Page 1

FILE NO.

Service Manual

Contents

Micro Component System

DC-DA370 (AU)

PRODUCT CODE No.

129 599 06

Specifications...................................................................1

System connections.........................................................1

Laser beam safety precaution..........................................2

CD pick-up maintenance..................................................2

CD player adjustments.....................................................2

Tape adjustments ............................................................3

Tuner adjustments ...........................................................4

What to do if.....................................................................5

When assembling the Rack Gear and CD Lid .................5

When replacing LED (D6310) .......................................... 5

Exploded view

(Cabinet & Chassis) ...................................................... 6

(Tape mechanism) ........................................................ 11

Parts list

(Cabinet & Chassis) ...................................................... 7

(CD mechanism) ...........................................................7

(Tape mechanism) ........................................................ 11

This service manual consists of "DC-DA370U" (Main unit : 129 598 06) and "SX-DA370L"

(Speaker system : 165 027 00) & "SX-DA370R" (Speaker system : 165 040 00).

IC block diagram & description ........................................ 11

LCD display description ................................................... 15

Schematic diagram

(CD)...............................................................................16

(FRONT) ....................................................................... 18

(AMPLIFIER )................................................................ 24

(TUNER) ....................................................................... 26

Wiring diagram

(CD & FRONT).............................................................. 20

(TUNER & AMPLIFIER ) ...............................................22

(PRIMARY + SECONDARY POWER

TRANSFORMER AND CD LID SWITCH)....................28

Voltage Table ...................................................................29

Wiring connection ............................................................31

REFERENCE No.

SM5810214

Page 2

SPECIFICATIONS

Tuner

Reception frequency.............. FM : 87.5 - 108.0 MHz

MW: 522 - 1710kHz (9kHz step)

520 - 1710kHz (10kHz step)

CD player

Channels................................ 2-channel stereo

Sampling frequency ............... 44.1 kHz

Pick-up................................... Optical 3-beam

semiconductor laser

Wow and Flutter..................... Below measurable limits

Wave length........................... 790 nm

Laser output........................... 0.6mW(Continuous wave max.)

Cassette deck section

Track system ......................... 4-track, 2-channel stereo

Frequency response .............. 60 Hz - 13.5 kHz

Signal to noise ratio ............... 50 dB

Wow and Flutter..................... 0.12% (WRMS)

Fast forward / Rewind time .... Approx. 110 sec. (C-60)

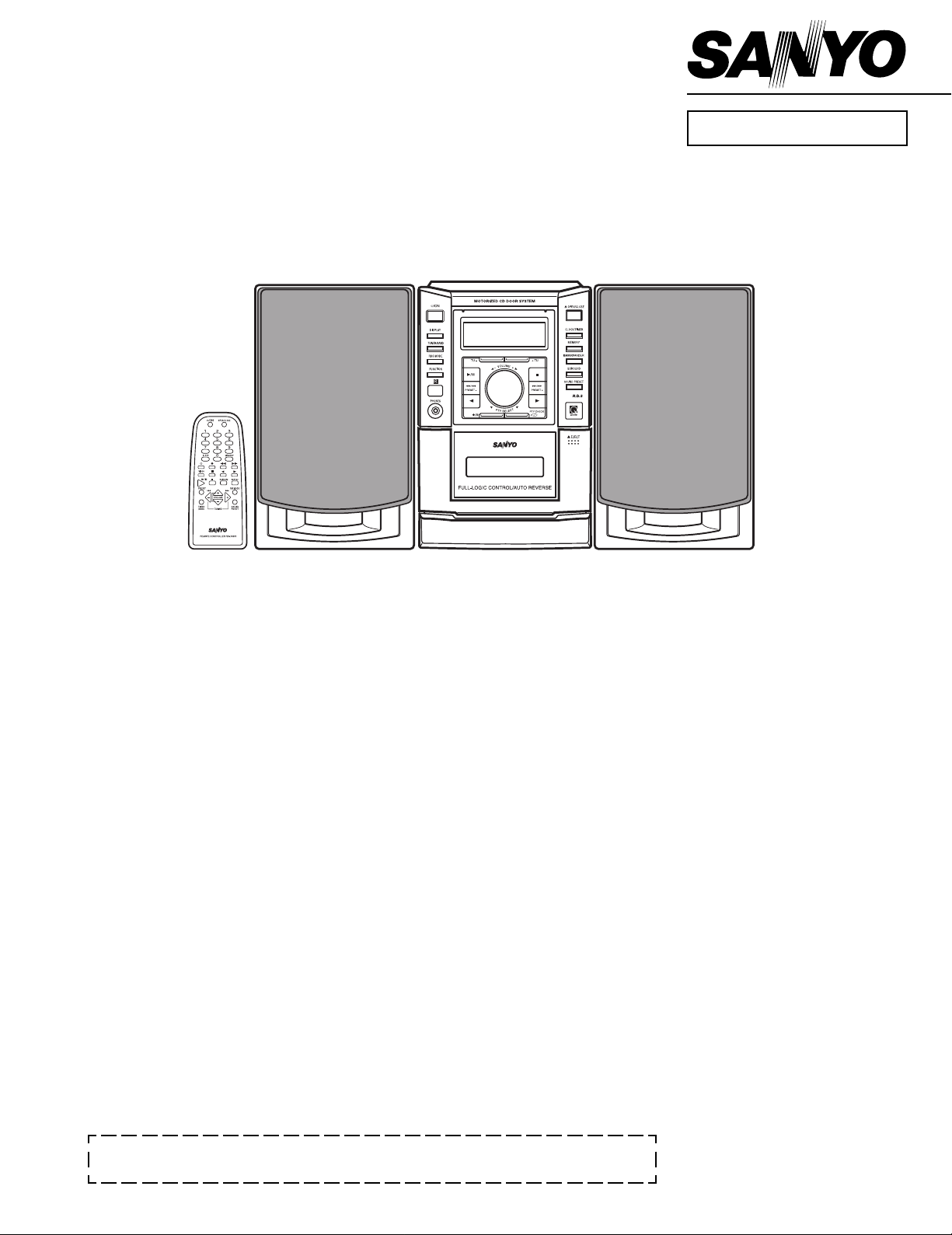

SYSTEM CONNECTIONS

General

Output power ......................... 12.5W x 2

(at 4 ohms, 10% distortion)

Inputs ..................................... VIDEO IN : 400 mV / 50k ohms

Outputs .................................. SPEAKERS : 4 ohms

PHONES : 8 - 32 ohms

OPTICAL OUT:Optical

Power requirements............... AC 230-240, 50Hz

Power consumption ............... 40 W

Dimensions (W x H x D) ........ Approx. 160 x 251 x 207 mm

Weight.................................... Approx. 3.2 kg

Speaker system

Type....................................... 3 way bass reflex

Unit used : Woofer ................. 10 cm cone type

: Mid range............. 5 cm cone type

: Tweeter................ 2 cm piezoelectric

Maximum

power-handling capacity ..... 25 Watts (peak)

Nominal impedance ............... 4 ohms

Dimensions (W x H x D) ........ Approx. 150 x 245 x 224 mm

Weight.................................... Approx. 1.9 kg (per speaker)

Specifications subject to change without notice.

FM outdoor aerial

OFF

220-240V

1

10-120V

VOLTAGESELECTOR

AM loop aerial

FM indoor aerial

Digital equipment

Video equipment

Amplifies subwoofer

(not supplied)

R ch speaker

L ch speaker

To an AC outlet

- 1 -

Page 3

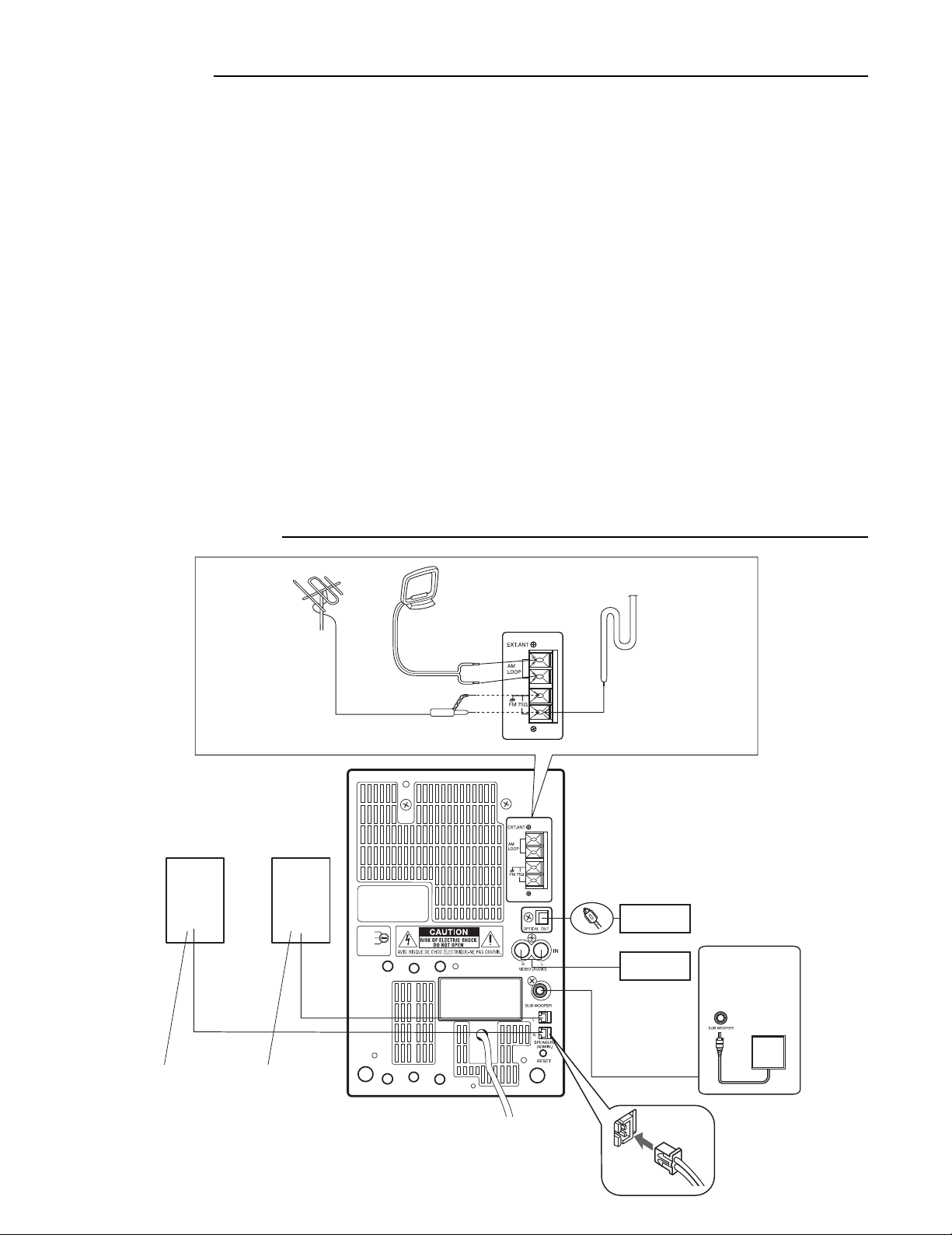

LASER BEAM SAFETY PRECAUTION

VOLTAGESELECTOR

OFF

220-240V

1

10-120V

• Pick-up that emits a laser beam is used in this CD player section.

CAUTION :

USE OF CONTROLS OR ADJUSTMENTS

OR PERFORMANCE OF PROCEDURES

OTHER THAN THOSE SPECIFIED HEREIN

MAY RESULT IN HAZARDOUS RADIATION

EXPOSURE

LASER OUTPUT..........0.6 mW Max. (CW)

WAVELENGTH .............790 nm

CAUTION – INVISIBLE LASER RADIATION WHEN OPEN AND

INTERLOCKS DEFEATED. AVOID EXPOSURE TO BEAM.

ADVARSEL – USYNLIG LASER STRÅLING VED ÅBNING, NÅR

SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION, UNDGÅ UDS ÆTTELSE

FOR STRÅLING.

VARNING – OSYNLIG LASER STRÅLNING NÄR DENNA DEL ÄR ÖPPNAD

OCH SPÄRR ÄR URKOPPLAD. STRÅLEN ÄR FARLIG.

VORSICHT – UNSICHTBARE LASERSTRAHLUNG TRITT AUS, WENN

DECKEL GEÖFFNET UND WENN SICHERHEITSVERRIEGELUNG

ÜBERBRÜCKT IST. NICHT, DEM STRAHL AUSSETZEN.

VARO – AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA

NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

CD PICK-UP MAINTENANCE

About pick-up (Optical lens) Cleaning

Clean a lens with swab of the cotton which moistened it with alcohol, cleaning paper or cleaning disc appointed.

Specified cleaning disc : LC-1 (Part code : 645 026 1961 ..... manufactured by SANYO.)

Show a clean procedure in the following in reference by swab of cotton.

1. Cotton swab is wrapped with Cleaning paper.

2. Add the isopropyl alcohol.

3. Gently move the tip of cotton swab just like a draw a whirlpool from inside to outside on the surface of lens.

CD PLAYER ADJUSTMENTS

1. ADJUSTMENTS

(1) Confirm the tracking balance

1. Turn on the POWER switch.

2. Connect an Oscilloscope to TP2 (TE) and TP4 (VC).

3. Set the test disc.

4. Press "PLAY" button to turn into the "PLAY" mode.

5. Keep holding "SKIP" button down so as to be "SERCH"

mode, then confirm that the oscilloscope waveform is

symmetrical on the top and bottom in relation to 0V (VC).

- 2 -

ˇ 200mV

div. 5ms

Page 4

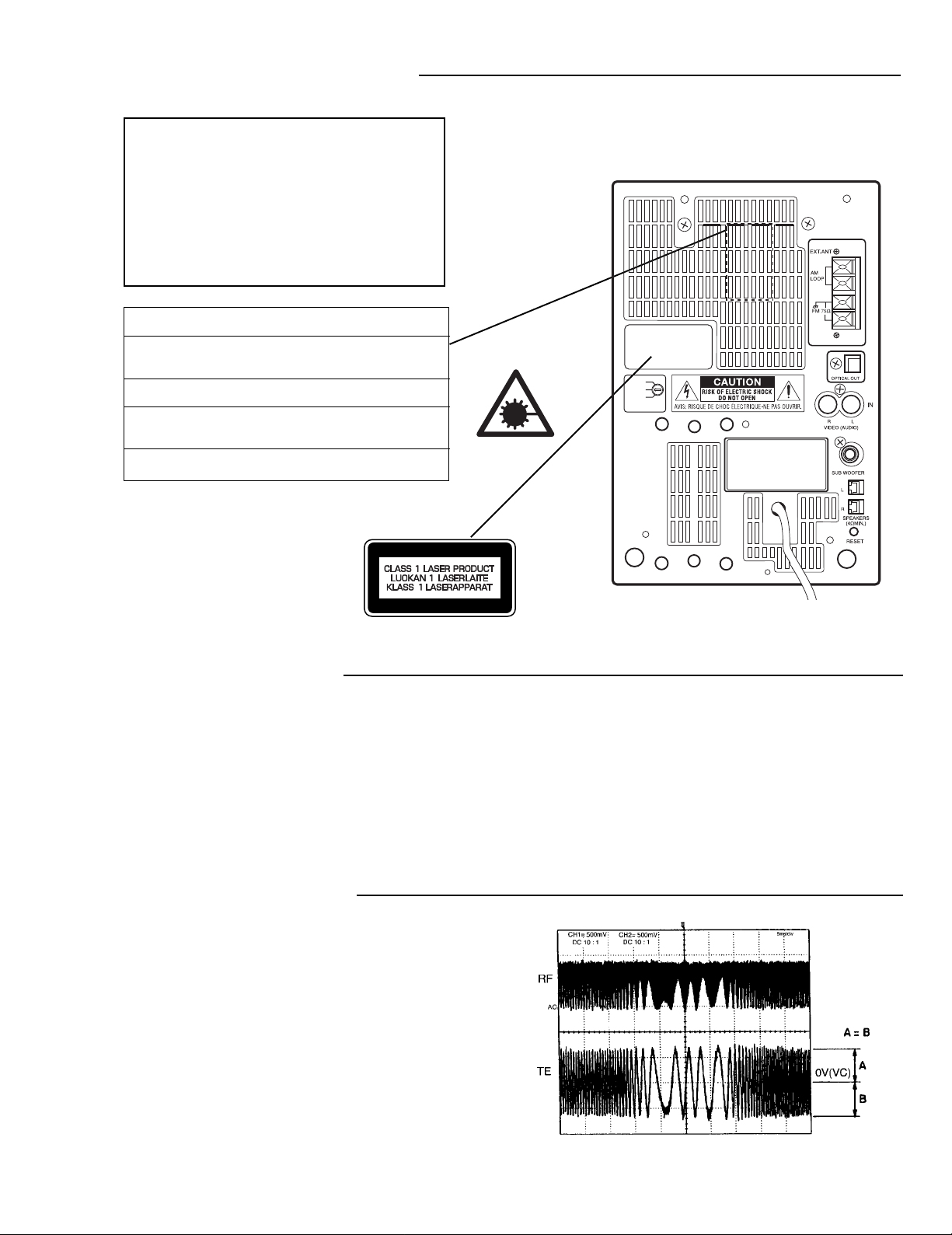

CD PLAYER ADJUSTMENTS

REVERSE

NORMAL

(2) Checking the "eye" pattern

1. Switch "ON" the POWER.

2. Connect an oscilloscope to TP1 (RF) and TP4 (VC).

3. Load the test disc.

4. Press the PLAY button.

5. Check to be sure that the "eye" pattern is at the center of

waveform and that the diamond shape is clearly defined.

6. Press the STOP button.

7. Turn off the POWER switch.

TAPE ADJUSTMENTS

1. Azimuth Adjustment

• Be sure to clean the heads before attempting to make any adjustment.

• Be sure both channels (1 and 2) are the same level.

(Using a dual-channel oscilloscope)

• Be sure both channel's waveform are same for the phase matching.

• After completion of the adjustment, use the threadlock (TB-1401B) to

secure the azimuth adjustment screws.

TP1

(RF)

TP4

(VC)

+

OSCILLOSCOPE

-

a

OPENING EXPANDED

b

1. Remove the cover deck as Fig.1.

2. Load a test tape (VTT-738 etc. : 10kHz) in the Deck.

3. Press the PLAY button. (Normal playback)

4. Use a + tip screwdriver to turn the screw for normal azimuth

adjustment so that the left and right outputs are maximized at

the same phase during normal playback. See Fig.2.

5. Press the PLAY button. (Reverse playback)

6. Use a + tip screwdriver to turn the screw for reverse azimuth

adjustment so that the left and right outputs are maximized

at the same phase during reverse playback.

7. Adjust so that the waveforms for the left and right channels are in alignment.

2. Tape Speed Adjustment

Fig.3

• Connect the Frequency Counter to TAPE OUT.

1. Insert the test tape (MTT-111N, etc.; 3,000Hz) into the DECK.

MOTOR

2. Press the PLAY button. .

3. Adjust a hole on the motor bottom so that a frequency counter reading of 3,000 ±5Hz is obtained.See Fig.3.

4. Press the STOP button, and eject the test tape.

3. Torque Measurement

Take-up Torque Back tention

Pulley tentionItem

Fig.1

Fig.2

hole for adjustment

Test Cassette

PLAY/REV.

F.FWD

REW

PLAY : TW2111A (FWD)

PLAY : TW2121A (REV)

F.FWD / REW : TW2231

30 ~ 65 grcm

30 ~ 65 grcm

70 ~ 140 grcm

PLAY : TW2111A (FWD)

PLAY : TW2121A (REV)

2 ~ 6 grcm

- 3 -

Driving power cassette :

TW-2412 (PLAY)

TW-2422(REV. PLAY)

>50grcm

-

70 ~140 grcm

-

Page 5

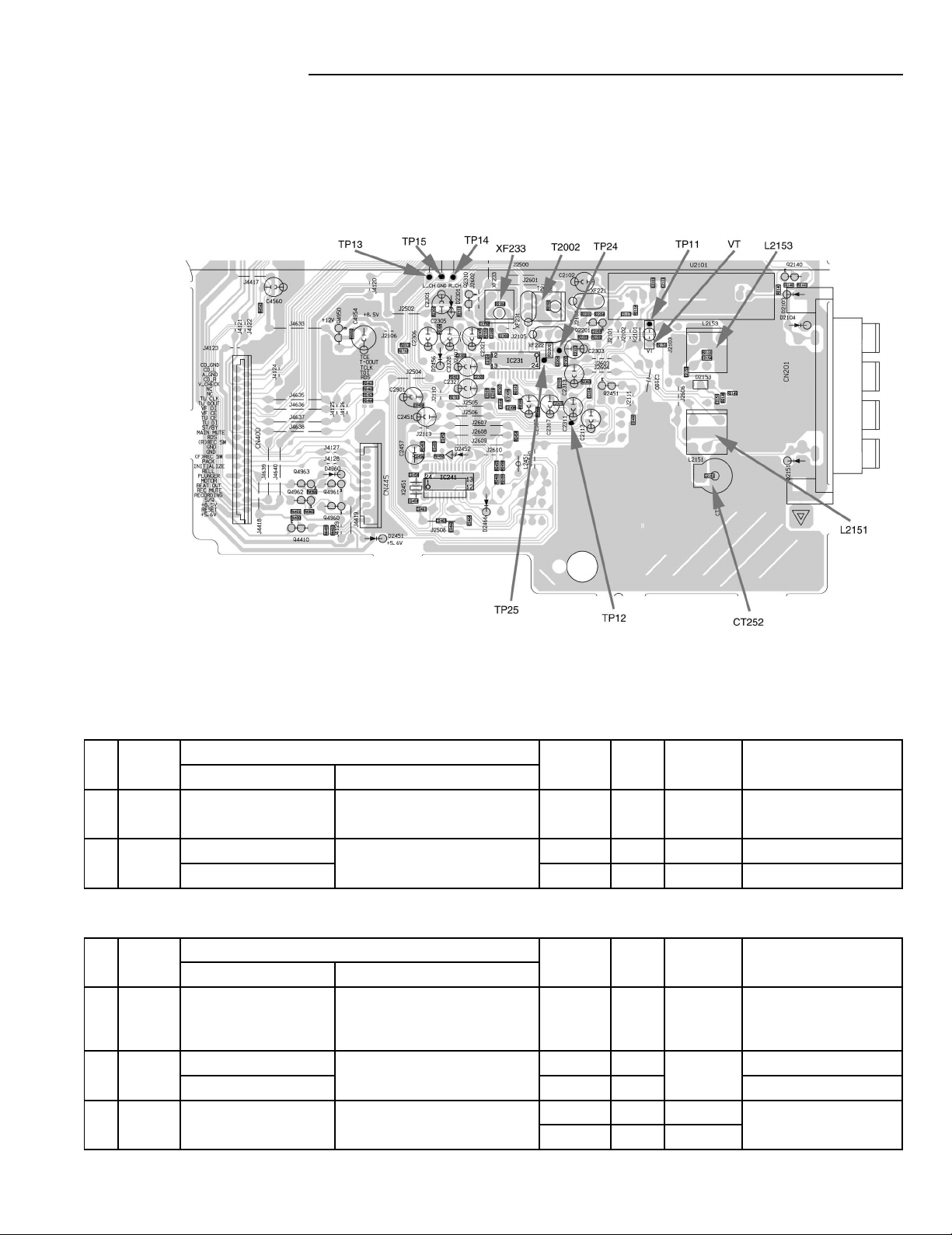

TUNER ADJUSTMENTS

• Use a plastic screw driver for adjustments.

• MODE : ST (Stereo)

• Speaker impedance : 4 ohm

• TUNING

FM : 87.5 - 108MHz

MW: 522 - 1710kHz (9kHz step)

520 - 1710kHz (10kHz step)

Standatd Input: 60dB

Antenna : 75 unbalanced , Modulation : 1 kHz

1. FM

Step Adjusting Connection SG Set Adjustment Remark

Circuit Input Output Frequency Position

1

IF(0V)

Adjustmen

2 Cover --- Connect Digital DC voltmeter to 87.5MHZ Lo w --- 1.55±0.05V

Voltage --- TP11(H), TP12(E). 108.0MHZ High --- 7.1±0.5V

98.0MHz.Input Level Alignment voltage IC231 Alignment voltage IC231

FM Antenna SG=66dBμV 3-22pin(TP24,25) is 0.0±0.05V 3-22pin is 0.0±0.05V

Dev. : ±22.5kHz(MONO) 22.5kHz(STEREO) ±6.75kHz(PILOT)

98MHz

Low XF233

SG Modulation : 1kHz, 30%

2. MW

Step Adjusting Connection SG Set Adjustment Remark

Circuit Input Output Frequency Position

1

2 Cover --- Connect Digital DC voltmeter to 522kHZ Lo w 1.00±0.05V

Voltage --- TP11(H )and TP12(E). 1710kHZ High 7.50±0.20V

3 Tracking

Connect AM SG to loop Connect Sweep generator to test 450kHz

IF Low T2002 AF Maximum

antenna

Connect AM SG to loop Connect to VTVM 603KHZ L ow L2151

loop antenna

point TP13(L)or TP14(R) and TP15(E). (at 999kHz)

point TP13(L)or TP14(R) and TP15(E).

Antenna, IRE Loop, Distance: 60 cm

L2153

AF Maximum

1404kHZ High CT252

- 4 -

Page 6

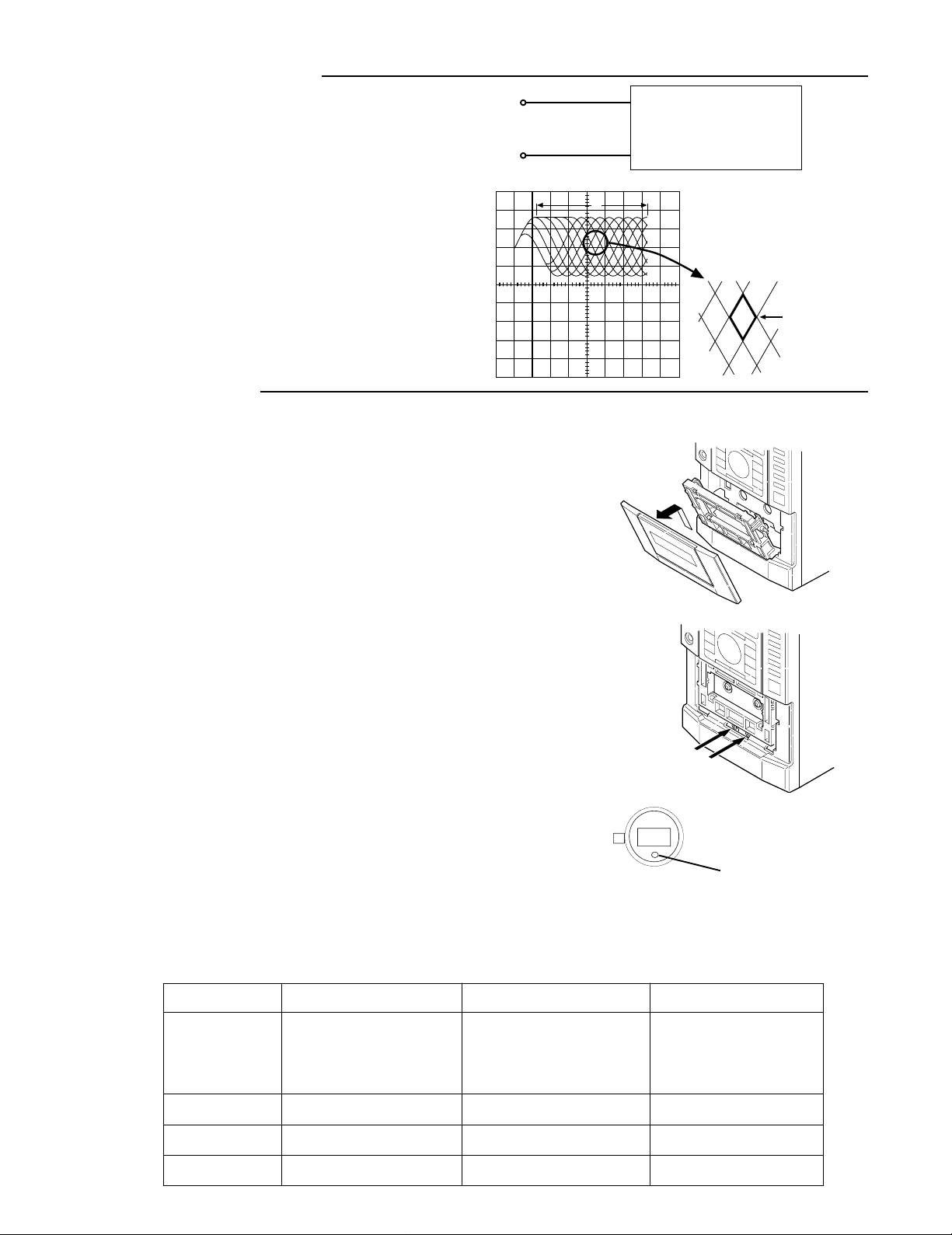

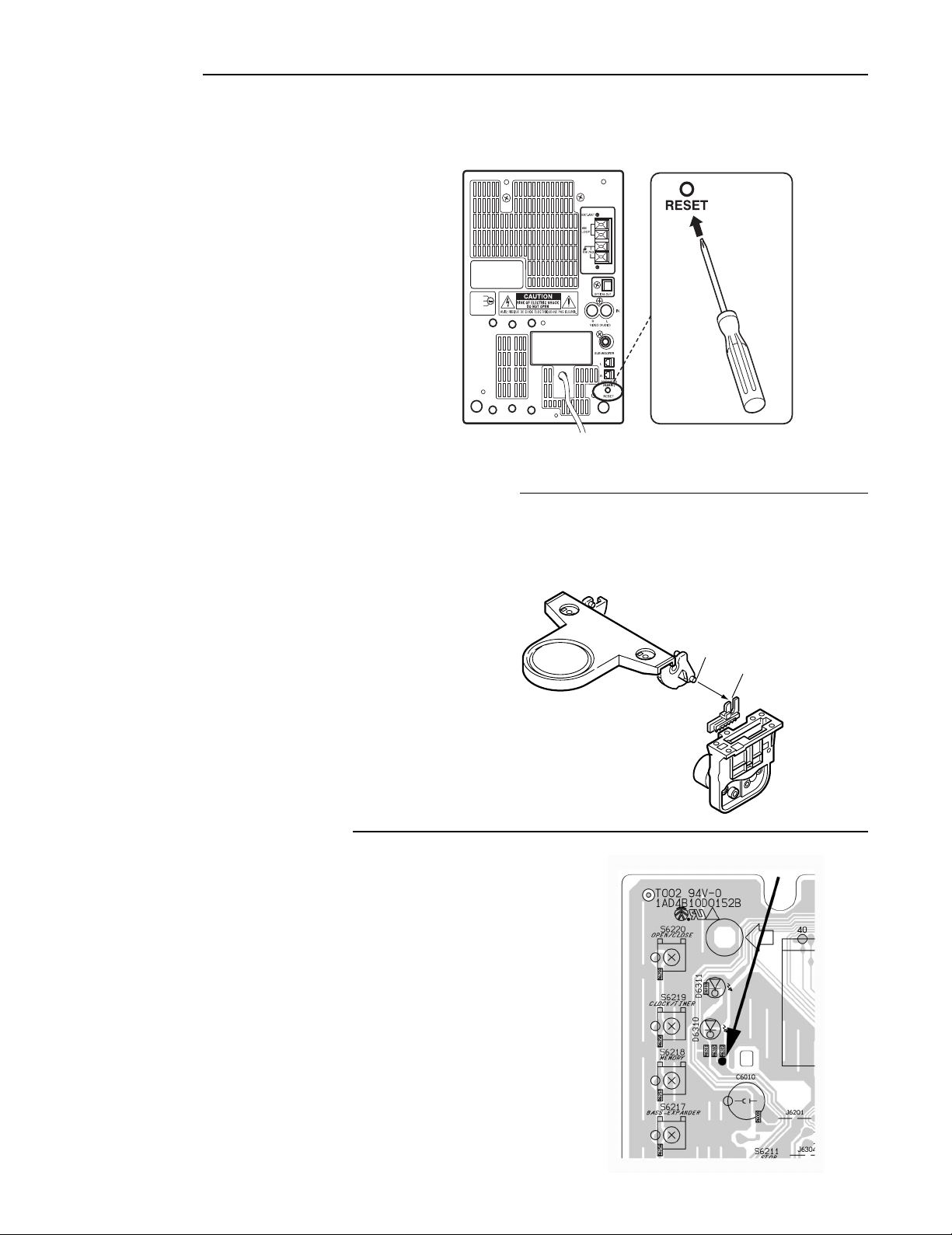

WHAT TO DO IF

If the operation of the unit or display is not normal, even though the appropriate buttons

have been pressed. Disconect the power cord from the AC outlet, then press "RESET"

(rear of the unit) for at least 30 seconds.

OFF

220-240V

1

10-120V

VOLTAGESELECTOR

WHEN ASSEMBLING THE RACK GEAR AND CD LID

When assembling the rack gear and CD lid, "A"part should be inserted into the "B" part.

WHEN REPLACING LED (D6310)

When replacing the LED (D6310);

If the pointed pattern is shorted, remove the soldering first.

Then replace LED (D6310) with new LED on the parts list.

A

B

- 5 -

FRONT P.W.BOARD

Page 7

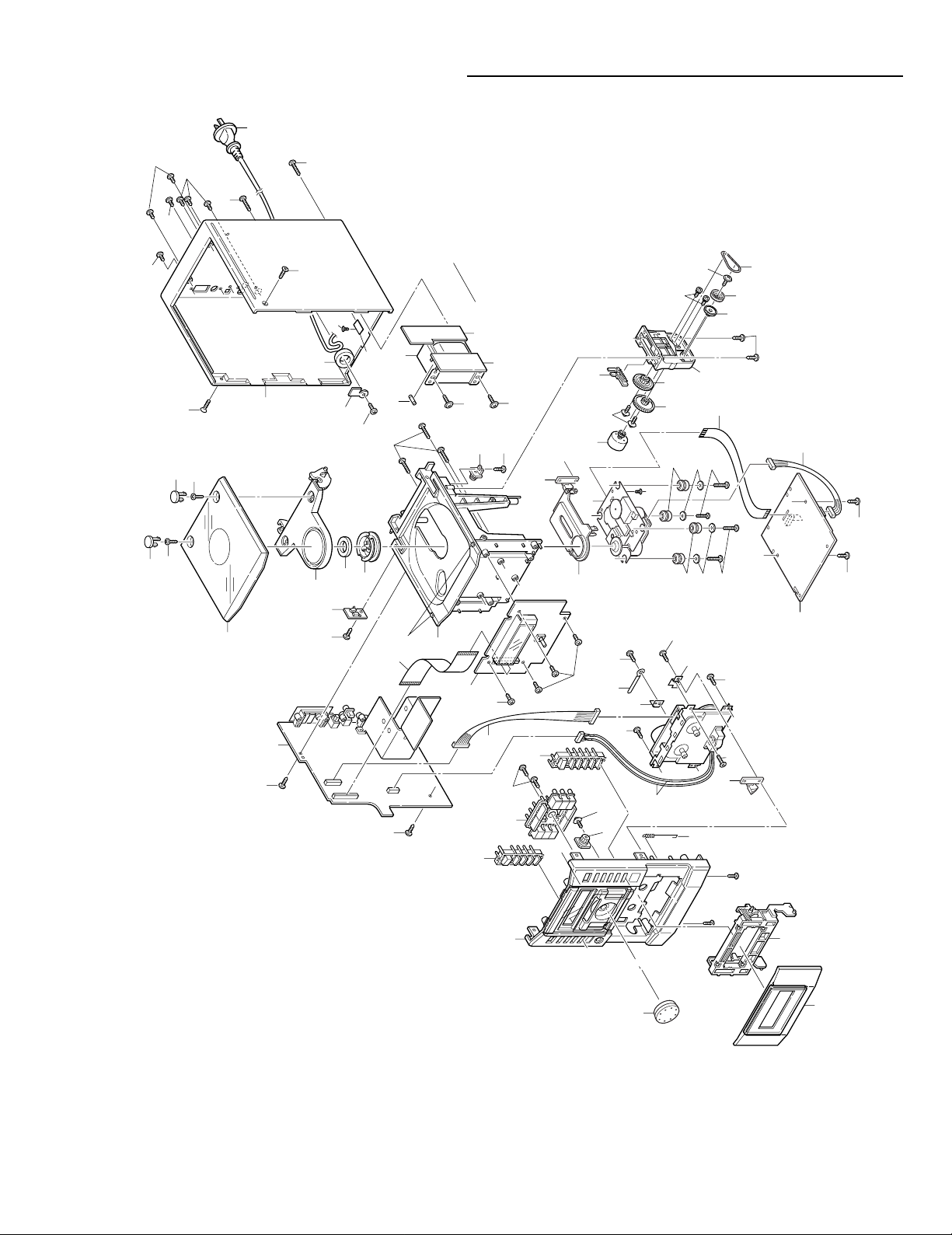

EXPLODED VIEW (CABINET & CHASSIS)

12

1

2

15

15

16

3

4

6

72

73

7

Y02

Y03

Y05

Y07

54

55

Y05

Y04

Y01

Y05

Y05

Y06

24

56

58

57

71

26

27

28

32

29

30

30

31

25

14

17

33

53

52

18

19

20

22

23

21

5

9

13

8

Y08

Y08

Y09

Y09

Y10

Y10

Y11

Y12

Y13

Y13

Y14

Y15

Y16

Y26

Y26

Y21

Y21

75

74

Y22

Y22

Y24

Y25

Y23

Y20

Y17

Y18

Y18

Y17

51

35

76

Y23

Y07

34

Y28

Y27

N.S.P

14

59

N.S.P : Not supplied as service parts.

- 6 -

Page 8

PARTS LIST

PRODUCT SAFETY NOTICE

EACH PRECAUTION IN THIS MANUAL SHOULD BE FOLLOWED DURING SERVICING. COMPONENTS IDENTIFIED WITH THE IEC

!!

SYMBOL

SPECIAL SIGNIFICANCE. WHEN REPLACING A COMPONENT IDENTIFIED BY

OR PARTS WITH THE SAME RATINGS OF RESISTANCE, WATTAGE OR VOLTAGE THAT ARE DESIGNATED IN THE PARTS LIST

IN THIS MANUAL. LEAKAGE-CURRENT OR RESISTANCE MEASUREMENTS MUST BE MADE TO DETERMINE THAT EXPOSED

PARTS ARE ACCEPTABLY INSULATED FROM THE SUPPLY CIRCUIT BEFORE RETURNING THE PRODUCT TO THE CUSTOMER.

CAUTION : Regular type resistors and capacitors are not listed. To know those values, refer to the schematic diagram.

!

IN THE PARTS LIST AND THE SCHEMATIC DIAGRAM DESIGNATED COMPONENTS IN WHICH SAFETY CAN BE OF

!!

!

, USE ONLY THE REPLACEMENT PARTS DESIGNATED,

Regular type resistors are less than 1/4 W Carbon type and Chip type resistors.

Regular type capacitors are less than 50 V and less than 1000 µF type of Ceramic type, Electrolytic type and Chip type.

PACKING & ACCESSORIES

REF.NO. PART NO. DESCRIPTION

614 316 2711 CARTON CASE

614 314 2850 CUSHION,REAR

614 314 2867 CUSHION,FRONT

614 316 2827 INSTRUCTION MANUAL

614 309 3435 NOTICE

645 041 9027 POLY SHEET-0430X0290*NC,SET

645 044 1110 REMOCON,***

614 318 9404 LID,BATTERY,SERVICE

645 005 1227 ASSY,ANTENA,LOOP

or 645 046 8322 ASSY,ANTENA,LOOP

614 245 0055 ANTENNA

614 314 2300 ASSY,BOX,SPEAKER,SPEAKER(L)

614 318 3068 ASSY,BOX,SPEAKER,SPEAKER(R)

614 314 2317 ASSY,GRILLE

CABINET & CHASSIS

REF.NO. PART NO. DESCRIPTION

1 614 314 2409 ASSY,DOOR,DECK

2 614 314 2645 LID,CASSETTE

3 614 303 5718 KNOB,VR

4 614 314 2430 ASSY,PANEL,FRONT

5 614 314 2454 BUTTON,POWER,5KEYS

6 614 314 2478 BUTTON,PLAY,10KEYS

7 614 314 2515 BUTTON,MEMORY,6KEYS

8 614 309 7969 ASSY,GEAR,LID CASSETTE

9 614 303 5794 SPRING,DOOR DECK

12 614 303 1277 LATCH,CAM,DECK,DOOR,LOCKING

13 614 316 0359 MOUNTING,HOOK,ASSY,MECHA

14 614 304 5700 HOLDER,MAIN PCB,MAIN PCB

15 614 310 3899 SPACER,MECHA,MTG CD+DA11

16 614 307 2072 COVER,PICK-UP

17 614 314 8067 RACK,GEAR-1

18 614 318 5079 ASSY,CLUTCH

19 614 314 8043 GEAR

20 614 314 8050 MOUNTING,MOTOR

21 614 314 8036 GEAR

22 614 237 7161 PULLEY

23 614 300 8293 BELT,SQUARE

24 614 314 2669 MOUNTING,CD

25 614 309 8270 ASSY,GEAR,LID,CD

26 614 307 8821 PULLEY

27 614 303 0256 LATCH,MAGNET

28 614 314 2652 LID,CD

29 614 314 2614 DEC,WINDOW,CD

30 614 315 9254 DEC,CAP

31 614 316 1967 ASSY,CABINET,REAR

32 614 316 1172 STOPPER

33 614 318 8841 ASSY,MOTOR

34 614 269 9621 SPACER, WINDOW, CD+WINDOW

35 614 307 9804 ASSY,MECHA,CDDA11N-SASH

614 129 9136 LUG,LEAD FIX

FIXING PARTS

REF.NO. PART NO. DESCRIPTION

Y01 411 165 3803 SCR S-TPG BIN 2.3X10,F-PANEL

Y02 411 021 3503 SCR S-TPG BIN 3X10,

F-PANEL+BUTTON,PLAY

Y03 412 003 1708 SPECIAL SCREW,FRONT+ASSY,GEAR

Y04 411 022 4608 SCR S-TPG FLT 3X8,

MECHA+MOUNTING,HOOK

Y05 411 021 3503 SCR S-TPG BIN 3X10,

F-PANEL+MECHA,CAM+MECHA

Y06 614 129 9136 LUG,LEAD FIX

Y07 411 021 3503 SCR S-TPG BIN 3X10,

MTG CD+CD PCB

Y08 411 021 1806 SCR S-TPG BIN 2.6X10,MTG CD+DA11

Y09 411 092 0906 WASHER Z 2.6X10X0.5,MTG CD+DA11

Y10 412 061 7803 SPECIAL SCREW,GEAR

Y11 411 021 3503 SCR S-TPG BIN 3X10,

ASSY,MOTOR+MOUNT CD

Y12 411 044 7502 SCR PAN+SW 2X5,MOTOR

Y13 411 021 3503 SCR S-TPG BIN 3X10,MTG CD+F-PCB

Y14 411 021 3503 SCR S-TPG BIN 3X10,

MOUNTING,CD+ASSY,GEAR

Y15 411 021 4906 SCR S-TPG BIN 3X20,

F-PANEL+MTG CD

Y16 411 021 3503 SCR S-TPG BIN 3X10,

SWITCH,PWB+MOUNTING CD

Y17 411 021 3503 SCR S-TPG BIN 3X10,MAIN PCB

Y18 411 165 3803 SCR S-TPG BIN 2.3X10,

LID CD+DEC WINDOW CD

Y20 411 021 3503 SCR S-TPG BIN 3X10,REAR+STOPPER

Y21 412 032 6408 SPECIAL SCREW,REAR+P-TRANS

Y22 411 021 4906 SCR S-TPG BIN 3X20,C-REAR

Y23 411 021 3404 SCR S-TPG BIN 3X10,

C-REAR(ANT TERMINAL)

Y24 411 021 3404 SCR S-TPG BIN 3X10,MTG CD+REAR

Y25 411 021 3404 SCR S-TPG BIN 3X10,C-REAR+OPT

Y26 411 098 7800 SCR S-TPG FLT 3X12,

C-REAR+MTG(L/R)

Y27 411 021 3503 SCR S-TPG BIN 3X10,

REAR+AC CORD PCB

Y28 411 156 2105 SCR S-TPG BIN 2.3X6,LUG45

ELECTRICAL PARTS

REF.NO. PART NO. DESCRIPTION

51

52

53

54 614 316 8041 ASSY,WIRE,CD-CD MECHA

55 614 316 8072 FLEXIBLE FLAT CABLE,CD-CD MECHA

56 614 316 8027 ASSY,WIRE,AMP-TAPE MECHA

57 614 316 8065 FLEXIBLE FLAT CABLE,AMP-FR

58 614 316 8010 ASSY,WIRE,R/P HEAD-AMP

59 645 031 7637 CORE,FERRITE

or 645 013 6498 CORE,FERRITE

- 7 -

!!

!

645 044 6061 POWER TRANSFORMER

!!

!

423 016 8103 FUSE 250V 4A

!!

!

645 032 1887 CORD,POWER-2.0MK

614 316 8034 ASSY,WIRE,CD-LID

Page 9

PARTS LIST

CD P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

71 614 314 9606 ASSY,PWB CD (Only Initial)

CN111 645 040 0513 SOCKET,FPC 15P

or 645 026 2463 SOCKET,FFC 15P

CN113 645 005 8127 PLUG,6P,BASEMECHA

or 614 310 2472 PLUG,6P,BASEMECHA

CN114 645 005 9292 PLUG,5P

or 614 310 2465 PLUG,5P

CN115 614 316 7990 ASSY,WIRE,WIRE

D1211 407 099 4603 ZENER DIODE MTZJ3.9B

D1402 407 099 5204 ZENER DIODE MTZJ5.1B

D1404 407 012 4406 DIODE 1SS133

IC101 409 396 8100 IC LA9241ML

IC102 409 435 2106 IC LC78622NE

!!

IC103

IC104

!

409 372 9602 IC LA6541

!!

!

409 441 4507 IC TA7291S(M)

L1451 645 031 7835 INDUCTOR,10U K

or 645 001 4550 INDUCTOR,10U K

!!

PR140

!

645 014 2499 PROTECTOR,0.4A 125V

Q1301 405 151 4608 TR KTA1270-O

or 405 151 4509 TR KTA1270-Y

or 405 008 6809 TR 2SB808-F-SPA

or 405 008 7103 TR 2SB808-G-SPA

!!

Q1401

or

or

R1211

!

405 009 5306 TR 2SB927-T

!!

!

405 009 5207 TR 2SB927-S

!!

!

405 141 3604 TR KTA1273-Y

!!

!

402 082 0709 RESISTOR 5.6 J- 2W

X1451 645 020 9024 OSC,CRYSTAL 16.9344MHZ

FRONT P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

72 614 315 1319 ASSY,PWB FRONT (Only Initial)

AH601 614 314 2621 HOLDER,LCD

AR601 614 315 6505 REFLECTOR,_LCD

AS601 614 314 3000 DEC,SHEET,LCD

C6010 403 350 7802 ELECT 1000U M 6.3V

or 403 325 0401 ELECT 1000U M 6.3V

or 403 196 4102 ELECT 1000U M 6.3V

CN601 645 012 5362 SOCKET,FPC 32P

D6010 407 012 4406 DIODE 1SS133

D6110 407 012 4406 DIODE 1SS133

D6111 407 012 4406 DIODE 1SS133

D6112 407 012 4406 DIODE 1SS133

D6113 407 012 4406 DIODE 1SS133

D6114 407 099 5303 ZENER DIODE MTZJ5.6B

D6115 407 099 4603 ZENER DIODE MTZJ3.9B

D6310 408 045 4401 LED FA5366X-2B0-C

D6311 407 222 3800 LED E1L55-7B0A

IC601 410 405 4204 IC LC867240A-5V46

L6010 645 001 5441 INDUCTOR,2.2U K

LCD60 645 043 6239 LCD

Q6101 405 019 2708 TR 2SC536-F-NP

or 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 019 3804 TR 2SC536-G-NP

Q6102 405 004 5004 TR 2SA608-G-NP

or 405 004 4502 TR 2SA608-F-NP

or 405 141 3505 TR KTA1266-Y

or 405 141 3406 TR KTA1266-GR

Q6103 405 004 5004 TR 2SA608-G-NP

or 405 004 4502 TR 2SA608-F-NP

or 405 141 3505 TR KTA1266-Y

or 405 141 3406 TR KTA1266-GR

REF.NO. PART NO. DESCRIPTION

Q6105 405 143 0007 TR KRC107M

or 405 000 3806 TR DTC114YS

Q6106 405 000 3806 TR DTC114YS

or 405 143 0007 TR KRC107M

Q6107 405 004 5004 TR 2SA608-G-NP

or 405 004 4502 TR 2SA608-F-NP

or 405 141 3505 TR KTA1266-Y

or 405 141 3406 TR KTA1266-GR

Q6108 405 017 9709 TR 2SC3330-U

or 405 017 9600 TR 2SC3330-T

or 405 011 8609 TR 2SC1740S-S

or 405 011 8500 TR 2SC1740S-R

or 405 143 8706 TR KTC3199-GR

S6001 645 044 6535 SWITCH,ROTARY(ENCODER)

S6110 645 006 5958 SWITCH,PUSH 1P-1T

or 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

S6111 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6112 614 220 5471 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 240 1002 SWITCH,TACT

S6113 645 006 5958 SWITCH,PUSH 1P-1T

or 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

S6114 645 006 5958 SWITCH,PUSH 1P-1T

or 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

S6115 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6116 614 220 5471 SWITCH,TACT

or 614 240 1002 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6117 645 006 5958 SWITCH,PUSH 1P-1T

or 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

S6118 645 006 5958 SWITCH,PUSH 1P-1T

or 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

S6119 645 006 5958 SWITCH,PUSH 1P-1T

or 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

S6210 614 220 5471 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

or 614 240 1002 SWITCH,TACT

S6211 645 006 5958 SWITCH,PUSH 1P-1T

or 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

S6212 645 006 5958 SWITCH,PUSH 1P-1T

or 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

S6213 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6214 645 006 5958 SWITCH,PUSH 1P-1T

or 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

S6215 645 006 5958 SWITCH,PUSH 1P-1T

or 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

S6216 645 006 5958 SWITCH,PUSH 1P-1T

or 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

- 8 -

Page 10

PARTS LIST

REF.NO. PART NO. DESCRIPTION

S6217 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

or 645 006 5958 SWITCH,PUSH 1P-1T

S6218 645 006 5958 SWITCH,PUSH 1P-1T

or 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

S6219 645 006 5958 SWITCH,PUSH 1P-1T

or 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

S6220 645 006 5958 SWITCH,PUSH 1P-1T

or 614 240 1002 SWITCH,TACT

or 614 220 5471 SWITCH,TACT

SE601 407 217 1101 PHOTO DIODE SPS-442-1G

X6101 645 032 1627 OSC,CRYSTAL 32.768KHZ

X6102 645 018 6103 OSC,CERAMIC 6.000MHZ

TUNER & AMPLIFIER P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

73 614 315 1388 ASSY,PWB AMP-TU (Only Initial)

C2457 403 259 0508 NP-ELECT 1U M 50V

C4601 403 057 3503 POLYESTER 0.1U K 50V

C4605 403 061 3605 POLYESTER 0.039U J 50V

C4606 403 061 7702 POLYESTER 4700P J 50V

C4607 403 059 3204 POLYESTER 2200P J 50V

C4608 403 060 2807 POLYESTER 0.027U K 50V

C4743 403 057 3503 POLYESTER 0.1U K 50V

C4843 403 057 3503 POLYESTER 0.1U K 50V

C4950 403 332 7400 ELECT 2200U M 50V

C4984 403 194 3800 ELECT 2200U M 25V

or 403 329 3309 ELECT 2200U M 25V

CN201 645 005 0695 TERMINAL,ANT

or 645 031 7910 TERMINAL

CN400 645 012 5362 SOCKET,FPC 32P

CN430 645 005 7373 PLUG,3P

or 614 310 2441 PLUG,3P

CN431 407 218 1100 PHOTO COUPLE GP1FA550TZ

or 407 215 1608 PHOTO COUPLE TOTX178A

CN440 614 310 2472 PLUG,6P

or 645 005 8127 PLUG,6P

CN441 614 310 2748 PLUG,3P,POWER

or 645 004 2898 PLUG,3P,POWER

CN445 614 310 2519 PLUG,10P

or 645 005 8158 PLUG,10P

CN450 614 276 6835 SOCKET,JACK

CN455 645 011 6384 JACK,PHONE D3.6,HEADPHONE

CN456 645 006 1875 PLUG,2P,SPEAKER

CN457 645 006 1875 PLUG,2P,SPEAKER

CN458 645 043 8905 JACK,RCA

CT252 645 032 5663 TRIMMER,7PF

D2103 407 012 4406 DIODE 1SS133

D2104 407 012 4406 DIODE 1SS133

D2151 407 012 4406 DIODE 1SS133

D2153 407 105 1602 VARACTOR DI SVC342M-V

or 407 105 1305 VARACTOR DI SVC342L-V

D2301 407 063 9108 ZENER DIODE MTZJ6.8B

D2451 407 012 4406 DIODE 1SS133

D2452 407 153 7502 ZENER DIODE GZS3.0B

D2453 407 012 4406 DIODE 1SS133

D2456 407 012 4406 DIODE 1SS133

D2466 407 012 4406 DIODE 1SS133

D4500 407 012 4406 DIODE 1SS133

D4960 407 012 4406 DIODE 1SS133

D4991 407 099 6805 ZENER DIODE MTZJ13B

D4992

!!

!

407 099 6003 ZENER DIODE MTZJ9.1B

REF.NO. PART NO. DESCRIPTION

D4993 407 012 4406 DIODE 1SS133

!!

D4994

!

407 098 3300 DIODE RL153-BF-S2

D4998 407 012 4406 DIODE 1SS133

HS401 614 314 3017 HEAT SINK,HEATSINK

IC231 409 474 3201 IC LA1844ML

IC241 409 439 4502 IC LC72121M-D

IC440 409 451 7406 IC AN7348K

IC441 409 500 2208 IC LC75343-MPB

!!

IC442

!

409 451 2104 IC TDA7269

IC443 409 189 3404 IC BA7755A

IC445 409 469 6200 IC MM1453XF

!!

IC446

!

409 039 9204 IC NJM78L05A

L2151 645 037 2377 TRANS,ANT,796KHZ

L2153 645 040 2739 TRANS,OSC,796KHZ

L2451 645 031 7842 INDUCTOR,100U K

or 645 001 4581 INDUCTOR,100U K

L4600 645 006 1523 INDUCTOR,470U J

L4601 645 006 1523 INDUCTOR,470U J

L4602 645 037 2858 CORE,PIPE

L4603 645 006 1523 INDUCTOR,470U J

L4604 645 037 2858 CORE,PIPE

!!

PR495

PR496

!

645 014 2505 PROTECTOR,0.8A 125V

!!

!

645 014 2512 PROTECTOR,1A 125V

Q2140 405 020 7402 TR 2SC945A-P

or 405 019 3705 TR 2SC536-G-AUD-SPA

or 405 017 9709 TR 2SC3330-U

or 405 017 9600 TR 2SC3330-T

or 405 011 8609 TR 2SC1740S-S

or 405 020 7204 TR 2SC945A-K

or 405 011 8500 TR 2SC1740S-R

or 405 143 8706 TR KTC3199-GR

Q2201 405 016 0806 TR 2SC2839-E

or 405 151 4103 TR KTC3193-Y

or 405 151 4202 TR KTC3193-O

Q2310 405 017 9600 TR 2SC3330-T

or 405 011 8609 TR 2SC1740S-S

or 405 017 9709 TR 2SC3330-U

or 405 019 3705 TR 2SC536-G-AUD-SPA

or 405 020 7204 TR 2SC945A-K

or 405 011 8500 TR 2SC1740S-R

or 405 143 8706 TR KTC3199-GR

or 405 020 7402 TR 2SC945A-P

Q2451 405 036 3702 TR 2SA1564

or 405 151 5209 TR KRA107M

or 405 000 0904 TR DTA114YS

or 405 078 2404 TR BN1A4P

Q4410 405 004 5004 TR 2SA608-G-NP

or 405 004 4502 TR 2SA608-F-NP

or 405 141 3505 TR KTA1266-Y

or 405 141 3406 TR KTA1266-GR

Q4501 405 000 3806 TR DTC114YS

or 405 143 0007 TR KRC107M

Q4502 405 000 3806 TR DTC114YS

or 405 143 0007 TR KRC107M

Q4600 405 155 0002 TR MPSA56

Q4601 405 000 3806 TR DTC114YS

or 405 143 0007 TR KRC107M

Q4602 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 019 2708 TR 2SC536-F-NP

or 405 019 3804 TR 2SC536-G-NP

Q4603 405 141 3307 TR KTC3198-GR

Q4700 405 000 3806 TR DTC114YS

or 405 143 0007 TR KRC107M

Q4800 405 000 3806 TR DTC114YS

or 405 143 0007 TR KRC107M

- 9 -

Page 11

PARTS LIST

REF.NO. PART NO. DESCRIPTION

Q4950 405 019 3804 TR 2SC536-G-NP

or 405 141 3307 TR KTC3198-GR

or 405 141 3208 TR KTC3198-Y

or 405 019 2708 TR 2SC536-F-NP

Q4960 405 155 0002 TR MPSA56

Q4961 405 155 0002 TR MPSA56

Q4962 405 000 3806 TR DTC114YS

or 405 143 0007 TR KRC107M

Q4963 405 000 3806 TR DTC114YS

or 405 143 0007 TR KRC107M

Q4990

or

or

Q4991

or

or

Q4992 405 141 3703 TR KTA1271-Y

or 405 008 2405 TR 2SB698-F

or 405 008 2504 TR 2SB698-G

Q4993 405 008 2405 TR 2SB698-F

or 405 008 2504 TR 2SB698-G

or 405 141 3703 TR KTA1271-Y

Q4994 405 000 3806 TR DTC114YS

or 405 143 0007 TR KRC107M

R4742

R4842

S0012 614 317 3311 SHIELD,PLATE

S4901 614 215 9828 SWITCH,TACT

SA401 411 021 6405 SCR S-TPG BIN 3X8

SA402 411 021 6405 SCR S-TPG BIN 3X8

SA403 411 021 6405 SCR S-TPG BIN 3X8

SA404 411 021 6405 SCR S-TPG BIN 3X8

SA405 411 021 6405 SCR S-TPG BIN 3X8

T2002 645 046 2023 FILTER,450KHZ

U2101 645 045 4073 TUNER,FM

X2451 645 023 4965 OSC,CRYSTAL 7.2MHZ

XF221 645 010 7665 CERAMIC FILTER 10.70MHZ

or 645 010 0079 CERAMIC FILTER 10.70MHZ

or 614 240 2917 FILTER,CERAM

XF222 645 010 7665 CERAMIC FILTER 10.70MHZ

or 645 010 0079 CERAMIC FILTER 10.70MHZ

or 614 240 2917 FILTER,CERAM

XF231 645 041 9324 CERAMIC FILTER 450KHZ

XF233 645 039 9923 TRANS,IF 10.7MHZ

or 645 040 9981 TRANS,IF 10.7MHZ

!!

!

405 138 6403 TR KTD2058Y

!!

!

405 095 1602 TR 2SD2061-E

!!

!

405 095 1701 TR 2SD2061-F

!!

!

405 138 6403 TR KTD2058Y

!!

!

405 095 1602 TR 2SD2061-E

!!

!

405 095 1701 TR 2SD2061-F

!!

!

402 071 1304 FUSIBLE RES 2.2 JA 1/4W

!!

!

402 071 1304 FUSIBLE RES 2.2 JA 1/4W

614 317 3397 CUSHION

POWER TRANSFORMER,

SECONDARY P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

75 614 315 1371 ASSY,PWB POWER TRANSFORMER,

SECONDARY (Only Initial)

CN420 614 020 1222 SOCKET,3P

CN421 614 316 8003 ASSY,WIRE,PT-AMPWIRE

!!

D4280

D4281

D4282

D4283

D4284

FCL41

or

FCL42

or

PR420

!

407 196 5800 DIODE 1N5402BD82

!!

!

407 196 5800 DIODE 1N5402BD82

!!

!

407 196 5800 DIODE 1N5402BD82

!!

!

407 196 5800 DIODE 1N5402BD82

!!

!

407 098 3300 DIODE RL153-BF-S2

!!

!

645 006 4760 HOLDER,FUSE

!!

!

645 031 7903 HOLDER,FUSE

!!

!

645 006 4760 HOLDER,FUSE

!!

!

645 031 7903 HOLDER,FUSE

!!

!

645 014 2567 PROTECTOR,2.5A 125V

CD LID SWITCH P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

76 614 316 5170 ASSY,PWB CD LID SW (Only Initial)

S1900 645 044 8799 SWITCH,LEVER

S1901 645 044 8782 SWITCH,LEVER

POWER TRANSFORMER,

PRIMARY P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

74 614 314 9613 ASSY,PWB POWER TRANSFORMER,

PRIMARY (Only Initial)

CN411 614 017 8203 TERMINAL BOARD

CN412 614 017 8203 TERMINAL BOARD

S4100

L4191 645 041 3087 INDUCTOR, 180U

or 645 038 6053 INDUCTOR, 181U

or 645 017 8061 INDUCTOR, 181M

!!

!

614 226 3624 SWITCH

- 10 -

Page 12

PARTS LIST(TAPE MECHANISM)

g

2

1

3

TAPE MECHANISM

REF.NO. PART NO. DESCRIPTION

614 315 4839 ASSY,MECHA,TM-DA370TN-SH

1 645 045 1799 R/P,E HEAD KC-9142EA-0321

2 645 010 9454 PINCH ROLLER(R) ASSY

3 645 010 9447 PINCH ROLLER(F) ASSY

4 645 045 1751 ASSY,MOTOR

5 645 045 1959 RF BELT

6 645 045 1997 MAIN BELT

7 645 045 2048 DETECT SWITCH MXS01190

5

6

7

4

* N.S.P : Not supplied as service parts.

IC BLOCK DIAGRAM & DESCRIPTION

IC101 LA9241M (Servo Signal Processor)

Vcc1 LDS LDD BH1 PH1 LF2 VR REF1 Vcc2

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

FIN2

FIN1

TESI

APC

1

2

I/V

3

E

4

F

5

TB

6

TE-

7

TE

8

9

SCI

10

TH

11

TA

12

TD-

13

TD

14

JP

15

TO

16

FD

BAL

TE

T.SERVO & T.LOGICK

RF DET

VCA

VCA

F.SERVO & F.LOGICK

FA-FAFD-

SP

AGND

FE-FE

REF

µ-com

INTER FACE

SPINDLE SERVO

FSS

DRF CE

DAT CL CLK DEF

SLED SERVO

SLC

RF Amp

IC103 LA6541 (Pick-up Actuator & Motor Driver)

Vcc Vref VIN4 VG4 Vo8 Vo7 GND Vo6 Vo5 VG3 VIN3 CD RES

Vcc

5

GND

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32313029282726252423222120191817

JP-SL+SL-SLDSLEQSPDSP-SPGSPI

11k

Level

Vcc

2

Level

Sift

Sift

NC

TBC

FSC

DGND

SLI

SLC

RFS-

RFSM

CV+

CV-

SLOF

HFL

TES

TOFF

TGL

JP+

123 456 789

Vcc Mute VIN1 VG1 Vo1 Vo2 GND Vo3 Vo4 VG2 VIN2 Re

IC104 TA7291S( Bridge Driver)

Vref

8

BTL

Driver

BTL

Driver

REG

Protective Circuit

(Heat Interception)

1

9

IN1

- 11 -

IN2

BTL

Driver

BTL

Driver

11k

Level

Sift

Level

Sift

11k11k

10 11 12

131415161718192021222324

RESET

Regulator

OUT Reg IN

6

7

3

Vs

OUT1

OUT2

Page 13

IC BLOCK DIAGRAM & DESCRIPTION

MUTE

IN-L

GND

IN-R

VSS

OUT-L

IN-L

OUT-R

5

7

9

11

4

8

3

1

6

10

2

+

+

-

-

IN-R

IN-R

IN-R

IC443 BA7755A (Head Switch)IC440 AN7348K ( Play/Rec Pre Amp)

L-REC OUT

17

Rec

Amp(L)

Rec

Amp(R)

Logic

Rec/PB

8

R-REC OUT

ALC

16

P

P

R

R

P

9

REC/PB SW

HI/LO

15

R

Nor/Cro

& Hi/Lo

Logic

10 1211

A/B SW

A/Rec

L-PB AMP

B

A/Rec

1

L-PB AMP

R-PB AMP

B

2

R-PB AMP

L-PB NF

PB Amp(L)

PB Amp(R)

3

R-PB NF

L-PB EO

21222324

Mute

Mute

4

R-PB EO

L-PB

AMP OUT

20

576

R-PB OUT

ALC

Logic

A/B

ALC

AB SW

L-REC IN

1819

R-REC IN

IC445 MM1453XF (Q Xpander with Spread Control)

CC

V

L

REF

IN

V

1718 16

QF2 QF3 QF4 QF5 QF6QF1

15 14 13 12 11 10

CRO/NOR

Ripple

Rejection

FILTER

VCC

1314

GND

1

VCC

HEAD

SWITCH

GND

4

CTRL2

52 3

CTRL1

IC442 TDA7269 ( Stereo Amplifier)

Bias

18

R

IN

PNR S/Q DET Q

34567

2

IC231 LA1844ML ( Tuner System)

24 23 22 21 20 19 18 17 16 15 14 13

ALC

BUFF

LEVEL

DET

FM

IF

VIRTUAL AUDIO

QXpander

PROCESSOR

IN

SPC R

AM

OSC

S-CURVE

FM

DET

AM

MIX

REG

AM/FM

IF

BUFF

AM

RF.AMP

OUTLOUT

AGC

IF

COMP

TUNING

DRIVE

GND

AM

DET

AM

9

GND

P-DET

ø

304kHz

DECODER

ANTI-BIRDIE

VCO

VCC

STEREO

SW

FF

38k

FF

19k

2

PILOT

CANCEL

FF

19k

PILOT

DET

1

2 3 4 5 6 7 8 9 10 11 12

- 12 -

Page 14

IC BLOCK DIAGRAM & DESCRIPTION

IC102 LC78622NE (Digital Signal Processor)

No. Pin Name I/ O Function

1 DEFI I Input terminal for detect signal of defect

2 TAI I Input terminal for test.

3 PDO O The phase comparison output terminal for

external VCO control.

4 VVSS - Ground terminal for built-in VCO

5 ISET I Resistance connection terminal for

electric current adjustment of PDO output.

6 VVDD - Built-in VCO power supply terminal.

7 FR I VCO frequency range adjustment.

8 VSS - Ground for Digital

9 EFMO O EFM signal output terminal for slice level control.

10 EFMIN I EFM signal input terminal for slice level control.

11 TEST2 I TEST pin. Normal time is non connection.

12 CLV+ O Output terminal for Disc motor control.

13 CLV- O Output terminal for Disc motor control.

14 V/P O Change of rough servo / phase control

Rough servo : "H", Phase control : "L"

15 HFL I Input terminal of track search signal.

16 TES I Input terminal of tracking error signal.

17 TOFF O Output terminal of tracking off.

18 TGL O Output terminal for change of tracking gain.

19 JP+ O Output terminal for tracking jump control.

20 JP- O Output terminal for tracking jump control.

21 PCK O Clock monitor output terminal for EFM data

playback. (4.3218 MHz)

22 FSEQ O Output terminal for detect of SYNC signal.

23 DVDD - +5V

24 CONT1 I/O

25 CONT2 I/O This output can control at serial control from

26 CONT3 I/O micro processor.

27 CONT4 I/O

28 CONT5 I/O

29 EMPH O Output terminal of de-emphasis monitor .

"H" : de-emphasis

30 C2F O Output terminal of C2 flag

31 DOUT O Output terminal of digital out

No. Pin Name I/O Function

32 TEST3 I Test pin.

33 TEST4 I Test pin.

34 NC - Non connection.

35 MUTEL O Mute output terminal for L-ch

36 LVDD - Power supply for L-ch

37 LCHO O Output terminal for L-ch

38 LVSS - GND for L-ch

39 RVSS - GND for R-ch

40 RCHO O Output terminal for R-ch

41 RVDD - Power supply for R-ch

42 MUTER O Mute output terminal for R-ch

43 XVDD - Power supply of crystal oscillation

44 XOUT O Connection terminal of crystal oscillation (16.9344MHz)

45 XIN I Connection terminal of crystal oscillation (16.9344MHz)

46 XVSS - GND of crystal oscillation

47 SBSY O Output terminal for synchronizing signal of

sub-cord block

48 EFLG O Output terminal for correction monitor of C1, C2,

Single and Double

49 PW O Output terminal for sub-cord of P, Q, R, S, T, U and W

50 SFSY O O utput terminal for synchronizing signal of

sub-cord frame

51 SBCK I Input terminal for readout clock of sub-cord

52 FSX O Output terminal of Synchronizing signal (7.35kHz)

53 WRQ O Output terminal for standby of sub-cord Q output

54 RWC I Input terminal of read / write control

55 SQOUT O Output terminal of sub-cord Q

56 COIN I Input terminal of command from micro processor

57 CQCK I Clock input for reading sub-cord from SQOUT

58 RES I Reset (turn on : L)

59 TST11 O Test pin

60 16M O 16.9344MHz

61 4.2M O 4.2336MHz

62 TEST5 I Test pin

63 CS I Chip select terminal

64 TEST1 I Test pin

DEFI

EFMIN

FSEQ

CLV+

CLV-

SBCK

SBSY

SFSY

WRQ

SQOUT

CQCK

COIN

RWC

TEST2 TEST4

EFMO VVDDVVSSPDO ISET FR PCK TAI

9

1

Slice level

Control

10

Syncrnous Detect

22

EFM Demodulation

12

13

14

V/P

PW

49

51

47

50

63

CS

53

55

57

56

54

CLV

Digital Servo

Subcode Dxract

QCRC

µCOM

Inter Fase

Servo Commander

15 16 17 20 19 58 18 24 25 26 27 28 29 48 60 61 46 52 45 44 43 39 41 42 40 37 35 38 36

6

TGL

RESJP+JP-TOFFTESHFL

4

357 2

VCO Clock Oscillator

& Clock Control

General Ports

CONT3

CONT1

CONT4

CONT2

TST11

TEST1 TEST3 TEST5

21

59 64 11 32 33 62

2KA~8bit

C1 C2 Error Detect &

Correct Control Flag

Timing Generator

4.2M16MEFLGEMPHCONT5

RAM

X'tal Root

XV

SS

VDDV

SS

23

8

Interpolalation Mute

Quadruple Over Sampling

RV

XV

XINFSX

XOUT

DD

DD

RV

SS

MUTER

- 13 -

RAM Address

Generatorl

Billingual

Digital Attenuator

Digital Filter

1bit DAC

L.P.F

RCHO

C2F

30

Digital Out

DD

MUTELLCHO

LV

LV

SS

31

DOUT

(NC)

34

Page 15

IC BLOCK DIAGRAM & DESCRIPTION

IC601 LC867240A-5V46 (Micro Processor)

Pin No Pin Name

1 P06

2 P07

3 P10/S00

4 P11/SIO/SB0

5 P12/SCK0

6 P13/S01

7 P14/SII/SB1

8 P15/SCK1

9 P16/BUZ

10 P17/PWM0

11 P70/INT0

12 RES/

13 XT1/P74 Sub Clock OSC

14 XT2/P75 Sub Clock OSC

15 VSS1

16 CF1 Main Clock OSC

17 CF2 Main Clock OSC

18 VDD1

19 P80/AN0

20 P81/AN1

21 P82/AN2

22 P83/AN3

23 P84/AN4

24 P85/AN5

25 P86/AN6

26 P87/AN7

27 P71/INT1

28 P72/INT2/TOIN

29 P73/INT2/TOIN

30 S0/PA0

31 S1/PA1

32 S2/PA2

33 S3/PA3

34 S4/PA4

35 S5/PA5

36 S6/PA6

37 S7/PA7

38 S8/PA8

39 S9/PB1

40 S10/PB2

41 S11/PB3

42 S12/PB4 O LCD Pin No5

43 S13/PB5 O LCD Pin No6

44 S14/PB6 O LCD Pin No7

45 S15/PB7 O LCD Pin No8

46 S16/PC0 O LCD Pin No9

47 S17/PC1 O LCD Pin No10

48 S18/PC2 O LCD Pin No11

49 S19/PC3 O LCD Pin No12

50 S19/PC4 O LCD Pin No13

Symbol

AMBER_LED

DSP_RESET

COIN

SQOUT

CQCK

VD_GND

Sift

RWC

JOG+

JOGDRF

Reset

Vss

Vdd

Key1

Key2

Open SW

Close SW

LIMIT_SW

C2F

M-Media

WRQ

RDS_IN

IR

V CHK

G_REVS

G_FWD

PACK

TAPE_INI

REEL

Tape Play PL

Motor

BEAT

R Mute

OSC

SURROUND

I/O Function

O AMBER_LED Output

O DSP Reset Signal

O CD_DSPInterface(command+data Output)

I CD_DSPInterface(SubQ dataInput)

O CD_DSPInterface(Clock)

O Processor Power Check (GND) Control

Output

O Shift Control for Micon Oscillatrion

Frequency

O CD_DSP Interface(Command latch Output)

I Jog Dial +

I Jog Dial -

I DRF Signal Input

Reset Switch

Gnd

Power Supply Terminal

A/D Key In

A/D Key In

I Top Lid Open Sens. Switch

I Top Lid Close Sens. Switch

I Limit Switch

I DSP C2F Input

I Multi Media Input

I CD DSP Interface (SubQ Request)

I Serial Data for RDS IC Input

I Remotecontrol Input

I Power failure Detect/Processor Power

Check Input

I Miss Recording SW(tapeAB side)Input

I Miss Recording SW(tapeB side)Input

I Tape Park Check Input

I Tape Deck Initialize

I Real Rotating signal Input

O Tape Play Plunger Output

O Tape Motor Output

O Beat Cancel Control

O Tape Recording Mute

O Tape Oscillation ON/OFF Control

O Surround Output

Pin No Pin Name Symbol I/O Function

51 S21/PC5 O LCD Pin No14

52 S22/PC6 O LCD Pin No15

53 S23/PC7 O LCD Pin No16

54 S24/PD0 O LCD Pin No17

55 S25/PD1 O LCD Pin No18

56 VDD2

57 VSS2

58 S26/PD2 O LCD Pin No19

59 S27/PD3 O LCD Pin No20

60 S28/PD4 O LCD Pin No21

61 S29/PD5 O LCD Pin No22

62 S30/PD6 O LCD Pin No23

63 S31/PD7 O LCD Pin No24

64 S32/PE0 O LCD Pin No25

65 S33PE1 O LCD Pin No26

66 S34/PE2 O LCD Pin No27

67 S35/PE3 O LCD Pin No28

68 S36/PE4 O LCD Pin No29

69 S37/PE5 O LCD Pin No30

70 S38/PE6 O LCD Pin No31

71 S39/PE7 O LCD Pin No32

72 S40/PF0 O LCD Pin No33

73 S41/PF1 O LCD Pin No34

74 S42/PF2 O LCD Pin No35

75 S43/PF3 O LCD Pin No36

76 S44/PF4 O LCD Pin No37

77 S45/PF5 O LCD Pin No38

78 S46/PF6 O LCD Pin No39

79 S47/PF7 O LCD Pin No40

80 V3/PL6

81 V2/PL5

82 V1/PL4

83 COM0/PL0

84 COM1/PL1

85 COM2/PL2

86 COM4/PL3

87 P30

88 P31

89 VSS3

90 VDD3

91 P32

92 P33

93 P34

94 P35

95 P00

96 P01

97 P02

98 P03

99 P04

100 P05

Vdd

Vss

LCD COM1

LCD COM2

LCD COM3

LCD COM4

D CHK

TU_DUT

Vss

Vdd

VF_DO

VF_CE

TU_CE

TU_DI

LID_M+

LID_MP_CON

PRE_MUTE

MAIN_MUTE

BLUE_LED

O Vdd

O Gnd

O LCD COM 1 (LCD Panel Pin1)

O LCD COM 2 (LCD Panel Pin2)

O LCD COM 3 (LCD Panel Pin3)

O LCD COM 4 (LCD Panel Pin4)

O Serial Clock Output for Tuner/Volume FUNC IC

O Serial Data Output for Tuner IC

Gnd

Power Supply Terminal

O Serial Data Output for VOL_FUNC IC

O Serial Data Output for VOL_FUNC IC

O Serial Latch Output for TU IC

I Serial Data Input for TU IC

O Top Lid Motor Control Output +

O Top Lid Motor Control Output O Power Control

O Pre Amp Mute Output

O Power Amp Mute

O Blue LED Output

IC241 LC72121M-D (Pll Synthesizer)

2

Vssx

1

XIN

XOUT

24

FMIN

17

16

AMIN

CE

3

DI

CL

DO

V

Vssd

4

5

6

DD

18

15

CCB

I / F

POWER

RESET

ON

1/2

REFERENCE

DIVIDER

SWALLOW COUNTER

1/16, 1/17 4bits

12bits PROGRAMMABLE

DIVIDER

DATA SHIFT REGISTER LATCH

9

8

7

BO1

BO2 BO3 BO4

10 11

- 14 -

IO1

14

IO2

PHASE DETECTOR

CHARGE PUMP

UNLOCK

DETECTOR

UNIVERSAL

COUNTER

19

PD

20

AIN

21

AOUT

22

Vssa

13

IFIN

Page 16

LCD DISPLAY DESCRIPTION

LCD60

S1

PAD NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

T2

401

18

T1

*1

S4S3

S2

S6

COM1

COM1

--

--

-1F

1A

1K

1B

2F

2A

2K

2B

3F

3A

3K

3B

4F

4A

4K

4B

COM2

--

COM2

--

--

1G

1I

1J

1H

2G

2I

2J

2H

3G

3I

3J

3H

4G

4I

4J

4H

COM3

--

--

COM3

-1E

1M

1N

1C

2E

2M

2N

2C

3E

3M

3N

3C

4E

4M

4N

4C

COL

P

S7S5

COM4

--

--

--

COM4

OFF

1L

1D

REC

SLEEP

2L

2D

S2

S3

3L

3D

S4

S5

4L

4D

S6

SURR.

PAD NO.

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

COM1

5F

5A

5K

5B

6F

6A

6K

6B

7F

7A

7K

7B

8F

8A

8K

8B

T1

ST

*1

V4

V1

COM2

5G

5I

5J

5H

6G

6I

6J

6H

7G

7I

7J

7H

8G

8I

8J

8H

T2

MONO

V1

V5

F

V7

T3

EC

*1

COM3

COM4

5E

5M

5N

5C

COL

6E

6M

6N

6C

RANDOM

7E

SURR.

7M

7N

7C

8E

REPEAT

MHz

8M

8N

8C

ON

RDS

V2

V6

A

J

IK

GH

LN

M

D

S7

5L

5D

P

6L

6D

7L

7D

8L

8D

KHz

S1

T3

V3

V7

B

- 15 -

Page 17

SCHEMATIC DIAGRAM (CD)

PRODUCT SAFETY NOTICE

Each precaution in this manual should

be followed during servicing.

Components identified with the IEC

!!

!

symbol

schematic diagram designated

components in which safety can be

of special significance. When

replacing a component identified by

!!

!

designated, or parts with the same

ratings of resistance, wattage or

voltage that are designated in the

parts list in this manual. Leakagecurrent or resistance measurements

must be made to determine that

exposed parts are acceptably

insulated from the supply circuit

before returning the product to the

customer.

in the parts list and the

, use only the replacement parts

This is a basic schematic diagram.

- 17 -- 16 -

Page 18

SCHEMATIC DIAGRAM (FRONT)

PRODUCT SAFETY NOTICE

Each precaution in this manual should be followed during servicing.

Components identified with the IEC symbol

schematic diagram designated components in which safety can be of

special significance. When replacing a component identified by

only the replacement parts designated, or parts with the same ratings of

resistance, wattage or voltage that are designated in the parts list in this

manual. Leakage-current or resistance measurements must be made to

determine that exposed parts are acceptably insulated from the supply

circuit before returning the product to the customer.

!!

!

in the parts list and the

!!

!

, use

This is a basic schematic diagram.

- 19 -- 18 -

Page 19

SCHEMATIC DIAGRAM (AMPLIFIER)

This is a basic schematic diagram.

PRODUCT SAFETY NOTICE

!!

Each precaution in this manual should be followed during servicing. Components identified with the IEC symbol

designated components in which safety can be of special significance. When replacing a component identified by

or parts with the same ratings of resistance, wattage or voltage that are designated in the parts list in this manual. Leakage-current or resistance measurements

must be made to determine that exposed parts are acceptably insulated from the supply circuit before returning the product to the customer.

!

in the parts list and the schematic diagram

, use only the replacement parts designated,

!!

!

- 25 -- 24 -

Page 20

SCHEMATIC DIAGRAM (TUNER)

This is a basic schematic diagram.

- 27 -- 26 -

Page 21

WIRING DIAGRAM(PRIMARY+ SECONDARY POWER TRANSFORMER AND CD LID SWITCH)

POWER TRANSFORMER, PRIMARY P.W.BOARD

POWER TRANSFORMER, SECONDARY P.W.BOARD

CD LID SWTICH P.W.BOARD

- 28 -

Page 22

VOLTAGE TABLE

IC101 LA9241M

PIN 123456789101112131415161718

VOL(V) 2.51 2.51 2.54 2.54 2.52 2.52 2.52 2.52 2.52 2.52 2.52 2.52 2.52 2.52 2.52 2.52 2.52 2.52

PIN 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

VOL(V) 2.52 2.52 2.52 0 2.52 2.52 2.52 2.52 2.52 2.52 2.02 2.28 2.28 0 0 4.98 4.98 0

PIN 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54

VOL(V) 0 4.98 0 0 1.62 2.44 2.46 2.55 0 2.54 2.52 0 0 2.32 4.71 4.71 0 0

PIN 55 56 57 58 59 60 61 62 63 64

VOL(V) 0 4.99 2.53 2.53 0.97 0.98 2.23 4.35 0 5.01

IC102 LC78622NE

PIN 123456789101112131415161718

VOL(V) 00001.53 4.97 0.1 0 2.54 2.44 0 0 0 4.95 0 0.06 4.96 4.96

PIN 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

VOL(V)

PIN 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54

VOL(V) 2.03 0 0 2.04 4.98 4.94 4.96 2.15 2.11 0 0.12 2.27 0 2.48 0.1 2.48 0 0

PIN 55 56 57 58 59 60 61 62 63 64

VOL(V) 0 4.71 4.63 4.75 0 2.01 2.22 0 0 0

0 0 2.46 0 4.97 4.86 000004.89 2.49 0 0 0 4.96 4.98

IC103 LA6541

PIN 123456789101112131415161718

VOL(V) 8.63 4.81 2.51 2.52 3.88 3.9 3.91 3.91 2.53 2.53 5.02 8.02 4.99 4.83 2.52 2.53 3.89 3.93

PIN 19 20 21 22 23 24

VOL(V) 3.93 3.93 2.53 2.53 2.53 8.63

IC104 TA7291

PIN 123456789

VOL(V) 4.76 8.64 0.56 0 0 8.61 0.56 4.03 4.76

IC231 LA1844ML

PIN 123456789101112131415161718

VOL(V) 2.31 6.7 2.31 2.31 0 4.65 4.65 6.7 6.7 0 5.61 5.69 3.21 3.21 2.25 2.31 2.05 2.53

PIN 19 20 21 22 23 24

VOL(V) 0 0.27 2.58 2.58 6.69 6.69

UNIT:V

UNIT:V

UNIT:V

UNIT:V

UNIT:V

IC241 LC72121M

PIN 123456789101112131415161718

VOL(V) 1.52 0 0.22 0.14 0.17 4.65 0 11.6 5.38 0 0.61 0 0 4.65 0 0.07 1.49 3.1

PIN 19 20 21 22 23 24

VOL(V) 0.9 0.9 1.43

0 1.52

0

IC440 AN7348K

PIN 123456789101112131415161718

VOL(V) 0 0 0.66 3.23 3.23 0.07 00004.99 0 6.99 00000

PIN 19 20 21 22 23 24

VOL(V) 0.16 3.2 3.91 0.67 0 0

IC441 LC75343M

PIN 123456789101112131415161718

VOL(V) 0 0 0 3.41 3.41 3.41 3.41 3.41 3.41 3.41 3.41 3.41 3.41 3.41 3.41 3.41 3.41 3.41

PIN 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

VOL(V) 3.41 3.41 3.41 3.41 3.41 3.41 3.41 3.41 3.41 3.41 3.41 3.41 3.41 3.41 3.41 3.41 6.83 0

IC442 TDA7269

PIN 1234567891011

VOL(V) 0 17.3 35.1 17.3 30.7 0 17.3 17.3 17.3 17.3 17.3

UNIT:V

UNIT:V

UNIT:V

UNIT:V

- 29 -

Page 23

VOLTAGE TABLE

IC443 BA7755A

PIN 12345

VOL(V) 8.22 0000

IC445 MM1453XF

PIN 123456789101112131415161718

VOL(V) 3.42 3.42 0 0 3.42 3.42 3.42 3.42 0 3.42 3.42 3.42 3.42 3.42 4.09 3.42 7.38

IC446 NJM78L05

PIN

VOL(V)

123

17.3 0.58 5.48

IC601 LC867240A

PIN 123456789101112131415161718

VOL(V) 0 4.75 4.75 0 4.75 4.75 0 0 4.83 4.83 0 4.75 2.55 2.66 0 2.1 2.4 0

PIN 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

VOL(V)

PIN 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54

VOL(V) 0 0 4.67 0 0 2.41 2.41 2.39 2.38 2.39 2.41 2.41 2.41 2.41 2.41 2.41 2.41 2.41

PIN 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72

VOL(V) 2.41 2.41 2.41 2.41 2.41 2.41 2.41 2.41 2.41 2.41 2.41 2.41 2.41 2.41 2.41 2.41 2.41 2.41

PIN 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90

VOL(V) 2.41 2.41 2.41 2.41 2.41 2.41 2.41 0 0 0.1 2.44 2.44 2.44 2.44 0 0 0 4.75

PIN 91 92 93 94 95 96 97 98 99 100

VOL(V) 0 0 0 4.73 4.76 4.76 4.71 4.75 0 4.71

TRANSISTOR

E 5.46 0 4.02 8.7 0000011.9 12.6 12.6 0 0 12.5 8.69 9.35 13.6

C 5.45 0 3.08 0 0.68 000011.3 0 0 12.3 12.1 17.6 17.6 9.33 13.6

B 4.81 4.67 4.68 8.67 0 0 0 2.23 4.73 11.6 12 12.1 0 0 13.1 9.33 8.67 12.9

E 0 4.97 8.64 0 4.52 4.52 0 0 4.76 0 0 10.3 0 0 10.7 10.7 10.7

C 0 1.53 5.04 4.76 3.88 4.46 7.18 0.12 4.6 0.66 0 0.16 8.44 6.69 10.6 0 11.6

B 4.67 4.33 8.04 0 11.8 3.88 0 4.71 4.74 0 0 0 0.67 0 0 10.6 5.96

0 4.85 4.85 0 0 4.75 0 0 0 4.66 4.83 4.6 4.83 4.83 4.83 4.83 2.01 0

Q4410 Q4501 Q4502 Q4600 Q4601 Q4602 Q4603 Q4700 Q4800 Q4950 Q4960 Q4961 Q4962 Q4963 Q4990 Q4991 Q4992 Q4993

Q4994 Q1301 Q1401 Q6101 Q6102 Q6103 Q6105 Q6106 Q6107 Q6108 Q2140 Q2158 Q2201 Q2310 Q2451 Q2452 Q2453

UNIT:V

UNIT:V

UNIT:V

UNIT:V

UNIT:V

- 30 -

Page 24

WIRING CONNECTION

TAPE DECK

MECHANISM

(10P)

P.T SECONDARY

P.W.B

CN420

FU421

T4A L 250V

(3P)

CN400

(32P)

TUNER & AMP P.W.B

PHONES

CN455

CN440

CN601

CN445

(10P)

(6P)

LCD60

(32P)

FRONT P.W.B

CN441

(3P)

CN201

CN430

(3P)

CN450

CN458

CN457

(2P)

CN456

(2P)

AM LOOP ANT.

FM ANT.

OPTICAL OUT

CN431

VIDEO(AUDIO) IN

SUB

WOOFER

L-CH

SPEAKER

BOX

R-CH

SPEAKER

BOX

AC IN

CN411

BW

BL

CN412

P.T PRIMARY

P.W.B

P.T

BRREBK

CD LID SWITCH

P.W.B

CN???

(3P)

CN113

CN111

(15P)

(15P)

(6P)

(6P)

CD P.W.B

CN114

(5P)

CD LID

M

MOTOR

CD MECHANISM

May / '01 / 450 BB Printed in Japan

SANYO Technosound Co., Ltd.

Osaka, Japan

Loading...

Loading...