Page 1

FILE NO.

SERVICE MANUAL

LED-LCD TV

LED-42XR10FH(B)

PRODUCT CODE No.

PRODUCT CODE No.

1 682 351 10: PAL-BG(TV) DTV

REFERENCE No.:SM0915177

Page 2

CONTENTS

Safety precautions………………………………………………………………………..…

Alignment instructions …………………………….…….…………………………………

Method of software upgrading instructions………………………………………………..

Working principle analysis of the unit……………………………….………….………….

Block diagram…………………………………..………………………………….…………

IC block diagram and instruction…………………………………………………………..……

Wiring diagram …………………………………………………………………………….

Troubleshooting guide ………………………………………………………………..……

Schematic diagram…………………………………………………………………………

APPENDIX-A: Main assembly list

APPENDIX-B: Exploded View

Installing the Stand or wall-mount bracket

Wall mounting instructions

3

5

13

17

19

20

29

30

33

Page 3

Attention: This service manual is only for service personnel to take reference with. Before

servicing please read the following points carefully.

Safety precautions

1. Instructions

Be sure to switch off the power supply before replacing or welding any components or

inserting/plugging in connection wire Anti static measures to be taken (throughout the entire

production process!):

a) Do not touch here and there by hand at will;

b) Be sure to use anti static electric iron;

c) It’s a must for the welder to wear anti static gloves.

Please refer to the detailed list before replacing components that have special safety requirements.

Do not change the specs and type at will.

2. Points for attention in servicing of LED

2.1 Screens are different from one model to another and therefore not interchangeable. Be sure to

use the screen of the original model for replacement.

2.2 The operation voltage of L

protecting yourself and the machine when testing the system in the course of normal operation or

right after the power is switched off. Please do not touch the circuit or the metal part of the module

that is in operation mode. Relevant operation is possible only one minute after the power is

switched off.

2.3 Do not use any adapter that is not identical with the TV set. Otherwise it will cause fire or

damage to the set.

2.4 Never operate the set or do any installation work in bad environment such as wet bathroom,

laundry, kitchen, or nearby fire source, heating equipment and devices or exposure to sunlight etc.

Otherwise bad effect will result.

2.5 If any foreign substance such as water, liquid, metal slices or other matters happens to fall into

the module, be sure to cut the power off immediately and do not move anything on the module lest it

should cause fire or electric shock due to contact with the high voltage or short circuit.

2.6 Should there be smoke, abnormal smell or sound from the module, please shut the power off at

once. Likewise, if the screen is not working after the power is on or in the course of operation, the

power must be cut off immediately and no more operation is allowed under the same condition.

2.7 Do not pull out or plug in the connection wire when the module is in operation or just after the

power is off because in this case relatively high voltage still remains in the capacitor of the driving

circuit. Please wait at least one minute before the pulling out or plugging in the connection wire.

2.8 When operating or inst

or extrusion, collision lest mishap should result.

2.9 As most of the circ

to pay attention to anti statics. Before servicing

ensure full grounding for all the parts that have to be grounded.

2.10 There are lots of connection wires between part

moving the set please take care not to touch or scratch them. Once they are damaged the screen

alling LED please don’t subject the LED components to bending, twisting

uitry in LED TV set is composed of CMOS integrated circuits, it’s necessary

ED screen is 700-825V. Be sure to take proper measures in

LED TV make sure to take anti static measure and

s behind the LED screen. When servicing or

Page 4

would be unable to work and no way to get it repaired.

If the connection wires, connections or components fixed by the thermotropic glue need to

disengage when service, please soak the thermotropic glue into the alcohol and then pull them out

in case of dagmage.

2.11 Special care must be taken in transporting or handling it. Exquisite shock vibration may lead to

breakage of screen glass or damage to driving circuit. Therefore it must be packed in a strong case

before the transportation or handling.

2.12 For the storage make sure to put it in a place where the environment can be controlled so as to

prevent the temperature and humidity from exceeding the limits as specified in the manual. For

prolonged storage, it is necessary to house it in an anti-moisture bag and put them altogether in one

place. The ambient conditions are tabulated as follows:

o

Temperature Scope for operation

5

~ +35

C

Scope for storage -15~ +45 oC

Humidity Scope for operation 20% ~ 80%

Scope for storage <= 80%

2.13 Display of a fixed picture for a long time may result in appearance of picture residue on the

screen, as commonly called “ghost shadow”. The extent of the residual picture varies with the

maker of LED screen. This phenomenon doesn’t represent failure. This “ghost shadow” may remain

in the picture for a period of time (several minutes). But when operating it please avoid displaying

still picture in high brightness for a long time.

3. Points for attention during installation

3.1 The front panel of LED screen is of glass. When installing it please make sure to put it in place.

3.2 For service or installation it’s necessary to use specified screw lest it should damage the screen.

3.3 Be sure to take anti dust measures. Any foreign substance that happens to fall down between

the screen and the glass will affect the receiving and viewing effect

3.4 When dismantling or mounting the protective partition plate that is used for anti vibration and

insulation please take care to keep it in intactness so as to avoid hidden trouble.

3.5 Be sure to protect the cabinet from damage or scratch during service, dismantling or mounting.

Page 5

Alignment instructions

1. Safety Instructions

Be sure to switch off the power supply before replacing or welding any components or

inserting/plugging in connection wire Anti static measures to be taken (throughout the entire

production process!):

a) Do not touch here and there by hand at will;

b) Be sure to use anti static electric iron;

c) It’s a must for the welder to wear anti static gloves.

Please refer to the detailed list before replacing components that have special safety requirements.

Do not change the specs and type at will.

2. Test equipment

VG-848 (VGA, YPbPr signal generator)

VG-849 (HDMI digital video signal generator)

CA210 (color analyzer)

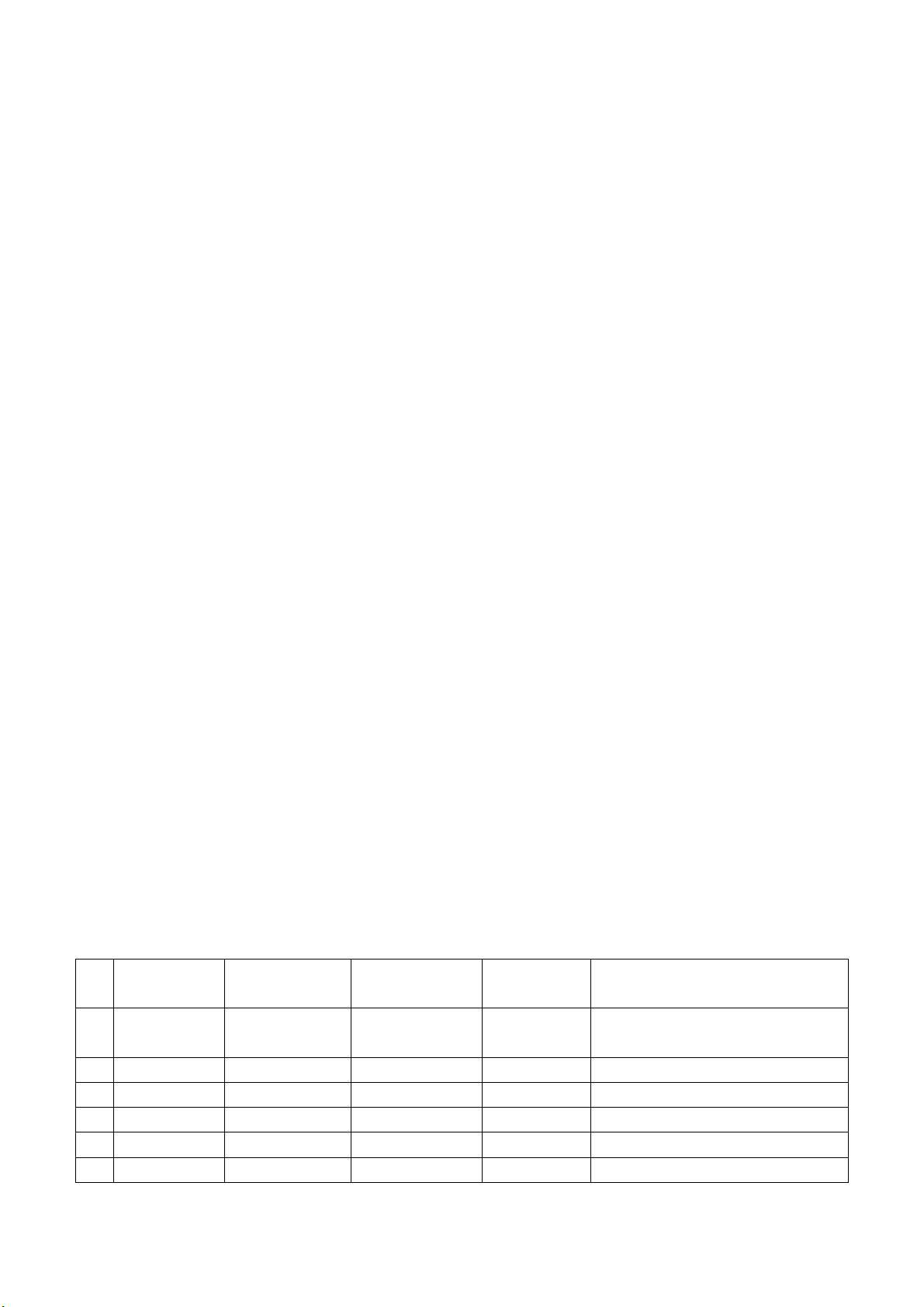

3 Alignment flow

3.1 Voltage of power supply test

According to the wiring specified by Product Specification, connect power board, main/data

processing board, IR/light sensor board, key board and backlight board correctly, then switch on main

power and press key “

” to turn on the TV set.

a) Test each pin voltage of socket X401 (< 26” models) and 13-pin power socket X601 (≥ 26”

models) in turn, please refer voltage of CCFL to Table 1, refer voltage of LED to Table 2:

Pin 1 2 3 4 5 6

Vol. ≥2.5 V 0 5 V±5% 0 5 V±5% N.C. 0 12 V±5% 0 ≥2.0 V ≥2.5 V

Table 1 Each pin voltage of 13-pin power socket for CCFL models

7、8 9、10

11 12 13

Table 2 Each pin voltage of 13-pin power socket for LED models

1

Pin 1 2 3

Vol. ≥2.5 V ≥2.0 V 0 12 V±5% 0 N.C. 5 V±5% 0 5 V±5% 0 ≥2.5 V

b) Test each pin voltage of 5-pin power socket X606 in turn ( ≥ 26” models), please refer voltage

to Table 3:

Pin

Vol. 24 V±5% 0

Table 3 Each pin voltage of 5-pin power socket

1、2 3、4、5

4、5 6、7

8 9

0

11

1

13

2

Page 6

3.2 Alignment flow chart shown as Fig. 1

Check if EDID, HDCP KEY, FLASH have been burned?

Combination alignment for general assembly

Connect to central signal source, check if TV functions are normal-omitted channel, analog

parameters control, etc.? Check if the output of earphones and speakers are normal?

Input composite AV signal, check if AV functions are normal?

Input component signal YPbPr, check if YPbPr functions are normal?

Input RGB signal, check if display and other functions are normal -

analog parameters control, H/V center, etc.?

Input digital HDMI signal, check if display and other functions are

normal - analog parameters control, H/V center, etc.?

Insert USB,check its functions.

Other functions checkup, such as LCN, OTA, etc.

White balance alignment

Setup before shipment

Accessories checkup and packing

Fig. 1 Alignment flow chart

Page 7

4 Alignment instructions

4.1 Unit adjustment

4.1.1 According to the wiring specified by Product Specification, connect power board, main/data

processing board, IR/light sensor board, key board and backlight board correctly, then switch on main

power and press key “

4.1.2 Using method of factory menu

a) Press key “SOURCE” first, then press keys “2, 5, 8, 0” in turn to enter into initial factory

menu;

b) Press keys “▲” and “▼” to move cursor to the item of factory menu;

c) Press keys “◄” and “►” to change the value when cursor is moved onto one item;

d) Press key “OK” to enter into the inferior factory menu from current menu page;

e) Press key “MENU” to exit current menu to its superior factory menu;

f) Press key “EXIT” to exit factory menu in any case;

g) Factory menu item: ADC ADJUST, for ADC calibration of RGB and YP

h) Factory menu item: W/B ADJUST, for white balance adjustment;

i) Factory menu item: POWER Mode, for setting power-on mode; the default setting is

“Standby” mode unless specified by customer;

Standby: TV set will be in “standby” mode after power-on;

MEM: TV set will keep states before last power-off;

ForceOn: TV set will turn on automatically; it also can be used as aging mode at factory;

j) Factory menu item: Other Setting->ISP Mode, the item will not be kept in memory, that is, it

will be always in “OFF” mode after turning on again;

“ON”: Upgrading unit software through D-SUB port while connecting to ISP device;

“OFF”: Normal DDC functions of D-SUB port will recover;

k) Factory menu item: EEPROM Init, for factory and customer data initialization; TV set will

reset and initial guiding interface will display after executing the item;

l) Factory menu item: Fac. Channel Preset., for factory channels presetting; it is necessary to

connect to central signal source before operating the item; now digital frequency of central signal

CH28(529.5 MHz)and CH33(564.5 MHz)are distributed to Australia programs DVB-T; original

preset digital programs will not change along with the modification of central signal, so please

operate relevant item of menu “Channel” to search programs;

m) Factory menu item: Shipment, all analog & digital programs for factory adjustment will be

cleared out first, then customer channels will be preset according to order requirements; the item

must be executed before shipment to clear out channels for factory adjustment;

n) Factory menu item: Other Setting->MST DEBUG, default setting is “OFF”, it will not be kept

in memory, that is, it will always in “OFF” mode after turning on TV set again;

“OFF”: RS232 functions of some engineering machines can match design specifications;

“ON”: It is convenient for design tools to debug the software;

o) Factory menu item: Backlight, for adjusting brightness of backlight; test voltage of 13-pin

power socket while adjusting the item to make it greater than PWM voltage corresponding to

mixture brightness described by panel specification; the item need not adjustment for it has been

preset by software;

p) Factory menu item: Other Setting->SSC ADJUST, for expanded spectrum adjustment; the

item need not adjustment for it has been preset by software;

” to turn on the TV set, check if the display is normal.

BPR

;

Page 8

q) Factory menu item: Other Setting->AUDIO Curve Setting, for sound curve adjustment; if

without special customer requirements, the item need not adjustment commonly for it has been

preset by software;

r) Factory menu item: Software Update, for software upgrade from USB port; at any channel,

insert USB memory device, select option “YES”, software will auto-search file “MERGE.bin” in

USB memory device to begin upgrade; please execute item “EEPROM Init” before adjustment

2

again, for old data still remain in E

4.1.3 ADC calibration of analog component YPbPr

a) Switch to analog component YPbPr channel;

b) Press key “SOURCE”, then press keys “2, 5, 8, 0” in turn to enter into initial factory menu;

c) Move cursor to item “ADC ADJUST” and press key “OK” to enter into inferior factory menu;

d) Input analog component Y/Pb/Pr signal(VG848 Timing 972(1080i), Pattern 918(8 Color & 16

Grey)); move cursor to item “MODE ”,press keys “▲” and “▼” to select item “YPbPr”,then

move cursor to item “AUTO ADC” and press key “OK” to begin auto-adjustment until prompt

“Success” displays which means successful auto-calibration;

4.1.4 ADC calibration of analog RGB

a) Switch to analog RGB channel;

b) Press key “SOURCE”, then press keys “2, 5, 8, 0” in turn to enter into initial factory menu;

c) Move cursor to item “ADC ADJUST” and press key “OK” to enter into inferior factory menu;

d) Input analog RGB signal(VG848: Timing 856(1024×768/60 Hz), Pattern 914(Color Temp.));

move cursor to item “MODE ”,press keys “▲” and “▼” to select item “RGB”,then move cursor

to item “AUTO ADC” and press key “OK” to begin auto-adjustment until prompt “Success”

displays which means successful auto-calibration.

4.2 White balance adjustment”

Unless specified by customer:

a) <

26” models:

Default color temperature “Cool” is 10000K and its chromatic coordinates is (280, 288); color

temperature “Normal” is 8000K and its chromatic coordinates is (295, 305); color temperature

“Warm” is 6500K and its chromatic coordinates is (323, 329);

b) ≥ 26” models:

Default color temperature “Cool” is 12000K and its chromatic coordinates is (272, 278); color

temperature “Normal” is 9300K and its chromatic coordinates is (285, 293); color temperature

“Warm” is 6500K and its chromatic coordinates is (323, 329);

4.3 Adjustment procedure

TV set should be working over 30 mins to be in stabler state before white balance adjustment; Use

white balance apparatus CA-210 and switch to its BBY channel;

a) Switch to HDMI1channel;

b) Press key “SOURCE”, then press keys “2, 5, 8, 0” in turn to enter into initial factory menu;

c) Move cursor to item “W/B ADJUST” and press key “OK” to enter into inferior factory menu;

d) Input HDMI signal (VG-848 Timing:856(1024×768/60 Hz),Pattern:921(Gray 16 step(H)); move

cursor to item “MODE”, press keys “▲” and “▼” to select item “HDMI1” or other HDMI channels,

then move cursor to item “Tem per..

e) Fix item “G-GAIN”, adjust items “R-GAIN, B-GAIN” to set chromatic coordinates of 13

the value of temperature “Normal”;

PROM after software upgrade.

” and press keys “▲” and “▼” to select item “Normal”;

th

scale as

Page 9

f) Fix item “G-OFFSET”, adjust items “R-OFFSET, B-OFFSET” to set chromatic coordinates of 4

th

scale as the value of temperature “Normal”;

g) During temperature “Normal” adjustment , make sure that chromatic coordinates errors of bright

scale are (x±10, y±15) and chromatic coordinates errors of dark scale are (x±10,y±25);

h) Move cursor to item “COPY ALL” again to copy data of white balance to other channels;

i) Check if chromatic coordinates of “Cool” and “Warm” meet the requirements or not, if not, adjust

items “R-GAIN/B-GAIN/R-OFFSET/B-OFFSET” to meet them:

“Cool”: chromatic coordinates errors of bright scale are (x±5, y±15), chromatic coordinates

errors of dark scale are (x±8, y±30);

“Warm”: chromatic coordinates errors of bright & dark scales are both (x±10, y±10);

j) Check if chromatic coordinates of other channels meet the requirements, if not, adjust them

respectively;

k) Check white balance of each channel by eye, check if the picture is normal;

l) Please refer to the adjusting rules as follows:

B Gun: coordinates of X and Y will increase when B gun is adjusted downwards;

coordinates of X and Y will decrease when B gun is adjusted upwards;

R Gun: adjusting R gun will effect coordinate of X, and value of Lv slightly;

coordinate of X will increase when R gun is adjusted upwards;

coordinate of X will decrease when R gun is adjusted downwards;

G Gun: adjusting G gun will effect coordinate of Y, and value of Lv greatly;

coordinate of Y will increase when G gun is adjusted upwards;

coordinate of Y will decrease when G gun is adjusted downwards.

5 Functions checkup

5.1 Analog & digital TV functions

Input central signal to RF port, enter into menu “CHANNEL”, then search channels automatically,

check if there is any omitted channel, check if the output of speakers and the picture are normal.

5.2 Composite video of AV port

Input composite video signal to AV port, check if the picture and the sound are normal under the

circumstances of power on/off, switching channel and format, etc.

5.3 Analog component YPbPr/YCbCr port

Input analog YP

signal from VG848 signal generator with YPBPR formats listed as Table 4

BPR

respectively, check if the picture and the sound are normal under the circumstances of power-on/off,

switching channel and format, etc.

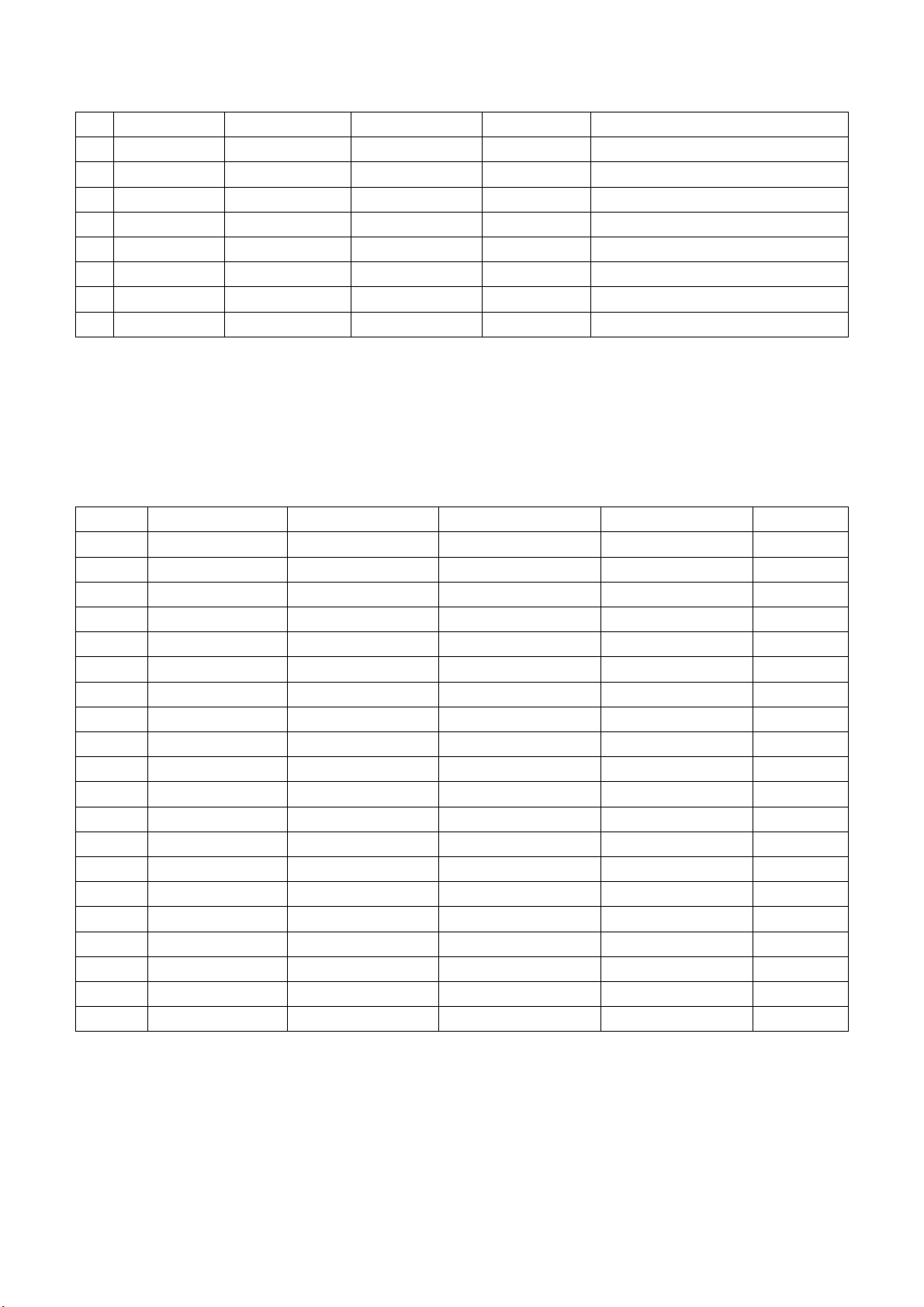

Table 4 YP

No.

1 720×480 15.734/15.75 59.94/60 13.5/13.514

2 720×576 15.625 50 13.5 576i (PAL, PAL-N, SECAM)

3 720×480 31.469/31.5 59.94/60 27/27.027 480p

4 720×576 31.25 50 27 576p

5 1280×720 37.5 50 74.25 720p (50p)

6 1280×720 44.955/45 59.94/60 74.176/74.25 720p (59.94p/60p)

Definition

H. - fre.(kHz) V. – fre.(Hz)

signal formats

BPR

Dot pulse fre.

(MHz)

Note

480i

(NTSC, NTSC4.43,PAL60,PAL-M)

Page 10

7 1920×1080 28.125 50 74.25 1080i (50i)

8 1920×1080 33.75 59.94/60 74.176/74.25 1080i (59.94i/60i)

9 1920×1080 26.973 23.976 74.176 1080p (23.97p)

10 1920×1080 27 24 74.25 1080p (24p)

11 1920×1080 28.125 25 74.25 1080p (25p)

12 1920×1080 33.716 29.97 74.176 1080p (29.97p)

13 1920×1080 33.75 30 74.25 1080p (30p)

14 1920×1080 56.25 50 148.5 1080p (50p)

15 1920×1080 67.432/67.5 59.94/60 148.35/148.5 1080p (59.94p/60p)

5.4 Analog R, G, B port

Input analog RGB signal from VG-848 signal generator to VGA port with VGA signal formats listed in

Table 5 respectively, check if the display and the sound are normal under the circumstances of

power-on/off, switching channel and format, etc. if there is any H/V offset, enter into main menu and select

items “PICTURE”->“Screen”->“Auto Ajust” in turn to make calibration automatically;

Table 5 Analog RGB signal formats

No. Definition

1 640×480 31.469 59.94 25.175 IBM

2 720×400 31.469 70.086 28.322 IBM

3 640×480 37.861 72.809 31.5 VESA

4 640×480 37.5 75 31.5 VESA

5 800×600 35.156 56.25 36 VESA

6 800×600 37.879 60.317 40 VESA

7 800×600 48.077 72.188 50 VESA

8 800×600 46.875 75 49.5 VESA

9 1024×768 48.363 60.004 65 VESA

10 1024×768 56.476 70.069 75 VESA

11 1024×768 60.023 75.029 78.75 VESA

12 1152×864 67.5 75 108 VESA

13 1280×960 60 60 108 VESA

14 1280×1024 63.98 60.02 108 VESA

15 1280×1024 80 75 135 SXGA

16 1360×768 47.7 60 85.5 WXGA

17 1440×900 55.9 60 106.5 WXGA+

18 1400×1050 65.22 60 122.61 SXGA+

19 1680×1050 65.3 60 146.25 WSXGA+

20 1920×1080 67.5 60 148.5

H. - fre.(kHz) V. – fre.(Hz) Dot pulse fre.(MHz)

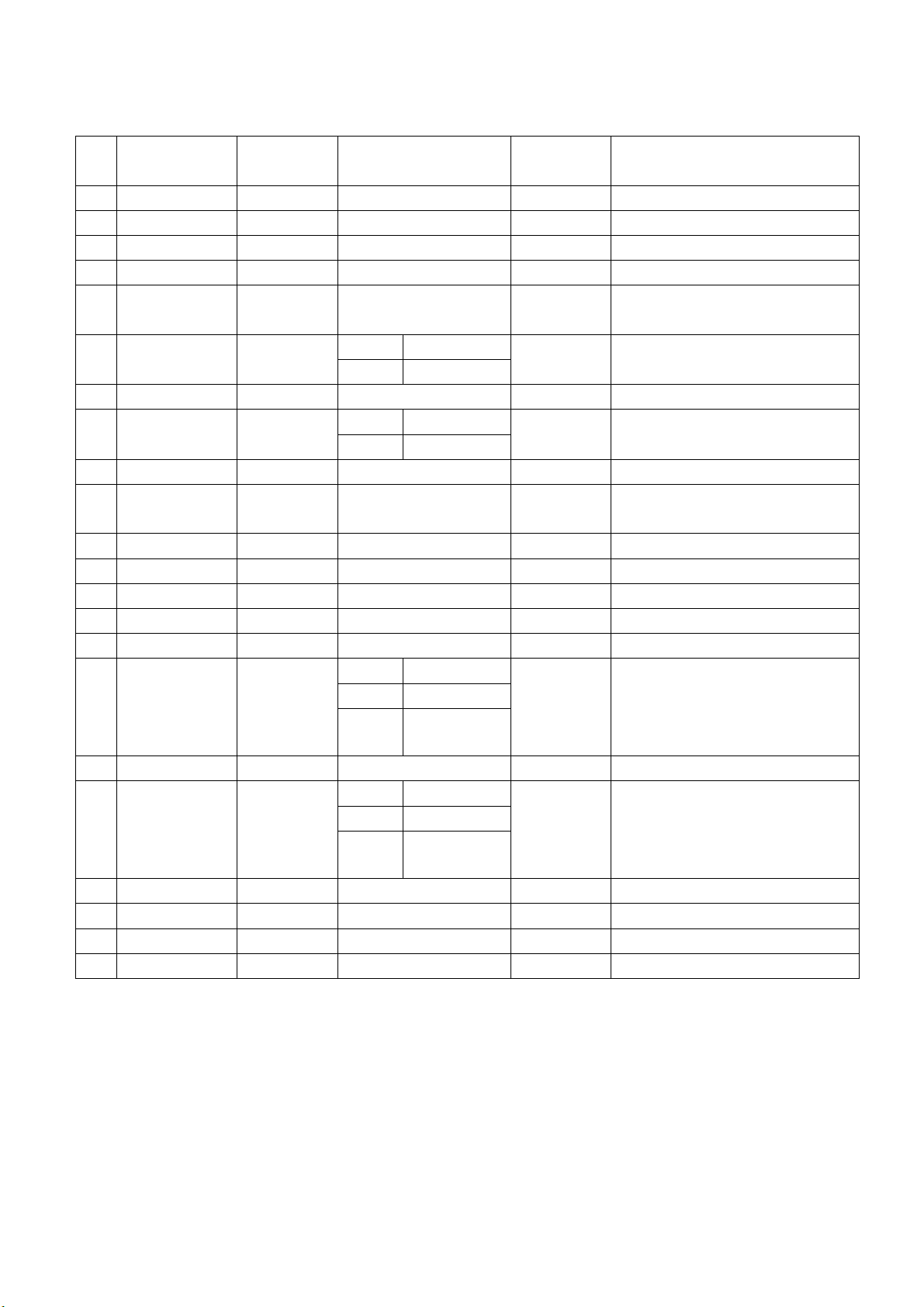

5.5 Digital HDMI port

Input HDMI signal from VG849 signal generator with the formats listed in Table 6 respectively, check

if the display and the sound (32 kHz, 44.1 kHz, 48 kHz) are normal under the circumstances of power-on,

switching channels or formats, etc.

Note

Page 11

Table 6 Digital HDMI signal format

No. Definition

1 640×480 31.469/31.5 59.94/60 25.175/25.2 640×480p@59.94/60 Hz

2 720×480 31.469/31.5 59.94/60 27/27.027 720×480p@59.94/60 Hz,4:3/16:9

3 1280×720 44.955/45 59.94/60 74.176/74.25 1280×720p@59.94/60 Hz

4 1920×1080 33.716/33.75 59.94/60 74.176/74.25 1920×1080i@59.94/60 Hz

5 720(1440)×480 15.734/15.75 59.94/60 27/27.027

6 720(1440)×240 15.734/15.75

7 (2880)×480 15.734/15.75 59.94/60 54/54.054 (2880)×480i@59.94/60 Hz,4:3/16:9

8 (2880)×240 15.734/15.75

9 1440×480 31.469/31.5 59.94/60 54/54.054 1440×480p@59.94/60 Hz,4:3/16:9

10 1920×1080 67.432/67.5 59.94/60

11 720×576 31.25 50 27 720×576p@50 Hz,4:3/16:9

12 1280×720 37.5 50 74.25 1280×720p@50 Hz

13 1920×1080 28.125 50 74.25 1920×1080i@50 Hz

14 720(1440)×576 15.625 50 27 720(1440)×576i@50 Hz,4:3/16:9

15 720(1440) ×288 15.625 Mode 1 49.761 27

16 (2880) ×576

17 (2880) ×288 15.625 Mode 1 49.761 54

18 1440×576

19 1920×1080 56.25 50 148.5 1920×1080p@50 Hz

20 1920×1080 26.973/27 23.97/24 74.176/74.25 1920×1080p@23.97/24 Hz

21 1920×1080 28.125 25 74.25 1920×1080p@25 Hz

22 1920×1080 33.716/33.75 29.97/30 74.176/74.25 1920×1080p@29.97/30 Hz

H. - fre.(kHz) V. – fre.(Hz)

Mode1 59.826/59.886

Mode 2 60.054/60.115

Mode 1 59.826/59.886

Mode 2 60.054/60.115

Mode 2 49.92

15.625

31.25

Mode 3 50.08

50 54

Mode 2 49.92

Mode 3 50.08

50 54

5.6 USB port

5.6.1 Media playing function

Insert USB memory containing files of picture, audio and video, check if the picture, the sound and

other functions are normal;

5.6.2 PVR function

Insert formatted USB memory containing recorded-program files, press key “Rec. List” to select and

play program, check if the picture, the sound and other functions are normal;

Dot pulse fre.

(MHz)

27/27.027

54/54.054 (2880)×240p@59.94/60 Hz,4:3/16:9

148.352/148.

5

(2880)×576i

@50

Hz,4:3/16:9

1440×576p

@50

Hz,4:3/16:9

Note

720(1440)×480i@59.94/60

Hz,4:3/16:9

720(1440)×240p@59.94/60

Hz,4:3/16:9

1920×1080p@59.94/60 Hz

720(1440)×288p@50 Hz,4:3/16:9

(2880)×288p@50 Hz,4:3/16:9

Page 12

5.7 MUSIC port

Input audio signal, check if the sound is normal;

5.8 Other functions checkup

a) Check if composite video out of AV port, digital audio port, earphone jack, etc., are normal;

b) Check if the functions of LCN, OTA are normal;

6 User menu setup before shipment

Enter into “LOCK” user menu, input initial password “0000”, select item “Restore Factory Default”

and then press key “OK” to make setup before shipment;

a) Clear out information of all programs;

b) Clear out information of program-lock, favorite programs, etc.;

c) Recover default analog parameters;;

d) Set menu language as “English”;

e) Set power-on mode as “Standby”.

Page 13

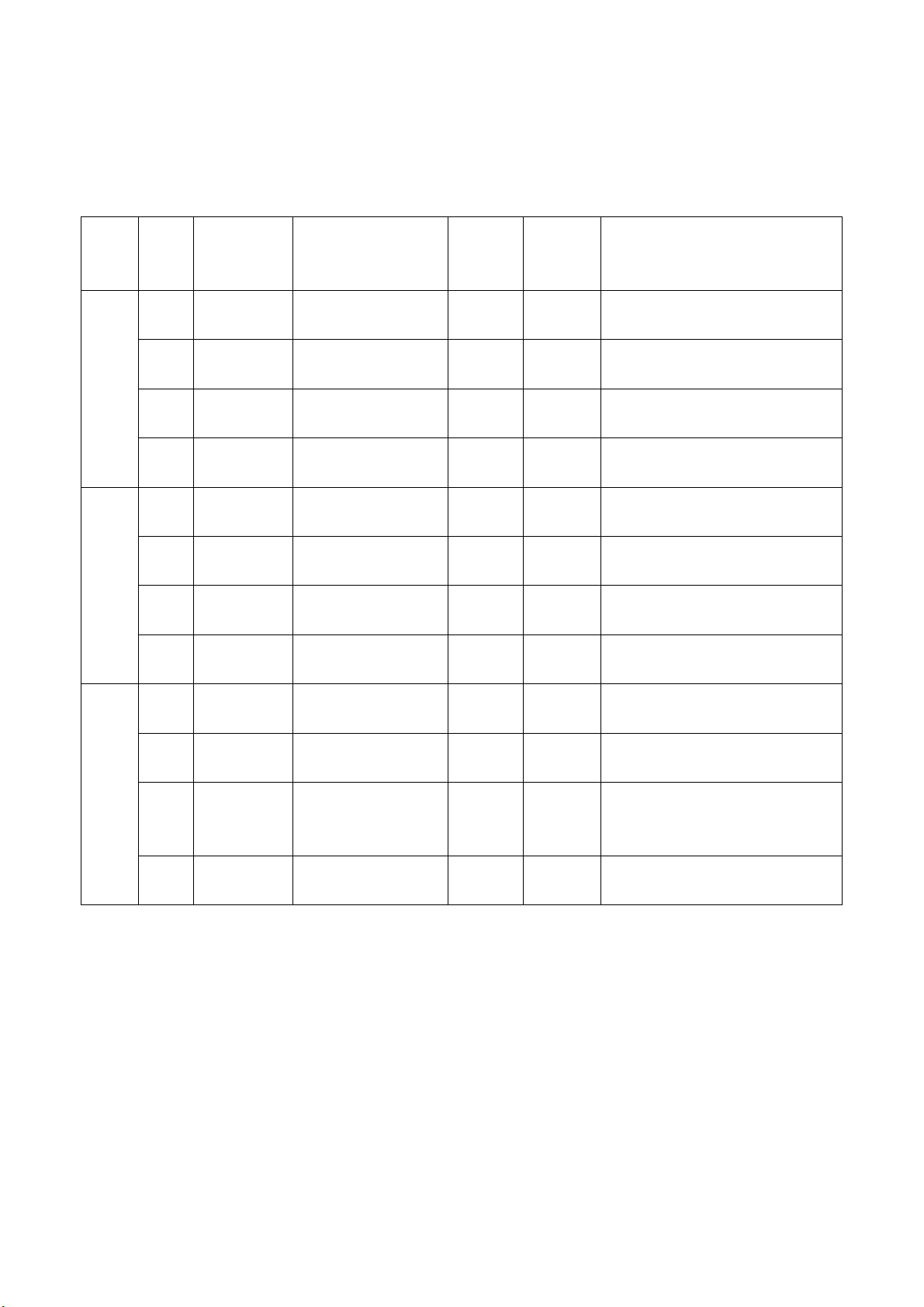

Method of software upgrading instructions

Factory software burned instructions listed as Table 7

Table 7 Factory software burned instructions

Burned

before

SMT

Yes

Yes Use ALL-100, etc.

Yes Use ALL-100, etc.

Yes Use ALL-100, etc.

Yes

Yes Use ALL-100, etc.

Yes Use ALL-100, etc.

Yes Use ALL-100, etc.

Yes

Yes Use ALL-100, etc.

Yes Use ALL-100, etc.

Yes Use ALL-100, etc.

Use ALL-100 with write-protect,

refer to Note 1 in detail.

Use ALL-100 with write-protect,

refer to Note 1 in detail.

Use ALL-100 with write-protect,

refer to Note 1 in detail.

Burning method

Model

<26”

CCFL

<26”

LED

≥26”

LED

Loc.

No.

N103 5272564002 EN25Q64-104HIP

N106 5272404005 CAT24C04WI-GT3

N301

N316

N305

N103 5272564002 EN25Q64-104HIP

N106

N301

N311

N305

N103 5272564002 EN25Q64-104HIP

N106

N302

N305

N316

N309

Part No. Part Type

5272402002 AT24C02BN10SU-1.8

5272402003 CAT24C02WI

5272402002 AT24C02BN10SU-1.8

5272402003 CAT24C02WI

5272404005 CAT24C04WI-GT3

5272402002 AT24C02BN10SU-1.8

5272402003 CAT24C02WI

5272402002 AT24C02BN10SU-1.8

5272402003 CAT24C02WI

5272404005 CAT24C04WI-GT3

5272402002 AT24C02BN10SU-1.8

5272402003 CAT24C02WI

5272402002 AT24C02BN10SU-1.8

5272402003 CAT24C02WI

Software

function

Main

program

HDCP

KEY

HDMI

EDID

VGA

EDID

Main

program

HDCP

KEY

HDMI

EDID

VGA

EDID

Main

program

HDCP

KEY

HDMI

EDID

VGA

EDID

Note 1: Method of write-protect setup: enter into burning interface of ALL-100, tick option “Config”,

press item “config Setting”, set option “Protect” as “All Protect”; make sure that option “Config”

must be ticked before burning software and write-protect must be reset after ALL-100 burning

software is opened every time.

Note 2: Method of burning and upgrading software online by using ISP burning device:

a) For main board upgrade: connect 4-pin cable of ISP burning device to Debug port of main board

(<26”: X404, ≥26”: X604); for unit upgrade, connect both D-SUB ports of ISP burning device and

main board, enter into factory menu and set item “Other Settings->ISP Mode” as “ON”;

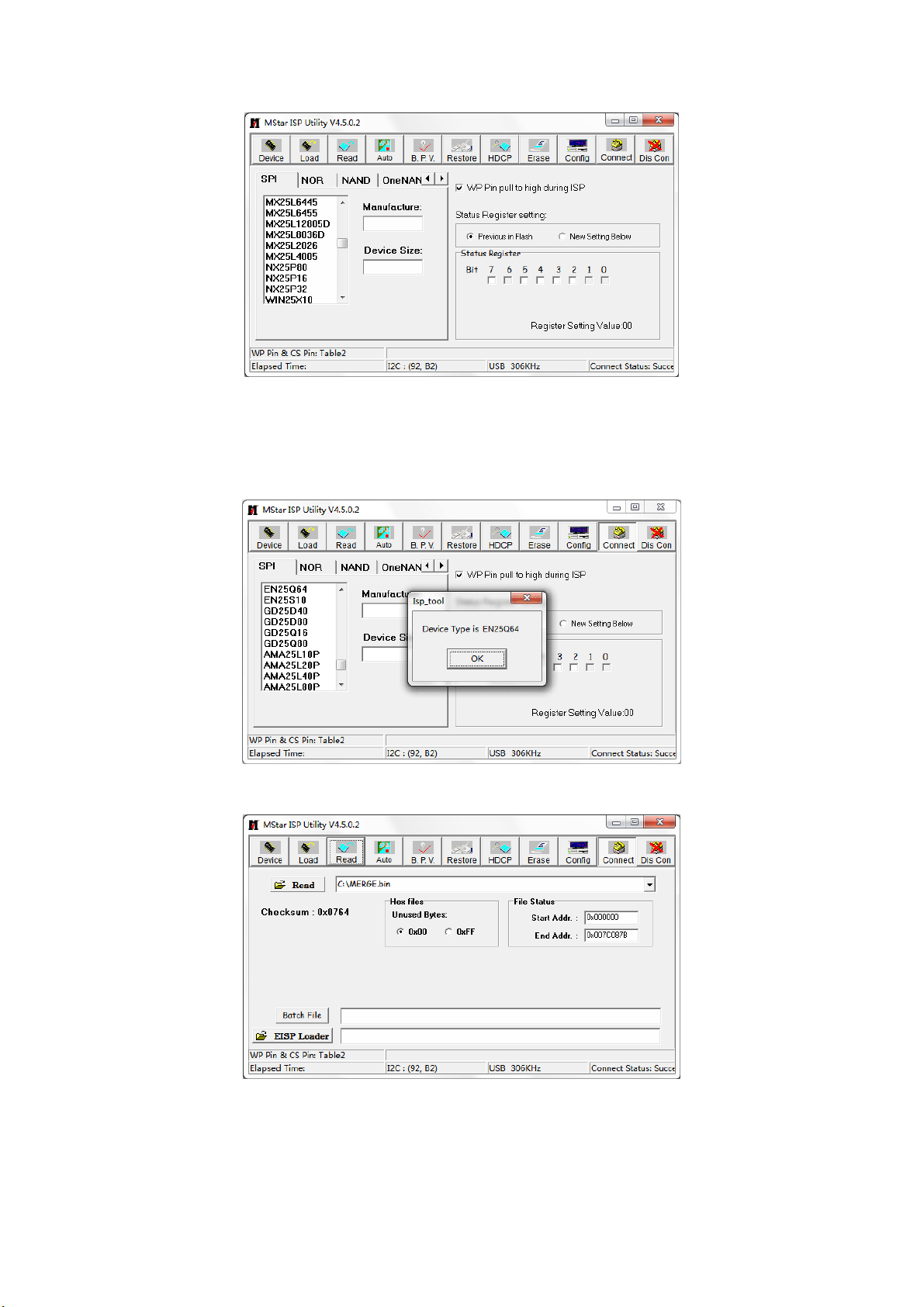

b) Using Mstar online burning program, enter into menu “Device”, tick option “WP Pin pull to high

during ISP” to ensure that hardware write-protect of Flash is removed and erasing process is

normal, please refer to Fig. 2;

Page 14

Fig. 2 Write-protect setup

c) Press menu “Connect”, a dialog box “Device Type is XXX (XXX is corresponding type of SPI

Flash)” will pop up, that is, connection has been successful, please refer to Fig. 3; if connection

is failed, press the first menu “Device” to select SPI Flash type manually, then press menu

“Connect” again;

Fig. 3 Successful connection

d) Press menu “Read”, select the burning file, such as “MERGE.bin”, please refer to Fig. 4;

Fig. 4 Burning file

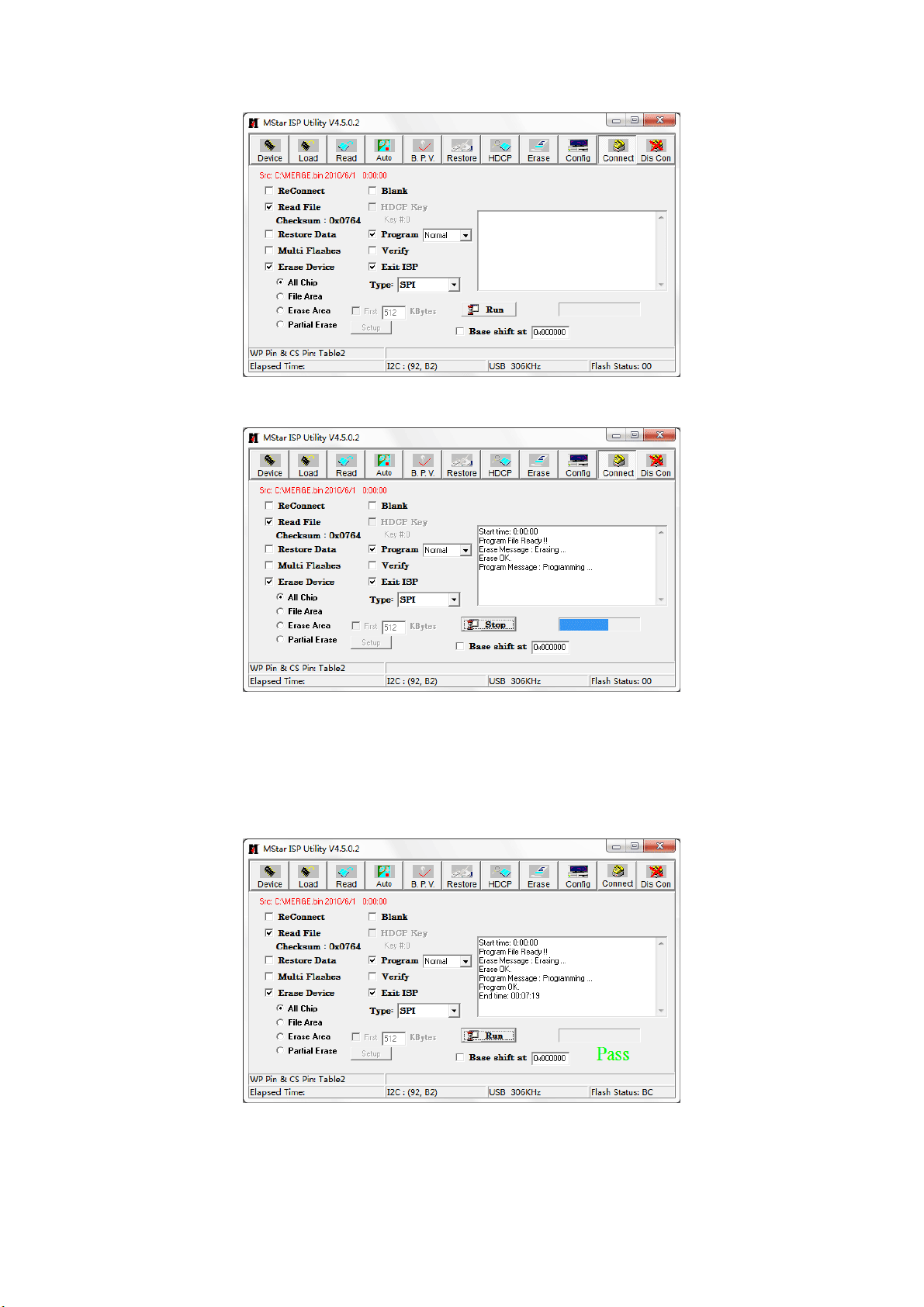

e) Press menu “Auto”, tick options “All chip”, “program” and relative option switches, please refer

to Fig.5, press key “Run” to begin burning;

Page 15

Fig. 5 Option switches

f) Burning process has two steps: Erase and Program; please refer to Fig. 6;

Fig. 6 Option switches

1) First, the step “Erasing…” will last for some time, or it is failed if it is passed by quickly,

please confirm procedure 2)and begin burning process again;

2) Then the following step is “Programming…;

3) A prompt “Pass” will display at last;

g) A prompt “Pass” will display if burning process is successful, please refer to Fig. 7;

Fig. 7 Successful burning process

h) If there are other machines to be burned, remain ISP burning interface and repeat procedures

c)to e)only;

Page 16

Note 3: Method of online burning and upgrade through USB:

a) Make sure that U disk is formatted as “FAT32”;

b) Copy firmware to U disk with name of “Merge.bin”;

c) Turn on the TV set, press key “SOURCE” first, then press keys “2, 5, 8, 0” in turn to enter into

initial factory menu at any channel;

d) Enter into factory menu, select item “Software Update”, press key “OK”, a prompt “Are you

sure?” will display, select option “Yes”, then software will auto-search file “MERGE.bin” in the

USB memory to begin upgrade, detailed upgrading processes are below:

1) Read data from USB memory, a prompt “Unknown image type” will display if upgrading file

is wrong;

2) If upgrading file is right, a prompt “Software upgrading...” and percent of upgrading

progress will display, while indicated light is twinkling at the same time;

3) The unit will restart after upgrading processes has completed;

e) Restart the unit, enter into factory menu, confirm software parameters - version and time, then

execute “EEPROM Init” to complete the whole upgrading processes;

f) USB burning method could not be sure to all kinds of U disks, so please try another U disk if one

is inapplicable.

Page 17

Working principle analysis of the unit

Signal Flow

1、 PAL/SECAM signal flow

Send PAL/SECAM analog RF signal received from antenna to TUNER FT21XX which is controlled

2

by main chip MSD209GL through I

outputted after demodulation;

CVBS video signal is sent into main chip MSD209GL to be processed by modules of video decoding,

deinterlacing, video processing and zoom, then LVDS signal will be outputted to drive display panel;

SIF audio differential signal is sent into main chip MSD209GL to be demodulated to analog audio

signal, then it is sent to earphone amplifier BH3547F to be amplified after the processes of

preamplification, acoustic effect processing and volume control, and then it is divided into two, one is sent

to earphone jack, the other is sent to audio power amplifier R2A15112FP (D class) to be amplified and

then drive speakers.

2、 DVB-T signal flow

Send DVB-T digital RF signal received from antenna to TUNER FT21XX which is controlled by main

2

chip MSD209GL through I

C BUS; after down frequency conversion, differential IF signal will be inputted

into demodulator IC MSB1210 to be demodulated; then it will be sent to main chip MSD209GL with the

standard format of serial or parallel TS stream for demultiplexing and decoding;

C BUS; CVBS video signal and SIF audio differential signal will be

Page 18

Video route: digital video signal is sent into main chip MSD209GL for decoding and video processing

after demultiplexing, then LVDS signal will be outputted to drive display panel;

Audio route: digital audio signal will be sent into main chip MSD209GL for decoding and audio

processing after demultiplexing, then dual-sound-track analog audio signal (stereo) is sent to earphone

amplifier BH3547F to be amplified after the processes of preamplification, acoustic effect processing and

volume control by main chip MSD209GL, then one is sent to earphone jack, the other is sent to audio

power amplifier R2A15112FP (D class) to be amplified and then drive speakers.

3、 AV input signal flow

AV video signal is sent into main chip MSD209GL to be processed by modules of video decoding,

deinterlacing, video processing and zoom, then LVDS signal will be outputted to drive display panel;

AV audio signal is sent into main chip MSD209GL for acoustic effect processing and volume control

after the processing of voltage division, impendence matching and AC coupling, then it is sent to

earphone amplifier BH3547F to be amplified, one is sent to earphone jack, the other is sent to audio

power amplifier TDA7266SA (AB class) to be amplified and then drive speakers.

4、 D-SUB/YPbPr input signal flow

D-SUB/YPbPr video signal is sent into main chip MSD209GL to be processed by modules of A/D

conversion, video decoding, deinterlacing, video processing and zoom, then LVDS signal will be

outputted to drive display panel;

D-SUB/YPbPr audio signal is sent into main chip MSD209GL for acoustic effect processing and

volume control after the processing of voltage division, impendence matching and AC coupling, then it is

sent to earphone amplifier BH3547F to be amplified, one is sent to earphone jack, the other is sent to

audio power amplifier R2A15112FP (D class) to be amplified and then drive speakers.

5、 HDMI input signal flow

HDMI video signal is sent into main chip MSD209GL to be processed by modules of video decoding,

video processing and zoom, then LVDS signal will be outputted to drive display panel;

HDMI audio signal is sent into main chip MSD209GL for audio processing, preamplification, acoustic

effect processing and volume control, then it is sent to earphone amplifier BH3547F to be amplified, one

is sent to earphone jack, the other is sent to audio power amplifier R2A15112FP (D class) to be amplified

and then drive speakers.

6、 AV input signal flow

Current active AV video signal is sent into main chip MSD209GL for video coding, then it is amplified

by peripheral video amplified circuits and then outputted;

Current active AV audio signal is sent into main chip MSD209GL for preamplification, acoustic effect

processing and volume control, then it is sent to operation amplifier to be amplified and then outputted.

7、 SPDIF input signal flow

Current active AV audio signal is sent into main chip MSD209GL for acoustic effect processing,

volume control and digital audio coding, then it is outputted.

8、 MEMC input signal flow

Current active AV video signal is sent into main chip MSD209GL for video coding, then LVDS signal

is outputted to MEMC chip 6M20S for frame insertion processing, and then frequency multiplication LVDS

signal is outputted to drive display panel.

Page 19

Block diagram

Page 20

IC Block Diagram and Instruction

1、 MSD209GL-LF

GENERAL DESCRIPTION

The MSD209GL is a highly integrated controller IC for LCD/PDP DTV applications with resolutions up to

full-HD(1920 x 1080). It is configured with an integrated triple-ADC/PLL, a multi-standard TV video and

audio decoder, a motion adaptive video de-interlacer, a scaling engine, the MStarACE-3 color engine, an

advanced 2D graphics engine, a transport processor, a high-definition (HD) MPEG video decoder, a

high-definition (HD) H.264 video decoder, a RealVideo decoder, a JPEG video decoder, a MPEG-4

decoder, and a 24-bit DSP for MPEG audio decoding, a DVI/HDCP/HDMI receiver, and a peripheral

control unit providing a variety of HDTV control functions.

For digital TV application, the MSD209GL comprises an MPEG-2 transport processor with advanced

section filtering capability, an MPEG-2 (MP@HL profile) video decoder, a MPEG-4 decoder, a H.264

video decoder, and an audio DSP decoder for MPEG audio streams, MPEG layer I and II digital audio

decoder with analog audio outputs that are designed to support existing and future DVB-T programs while

handling conditional access. Furthermore,it is also possible to decode JPEG, RealVideo streams, and

MP3 formats from external sources such as USB interface.

For analog TV, the MSD209GL includes NTSC/PAL/SECAM multi-standard video decoder comprising a

3D motion adaptive comb filter and time-based correction, and a NICAM/A2 audio decoder to support

worldwide television standards. The MSD209GL is also configured with a VBI processor to decode digital

information such as Close Caption/V-chip/teletext/WSS/CGMS-A/VPS. In addition, the MStar advanced

LCD TV processor enhances video quality, motion adaptive de-interlacer, picture quality adjustment units,

and MStarACE-3 color engine.

With USB 2.0 host controllers, UART, IR, SPI, I2C, and PWM, the MSD209GL fulfills all requirements in

advanced DTV sets. To reduce system costs, the MSD209GL also integrates intelligent power

management control capability for green-mode requirements and spread-spectrum support for EMI

management.

MSD209GL Features:

Twin-turbo 8051 Micro-controller

z Twin-turbo 8051 MCU

z Interrupt controller

z Supports ISP

z Two full duplex UARTs

z DMA engine to speed up large data movement

Transport Stream De-multiplexer

z One external TS input and one internal TS data path

z Supports serial TS interface, with or without sync signal

z Maximum TS data rate is 104 Mb/sec

z 32 general purpose PID filters and section filters for each transport stream de-multiplexer

z One video PES and one audio PES channel

z Supports DVB subtitle and digital teletext

Page 21

z Supports additional audio/video/PCR filters

z Supports TS DMA channel for time-shift

z Supports AES encryption/decryption

MPEG-2 A/V Decoder

z ISO/IEC 13818-2 MPEG-2 video MP@HL

z Automatic frame rate conversion

z Supports resolution in HDTV (1080i, 720p) and SDTV

z Supports MPEG-1, MPEG-2 (Layer I/II), Dolby Digital (AC-3), and AAC audio decoding

z Optionally Supports Dolby Digital Plus (E-AC-3) decoding, and Dolby Digital Compatible Output

(DDCO) for HE-AAC to DD transcoding

MPEG-4 Video Decoder

z ISO/IEC 14496-2 MPEG-4 ASP video decoding

z Supports resolution in HDTV (1080p@30fps)

3

z Supports DivX

Home Theater or HD profile

H.264 Decoder

z ITU-T H.264, ISO/IEC 14496-10 (main and high

z profile up to level 4.0) video decoding

z Supports resolutions for all DVB, ATSC, HDTV,DVD and VCD

z Supports resolution up to 1080p@30fps

z Supports CABAC and CAVLC stream types

z Processing of ES and PES streams, extractions and provision of time stamps

RealMedia Decoder

z Supports maximum resolution up to 720p@30fps

z Supports RV8, RV9, RV10, RA8-LBR and HE-AAC decoders

z Supports file formats with RM and RMVB

z Supports Picture Re-sampling

z Supports in-loop de-block for B-frame

Hardware JPEG

z Supports sequential mode, single scan

z Supports both color and grayscale picture

z Operates in scan unit; hardware decoder will handle the bit stream after scan header

z Supports programmable region of interest (ROI)

z Supports format: 422/411/420/444/422T

z Decoded picture will be stored in DRAM with UYVY format

z Supports scaling down ratio: 1/2, 1/4, 1/8,applied to height and width simultaneously

z Supports picture rotation

NTSC/PAL/SECAM Video Decoder

z Supports NTSC-M, NTSC-J, NTSC-4.43, PAL (B,D, G, H, M, N, I, Nc), and SECAM

z Automatic TV standard detection

z Motion adaptive 3D comb filter for NTSC/PAL

z Seven configurable CVBS & Y/C S-video inputs

z Supports Teletext level-1.5, Closed Caption(analog CC 608/ analog CC 708/digital CC 608/digital CC

708), V-chip and SCTE

z Two CVBS video outputs

Page 22

Multi-Standard TV Sound Processor

z Supports BTSC/A2/EIA-J demodulation in NTSC and A2/NICAM/FM/AM demodulation in PAL

z Supports MTS Mode Mono/Stereo/SAP in BTSC/EIA-J and Mono/Stereo/Dual in A2/NICAM

z L/R audio line-in x5 and SIF audio input

z L/R speaker and 2 additional L/R audio line-out

z Built-in audio sampling rate conversion (SRC)

z Built-in audio ADC

z Built-in audio DAC’s

z Audio processing for loudspeaker channel,including volume, balance, mute, tone, EQ,virtual

stereo/surround, and treble/bass

z Advanced soundOptional available (Dolby, SRS,BBE… etc)

z Supports digital audio format decoding:

¾ MPEG-1, MPEG-2 (Layer I/II), MP3, AC-3 (Dolby Digital), AAC-LC, WMA

¾ E-AC-3 (Dolby Digital Plus) decoding and E-AC-3 to AC-3 conversion at the same time

Digital Audio Interface

2

S digital audio input & output

z I

z S/PDIF digital audio input & output

z HDMI audio channel processing capability

z Programmable delay for audio/video synchronization

Analog RGB Compliant Input Ports

z Three analog ports support up to 1080P

z Supports PC RGB input up to SXGA@75Hz

z Supports HDTV RGB/YPbPr/YCbCr

z Supports Composite Sync and SOG (Sync-on-Green) separator

z Automatic color calibration

Auto-Configuration/Auto-Detection

z Auto input signal format and mode detection

z Auto-tuning function including phasing,positioning, offset, gain, and jitter detection

z Sync Detection for H/V Sync

DVI/HDCP/HDMI Compliant Input Port

z Three DVI/HDCP/HDMI input ports support up to 225MHz @ 1080P 60Hz with 12-bit deep-color

resolution

z Single link on-chip DVI 1.0 compliant receiver

z High-bandwidth Digital Content Protection

z (HDCP) 1.1 compliant receiver

z High Definition Multimedia Interface (HDMI) 1.3 compliant receiver with CEC (Consumer Electronics

Control) support

z Long-cable tolerant robust receiving

MACE-4, MStar Advanced Color Engine year 2009 Edition, provides superb visual quality for wider

gamut FHD panels

z Fully programmable shrink/zoom capabilities

z Panorama and various scaling supports

z 3D motion adaptive video de-interlacers with de-flickering and edge smoothing functions

z Automatic 3:2 pull-down & 2:2 pull-down detection and recovery

Page 23

z Automatic picture enhancement:

¾ Dynamic brilliant and fresh color

¾ Dynamic Blue Stretch

¾ Intensified contrast and details

¾ Dynamic Vivid Skin

¾ Dynamic sharpened Luma/Chroma edges

¾ Enhanced depth of field perception

¾ Accurate and independent color control

z Supports sRGB and xvYCC color processing

z Supports HDMI 1.3 deep color format

z Supports linear/nonlinear color mapping for wider gamut panels

z 10-bit internal data processing

z Programmable 12-bit RGB gamma CLUT

z 3D video noise reduction

z MPEG artifact removal including de-blocking and mosquito noise reduction

z Frame rate conversion

Output Interface

z Supports up to 10-bit dual LVDS full-HD (1920 x 1080) panel interface

z Supports 2 data output formats: Thine & TI data mappings

z Compatible with TIA/EIA

z With 6/8 bits optional dithered output

z Spread spectrum output frequency for EMI suppression

CVBS Video Output

z Supports CVBS bypass output

z Built-in video encoder for encoding digital video into CVBS output

2D Graphics Engine

z Point draw, line draw, rectangle draw/fill and text draw

z BitBlt and stretch BitBlt

z Raster Operation (ROP)

Miscellaneous

z DRAM controller to support 16-bit DDR2 interface

z SPI serial interface for external SPI flash

z High efficiency power control module

z Two ports of USB 2.0 host controller with the flexibility for connecting external storage devices

z 256-pin LQFP package

z Operating at 1.26V (core), 1.8V (DDR2), and 3.3V (I/O and analog)

Page 24

2、 MSB1210-LF

Integrated DVBT receiver

z Compliant with DVBT(ETSI ET 300 744)

z Supports 2K, 4K, 8K and 1/4, 1/8, 1/16, 1/32 guard interval (GI) and hierarchical,non-hierarchical

modes

z Nordig Unified 1.0.3, D-Book, E-Book,IEC62002 (MBRAI) compliant

z Dual 11-bit ADCs: accept IF, low IF, zero-IF inputs in 5, 6, 7, 8MHz channel bandwidths

z All digital demodulation and timing recovery loops

z CCI and ACI rejection capability

z Independent ADC controls (for IF and RF)

z Configurable parallel/serial MPEG-2 transport stream interface

z Impulse-Noise suppression

z Advanced performance for SFN networks

z Supports single or dual AGC control

z Direct 36MHz, 44MHz IF sampling scheme from tuner

z Full-digital frequency offset recovery with wide acquisition range (+/-500kHz)

z IQ imbalance compensation for ZIF

Integrated VIF receiver

z Multi-standard analog TV receiver applications

z Digital low IF architecture

z Maximum IF gain of 48dB

z Programmable TOP to accommodate different tuner gain to optimize noise and linearity performance

Page 25

Miscellaneous

z Embedded 8-bit MCU

z Clock generation from a single 20.48/ 28.8MHz crystal

z Supports I2C interface with bypass mode

z Operating voltage: 3.3V and 1.2V

z 48-pin LQFP package

3、 FT21XX

FT 21XX are newly developed low-cost Half-NIM modules designed for both digital (DVB-T/C) and analog

TV reception in compliance with the European ATV standards for analogue, as well as with the terrestrial

standard ETS 300 744 and cable standard ETS 300429 for digital. It consists of a 3-band RF tuner, which

receives RF signal and down-converts it to an IF frequency of 36MHz for digital and 38.9MHz for analog

IF. The analogue IF output can directly drive a SAW filter. A digital IF Stage, which consists of one SAW

filter & gaincontrollable IF that offers a sufficient output level to be connected directly to an A/D converter.

Page 26

4、 R2A15112FP

R2A15112FP is a Digital Power Amplifier IC developed for TV.

R2A15112FP has a maximum power of 15W(typ) × 2ch.(VD = 24V,THD = 1%, SE) at a 4 Ω load.

It is possible to replace a conventional analog amplifier with a digital amplifier easily.

Feature

z Maximum power out put (No external heat sink)

(note) These apply when the thermal pad is soldered to the printed-circuit board directly.

Recommended Power Condition

SE operation mode :15Wx2ch(VD=24V,4Ω load,THD+N:1%)

BTL operation mode:30Wx1ch(VD=21V,8Ω load,THD+N:10%)

z Highly efficient, low noise, and low distortion

z Popless

z Built-in protection - Overcurrent, overheat, and undervoltage

z Built-in Mute and Standby function

z The gain can be changed to four settings by two terminals.

Page 27

5、 MST6M20S

Input Interface

z Single/dual channel 8/10 bit LVDS input

z Each input LVDS channel frequency supports up to 100 MHz

z One channel input supports up to WXGA(1366x768)

z Two channel inputs support up to Full HD(1920x1080)

z Input mode supports JEIDA / VESA mode

z Image capturing window is defined by DE signal

z Supports flexible aging mode

Output Interface

z Single/dual/quad link 8/10 bit LVDS output

z Each output LVDS channel frequency supports up to 90 MHz

z Supports two channel LVDS up to WXGA (1366x768) @ 120Hz

z Supports four channel LVDS up to Full HD (1920x1080) @ 120Hz

z Supports 2/4 phase output

z Supports left-right screen partition

z Supports TH/TI format

z Supports dithering options

z Spread spectrum output frequency for EMI suppression

Video Processing

z MFCPRO (Motion Frame Conversion Professional) supports:

z Wider searching range

z Refined judder-free motion video and film

z Motion blur elimination to improve MPRT

z Advanced halo and artifact elimination

z Output frame rate 50/60/100/120 f/sec

z Supports MFCPRO under Full-HD resolution

z Automatic 2:2 / 3:2 film mode detection

z Supports 2:2 / 3:2 pull-down reverse processing

z Support 1080p 24fps 5:5 pull-down

z Supports 10-bit 4:4:4 processing

z Brightness contrast saturation adjustment

z White balance adjustment

z Supports Gamma correction per bit and FRC function for 16.7M color selection

Page 28

z Supports black insertion

z Supports OSD area handling

z Splits screen demo for motion frame conversion

Miscellaneous

z Embedded 8-bit Microcontroller

z Supports 16-bit DDR2 interface

z Supports I2C, SPI, PWM, and GPIOs

z Supports booting from internal SRAM, external EEPROM, and SPI flash

z 216-pin LQFP package

Page 29

WIRING DIAGRAM

Board

Backlight Board

Panel

Sound Box (Bass)

Power Board

Board

Amp. Power

Sound Box

Key

IR / Light sensor

Bass

Power

Main Board

Debug

Key Board

Power Switch

Sound Box

IR / Light sencor Board

Page 30

Troubleshooting guide LED-42XR10FH(B)

1、 No Backlight

Page 31

2、 No Picture, but backlight is normal.

Page 32

3、 No sound, but picture is normal.

Check if

voltage of N6094#/5#/32#/33# is

+24V?

Yes

Check if

N320-3# / 5#

has input

signal?

Yes

Check if

voltage of N60910# / 27# is high

level?

Check mute circuits of

power amplifier

Check if

N609-12# /

25# has input

signal?

No

Yes

No

Check peripheral

circuits of power

amplifier.

No

Check +24V of power

board and its related

circuits.

Check earphone

amplified circuits

Yes No

Check audio output

circuits of main chip

Page 33

ABCDEFGH

1

+3.3V

AT24C04N-10SI-2.7

R156

10K

2

3

4

5

6

N105

AT24LC32A/SN

1

A0

Vcc

2

A1

3

A2

SCL

GND4SDA

N106

1

AO

Vcc

2

A1

3

A2

SCL

GND4SDA

+3.3V

R155

8

10K

E2PWP-

R154 33

7

WP

6

5

C172

100n

GND-D

+3.3V

8

7

WP

6

5

C173

100n

GND-D

R153 33

R152 33

R159

10K

R158 33

R157 33

R160

0

YPBPR-PB_IN003:D1

YPBPR-SOG_IN003:D1

YPBPR-PR_IN003:D1

GND-D

GND-D

HDMI1-RXC-003:A2

HDMI1-RXC+003:A2

HDMI1-RX0-003:A2

HDMI1-RX0+003:A2

HDMI1-HP-003:B3

HDMI1-RX1-003:A2

HDMI1-RX1+003:A2

HDMI1-RX2-003:A2

HDMI1-RX2+003:A2

HDMI2-RXC-003:A4

HDMI2-RXC+003:A4

HDMI2-RX0-003:A4

HDMI2-RX0+003:A4

HDMI2-RX1-003:A3

HDMI2-RX1+003:A3

HDMI2-RX2-003:A3

HDMI2-RX2+003:A3

HDMI2-HP-003:B4

VGA-B_IN003:A6

VGA-SOG_IN003:A6

VGA-G_IN003:A6

VGA-R_IN003:A6

YPBPR-Y_IN003:D1

CVBS1_IN003:D3

ATV-CVBS+002:A3

ATV-CVBS-002:A3

CVBS_OUT003:D4

ATV-SIF+002:A2

ATV-SIF-002:A3

SCL

SDA

SCL

SDA

+3.3V-DVI

R104 47

R105 47

R106 47

R107 47

BG1608B121

GND-D

APX810-29SAG-7

HDMI1-RXCHDMI1-RXC+

HDMI1-RX0HDMI1-RX0+

HDMI1-HPHDMI1-RX1HDMI1-RX1+

+3.3V-DVI

HDMI1-RX2HDMI1-RX2+

HDMI2-RXCHDMI2-RXC+

HDMI2-RX0HDMI2-RX0+

+3.3V-ADC

HDMI2-RX1HDMI2-RX1+

HDMI2-RX2HDMI2-RX2+

HDMI2-HP-

R103 390

C133 100n

C134 100n

C135 100n

VGA-SOG_IN

GND-D

C136 47n

YPBPR-PB_IN

C137 47n

YPBPR-Y_IN

YPBPR-SOG_IN

C138 47n

YPBPR-PR_IN

+3.3V-ADC

C139 47n

ATV-CVBS+

ATV-CVBS-

+3.3V-ADC

C140 10u

C141 100n

GND-D

+1.2V-VDDC

L110

N102

C153

100n

1%

VGA-B_IN

VGA-G_IN

VGA-R_IN

CVBS1_IN

CVBS_OUT

ATV-SIF+

ATV-SIF-

C143 100n

C144 10u

C145 100n

C146 10u

+3.3V-S

Vcc

RESET

GND

GND-D

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

ISP_EN 003:B5

IR 005:C2

VGA-VSYNC 003:A5

VGA-HSYNC 003:A5

IR

ISP_EN

VGA-HSYNC

VGA-VSYNC

249

250

251

252

253

254

IRIN

HSYNC0

VSYNC0

HSYNC1

VSYNC1

GPIO140

HDMI-in x2

RGB-in x3

CVBS-in x7

(incl. S-video)

CVBS-O x2

SIF x1

VIF x1(NC)

AUDIO,

Linx5, Lout x3

CVBS1-RIN

CVBS1-LIN

YPBPR-RIN

C142

100n

CVBS1-LIN003:D4

YPBPR-RIN003:D2

CVBS1-RIN003:D4

R109

C147

13K

22n

PWR_SW 005:B2

UART-RXSTB 003:A1

PWR_SW

UART-RXSTB

246

247

248

GPIO135

GPIO138

GPIO139

PM SAR

AUVRP77AUVAG78AVDD_AU

76

R111

13K

GND-D

HDMI-CEC 003:A2;003:A4;003:G2

R130

10K

R131

10K

C154

RESET

1n

R129 33

255CE256

257

PAD

HWRESET

B_RXCN

B_RXCP

B_RX0N

B_RX0P

HOTPLUGB

B_RX1N

B_RX1P

AVDD_338

RXB2N

RXB2P

RXACKN

RXACKP

RXA0N

RXA0P

AVDD_33_15

RXA1N

RXA1P

RXA2N

RXA2P

HOTPLUGA

REXT

VCLAMP

REFP

REFM

BIN1

SOGIN1

GIN1P

RIN1P

BIN0M

BIN0P

GINM

GIN0P

SOGIN0

RIN0M

RIN0P

AVDD_33_36

BIN2P

GIN2P

SOGIN2

RIN2P

CVBS6P

CVBS5P

CVBS4P

CVBS3P

CVBS2P

CVBS1P

VCOM1

CVBS0

VCOM0

AVDD_33_50

CVBSOUT1

CVBSOUT0

TAGC

VR27

SIF0P

SIF0M

VIFM

VIFP

AVSS_VIF

AVDD_VIF

VDDC_61

AUVRM

AUOUTL1

AUOUTR1

AUL066AUR067AUL168AUR169AUL270AUR271AUL372AUR373AUCOM74AUL475AUR481AUOUTL082AUOUTR083VDDC_8384DDCA_CK85DDCA_DA86DDCDA_CK87DDCDA_DA88DDCDB_CK89DDCDB_DA90GPIO2091VDDP_9192VDDC_9293UART2_RX94UART2_TX95DDCDC_CK96RXCCKN97RXCCKP98DDCDC_DA99RXC0N

65

VGA-LIN

VGA-RIN

YPBPR-LIN

VGA-LIN003:A5

VGA-RIN003:A5

YPBPR-LIN003:D2

CVBS-LOUT003:D6

CVBS-ROUT003:D5

G101

12MHz

R128

1M

C152

33p

XTALO

XTALI

+3.3V-MPLL

242

243

244

245

XIN

XOUT

AVDD_MPLL

AUOUTL280AUOUTR2

79

R110 100

R112 100

R108 100

+3.3V-AUSDM

CVBS-LOUT

HPAMP-LIN

CVBS-ROUT

C148

22n

GND-D

E2PWP-

KEY 005:C1

SDA

C151

SCL

33p

KEY

237

238

239

240

241

SAR0

SAR1

SAR2

SAR3

PM_SPI_DO

PM_SPI_CZ

PM-

x4 SPI

I2C-S

UART-TX

UART-RX

R114 100

+1.2V-VDDC

UART-TX

UART-RX

HPAMP-RIN

003:A5;003:A1;005:D1

C149

R113

22n

13K

+3.3V

BL_PWM 004:B2;005:B2

SCL 002:D3;004:B2;005:C2

SDA 002:D3;004:B2;005:C2

R125

10K

BL_PWM

231

232

233

234

PWM2

GND_232

USB0_DM

USB0_DP

USB

x1

UART I2S-O&I

&I2C-M

SPDIF 003:H4

SPDIF

R126 33

R124 33

228

229

230

SPDIFO

UART2_RX/I2CM_SDA

UART2_TX/I2CM_SCK

R127

10K

235

236

PM_SPI_CK

PM_SPI_DI

N101

MSD209GL-LF

DDCx2

SIF-CTL

HDMI2-SDA

HDMI1-SCL

HDMI2-SCL

HDMI1-SDA

+3.3V-VDD

+1.2V-VDDC

SIF-CTL002:E4

HDMI2-SDA003:A4

HDMI2-SCL003:A4

HDMI1-SDA003:A2

HDMI1-SCL003:A2

HPAMP-RIN 003:G3

003:A5;003:A1;005:D1

HPAMP-LIN 003:G4

C150

R115

22n

13K

STB-AMP 005:F1

BL_SW- 005:B1

BL_SW-

E2PWP-

+3.3V-USB

+1.2V-VDDC

STB-AMP

SPI_WP-

220

221

222

223

224

225

226

227

VDDP_224

VDDC_225

I2S_IN_SD

I2S_OUT_WS

I2S_OUT_SD

I2S_OUT_MCK

I2S_OUT_BCK

DDC x1 X1 SPI

RXC0P

100

101

HDMI3-SCL

HDMI3-SDA

HDMI3-RXC+

HDMI3-RXC-

HDMI3-RX0-

HDMI3-RX0+

HDMI3-SCL003:G2

HDMI3-SDA003:G2

HDMI3-RXC-003:G1

HDMI3-RXC+003:G1

HDMI3-RX0-003:G1

HDMI3-RX0+003:G1

PNPWR_SW 005:A5

MCKE

+1.2V-VDDC

MADR[9]

MADR[7]

MADR[5]

MADR[3]

MADR[12]

PNPWR_SW

212

213

214

215

216

217

218

219

MCLKE

MADR[9]

MADR[7]

MADR[3]

MADR[12]

VDDC_218

I2S_IN_WS/GPIO67

I2S_IN_BCK/GPIO68

USBHDMI-in x1

GND_101

RXC1N

RXC1P

AVDD_DM

RXC2N

RXC2P

HOTPLUGC

102

103

104

105

106

107

108

USB-D-

HDMI3-HP-

HDMI3-RX2-

HDMI3-RX2+

HDMI3-RX1-

HDMI3-RX1+

+3.3V-DVI

HDMI3-HP-003:G2

HDMI3-RX2-003:G1

HDMI3-RX1+003:G1

HDMI3-RX2+003:G1

HDMI3-RX1-003:G1

MBA[0]

+1.8V-DDR2

MADR[1]

MADR[10]

208

209

210

211

MADR[1]

MADR[5]

MADR[10]

AVDD_DDR_211

DDR2 x16

-Addr, CLK

USB1_DM

USB1_DP

SCK

SDI

109

110

111

112

SPI_DI

SPI_DO

USB-D+

SPI_CK

USB-D+003:G2

USB-D-003:G3

SDI

SDO

SCLK

MBA[2]

206

207

BADR[1]

BADR[0]

SDO

SCZ

113

114

SPI_CZ

R116 1K

R132

33

SCS- MBA[1]

MWE-

MADR[8]

MADR[11]

203

204

205

WEZ

MADR[8]

BADR[2]

MADR[11]

DDR2 x16

-Data

Serial TS

Ethernet

LVDS X2

(10 bits)

PWM0

PWM1

LVA4P

115

116

RFAGC-SEL-

R117 1K

R118 33

+3.3V-VDD

RXE4+004:B2

RFAGC-SEL-002:C2

MADR[4]

MADR[6]

201

202

MADR[4]

MADR[6]

LVA4M

LVA3P

117

118

RXE3+004:B2

RXE4-004:B2

MADR[2]

200

MADR[2]

LVA3M

119

RXE3-004:B2

MODT

MRAS-

MCAS-

MVREF

+3.3V-VDD

MADR[0]

193

194

195

196

197

198

199

ODT

RASZ

CASZ

MVREF

MADR[0]

VDDP_194

GPIO152_I2S_OUT_SD3

GPIO151_I2S_OUT_SD2

GPIO150_I2S_OUT_MUTE

LVACKP

LVACKM

LVA2P

LVA2M

LVA1P

LVA1M

120

121

122

123

124

125

126

R119 33

R120 33

RXE1+004:B2

RXEC+004:B2

RXE2-004:B2

RXE2+004:B2

RXEC-004:B2

RXE1-004:B2

+3.3V-MEMPLL

AVDD_MEMPLL

MCLKZ

MCLK

MDATA[5]

MDATA[2]

MDATA[0]

MDATA[7]

AVDD_DDR_185

MDATA[13]

MDATA[10]

MDATA[8]

MDATA[15]

AVDD_DDR_180

DDR2_DQSB[1]

DDR2_DQS[1]

VDDP_177

AVDD_DDR_176

DDR2_DQSB[0]

DDR2_DQS[0]

DDR2_DQM[0]

DDR2_DQM[1]

AVDD_DDR_171

MADTA[14]

MADTA[9]

MADTA[12]

MADTA[11]

AVDD_DDR_166

MADTA[6]

MADTA[1]

MADTA[3]

MADTA[4]

VDDC_161

TS1CLK

TS1SYNC

TS1VALID

TS1DATA

GPIO105

VDDP_155

GPIO104

GPIO101

GPIO100

GPIO95

GPIO94

GPIO93

GPIO92

GPIO89

GPIO153

VDDC_142

AVDD_LPLL

LVB0M

LVB0P

LVB1M

VB1P

LVB2M

LVB2P

LVBCKM

LVBCKP

LVB3M

LVB3P

LVB4M

LVB4P

LVA0P

LVA0M

VDDP_128

127

128

+3.3V-VDD

SCS-

SDO

SPI_WP-

RXE0+004:B2

RXE0-004:B2

GND

192

191

190

189

188

187

186

185

184

183

182

181

180

179

178

177

176

175

174

173

172

171

170

169

168

167

166

165

164

163

162

161

160

159

158

157

156

155

154

153

152

151

150

149

148

147

146

145

144

143

142

141

140

R123 33

139

138

137

136

R122 33

135

134

133

132

R121 33

131

130

129

GND-D

R133 33

MCLK-

MCLK+

MDATA[5]

MDATA[2]

MDATA[0]

MDATA[7]

+1.8V-DDR2

MDATA[13]

MDATA[10]

MDATA[8]

MDATA[15]

+1.8V-DDR2

MUDQSMUDQS+

+3.3V-VDD

+1.8V-DDR2

MLDQSMLDQS+

MLDM

MUDM

+1.8V-DDR2

MDATA[14]

MDATA[9]

MDATA[12]

MDATA[11]

+1.8V-DDR2

MDATA[6]

MDATA[1]

MDATA[3]

MDATA[4]

+1.2V-VDDC

TSCLK

TSSYNC

TSVALID

TSDATA

+3.3V-VDD

LED

HP-DCT-

HP-MUTE-

RST-DM-

MUTE-AMP

+1.2V-VDDC

+3.3V-LPLL

+3.3V

R134

10K

C156

EN25Q64-104HIP

1

CS

2

DO/DQ1

3

SWP-

WP/DQ2

4

VSS5DI/DQ0

1n

TSCLK 002:D2

TSSYNC 002:D2

TSVALID 002:D2

TSDATA 002:D2

LED 005:C2

HP-DCT- 003:H4

HP-MUTE- 003:G3

RST-DM- 002:D3

MUTE-AMP 005:E3

RXO0- 004:B1

RXO0+ 004:B1

RXO1- 004:B1

RXO1+ 004:B1

RXO2- 004:B1

RXO2+ 004:B1

RXOC- 004:B1

RXOC+ 004:B2

RXO3- 004:B2

RXO3+ 004:B2

RXO4- 004:B2

RXO4+ 004:B2

N103

8

VCC

7

NC/DQ3

6

CLK

GND-D

C155

100n

+3.3V

SCLK

SDI

+3.3V

+3.3V

+3.3V-S

MCKE

MADR[3]

MADR[7]

MADR[12]

MADR[9]

MADR[5]

MADR[10]

MADR[1]

MBA[0]

MBA[1]

MBA[2]

MWE-

MADR[11]

MADR[8]

MADR[6]

MADR[4]

MADR[2]

MADR[0]

MCASMRAS-

MODT

MCLKMCLK+

MDATA[5]

MDATA[2]

MDATA[0]

MDATA[7]

MDATA[13]

MDATA[10]

MDATA[8]

MDATA[15]

MUDQSMUDQS+

MLDQSMLDQS+

MLDM

MUDM

MDATA[14]

MDATA[9]

MDATA[12]

MDATA[11]

MDATA[6]

MDATA[1]

MDATA[3]

MDATA[4]

+1.2V-VDDC

C101

100n

L101

BG1608B121

L105

BG1608B121

L107

BG1608B121

R137 56

R138 56

R139 56

R140 56

R141 56

R142 56

R144 22

R145 22

R146 22

R147 22

R148 22

R149 22

R150 22

R151 22

C102

100n

+3.3V-AUSDM

GND-D

+3.3V-VIF

GND-D

+3.3V-ADC

GND-D

GND-D

GND-D

C103

100n

C116

100n

C124

100n

C126

100n

M_ADR[3]

M_ADR[7]

M_ADR[12]

M_ADR[9]

M_ADR[5]

M_ADR[10]

M_ADR[1]

M_ADR[11]

M_ADR[8]

M_ADR[6]

M_ADR[4]

M_ADR[2]

M_ADR[0]

R143

M_DATA[5]

M_DATA[2]

M_DATA[0]

M_DATA[7]

M_DATA[13]

M_DATA[10]

M_DATA[8]

M_DATA[15]

M_DATA[14]

M_DATA[9]

M_DATA[12]

M_DATA[11]

M_DATA[6]

M_DATA[1]

M_DATA[3]

M_DATA[4]

+3.3V+3.3V-VIF

+3.3V

+1.8V-DDR2

C107

C106

100n

100n

GND-D

+3.3V-MEMPLL

C118

C117

100n

1u

GND-D

+3.3V-USB

C125

100n

GND-D

L108

BG1608B121

M_ADR[0]

M_ADR[1]

M_ADR[2]

M_ADR[3]

M_ADR[4]

M_ADR[5]

M_ADR[6]

M_ADR[7]

M_ADR[8]

M_ADR[9]

M_ADR[10]

M_ADR[11]

M_ADR[12]

M_CLK+

M_CLK-

M_CKE

M_BA[0]

M_BA[2]

M_RASM_CAS-

M_WE-

+1.8V-DDR2

M_VREF

C157

100n

+1.8V-DDR2

GND-D

BG1608B121

+3.3V

+3.3V-DVI

GND-D

M_CKE

M_BA[0]

M_BA[1]

M_BA[2]

M_CASM_RAS- M_BA[1]

M_ODT

M_CLK-

150

M_CLK+

M_UDQSM_UDQS+

M_LDQSM_LDQS+

M_LDM

M_UDM

C104

C105

100n

100n

L102

BG1608B121

L106

BG1608B121

+3.3V-S

C128

C127

100n

100n

DRAWN BY

APPROVED BY

C158

100n

C108

100n

L103

C129

100n

K4T1G164QE-HCF7

M8

A0

M3

A1

M7

A2

N2

A3

N8

A4

N3

A5

N7

A6

P2

A7

P8

A8

P3

A9

M2

A10

P7

A11

R2

A12

J8

CK

K8

CK

K2

CKE

L2

BA0

L3

BA1

L1

BA2

K7

RAS

L7

CAS

K3

WE

L8

CS

A1

VDD1

E1

VDD2

J9

VDD3

M9

VDD4

R1

VDD5

A9

VDDQ1

C1

VDDQ2

C3

VDDQ3

C7

VDDQ4

C9

VDDQ5

E9

VDDQ6

G1

VDDQ7

G3

VDDQ8

G7

VDDQ9

G9

VDDQ10

J1

VDDL

J2

VREF

C159

C160

100n

100n

C109

C110

100n

100n

+3.3V-LPLL

+3.3V

C119

100n

GND-D

BG1608B121

+3.3V-S

C130

100n

N104

G8

M_DATA[0]

DQ0

G2

M_DATA[1]

DQ1

H7

M_DATA[2]

DQ2

M_DATA[3]

H3

DQ3

H1

M_DATA[4]

DQ4

H9

M_DATA[5]

DQ5

F1

M_DATA[6]

DQ6

F9

M_DATA[7]

DQ7

C8

M_DATA[8]

DQ8

C2

M_DATA[9]

DQ9

D7

M_DATA[10]

DQ10

D3

M_DATA[11]M_WE-

DQ11

D1

M_DATA[12]

DQ12

D9

M_DATA[13]

DQ13

M_DATA[14]

B1

DQ14

B9

M_DATA[15]

DQ15

M_LDQS+

F7

LDQS

E8

M_LDQS-

LDQS

B7

M_UDQS+

UDQS

A8

M_UDQS-

UDQS

M_LDM

F3

LDM

B3

M_UDM

UDM

K9

M_ODT

ODT

A3

VSS1

E3

VSS2

J3

VSS3

N1

VSS4

P9

VSS5

A7

VSSQ1

B2

VSSQ2

B8

VSSQ3

D2

VSSQ4

D8

VSSQ5

E7

VSSQ6

F2

VSSQ7

F8

VSSQ8

H2

VSSQ9

H8

NC#E2

NC#A2

E2

A2

C161

100n

C111

100n

BG1608B121

L109

NC#R3

NC#R7

R3

R7

R8

C162

100n

C112

100n

GND-D

L104

+3.3V-MPLL

C131

1u

GND-D

VSSQ10

VSSDL

NC#R8

C163

100n

C113

100n

+3.3V-VDD

C132

100n

J7

GND-D

C164

100n

+1.8V-DDR2

C120

100n

GND-D

C165

100n

C121

100n

+1.8V-DDR2

R135

1K

1%

R136

1K

1%

C166

C167

100n

100n

R101

1K

1%

R102

1K

1%

C123

C122

100n

100n

C170

C168

100n

C114

M_VREF

1n

GND-D

GND-D

MVREF

1n

GND-D

TITLE: DWG NO.

Core & Memory 9232KH5101DL

REV.

Sheet to

XOCECO

XIAMEN OVERSEAS CHINESE

ELECTRONIC CO., LTD.

C171

100n

C169

100n

C115

100n

A1.0

91

Page 34

ABCDEFGH

1

+5V

R224

R225

+1.2V-DE

47

VDDC_47

+3.3V-DE

10K

GND-D

45

46

TS_DATA[0]

C214

100n

V202

BC857AW

C229

22n

V201

BC847AW

GND-D

43

44

TS_DATA[2]

TS_DATA[1]

MSB1210-LF

C215

100n

C216

100n

GND-D

R228

R227

100K

1K

R226

10K

40

41

42

TS_DATA[5]

TS_DATA[4]

TS_DATA[3]

N201

C217

C218

100n

100n

R208

R207

+3.3V-DE

2K

2K

STLI1608_R33KT

GND-D

L203

STLI1608_R33KT

C219

5.6p

+5V

RFAGC-SEL- 001:D5

38

39

TS_VALID

TS_DATA[7]

TS_DATA[6]

C223

C221

100n

100n

R210

R209

100

100

L204

C220

51p

STLI1608_R33KT

DIF+

DIF-

37

TS_SYNC

TS_CLK

I2CS_SDA

I2CS_SCL

GND_33

VDDC_32

I2CM_SDA

I2CM_SCL

EXTRSTN

GND_28

IF_AGC

AVDD_33_26

XOUT

G201

24MHz

R211

C224

33p

L205

C222

5.6p

GND-DGND-D

RF_AGC

R223

33

TSDATA

TSSYNC

TSCLK

+5V

R218

4.7K

R214

10K

GND-D

R220

4.7K

C226

22n

TSDATA 001:E4

TSVALID 001:E3

TSSYNC 001:E3

TSCLK 001:E3

SDA 001:C1;004:B2;005:C2

SCL 001:C1;004:B2;005:C2

+3.3V-DE

SDA-T

SCL-T

R216

R215

1K

33

C227

1n

GND-D

RST-DM- 001:E4

VIF+

VIF-

SIF-

SIF+

C243

100n

C244

100n

C245

100n

C246

100n

1

C234

NC_1

2

NC_2

3

RF_AGC

4

Vt

5

AS

6

SCL

7

SDA

8

Vcc

9

IF_AGC

D-IF_out+

D-IF_out-

IF_out

TUNER201 FT2130

10

11

12

10n

GND-D

L206

+5V

22uH

C230

C231

220u

16V

GND-D

L207

+5V

L209

0.68uH

V203

2SC4215

C238

?

R240

R241

+12V

680

39

GND-D

Z201

K3953

12345

C242

5.6p

SIF-CTL001:C5

+5V

GND-D

R244

C241

GND-D

R246

10K

V204

BC847AW

K9656

Z202

D201

BA891

12345

R245

1K

10K

1n

GND-D

R242

10K

R243

10K

C239

C240

+12V-AIF

10n

10n

R236

R238

5.1K

R239

22uH

C232

220u

R237

C237

16V

GND-D

C235

C236

220u

100n

16V

0

GND-D

10n

300

1K

100n

C233

100n

R235

RF_AGC

R231 33

SCL-T

R232 33

SDA-T

R229

R230

0.56uH

100

GND-D

L208

R233 33

SCL-T

0

R234 33

SDA-T

0

IF_AGC

DIF+

DIF-

AIF

TSVALID

C228

?

GND-D

36

R222

35

33

R221

34

33

33

32

+1.2V-DE

R219

33

31

R217

33

30

+5V

29

28

R213

1K

IFAGC

27

26

+3.3V-DE

25

R212

0

1M

C225

33p

GND-D

6.8K

2

C208

R202

100n

C209

100n

C210

100n

C211

100n

47

R201

R203

300

47

+3.3V-DE

GND-D

R205

47

R204

R206

300

47

TP201

GND-D

+3.3V-DE

C213

C212

1n

1u

SIF+

SIF- IF_AGC

VIF-

VIF+

ATV-SIF+001:B4

ATV-SIF-001:B4

ATV-CVBS+001:B4

ATV-CVBS-001:B4

3

GND-D

RFAGC

48

RF_AGC

1

GND_1

2

AVDD_33_2

3

SSIFO

4

CVBSOUT

5

GND_5

6

CLKO

7

AVDD_33_7

8

VR27

9

SIFIP

10

SIFIM

11

VIFIM

12

VIFIP

GND_1314AVDD_33_1415GND_1516VREFM17VREFP18AVDD_33_1819ZIF_QM20ZIF_QP21ZIF_IM22ZIF_IP23GND_2324XIN

13

4

+1.2V-VDDC

L201

BG1608B121

+1.2V-DE

GND-D

C201

100n

C202

100n

+3.3V

L202

BG1608B121

+3.3V-DE

C203

100n

GND-D

C204

100n

C205

100n

C206

100n

C207

100n

5

TITLE: DWG NO.

RF Demodulation 9232KH5101DL

6

DRAWN BY

APPROVED BY

REV.

Sheet to

XIAMEN OVERSEAS CHINESE

ELECTRONIC CO., LTD.

A1.0

92

XOCECO

Page 35

ABCDEFGH

N301

MAX232CSE

C302 100n

1

16

C1+

C305

100n

+5V-HDMI1

R312

1K

R325

1K

R340 47

1nC315

D303

MMBD1204

2

V+

3

C1-

4

C2+

5

C2-

6

V-

7

T2OUT

R2IN8R2OUT

R313

1K

R326

VGA-SCL

VGA-SDA

R314

10K

10K

47R342

47R338

47R335

15KR336

47R333

Vcc

15

GND

14

T1OUT

13

R1IN

12

R1OUT

11

T1IN

10

T2IN

9

GND-D

CM1213-08MS

1

2

3

4

GND-D

+5V-HDMI1

GND-D

1

2

3

4

GND-D

+5V-HDMI2

V302

BC847AW

GND-D

CM1213-08MS

R327

C303 100n

+5V-S

C304 100n

1

UART-RXSTB

001:C5;003:A5;005:D1

001:C5;003:A5;005:D1

HDMI1-RX2+001:B2

HDMI1-RX2-001:B2

HDMI1-RX1+001:B2

24C02N-10SI27

1

AO

2

A1

3

A2

GND4SDA

GND-D

N302

HDMI1-RX1-001:B2

HDMI1-RX0+001:B2

HDMI1-RX0-001:B2

HDMI1-RXC+001:B2

HDMI1-RXC-001:B2

HDMI1-SCL001:C5

HDMI1-SDA001:C5

8

Vcc

7

WP

6

SCL

5

2

001:C1

UART-TX

UART-RX

HDMI-CEC001:B1;003:A4;003:G2

R310 10K

R309 33

R307 33

R311 0

R301

33

R302

33

R303

33

R304

10

R305

10

R308 4.7K

R306 4.7K

+5V

GND-D

+5V-HDMI1

D301

MMBD1204

HDMI1-HP-

C306

100n

+3.3V

001:B2

3

R316

R322 10K

R321 33

R319 33

R323 0

VGA-LIN

001:B5

VGA-RIN

001:B5

UART-RX

UART-TX

001:B1

001:B1

001:B3

001:B3

001:B3

001:B3

N309

24C02N-10SI27

1

AO

2

A1

3

A2

4

GND5SDA

Vcc

WP

SCL

10

R317

10

R320 4.7K

R318 4.7K

1uC309

1uC311

C308

47p

R345

33

R347

33

8

7

6

+5V

R329

12K

V303

BC847AW

V304

BC847AW

10KR352

33R351

33R349

0R353

+5V-HDMI2

HDMI2-HP-

C307

100n

GND-D

C310

47p

D302

MMBD1204

001:B3

+3.3V-S

R344

10K

R346

10K

R331

12K

V305

BC847AW

4.7KR350

4.7KR348

+5V-HDMI2

+3.3V

R324

1K

10KR328

10KR330

R343

1K

ISP_EN

001:C1

47nC316

47nC314

47nC313

+5V

VCC-VGA

C317