Page 1

ECOi

Variable Refrigerant Flow (VRF),

Multi-Zone, Heat Pump & Heat Recovery Systems

TM

Page 2

INTRODUCTION....................................................2

ECOi™ Building Your Business..................................3

ECOi™. Your Building Life Tool..................................4

We are committed

to becoming an

indispensable element

in the lives of people

all over the world.

SANYO OUTDOOR Units..................................6

3 Pipe VRF Heat Recovery ................................6

ECOi Mini VRF...............................11

2 Pipe VRF Heat Pump..............................12

SANYO INDOOR Units.....................................17

KHX series.....................................17

THX series.................................18

AHX series.................................19

XMHX series..............................20

XHX series................................21

UMHX series..............................22

UHX series.................................23

DHX series.................................24

FHX/FMHX series.........................25

SANYO Control System.................................26

ACCESSORIES....................................................30

SERVICES.............................................................31

Company Information................................................32

Page 3

SANYO's Brand Vision

SANYO HVAC consistently builds new ideas to help build

your business. By delivering multi-zone options, space-saving

and environmentally friendly designs, our solutions are evolving,

improving solutions.

Flexible Combinations: ECOi allows multiple indoor unit

combinations that provide you with the utmost in flexible

solutions. The system also allows multiple unit connectivity

providing up to 130% of the total capacity of the condensing

unit. This provides for up to 17 indoor units connected to one

condensing unit.

Inverter Control Compressor: All ECOi systems utilize highly

advanced inverter controlled compressor technology. By varying

the rotational speed of the compressor, the inverter control can

precisely match the amount of refrigerant being delivered to

the needs of each zone. This intelligent approach helps realize

excellent efficiencies during partial-load conditions. This allows

all occupants to enjoy consistent room temperature, regardless

of any increases or decreases in the heat load during the day.

ECOi quite simply knows what you need, and when you need

it throughout the day. And even better, it does so with energy

efficiency in mind.

Lower running and life cycle costs: SANYO Ecoi VRF

systems are amongst the most efficient VRF systems on the

market, offering COPs in excess of 4.0 at full load conditions.

The system is also designed to make sure that we reduce the

running cost of each system by using our unique road map

control routine to ensure that the most efficient combination

of compressors are running at any one time. Improved defrost

sequencing also reduces running cost by defrosting each out

door coil in turn when conditions allow.

INTRODUCTION

ECOi™.

Building

Your Business.

SANYO has a proud global heritage and over 25 years

experience in the United States. By delivering more multi-zone

options, space-saving designs and offering solutions protect

the environment. Our products reduce your energy costs and

create a more comfortable environment.

Today every conditioning solution must answer multitudes

of project needs, including tighter budgets, flexibility, energy

efficiency and ease of installation, to name a few. ECOi is the

answer. It’s an all-in-one solution that responds to the many

commercial and residential applications.

03

Page 4

For the Living

Inside & Out.

Contractors. Building Support.

At SANYO, we realize contractors are looking for turnkey

installation and support. ECOi™ is quite simply the perfect

building solution. With its modular design and ease of

installation, it’s a solution that can grow with any building

project. In fact, ECOi may just make you remember why you

got into the business in the first place.

Engineers. Designing Confidence.

ECOi™ is absolute confidence. Its flexibility allows

multiple applications and installation configurations. With

a maximum pipe length of up to 984 feet and up to 40

units connected to one outdoor system you can engineer

a perfect solution for all your project needs. ECOi is a

superior modular option that provides for floor-by-floor

commissioning.

Architects. Design Freedom.

Now There’s An Idea.

Of course, nobody understands this more than the

architects who design them. That’s why the ECOi HVAC

system provides more freedom to meet any design need.

grow with you. As remodeling occurs and building extensions are

planned, ECOi’s modularity lets you simply add on to the system.

With intelligent controllers, VRF technology and R410A refrigerant,

ECOi guarantees continued energy savings and environmental

friendship for years to come.

ECOi™.

Your Building

Life Tool.

ECOi has a number of diverse features to meet all your

conditioning needs, including: Flexible Combinations: ECOi

allows multiple indoor unit combinations that provide you with

the utmost in flexible solutions. The system also allows multiple

unit connectivity providing up to 130% of the total capacity of the

condensing unit. This provides for up to 17 indoor units connected

to one condensing unit.

With space saving designs, environmental friendship and

ultimate efficiency, you can design your vision first then

marry our system fluidly within your plans.

Owners & Tenants.

With immediate response to changing room capacity

heat loads and varying sun exposures throughout the day,

everybody stays cool and comfortable. ECOi also ensures

individual zone temperature control so each office or

room can be adjusted for personalized comfort. ECOi can

04

Inverter Control Compressor: All ECOi systems utilize highly

advanced inverter controlled compressor technology. By varying

the rotational speed of the compressor, the inverter control can

precisely match the amount of refrigerant being delivered to

the needs of each zone. This intelligent approach helps realize

excellent efficiencies during partial-load conditions. This allows all

occupants to enjoy consistent room temperature, regardless of any

increases or decreases in the heat load during the day. ECOi quite

simply knows what you need, and when you need it throughout the

day. And even better, it does so with energy efficiency in mind.

Page 5

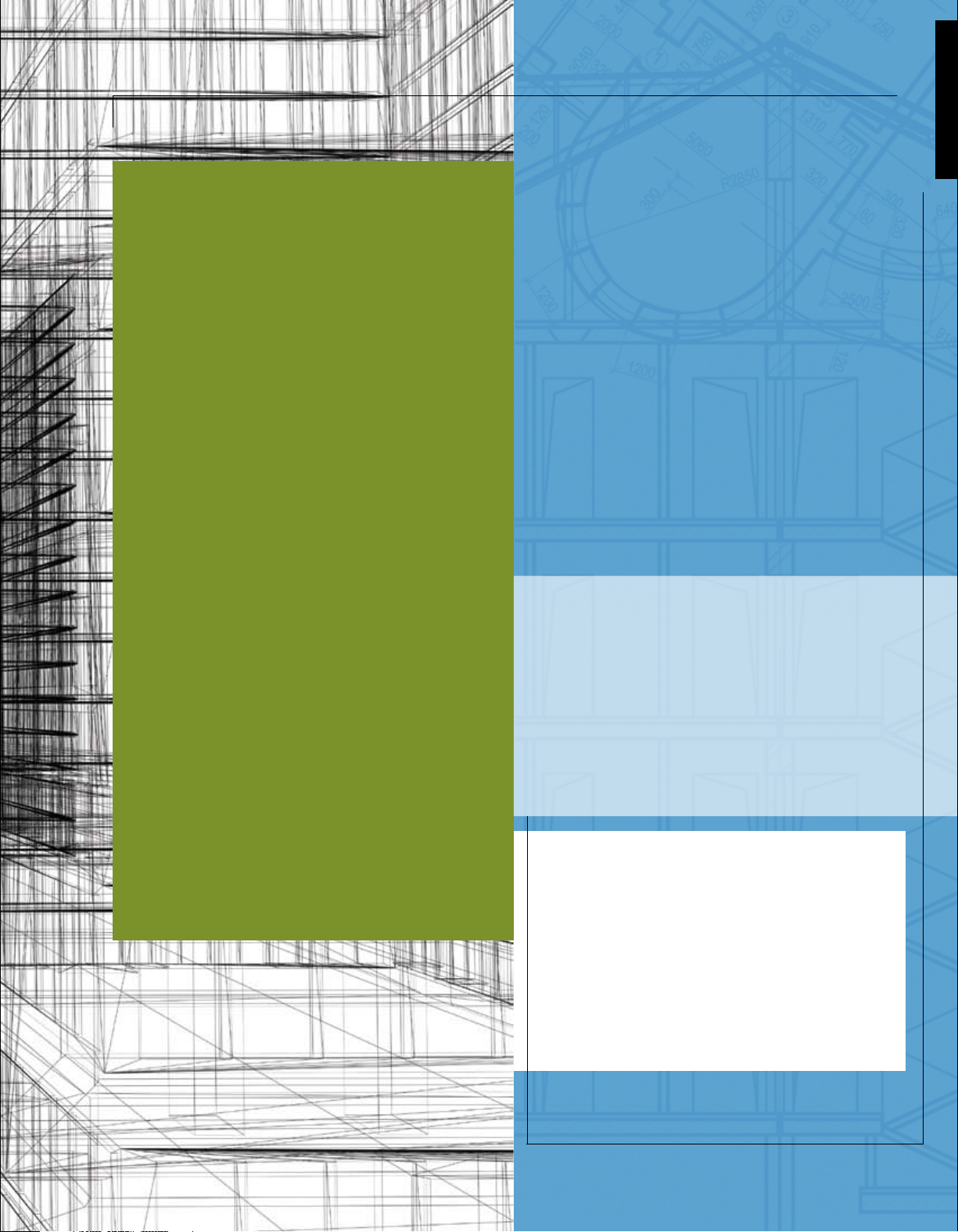

3-Way ECOiTM VRF Heat Recovery

Commercial of fice buildings are subject to fluctuating heat levels generated from electronic office equipment,

lighting and varying occupant levels. Also, hotels, nursing homes and other commercial living spaces often have

times when occupants will want either heating or cooling at the same time. The heat recovery system offers the

perfect solution for stabilizing the air temperature by providing all the features of a heat pump system - and the

added flexibility of simultaneous cooling and heating from one refrigerant pipe network.

CHDZSERIES

INTRODUCTION

For the buildings requiring simultaneous heating and cooling,

SANYO 3-Way ECOi™ system provides the perfect solution

TM

2- Way ECOi

SANYO’s Combined ECOi 2-Way conditioning solution offers superior heating and cooling coupled with cost effective

installation. A smar t conditioning solution for large capacity jobs.

Cooling Heating

VRF Heat Pump

CHDXSERIES

0505

Page 6

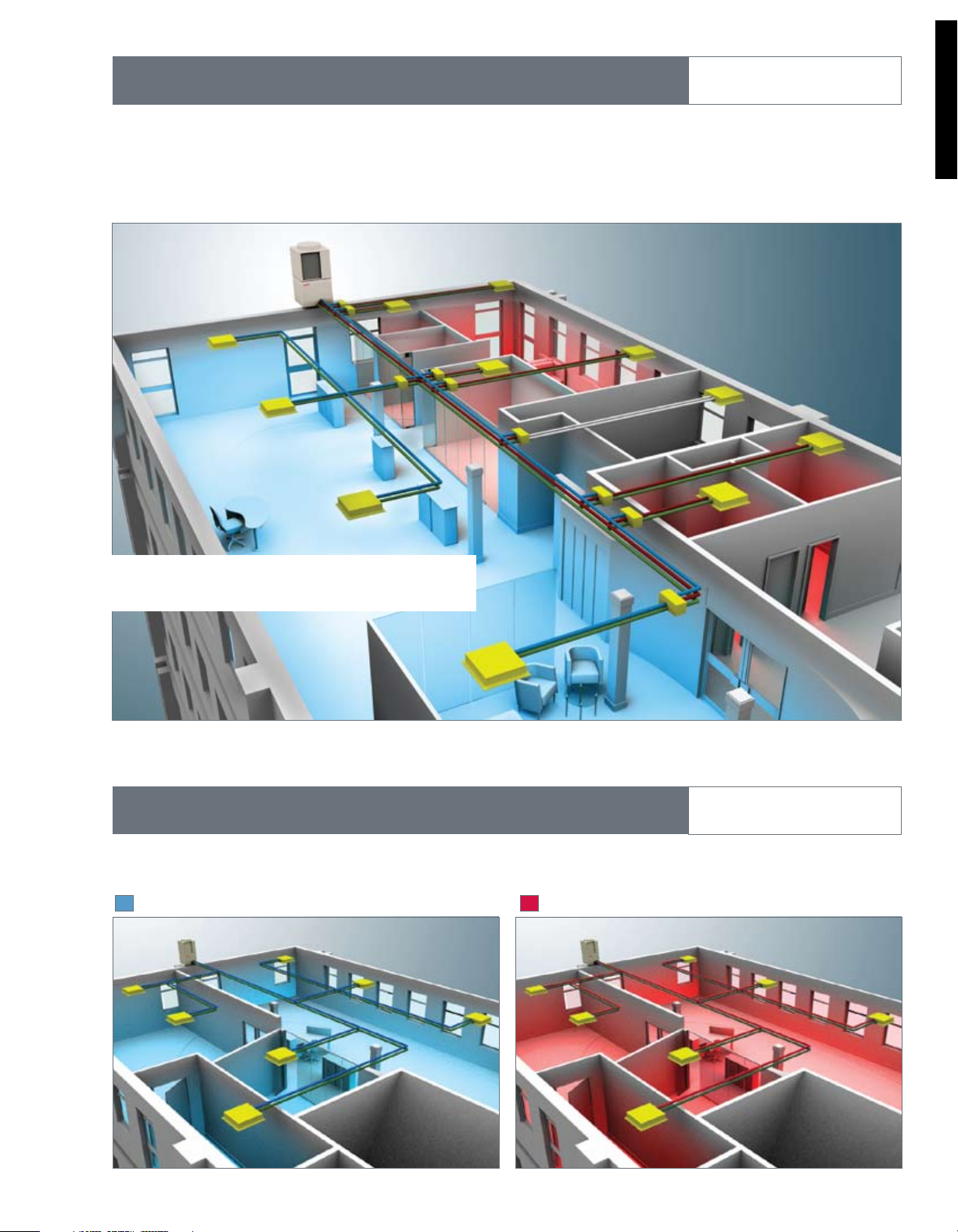

CHDZSERIES

SANYO’s ECOi Heat Recovery series offers

the ability to heat and cool different

zones simultaneously.

SANYO was the first manufacturer in the

world to develop this energy saving heat

recovery solution. Offering all the features

of our standard heat pump series, the 3-Way

solution can offer even higher energy savings

for the building owner.

3-Way ECOi VRF Heat Recovery

CHDZ 07263 / CHDZ (R)07263

CHDZ 09663 / CHDZ (R)09663

KEY FEATURES:

* “ECO Friendly” R410A Refrigerant

* Heat Recovery system simultaneous heating-cooling

* One Outdoor Unit Connects As Many As 17 Indoor Units

(50%-130% ratio of indoor to outdoor capacity)

* Heat Pump

* One Outdoor Unit Connects As Many As 17 Indoor Units

(50%-130% ratio of indoor to outdoor capacity)

* CHDZ07263 includes one inverter driven Rotary compressor

* CHDZ09663 includes one inver ter driven Rotary compressor

and one AC Constant Speed Scroll Compressor

* Operating Range (Outdoor Ambient)

- Cooling 14 FDB to 113 FDB

- Heating -4 FWB to 59 FWB

* Ultra Quiet Operation As Low As 51.5dB (a)

* Variable Speed DC Fan Motor (ESP adjustable to 0.25” wc)

* Flexible Piping Design:

- 984 Feet - Maximum Total Liquid Line

- 492 Feet - Maximum Outdoor To Most Distant Indoor Unit

- 164 Feet - Maximum Vertical Between Indoor and Outdoor

(Outdoor Above Indoor)

- 131 Feet - Maximum Vertical Between Indoor and Outdoor

(Outdoor Below Indoor)

MODELS

CHDZ 07263

CHDZ R07263

CHDZ 09663

CHDZ R09663

(Type: Nominal Cooling Capacity, etc)

72,000 BTU Heat Recovery 208-230V/60 HZ 3

72,000 BTU Heat Recovery

With Salt Protection - Special Order

96,000 BTU Heat Recovery 208-230V/60 HZ 3

96,000 BTU Heat Recovery

With Salt Protection - Special Order

208-230V/60 HZ 3

208-230V/60 HZ 3

* NOTE: *460 Volt Step Down Transformers (460-230) available for 6 and 8 ton condensers

06

Volt PH

Page 7

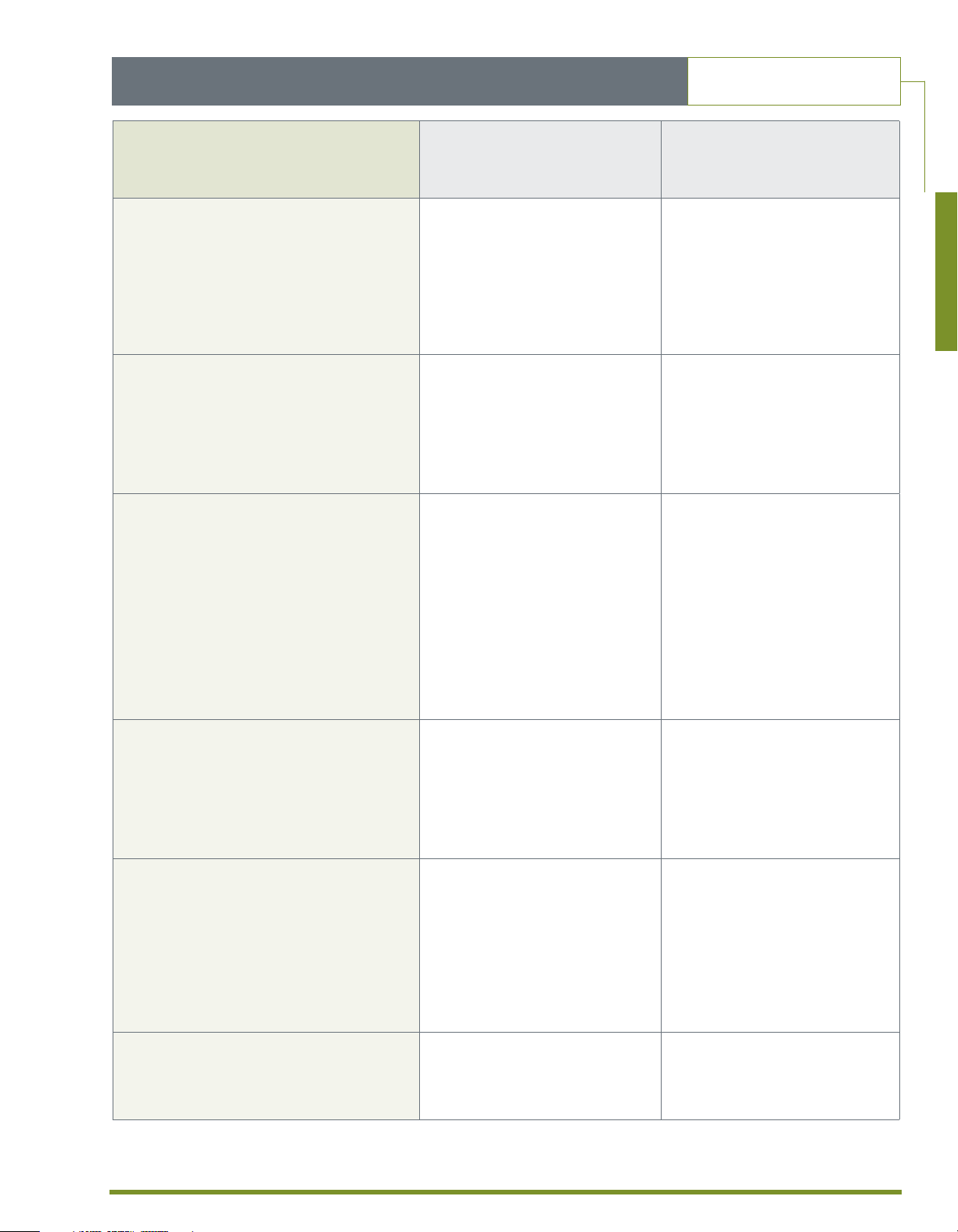

3-Way ECOi VRF Heat Recovery

CHDZSERIES

DESCRIPTION

PERFORMANCE

COOLING CAPACITY: BTU/H

POWER INPUT: KW

HEATING CAPACITY: BTU/H

POWER INPUT: KW

ELECTRICAL RATINGS

VOLTAGE RATING

COOLING RUNNING AMPERES

HEATING RUNNING AMPERES

MIN. CIRCUIT AMPACITY

MAX. CIRCUIT AMPACITY

COMPRESSOR

TYPE - QUANTITY

MOTOR OUTPUT

REFRIGERATION OIL TYPE

REFRIGERATION OIL CHARGE AMOUNT

CRANKCASE HEATER

REFRIGERANT AMOUNT AT SHIPMENT

REFRIGERANT CONTROL

DEFROST METHOD

HEAT EXCHANGER

CAPACITY CONTROL

CHDZ (R)

72,000

5.3

81,000

5.79

208 - 230 V

15.1 - 14.2 A

16.5 - 15.5 A

24 A

40 A

Inverter Driven Rotary Type

4.1 kw

FV68S (Ether oil - PVE)

1.4 gal

25 w

R410A - 25.9 lbs

Electronic expansion valve

Reverse-cycle, outdoor unit cycle

Aluminum plate fin / Copper tube

10-100%

07263 CHDZ (R) 09663

96,000

7.75

108,000

8.6

SANYO OUTDOOR

208 - 230 V

23.2 - 21.6 A

25.4 - 23.7 A

34 A

45 A

Inverter Driven Rotary 1 Fixed Scroll Hermetic

(2.7 + 3.5) kw

FV68S (Ether oil - PVE)

1.96 gal

25 + 32 w

R410A - 25.9 lbs

Electronic expansion valve

Reverse-cycle, outdoor unit cycle

Aluminum plate fin / Copper tube

10-100%

FAN DEVICE

TYPE - QUANTITY

MOTOR OUTPUT

PROTECTIVE DEVICES

CFM

EXTERNAL STATIC PRESSURE

TUBING

REFRIGERANT TUBING GAS TUBE

REFRIGERANT TUBING LIQUID TUBE

REF. TUBING DISCHARGE TUBE

REFRIGERANT TUBING BALANCE TUBE

EXTERNAL AIR TEMP. OPERATION RANGE

OPERATION SOUND (HI)

UNIT DIMENSIONS

Inches (") / lbs.

Color (Munsell code)

Propeller fan x 1

0.7 kw

High pressure switch, overcurrent (CT method)

5.300

0.04 / 0.25

3/4" (Brazing)

ø3/8" (Brazing)

ø5/8" (Brazing)

ø3/8" (Flare)

Cooling: 14 to 109 (DB) / Heating: -4 to 59 (WB) °F

54.5 (Quiet mode: 51.5) dB-A

81.5"/ 35"/ 35"/ 573 lbs.

Height/ Width/ Depth/ Net Weight

Silky shade (1y 8.5/0.5)

Propeller fan x 1

0.7 kw

High pressure switch, overcurrent (CT method)

5.650

0.04 / 0.25

ø7/8" (Brazing)

ø3/8" (Brazing)

ø3/4" (Brazing)

ø3/8" (Flare)

Cooling: 14 to 109 (DB) / Heating: -4 to 38 (WB) °F

55.0 (Quiet mode: 52.0) dB-A

82"/ 35"/ 35"/ 672 lbs.

Height/ Width/ Depth/ Net Weight

Silky shade (1y 8.5/0.5)

(R) indicates with salt protection - Special Order

* NOTE: *460 Volt Step Down Transformers (460-230) available for 6 and 8 ton condensers

07

Page 8

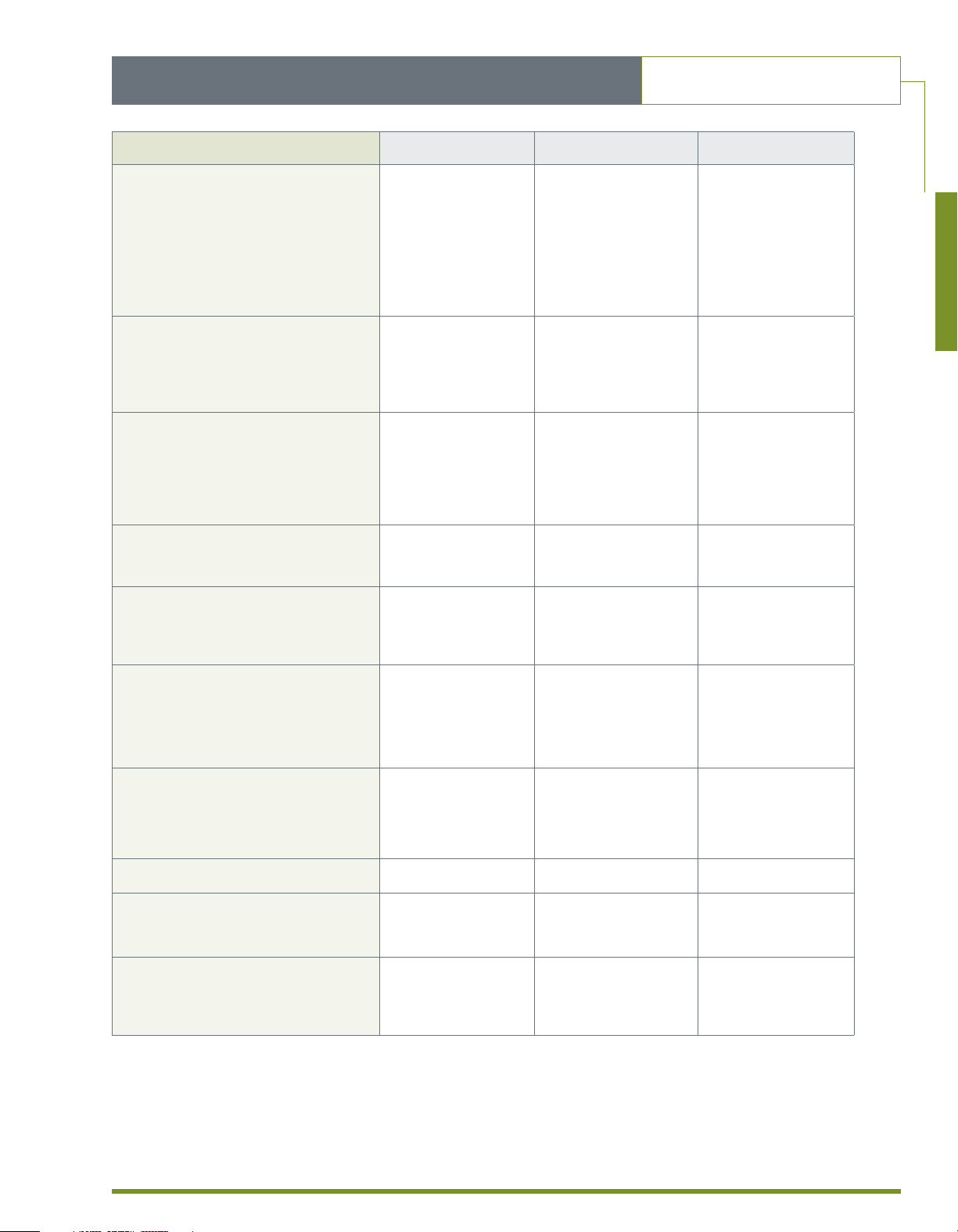

WCHDZSERIES

3-Way ECOi VRF Heat Recovery Combined Units

SANYO’s Combined ECOi 3-Way conditioning solution offers

superior heating and cooling coupled with cost effective

installation. Providing a single refrigerant pipe network means

there’s only one penetration into the building and ultimately

less piping material required, saving you time and money.

A smart conditioning solution for large capacity jobs that

require simultaneous heating and cooling.

WCHDZ 14463 / WCHDZ 16863 / WCHDZ 19263

WCHDZ 21663 / WCHDZ 24063

WCHDZ 26463 / WCHDZ 28863

KEY FE ATURES:

* Three-Way Heat Recovery

* Combine 3 outdoor units up to 24 tons

* “ECO Friendly” R410A Refrigerant

* 208/230V, 3 Phase, 60Hz

* Multiple Compressors For Extra Reliability and Partial Redundancy

* Operating Range (Outdoor Ambient)

-Cooling 14 FDB to 113 FDB

-Heating -4 FWB to 59 FWB

* Ultra Quiet Operation As Low As 52dB(a)

* Variable Speed DC Fan Motors

* Flexible Piping Design:

- 984 Feet - Maximum Total Liquid Line

- 492 Feet - Maximum Outdoor To Most Distant Indoor Unit

- 164 Feet - Ma ximum Vertical Between Indoor and Outdoor

(Outdoor Above Indoor)

- 131 Feet - Maximum Vertical Between Indoor and Outdoor

(Outdoor Below Indoor)

WCHDZ HEAT RECOVERY COMBINED SERIES.

SYSTEM

WCHDZ 14463

WCHDZ

WCHDZ

WCHDZ

WCHDZ

WCHDZ 26463 CHDZ 09663

WCHDZ 28863 CHDZ 09663

16863

19263

21663

24063

Outdoor Unit Cooling & Heating Power input Control Range

CHDZ 07263

CHDZ 07263

CHDZ 09663

CHDZ 09663

CHDZ 07263

CHDZ 07263

CHDZ 09663

CHDZ 07263

(quantity of 2) 144,000 & 162,000 BTU/H 10.56/ 11.58 kW 6 - 100%

168,000 & 189,000 BTU/H 12.97/ 14.39 kW 6 - 100%

(quantity of 2) 192,000 & 216,000 BTU/H 15.38/ 17.2 kW 6- 100%

(quantity of 3) 216,000 & 243,000 BTU/H 15.84/ 17.37 kW 6 - 100%

(quantity of 2)

(quantity of 2)

(quantity of 3)

240,000 & 270,000 BTU/H 18.25/ 20.18 kW 6- 100%

264,000 & 297,000 BTU/H

288,000 & 324,000 BTU/H

20.66/ 22.99 kW 6 - 100%

23.07/ 25.8 kW 6 - 100%

(R) indicates with salt protection - Special Order

* NOTE: *460 Volt Step Down Transformers (460-230) available for 6 and 8 ton condensers

08

Page 9

3-Way ECOi VRF Heat Recovery Combined Units

WCHDZSERIES

DESCRIPTION

PERFORMANCE

COOLING CAPACITY: BTU/H

POWER INPUT: KW

HEATING CAPACITY: BTU/H

POWER INPUT: KW

COOLING MODE NOMINAL CONDITIONS

INDOOR: °F WB/ °F DB

OUTDOOR: °F DB

PIPE LENGTH: FEET

LEVEL DIFFERENCE: FEET

HEATING MODE NOMINAL CONDITIONS

INDOOR: °F DB

OUTDOOR: °F DB/ °F WB

PIPE LENGTH: FEET

LEVEL DIFFERENCE: FEET

OPERATING RANGE

COOLING: °F DB

HEATING: °F WB

COMPRESSOR

TYPE/QUANTITY

CAPACITY CONTROL RANGE: %

WCHDZ

includes (1) CHDZ07263

and (1) CHDZ07263

144,000

10.56

162,000

11.58

80/67

95

25

0

70

47/43

25

0

14 to 113

-4 to 59

2 Inverter driven Rotary

6 - 100%

14463 WCHDZ 16863 WCHDZ 19263

includes (1)CHDZ07263 and

(1) CHDZ09663

168,000

12.97

189,000

14.39

80/67

95

25

0

70

47/43

25

0

14 to 113

-4 to 59

2 Inverter driven Rotary

& 1 fixed speed scroll

6 - 100%

includes (1) CHDZ09663

and (1) CHDZ09663

192,000

15.38

216,000

17.2

80/67

95

25

0

70

47/43

25

0

14 to 113

-4 to 59

2 Inverter driven Rotary

& 2 fixed speed scroll

6- 100%

SANYO OUTDOOR

FAN

TYPE/QUANTITY

FAN MOTOR OUTPUT: (KW)

EXTERNAL STATIC PRESSURE

POWER SUPPLY

V/PH/HZ

MINIMUM CIRCUITS AMPS (MCA): (A)

MAX. OVERCURRENT PROTECTION (MOCP): (A)

WEIGHT: (LBS)

COIL:

COIL FACE AREA:(SQ. FT.)

NUMBER OF ROWS:

PROTECTION DEVICES

HIGH PRESSURE SWITCH/OVERCURRENT

(CT METHOD)

CRANKCASE HEATERS:(W)

1 Propeller (ea)

0.7 kW (ea)

.04 / .25

208 - 230/ 3/ 60

52

80

1168 1267 1366

29.5(ea)

4(ea)

Yes

25 + 25

1 Propeller (ea)

0.7 kW (ea)

.04 / .25

208 - 230/ 3/ 60

60

85

29.5(ea)

4(ea)

Yes

25 + 25 + 32

1 Propeller (ea)

0.7 kW (ea)

.04 / .25

208 - 230/ 3/ 60

68

90

29.5(ea)

4(ea)

Yes

25 + 32 X 2

EACH OUTDOOR UNIT REQUIRES A SEPARATE ELECTRICAL FUSED DISCONNECT,

SEE INDIVIDUAL OUTDOOR REQUIREMENTS.

(R) indicates with salt protection - Special Order

* NOTE: *460 Volt Step Down Transformers (460-230) available for 6 and 8 ton condensers

09

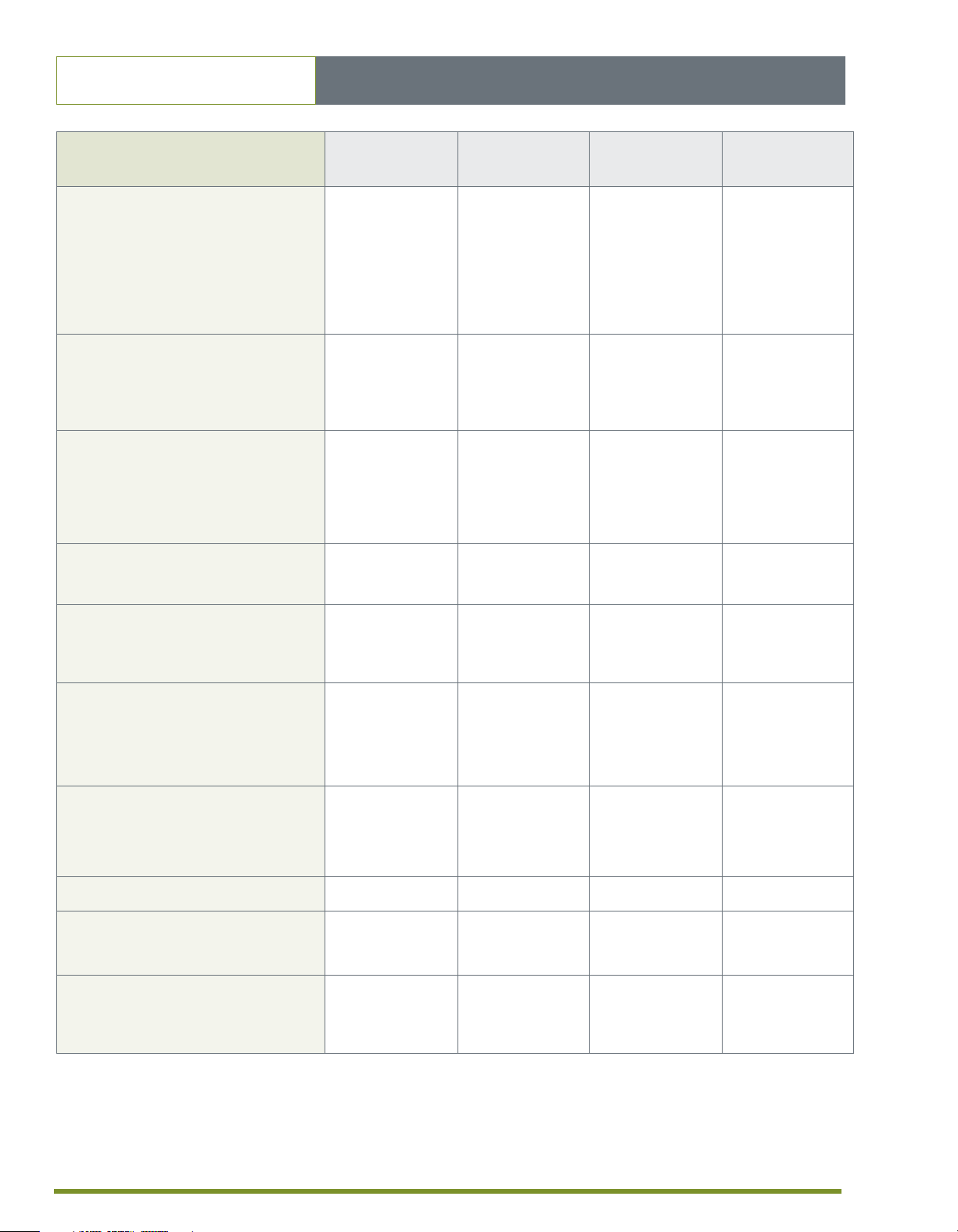

Page 10

WCHDZSERIES

3-Way ECOi VRF Heat Recovery combined units

DESCRIPTION

PERFORMANCE

COOLING CAPACITY: BTU/H

POWER INPUT: KW

HEATING CAPACITY: BTU/H

POWER INPUT: KW

COOLING MODE NOMINAL CONDITIONS

INDOOR: °F WB/ °F DB

OUTDOOR: °F DB

PIPE LENGTH: FEET

LEVEL DIFFERENCE: FEET

HEATING MODE NOMINAL CONDITIONS

INDOOR: °F DB

OUTDOOR: °F DB/ °F WB

PIPE LENGTH: FEET

LEVEL DIFFERENCE: FEET

OPERATING RANGE

COOLING: °F DB

HEATING: °F WB

WCHDZ

21663

includes (3)

CHDZ07263

216,000

15.84

243,000

17.37

80/67

95

25

0

70

47/43

25

0

14 to 113

-4 to 59

WCHDZ

24063

includes (2)

CHDZ07263 and (1)

CHDZ09663

240,000

18.25

270,000

20.18

80/67

95

25

0

70

47/43

25

0

14 to 113

-4 to 59

WCHDZ

26463

includes (1)

CHDZ07263 and (2)

CHDZ09663

264,000

20.66

297,000

22.99

80/67

95

25

0

70

47/43

25

0

14 to 113

-4 to 59

WCHDZ

28863

includes (3)

CHDZ09663

288,000

23.07

324,000

25.8

80/67

95

25

0

70

47/43

25

0

14 to 113

-4 to 59

COMPRESSOR

TYPE/QUANTITY

CAPACITY CONTROL RANGE: %

TYPE/QUANTITY

FAN MOTOR OUTPUT: (KW)

EXTERNAL STATIC PRESSURE

POWER SUPPLY

MINIMUM CIRCUITS AMPS (MCA): (A)

MAX. OVERCURRENT PROTECTION (MOCP): (A)

WEIGHT: (LBS)

COIL FACE AREA:(SQ. FT.)

NUMBER OF ROWS:

PROTECTION DEVICES

HIGH PRESSURE SWITCH/OVERCURRENT (CT

CRANKCASE HEATERS:(W)

FAN

V/PH/HZ

COIL:

METHOD)

3 Inverter driven Rotary

6 - 100%

1 Propeller (ea)

0.7 kW

.04 / .25

208 - 230/ 3/ 60

78

120

1752 1851 1950 2049

29.5(ea)

4(ea)

Yes

25 + 25 + 25

3 Inverter driven Rotary

& 1 fixed speed scroll

6 - 100%

1 Propeller (ea)

0.7 kW

.04 / .25

208 - 230/ 3/ 60

86

125

29.5 (ea)

4

Yes

25 + 25 + 25 + 32

3 Inverter driven Rotary

& 2 fixed speed scroll

6 - 100%

1 Propeller (ea)

0.7 kW

.04 / .25

208 - 230/ 3/ 60

94

130

29.5 (ea)

4

Yes

(2 X 25 + 32) + 25

3 Inverter driven Rotary

& 3 fixed speed scroll

6 - 100%

1 Propeller (ea)

0.7 kW

.04 / .25

208 - 230/ 3/ 60

102

135

29.5 (ea)

4

Yes

3 X 25 + 32

EACH OUTDOOR UNIT REQUIRES A SEPARATE ELECTRICAL FUSED DISCONNECT,

SEE INDIVIDUAL OUTDOOR REQUIREMENTS.

(R) indicates with salt protection - Special Order

* NOTE: *460 Volt Step Down Transformers (460-230) available for 6 and 8 ton condensers

10

Page 11

SANYO’s Mini ECOi is suited

for numerous commercial and

premium residential applications.

Mini ECOi Multi Split VRF Heat Pump

CHXSERIES

CHX (R) 03652 / CHX (R) 05252

KEY FEATURES:

* Single Phase 208/230 volts

* One Outdoor Unit Connects As Many As 9 Indoor Units

(50%-130% ratio of indoor to outdoor capacity)

* Inverter Driven Twin Rotary Compressor

* Operating Range (Outdoor Ambient)

- Cooling 14 FDB to 113 FDB

- Heating -4 FWB to 59 FWB

* Ultra Quiet Operation As Low As 51dB(a)

* Variable Speed DC Fan Motor

* Piping:

-656 Feet - Maximum Total Liquid Line

-164 Feet - Maximum Vertical Between Indoor and Outdoor (Outdoor Above Indoor)

-131 Feet - Maximum Vertical Between Indoor and Outdoor (Outdoor Below Indoor)

* Defrost control, Reverse cycle, microprocessor control

* External finish: Galvanized steel plate with powder paint

* Refrigerant control: Electronic expansion valve

SANYO OUTDOOR

DESCRIPTION

POWER SOURCE

PERFORMANCE

COOLING CAPACITY

SEER

HEATING CAPACITY

HSPF

AIR CIRCULATION (HI)

ELECTRICAL RATINGS

VOLTAGE RATING

AVAILABLE VOLTAGE RANGE

RUNNING AMPERES

MAX. RUNNING AMPERES

POWER INPUT

MAX. POWER INPUT

MIN. CIRCUIT AMPACITY

MAX CIRCUIT AMPACITY

REFRIGERANT TUBING

LIMIT OF TUBING LENGTH

LIMIT OF ELEVATION DIFFERENCE

BETWEEN THE 2 UNITS

REFRIGERANT TUBE DIAMETER

LIQUID TUBE IN.

GAS TUBE IN.

CHX (R)

208-230V/1PH/60Hz 208-230V/1PH/60Hz

Ducted Non-Ducted Mix

40,000 39,000 39,000 BTU/H

14.20 16.40 15.30

40,500 42,500 41,500 BTU/H

8.20 9.60 8.90

COOLING HEATING

208 / 230 V 208 / 230 V

187—253 V 187—253 V

14.6 / 13.6 A 14.6 / 13.6 A

23.6 / 23.6 A 23.6 / 23.6 A

2.76 / 2.76 Kw 2.88 / 2.88 Kw

4.85 / 4.85 Kw 4.85 / 4.85 Kw

Outdoor unit is higher than indoor unit: 164

Outdoor unit is lower than indoor unit: 131

03652 CHX (R) 05252

Ducted Non-Ducted Mix

51,500 52,000 51,500 BTU/H

14.6 17.3 16

57,500 58,000 58,500 BTU/H

7.7 9.5 8.6

3,530 CFM

COOLING HEATING

208 / 230 V 208 / 230 V

187—253 V 187—253 V

23.5 / 21.9 A 23.5 / 21.9 A

28 / 28 A 28 / 28 A

4.57 / 4.57 Kw 4.58 / 4.58 Kw

5.72 / 5.72 Kw 5.7 2 / 5.72 Kw

18 A

30 A

656 ft

Outdoor unit is higher than indoor unit: 164

Outdoor unit is lower than indoor unit: 131

3/8"

5/8"

3,530 CFM

29 A

50 A

656 ft

3/8"

3/4"

UNIT DIMENSIONS

INCHES (") / LBS.

SHIPPING WEIGH / VOLUME

EXTERNAL AIR TEMP. OPERATION RANGE

Height/ Width/ Depth/ Net Weight

49”/ 37”/ 14”/ 229 lbs.

247 lbs. / 19.8 ft.

Cooling:14 to 113 (DB)/Heating: -4 to 59 (WB)

3

* NOTE: *(R) in Model # indicates Salt Protection - Special Order

Height/ Width/ Depth/ Net Weight

49”/ 37”/ 14”/ 229 lbs.

247 lbs. / 19.8 ft.

Cooling:14 to 113 (DB)/Heating: -4 to 59 (WB)

3

11

Page 12

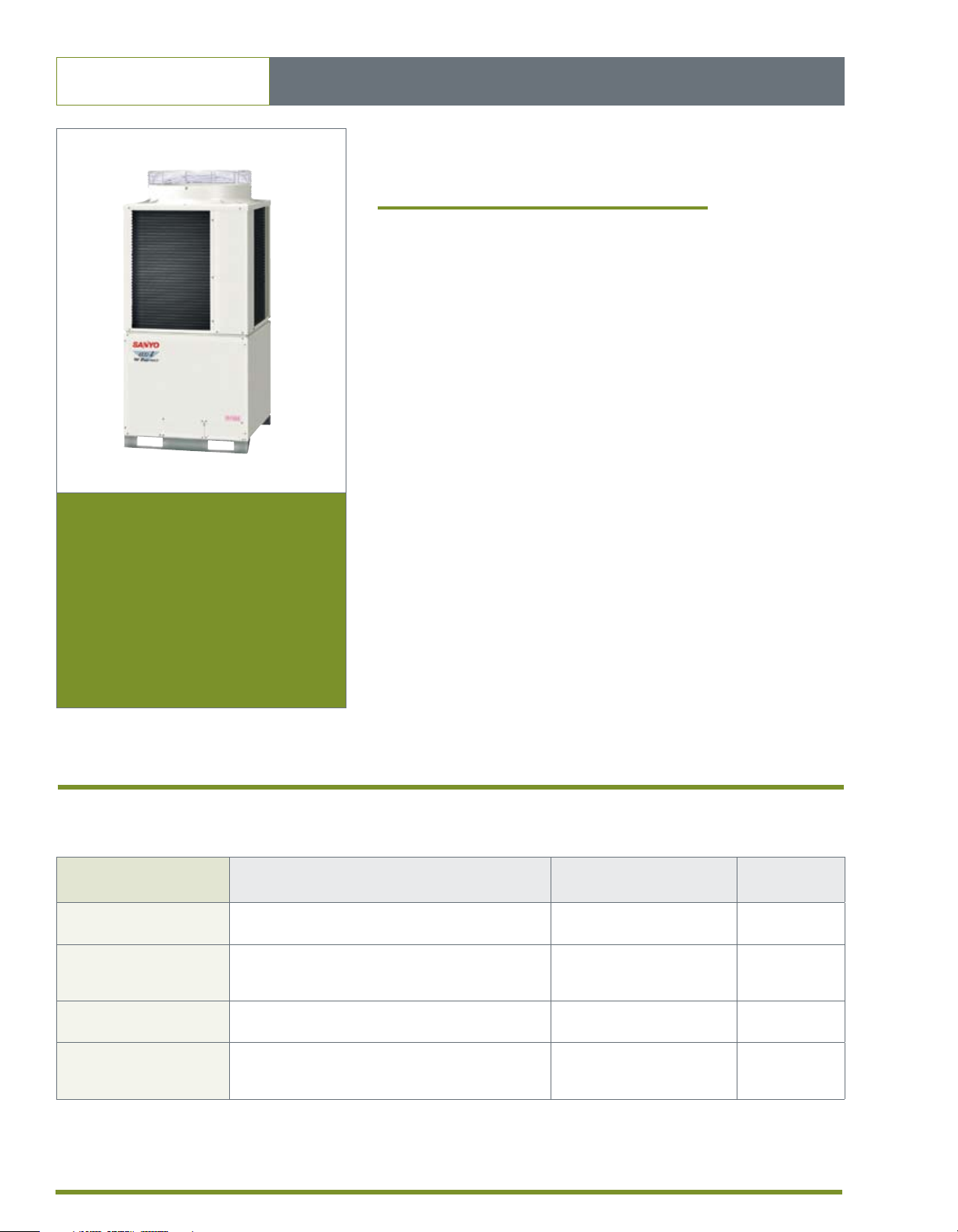

CHDXSERIES

SANYO’s ECOi is an all-in-one modular

conditioning solution. Suited for

numerous commercial and industrial

applications it offers flexible installation,

superior heating and cooling.

2-Way ECOi VRF Heat Pump

CHDX 07263 / CHDX (R) 07263

CHDX 09663 / CHDX (R) 09663

KEY FEATURES:

* One Outdoor Unit Connects As Many As 17 Indoor Units

(50%-130% ratio of indoor to outdoor capacity)

* CHDX07263 one Inverter Driven Rotary Compressor

* CHDX09663 includes one Inverter Driven Rotary Compressor

and One AC Constant Speed Scroll Compressor

* Operating Range (Outdoor Ambient)

- Cooling 14 FDB to 113 FDB

- Heating -4 FWB to 59 FWB

* Ultra Quiet Operation As Low As 52dB(a)

* Variable Speed DC Fan Motor (ESP adjustable to 0.25” wc)

* Flexible Piping Design:

- 984 Feet - Maximum Total Liquid Line

- 492 Feet - Maximum Outdoor To Most Distant Indoor Unit

- 164 Feet - Maximum Vertical Between Indoor and Outdoor

(Outdoor Above Indoor)

- 131 Feet - Maximum Vertical Between Indoor and Outdoor

(Outdoor Below Indoor)

(R) indicates with salt protection - Special Order

DESCRIPTION

CHDX 07263 * 72,000 BTU Heat Pump 208-230V/60 HZ 3

CHDX (R) 07263 * 72,000 BTU Heat Pump

CHDX 09663 * 96,000 BTU Heat Pump 208-230V/60 HZ 3

CHDX (R) 09663 * 96,000 BTU Heat Pump

(Type: Nominal Cooling Capacity, etc) Volt PH

208-230V/60 HZ 3

With Salt Protection - Special Order

208-230V/60 HZ 3

With Salt Protection - Special Order

* NOTE: *460 Volt Step Down Transformers (460-230) available for 6 and 8 ton condensers

12

Page 13

2- Way ECOi VRF Heat Pump

CHDXSERIES

DESCRIPTION

PERFORMANCE

COOLING CAPACITY: BTU/H

POWER INPUT: KW

HEATING CAPACITY: BTU/H

POWER INPUT: KW

ELECTRICAL RATINGS

VOLTAGE RATING

COOLING RUNNING AMPERES

HEATING RUNNING AMPERES

MIN. CIRCUIT AMPACITY

MAX. CIRCUIT AMPACITY

COMPRESSOR

TYPE - QUANTITY

MOTOR OUTPUT

REFRIGERATION OIL TYPE

REFRIGERATION OIL CHARGE AMOUNT

CRANKCASE HEATER

REFRIGERANT AMOUNT AT SHIPMENT

REFRIGERANT CONTROL

DEFROST METHOD

HEAT EXCHANGER

CAPACITY CONTROL

CHDX (R)

72,000

5.28

81,000

5.79

208 - 230 V

15.1 - 14.1 A

16.5 - 15.5 A

26 A

40 A

Inverter Driven Rotary Type

4.1 kw

FV68S (Ether oil - PVE)

1.4 gal

25 w

R410A - 25.9 lbs

Electronic expansion valve

Reverse-cycle, outdoor unit cycle

Aluminum plate fin / Copper tube

10-100%

07263 CHDX (R) 09663

96,000

7.69

108,000

8.6

SANYO OUTDOOR

208 - 230 V

23.0 - 21.4 A

25.4 - 23.7 b A

34 A

45 A

Inverter Driven Rotary

(3 + 3.75) kw

FV68S (Ether oil)

1.56 gal

25 + 32 w

R410A - 25.9 lbs

Electronic expansion valve

Reverse-cycle, outdoor unit cycle

Aluminum plate fin / Copper tube

10-100%

FAN DEVICE

TYPE - QUANTITY

MOTOR OUTPUT

PROTECTIVE DEVICES

CFM

EXTERNAL STATIC PRESSURE

TUBING

REFRIGERANT TUBING GAS TUBE

REFRIGERANT TUBING LIQUID TUBE

REFRIGERANT TUBING BALANCE TUBE

EXTERNAL AIR TEMP. OPERATION RANGE

OPERATION SOUND (HI)

UNIT DIMENSIONS

Inches (") / lbs.

Color (Munsell code)

Propeller fan x 1

0.7 kw

High pressure switch, overcurrent (CT method)

5.300

0.04 / 0.25

3/4" (Brazing)

ø3/8" (Brazing)

ø3/8" (Flare)

Cooling: 14 to 113 (DB) / Heating: -4 to 59 (WB) °F

54.5 (Quiet mode: 51.5) dB-A

82"/ 35"/ 35"/ 584 lbs.

Height/ Width/ Depth/ Net Weight

Silky shade (1y 8.5/0.5)

Propeller fan x 1

0.7 kw

High pressure switch, overcurrent (CT method)

5.650

0.04 / 0.25

7/8" (Brazing)

3/8" (Brazing)

ø3/8" (Flare)

Cooling: 14 to 113 (DB) / Heating: -4 to 38 (WB) °F

55.0 (Quiet mode: 52.0) dB-A

82"/ 35"/ 35"/ 683 lbs.

Height/ Width/ Depth/ Net Weight

Silky shade (1y 8.5/0.5)

(R) indicates with salt protection - Special Order

* NOTE: *460 Volt Step Down Transformers (460-230) available for 6 and 8 ton condensers

13

Page 14

WCHDXSERIES

SANYO’s Combined ECOi outdoor units offer

superior heating and cooling coupled with cost

effective installation. Providing a single refrigerant

pipe network means there’s only one penetration

into the building and ultimately less piping material

required, saving you time and money. A smart

conditioning solution for large capacity jobs.

WCHDX COMBINED SERIES.

W 2-Way ECOi VRF Heat Pumps combined units

WCHDX 14463 / WCHDX 16863 / WCHDX 19263

WCHDX 21663 / WCHDX 24063

WCHDX 26463 / WCHDX 28863

KEY FEATURES:

* Heat Pump

* Combine 3 outdoor units up to 24 tons

* Combined Series Allows Up to 40 Indoor Units (50%-130% ratio of

indoor to outdoor capacity)

*“ECO Friendly” R410A Refrigerant

* 208/230V, 3 Phase, 60Hz

* Multiple Compressors For Precise and Efficient Operation

* Operating Range (Outdoor Ambient)

-Cooling 14 FDB to 113 FDB

-Heating -4 FWB to 59 FWB

* Ultra Quiet Operation As Low As 51.5dB (a)

* Variable Speed DC Fan Motors

* Flexible Piping Design:

- 984 Feet - Maximum Total Liquid Line

- 492 Feet - Maximum Outdoor To Most Distant Indoor Unit

- 164 Feet - Ma ximum Vertical Between Indoor and Outdoor

(Outdoor Above Indoor)

- 131 Feet - Maximum Vertical Between Indoor and Outdoor

(Outdoor Below Indoor)

SYSTEM

Outdoor Unit Cooling & Heating Power input

208/230

WCHDX 14463

WCHDX

WCHDX

WCHDX

WCHDX

WCHDX 26463 CHDX 09663

WCHDX 28863 CHDX 09663

(R) indicates with salt protection - Special Order

16863

19263

21663

24063

CHDX 07263

CHDX 07263

CHDX 09663

CHDX 09663

CHDX 07263

CHDX 07263

CHDX 09663

CHDX 07263

(quantity of 2) 144,000 & 162,000 BTU/H 10.56/11.58 kW 6 - 100%

168,000 & 189,000 BTU/H 12.97/ 14.39 kW 6 - 100%

(quantity of 2) 192,000 & 216,000 BTU/H 15.38/ 17.2 kW 6 - 100%

(quantity of 3) 216,000 & 243,000 BTU/H 15.84/ 17.37 kW 6 - 100%

(quantity of 2)

(quantity of 2)

(quantity of 3)

240,000 & 270,000 BTU/H 18.25/ 20.18 kW 6 - 100%

264,000 & 297,000 BTU/H

288,000 & 324,000 BTU/H

20.66/ 22.99 kW 6 - 100%

23.07/ 25.8 kW 6 - 100%

* NOTE: *460 Volt Step Down Transformers (460-230) available for 6 and 8 ton condensers

14

Control Range

Page 15

W 2-Way ECOi VRF Heat Pumps combined units

WCHDXSERIES

DESCRIPTION

PERFORMANCE

COOLING CAPACITY: BTU/H

POWER INPUT: KW

HEATING CAPACITY: BTU/H

POWER INPUT: KW

COOLING MODE NOMINAL CONDITIONS

INDOOR: °F WB/ °F DB

OUTDOOR: °F DB

PIPE LENGTH: FEET

LEVEL DIFFERENCE: FEET

HEATING MODE NOMINAL CONDITIONS

INDOOR: °F DB

OUTDOOR: °F DB/ °F WB

PIPE LENGTH: FEET

LEVEL DIFFERENCE: FEET

OPERATING RANGE

COOLING: °F DB

HEATING: °F WB

COMPRESSOR

TYPE/QUANTITY

CAPACITY CONTROL RANGE: %

WCHDX

includes (2) CHDX07263

144,000

10.56

162,000

11.58

80/67

95

25

0

70

47/43

25

0

14 to 113

-4 to 59

2 Inverter driven Rotary

6 - 100%

14463 WCHDX 16863 WCHDX 19263

includes (1) CHDX07263 and

(1) CHDX09663

168,000

12.97

189,000

14.39

80/67

95

25

0

70

47/43

25

0

14 to 113

-4 to 59

2 Inverter driven Rotary

& 1 fixed speed scroll

6-100%

includes (2) CHDX09663

192,000

15.38

216,000

17.2

80/67

95

25

0

70

47/43

25

0

14 to 113

-4 to 59

2 Inverter driven Rotary

& 2 fixed speed scroll

6-100%

SANYO OUTDOOR

FAN

TYPE/QUANTITY

FAN MOTOR OUTPUT: (KW)

EXTERNAL STATIC PRESSURE

POWER SUPPLY

V/PH/HZ

MINIMUM CIRCUITS AMPS (MCA): (A)

MAX. OVERCURRENT PROTECTION (MOCP): (A)

WEIGHT: (LBS)

COIL FACE AREA:(SQ. FT.)

NUMBER OF ROWS:

PROTECTION DEVICES

HIGH PRESSURE SWITCH/OVERCURRENT

(CT METHOD)

CRANKCASE HEATERS:(W)

1 Propeller (ea)

0.7 kW (ea)

.04 / .25

208 - 230/ 3/ 60

52

80

1168 1267 1366

COIL:

29.5(ea)

4(ea)

Yes

25 + 25

EACH OUTDOOR UNIT REQUIRES A SEPARATE

ELECTRICAL FUSED DISCONNECT, SEE INDIVIDUAL

OUTDOOR REQUIREMENTS.

1 Propeller (ea)

0.7 kW (ea)

.04 / .25

208 - 230/ 3/ 60

60

85

29.5(ea)

4(ea)

Yes

25 + 25 + 32

1 Propeller (ea)

0.7 kW (ea)

.04 / .25

208 - 230/ 3/ 60

68

90

29.5(ea)

4(ea)

Yes

25 + 32 X 2

(R) indicates with salt protection - Special Order

* NOTE: *460 Volt Step Down Transformers (460-230) available for 6 and 8 ton condensers

15

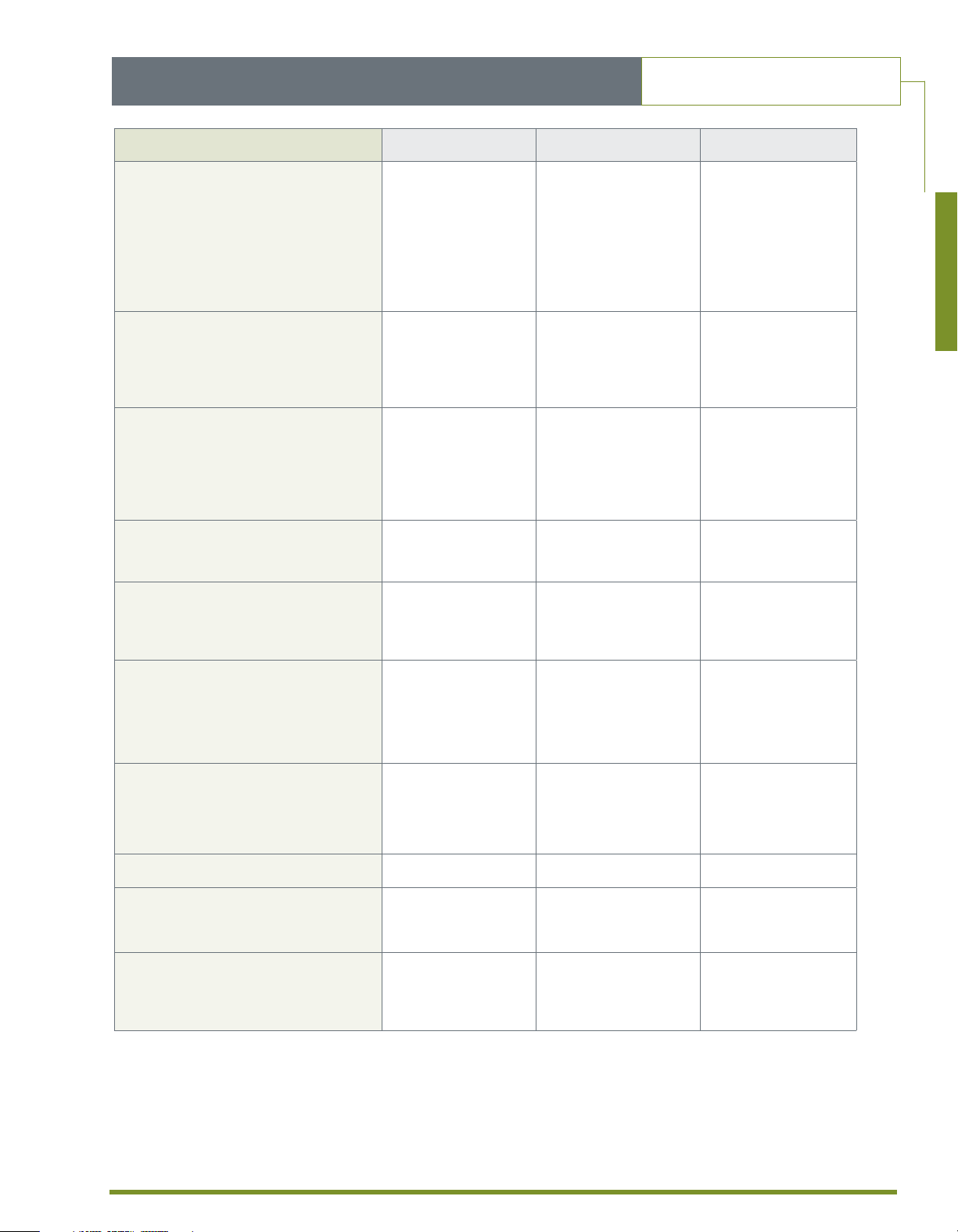

Page 16

WCHDXSERIES

DESCRIPTION

W 2-Way ECOi VRF Heat Pumps combined units

WCHDX

21663

WCHDX

24063

WCHDX

26463

WCHDX

28863

PERFORMANCE

COOLING CAPACITY: BTU/H

POWER INPUT: KW

HEATING CAPACITY: BTU/H

POWER INPUT: KW

COOLING MODE NOMINAL CONDITIONS

INDOOR: °F WB/ °F DB

OUTDOOR: °F DB

PIPE LENGTH: FEET

LEVEL DIFFERENCE: FEET

HEATING MODE NOMINAL CONDITIONS

INDOOR: °F DB

OUTDOOR: °F DB/ °F WB

PIPE LENGTH: FEET

LEVEL DIFFERENCE: FEET

OPERATING RANGE

COOLING: °F DB

HEATING: °F WB

COMPRESSOR

TYPE/QUANTITY

CAPACITY CONTROL RANGE: %

includes (3)

CHDX07263

216,000

15.84

243,000

17.37

80/67

95

25

0

70

47/43

25

0

14 to 113

-4 to 59

3 Inverter driven

Rotary

6 - 100%

includes (2)

CDDX07263 and (1)

CHDX09663

240,000

18.25

270,000

20.18

80/67

95

25

0

70

47/43

25

0

14 to 113

-4 to 59

3 Inverter driven Rotary

& 1 fixed speed scroll

6 - 100%

includes (1)

CHDX07263 and (2)

CHDX09663

264,000

20.66

297,000

22.99

80/67

95

25

0

70

47/43

25

0

14 to 113

-4 to 59

3 Inverter driven Rotary

& 2 fixed speed scroll

6 - 100%

includes (3)

CHDX09663

288,000

23.07

324,000

25.8

80/67

95

25

0

70

47/43

25

0

14 to 113

-4 to 59

3 Inverter driven

Rotary

& 3 fixed speed scroll

6 - 100%

FAN

TYPE/QUANTITY

FAN MOTOR OUTPUT: (KW)

EXTERNAL STATIC PRESSURE

POWER SUPPLY

V/PH/HZ

MINIMUM CIRCUITS AMPS (MCA): (A)

MAX. OVERCURRENT PROTECTION (MOCP): (A)

WEIGHT: (LBS)

COIL:

COIL FACE AREA:(SQ. FT.)

NUMBER OF ROWS:

PROTECTION DEVICES

HIGH PRESSURE SWITCH/OVERCURRENT (CT

METHOD)

CRANKCASE HEATERS:(W)

1 Propeller (ea)

0.7 kW (ea)

.04 / .25

208 - 230/ 3/ 60

78

120

1752 1851 1950 2049

29.5(ea)

4(ea)

Yes

25 + 25 + 25

1 Propeller (ea)

0.7 kW (ea)

.04 / .25

208 - 230/ 3/ 60

86

125

29.5(ea)

4(ea)

Yes

25 + 25 + 25 + 32

1 Propeller (ea)

0.7 kW (ea)

.04 / .25

208 - 230/ 3/ 60

94

130

29.5(ea)

4(ea)

Yes

(2 X 25 + 32) + 25

EACH OUTDOOR UNIT REQUIRES A SEPARATE ELECTRICAL FUSED DISCONNECT,

SEE INDIVIDUAL OUTDOOR REQUIREMENTS.

(R) indicates with salt protection - Special Order

* NOTE: *460 Volt Step Down Transformers (460-230) available for 6 and 8 ton condensers

16

1 Propeller

0.7 kW

.04 / .25

208 - 230/ 3/ 60

102

135

29.5(ea)

4(ea)

Yes

3 X 25 + 32

Page 17

SANYO’s wall-mounted units work well with any interior

design. Flexible and compact, offering individualized zoned

comfort for complete temperature control throughout the day.

Over five different air flow directions and wireless remotes

provide control in the palm of your hand.

Wall-Mounted Unit

KHXSERIES

KHX 0752 / KHX 0952 / KHX 1252 / KHX 1862

KHX 1962 / KHX 2452 / ATK-SVRK56BA

KEY FEATURES:

* “ECO Friendly” R410A Refrigerant

* 208/230V, 1 Phase, 60Hz

* Easy Wall Mount for Any Application

* Washable Long Life Filter

* Electronic E xpansion Valve (EEV)

for Accurate Refrigerant Control

* Light Weight, Only 31 lbs. (KHX2452 is 46 lbs.)

* Wired or Wireless Remote Control

* Easy Service

MODELS

KHX 0752

KHX 0952

KHX 1252

KHX 1862

KHX 1962

KHX 2452

ATK-SVRK56BA

(Type: Nominal Cooling Capacity, etc)

7500 BTU 208-230V/60 HZ 1

9600 BTU 208-230V/60 HZ 1

12000 BTU 208-230V/60 HZ 1

18000 BTU 208-230V/60 HZ 1

19000 BTU (special order) 208-230V/60 HZ 1

25000 BTU 208-230V/60 HZ 1

External EEV (required for use with

DESCRIPTION

PERFORMANCE

COOLING CAPACITY

HEATING CAPACITY

CURRENT

COOLING

HEATING

POWER INPUT

COOLING

HEATING

HEAT EXCHANGER

FAN TYPE X QUANTIT Y

FAN AIRFLOW RATE

FAN EXT. STATIC PRESS (230V)

FAN MOTOR TYPE

FAN MOTOR OUTPUT

KHX

7,500 BTU/H

8,500 BTU/H

0.25/0.26 A

0.25/0.26 A

50/56 W

50/56 W

CROSS FLOW X1

350/280/210

0 IN. WC

AC

30 W

0752 KHX 0952 KHX 1252 KHX 1862

9,600 BTU/H

11,000 BTU/H

0.20/0.21 A

0.20/0.21 A

50/56 W

50/56 W

CROSS FLOW X1

350/280/210

0 IN. WC

AC

30 W

KHX 1962)

12,000 BTU/H

14,000 BTU/H

0.20/0.21 A

0.20/0.21 A

50/56 W

50/56 W

CROSS FLOW X1

350/280/210

0 IN. WC

AC

30 W

Volt PH

N/A N/A

KHX 1962

needs ATK-SVRK56BA

18,000 BTU/H

20,000 BTU/H

0.30/0.32 A

0.30/0.32 A

61/72 W

61/72 W

CROSS FLOW X1

565/495/353

0 IN. WC

AC

30 W

19,000 BTU/H

21,000 BTU/H

0.30/0.32 A

0.30/0.32 A

61/72 W

61/72 W

CROSS FLOW X1

565/495/353

0 IN. WC

AC

30 W

SANYO INDOOR

KHX 2452

25,000 BTU/H

27,000 BTU/H

0.37/0.39 A

0.38/0.32 A

72/83 W

72/83 W

CROSS FLOW X1

565/495/350

0 IN. WC

AC

30 W

REFRIGERANT PIPE DIMENSIONS

LOW PRESSURE (FLARE)

HIGH PRESSURE (FL ARE)

UNIT DIMENSIONS

Inches (") / lbs.

DRAINPIPE DIMENSION

SOUND LEVELS

(LOW-MED-HIGH) DB(A) @ 230V

1/4"

1/2"

28/32/36 28/32/36 28/32/36 35/38/42 35/38/42 35/38/42

1/4"

1/2"

11.5"/ 39.5"/ 8"/ 31 LBS.

HEIGHT/ WIDTH/ DEPTH/ NET WEIGHT

1/4"

1/2"

1/4"

1/2"

3/4" OD

1/4"

1/2"

13"/ 45"/ 9"/ 46 LBS.

HEIGHT/ WIDTH/ DEPTH/ NET WEIGHT

3/8"

5/8"

17

Page 18

THXSERIES

Ceiling Suspended Unit

SANYO’s ceiling suspended units are an ideal solution for

any medium to light commercial space perfectly.

Suited for retail stores, schools and restaurant applications,

its wide air opening provides comfortable airflow and ultra

quiet operation.

THX 1252 / THX 1852 / THX 2452

KEY FEATURES:

* “ECO Friendly” R410A Refrigerant

* 208/230V, 1 Phase, 60Hz

* Low Profile Design Fits Into Numerous Ceiling

Suspended Locations

* One Way Air Discharge with Vanes and Auto

Louvre for Efficient Air Distribution

* Washable Long Life Air Filter

* Electronic Expansion Valve (EEV) for Accurate

Refrigerant Control

* Less Than 9 Inches Tall and Less than 36 Inches

Wide (47 Inches Wide For THX2452)

* Wired or Wireless Remote Control

* Easy Service

MODELS

THX 1252

THX 1852

THX 2452

(Type: Nominal Cooling Capacity, etc)

12,000 BTU 208-230V/60 HZ 1

18,000 BTU 208-230V/60 HZ 1

24,000 BTU 208-230V/60 HZ 1

DESCRIPTION

CAPACITY

COOLING

HEATING

CURRENT

COOLING

HEATING

POWER INPUT

COOLING

HEATING

UNIT DIMENSIONS

Inches (") / lbs.

HEAT EXCHANGER

FAN TYPE X QUANTITY

FAN AIRFLOW RATE

FAN EXT. STATIC PRESS (230V)

FAN MOTOR TYPE

FAN MOTOR OUTPUT

Volt PH

THX

1252 THX 1852 THX 2452

12,000 BTU

14,000 BTU

0.14/0.17 A

0.14/0.15 A

15/16 W

15/16 W

8.5"/ 36"/ 27"/ 46 lbs.

Height/ Width/ Depth/ Net Weight

SCIROCCO X1

450/390/320 - CFM - (H/M/L)

0 - In. WC

DC

60 - W

19,000 BTU

21,000 BTU

0.15/0.14 A

0.15/0.17 A

16/16 W

16/18 W

SCIROCCO X1

450/390/320 - CFM - (H/M/L)

0 - In. WC

DC

60 - W

25,000 BTU

27,000 BTU

0.34/0.31 A

0.34/0.36 A

38/37 W

40/40 W

8.5"/ 46.5"/ 27"/ 55 lbs.

Height/ Width/ Depth/ Net Weight

SCIROCCO X1

653/530/495 - CFM - (H/M/L)

0 - In. WC

DC

60 - W

REFRIGERANT PIPE DIMENSIONS

LOW PRESSURE (FLARE)

HIGH PRESSURE (FLARE)

DRAINPIPE DIMENSION

SOUND LEVELS

(LOW-MED-HIGH)

1/4"

1/2"

1" OD 1" OD 1" OD

30/32/35 - DB(A) @ 230V 30/33/36 - DB(A) @ 230V 33/36/38 - DB(A) @ 230V

1/4"

1/2"

3/8"

5/8"

18

Page 19

SANYO’s semi-concealed ceiling

units are flexible and spacesaving. A perfect conditioning

solution for small spaces. Barely

visible, the unit blends with any

interior design. Powerful enough

to cool and comfort those inside.

ONE WAY Ceiling Cassette, with condensate Pump

07 AHX 52 / 09 AHX 52/ 12 AHX 52

KEY FEATURES:

*“ECO Friendly” R410A Refrigerant

* 208/230V, 1 Phase, 60Hz

* One-Way Air Throw – Perfect for Small Spaces

* Washable Long Life Air Filter

* Built-In Drain Pump – 24 Inch Lift Possible Above

Outlet Drain Connection

* Electronic E xpansion Valve (EEV) for Accurate

Refrigerant Control

*Only 13 Inches Tall ( Not Including Decorative Panel),

30 Inches Wide and 25 Inches Deep

* Wired or Wireless Remote Control

* Optional Fresh Air Intake

* Easy Service

AHXSERIES

SYSTEM/MODEL

07AHX 52

09 AHX 52

12 AHX 52

Components (Type: Nominal Cooling Capacity, etc)

System 7500 BTU 1-Way Ceiling cassette (includes grille) 208-230V/60 HZ 1

AHX 0752 cassette 208-230V/60 HZ 1

PNR-AH1252 grille

System 9000 BTU 1-Way Ceiling cassette (includes grille) 208-230V/60 HZ 1

AHX 0952 cassette 208-230V/60 HZ 1

PNR-AH1252 grille

System 12000 BTU 1-Way Ceiling cassette (includes grille) 208-230V/60 HZ 1

AHX 1252 cassette 208-230V/60 HZ 1

PNR-AH1252 grille

DESCRIPTION

PERFORMANCE

COOLING CAPACITY

HEATING CAPACITY

CURRENT

COOLING

HEATING

POWER INPUT

COOLING

HEATING

HEAT EXCHANGER

FAN TYPE X QUANTIT Y

FAN AIRFLOW RATE

FAN EXT. STATIC PRESS (230V)

FAN MOTOR TYPE

FAN MOTOR OUTPUT

REFRIGERANT PIPE DIMENSIONS

LOW PRESSURE (FLARE)

HIGH PRESSURE (FL ARE)

UNIT DIMENSIONS

Inches (") / lbs.

DRAINPIPE DIMENSION

SOUND LEVELS

(LOW-MED-HIGH) DB(A) @ 230V

07AHX 52 09 AHX 52 12 AHX 52

7,500 BTU/H

8,500 BTU/H

0.29/0.28 A

0.28/0.26 A

48/50 W

44/46 W

SCIRROCO X1

282/247/212

0 IN. WC

DC

60 W

1/4"

1/2"

9,600 BTU/H

11,000 BTU/H

0.29/0.28 A

0.28/0.26 A

48/50 W

44/46 W

SCIRROCO X1

282/247/212

0 IN. WC

DC

60 W

1/4"

1/2"

13"/ 30"/ 24.5"/ 43 LBS.

HEIGHT/ WIDTH/ DEPTH/ NET WEIGHT

1 1/4" OD

29/31/33

12,000 BTU/H

14,000 BTU/H

0.32/0.31 A

0.34/0.32 A

52/55 W

50/52 W

SCIRROCO X1

320/280/250

IN. WC

DC

60 W

1/4"

1/2"

Volt PH

SANYO INDOOR

19

Page 20

XMHXSERIES

Concealed Ducted - Low Profile, Low Static, with Condensate Pump4-Way Ceiling Cassette 24" x 24", with Condensate Pump

SANYO’s 4-Way semi-concealed ceiling

units are flexible, efficient and space-saving.

Now available to fit within standard

24"x24"ceiling grids.

12 XMHX 52 / 18 XMHX 52

KEY FEATURES:

* “ECO Friendly” R410A Refrigerant

* 208/230V, 1 Phase, 60Hz

* Four Way Air Throw

* Washable Long Life Air Filter

* Built-In Drain Pump – 25 Inch Lif t

Possible Above Outlet Drain Connection

* Electronic Expansion Valve (EE V)

for Accurate Refrigerant Control

* A Low Profile Unit Perfectly Suited

for Compact Ceiling Voids (as little as 12-14 inches)

* Wired or Wireless Remote Control

* Easy Service

* Optional Fresh Air Intake

SYSTEM/MODEL

12 XMHX 52

18 XMHX 52

DESCRIPTION

PERFORMANCE

COOLING CAPACITY

HEATING CAPACITY

POWER INPUT

HEAT EXCHANGER

FAN TYPE X QUANTIT Y

FAN AIRFLOW RATE

FAN MOTOR TYPE

FAN MOTOR OUTPUT

Components (Type: Nominal Cooling Capacity, etc)

System 12000 BTU 4-Way Ceiling cassette 24" x 24" (includes grille) 208-230V/1ø/60 HZ 1

XMHX 1252 cassette 208-230V/1ø/60 HZ 1

PNR-XMH1252 grille

System 18000 BTU 4-way Ceiling cassette 24" x 24" (includes grille) 208-230V/1ø/60 HZ 1

XMHX 1852 cassette 208-230V/1ø/60 HZ 1

PNR-XMH1852 grille

Volt PH

12 XMHX 52 18 XMHX 52

CURRENT

COOLING

HEATING

COOLING

HEATING

12,000 BTU/H

14,000 BTU/H

0.22/0.20 A

0.19/0.17 A

38/43 W

30/35 W

TURBO X1

320/280/250

DC

20 W

19,000 BTU/H

21,000 BTU/H

0.30/0.32 A

0.27/0.30 A

52/56 W

48/47 W

TURBO X1

440/370/320

DC

20 W

REFRIGERANT PIPE DIMENSIONS

LOW PRESSURE (FLARE)

HIGH PRESSURE (FL ARE)

UNIT DIMENSIONS

DRAINPIPE DIMENSION

(LOW-MED-HIGH) DB(A) @ 230V

20

Inches (") / lbs.

SOUND LEVELS

1/4"

1/2"

12.5"/ 24.75"/ 24.75"/ 41 LBS.

HEIGHT/ WIDTH/ DEPTH/ NET WEIGHT

27/29/31 33/37/41

1/4"

1/2"

1 1/4" OD

4-WAY AIR DISCHARGE

24" X 24" SYSTEM

(INCLUDES GRILLE)

Page 21

4-Way Ceiling Cassette 35" x 35", with Condensate Pump

SANYO’s 4-Way semi-concealed ceiling

units are flexible, efficient and

space-saving. Two sides can be adjusted

simply to accommodate corner airflow.

XHXSERIES

24 XHX 52 / 36 XHX 52

KEY FEATURES:

* “ECO Friendly” R410A Refrigerant

* 208/230V, 1 Phase, 60Hz

* Four Way Air Throw

* Washable Long Life Air Filter

* Built-In Drain Pump – 25 Inch Lif t

Possible Above Outlet Drain Connection

* Electronic Expansion Valve (EE V)

for Accurate Refrigerant Control

* A Low Profile Unit Perfectly Suited

for Compact Ceiling Voids (as little as 12-14 inches)

* Wired or Wireless Remote Control

* Easy Service

* Branch Duct Available

* Optional Fresh Air Intake

SYSTEM/MODEL

24 XHX 52

36 XHX 52

DESCRIPTION

PERFORMANCE

COOLING CAPACITY

HEATING CAPACITY

POWER INPUT

HEAT EXCHANGER

FAN TYPE X QUANTIT Y

FAN AIRFLOW RATE

FAN MOTOR TYPE

FAN MOTOR OUTPUT

Components (Type: Nominal Cooling Capacity, etc)

System 25000 BTU 4-Way Ceiling cassette 35" x 35" (includes

grille)

XMX 2452 cassette 208-230V/60 HZ 1

PNR-XMH1252 grille

System

XMX 3652 cassette 208-230V/60 HZ 1

PNR-XMH1852 grille

36000 BTU 4-Way Ceiling cassette 35" x 35" (includes grille)

208-230V/60 HZ 1

208-230V/60 HZ 1

Volt PH

24 XMHX 52 36 XMHX 52

CURRENT

COOLING

HEATING

COOLING

HEATING

25,000 BTU/H

27,000 BTU/H

0.29/0.26 A

0.30/0.31 A

38/40 W

33/33 W

TURBO X1

705/565/495

DC

50 W

36,000 BTU/H

39,000 BTU/H

0.51/0.46 A

0.54/0.49 A

74/79 W

76/76 W

TURBO X1

990/810/740

DC

90 W

SANYO INDOOR

REFRIGERANT PIPE DIMENSIONS

LOW PRESSURE (FLARE)

HIGH PRESSURE (FL ARE)

UNIT DIMENSIONS

Inches (") / lbs.

DRAINPIPE DIMENSION

SOUND LEVELS

(LOW-MED-HIGH) DB(A) @ 230V

3/8"

5/8"

12"/ 35"/ 35"/ 58 LBS.

HEIGHT/ WIDTH/ DEPTH/ NET WEIGHT

28/31/34 33/36/39

3/8"

5/8"

12" / 35" / 35" / 58 LBS.

HEIGHT/WIDTH/DEPTH/NET WEIGHT

1 1/4 "OD

TWO SIDES CAN BE

ADJUSTED SIMPLY TO

ACCOMMODATE

CORNER AIRFLOW.

21

Page 22

UMHXSERIES

8 inches high

Low Profile fits into tight ceiling spaces.

Concealed Ducted - Low Profile, Low Static, with Condensate Pump

UMHX 0762 / UMHX 0962 / UMHX 1262

UMHX 1562 / UMHX 1862

KEY FEATURES:

* “EC O Friendly” R 410A Refriger ant

* 208/230V, 1 Phase, 60 Hz

* Elect ronic Expansion Valve (EEV) for A ccur ate

Refrigerant Control

* Adjust able E xternal S tatic Pressure

* Built-In Drain Pump – 20 In ch Lif t

* Wired or Wireless Remote Contr ol

* Bottom or Rear Return Air

* Easy Service

* 8 inches high"

* Low Profile fits into tight ceiling sp aces

* Optional Fre sh Air In take

* Washable Long Life Filter

MODELS

UMHX 0762

UMHX 0962

UMHX 1262

UMHX 1562

UMHX 1862

(Type: Nominal Cooling Capacity, etc)

7500 BTU ESP = 0.04 / 0.12 208-230V/60 HZ 1

9600 BTU ESP = 0.06 / 0.12 208-230V/60 HZ 1

12000 BTU ESP = 0.06 / 0.16 208-230V/60 HZ 1

15000 BTU ESP = 0.06 / 0.16 208-230V/60 HZ 1

19000 BTU ESP = 0.16 / 0.16 208-230V/60 HZ 1

DESCRIPTION

PERFORMANCE

COOLING CAPACITY

HEATING CAPACITY

CURRENT

COOLING

HEATING

POWER INPUT

COOLING

HEATING

HEAT EXCHANGER

FAN T YPE

FAN AIRFLOW RATE

FAN EXT. STATIC PRESS (230V)

FAN MOTOR TYPE

FAN MOTOR OUTPUT

UMHX

7,500 BTU/H

8,500 BTU/H

0.22/0.21 A

0.23/0.22 A

32/30 W

32/30 W

CENTRIFUGAL

212 / 247 / 283

0.04 / 0.12 IN. WC

AC

50 W

0762 UMHX 0962 UMHX 1262 UMHX 1562 UMHX 1862

9,600 BTU/H

11,000 BTU/H

0.261/0.25 A

0.28/0.28 A

35/37 W

37/40 W

CENTRIFUGAL

230 / 265 / 300

0.06 / 0.12 IN. WC

AC

50 W

12,000 BTU/H

14,000 BTU/H

0.28/0.26 A

0.30/0.37 A

37/39 W

39/40 W

CENTRIFUGAL

247 / 283 / 318

0.06 / 0.16 IN. WC

AC

50 W

Volt PH

15,000 BTU/H

17,000 BTU/H

0.34/0.33 A

0.36/0.35 A

44/46 W

47/49 W

CENTRIFUGAL

283 / 336 / 371

0.06 / 0.16 IN. WC

AC

50 W

19,000 BTU/H

21,000 BTU/H

0.47/0.43 A

0.51/0.47 A

59/61 W

63/64 W

CENTRIFUGAL

0353 / 406 / 442

0.06 / 0.16 IN. WC

AC

50 W

REFRIGERANT PIPE DIMENSIONS

LOW PRESSURE (FLARE)

HIGH PRESSURE (FL ARE)

UNIT DIMENSIONS

DRAINPIPE DIMENSION

(LOW-MED-HIGH) DB(A) @ 230V

22

Inches (") / lbs.

SOUND LEVELS

1/4"

1/2"

25/27/28 27/29/30 28 / 30 / 32 30 / 32 / 34 31 / 33 / 35

1/4"

1/2"

1/4"

1/2"

7 7/8", 29 17/32", 25 13/64", 42 LBS

HEIGHT/ WIDTH/ DEPTH/ NET WEIGHT

1 1/4" OD

1/4"

1/2"

1/4"

1/2"

Page 23

SANYO’s concealed ceiling units are compact and space

saving. Advanced zoning capabilities. Efficient design.

A perfect conditioning solution for shorter duct runs.

Concealed Ducted - Medium Static

UHX 0762 / UHX 0962 / UHX 1262

UHX 1562 / UHX 1862 / UHX 2462

UHX 3662 / UHX 4862 / UHX 5462

KEY FEATURES:

* “ECO Friendly” R410A Refrigerant

* 208/230V, 1 Phase, 60 Hz

* Includ es 8" rou nd duc t connec tions (t wo 8" d uc t collars fo r 7-15, 000 B TU uni ts thr ee

8" d uct co llars for 18-24, 000 B TU uni t and f our 8" duc t colla rs for 36- 54,0 00 BT Us units )

can be remove d for plenum duc ting.

* Elect ronic Expansion Valve (EEV) for A ccur ate

Refrigerant Control

* Adjust able E xternal S tatic Pressure

* Built-In Drain Pump – 20 In ch Lif t

* Wired or Wireless Remote Contr ol

* Bottom or Rear Return Air

* Easy Service

* Optional Fre sh Air In take

UHXSERIES

MODELS

UHX 0762

UHX 0962

UHX 1262

UHX 1562

UHX 1862

UHX 2462

UHX 3662

UHX 4862

UHX 5462

DESCRIPTION

PERFORMANCE

COOLING CAPACITY

HEATING CAPACITY

CURRENT

COOLING

HEATING

POWER INPUT

COOLING

HEATING

(Type: Nominal Cooling Capacity, etc)

Volt PH

7500 BTU 0.28 / 0.40 ESP 208-230V/60 HZ 1

9600 BTU 0.28 / 0.40 ESP 208-230V/60 HZ 1

12000 BTU 0.28 / 0.40 ESP 208-230V/60 HZ 1

15000 BTU 0.28 / 0.44 ESP 208-230V/60 HZ 1

19000 BTU 0.32 / 0.48 ESP 208-230V/60 HZ 1

25000 BTU 0.32 / 0.48 ESP 208-230V/60 HZ 1

36000 BTU 0.32 / 0.49 ESP 208-230V/60 HZ 1

48000 BTU 0.31 / 0.45 ESP 208-230V/60 HZ 1

54600 BTU 0.31 / 0.45 ESP 208-230V/60 HZ 1

UHX 0762 UHX 0962 UHX 1262 UHX 1562 UHX 1862 UHX 2462 UHX 3662 UHX 4862 UHX 5462

7,500 BTU/H

8,500 BTU/H

0.45/0.49 A

0.42/0.46 A

92/112 W

87/104 W

9,600 BTU/H

11,000 BTU/H

0.45/0.49 A

0.42/0.46 A

92/112 W

87/104 W

12,000 BTU/H

14,000 BTU/H

0.52/0.55 A

0.49/0.54 A

107/125 W

100/122 W

15,00 0 BTU/H

17,000 BTU/H

0.52/0.55 A

0.49/0.54 A

107/125 W

100/122 W

19,00 0 BTU/H

21,000 BTU/H

0.90/0.96 A

0.89/0.95 A

183/219 W

182/214 W

25,0 00 BTU/H

27,000 BTU/H

0.90/0.96 A

0.89/0.95 A

183/219 W

182/214 W

36,0 00 BTU/H

39,0 00 BTU/H

1.15/1.25 A

1.10/1.18 A

235/282 W

224/267 W

47,800 BTU/H

54,600 BTU/H

1.25/1.34 A

1.13/120 A

254/301 W

230/271 W

54,600 BTU/H

61,40 0 BTU/H

1.25/1.34 A

1.13/120 A

254/301 W

230/271 W

SANYO INDOOR

HEAT EXCHANGER

FAN T YPE

HI/MED/ LOW FAN AIR FLOW RATE

FAN EXT. STATIC PRES S (230V )

FAN MOTOR T YPE

FAN MOTOR OU TPUT

REFRIGERANT PIPE DIMENSIONS

LOW PRESSURE (FLARE)

HIGH PRESSURE (FL ARE )

UNIT DIMENSIONS

Inches (") / lbs.

DRAINPIPE DIMENSION

SOUND LEVELS

(L OW-ME D-HIGH ) DB(A ) @

CENTRIFUGAL X1

353/300/247

0.40 IN. WC

AC

50 W

1/4"

1/2"

CENTRIFUGAL X1

353/300/247

0.40 IN. WC

AC

50 W

1/4"

1/2"

12.5"/ 27.5"/ 25"/ 53 LBS.

HEIGHT/ WIDTH/ DEPTH/ NET WEIGHT

CENTRIFUGAL X1

424/371/318

0.40 IN. WC

AC

70 W

1/4"

1/2"

CENTRIFUGAL X1

424/371/318

0.44 IN. WC

AC

70 W

1/4"

1/2"

CENTRIFUGAL X1

671/565/459

0.48 IN. WC

AC

100 W

1/4"

1/2"

12.5"/ 39.5"/ 25"/ 71LBS.

HEIGHT/ WIDTH/ DEPTH/ NET WEIGHT

CENTRIFUGAL X1

671/565/459

0.48 IN. WC

AC

100 W

3/8"

5/8"

CENTRIFUGAL X1

1060/919/742

0.49 IN. WC

AC

140 W

3/8"

5/8"

12.5"/58.5"/ 25"/ 104LBS.

HEIGHT/ WIDTH/ DEPTH/ NET WEIGHT

CENTRIFUGAL X1

1116/1060/883

0.45 IN. WC

AC

140 W

3/8"

5/8"

12.5"/ 58.5"/ 25"/104 LBS.

HEIGHT/ WIDTH/ DEPTH/ NET WEIGHT

1 1/4" OD

24/28/31 24/28/31 24/28/31 26/30/33 27/32/36 27/32/36 31/33/38 33/37/40 33/37/40

230V

CENTRIFUGAL X1

1166/1060/883

0.45 IN. WC

AC

140 W

3/8"

5/8"

12.5"/ 58.5"/ 25"/ 104 LBS.

HEIGHT/ WIDTH/ DEPTH/ NET WEIGHT

23

Page 24

DHXSERIES

Concealed Ducted - Medium-High Static

SANYO’s concealed ceiling units are flexible and space saving,

helping maximize floor and wall space. Advanced zoning

capabilities condition large areas simply and efficiently.

Completely concealed, they offer simple installation.

DHX 3652 / DHX 4852

KEY FEATURES:

* “ECO Friendly” R410A Refrigerant

* 208/230V, 1 Phase, 60Hz

* Electronic Expansion Valve (EEV) for

Accurate Refrigerant Control

* Perfect for Long Duct Runs

* Wired or Wireless Remote Control

* Easy Service

* Built-in float safety

A PERFECT APPLICATION FOR

LONGER DUCT RUN INSTALLATIONS.

MODELS

DHX 3652

DHX 4852

(Type: Nominal Cooling Capacity, etc)

36,000 BTU ESP = 0.70" 208-230V/60 HZ 1

48,000 BTU ESP = 0.67" 208-230V/60 HZ 1

DESCRIPTION

CAPACITY

COOLING

HEATING

CURRENT

COOLING

HEATING

POWER INPUT

COOLING

HEATING

UNIT DIMENSIONS

Inches (") / lbs.

HEAT EXCHANGER

FAN TYPE X QUANTITY

FAN AIRFLOW RATE

FAN EXT. STATIC PRESS (230V)

FAN MOTOR TYPE

FAN MOTOR OUTPUT

DHX

3652 DHX 4852

36,000 BTU

39,000 BTU

2.84/2.89 A

2.74/2.80 A

548/620 W

528/602 W

16.5"/ 42"/ 24.5"/ 110 lbs.

Height/ Width/ Depth/ Net Weight

CENTRIFUGAL X1

1,060/988/883 - CFM - (H/M/L)

0.70 - In. WC

AC

200 - W

Volt PH

47,800 BTU

54,600 BTU

3.24/3.19 A

3.17/3.42 A

644/695 W

627/756 W

18"/ 42"/ 24.5"/ 119 lbs.

Height/ Width/ Depth/ Net Weight

CENTRIFUGAL X1

1,272/1,237/1,160 - CFM - (H/M/L)

0.67 - In. WC

AC

400 - W

REFRIGERANT PIPE DIMENSIONS

LOW PRESSURE (FLARE)

HIGH PRESSURE (FLARE)

DRAINPIPE DIMENSION

SOUND LEVELS

(LOW-MED-HIGH)

24

3/8"

5/8"

1 1/4" OD 1 1/4" OD

42/44/45 - DB(A) @ 230V 44/46/47 - DB(A) @ 230V

3/8"

5/8"

Page 25

FLOOR MOUNTED

WITH DECORATIVE PANEL

Floor Mounted

FHX 0762 / FHX 0962 / FHX 1262

FHX 1562 / FHX 1862 / FHX 2462

KEY FEATURES:

* “ECO Friendly” R410A Refrigerant

* 208/230V, 1 Phase, 60Hz

* Electronic Expansion Valve (EEV) for

Accurate Refrigerant Control

* Wired or Wireless Remote Control

* Easy Service

* Washable Long Life filter

FMHX 0762 / FMHX 0962 / FMHX 1262

FMHX 1562 / FMHX 1862 / FMHX 2462

FHX/FMHXSERIES

FLOOR MOUNTED

WITH OUT DECORATIVE PANEL

DESCRIPTION

CAPACITY

COOLING

HEATING

CURRENT

COOLING

HEATING

POWER INPUT

COOLING

HEATING

FHX UNIT DIMENSIONS

Inches (") / lbs.

FMHX UNIT DIMENSIONS

Inches (") / lbs.

HEAT EXCHANGER

FAN TYPE X QUANTITY

FAN AIRFLOW RATE

FAN MOTOR OUTPUT

REFRIGERANT

PIPE DIMENSIONS

LOW PRESSURE (FLARE)

HIGH PRESSURE (FLARE)

DRAINPIPE DIMENSION

SOUND LEVELS

(LOW-MED-HIGH)

FHX/FMHX

0762

7,500 BTU

8,500 BTU

.22/.24 A

.22/.23 A

45/54 W

43-50 W

24.25"/42"/9"/64 lbs.

Height/ Width/ Depth/ Net Weight

24.25"/35.5"/9"/46 lbs.

Height/ Width/ Depth/ Net Weight

Centrifugal

247/212/177

10 W

1/4"

1/2"

1 1/4" OD 1 1/4" OD 1 1/4" OD 1 1/4" OD 1 1/4" OD 1 1/4" OD

28/30/33 28/30/33 29/35/39 31/35/38 31/36/39 35/38/41

FHX/FMHX

0962

9.600 BTU

11,000 BTU

.22/.24 A

.22/.23 A

45/54 W

43-50 W

24.2"/42"/9"/64 lbs.

Height/ Width/ Depth/ Net Weight

24.25"/35.5"/9"/46 lbs.

Height/ Width/ Depth/ Net Weight

Centrifugal

247/212/177

10 W

1/4"

1/2"

KEY FEATURES:

* “ECO Friendly” R410A Refrigerant

* 208/230V, 1 Phase, 60Hz

* Electronic Expansion Valve (EEV) for

Accurate Refrigerant Control

* Wired or Wireless Remote Control

* Easy Service

* Washable Long Life filter

FHX/FMHX

1262

12,000 BTU

14,000 BTU

.42/.44

.40/.42

86/101

83/96

24.2"/42"/9"/64 lbs.

Height/ Width/ Depth/ Net Weight

24.25"/35.5"/9"/46 lbs.

Height/ Width/ Depth/ Net Weight

Centrifugal

318/247/212

20 W

1/4"

1/2"

FHX/FMHX

1562

15,000 BTU

17,000 BTU

.58/.60

.53/.55

116/134

106/122

24.0"/54.5"/9"/86 lbs.

Height/ Width/ Depth/ Net Weight

24.25"/48"/9"/62 lbs.

Height/ Width/ Depth/ Net Weight

Centrifugal

424/318/283

20 W

1/4"

1/2"

FHX/FMHX

1862

19,000 BTU

21,000, BTU

.58/.60

.53/.55

116/134

106/122

24.0"/54.5"/9"/62 lbs.

Height/ Width/ Depth/ Net Weight

24.25"/48"/9"/62 lbs.

Height/ Width/ Depth/ Net Weight

Centrifugal

530/459/389

30 W

1/4"

1/2"

SANYO INDOOR

FHX/FMHX

2462

24,000 BTU

27,000 BTU

.61/.63

.56/.58

119/138

109/125

24.0"/54.5"/9"/62 lbs.

Height/ Width/ Depth/ Net Weight

24.25"/48"/9"/62 lbs.

Height/ Width/ Depth/ Net Weight

Centrifugal

601/495/424

60 W

3/8"

5/8"

25

Page 26

CONTROL SYSTEMS

Simple System Control Network S-Net

SANYO’s system control network is the heart and soul

of the ECOi™ unit, enabling it to live with the living

inside. With a simple two-wire loop installation,

we put control in your hands, literally. No outside

specialists required, it’s an all-in-one solution for

you, and a way to further build profits by keeping

installation in-house. The logic resides in the ECOi

system and the control is the gateway.

NO OUTSIDE SPECIALISTS REQUIRED,

IT’S AN ALL-IN-ONE SOLUTION FOR YOU.

PART NUMBER

RCS-TM80BG

DESCRIPTION

WIRED REMOTE CONTROLLER — 7- day setback, mode, temp, service, etc.

RCS-TM80BG / RCS-BH80AAB.WL / RCS-SH80AAB.WL

RCS-TRP80AAB.WL / RCS-XM18AAB.WL

RCS-SH1AAB.WL / RCS-KR1EG / SHA-KC64UG

SHA-TM64AGB / SHA-KT256EA / SHA-KA128AAB

ART-K45AGB / SHA-LN16UBA / BMS-CTRL1

TECS-5000KA / TECS-5000AA / TECS-5000GA

TECS-5000BA / TECS-5000WA

NOTES

RCS-BH80AAB.WL

RCS-SH80AAB.WL

RCS-TRP80AAB.WL

RCS-XM18AAB.WL

RCS-SH1AAB

RCS-KR1EG

SHA-KC64UG

SHA-TM64AGB

SHA-KT256EA

SHA-KA128AAB

ART-K45AGB

SHA-LN16UAB

BMS-CTRL1

TECS-5000KA

TECS-5000AA

WIRELESS REMOTE CONTROLLER — For use with UHX, UMHX, DHX, FHX and FMHX models

WIRELESS REMOTE CONTROLLER — For use with XHX models

WIRELESS REMOTE CONTROLLER — For use with AHX and THX models

WIRELESS REMOTE CONTROLLER — For use with XMHX models

WIRELESS REMOTE CONTROLLER — For use with KHX models

SIMPLE REMOTE CONTROLLER (wired) — on/off, Mode, Temp, Fan Speed, Flap, Service Function

SYSTEM CONTROLLER — Set individual indoor unit temps for up to 4 zones, 16 indoor units max per zone

SCHEDULE TIMER — Thermal On/Off at program times only, no set back temperature

INTELLIGENT CONTROLLER ( Web Enabled ) — Controls Max of 256 indoor units with SHA-KA128AAB

COMMUNICATIONS ADAPTOR — Used with INTELLIGENT CONTROLLER and BMS interface

REMOTE SENSOR

LONWORKS INTERFACE — Maximum of 16 indoor units

BMS INTERFACE — BACnet, LONworks, N2 or MODBUS (also requires SHA-KA128AAB)

STAIMS — Base Software Package

STAIMS — Electrical Power Distribution Proportioning Software (also requires TECS-5000KA)

TECS-5000GA

TECS-5000BA

TECS-5000WA

26

STAIMS — Layout Graphic Display Software (also requires TECS-5000KA)

STAIMS — BACnet Interface Software (also requires TECS-5000KA)

STAIMS — Web Enabling Software (also requires TECS-5000KA)

Page 27

RCS-SH80AAB.WL

For Us e With X HX Indoor Units

RCS-TRP80AAB.WL

For Us e With A HX and THX I ndoor Units

Simple System Control Network

RCS-SH1AAB

For Us e With K HX Indoor Units

RCS-BH80AAB.WL

For Use W ith UH X, UM HX,

DHX , FHX a nd FMH X Indoor Unit s

CONTROL SYSTEMS

WIRELESS REMOTES

CONTROL IN THE PALM

OF YOUR HAND.

They enable the user to truly take control of the entire

system, from mode, temperature, airflow, and system

diagnosis, all through an easy-to-read liquid crystal

display. Control at your fingertips.

KEY FEATURES:

* Thin and Easy To Read

* Simple To Install and Use

* Can Be Adapted for Use On All ECOi Indoor Units

* Fan Speed Control

* Timer Mode Start/Stop

* Timer Mode On/Off

* Operating Mode

* Inspection/Test Indication

* Remote Can Be Configured To Sense Temperature

SANYO’s wireless remotes control more than comfort.

Simple remotes offer control where minimal functionality is best suited for those

inside. SANYO’s Standard Remote with 7 Day Timer is perfectly suited

for those requiring more programmed management over multiple zones.

By offering immediate diagnostics and up to six-daily set temperature schedules,

it’s a perfectly controlled solution offering intuitive simplicity.

RCS-KR1EG

Simple R emote Cont roller

RCS-TM80BG

Stan dard Remote/ 7 Day Timer

For Us e With A ll Indoor Unit s

SANYO’s wired remote controls offer multiple conditioning solutions

to meet the needs of any project.

WIRED REMOTES

SIMPLE TO INSTALL

KEY FEATURES (STANDARD REMOTE/7 DAY TIMER):

* Thin and Easy To Read

* Simple To Install and Use

* Can Be Adapted for Use On All ECOi Indoor Units

* Fan Speed Control

* Airflow Direction

* Operating Mode (Heating/Cooling/Auto/Dry/Fan)

* Vacation Mode for Continued Energy Efficiencies

* Full 7 Day Set-Back Functionality, With Up To 6 Time

Periods/Day

* Full System Diagnostic Capability

(Diagnostic Histor y Provides Immediate View of System

Past and Present.)

KEY FEATURES: (SIMPLE REMOTE)

* Thin and Easy To Read

* Simple To Install and Use

* Can Be Adapted for Use On All ECOi Indoor Units

* Mode

* Operating Mode (Heating/Cooling/Auto/Dry/Fan)

* Vacation Mode for Continued Energy Efficiencies

* Fan Speed Control

* Set Temperature

* On/Off

* Airflow Direction

* Perfectly Suited for A pplications W here Simpler

Functionality is Required (ie: Hotel Rooms, Nursing

Homes, Offices)

SANYO Control System

27

Page 28

CONTROL SYSTEMS

SHA-KC64UG

Syst em Con troller

Simple System Control Network

MULTIPLE ZONE

CONTROLLERS

THE HEART AND SOUL

OF CONDITIONING.

KEY FEATURES (SYSTEM CONTROL):

Controls Up To 64 Units Into

*

4 Individualized Zones

* Alarm and Operational Signal Output

* Single Access Points for All Connected

Wired Remotes

Controls Up To 64 Units Into 4 Individualized Zones

SANYO’s system and intelligent controls are the central nervous system

to the conditioning system. The gateway to all data, temperature and

system diagnostics.

SHA-KT256BA

Intelligent Controller

Web Accessible/Real Time Diagnostics Through Individual IP Address

CONTROLS UP TO

256 INDOOR UNITS

KEY FEATURES (INTELLIGENT CONTROL):

6.5 Inch Touch Screen Panel

*

* Controls up to 256 Indoor units with added

Communication Adapter (128 indoors without)

* New Control Wiring System (S Net) Connects Up

To 64 Units To a Single Control Line

* Offers a Maximum Installation of Two System

Controls (One Main, One Sub)

* Provides Individual Tenant Billing data for

3 systems addition systems are done by adding

Communication Adapters. Requires wat t hour meters

* Provides Individual Tenant Billing Data Through

Calculations Based on a Per-Tenant Basis

* Individual Zone Override Feature

(High/Low Setting)

* Web Accessible/ Real Time Diagnostics

Through Individual IP Address

* Diagnostic History of System Past and Present

28

Page 29

Building Management Integration

SHA-LN16UAB

LonWorks Interface

SANYO’s LonWorks interface integrates into many compatible

Building Management Systems. Single point of control. Access

to all of the ECOi™ conditioning mechanics.

BMS-CTRL1

BacNet Interface

SANYO’s BMS Controller sets a new standard for multiple

equipment protocol conversion.

CONTROL SYSTEMS

LONWORKS INTERFACE

SINGLE POINT OF CONTROL

KEY FEATURES:

Communicate With LonWorks Compatible Systems

*

* Start/Stop

* Controls Up To 16 Groups (Maximum 64 Indoor Units)

* For 17 or more groups of indoor units connect additional

interface units.

* Temperature Setting, Fan Speed, etc.

* Schedule Time Setting

* Alarm Notification

BMS CONTROLLER

BMS-CTRL1

KEY FEATURES:

Able to provide BMS integration to a variety of BMS

*

protocols including BACnet, Modbus LonWorks and N2

* Communicates with up to 90 indoor units and 10 out

door units (note; N2 can communicate with 40 indoor

and 10 outdoor units)

* Provides control of operating mode, fan, set temperature

* Provides status of operating modes and alarm status

Building Automation

System

BACnet

LonWorks

Modbus

N2

NETWORK DIAGRAM

Communication

Adaptor

BMS-CTRL1

OEMPrtl Pro

(Up t o 10 outdoor units & 9 0

indoor units)

Outdoor unit

Remote

Controller

Group control

Weekly

Timer

Group control

Remote

Controller

SANYO Control System

29

Page 30

ACCESSORIES

Simple System Control Network

PART NUMBER

APR-P160UK

APR-P680UK

APR-P1350UK

APR-CHP680UK

APR-CHP1350UK

APR-RZP224UK

APR-RZP680UK

APR-RZP1350UK

APR-CHRZP900UK

AT K-RZP56BAWB

AT K-RZP160BAWB

BVT 14

BVT 38

BVT 12

BVT 58

BVT 34

BVT 78

BVT 118

BVT 138

BVT 158

DESCRIPTION 2-Way Distribution Kits (cut to fit)

DISTRIBUTION JOINT KIT CUT TO FIT Used with 2 Pipe indoor Unit Piping - Up to 76,400 BTUs

DISTRIBUTION JOINT KIT CUT TO FIT Used with 2 Pipe indoor Unit Piping - 76,500 to 232,000 BTUs

DISTRIBUTION JOINT KIT CUT TO FIT Used with 2 Pipe indoor Unit Piping - 232,200 to 460,700 BTUs

DISTRIBUTION JOINT KIT CUT TO FIT Used to Connect Multiple 2 Pipe Outdoor Units - Up to 232,000 BTUs

DISTRIBUTION JOINT KIT CUT TO FIT Used to Connect Multiple 2 Pipe Outdoor Units - 232,200 to 460,700 BTUs

3-Way Distribution Kits (cut to fit)

DISTRIBUTION JOINT KIT CUT TO FIT Used with 3 Pipe Indoor Unit Piping - Up to 76,400 BTUs

DISTRIBUTION JOINT KIT CUT TO FIT Used with 3 Pipe Indoor Unit Piping - 76,500 to 232,000 BTUs

DISTRIBUTION JOINT KIT CUT TO FIT Used with 3 Pipe Indoor Unit Piping - 232,200 to 460,700 BTUs

DISTRIBUTION JOINT KIT CUT TO FIT Used to Connect Multiple 3 Pipe Outdoor Units - Up to 307,100 BTUs

3-Way Solenoid Valve Kits

SOLENOID VALVE KIT Total Indoor Capacity of Less than 19,000 BTUs (for 3 Pipe System)

SOLENOID VALVE KIT Total Indoor Capacity of 19,100 to 54,600 BTUs (for 3 Pipe System)

Ball Valves

1/4" Ball Valve With Access Port Fitting

3/8" Ball Valve With Access Port Fitting

1/2" Ball Valve With Access Port Fitting

5/8" Ball Valve With Access Port Fitting

3/4" Ball Valve With Access Port Fitting

7/8" Ball Valve With Access Port Fitting

1-1/8" Ball Valve With Access Port Fitting

1-3/8" Ball Valve With Access Port Fitting

1-5/8" Ball Valve With Access Port Fitting

Mini Condensate Pumps

ASP-MA115

ASP-MA230

ASP-ML115

ASP-ML230

ASP-MO115

ASP-MO230

CMB-FS140AA

115 VOLT MINI AQUA ASPEN CONDENSATE PUMP Max 26' Lift, 3.7 GPH @ 0 Lift, 0.8 GPH @ 26'

230 VOLT MINI AQUA ASPEN CONDENSATE PUMP Max 26' Lift, 3.7 GPH @ 0 Lift, 0.8 GPH @ 26'

115 VOLT MINI LIME ASPEN CONDENSATE PUMP Max 26' Lift, 3.7 GPH @ 0 Lift, 0.8 GPH @ 26'

230 VOLT MINI LIME ASPEN CONDENSATE PUMP Max 26' Lift, 3.7 GPH @ 0 Lift, 0.8 GPH @ 26'

115 VOLT MINI ORANGE ASPEN PUMP Max 26' Lift, 3.7 GPH @ 0 Lift, 0.8 GPH @ 26'

230 VOLT MINI ORANGE ASPEN PUMP Max 26' Lift, 3.7 GPH @ 0 Lift, 0.8 GPH @ 26'

FRESH AIR CHAMBER For Use With XHX2452 and XHX3652 Indoor Units Only (Requires CMB-GS140AA)

460 Transformers

ACC-195674

ACC-195679

30

460V TO 230V, 11 KVA TRANSFORMER For Use With CHDX07263, or CHDZ07263, One Per Outdoor Unit

460V TO 230V, 14 KVA TRANSFORMER For Use With CHDX09663, or CHDZ09663, One Per Outdoor Unit

Page 31

Simple System Control Network

SERVICES

ACC-CR-USB

PART NUMBER

ECO-SC-4

IC-SC-1

IC-SC-INDOOR

LW-SC-1

LW-SC-INDOOR

PP-SC-1

PP-SC-INDOOR

CA-SC-1

CA-SC-INDOOR

STAIMS-SC-1

STAIMS-SC-INDOOR

AC-SC-1

Pac Checker Service & diagnostics tool for all ECOi and SANYO Splits greater than 26,000 BTUs

DESCRIPTION

ECOi COMMISSIONING (Per normal business day, up to 24 tons)

COMMISSIONING OF INTELLIGENT CONTROLLER (Base fee for each Intelligent Controller)

COMMISSIONING OF INTELLIGENT CONTROLLER (Indoor Units)

COMMISSIONING OF LONWORKS INTERFACE MODULE (Base fee)

COMMISSIONING OF LONWORKS INTERFACE (Indoor Units fee)

COMMISSIONING OF INTELLIGENT BACnet INTERFACE (Base fee for each BMS-CTRL 1)

COMMISSIONING OF INTELLIGENT BACnet (Indoor Units fee)

COMMISSIONING OF COMMUNICATIONS ADAPTER (Base fee for each Comm. Adapter)

COMMISSIONING OF COMMUNICATIONS ADAPTER (Indoor Units fee)

COMMISSIONING OF STAIMS MANAGEMENT SYSTEM (Base fee for each overall system)

COMMISSIONING OF STAIMS MANAGEMENT SYSTEM (Indoor Units fee)

PROGRAM 2-WAY SYSTEM TO ENABLE AUTO CHANGEOVER OF MODE (Base fee /Indoor Units fee)

AC-SC-INDOOR

IPO-SC-1

IPO-SC-INDOOR

CNBH

COUS

RP-SIT-1

RP-SIT-2

ECOi-IST

ECOi-SERT

TOUS

ECO-SIT-4

ECO-SIT-NR

ECO-SIT-OS

PROGRAM 2-WAY SYSTEM TO ENABLE AUTO CHANGEOVER OF MODE (Indoor Units fee)

PROGRAM "IGNORE INDOOR POWER OFF FAILURE" FOR 2-WAY SYSTEM (Base fee /Indoor Units fee)