7204

405 011 8609

405 012 2002

405 020 7204

405 011 8609

405 012 2002

405 020 7204

405 011 8609

405 012 2002

405 020 7204

405 011 8609

405 012 2002

405 020 7204

405 011 8609

405 012 2002

405 020 7204

Description

MX

COIL

CHOKE 3,3UH

INDUCTOR,FERITE

FILTER 6,8MH

MX

COIL

MX COIL

CHOKE

INOUCTOR,FERITE

FILTER

MX

COIL

TRANS,OSC

TR 2SA1015-GR

TR 2SA733-P

TR 2SA1015-GR

TR 2SA733-P

TR 2SC1740S-S

TR 2SC1815-GR

TR 2SC945A-K

TR 2SA1015-GR

TR 2SA733-P

TR 2SC1740S-S

TR 2SC1815-GR

TR 2SC945A-K

TR 2SC2001-K

TR 2SC2120-Y

TR 2SC1740S-S

TR 2SC1615-GR

TR 2SC945A-K

TR 2SC1740S-S

TR 2SC1815-GR

TR 2SC945A-K

TR 2SC1740S-S

TR 2SC1815-GR

TR 2SC945A-K

TR 2SC1740S-S

TR 2SC1815-GR

TR 2SC945A-K

TR 2SC1740S-S

TR 2SC1815-GR

TR 2SC945A-K

TR 2SC1740S-S

TR 2SC1815-GR

TR 2SC945A-K

TR 2SC1740S-S

TR 2SC1815-GR

TR 2SC945A-K

TR 2SC1740S-S

TR 2SC1815-GR

TR 2SC945A-K

TR 2SC1740S-S

TR 2SC1815-GR

TR 2SC945A-K

TR 2SC1740S-S

TR 2SC1815-GR

TR 2SC945A-K

TR 2SC1740S-S

TR 2SC1815-GR

TR 2SC945A-K

TR 2SC1740S-S

TR 2SC1815-GR

TR 2SC945A-K

TR 2SC1740S-S

TR 2SC1815-GR

TR

2SC945A-K

Ref. No.

Part No. Description

Q602 405

011 8609 TR 2SC1740S-S

or

405 012 2002 TR 2SC1815-GR

405 020 7204 TR 2SC945A-K

;;04 405

011 8609

TR 2SC1740S-S

or 405 012 2002 TR 2SC1815-GR

405 020 7204’ TR 2SC945A-K

;;05

405 011 8609

TR 2SC1740S-S

or 405 012 2002 TR 2SC1815-GR

405 020 7204 TR 2SC945A-K

;;06 405 011 8609 TR 2SC1740S-S

or

405 012 2002 TR 2SC1815-GR

405 020 7204 TR 2SC945A-K

:;07 405

011 8609 TR 2SC1740S-S

or

405 012 2002 TR 2SC1815-GR

405 020 7204 TR 2SC945A-K

;;08

405

011 8609 TR 2SC1740S-S

or 405 012 2002 TR 2SC1815-GR

405 020 7204 TR 2SC945A-K

;;09 405

011 8609 TR 2SC1740S-S

or 405 012 2002 TR 2SC1615-GR

405 020 7204 TR 2SC945A-K

;;81

405 012 2002 TR 2SC1815-GR

405 020 7204

TR 2SC945A-K

;;82 405

011 8609 TR 2SC1740S-S

or 405 012 2002 TR 2SC1815-GR

405 020 7204 TR 2SC945A-K

;;83 405 012 2002 TR 2SC1815-GR

405 020 7204 TR 2SC945A-K

:i84 405

011 8609 TR 2SC1740S-S

or

405 012 2002 TR 2SC1815-GR

405 020 7204 TR 2SC945A-K

;;85 405

011 1907 TR 2SC1627-Y

Svool 614 204 1871 SEMI V,R,2K

SV501 614 003 6183 SEMI V,R,1OK

SV502 614 003 6183 SEMI V.R,1OK

SV503

614 003 6183 SEMI V.R,1OK

SV504 614 003 6237 SEMI V.R,200K

SV601 614 003 6183 SEMI V.R,1OK

SV602 614 003 6183 SEMI V,R,1OK

SV603 614 003 6183 SEMI V.R,1OK

SV604

614 003 6237 SEMI V.R,200K

&614 130 6926 TUBE, FOR R981 20X2

TUNER MAIN P.C.BOARD ASSY

Ref. No. Part No. Description

60

614 245 9447 ASSY,PCB,TU MAIN

C231O

403 080 8902 POLYPRO 1500P J 100V

CF201

614 030 5630 IF

FILTER,REO

or 614 030 5647

IF FILTER,BLUE

or 614 030 5654 IF FILTER,ORANGE

or 614 030 5661 IF FILTER,BLACK

or

614 030 5678 IF FILTER,WHITE

CF203

614 030 5197 IF FILTER,455KHZ

CN201

614 020 6579 SOCKET*5P

CN202

614 020 6548 SOCKET*2P

CN203

614 017 2263 PLUG,4P

02101 407 012 4406 DIOOE 1SS133

407 007 9904 DIOOE GMAO1

:;301 407 012 4406 DIOOE 1SS133

or

407 007 9904 DIOOE GMAO1

F2101

614 228 4704

FILTER,LC

IC201

409 049 2103 IC TA7358P

i

-17-

Page 19

..,, .,,..:.... .

,., ,,..,.

,’.

.. :...,.

PARTS LIST

Ref. No.

IC202

L2102

L2103

L2151

L2152

SVR21

SW201

T2201

T2202

T2203

TP201

VC201

Part No.

409 163 3802

814 034 e74g

614 035 0012

0

614 221 6814

614 034 1638

614 204 1901

614 239 7343

614 030 4091

614 030 3742

614 030 3803

614 017 6964

614 239 2416

Description

IC LA1805-SS

VHF

COIL

VHF COIL

TRANS,RF

O.S.C

COIL

SEMI

V,R,1OK

SWITCH,SLIDE

I.F,T,FM

I.F.T,FM

I.F,T,AM

+,,

TERMINAL BOARD

Vc

ANTENNA P.C.BOARD ASSY

Ref. No.

Part No.

I

Description

81

I

614 245 94541 ASSY,PCB.ANT

CN211 614 020 6579 SOCKET,5P

CN213 614 239 1686 TERMINAL,4P

LED P.C.BOARDASSY

Ref. No.

Part No.

82

614 245 9461

CN212 614 020 6548

D2401

408 014 6504

Description

ASSY,PCB,LED

SOCKET,2P

LED SLZ-138B-17-T1

:D MAII

Ref. No.

83

CN101

CN102

CN103

CN104

CN105

IC101

IC102

IC104

IC105

Q101

Q102

Q105

Q106

Q107

SVR1l

TP101

TP102

TP103

TP104

TP105

Xlol

P.C.BOARDASSY

Part No.

614 240 7967

614 227 7935

614 017 3833

614 017 3826

614 227 7942

614 017 3871

409 245 4802

~400 2470000

409 261 0406

409 285 0307

405 002 0308

405 014 4509

405 014 4509

405 014 4509

405 014 4509

614 223 1906

614 221 6839

614 227 6839

614 227 6839

614 227 6B39

614 227 6639

614 236 1818

Description

ASSY,PCB,CD MAIN

SOCKET,FOR PICK,13P

PLUG,FOR MOTOR,4P

PLUG,FOR MOTOR,3P

SOCKET,FOR CTL,14P >,,

PLUG,FOR DG,8P

IC LA921OM

IC LA6524,PICK ACT MOTOR

DRV

IC LC7861E

IC TDA1311T,DAC

TR 2SA1037K-R,LASER DRV

TR 2SC2412K-R

TR 2SC2412K-R,DAC VREF REG

TR 2SC2412K-R

TR 2SC2412K-R

POTENTIOMETER,T.BAL ADJ,1OK

TERMINAL,RF

TERMINAL,FE

TERMINAL,TE

TERMINAL,GND

TERMINAL,PLL

RESONATOR

.,

STOP SWITCH P.C.BOARDASSY

Ref. No. Part No.

Description

614 242 4858

ASSY,P@,STOP SW

::058

014 020 8!548 SOcKEl, STOP SW,2P

S008 614 203 7911 SWITcH,STOP SW

i

-18-

Page 20

i

PARTS LIST & EXPLODED VIEW -

“URNTA

Ref. No.

PI

P2

P4

P5

P6

P7

P8

P9

Plo

Pll

P12

P13

P14

P15

P16

P17

PIE

P19

P20

P21

P22

P24

or

P25

P26

P28

P30

P31

P32

P33

P44

P45

P46

P47

,E MECHANISM (

Part No.

614 120 0118

411 001 0508

614 225 8866

614 225 8835

412 037 6700

614 225 8873

412 037 6809

614 225 8941

614 225 8965

412 029 9702

614 225 8842

614 225 8248

614 225 8217

614 201 8385

614 225 9009

614 202 0920

411 022 7807

411 023 4003

614 225 9085

411 002 7209

614 225 9016

614 225 9146

614 225 8811

614 225 8781

614 225 8170

614 225 8590

412 037 1002

614 225 8910

614 225 9023

614 225 8514

614 225 8774

614 230 6499

614 225 8804

411 022 7807

P.C.BOARDASSY

Ref.No. I Part No.

1

P23 614 225 8163

614 006 9655

614 016 8105

TONE AF

F

Ref.No,

P34

P35

P36

P37

P38

P39

P40

P41

P42

P43

I ASSY

Part No.

614 225 8231

614 225 8798

614 225 8675

614 225 9092

411 022 9900

614 225 8743

614 225 9061

614 225 8934

614 225 8736

614 226 1057

614 225 9115

614 001 7779

~M-x701s/ML)

Description

SPACER,45 ADAPTOR

RING E 6,

TURNTABLE,

,.

GEAR,CENTER GEAR

SPECIAL WASHER,TURNTABLE

BELT,FLAT

SPECIAL WASHER

LEVER,TRIP POWL

LEVER,TRIP CLUTCH

SPECIAL WASHER

GEAR

ASSY,SLIDE

ASSY,CHASSIS

SPRING COIL

LEVER,TRIP LEVER

SWITCH

SCR S-TPG PAN 2X6

SCR S-TPG PAN 3X1O

SPRING,TENS

:,

SCR PAN 3X16

,,

LEVER

swITcH,sLIDE,45/33 ‘r ,:

CLAMP,ARM ROCK

CUSHION,RUBBER

:!

ASSY,MOTOR

CHASSIS

,:

SPECIAL SCREW,MOTOR

FIX :

LIFTER

ROO,CUE ROD

KNOB,CUE KNOB

,,

CUSHION,RUBBER

ROD

FIXER

SCR S-TPG PAN 2X6

::

Description

ASSY,PCB

VR,1OK

!{,

PLUG,5P

Description ‘

ASSY,TONEARM

HOLDER

SHAFT

SPRING,TENSION

SCR S-TPG

PAN 2.3X5

SUPPORT

PIPE

HEAD SHELL

LUG

ASSY,WIRE

CARTRIDGE

NEEOLE CARTRIOGE “’

,,,.

,.,,,

,.

c

P5-+

P7

P6—

P40JP37-.A

.@-’-P8 P43-6@ ,

/i!!!-

22

pzos

<

21

P46

/’

6

1.-”

P26 ‘-”

;)’

,’,

Page 21

,.. .

,,

,,’

EXPLODED

,...

(

CM

CM

VIEW (CD MECHANISM)

CM1--$?

~-CM28

>

. ..

.

,

Q

,’

CM’57

:-CM” ‘iM54(MoT0R)

7

‘CH)

,.

Page 22

i

PARTS LIST (CD MECHANISM)

D MECI

Ref. No.

CMO1

;M02

;M03

CM04

CM05

CM06

CM07

CM08

CM09

or

CM1O

CM1l

CM12

CM13

CM14

CM15

CM16

CM17

CM18

CM19

CM20

CM21

CM22

CM23

CM24

CM25

CM26

CM27

CM28

CM29

CM30

,NISM (PM-DAD

Part No.

411 119 8908

411 087 4704

614 224 2056

411 119 8908

411 087 4704

614 224 2049

411 152 4301

614 237 9172

614 238 4794

614 243 6455

412 031 2104

411 152 4301

614 224 1998

412 045 4101

614 233 6311

614 224 2094

614 224 2018

412 031 2104

614 225 0884

614 224 2001

614 224 2032

412 031 2104

614 242 8665

614 237 8304

411 044 7205

614 018 9223

614 018 9223

614 202 5277

411 020 9803

614 224 1967

614 243 2594

x22s/sP)

Description

SCR S-TPG PAN 2X14,GEAR

FIX

tiASHER V 2X6X0,4,GEAR FIX

GEAR TRAY MOVE

SCR S-TPG PAN 2X14,GEAR

FIX

WASHER V 2X6X0.4,GEAR FIX

GEAR,TRAY

SCR

S-TPG PAN PCS 1.7X6,

GEAR

FIX

ASSY,GEAR,CLUTCH INNER

GEAR,CLUTCHOUTER

GEAR,CLUTCHOUTER

SPECIAL SCREW,SLIDE FIX

SCR S-TPG PAN PCS 1.7X6,

GEAR

FIX

GEAR,PICK SLED

SPECIAL WASHER,PICK GEAR

SLIDE,BASE UPiDOWN

SLIDE,TRAY

GEAR,PICK RACK UPPER

SPECIAL SCREW,GEAR FIX

SPRING,COMP,RACK BACK

GEAR,PICK RACK LOWER

GEAR,BASE/TRAY TIMING

SPECIAL SCREW,GEAR FIX

SPRING,TENS,GEAR TENSION

GEAR,TIMING

SCR PAN+SW 2X4,SLED MOTOR

SWITCH,LIMIT

SWITCH,TRAY OPEN

SPRING PLATE,CHUCKING

SCR S-TPG BRZ+FLG 3X6,

CHUCK BRACKET

BRACKET-M,CHUCKING

ASSY,PULLEY

Ref. No,

ZM31

ZM32

;M33

;M34

;M35

ZM36

ZM37

CM38

CM39

or

CM40

CM41

CM42

CM43

CM44

CM49

CM50

CM51

CM52

or

CM53

CM54

;:55

or

CM56

CM57

Part No.

411 022 7807

614 224 3176

411 022 7807

614 224 3183

614 233 6304

514 226 5536

411 020 9902

614 225 4820

614 228 5855

614 242 8641

412 031 2104

614 129 9136

411 021 5705

614 230 0411

614 229 4529

614 228 5084

614 247 1950

411 020 9803

614 239 1303

614 231 6047

614 232 2062

614 246 2959

614 246 2966

614 246 2973

614 246 2980

412 014 2800

614 125 6528

Description

SCR S-TPG PAN 2X6,BRACKET

BRACKET-M,TRAY GUIDE(L)

SCR S-TPG PAN 2X6,BRACKET

BRACKET-M,TRAY GUIOE(R)

LEVER,BASE

SPRING,COMP,BASE LEVER MOVE

SCR S-TPG BRZ+FLG 3X8,LEVER

ASSY,MOTOR,LOAOING/SLEO

CHASSIS,LOADING CHASSIS

CHASSIS,LOADING CHASSIS

SPECIAL SCREW,REINFORCEMENT

LUG,WIRE DRESS

SCR S-TPG BIN 3X6,LUG

FIX

SHAFT,PICK RAIL

SPRING,WIRE,PICK BACK

SPRING,TENS,BASE CHASSIS

PULL UP

ASSY,CHASSIS,W/SPINDLE

MOTOR+TURNTABLE

SCR S-TPG BRZ+FLG 3X6,BASE

CHASSIS FIX

PICKUP,LASER,PLASTIC

(SF-PIPS)

PICKUP,LASER,ALMINUM

(SF-90PS)

CORD, 13P,PICK UP

ASSY,CONNECTOR-S,4P,

SPINDLE/SLED MOTOR

ASSY,CONNECTOR-S,3P,

LIMIT/TRAY OPEN SWITCH

SPECIAL WASHER,GEAR FIX

CUSHION,MOTOR LEAD FIX

~.,,

.,

‘..:

.!:

.,!

,,

1

....

-21-

Page 23

EXPLODED

M76

T

VIEW (TAPE MECHANISM)

M97

&

-M52

‘1 ‘$

M53

\

w, 1.1-U

I L,ul .’.-..’. -.. --,

pl.J

‘M72

u

-M40

pM85

–Mel

8

M89

,,.,

-22-

Page 24

PARTS LIST

7APEMECHANISM [TM-Mc949TN/sP)

Ref.No.

Ml

M2

M3

M4

!45

M6

Ml

hf8

M9

M1O

Mll

M12

M13

t414

M15

M16

M17

M19

M20

M21

M22

M23

M24

M25

M26

M27

M28

M29

M30

M33

M34

M35

M38

M39

M40

M43

M44

M45

M46

M47

M49

M50

M51

M52

ht53

M55

M56

M57

Part No.

614 067 3258

614 201 1744

614 201 1737

614 196 0500

614 196 0555

614 196 0517

614 196 0524

614 196 0531

614 208 0313

614 152 1244

614 208 0320

614 151 7186

614 129 0669

614 152 1251

614 067 2770

614 152 1275

614 152 1282

614 140 1539

614 129 0676

614 152 1305

614 152 1268

614 024 1693

614 151 4703

614 211 6944

614 210 6822

614 146 5111

614 196 0470

614 210 3432

614 152 1299

614 151 5090

614 151 7162

614 210 3302

614 140 1614

614 069 2273

614 195 5087

614 204 8672

614 068 1871

614 151 8312

614 070 0916

614 134 9053

614 134 9046

614 205 1337

614 211 3868

614 211 3875

614 195 5094

614 122 9553

614 126 6831

412 026 1907

,

Description

SUB CHASSIS ASSY,BASE ASSY’

SLIDE,SWITCH ACTUATOR

SLIDE,PUSH BUTTON ACTUATOR

LEVER;REC BUTTON LEVER

LEVER,PLAY BUTTON LEVER

LEVER,REW BUTTON LEVER

LEVER,FF BUTTON LEVER

LEVER,STOP BUTTON LEVER

LEVER,PAUSE BUTTON LEVER

SPRING WIRE,P CONTROL

SPRING

LEVER,PAUSE LEVER (E)

SPRING COIL,PAUSE LEVER

SPRING

BOSS,PAUSE STOPPER

SPRING WIRE,BUTTON LEVER

SPRING(A)

CHASSIS ASSY,CHASSIS ASSY

SPRING WIRE,E ACTUATOR

SPRING

SPRING WIRE,P.S LEVER

SPRING

LEVER,E KICK LEVER

BOSS,PR STOPPER

SPRING WIRE,REC BUTTON

LEVER SPRING

SPRING WIRE,BUTTON LEVER

SPRING(B)

SWITCH,LEAF SWITCH MSW1541F

SPRING COIL,PLAY BUTTON

LEVER SP (S)

SLIDE,HEAD PANEL

SLIDE,HEAD PANEL

BRACKET TAPE GUIDE,HEAD

BASE

BRACKET HEAD,HEAD BASE

SPRING WIRE,PANEL(P)SPRING

SPRING WIRE,M CONTROL

SPRING

SPRING COIL,EH SPRING

SPRING COIL,AZIMUTH SPRING

LEVER PINCH ROLLER

ASSY,PINCH ROLLER ARM ASSY

LEVER,SENSING LEVER

PULLEY ASSY,RF CLUTCH ASSY

SQUARE BELT,RF BELT

FLYWHEEL ASSY,FLYWHEEL ASSY

FLYWHEEL DISK ASSY,FLYWHEEL

ASSY

SPRING PLATE,GEAR PLATE

SPRING

LEVER ASSY,GEAR PLATE ASSY

SEAR,CAM GEAR

GEAR,FF GEAR

SPRING COIL,BACK TENSION

SPRING

REEL ASSY,SUPPLY REEL ASSY

REEL ASSY,TAKE UP REEL ASSY

LEVER,SENSER

BRACKET MOTOR,MOTOR BRACKET

CUSHION,MOTOR RUBBER ‘,

SPECIAL SCREW,MOTOR COLLAR

SCREW

Ref. No.

M59

M60

M62

M64

M65

M66

M67

M68

M69

M71

M72

M73

M74

M75

M76

M77

M18

M79

M80

M81

M83

M84

M85

M87

M88

M89

M9.I

M92

M93

M94

M95

M97

M98

M1OO

Part No,

614 133 4127

614 126 6848

614 140 1522

614 151 8299

614 208 4069

614 208 4052

614 021 8831

614 211 3752

614 140 1506

412 026 1402

412 026 2003

412 026 2201

412 026 2300

412 026 1501

412 036 8200

412 031 6607

412 026 1709

412 031 7901

614 124 4594

412 023 0903

412 013 5000

412 026 1808

412 013 8902

614 196 9756

614 195 4424

614 209 3849

614 140 1676

614 139 8679

412 005 8101

614 129 0683

614 151 4758

614 197 0219

614 197 0202

614 208 0276

Description

SQUARE BELT,MAIN BELT

CUSHION,ANTI VIBRATION FELT

MAT

LEVER,EJECT SLIOE LEVER

SPRING PLATE,PACK SPRING

HEAD,PLAY,P.HEAD

HEAO,R/P,R.P.HEAD

MAGNETIC HEAD,E,HEAO

COMMUTATE MOTOR ASSY

LEVER,RECORD SAFETY LEVER

SPECIAL SCREW,C TAPPING

SCREW M2X3

SPECIAL SCREW,C TAPPING

SCREW M2X4

SPECIAL SCREW,P TAPP

BING

SCREW M2X5

SPECIAL SCREW,CAMERA TAPP

M2X4.5

SPECIAL SCREW,SCREW M2X6

SPECIAL SCREW,+- CUP SCREW

M2X7,5

SPECIAL SCREW,(+)BIND

SCREW

M2X3

SPECIAL SCREW,AZIMUTH SCREW

M2X7

SPECIAL SCREW,C TAPPING

SCREW M2X6

OROER SCREW,+C TAPP 2X5

SPECIAL SCREW,+C TAPP 2X5

SPECIAL WASHER,P WASHER CUT

1,2X3 8X0.3

SPECIAL WASHER,PW

CUT

1.45X3,8X0.5

SPECIAL WASHER,PW 2X3,5X0,3

SWITCH,REC SW

SWITCH,LEAF SWI

MSW-

17820MVD0

SWITCH,LEAF,LEAF SW MSW-

1664

LEVER,P KICK LEVER(B)

LEVER,P KICK LEVER(A)

SPECIAL SCREW,PK COLLAR

SCREW(A)

BOSS,COLLAR(B)

SPRING COIL,P KICK LEVER

SPRING

LEVER,SW LEVER

BOSS,SW LEVER COLLER

LUG,LUG

j.

Page 25

ii

[C BLOCK DIAGRAM

,.

CD SECTION

Iclo LA9210M (Servo Signal Processor)

PIN NAME 11/0 ] FUNCTION

No. I PIN NAME I 1/0 I

FUNCTION

NC

I

Non Connection

VEE

I

-5V

41

NC

Non Connection

42

JP- 1 -

Input of Track Jump Pulse Amplifier

43 JP + I

+ lnDut of Track

Jumo Puke Amr)lifier

t

3

4

E

Ill

IV Convert Input (from Photo Diode E)

F

II

I IV

Convert Input (from Photo diode F)

FN I IV Converter Ingut

44

THLD I I I Hold of

Output Voltage of Tracking Servo

45

I

TGL I I

] Track[no Gain Low

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

FO

I O I lV Converter Outcrut

46

I

TOFF I I Input For Off the Tracking Servo

47

TES O I Trackincj Error Sianal

TEAO

! O I Tracking Error Amplifw?r

CMJtpUt

VREF2 I

I Reference Voltaae 2 ,

48 HFL I O I Detect Track Signal

49

FZD

O I Detect S

Carve of Focus Error Sianal

VREF3 I I Reference Voltage 3

TES1 I

I Test Incwt

50

FOCS I

Input For Off the Focus Servo

51

CLV-

1 - Input of CLV Error Amplifier

52

CLV + I

+ Intwt of CLV Error Am Dlifier

ATSC

II+ Input of Anti Shock Detect Amplifier

ATSC-

1 I - Input of Anti Shock Detect Am Dlifier

TPA +

I

I ]- Input of Tracking Pulse Amplifier

TPA-

I

+ Input of Tracking Pulse Amplifier

53

SLCOIO ISliceLevelControlAmplifierOutput

54

EFMO I I ]EFMO

(RF) Sianal

TPAO O I Tracking Pulse Amplifier Output

TOFS

I

I

] lnDut for Trackina Offset

55

Al

Ill

EFMO

(RF) Signal

56 I

VDD

+ 5V

THDS I I Tracking Servo Hold Switch

TD +

I

I I Add the Track Jumo Pulse

57

PDO I + Input of VCO Control Amplifier

58

PDO-

1

- Input of VCO Control Amplifier

59

Vcoc

I VCO Control Amplifier Output

60

Vcoo

o VCO

OUtDUt

JPO o

I Track Jump Pulse Amplifier Output

SLEQ

I

I ] Input for Sled Servo Eaualizer

TDO o I Tracking Actuator Coil Driver Output

FDO

I

O I Focus Actuator Coil Driver OutOut

61

I

LF1

II

Input of Low Pass Filter

62

CLK I I I Clock

FD- 1 Input for Focus Actuator Coil Driver

FSW I I Focus Servo Switch

63

LASER I I I Laser Control Signal

64

66/60

I I I Select of DSP LC7866 / LC7860

k

25

26

27

NC I Non Connection

FEAO

I

O ] Focus Error Amplifier Output

65

I

NC

Non Connection

66

DF2

I I ] Incwt for Defect Pulse width Control

FE+ I + Input of Focus Error Amplifier

FD + I + Input of Focus Actuator Coil Driver

SPO

o CLV Error Amolifier Outaut

67

DF1

I Input for Defect Pulse width Control

68

I

PH3 I O I Defect Detect Timino

28

29

69

I

8H

I

I Track Detect Timing

70

PH

I Focus Detect Timina

30

31

sPo-

1 Input for Spindle Motor Driver

SPDO

o Spindle Motor Driver Output

VFF

-5V

71

I

GND

I

I Ground

72

RF SUM ]

O I RF SUM Am Dtifier Outout

32

33

73

I

RFS-

1

0 I IV Converter Output

74

LDO O ] Laser Diode ON

75

I

LDS I I I Input of Auto Laser Power Control

76

LDC I I I InDut of Auto Laser Power Control

E

36

37

38

39

40

SLSW

I

Sled Servo Switch

DEFO

o Defect Signal Output

2FREQ

I Inrwt for VCO

77

I

VDD

I I

+ 5V

78 FIN1 I I ] IV Convert Inout (From Photo Diode A + C)

79 I

FIN2 I I I IV Convert lnrmt (From Photo Diode B + D)

~—-,-. .. —-—.._ ,

DRF

I

o I Focusing Servo ON : High Level

80 I

VREF1 I I IReferenceVoltaae1

ICI02 LA6524 (Dual Motor & Actuator Coil Driver)

-24-

Page 26

IC BLOCK DIAGRAM

ICI04 LC7861E(Digital Signal Processor)

No

PIN

NAME

1/0

DESCRIPTION

w FL’;,1“01

DESCRIPTION

1

TESTI I For 1S1 testing, Not connecting normally.

2

AO I Pin for inputting the VCO output built in the

3

Al I LA921O.(8.6436MHZ) POO is the phase output of the EFM

4 Poo

o

signal. Set it to raise the frequency at +

31

32

33

34

35

SMP2 o

SMP1 o

LRCLK o

SMP

o

OFOUT o

Output of signal to OAC, Signal of Latch & L/R select,

Signal

for Sampling Hold

6

EQO

Input the HF

signalof 1 to 2V p-p to EFMIN, EFM signals

7 EFMO o

inmutually reverse phases are output from EFMO and EFMO

8 EFMIN

via the amplification limiter,

9

TEST2 I

For TEST. Normal time is non connection,

10

CLV + o Output for DISC MOTOR CONTROL.

11 CLW o Output for OISC MOTOR CONTROL.

CLV rough Servo time : Output ‘li-

12 VIP 0

Phase control time : Oulput”L.

13 FOCS

o Ou[put .1+. :

Lens pull up with slowly than stop the Focus

14

FST

o

Servo. 11=0 generate, it reset output of FOCS. For Iead-in of

—

1

36

37

38

39

40

41

~

For TEST. Normal time is non connection.

For output of signal that Comply with CO-ROM

C2FLCK I I

42

C2F

43

OOUT

o

Output of OIGITAL OUT

44 SBSY o

Synchronizing signal of sub-code block.

45

EFLGIo

For correction monitor of Cl, C2, single, double.

46

Pw

o I SFSY Is Synchronizing signal of sub-code & frame. Clock of

47

48

—

49

—

50

51

51

53

S4

—

55

—

&

57

—

2

SFSY O

SBCK

FSX

o

WRQ O

RWC

SQOUT O

COIN

CQCK

RES

MIL

LASER O

eighth send to S13CK then read out the sub.code of P, Q, R, S

Comply with command of track jump, it

oscillate kick Pulse,

16 HFL I

JP + & JP_. It jump the prescribed number of track (1,4,16,64).

Comply with command of track jump, It oscillate kick Puke,

17 TES I

Jp + & Jr, It

jump the prescribed number of track (1,4,16,64).

18 PCK o

PCK Monitor (4.3218MHz)

SYNC (FS of truth) detected from EFM signal = SYNC of

19 FSEQ

o

counter : ‘H- (Latch Output during In 1 frame)

20

TOFF

o

Comply with command of track jump, It oscillate kick Pulse,

21 TGL o

22

THLD

o

JP + & JP_. It jump the prescribed number of track (1.4,16.64).

23

TEST3 I For TEST. Normal time b non connection.

24 VOD

+ 5V

T, U, V, & W.

Output of Synchronizing signal (7.35KHz)

Oata sub-code Q pass the CRC check then WRQ do “H-. It

detect at errternal, Oata read out from SQOUT by send the

CQCK. RWC set the ‘H” by Micro Processor then It let

command by send with Synchronizing CQCK command data.

Turn on the Power Supply time : Once “L-

Oata of SC?OUT want at the LBS first time : M / L set the ‘L’

This output can control at Serial Control from Micro Processo

58

—

16M

o

16M Output (16.9344 Mtiz)

4M

o

4M output (4.2336MHz)

CONT

o

This output can control at Serial Control from Micro Proces$o

LASER I

For LSI Setting. Normal time is non connection.

Chip select Terminal. This terminal ‘L. : LC7866 is active

Cs

I

(Internal Resistor : Pull Oown)

XIN

I

Connection Terminal of crystal oscillation (16.9344MHz)

XOUT

o

25

Jp+

o

Comply with command of track jump, it oscillate kick Pulse,

26

JV

o

Jp + & Jp_, It jump the prescribed number of track (1,4,16,64).

27

oEMO

I

For adjustment of production process. Sound on function.

28 TESTIS

I For TEST. Normal time is non connection.

29 EMPH

o Output Is “H” time, it need de-emphasis

30

DFOFF I

Digital filter ON/OFF switch.The filter b OFF when the output

is [H],

59

—

62

63

64

—

43218 t 9232861245

Y~w

CXCLK

Cnsv

C2F

rfculJ1

L

-EEn---

‘Wi=r@=lll’”

Cal,

crmF

W m

#

-25-

“.”..,.

:.: ,.’.

.,. .

. . . . . . . ..

Page 27

i

IC BLOCK DIAGRAM

1CI05 TDA1311T( Filter

for Digital Audio)

I

LEFT INPUT FfGISTER

.

LEF 1 OUTPUT REGISTER

-- —

LEFT BIT SWITCHES

10L

t

t

1i&mE!.QTED

SOURCE

d==

VOR

0

1

8

2

DIL8 ‘7

3

6

4

5

;.

3.

4.

5.

6.

:

BCK

Ws

DATA

GND

Bit clock in~t

Word seleci input

Data input

Ground

Supply voltage

Left channel output

Not connected

Right channel output

VDD

ICI08Pin Function of CXP5078-523Q (Micro’ Processor)

No

I

Pin Name n/01

Description

1 SEG18

o

NOT USED

I

No Pin Name 11/01

Description

I

41 OUB IN

REC STATE SIGNAL INPUT FROM TAPE OECK

I

OURING REC PAUSE : “H- LEVEL

42

XRST

o =T CONTROL SIGNAL OF D$P

1!

2 SEG17 o

NOT USEO

3 SEG16 o

NOT LKEO

4 I SEG15

I

o I LCO SEGMENT SIGNAL 15

I

I

43 I NC

I

I NON CONNECTION (OPEN)

I

II

5 S[G14 0

LC12 SEGMENT SIGNAL 14

6 SEG13

I

o

LCD SEGMENT SIGNAL 13

44

CC3CK

I

o

CQCK SIGNAL TO LC7866E

45

COIN

o I COIN SIGNAL TO LC7866E

i

7

SEG12 o

LCD SEGMENT SIGNAL 12

8 SEG1l o

LCO SEGMENT SIGNAL 11

9 SEG1O o

LCO SEGMENT SIGNAL 10

46

SC30UT

I

SC20UT SIGNAL FROM LC7866E

47 RWC o

RWC SIGNAL TO LC7866E

48 WRQ

I WRC2 SIGNAL FROM LC7866E

10

I SEG9 o I LCD SEGMENT SIGNAL 9

11

SEG8 o LCD SEGMENT SIGNAL 8

I

49 SLEO IN o

TRAY 0pEN (SLED INTERNAL) DIRECTION

50 SLED OUT

o

TRAY CLOSE (SLED OUTER) OIRECTION

51

oRF

I DRF SIGNAL FROM LA921OM

52 CD FUNC

I

CO FUNCTION SIGNAL (“H” PULSE)

<a PC?

I

NOT USEO

12

I SEG7 o

LCD SEGMENT SIGNAL 7

13 I SEG6

I

o

I.CO SEGMENT SIGNAL 6

14

SEG5 o

LCO SEGMENT SIGNAL 5

15

SEG4 o

LCD SEGMENT SIGNAL 4

16

SEG3 o

LCD SEGMENT SIGNAL 3

17

SEG2

o

Lco SEGMENT SIGNAL 2

18

SEG1 o

LCD S.EGMENT SIGNAL 1

4

54

PF3

I

NOT USEO

55 OPEN SW

I

OPEN SWITCH SIGNAL

56 LIMIT SW

I

LIMIT SWITCH SIGNAL

57 C STOP

I

CALL STOP PULSE SIGNAL (LEVEL ‘H”)

58

POWER

I

POWER ON SIGNAL( “H” PULSE)

59 CREC LEO

o

COMPUTER REC LED SIGNAL

hn PI Av l-l

0

NOT USEO

19

I SEGO o

NOT USEO

20 COM3

o

LCD COMMON 3

I

I

21 I COM2 o [ LCD COMMON 2

22

COM1

o

LCO COMMON 1

23

COMO o

LCO COMMON O

24 VLC1 LCD BIAS POWER SOURCE 1

25 VLC2 LCD BIAS POWER SOURCE 2

61

PY2

1

NOT USEO

62

PY3

I

NOT USED

63 c COPY

COMPUTER COPY SIGNAL TO TAPE OECK

o

‘H” PULSE : 150

msec

6A FIINC (1

c1

CO FUNCTION SIGNAL

26

V1C3

LCD BIAS POWER SOURCE 3

27 VL

o

NOT USEO (LEVEL “L”)

28 RMC I

REMOCON SIGNAL INPUT

29 INT

I

NOT USED (!/$$)

30

XTAL

o

4,19 MHz OSCILLATION

31

EXTAL

I

4.19 MHz OSCILLATION

. . ----

65 LATCH

I

0

I LATCH SIGNAL TO OAC

66 I OFF IFD