Page 1

FILE NO.

Service Manual

z/ON

123

TUNER

/BAND

456

PRESET

789

SLEEP

0

ADJUST

SET/CLEAR

CLOCKTIMER

TIME SET

DISC SELECT

fe

i

REPEAT

RANDOM MEMORY

n

TAPE-A/B REC MUTE

a

ncjd

SOUND

VIDEO/DVD

PRESET

MUTE

VOLUME

REMOTE CONTROL REM-C30

Micro Component System

DC-S800 (XE)

Contents

Specifications...................................................................1

What to do if.....................................................................1

Laser beam safety precaution.......................................... 2

CD pick-up maintenance.................................................. 2

Service mode ................................................................... 2

CD player adjustments..................................................... 3

Tape adjustments ............................................................4

Tuner adjustments ...........................................................6

Exploded view

(Cabinet & Chassis) ...................................................... 7

(Tape mechanism) ........................................................ 15

(CD changer mechanism) ............................................. 16

(CD base mechanism) ..................................................17

Parts list

(Cabinet & Chassis) ...................................................... 8

(Tape mechanism) ........................................................ 15

(CD mechanism) ...........................................................17

This service manual consists of "DC-S800U" (Main unit : 129 574 02), "RB-C30" (Remote control),

"SX-S800L" (Speaker system : 165 007 02) and "SX-S800R" (Speaker system : 165 008 02).

IC block diagram & description ........................................ 18

IC & Transistor voltages...................................................23

FL display description ...................................................... 24

Schematic diagram

(TUNER) ....................................................................... 26

(AMPLIFIER).................................................................28

(FRONT) ....................................................................... 34

(CD)...............................................................................38

(DECK)..........................................................................42

Wiring diagram

(TUNER & AMPLIFIER) ................................................30

(POWER TRANSFORMER) ........................................ 32

(HEADPHONE, LED & REGULATOR) .........................33

(FRONT) ....................................................................... 36

(CD)...............................................................................40

(DECK)..........................................................................41

(OPTICAL DIGITAL OUT & SUB TRANS )...................44

Wiring connection ............................................................45

PRODUCT CODE No.

129 575 02

REFERENCE No.

SM5810143

Page 2

This file was downloaded and provided FREE OF CHARGE

from the ManualDirectory community.

You can find many free to download Service Manuals & Schematics at

http://www.manualdirectory.co.uk

Page 3

SPECIFICATIONS

Tuner section

Reception frequency

(FM)

Frequency range.................... 87.5 MHz - 108 MHz

(MW)

Frequency range.................... 522 kHz - 1611 kHz

(LW)

Frequency range.................... 144 kHz - 288 kHz

Cassette deck section

Track system ......................... 4-track, 2-channel stereo

Frequency response .............. 120 Hz - 14 kHz

Signal to noise ratio ............... 48 dB

Wow and Flutter..................... 0.12 % (WRMS)

Fast forward / Rewind time .... Approx. 110 sec. (C-60)

General

Output power ......................... 100Wx2 (at 6ohm, 10% distortion)

Input

VIDEO/DVD IN .................... 550 mV/ 50 kohms

Outputs

Speakers.............................. 6 ohms

PHONES.............................. 8 - 32 ohms

OPTICAL DIGITAL OUT...... Optical

Power requirements............... AC 230V, 50Hz

Power consumption ............... 120 Watts

1.4W (Eco On standby mode)

Dimensions (W x H x D) ........ Approx.

270(W)x330(H)x317(D)mm

Weight.................................... Approx. 8.9kg

CD changer section

Type....................................... Changer, 3-disc

Channels................................ 2-channel stereo

Sampling frequency ............... 44.1 kHz

Pick-up................................... Optical 3-beam

semiconductor laser

Laser output........................... 0.6mW (Continuous wave max.)

Wave length........................... 790 nm

Wow and Flutter..................... Below measurable limits

WHAT TO DO IF

Speaker system

Type....................................... 3 way acoustic bass tube

United used............................ Woofer : 16 cm cone type

Mid range : 8 cm cone type

Tweeter : piezoelectric

Maximum

Power-handling capacity..... 180 Watts (peak)

Nominal impedance ............... 6 ohms

Dimensions (W x H x D) ........ Approx.

275(W) x 330(H) x 304(D)mm

Weight.................................... 5.6kg (per speaker)

Specifications subject to change without notice.

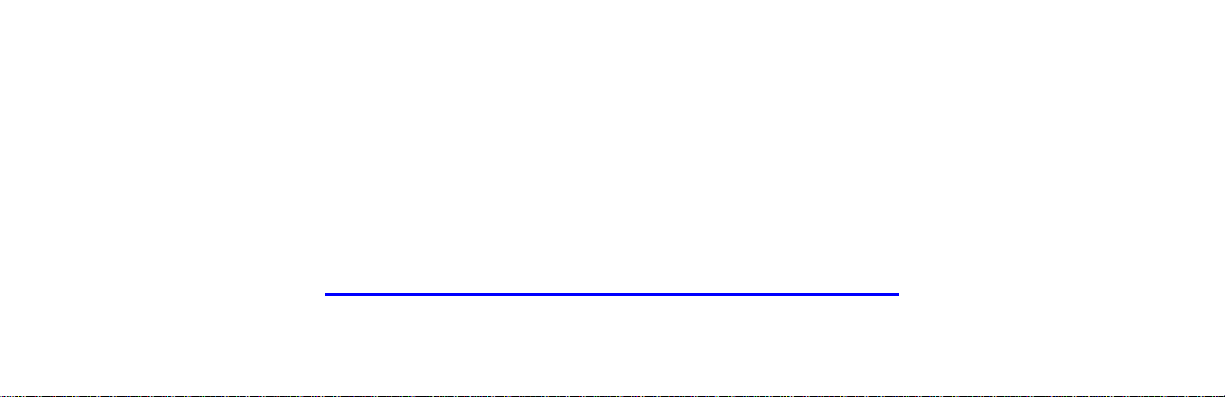

• If the operation of the unit or display is not normal, or you wish

to clear the contents of the memory.

1. Disconnect the power cord from AC outlet.

2. Press the RESET button for at least 20 seconds.

3. Connect the power cord.

4. Press the POWER button to turn the power on.

- 1 -

RESET

FM

75

AM

LOOP

RESET

VIDEO/DVD

(AUDIO)

R

L

IN

R

L

SPEAKERS

(6ΩMIN.)

SUB WOOFER

Page 4

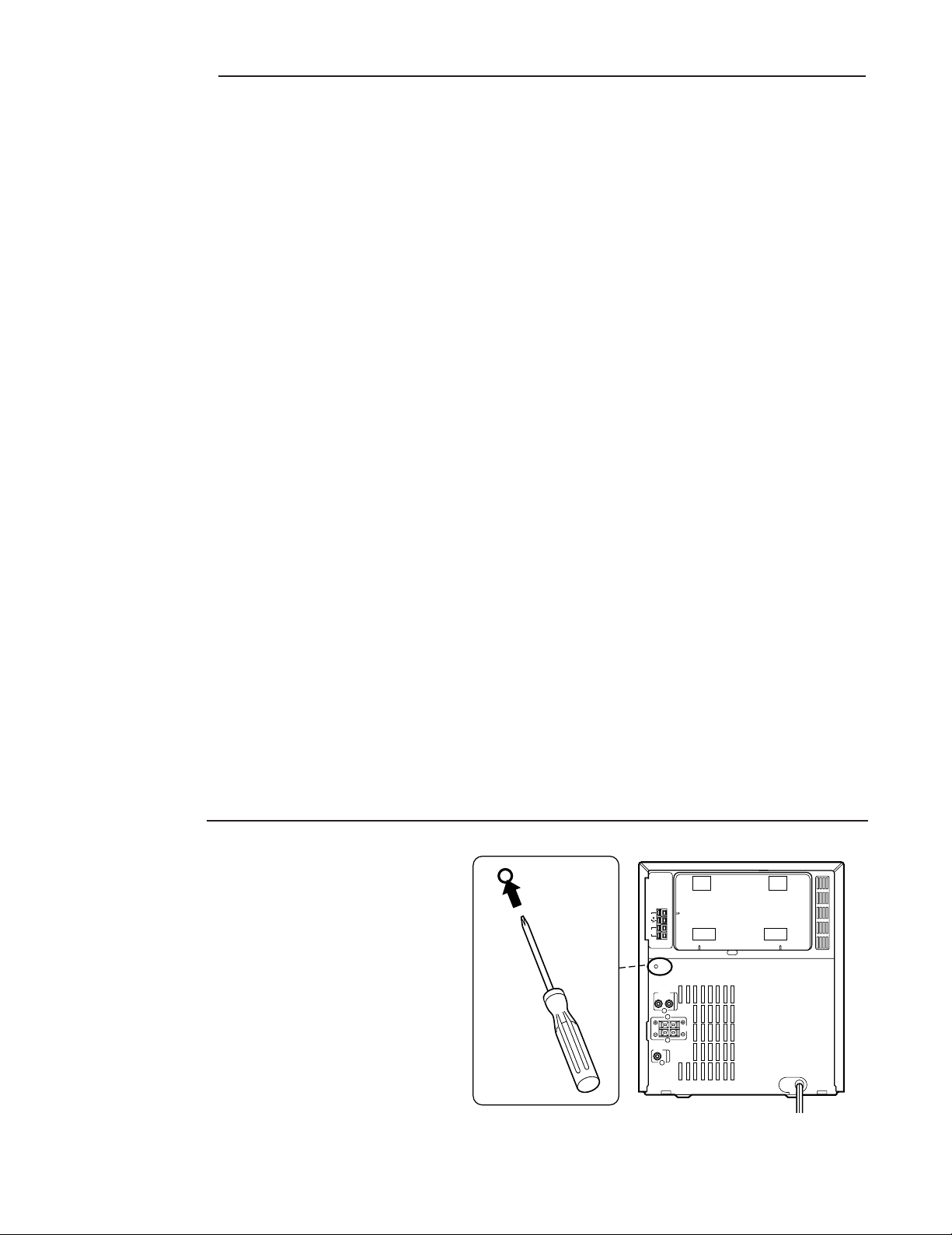

LASER BEAM SAFETY PRECAUTION

CAUTION – INVISIBLE LASER RADIATION WHEN OPEN AND

INTERLOCKS DEFEATED. AVOID EXPOSURE TO BEAM.

EXT.

ANT.

FM

75

AM

LOOP

ANT.

ADVARSEL – USYNLIG LASER STRÅLING VED ÅBNING, NÅR

SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION, UNDGÅ UDS ÆTTELSE

FOR STRÅLING.

VARNING – OSYNLIG LASER STRÅLNING NÄR DENNA DEL ÄR ÖPPNAD

RESET

VIDEO/DVD

R

(AUDIO)

L

IN

R

L

SPEAKERS

(6ΩMIN.)

OUT

OPTICAL DIGITAL

OCH SPÄRR ÄR URKOPPLAD. STRÅLEN ÄR FARLIG.

VORSICHT – UNSICHTBARE LASERSTRAHLUNG TRITT AUS, WENN

DECKEL GEÖFFNET UND WENN SICHERHEITSVERRIEGELUNG

ÜBERBRÜCKT IST. NICHT, DEM STRAHL AUSSETZEN.

VARO – AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA

NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

CD PICK-UP MAINTENANCE

About pick-up (Optical lens) Cleaning

Clean the lens with the specified cleaning disc or moisten a cotton swab with isopropyl alcohol and cleaning paper.

Specified cleaning disc : LC-1 (Part code : 645 026 1961 ..... manufactured by SANYO.)

Regarding procedure of cleaning with moisten cotton swab, please refer to the attached as follows.

1. Cotton swab wrapped with Cleaning paper.

2. Add the isopropyl alcohol.

3. Gently move the tip of cotton swab just like a draw a whirlpool from inside to outside on the surface of lens.

SERVICE MODE

1. Preparation

Press the unit's STOP and FM MODE buttons at the same time. (This initiates service mode entry status.)

Next, press another button on the unit to switch to the corresponding service mode.

The unit enters a service mode only if another button is pressed during that 1 second.

2. CD Repair

1. Within 1 second of activating service mode entry status, press the CD BACK button to enter this service mode.

2. When in the CD function mode the LCD segment displays a CD operation indication that is different from its normal indication.

If a CD error occurs, a display appears as shown in below.

Also, from the point at which the error occurred onward, the CD operation display is fixed. The fixed displays is canceled by

pressing the STOP button when the CD is stopped.

3. Press the POWER button to cancel this mode.

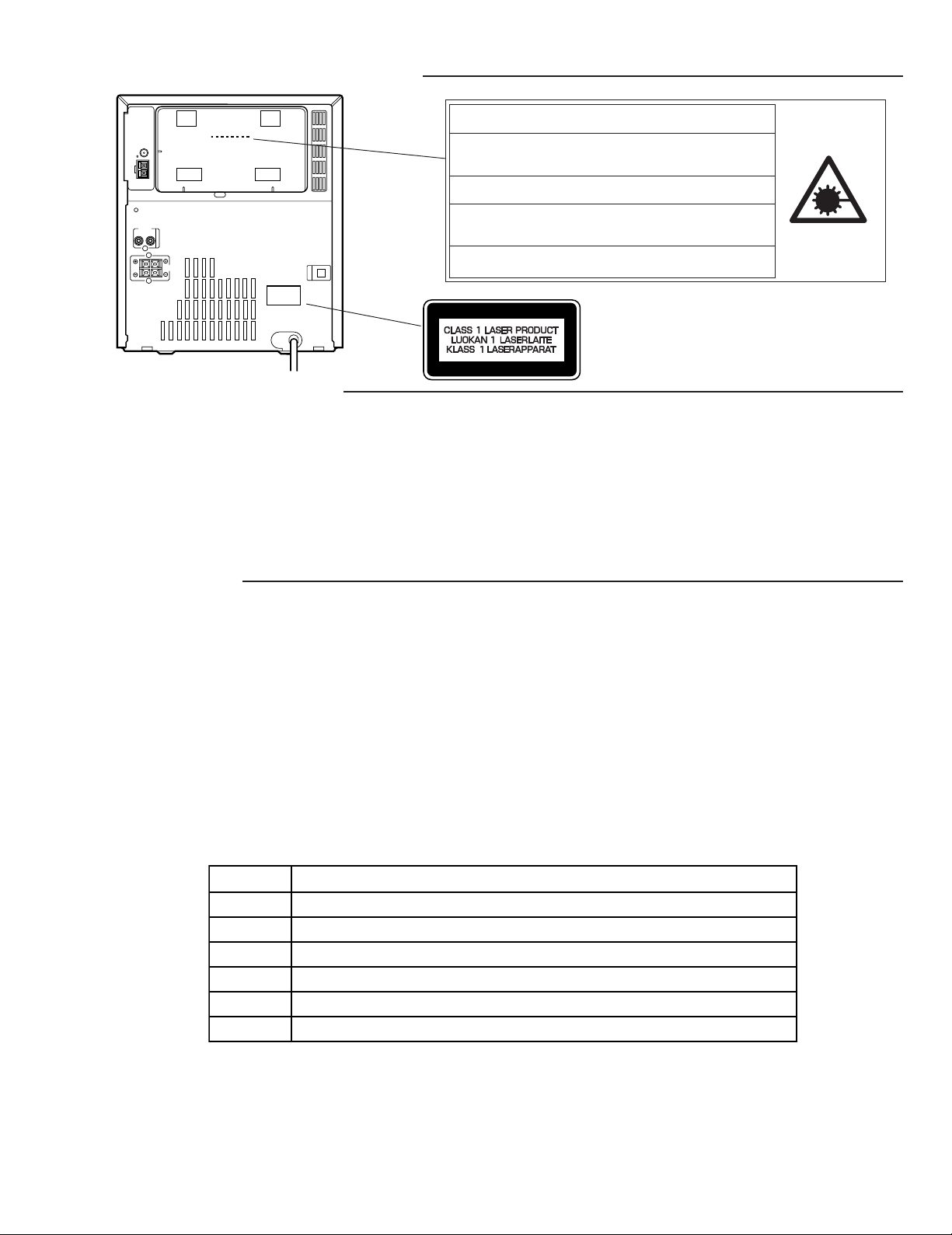

Disc No. State of CD Error

0 Good

1 Focusing is not possible in focus serch.

2 The subcode is not input during disc startup.

3 TOC can not be read.

4 Focus was lost while the servo was on. (during playing, etc.)

5 The subcode is not input while the servo in on. (during playing, etc.)

3. Checking the FL connection

1. Within 1 second of activating service mode entry status, press the TUNING UP button to enter this service mode.

2. FL and LED turns on order when enter this mode.

3. When every indication turns on, become on and off light indication.

4. Press the POWER button to cancel this mode.

- 2 -

Page 5

CD PLAYER ADJUSTMENTS

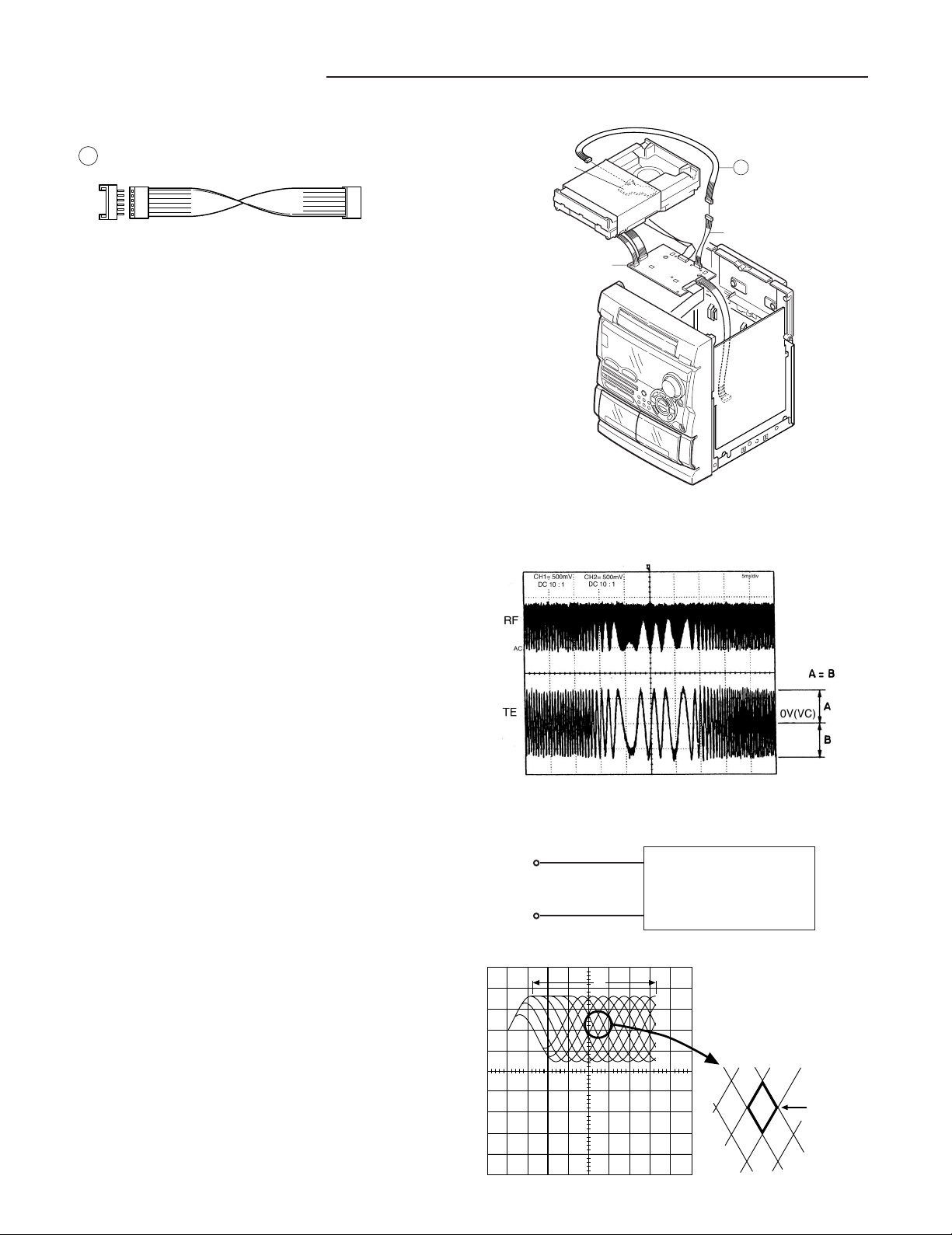

1. CABLE CONNECTION

1 ASSY, CONNECTOR-S (614 303 5633)

2. ADJUSTMENTS

(1) Confirm the tracking balance

1. Connect an Oscilloscope to TP2 (TE) and TP1 (VC).

2. Turn on the POWER switch.

3. Set the test disc. (DISC 1)

4. Press "STOP" button and "FM MODE" button simultaneously.

Within 1 second after pressing the "PLAY/PAUSE" button.

(SERVICE MODE : Tracking balance adjustment mode)

5. Confirm that the oscilloscope waveform is symmetrical on the

top and bottom in relation to 0V (VC).

SPINDLE / SLED

MOTOR P.W.B

CD P.W.B

1

CONNECTOR 6pin

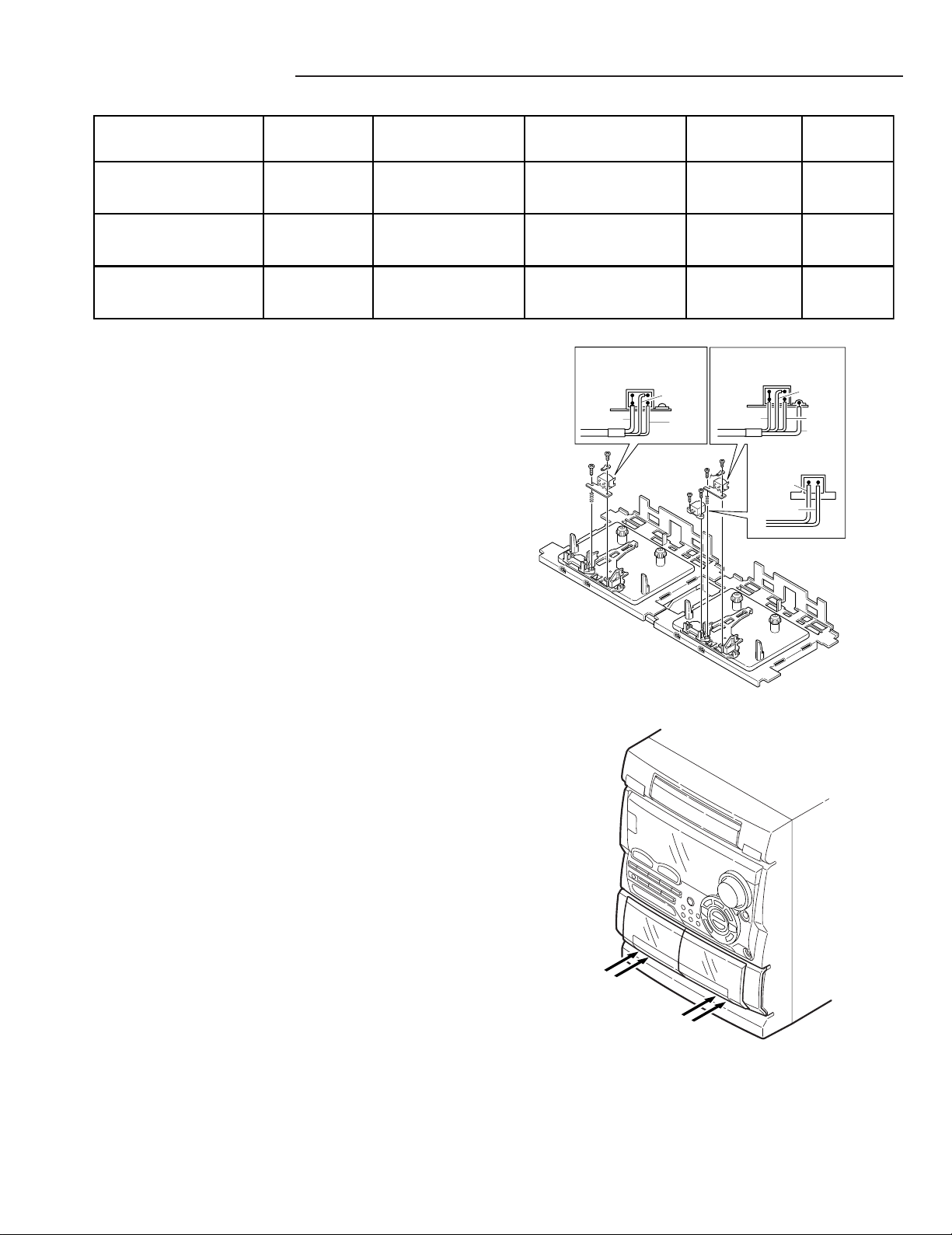

(2) Checking the "eye" pattern

1. Switch "ON" the POWER.

2. Connect an oscilloscope to TP4 (RF) and TP1 (VC).

3. Load the test disc.

4. Press the PLAY button.

5. Check to be sure that the "eye" pattern is at the center of

waveform and that the diamond shape is clearly defined.

6. Press the STOP button.

7. Turn off the POWER switch.

- 3 -

200mV/div.

5ms/div.

TP4

(RF)

TP1

(VC)

+

OSCILLOSCOPE

-

a

OPENING EXPANDED

b

Page 6

TAPE ADJUSTMENTS

Adjustment Item Test Tape Measuring Output connection Adju st Adjus t

Instrument location value

(a) HEAD AZIMUTH VTT738 etc. AC-voltmeter SPEAKER TERMINAL HEAD AZIMUTH Max.

DECK "A" (10KHz) SCREW

(b) HEAD AZIMUTH VTT738 etc. AC-voltmeter SPEAKER TERMINAL HEAD AZIMUTH Max.

DECK "B" (10KHz) SCREW

(c) MOTOR SPEED MTT-111 FREQUENCY SPEAKER TERMINAL VR311 3,000Hz

(NORMAL) (3,000Hz) COUNTER

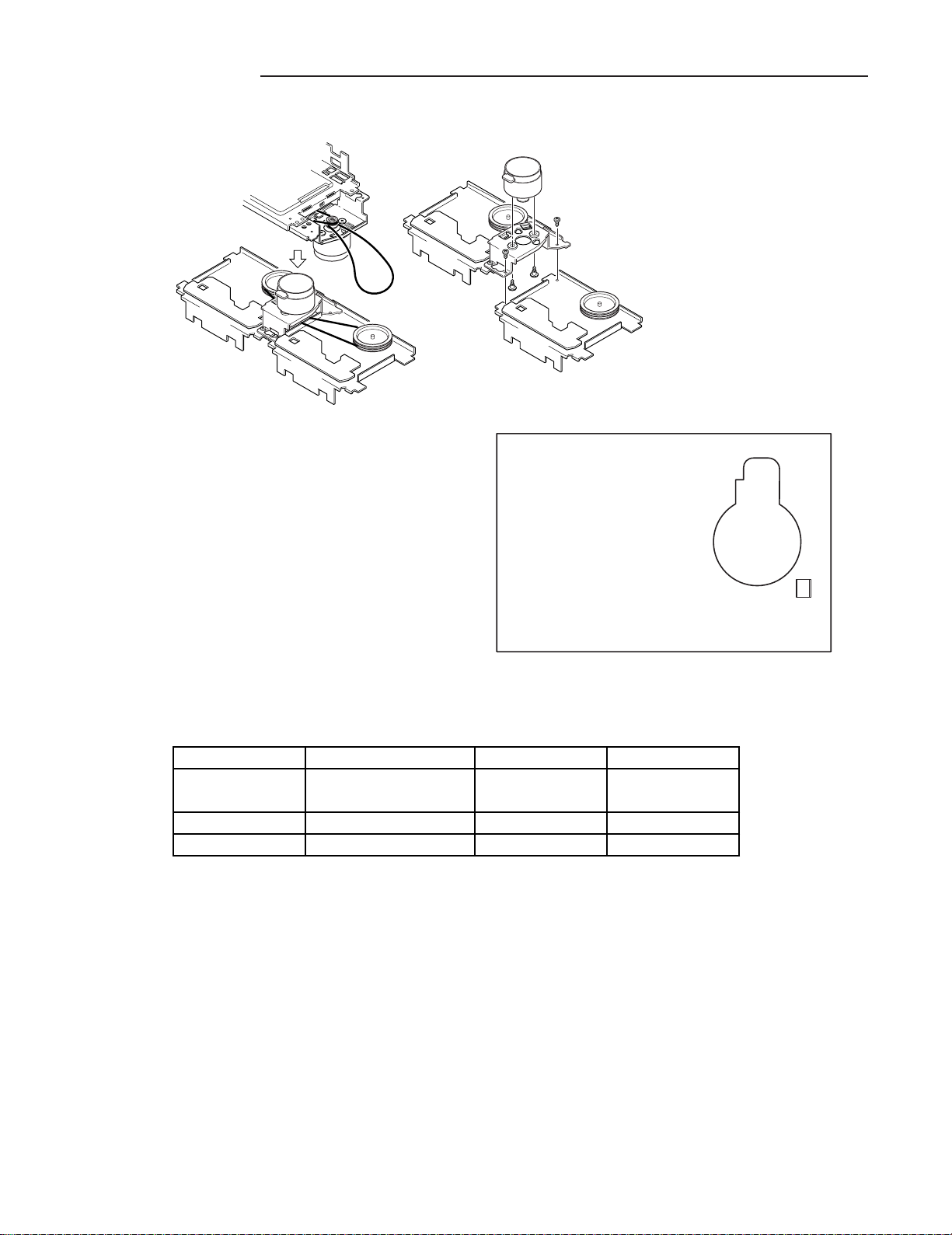

1. HEAD REPLACEMENT AND AZIMUTH ADJUSTMENT

(1) Head replacement

1. After replacement, demagnetize the heads by using a

degausser.

2. Be sure to clean the heads before attempting to make any

adjustments.

3. Be sure both channels (1 and 2) are the same level.

(Using a dual-channels oscilloscope).

4. All wiring should be returned to the original position after

work is completed.

(2) Head azimuth

• DECK "A"

1. Load a test tape (VTT-738,etc.: 10kHz) for azimuth

adjustment.

2. Press the PLAY button.

3. Use a flat-tip (-) screwdriver to turn the screw for normal

azimuth adjustment so that the left and right outputs are

maximized at the same phase during normal playback.

4. Press the STOP button.

TAPE ’’A’’

PLAY HEAD

EARTH

RED

WHITE

YELLOW

TAPE ’’B’’

R/P HEAD

RED

WHITE

EARTH

E. HEAD

YELLOW

ORANGE

• DECK "B"

1. Load a test for azimuth adjustment.

2. Press the PLAY button.

3. Azimuth screw adjustment.

4. Press the STOP button.

REVERSE

NORMAL

TAPE "A"

REVERSE

NORMAL

TAPE "B"

• After making the adjustment, secure the azimuth

adjustment screw by applying screw lock (TB-1401B).

- 4 -

Page 7

TAPE ADJUSTMENTS

2. MOTOR REPLACEMENT AND SPEED ADJUSTMENT

(1) Motor replacement

(2) Motor speed

1. Insert the test tape (MTT-111 or etc. 3,000 Hz) into DECK A.

2. Press the PLAY button.

3. Adjust VR311 so that the frequency counter show a reading

of 3,000 ± 10 Hz.

4. Press the STOP button.

3. CHECKING THE MECHANISM TORQUES

• Clean the head, capstan and pinch roller before making any measurement.

DECK " A & B"

Measureent Take-up torque Back tension Tape tension

Cassette for PLAY : TW-2111A PLAY : TW-2111A Drive-power cassette

measurement F.FWD/REW : TW-2231 TW-2412

PLAY 25 ~ 63 gr.cm 2.0 ~ 6.0 gr.cm 70 gr or more

F.FWD/REW 60 ~ 120 gr.cm - -

TAPE SPEED

ADJUSTMENT

VR311

- 5 -

Page 8

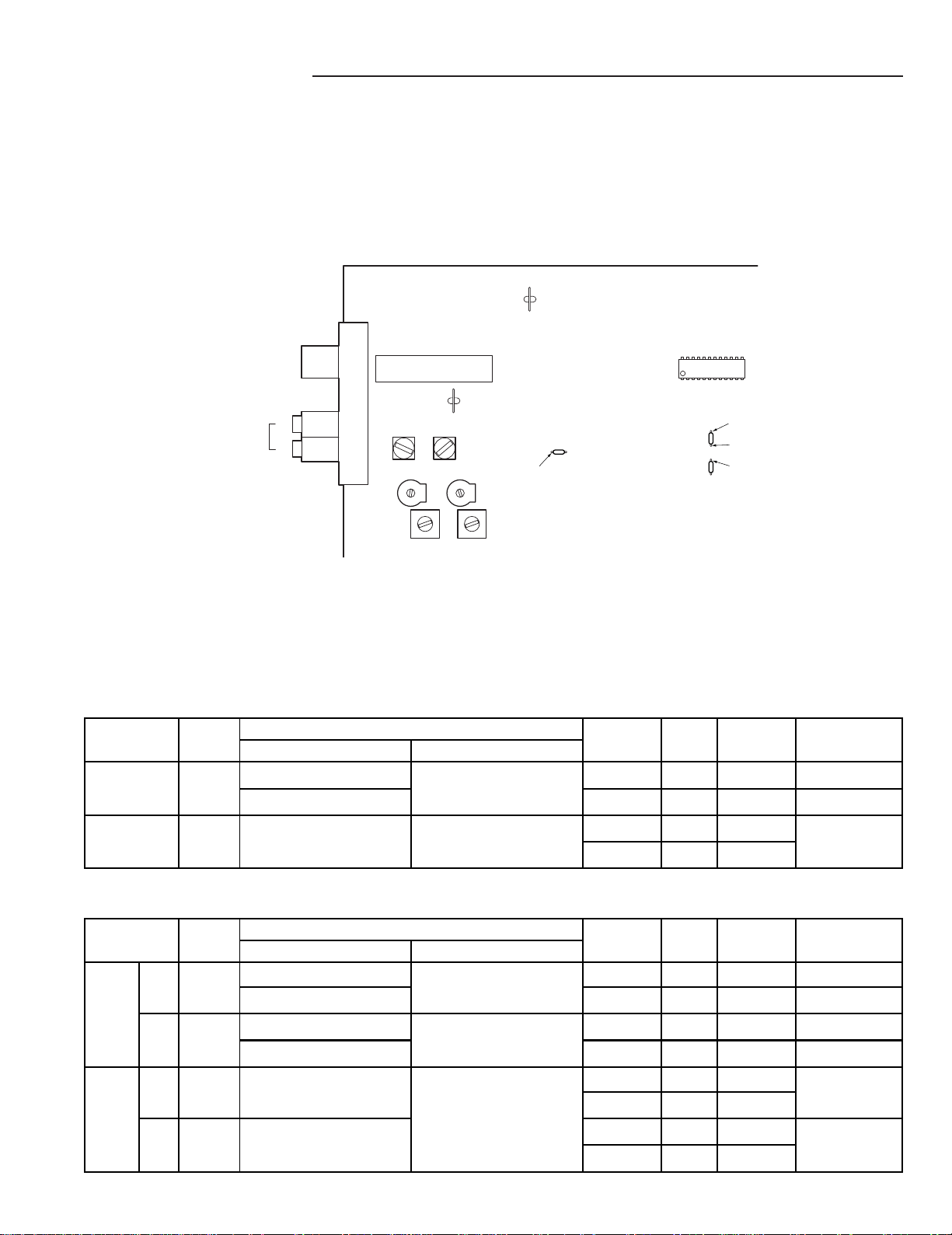

TUNER ADJUSTMENTS

o

o

o

• Use a plastic screw driver for adjustments.

• MODE : STEREO

• Speaker impedance : 6 ohm

• TUNING

FM : 87.5 - 108.0MHz (50kHz step)

MW : 522 - 1611kHz (9kHz step)

LW : 144 - 288kHz (9kHz step)

FM ANT 75ohm

COAXIAL CABLE

AM LOOP

ANT

(E)

(H)

CN201

L2154

L2153

CT251 CT252

TP11

(COVER V)

J2110

TP12

(E)

J2102

R2303

R2325

R2326

TP25

(L CH)

TP27

(E)

TP26

(R CH)

L2151

L2152

SG RF Level : 75 open Voltage dBµV

Antenna : 75 unbalanced , Modulation : 1 kHz

1.FM

Step Adjusting

Circuit

1 Cover --- Connect Digital DC voltmeter t

voltage --- TP11(H), TP12(E). 108.0 MHZ High --- less than 9.0V

2 Cover Connect FM SG to FM Antenn Connect to VTVM 90.0 MHZ Low ---

voltage

Input Output

SG≒8dBμV

Dev. : ±22.5kHz(MONO) ±22.5kHz(STEREO) ±6.75kHz(PILOT)

Connection

TP25(L) or TP26(R), TP27(E) 106.0 MHZ High ---

SG Set Adjustment Remark

Frequency Position

87.5 MHZ Low --- more than 0.9V

SG Modulation : 1kHz, 30%

2.AM

Step Adjusting

Circuit

MW Cover --- Connect Digital DC voltmeter t

1 voltage --- TP11(H), TP12(E). 1611 kHZ High --- less than 9.0V

Input Output

Antenna, IRE Loop, Distance: 60 cm

Connection

SG Set Adjustment Remark

Frequency Position

522 kHZ Low L2153

1.0V±0.05V

LW Cover --- Connect Digital DC voltmeter t

144 kHZ Low L2154

voltage --- TP11(H), TP12(E). 288 kHZ High --- less than 9.0V

M W Tracking Connect AM SG to Loop Ant. Connect to VTVM 603 kHZ Low L2152 Max.

2

SG≒80dBμV

TP25(L) or TP26(R), TP27(E). 1404 kHZ High CT252

LW Tracking Connect AM SG to Loop Ant. 162 kHZ Low L2151 Max.

SG≒85dBμV

279 kHZ High CT251

- 6 -

1.0V±0.05V

Page 9

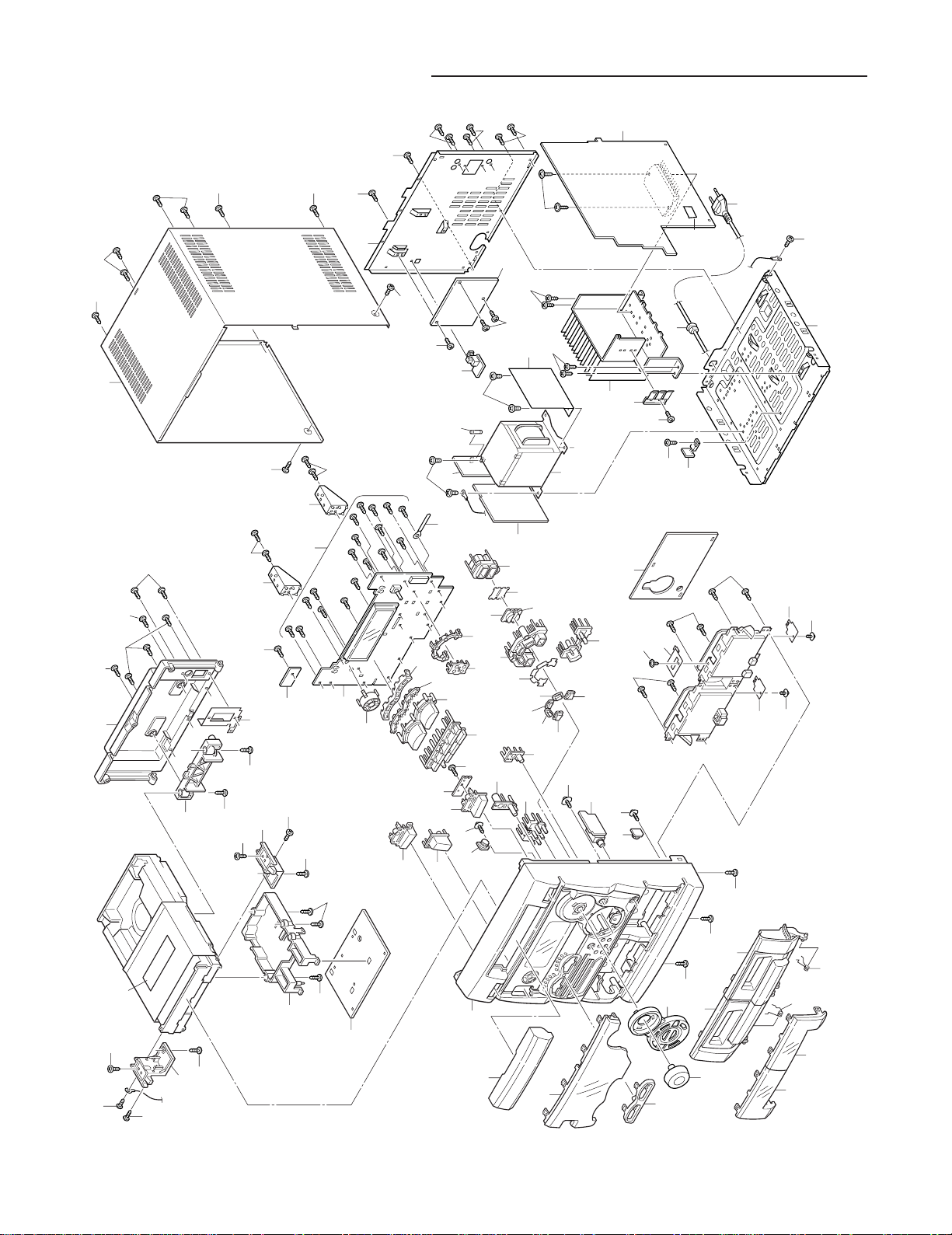

EXPLODED VIEW (CABINET & CHASSIS)

49

Y20

Y20

Y29

Y29

Y20

Y20

Y20

Y20

Y20

50

53

64

52

66

Y21

Y22

Y22

Y22

Y21

48

Y19

Y17

Y17

Y18

Y16

Y16

Y11

Y12

Y13

9

1

7

8

10

11

12

15

15

13

13

14

42

42

45

43

54

44

46

Y11

Y12

Y15

Y13

Y14

Y15

Y02

Y02

Y02

Y03

Y03

Y03

Y25

Y24

Y25

Y28

Y27

Y26

Y10

Y10

Y04

Y05

Y04

Y01

Y01

Y01

75

71

72

78

80

81

79

63

61

Y23

Y23

76

77

62

51

2

3

4

5

6

16

17

18

19

21

20

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

39

38

40

41

47

73

74

Y07

Y08

Y06

Y09

55

- 7 -

Page 10

PARTS LIST

PRODUCT SAFETY NOTICE

EACH PRECAUTION IN THIS MANUAL SHOULD BE FOLLOWED DURING SERVICING. COMPONENTS IDENTIFIED WITH THE IEC

!!

SYMBOL

SPECIAL SIGNIFICANCE. WHEN REPLACING A COMPONENT IDENTIFIED BY

OR PARTS WITH THE SAME RATINGS OF RESISTANCE, WATTAGE OR VOLTAGE THAT ARE DESIGNATED IN THE PARTS LIST

IN THIS MANUAL. LEAKAGE-CURRENT OR RESISTANCE MEASUREMENTS MUST BE MADE TO DETERMINE THAT EXPOSED

PARTS ARE ACCEPTABLY INSULATED FROM THE SUPPLY CIRCUIT BEFORE RETURNING THE PRODUCT TO THE CUSTOMER.

CAUTION : Regular type resistors and capacitors are not listed. To know those values, refer to the schematic diagram.

!

IN THE PARTS LIST AND THE SCHEMATIC DIAGRAM DESIGNATED COMPONENTS IN WHICH SAFETY CAN BE OF

!!

!

, USE ONLY THE REPLACEMENT PARTS DESIGNATED,

Regular type resistors are less than 1/4 W carbon type and 0 ohm chip resistors.

Regular type capacitors are less than 50 V and less than 1000 µF type of Ceramic type and Electrical type.

PACKING & ACCESSORIES

REF.NO. PART NO. DESCRIPTION

614 310 6234 CARTON CASE

614 308 7663 CUSHION,TOP

614 308 7670 CUSHION,BOTTOM

614 271 6656 CUSHION,SET

614 310 6241 INSTRUCTION MANUAL

614 312 3231 INSTRUCTION MANUAL,GREEK

645 005 1227 ASSY,ANTENA,LOOP

614 308 5515 ANT,FM ANT

or 614 229 4635 ANT,FM ANT

645 034 1571 REMOCON,RB-C30ARD,SANYO

645 035 8098 BATTERY COVER,SERVICE PARTS

CABINET & CHASSIS

REF.NO. PART NO. DESCRIPTION

1 614 308 7335 DEC,WINDOW,CAS,L

2 614 308 7342 DEC,WINDOW,CAS,R

3 614 310 6081 LID,CASSETTE,L,AUTO REVERSE

4 614 308 7410 LID,CASSETTE,R

5 614 308 7526 SPRING,WIRE,LID CASSETTE L

6 614 308 7533 SPRING,WIRE,LID CASSETTE R

7 614 308 7397 KNOB,ROTARY

8 614 308 7199 DEC,VOL

9 614 308 7205 DEC,BASS

10 614 312 1480 DEC,WINDOW,FL,BASS XPANDER

11 614 308 7212 DEC,CD,TRAY

12 614 310 6043 ASSY,CABINET,FRONT

13 614 289 1117 MOUNTING,BRACKET,

DECK MECHA BOTTOM

14 614 289 1100 MOUNTING,BRACKET,

DECK MECHA TOP

15 614 309 7969 ASSY,GEAR,(SESK)

16 614 308 7083 BUTTON,SOUND

17 614 308 7069 BUTTON,POWER

18 614 308 7076 BUTTON,CD,OPEN

20 614 308 7106 BUTTON,CLOCK

21 614 308 7137 BUTTON,REC

22 614 308 7168 BUTTON,FUNCTION

23 614 310 3820 BUTTON,TAPE,AUTO REVERSE

24 614 308 7090 BUTTON,BASS

25 614 308 7243 DEC,WINDOW,BASS

26 614 308 7489 REFLECTOR,BASS

27 614 308 7472 REFLECTOR,SOUND

28 614 308 7519 REFLECTOR,CD

29 614 308 7502 REFLECTOR,DISC

30 614 308 7298 DEC,WINDOW,CD,REW

31 614 308 7304 DEC,WINDOW,CD,FF

32 614 308 7267 DEC,WINDOW,DISC,1

33 614 308 7274 DEC,WINDOW,DISC,2

34 614 308 7281 DEC,WINDOW,DISC,3

REF.NO. PART NO. DESCRIPTION

35 614 308 7366 DEC,SHEET,DISC

36 614 308 7120 BUTTON,DISC

37 614 308 7151 BUTTON,MEMORY

38 614 308 7311 DEC,WINDOW,CD,PLAY

39 614 308 7328 DEC,WINDOW,CD,STOP

40 614 308 7373 DEC,SHEET,CD

41 614 308 7144 BUTTON,CD

42 614 301 6533 MOUNTING,CD,FRONT,

FRONT/CD MECHA

43 614 301 6526 MOUNTING,CD,RIGHT,

FRONT/CD MECHA

44 614 301 6519 MOUNTING,CD,LEFT,

FRONT/CD MECHA

45 614 300 3113 COVER PICK,CD PICK COVER

46 614 302 1834 MOUNTING,CD,REAR,

PANEL REAR/CD MECHA

47 614 302 1902 TERMINAL,ANT,PANEL REAR/ANT

48 614 309 8614 PANEL,REAR,CD MECHA

49 614 310 6470 ASSY,CABINET,AFTER BENDING

50 614 310 3868 PANEL,REAR

52 614 129 1901 FIXER,AC CORD

or 614 284 1884 FIXER,AC CORD

53 614 290 4954 ASSY,CABINET,BOTTOM

54 614 274 8190 LABEL,SAFETY,LASER

55 614 225 8569 STAND,MAIN PWB

FIXING PARTS

REF.NO. PART NO. DESCRIPTION

Y01 411 021 3503 SCR S-TPG BIN 3X10,BOTTOM/FRONT

Y02 411 024 3708 SCR S-TPG PAN+FLG 2X6,

DECK MECHA/MOUNTING PWB

Y03 411 021 3503 SCR S-TPG BIN 3X10,DECK MECHA

Y04 412 003 1708 SPECIAL SCREW,GEAR CASSETTE

Y05 412 032 6408 SPECIAL SCREW,HEAD PHONE

Y07 614 129 9136 LUG,CN423 FIX

Y08 411 021 3503 SCR S-TPG BIN 3X10,FRONT PWB

Y09 411 021 3503 SCR S-TPG BIN 3X10,SUB PWB

Y10 411 021 3503 SCR S-TPG BIN 3X10,

MOUNTING CD FRONT

Y11 411 021 3503 SCR S-TPG BIN 3X10,

CD MECHA/COVERPICK

Y12 411 021 3503 SCR S-TPG BIN 3X10,

MOUNING FRONT/MOUNTING L

Y13 411 021 1806 SCR S-TPG BIN 2.6X10,

CD MECHA/MOUNTING L,R(SI

Y14 411 027 3101 SCR S-TPG BIN 3X8,CD PWB GRAND

Y15 411 021 3503 SCR S-TPG BIN 3X10,

CD MECHA/MOUNTING L,R(BT

Y16 411 021 3503 SCR S-TPG BIN 3X10,

CD MECHA/MOUNTING REAR

- 8 -

Page 11

PARTS LIST

REF.NO. PART NO. DESCRIPTION

Y17 411 021 3701 SCR S-TPG BIN 3X10,

CD MECHA/REAR

Y18 411 021 3701 SCR S-TPG BIN 3X10,REAR/REAR

Y19 411 021 3701 SCR S-TPG BIN 3X10,

REAR/ELECT PARTS

Y20 411 021 3701 SCR S-TPG BIN 3X10,CABINET TOP

Y21 411 021 3701 SCR S-TPG BIN 3X10,

BOTTOM/PANEL REAR(PAF002

Y23 411 001 3905 SCR S-TPG BIN 4X6,TRANS

Y24 411 020 9506 SCR S-TPG BRZ+FLG 3X16,

POWER AMP 1

Y25 411 021 3503 SCR S-TPG BIN 3X10,

BOTTOM/HEAT SINK

Y26 411 021 3503 SCR S-TPG BIN 3X10,TR HOLDER

Y27 411 021 6405 SCR S-TPG BIN 3X8,POWER IC

Y28 411 021 6405 SCR S-TPG BIN 3X8,AMP-GND

Y29 411 021 3503 SCR S-TPG BIN 3X10,

REAR/SUB TRANS PWB

ELECTRICAL PARTS

REF.NO. PART NO. DESCRIPTION

61

62

63

64

or

65 614 305 6768 SHIELD,TRANS,PT SHIELD

66

CN381 614 308 0206 ASSY,WIRE,DECK A

or 614 304 7896 ASSY,WIRE,DECK A

CN382 614 308 0190 ASSY,WIRE,DECK B

or 614 303 6388 ASSY,WIRE,DECK B

CN383

CN384 645 028 5509 FLEXIBLE FLAT CABLE,FRONT-DECK

CN681 645 041 1793 FLEXIBLE FLAT CABLE,CD

CN682 614 304 8596 ASSY,WIRE,CD

or 614 302 2107 ASSY,WIRE,CD

CN683 614 312 2586 ASSY,WIRE,CD-DIGITAL OUT

CN691 645 013 7907 FLEXIBLE FLAT CABLE,FRONT-CD

LUG01

LUG02

SA404 411 001 3905 SCR S-TPG BIN 4X6,FOR LUG

SA405 411 021 5705 SCR S-TPG BIN 3X6,FOR LUG

!!

!

423 016 7809 FUSE 250V 2A

!!

!

645 033 8540 POWER TRANSFORMER

!!

!

614 310 5619 ASSY,HEAT SINK

!!

!

645 016 9939 CORD,POWER-1.74MK,FOR XE/PA

!!

!

614 255 2513 POWER CORD,FOR XE/PA

!!

!

614 291 6568 MOUNTING,PWB,TR HOLDER

!!

!

645 041 2356 FLEXIBLE FLAT CABLE,AMP-DECK

!!

!

614 130 0382 LUG

!!

!

614 130 0382 LUG

!!

!

614 086 2164 COVER,CAPACITOR(C4316)

DECK P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

71 614 306 5357 ASSY,PWB,DECK (Only Initial)

C3606 403 061 7306 POLYESTER 4700P J 50V

C3607 403 061 9607 POLYESTER 0.047U J 50V

CN301 645 012 5089 SOCKET,FPC 10P

or 645 005 4181 SOCKET,10P

CN302 645 012 5096 SOCKET,FPC 12P

or 645 005 4204 SOCKET,12P

CN311 614 035 4959 SOCKET,DIP 6P

or 645 012 7823 SOCKET,DIP 6P

CN312 614 020 6562 SOCKET,4P

or 614 223 9223 SOCKET

CN313 645 012 2729 SOCKET,DIP 7P

or 645 012 7830 SOCKET,DIP 7P

CN321 614 303 6647 CORD,6P CONNECTOR,A_MECHA

or 614 308 0336 CORD,6P CONNECTOR,A_MECHA

CN323 614 303 6654 CORD,7P CONNECTOR,B_MECHA

or 614 308 0343 CORD,7P CONNECTOR,B_MECHA

REF.NO. PART NO. DESCRIPTION

CN371 645 005 7373 PLUG,3P

or 645 007 0068 PLUG,3P

CN372 645 005 8127 PLUG,6P

or 645 007 0099 PLUG,6P

CN373 645 005 8226 PLUG,3P

or 645 009 6433 PLUG,3P

CN374 614 305 6317 CORD,1P CONNECTOR

!!

D3101

D3102

!

407 148 6701 DIODE 1A3-I

!!

!

407 148 6701 DIODE 1A3-I

D3601 407 099 5105 ZENER DIODE MTZJ4.7B

D3621 407 012 4406 DIODE 1SS133

D3622 407 012 4406 DIODE 1SS133

D3623 407 012 4406 DIODE 1SS133

D3624 407 012 4406 DIODE 1SS133

HS301 614 215 9347 HEAT SINK

HS302 614 215 9347 HEAT SINK

IC361 409 346 2301 IC BU2090F

IC362 409 050 8200 IC TC4011BF

IC363 409 189 3404 IC BA7755A

IC371 409 251 1000 IC TA8189N

L3601 645 032 5823 TRANS,OSC,85KHZ

L3701 645 004 0580 INDUCTOR,1M J

L3801 645 004 0580 INDUCTOR,1M J

Q3122 405 141 3703 TR KTA1271-Y

or 405 008 2405 TR 2SB698-F

or 405 008 2504 TR 2SB698-G

or 405 006 3909 TR 2SA952-K

or 405 006 4005 TR 2SA952-L

Q3124 405 141 3703 TR KTA1271-Y

or 405 008 2405 TR 2SB698-F

or 405 008 2504 TR 2SB698-G

or 405 006 3909 TR 2SA952-K

or 405 006 4005 TR 2SA952-L

Q3125 405 141 3703 TR KTA1271-Y

or 405 008 2405 TR 2SB698-F

or 405 008 2504 TR 2SB698-G

or 405 006 3909 TR 2SA952-K

or 405 006 4005 TR 2SA952-L

Q3601 405 141 3703 TR KTA1271-Y

or 405 008 2405 TR 2SB698-F

or 405 008 2504 TR 2SB698-G

or 405 006 3909 TR 2SA952-K

or 405 006 4005 TR 2SA952-L

Q3602 405 143 8706 TR KTC3199-GR

or 405 011 8609 TR 2SC1740S-S

or 405 011 8500 TR 2SC1740S-R

or 405 017 9600 TR 2SC3330-T

or 405 017 9709 TR 2SC3330-U

Q3603 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 019 3804 TR 2SC536-G-NP

or 405 019 2708 TR 2SC536-F-NP

Q3605 405 151 4905 TR KTC3200-GR

or 405 151 5001 TR KTC3200-BL

or 405 011 1907 TR 2SC1627-Y

or 405 012 8103 TR 2SC2003-L

or 405 137 6404 TR 2SC2003-K

Q3611 405 109 9204 TR KRC102M-A

or 405 000 3103 TR DTC114ES

or 405 078 3005 TR BA1L4M

Q3621 405 109 9402 TR KRC111M

or 405 000 3400 TR DTC114TS

Q3622 405 109 9204 TR KRC102M-A

or 405 000 3103 TR DTC114ES

or 405 078 3005 TR BA1L4M

Q3701 405 109 9402 TR KRC111M

or 405 000 3400 TR DTC114TS

- 9 -

Page 12

PARTS LIST

REF.NO. PART NO. DESCRIPTION

Q3702 405 095 2708 TR 2SJ40-D

or 405 095 2807 TR 2SJ40-E

or 405 149 6003 TR 2SJ498

or 405 085 9106 TR 2SJ105-GR

or 405 095 3408 TR 2SJ105-BL

Q3703 405 095 2708 TR 2SJ40-D

or 405 095 2807 TR 2SJ40-E

or 405 149 6003 TR 2SJ498

or 405 085 9106 TR 2SJ105-GR

or 405 095 3408 TR 2SJ105-BL

Q3704 405 109 9204 TR KRC102M-A

or 405 000 3103 TR DTC114ES

or 405 078 3005 TR BA1L4M

Q3801 405 109 9402 TR KRC111M

or 405 000 3400 TR DTC114TS

Q3802 405 095 2708 TR 2SJ40-D

or 405 095 2807 TR 2SJ40-E

or 405 149 6003 TR 2SJ498

or 405 085 9106 TR 2SJ105-GR

or 405 095 3408 TR 2SJ105-BL

Q3803 405 095 2708 TR 2SJ40-D

or 405 095 2807 TR 2SJ40-E

or 405 149 6003 TR 2SJ498

or 405 085 9106 TR 2SJ105-GR

or 405 095 3408 TR 2SJ105-BL

Q3804 405 109 9204 TR KRC102M-A

or 405 000 3103 TR DTC114ES

or 405 078 3005 TR BA1L4M

R3608 401 011 4900 CARBON 82 JA 1/2W

VR311 645 003 5685 VR,SEMI,2.2K N

HEADPHONE P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

72 614 310 6838 ASSY,PWB,HEADPHONE (Only Initial)

CN422 645 009 0042 JACK,PHONE D6.43

CN432 645 005 8110 PLUG,4P

FRONT P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

73 614 310 6821 ASSY,PWB,FRONT (Only Initial)

BR601 614 308 7380 HOLDER,FL,FL_MOUNT

C6095 403 291 5608 ELECT 1000U M 6.3V

CN601 645 032 5809 PLUG,22P,FRONT-PRE

CN602 614 035 4935 SOCKET,DIP 4P

or 645 012 7809 SOCKET,DIP 4P

CN603 645 012 5249 SOCKET,FPC 20P

or 645 005 4280 SOCKET,20P

CN604 645 012 5096 SOCKET,FPC 12P

or 645 005 4204 SOCKET,12P

CN607 614 035 4911 SOCKET,DIP 2P

CN612 614 308 0329 CORD,4P CONNECTOR,FRONT-PT2

or 614 303 6623 CORD,4P CONNECTOR,FRONT-PT2

D6001 407 012 4406 DIODE 1SS133

D6004 407 012 4406 DIODE 1SS133

D6007 407 099 4603 ZENER DIODE MTZJ3.9B

D6202 408 039 4400 LED SLZ-981B-09H-AB-T1,

SOUND_PRESET_LED

D6203 408 036 0504 LED SLZ-381C-09H-AB-T1,

SOUND_LED

D6204 408 037 4204 LED SLP-3118B-51HAB-T1,

BASS_PASS_LED

D6205 408 037 4204 LED SLP-3118B-51HAB-T1,

BASS_PASS_LED

REF.NO. PART NO. DESCRIPTION

D6206 408 037 4204 LED SLP-3118B-51HAB-T1,

BASS_PASS_LED

D6208 408 037 4204 LED SLP-3118B-51HAB-T1,

BASS_PASS_LED

D6210 408 037 4204 LED SLP-3118B-51HAB-T1,

BASS_PASS_LED

D6212 408 037 4204 LED SLP-3118B-51HAB-T1,

BASS_PASS_LED

D6214 408 039 4400 LED SLZ-981B-09H-AB-T1,

SOUND_PRESET_LED

D6216 408 039 4400 LED SLZ-981B-09H-AB-T1,

SOUND_PRESET_LED

D6217 408 039 4400 LED SLZ-981B-09H-AB-T1,

SOUND_PRESET_LED

D6301 408 043 2607 LED SLZ-336A-14H-AB-T2,DISC_LED

D6302 408 043 2607 LED SLZ-336A-14H-AB-T2,DISC_LED

D6303 408 043 2607 LED SLZ-336A-14H-AB-T2,DISC_LED

D6304 408 043 2607 LED SLZ-336A-14H-AB-T2,DISC_LED

D6305 408 043 2607 LED SLZ-336A-14H-AB-T2,DISC_LED

D6306 408 043 2607 LED SLZ-336A-14H-AB-T2,DISC_LED

D6307 408 043 2607 LED SLZ-336A-14H-AB-T2,DISC_LED

D6308 408 043 2607 LED SLZ-336A-14H-AB-T2,DISC_LED

D6309 408 043 2607 LED SLZ-336A-14H-AB-T2,DISC_LED

DS601 407 217 1101 PHOTO DIODE SPS-442-1G,IR

FL601 645 040 1220 FLOURESCENT TUBE,FL

IC601 410 377 5100 IC LC866556B-5R77,MICOM

IC602 409 426 1903 IC KIA4558F,OP_AMP

or 409 039 7804 IC NJM4558M,OP_AMP

IC604 409 346 2301 IC BU2090F,LED_DRIVER

IC605 409 346 2301 IC BU2090F,LED_DRIVER

L6000 645 001 4550 INDUCTOR,10U K

or 645 031 7835 INDUCTOR,10U K

Q6001 405 143 8706 TR KTC3199-GR

or 405 017 9600 TR 2SC3330-T

or 405 017 9709 TR 2SC3330-U

or 405 011 8500 TR 2SC1740S-R

or 405 011 8609 TR 2SC1740S-S

Q6002 405 143 6504 TR KTA1267-GR

or 405 004 4601 TR 2SA608-F-SPA

or 405 004 5103 TR 2SA608-G-SPA

or 405 006 1806 TR 2SA933S-R

or 405 006 1905 TR 2SA933S-S

Q6003 405 141 3703 TR KTA1271-Y

or 405 008 2405 TR 2SB698-F

or 405 008 2504 TR 2SB698-G

Q6005 405 143 8706 TR KTC3199-GR

or 405 017 9600 TR 2SC3330-T

or 405 017 9709 TR 2SC3330-U

or 405 011 8500 TR 2SC1740S-R

or 405 011 8609 TR 2SC1740S-S

Q6006 405 143 8706 TR KTC3199-GR

or 405 017 9600 TR 2SC3330-T

or 405 017 9709 TR 2SC3330-U

or 405 011 8500 TR 2SC1740S-R

or 405 011 8609 TR 2SC1740S-S

Q6007 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

Q6008 405 143 6504 TR KTA1267-GR

Q6202 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

Q6203 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

Q6204 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

Q6205 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

- 10 -

Page 13

PARTS LIST

REF.NO. PART NO. DESCRIPTION

Q6206 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

Q6208 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

Q6210 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

Q6212 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

Q6214 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

Q6216 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

Q6217 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

Q6302 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

Q6303 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

Q6305 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

Q6306 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

Q6307 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

Q6308 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

Q6309 405 110 5400 TR KRA102M-A

or 405 000 0508 TR DTA114ES

S6001 645 033 3460 SWITCH,ROTARY(ENCODER),VOL

S6100 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6101 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6102 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6103 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6104 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6105 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6106 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6107 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6108 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6109 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6110 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6111 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

REF.NO. PART NO. DESCRIPTION

S6115 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6116 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6117 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6118 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6119 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6120 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6121 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6122 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6123 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6124 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6130 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6131 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6132 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6133 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6134 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6135 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6136 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6137 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6138 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6140 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

S6141 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 220 5471 SWITCH,TACT

TA601 614 112 1451 DOUBLE FACE,FL_MOUNT

X6001 645 032 1627 OSC,CRYSTAL 32.768KHZ,XTAL

X6002 645 018 6103 OSC,CERAMIC 6.000MHZ,6MHZ

- 11 -

Page 14

PARTS LIST

LED P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

74 614 310 6814 ASSY,PWB, LED (Only Initial)

CN661 614 035 4911 SOCKET,DIP 2P

D6601 408 043 2508 LED SLZ-190B-06H-AB-T2,

STAND-BY LED

CD P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

75 614 312 2777 ASSY,PWB,CD (Only Initial)

CN101 645 005 8110 PLUG,4P,TP1-4

or 614 310 2458 PLUG,4P,TP1-4

CN111 645 039 1972 SOCKET,FPC 15P,CD_PICKUP

CN113 614 310 2472 PLUG,6P,BASEMECHA

or 645 005 8127 PLUG,6P,BASEMECHA

CN114 614 223 9223 SOCKET

or 614 020 6562 SOCKET,4P

CN115 614 223 9261 SOCKET

or 614 020 6609 SOCKET,8P

CN122 645 012 5539 SOCKET,FPC 20P

CN123 645 006 0946 PLUG,7P

CN124 614 304 8572 ASSY,WIRE,CD-CDMECHA_4P

or 614 302 2084 ASSY,WIRE,CD-CDMECHA_4P

CN125 614 304 8589 ASSY,WIRE,CD-CDMECHA_8P

or 614 302 2091 ASSY,WIRE,CD-CDMECHA_8P

CN131 614 310 2441 PLUG,3P

or 645 005 7373 PLUG,3P

D1211 407 063 9108 ZENER DIODE MTZJ6.8B

D1221 407 099 5303 ZENER DIODE MTZJ5.6B

D1480 407 012 5809 DIODE 1SS176

or 407 012 4406 DIODE 1SS133

!!

D1601

D1602

D1603

D1604

!

407 148 6701 DIODE 1A3-I

!!

!

407 148 6701 DIODE 1A3-I

!!

!

407 148 6701 DIODE 1A3-I

!!

!

407 148 6701 DIODE 1A3-I

D1981 407 099 5204 ZENER DIODE MTZJ5.1B

IC101 409 396 8100 IC LA9241ML

IC102 409 435 2106 IC LC78622NE,CD_DSP

!!

IC103

IC131

IC132

!

409 372 9602 IC LA6541

!!

!

409 441 4507 IC TA7291S(M),CD_MECHA_DRIVER

!!

!

409 441 4507 IC TA7291S(M),CD_MECHA_DRIVER

L1451 645 031 7835 INDUCTOR,10U K

LG101 614 129 9082 LUG,CD-MECHA

!!

PR101

!

645 014 2482 PROTECTOR,0.315A 125V

Q1301 405 008 6809 TR 2SB808-F-SPA

or 405 008 7202 TR 2SB810-E

or 405 008 7301 TR 2SB810-F

!!

Q1401

or

or

R1211

or

R1221

or

T1001

!

405 141 3604 TR KTA1273-Y

!!

!

405 001 9302 TR 2SA1020-Y

!!

!

405 009 5207 TR 2SB927-S

!!

!

402 082 0709 RESISTOR 5.6 J- 2W

!!

!

402 072 0207 RESISTOR 5.6 J- 2W

!!

!

402 082 0709 RESISTOR 5.6 J- 2W

!!

!

402 072 0207 RESISTOR 5.6 J- 2W

!!

!

407 212 0505 THERMISTOR RXE065

X1451 645 020 9024 OSC,CRYSTAL 16.9344MHZ

POWER TRANSFORMER,

PRIMARY P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

76 614 310 6845 ASSY,PWB,PT1 (Only Initial)

CN498 645 031 7903 HOLDER,FUSE

or 645 006 4760 HOLDER,FUSE

CN499 645 031 7903 HOLDER,FUSE

or 645 006 4760 HOLDER,FUSE

POWER TRANSFORMER,

SECONDARY P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

77 614 312 2784 ASSY,PWB,PT2 (Only Initial)

C4936 403 329 6201 ELECT 2200U M 35V

C4937 403 329 6201 ELECT 2200U M 35V

C4938 403 062 6506 POLYESTER 0.056U J 50V

CN493 645 006 0915 PLUG,4P

or 645 009 6440 PLUG,4P

CN495 645 023 4378 SOCKET,7P

CN497 614 035 4928 SOCKET,DIP 3P

or 614 237 9769 SOCKET

!!

D4930

D4931

D4932

D4933

D4934

D4935

D4950

D4951

!

407 196 5800 DIODE 1N5402BD82

!!

!

407 196 5800 DIODE 1N5402BD82

!!

!

407 196 5800 DIODE 1N5402BD82

!!

!

407 196 5800 DIODE 1N5402BD82

!!

!

407 148 6701 DIODE 1A3-I

!!

!

407 148 6701 DIODE 1A3-I

!!

!

407 148 6701 DIODE 1A3-I

!!

!

407 148 6701 DIODE 1A3-I

D4952 407 100 0709 ZENER DIODE MTZJ39B

D4953 407 099 6102 ZENER DIODE MTZJ10B

LUG49 614 051 9808 LUG

!!

PR493

PR495

PR497

!

645 025 5137 PROTECTOR,7A 125V

!!

!

645 025 5137 PROTECTOR,7A 125V

!!

!

645 014 2512 PROTECTOR,1A 125V

Q4950 405 141 3406 TR KTA1266-GR

or 405 141 3505 TR KTA1266-Y

or 405 005 2002 TR 2SA733-P

or 405 005 1906 TR 2SA733-K

or 405 004 4502 TR 2SA608-F-NP

or 405 004 5004 TR 2SA608-G-NP

!!

R4954

R4955

R4970

R4971

!

402 083 3105 RESISTOR 2.2 J- 1/2W

!!

!

402 081 1004 FUSIBLE RES 10 JA 1/4W

!!

!

402 082 2802 RESISTOR 10 J- 1W

!!

!

402 081 0809 RESISTOR 680 J- 1W

REGULATOR P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

78 614 305 2388 ASSY,PWB,REG (Only Initial)

CN425 614 035 4928 SOCKET,DIP 3P

or 614 237 9769 SOCKET

!!

IC425

or

!

409 396 8704 IC KIA7805PI

!!

!

409 145 2809 IC NJM7805FA

or 409 463 6701 IC KIA7805API

SUB TRANS P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

79 614 310 6791 ASSY,PWB,SUB TRANS (Only Initial)

C4311 403 329 5501 ELECT 2200U M 16V

C4316

or

or

C4320 403 313 4602 ELECT 1000U M 16V

CN335 614 017 8203 TERMINAL BOARD

CN336 614 017 8203 TERMINAL BOARD

CN337 614 017 8203 TERMINAL BOARD

CN338 614 017 8203 TERMINAL BOARD

CN432 645 005 8110 PLUG,4P

or 645 007 0075 PLUG,4P

D4300 407 012 4406 DIODE 1SS133

D4308 407 012 4406 DIODE 1SS133

D4309

!!

!

404 033 3401 CERAMIC 0.01U Z 400V

!!

!

404 033 3302 CERAMIC 0.01U M 400V

!!

!

404 000 1607 CERAMIC 0.01U F 400V

!!

!

407 148 6701 DIODE 1A3-I

- 12 -

Page 15

PARTS LIST

REF.NO. PART NO. DESCRIPTION

!!

D4310

D4311

D4312

D4320

D4321

!

407 148 6701 DIODE 1A3-I

!!

!

407 148 6701 DIODE 1A3-I

!!

!

407 148 6701 DIODE 1A3-I

!!

!

407 148 6701 DIODE 1A3-I

!!

!

407 148 6701 DIODE 1A3-I

D4322 407 099 5402 ZENER DIODE MTZJ6.2B

D4350 407 065 1308 ZENER DIODE MTZJ3.6B

D4352 407 012 4406 DIODE 1SS133

!!

IC430

L4300

!

409 169 7804 IC NJM78M05FA

!!

!

645 038 7364 INDUCTOR,70U

Q4300 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 020 7402 TR 2SC945A-P

or 405 020 7204 TR 2SC945A-K

or 405 012 2002 TR 2SC1815-GR

Q4320 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 020 7402 TR 2SC945A-P

or 405 020 7204 TR 2SC945A-K

or 405 012 2002 TR 2SC1815-GR

Q4350 405 141 3406 TR KTA1266-GR

or 405 141 3505 TR KTA1266-Y

or 405 005 2002 TR 2SA733-P

or 405 005 1906 TR 2SA733-K

or 405 004 4502 TR 2SA608-F-NP

or 405 004 5004 TR 2SA608-G-NP

Q4351 405 141 3406 TR KTA1266-GR

or 405 141 3505 TR KTA1266-Y

or 405 005 2002 TR 2SA733-P

or 405 005 1906 TR 2SA733-K

or 405 004 4502 TR 2SA608-F-NP

or 405 004 5004 TR 2SA608-G-NP

!!

RY431

or

T4301

!

645 030 5597 RELAY,PRIMARY

!!

!

645 035 6575 RELAY,PRIMARY

!!

!

645 041 4954 TRANS,POWER

AMPLIFIER & TUNER P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

80 614 310 6784 ASSY,PWB,AMP-TU (Only Initial)

C2152 403 082 0201 POLYPRO 470P J 100V

C2155 403 082 2205 POLYPRO 560P J 100V

C2457 403 259 0508 NP-ELECT 1U M 50V

or 403 106 1603 NP-ELECT 1U Q 50V

C4440 403 262 8607 DL-ELECT 0.047F Z 5.5V

or 403 304 4802 DL-ELECT 0.047F Z 5.5V

C4447 403 291 5707 ELECT 2200U M 6.3V

C4513 403 168 6202 MT-POLYEST 0.33U J 50V

C4514 403 168 6202 MT-POLYEST 0.33U J 50V

C4613 403 168 6202 MT-POLYEST 0.33U J 50V

C4614 403 168 6202 MT-POLYEST 0.33U J 50V

C4705 403 057 2407 POLYESTER 0.1U J 50V

C4706 403 057 2407 POLYESTER 0.1U J 50V

C4750 403 185 0108 MT-POLYEST 0.47U J 50V

C4751 403 184 9805 MT-POLYEST 0.22U J 50V

C4805 403 057 2407 POLYESTER 0.1U J 50V

C4806 403 057 2407 POLYESTER 0.1U J 50V

C4850 403 185 0108 MT-POLYEST 0.47U J 50V

C4851 403 184 9805 MT-POLYEST 0.22U J 50V

C4902 404 079 4301 ELECT 2200U M 63V

C4903 404 079 4301 ELECT 2200U M 63V

CN201 614 255 5750 TERMINAL

or 645 032 6394 TERMINAL

CN412 645 012 2729 SOCKET,DIP 7P

or 614 249 6770 SOCKET

CN423 614 035 4935 SOCKET,DIP 4P

or 614 237 9776 SOCKET

REF.NO. PART NO. DESCRIPTION

CN452 614 249 8613 SOCKET,VIDEO

CN454 645 012 5089 SOCKET,FPC 10P

or 645 005 4181 SOCKET,10P

CN455 645 032 5816 SOCKET,22P

CN460 614 308 0312 CORD,7P CONNECTOR,AMP-CD

or 614 302 6396 CORD,7P CONNECTOR,AMP-CD

CN470 645 033 3071 TERMINAL,SPEAKER

CN489 614 310 6883 ASSY,WIRE,AMP-SUB

CN490 614 310 6890 ASSY,WIRE,AMP-HP

CN491 614 035 4935 SOCKET,DIP 4P

or 614 237 9776 SOCKET

CN492 645 023 4378 SOCKET,7P

CT251 645 032 5670 TRIMMER,27PF

CT252 645 032 5663 TRIMMER,7PF

D2151 407 091 5004 VARACTOR DI SVC321SPA-C-2

D2152 407 091 5004 VARACTOR DI SVC321SPA-C-2

D2451 407 012 4406 DIODE 1SS133

D2452 407 153 7502 ZENER DIODE GZS3.0B

D2454 407 012 4406 DIODE 1SS133

D2455 407 012 4406 DIODE 1SS133

D2456 407 012 4406 DIODE 1SS133

D2461 407 012 4406 DIODE 1SS133

D2464 407 012 4406 DIODE 1SS133

D2466 407 012 4406 DIODE 1SS133

D2467 407 012 4406 DIODE 1SS133

D4110 407 012 4406 DIODE 1SS133

D4111 407 012 4406 DIODE 1SS133

D4112 407 012 4406 DIODE 1SS133

D4114 407 012 4406 DIODE 1SS133

D4410 407 012 4406 DIODE 1SS133

D4414 407 012 4406 DIODE 1SS133

!!

D4416

!

407 148 6701 DIODE 1A3-I

D4700 407 063 9108 ZENER DIODE MTZJ6.8B

D4701 407 063 9108 ZENER DIODE MTZJ6.8B

!!

D4900

D4901

D4902

D4903

!

407 196 5800 DIODE 1N5402BD82

!!

!

407 196 5800 DIODE 1N5402BD82

!!

!

407 196 5800 DIODE 1N5402BD82

!!

!

407 196 5800 DIODE 1N5402BD82

D4920 407 099 6805 ZENER DIODE MTZJ13B

D4921 407 099 4603 ZENER DIODE MTZJ3.9B

D4940 407 099 6805 ZENER DIODE MTZJ13B

D4960 407 099 6805 ZENER DIODE MTZJ13B

IC231 409 379 2705 IC LA1832ML

IC245 409 439 4502 IC LC72121M-D

IC251 409 447 3900 IC LC72722

IC411 409 426 1804 IC KIA4558S

IC413 409 478 1104 IC LA2615M,SURROUND

IC458 409 474 6103 IC LC75342M

IC459 409 426 1804 IC KIA4558S

!!

IC470

!

409 437 8007 IC STK411-200E

L2151 645 038 8118 TRANS,RF,252KHZ

or 614 255 5798 TRANS,RF

L2152 645 038 8125 TRANS,RF,796KHZ

or 614 255 5781 TRANS,RF

L2153 614 255 5767 TRANS,OSC

L2154 614 255 5774 TRANS,OSC

L2301 645 004 0580 INDUCTOR,1M J

L2451 645 001 4581 INDUCTOR,100U K

or 645 031 7842 INDUCTOR,100U K

L2501 645 001 4581 INDUCTOR,100U K

or 645 031 7842 INDUCTOR,100U K

L2502 645 001 4581 INDUCTOR,100U K

or 645 031 7842 INDUCTOR,100U K

L2901 645 004 0511 INDUCTOR,270U J

L4700 614 202 1712 V.H.F COIL 1AV4L20B0320N

or 614 196 9763 V.H.F COIL

L4800 614 202 1712 V.H.F COIL 1AV4L20B0320N

- 13 -

Page 16

PARTS LIST

REF.NO. PART NO. DESCRIPTION

or 614 196 9763 V.H.F COIL

LUG45 614 051 9808 LUG

Q2140 405 141 3208 TR KTC3198-Y

or 405 141 3307 TR KTC3198-GR

or 405 019 2708 TR 2SC536-F-NP

or 405 019 3804 TR 2SC536-G-NP

Q2152 405 141 3208 TR KTC3198-Y

or 405 141 3307 TR KTC3198-GR

or 405 019 2708 TR 2SC536-F-NP

or 405 019 3804 TR 2SC536-G-NP

Q2153 405 141 3208 TR KTC3198-Y

or 405 141 3307 TR KTC3198-GR

or 405 019 2708 TR 2SC536-F-NP

or 405 019 3804 TR 2SC536-G-NP

Q2154 405 141 3208 TR KTC3198-Y

or 405 141 3307 TR KTC3198-GR

or 405 019 2708 TR 2SC536-F-NP

or 405 019 3804 TR 2SC536-G-NP

Q2155 405 141 3208 TR KTC3198-Y

or 405 141 3307 TR KTC3198-GR

or 405 019 2708 TR 2SC536-F-NP

or 405 019 3804 TR 2SC536-G-NP

Q2156 405 141 3208 TR KTC3198-Y

or 405 141 3307 TR KTC3198-GR

or 405 019 2708 TR 2SC536-F-NP

or 405 019 3804 TR 2SC536-G-NP

Q2157 405 026 9004 TR 2SK222-D

Q2201 405 151 4202 TR KTC3193-O

or 405 151 4103 TR KTC3193-Y

or 405 016 0806 TR 2SC2839-E

Q2310 405 141 3208 TR KTC3198-Y

or 405 141 3307 TR KTC3198-GR

or 405 019 2708 TR 2SC536-F-NP

or 405 019 3804 TR 2SC536-G-NP

Q2451 405 151 5209 TR KRA107M

or 405 000 0904 TR DTA114YS

Q2452 405 151 5209 TR KRA107M

or 405 000 0904 TR DTA114YS

Q2453 405 151 5209 TR KRA107M

or 405 000 0904 TR DTA114YS

Q2501 405 141 3208 TR KTC3198-Y

or 405 141 3307 TR KTC3198-GR

or 405 019 2708 TR 2SC536-F-NP

or 405 019 3804 TR 2SC536-G-NP

Q2502 405 151 5209 TR KRA107M

or 405 000 0904 TR DTA114YS

Q4110 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 020 7402 TR 2SC945A-P

or 405 020 7204 TR 2SC945A-K

or 405 012 2002 TR 2SC1815-GR

Q4401 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 020 7402 TR 2SC945A-P

or 405 020 7204 TR 2SC945A-K

or 405 012 2002 TR 2SC1815-GR

Q4410 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 020 7402 TR 2SC945A-P

or 405 020 7204 TR 2SC945A-K

or 405 012 2002 TR 2SC1815-GR

Q4411 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 020 7402 TR 2SC945A-P

or 405 020 7204 TR 2SC945A-K

or 405 012 2002 TR 2SC1815-GR

REF.NO. PART NO. DESCRIPTION

Q4431 405 141 3406 TR KTA1266-GR

or 405 141 3505 TR KTA1266-Y

or 405 005 2002 TR 2SA733-P

or 405 005 1906 TR 2SA733-K

or 405 004 4502 TR 2SA608-F-NP

or 405 004 5004 TR 2SA608-G-NP

Q4432 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 020 7402 TR 2SC945A-P

or 405 020 7204 TR 2SC945A-K

or 405 012 2002 TR 2SC1815-GR

Q4433 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 020 7402 TR 2SC945A-P

or 405 020 7204 TR 2SC945A-K

or 405 012 2002 TR 2SC1815-GR

Q4434 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 020 7402 TR 2SC945A-P

or 405 020 7204 TR 2SC945A-K

or 405 012 2002 TR 2SC1815-GR

Q4435 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 020 7402 TR 2SC945A-P

or 405 020 7204 TR 2SC945A-K

or 405 012 2002 TR 2SC1815-GR

Q4436 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 020 7402 TR 2SC945A-P

or 405 020 7204 TR 2SC945A-K

or 405 012 2002 TR 2SC1815-GR

Q4438 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 020 7402 TR 2SC945A-P

or 405 020 7204 TR 2SC945A-K

or 405 012 2002 TR 2SC1815-GR

Q4439 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 020 7402 TR 2SC945A-P

or 405 020 7204 TR 2SC945A-K

or 405 012 2002 TR 2SC1815-GR

Q4500 405 151 4400 TR KTD1303

or 405 021 0600 TR 2SD1012-G-SPA

Q4600 405 151 4400 TR KTD1303

or 405 021 0600 TR 2SD1012-G-SPA

Q4700 405 151 4400 TR KTD1303

or 405 021 0600 TR 2SD1012-G-SPA

Q4701 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 020 7402 TR 2SC945A-P

or 405 020 7204 TR 2SC945A-K

or 405 012 2002 TR 2SC1815-GR

Q4702 405 141 3406 TR KTA1266-GR

or 405 141 3505 TR KTA1266-Y

or 405 005 2002 TR 2SA733-P

or 405 005 1906 TR 2SA733-K

or 405 004 4502 TR 2SA608-F-NP

or 405 004 5004 TR 2SA608-G-NP

Q4800 405 151 4400 TR KTD1303

or 405 021 0600 TR 2SD1012-G-SPA

Q4920 405 141 3406 TR KTA1266-GR

or 405 141 3505 TR KTA1266-Y

or 405 005 2002 TR 2SA733-P

or 405 005 1906 TR 2SA733-K

or 405 004 4502 TR 2SA608-F-NP

or 405 004 5004 TR 2SA608-G-NP

- 14 -

Page 17

PARTS LIST

REF.NO. PART NO. DESCRIPTION

Q4921 405 141 3406 TR KTA1266-GR

or 405 141 3505 TR KTA1266-Y

or 405 005 2002 TR 2SA733-P

or 405 005 1906 TR 2SA733-K

or 405 004 4502 TR 2SA608-F-NP

or 405 004 5004 TR 2SA608-G-NP

!!

Q4940

!

405 138 6403 TR KTD2058Y

Q4941 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 020 7402 TR 2SC945A-P

or 405 020 7204 TR 2SC945A-K

or 405 012 2002 TR 2SC1815-GR

Q4960 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 020 7402 TR 2SC945A-P

or 405 020 7204 TR 2SC945A-K

or 405 012 2002 TR 2SC1815-GR

Q4961 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 020 7402 TR 2SC945A-P

or 405 020 7204 TR 2SC945A-K

or 405 012 2002 TR 2SC1815-GR

!!

Q4962

!

405 138 6403 TR KTD2058Y

R4437 614 241 3449 RESISTOR 0.22 K- 5W

R4438 614 241 3449 RESISTOR 0.22 K- 5W

!!

R4706

R4707

R4716

R4717

R4718

!

402 081 0403 RESISTOR 4.7 J- 2W

!!

!

402 081 0502 RESISTOR 330 J- 3W

!!

!

402 081 1103 FUSIBLE RES 100 JA 1/4W

!!

!

402 081 1103 FUSIBLE RES 100 JA 1/4W

!!

!

402 081 0403 RESISTOR 4.7 J- 2W

R4750 614 241 3449 RESISTOR 0.22 K- 5W

!!

R4806

R4807

R4818

!

402 081 0403 RESISTOR 4.7 J- 2W

!!

!

402 081 0502 RESISTOR 330 J- 3W

!!

!

402 081 0403 RESISTOR 4.7 J- 2W

R4850 614 241 3449 RESISTOR 0.22 K- 5W

!!

R4920

R4940

R4963

R4964

!

402 081 1103 FUSIBLE RES 100 JA 1/4W

!!

!

402 081 8904 RESISTOR 1 J- 1/2W

!!

!

402 081 0601 RESISTOR 1K J- 2W

!!

!

402 081 8904 RESISTOR 1 J- 1/2W

RY441 614 224 4531 RELAY,SPEAKER

or 645 035 6582 RELAY,SPEAKER

S4900 614 215 9828 SWITCH,TACT,RESET

REF.NO. PART NO. DESCRIPTION

T2301 645 038 3687 FILTER,LP 75KHZ

U2101 645 033 5327 TUNER,FM

X2301 614 246 0870 RESONATOR

X2451 645 023 4965 OSC,CRYSTAL 7.2MHZ

X2501 645 035 8326 OSC,CRYSTAL 4.332MHZ

XF221 645 010 0079 CERAMIC FILTER 10.70MHZ

or 614 240 2917 FILTER,CERAM

or 614 254 3214 FILTER

XF222 645 010 0079 CERAMIC FILTER 10.70MHZ

or 614 240 2917 FILTER,CERAM

or 614 254 3214 FILTER

XF231 614 246 0849 FILTER

XF233 645 018 8824 DISCR,CERAMIC

or 645 018 8718 DISCR,CERAMIC

OPTICAL DIGITAL OUT P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

81 614 310 6852 ASSY,PWB,DIGITAL OUT (Only Initial)

CN168 645 005 7373 PLUG,3P

CN169 614 240 5703 OPTO CONNECTOR

SPEAKERS (SX-S800L,R/XE)

REF.NO. PART NO. DESCRIPTION

1 614 309 6511 ASSY,GRILLE(R)

614 309 6528 ASSY,GRILLE(L)

2 614 312 3248 ASSY,BOX,SPEAKER(R)

614 312 3255 ASSY,BOX,SPEAKER(L)

2

1

EXPLODED VIEW (TAPE MECHANISM)

TM05

TM08

TM06

TM03

TM02

TM01

TM03

TM04

TM07

TAPE MECHANISM (TM-C50PRMEC-SH

. . . Only Initial)

REF.NO. PART NO. DESCRIPTION

614 303 0225 ASSY,MECHA,TM-C50PRMEC-SH

TM01 614 293 6634 HEAD,R/P

TM02 645 033 3354 HEAD,ERASE

TM03 645 028 0030 ASSY,PINCH-ARM

TM04 645 025 5892 MAIN-BELT

TM05 645 029 6246 MAIN-BELT

TM06 614 293 9505 ASSY,MOTOR,PLAY MECHA MOTOR

TM07 645 028 0542 ASSY,PINCH-ARM

TM08 645 036 3726 HEAD,PLAY,AUDIO

- 15 -

Page 18

EXPLODED VIEW (CD CHANGER MECHANISM)

CM61

CM61

CM03

CM19

CM23

CM19

CM61

CM14

CM11

CM52

CM61

CM62

CM02

CM63

CM18

CM19

CM17

CM10

CM67

CM62

3

CM62

CM12

CM13

CM63

CM07

1

2

CM62

A

CM08

CM19

CM04

CM65

CM32

CM34

CM25

CM29

CM45

CM60

CM47

CM39

CM40

CM36

CM66

CM66

CM49

CM38

CM35

CM46

CM44

CM60

CM31

CM30

CM48

CM37

CM51

CM43

CM50

CM33

CM41

CM43

CM50

CM06

CM09

B

CM64

CM65

CM65

CM64

CD BASE

MECHANISM

CM01

CM65

CM16

CM15

CM27

CM28

CM24

B

A

CM26

CM61

CM05

CM61

- 16 -

Page 19

PARTS LIST

CD MECHANISM

(PM-CDS800TP-SH ... Only Initial)

REF.NO. PART NO. DESCRIPTION

CM01 645 033 6072 ASSY,CHASSIS,CHASSIS ASSY

CM02 645 033 7512 DRAWER 2

CM03 645 033 5976 ASSY,HOLDER L,

DRAWER HOLDER L ASS

CM04 645 033 6898 ASSY,HOLDER R3B,

DRAWER HOLDER R ASSY

CM05 645 033 6041 ASSY,PC BOARD A

CM06 645 033 6065 ASSY,PC BOARD B

CM07 645 033 6058 ASSY,PC BOARD C

CM08 645 033 5945 LEAD WIRE

CM09 645 033 5952 LEAD WIRE

CM10 645 033 6713 SPACER SW

CM11 645 033 6027 ASSY,GEAR DRIVE,

SINCHRO GEAR ASSY

CM12 645 041 2417 ASSY,CRG 101,CARRIAGE NO.1

CM13 645 041 2424 ASSY,CRG 201

CM14 645 041 2431 ASSY,CRG 301

CM15 645 033 5877 INSULATER

CM16 645 033 5884 INSULATER

CM17 645 033 5907 CUSHION

CM18 645 033 6324 BEVEL GEAR 4

CM19 645 033 5990 ASSY,GEAR STAR,

CARRIAGE LIFT GEAR

CM23 645 033 6089 COVER 2

CM24 645 033 6539 SHAFT

CM25 645 033 6461 SLIDER 4

CM26 645 033 6201 GEAR SPLINE

CM27 645 033 6232 BEVEL GEAR 1

CM28 645 033 6270 GEAR IDLER 1

CM29 645 033 6102 PLATE SPRING

CM30 645 033 6287 BEVEL GEAR 3

CM31 645 033 6225 PULLEY C

CM32 645 041 2448 ASSY,CLAMPER SA,CLAMPER

(SANYO)

REF.NO. PART NO. DESCRIPTION

CM33 645 033 6140 ARM SLIDER R

CM34 645 033 6157 ARM SLIDER L

CM35 645 033 6430 SLIDER 1

CM36 645 033 5969 ASSY,SLIDER 2,

FWD/RVS SLIDE ASSY

CM37 645 033 6980 ARM STOPPER A2

CM38 645 033 6416 ARM STOPPER B

CM39 645 033 6263 GEAR IDLER A2

CM40 645 033 6218 GEAR IDLER C

CM41 645 033 6447 LEVER

CM43 645 033 6454 LIFTER,CARRIGE LIFT UP

CM44 645 033 5778 BELT

CM45 645 033 5785 BELT

CM46 645 033 7048 SPRING

CM47 645 033 6393 PULLEY A

CM48 645 033 6003 ASSY,MOTOR CRG S,

CARRIGE MOTOR ASSY

CM49 645 033 6010 ASSY,MOTOR DRW S,

DRAWER MOTOR ASSY

CM50 645 033 5723 SPRING

CM51 614 303 7545 SPRING

CM52 645 033 5747 SPRING

CM60 645 033 5648 WASHER

CM61 645 033 5594 SCREW

CM62 645 033 7031 SCREW

EXPLODED VIEW (CD BASE MECHANISM)

PM09

PM02

PM09

PM08

PM07

PM06

PM03

PM08

PM04

PM05

PM01

PM10

CD BASE MECHANISM (CDDA11-SASH...Only Initial)

REF.NO. PART NO. DESCRIPTION

PM01 620 021 8436 PLUG 6P

PM02 620 233 0853 ASSY MOTOR

PM03 620 236 3776 COVER,GEAR

PM04 620 230 8753 GEAR, MIDDLE

PM05 620 230 8760 GEAR,DRIVE

PM06 620 231 0596 SHAFT SLIDE

PM07 620 233 0860 SWITCH LEAF

PM08 411 104 8401 SCR PAN PCS 2X3

PM09 411 027 5402 SCR S-TPG FLT 2.6X6

PM10 620 236 0836 PWB,MOTOR

- 17 -

Page 20

IC BLOCK DIAGRAM & DESCRIPTION

IC101 LA9241ML (Servo Signal Processor)

No. Pin Name I/O Function

1 FIN2 I Connection Pin for Photo Diode of Pickup.

2 FIN1 I FIN2 + FIN1 = RF, FIN2 - FIN1 = FE

3 E I Connection Pin for Photo Diode of Pickup.

4 F I E - F = TE

5 TB I Input Pin for DC ingredient of TE Signal.

6 TE- I Connection Pin for Gain Setting Resistor of TE

Signal to TE Signal Pin.

7 TE O Output Pin for Tracking Error Signal.

8 TESI I Input Pin for Track Error Sense Comparator.

TE Signal through Band Pass, and Inputted.

9 SCI I Input Pin for Shock Detection.

10 TH I Connection Pin for Time Constant Setting of

Tracking Gain.

11 TA O Output Pin for TA Amplifier.

12 TD- I Connection Pin for Constant Tracking Phase

Compensation, Consist of between TD and VR.

13 TD I Connection Pin for Constant of Tracking Phase

Compensation.

14 JP I Connection Pin for Amplitude Setting of Tracking

Jump (Kick Pulse) Signal.

15 TO O Output Pin for Tracking Control Signal.

16 FD O Output Pin for Focusing Control Signal.

17 FD- I Connection Pin for Constant of Focusing Phase

Compensation, Consist of between FD and FA.

18 FA+ I Connection Pin for Constant of Focusing Phase

Compensation, Consist of between FD- and FA-.

19 FA- I Connection Pin for Constant of Focusing Phase

Compensation, Consist of between FA and FE.

20 FE O Output Pin for Focusing Error Signal.

21 FE- I Connection Pin for Gain Setting Resistor of FE

Signal to FE Signal Pin.

22 AGND - Ground for Analog Signal.

23 SP O Output Pin for Single End of Input Signal of the

CV+, CV- Pin.

24 SPI I Input Pin for Spindle Amplifier.

25 SPG I Connection Pin for Gain Setting Resistor, when

Spindle 12 cm Mode.

26 SP- I Connection Pin for Constant of Spindle Phase

Compensation with SPD Pin.

27 SPD O Output Pin for Spindle Control Signal.

28 SLEQ I Connection Pin for Constant of Sled Phase

Compensation.

29 SLD O Output Pin for Sled Control Signal.

30 SL- I Input Pin for Sled Signal from Micro Processor.

31 SL+ I

32 JP- I Input Pin for Tracking Jump Signal from Digital

33 JP+ I Signal Processor.

No. Pin Name I/O Function

34 TGL I Input Pin for Tracking Gain Control Signal from

Digital Signal Processor. TGL = H : Gain Low

35 TOFF I Input Pin for Tracking Off Control Signal from Digital

Signal Processor. TOFF = H : OFF

36 TES O Output Pin for Track Error Sense Signal to Digital

Signal Processor.

37 HFL I High Frequency Level Signal Use Detection

Main-Beam Position is on the pit or mirror.

38 SLOF I Input Pin for Sled Servo Off Control.

39 CV- I Input Pin for Constant Linear Velocity Error

40 CV+ I Signal from Digital Signal Processor.

41 RFSM O Output Pin for RF Signal.

42 RFS- I Connection Pin for Gain Setting of RF and

Constant Setting of 3T Compensation of the

EFM Signal with RFSM Pin.

43 SLC O Slice Level Control Signal is Output Pin.

It Control Level of Data-Slice by Digital Signal

Processor of the RF Waveform.

44 SLI I Input Pin for Level Control of Data-Slice by

Digital Signal Processor.

45 DGND - Ground for Digital Signal.

46 FSC O Output Pin for Focus Search Smooth Condenser

47 TBC O Connection Pin for Variable Range Setting of

EF Balance.

48 NC - No Connect

49 DEF O Output Pin for Defect Detection of Disc.

50 CLK I Input Pin for Reference Clock Pulse.

(4.23 MHz of Digital Signal Processor)

51 CL I Input Pin of Clock Pulse for Command from

Micro Processor.

52 DAT I Input Pin of Data for Command from Micro

Processor.

53 CE I Input Pin of Chip Enable for Command from Micro

Processor.

54 DRF O Output Pin for Detect of RF Level.

55 FSS I Select Pin for Focus Search Mode

56 VCC2 - VCC for Servo and Digital Root.

57 REFI I Bus Control Connection Pin for Reference Voltage.

58 VR O Output Pin for Reference Voltage.

59 LF2 I Connection Pin for Time Constant Setting of

Detect Detection of the Disc.

60 PH1 I Capacitor Connection Pin for Peak-hold of RF Signal.

61 BH1 I Capacitor Connection Pin for Bottom-hold of

RF Signal.

62 LDD O Output Pin of APC (Automatic Power Control) Circuit.

63 LDS I Input Pin of APC (Automatic Power Control) Circuit.

64 VCC1 I VCC for RF Root.

- 18 -

Page 21

IC BLOCK DIAGRAM & DESCRIPTION

IC102 LC78622NE (Digital Signal Processor)

No. Pin Name I/O Function

1 DEFI I Input terminal for detect signal of defect

2 TAI I Input terminal for test.

3 PDO O The phase comparison output terminal for

external VCO control.

4 VVSS - Ground terminal for built-in VCO

5 ISET I Resistance connection terminal for

electric current adjustment of PDO output.

6 VVDD - Built-in VCO power supply terminal.

7 FR I VCO frequency range adjustment.

8 VSS - Ground for Digital

9 EFMO O EFM signal output terminal for slice level control.

10 EFMIN I EFM signal input terminal for slice level control.

11 TEST2 I TEST pin. Normal time is non connection.

12 CLV+ O Output terminal for Disc motor control.

13 CLV- O Output terminal for Disc motor control.

14 V/P O Change of rough servo / phase control

Rough servo : "H", Phase control : "L"

15 HFL I Input terminal of track search signal.

16 T ES I Input terminal of tracking error signal.

17 TOFF O Output terminal of tracking off.

18 TG L O Output terminal for change of tracking gain.

19 JP+ O Output terminal for tracking jump control.

20 JP- O Output terminal for tracking jump control.

21 PCK O Clock monitor output terminal for EFM data

playback. (4.3218 MHz)

22 FSEQ O Output terminal for detect of SYNC signal.

23 DVDD - +5V

24 CONT1 I/O

25 CONT2 I/O This output can control at serial control from

26 CONT3 I/O micro processor.

27 CONT4 I/O

28 CONT5 I/O

29 EMPH O Output terminal of de-emphasis monitor .

"H" : de-emphasis

30 C2F O Output terminal of C2 flag

31 DOUT O Output terminal of digital out

DEFI

EFMIN

EFMO VVDDVVSSPDO ISET FR PCK TAI

9

1

Slice level

10

Control

4

6

VCO Clock Oscillator

& Clock Control

357 2

No. Pin Name I/O Function

32 TEST3 I Test pin.

33 TEST4 I Test pin.

34 NC - Non connection.

35 MU TEL O Mute output terminal for L-ch

36 LVDD - Power supply for L-ch

37 LCHO O Output terminal for L-ch

38 LVSS - GND for L-ch

39 RVSS - GND for R-ch

40 RCHO O Output terminal for R-ch

41 RVDD - Power supply for R-ch

42 MUTER O Mute output terminal for R-ch

43 XVDD - Power supply of crystal oscillation

44 XOUT O Connection terminal of crystal oscillation (16.9344MHz)

45 XIN I Connection terminal of crystal oscillation (16.9344MHz)

46 XVSS - GND of crystal oscillation

47 SBSY O Output terminal for synchronizing signal of

sub-cord block

48 EFLG O Output terminal for correction monitor of C1, C2,

Single and Double

49 PW O Output terminal for sub-cord of P, Q, R, S, T, U and W

50 SFSY O Output terminal for synchronizing signal of

sub-cord frame

51 SBCK I Input terminal for readout clock of sub-cord

52 FSX O Output terminal of Synchronizing signal (7.35kHz)

53 WRQ O Output terminal for standby of sub-cord Q output

54 RWC I Input terminal of read / write control

55 SQOUT O Out put t ermi nal o f sub-cord Q

56 COIN I Input terminal of command from micro processor

57 CQCK I Clock input for reading sub-cord from SQOUT

58 RES I Reset (turn on : L)

59 TST11 O Test pin

60 16M O 16.9344MHz

61 4.2M O 4.2336MHz

62 TEST5 I Test pin

63 CS I Chip select terminal

64 TEST1 I Test pin

TEST2 TEST4

21

TST11

TEST1 TEST3 TEST5

59 64 11 32 33 62

2K ~8bit

RAM

VDDV

23

SS

8

RAM Address

Generatorl

FSEQ

CLV+

CLV-

SBCK

SBSY

SFSY

WRQ

SQOUT

CQCK

COIN

RWC

Syncrnous Detect

22

EFM Demodulation

12

13

14

V/P

PW

49

51

47

50

63

CS

53

55

57

56

54

CLV

Digital Servo

Subcode Dxract

QCRC

µCOM

Inter Fase

TGL

General Ports

CONT3

CONT1

CONT2

CONT4

Servo Commander

15 16 17 20 19 58 18 24 25 26 27 28 29 48 60 61 46 52 45 44 43 39 41 42 40 37 35 38 36

RESJP+JP-TOFFTESHFL

C1 C2 Error Detect &

Correct Control Flag

X'tal Root

Timing Generator

4.2M16MEFLGEMPHCONT5

XV

SS

XV

DD

XINFSX

XOUT

Interpolalation Mute

Quadruple Over Sampling

RV

DD

RV

SS

MUTER

- 19 -

Billingual

Digital Attenuator

Digital Filter

1bit DAC

L.P.F

RCHO

C2F

30

Digital Out

LV

DD

MUTELLCHO

LV

SS

31

DOUT

(NC)

34

Page 22

g

2

8

6

7

3

5

1

9

Vcc

Vref

Vs

OUT1

OUT2

GND

IN1

IN2

Protective Circuit

(Heat Interception)

REG

IC BLOCK DIAGRAM & DESCRIPTION

1

2

3

4 5 6 7 8

16

1514131211

10

9

VSS

DATA

CLOCK

Q0Q1Q2

Q3

Q5Q6Q7Q8Q9

Q10

VDD

CONTROL

CURCUIT

Q11

Q4

12 BIT SHIFT

RESISTOR

LATCH

OUTPUT BUFFER (OPEN DLAIN)

IC103 LA6541 (Pickup Actuator & CD Mechanism Motor)

Vcc Vref VIN4 VG4 Vo8 Vo7 GND Vo6 Vo5 VG3 VIN3 CD RES

11k

Vcc

11k

IC131, IC132 TA7291S (Bridge Driver)

131415161718192021222324

Level

Sift

Level

Sift

123456 789

Vcc Mute VIN1 VG1 Vo1 Vo2 GND Vo3 Vo4 VG2 VIN2 Re

BTL

Driver

BTL

Driver

BTL

Driver

BTL

Driver

IC211 TA8176SN (FM Front End)

RF OUT

MIX IN

MIX OUT

AGC

BY-PASS

RF IN

IF OUT

5

7

Vcc

1

2

3

Vcc

MIXER

AGC DET

9 4 6 10

8

IF

Buffer

Amp

BIAS

Vcc

Buffer

Buffer

GND

FM/TV SW

Local

11

12

Level

Sift

Level

Sift

11k11k

10 11 12

RESET

Regulator

OUT Reg IN

IC231 LA1832ML (AM / FM IF Amplifier & FM-MPX)

AGC

COMP

TUNING

DRIVE

18

6

DET

7

MUTE

16

REG

FF FF FF

VCO

AM

/FM

SW

12

OSC

OSC

BUFFER

OUT

23

ALC

AM

OSC

BUFF

4

24

LEVEL

DET

22

FM

IF

S-CURVE

FM

DET

1

2

AM

AM

RF

MIX

AMP

AM/FM

IF BUFF

8

10

21 20 19

AMIFAM

AM

FM

3

GND

STEREO

DRIVE

PHASE DET

5

11

9

VCC

STEREO

SW

TRIG

PILOT

DET

DECODER

15 14

17

13

IC245 LC72121M (PLL Synthesizer)

2

Vssx

XIN

XOUT

FMIN

AMIN

V

Vssd

1

24

17

16

CE

3

DI

4

CL

5

6

DO

DD

18

15

1/2

CCB

I / F

POWER

ON

RESET

REFERENCE

DIVIDER

SWALLOW COUNTER

1/16, 1/17 4bits

12bits PROGRAMMABLE

DIVIDER

DATA SHIFT REGISTER LATCH

8910 11

7

BO2 BO3 BO4

BO1

IC362 TC4011BF (NAND Gate)

VDD A4

14

1

B4 X4 X3 B3 A3

12

13

3

2

X1 X2A1 B1 B2 A2 VSS

IC361 BU2090F (12bit Serial Parallel Converter)

19

20

21

22

13

PD

AIN

AOUT

Vssa

IFIN

No.

Pin Name Port Name

Function

1 VSS VSS Ground

2 DATA D-OUT Data input

3 CLOCK EX1-CLK Clock input

4 Q 0 BEAT Tape beat chancel output (L=Pos1, H=Pos.2)

5 Q 1 OSC Tape oscillation circuit control (L=OFF, H=ON)

6 Q 2 Not used

7 Q 3 R-MUTE Tape REC mute output (L=OFF, H=ON)

8 Q 4 DECK-A/B Deck A / B control (L=B, H=A)

9 Q 5 Not used

10 Q6 R/P Tape Rec / Play control (L=Rec, H=Play)

11 Q7 Not used

12 Q8 MOTOR Tape motor output (H=OFF,L=ON)

13 Q9 A-PLY-PL Dack A Play Plunger output (H=OFF,L=ON)

14 Q1 0 B-PLY-PL Dack B Play Plunger output (H=OFF,L=ON)

15 Q1 1 Not used

16 VDD VDD Power supply

- 20 -

PHASE DETECTOR

CHARGE PUMP

UNLOCK

DETECTOR

UNIVERSAL

COUNTER

14

IO2

IO1

11

4

5

8910

6

7

Page 23

IC BLOCK DIAGRAM & DESCRIPTION

IC363 BA7755A (Head Switch)

IC371 TA8189N (Pre-Amplifier for Tape Deck)

1

VCC

HEAD

SWITCH

GND

CTRL2

52 3

4

CTRL1

IC425 NJM7805FA (3-Terminal Voltage Regulator)

IC458 LC75342M (Electronically controllable

electronic volume)

CL

VDD

VREFNCROUT

RBASS2

RBASS1

RTRE

RIN

LBASS1

LTRE

LIN

RSEL0R4R3R2R1

L4L3L2

LSEL0

30 29 28 27 26 25 24 23 222120

123456789101112131415

DI

CE

VSS

TEST

LOUT

LBASS2

19 18 17 16

L1

NC

NC

IC604, IC605 BU2090F (12bit Serial Parallel Converter)

VSS

VDD

1

16

DATA

CLOCK

2

3

CONTROL

CURCUIT

OUTPUT BUFFER (OPEN DLAIN)

12 BIT SHIFT

RESISTOR

LATCH

IC413 LA2615M (Surround)

GDR GUR ACG LPFC LED VCC L-OUT R-OUT

16 15 14 13 12 11 10 9

ANALOG

SURROUND

VREF

On/Off H/L H/L GND HPFC VREF L-IN R-IN

IC602 NJM4558M (Operation Amplifier)

A OUTPUT

A -INPUT

A +INPUT

1

A

2

B

3

8

7

6

VCC(+)

B OUTPUT

B -INPUT

87654321

4 5 6 7 8

Q0Q1Q2

Q3

9

10

Q4

Q5Q6Q7Q8Q9

Q10

VEE(-)

4

1514131211

Q11

5

B +INPUT

IC604 BU2090F (12bit Serial Parallel Converter) IC605 BU2090F (12bit Serial Parallel Converter)

No.

No.

Pin Name Port Name

Function

1 VSS VSS Ground

2 DATA D-OUT Da ta input

3 CLOCK EX2_CLK Clock input

4 Q 0 Not used

5 Q 1 SUR_3 Output for Surround LSI control

6 Q 2 SUR_2 Output for Surround LSI control

7 Q 3 SUR_1 Output for Surround LSI control

8 Q 4 LED_0 Not used

9 Q 5 LED_1 DISC_3 LED OUTPUT (L=ON)

10 Q6 LED_2 CD STOP KEY LED OUTPUT (L=ON)

11 Q7 LED_3 FWD KEY LED OUTPUT (L=ON)

12 Q8 LED_4 CD PLAY KEY LED OUTPUT (L=ON)

13 Q9 LED_5 DISC_1 LED OUTPUT (L=ON)

14 Q10 LED_6 BACK KEY LED OUTPOUT (L=ON)

15 Q11 LED_7 DISC_2 LED OUTPUT (L=ON)

16 VDD VDD Power supply

Pin Name Port Name

1 VSS VSS Ground

2 DATA D_OUT Data input

3 CLOCK EX3_CLK Clock input

4 Q 0 S20 FL-S20 control

5 Q 1 LED_8 PASS_HI LED OUTPUT (L=ON)

6 Q 2 LED_9 PASS_MID LED OUTPUT (L=ON)

7 Q3 LED_10 PASS_LOW LED OUTPUT (L=ON)

8 Q4 LED_11 SOUND JAZZ LED OUTPUT (L=ON)

9 Q5 LED_12 SOUND ROCK

10 Q6 LED_13 SOUND POP LED OUTPUT (L=ON)

11 Q7 LED_14 SOUND CLASSIC LED OUTPUT (L=ON)

12 Q8 LED_15 SOUND LED OUTPUT (L=ON)

13 Q9 LED_16 BASS_HI LED OUTPUT (L=ON)

14 Q 1 0 LED_17 BASS_MID LED OUTPUT (L=ON)

15 Q 1 1 LED_18 BASS_LOW LED OUTPUT (L=ON)

16 VDD VDD Power supply

- 21 -

Function

Page 24

IC BLOCK DIAGRAM & DESCRIPTION

(ON=Low)

IC601 LC866548A (Micro Processor)

No. Name I/O Function

1 JOG+ I Input JogDial

2 JOG- I Input JogDial

3 D_CLK O Serial clock output for Tu/Vol_Func IC

4 D_OUT O

5 EXI_CLK O Serial clock output for extend IC1(DECK)

6 EX2_CLK O Serial clock output for extend IC2(LED)

7 EX3_CLK O Serial clock output for extend IC3(LED)

8 VF_CE O Serial latch output for Vol_Func IC

9 TU_CE O Serial latch output for Tuner IC

10 TU_DI I Serial date output for Tuner IC

11 O Not used

12 RESET I Reset terminal

13 XT1 I Sub clock connection terminal

14 XT2 O Sub clock connection terminal

15 VSS Ground

16 CF1 I Main clock connection terminal (6MHz)

17 CF2 O Main clock connection terminal (6MHz)

18 VDD Power supply (+5V)

19 KEY0 I Key input

20 KEY1 I Key input

21 KEY2 I Key input

22 CD_SW0 I SW input SW2(EXTRA) SW3(HOME)

23 CD_SW1 I SW input SW4(C_No.) SW5(C_No.)