Page 1

FILE NO.

Service Manual

123

SLEEP

z/ON

dc

fe

i

FM MODE RANDOM

PRESET

VOLUME

TUNER/BAND SOUND PRESET

REMOTE CONTROLLER RB-DA100

Micro Component System

DC-DA150 (SS)

(AU)

(KR)

z/ON

TUNING

TUNER/BAND FUNCTION

U

L

O

V

b

i

f

564

8097

MEMORY

TAPEVIDEO

n

REPEAT

PHONES

d

REC PLAY REW F FWD STOP/EJECT PAUSE

madcn/qk

CLOCK/TIMER

MEMORY

BASSXPANDER

M

E

+

a

SURROUND

SOUND PRESET

n

e

c

Contents

Specifications...................................................................1

Laser beam safety precaution.......................................... 1

CD pick-up maintenance.................................................. 2

CD player adjustments..................................................... 2

Tape deck adjustments....................................................3

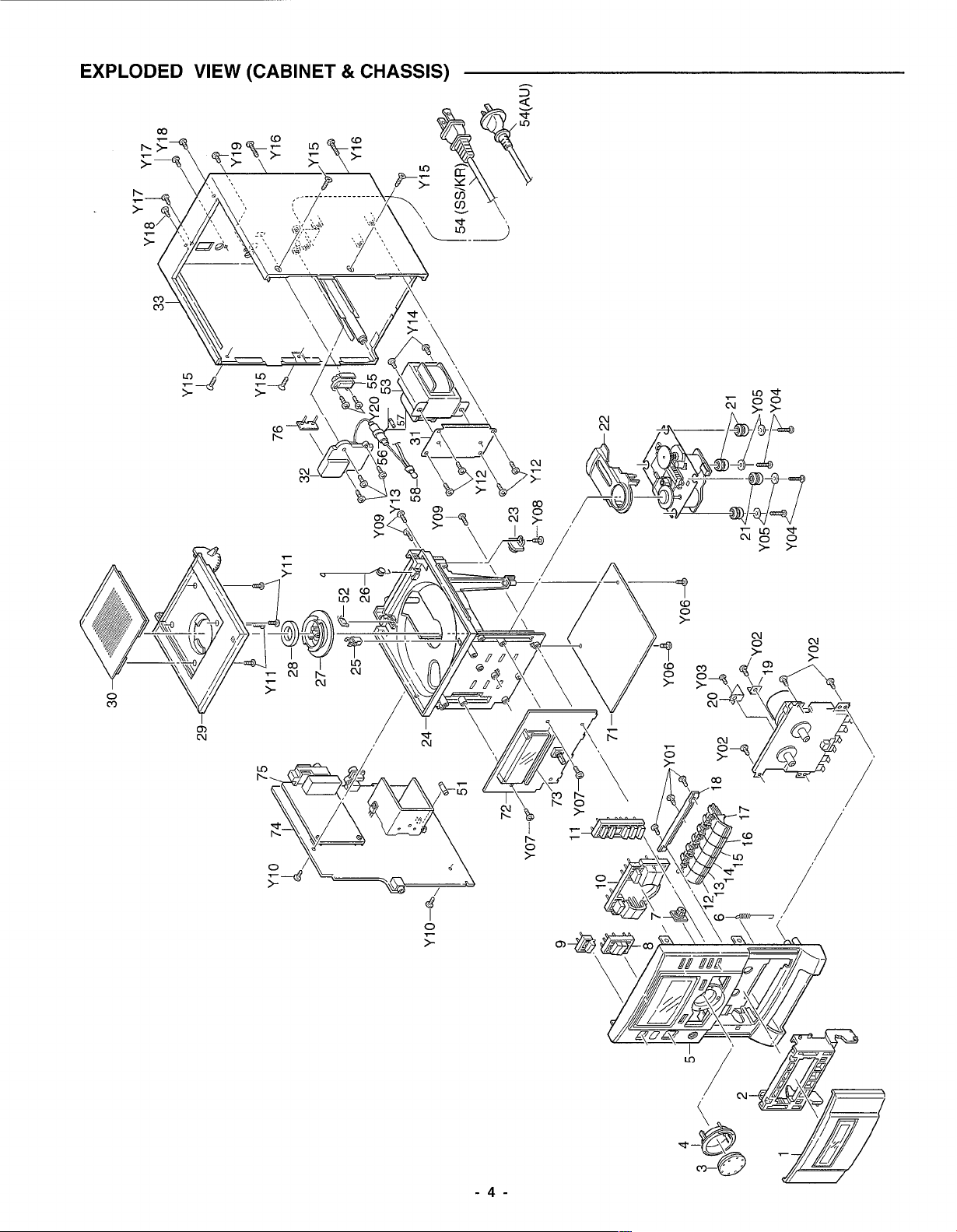

Exploded view

(Packing & Accessory, Cabinet & Chassis,

Fixing Parts, Electrical Parts & PWB Assy) ................. 4

(Tape mechanism) ........................................................9

(CD mechanism) ...........................................................9

Parts list

(Cabinet & Chassis) ......................................................5

(Tape mechanism) ........................................................9

(CD mechanism) ...........................................................9

PRODUCT CODE No.

129 587 02 (SS)

129 587 04 (AU)

129 587 06 (KR)

IC block diagram & description ........................................10

Schematic diagram

(CD)...............................................................................12

(FRONT) .......................................................................16

(AMPLIFIER)................................................................. 20

Wiring diagram

(CD, FRONT, LED for SS & KR)................................... 14

(CD, FRONT, LED for AU) ............................................ 18

(AMPLIFIER for SS & KR) ............................................22

(AMPLIFIER for AU)......................................................24

FL display description ......................................................26

Wiring connection ............................................................ 27

REFERENCE No.

SM5810137

Page 2

SPECIFICATIONS

Tuner

Reception frequency.............. FM : 87.5 - 108.0 MHz

MW :522-1710 kHz(9kHz step)

520 -1710 kHz(10kHz)

CD player

Channels................................ 2-channel stereo

Sampling frequency ............... 44.1 kHz

Pick-up................................... Optical 3-beam

semiconductor laser

Wow and Flutter..................... Below measurable limits

Cassette deck section

Track system ......................... 4-track, 2-channel stereo

Frequency response .............. 80 Hz - 13.5 kHz (Normal tape)

Signal to noise ratio ............... 45 dB

Wow and Flutter..................... 0.15% (WRMS)

Fast forward / Rewind time .... Approx. 110 sec. (C-60)

General

Output power ......................... 6 W x 2 (at 4 ohms, 10% distortion)

Inputs ..................................... VIDEO IN : 400 mV / 50k ohms

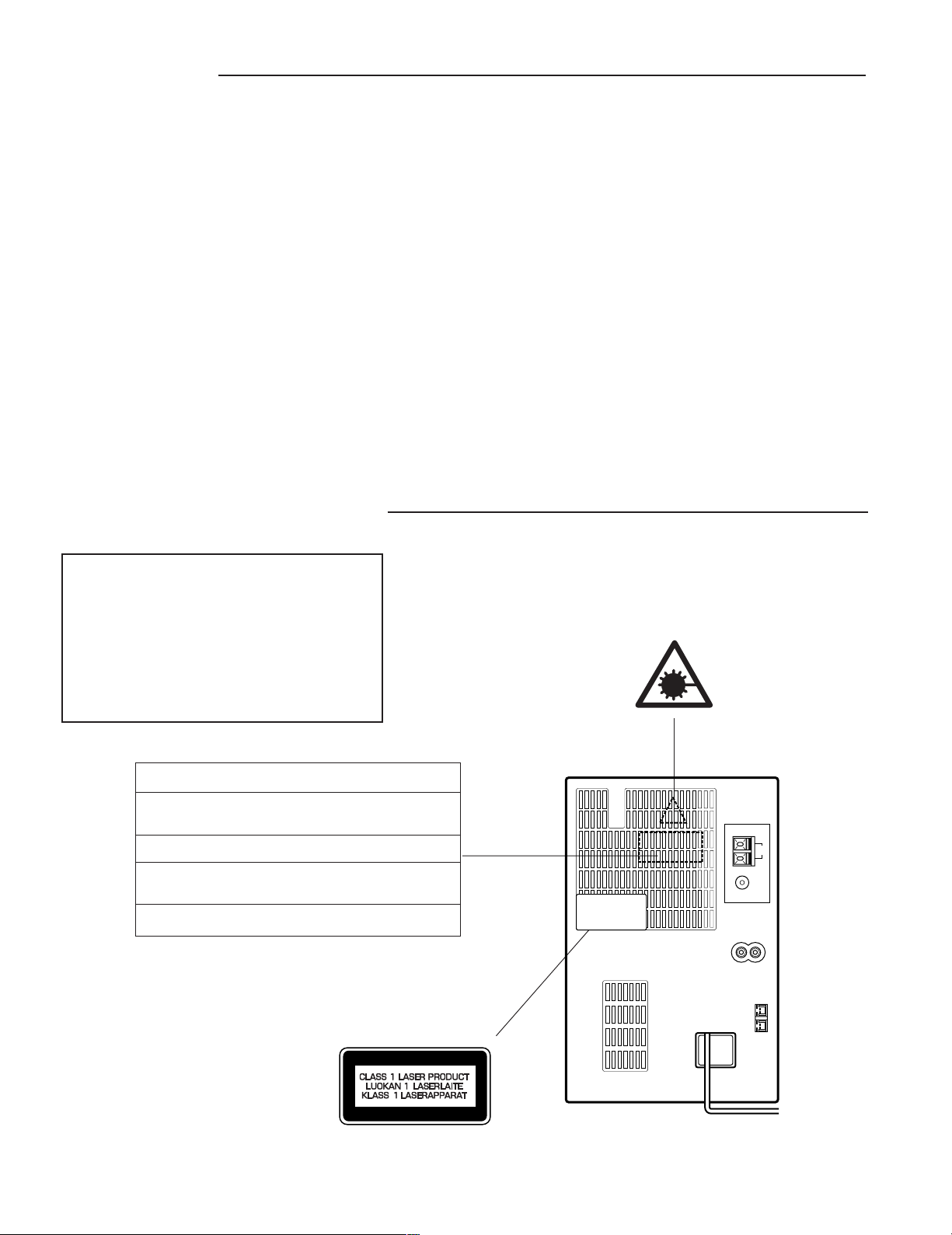

LASER BEAM SAFETY PRECAUTION

Outputs .................................. SPEAKERS : 4 ohms

PHONES : 8 - 32 ohms

Power requirements............... AC 110-120/220-240V

50/60 Hz (SS)

AC 230 -240V, 50 Hz (AU)

AC 220V, 60 Hz (KR)

Power consumption ............... 30 W

Dimensions (W x H x D) ........ Approx. 160 x 250 x 213 mm

Weight.................................... Approx. 2.8 kg

Speaker system

Type....................................... 2 Way bass reflex

Drivers ................................... 10 cm cone type (woofer)

5 cm cone type (tweeter)

Maximum

power-handling capacity ..... 12 Watts (peak)

Nominal impedance ............... 4 ohms

Dimensions (W x H x D) ........ Approx. 160 x 250 x 222 mm

Weight.................................... Approx. 1.9 kg (per speaker)

Specifications subject to change without notice.

• Pick-up that emits a laser beam is used in this CD player section.

CAUTION :

USE OF CONTROLS OR ADJUSTMENTS

OR PERFORMANCE OF PROCEDURES

OTHER THAN THOSE SPECIFIED HEREIN

MAY RESULT IN HAZARDOUS RADIATION

EXPOSURE

LASER OUTPUT..........0.6 mW Max. (CW)

WAVELENGTH ............. 790 nm

CAUTION – INVISIBLE LASER RADIATION WHEN OPEN AND

INTERLOCKS DEFEATED. AVOID EXPOSURE TO BEAM.

ADVARSEL – USYNLIG LASER STRÅLING VED ÅBNING, NÅR

SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION, UNDGÅ UDS ÆTTELSE

FOR STRÅLING.

VARNING – OSYNLIG LASER STRÅLNING NÄR DENNA DEL ÄR ÖPPNAD

OCH SPÄRR ÄR URKOPPLAD. STRÅLEN ÄR FARLIG.

VORSICHT – UNSICHTBARE LASERSTRAHLUNG TRITT AUS, WENN

DECKEL GEÖFFNET UND WENN SICHERHEITSVERRIEGELUNG

ÜBERBRÜCKT IST. NICHT, DEM STRAHL AUSSETZEN.

VARO – AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA

NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

EXT.ANT

AM

LOOP

FM

75Ω

IN

RRL

VIDEO

(AUDIO)

- 1 -

L

SPEAKERS

4Ω MIN

Page 3

CD PICK-UP MAINTENANCE

About pick-up (Optical lens) Cleaning

Clean a lens with swab of the cotton which moistened it with alcohol, cleaning paper or cleaning disc appointed.

Specified cleaning disc : LC-1 (Part code : 645 026 1961 ..... manufactured by SANYO.)

Show a clean procedure in the following in reference by swab of cotton.

1. Cotton swab is wrapped with Cleaning paper.

2. Add the isopropyl alcohol.

3. Gently move the tip of cotton swab just like a draw a whirlpool from inside to outside on the surface of lens.

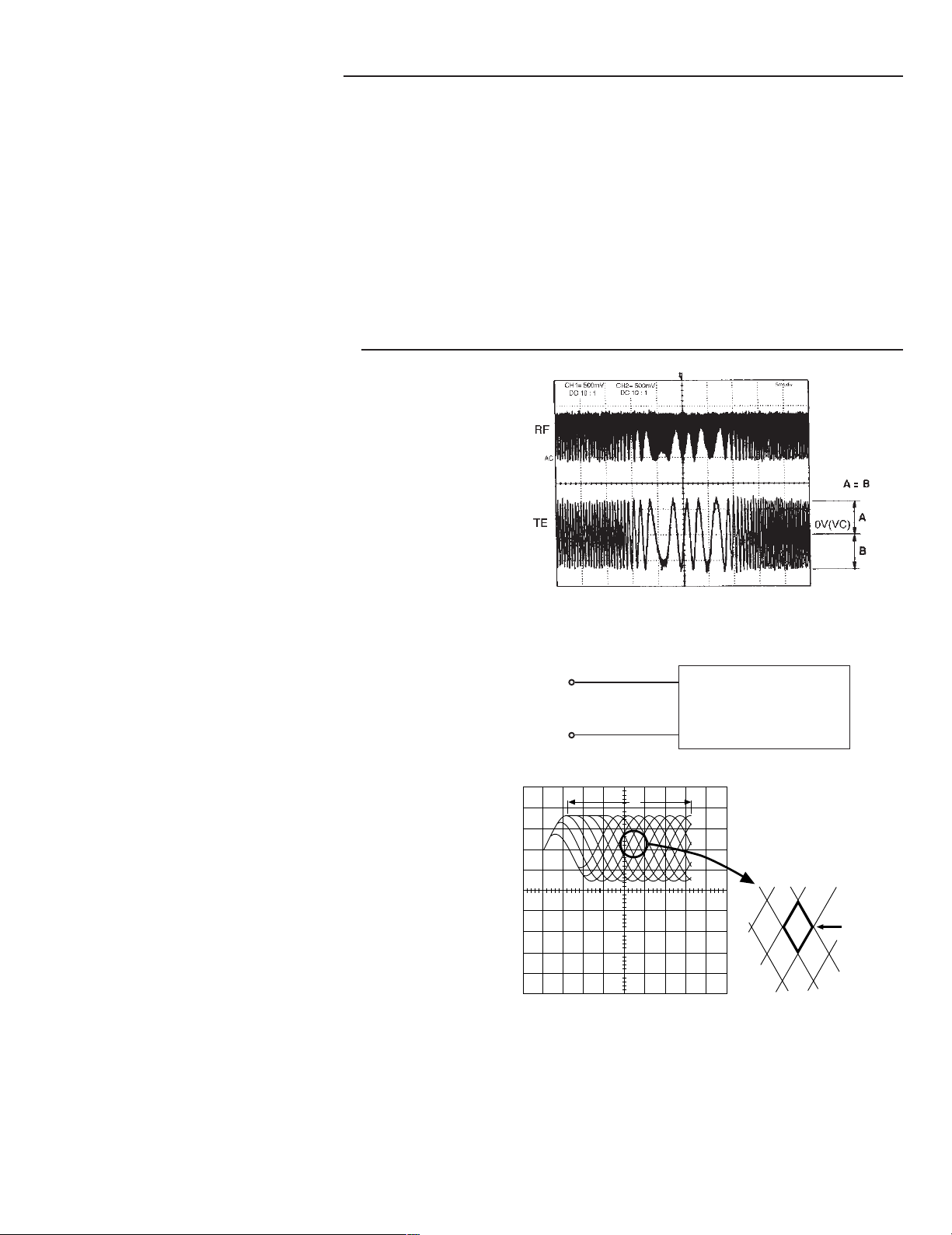

CD PLAYER ADJUSTMENTS

1. ADJUSTMENTS

(1) Confirm the tracking balance

1. Connect an Oscilloscope to TP2 (TE) and TP4 (VC).

2. Turn on the POWER switch.

3. Set the test disc. (DISC 1)

4. Press "MEMORY" button and "BACK SKIP" button

simultaneously. Within 1 second after pressing the "PLAY/

PAUSE" button.

5. Confirm that the oscilloscope waveform is symmetrical on the

top and bottom in relation to 0V (VC).

(2) Checking the "eye" pattern

1. Switch "ON" the POWER.

2. Connect an oscilloscope to TP1 (RF) and TP4 (VC).

3. Load the test disc.

4. Press the PLAY button.

5. Check to be sure that the "eye" pattern is at the center of

waveform and that the diamond shape is clearly defined.

6. Press the STOP button.

7. Turn off the POWER switch.

200mV/div.

5ms/div.

TP1

(RF)

TP4

(VC)

+

OSCILLOSCOPE

-

a

OPENING EXPANDED

b

- 2 -

Page 4

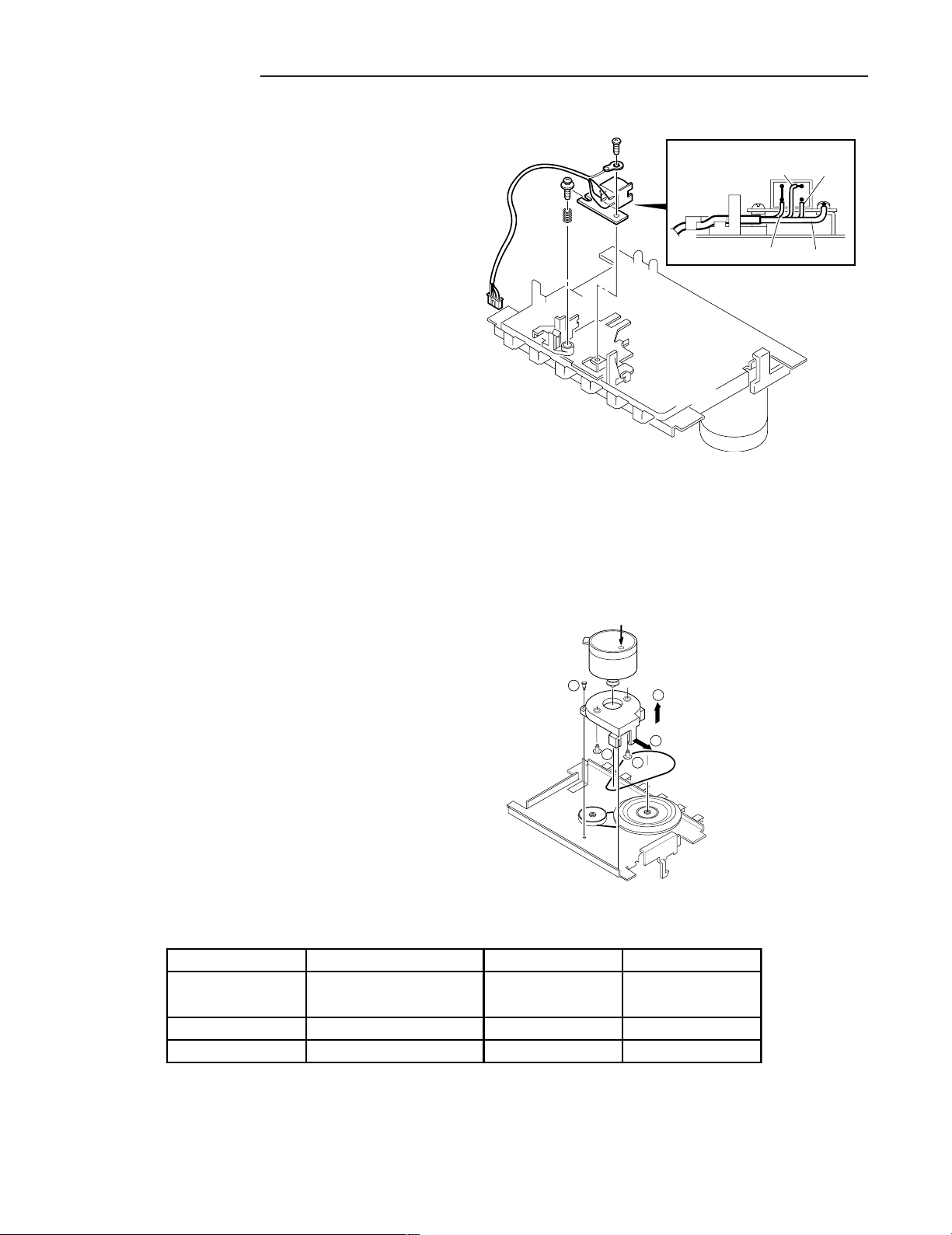

TAPE ADJUSTMENTS

a. Replacing the head

1. After replacement, demagnetize the heads by using a

degausser.

2. Be sure to clean the heads before attempting to make any

adjustments.

3. Be sure both channels (1 and 2) are the same level.

(Using a dual-channels oscilloscope).

4. All wiring should be returned to the original position after

work is completed.

b. Adjusting head azimuth

1. Load a test tape (VTT-738, etc. :10kHz) for azimuth

adjustment.

2. Press the PLAY button.

3. Use a cross-tip screwdriver to turn the screw for normal

azimuth adjustment so that the left and right outputs are

maximized at the same phase during normal playback.

4. Press the STOP button.

R / P HEAD

RED

WHITE

YELLOW EARTH

c. Adjusting motor speed

d. Replacing the motor

1. Insert the test tape (MTT-111 or etc. 3,000 Hz).

2. Press the PLAY button.

3. Use a flat-tip screwdriver to turn the SVR to adjust so that

the frequency counter becomes 3,000 Hz.

4. Press the STOP button.

e. Checking the mechanism torques

• Clean the head, capstan and pinch roller before making any measurement.

Measureent Take-up torque Back tension Tape tension

Cassette for PLAY : TW-2111A PLAY : TW-2111A Drive-power cassette

measurement F.FWD/REW : TW-2231 TW-2412

PLAY 30 ~ 70gr.cm 1.0 ~ 6.0gr.cm 80 gr or more

F.FWD/REW 55 gr or more - -

MOTOR SPEED

ADJUSTMENT

1

4

3

2

4

- 3 -

Page 5

Page 6

PARTS LIST

PRODUCT SAFETY NOTICE

EACH PRECAUTION IN THIS MANUAL SHOULD BE FOLLOWED DURING SERVICING. COMPONENTS IDENTIFIED WITH THE IEC

!!

SYMBOL

SPECIAL SIGNIFICANCE. WHEN REPLACING A COMPONENT IDENTIFIED BY

OR PARTS WITH THE SAME RATINGS OF RESISTANCE, WATTAGE OR VOLTAGE THAT ARE DESIGNATED IN THE PARTS LIST

IN THIS MANUAL. LEAKAGE-CURRENT OR RESISTANCE MEASUREMENTS MUST BE MADE TO DETERMINE THAT EXPOSED

PARTS ARE ACCEPTABLY INSULATED FROM THE SUPPLY CIRCUIT BEFORE RETURNING THE PRODUCT TO THE CUSTOMER.

CAUTION : Regular type resistors and capacitors are not listed. To know those values, refer to the schematic diagram.

!

IN THE PARTS LIST AND THE SCHEMATIC DIAGRAM DESIGNATED COMPONENTS IN WHICH SAFETY CAN BE OF

!!

!

, USE ONLY THE REPLACEMENT PARTS DESIGNATED,

Regular type resistors are less than 1/4 W carbon type and 0 ohm chip resistors.

Regular type capacitors are less than 50 V and less than 1000 µF type of Ceramic type and Electrical type.

PACKING & ACCESSORIES

REF.NO. PART NO. DESCRIPTION

614 311 3263 CARTON CASE (SS)

614 311 3287 CARTON CASE (AU)

614 312 4894 CARTON CASE (KR)

614 303 0652 CUSHION,FRONT

614 303 0669 CUSHION,REAR

614 311 3379 INSTRUCTION MANUAL (SS)

614 311 3393 INSTRUCTION MANUAL (AU)

614 312 5105 INSTRUCTION MANUAL (KR)

645 041 9027 POLY SHEET-0430X0290*NC,SET

645 037 9833 POLY BAG-0180X0250*NC,

1AV0L90B00200

645 036 6727 BATTERY COVER,SERVICE PART

614 310 0058 ASSY,BOX,SPEAKER, (L,R) (SS/AU)

614 312 4986 ASSY,BOX,SPEAKER, (L,R) (KR)

614 304 5311 ASSY,GRILLE

614 245 0055 ANTENNA,FM ANT

645 005 1227 ASSY,ANTENA,LOOP

645 017 2175 PLUG,ADAPTOR AC (SS)

or 645 006 4630 PLUG,ADAPTOR AC (SS)

645 034 7955 REMOCON,RB-DA100

614 309 3435 NOTICE (AU)

CABINET & CHASSIS

REF.NO. PART NO. DESCRIPTION

1 614 309 9734 ASSY,DOOR,DECK

2 614 302 5115 LID,CASSETTE

3 614 302 5092 KNOB,VR

4 614 306 4527 CAP,DECORATION

5 614 309 9758 ASSY,PANEL,FRONT

6 614 303 5794 SPRING,DOOR DECK

7 614 307 1396 ASSY,GEAR

8 614 302 9847 BUTTON,TUNER,2KEY

9 614 302 4859 BUTTON,POWER,1KEY

10 614 302 4927 BUTTON,PLAY,6KEY

11 614 302 4880 BUTTON,MEMORY,5KEY

12 614 309 9857 KNOB,DECK,MECHA,REC

13 614 309 9864 KNOB,DECK MECHA,PLAY

14 614 309 9871 KNOB,DECK MECHA,REW

15 614 309 9888 KNOB,DECK MECHA,FFWD

16 614 309 9895 KNOB,DECK MECHA,STOP/EJECT

17 614 309 9901 KNOB,DECK MECHA,PAUSE

18 614 309 9918 MOUNTING,DECK,KNOB

19 614 304 5700 HOLDER,MAIN PCB,MAIN PCB

20 614 303 0003 SPRING,DECK REC

21 614 298 8886 SPACER,MECHA,DAMPING KSM-213

22 614 302 4965 COVER,PICK-UP

24 614 302 5184 MOUNTING,PICK-UP

25 614 303 0263 LATCH,PUSH,CD DOOR LOCKING

26 614 303 0027 SPRING,DOOR CD

REF.NO. PART NO. DESCRIPTION

27 614 309 9239 PULLEY,CHECK PULLEY

28 614 303 0256 LATCH,MAGNET

29 614 309 9789 DOOR,CD

30 614 302 9878 DEC,DOOR CD

31 614 302 9915 HOLDER,POWER TRANS

32 614 307 8234 STOPPER,AC CORD

33 614 311 3058 ASSY,COVER,REAR (SS)

33 614 311 3072 ASSY,COVER,REAR (AU)

33 614 312 5006 ASSY,COVER,REAR (KR)

614 129 9136 LUG (KR)

FIXING PARTS

REF.NO. PART NO. DESCRIPTION

Y01 411 021 3503 SCR S-TPG BIN 3X10,

F-PANEL+DECK MECHA

Y02 411 021 3503 SCR S-TPG BIN 3X10,

F-PANEL+MTG DECK KNOB

Y03 411 126 1404 SCR S-TPG BIN 2X4,

SPRING DECK REC

Y04 411 021 1806 SCR S-TPG BIN 2.6X10,

MTG PK-UP+KSM-213

Y05 411 092 0906 WASHER Z 2.6X10X0.5,

MTG PK-UP+KSM-213

Y07 411 021 3503 SCR S-TPG BIN 3X10,

MTGPK-UP+FRONT PCB/CDPCB

Y08 411 021 3503 SCR S-TPG BIN 3X10,

MTG PK-UP+ASSS.GEAR

Y09 411 021 4500 SCR S-TPG BIN 3X16,

F-PANEL+MTG PK-UP

Y10 411 021 3503 SCR S-TPG BIN 3X10,MAIN PCB

Y11 411 021 2704 SCR S-TPG BIN 2.6X6,

DOOR CD+DEC DOOR CD

Y12 411 021 3503 SCR S-TPG BIN 3X10,

C-REAR+HOLDER P-TRANS

Y13 411 021 3503 SCR S-TPG BIN 3X10,

C-REAR+STOPPER CORD

Y14 411 020 9902 SCR S-TPG BRZ+FLG 3X8,

HOLDER P-TRANS+P-TRANS

Y15 411 098 7701 SCR S-TPG FLT 3X10,

C-REAR(L/R SIDE)

Y16 411 021 4500 SCR S-TPG BIN 3X16,C-REAR

Y17 411 021 3404 SCR S-TPG BIN 3X10,

C-REAR (ANT TERMINAL)

Y18 411 021 3404 SCR S-TPG BIN 3X10,C-REAR

Y19 411 021 3404 SCR S-TPG BIN 3X10,

C-REAR (RCA JACK)

Y20 411 021 3503 SCR S-TPG BIN 3X10,

VOLTAGE SELECT SW (SS)

- 5 -

Page 7

PARTS LIST

ELECTRICAL PARTS

REF.NO. PART NO. DESCRIPTION

614 305 9653 SHIELD

!!

51

!

423 016 7908 FUSE 250V 2.5A,LITTLE

52 645 013 5224 SWITCH,LEVER 1P-1T

!!

53

53

53

54

54

54

55

56

57

58

CN381

or

or

CN383

or

or

CN681

or

CN683

or

or

CN691

!

645 037 1813 TRANS,POWER (SS)

!!

!

645 037 1837 TRANS,POWER (AU)

!!

!

645 040 3149 TRANS,POWER (KR)

!!

!

645 037 7655 CORD,POWER (SS)

!!

!

645 037 7662 CORD,POWER (AU)

!!

!

645 039 9473 CORD,POWER (KR)

!!

!

645 037 1844 SWITCH,SLIDE 1P-1T (SS)

!!

!

423 016 9506 FUSE 250V 0.315A (KR)

!!

!

645 037 7501 ASSY, HOLDER, FUSE (KR)

!!

!

645 037 9888 TERMINAL CN555 (KR)

!!

!

614 311 0781 ASSY,WIRE

!!

!

614 304 1481 ASSY,WIRE

!!

!

614 308 2453 ASSY,WIRE

!!

!

614 311 0811 ASSY,WIRE

!!

!

614 304 1511 ASSY,WIRE

!!

!

614 308 2484 ASSY,WIRE

!!

!

645 036 3955 FLEXIBLE FLAT CABLE

!!

!

645 033 7413 FLEXIBLE FLAT CABLE

!!

!

614 304 1498 ASSY,WIRE

!!

!

614 308 2460 ASSY,WIRE

!!

!

614 311 0798 ASSY,WIRE

!!

!

645 041 2547 FLEXIBLE FLAT CABLE

FE001 645 013 6498 CORE,FERRITE (AU)

614 129 9136 LUG (AU)

CD P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

!!

71

71

71

C604 403 058 2901 POLYESTER 0.015U J 50V

C607 403 058 2901 POLYESTER 0.015U J 50V

C612 403 059 8209 POLYESTER 0.22U K 50V

C614 403 060 8700 POLYESTER 0.033U K 50V

C615 403 059 8209 POLYESTER 0.22U K 50V

C620 403 058 9504 POLYESTER 0.018U J 50V

C630 403 056 7502 POLYESTER 1000P J 50V

C631 403 060 8700 POLYESTER 0.033U K 50V

CN682

or

or

CP601 645 033 8168 SOCKET,FPC 16P

CP603 645 005 7366 PLUG,2P

or 614 310 2434 PLUG,2P (KR)

D601 407 012 4406 DIODE 1SS133

D602 407 012 0309 DIODE 1N4003

or 407 189 3301 DIODE 1N4004A

D603 407 012 0309 DIODE 1N4003

or 407 189 3301 DIODE 1N4004A

D604 407 099 5204 ZENER DIODE MTZJ5.1B

D605 407 099 5204 ZENER DIODE MTZJ5.1B

D841 407 012 0309 DIODE 1N4003

or 407 189 3301 DIODE 1N4004A

IC601 409 396 8100 IC LA9241ML

IC602 409 435 2106 IC LC78622NE

IC603 409 372 9602 IC LA6541

L600 645 037 2858 CORE,PIPE

L601 645 001 5519 INDUCTOR,47U K

L602 645 001 5519 INDUCTOR,47U K

L603 645 037 2858 CORE,PIPE

!

614 311 2297 ASSY,PWB,CD (SS) (Only Initial)

!!

!

614 311 2396 ASSY,PWB,CD (AU) (Only Initial)

!!

!

614 312 5365 ASSY,PWB,CD (KR) (Only Initial)

!!

!

614 304 1504 ASSY,WIRE

!!

!

614 311 0804 ASSY,WIRE

!!

!

614 308 2477 ASSY,WIRE

REF.NO. PART NO. DESCRIPTION

Q600 405 141 3505 TR KTA1266-Y

Q601 405 141 3505 TR KTA1266-Y

Q604 405 138 6403 TR KTD2058Y

Q605 405 000 3806 TR DTC114YS

or 405 143 0007 TR KRC107M

X600 614 231 2667 RESONATOR

FRONT P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

!!

72

72

72

AM001 614 304 5687 DEC,SHEET,LCD,LCD DIFFUSER

BRLCD 614 302 5085 HOLDER,LCD

CP101 645 012 5270 SOCKET,FPC 23P

D101 407 012 4406 DIODE 1SS133

D102 407 012 0804 DIODE 1N4148

D103

D104 407 099 6003 ZENER DIODE MTZJ9.1B

D114 407 012 0804 DIODE 1N4148

D115 407 012 4406 DIODE 1SS133

D116 407 012 0804 DIODE 1N4148

DMC10 407 203 9203 PHOTO DIODE SPS-442-1-E

IC101 410 345 9604 IC CXP83240A-110Q

IC102 409 451 2203 IC M24C02—MN6

J106 401 037 5004 MT-GLAZE 0.000 ZA 1/10W

J146 401 037 5004 MT-GLAZE 0.000 ZA 1/10W,

J147 401 037 5004 MT-GLAZE 0.000 ZA 1/10W,

J148 401 037 5004 MT-GLAZE 0.000 ZA 1/10W,

J203 401 037 5004 MT-GLAZE 0.000 ZA 1/10W

J204 401 037 5004 MT-GLAZE 0.000 ZA 1/10W,

J205 401 037 5004 MT-GLAZE 0.000 ZA 1/10W,

J206 401 037 5004 MT-GLAZE 0.000 ZA 1/10W,

J27 401 037 5004 MT-GLAZE 0.000 ZA 1/10W

L101 645 001 5441 INDUCTOR,2.2U K

LCD10 645 036 3931 LCD

Q101 405 000 3806 TR DTC114YS

or 405 143 0007 TR KRC107M

Q102 405 141 3307 TR KTC3198-GR

Q606 405 123 1208 TR DTC323TK

R101 401 038 6505 MT-GLAZE 47K JA 1/10W

R102 401 037 5608 MT-GLAZE 10K JA 1/10W

R103 401 037 5608 MT-GLAZE 10K JA 1/10W

R104 401 037 5608 MT-GLAZE 10K JA 1/10W

R105 401 037 5608 MT-GLAZE 10K JA 1/10W

R106 401 037 5608 MT-GLAZE 10K JA 1/10W

R107 401 037 5608 MT-GLAZE 10K JA 1/10W

R108 401 037 5608 MT-GLAZE 10K JA 1/10W

R109 401 038 0800 MT-GLAZE 22K JA 1/10W

R110 401 038 6406 MT-GLAZE 4.7K JA 1/10W

R111 401 038 7601 MT-GLAZE 560 JA 1/10W

R112 401 038 7601 MT-GLAZE 560 JA 1/10W

R113 401 038 7502 MT-GLAZE 56 JA 1/10W

R114 401 038 7502 MT-GLAZE 56 JA 1/10W

R115 401 038 7502 MT-GLAZE 56 JA 1/10W

R116 401 037 5202 MT-GLAZE 100 JA 1/10W

R117 401 038 6505 MT-GLAZE 47K JA 1/10W

R118 401 038 6505 MT-GLAZE 47K JA 1/10W

R119 401 037 5400 MT-GLAZE 1K JA 1/10W

!

614 311 2327 ASSY,PWB,FRONT (SS) (Only Initial)

!!

!

614 311 2426 ASSY,PWB,FRONT (AU) (Only Initial)

!!

!

614 312 5396 ASSY,PWB,FRONT (KR) (Only Initial)

!!

!

407 099 5303 ZENER DIODE MTZJ5.6B

CHIP JUMPER

CHIP JUMPER

CHIP JUMPER

CHIP JUMPER

CHIP JUMPER

CHIP JUMPER

- 6 -

Page 8

PARTS LIST

REF.NO. PART NO. DESCRIPTION

R120 401 037 5202 MT-GLAZE 100 JA 1/10W

R121 401 037 5608 MT-GLAZE 10K JA 1/10W

R122 401 037 5608 MT-GLAZE 10K JA 1/10W

R123 401 037 5400 MT-GLAZE 1K JA 1/10W

R124 401 037 7909 MT-GLAZE 1.5K JA 1/10W

R125 401 037 9200 MT-GLAZE 1.8K JA 1/10W

R126 401 038 2101 MT-GLAZE 2.7K JA 1/10W

R127 401 038 3603 MT-GLAZE 3.3K JA 1/10W

R128 401 038 7700 MT-GLAZE 5.6K JA 1/10W

R129 401 037 5608 MT-GLAZE 10K JA 1/10W

R130 401 037 9309 MT-GLAZE 18K JA 1/10W

R131 401 037 5400 MT-GLAZE 1K JA 1/10W

R132 401 037 7909 MT-GLAZE 1.5K JA 1/10W

R133 401 037 9200 MT-GLAZE 1.8K JA 1/10W

R134 401 038 2101 MT-GLAZE 2.7K JA 1/10W

R135 401 038 3603 MT-GLAZE 3.3K JA 1/10W

R136 401 038 7700 MT-GLAZE 5.6K JA 1/10W

R137 401 037 5608 MT-GLAZE 10K JA 1/10W

R138 401 037 5608 MT-GLAZE 10K JA 1/10W

R139 401 037 5608 MT-GLAZE 10K JA 1/10W

R140 401 038 6505 MT-GLAZE 47K JA 1/10W

R141 401 038 6505 MT-GLAZE 47K JA 1/10W

R145 401 037 5608 MT-GLAZE 10K JA 1/10W

R146 401 037 5608 MT-GLAZE 10K JA 1/10W

R147 401 037 5608 MT-GLAZE 10K JA 1/10W

R667 401 037 5202 MT-GLAZE 100 JA 1/10W

R668 401 037 5608 MT-GLAZE 10K JA 1/10W

SP101 401 037 5004 MT-GLAZE 0.000 ZA 1/10W

SW101 614 220 5471 SWITCH,TACT

SW102 614 220 5471 SWITCH,TACT

SW103 614 220 5471 SWITCH,TACT

SW104 614 220 5471 SWITCH,TACT

SW105 614 220 5471 SWITCH,TACT

SW106 614 220 5471 SWITCH,TACT

SW109 614 220 5471 SWITCH,TACT

SW110 614 220 5471 SWITCH,TACT

SW111 614 220 5471 SWITCH,TACT

SW112 614 220 5471 SWITCH,TACT

SW113 614 220 5471 SWITCH,TACT

SW114 614 220 5471 SWITCH,TACT

SW116 614 220 5471 SWITCH,TACT

SW117 614 220 5471 SWITCH,TACT

VOL10 645 033 3460 SWITCH,ROTARY(ENCODER)

X101 645 036 5102 OSC,CERAMIC 10.0MHZ

X102 645 032 1627 OSC,CRYSTAL 32.768KHZ

LED P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

!!

73

73

73

CN102 614 311 0774 ASSY,WIRE,FOR LED PCB

or 614 304 1474 ASSY,WIRE,FOR LED PCB

or 614 308 2446 ASSY,WIRE,FOR LED PCB

D105 408 037 4204 LED SLP-3118B-51HAB-T1

D106 408 037 4204 LED SLP-3118B-51HAB-T1

D107 408 037 4204 LED SLP-3118B-51HAB-T1

D108 408 037 4204 LED SLP-3118B-51HAB-T1

D109 408 037 4204 LED SLP-3118B-51HAB-T1

D110 408 037 4204 LED SLP-3118B-51HAB-T1

D111 408 037 4204 LED SLP-3118B-51HAB-T1

D112 408 037 4204 LED SLP-3118B-51HAB-T1

D113 408 037 4204 LED SLP-3118B-51HAB-T1

!

614 311 2303 ASSY,PWB,LED (SS) (Only Initial)

!!

!

614 311 2402 ASSY,PWB,LED (AU) (Only Initial)

!!

!

614 312 5372 ASSY,PWB,LED (KR) (Only Initial)

MAIN P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

!!

!

74

74

74

C201 403 058 2901 POLYESTER 0.015U J 50V

C209 403 058 2901 POLYESTER 0.015U J 50V

C216 403 060 8601 POLYESTER 0.033U K 50V

C404 403 057 5507 POLYESTER 1200P J 50V

C405 403 058 9504 POLYESTER 0.018U J 50V

C406 403 060 8700 POLYESTER 0.033U K 50V

C416 403 060 8700 POLYESTER 0.033U K 50V

C421 403 057 3503 POLYESTER 0.1U K 50V

C422 403 057 5507 POLYESTER 1200P J 50V

C427 403 059 5505 POLYESTER 0.022U J 50V

C428 403 062 4700 POLYESTER 5600P J 50V

C429 403 059 3204 POLYESTER 2200P J 50V

C434 403 060 8700 POLYESTER 0.033U K 50V

C507 403 277 4106 ELECT 1000U M 25V

C508 403 277 4106 ELECT 1000U M 25V

C509 403 057 2407 POLYESTER 0.1U J 50V

C510 403 057 2407 POLYESTER 0.1U J 50V

C516 403 334 5503 ELECT 3300U M 35V

CP201 645 012 5270 SOCKET,FPC 23P

CP202 645 004 2904 PLUG,4P

CP203 645 005 8110 PLUG,4P

CP204 645 007 1447 PLUG,2P,FOR PT LEAD

CP205 645 006 1875 PLUG,2P

CP206 645 006 1875 PLUG,2P

D201 407 099 5204 ZENER DIODE MTZJ5.1B

D202 407 127 5008 ZENER DIODE MTZJ2.2B

D401 407 012 0804 DIODE 1N4148

D501 407 099 5204 ZENER DIODE MTZJ5.1B

D502 407 012 0804 DIODE 1N4148

D504 407 099 5204 ZENER DIODE MTZJ5.1B

D505 407 012 0804 DIODE 1N4148

D508 407 189 3301 DIODE 1N4004A

or 407 012 0309 DIODE 1N4003

D509 407 189 3301 DIODE 1N4004A

or 407 012 0309 DIODE 1N4003

D510 407 012 0309 DIODE 1N4003

or 407 189 3301 DIODE 1N4004A

D511 407 189 3301 DIODE 1N4004A

or 407 012 0309 DIODE 1N4003

D512 407 012 0804 DIODE 1N4148

D513 407 099 6201 ZENER DIODE MTZJ10C

D514 407 012 0804 DIODE 1N4148

D515 407 012 0804 DIODE 1N4148

E002 645 031 7903 HOLDER,FUSE

or 645 006 4760 HOLDER,FUSE

E004 645 031 7903 HOLDER,FUSE

or 645 006 4760 HOLDER,FUSE

H/P1 645 011 6384 JACK,PHONE D3.6

HS401 614 302 9892 HEAT SINK

HTU01 614 304 5694 HOLDER,TU PCB

HTU02 614 304 5694 HOLDER,TU PCB

IC201 409 445 4503 IC M62439SP

IC401 409 451 7406 IC AN7348K

IC501 409 451 2104 IC TDA7269

JACK2 614 276 6835 SOCKET

L102 645 001 5441 INDUCTOR,2.2U K

L103 645 001 5441 INDUCTOR,2.2U K

L401 645 006 1523 INDUCTOR,470U J

L402 645 006 1523 INDUCTOR,470U J

L403 645 006 1523 INDUCTOR,470U J

L404 645 037 2858 CORE,PIPE

L405 645 037 2858 CORE,PIPE

614 311 2280 ASSY,PWB,MAIN (SS) (Only Initial)

!!

!

614 311 2389 ASSY,PWB,MAIN (AU) (Only Initial)

!!

!

614 312 5358 ASSY,PWB,MAIN (KR) (Only Initial)

- 7 -

Page 9

REF.NO. PART NO. DESCRIPTION

L406 645 037 2858 CORE,PIPE

L407 645 037 2858 CORE,PIPE

Q201 405 154 5909 TR KRC231M

Q202 405 154 5909 TR KRC231M

Q203 405 143 0007 TR KRC107M

or 405 000 3806 TR DTC114YS

Q204 405 151 5209 TR KRA107M

or 405 000 0904 TR DTA114YS

Q401 405 141 3307 TR KTC3198-GR

Q402 405 141 3307 TR KTC3198-GR

Q403 405 155 0002 TR MPSA56

Q404 405 143 0007 TR KRC107M

or 405 000 3806 TR DTC114YS

Q501 405 143 0007 TR KRC107M

or 405 000 3806 TR DTC114YS

Q502 405 143 0007 TR KRC107M

or 405 000 3806 TR DTC114YS

Q503 405 151 5209 TR KRA107M

or 405 000 0904 TR DTA114YS

Q504 405 158 9309 TR KTC3202-Y

Q505 405 154 9907 TR KTK117Y

Q506 405 151 5209 TR KRA107M

or 405 000 0904 TR DTA114YS

Q507 405 138 6502 TR KTB1366Y

Q508 405 141 3307 TR KTC3198-GR

Q509 405 141 3307 TR KTC3198-GR

Q510 405 143 0007 TR KRC107M

or 405 000 3806 TR DTC114YS

R201 401 038 0701 MT-GLAZE 2.2K JA 1/10W

R202 401 038 0800 MT-GLAZE 22K JA 1/10W

R203 401 038 0800 MT-GLAZE 22K JA 1/10W

R204 401 038 0800 MT-GLAZE 22K JA 1/10W

R205 401 038 7700 MT-GLAZE 5.6K JA 1/10W

R206 401 037 5608 MT-GLAZE 10K JA 1/10W

R207 401 037 5608 MT-GLAZE 10K JA 1/10W

R208 401 038 7700 MT-GLAZE 5.6K JA 1/10W

R209 401 038 2200 MT-GLAZE 27K JA 1/10W

R210 401 038 9209 MT-GLAZE 6.8K JA 1/10W

R211 401 038 2200 MT-GLAZE 27K JA 1/10W

R212 401 038 9209 MT-GLAZE 6.8K JA 1/10W

R213 401 038 0800 MT-GLAZE 22K JA 1/10W

R215 401 038 0800 MT-GLAZE 22K JA 1/10W

R216 401 037 6704 MT-GLAZE 1.2K JA 1/10W

R217 401 038 0701 MT-GLAZE 2.2K JA 1/10W

R218 401 038 3603 MT-GLAZE 3.3K JA 1/10W

R219 401 038 9209 MT-GLAZE 6.8K JA 1/10W

R220 401 038 3603 MT-GLAZE 3.3K JA 1/10W

R221 401 038 9209 MT-GLAZE 6.8K JA 1/10W

R222 401 038 0800 MT-GLAZE 22K JA 1/10W

R226 401 038 6307 MT-GLAZE 470 JA 1/10W

R227 401 038 0800 MT-GLAZE 22K JA 1/10W

R228 401 038 0800 MT-GLAZE 22K JA 1/10W

R229 401 038 0800 MT-GLAZE 22K JA 1/10W

R230 401 038 0800 MT-GLAZE 22K JA 1/10W

R231 401 038 0800 MT-GLAZE 22K JA 1/10W

R232 401 038 0800 MT-GLAZE 22K JA 1/10W

R233 401 038 6505 MT-GLAZE 47K JA 1/10W

R234 401 037 5608 MT-GLAZE 10K JA 1/10W

R235 401 037 6704 MT-GLAZE 1.2K JA 1/10W

R236 401 037 5608 MT-GLAZE 10K JA 1/10W

R401 401 094 1902 MT-GLAZE 10M JA 1/10W

R402 401 037 5608 MT-GLAZE 10K JA 1/10W

R403 401 037 6902 MT-GLAZE 120K JA 1/10W

R404 401 038 6307 MT-GLAZE 470 JA 1/10W

R405 401 038 3405 MT-GLAZE 33 JA 1/10W

R406 401 038 0800 MT-GLAZE 22K JA 1/10W

R407 401 038 0800 MT-GLAZE 22K JA 1/10W

R408 401 038 3405 MT-GLAZE 33 JA 1/10W

REF.NO. PART NO. DESCRIPTION

R409 401 038 6307 MT-GLAZE 470 JA 1/10W

R410 401 037 6902 MT-GLAZE 120K JA 1/10W

R411 401 038 0800 MT-GLAZE 22K JA 1/10W

R412 401 038 0800 MT-GLAZE 22K JA 1/10W

R413 401 037 5608 MT-GLAZE 10K JA 1/10W

R414 401 038 0800 MT-GLAZE 22K JA 1/10W

R415 401 038 0800 MT-GLAZE 22K JA 1/10W

R416 401 037 5400 MT-GLAZE 1K JA 1/10W

R417 401 038 0800 MT-GLAZE 22K JA 1/10W

R418 401 038 5300 MT-GLAZE 39K JA 1/10W

R419 401 038 9308 MT-GLAZE 68K JA 1/10W

R420 401 038 5300 MT-GLAZE 39K JA 1/10W

R421 401 038 7809 MT-GLAZE 56K JA 1/10W

R423 401 037 8005 MT-GLAZE 15K JA 1/10W

R424 401 037 5608 MT-GLAZE 10K JA 1/10W

R425 401 037 5608 MT-GLAZE 10K JA 1/10W

R426 401 037 5608 MT-GLAZE 10K JA 1/10W

R427 401 038 6505 MT-GLAZE 47K JA 1/10W

R428 401 038 7601 MT-GLAZE 560 JA 1/10W

R501 401 038 5300 MT-GLAZE 39K JA 1/10W

R502 401 037 5608 MT-GLAZE 10K JA 1/10W

R503 401 037 5400 MT-GLAZE 1K JA 1/10W

R504 401 037 8005 MT-GLAZE 15K JA 1/10W

R505 401 037 5608 MT-GLAZE 10K JA 1/10W

R506 401 037 8005 MT-GLAZE 15K JA 1/10W

R507 401 038 0602 MT-GLAZE 220 JA 1/10W

R509 401 037 8005 MT-GLAZE 15K JA 1/10W

R510 401 038 7601 MT-GLAZE 560 JA 1/10W

R511 401 038 7601 MT-GLAZE 560 JA 1/10W

R512 401 037 5806 MT-GLAZE 1M JA 1/10W

R513 401 038 6505 MT-GLAZE 47K JA 1/10W

R514 401 037 5400 MT-GLAZE 1K JA 1/10W

R518 401 037 8005 MT-GLAZE 15K JA 1/10W

R519 401 038 6406 MT-GLAZE 4.7K JA 1/10W

R520 401 037 5202 MT-GLAZE 100 JA 1/10W

R521 401 038 0602 MT-GLAZE 220 JA 1/10W

R522 401 038 6406 MT-GLAZE 4.7K JA 1/10W

R523 401 037 5400 MT-GLAZE 1K JA 1/10W

R528 401 037 5608 MT-GLAZE 10K JA 1/10W

R529 401 038 6307 MT-GLAZE 470 JA 1/10W

R530 401 037 6605 MT-GLAZE 120 JA 1/10W

S401 645 036 3924 SWITCH,LEAF,R/P SW

SA001 411 021 6405 SCR S-TPG BIN 3X8,HEAT SINK IC401

SA002 411 021 6405 SCR S-TPG BIN 3X8,HEAT SINK Q507

SA003 411 021 6405 SCR S-TPG BIN 3X8,TUNER ASSY

SA004 411 021 6405 SCR S-TPG BIN 3X8,YUNER ASSY

SHANT 614 305 3637 SHIELD,ANTENA

TU001 645 037 1776 TUNER,MW/FM (SS/AU)

TU001 645 037 1783 TUNER,MW/FM (KR)

AC TERMINAL P.W.BOARD ASSY

REF.NO. PART NO. DESCRIPTION

76

76

76

T901 614 017 8203 TERMINAL BOARD

T902 614 017 8203 TERMINAL BOARD

!!

!

614 311 2310 ASSY,PWB,ACCORD(SS) (Only Initial)

!!

!

614 311 2419 ASSY,PWB,ACCORD(AU) (Only Initial)

!!

!

614 312 5389 ASSY,PWB,ACCORD(KR) (Only Initial)

- 8 -

Page 10

EXPLODED VIEW (TAPE MECHANISM)

TM03

TM05

TM04

TM06

TM01

TM02

TAPE MECHANISM (TM-DA70TN-SH ... Only Initial)

REF.NO. PART NO. DESCRIPTION

614 309 7976 ASSY,MECHA,TM-DA70TN-SH

TM01 645 041 3025 R.P HEAD AP-4211F

TM02 645 009 1612 PINCH ROLLER ARM ASSY

TM03 645 033 8625 E HEAD 6PA

TM04 645 009 1766 RF BELT

TM05 645 033 3415 MAIN BELT

TM06 614 304 1467 ASSY,MOTOR

EXPLODED VIEW (CD MECHANISM)

PM05

PM03

PM04

PM01-1

PM02

PM08

PM06

PM09

CD MECHANISM(CD213CDM/SNSH... Only initial)

REF.NO. PART NO. DESCRIPTION

PM01 614 304 5571 ASSY,MOTOR CHASSIS,

BASE CHASSIS

PM01-1 645 033 6812 GEAR B RP,SLED GEAR

PM02 645 033 6744 ASSY,MOTOR GEAR,

SLED MOTOR ASSY

PM03 645 033 6805 SLED SHAFT,PICK RAIL

PM01

PM04 645 033 6799 GEAR A S,PICK DRIVE GEAR

PM05 645 033 6829 SCREW+P2*3,SLED MOTOR FIX

PM06 645 033 6775 LEAF SWITCH,LIMIT SWITCH

PM07 645 033 6782 MOTOR 6P S PCB,PCB

PM08 645 033 6768 CONNECTOR PIN 6P,CONNECTOR

PM09 614 303 5626 PICK UP

PM07

- 9 -

Page 11

Page 12

IC BLOCK DIAGRAM & DESCRIPTION

IC602 LC78622E (Digital Signal Processor)

No. Pin Name I/O Function

1 DEFI I Input terminal for detect signal of defect

2 TAI I Input terminal for test.

3 PDO O The phase comparison output terminal for

external VCO control.

4 VVSS - Ground terminal for built-in VCO

5 ISET I Resistance connection terminal for

electric current adjustment of PDO output.

6 VVDD - Built-in VCO power supply terminal.

7 FR I VCO frequency range adjustment.

8 VSS - Ground for Digital

9 EFMO O EFM signal output terminal for slice level control.

10 EFMIN I EFM signal input terminal for slice level control.

11 TEST2 I TEST pin. Normal time is non connection.

12 CLV+ O Output terminal for Disc motor control.

13 CLV- O Output terminal for Disc motor control.

14 V/P O Change of rough servo / phase control

Rough servo : "H", Phase control : "L"

15 HFL I Input terminal of track search signal.

16 T ES I Input terminal of tracking error signal.

17 TOFF O Output terminal of tracking off.

18 T GL O Output terminal for change of tracking gain.

19 JP+ O Output terminal for tracking jump control.

20 JP- O Output terminal for tracking jump control.

21 PCK O Clock monitor output terminal for EFM data

playback. (4.3218 MHz)

22 FSEQ O Output terminal for detect of SYNC signal.

23 DVDD - +5V

24 CONT1 I/O

25 CONT2 I/O This output can control at serial control from

26 CONT3 I/O micro processor.

27 CONT4 I/O

28 CONT5 I/O

29 EMPH O Output terminal of de-emphasis monitor .

"H" : de-emphasis

30 C2F O Output terminal of C2 flag

31 DOUT O Output terminal of digital out

No. Pin Name I/O Function

32 TEST3 I Test pin.

33 TEST4 I Test pin.

34 NC - Non connection.

35 MUTEL O Mute output terminal for L-ch

36 LVDD - Power supply for L-ch

37 LCHO O Output terminal for L-ch

38 LVSS - GND for L-ch

39 RVSS - GND for R-ch

40 RCHO O Output terminal for R-ch

41 RVDD - Power supply for R-ch

42 MUTER O Mute output terminal for R-ch

43 XVDD - Power supply of crystal oscillation

44 XOUT O Connection terminal of crystal oscillation (16.9344MHz)

45 XIN I Connection terminal of crystal oscillation (16.9344MHz)

46 X VS S - GND of crystal oscillation

47 S BSY O Output terminal for synchronizing signal of

sub-cord block

48 EFLG O Output terminal for correction monitor of C1, C2,

Single and Double

49 PW O Output terminal for sub-cord of P, Q, R, S, T, U and W

50 SFSY O Output terminal for synchronizing signal of

sub-cord frame

51 SBCK I Input terminal for readout clock of sub-cord

52 FS X O Output terminal of Synchronizing signal (7.35kHz)

53 WRQ O Output terminal for standby of sub-cord Q output

54 RWC I Input terminal of read / write control

55 SQOUT O Out put t ermi nal o f sub-cord Q

56 COIN I Input terminal of command from micro processor

57 CQCK I Clock input for reading sub-cord from SQOUT

58 RES I Reset (turn on : L)

59 TST11 O Test pin

60 16M O 16.9344MHz

61 4.2M O 4.2336MHz

62 TEST5 I Test pin

63 CS I Chip select terminal

64 TEST1 I Test pin

DEFI

EFMIN

FSEQ

CLV+

CLV-

SBCK

SBSY

SFSY

WRQ

SQOUT

CQCK

COIN

RWC

EFMO VVDD VVSS PDO ISET FR

9

1

Slice level

Control

10

Syncrnous Detect

22

EFM Demodulation

12

13

14

V/P

PW

49

51

47

50

63

CS

53

55

57

56

54

CLV

Digital Servo

Subcode Dxract

QCRC

COM

Inter Fase

Servo Commander

15 16 17 20 19 58 18 24 25 26 27 28 29 48 60 61 46 52 45 44 43 39 41 42 40 37 35 38 36

4

6

TGL

RESJP+JP-TOFFTESHFL

357 2

VCO Clock Oscillator

& Clock Control

General Ports

CONT3

CONT1

CONT4

CONT2

PCK

TAI

21

TST11

TEST1 TEST3 TEST5

59 64 11 32 33 62

2K~8bit

RAM

C1 C2 Error Detect &

Correct Control Flag

X’tal Root

Timing Generator

4.2M16MEFLGEMPHCONT5

XVSS

VDDVSS

23

8

RAM Address

Interpolalation Mute

Digital Attenuator

Quadruple Over Sampling

Digital Filter

RVDD

XVDD

XINFSX

RVSS

XOUT

MUTER

TEST2 TEST4

- 11 -

Generatorl

Billingual

1bit DAC

L.P.F

RCHO

Digital Out

MUTELLCHO

LVSS

LVDD

C2F

30

31

DOUT

(NC)

34

Page 13

SCHEMATIC DIAGRAM (CD)

This is a basic schematic diagram.

PRODUCT SAFETY NOTICE

Each precaution in this manual should be followed during servicing. Components identified with the IEC symbol

designated components in which safety can be of special significance. When replacing a component identified by

designated, or parts with the same ratings of resistance, wattage or voltage that are designated in the parts list in this manual. Leakage-current or resistance

measurements must be made to determine that exposed parts are acceptably insulated from the supply circuit before returning the product to the customer.

in the parts list and the schematic diagram

!!

!

!!

!

, use only the replacement parts

- 13 -- 12 -

Page 14

WIRING DIAGRAM (CD, FRONT, LED for SS & KR)

<TOP VIEW>

FRONT P.W.B

CD P.W.B

- 14 -

Page 15

WIRING DIAGRAM (CD, FRONT, LED for SS & KR)

<BOTTOM VIEW>

FRONT P.W.B

LED P.W.B

TOP

CD P.W.B

- 15 -

Page 16

SCHEMATIC DIAGRAM (FRONT)

This is a basic schematic diagram.

- 17 -- 16 -

Page 17

WIRING DIAGRAM (CD, FRONT, LED for AU)

<TOP VIEW>

FRONT P.W.B

CD P.W.B

- 18 -

Page 18

WIRING DIAGRAM (CD, FRONT, LED for AU)

<BOTTOM VIEW>

FRONT P.W.B

LED P.W.B

TOP

CD P.W.B

- 19 -

Page 19

SCHEMATIC DIAGRAM (AMPLIFIER)

This is a basic schematic diagram.

PRODUCT SAFETY

NOTICE

Each precaution in this

manual should be

followed during servicing.

Components identified

with the IEC symbol

the parts list and the

schematic diagram

designated components

in which safety can be of

special significance.

When replacing a

component identified by

!!

!

, use only the

replacement parts

designated, or parts with

the same ratings of

resistance, wattage or

voltage that are

designated in the parts

list in this manual.

Leakage-current or

resistance

measurements must be

made to determine that

exposed parts are

acceptably insulated from

the supply circuit before

returning the product to

the customer.

in

!!

!

- 21 -- 20 -

Page 20

WIRING DIAGRAM (AMPLIFIER for SS & KR)

<TOP VIEW>

- 22 -

Page 21

WIRING DIAGRAM (AMPLIFIER for SS & KR)

<BOTTOM VIEW>

- 23 -

Page 22

WIRING DIAGRAM (AMPLIFIER for AU)

<TOP VIEW>

- 24 -

Page 23

WIRING DIAGRAM (AMPLIFIER for AU)

<BOTTOM VIEW>

- 25 -

Page 24

FL DISPLAY DESCRIPTION

S1

T1

T2

1

2

S2

S3

3

45 67

S4

S6

S5

COM1 COM2 COM3 COM4

1 COM1 - - 2 - COM2 - 3 - - COM3 4 - - - COM4

5 1F 1G 1E OFF

8

COL

P

S7

T3

V1

V2

V3

V4 V5 V6

*1

V7

COM1 COM2 COM3 COM4

23 5K 5J 5N 5D

24 5B 5H 5C COL

25 6F 6G 6E P

26 6A 6I 6M 6L

27 6K 6J 6N 6D

A

FI K

J

G

H

M

E

L

N

D

B

C

6 1A 1I 1M 1L

7 1K 1J 1N 1D

8 1B 1H 1C REC

9 2F 2G 2E SLEEP

10 2A 2I 2M 2L

11 2K 2J 2N 2D

12 2B 2H 2C S2

13 3F 3G 3E S3

14 3A 3I 3M 3L

15 3K 3J 3N 3D

16 3B 3H 3C S4

17 4F 4G 4E S5

18 4A 4I 4M 4L

19 4K 4J 4N 4D

20 4B 4H 4C S6

21 5F 5G 5E S7

22 5A 5I 5M 5L

28 6B 6H 6C RANDOM

29 7F 7G 7E SURR.

30 7A 7I 7M 7L

31 7K 7J 7N 7D

32 7B 7H 7C REPEAT

33 8F 8G 8E MHz

34 8A 8I 8M 8L

35 8K 8J 8N 8D

36 8B 8H 8C KHz

37 T1 T2 ON S1

38 ST MONO RDS T3

39 21019

40 412311

41 614513

42 816715

43 *1 V1 V2 V3

44 V4 V5 V6 V7

- 26 -

Page 25

Loading...

Loading...