Sanyo ECD-780 Service manual

FILE NO.

SERVICE MANUAL

REL

VOL

TUN

TRK

Specifications

FM TUNER

Tuning Range.............................................................................. 87.5 - 107.9 MHz. (200 KHz. step)

Sensitivity .................................................................................... 1.5 µV

Separation................................................................................... 30 dB

Signal-to-Noise Ratio .................................................................. 65 dB (stereo), 70 dB (mono)

Full Panel Detachable

High Power

FM / AM Stereo Receiver

Compact Disc Player

LO/DX

LOUD

AUD

FM/AM CD RECEIVER ECD-780 45W x 4

PRESET

TRACK

CD

FMIII

AMII

LOUD ST LOC

L

R

BASS MANU TRE

R

F

SCAN

SHF

RPT

RPTSHFDISC

ECD-780

114782838

BAND

ATP

FRONT

CDC

CD

DISP

PWR

MUTE

AM TUNER

Tuning Range.............................................................................. 530 - 1,710 KHz. (10 KHz. step)

Sensitivity .................................................................................... 20 µV

Signal-to-Noise Ratio .................................................................. 45 dB

CD PLAYER

Frequency Response .................................................................. 20 - 20,000 Hz.

Signal-to-Noise Ratio .................................................................. 90 dB

Channel Separation .................................................................... 60 dB

Dynamic Range .......................................................................... 90 dB

Harmonic Distortion..................................................................... 0.2 %

AUDIO AMPLIFIER & GENERAL

Maximum Output Power ............................................................. 45 W x 4 channels

Output Wiring .............................................................................. Floating-Ground type designed for

4-speaker use

RCA low-level outputs: 2 channels

Output Impedance ...................................................................... 4 - 8 ohms

Power Supply .............................................................................. 12 volts DC, negative ground

Specifications are subject to change without notice.

REFERENCE No. SM-7900004

CONTENTS

SERVICE NOTES and PRECAUTIONS.........................................................................2-4

ELECTRICAL ADJUSTMENTS.......................................................................................5-8

TERMINOLOGY REFERENCE ....................................................................................9-13

BLOCK DIAGRAM ........................................................................................................... 14

IC/TRANSISTOR LEAD IDENTIFICATION...................................................................... 15

CD MECHANISM EXPLODED VIEW .............................................................................. 16

PARTS LIST - CD MECHANISM.................................................................................17-18

CABINET & CHASSIS EXPLODED VIEW....................................................................... 19

PARTS LIST - CABINET, CHASSIS AND ACCESSORIES.............................................. 20

PARTS LIST-MAIN ......................................................................................................21-25

PARTS LIST-DISP ......................................................................................................26-27

PARTS LIST-RF33 ......................................................................................................28-30

CIRCUIT BOARD DIAGRAM ............................................................... SEPARATE SHEET

SCHEMATIC DIAGRAM ...................................................................... SEPARATE SHEET

— 1 —

SERVICE NOTES AND PRECAUTIONS

SERVICE NOTES

1. Make sure that the power lead is connected properly to

power source, otherwise damage to radio may result. If a

battery eliminator is used as a power source in place of a

battery, it must be filtered and regulated. (The power supply capacity should be more than 5 amps.)

2. Integrated circuits (ICs) are used in this unit. Because the

ICs are direc-coupled devices, as to all electronic equipment, reading within 10% of the indicated values are acceptable. Allowance must also be made for variations in

supply voltage. It is expected that any breakdown within

the IC results in drastic changes of the operating voltages

at the terminals.

3. When replacing a power output IC, remember to use the

IC specified in the parts list; Coat the IC-fin with silicon

grease.

WARNING

ln using meters, signal generator and any tool in servicing

Ics, extreme care is needed. DO NOT SHORT THE IC TERMINALS TO THE PATTERN ON THE PC BOARD OR TO

EACH OTHER. THE IC WILL BE INSTANTANEOUSLY DESTROYED.

ALIGNMENT PROCEDURE

Alignment is performed at factory with laboratory equipment.

Therefore, before alignment is attempted, the unit should be

thoroughly checked for circuit troubles.

NOTES:

1. Check for specified source voltage-DC, 14.4volts.

2. Connect an AC voltmeter (AC VM) across speaker or

dummy load (4 ohms. 20W , wirewound resistor)...see Fig.

1-3. (ELECTRICAL ADJUSTMENTS)

3. Signal input must be kept as low as possible to avoid overload and clipping (use highest sensitivity of output indicator).

4. Repeat adjustment to ensure good results.

5. Non-metallic alignment tools must be used (especially at

FM alignment).

6. For alignment location details, refer to CIRCUIT BOARD

PARTS LOCATION.

INSTALLATION PROCEDURE

1. To prevent a short circuit, remove the key from the ignition and disconnect the

2. Make the proper input and output wire connections for

each unit.

3. Connect the wiring harness wires in the following order:

ground, speakers, battery, ignition.

4. Connect the wiring harness connector to the unit.

5. Install the unit in your car.

6. Reconnect the

7. Disinstall by reversing the installation procedure.

battery.

battery.

CAUTI0N

• The rear-panel which also heatsink is very hot. Don’t burn!!

• If your car’s ignition does not have an ACC position, connect the ignition wires to a power source that can be turned

on and off with the ignition key . If you connect the ignition

wire to a power source with a constant voltage supply, as

with battery wires, the battery may die.

• If the console has a lid, make sure to install the unit so

that the cover will not hit the lid when closing and opening.

• If the fuse blows, first make sure the wires aren’t touching

to cause a short circuit, then replace the old fuse with one

with the same rating.

• Do not let unconnected wires or terminals touch metal on

the car or anything else conducting electricity. To prevent

a short circuit, do not remove the caps on the ends of the

unconnected wires or the terminals.

• Connect the speaker wires correctly to the terminals to

which they correspond. The unit may be damaged or fail

to work if you share the

metal part in the car.

• After the unit is installed, check whether the brake lamps,

blinkers, wipers, etc. on the car are working properly.

• Insulate unconnected wires with vinyl tape or other similar material .

wires or ground them to any

— 2 —

SERVICE NOTES AND PRECAUTIONS

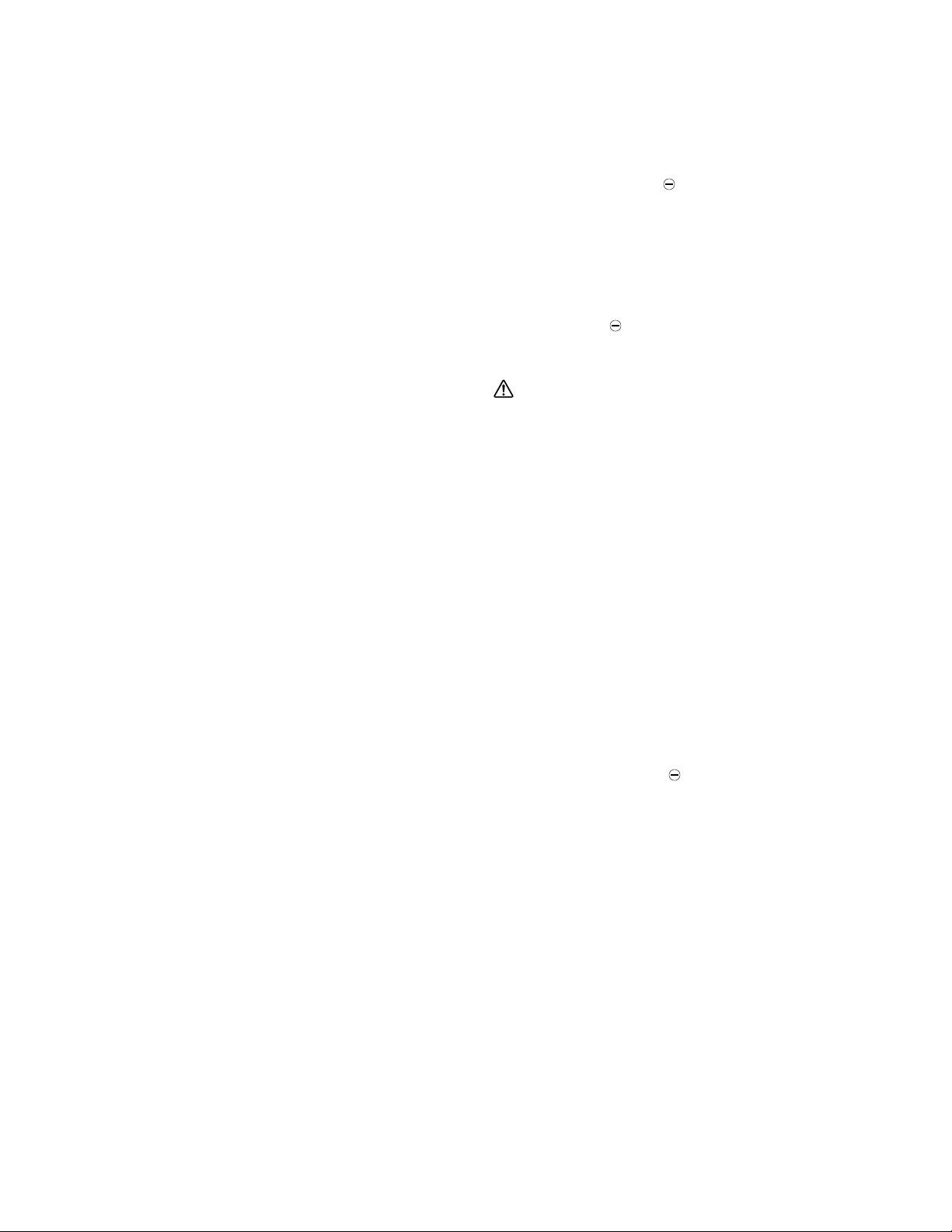

LASER BEAM SAFETY PRECAUTIONS

NOTES FOR TRANSPORT AND STORAGE

1. The pickup should always be kept in its conductive bag

until use.

2. The pickup should never be subjected to external pressure or impact.

Storage in conductive bag Drop impact

GOOD

REPAIR NOTES

1. The pickup incorporates a strong magnet, and so should

never be brought close to magnetic materials.

NG

3. Each and every pickup is already individually adjusted to

a high degree of precision, and for that reason the adjustment point and installation screws should be absolutely

never be touched.

4. Laser beam may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part

(lens, etc.) of the pickup if it is damaged.

Laser Beam

NEVER look directly at the

laser, and do not let contact

fingers of other exposed

skin.

NG

Magnet

NG

2. The pickup should always be handled correctly and carefully, taking care to avoid external pressure and impact. If

it is subjected to strong pressure or impact, the result may

be an operational malfunction and/or damage to the

printed circuit board.

Pressure

Pressure

5. Cleaning the lens surface

If there is dust on the lens surface, the dust should be

cleaned away by using an air brush (such as one used for

camera lens). The lens is held by a delicate spring.

Conductive Sheet

6. Never attempt to disassemble the pickup.

— 3 —

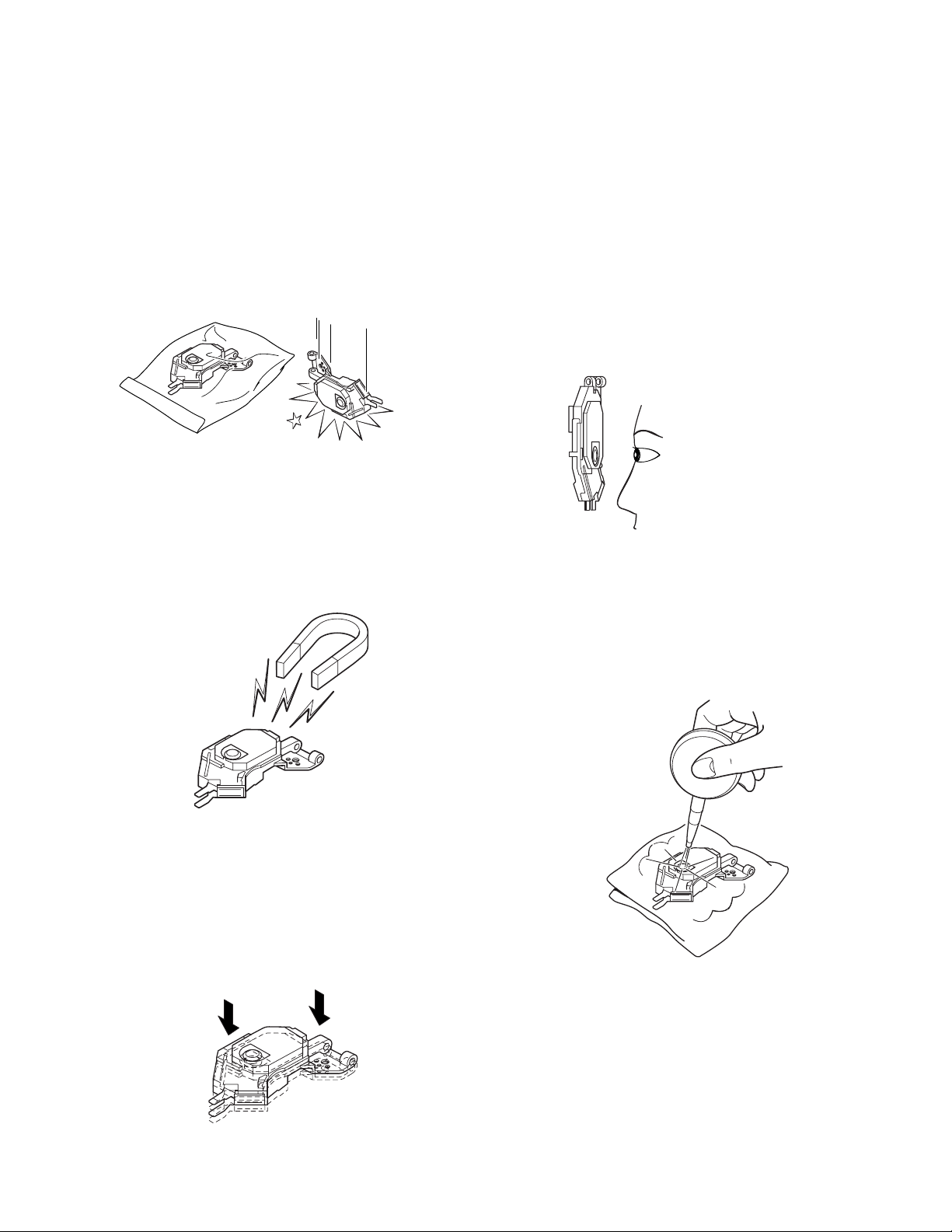

SERVICE NOTE AND PRECAUTIONS

STATIC ELECTRICITY

The CD pickup might suffer destruction by static electricity during spare-parts maintenance or replacement, although it is stable

when connected to the circuit in the CD unit. The destruction might be caused because the laser diode terminal will be electrically open. To prevent the terminal from being open, do the following steps:

1. When you replace the CD pickup, or remove the CD unit from the car stereo unit for any maintenance purpose, solder the

copper foil pattern indicated in Fig. 1 and Fig. 2 below to short-circuit the connector PCB and flexible wire of the CD unit.

Perform your intended maintenance work with the flexible wire short-circuited.

2. If the original CD pickup may possibly be reused, make a short circuit in the area indicated in Fig. 3 first. Then remove the

pickup and perform the work.

3. The CD Pickup OPTIMA-715K2, which is supplied as one of the spare parts, is already short-circuited with the copper foil

pattern pre-soldered indicated in Fig. 3 below. To handle this CD Pickup, keep the short circuit as it is. Then attach the

Pickup to the unit and connect the flexible wire to the connector.

4. After performing the work, eliminate the short circuit by removing the solder at its respective short-circuited area described

in 1, 2 and 3 above.

5. Insert a CD. If the E-01 or E-02 error should appear on the display on the face plate, check the area mentioned in 4 above,

where the short circuit may not have been eliminated.

6. Note that the semi-fixed VR equipped with the CD Pickup OPTIMA-715K2 must not be turned. You cannot make any

adjustment to the semi-fixed VR, which is completely adjusted when shipped at the factory.

Fig. 3Fig. 2

Fig. 1

— 4 —

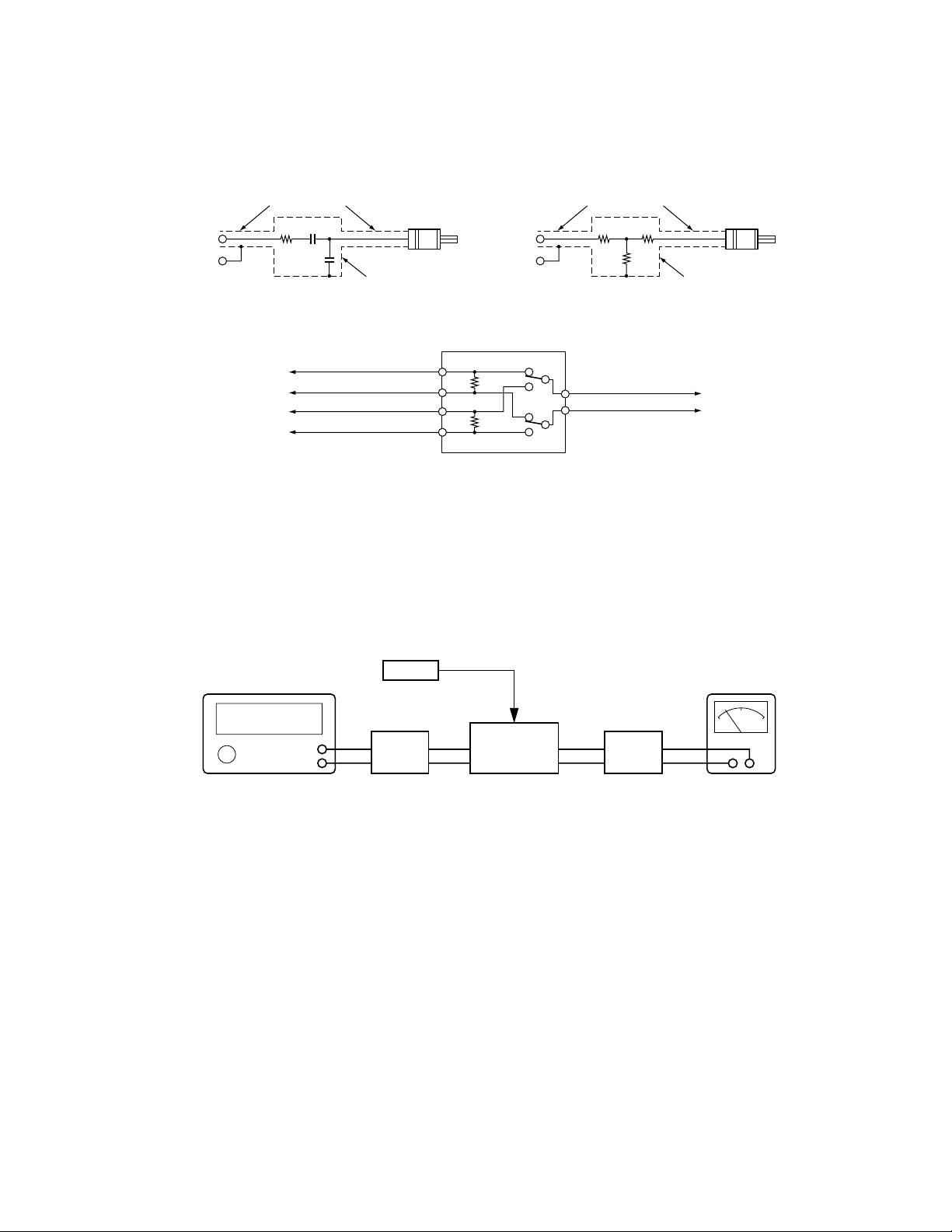

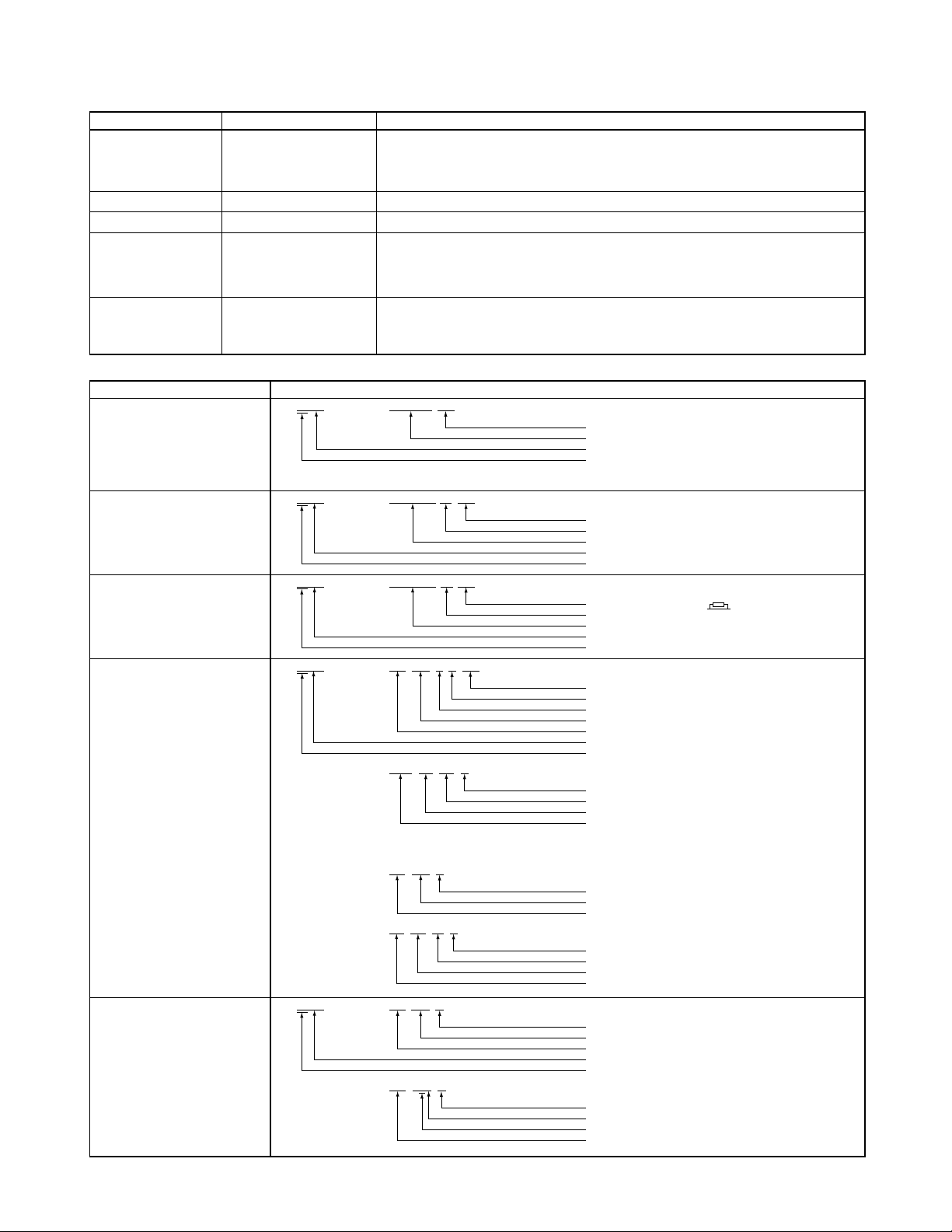

DUMMY BOX SCHEMATIC

ELECTRICAL ADJUSTMENTS

AM S.G.

(50Ω)

CO-AX CABLE

33Ω 15PF

60PF

PLUG TO FIT ANTENNA

RECEPTACLE OF UNIT

METAL SHIELD CAN

FM S.G.

(50Ω)

CO-AX CABLE

10Ω 45Ω

60Ω

PLUG TO FIT ANTENNA

RECEPTACLE OF UNIT

METAL SHIELD CAN

AM DUMMY ANTENNA FM DUMMY ANTENNA

Fig. 1-1 Fig. 1-2

4Ω 20W

LEFT CHANNEL OUTPUT

UNIT

RIGHT CHANNEL OUTPUT

4Ω 20W

L

R

L

R

AC V.T.V.M. OR SCOPE

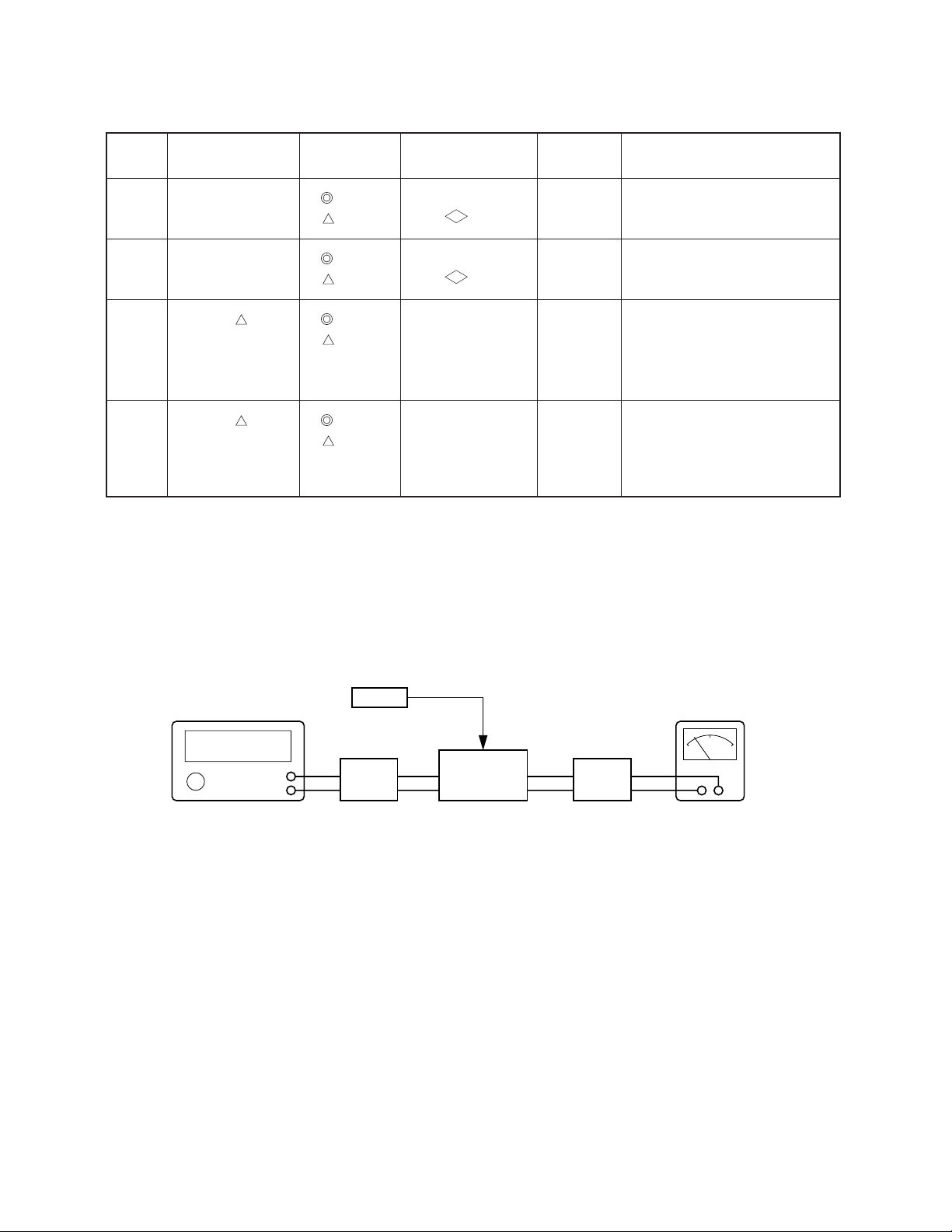

DUMMY LOAD & SWITCH BOX (FOR STEREO UNIT)

Fig. 1-3

ALIGNMENT OF AM RF & lF SECTI0N

Set the radio for AM reception. AM signal generator should be coupled with antenna receptacle through dummy (see Fig.1-1).

Set VOLUME control to maximum and TONE to center. Attenuate signal generator output to maintain 0.5 watts (1.4 volts across

4 ohms load) on AC voltmeter.

FM SG

&

STEREO SG

VTVM

(See Fig. 1.2)

FM

DUMMY

ANTENNA

DISTORTION METER

AC VOLTMETER

T.P

SET

(See Fig. 1.3)

DUMMY

LOAD &

SW BOX

Fig. 2 * SG frequency should be as accurate as possible.

— 5 —

ELECTRICAL ADJUSTMENTS

STEP

1

2

3

GENERATOR

FREQUENCY

Non-Mod.

Non-Mod.

1000kHz, 999kHz

400Hz

30% MOD

RADIO DIAL

SETTING

530kHz

531kHz

1710kHz

1602kHz

1000kHz

999kHz

OUTPUT

INDICATOR

DC VTVM to test

point

DC VTVM to test

point

AC VTVM across

speaker(L or R) or 4

ohms load

SG att: 20dBµ

4

1000kHz, 999kHz

400Hz

30% MOD

1000kHz

999kHz

TEST MODE

Adjust so that the

“ST” mark of LCD

Display appears

SG att: 30dBµ

SETTING UP TEST MODE AT STEP 4 - SEE PAGE 8

ADJUST-

MENT

—

VT

—

VT

L108

Check the voltage more than

2.2V

Check the voltage less than 7.5V.

Adjust for Maximum Level.

REMARKS

AM IFT1

L111

AM IFT2

R124

AM SD

Sensitivity of the seeking frequency.

ALIGNMENT OF FM RF & IF SECTION

Set the radio for FM reception. FM signal generator should be coupled with antenna receptacle, through dummy (see Fig.1-2).

FM SG

&

STEREO SG

VTVM

(See Fig. 1.2)

FM

DUMMY

ANTENNA

T.P

SET

(See Fig. 1.3)

DUMMY

LOAD &

SW BOX

DISTORTION METER

AC VOLTMETER

Fig. 3 * SG frequency should be as accurate as possible.

— 6 —

ELECTRICAL ADJUSTMENTS

STEP

1

2

3

4

5

6

GENERATOR

FREQUENCY

Non-Mod.

Non-Mod.

98.1MHz

1kHz, 22.5kHz dev .

SG att:66dBµ(1mV)

98.1MHz

1kHz, 22.5kHz dev .

SG att:6dBµ

98.1MHz

SG att:6dBµ

88.5MHz

107.1MHz

SG att:6dBµ

RADIO DIAL

SETTING

87.5MHz

107.9MHz

108MHz

98.1MHz

98.1MHz

98.1MHz

88.5MHz

107.1MHz

OUTPUT

INDICATOR

DC VTVM to test

VT

point

DC VTVM to test

VT

point

AC VTVM to test

point*

AC VTVM across

speaker or 4 ohms

load

AC VTVM across

speaker or 4 ohms

load

AC VTVM across

speaker or 4 ohms

load

ADJUST-

MENT

—

L103

FM OSC

L110

FM DET

L107

FM MIX

L100

FM ANT

L102

FM RF

L100

FM ANT

L102

FM RF

REMARKS

Check the voltage more than 1.1V

Adjust for 6.9 앐0.1V

NULL VOLTAGE to become -20

앐20mV

Adjust for Maximum Level.

Adjust for Maximum LeveL.

Check for SPEC.

7

98.1MHz

SG att:25dBµ

98.1MHz

TEST MODE

Adjust so that the

“ST” mark of LCD

Display appears

SETTING UP TEST MODE AT STEP 7 - SEE PAGE 8

ALIGNMENT OF FM MULTIPLEX SECTION

FM signal generator should be modulated by FM stereo signal generator.

Modulation level: 19kHz 10% (7.5kHz dev)

1000Hz 30% (22.5kHz dev)

FM signal generator output level: 66dBµ (1mV)

Frequency: 98.1 MHz.

STEP

1

2

MODULATION

FREQUENCY

19kHz & 1000Hz

(Left Channel)

SG att:66dBµ

19kHz & 1000Hz

(Right Channel)

OUTPUT INDICATOR

AC VTVM across Right speaker or

Right channel load

AC VTVM through Left speaker or

Left channel load

R129

FM SD

Set the radio for FM reception and tune to signal. Adjust volume control to provide 0.5 watt on AC VTVM and tone to

center. Set L/R balance control for equal output at each channel.

ADJUST-

MENT

R137

R137

Sensitivity of the seeking frequency.

REMARKS

Adjust for minimum.

Check for minimum.

3

19kHz & 1000Hz

(Left Channel)

SG att:47dBµ

AC VTVM across Right speaker or

Right channel load

— 7 —

R156

Adjust for 20dB Separation.

ELECTRICAL ADJUSTMENTS

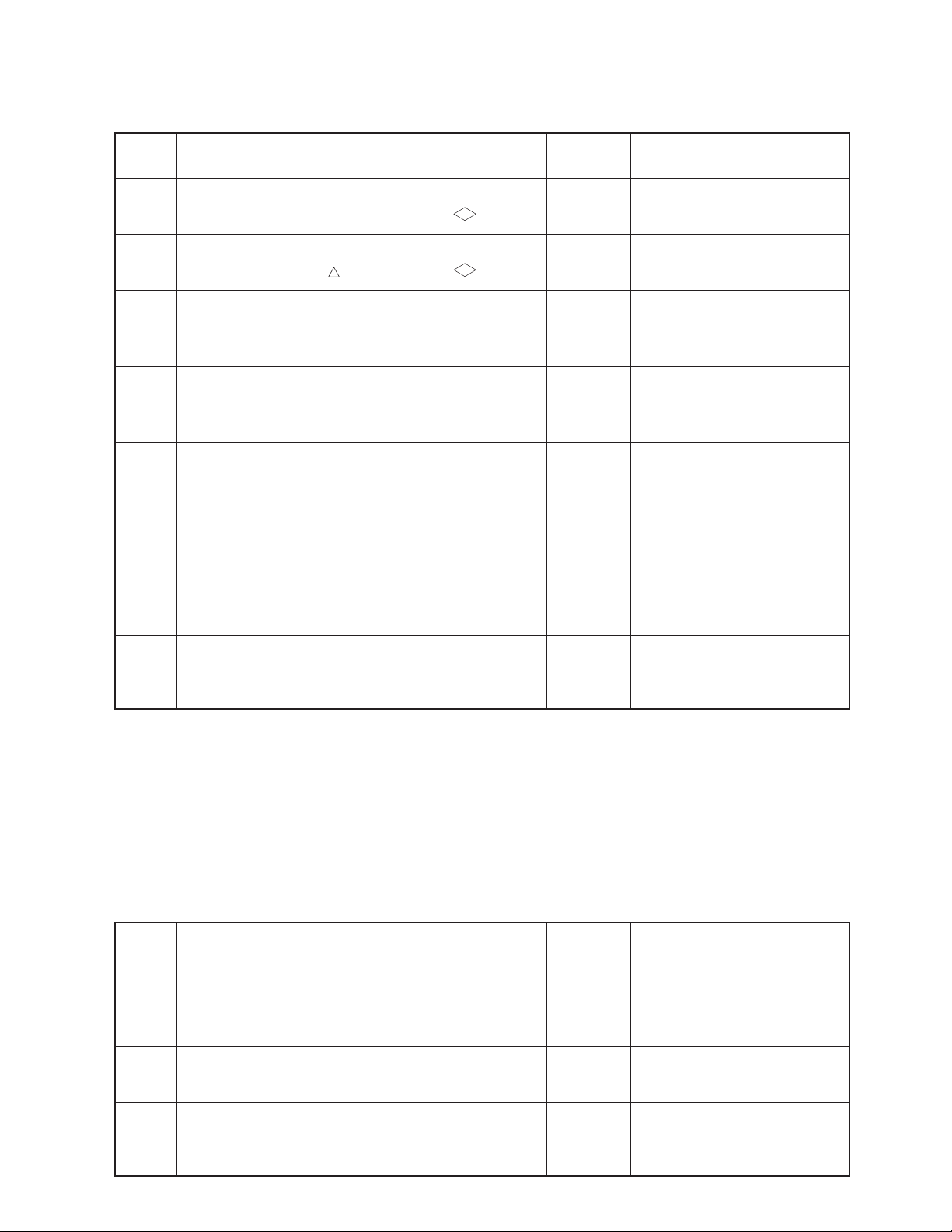

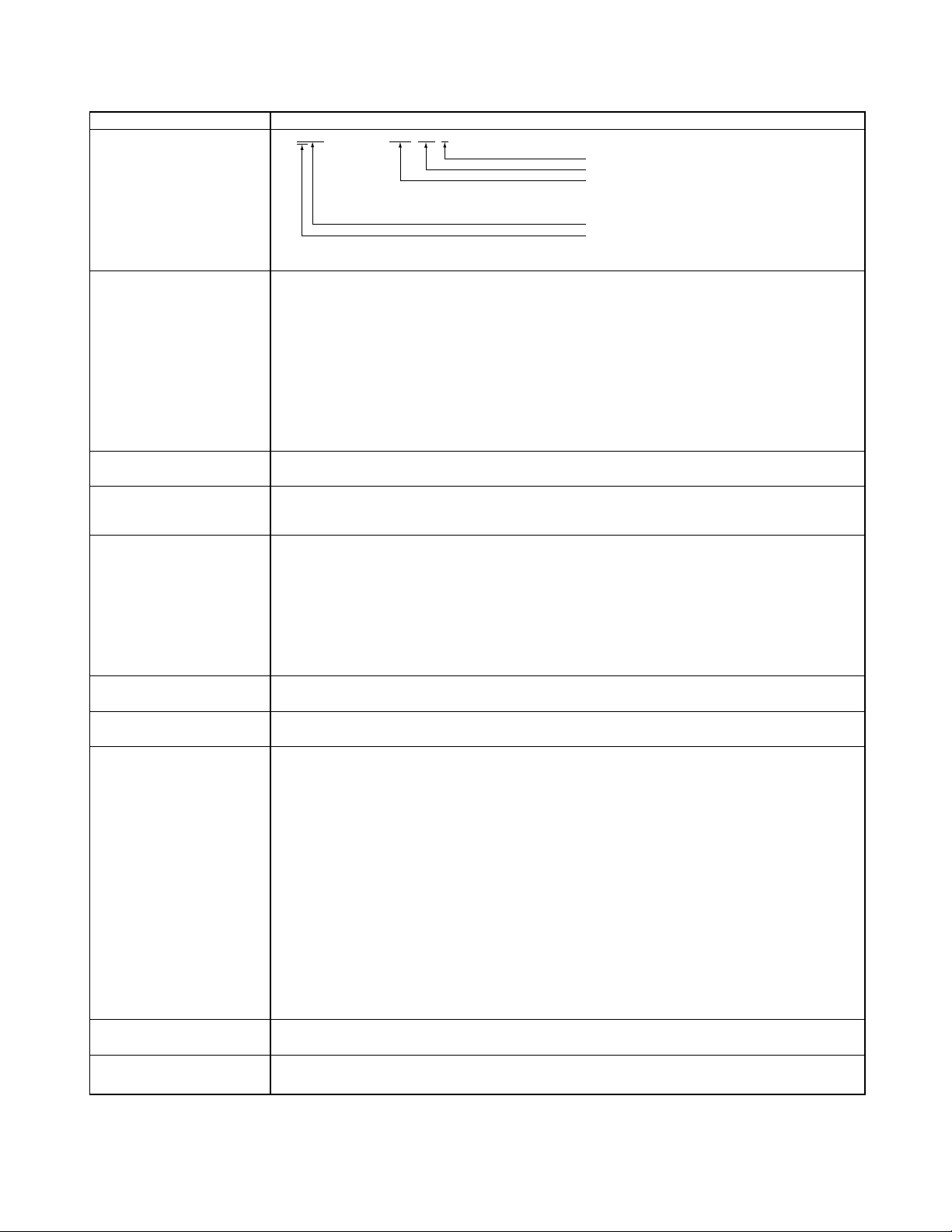

SETTING UP TEST MODE AT STEP 4 FOR AM & STEP 7 FOR FM

Press the e

the mode to the test mode shown in Step 4 for AM and Step 7 for FM.

PWR

button to turn the power off. Next, use the following procedure with the front panel switches to set

w

REL

VOL

TUN

TRK

LO/DX

LOUD

AUD

FM/AM CD RECEIVER ECD-780 45W x 4

PRESET

TRACK

CD

FMIII

AMII

LOUD ST LOC

L

R

BASS MANU TRE

R

F

SCAN

SHF

RPT

RPTSHFDISC

FRONT

BAND

ATP

CD

CDC

DISP

PWR

MUTE

er q

Fig. 4

1. While the power is off, press the q

to enable the w

BAND

button to be used at the moment the power comes on.

PRESET 1

button. Then press the w

BAND

button and e

PWR

button simultaneously

2. If the above operation is successful all the figures on the LCD light up, check that you have entered test mode. Fig. 5(A).

3. Press the r

AUD

button once. The display shown in Fig. 5(B) appears on the LCD and the unit enters DX mode.

Then, while receiving FM 98.1MHz rotate the Semi-fixed VR R129 on the TUNER UNIT (RF33) to adjust the LCD until the

stereo mark light “ST” is on. Fig. 5(B)’.

4. Press the r

AUD

button, if the display changes to that shown in Fig. 5(C) the unit is in Local mode. Check that the “ST” mark

is displayed (for specific: Input level is 12 ~ 28dB higher than that of the DX mode).

5. Press the w

6. Then press the r

BAND

button, if the display changes to that shown in Fig. 5(D) or (D)’ receiving AM 1000 kHz or *(999) kHz.

AUD

button, if the display changes to that shown in Fig. 5(E) the unit is in DX mode. Rotate the Semi-fixed

VR R124 on the TUNER UNIT (RF33) to adjust the LCD until “ST” mark lights up.

7. Then press the r

AUD

button, if the display changes to that shown in Fig. 5(F) the unit is in Local mode. Check that the “ST”

mark is displayed. (for specific: Input level is 12 ~ 28dB higher than that of DX mode).

8. Turn off the power to release the test mode.

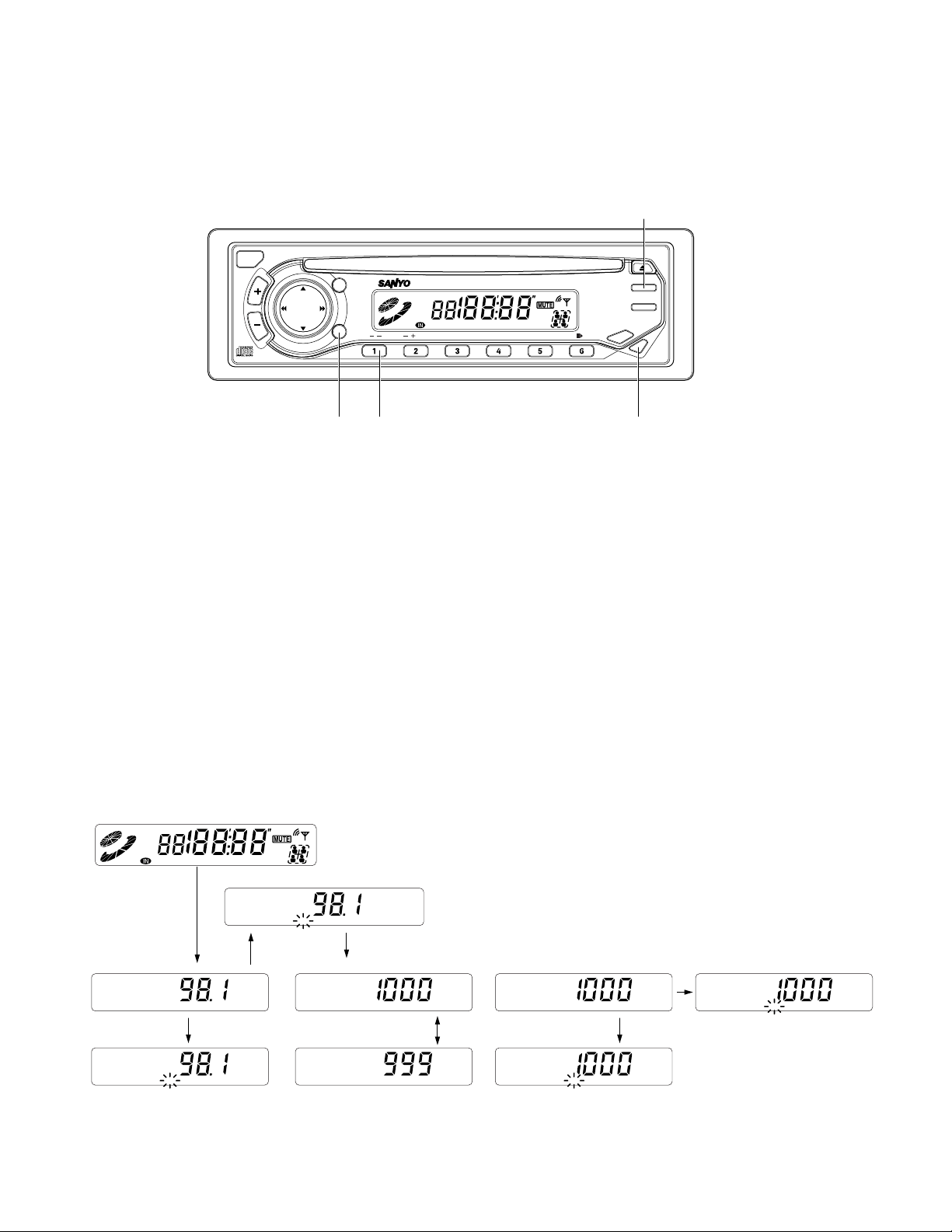

TEST MODE CHART

(A) Enter the Test Mode

PRESET

CD

FMIII

AMII

LOUD ST LOC

TRACK

L

R

R

F

SCAN

SHF

BASS MANU TRE

RPT

(C) FM Local Mode OK

FMI

FRONT

ST LOC

(B) FM DX Mode

FMI

(B’) CK

FMI

ST

(D) Receiving 1000kHz

AMI

(D’) Receiving 999kHz

AMI

(E) AM DX Mode

(F) AM Local Mode

Fig. 5

— 8 —

AMI

AMI

ST LOC

(E’) OK

AMI

ST

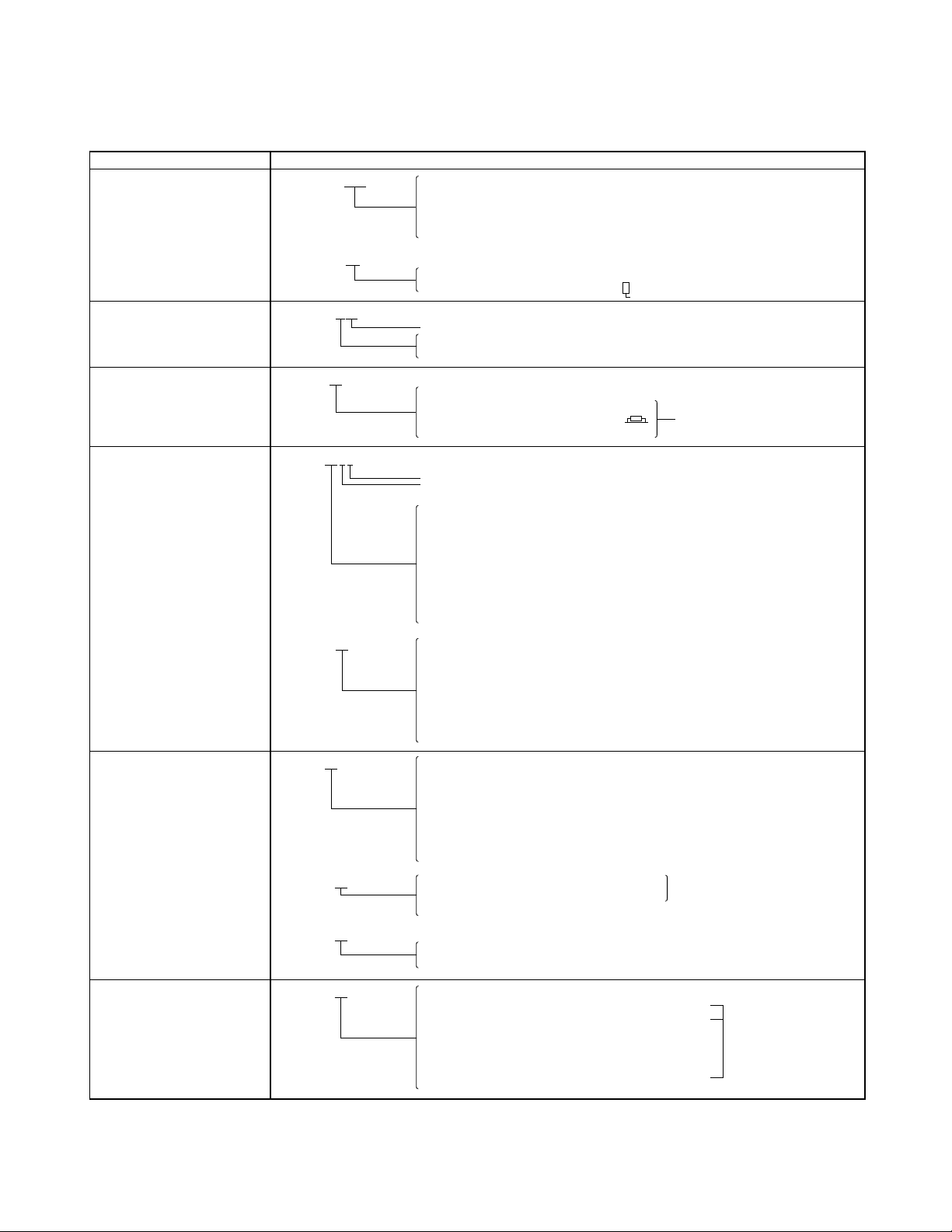

TERMINOLOGY REFERENCE

Parts Name CAD-Code Numerical Value

Chip Capacitor CAR75C R75=0.75pF

Chip Tantalum CAT0.1/35E 0.1/35=0.1µF / 35V

Electrolytic Capacitor ES47/16 47/16=47µF / 16V

Chip Resistor RBR68 R68=0.68 Ω

Coil LAUR22T R22=0.22 µH

The following terms have been changed as a result of the use of a new CAD system.

Parts Name

IC IC101 LA3373. MT

Hybrid IC IC102 HIC . . . . . . Code No. (3-8 Column 씮 11. . . . . .0)

Transistor Q101 2SC2785 T. E.F

Diode D101 MTZJ3.0. A. RT

Chip Capacitor C101 CA 102 S J 100

Chip Tantalum C102 CAT 0.1 /35 E

Chip Trimmer C103 CT. . . . . . Code No. (3-8 Column 씮 15. . . . . .0)

Trimmer Capacitor C104 CT. . . . . . Code No. (3-8 Column 씮 15. . . . . .0)

Ceramic Capacitor C105 CH 102 H

Electrolytic Capacitor C106 ES 47/ 16 H

Chip Resistor R101 RA 202 G

Resistor R102 RC 1R0 R

CA3R0C 3R0=3.0pF

CA100U 100=10 x 10

CA333B 333=33 x 10

CA104F 104=10 x 10

RA1R0 1R0=1.0 Ω

RA180 180=18 x 10

RA821 821=82 x 10

RA102 102=10 x 10

LAY2R2T 2R2=2.2 µH

LAY330T 330=33 x 10

LAY151T 151=15 x 10

Circuit Ref. No. CAD Code Description

0

=10pF

3

=33000pF=0.033µF

4

=0.1 x 106pF=0.1µF

0

=18 Ω

1

=820 Ω

2

=1000 Ω=1KΩ

0

=33 µH

1

=150 µH

Taping or Forming Type

Description (LA3373)

Circuit Ref. Number

Head Name

hfe Rank

Taping Type

Description (2SC2785)

Circuit Ref. Number

Head Name

Taping or Forming Type

Rank

Description (MTZJ3.0)

Circuit Ref. Number

Head Name

Voltage Proof

Tolerance

Temperature Characteristic

Capacitance (10 x 102=0.1 x 104pF=0.001µF)

Chip Capacitor Type

Circuit Ref. Number

Head Name

Maker Mark

Voltage Proof (35V)

Capacitance (0.1µF)

Chip Tantalum Capacitor Type

Taping or Forming Type

Capacitance (12 x 10

Temperature Characteristic

Taping or Forming Type

Voltage Proof (16V)

Capacitance (47µF)

Electrolytic Capacitor Type

Resistance Tolerance

Resistance (20 x 102=2KΩ)

Chip Resistor Type

Circuit Ref. Number

Head Name

Taping or Forming Type

Resistance (1.0Ω)

R : Decimal Point Mark

Resistor Type

0

=12pF)

— 9 —

TERMINOLOGY REFERENCE

Parts Name Circuit Ref. No. CAD Code Description

Coil L101 LAY 151 T

Taping or Forming Type

Inductance (15 x 10

Coil Type

L : Fixed Letter

A : Maker Mark

Y : Part Forming (or Size)

Circuit Ref. Number

Head Name

Transformer L101 L . . . . . . Code No. (3-8 Column 씮 17. . . . . .0)

Antenna ANT101 ANT. . . . . . Code No. (3-8 Column 씮 10. . . . . .0)

Battery BT101 BT. . . . . .

Buzzer BUZ101 BUZ. . . . . .

Dew Sensor PQ101 Code No. Code No. 1000. . . . . .

Electric Tuner ET101 ET. . . . . .

Relay K101 K. . . . . .

Emblem SW Assy MB101 MB. . . . . .

Microphone MC101 MC. . . . . .

Module MD101 MD. . . . . .

Motor Stator Assy MS101 MS. . . . . .

Manual Tuner MT101 MT. . . . . .

Push Button Tuner PT101 PT. . . . . .

Switch Power Unit PW101 PW. . . . . .

CR Component CR101 CR. . . . . . Code No. (3-8 Column 씮 11. . . . . .0)

IN-line Block IB101 IB. . . . . .

Surge Absorber Z101 Z. . . . . . Code No. (3-8 Column 씮 13. . . . . .0)

Ceramic Varistor Z102 Z. . . . . .

Silicon Varistor Z103 Z. . . . . .

FIP H101 FIP. . . . . . Code No. (3-8 Column 씮 14. . . . . .0)

LCD H102 LCD. . . . . .

LED LD101 LED. . . . . .

Neon Bulb NE101 NE. . . . . .

Photo Diode PD101 PD. . . . . .

Photo Coupler PH101 PH. . . . . .

Photo Interruptor PI101 PI. . . . . .

Pilot Lamp PL101 PL. . . . . .

Photo Transistor PQ101 PQ. . . . . .

CCD Y101 Y. . . . . .

Ceramic Filter F101 F. . . . . . Code No. (3-8 Column 씮 17. . . . . .0)

Crystal F102 F. . . . . .

Printeed Circuit Board W101 Code No. Code No. 18. . . . . .

Block PC Assy BL101

Wire N101 Code No. Code No. 191. . . . . .

QS-CONN N102

Shield Wire N103

Flat Wire N104

Coaxial N105

Strip Wire N106

Flat Wire N107

Flexible Wire N108

Strip Wire N109

QS-CONN N110

" N111

" N112

" N113

Antenna Jack AJ101

QS-CONN N101

POST P101

Jumper J101

RT Pin TP101

Check Pin TP102

IC Socket P102

Switch SW101 Code No. 23. . . . .

Volume Rv101

Fuse Z101

Fuse Holder FH101

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

Code No. 192. . . . . .

"

"

Code No. 193. . . . . .

Code No. 194. . . . . .

"

Code No. 195. . . . . .

Code No. 1960. . . . .

Code No. 1961. . . . .

Code No. 1962. . . . .

Code No. 1963. . . . .

Code No. 1965. . . . .

Code No. 196A. . . . .

Code No. 1981. . . . .

Code No. 1983. . . . .

Code No. 1984. . . . .

"

Code No. 1985. . . . .

"

"

"

1

=150µH)

— 10 —

TERMINOLOGY REFERENCE

Details of CAD Code

Parts Name CAD Code Mark Name Taping or Forming Type

IC UPC4570C. ** No Mark Hand Insert

MT Stick

CT Chip

MF Mini Flat

YC Tray

HIC500850 *

No Mark Straight Type

L L Type

Transistor 2SC2785*. * *Z

*.* (* and *) hfe Rank

No Mark Hand Insert

T Radial/Chip—Z : Cancel Machine Insert

Diode 1SS245 *

No Mark Hand Insert

.FT Forming Type

.RT Radial

T Axial

Chip CA100 * * *

Capacitor Voltage limit

Tolerance

Temperature Characteristic

C : CH (0앐60PPM/ ˚C) (-55~+125˚C)

: CJ (0앐120PPM/ ˚C) (-55~+125˚C)

: CK (0앐250PPM/ ˚C) (-55~+125˚C)

U : UJ (-750앐120PPM/ ˚C) (-25~+85˚C)

S : SL (+350~-1000PPM/ ˚C) (-25~+85˚C)

B: B (앐10PPM/ ˚C) (-25~+85˚C)

R : RH (-220앐60PPM/ ˚C) (-25~+85˚C)

F : F (+30 ~ -80 ~) (-25~+85˚C)

The other Capacitors ES3.3/50 * Z No Mark Radial (5mm Pitch)

F Hi—F Part

S Straight Type

L Radial (2.5mm Pitch)

H Hand Insert

SH No kink (Straight)

FSH With Kink (Short Lead/Radial type)

KSH With kink (Short Lead)

Z : Cancel Machine Insert

Chip Resistor RA100 * Tolerance

B(앐0.1%)

D(앐0.5%)

F(앐1%)

G(앐2%)

J(앐5%) : No Mark

K(앐10%)

M(앐20%)

Resistor (1/6 [W]) RC100 * Z No Mark Axial

R Radial

H Hand Insert

The other Resistors RCAR47 *

H Hand Insert

HP Press Forming (Hand Insert)

Coil LAY151 * No Mark Hand Insert

A Axial

C Chip

K With kink (Hand Insert)

L Long Lead

M Stick

R Radial

T Radial

— 11 —

Z : Cancel Machine Insert

Z : Cancel Machine Insert

Loading...

Loading...