Page 1

OUTDOOR MODEL No. PRODUCT CODE No. APPLICABLE INDOOR MODEL No. V/ø/Hz

CHDX09053 85403301 AHX,UHX,KHX 0752

CHDX14053 85403302 AHX,KHX 0952 OUTDOOR

XHX,AHX,UHX,THX,KHX 1252 208-230/3ø/60

XHX,UHX,THX,KHX 1852

XHX,UHX,THX,KHX 2452 INDOOR

XHX,UHX,DHX 3652 208-230/1ø/60

DHX 4852

85464869238002

REFERENCE NO.

TD831138-02

Page 2

i

Page 3

Check of Density Limit

NO TE

Outdoor unit

Refrigerant tubing

Indoor unit

e.g., charged

amount (353 oz)

Outdoor unit

Indoor unit

Room A Room B Room C Room D Room E Room F

e.g., charged

amount (529 oz)

Refrigerant tubing

Outdoor unit

Very

small

room

Indoor unit

Small

room

Medium

room

Large room

Mechanical ventilation device – Gas leak detector

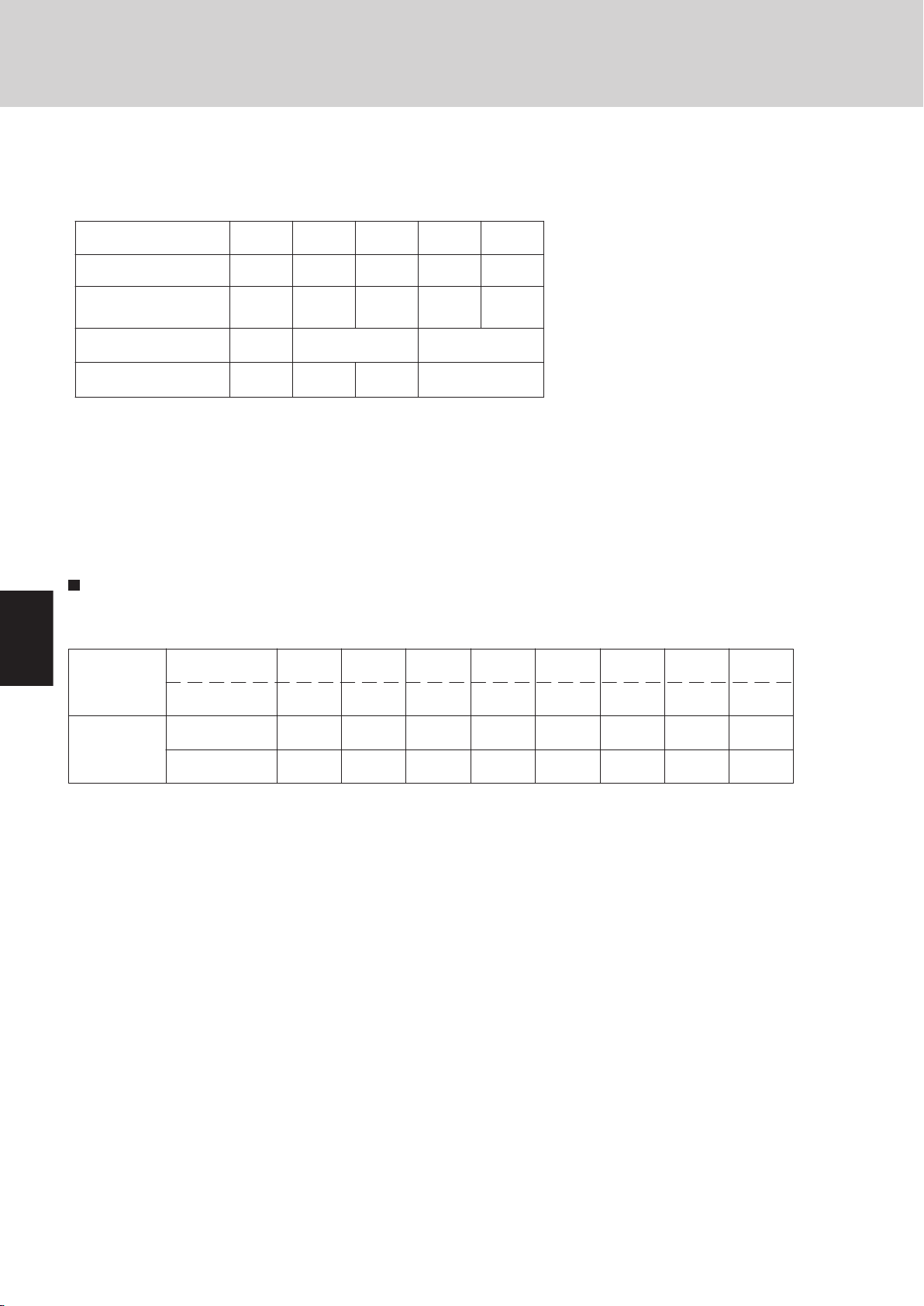

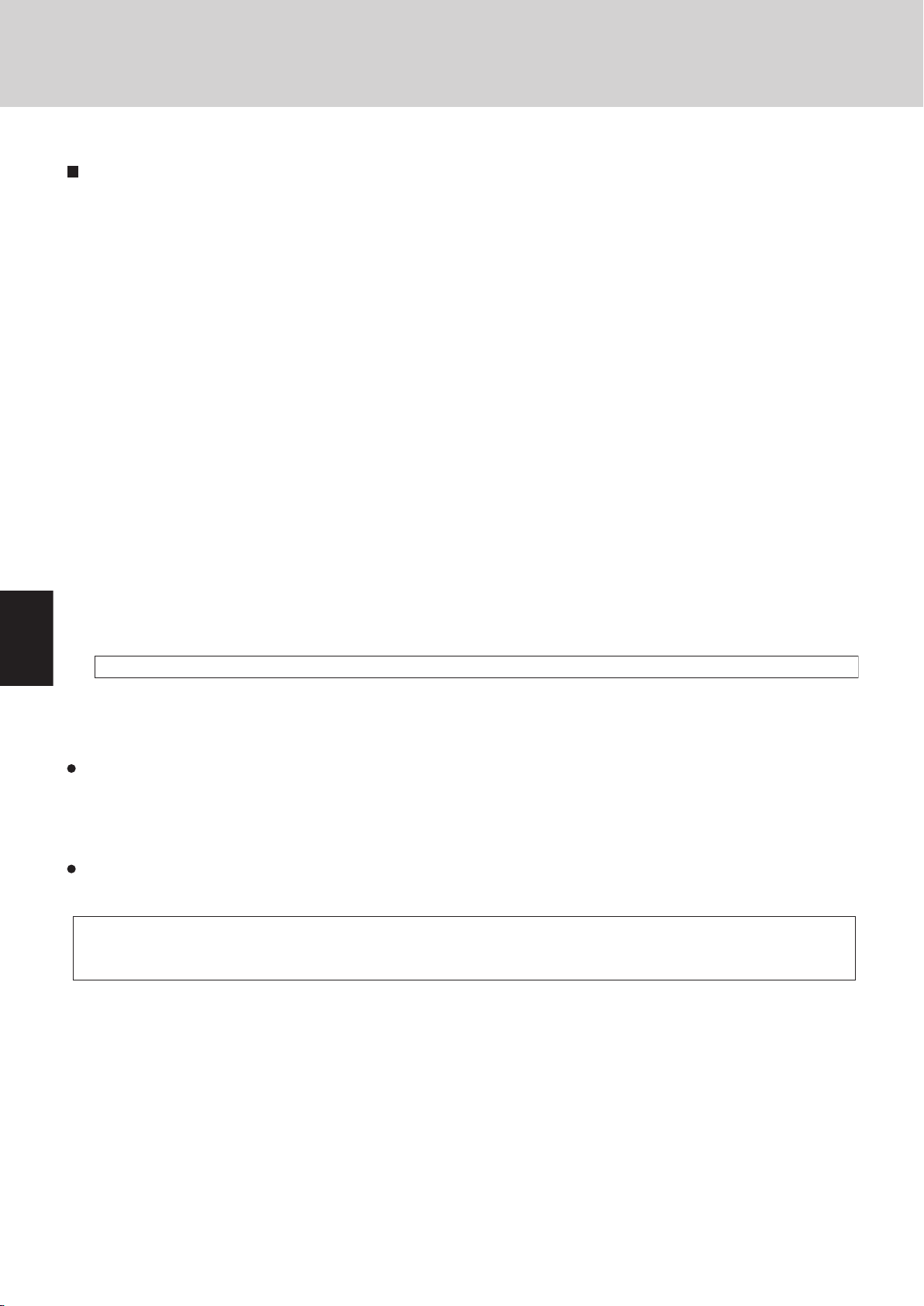

0 0

57

114

170

227

284

341

398

454

0

500

1000

1500

2000

2500

3000

3500

4000

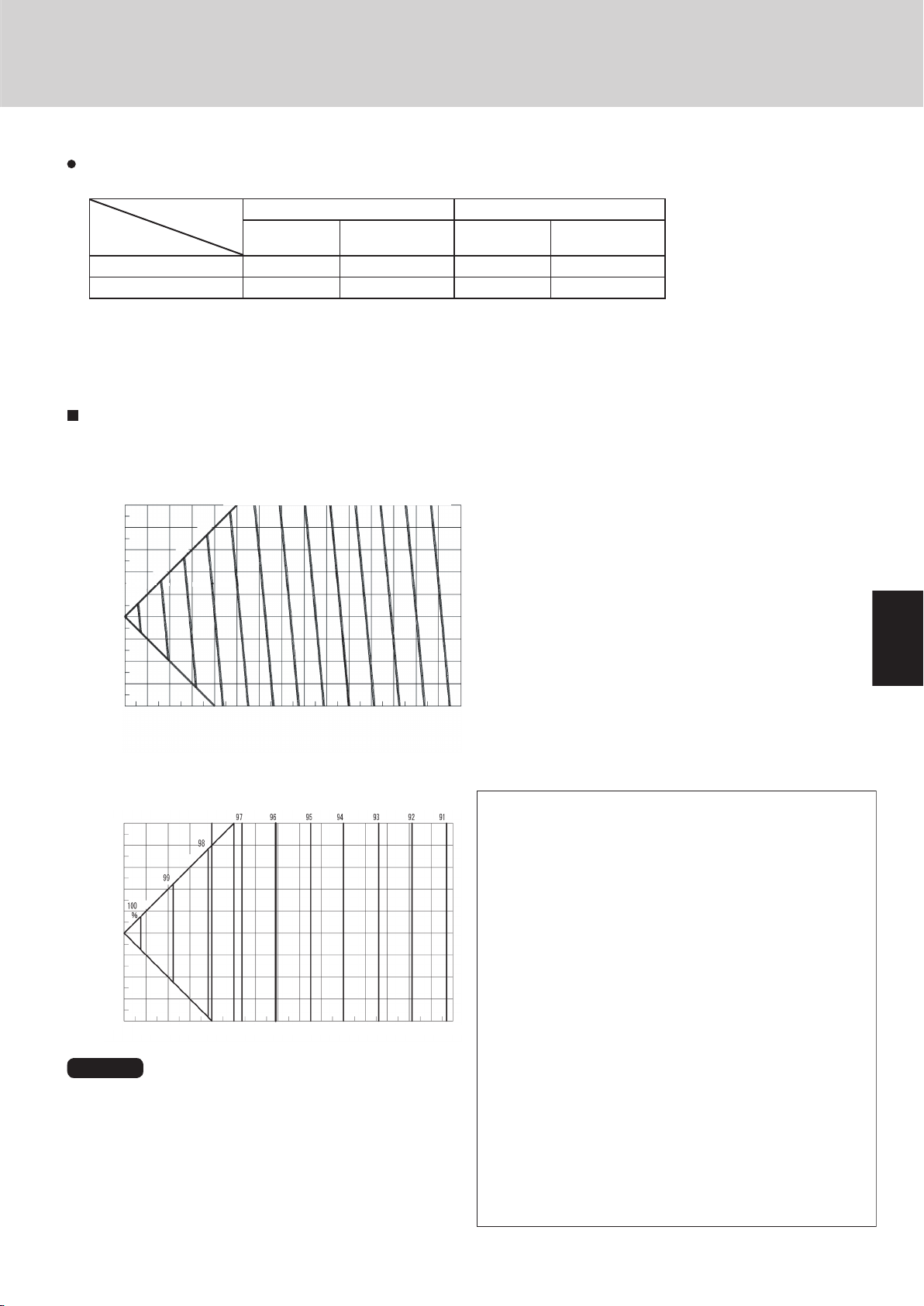

400200 600 800 1000 1200

Total amount of refrigerant

Min. indoor volume

Min. indoor floor area

(when the ceilin

g

is 8.8 ft. hi

g

h)

ft.

3

ft.

2

oz

Range above

the density limit of

0.3 oz/ft.

3

(countermeasures

needed)

Range below

the density limit of

0.3 oz/ft.

3

(countermeasures

not needed)

The room in which the air conditioner is to be

installed requires a design that in the event of refrigerant gas leaking out, its density will not exceed a set

limit.

The refrigerant (R410A), which is used in the air conditioner, is safe, without the toxicity or combustibility of

ammonia, and is not restricted by laws imposed to protect

the ozone layer. However, since it contains more than air,

it poses the risk of suffocation if its density should rise

excessively. Suffocation from leakage of refrigerant is

almost non-existent. With the recent increase in the number of high density buildings, however, the installation of

multi air conditioner systems is on the increase because of

the need for effective use of floor space, individual control,

energy conservation by curtailing heat and carrying power,

etc.

Most importantly, the multi air conditioner system is able

to replenish a large amount of refrigerant compared to

conventional individual air conditioners. If a single unit

of the multi air conditioner system is to be installed in a

small room, select a suitable model and installation procedure so that if the refrigerant accidentally leaks out,

its density does not reach the limit (and in the event of

an emergency, measures can be made before injury can

occur).

In a room where the density may exceed the limit, create

an opening with adjacent rooms, or install mechanical

ventilation combined with a gas leak detection device.

The density is as given below.

2. The standards for minimum room volume are as follows.

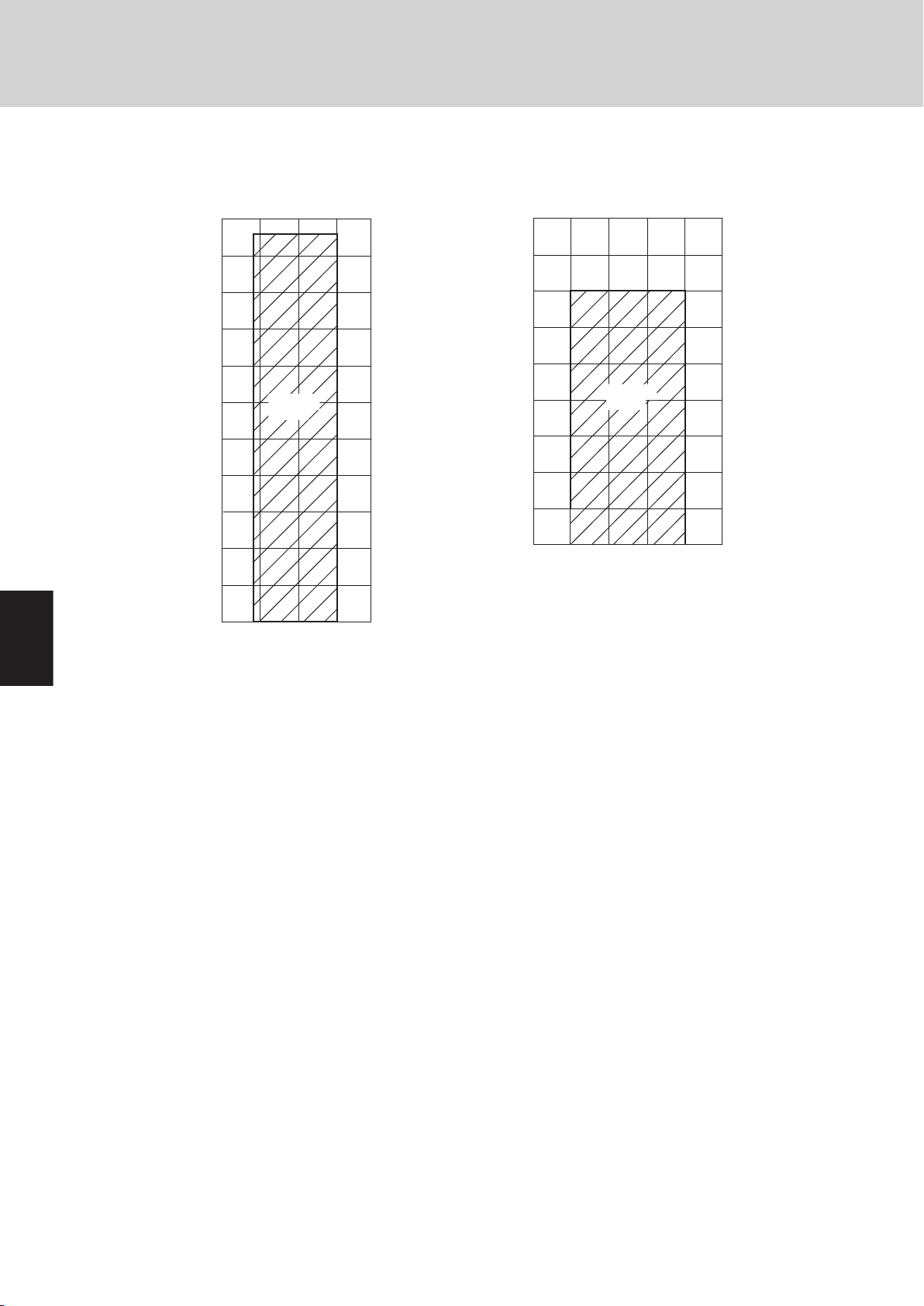

(1) No partition (shaded portion)

(2) When there is an effective opening with the adjacent

room for ventilation of leaking refrigerant gas (opening without a door, or an opening 0.15% or larger

than the respective floor spaces at the top or bottom

of the door).

(3) If an indoor unit is installed in each partitioned room

and the refrigerant tubing is interconnected, the

smallest room of course becomes the object. But

when mechanical ventilation is installed interlocked

with a gas leakage detector in the smallest room

where the density limit is exceeded, the volume of the

next smallest room becomes the object.

Total amount of refrigerant (lbs)

Min. volume of the indoor unit installed room (ft.3)

<

Density limit (oz/ft.3)

The density limit of refrigerant which is used in multi air

conditioners is 0.3 oz/ft.3 (ISO 5149).

1.If there are 2 or more refrigerating systems in a single

refrigerating device, the amount of refrigerant should be

as charged in each independent device.

For the amount of charge in this example:

The possible amount of leaked refrigerant gas in

rooms A, B and C is 353 oz.

The possible amount of leaked refrigerant gas in

rooms D, E and F is 529 oz.

3. The minimum indoor floor space compared with the

amount of refrigerant is roughly as follows: (When the

ceiling is 8.8 ft. high)

ii

Page 4

Contents

Section 1: OUTLINE OF W-2WAY ECO-i SYSTEM ................................................................1-1

1. Line-up .............................................................................................................1-2

2. Features of W-2WAY ECO-i SYSTEM .............................................................1-4

Section 2: DESIGN OF W-2WAY ECO-i SYSTEM ..................................................................2-1

1. Model Selecting and Capacity Calculator ........................................................2-2

2. System Design ...............................................................................................2-17

3. Electrical Wiring .............................................................................................2-23

4. Installation Instructions ..................................................................................2-27

Section 3: Control of W-2WAY ECO-i SYSTEM .....................................................................3-1

1. Main Operating Functions ................................................................................3-3

2. Wireless Remote Controller .............................................................................3-5

3. Timer Remote Controller................................................................................3-22

4. System Controller ..........................................................................................3-38

5. Simplified Remote Controller .........................................................................3-56

6. Remote Sensor ..............................................................................................3-64

Section 4: W-2WAY ECO-i SYSTEM UNIT SPECIFICATIONS ..............................................4-1

1. Outdoor Unit ....................................................................................................4-2

2. 4-Way Air Discharge Semi-concealed Type (X Type) .....................................4-12

3. 1-Way Air Discharge Semi-concealed Type (A Type) .....................................4-24

4. Concealed Duct Type (U Type) .......................................................................4-33

5. Concealed Duct High-Static Pressure Type (D Type) .....................................4-50

6. Ceiling-Mounted Type (T Type) ......................................................................4-57

7. Wall-Mounted Type (K Type) ..........................................................................4-66

Section 5: TEST RUN ..............................................................................................................5-1

1. Preparing for Test Run .....................................................................................5-2

2. Test Run Procedure .........................................................................................5-3

3. Main Outdoor Unit PCB Setting .......................................................................5-4

4. Auto Address Setting .......................................................................................5-6

5. Remote Controller Test Run Settings .............................................................5-12

6. Caution for Pump Down .................................................................................5-13

7. Meaning of Alarm Messages .........................................................................5-14

Section 6: ELECTRICAL DATA ...............................................................................................6-1

1. Outdoor Unit ....................................................................................................6-2

2. Indoor Unit .......................................................................................................6-6

Section 7: PCB AND FUNCTIONS .........................................................................................7-1

1. Outdoor Unit Control PCB ...............................................................................7-2

2. Indoor Unit Control PCB Switches and Functions ...........................................7-6

iii

Page 5

Outline of W-2Way ECO-i SYSTEM

1

2

3

4

5

6

7

8

Contents

1. OUTLINE OF W-2Way ECO-i MULTI SYSTEM

1. Line-up .................................................................................................................................1-2

2. Features of W-2WAY ECO-i SYSTEM .................................................................................1-4

1-1

Page 6

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

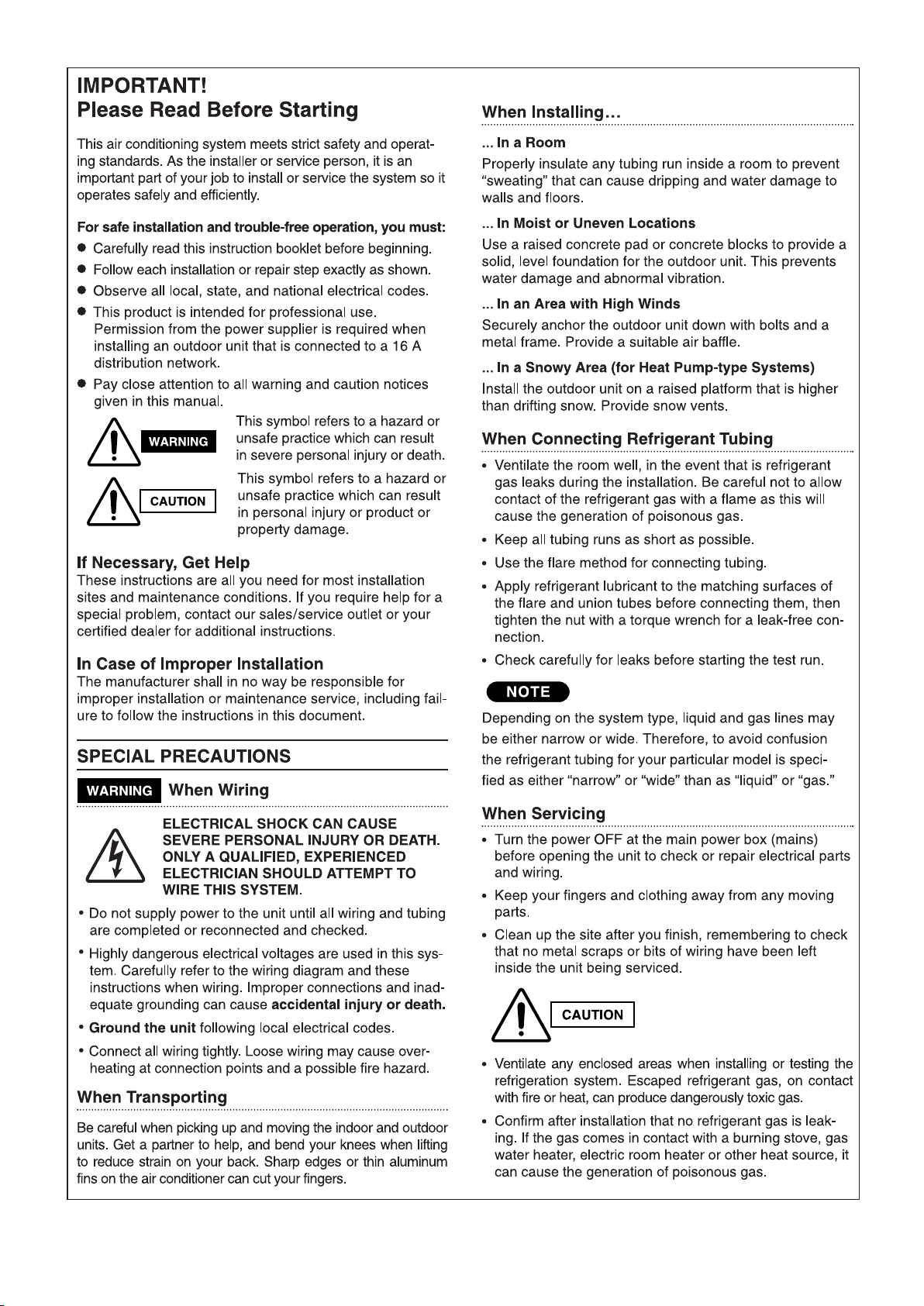

1. Line-up

Capacity: BTU/h

(kW)

Cooling

/

Heating

Type

97 12 18 24 36 48

XHX1252 XHX1852 XHX2452 XHX3652

KHX0952 KHX1252 KHX2452KHX1852

AHX0952 AHX1252

THX1852THX1252 THX2452

UHX0752 UHX1252 UHX1852 UHX2452

DHX4852

Wall-Mounted

Type

(K Type)

Concealed Duct

Type

(U Type)

7,500 (2.2)

8,500 (2.5)

/

9,600 (2.8)

11,000 (3.2)

/

12,000 (3.6)

14,000 (4.2)

/

36,000 (10.6)

39,000(11.4)

/

47,800 (14.0)

54,600(16.0)

/

25,000 (7.3)

27,000(8.0)

/

19,000 (5.6)

21,000(6.3)

/

KHX0752

AHX0752

4-Way Air

Discharge SemiConcealed Type

(X Type)

Ceiling-Mounted

Type

(T Type)

1-Way Air

Discharge SemiConcealed Type

(A Type)

Concealed Duct

High-Static Pressure

Type(D Type)

DHX3652

UHX3652

Indoor units

Outline of W-2Way ECO-i SYSTEM

1-2

Page 7

1

2

3

4

5

6

7

8

1-3

Outline of W-2Way ECO-i SYSTEM

1

2

3

4

5

6

7

8

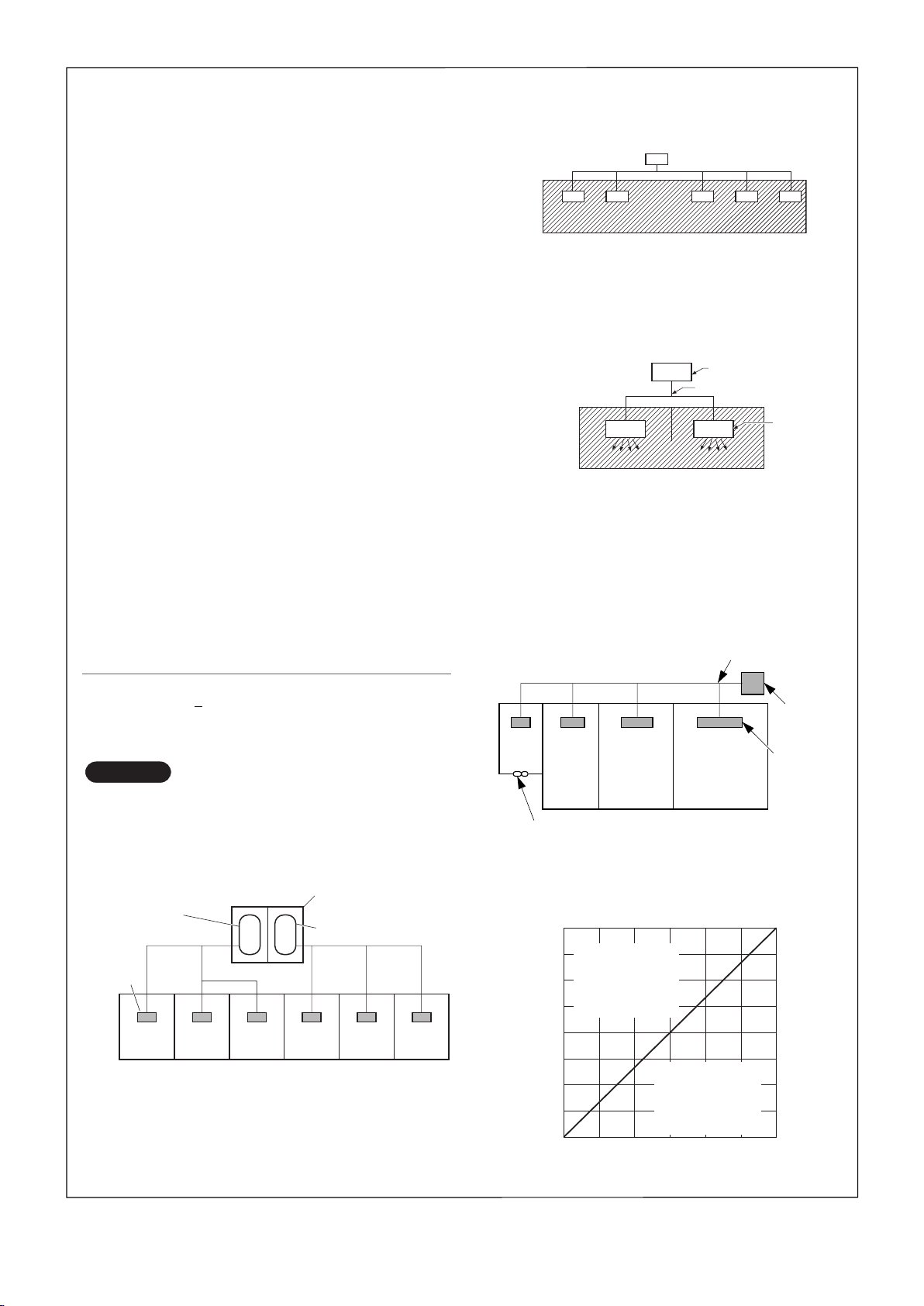

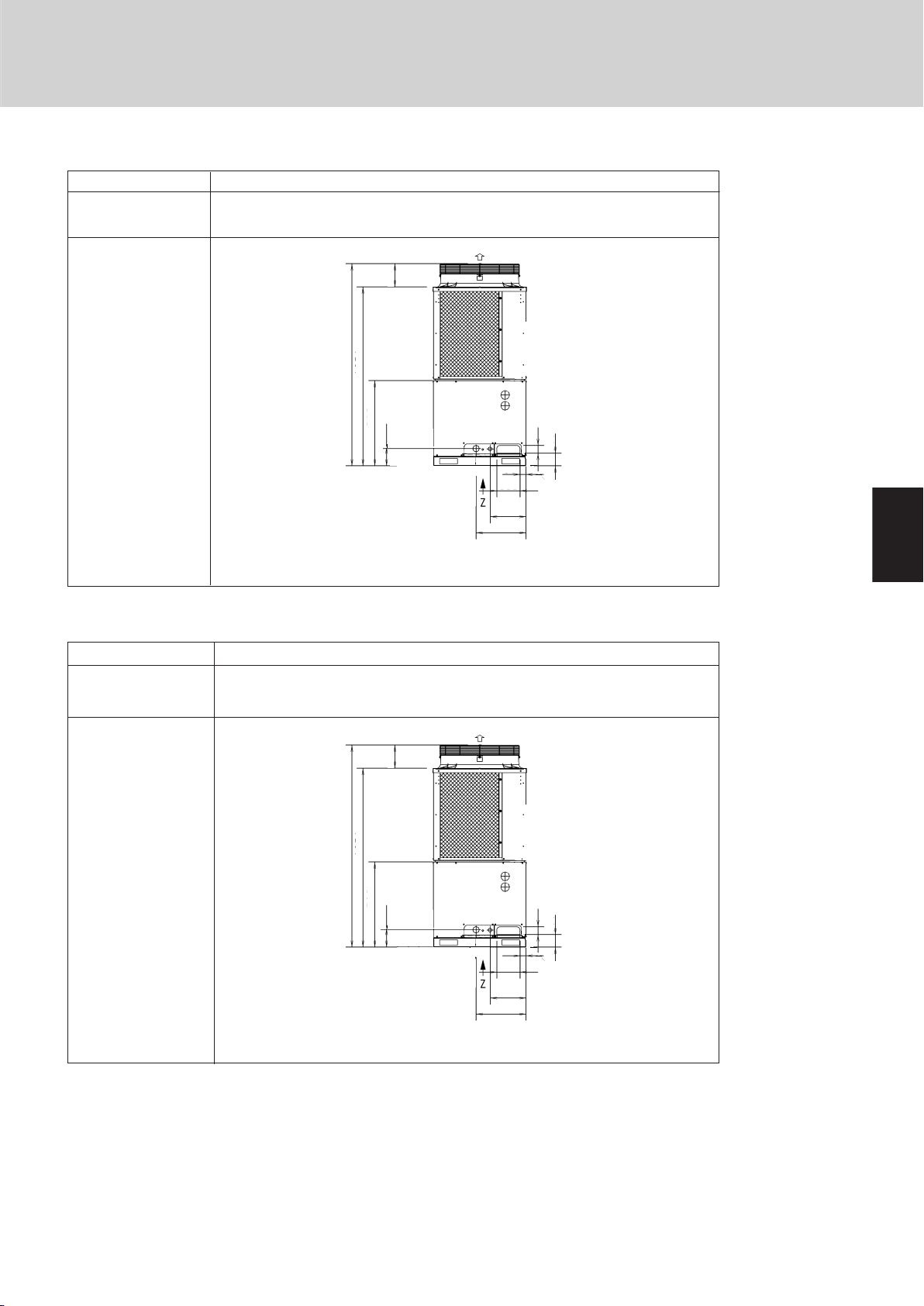

1. Line-up

Type

Type

90

Capacity: BTU/h (kW)

95,500 (28.0)

Cooling / Heating / 107,500 (31.5)

Outdoor Unit

Capacity: BTU/h (kW)

Cooling / Heating

Outdoor Unit

CHDX14053

CHDX09053

153,600 (45.0)

140

/ 170,600 (50.0)

Air direction

Air direction

2-11/64

8-47/64

13-5/16

18-5/8

4-39/64

2-59/64

6-15/16

31-19/64

65-25/32

(8-1/2)

74-19/64

2-11/64

8-47/64

13-5/16

18-5/8

4-39/64

2-59/64

6-15/16

31-19/64

65-25/32

(8-1/2)

74-19/64

Outdoor units

Page 8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

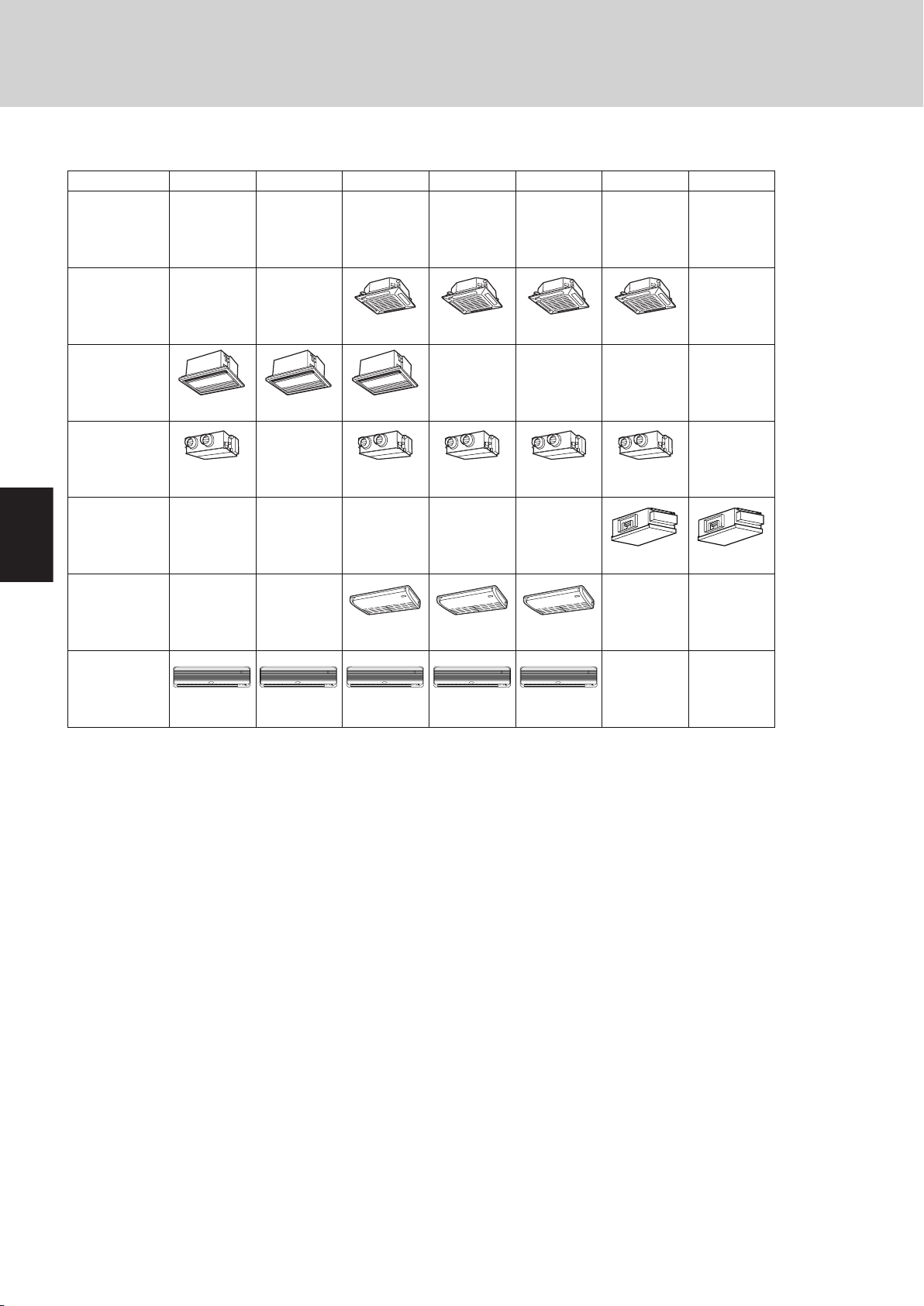

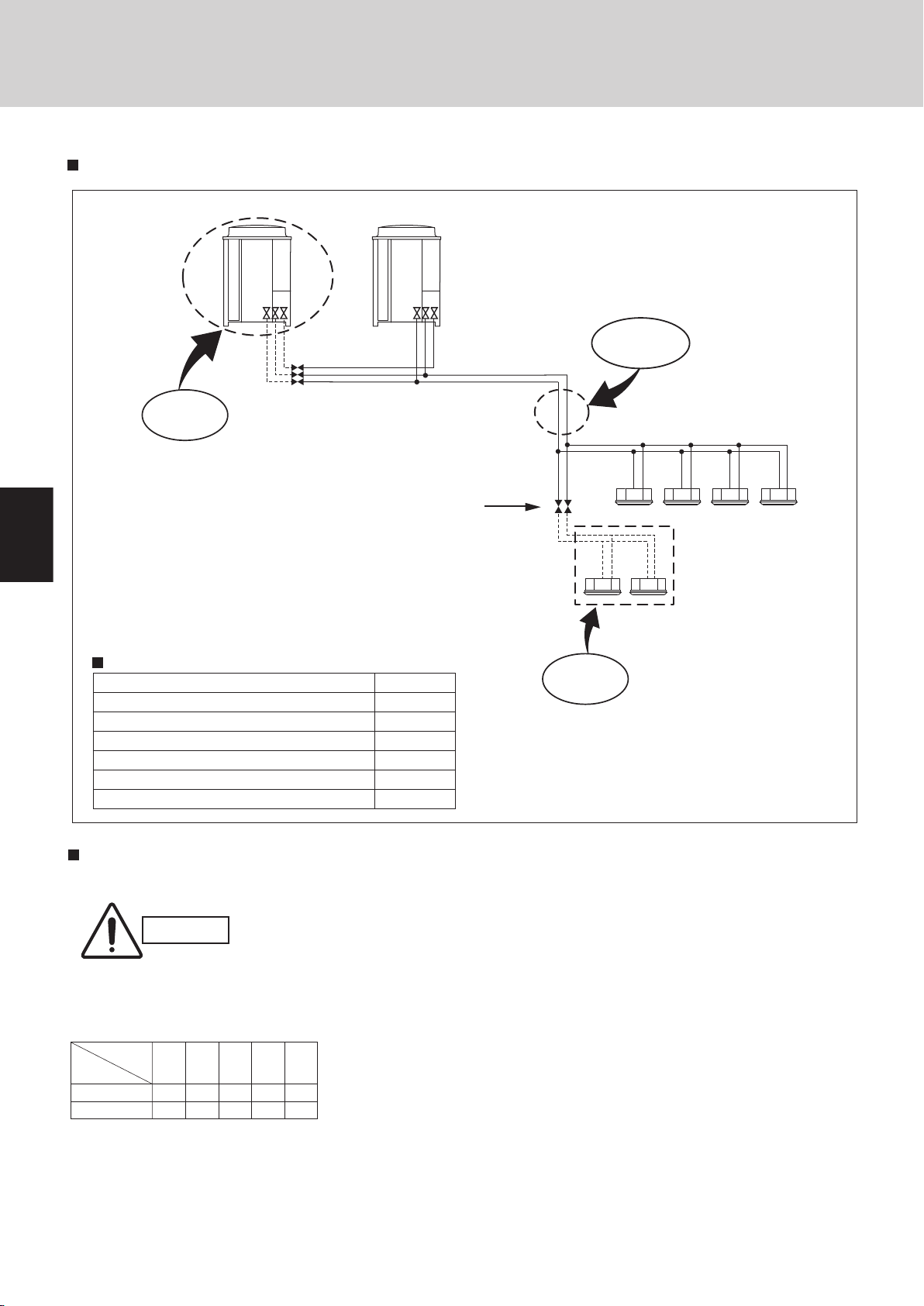

ADDITION

CONCENTRATION

If indoor/outdoor units need servicing, a ball

valve (field supply) cuts off non-operational

units to let other units stay running.

* The capacity after the setting

must not exceed 32 PS.

Since all tubings are

concentrated into

one pipe shaft, you

can minimize piping

space and construction labor

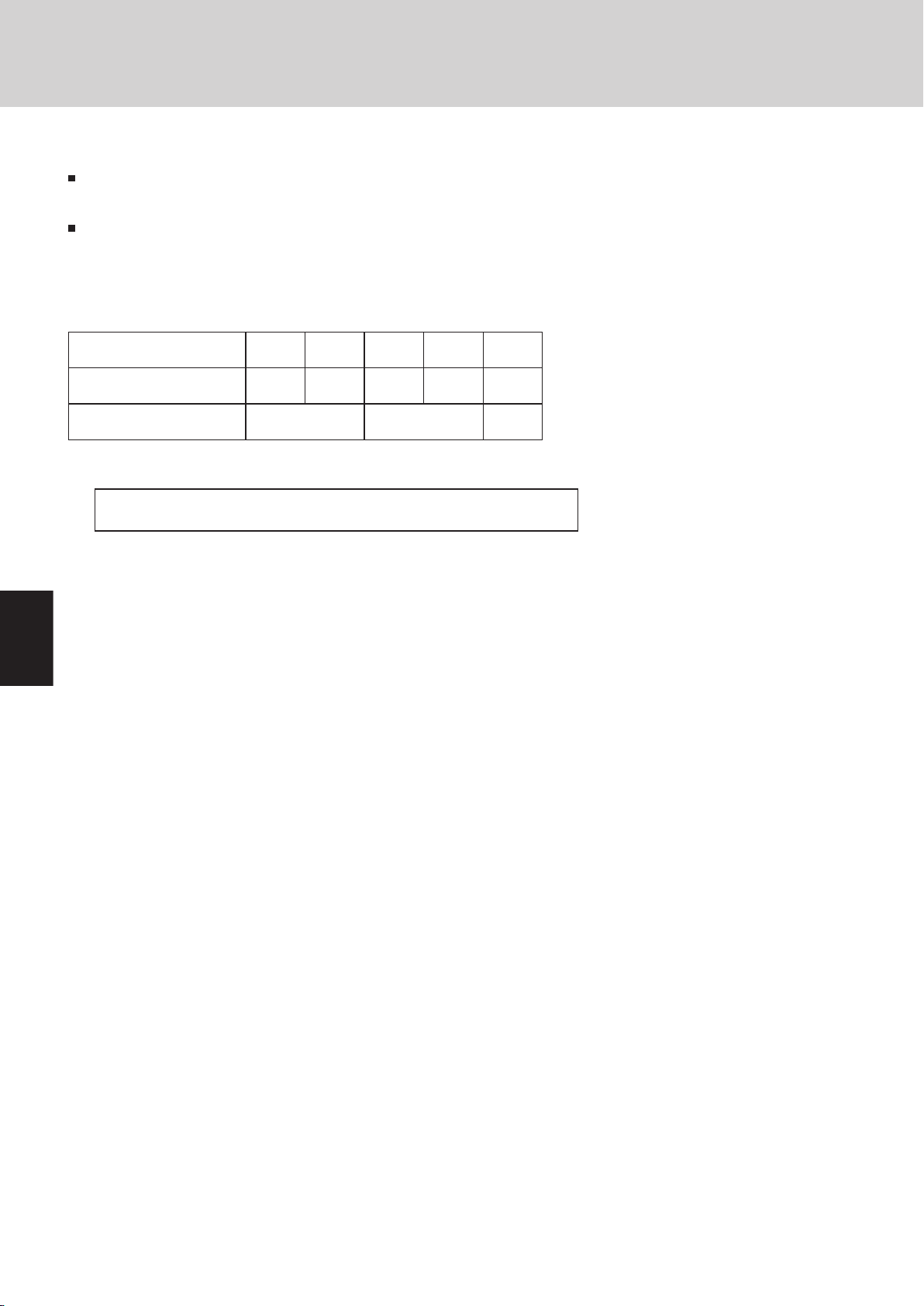

Maximum number of combined outdoor units

Maximum horsepower of combined outdoor units

Maximum number of connectable indoor units

Indoor/outdoor unit capacity ratio

Maximum actual tubing length

Maximum level difference (when outdoor unit is lower)

Maximum total tubing length

2

32 HP

40

50~130%

492 ft

164 (131) ft

984 ft

System limitations

CONNECTION

If your indoor capacity load

changes in the future, it’s easy to

add on both indoor and outdoor

units using the same tubing.

*If addi tional i nst allat ion of outd oor and ind oor u nit s is

exp ect ed, the sizeof refr igera nt tube sho uld be d ecided

accordin g to the to tal c apa city aft er the a ddi tion.

Combination of outdoor units

The DC inverter unit can be used independently or in combination.

CAUTION

R407C models and R22 models must not be used in combination with each

other.

1

1

2

10

16

10

16

20 26 32

Total horse

power

Inverter unit

Combination of outdoor units

1

2

1

2. Features of W-2WAY ECO-i SYSTEM

2-1. Outline of W-2WAY ECO-i SYSTEM

System example

Outline of W-2Way ECO-i SYSTEM

1-4

Page 9

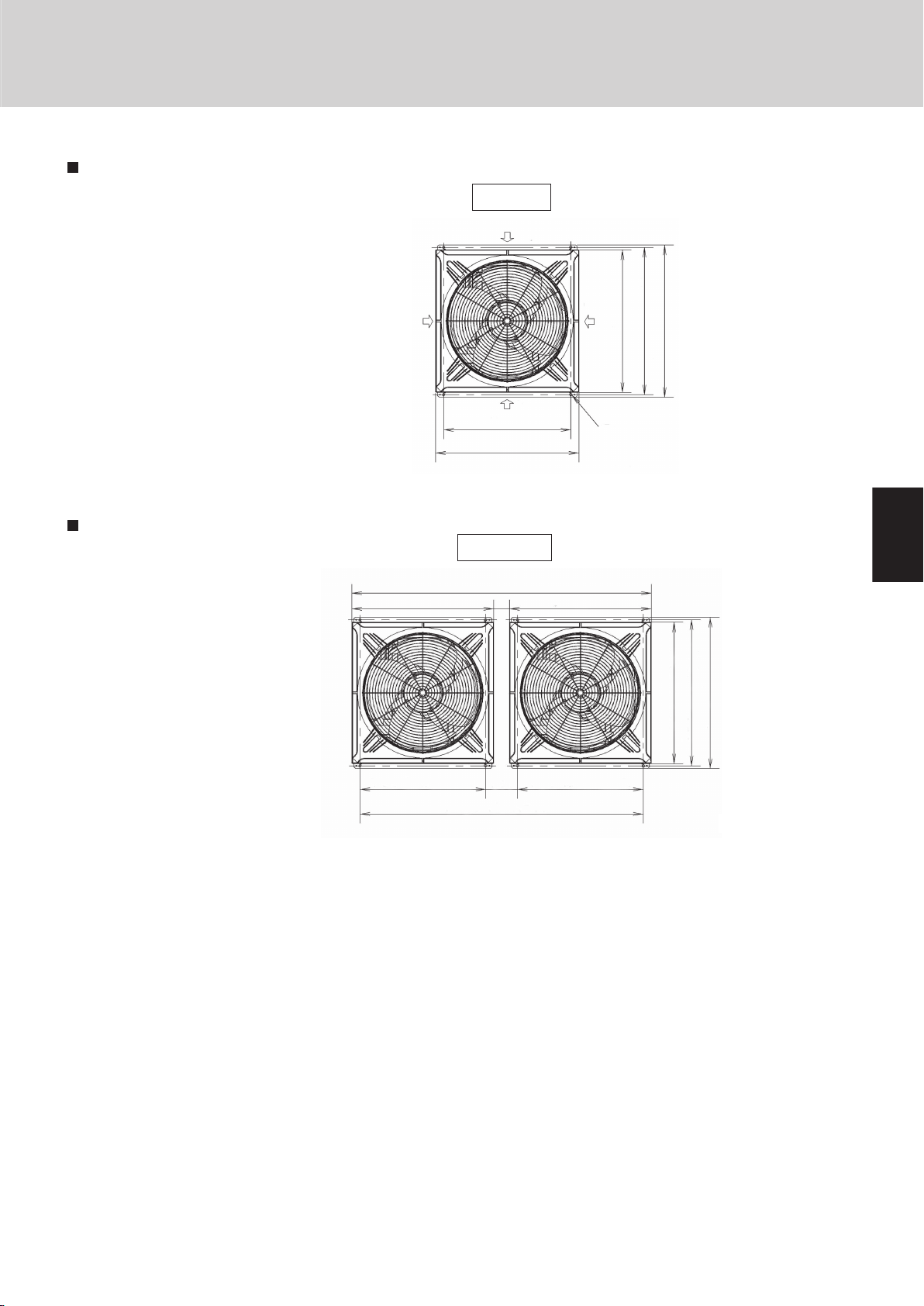

2. Features of W-2WAY ECO-i SYSTEM

Dimensions

10HP CHDX09053

16HP CHDX14053

Air direction

(Ceiling panel dimensions)

10,16 HP

Air direction

Air direction

31-7/64

(Installation hole pitch)

35-3/64

Top view

Outline of W-2Way ECO-i SYSTEM

Air direction

(Maximum dimensions)

(Installation hole pitch)

(Ceiling panel dimensions)

36-7/32

37-13/32

35-3/64

Unit: in.

Dimensions of unit combinations

20,26,32 HP

74-1/64 (Ceiling panel dimensions)

35-3/64 (Ceiling panel dimensions) 35-3/64 (Ceiling panel dimensions)

35-3/64 (Ceiling panel dimensions)

31-7/64 (Installation hole pitch)

70-5/64 (Installation hole pitch)

31-7/64 (Installation hole pitch)

Top view

36-7/32 (Installation hole pitch)

37-13/32 (Maximum dimensions)

Unit: in.

1

2

3

4

5

1-5

6

7

8

Page 10

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

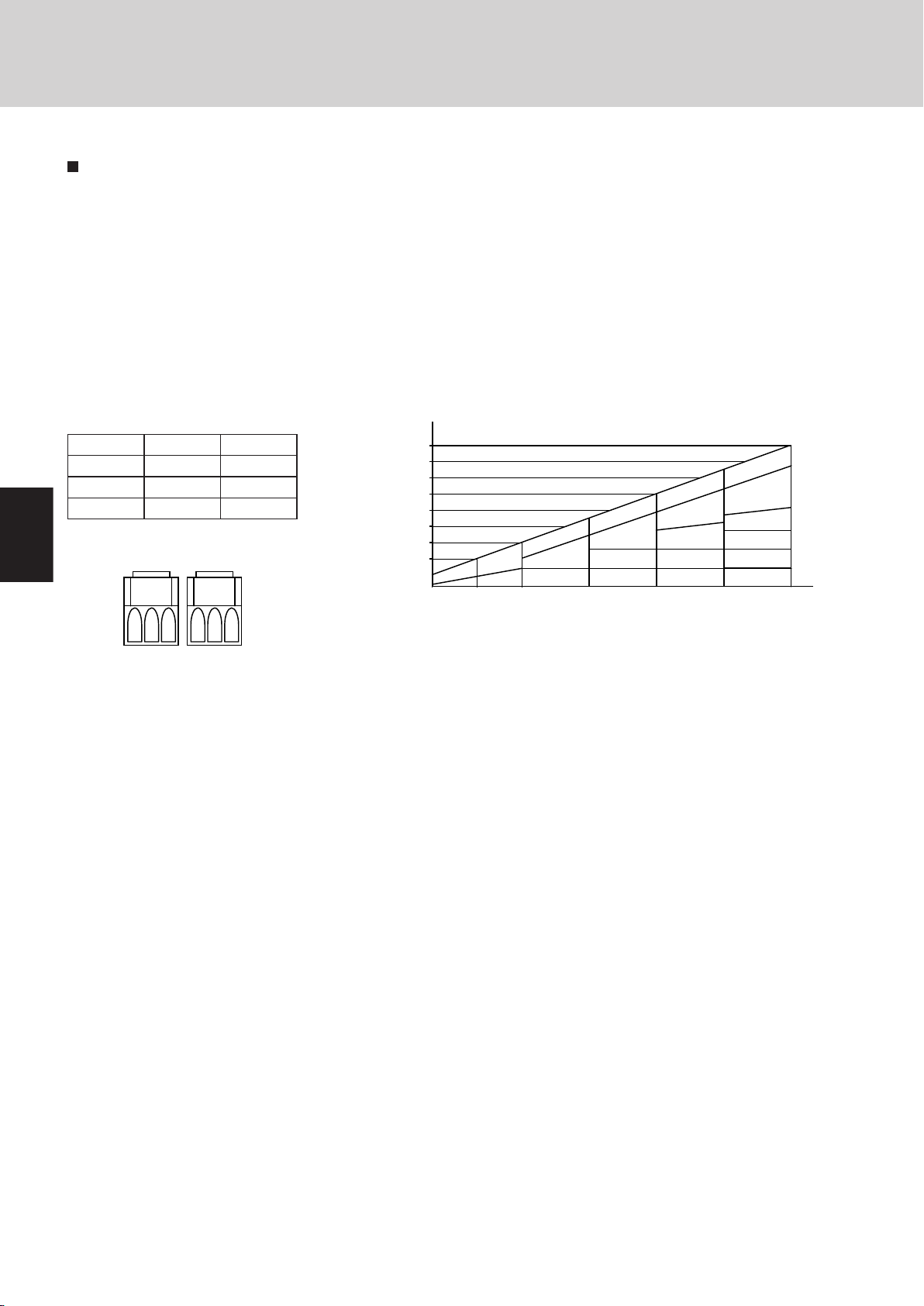

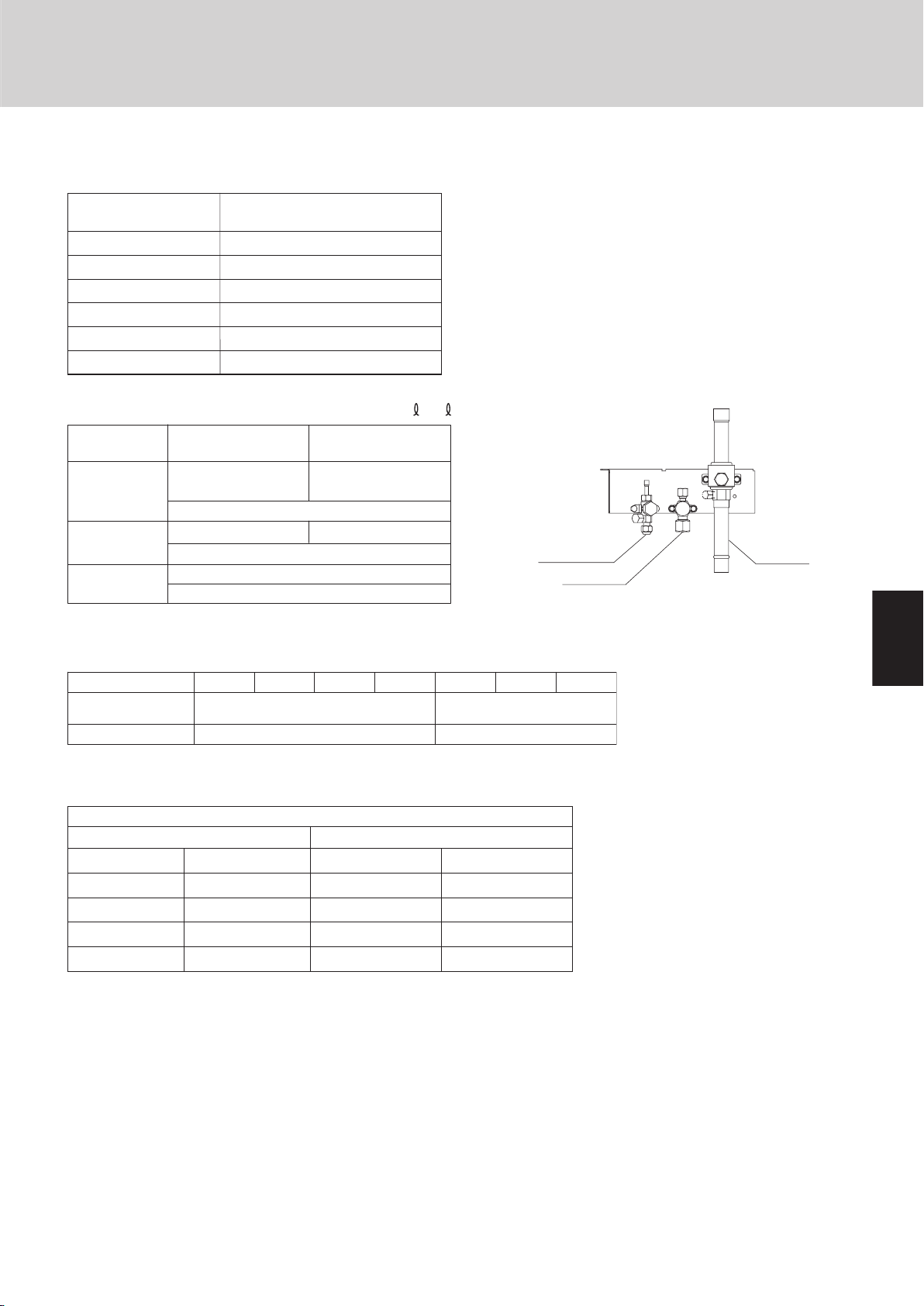

In case of 32 HP system

Capacity

32

28

24

20

16

12

8

4

DC1

DC2

AC11

AC21

AC12

AC22

DC1

DC1

DC2

AC11

DC1

DC2

AC11

AC21

DC1

DC2

AC11

AC21

AC12

DC2

DC1

DC2

LOAD --->

Example of 2 unit connection

DC1

AC11

AC12

Unit 1

DC2

AC21

AC22

Unit 2

DC3

AC31

AC32

Unit 3

Outline of W-2Way ECO-i SYSTEM

2. Features of W-2WAY ECO-i SYSTEM

Capacity control

The compressor combination (DC inverter compressor + constant-speed compressor) allows smooth capacity control from 0.8

HP to 32 HP.

Realization of smooth capacity control

from 0.8HP to 32HP

Capacity control is possible smoothly with a DC

inverter compressor.The right graph shows the

image of the operating combination of compressors in case of 32HP system.In actual operation,

the combination will be changed by operationg

condition, operating time amount, priority of compressor and so on.

Comp. HP Unit1(main) Unit2(sub1)

DC comp. 4.0 4.0

AC1 comp. 6.0 6.0

AC2 comp. 6.0 6.0

*32HP = CHDX14053 Type x2

1-6

Page 11

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1

2

3

4

5

6

7

8

Contents

2. DESIGN OF W-2WAY ECO-i SYSTEM

1. Model Selecting and Capacity Calculator ........................................................................2-2

2. System Design ..................................................................................................................2-17

3. Electrical Wiring ................................................................................................................2-23

4. Installation Instructions ...................................................................................................2-27

2-1

Page 12

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

50

14

23

32

41

50

59

68

77

86

95

104

113

Indoor air intake temp.

°

F (WB)

Outdoor air intake temp.

°

F (DB)

59

57

109

68 77 86

Operating

range

50

5

-4

14

23

32

41

50

59

68

77

Indoor air intake temp.

°

F (DB)

Outdoor air intake temp. °F (WB)

59 68 77 86 95

Operating

range

Cooling

Heating

1. Model Selecting and Capacity Calculator

1-1. Operating Range

2-2

Page 13

1

2

3

4

5

6

7

8

2-3

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1

2

3

4

5

6

7

8

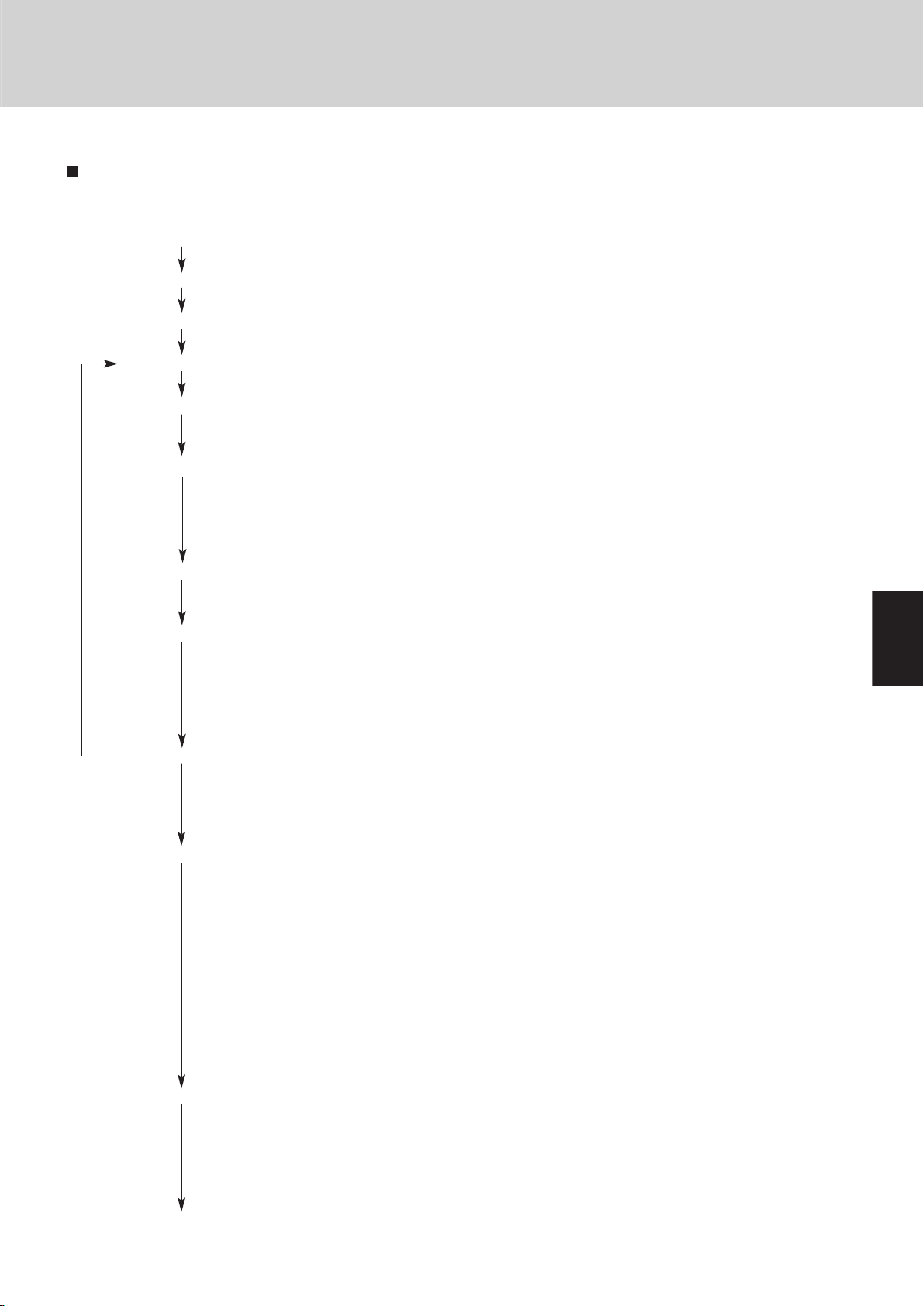

Select the model and calculate the capacity for each refrigerant system according to the procedure shown below.

Calculation of the indoor air-conditioning load

●

Calculate the maximum air-conditioning load for each room or zone.

Selection of an air conditioning system

●

Select the ideal air conditioning system for air conditioning of each room or zone.

Design of the control system

●

Design a suitable control system for the selected air conditioning system.

Preliminary selection of indoor and outdoor units

●

Make preliminary selections that are within the allowable range for the system.

........

2-4 ~ 2-10

Check of the tubing length and elevation difference

●

Check that the length of refrigerant tubing and the elevation difference are within the allowable

ranges.......................................................................................................................................

2-4

Calculation of the corrected outdoor unit capacity

●

Capacity correction coefficient for model.................................................................... 2-11, 13, 14

●

Capacity correction coefficient for outdoor temperature conditions ..................................2-11, 13

●

Capacity correction coefficient for tubing length and elevation difference ........................ 2-11, 14

●

Heating capacity correction coefficient for frosting/defrosting .......................................... 2-11, 13

Calculation of the corrected capacity for each indoor unit

●

Capacity correction coefficient for indoor temperature conditions .................................... 2-11, 14

●

Capacity distribution ratio based on the tubing length and elevation difference .............. 2-11, 14

Calculation of the actual capacity for each indoor unit

●

Calculate the corrected indoor/outdoor capacity ratio, based on the corrected outdoor unit

capacity and the total corrected capacity of all indoor units in the same system. Use the result to

calculate the capacity correction coefficient for the indoor units.................................

2-11 ~ 2-14

●

Multiply the corrected capacity of each indoor unit by the capacity correction coefficient to calcu-

late the actual capacity for each indoor unit. .......................................................................... 2-12

Recheck of the actual capacity for each indoor unit

●

If the capacity is inadequate, reexamine the unit combinations.

Example 1: Increasing the outdoor unit capacity.................................................................... 2-18

Example 2: Increasing the indoor unit capacity ...................................................................... 2-19

●

Increasing the tubing size ...................................................................................................... 2-20

Design of tubing

●

Create a tubing design which minimizes the amount of additional refrigerant charge as much as

possible. .......................................................................................................................... 2-4 ~ 2-6

●

If tubing extension for additional unit is expected in the future, create the tubing design with

adequate consideration for this extension.

●

Select the tubing size for the main tube (LA) up to the No. 1 distribution joint based on the rated

cooling capacity of the outdoor unit. Select tubing sizes after the distribution point based on the

total rated cooling capacity of the connected indoor units.

●

Increasing the tubing size of the wide tubes can reduce the loss of capacity caused by longer

tubing lengths. (Only the main wide tube with the largest tube diameter (main tube LA and main

tubes after the distribution point that are the same size as LA) can be changed.) In this case, it is

necessary to recalculate the actual indoor unit capacities. ....................................................

2-20

Calculation of additional refrigerant charge amount

●

Calculate the additional refrigerant charge from the diameters and lengths of the refrigerant tubing. Even if the wide tubing diameter was increased, determine the additional refrigerant charge

based only on the narrow tubing size.....................................................................................

2-21

●

Check the minimum indoor capacity (limit density) with respect to the amount of refrigerant. If the

limit density is exceeded, be sure to install ventilation equipment or take other corrective steps. 2-22

Design of electrical wiring capacity

●

Select a wiring capacity according to the method of power supply. ...................................... 2-24

1. Model Selecting and Capacity Calculator

1-2. Procedure for Selecting Models and Calculating Capacity

Model Selection Procedure

Page 14

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

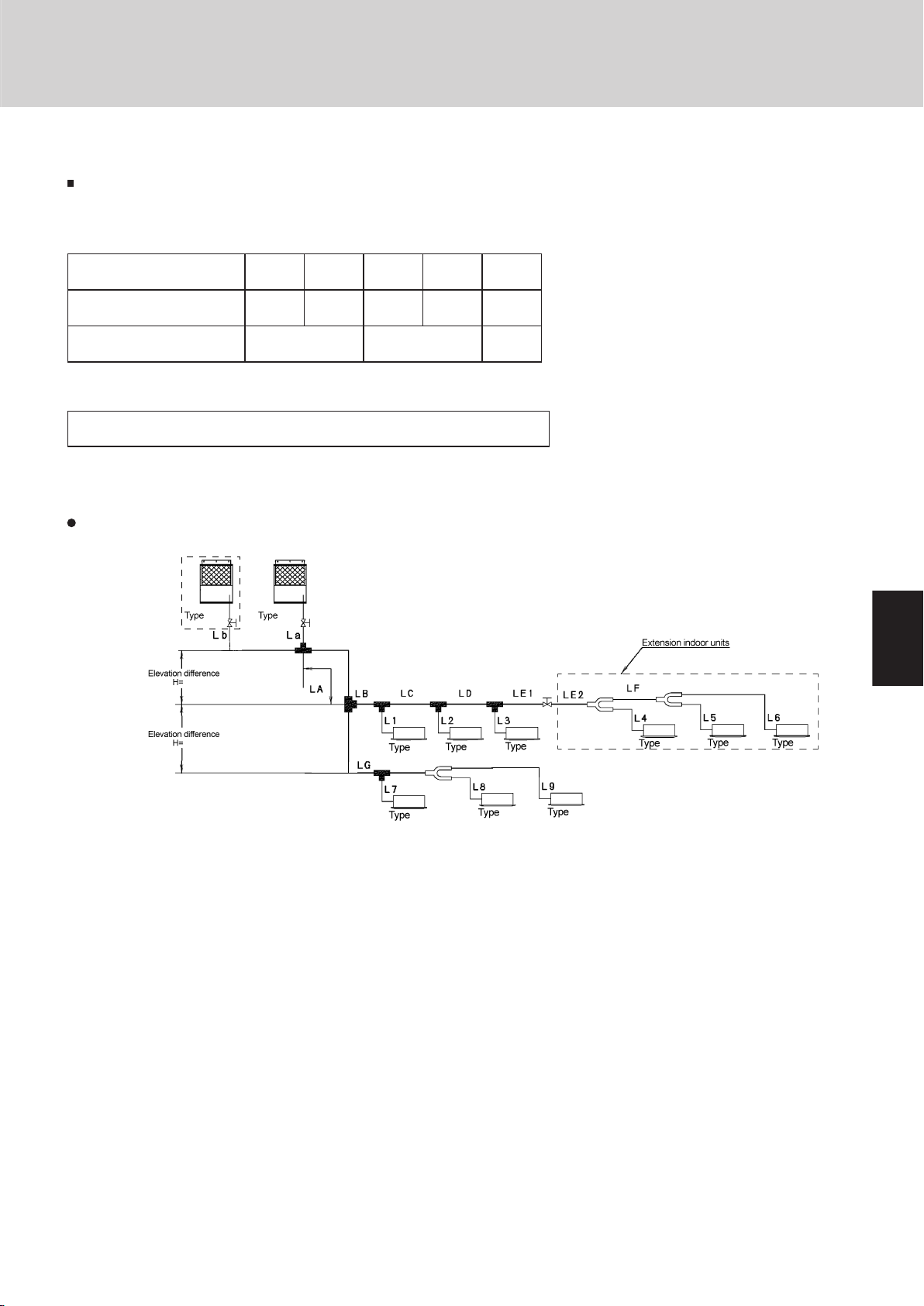

R410A distribution joint

APR-CHP680BA (for outdoor unit)

APR-CHP680BA (for outdoor unit)

APR-CHP680BA (for outdoor unit)

APR-CHP680BA (for outdoor unit)

APR-P1350BA (for indoor unit)

Explanation of symbols

Distribution joint

(APR: purchased separately)

Solidly welded shut

(pinch weld)

Balance tubing

( 1/4")

Main distribution tubes LC – LG are selected according to the capacity after the distribution joint.

Sizes of indoor unit connection tubing 1 – 40 are determined by the connection tubing sizes on the indoor units.

Main tubing length LM = LA + LB … 262 ft

1.

2.

3. The outdoor connection main tubing ( B portion) is determined by the total capacity of the outdoor units that are connected to the tube ends.

4.

Ball valve (field supply)

T-joint (field supply)

Note: Do not use commercially available T-joints for the liquid tubing and parts.

* Be sure to use special R410A distribution joints (APR: purchased separately) for outdoor unit connections and tubing branches.

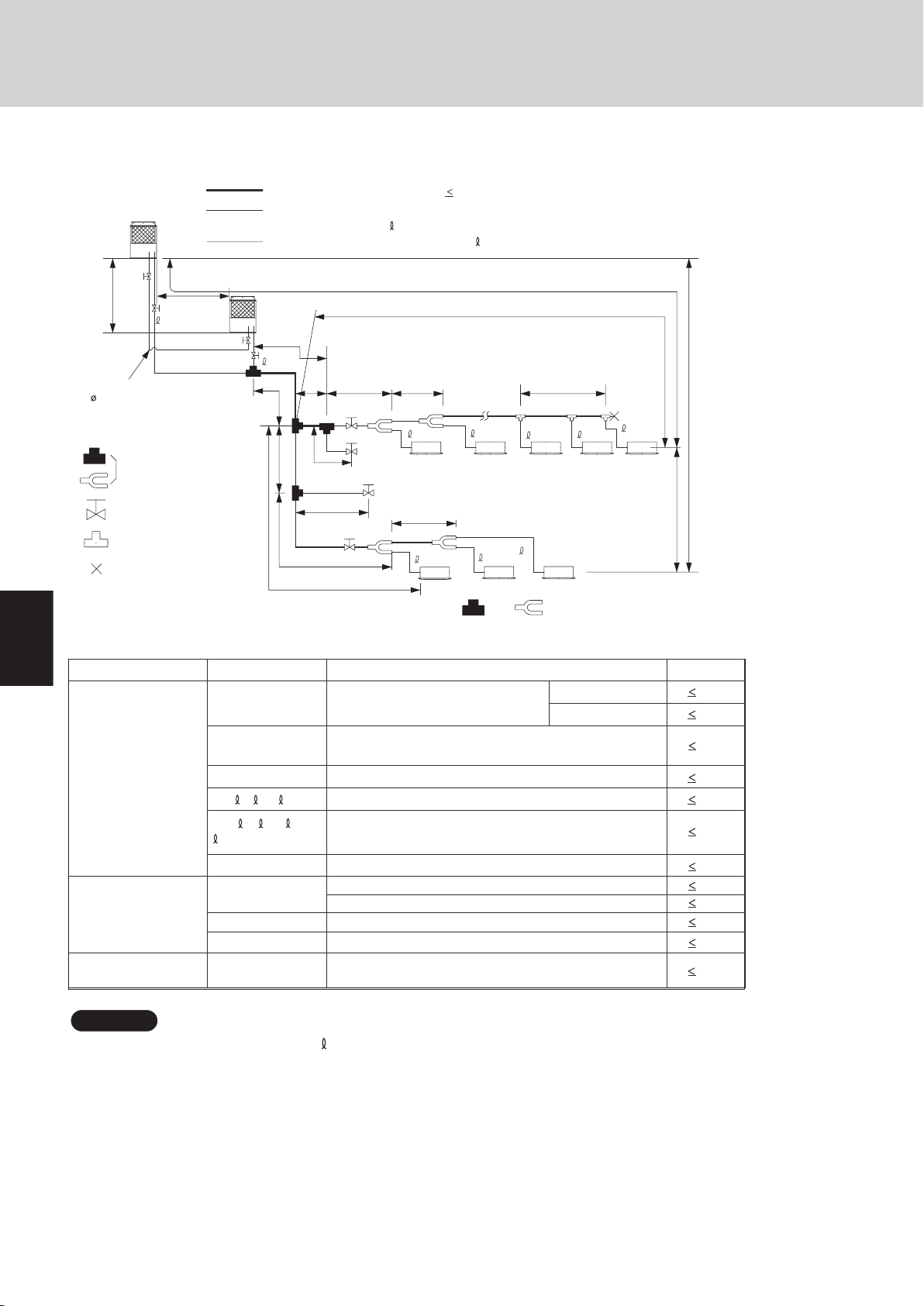

Table 2-1 Ranges that Apply to Refrigerant Tubing Lengths and to Differences in Installation Heights

Select the installation location so that the length and size of refrigerant tubing are within the allowable range shown in the figure below.

Item Mark Contents Length (ft.)

L1 Max. tubing length

Actual length 492

Equivalent length 574

L (L2 – L4)

Difference between max. length and min.

length from the No.1 distribution joint

131

LM Max. length of main tubing (at max. diameter) 262

1, 2... 40

Max. length of each distribution tube 98

L1+ 1+ 2... 39+

A+LE+LF+LG

Total max. tubing length including length of

each distribution tube (only liquid tubing)

984

L5

L3

Distance between outdoor units

32

H1

When outdoor unit is installed higher than indoor unit 164

When outdoor unit is installed lower than indoor unit 131

H2

Max. difference between indoor units 49

H3 Max. difference between outdoor units

13

L = Length, H=Height

Allowable tubing

length

Allowable elevation

difference

*3

6.6

Allowable length of

joint tubing

T-joint tubing (field-supply); Max. tubing length between

the first T-joint and solidly welded-shut end point

1: The outdoor connection main tubing ( B portion) is determined by the total capacity of the outdoor units that are connected to

the tube ends.

2: If the longest tubing length (L1) exceeds 295 ft. (equivalent length), increase the sizes of the main tubes (LM) by 1 rank for gas

tubes and liquid tubes. (Use a field supply reducer.) (Select the tube size from the table of main tube sizes (Table 2-5) on the

following page (LA table), and from the table of refrigerant tubing sizes (Table 2-10) on the second following page.)

3: If the longest main tube length (LM) exceeds 164 ft., increase the main tube size at the portion before 164 ft. by 1 rank for the

gas tubes. (Use a field supply reducer.)

(For the portion that exceeds 164 ft., set based on the main tube sizes (LA) listed in the table on the following page.)

4: If the size of the existing tubing is already larger than the standard tubing size, it is not necessary to further increase the size.

* If the existing tubing is used, and the amount of on-site additional refrigerant charge exceeds the value listed below, then

change the size of the tubing to reduce the amount of refrigerant.

Max. additional charge for 1 outdoor unit: 62 lbs

Max. additional charge for 2 outdoor units: 111lbs

NOTE

L5

LA

LE

LM

LB LC

L2

L4

LF

LD L3

LG

H2

H3

H1

L1

2

3

1

5

4

A

B

38

39

40

For

extension

For

extension

Max. 1.3ft

Max. 1.3ft

1. Model Selecting and Capacity Calculator

1-3. Tubing Length

2-4

Page 15

1

2

3

4

5

6

7

8

2-5

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1

2

3

4

5

6

7

8

1. Model Selecting and Capacity Calculator

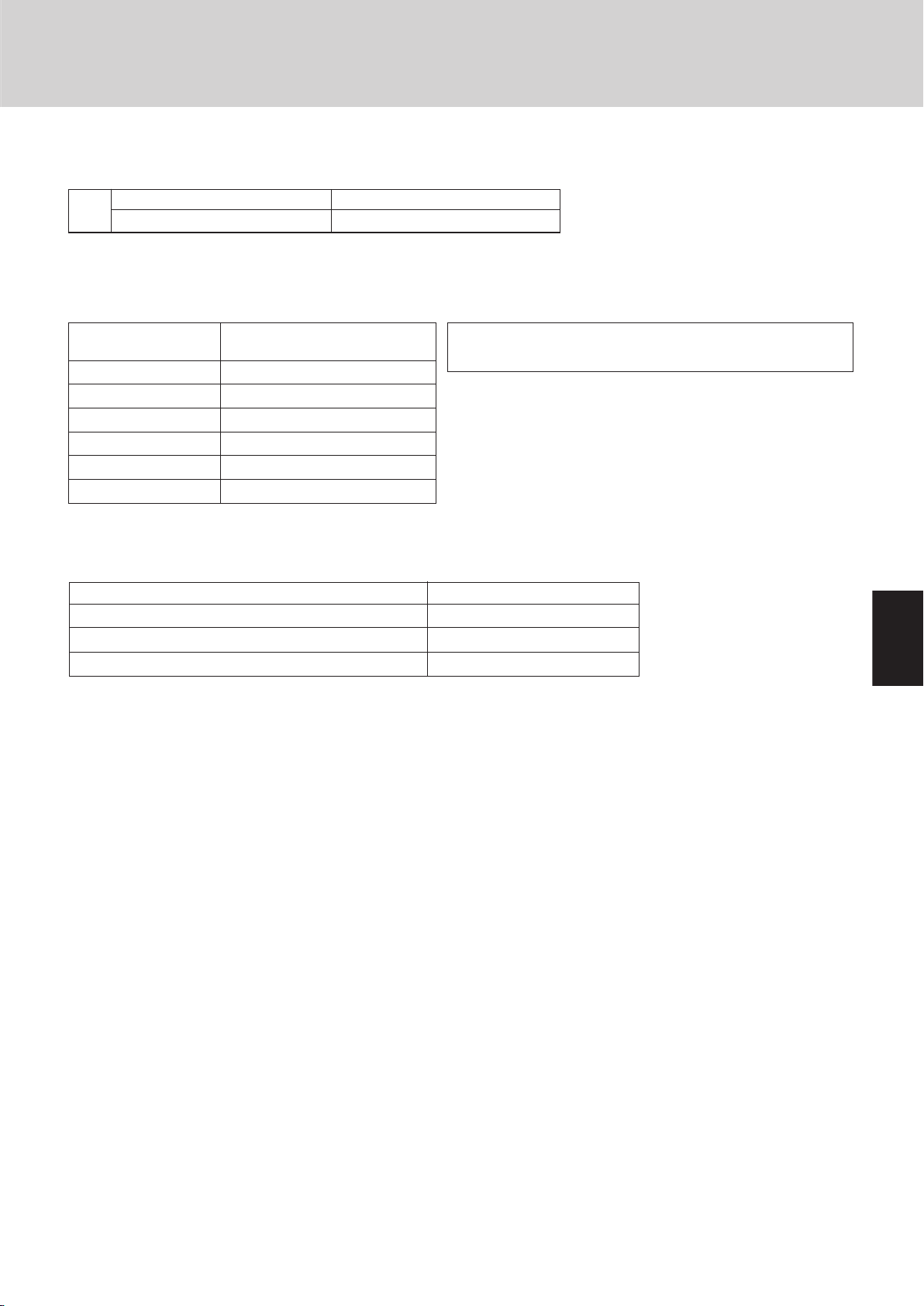

Table 2-2 Refrigerant Charge Amount at Shipment (for outdoor unit)

DC

(oz)

Additional refrigerant charge amount is calculated from the liquid tubing total length as follows.

Table 2-3 Amount of Refrigerant Charge Per Meter, According to Liquid Tubing Size

Liquid tubing size Amount of refrigerant

(in. (mm)) charge (oz/ft.)

ø1/4" (ø6.35) 0.279

ø3/8" (ø9.52) 0.602

ø1/2" (ø12.7) 1.38

ø5/8" (ø15.88) 1.99

ø3/4" (ø19.05) 2.78

ø7/8" (ø22.22) 3.93

CHDX09053 CHDX14053

423 458

Required amount of charge = (Amount of refrigerant charge per

meter of each size of liquid tube × its tube length) + (...) + (...)

* Always charge accurately using a scale for weighing.

* If the existing tubing is used, and the amount of on-site additional

refrigerant charge exceeds the value listed below, then change the

size of the tubing to reduce the amount of refrigerant.

Max. additional charge for 1 outdoor unit : 62 lbs

Max. additional charge for 2 outdoor units : 111 lbs

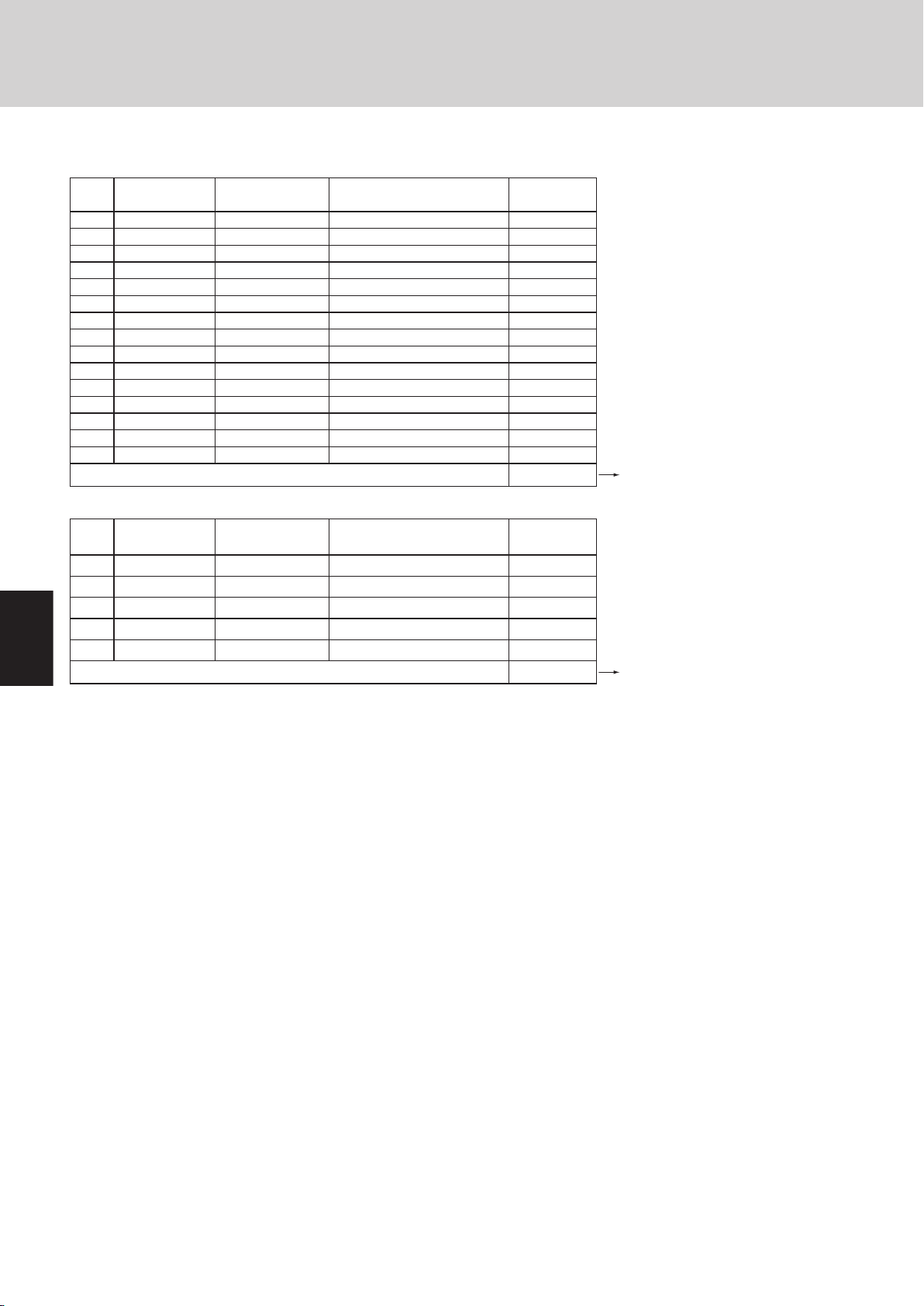

Table 2-4 System Limitations

Max. No. allowable connected outdoor units 2

Max. capacity allowable connected outdoor units 307,100 BTU/h (32 hp, 90 kW)

Max. connectable indoor units 40

Max. allowable indoor/outdoor capacity ratio 50 – 130 %

*1: Up to 2 units can be connected if the system has been extended.

*1

Page 16

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

32

249,100

(73.0)

26

ø7/8"

(ø22.22)

10

95,500

(28.0)

ø1/2"

(ø12.7)

153,600

(45.0)

16

ø1-1/8"

(ø28.58)

ø5/8"

(ø15.88)

10

10

16

10

16

16

191,100

(56.0)

20

ø3/4"

(ø19.05)

ø1-3/8"

(ø34.92)

ø3/8"

(ø9.52)

307,100

(90.0)

16 10

BTU/h

(kW)

Total system horsepower

Combined outdoor units

Gas tubing

Liquid tubing

ø3/4"

(ø19.05)

ø1-3/8"

(ø34.93)

ø5/8"

(ø15.88)

ø1-1/8"

(ø28.58)

ø1/2"

(ø12.7)

ø1-1/8"

(ø28.58)

ø3/8"

(ø9.52)

ø3/4"

(ø19.05)

ø3/8"

(ø9.52)

ø5/8"

(ø15.88)

ø3/8"

(ø9.52)

ø1/2"

(ø12.7)

Gas tubing

Liquid tubing

–

238,900

(25 hp)

178,800

(19 hp)

ø1/2"

(ø12.7)

ø1-1/8"

(ø28.58)

178,800

(19 hp)

143,300

(15 hp)

24,200

(2.5 hp)

24,200

(2.5 hp)

–

54,600

(6 hp)

54,600

(6 hp)

238,900

(25 hp)

76,800

(8.1 hp)

ø3/8"

(ø9.52)

ø7/8"

(ø22.22)

76,800

(8.1 hp)

102,400

(11 hp)

102,400

(11 hp)

Below BTU/h

Over BTU/h

143,300

(15 hp)

hp = horsepower

Tubing size

Total capacity

after distribution

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1. Model Selecting and Capacity Calculator

1-4 Tubing Size

Table 2-5 Main Tubing Size (LA)

*1: If future extension is planned, select the tubing diameter based on the total horsepower after extension.

However extension is not possible if the resulting tubing size is two ranks higher.

*2: The balance tube (outdoor unit tube) diameter is ø1/4".

*3: Type 1 tubing should be used for the refrigerant tubes.

*4: If the length of the longest tube (L1) exceeds 295 ft. (equivalent length), increase the main tube (LM) size by 1 rank for the gas

and liquid tubes. (Use field-supply reducers.) (Select from Table 2-5 and Table 2-10.)

*5: If the longest main tube length (LM) exceeds 164 ft., increase the main tube size at the portion before 164 ft. by 1 rank for the

gas tubes.

(For the portion that exceeds 164 ft., set based on the main tube sizes (LA) listed in the table above.)

Unit: in. (mm)

Size of tubing (lB) between outdoor units

Select the size of tubing between outdoor units based on the main tubing size (LA) as given in the table above.

Table 2-6 Main Tubing Size After Distribution (LB, LC...)

Note: In case the total capacity of connected indoor units exceeds the total capacity of the outdoor units, select the main tubing

size for the total capacity of the outdoor units. (Especially the main tubing segments of LA, LB and LF.)

Unit: in. (mm)

2-6

Page 17

1

2

3

4

5

6

7

8

2-7

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1

2

3

4

5

6

7

8

ø7/8"

(ø22.22)

ø3/8" (ø9.52)

ø1/4" (ø6.35)

95,500

(28.0)

153,600

(45.0)

ø1-1/8"

(ø28.58)

Flare connection

Brazing connection

ø1/2" (ø12.7)

Flare connection

( A – B)

Balance tubing

Liquid tubing

Gas tubing

BTU/h

(kW)

Balance tube

Liquid tube

Gas tube

ø5/8" (ø15.88)

ø3/8" (ø9.52) ø1/4" (ø6.35)

ø1/2" (ø12.7)

Gas tubing

Liquid tubing

Indoor unit type 7 9 12 18

24

36 48

1. Model Selecting and Capacity Calculator

Table 2-7 Amount of Refrigerant Charge

Liquid tubing size Amount of refrigerant

(in. (mm)) charge (oz/ft.)

ø1/4" (ø6.35) 0.279

ø3/8" (ø9.52) 0.602

ø1/2" (ø12.7) 1.38

ø5/8" (ø15.88) 1.99

ø3/4" (ø19.05) 2.78

ø7/8" (ø22.22) 3.93

Table 2-8 Outdoor Unit Tubing Connection Size

Unit: in. (mm)

Table 2-9 Indoor Unit Tubing Connection Size

Note: Use C1220T-1/2H material for tubing over ø3/4" (ø22.22).

Table 2-10 Refrigerant tubing (Existing tubing can be used.)

Material O Material 1/2H • H

ø1/4" (ø6.35) t1/32" (0.8) ø7/8" (ø22.22) t5/128" (1.0)

ø3/8" (ø9.52) t1/32" (0.8) ø1" (ø25.40) t5/128" (1.0)

ø1/2" (ø12.7) t1/32" (0.8) ø1-1/8" (ø28.58) t5/128" (1.0)

ø5/8" (ø15.88) t5/128" (1.0) ø1-1/4" (ø31.75) t3/64" (1.1)

ø3/4" (ø19.05) over t5/128" (1.0) ø1-3/8" (ø34.93) over t3/64" (1.15)

Tubing size (in. (mm))

Unit: in. (mm)

* When bending the tubes, use a bending

radius that is at least 4 times the outer

diameter of the tubes.

In addition, take sufficient care to avoid

crushing or damaging the tubes when

bending them.

Page 18

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

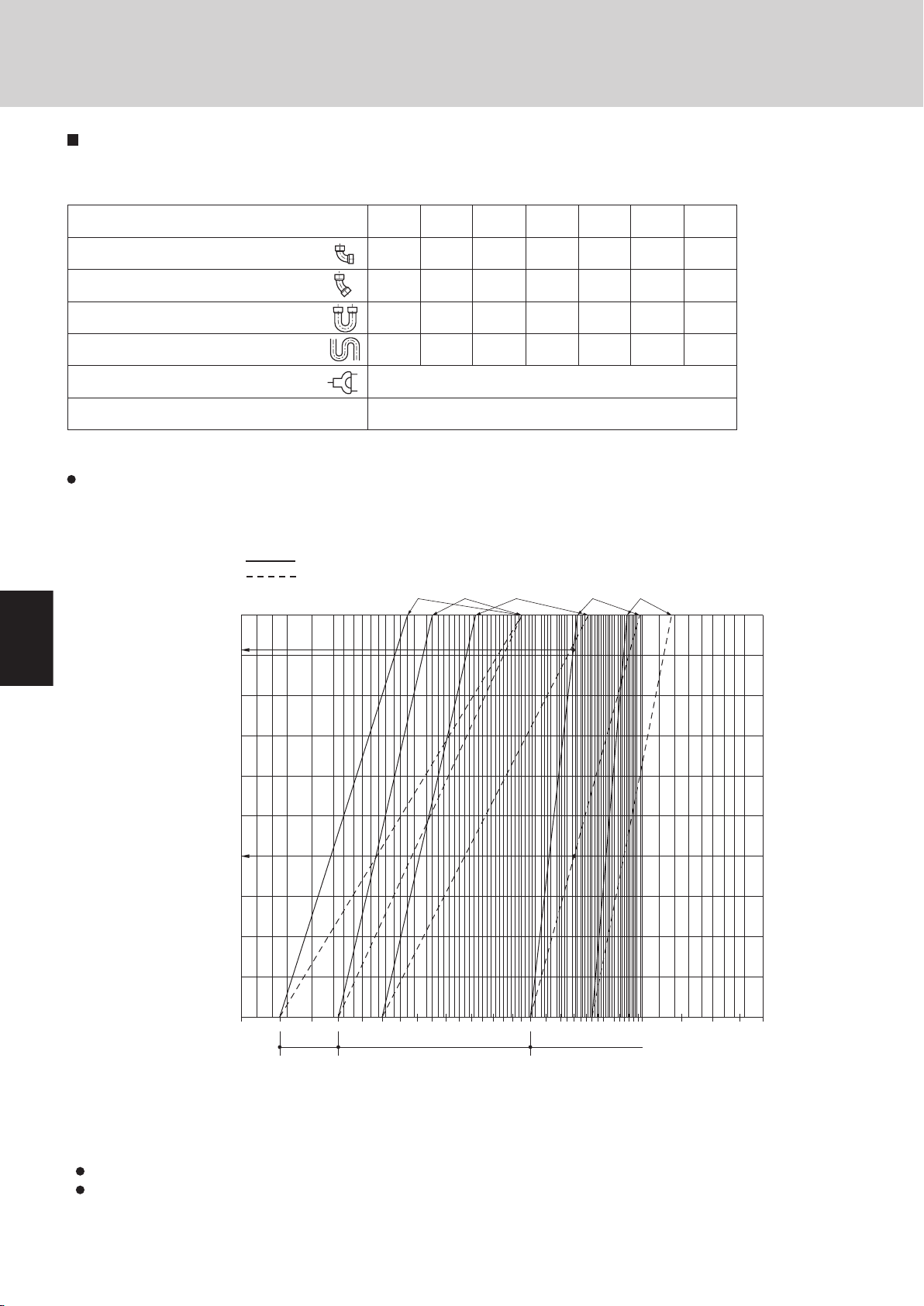

Wide tubing size (mm) 12.7 15.88 19.05 22.22 25.4 28.58 31.8 38.1

90o elbow 0.3 0.35 0.42

0.48

0.52 0.57 0.7

0.79

45o elbow 0.23 0.26 0.32

0.36

0.39 0.43 0.53 0.59

U-shape tube bent (R60 100 mm) 0.9 1.05 1.26 1.44 1.56 1.71 2.1

2.37

Trap bend

2.3

2.8 3.2 3.8 4.3 4.7 5.0

5.8

Y-branch distribution joint Equivalent length conversion not needed.

Ball valve for service Equivalent length conversion not needed.

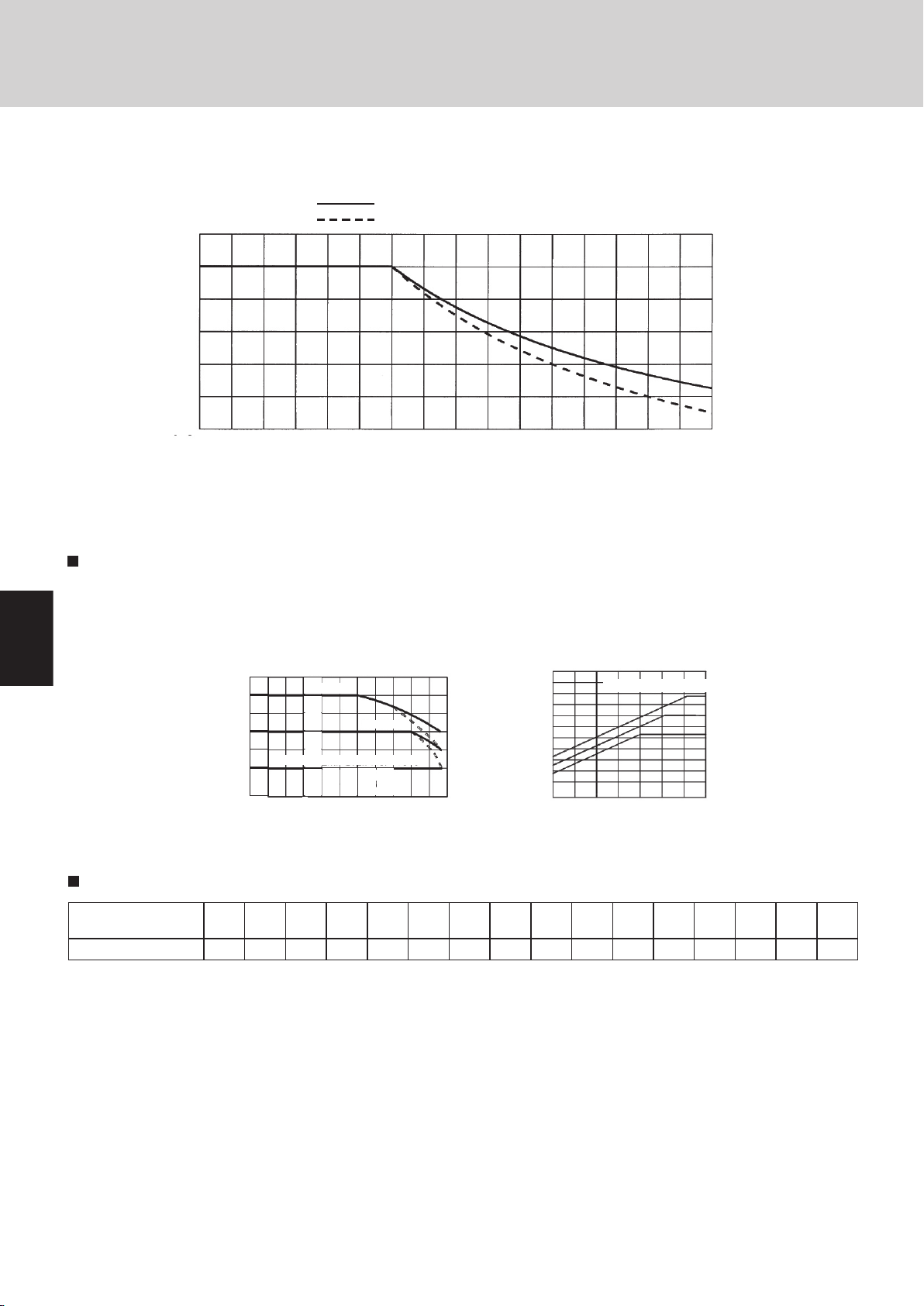

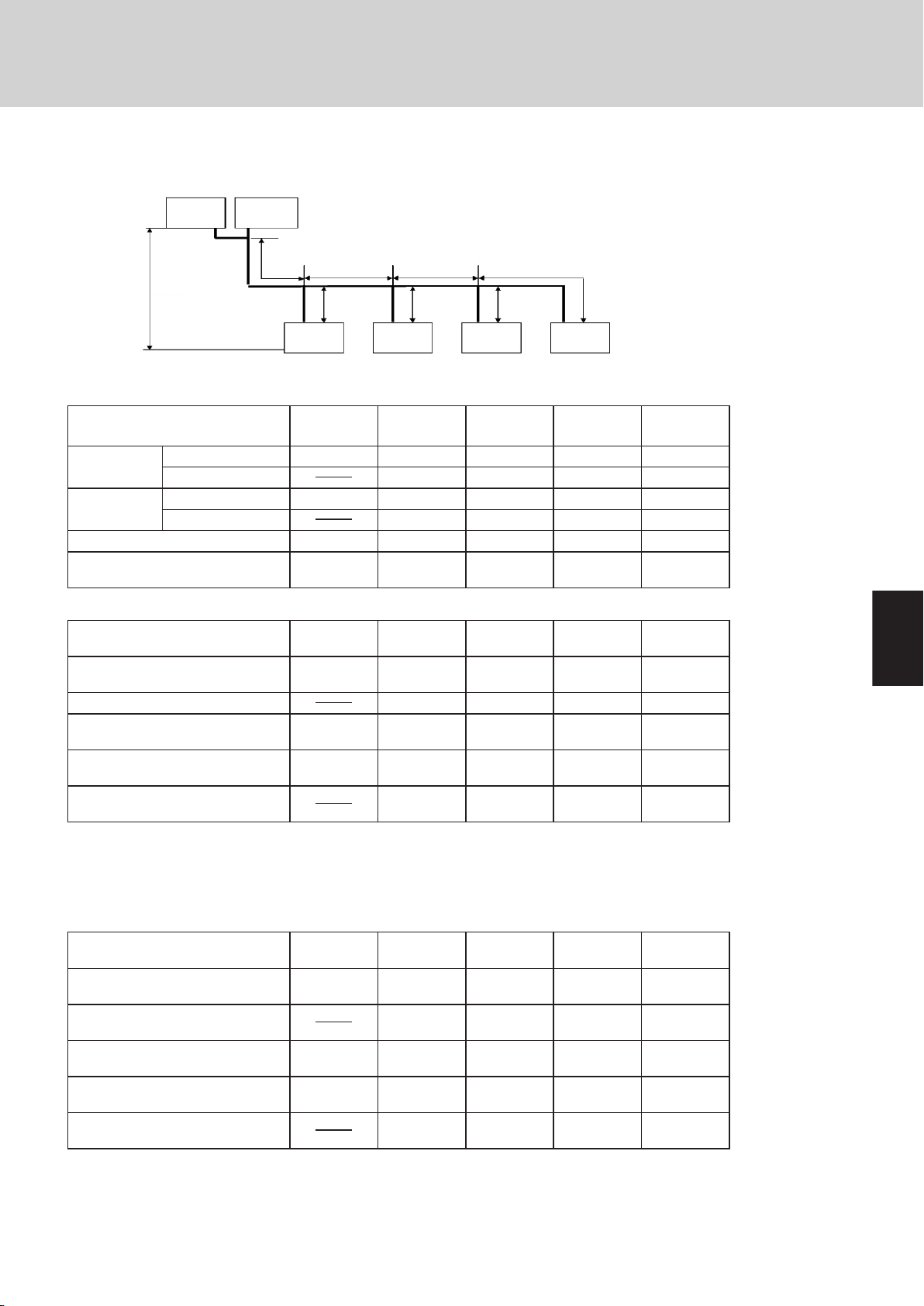

Cooling

Heating

95

94

93

92

91

90

96

97

98

99

100

Capacity ratio based on Gas

tube diameter (%)

Recommended Gas tubes diameter (in)

ø3/4” ø7/8”

ø7/8” ø1-1/8”

ø1-1/8”

ø1-3/8”

ø1-3/8”

ø1”

10 12 14 16 18 20 26 30 35 40 45 46 47 48

Gas tubing size (in. (mm))

1/2"

(12.7)

5/8"

(15.88)

3/4"

(19.05)

7/8"

(22.22)

1"

(25.4)

1-1/8"

(28.58)

1-3/8"

(34.93)

90° elbow

1 1.1 1.4 1.6 1.7 1.9 2.5

45° elbow 0.8 0.9 1

1.2

1.3 1.4 1.8

U-shape tube bent (R2-3/8" – 4" (60 – 100)) 3 3.4 4.1 4.7 5.1 5.6 7.4

Trap bend

7.5 9.2 10.5 12.5 14.1 15.4 19.2

Y-branch distribution joint Equivalent length conversion not needed.

Ball valve for service Equivalent length conversion not needed.

1. Model Selecting and Capacity Calculator

Straight equivalent length of joints

Design the tubing system by referring to the following table for the straight equivalent length of joints.

Table 2-11 Straight Equivalent Length of Joints

Capacity loss caused by differences in tubing diameters

* Capacity loss will occur if a tubing system that matches the horsepower is not selected (for example, if a tubing system was

determined and installed with no plan for extension and extension occurs later). The loss rate can be found from the graph

below.

Unit: ft.

(Reading the graph)

<Example 1>

Currently a 16 HP system and ø1-1/8" Gas tubings are used. Subsequently the system is expanded, with 16 HP added to the

same tubing system.

Horsepower after extension: 16 + 16 = 32 HP

From the graph above: Cooling: Capacity ratio is 90.8%. Actual capacity = 32 × 0.908 = 29.1 HP

Heating: Capacity ratio is 96.0%. Actual capacity = 32 × 0.960 = 30.7 HP

2-8

Page 19

1

2

3

4

5

6

7

8

2-9

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1

2

3

4

5

6

7

8

WARNING

CAUTION

WARNING

0 0

57

114

170

227

284

341

398

454

511

568

625

682

738

795

852

909

966

1022

1079

1136

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

10000

1000500 1500 2000 2500 3000

Total amount of refrigerant

Min. indoor volume

Min. indoor floor area

(when the ceilin

g

is 8.8 ft. hi

g

h)

ft.

3

ft.

2

oz

Range above

the density limit of

0.3 oz/ft.

3

(countermeasures

needed)

Range below

the density limit of

0.3 oz/ft.

3

(countermeasures

not needed)

1. Model Selecting and Capacity Calculator

Additional refrigerant charge amount

Additional refrigerant charge amount is calculated from the liquid tubing total length as follows.

Table 2-12 Amount of Refrigerant Charge Per Meter, According to Liquid Tubing Size

Liquid tubing size Amount of refrigerant

(in. (mm)) charge (oz/ft.)

ø1/4" (ø6.35) 0.279

ø3/8" (ø9.52) 0.602

ø1/2" (ø12.7) 1.38

ø5/8" (ø15.88) 1.99

ø3/4" (ø19.05) 2.78

ø7/8" (ø22.22) 3.93

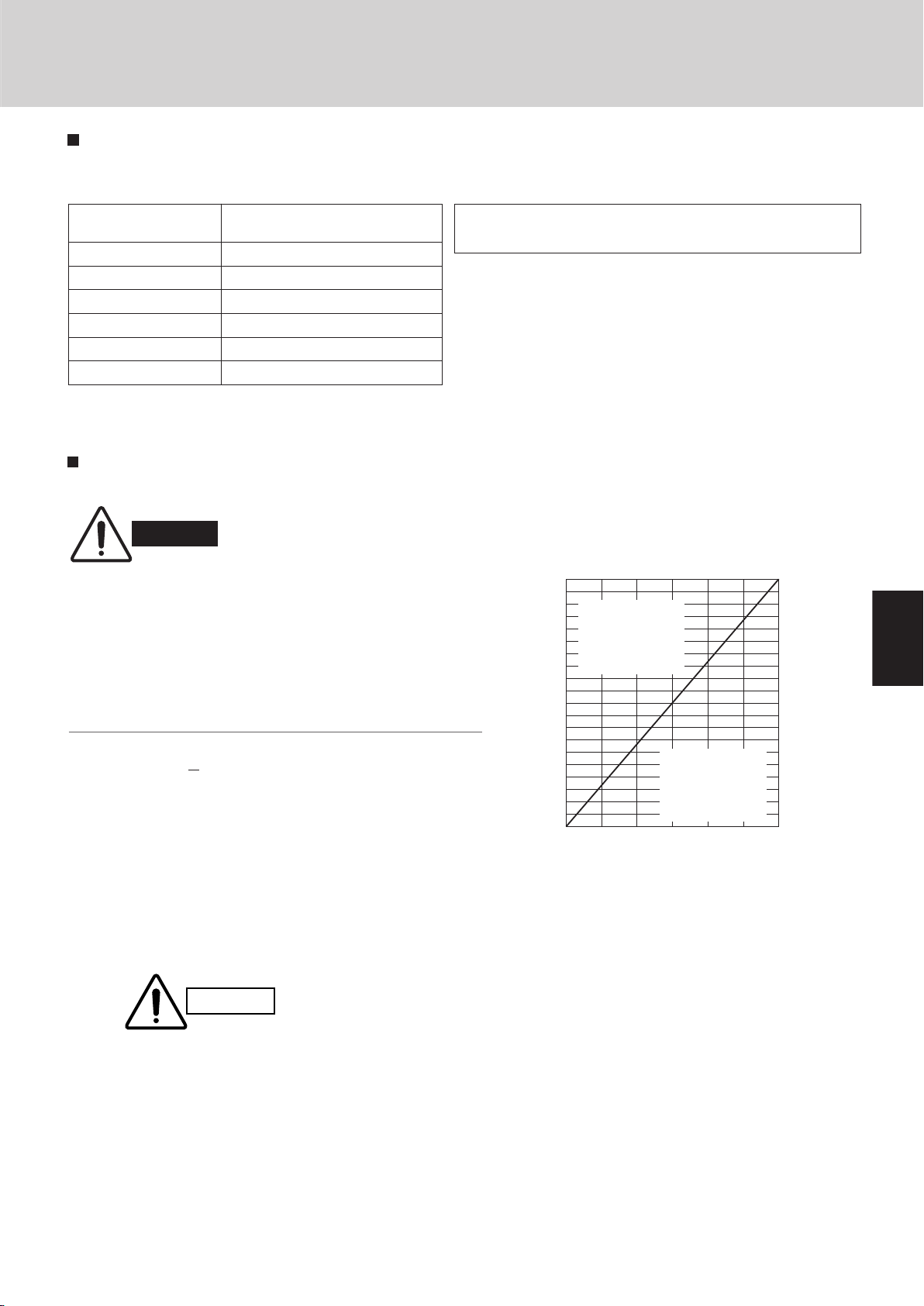

Check of limit density

Required amount of charge = (Amount of refrigerant charge per

meter of each size of liquid tube × its tube length) + (...) + (...)

* Always charge accurately using a scale for weighing.

1-5. Check of Limit Density

When installing an air conditioner in a room, it is necessary to

ensure that even if the refrigerant gas accidentally leaks out, its

density does not exceed the limit level for that room.

If the density could exceed the limit level, it is necessary to provide

an opening between the unit and the adjacent room, or to install

mechanical ventilation which is interlocked with a leak detector.

(Total refrigerant charged amount: oz)

(Min. indoor volume where the indoor unit is installed: ft.3)

<

The limit density of refrigerant R410A which is used in this unit is

0.3 oz/ft.3 (ISO 5149).

The shipped outdoor unit comes charged with the amount of refrigerant fixed for each type, so add it to the amount that is charged in

the field. (For the refrigerant charge amount at shipment, refer to the

unit’s nameplate.)

Always check the gas density

limit for the room in which the

unit is installed.

Limit density 0.3 (oz/ft.3)

Pay special attention to any location,

such as a basement, etc., where leaking

refrigerant can accumulate, since

refrigerant gas is heavier than air.

Minimum indoor volume & floor area as against the amount

of refrigerant is roughly as given in the following table.

Page 20

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

Capacity distribution ratio for each indoor unit (3) = Correction coefficient for that indoor unit / Correction coefficient for the outdoor uni

t

However, the corrected cooling capacity of each indoor unit is found as shown below.

If (2) < 100% and (2)

×

(3) > 100%: Corrected cooling capacity for that indoor unit [5] = Rated cooling capacity for that indoor unit

If (2) ≥ 100%: Corrected cooling capacity for that indoor unit (5) = Rated cooling capacity for that indoor unit

×

(2)

Capacity distribution ratio for each indoor unit (3) = Correction coefficient for that indoor unit / Correction coefficient for the outdoor uni

t

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1. Model Selecting and Capacity Calculator

1-6. Calculation of Actual Capacity of Indoor Unit

Calculating the actual capacity of each indoor unit

Because the capacity of a multi air-conditioner changes according to the temperature conditions, tubing length, elevation difference and other factors, select the correct model after taking into account the various correction values. When selecting The

model, calculate the corrected capacities of the outdoor unit and each indoor unit. Use the corrected outdoor unit capacity and

the total corrected capacity of all the indoor units to calculate the actual final capacity of each indoor unit.

1. Outdoor unit capacity correction coefficient

Find the outdoor unit capacity correction coefficient for the following items.

(1) Capacity correction for the outdoor unit model

The capacity correction coefficient is 1.00.

(2) Capacity correction for the outdoor unit temperature conditions

From the graph of capacity characteristics on page 2-12, use the outdoor temperature to find the capacity correction coefficient.

(3) Capacity correction for the outdoor unit tubing length and elevation difference

From the graph of capacity change characteristics on page 2-13, use the tubing length and elevation difference to find the

capacity correction coefficient.

The outdoor unit correction coefficient is the value which corresponds to the most demanding indoor unit.

(4) Capacity correction for outdoor unit frosting/defrosting during heating

From the table on page 2-12, find the capacity correction coefficient.

2. Indoor unit capacity correction coefficients

Find the indoor unit capacity correction coefficient for the following items.

(2) Capacity correction for the indoor unit temperature conditions

From the graph of capacity characteristics on page 2-13, use the indoor temperature to find the capacity correction coefficient.

(3) Capacity distribution ratio based on the indoor unit tubing length and elevation difference

First, in the same way as for the outdoor unit, use the tubing length and elevation difference for each indoor unit to find the

correction coefficient from the graph of capacity change characteristics on page 2-13. Then divide the result by the outdoor

unit correction coefficient to find the capacity distribution ratio for each indoor unit.

3. Calculating the corrected capacities for the outdoor unit and each indoor unit

The corrected capacities for the outdoor unit and each indoor unit are calculated form the formula below.

<Cooling>

Outdoor unit corrected cooling capacity (5) = Outdoor unit rated cooling capacity × Correction coefficient for model ((1)

Page 2-12) × Correction coefficient for outdoor temperature conditions ((2)

Page 2-12) × Correction coefficient for tubing length and elevation difference

((3) Page 2-13)

* However, if the outdoor unit corrected cooling capacity [5] is greater than 100%, then the outdoor unit corrected cooling

capacity [5] is considered to be 100%.

Corrected cooling capacity of each indoor unit (5) = Rated cooling capacity for that indoor unit × Correction coefficient for

indoor temperature conditions at that indoor unit ((2) Page 2-13) × Distribution ratio based on tubing length and elevation difference at that indoor unit ((3) Page 2-13)

2-10

Page 21

1

2

3

4

5

6

7

8

2-11

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1

2

3

4

5

6

7

8

However, the corrected heating capacity of each indoor unit is found as shown below.

If (2) < 100% and (2) ×(3) > 100%: Corrected heating capacity for that indoor unit (5) = Rated heating capacity for that indoor unit

If (2) ≥ 100%: Corrected heating capacity for that indoor unit (5) = Rated heating capacity for that indoor unit ×(2)

1. Model Selecting and Capacity Calculator

<Heating>

Outdoor unit corrected heating capacity (5) = Outdoor unit rated heating capacity × Correction coefficient for model ((1)

Page 2-12) × Correction coefficient for outdoor temperature conditions ((2)

Page 2-12) × Correction coefficient for tubing length and elevation difference

((3) Page 2-13) × Correction coefficient for frosting/defrosting ((4) Page

* However, if the outdoor unit corrected heating capacity [5] is greater than 100%, then the outdoor unit corrected heating

capacity is considered to be 100%.

Corrected heating capacity of each indoor unit (5) = Rated heating capacity for that indoor unit × Correction coefficient for

indoor temperature conditions at that indoor unit ((2) Page 2-13) × Distribution ratio based on tubing length and elevation

difference at that indoor unit.

* Characteristic graphs are shown on the pages listed above next to each correction item. Find each correction coefficient

from the appropriate conditions.

2-12)

4. Calculating the actual indoor unit capacity based on the indoor/outdoor corrected capacity ratio

Calculate the actual capacity of each indoor unit from the values (found in (3)) for the corrected outdoor unit capacity and the

corrected capacity of each indoor unit.

<Cooling capacity>

Corrected indoor/outdoor capacity ratio during cooling (Ruc) = Total corrected cooling capacity of all indoor units in that system /

Corrected outdoor unit cooling capacity

If the corrected outdoor unit cooling capacity is greater than or equal to the total corrected unit cooling capacity of all indoor units

in that system (Ruc 1), then:

Actual cooling capacity of each indoor unit (7) = Corrected cooling capacity of each indoor unit (5) (In other words, the correction coefficient (6), based on the corrected indoor/outdoor capacity ratios for each indoor unit, is 1.)

If the corrected outdoor unit cooling capacity is less than the total corrected unit cooling capacity of all indoor units in that system (Ruc > 1), then:

(Actual cooling capacity of each indoor unit (7)) = (Corrected cooling capacity of each indoor unit (5)) × (0.25 × Ruc + 0.75)

/ Ruc

(In other words, the correction coefficient (6), based on the corrected indoor/outdoor capacity ratios for each indoor unit, is

the underlined part in the formula above.)

<Heating capacity>

Corrected indoor/outdoor capacity ratio during heating (Ruh) = Total corrected heating capacity of all indoor units in that system

/ Corrected outdoor unit heating capacity

If the corrected outdoor unit heating capacity is greater than or equal to the total corrected unit heating capacity of all indoor

units in that system (Ruh 1), then:

Actual heating capacity of each indoor unit (7) = Corrected heating capacity of each indoor unit (5)

(In other words, the correction coefficient (6), based on the corrected indoor/outdoor capacity ratios for each indoor unit, is 1.)

If the corrected outdoor unit heating capacity is less than the total corrected unit heating capacity of all indoor units in that system (Ruh > 1), then:

(Actual heating capacity of each indoor unit (7)) = (Corrected heating capacity of each indoor unit (5)) × (0.1 × Ruh + 0.9) /

Ruh

(In other words, the correction coefficient (6), based on the corrected indoor/outdoor capacity ratios for each indoor unit, is

the underlined part in the formula above.)

Page 22

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

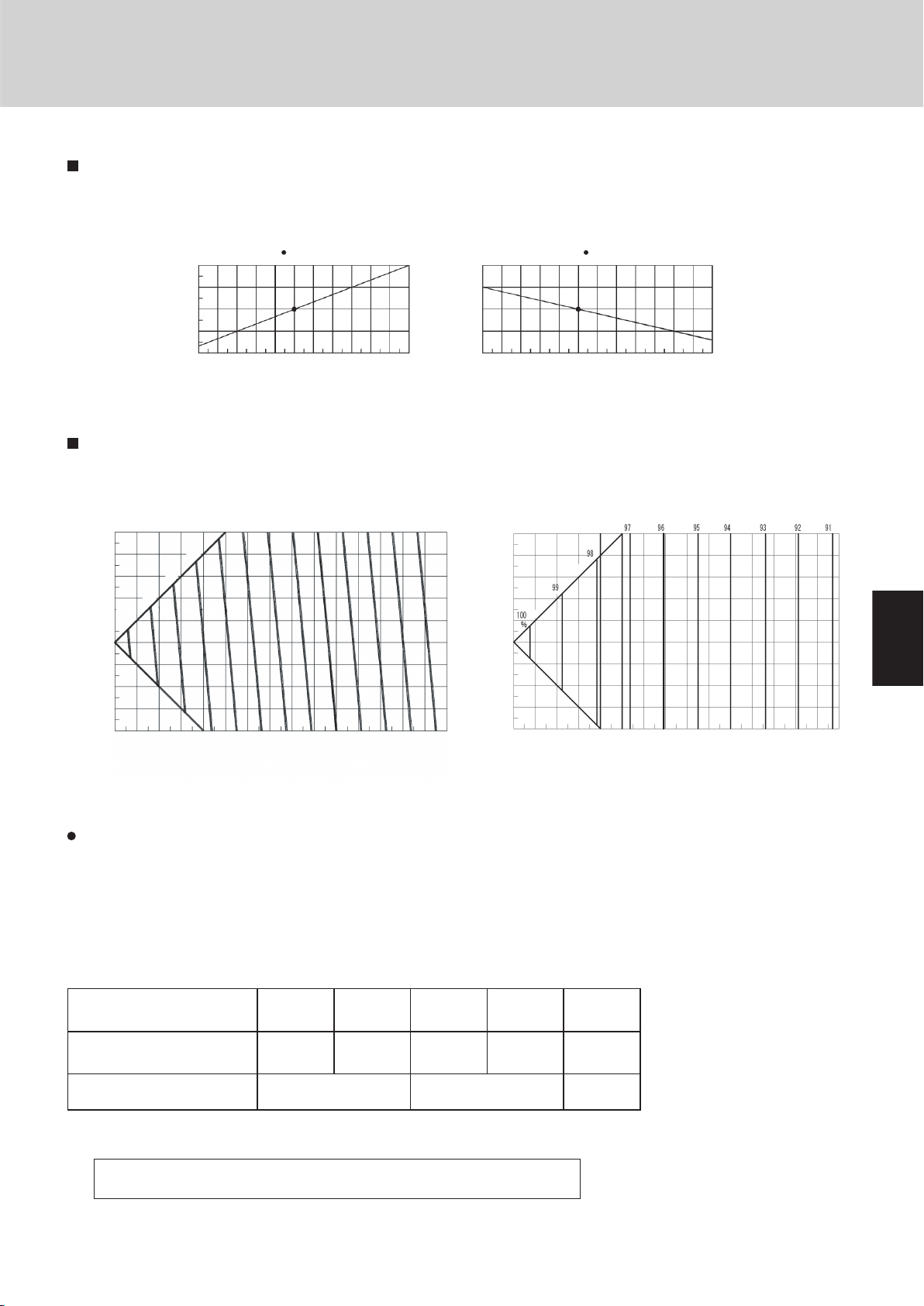

Indoor unit capacity correction coefficient for Ruc (cooling)

Indoor unit capacity correction coefficient for Ruh (heating)

1.0

0.9

0.8

0.7

0.6

0.5

0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9

2.0

Indoor unit capacity correction coefficient

Corrected indoor/outdoor capacity ratio (Ruc or Ruh)

Outdoor unit cooling capacity

characteristics

Outdoor unit heating capacity

characteristics

Rate of cooling capacity change (%)

Rate of heating capacity change (%)

* Broken line indicates a 16 HP

DC inverter unit

Outdoor air intake temp. (°F DB)

WB = 66°F

Indoor air intake temp. (°F DB)

59

68

77

130

120

110

100

90

80

70

60

50

40

130

120

110

100

90

80

-4 5 14 23 32 41 50 5923 32 41 50 14 59 68 77 86 95 104 113

Outdoor air intake temp. (°F WB)

Indoor air intake temp. (WB) = 60°F

WB = 71°F

1. Model Selecting and Capacity Calculator

Refer to the graph below for the correction coefficients for Ruc and Ruh.

Note: When Ruc or Ruh is less than or equal to 1.0, the indoor unit capacity correction coefficient for both Ruc and Ruh is 1.0.

5. Graph of capacity correction coefficients

Graph of outdoor unit capacity characteristics (1 – (2))

Outdoor unit heating capacity correction coefficient during frosting/defrosting (1 – (4))

Outdoor intake air

(°FWB RH85%)

temp.

Correction coefficient 0.97 0.97 0.97 0.96 0.94 0.91 0.89 0.87 0.87 0.87 0.88 0.89 0.91 0.92 0.95 1.0

* To calculate the heating capacity with consideration for frosting/defrosting operation, multiply the heating capacity found

from the capacity graph by the correction coefficient from the table above.

– 4 5 14 17 21 23 24 28 30 32 33 35 37 39 41 42

2-12

Page 23

1

2

3

4

5

6

7

8

2-13

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1

2

3

4

5

6

7

8

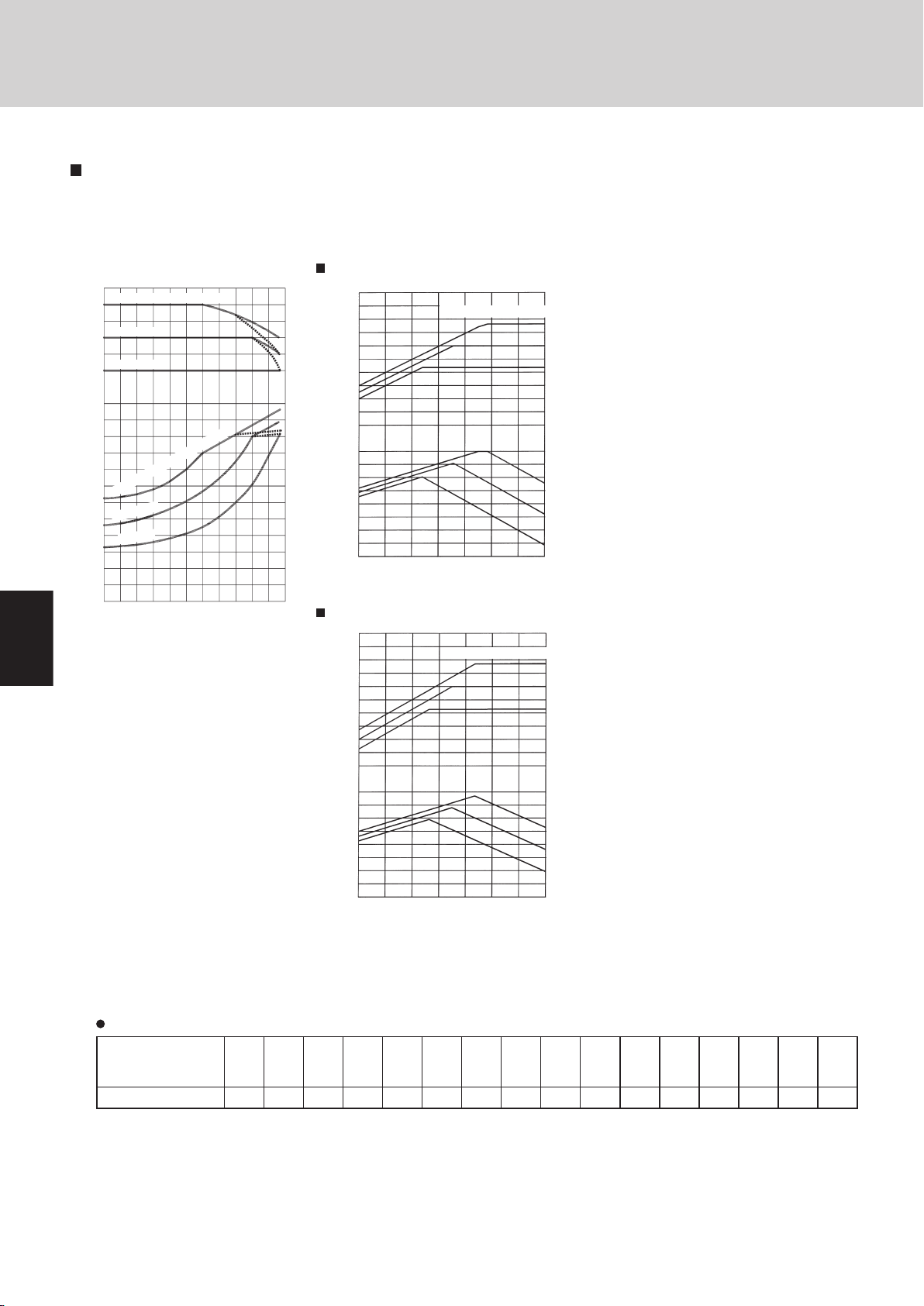

Rate of cooling capacity change (%)

Indoor unit cooling capacity characteristics Indoor unit heating capacity characteristics

indicates the rating point. indicates the rating point.

Indoor air intake temp. (°F WB)

Rate of heating capacity change (%)

Indoor air intake temp. (°F DB)

120

110

100

90

80

110

105

100

95

90

57 59 60 62 64 66 68 69 71 73 75 77 59 60 62 64 66 68 69 71 73 75 77 78

80

<Cooling>

Elevation difference (ft)

Base capacity

change rate

Elevation difference (ft)

*1

92 90 88 86 84 82 80 78 76

94

96

98

100

%

0 98 66 33 131 164 197 230 262 295 328 361 394 427 459 492

164

131

98

66

33

0

-33

-66

-98

-131

Equiv

0 98 66 33 131 164 197 230 262 295 328 361 394 427 459 492

alent length (ft)

Equivalent length (ft)

<Heating>

Base capacity

change rate

164

131

98

66

33

0

-33

-66

-98

-131

1. Model Selecting and Capacity Calculator

Graph of indoor unit capacity characteristics (2 – (2))

Graph of capacity change characteristics resulting from tubing length and elevation difference (1 / 2 – (3))

The positive side for the elevation difference indicates that the outdoor unit is installed at a higher position than the indoor units.

The negative side indicates the opposite.

The capacity loss that is caused by the tubing length can be reduced by increasing the sizes of the discharge tubes and suc-

tion tubes. Refer to Table 2-13 and make the appropriate changes. However be sure that the total length does not exceed the

maximum.

* The only sizes which can be increased are the LM (main tube with the largest diameter) gas tubes, and the changes are

limited to those shown in Table 2-13.

In addition, note that the additional refrigerant charge is determined only by the narrow-tube size.

Table 2-13 Equivalent Length Correction Coefficient when the Size of the Discharge Tubes and Suction Tubes (LM)

is Increased

Standard tubing diameter

(gas tube, in.(mm))

Tubing diameter after change

(gas tube,in.(mm))

Equivalent length correction

coefficient

* If the size of the discharge tubes and suction tubes (LM) have been increased, apply the correction coefficient from Table

2-13 and calculate the equivalent length of the LM section.

Equivalent length of tubing after size increase

= Standard tubing equivalent length × Equivalent length correction coefficient

ø1/2"

(ø12.7)

ø5/8" ø3/4" ø7/8" ø1-1/8" ø1-3/8"

(ø15.88) (ø19.05) (ø22.22) (ø28.58) (ø34.93)

ø5/8"

(ø15.88) (ø19.05) (ø22.22) (ø28.58)

0.4 0.5 0.6

ø3/4" ø7/8" ø1-1/8"

Page 24

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

<Cooling>

<Heating>

16HP

10HP

Indoor air intake temp. (°F DB)

59

68

77

59

68

77

Capacity ratio (%)

Input ratio (%)

130

120

110

100

90

80

70

60

50

40

130

120

110

100

90

80

70

60

50

– 4 5 14 23 32 41 50 59

Outdoor air intake temp. (°F WB)

Indoor air intake temp. (°F DB)

59

68

77

59

68

77

Capacity ratio (%)

Input ratio (%)

130

120

110

100

90

80

70

60

50

40

130

120

110

100

90

80

70

60

50

– 4 5 14 23 32 41 50 59

Outdoor air intake temp. (°F WB)

* Broken line indicates 16 HP DC inverter unit

Outdoor air intake temp. ( °F DB)

130

120

110

100

90

80

120

110

100

90

80

70

60

50

40

30

20

10

)

%

(

o

i

t

ar

y

t

i

cap

a

C

)

%( oitar tu

pn

I

14 23 32 41 50 59 68 77 86 95 104 113

WB = 66

°

F

Indoor air intake temp. (WB) = 71°F

WB = 60°F

Indoor air intak

e tem

p

.

(WB) = 71

°

F

WB = 66

°

F

WB = 60

°

F

1. Model Selecting and Capacity Calculator

1-7. Capacity Correction Graph According to Temperature Condition

Capacity characteristics

(The corrected capacity for specific temperature conditions can be found from the graphs below.)

Heating capacity correction coefficients for frost/defrost operation

Outdoor intake air

temp.

(°F WB RH85%)

Correction coefficient 0.97 0.97 0.97 0.96 0.94 0.91 0.89 0.87 0.87 0.87 0.88 0.89 0.91 0.92 0.95 1.0

* The heating capacity when frost/defrost operation is considered is calculated by multiplying the heating capacity found

from the capacity graph by the correction coefficient from the table above.

– 4 5 14 17 21 23 24 28 30 32 33 35 37 39 41 42

2-14

Page 25

1

2

3

4

5

6

7

8

2-15

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1

2

3

4

5

6

7

8

<Cooling>

Elevation difference (ft)

Base capacity

change rate

*1

92 90 88 86 84 82 80 78 76

94

96

98

100

%

0 33 66 98 131 164 197 230 262 295 328 361 394 427 459 4920 33 66 98 131 164 197 230 262 295 328 361 394 427 459 492

164

131

98

66

33

0

–33

–66

–98

–131

Equivalent length (ft)

*1 Sample calculations

(System: 20 HP, 164ft equivalent length, 49ft elevation

difference

The cooling capacity and heating capacity for this system are

found as shown below.)

●

Cooling operation

From the table, the correction coefficient for that horsepower

level is found to be 1.00.

From the graph, the base capacity change rate is found to be

92.0%.

92.0%×1.00 = 92.0%

Capacity change rate is 92.0%.

(56.0kW×92.0% = 51.5kW)

92.0% = 175,800 BTU/h

Cooling capacity is

175,800 BTU/h (51.5 kW)

●

Heating operation

From the table, the correction coefficient for that horsepower

level is found to be 1.00.

From the graph, the base capacity change rate is found to be

97.2%.

97.2%

×

1.00 = 97.2%

Because the calculation result exceeds 97.2%, the capacity

change rate is 97.2%.

(63.0kW

×

97.2% = 61.2kW) Heating capacity is

209,000 BTU/h (61.2 kW)

Cooling Heating

Item

Model (SPW-)

Cooling

capacity

(kW)

Power

consumption

(kW)

Heating

capacity

(kW)

Power

consumption

(kW)

<50Hz models>

22.4

28.0

33.5

40.0

45.0

5.99

7.90

9.58

11.6

13.3

25.0

31.5

37.5

45.0

50.0

6.17

7.15

9.60

11.5

13.2

Equivalent length (ft)

<Heating>

Base capacity

change rate

164

131

98

66

33

0

–33

–66

–98

–131

0 33 66 98 131 164 197 230 262 295 328 361 394 427 459 492

Elevation difference (ft)

191,100 BTU/h

×

97.2% = 209,000 BTU/h215,000 BTU/h

×

1. Model Selecting and Capacity Calculator

Rated performance values

Type

1-8. Capacity Correction Graph According to Tubing Length and Elevation Difference

90 95,500(28.0) 27,000(7.90) 107,500(31.5) 26,500(7.75)

140 153,600(45.0) 45,400(13.3) 170,600(50.0) 45,000(13.2)

Item Cooling Heating

Cooling capacity

BTU/h(kW)

Capacity change characteristics

Power consumption

BTU/h(kW)

Heating capacity

BTU/h(kW)

Power consumption

BTU/h(kW)

NOTE

The positive side for the elevation difference indicates that

the outdoor unit is installed at a higher position than the

indoor units. The negative side indicates the opposite.

Page 26

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1. Model Selecting and Capacity Calculator

If the maximum tubing length (L1) exceeds 295 ft (equivalent length), increase the tubing size of the main liquid, gas tubes (LM)

by one rank.

However, the upper limit for the gas tube size is ø1-5/8".

Increasing the tubing size of the gas tubes can reduce the loss of capacity caused by longer tubing lengths.

Refer to Table 2-13 to increase the tubing size. However, the maximum allowable tubing length must not be exceeded.

* The amount of additional refrigerant charge is determined from the liquid tube size only.

Table 2-13 Correction coefficient for equivalent length when the size of the gas tube (LM) is increased

Standard tube diameter

(gas tube, in.(mm))

Tube diameter after change

(gas tube, in.(mm))

Equivalent length correction

coefficient

* When increasing the size of the suction and discharge tubing (LM), multiply by the

correction coefficient from Table 2-13 and calculate the equivalent length for section LM.

Tubing equivalent length after size increase

= Standard tubing equivalent length × Equivalent length correction coefficient

ø1/2"

(ø12.7)

ø5/8"

(ø15.88)

ø5/8"

(ø15.88)

ø3/4"

(ø19.05)

0.4 0.5 0.6

ø3/4"

(ø19.05)

ø7/8"

(ø22.22)

ø7/8"

(ø22.22)

ø1-1/8"

(ø28.58)

ø1-1/8"

(ø28.58)

ø1-3/8"

(ø34.93)

2-16

Page 27

1

2

3

4

5

6

7

8

Outdoor

unit 1

Indoor

unit 1

Indoor

unit 2

Indoor

unit 3

Indoor

unit 4

Outdoor

unit 2

Elevation

difference: 33 ft

164 ft

33 ft 33 ft 66 ft

33 ft 33 ft 33 ft

Design of W-2WAY ECO-i SYSTEM Unit Specifications

2. System Design

2-1. System Example

(1) Below are the tables created using the “Sanyo PAC System Diagram Software.” Details of the calculations are shown in (2).

Selection conditions

Assumes that installation is in a 60 Hz region.

Outdoor unit

Cooling

Heating

Actual tubing length 291 ft 197 ft 230 ft 263 ft 296 ft

Equivalent length (with consideration

for curves, etc.)

Air condition (DB/WB) 91.0 / 72.0 78.0 / 64.0 78.0 / 64.0 78.0 / 64.0 78.0 / 64.0

Max. load (BTU/h) 40,000 40,000 30,000 18,000

Air condition (DB/WB) 37.0 / 35.0 69.0 / 55.0 69.0 / 55.0 69.0 / 55.0 69.0 / 55.0

Max. load (BTU/h) 46,000 46,000 35,000 23,000

365 ft 236 ft 276 ft 316 ft 355 ft

Room 1

(indoor unit 1)

Room 2

(indoor unit 2)

Room 3

(indoor unit 3)

Room 4

(indoor unit 4)

Preliminary selection

Outdoor unit

Selected model

Load (cooling/heating) (BTU/h) 40,000 40,000 30,000 18,000

Rated capacity

(cooling/heating) (BTU/h)

(5) Corrected capacity (cooling/

heating) (BTU/h)

(7) Actual capacity

(cooling/heating) (BTU/h)

Type

09053+09053

191,000 /

215,000

159,600 /

156,100

Room 1

(indoor unit 1)

Type 4852 Type 4852 Type 3652 Type 1852

47,800 /

54,600

47,400 /

54,600

47,400 /

50,900

Room 2

(indoor unit 2)

47,800 /

54,600

46,300 /

54,600

46,300 /

50,900

Room 3

(indoor unit 3)

36,000 /

39,000

34,000 /

38,900

34,000 /

36,300

Room 4

(indoor unit 4)

19,000 /

21,000

17,500 /

20,600

17,500 /

19,200

Total corrected capacity of indoor units (cooling/heating) = 145,200/168,700

Ruc = 145,200/159,600 = 0.910 < 1 Ruh = 168,700/156,100 = 1.081 > 1

Outdoor unit changes

During heating, the corrected outdoor unit capacity is less than the total corrected capacity of all indoor units in the system. As a

result, the actual capacity of each indoor unit is less than the maximum load. Therefore the outdoor unit is increased by one rank.

Room 1

(indoor unit 1)

Type 4852 Type 4852 Type 3652 Type 1852

40,000 40,000 30,000 18,000

47,800 /

54,600

47,400 /

54,600

47,400 /

54,600

Selected model

Maximum load

(cooling/heating) (BTU/h)

Rated capacity

(cooling/heating) (BTU/h)

(5) Corrected capacity (cooling/

heating) (BTU/h)

(7) Actual capacity

(cooling/heating) (BTU/h)

Outdoor unit

Type

14053+09035

249,100 /

278,100

208,100 /

201,900

Total corrected capacity of all indoor units (cooling/heating) = 145,200/163,700

Ruc = 145,200/208,100 = 0.698 < 1 Ruh = 168,700/201,900 = 0.835 < 1

Room 2

(indoor unit 2)

2-17

47,800 /

54,600

46,300 /

54,600

46,300 /

54,600

Room 3

(indoor unit 3)

36,000 /

39,000

34,000 /

38,900

34,000 /

38,900

Room 4

(indoor unit 4)

19,000 /

21,000

17,500 /

20,600

17,500 /

20,600

Page 28

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

2. System Design

Indoor unit changes

The indoor unit in room 4, where the corrected indoor unit capacity is less than the maximum load, is increased by one rank.

Outdoor unit

Selected model

Maximum load

(cooling/heating) (BTU/h)

Rated capacity

(cooling/heating) (BTU/h)

(5) Corrected capacity

(cooling/heating) (BTU/h)

(7) Actual capacity

(cooling/heating) (BTU/h)

Total corrected capacity of all indoor units (cooling/heating) = 150,700/174,500

Ruc = 150,700/208,100 = 0.724 < 1 Ruh = 174,500/201,900 = 0.864 < 1

For both cooling and heating in all rooms, actual capacity is now greater than or equal to the maximum load. Selection is

completed.

Type 14053+09053

249,100 / 278,100 47,800 / 54,600 47,800 / 54,600 36,000 / 39,000 25,000 / 27,000

208,100 / 201,900 47,400 / 54,600 46,300 / 54,600 34,000 / 38,900 23,000 / 26,400

Room 1

(indoor unit 1)

Type 4852 Type 4852 Type 3652 Type 2452

40,000 / 46,000 40,000 / 46,000 30,000 / 35,000 18,000 / 23,000

47,400 / 54,600 46,300 / 54,600 34,000 / 38,900 23,000 / 26,400

Room 2

(indoor unit 2)

Room 3

(indoor unit 3)

Room 4

(indoor unit 4)

(2) Calculate the final selection results according to the capacity calculation procedure.

[From calculation of the correction coefficient to calculation of actual capacity] (Cooling/heating)

Outdoor unit

Rated capacity (BTU/h) 249,100 / 278,100 47,800 / 54,600 47,800 / 54,600 36,000 / 39,000 25,000 / 27,000

(1) Model 1.00 / 1.00

(2) Temp. condition 1.020 / 0.937 0.921 / 0.780 0.921 / 0.980 0.921 / 0.980 0.921 / 0.980

(3) Tubing length,

elevation difference

Correction coefficient

(4) Frosting/defrosting 0.89

Result of (2) × (3) 0.992 / 1.031 0.969 / 1.014 0.945 / 0.997 0.921 / 0.980

Correction coefficient

applied to indoor unit *1

(5) Corrected capacity (BTU/h) *2 208,100 / 201,900 47,400 / 54,600 46,300 / 54,600 34,000 / 38,900 23,000 / 26,400

(6) Correction coefficient

for corrected capacity ratio

(7) Actual capacity (BTU/h) 47,400 / 54,600 46,300 / 54,600 34,000 / 38,900 23,000 / 26,400

*1: This varies depending on the values of (2) and (2) × (Distribution ratio in (3)).

*2: Corrected outdoor unit capacity = Rated outdoor unit capacity × (1) × (2) × (3) × (4)

The actual capacity is calculated as shown below.

Cooling: Ruc = (47,400 + 46,300 + 34,000 + 23,000) / 208,100 = 0.724 < 1

Therefore,

Actual cooling capacity of each indoor unit = Corrected cooling capacity of each indoor unit

(In other words, the correction coefficient (6) for the corrected capacity ratio is 1.)

Heating: Ruh = (54,600 + 54,600 + 38,900 + 26,400) / 201,900 = 0.864 < 1

Therefore,

Actual heating capacity of each indoor unit = Corrected heating capacity of each indoor unit × (0.1 × Ruh + 0.9) / Ruh

(In other words, the correction coefficient (6) for the corrected capacity ratio is (0.1 × Ruh + 0.9) / Ruh.)

0.819 / 0.871

Room 1

(indoor unit 1)

1.077 / 1.052 1.052 / 1.035

0.99 / 1.03 0.97 / 1.01 0.95 / 1.00 0.92 / 0.98

Room 2

(indoor unit 2)

Room 3

(indoor unit 3)

1.00 / 1.00

Room 4

(indoor unit 4)

1.026 / 1.017 1.00 / 1.00

2-18

Page 29

1

2

3

4

5

6

7

8

2-19

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1

2

3

4

5

6

7

8

964

09053 14053

3652

4852

1852

1852

1852 0952

3652 3652 1852

LH

16.4ft

16.4ft

2. System Design

(3) Increasing the size of the refrigerant tubing

Increasing the tubing size of the gas tubes can reduce the loss of capacity caused by longer tubing lengths.

Refer to Table 2-13 to increase the tubing size. However, the maximum allowable tubing length must not be exceeded.

* The amount of additional refrigerant charge is determined from the liquid tube size only.

Table 2-13 Correction coefficient for equivalent length when the size of the gas tube (LM) is increased

Standard tube diameter

(gas tube, in.(mm))

Tube diameter after change

(gas tube, in.(mm))

Equivalent length correction

coefficient

* When increasing the size of the suction and discharge tubing (LM), multiply by the correction coefficient from Table 2-13 and

calculate the equivalent length for section LM.

Tubing equivalent length after size increase

= Standard tubing equivalent length × Equivalent length correction coefficient

ø1/2"

(ø12.7)

ø5/8"

(ø15.88)

ø5/8"

(ø15.88)

ø3/4"

(ø19.05)

0.4 0.5 0.6

ø3/4"

(ø19.05)

ø7/8"

(ø22.22)

ø7/8"

(ø22.22)

ø1-1/8"

(ø28.58)

ø1-1/8"

(ø28.58)

ø1-3/8"

(ø34.93)

2-2. Example of Tubing Size Selection for Extension and Additional Charge Amount

Sample calculation for the system below

Page 30

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

2. System Design

Additional refrigerant charge before extension

Liquid tube

diameter

La ø1/2 6.6 1.38 9.055

Lb ø3/8 65.6 0.602 39.501

LA ø3/4 26.2 2.78 72.966

LB ø1/2 19.7 1.38 27.165

LC ø1/2 19.7 1.38 27.165

LD ø1/2 19.7 1.38 27.165

LE1 ø3/8 16.4 0.602 9.875

LG ø5/8 26.2 1.99 52.231

LH ø3/8 13.1 0.602 7.900

L1 ø3/8 9.8 0.602 5.925

L2 ø1/4 9.8 0.279 2.746

L3 ø1/4 9.8 0.279 2.746

L7 ø3/8 9.8 0.602 5.925

L8 ø1/4 9.8 0.279 2.746

L9 ø1/4 13.1 0.279 3.661

Tubing length (ft)

(A)

Total (oz) 296.775 297 oz

Additional refrigerant charge

per 1 ft (oz/ft) (B)

(A) × (B) oz

Additional refrigerant charge after extension

Liquid tube

diameter

LE2 ø3/8 13.1 0.602 7.900

LF ø3/8 16.4 0.602 9.875

L4 ø3/8 13.1 0.602 7.900

L5 ø3/8 19.7 0.602 11.850

L6 ø1/4 23.0 0.279 6.407

Calculation of additional refrigerant charge for the entire 2-WAY ECO-i system

(Additional refrigerant charge for entire 2-WAY ECO-i system)

= (Refrigerant charge at outdoor unit) + (Additional refrigerant charge)

= 881 + 341 = 1222 oz (after extension)

[Before extension: 458 + 297 = 755 oz]

Tubing length (ft)

(A)

Total (oz) 43.934 44 oz

Additional refrigerant charge

per 1 ft (oz/ft) (B)

(A) × (B) oz

2-20

Page 31

1

2

3

4

5

6

7

8

2-21

Design of W-2WAY ECO-i SYSTEM Unit Specifications

1

2

3

4

5

6

7

8

WARNING

2. System Design

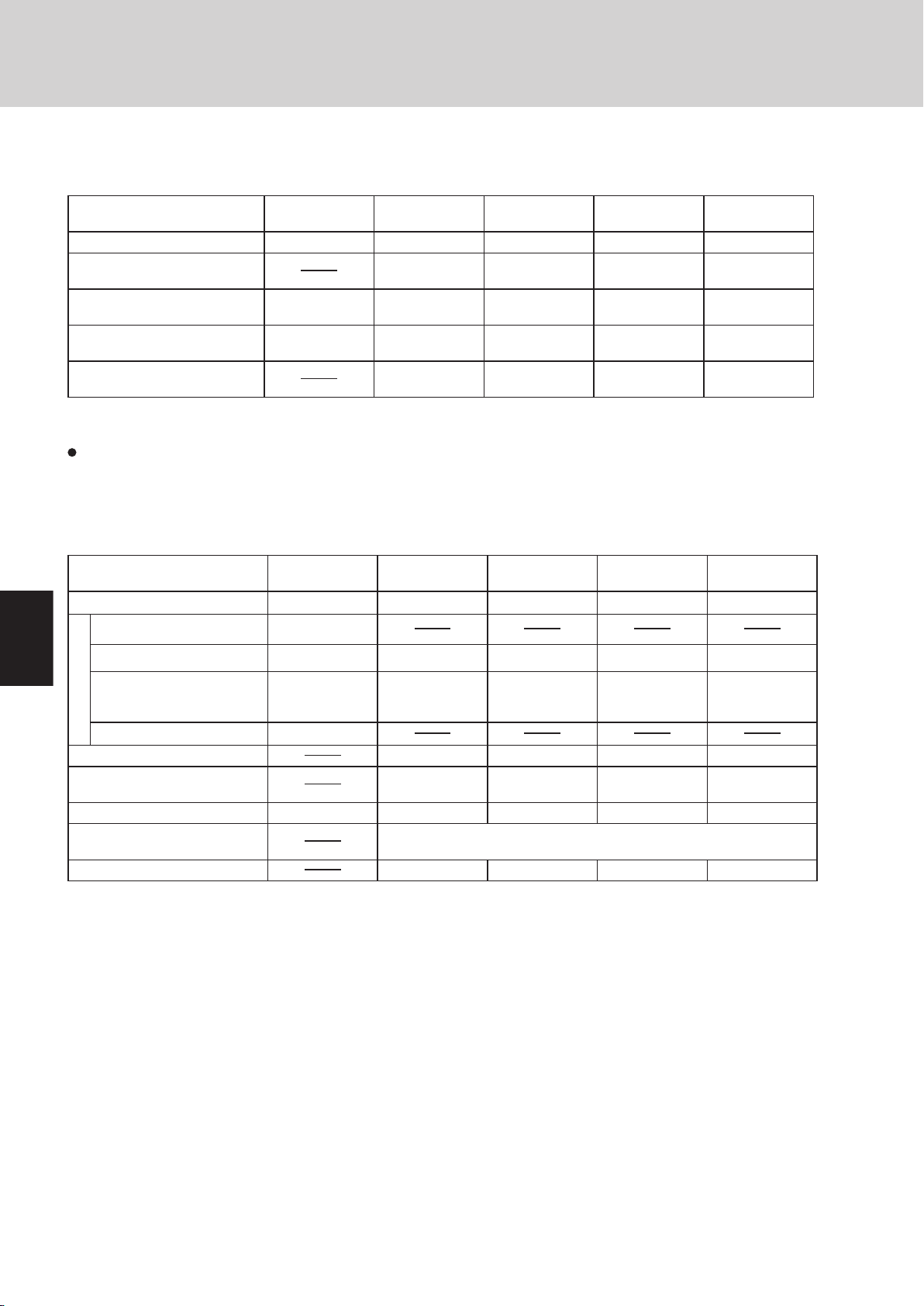

0 0

57

114

170

227

284

341

398

454

511

568

625

682

738

795

852

909

966

1022

1079

1136

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

10000

1000500 1500 2000 2500 3000

Total amount of refrigerant

Min. indoor volume

Min. indoor floor area

(when the ceilin

g

is 8.8 ft. hi

g

h)

ft.

3

ft.

2

oz

Range above

the density limit of

0.3 oz/ft.

3

(countermeasures

needed)

Range below

the density limit of

0.3 oz/ft.

3

(countermeasures

not needed)

Checking of limit density

The limit density judgment is made based on the room with the

indoor unit having the smallest capacity in the system after extension.

The volume of the room where a type 1852 indoor unit is used

(connected to tubing L9) is calculated as follows:

floor area 166 ft2 × Ceiling height 8.8 ft = 1,410 ft3. From the graph

below, the minimum room volume for 1,222 oz of refrigerant is

4,070 ft3 (floor area 463 ft2). Therefore an opening for ventilation is

required.

<Judgment by calculation>

Total refrigerant charge for the refrigeration equipment (oz)

Smallest room volume of all rooms where indoor units are

installed (ft3)

1,222 (oz)

=

1,410 (ft3)

= 0.86 (oz/ft3) > 0.3 (oz/ft3)

In this case, an opening is required for ventilation.

Always check the gas

density limit for the room in

which the unit is installed.

Checking of limit density

When installing an air conditioner in a room, it is necessary to

ensure that even if the refrigerant gas accidentally leaks out, its

density does not exceed the limit level for that room.

If the density could exceed the limit level, it is necessary to provide

an opening between the unit and the adjacent room, or to install

mechanical ventilation which is interlocked with a leak detector.

(Total refrigerant charged amount: oz)

(Min. indoor volume where the indoor unit is installed: ft.3)

<

Limit density 0.3 (oz/ft.3)

The limit density of refrigerant R410A which is used in this unit is

0.3 oz/ft.3 (ISO 5149).

The shipped outdoor unit comes charged with the amount of refrigerant fixed for each type, so add it to the amount that is charged in the

field. (For the refrigerant charge amount at shipment, refer to the

unit’s nameplate.)

Minimum indoor volume & floor area as against the amount

of refrigerant is roughly as given in the following table.

Page 32

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

15 to 30

°

B

A

B

A

Arrow view

Horizontal

line

View as seen

from arrow

Ball valve

(BV: purchased

separately)

Main tubing

Types of vertical trap specifications

(If only 1 unit is connected, a ball

valve is also needed on this side.)

Indoor unit (1)

(When not using ball valve)

(When using ball valve)

Branch tubing is

directed upward.

(Each unit is

connected to tubing

that is either level or

is directed

downward.)

Main tubing

Indoor unit

More than

8 in

Indoor unit (more than 2 units)

Horizontal

Indoor unit is directed downward

2. System Design

Design of W-2WAY ECO-i SYSTEM Unit Specifications

Installing distribution joint

(1) Refer to “HOW TO ATTACH DISTRIBUTION JOINT”

enclosed with the optional distribution joint kit (APRCHP680BA, CHP1350BA, P160BA, P680BA,

P1350BA).

(2) In order to prevent accumulation of refrigerant oil in

stopped units, if the main tubing is horizontal then

each branch tubing length should be at an angle that

is greater than horizontal. If the main tubing is vertical,

provide a raised starting portion for each branch.

(3) If there are height differences between indoor units

or if branch tubing that follows a distribution joint is

connected to only 1 unit, a trap or ball valve must be

added to that distribution joint. (When adding the ball

valve, locate it within 1.3 ft of the distribution joint.)

(Consult with SANYO separately concerning the ball

valve.)

If a trap or ball valve is not added, do not operate