Page 1

FILE NO.

Service Manual

REMOTE CONTROLLER RB-DVD1JP

DVD Micro Component

System

DC-PT70

(UK)

(XE)

CONTENTS

Laser beam safety precaution .......................................... 1

DVD Mechanism Replacement ........................................ 1

Service mode ................................................................... 2

Important Note ................................................................. 5

How to load software for MPEG P.W.Board .................... 5

Cautions for PWB or IC assy exchange ........................... 5

Cautions FM antenna wire ............................................... 5

How to take out a disk ...................................................... 5

Tuner adjustment ............................................................. 6

Exploded View (Cabinet & Chassis) ................................ 7

Parts List .......................................................................... 8

Wiring Connection ........................................................... 13

IC Block Diagram & Description ....................................... 14

Schematic Diagram .......................................................... 30

Wiring diagram ................................................................. 42

PRODUCT CODE No.

129 696 03 UK

129 696 04 XE

REFERENCE No.

SM5810572

Page 2

LASER BEAM SAFETY PRECAUTION

• Pick-up that emits a laser beam is used in this CD player section.

CAUTION :

USE OF CONTROLS OR ADJUSTMENTS

OR PERFORMANCE OF PROCEDURES

OTHER THAN THOSE SPECIFIED HEREIN

MAY RESULT IN HAZARDOUS RADIATION

EXPOSURE

LASER OUTPUT..........0.6 mW Max. (CW)

WAVELENGTH .............790 nm

CAUTION – INVISIBLE LASER RADIATION WHEN OPEN AND

INTERLOCKS DEFEATED. AVOID EXPOSURE TO BEAM.

ADVARSEL – USYNLIG LASER STRÅLING VED ÅBNING, NÅR

SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION, UNDGÅ UDS ÆTTELSE

FOR STRÅLING.

VARNING – OSYNLIG LASER STRÅLNING NÄR DENNA DEL ÄR ÖPPNAD

OCH SPÄRR ÄR URKOPPLAD. STRÅLEN ÄR FARLIG.

VORSICHT – UNSICHTBARE LASERSTRAHLUNG TRITT AUS, WENN

DECKEL GEÖFFNET UND WENN SICHERHEITSVERRIEGELUNG

ÜBERBRÜCKT IST. NICHT, DEM STRAHL AUSSETZEN.

VARO – AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA

NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

DVD MECHANISM REPLACEMENT

1. Cautionary instructions in handling the assy

(Safety instructions)

Optical pickup

The laser beam used in the pickup is classified as "class 2". Exposing your eyes or skin to the beam is harmful. Take care not to

do so.

(Caution against static electricity and leakage voltage)

Ground securely the work tables, tools, fixtures, soldering irons

(including those made of ceramic) and measuring instruments

used in the production lines and inspection departments that

handle loaders. The workers shall also be grounded.

(Cautionary instructions in handling)

Do not touch the object lens when handling a loader, or the lens

will be stained, resulting in inadequate playability.

There is no power supply protection circuit provided for this product or adjustment/inspection device. Short-circuiting may lead to

fire or damage.

Ta ke care so as to protect from exposure to water, the entry of

metallic pieces or dew condensation.

In particular, a strong magnet adjacent to the pickup will not only

get inoperative but can damage the pickup if a small metallic

piece, such as a screw or swarm, enters.

The loader edge can cause injury if inadvertently handled.

Do not touch a rotating disk, or injury may result.

(Connectors)

Do not connect or disconnect while power is on.

Connecting or disconnecting signal wires or the main power cord

when the power is on may destruct the unit or fixture.

When connecting, push all the way in securely.

An insufficient insertion may cause a bad contact, leading to an

erroneous operation.

Do not connect or disconnect roughly by an excessively strong

force, or a broken wire or bad contact may result.

Semiconductors are connected. Do not touch connector terminals directly.

If the worker is grounded, there is nothing to worry about static

electricity, but the rust on the connector terminal surface caused

by the touch may result in bad contact.

(Caution)

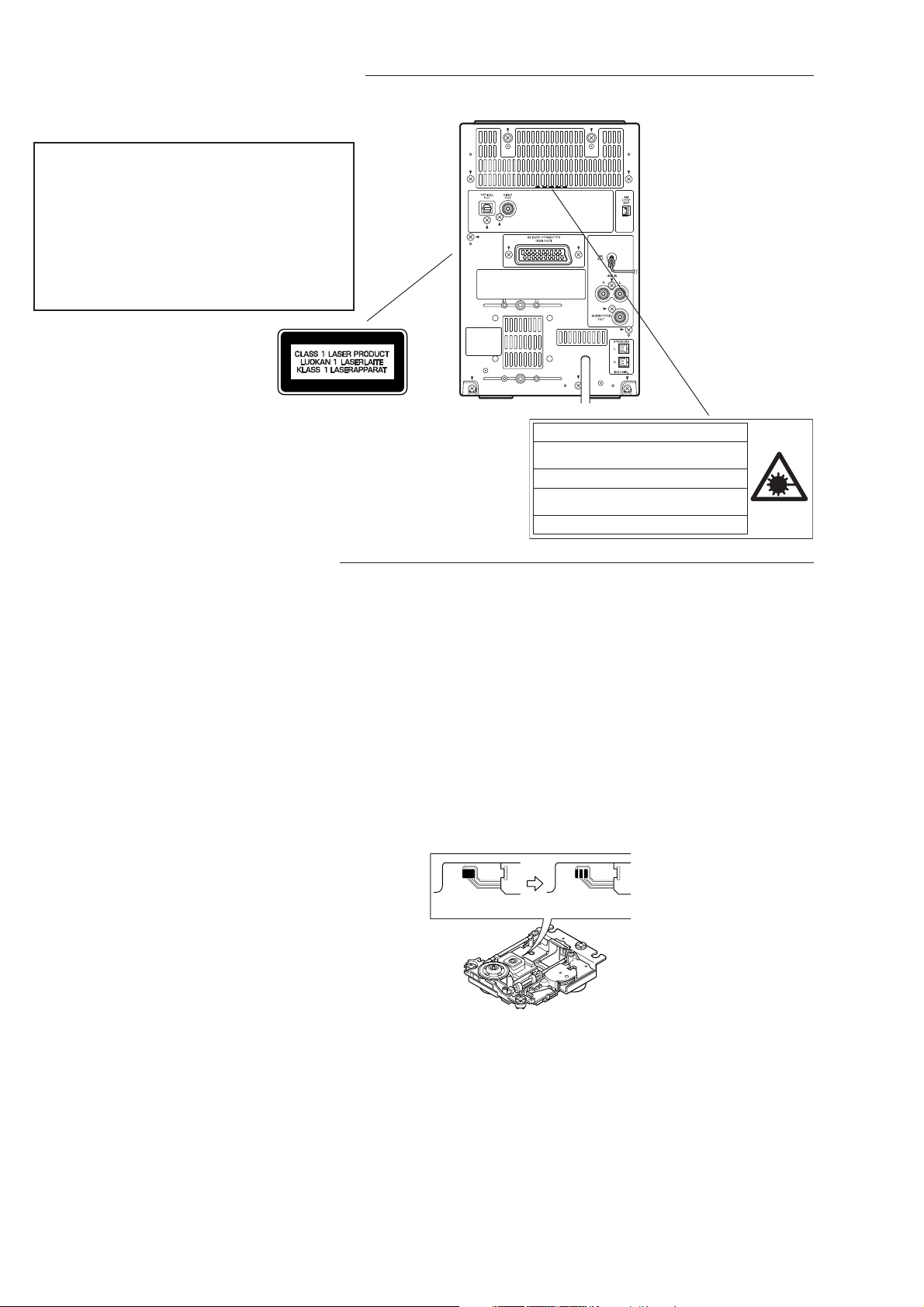

Before disconnecting FFC

cable, make it "SHORT" as

shown left.

After connecting FFC

cable,make it "OPEN" as

(OPEN)(SHORT)

shown left.

This product is a precision device. Handle carefully.

A shock or dropping will cause misalignment or destruction. If it

should occur, refer to clause 2.

This product is so designed as to endure an initial shock equivalent to a drop from a height of approx. 90 cm under the packed

condition.

After the initial shock, the resistivity will still remain at a level of

50 to 60 G, but the mechanical robustness will weaken.

Do not place in a dusty location.

The entry and deposition of dirt into or on the pickup lens or

moving section will cause malfunction or degradation.

(Power source)

The power source need be good in quality (free from instantaneous interruptions or noises).

A low quality power source may well cause malfunction.

(Storage)

Do not place or store in a dusty place or a place where dew

condensation is possible.

The entry and deposition of dirt or dust into or on the pickup lens

or moving section will cause malfunction or degradation.

Also, dew condensation causes rust; the rust penetrate into the

precision part of a pickup, causing malfunction, or degrading the

optical quality of the internal lens and reflector, which also leads

to malfunction.

- 1 -

Page 3

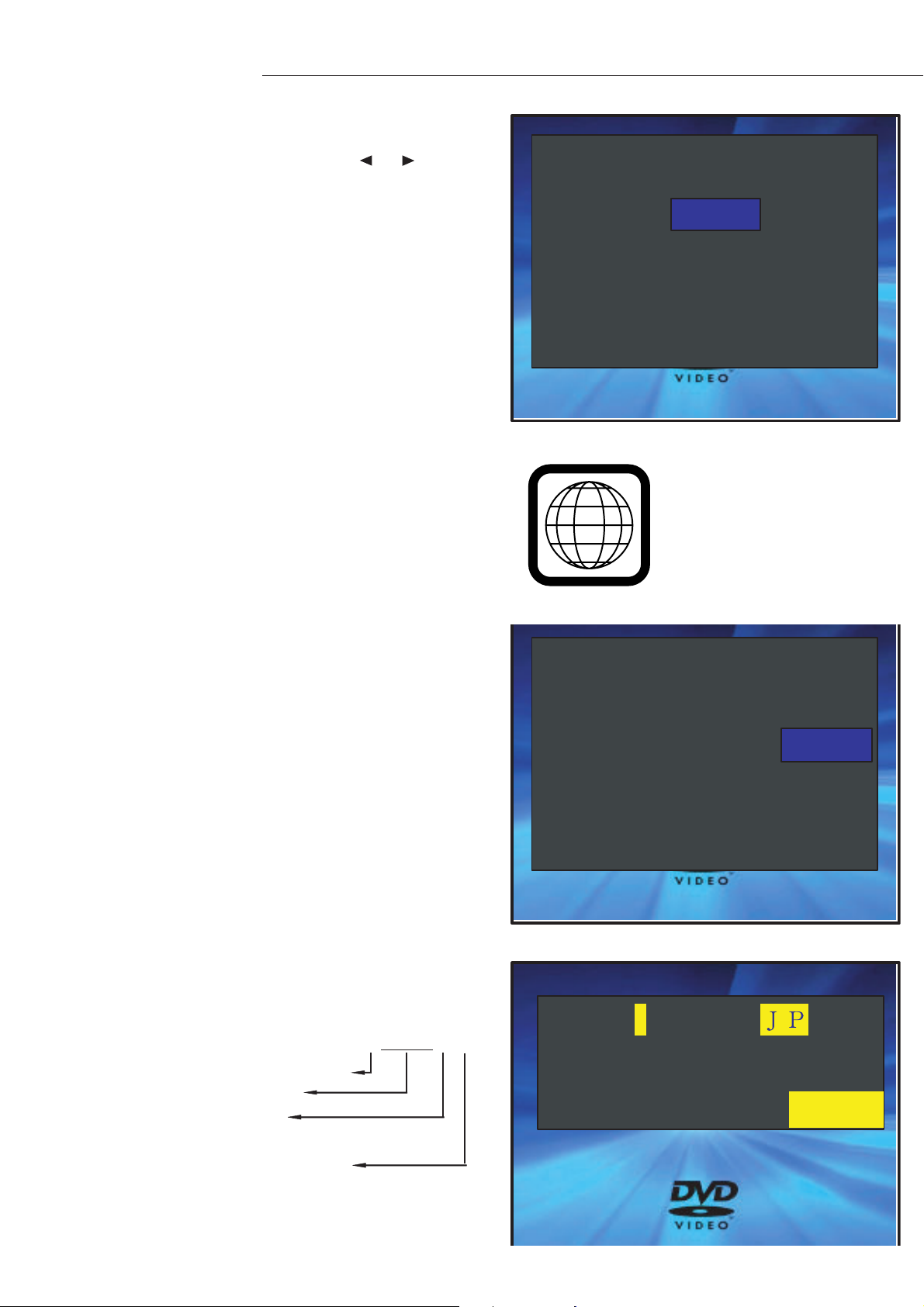

SERVICE MODE

A. Market / Region SETUP

In the initial condition for this model, Market and Region

information are undefined.

In the following cases, be sure to set up Market/Region.

1. When updating the system using CD-R

(Part code :0PRADC9695--A ).

2. When replacing a DVD substrate.

While Market/Region information are undefined, the message

"Region Undefined" is displayed on the screen.

NOTE: Even if the condition is not under 1 or 2 above, if the

message "Region Undefined" is displayed, be sure to set up

Market/Region.

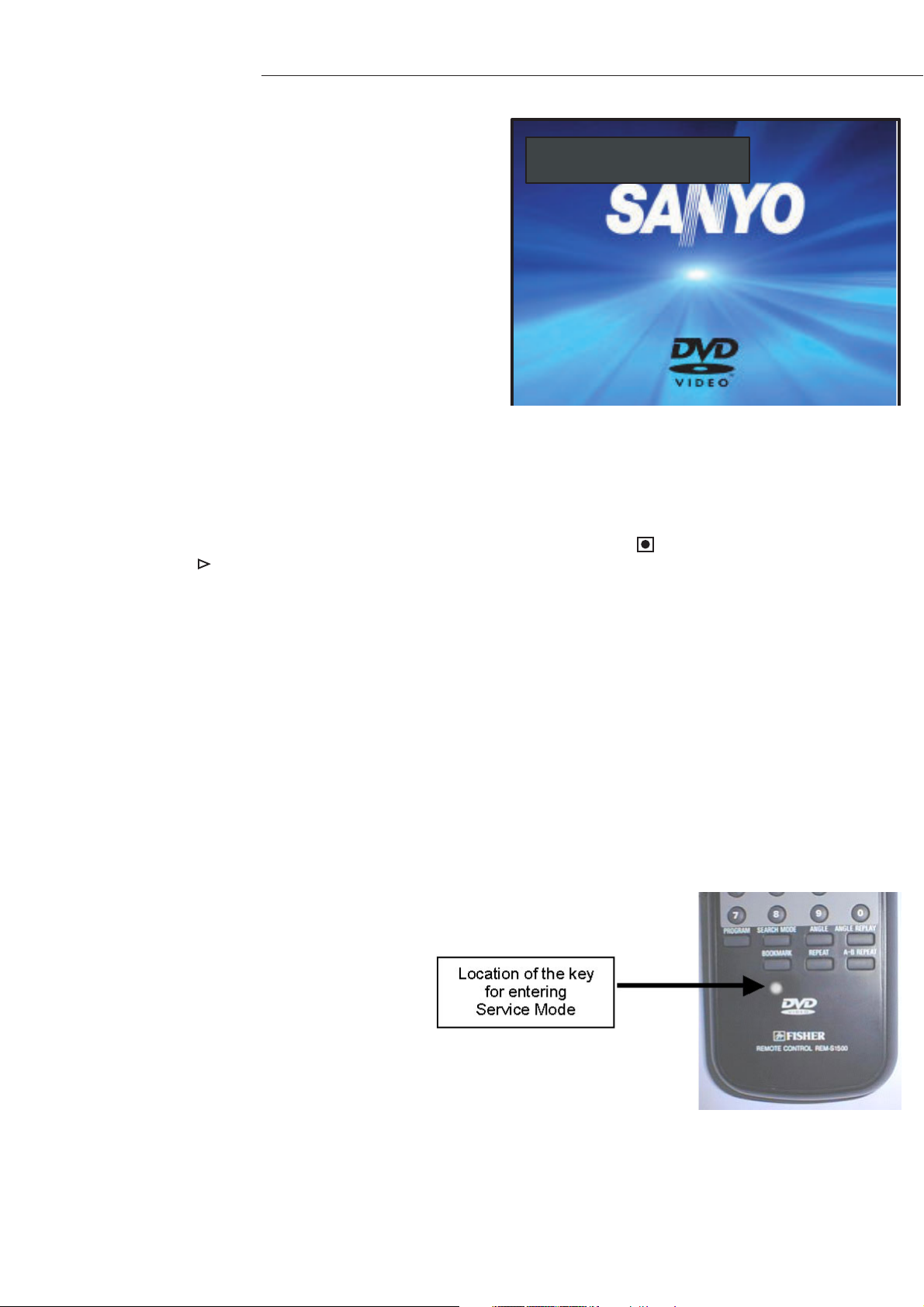

B. How to enter Service Mode.

You can enter Service Mode in any one of the following ways (1 to 3).

1. Using the buttons on the main unit

1-1. Dislay on "No Disc" by Function button.

1-2. Immediately (within one second) after pushing sound preset button both and buttons simultaneously,

push button.

Region Undefined

2. Pushing the covered key located beneath Book Mark key on RB-

1500 or REM-S1500.

3. Simultaneously pushing both Shift key and ON SCREEN key on RB-TS780.

- 2 -

Page 4

SERVICE MODE

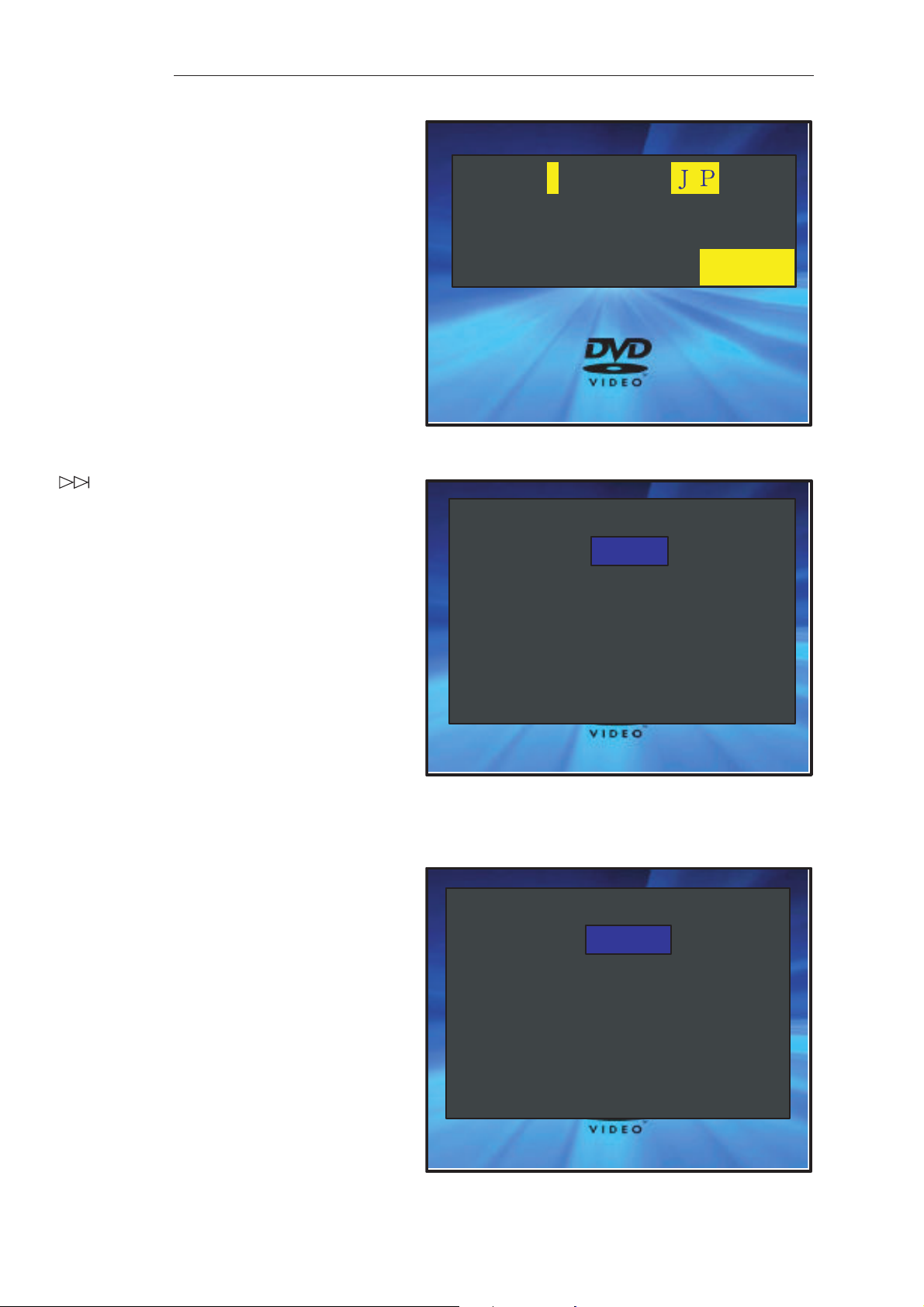

C. Setup Procedures

1. Displaying SERVICE MODE screen

Display Service Mode screen following the instructions "How to

enter Service Mode" above.

2. Displaying Internal Setup screen

Push button within three seconds after operating the

Service Mode display.

On the Internal Setup screen shown on the right, set up Market

and Region.

Region 0 Market

BackendVersion

S

31130

Loader Version 17 Z09 Y03

Value

(Reference figure)

Internal Setup

Market WM

09

A0

3. Setting Market code

3.1. While a highlighted indicator is displayed on the right side

of the Market denotation, push numeric buttons on the

remote controller.

When you push wrong number , push CLEAR button.

(The indicator reset to "00")

Be sure to input by double figures.

Maket code of UK model is "02", and XE model is "03".

Region 2

Exit

00-WM 01-SFC 02-UK 03-XE 04-S18

SS 06-PA 07-AU 08-CN 09-JP

0510-FXE 11-MX 12-NT

(Reference figure)

Internal Setup

Market WM

00

Region 1

Exit

3.2. Specify the code of the model in accordance with the

Market/Region Setup Table above.

3.3 Once the desired code is displayed, push p button to

move the highlighted indicator to the Region input area.

- 3 -

00-WM 01-SFC 02-UK 03-XE 04-S18

05-

SS 06-PA 07-AU 08-CN 09-JP

10-FXE 11-MX 12-NT

(Reference figure)

Page 5

SERVICE MODE

4. Setting REGION code

4.1 While a highlighted indicator is displayed on the right side

of the Region denotation, push ENT, and each button

on the remote controller. With each push the indicator will

advance as shown below.

1 <-> 2 <-> 3 <-> 4 <-> 5 <-> 6

4.2 Set up the region coder currently displayed on the set.

4.3 Once the desired number is displayed, push p button to

move the highlighted indicator to Exit area.

Internal Setup

Market 00

Region 1

1

Exit

00-WM 01-SFC 02-UK 03-XE 04-S18

05-

SS 06-PA 07-AU 08-CN 09-JP

10-FXE 11-MX 12-NT

(Reference figure)

The sample of a display of a region

3

code.

5. Saving settings

5.1 Make sure that the Market and Region settings are properly

set.

(If any of the settings are incorrect, you can make a change

by moving the indicator using o button, and following

procedures 3 and 4 above. )

5.2 After ensuring that the settings are all correct, push ENT

button while the indicator is on Exit area. The settings are

now saved.

6. Finishing settings

6.1 After a few seconds, the Internal Setup screen disappears,

and then the Service Mode screen is displayed again for

three seconds as shown on the right.

You should check the settings.

Backend version

Brand (S : SANYO , F : FISHER)

Version ( 2 0 0 2 . 12 . 25)

Sub Version (A,B,......Z)

Region ( 0 : Region undefined

1 ~ 6 : Region defined )

Loader Version (17 Z09 Y03)

S 31204 A 2

Internal Setup

Market 00

Region 1

00-WM 01-SFC 02-UK 03-XE 04-S18

05- SS 06-PA 07-AU 08-CN 09-JP

10-FXE 11-MX 12-NT

Exit

(Reference figure)

Region 2 Market

BackendVersion

Loader Version 17

31204A2

S

Z09 Y03

Value

6.2 Power OFF.

(Reference figure)

- 4 -

Page 6

SERVICE MODE

D. IMPORTANT NOTE

1. Once the "Market/Region" settings are written into EEPROM (IC801) on the DVD substrate, they cannot be reset.

(However, updating the system using CD-R enables you to make new settings.)

2. While the Internal Setup screen is displayed, pushing the Power button enables you to terminate the operations without

making any settings.

HOW TO LOAD SOFTWARE FOR MPEG P.W.BOARD

1. Power on, then open disk lid.

2. The function key of remote control is pushed and it is made DVD/CD mode.

3. It take on CD-ROM for UPDATE software to the tray, and disk lid close.

4. It is displayed on a screen as "Reading" and is displayed on LCD as "READING."

5. A screen will become noise-like if UPDATE is started.

Cautions) update is not ended even if rotation of a disk stops.

3. For the time being, tray open and FL display remain "UP DATING".

4. Loading of software will be completed, if update is started and about 60 seconds pass,

then the display of "update" of LCD will be "GOOD-BY" and disappears soon.

5.The disk for update is taken out.

6. Next, set up market code and region code by "SERVICE MODE"

CD-ROM part code is "0PRADC9695--A".

CAUTIONS FOR PWB OR IC ASSY EXCHANGE

After an MAIN board(614 329 5587) or IC ASSY(410 507 6601) exchange should carry out loading of the software by the

newest CD-R, and should check operation.

CAUTIONS FM ANTENNA WIRE

The knot is made so that FM antenna line may not enter during a set of a line. If it enters in a set of FM antenna line, There is a

danger that a line will melt into the high-fever part in a set.

Be careful of below at things at the time of disassembly of a set, and an assembly.

At the time of disassembly of a set

Remove thermal shrinkage tube, and disassemble a set after loosening the knot of a line.

At the time of the assembly of a set

Make a knot to the place distant from the end of a line 885mm or more, fix a knot to it by thermal shrinkage tube(parts code :

614 330 9918 ULSUMITUBE-F2,D4.0), and a line should not enter it from a knot.

REAR CABINET

885 mm or more

FM ANT.

Thermal shrinkage tube

(parts code : 614 330 9918 ULSUMITUBE-F2,D4.0)

- 5 -

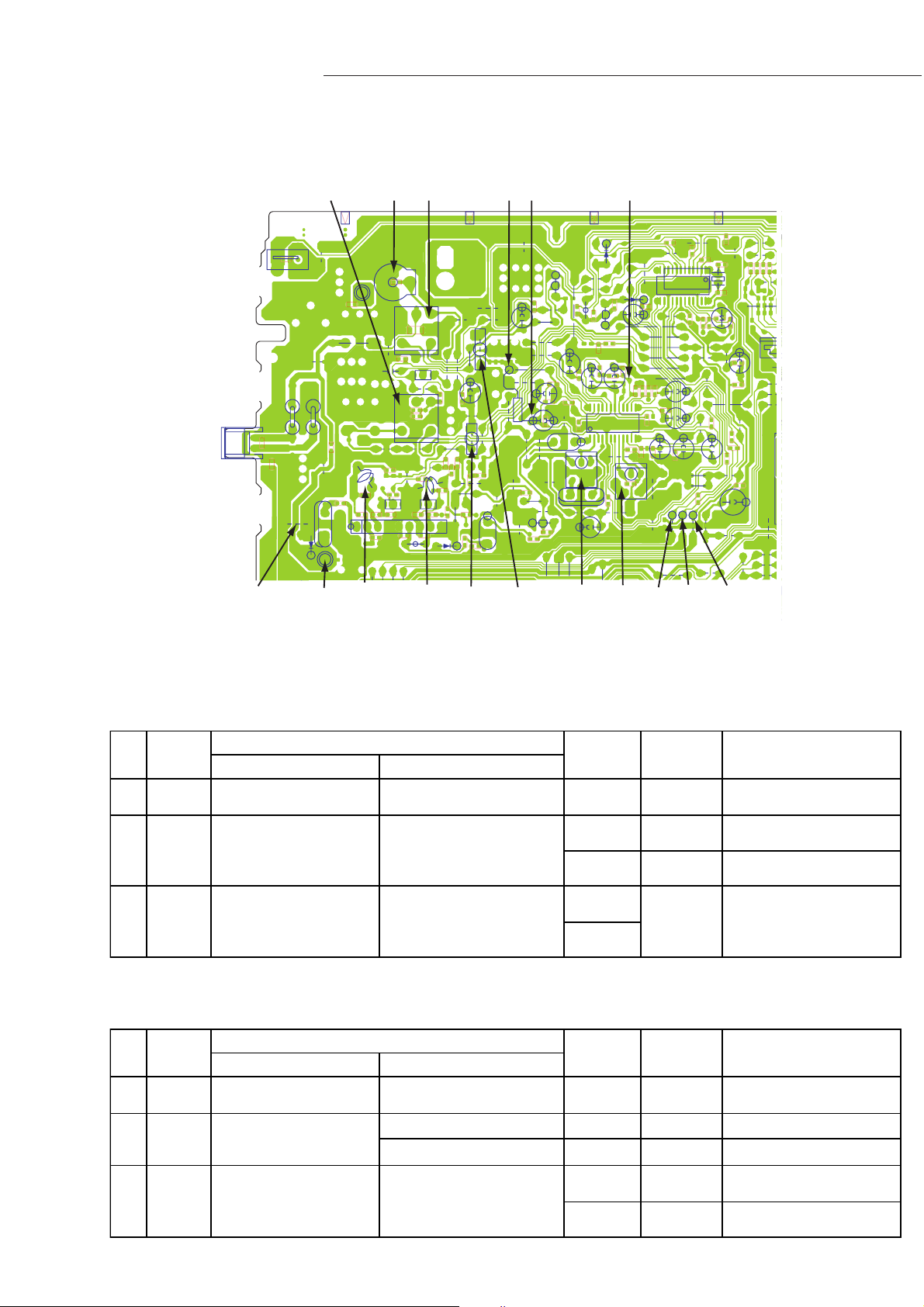

Page 7

'

TUNER ADJUSTMENT

E

E

D

4

TU DI

4

0

0

2

J

• Use a plastic screw driver for adjustments. • MODE : ST (Stereo)

• Speaker impedance : 8 ohms • TUNING FM : 87.5 - 108MHz

AM : 522 - 1710 kHz

L2151

1. FM

Adjusting

Step

1

Adjustment

2 Cover

Circuit

IF

DIP

FM ANT.(E)

CN203

SG202

J2102

C2105

1

XF211

C2102

C2107

LA1186N

C2101

CT252

C2151

J2029

C2103

L2102

R2103

R2102

C2141

J2019

R2149

L2153

C2113

D2153

C2154

R2131

J2030

R2106

J2034

D2101

R2107

IC211

L2104

J2017

J2023

J2035

D2102

C2112

CT252

L2151

C2152

R2101

L2103

C2111

R2108

D2104

J2210

C2115

L2153

ABCD

ABCD

C2600

J2007

S2001

J2020

L2101

L2100

CN202

SG201

C2998

R2100

J2038

R2111

J2219

D2103

CN201

FM ANT.(H)

J4418

L2102

4420

4421

4422

4423

L2103

4131

26

Antenna : 75Ω unbalanced direct, Modulation : 1 kHz

Dev. : ±22.5kHz(MONO), ±22.5kHz(STEREO),±6.75kHz(PILOT)

RF Level : dBuV EMF

Output Level : about 100mV at TP13, TP14, TP15

Connection

Input Output

FM Ant

SG=66dBµV

---

IC231 3-22Pin

TP11 (H)

TP12 (E)

J2203

J2014

R2148

J2211

R2151

J2026

J2031

TP11(H)

C2104

C2106

R2120

R2105

J2217

R2202

C2109

C2110

R2109

XF221

R2110

C2114

TP11

R4123

4129

TP24,25

J2015

C2116

TP25

J2208

TP12(E)

J2032

C2140

J2212

C2303

J2033

J2036

J2040

TP12

R4121

4127

J2106

J2209

J2024

0V-ADJ

J2214

C2203

R2203

J2046

TP24

J2001

J2012

R2456

R2140

J2205

J2207

J2215

J2041

E

R2201

J2009

E

J2011

Q2451

R2459

L2451

R2460

J2206

Q2450

E

C2314

R2303

C2311

C2317

C2308

C2310

C2313

R2302

IC231

24

C2323

C2312

T2002

XF231

Q2201

J4412

J2028

J2042

J4413

C2318

1

IC231

LA1844ML

C2304

XF222

J2039

R2204

J4411

T2002

SG

Frequency

98.0MHz XF233

87.5MHz

108.0MHz

TP26

D2453

R2450

C2307

R2309

C2302

J2213

XF233

R2358

J2218

C2301

J4414

VGND

XF233

D2450

R2451

R2308

13

12

R2304

AGND

DVD/TV-L

0

J2008

C2328

C2309

R2307

C2330

DVD/TV-R

J2201

C2464

J2004

12

J2202

IC241

IC241

LC72121M

C2451

13

J2013

J2204

C2452

J2101

J2103

J2104

J2105

J2107

C2316

C2320

C2319

C2327

C2315

C2321

R2305

R2306

R2301

R2311

GND

L_CH

J2216

J2044

J2043

J2047

D9V

DGND

DGND

LID_SW

FR_GND

J4416

TP15

TP13

1

Adjustment

L2103

---

C2463

C2461

24

R2452

J2016

J2018

J2022

C2305

R2712

R_CH

J2045

D5.6V

D-MUTE

J4016

J2002

C2462

J2005

1

J2006

C2453

R2464

R2462

R2461

R2463

J2010

X2451

C2454

J4400

C2456

C2457

R2453

J2021

J2108

C2322

J2027

J2037

C2901

J2048

J4012

+9.0V

DVD_PCON

C2455

CN400

R2455

R2454

R2801

C2306

R2812

R2701

J4019

J2025

C2902

C2458

J4013

J4015

J4018

GND

TU_DOUT

J4

J44

J4

J44

J

CN445

J4408

TP14

R4602

Confirm voltage is < 8.0V

Remark

0.0±0.05V

About 1.1V

Tracking3

2. AM

Adjusting

Step

Circuit

1

Adjustment

2

Voltage

3 Tracking

IF

Cover

FM Ant

SG=8dBµV

Input

Loop Ant

---

Loop Ant

SG=80dBµV/m

Connection

TP13 (L)

TP14 (R)

TP15 (E)

Anntena : IRE Loop(SG), Moduration : 1kHz 30%

RF Level : dBuV EMF

Output Level : about 100mV at TP13, TP14, TP15

Output

IC231 19Pin_DCCUT

(TP26)-GND

TP11 (H)

TP12 (E) 1710kHz

TP13 (L)

TP14 (R)

TP15 (E)

- 6 -

90.0MHz

L2102 Max.

106.0MHz

SG

Frequency

522kHz T2002 Max.

522kHz

Adjustment

L2153

---

Confirm voltage is < 8.5 V.

603kHz L2151 Max.

1404kHz CT252 Max.

Remark

1.0±0.1V

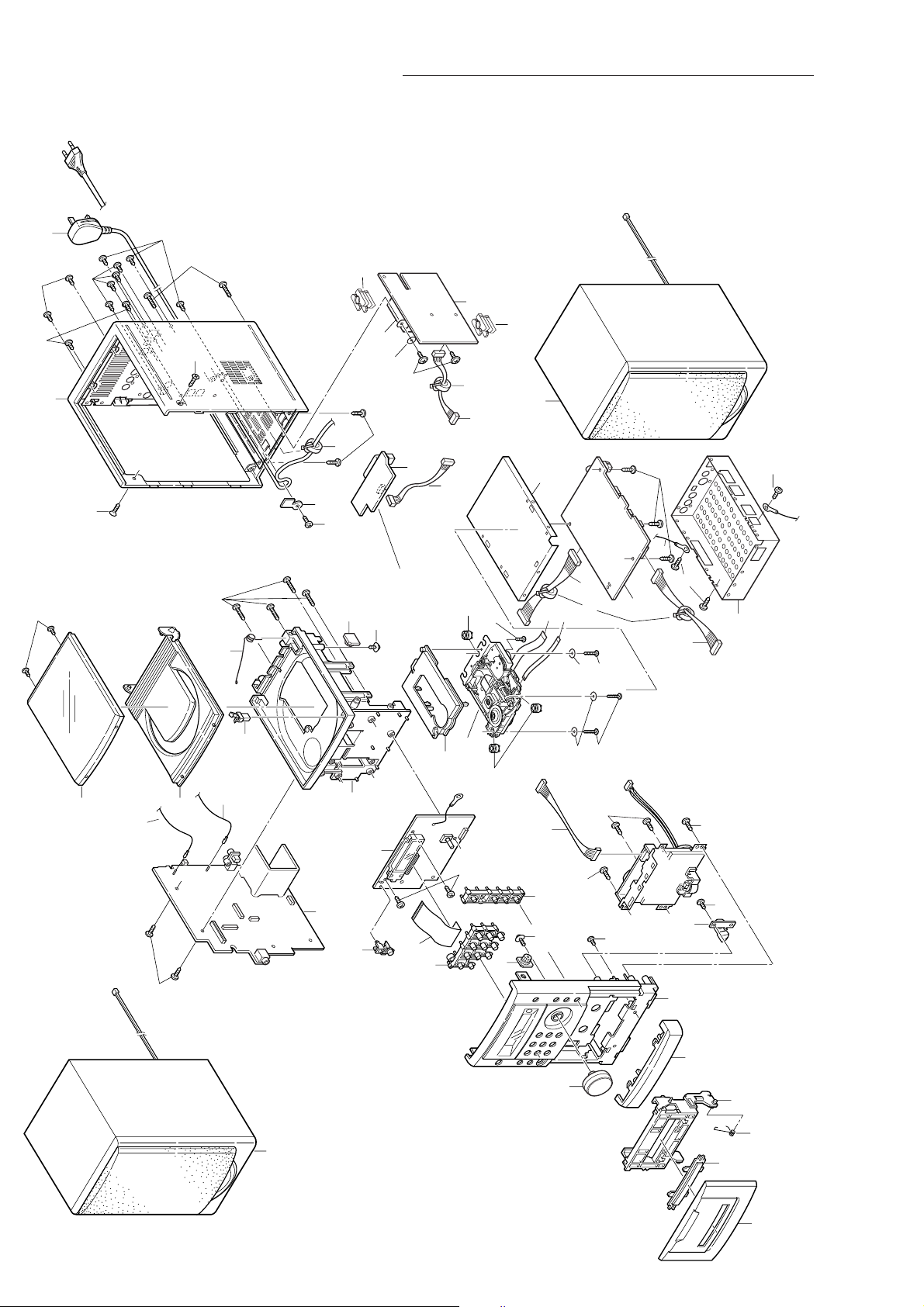

Page 8

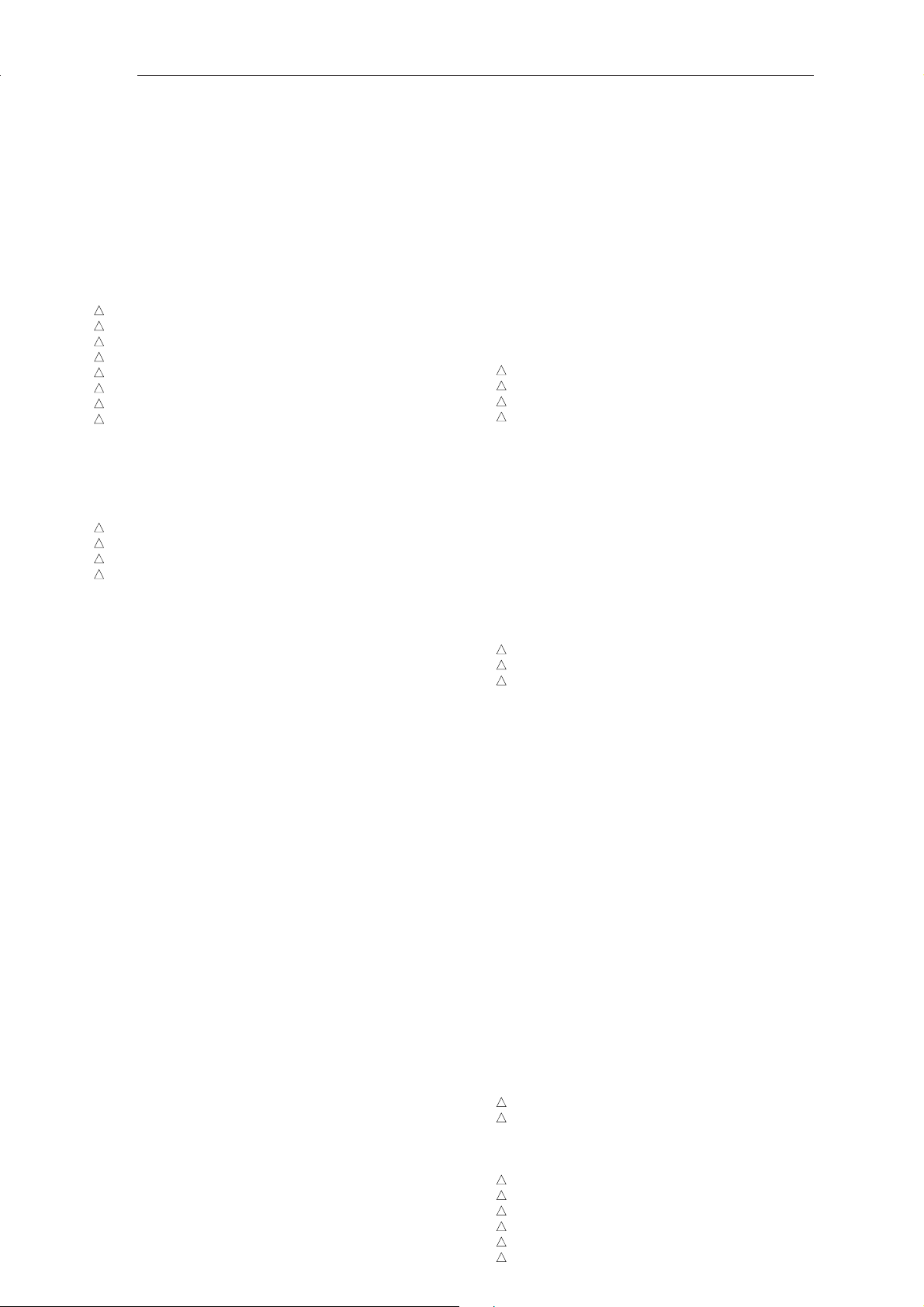

EXPLODED VIEW (CABINET & CHASSIS)

60(UK)

60(XE,SS,KR)

Y05

Y01

Y06

Y15

Y13

Y17

Y19

Y18

Y20

Y20

Y21

Y24

Y24

Y21

Y25

Y14

Y16

Y02

1

2

3

4

5

6

7

8

9

10

13

14

15

15

72

16

71

73

30

27

25

26

62

59

61

20

18

19

21

22

11

74

12

17

53

58

51

30

54

55

56

57

52

Y03

Y03

Y07

Y09

Y10

Y09

Y10

Y12

Y07

Y08

Y03

28

29

29

Y11

52

62

63

75

SCART PWB(UK,XE Only)

- 7 -

Page 9

PARTS LIST

PRODUCT SAFETY NOTICE

EACH PRECAUTION IN THIS MANUAL SHOULD BE FOLLOWED DURING SERVICING. COMPONENTS IDENTIFIED WITH THE

!!

IEC SYMBOL

PERFORMANCE CAN BE OF SPECIAL SIGNIFICANCE. WHEN REPLACING A COMPONENT IDENTIFIED BY

REPLACEMENT PARTS DESIGNATED, OR PARTS WITH THE SAME RATINGS OF RESISTANCE, WATTAGE OR VOLTAGE THAT

ARE DESIGNATED IN THE PARTS LIST IN THIS MANUAL. LEAKAGE-CURRENT OR RESISTANCE MEASUREMENTS MUST BE

MADE TO DETERMINE THAT EXPOSED PARTS ARE ACCEPTABLY INSULATED FROM THE SUPPLY CIRCUIT BEFORE

RETURNING THE PRODUCT TO THE CUSTOMER.

CAUTION : Regular type resistors and capacitors are not listed. To know those values, refer to the schematic diagram.

PACKING & ACCESSORIES

REF.NO. PART NO. DESCRIPTION

30 614 330 1028 ASSY,BOX,SPEAKER(UK)

30 614 330 1721 ASSY,BOX,SPEAKER(XE)

CABINET & CHASSIS

REF.NO. PART NO. DESCRIPTION

1 614 319 6983 COVER,DECK(UK)

1 614 325 7981 COVER,DECK(XE)

2 614 319 7003 DEC,WINDOW,DECK(UK)

2 614 326 3043 DEC,WINDOW,DECK(XE)

3 614 320 3520 SPRING,WIRE,DOOR DECK

4 614 319 7096 LID,CASSETTE

5 614 329 0469 PANEL

6 614 329 5228 ASSY,PANEL FRONT(XE)

6 614 329 5211 ASSY,PANEL FRONT(UK)

7 614 319 7072 KNOB,VOLUME

8 614 303 1277 LATCH,CAM,DECK DOOR LOCKING

9 614 309 7969 ASSY,GEAR,LID CASSETTE

10 614 330 0816 BUTTON,OPERATION,11 KEYS(UK)

10 614 330 0809 BUTTON,OPERATION,11 KEYS(XE)

11 614 319 6945 BUTTON,RIGHT,4 KEYS

12 614 325 7974 BUTTON,POWER

13 614 328 7322 SHIELD,MPEG

14 614 328 7254 MOUNTING,MPEG

15 614 325 5369 SPACER,MECHA,BASE MECHA FIX

16 614 328 7193 COVER,PICK UP

17 614 328 7261 MOUNTING,DVD

18 614 322 2125 ASSY,GEAR,LID DVD

19 614 303 0263 LATCH,PUSH,DVD DOOR LOCKING

20 614 328 8442 SPRING,LID DVD

21 614 328 7247 LID,DVD

22 614 330 0847 DEC,WINDOW,DVD(XE)

22 614 330 0854 DEC,WINDOW,DVD,LID(UK)

25

27 614 329 5150 ASSY,CABINET,REAR(XE)

27 614 329 5143 ASSY,CABINET,REAR(UK)

!

IN THE PARTS LIST AND THE SCHEMATIC DIAGRAM DESIGNATED COMPONENTS IN WHICH SAFETY AND

!!

!

, USE ONLY THE

Regular type resistors are less than 1/4 W carbon type and 0 ohm chip resistors.

Regular type capacitors are less than 50 V and less than 1000 µF type of Ceramic type and Electrical type.

REF.NO. PART NO. DESCRIPTION

28 614 328 2877 ASSY,MECHA,

645 063 7483 ASSY,ANTENA,LOOP

645 066 9330 CABLE,VIDEO,CABLE,VIDEO

614 329 5303 CARTON CASE(UK)

614 329 5310 CARTON CASE(XE)

614 329 0315 CUSHION,FRONT

614 329 0322 CUSHION,REAR

614 329 5365 INSTRUCTION MANUAL(UK)

614 329 5372 INSTRUCTION MANUAL(XE)

614 329 5426 INSTRUCTION MANUAL,GREEK(XE)

645 037 8102 POLY BAG-0150X0500*NC,

AC CORD(UK)

645 042 3628 POLY BAG-0150X0500*NC,

AC CORD(XE)

645 067 3887 POLY BAG-0180X0250*NC,

ACCESSORY

645 066 4410 POLY BAG-0250X0350*NC,

INST MANUAL

645 066 3864 POLY SHEET-0900X0300*NC,

SET(UK)

645 067 5164 POLY SHEET-0900X0300*NC,

SET(XE)

645 064 9356 REMOCON,RB-PT70,RB-PT70

29 614 329 8465 MOUNTING,TRANS,

FIXING PARTS

REF.NO. PART NO. DESCRIPTION

Y01 411 156 2105 SCR S-TPG BIN 2.3X6,

Y02 411 021 3503 SCR S-TPG BIN 3X10,

Y03 411 021 3503 SCR S-TPG BIN 3X10,

Y05 411 020 8905 SCR S-TPG BRZ+FLG 3X10,

Y06 411 021 3503 SCR S-TPG BIN 3X10,

Y07 411 021 6405 SCR S-TPG BIN 3X8,

Y08 411 021 6405 SCR S-TPG BIN 3X8,MPEG FIX

Y09 411 132 4703 SCR S-TPG BIN 2X10,DVD MECHA

Y10 411 185 0103 WASHER Z 2.1X9.5X0.5,

Y11 411 153 0708 WASHER Z 3X15X0.8,

Y12 411 021 0809 SCR S-TPG BIN 2X6,

Y13 411 020 8905 SCR S-TPG BRZ+FLG 3X10,

Y14 411 021 4906 SCR S-TPG BIN 3X20,

Y15 411 021 3503 SCR S-TPG BIN 3X10,

Y16 411 184 0906 SCR S-TPG BIN 2.3X10,

Y17 411 098 4403 SCR S-TPG BIN 3X25,

Y18 411 021 3503 SCR S-TPG BIN 3X10,

Y19 411 098 4403 SCR S-TPG BIN 3X25,

Y20 411 098 7800 SCR S-TPG FLT 3X12,

Y21 411 021 6405 SCR S-TPG BIN 3X8,

Y24 411 021 3404 SCR S-TPG BIN 3X10,REAR+OUT

Y25 411 021 3404 SCR S-TPG BIN 3X10,

KIT800 SE BASE,BASE MECHA

TRANS

PANEL+PANEL FRONT

F-PANEL+LATCH CAM

F-PANEL+DECK MECHA

MTG DVD+ASSY.GEAR LID DV

FRONT PWB+MTG DVD

SHIELD MPEG FIX

DVD MECHA

REAR+P-TRANS

DVD MECHA COVER

F-PANEL+ASSY.GEAR DECK

F-PANEL+MOUNTING DVD

MAIN PWB +MTG DVD

LID DVD+DEC WINDOW DVD

REAR+P-TRANS

REAR+PWB STOPPER

REAR+PANEL FRONT

REAR+MTG(L/R)

SHIELD BOTTOM

SHIELD REAR FIX(XE)

ELECTRICAL-PARTS

REF.NO. PART NO. DESCRIPTION

26 645 031 7637 CORE,FERRITE,FOR AC CORD

or 645 051 0649 CORE,FERRITE,FOR AC CORD

51 614 329 9516 ASSY,WIRE,AMP-DECK

52 614 330 9093 CORD,1P CONNECTOR,

!!

!

614 330 0465 PWB,STOPPER,STOPPER

53 645 067 5577 FLEXIBLE FLAT CABLE

54 614 330 6122 ASSY,WIRE,AMP-DVD

55 614 329 0414 ASSY,WIRE,FRONT-DVD

- 8 -

TUNER GND-SHIELD

Page 10

PARTS LIST

REF.NO. PART NO. DESCRIPTION

56 645 066 2430 FLEXIBLE FLAT CABLE,MECHA

57 645 066 2423 FLEXIBLE FLAT CABLE,PICK-UP

58 614 274 2013 CORD,ID CONNECTOR,FM ANT

59 614 329 3170 ASSY,WIRE,AMP-DG

!!

60

or

or

60

or

61

!

645 036 9797 CORD,POWER-1.6MK,FOR UK(UK)

!!

!

645 036 9803 CORD,POWER-1.6MK,FOR UK(UK)

!!

!

645 054 0233 CORD,POWER-1.6MK,FOR UK(UK)

!!

!

645 016 9939 CORD,POWER-1.74MK,FOR XE(XE)

!!

!

614 255 2513 POWER CORD,FOR XE(XE)

!!

!

645 067 0282 TRANS,POWER

62 645 051 0656 CORE,FERRITE,

DG-MAIN,DVD-MAIN,FRONT-DVD

or 645 042 8999 CORE,FERRITE,

DG-MAIN,DVD-MAIN,FRONT-DVD

63 614 330 6139 ASSY,WIRE,DVD-SCART

FRONT P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

71 614 329 9851 ASSY,PWB,FRONT(UK)(Only initial)

71 614 330 1738 ASSY,PWB,FRONT(XE)(Only initial)

BRC60 614 328 7209 COVER,LED,COVER_LED

BRH60 614 328 7230 HOLDER,LCD,HOLDER_LCD

BRS60 614 327 1512 DEC,SHEET,LCD,DEC_SHEET_LCD

CN601 645 009 8444 SOCKET,FFC 24P

CN602 614 310 2656 PLUG,9P

or 645 006 0960 PLUG,9P

D6211 407 225 7300 LED LT03B3-43-URE1(UK)

D6211 408 053 4004 LED LT0334-43-UBC1,

DS601 407 232 4002 PHOTO DIODE SPS-440-1-VG

IC601 410 507 6908 IC LC877440A-53C2

IC602 410 429 7908 IC AT24C02N-10SI-2.7

or 410 448 8504 IC S524A40X21-SCB0

or 410 448 8405 IC S524A40X21-SCT0

IC603 409 575 1908 IC PST3645U

L6010 645 001 4550 INDUCTOR,10U K

LCD61 645 065 1656 LCD

LG601 614 129 9082 LUG

Q6108 405 011 8500 TR 2SC1740S-R

or 405 011 8609 TR 2SC1740S-S

or 405 017 9600 TR 2SC3330-T

or 405 017 9709 TR 2SC3330-U

or 405 143 8706 TR KTC3199-GR

Q6211 405 000 3806 TR DTC114YS

or 405 143 0007 TR KRC107M

Q6212 405 000 3806 TR DTC114YS

or 405 143 0007 TR KRC107M

Q6271 405 000 3806 TR DTC114YS

or 405 143 0007 TR KRC107M

Q6272 405 004 4601 TR 2SA608-F-SPA

or 405 004 5103 TR 2SA608-G-SPA

or 405 006 1806 TR 2SA933S-R

or 405 006 1905 TR 2SA933S-S

or 405 143 6504 TR KTA1267-GR

S6001 645 054 1230 SWITCH,ROTARY(ENCODER)

S6110 614 220 5471 SWITCH,TACT

or 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6111 614 220 5471 SWITCH,TACT

or 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6112 614 220 5471 SWITCH,TACT

or 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6113 614 220 5471 SWITCH,TACT

or 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6114 614 220 5471 SWITCH,TACT

or 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6115 614 220 5471 SWITCH,TACT

or 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

AMBER_LED(XE)

REF.NO. PART NO. DESCRIPTION

S6116 614 220 5471 SWITCH,TACT

or 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6117 614 220 5471 SWITCH,TACT

or 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6210 614 220 5471 SWITCH,TACT

or 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6211 614 220 5471 SWITCH,TACT

or 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6212 614 220 5471 SWITCH,TACT

or 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6213 614 220 5471 SWITCH,TACT

or 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6214 614 220 5471 SWITCH,TACT

or 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6215 614 220 5471 SWITCH,TACT

or 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6216 614 220 5471 SWITCH,TACT

or 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6217 614 220 5471 SWITCH,TACT

or 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

SG601 645 055 3202 SURGE-ABSORBER

X6000 645 032 1627 OSC,CRYSTAL 32.768KHZ,XTAL

X6102 645 018 6103 OSC,CERAMIC 6.000MHZ,6MHZ

DVD P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

72 614 329 5587 ASSY,PWB,DVD(Only initial)

C8535

CN100 645 065 3797 SOCKET,FPC 24P

CN110 614 310 2595 PLUG,3P

or 645 005 8226 PLUG,3P

CN162 645 057 5945 SOCKET,FPC 6P

CN870 645 037 3831 JACK,RCA

CN871 407 234 1801 PHOTO COUPLE GP1FA513TZM

CN873 614 310 2656 PLUG,9P

or 645 006 0960 PLUG,9P

CN874 614 310 2694 PLUG,13P

or 645 005 8233 PLUG,13P

CN875 614 310 2663 PLUG,10P

or 645 006 0977 PLUG,10P

D1000 407 221 1906 DIODE KDS121E

or 407 162 8507 DIODE DAN222

D1001 407 221 1807 DIODE KDS120E

or 407 179 1805 DIODE DAP222

D1002 407 149 0807 DIODE 1SS355

D1700 407 149 0807 DIODE 1SS355

IC100 409 564 4507 IC LA9703WLS-MPB

or 409 518 1507 IC LA9703WL-MPB

IC101 409 543 7208 IC KTC801U-Y

IC102 409 543 7208 IC KTC801U-Y

IC130 409 564 5702 IC LC78663NRW-UST

or 409 531 6107 IC LC78663NRW

IC131 410 433 0308 IC M11L416256SA-35T

IC160 409 562 8804 IC IKE80-E

IC800 409 546 2002 IC ZR36748

IC801 410 448 8405 IC S524A40X21-SCT0

or 410 448 8504 IC S524A40X21-SCB0

or 410 429 7908 IC AT24C02N-10SI-2.7

IC802 409 505 0803 IC PST3627U

IC806 410 430 9403 IC 74VHCT08AMTCX

IC807 409 521 9606 IC CD4066BCM

- 9 -

!!

!

403 373 7902 ELECT 150U M 6.3V

Page 11

PARTS LIST

IC818 410 507 6601 IC ASSY

(IC SST39VF800A-70-4C-EK or

SST39VF800-70-4C-EK or

LE28DW8163T-70T-MPB or

IC822 410 470 5007 IC M12L16161A-7T

or 410 453 9602 IC LC3816161ET-70-MPB

or 409 482 0209 IC K4S161622D-TC80

or 409 482 0209 IC K4S161622D-TC80

!!

IC850

IC851

IC852

!

409 534 5800 IC PQ2L2182MS

!!

!

409 509 9208 IC PQ070XZ01Z

!!

!

409 543 0100 IC PQ1X501M2Z

IC859 409 489 9700 IC NC7SZ157P6

IC871 409 581 9400 IC PCM1755DBQ,DAC_2CH

IC881 409 543 6409 IC KRX101U

L1002 645 034 7887 INDUCTOR,1000 OHM

or 645 020 1813 INDUCTOR,1000 OHM

or 645 045 7869 IMPEDANCE,1000 OHM P

L1302 645 034 7887 INDUCTOR,1000 OHM

or 645 020 1813 INDUCTOR,1000 OHM

or 645 045 7869 IMPEDANCE,1000 OHM P

L8060 645 034 7887 INDUCTOR,1000 OHM

or 645 020 1813 INDUCTOR,1000 OHM

or 645 045 7869 IMPEDANCE,1000 OHM P

L8202 645 034 7887 INDUCTOR,1000 OHM

or 645 020 1813 INDUCTOR,1000 OHM

or 645 045 7869 IMPEDANCE,1000 OHM P

L8203 645 034 7887 INDUCTOR,1000 OHM

or 645 020 1813 INDUCTOR,1000 OHM

or 645 045 7869 IMPEDANCE,1000 OHM P

L8400 645 040 6430 INDUCTOR,2.2U M

L8410 645 040 6430 INDUCTOR,2.2U M

L8420 645 040 6430 INDUCTOR,2.2U M

L8440 645 040 6430 INDUCTOR,2.2U M

L8582 645 034 7887 INDUCTOR,1000 OHM

or 645 020 1813 INDUCTOR,1000 OHM

or 645 045 7869 IMPEDANCE,1000 OHM P

L8701 645 034 7887 INDUCTOR,1000 OHM

or 645 020 1813 INDUCTOR,1000 OHM

or 645 045 7869 IMPEDANCE,1000 OHM P

Q1005 405 158 5905 TR KTA1505-Y

or 405 035 5509 TR 2SA1036K-R

Q1006 405 158 5905 TR KTA1505-Y

or 405 035 5509 TR 2SA1036K-R

Q1007 405 146 1605 TR KRC102S

or 405 132 3101 TR DTC114EKA

Q8000 405 151 6107 TR KRA107S

or 405 141 5707 TR DTA114YKA

Q8001 405 159 0503 TR KRC107S

or 405 141 5608 TR DTC114YKA

Q8313 405 159 0503 TR KRC107S

or 405 141 5608 TR DTC114YKA

Q8314 405 159 0503 TR KRC107S

or 405 141 5608 TR DTC114YKA

RN100 645 057 4252 R-NETWORK 8.2KX4 1/16W

RN101 645 057 4290 R-NETWORK 47KX4 1/16W

RN103 645 057 2159 R-NETWORK 1KX4 1/16W

RN131 645 057 2135 R-NETWORK 47X4 1/16W

RN132 645 057 2135 R-NETWORK 47X4 1/16W

RN133 645 057 2135 R-NETWORK 47X4 1/16W

RN801 645 057 4238 R-NETWORK 33X4 1/16W

SG872 645 055 3202 SURGE-ABSORBER

SG873 645 055 3202 SURGE-ABSORBER

X1500 645 065 2479 OSC,CERAMIC 16.93MHZ

or 645 059 7060 OSC,CERAMIC 16.93MHZ

or 645 017 0157 OSC,CERAMIC 16.93MHZ

X8230 645 053 4270 OSC,CRYSTAL 27.000MHZ

or 645 045 8293 OSC,CRYSTAL 27.000MHZ

MAIN,AMP-TUNER P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

73 614 329 5617 ASSY,PWB,MAIN,A

SST39VF800A-70-4C-EK,D)

MP-TUNER(Only initial)

REF.NO. PART NO. DESCRIPTIONREF.NO. PART NO. DESCRIPTION

C2457 403 259 0508 NP-ELECT 1U M 50V

C4134 403 058 4608 POLYESTER 0.15U J 50V

C4136 403 350 8403 ELECT 1000U M 16V

or 403 366 5205 ELECT 1000U M 16V

C4234 403 058 4608 POLYESTER 0.15U J 50V

C4236 403 350 8403 ELECT 1000U M 16V

or 403 366 5205 ELECT 1000U M 16V

C4601 403 057 3503 POLYESTER 0.1U K 50V

C4605 403 061 3605 POLYESTER 0.039U J 50V

C4606 403 396 0201 PORYESTER 4700P J 200V

C4607 403 396 0102 POLYESTER 470P J 200V

C4608 403 060 2807 POLYESTER 0.027U K 50V

!!

C4801

C4805

C4815

!

403 370 3402 ELECT 220U M 35V

!!

!

403 370 3402 ELECT 220U M 35V

!!

!

403 370 3402 ELECT 220U M 35V

CN201 614 221 8273 TERMINAL

CN202 614 310 2298 PLUG,2P

or 645 004 2683 PLUG,2P

CN203 614 221 8273 TERMINAL

CN400 645 009 8444 SOCKET,FFC 24P

CN401 645 006 1875 PLUG,2P,SPEAKER

CN402 645 006 1875 PLUG,2P,SPEAKER

CN410 614 310 2489 PLUG,7P

or 645 006 0861 PLUG,7P

CN420 614 310 2540 PLUG,13P

or 645 006 0885 PLUG,13P

CN440 614 310 2472 PLUG,6P

or 645 005 8127 PLUG,6P

CN442 645 065 5920 JACK,RCA-2

CN443 645 055 1017 JACK,PHONE D3.6,HEADPHONE

or 645 011 6384 JACK,PHONE D3.6,HEADPHONE

CN445 614 310 2502 PLUG,9P

or 645 005 8141 PLUG,9P

CN470 645 046 1866 JACK,RCA

CT252 645 032 5663 TRIMMER,7PF

D2101 407 157 8109 VARACTOR DI SVC211-B

D2102 407 157 8109 VARACTOR DI SVC211-B

D2103 407 012 4406 DIODE 1SS133

D2104 407 012 4406 DIODE 1SS133

D2153 407 105 1305 VARACTOR DI SVC342L-V

or 407 105 1602 VARACTOR DI SVC342M-V

D2450 407 012 4406 DIODE 1SS133

D2454 407 012 4406 DIODE 1SS133

D4400 407 099 5303 ZENER DIODE MTZJ5.6B

D4500 407 012 4406 DIODE 1SS133

!!

D4800

!

408 044 6307 DIODE SB140L 19C2-004

D4801 407 099 5402 ZENER DIODE MTZJ6.2B

!!

D4810

!

408 044 6307 DIODE SB140L 19C2-004

D4811 407 099 6102 ZENER DIODE MTZJ10B

D4820 407 012 4406 DIODE 1SS133

D4830 407 099 6607 ZENER DIODE MTZJ12B

D4851 407 099 6102 ZENER DIODE MTZJ10B

D4852 407 012 4406 DIODE 1SS133

D4860 407 012 4406 DIODE 1SS133

HS401 614 319 7065 HEAT SINK,HEATSINK

IC211 409 016 0200 IC LA1186N-AUDIO

IC231 409 474 3201 IC LA1844ML

IC241 409 439 4502 IC LC72121M-D

IC440 409 451 7406 IC AN7348K

IC441 409 474 6103 IC LC75342M

!!

IC442

!

409 313 0705 IC TA8223K

IC443 409 189 3404 IC BA7755A

!!

IC480

!

409 578 5002 IC SPI-8002TW

L2100 645 006 3602 INDUCTOR,1.1UH

L2101 645 006 3602 INDUCTOR,1.1UH

L2102 645 018 0163 COIL,AIR

L2103 645 018 0255 COIL,AIR

L2104 645 002 1534 INDUCTOR,8.2U K

L2151 645 037 2377 TRANS,ANT,796KHZ

L2153 645 040 2739 TRANS,OSC,796KHZ

L2451 645 001 4581 INDUCTOR,100U K

L4181 645 002 1459 INDUCTOR,22U K

L4182 645 002 1459 INDUCTOR,22U K

L4183 645 034 7887 INDUCTOR,1000 OHM

- 10 -

Page 12

PARTS LIST

or 645 020 1813 INDUCTOR,1000 OHM

or 645 045 7869 IMPEDANCE,1000 OHM P

L4281 645 002 1459 INDUCTOR,22U K

L4282 645 002 1459 INDUCTOR,22U K

L4283 645 034 7887 INDUCTOR,1000 OHM

or 645 020 1813 INDUCTOR,1000 OHM

or 645 045 7869 IMPEDANCE,1000 OHM P

L4600 645 006 1523 INDUCTOR,470U J

L4601 645 006 1523 INDUCTOR,470U J

L4602 645 037 2858 CORE,PIPE

L4603 645 006 1523 INDUCTOR,470U J

L4604 645 037 2858 CORE,PIPE

L4800

or

L4801

L4802

or

L4811

L4812

or

L4820 645 034 7887 INDUCTOR,1000 OHM

or 645 020 1813 INDUCTOR,1000 OHM

or 645 045 7869 IMPEDANCE,1000 OHM P

LUG01 645 006 4425 FIXER

LUG02 645 006 4425 FIXER

LUG20 645 023 8987 FIXER

PR480

PR481

PR482

PR483

Q2201 405 151 4202 TR KTC3193-O

or 405 151 4103 TR KTC3193-Y

or 405 016 0806 TR 2SC2839-E

Q2450 405 143 8706 TR KTC3199-GR

or 405 017 9600 TR 2SC3330-T

or 405 017 9709 TR 2SC3330-U

or 405 011 8500 TR 2SC1740S-R

or 405 011 8609 TR 2SC1740S-S

Q2451 405 151 5209 TR KRA107M

or 405 000 0904 TR DTA114YS

or 405 078 2404 TR BN1A4P

or 405 036 3702 TR 2SA1564

Q4100 405 151 4400 TR KTD1303

or 405 021 0204 TR 2SD1012-F-SPA

or 405 021 0600 TR 2SD1012-G-SPA

or 405 033 6706 TR 2SD1468S-R

or 405 033 6805 TR 2SD1468S-S

Q4101 405 143 0007 TR KRC107M

or 405 000 3806 TR DTC114YS

Q4151 405 151 4400 TR KTD1303

or 405 021 0204 TR 2SD1012-F-SPA

or 405 021 0600 TR 2SD1012-G-SPA

or 405 033 6706 TR 2SD1468S-R

or 405 033 6805 TR 2SD1468S-S

Q4200 405 151 4400 TR KTD1303

or 405 021 0204 TR 2SD1012-F-SPA

or 405 021 0600 TR 2SD1012-G-SPA

or 405 033 6706 TR 2SD1468S-R

or 405 033 6805 TR 2SD1468S-S

Q4201 405 143 0007 TR KRC107M

or 405 000 3806 TR DTC114YS

Q4251 405 151 4400 TR KTD1303

or 405 021 0204 TR 2SD1012-F-SPA

or 405 021 0600 TR 2SD1012-G-SPA

or 405 033 6706 TR 2SD1468S-R

or 405 033 6805 TR 2SD1468S-S

Q4400 405 141 3208 TR KTC3198-Y

or 405 141 3307 TR KTC3198-GR

or 405 019 2708 TR 2SC536-F-NP

or 405 019 3804 TR 2SC536-G-NP

Q4410 405 141 3505 TR KTA1266-Y

or 405 141 3406 TR KTA1266-GR

or 405 004 4502 TR 2SA608-F-NP

or 405 004 5004 TR 2SA608-G-NP

!!

!

645 048 4469 INDUCTOR,22U

!!

!

645 045 8613 INDUCTOR,10U

!!

!

645 065 9362 INDUCTOR,95U

!!

!

645 048 4469 INDUCTOR,22U

!!

!

645 045 8613 INDUCTOR,10U

!!

!

645 065 9362 INDUCTOR,95U

!!

!

645 048 4469 INDUCTOR,22U

!!

!

645 045 8613 INDUCTOR,10U

!!

!

645 042 2683 PROTECTOR,3A 125V

!!

!

645 042 2645 PROTECTOR,1.25A 125V

!!

!

645 042 2683 PROTECTOR,3A 125V

!!

!

645 042 2553 PROTECTOR,0.63A 125V

REF.NO. PART NO. DESCRIPTIONREF.NO. PART NO. DESCRIPTION

Q4500 405 151 6107 TR KRA107S

or 405 141 5707 TR DTA114YKA

Q4501 405 151 6107 TR KRA107S

or 405 141 5707 TR DTA114YKA

Q4600 405 141 3703 TR KTA1271-Y

or 405 008 2405 TR 2SB698-F

or 405 008 2504 TR 2SB698-G

Q4601 405 143 0007 TR KRC107M

or 405 000 3806 TR DTC114YS

Q4602 405 151 4905 TR KTC3200-GR

or 405 151 5001 TR KTC3200-BL

or 405 011 1907 TR 2SC1627-Y

Q4603 405 141 3307 TR KTC3198-GR

Q4830 405 141 3109 TR KTC3203-Y

or 405 024 9907 TR 2SD734-F

or 405 025 0200 TR 2SD734-G

!!

Q4850

or

or

or

!

405 158 2102 TR KTC2026-Y

!!

!

405 138 6403 TR KTD2058Y

!!

!

405 095 1602 TR 2SD2061-E

!!

!

405 095 1701 TR 2SD2061-F

Q4851 405 141 3208 TR KTC3198-Y

or 405 141 3307 TR KTC3198-GR

or 405 019 2708 TR 2SC536-F-NP

or 405 019 3804 TR 2SC536-G-NP

Q4860 405 141 3703 TR KTA1271-Y

or 405 008 2405 TR 2SB698-F

or 405 008 2504 TR 2SB698-G

Q4861 405 141 3703 TR KTA1271-Y

or 405 008 2405 TR 2SB698-F

or 405 008 2504 TR 2SB698-G

Q4862 405 143 0007 TR KRC107M

or 405 000 3806 TR DTC114YS

Q4863 405 143 0007 TR KRC107M

or 405 000 3806 TR DTC114YS

!!

R4141

R4241

R4822

!

402 096 5103 RESISTER 3.3 J- 1/2W

!!

!

402 096 5103 RESISTER 3.3 J- 1/2W

!!

!

402 096 4106 FUSIBLE RES 27 JA 1/4W

S2001 645 023 5795 SWITCH,LEVER

SA401 411 021 6405 SCR S-TPG BIN 3X8

SA402 411 021 6405 SCR S-TPG BIN 3X8

SG201 645 055 3202 SURGE-ABSORBER

SG202 645 055 3202 SURGE-ABSORBER

T2002 645 046 2023 FILTER,450KHZ

X2451 645 023 4965 OSC,CRYSTAL 7.2MHZ

XF211 645 026 2975 FILTER,BP 108MHZ

or 614 252 1045 FILTER,LC

or 645 059 0047 FILTER,BP

XF221 645 010 7665 CERAMIC FILTER 10.70MHZ

or 645 054 1223 CERAMIC FILTER 10.70MHZ

or 614 231 0199 FILTER

or 614 030 5074 I.F FILTER

XF222 645 010 7665 CERAMIC FILTER 10.70MHZ

or 645 054 1223 CERAMIC FILTER 10.70MHZ

or 614 231 0199 FILTER

or 614 030 5074 I.F FILTER

XF231 645 059 0054 CERAMIC FILTER 450KHZ

or 645 041 9324 CERAMIC FILTER 450KHZ

XF233 645 039 9923 TRANS,IF 10.7MHZ

or 645 040 9981 TRANS,IF 10.7MHZ

POWER SUPPLY P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

74 614 329 5679 ASSY,PWB,DG(Only initial)

C4905

or

C4914 403 325 0302 ELECT 2200U M 25V

CN490 614 310 2489 PLUG,7P

or 645 006 0861 PLUG,7P

D4900

D4901

D4902

D4903

D4904

D4910

- 11 -

!!

!

403 349 3303 CERAMIC 0.01U M 250V

!!

!

403 366 7803 CERAMIC 0.01U M 250V

!!

!

407 098 3300 DIODE RL153-BF-S2

!!

!

407 098 3300 DIODE RL153-BF-S2

!!

!

407 098 3300 DIODE RL153-BF-S2

!!

!

407 098 3300 DIODE RL153-BF-S2

!!

!

407 097 8009 DIODE MPG06G

!!

!

407 097 8009 DIODE MPG06G

Page 13

PARTS LIST

REF.NO. PART NO. DESCRIPTION

!!

D4911

D4912

D4913

D4914

!

407 097 8009 DIODE MPG06G

!!

!

407 097 8009 DIODE MPG06G

!!

!

407 097 8009 DIODE MPG06G

!!

!

407 097 8009 DIODE MPG06G

D4920 407 012 4406 DIODE 1SS133

!!

IC490

L4900

or

PA001

!

409 463 6701 IC KIA7805API

!!

!

645 041 3087 INDUCTOR,180U

!!

!

645 038 6053 INDUCTOR,181U

!!

!

614 086 2164 COVER,FOR C4905

Q4920 405 143 8706 TR KTC3199-GR

or 405 017 9600 TR 2SC3330-T

or 405 017 9709 TR 2SC3330-U

or 405 011 8500 TR 2SC1740S-R

or 405 011 8609 TR 2SC1740S-S

!!

RY491

or

T4910

!

645 059 0306 RELAY,PRIMARY

!!

!

645 030 5597 RELAY,PRIMARY

!!

!

645 057 9110 TRANS,POWER

WR490 614 017 8203 TERMINAL BOARD

WR491 614 017 8203 TERMINAL BOARD

EXPLODED VIEW (TAPE DECK MECHANISM)

SCART P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

75 614 329 5624 ASSY,PWB,SCART(Only initial)

CN301 614 310 2663 PLUG,10P

or 645 006 0977 PLUG,10P

CN302 645 041 8433 SOCKET,RGB 21P

D3000 407 206 5608 ZENER DIODE UDZS10B

D3001 407 206 5608 ZENER DIODE UDZS10B

D3002 407 206 5608 ZENER DIODE UDZS10B

L3001 645 001 4550 INDUCTOR,10U K

L3002 645 001 4550 INDUCTOR,10U K

L3003 645 001 4550 INDUCTOR,10U K

SG302 645 055 3202 SURGE-ABSORBER

SG303 645 055 3202 SURGE-ABSORBER

SG304 645 055 3202 SURGE-ABSORBER

SG305 645 055 3202 SURGE-ABSORBER

SG306 645 055 3202 SURGE-ABSORBER

SG307 645 055 3202 SURGE-ABSORBER

SG308 645 055 3202 SURGE-ABSORBER

SH601 614 314 0733 SHIELD,SHIELD

4

Not available as service parts.

This figure is deference figure.

PARTS LIST

DECK MECHANISM ASSY

REF.NO. PART NO. DESCRIPTION

614 329 8441 ASSY,MECHA,TM-PT70TN-SH

1 645 052 2888 RP HEAD C-9142-BD-1025

3 645 010 9447 PINCH ROLLER(F) ASSY

4 645 067 2934 ASSY,MOTOR

5 645 045 1959 RF BELT

6 645 052 4158 MAIN BELT

7 645 045 2048 DETECT SWITCH MXS01190

1

3

7

5

6

- 12 -

Page 14

WIRING CONNECTION

A

E

H

O

N

LCD61

DVD MECHANISM

SCART

P.W.B

(UK,XE Only)

OPTICAL

PICK UP

(24P)

CN002

(6P)

A/V EURO/TV(AUDIO) IN

CN301

(10P)

COMPOSITE

OUT

CN870

CN875

(10P)

CN100

(24P)

CN162

(6P)

CN110

(3P)

S-VIDEO

CN872

CN873

(9P)

OUT

CN871

CN302

OUT

DVD P.W.B

CN874

(12P)

CN400

(24P)

CN601

(24P)

CN445

CN440

(6P)

(10P)

FRONT P.W.B

CN602

(9P)

AMP / TUNER

P. W. B

CN420

(12P)

CN410

(7P)

CN202

(2P)

CN402

(2P)

CN401

(2P)

AM L

FM

SPEAK

L-CH

R-C

A

(10P)

TAPE DECK MECHANISM

POWER SUPPLY

P. W. B

PT490

CN490

(7P)

WR491

WH

WR490

BK

AC IN

- 13 -

This is a basic wiring connection.

Page 15

Functions

Customer OP amp. + input

Power supply (For DPD)

Pickup signal input

Pickup signal input

Pickup signal input

Pickup signal input

Pickup signal input

Ground (For DPD)

Pickup signal input

Pickup signal input

Pickup signal input

Pickup signal input

Pickup signal input

Pickup signal input

APC 1 output

APC 1 monitor input

APC 2 output

APC 2 monitor input

Ground (Servo system)

APC 1 threshold change

APC 1 laser ON

APC 2 laser ON

RFAGC OFF

PH discharge coeffcient change

RF, servo signal gain up

RF, EQL band change

TE output change

WO output change

Power supply (Servo system)

Tracking hold (H:hold)

Tracking bottom band change (High band)

Servo gain control (RREC, FE, PP, TE)

Terminal No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Symbole

CAP

VCC

PDRF

PD1

PD2

PD3

PD4

GND

FIN1

FIN2

PIN1

PIN2

TIN1

TIN2

LDD1

LDS1

LDD2

LDS2

GND

LDTH

LDON1

LDON2

AGOF

BCA

GU

DVD/CD

DPD/TE

WO/PP

VCC

TH

XHTR

SGC

Terminal No Symbole

Functions

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

BST

FC

FEBL

TEBL

CP

RREC

FE

TE

WO

PP

PPN

WOC

ISET

BH

PH

SREFI

BCAI

PHC

SREF

LPC

N/C

RFON

RFOP

GND

FSET

PREF

RFN

N/C

RFP

CAO

VCC

CAN

EQL boost adjusting

EQL I/O control

FE balance adjusting

TE balance adjusting

Charge pump gain setting resistor, condenser connect

Peflection output

Focus error output

Tracking error output

WO/push-pull output

Push/pull output

Push/pull gain setting resistor connect

DC cut capacity connect

BPF center frequency setting resistor connect

RF bottom detection output

RF peak detection output

SREF setting

Peak hold detection setting resistor connect (When SCA)

RF-AGC PH detection conderser connect

Servo signal voltage reference output

RE DC servo condenser connect

N/C

RF - output

RF + output

Ground (RF system)

EQL frequency setting resistor connect

Voltage refernce output (For pick)

RF signal - input

N/C

RF signal + input

Customer OP amp. output

Power supply (RF system)[

Customerm OP amp. - input

IC BLOCK DIAGRAM & DESCRIPTION

IC100 LA9703WL-MPB (DVD Player Frontend Processor)

FSET

PREF

GU

LDON1

N/C

AGOF

AGOF

LDON2

LDON1

RFN

PREF

GU

SGC

AGOF

LDON2

EQ

SREF

BCA GU

AGOF

FC BSTDVD/CD

SGC

SGC

SREF

BCA

CAP

VCC

PDRF

PD1

PD2

PD3

PD4

GND

FIN1

FIN2

PIN1

PIN2

TIN1

TIN2

LDD1

LDS1

RFP

CAO

VCC

CAN

VCC

1

VCC

2

3

4

5

6

7

DPD

SREF

8

9

PREF

10

FEBL

FEBL

11

12

13

PREF

14

LDTH

GND

TEBL

TEBL

LDTH

LDTH

15

APC

16

LDON1

APC

LDON2

17 18 19 20 21 22 23 24 25 27 28 29 30 31 32

LDS2

LDD2

LPC

N/C

RFON

RFOP

GND

SREF

BCA

PH

BCA

PH

BCA

BH

XHTR

BPF

DOOUT

SREF

SREF

DPD/TE

LPF1

LPF2

XHTR

LPF1

LPF2

GU

GU

GU

SGC

DVD/CD DPD/TE WO/PP VCC THTHXHTR SGC

26

GU

DPD/TE

DVD/CD

WO/PP

VCC

SREF

XHTR

TH

SREF

PHC

XHTR

495051525354555657596061626364 58

BCAI

WO/PP

TEBL

FEBL

FC

BST

SGC

SREF1

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

SREF1

PH

BH

ISET

WOC

PPN

PP

WO

TE

FE

RREC

CP

TEBL

FEBL

FC

BST

- 14 -

Page 16

IC BLOCK DIAGRAM & DESCRIPTION

IC130 LC78663NRW (DSP)

FE

TE

RF-PH

RF-BH

JV

RREC

AD0

AD1

BHC

WO

TEC

FG

EVENT

RFP[3:0]

DEFECTI

DEFECTO

EFMP

EFMN

SLCO1

SLCO2

SLCLPF0

SLCLPF1

EFMOUT

PISET

FISET

LF1

LF2

LF3

PCN

PPDO

FPDO

VCOCTL

DVDFR

CDFR

PCK

JVAO

JVAIN

JVRVO

JVCPC

JVCPI

XIN

XOUT

X16MIO

DVDCKIO

VPDO

VCOC

VRPFR

HDAT[7:0]

HADR[12:0]

HRDB

HWRB

HCSB

HWAITB

HWAITB

8

7

5

6

3

4

2

1

19

20

21

36

43

169~172

167

168

10

12

15

16

13

14

104

115

116

111

112

113

114

109

110

108

118

117

105

123

124

125

122

121

134

135

137

139

128

130

129

43,

46~52

53~59,

78~82

40

41

42

38

37

A/D Block D/A BlockServo Block

8 bits

A/D

MPX

RF I/F Block

FC Counter

TR Counter

EV Counter

FG Counter

FG Counter

SLC Block

CLV/CAV Block BCA Buff Block

EFM PLL Block

CD Frame Sync

DVD Frame Sync

EMF Block

Frame Synchronous

protection

Frame Synchronous

internal push

EMF demodulation

CIRC Dec Block

JV Block

CD-ROM Dec Block

CLK GEN Block

SYS PLL Block

DVD Dec Block

CPU I/F Block

8 bits

D/A

(AD0)

(TEC)

(WO)

(RF BH)

(BHC)

DRAM I/F Block

SUBCODE I/F Block

Audio OUT Block

AV Dec I/F Block

CMP

CMP

145~148,150~153,

156~159,161~164

33

32

30

31

29

28

27

26

25

24

23

173

174

90

140

141

142

87

86

85

84

62~65,

68~74

61

76

77

75

60

92

91

93

94

95

97~103

FDO

TDO

SLDO

SPDO

SGC

TBAL

FBAL

BST

FO

TSTDO

TSTDI

TESTO

HFLIO

EMPH

FSX

EFLG

DOUT

LRSY

ROMCK

ROMXA

C2F

MD[15:0]

MA[10:0]

MRASLB

MRASUB

MCASLB

MOEB

MWEB

AVACKO

AVREQI

AVDACK

AVSCTB

AVERRB

AVD[7:0]

- 15 -

Page 17

IC BLOCK DIAGRAM & DESCRIPTION

IC130 LC78663NRW (DSP)

Block

A/D

TEST pin

SLC

TEST pin

Power

supply

CMP

D/A

Power

supply

RF I/F

Microcomputer I/F

Power

supply

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

Pin Name

AD1

AD0

JV

RREC

RF-PH

RF-RH

TE

FE

TEST0

EFMINP

TEST1

EFMINN

SLCLPF0

SLCLPF1

SLCO1

SLCO2

AVDDI

AVSS

BHC

WO

TEC

VREF

TSTD1

TSTD0

FO

BST

TBAL

FBAL

SGC

SLDO

SPDO

TDO

FDO

DVDDO

DVSS

FG

HIRQB

HWAITB

HRESB

HRDB

HWRB

HCSB

HDATO

DVDD1

Supplementation

I/O

Servo A/D AD1

I

Servo A/D AD0

I

Servo A/D JV

I

Servo A/D RREC

I

Servo A/D RF-PH

I

Servo A/D RF-BH

I

Servo A/D TE

I

Servo A/D FE

I

Test input 0

I

(Input "L" level)

EFM/EFM+ Input

I

Test input 1

I

(Input "L" Input)

EFM- Input

I

SLC

SLC

SLC

SLC

A/D D/A SLC Power source

[Analogue 3.3V]

Analogue GND

Comparator input

I

(RE-BH)

Comparator input

I

Comparator input

I

(TE)

Sarvo D/A Voltage reference

O

Sarvo D/A

O

Sarvo D/A TSTD0

O

Sarvo D/A FO

O

Sarvo D/A BST

O

Sarvo D/A TBAL

O

Sarvo D/A FBAL

O

Sarvo D/A SGC

O

Sarvo D/A SLDO

O

Sarvo D/A SPDO

O

Sarvo D/A TDO

O

Sarvo D/A FDO

O

Internal logic power source

[Digital 2.5V]

Digital GND

FG Counter input General-purpose port in/output

I/O

Interrupt signal output

O

Wait signal output

I

Servo reset input

I

Reag reset input

I

Write signsl input

I

Chip select signal input

I

DTA BUS 0

I/O

I/O Power source [Digital 3.3V]

-

Block

Microcomputer I/F

DRAM I/F

NC

DRAM I/F

Microcomputer I/F

CD data

CD data

NO.

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

Pin Name

DVSS

HDAT1

HDAT2

HADT3

HADT4

HDAT5

HDAT6

HADT7

HADR0

HADR1

HADR2

HADR3

HADR4

HADR5

HADR6

MWEB

MRASIB

MA0

MA1

MA2

MA3

NC

NC

MA4

MA5

MA6

MA7

MA8

MA9

MA10

MOEB

MCASUB

MCASLB

HADR7

HADR8

HADR9

HADR10

HADR11

HADR12

C2F

ROMXA

ROMCK

LRSY

DVDD1

DVSS

EMPH

Supplementation

I/O

Digital GND

Data bus 1

I/O

Data bus 2

I/O

Data bus 3

I/O

Data bus 4

I/O

Data bus 5

I/O

Data bus 6

I/O

Data bus 7

I/O

Address bus 0

I

Address bus 1

I

Address bus 2

I

Address bus 3

I

Address bus 4

I

Address bus 5

I

Address bus 6

I

WE Output

O

RAS Output I

O

DRAM Address bus 0

O

DRAM Address bus 1

O

DRAM Address bus 2

O

DRAM Address bus 3

O

NC pin which set,"H" or "L"

(662; DRAM Power ssupply [Digital 3.3V])

NC pin which set,"H" or "L"

(662;Digital GND)

DRAM Address bus 4

O

DRAM Address bus 5

O

DRAM Address bus 6

O

DRAM Address bus 7

O

DRAM Address bus 8

O

DRAM Address bus 9

O

DRAM Address bus 10

O

OE Output

O

CAS Output (Upper Byte)

O

CAS Output (Lower Byte)

O

Address bus 7

I

Address bus 8

I

Address bus 9

I

Address bus 10

I

Address bus 11

I

Address bus 12

I

Buffer memory access selector

C2 flag output Monitor pin 4

O

CD data output Monitor pin 3

O

CD dast output Monitor pin 2

O

shift clock output

CD data output L/R clock output Monitor pin 1

O

I/O power source

Digital GND

Deemphasis monitor pin Monitor pin 0

O

IC101,102 KTC801U(Switching Transistor)

6

Q1

1

5

2

4

Q2

3

IC211 LA1186N(OSC & AFC)

Vref BUFFER

RF MIX REG OSC

1 2 3 4 5 6 7 8 9

RF IN GND IF OUT Vcc

- 16 -

Page 18

IC BLOCK DIAGRAM & DESCRIPTION

g

IC130 LC78663NRW (DVD/CD Servo Controller)

Block

AV data

I/F

RF I/F

Powe r

supply

EFM PLL

Powe r

supply

JV

Powe r

supply

System

CLK

Powe r

supply

Power supply

System

CLK

Power supply

* TEST0~2; "L" setting

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

Pin name

AVREQI

AVACKO

AVDACK

AVSCTB

AVERRB

AVD0

AVD1

AVD2

AVD3

AVD4

AVD5

AVD6

AVD7

EFMOUT

PCK

DVDD0

DVSS

VCOCTL

PPDO

FPDO

LF1

LF2

LF3

PCN

PISET

FISET

CDFR

DVDFR

AVDD2

AVSS

JVCPI

LVCPC

JVAO

JVAIN

JVRVO

AVDD3

AVSS

VPDO

VRPFR

VCOC

DVDD0

DVSS

DVDD2

XIN

XOUT

DVSS

I/O

Supplementation

I

AV data requirement flag input

O

AV data read strobe output

O

AV data read output

O

AV output selector synchronization outpun

O

AV data reliable flag output

O

AV data bus 0

O

AV data bus 1

O

AV data bus 2

O

AV data bus 3

O

AV data bus 4

O

AV data bus 5

O

AV data bus 6

O

AV data bus 7

O

EFM 2 value signal output

O

EFM playback shift clock output

-

Internel logic power source [Digital 2.5V]

-

Digital GND

-

VCO filter connect

-

Phase comparison filter connect

-

Frequency comparison filter connect

-

Filter connect 1

-

Filter connect 2

-

Filter connect 3

-

Voltage monitor pin(Phase comparson

charge pomp PCH control voltage)

-

Current setting pin for the constant current

phase comparison charge pomp

-

Current setting pin for the constant

frequcncy comparison charge pomp

-

EFM playback VCO oscillator range setting

pin [CD]

-

EFM playback VCO oscillator range setting

pin [DVD]

-

EFM PLL JV power supply [Analog 3.3V]

-

Analog GND

-

JV control

-

JV control

O

EFM playback PLL clock jitter output

-

JV control

-

JV control

-

SYSTEM PLL power supply [Analog 2.5V]

-

Analog GND

-

SYSTEM PLL filter connect

-

SYSTEM PLL VCO oscillator renge setting

-

SYSTEM PLL filter connect

-

Internal logic power source [Digital 2.5V]

-

Digital GND

-

Oscillation circuit power source [Digital 3.3V]

I

Oscillation circuit input

O

Oscillation circuit output

-

Digital GND

NO.

IC443 BA7755A(Rec/Play Switch)

Block

System

CLK

Moniter

CD data

Powe r

supply

DRAM I/F

NC

DRAM I/F

NC

DRAM I//F

NC

DRAM I/F

Powe r

supply

RF I/F

Powe r

supply

NO.

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

Pin name

X16MIO

TEST2

DVDCKIO

FSX

EFLG

DOUT

DVDD1

DVSS

MD8

MD9

MD10

MD11

NC

MD12

MD13

MD14

MD15

NC

NC

MD0

MD1

MD2

MD3

NC

MD4

MD5

MD6

MD7

DVDD1

DVSS

DEFECTI

DEFECTO

RFP0

RFP1

RFP2

RFP3

TESIO

HFLIO

DVDD0

DVSS

Supplementation

I/O

External 16MHz output

I/O

Test input 2

I

(Input; "L" level set)

External DVD clock input

I/O

CD1 frame synchronization signal Monitor 6

O

Error correction C1,C2 correction Monitor 5

O

conditions monitor oins

Audio EIAJ data output Monitor 7

O

I/O power supply [Digital 3.3V]

Digital GND

-

I/O

DRAM data bus 8

I/O

DRAM data bus 9

I/O

DRAM data bus 10

I/O

DRAM data bus 11

NC pin which set "H" or "L"

(662;Digital GND)

I/O

DRAM data bus 12

I/O

DRAM data bus 13

I/O

DRAM data bus 14

I/O

DRAM data bus 15

-

NC pin which set "H" or "L"

(662;Digital GND)

-

NC pin which set "H" or "L"

(662;DRAM power source [Digital 3.3V])

I/O

DRAM data bus 0

I/O

DRAM data bus 1

I/O

DRAM data bus 2

I/O

DRAM data bus 3

-

NC pin which set "H" or "L"

(662;DRAM power source [Digital 3.3V])

I/O

DRAM data bus 4

I/O

DRAM data bus 5

I/O

DRAM data bus 6

I/O

DRAM data bus 7

I/O power supply [Digital 3.3V]

Digital GND

I/O

Defect signal input General-purpose port

I/O 0

O

Defect signal output

I/O

RF general-ourpose port WRQ output

I/O 0

I/O

RF general-ourpose port

I/O 1

I/O

RF general-ourpose port HBUSYB output

I/O 2

I/O

RF general-ourpose port HFBUSYB output

I/O 3 EVENT counter input

I/O

Tr acking margin signal I/O

I/O

Mirror detast signal I/O

Internal logic power supply [Digital 2.5V]

Digital GND

IC859 NC7SZ157P6(Multiplexer)

1 4 52 3

- 17 -

I

1

1

2

GND

3

I

0

Pin Descriptions

Pin Name

I

0

, I

1

S

Z

1

0

(Top View)

6

Vcc

5

4SZ

Description

Data Inputs

Control Inputs

Output

Page 19

IC BLOCK DIAGRAM & DESCRIPTION

IC131 M11L416256SA-35T(256k x 16 DRAM)

WE

RA

CAS

CAS

S

L

H

A0

A1

A2

A3

A4

A5

A6

A7

A8

CONTROL

LOGIC

GENERATOR

COLUMN

9

ADDRESS

BUFFER

REFRESH

CONTROLER

REFRESH

COUNTER

ROW.

9

AD DR ESS

BUFFERS(9)

CLOCK

9

9

9

R

9

512

ROW

DECODE

PIN DESCRIPTIONS

PIN NO. PIN NAME TYPE DESCRIPTION

16~19,22~26 A0~A8 Input

14

28

29

13

27

RAS

CASH

CASL

WE

OE

Input Row Address Strobe

Input Column Address Strobe / Upper Byte Control

Input Column Address Strobe / Lower Byte Control

Input Write Enable

Input Output Enable

2~5,7~10,31~34,36~39 I/O0 ~ I/O15 Input / Output Data Input / Out

1,6,20 V

21,35,40 V

CC

SS

Supply Power, 3.3V

Ground Ground

11, 1 2,15,3 0 NC - N o Conne

Address Input

Row Address : A0~A8

Column Address : A0~A

DATA-IN BUFFER

COLUMN

R

DECODE

512

SENSE AMPLIFIERS

I/O GATING

512 x 16

512 x 512 x 16

MEMORY

ARRAY

BB

GENERATOR

V

ct

IO0

16

:

IO15

DATA-OUT

BUFFER

16

16

8

V

CC

V

SS

OE

8

put

IC231 LA1844ML(AM/FM-ZF/MPX)

24 23 22 21 20 19 18 17 16 15 14

ALC

BUFF

LEVEL

DET

FM

IF

1

AM

OSC

S-CURVE

FM

DET

2345678910 11 12

AM

MIX

REG

RF.AMP

AM/FM

IF

BUFF

AM

AM

IF

AGC

COMP

TUNING

DRIVE

GND

AM

DET

P-DET

VCO

304kHz

DECODER

ANTI-BIRDIE

STEREO

SW

FF

38k

VCC

FF

19k

2

PILOT

CANCEL

FF

19k

13

PILOT

DET

- 18 -

Page 20

IC BLOCK DIAGRAM & DESCRIPTION

IC160 IKE80-E(Power Amp.)

REV

VCCP2

VLO-

VLO+

1FWD

Input

2

3

4

5

6VO4+

7VO4-

8VO3+

9VO3-

Power

stem

GND

10VO2+

11VO2-

Thermal shutdown

Output

control

Level

shift

Level

shift

Level

shift

(Load outout voltage set)

MUTE

Match CH:ON/OFF

H:Output ON, L:Output OFF

44k

REG IN

REG OUT

Signal stem GND

11k

(VCC)

CH1

CH2,3,4

To VREFOUT

Power

stem

GND

36

SGND

35

VCONT

34

MUTE1

MUTE234

33

32 VIN4-

31 VIN4

30 VREF_IN

29 VREF_OUT

28

REG_OUT

FRFR

27 REG_IN

26 VIN+OP

VO1-

VO1+

VCCS

12

13

14VCCP1

15

16VIN1+

17VIN1-

18VIN1

Signal stem

power supply

11k

Level

shift

44k

44k

44k

11k

11k

To VREFOUT

25 VIN-OP

24

VO_OP

23 VIN3

22 VIN3-

21 VIN2

20 VIN2-

VIN2+

19

- 19 -

Page 21

IC BLOCK DIAGRAM & DESCRIPTION

IC241 LC72121M-D(PLL Synthesizer)

Vssx

XIN

XOUT

FMIN

AMIN

CE

DI

CL

DO

V

DD

Vssd

24

17

16

18

15

2

19

20

21

22

PD

AIN

AOUT

Vssa

1

1/2

REFERENCE

DIVIDER

SWALLOW COUNTER

1/16, 1/17 4bits

PHASE DETECTOR

CHARGE PUMP

UNLOCK

DETECTOR

12bits PROGRAMMABLE

DIVIDER

3

4

5

CCB

I / F

DATA SHIFT REGISTER LATCH

UNIVERSAL

COUNTER

13

IFIN

6

POWER

ON

RESET

IC440 AN7348K(Play/Rec Pre. Amp.)

L-PB

AMP OUT

20

576

R-PB OUT

ALC

Logic

A/B

ALC

AB SW

L-REC IN

1819

R-REC IN

17

Amp(L)

Amp(R)

8

A/Rec

L-PB AMP

B

A/Rec

1

L-PB AMP

R-PB AMP

B

2

R-PB AMP

L-PB NF

PB Amp(L)

PB Amp(R)

3

R-PB NF

L-PB EO

21222324

Mute

Mute

4

R-PB EO

9

8

7

BO1BO2 BO3 BO4

ALC

16

P

R

R

Logic

9

REC/PB SW

HI/LO

15

R

P

Nor/Cro

& Hi/Lo

Logic

P

10 1211

A/B SW

CRO/NOR

Ripple

Rejection

FILTER

L-REC OUT

Rec

Rec

Rec/PB

R-REC OUT

IO1

14

IO2

10 11

IC441 LC75342M(Electric Volume)

LSELO LIN LTRE LBASS1 LBASS2 LOUT

VCC

1314

L4

11

L3

12

L2

13

L1

14

NC

15

NC

16

R1

17

R2

18

R3

19

R4

20

GND

10 9 7 6 58

CONTROL

CIRCUIT

LOGIC

CIRCUIT

CONTROL

CIRCUIT

21 22 24 25 2623

RSELO RIN RTRE RBASS1 RBASS2 ROUT

LVref

CCB

INTERFACE

RVref

4

TEST

3

SS

V

2

CE

1

DI

30

CL

29

DD

V

28

Vref

27

NC

- 20 -

Page 22

IC BLOCK DIAGRAM & DESCRIPTION

IC442 TA8223K(Power Amp.) IC806 74VHCT08AMTCX(AND)

114

0

A

2

0

B

3

O

0

4

A

1

5

1

B

6

O

1

7

GND

V

CC

13

2

A

12

B

2

11

O

2

10

3

A

9

B

3

8

3

O

IC602,801 S524A40X21-SCT0(EEPROM)

8

Vcc

GND

4

WP

SCL

SDA

A

A

A

7

6

5

2

3

1

2

0

1

START

STOP

LOGIC

DEVICE

ADDRESS

COMPARATOR

LOAD

R/W

SERIAL

CONTROL

LOGIC

COMP

LOAD INC

DATA WOR D

ADDR/COUNTER

A

L

L

H

H

Pin Names

A

n' BN

O

EN

N

H,V. PUMP/TIMING

DATA RECOVERY

X DEC

B

L

H

L

H

2

E PROM

O

L

L

L

H

Description

Inputs

Outputs

IC881 KRX101U(Switching)

5

Q1

1

2 3

Y DEC

D

IN

SERIAL MUX

D

OUT

/ACK

LOGIC

D

OUT

IC401 KIA7805API(Regulator)

4

Q2

1. INPUT

2. COMMON

3. OUTPUT

123

- 21 -

Page 23

IC BLOCK DIAGRAM & DESCRIPTION

IC818 SST39VF800A-70-4C-EK(Flash Memory)

Memory Address

Symbol

AMS

1-A0

DQ15-DQ

CE#

OE#

WE#

V

DD

V

SS

NC

Pin Name

Address Inputs

Data Input/output

0

Chip Enable

Output Enable

Write Enable

Power Supply

Ground

No connection

IC850 PQ2L2182MS(regulater)

CE#

OE#

WE#

X-Decoder

Address Buffer

& Latches

Control Logic

Function

To provide memory addresses. During Sector-Erase AMS-A11 address

lines will select the sector. During Block-Erase A

select the block.

To output data during Read Cycles and receive input data during Write

Cycles.

Data is internally latched during a Write Cycle.

The outputs are in tri-state when OE# or CE# is high.

To activate the device when CE# is low.

To gate the data output buffers.

To control the Write operations.

To provide power supply voltage:

Unconnected pins

SuperFlash

Memory

Y-Decoder

I/O Buffer and Data

Latches

DQ

15

-DQ

0

MS-A15

address lines will

3.0-3.6V for SST39LF200A/400A/800A

2.7-3.6V for SST39LF200A/400A/800A

IC851 PQ070XZ01Z(Regulater)

15

4

CONTROL

3

1

2 3 4 5

2

Description

Symbols

IC852 PQ1X501M2Z(Regulater)

15

CONTROL

2

GND

ON/OFF control : Vc

34

DC output : VoDC input : Vin

Noise reduction : Nr

Pin No.

1

2

3

4

5

DC INPUT

Vin

ON/OFF CONTROL

Vc

DC OUTPUT

Vo

OUTPUT VOLTAGE ADJUSTMENT

Vadj

GND

- 22 -

Page 24

IC BLOCK DIAGRAM & DESCRIPTION

IC822 M12L1616A-7T(SDRAM)

ADD

35CLK

20~24

27~32

LCKE

Bank select

Row buffer

refresh counter

Address registor

LCBR

LRAS

LRAS

35 34 18 17 16

CLK CKE

LCBR

LWE LDQM

Timing register

Row decoder

buffer

Column address

LCAS

Data input register

I/O controlOutput buffer

512K X 16

AMP

512K X 16

Column decoder

Latency & burst length

Progremming register

LWCBR

15

CASRASCS

WE

L(U)DQM

OSense

14,36

LWE

14 LDQM

2,3,

5,6,

8,9,

11,12,

39,40,

42,43,

45,46,

48,49

DQi

No.

35

18

34

20,21~24

27~32

19

17

16

15

14,36

2,3,5,6,8,9,11,

12,39,40,42,43,

45,46,48,49

1,50

7,41

37

Pin

CLK

CS

CKE

A0 to A10/AP

BA

RAS

CAS

WE

L(U)DQM

DQ0 to 15

VDD/VSS

VDDQ/VSSQ

N.C/RFU

Name

System clock

Chip select

Clock enable

Address

Bank select address

Row address strobe

Column address strobe

Write enable

Data mask ensble

Data input/output

Power supply/ground

Output buffer power/ground

No connection

Input Function

Active on the positive going edge to sample all inputs.