Page 1

FILE NO.

SERVICE MANUAL

DVD built-in LCD TV

LCD-22VT10DVD(B)

PRODUCT CODE NO.:

1 682 348 96

REFERENCE No. SM0948001

Page 2

CONTENTS

Safety precautions………………………………………………………………………..…

Alignment instructions …………………………….…….…………………………………

Method of software upgrading……………………………………………………………..

Working principle analysis of the unit……………………………….………….………….

Block diagram…………………………………..………………………………….…………

IC block diagram………………………………………………………………………..……

Wiring diagram …………………………………………………………………………….

Troubleshooting guide ………………………………………………………………..……

Schematic diagram…………………………………………………………………………

APPENDIX-A: Assembly list

APPENDIX-B: Exploded View

Removing or Installing the Stand

Wall mounting instructions

Page 3

Safety precautions

1. Instructions

Be sure to switch off the power supply before replacing or welding any components or

inserting/plugging in connection wire Anti static measures to be taken (throughout the entire

production process!):

a) Do not touch here and there by hand at will;

b) Be sure to use anti static electric iron;

c) It’s a must for the welder to wear anti static gloves.

Please refer to the detailed list before replacing components that have special safety

requirements.

Do not change the specs and type at will.

2. Points for attention in servicing of LCD

2.1 Screens are different from one model to another and therefore not interchangeable. Be sure to

use the screen of the original model for replacement.

2.2 The operation voltage of LCD screen is 700-825V. Be sure to take proper measures in

protecting yourself and the machine when testing the system in the course of normal operation or

right after the power is switched off. Please do not touch the circuit or the metal part of the module

that is in operation mode. Relevant operation is possible only one minute after the power is

switched off.

2.3 Do not use any adapter that is not identical with the TV set. Otherwise it will cause fire or

damage to the set.

2.4 Never operate the set or do any installation work in bad environment such as wet bathroom,

laundry, kitchen, or nearby fire source, heating equipment and devices or exposure to sunlight etc.

Otherwise bad effect will result.

2.5 If any foreign substance such as water, liquid, metal slices or other matters happens to fall into

the module, be sure to cut the power off immediately and do not move anything on the module

lest it

should cause fire or electric shock due to contact with the high voltage or short circuit.

2.6 Should there be smoke, abnormal smell or sound from the module, please shut the power off

at

once. Likewise, if the screen is not working after the power is on or in the course of operation, the

power must be cut off immediately and no more operation is allowed under the same condition.

2.7 Do not pull out or plug in the connection wire when the module is in operation or just after the

power is off because in this case relatively high voltage still remains in the capacitor of the driving

circuit. Please wait at least one minute before the pulling out or plugging in the connection wire.

2.8 When operating or installing LCD please don’t subject the LCD components to bending,

twisting

or extrusion, collision lest mishap should result.

2.9 As most of the circuitry in LCD TV set is composed of CMOS integrated circuits, it’s necessary

to pay attention to anti statics. Before servicing LCD TV make sure to take anti static measure and

ensure full grounding for all the parts that have to be grounded.

2.10 There are lots of connection wires between parts behind the LCD screen. When servicing or

moving the set please take care not to touch or scratch them. Once they are damaged the screen

Attention: This service manual is only for service personnel to take reference with. Before

servicing please read the following points carefully.

2

would be unable to work and no way to get it repaired.

If the connection wires, connections or components fixed by the thermotropic glue need to

Page 4

disengage when service, please soak the thermotropic glue into the alcohol and then pull them

out

in case of dagmage.

2.11 Special care must be taken in transporting or handling it. Exquisite shock vibration may lead

to

breakage of screen glass or damage to driving circuit. Therefore it must be packed in a strong

case

before the transportation or handling.

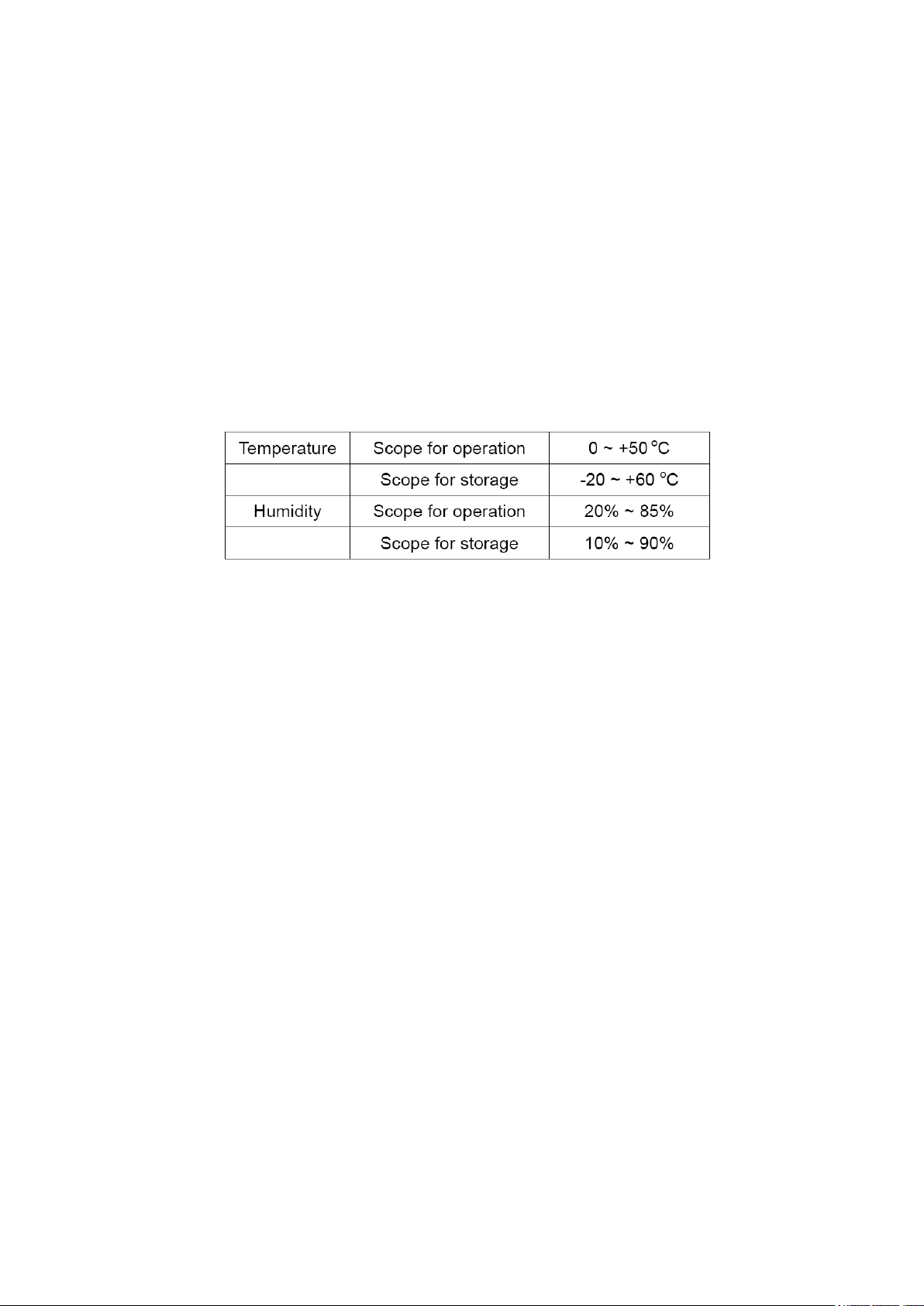

2.12 For the storage make sure to put it in a place where the environment can be controlled so as

to

prevent the temperature and humidity from exceeding the limits as specified in the manual. For

prolonged storage, it is necessary to house it in an anti-moisture bag and put them altogether in

one

place. The ambient conditions are tabulated as follows:

2.13 Display of a fixed picture for a long time may result in appearance of picture residue on the

screen, as commonly called “ghost shadow”. The extent of the residual picture varies with the

maker of LCD screen. This phenomenon doesn’t represent failure. This “ghost shadow” may

remain

in the picture for a period of time (several minutes). But when operating it please avoid displaying

still picture in high brightness for a long time.

3. Points for attention during installation

3.1 The front panel of LCD screen is of glass. When installing it please make sure to put it in

place.

3.2 For service or installation it’s necessary to use specified screw lest it should damage the

screen.

3.3 Be sure to take anti dust measures. Any foreign substance that happens to fall down between

the screen and the glass will affect the receiving and viewing effect

3.4 When dismantling or mounting the protective partition plate that is used for anti vibration and

insulation please take care to keep it in intactness so as to avoid hidden trouble.

3.5 Be sure to protect the cabinet from damage or scratch during service, dismantling or

mounting.

Page 5

Alignment instructions

1. Test equipment

VG-848 (YPbPr,VGA signal generator)

VG-849 (HDMI signal generator)

CA210 (white balancer)

2. Power test

Connect power board, digital processing board, IR board and backlight board according the wiring

diagram, connect the power and press to turn on the TV.

Test the pin voltage of X401, the data is shown in table1:

Table1 voltage data of X401

X401 Pin1 2 3 4 5, 6 7, 8 9 10 11 12 13

Voltage 5V±5% 0 5V±5% 0 12V±5% 0

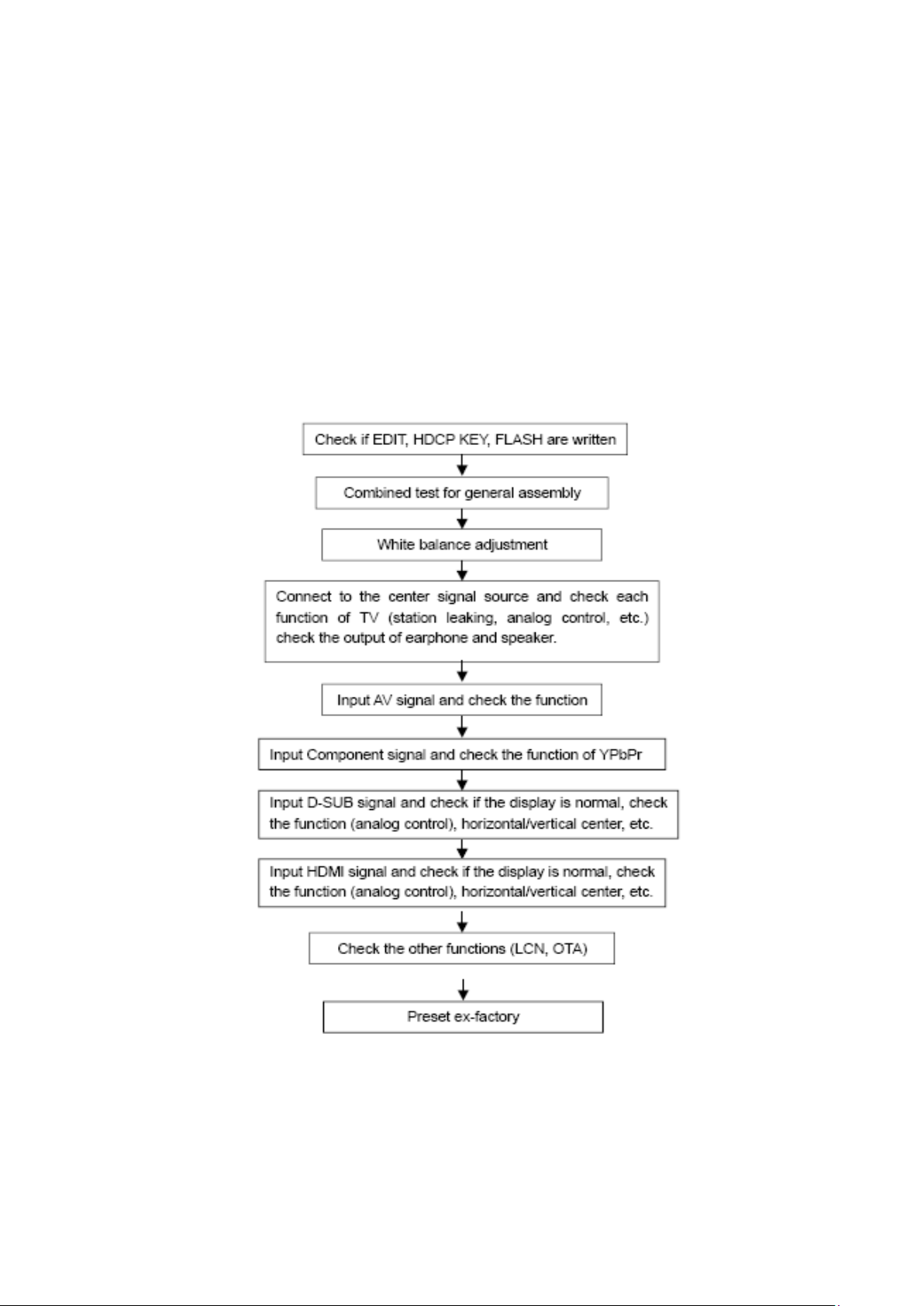

3. Alignment flow-chart

≤3.3V ≤5V ≤3.3V 32V±5% 0

Fig-1 adjustment flow-chart

4. Adjustment instruction

4.1 Unit adjustments

4.1.1Connect all the boards according to wiring diagram, then power on and observe the display.

4.1.2 Method for entering factory menu:

a) Press “SOURCE”, “2”, “5”, ”8” and “0” in turn to enter factory menu;

b) Press “

” and “” to move the cursor to the adjustment page of the level one factory menu,

Page 6

then press ”OK” to enter;

c) Press “

d) Press “

” and “” to move the cursor up and down;

” and “” to adjust the item when the cursor move to a certain adjust item;

e) Press “MENU” to exit to the previous factory menu;

f) Press “EXIT” to exit the factory menu at any situation;

g) Press “OK” to enter the sub factory menu;

h)

ADC ADJUST, ADC correction of VGA, Component channel;

i)

W/B ADJUST, white balance adjustment;

j)

POWER MODE, set the turn-on modes. Standby---standby when power on; Mem---memory;

ForceOn---power on; ForceOn can be used for aging; set the “power mode” to “Standby” when

preset ex-factory unless the client appointed it;

k)

ISP MODE, ON---soft upgrading through VGA port with ISP instrument, OFF---DDC function of

VGA; the setting will not be memory and will be “OFF” when power on again;

l)

RESTALL, initialization of the factory and user data; after this item is confirm, the unit will restart

and display the guiding image.

m)

FACTORYDATAREST, factory data initialization (including white balance adjustment, ADC

correction and other adjusted data);

n)

FACEORY Channel PRESET, preset the factory channel; please connect to the center signal

source when operating; the present digital frequency is CH28(529.5MHz), CH33(564.5MHz) for

Australia, if the signal changes, perform “DTV manual search” in “Channel” menu and the

operation needs 15s or so.

o)

CUSTOM Channel PRESET, preset the custom ATV channel, they are CH2(66.5MHz),

CH7(184.5MHz), CH9(198.5MHz), CH10(212.5MHz), CH28(529.5MHz);

p)

MST DEBUG, the default is OFF. OFF---RS-232 should match the design criterion; ON--- it

should be convenient for using exploitation tool to adjust. The setting will not be memory and will

be “OFF” when power on again;

q)

BACKLIGHT: adjust the backlight brightness, adjust the data and test the voltage of X804 pin2

(PWM), let the voltage to be the corresponding PWM voltage which the brightness is maximum.

It will be preset and doesn’t need adjust.

r)

SSC ADJUST, adjust the frequency spectrum expand, it will be preset and doesn’t need adjust.

s)

AUDIO CURVE, adjust the sound curve, it will be preset and doesn’t need adjust.

t)

RF AGC delay Adj, adjust ATV RF AGC-take;

u) There is data in EEPROM after software upgrade, please perform REST ALL before the first

adjustment.

Preset ex-factory

5

4.1.3 ADC correction in D-SUB channel

a) Switch to D-SUB channel

b) Press” SOURCE”, then press “2, 5, 8, 0” in turn to enter the level one factory menu.

c) Move the cursor to “ADC ADJUST” and press OK to enter the sub-menu.

d) Input D-SUB signal (VG-848 Timing:856(1024x768/60Hz), Pattern:920 8step Gray). Move the

cursor to “MODE”, press

and to select “RGB”, move the cursor to “AUTO ADC” and press

OK to adjust automatically till display “success”.

4.1.4 ADC correction of Component channel

a) Switch to Component channel.

b) Press” SOURCE”, then press “2, 5, 8, 0” in turn to enter the level one factory menu.

c) Move the cursor to “ADC ADJUST” and press OK to enter the sub-menu.

d) Input Component signal (VG-848 Timing:969(PAL), Pattern:918 100% color bar). Move the

cursor to “MODE”, press

and to select “YPbPr(SD)”, move the cursor to “AUTO ADC” and

press OK to adjust automatically till display “success”.

e) Input Component signal (VG-848 Timing:972(1080i), Pattern:918 100% color bar). Move the

cursor to “MODE”, press

and to select “YPbPr(HD)”, move the cursor to “AUTO ADC” and

press OK to adjust automatically till display “success”.

4.2 White balance adjustment

Page 7

The default of color temperature of COOL is 12000K and the coordinate is (272, 278); color

temperature of NORMAL is 9300K and the coordinate is (285,293), color temperature of WARM is

6500K and the coordinate is (313,329).

4.3 Adjustment steps

Before the white balance adjustment, please let the unit working at least 30 minutes and at a

stable situation, use BBY channel of the white balancer CA-210 (19” for example).

a) Switch to HDMI channel;

b) Press” SOURCE”, then press “2, 5, 8, 0” in turn to enter the level one factory menu.

c) Move the cursor to “W/B ADJUST” and press OK to enter the sub-menu.

d) Input HDMI signal (VG-848 Timing:856(1024X768/60Hz), Pattern:921 16 step Gray). Move the

cursor to “MODE”, press

press

and to select “COOL”.

and to select “HDMI”, move the cursor to “TEMPERTURE” and

e) Fix G GAIN, adjust R GAIN, B GAIN and let the color coordinate of the thirteenth scale be

(272,278).

f) Fix G OFFSET, adjust R OFFSET, B OFFSET and let the color coordinate of the forth scale be

(272,278).

g) When adjusting, please keep the color temperature of high light to be X=272±5, Y=278±15 and

the low light to be X=272±8, Y=278±30;

h) Move the cursor to “COPY ALL” and copy the data to the other channels (except DTV);

i) Check if the color temperatures of NORMAL and WARM are up to the mustard (NORMAL high

light acceptable error: x±10, y±15, NORMAL low light acceptable error: x±10, y±25; WARM high

light and low light acceptable error: x±10, y±10), if not, adjust R-GAIN/B-GAIN/R-OFF/B-OFF.

j) Check the white balance of other channels, if they are not up to the mustard then adjust and

store the data separately.

k) Select DTV channel and 16-level gray scale signal.

l) Press “SOURCE” and “2, 5, 8, 0” one by one to enter the level one factory menu.

m) Move the cursor to “W/B ADJUST” and press OK to enter the sub-menu.

6

n) Move the cursor to “MODE”, pressand to select “DTV”, move the cursor to “TEMPERTURE”

and press

and to select “COOL”.

o) Repeat the steps e)-I);

p) After adjustment, check if the pictures are normal.

q) The reference of adjustment rule is below:

B gun: lower B gun to increase X, Y coordinate data, while raise B gun to decrease the data;

R gun: raise R gun to increase X coordinate data, while lower R gun to decrease the data; (R

gun adjustment will affect X and Lv slightly)

G gun: raise G gun to increase Y coordinate data, while lower G gun to decrease the data; (G

gun adjustment will affect Y and Lv greatly)

5. Performance check

5.1 TV function

Connect RF to the center signal source, enter Channel menu

channels be skipped, check if the picture and speaker are normal.

5.2 AV terminals

Input AV signal, check if the picture and sound are normal.

5.3 Component terminal

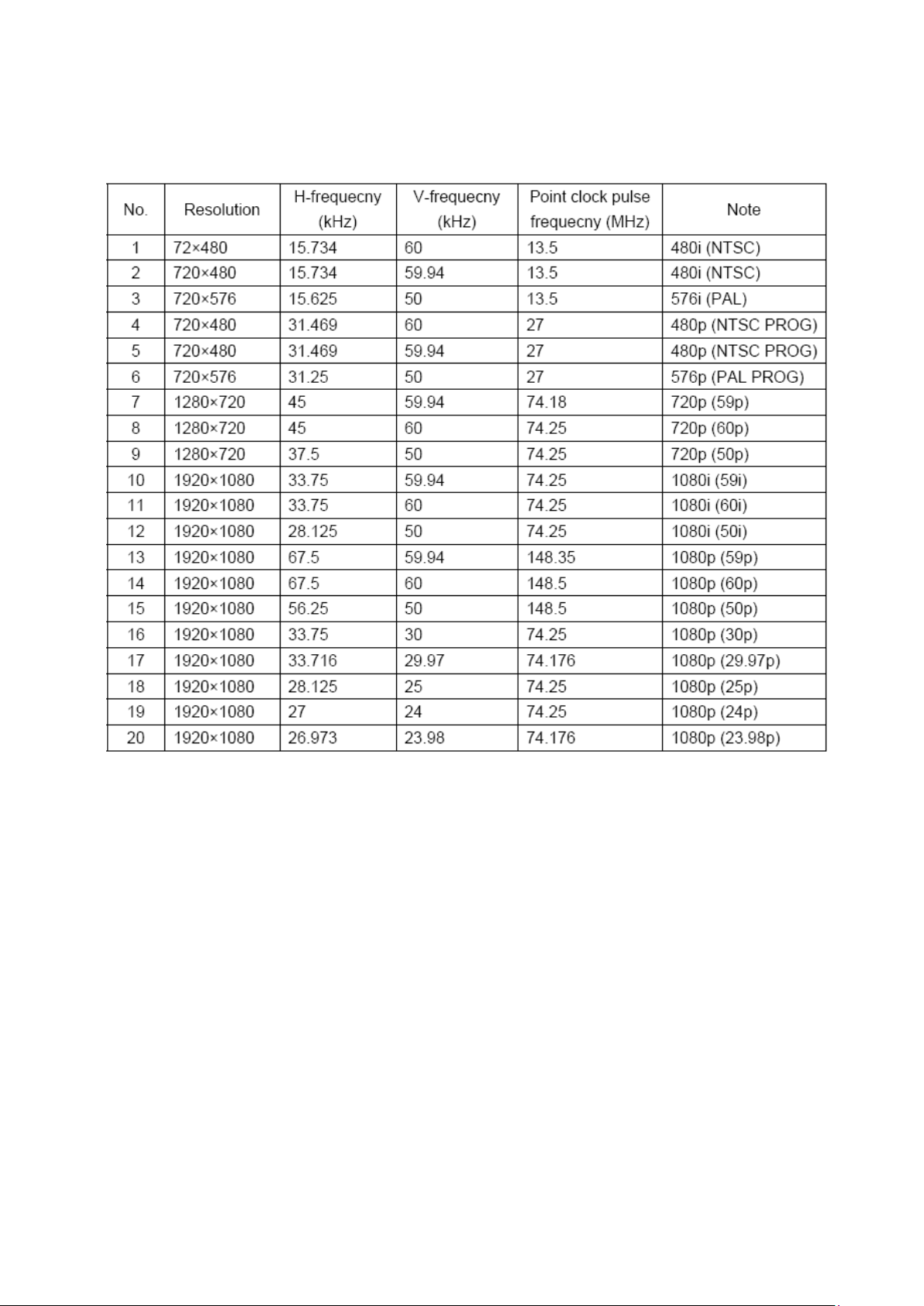

Input Component signal (VG-848 signal generator), separately input the Component signals listed

in table2 and check if the display and sound are normal at any situation (power on, channel switch

and format switch, etc.)

→ auto search, check if there are

Page 8

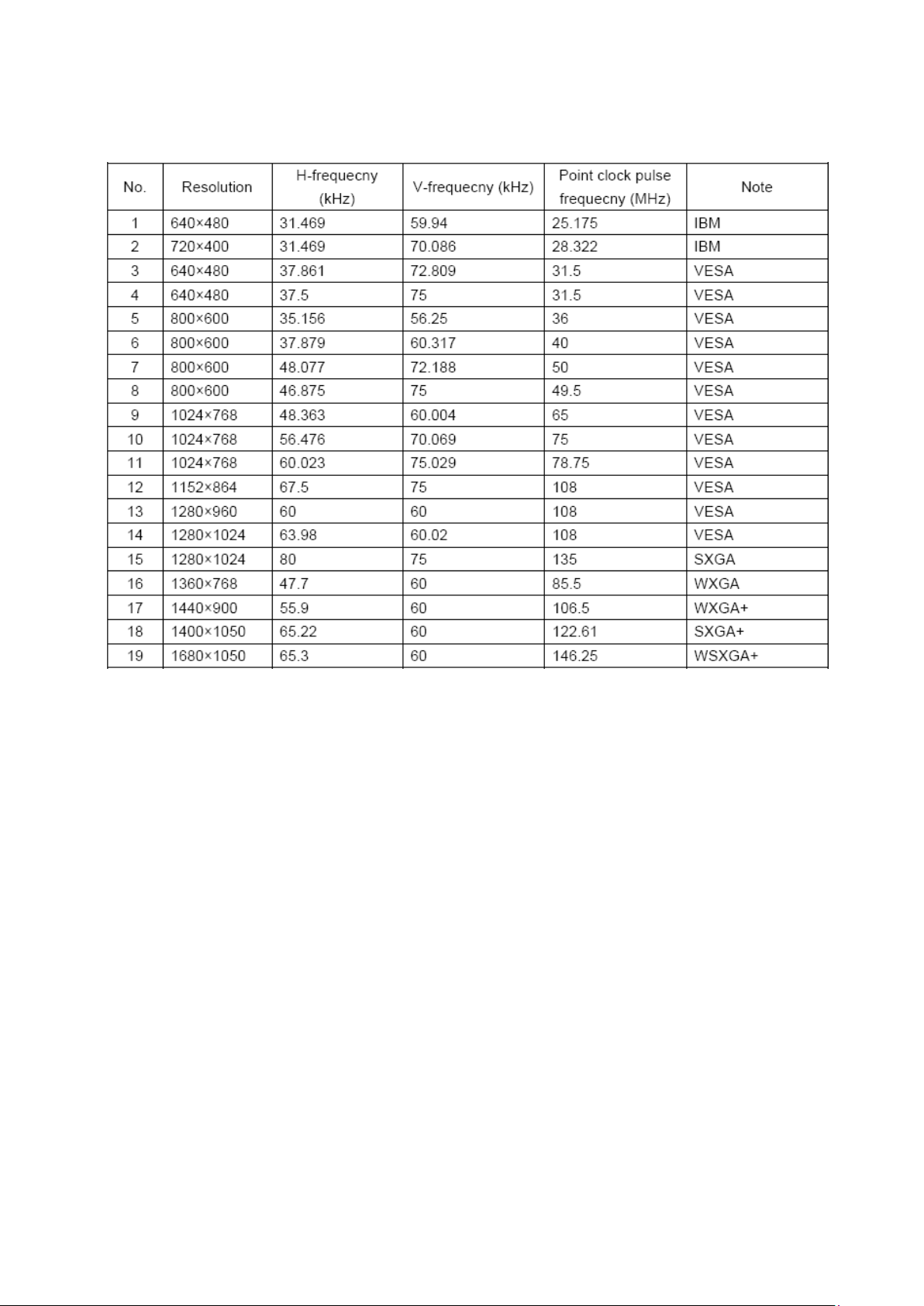

Table2 Component signal format

5.4 D-SUB terminal

Input D-SUB signal (VG-848 signal generator), separately input the signals listed in table3 and

check the display and sound. If the image is deflection of the Horizontal and vertical, select

Picture->Screen->Auto Adjusting to perform auto-correct.

Table3 D-SUB signal format

Page 9

5.5 HDMI terminal

Input HDMI signal (VG-849 signal generator), separately input the signals listed in table2 and

table3

and check the display and sound (32KHz, 44.1KHz, 48KHz) at any situation (power on, channel

switch and format switch, etc.)

5.6 other functions check

a) Check the turn on/turn off timer, asleep timer, picture/sound mode, OSD, stereo and digital

sound port, etc.

b) Check the digital program, if Audio Only is normal.

c) Check logical channel number (LCN) for Australia.

d) Check OTA function for Australia special custom.

6. Presetting before ex-factory

Enter user menu LOCK page, select “Restore Factory Default” to preset the ex-factory.

a) Clear the program information

b) Clear VCHIP, parental control, etc.

c) Set the default data of user menu

8

d) Set Menu Language to English

e) Set Power on Mode to Off

Page 10

Software instruction

17MB37 Analog Part Software Update With Bootloader Procedure

1.1 The File Types Used By The Bootloader

All file types that used by the bootloader software are listed below:

1. The Binary File : It has “.bin” extension and it is the tv application. Its size is 1920 Kb.

2. The Config Binary File : It has “.cin extension and it is the config of the tv application.

Its size may be 64 Kb or a few times 64 Kb.

3. The Test Script File : It has “.txt” extension and it is the test script that is parsed and

executed by the bootloader. It don’t have to be any times of 64 Kb.

4. The Test Binary File : It has “.tin” extension and it is used and written by the test

groups. It is run to understand the problem part of the hardware.

Alltough a file that is used by the bootloader can be had any one of these extensions, its

name has to be “VESTEL_S” and it has to be located in the root directory of the usb

device.

1.2 Usage of The Bootloader

1. The starting to pass through : The chassis is only powered up.

2. The starting to download something : When chassis is powered up the menu key has to

be pushed.Before the chassis is powered up and if any usb device is plugged to the usb

port, the programme is downloaded from usb firstly.

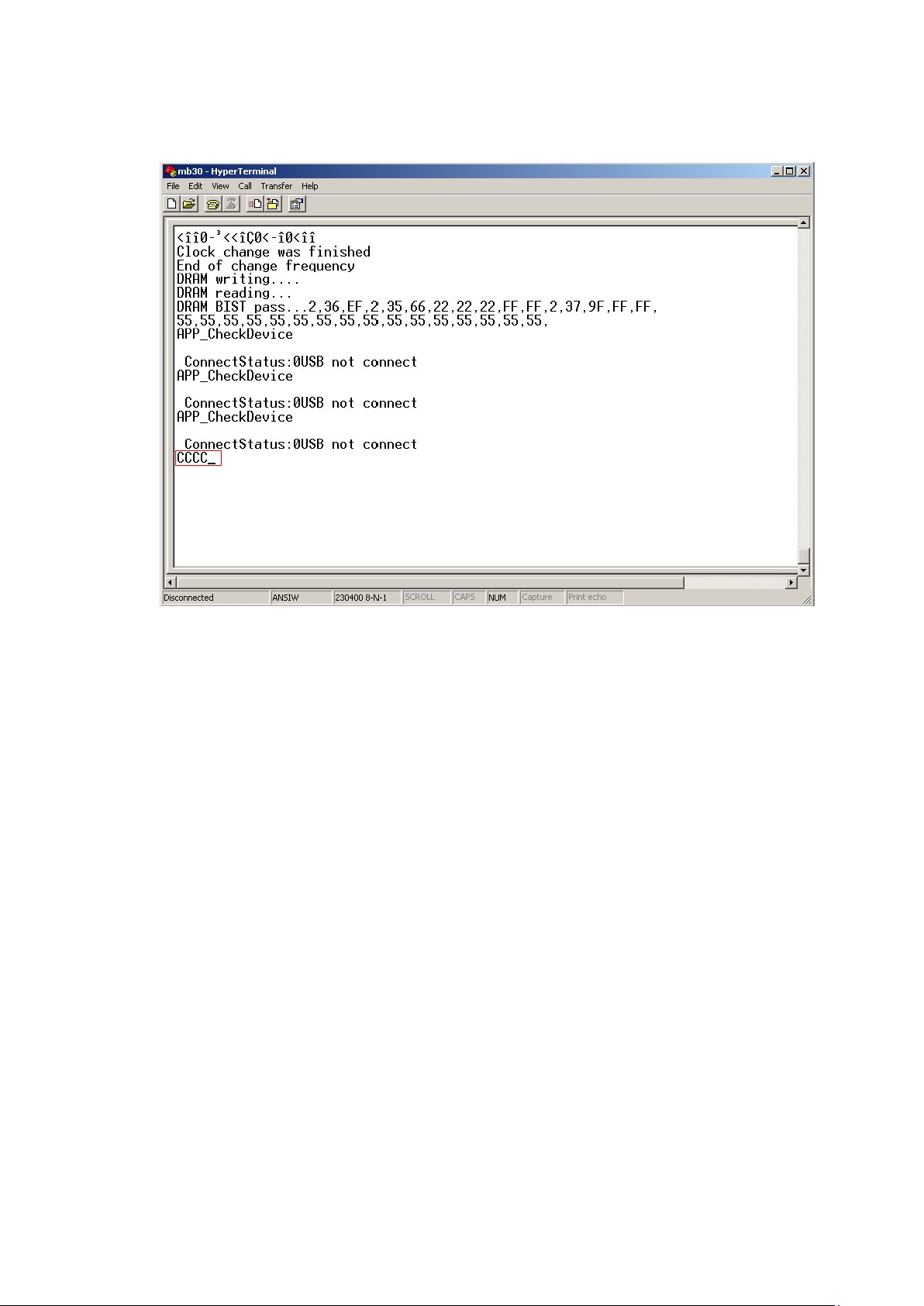

Any usb device is plugged to usb port , user must open hyperterminal in the pc and

connect pc to chassis via Mstar debug tool and any one of scart,dsub9 or I2c connectors.

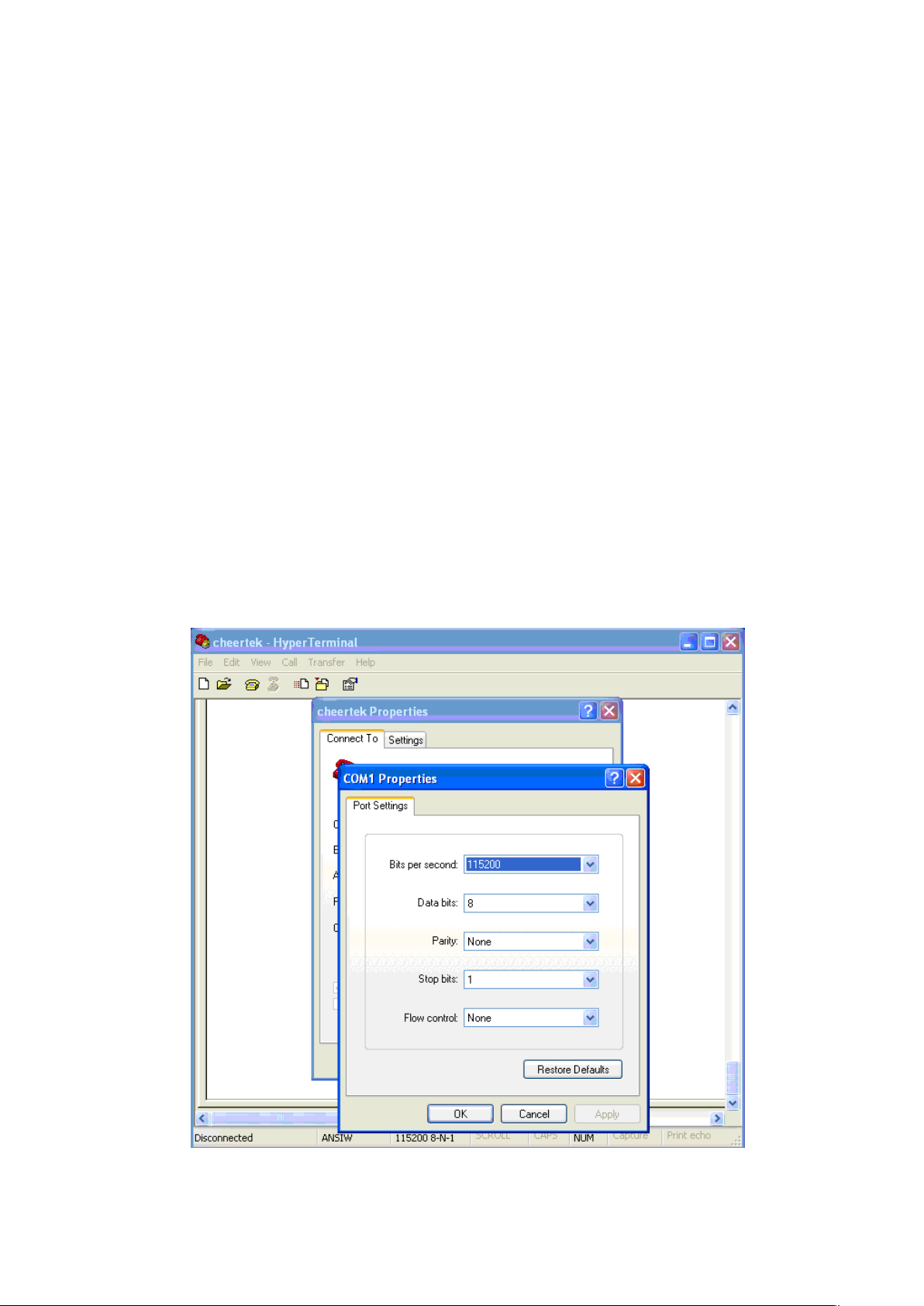

Serial connection settings are listed below:

- Bit per second: 115200

- Data bits: 8

- Parity: None

- Stop bits: 1

- Flow control: None

In this case the bootloader sofware puts “C” character to uart. After repeating “C”

characters are seen in the hyperterminal user can send any file to chassis by selecting

Transfer -> Send File menu item and choosing “

1K Xmodem” from protocol section.

Page 11

Figure 1. The Sample Output Before Sending The File

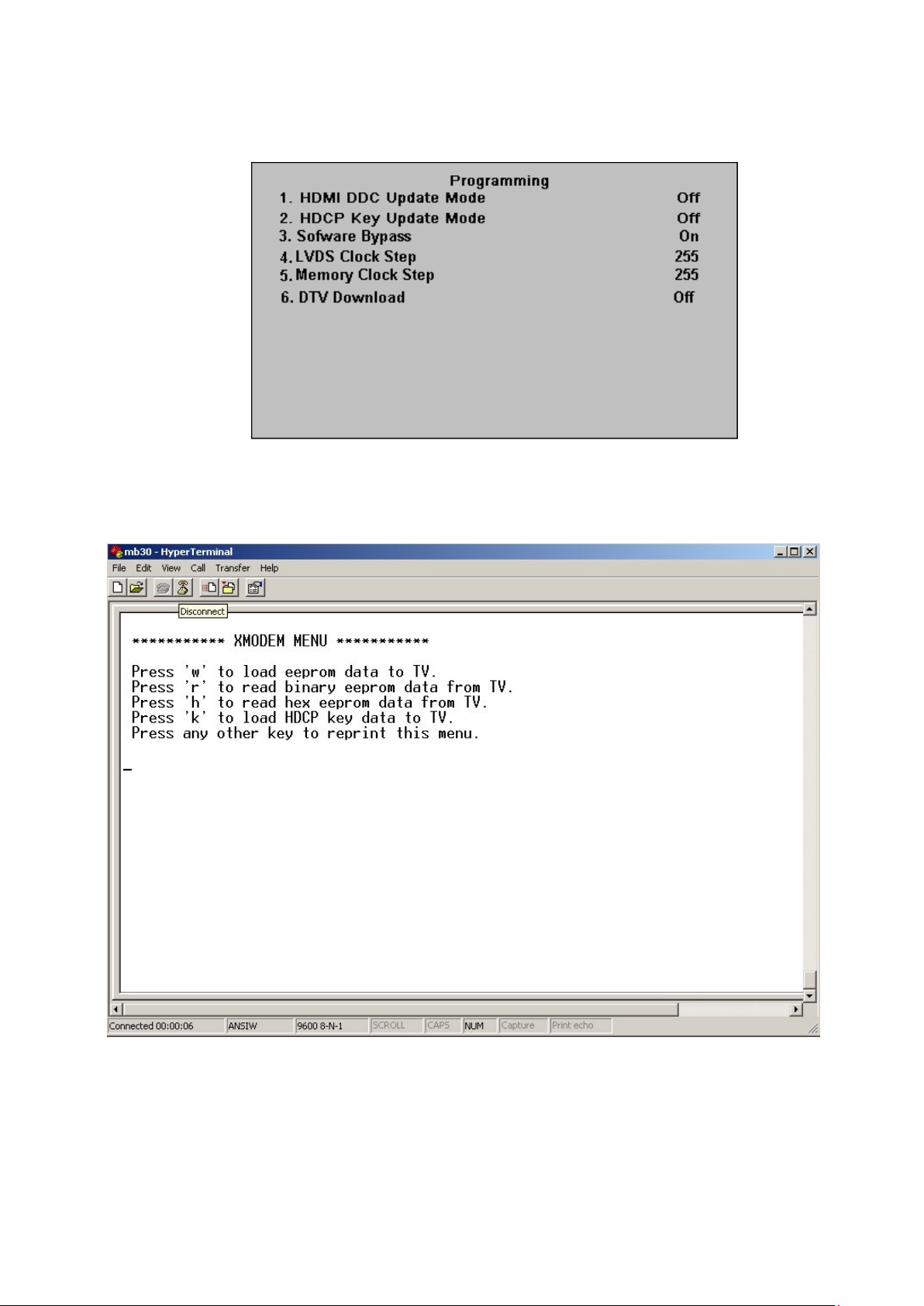

EEProm update

To Update eeprom content via uart scart,dsub9 or i2c with Mstar tool can used.

Serial connection settings are listed below:

- Bit per second: 9600

- Data bits: 8

- Parity: None

- Stop bits: 1

- Flow control: None

Programming menu item is choosed in the service menu and switch “HDCP Key Update

Mode” from off to on.

Page 12

Figure 2. The Programming Service Menu

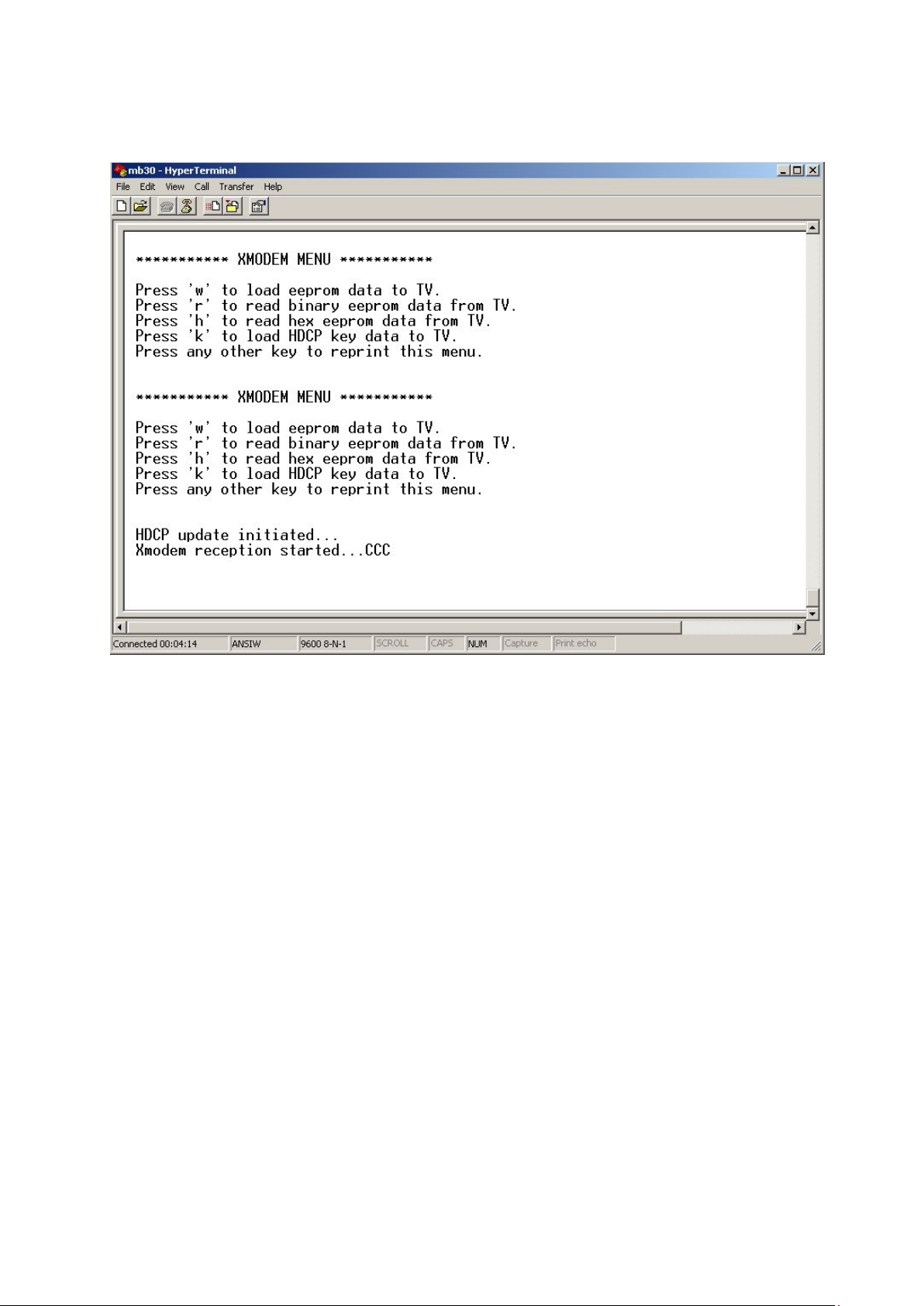

After then you must see Xmodem menu in the hyperterminal.To download hdcp key press

k or to download eeprom content press w.

Figure 3. Xmodem Menu

If the repeated “C” characters are seen you can transfer file content via select Transfer>Send File and choose “

Xmodem” protocol and click the “Send” button.

Page 13

Figure 4. The Starting To Send

17MB37 HDCP key upload procedure.

1) Turn on TV set.

2) Open a COM connection using fallowing parameters and select ISP COM Port No

Baud Rate: 9600 bps

Data Bits: 8

Stop Bits: 1

Parity: None

Flow Control: None

3) Enter service menu by pressing “4” “7” “2” 5” consecutively while main menu is

open

4) Select “9. Programming”

5) Select “HDMI HDCP Update Mode” yes.

6) On Hyper Terminal Window press “k”

7) Click on send file under Transfer Tab.

8) Select Xmodem and choose the HDCP key to be uploaded.

9) Press send button

10)Restart TV set

Page 14

17MB37 Digital Software Update From SCART

Adjusting DTV Download Mode:

1. Power on the TV.

2. Exit the Stby Mode.

3. Enter the “Tv Menu”.

4. Enter “4725” for jumping to “Service Settings”.

5. Select “8. Programming” step.

6. Change “6. DTV Download” to “On”.

7. Switch to the Stby mode.

Adjusting HyperTerminal:

1. Connect the “MB37 SCART Interface” to SCART1 (bottom SCART plug).

2. Also connect the “MB37 SCART Interface” to PC.

3. Open “HyperTerminal”.

4. Determine the “COM” settings listed and showed below.

Bit per second: 115200

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

COM Properties Window

Page 15

6. Click “OK”.

Software Updating Procedure

1. In the HyperTerminal Menu, click the “Connect” button.

2. Exit the Stby Mode.

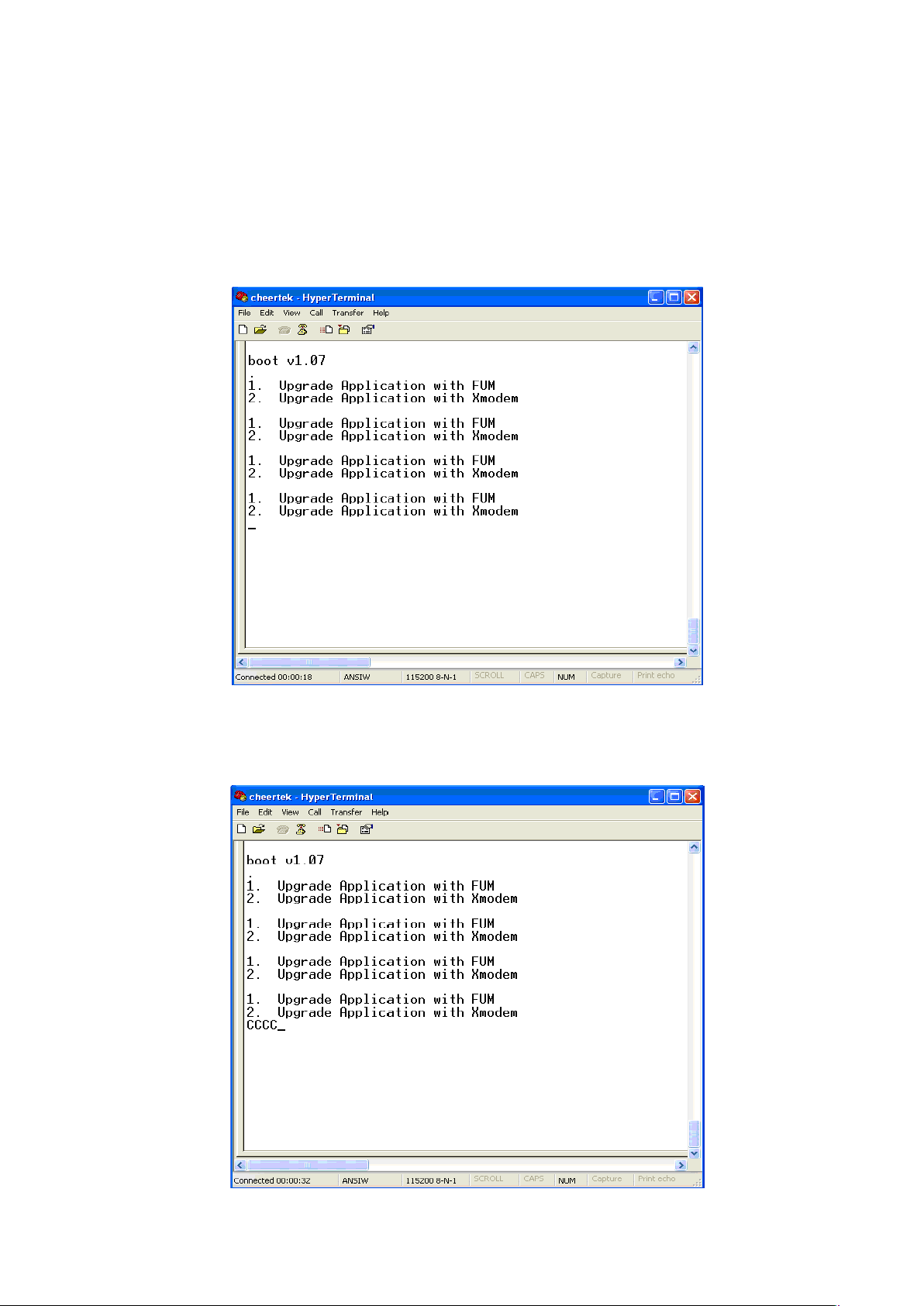

3. The “Space” button on the keyboard must be pressed, when the following window can

be seen.

Selection Window

4. Press the “2” button on the keyboard for choosing “2. Upgrade Application with

Xmodem”.

5. Repeating “C” characters are seen in the “HyperTerminal” menu.

Page 16

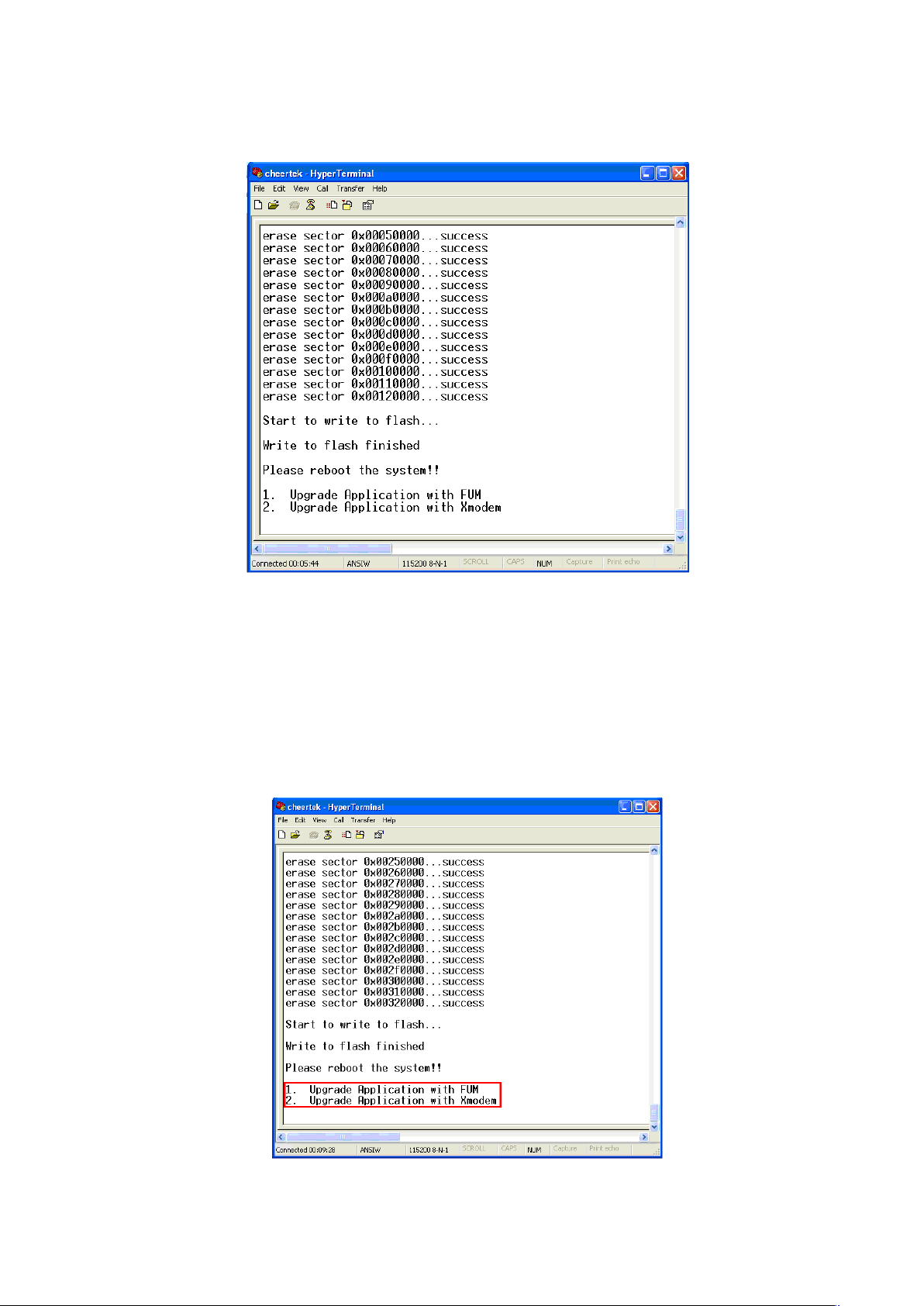

The Sample Output Before Sending The File

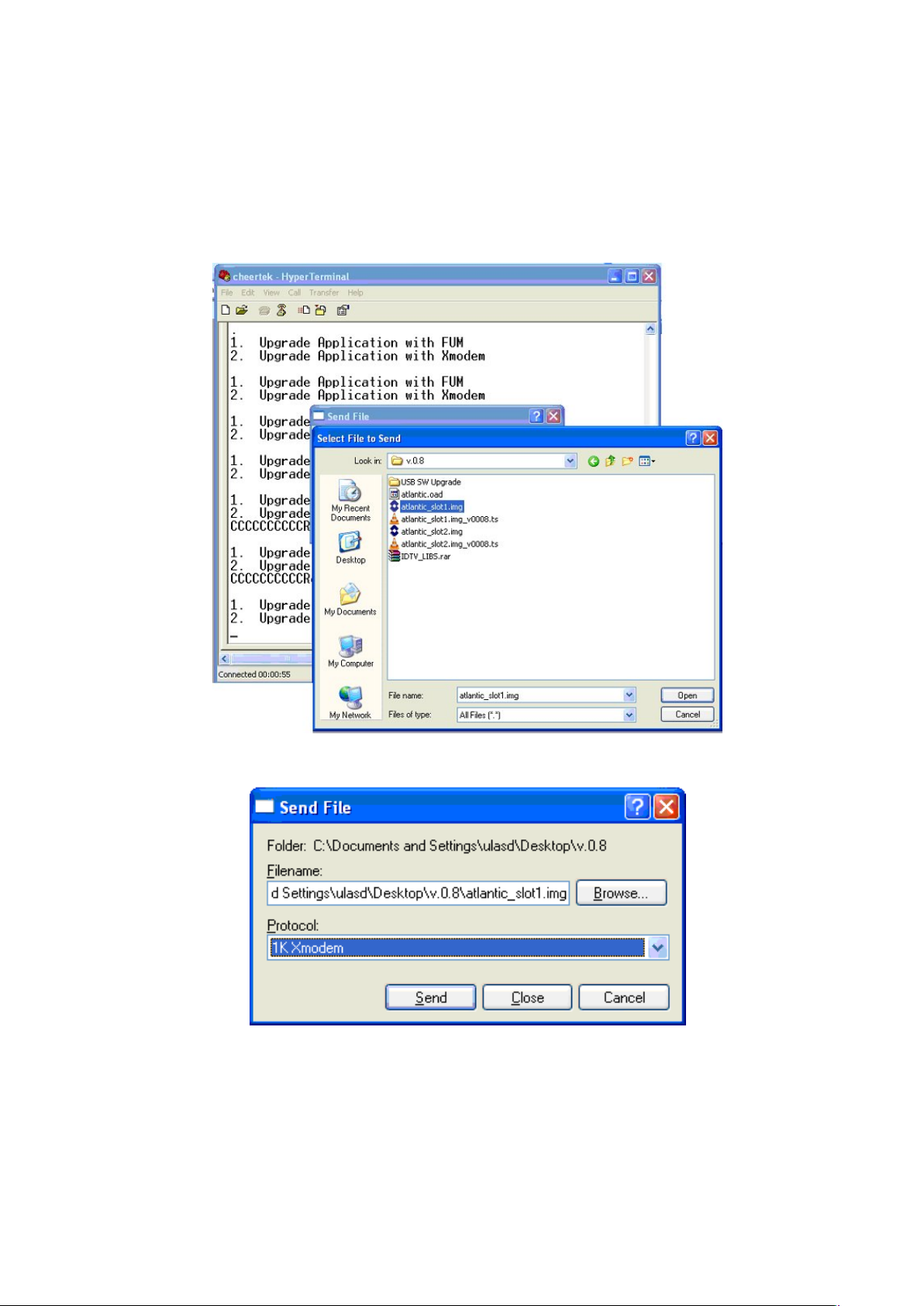

6. Click the “Send” button on the HyperTerminal

7. Select the “Filename

xxxx_slot1.img” using “Browse”.

8. Choose the “1K Xmodem” from “Protocol” option.

Selection of File

File and Protocol Selection Window

Note: In the Software updating Procedure section, when the first “C” character is seen,

the filename selection process must be finished before 10 seconds. If the process can not

be finished, the file sending operation will be cancelled. The following figure shows this

situation.

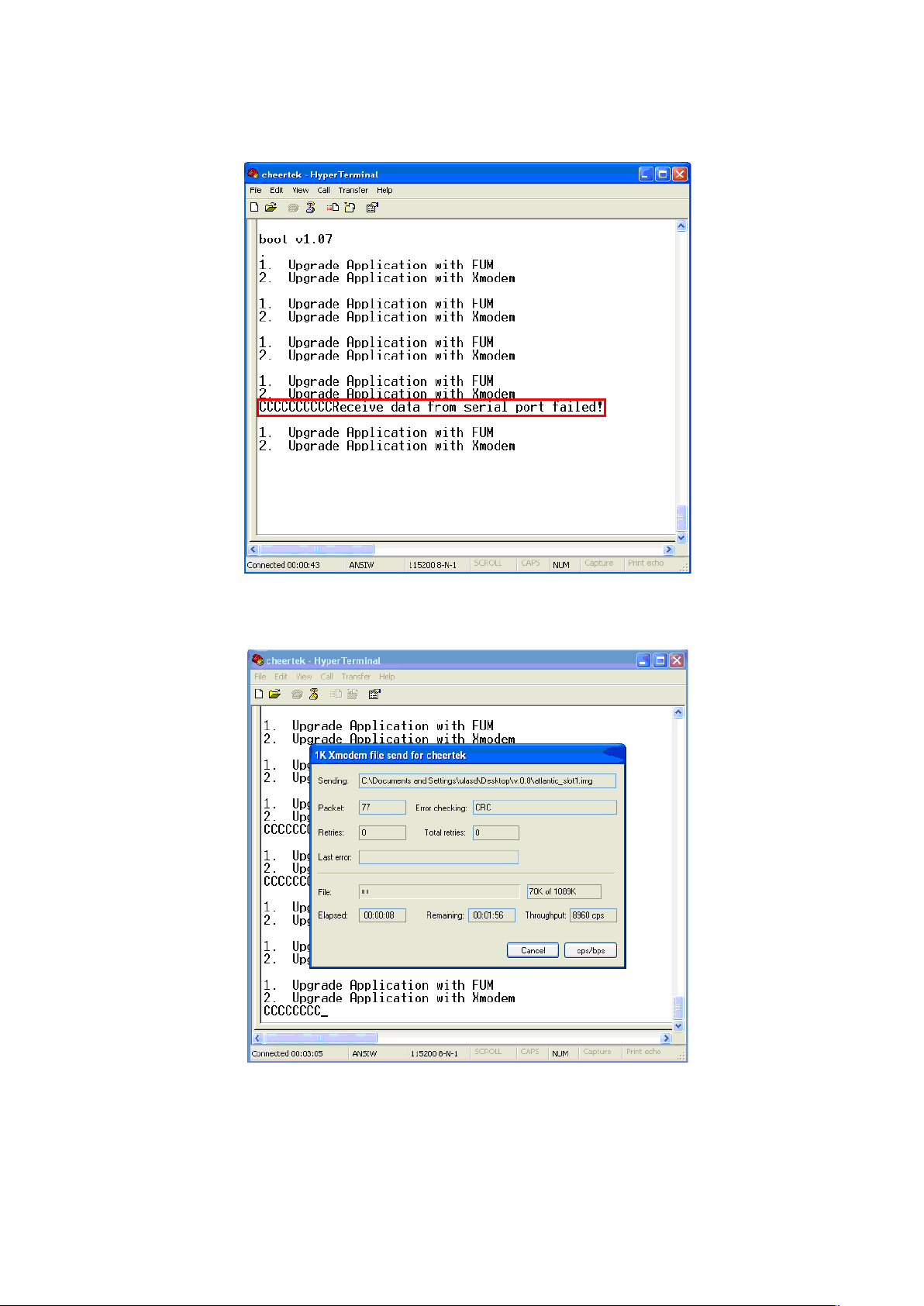

Page 17

Capture of Receving Data Failing

9. When sending the file the following window must be seen.

Capture of Sending Process

10. After the sending process the following HyperTerminal window must be seen.

Page 18

Capture of End of The Sending Process

11. For sending second program file, the Software Updating Procedure must be repeated

from the step

X. Select the “Filename xxxx_slot2.img” using “Browse”.

12. After sending the second program file, the Software Updating Procedure will be

succesful.

Note: After the File Sending Process,

1. Upgrade Application with FUM

2. Upgrade Application with Xmodem, options must be seen.

End of The Sending Process

Page 19

Checking Of The New Software

1. Turn off and on the TV.

2. Enter the “Setup” submenu in the “DTV Menu”.

3. Choose the “Configuration” option.

4. For controlling new software, check the “Receiver Upgrade” option.

17MB37 Digital Software Update From USB

Software upgrade is possible via USB disk by folowing the steps below.

1. Copy the bin file, including higher version than the software loaded in flash, into the

USB flash memory root directory. This file should be named up.bin.

2. Insert the USB disk.

3. Digital module performs version and CRC check. If version and CRC check is

successful, then a message prompt appears to notify user about new version. If the

user confirms loading of new version, upgrade.bin file is written into flash unused

slot.

4. Digital module disables the previous software in the flash and then a system reset

is performed.

5. After the reset, digital module starts with new software.

Revert operation:

With revert operation, it is possible to downgrade the software.

Revert operation is very similar to upgrade process. In the revert operation, file name

should be f_up.bin. Also user confirmation is not asked.

1. Copy the bin file into the USB flash memory root directory. This file should be

named force_upgrade.bin.

2. Insert the USB disk.

3. A lower version than the software in flash can be loaded with revert operation.

Digital module performs only CRC check. If CRC check is successful, then

force_upgrade.bin file is written into flash unused slot.

4. Digital module disables the previous software in the flash.

5. A message prompt is displayed to notify user about end of revert process.

6. Power off/on is required to start digital module with the new software.

For controlling new software, check the “Receiver Upgrade” option.

Page 20

*****

****-

Block Diagram

Page 21

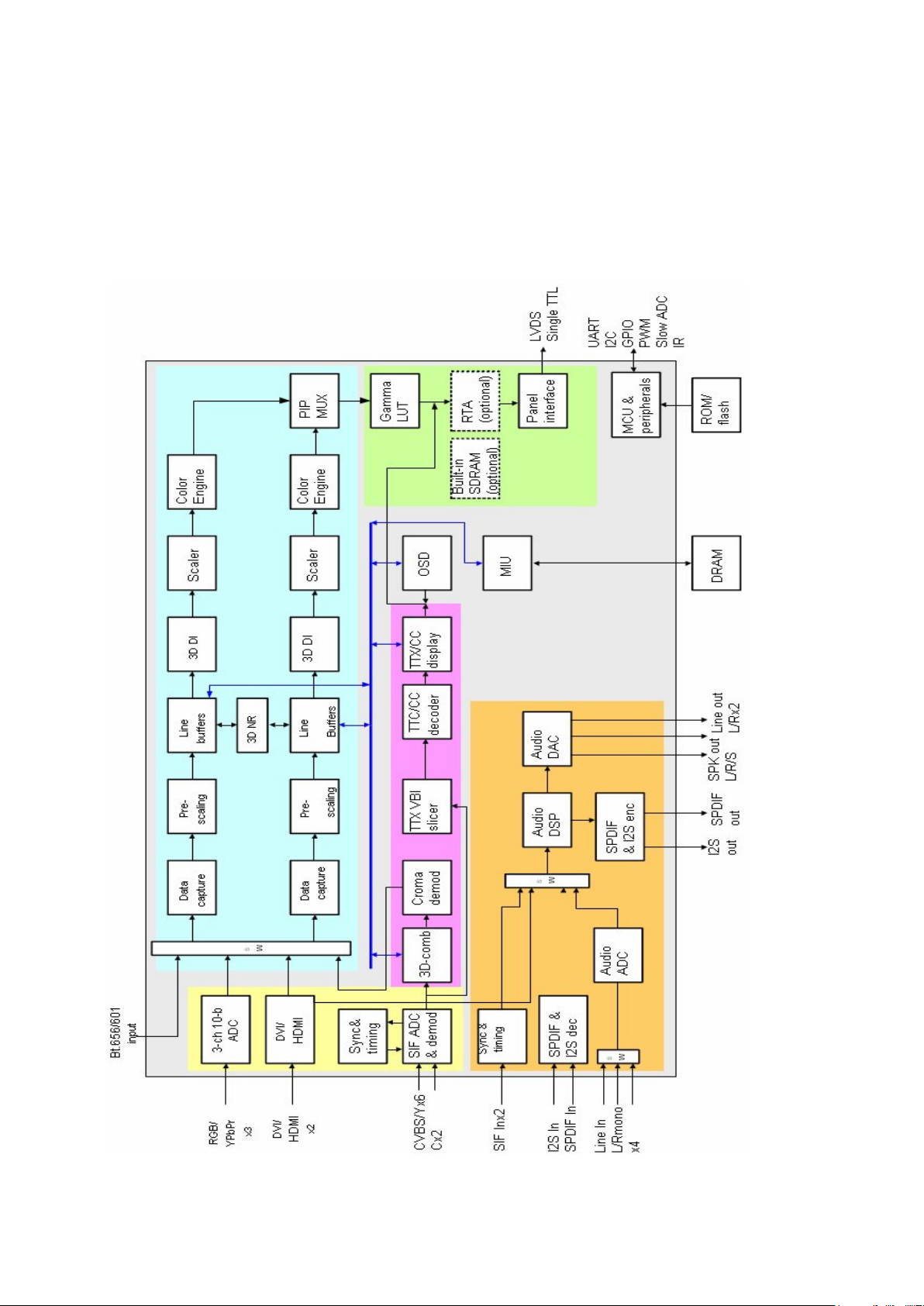

IC Block Diagram

STI7101YWC

The MST6WB7GQ-3 is a high performance and fully integrated IC for multi-function LCD

monitor/TV with resolutions up to full HD (1920x1080). It is configured with an integrated

triple-ADC/PLL, an integrated DVI/HDCP/HDMI receiver, a multi-standard TV video and audio

decoder, two video de-interlacers, two scaling engines, the MStarACE-3 color engine, an on-screen

display controller, an 8-bit MCU and a built-in output panel interface. By use of external frame

buffer, PIP/POP is provided for multimedia applications. Furthermore, 3-D video decoding and

processing are fulfilled for high-quality TV applications. To further reduce system costs, the

MST6WB7GQ-3 also integrates intelligent power management control capability for greenmode requirements and spread-spectrum support for EMI management.

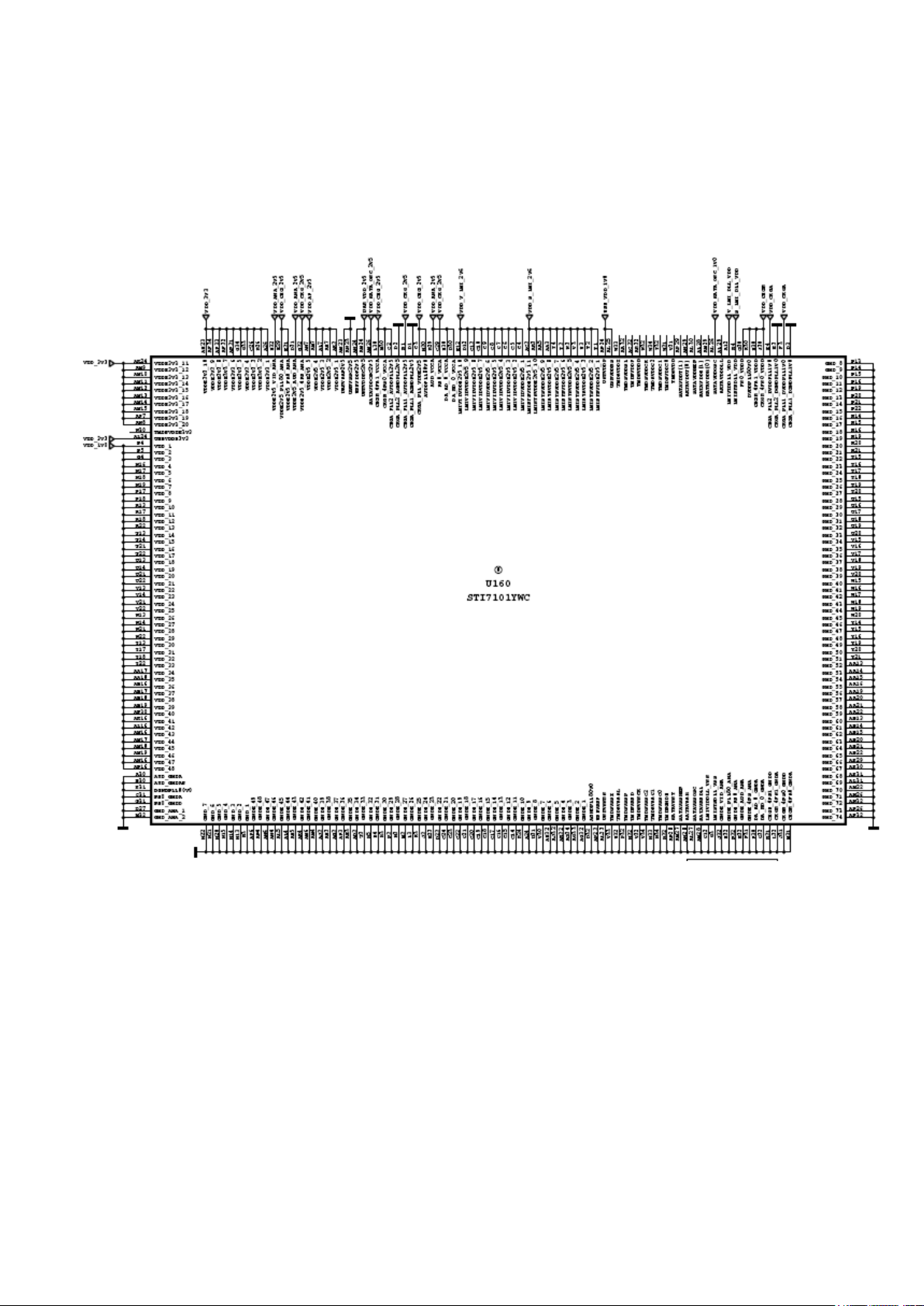

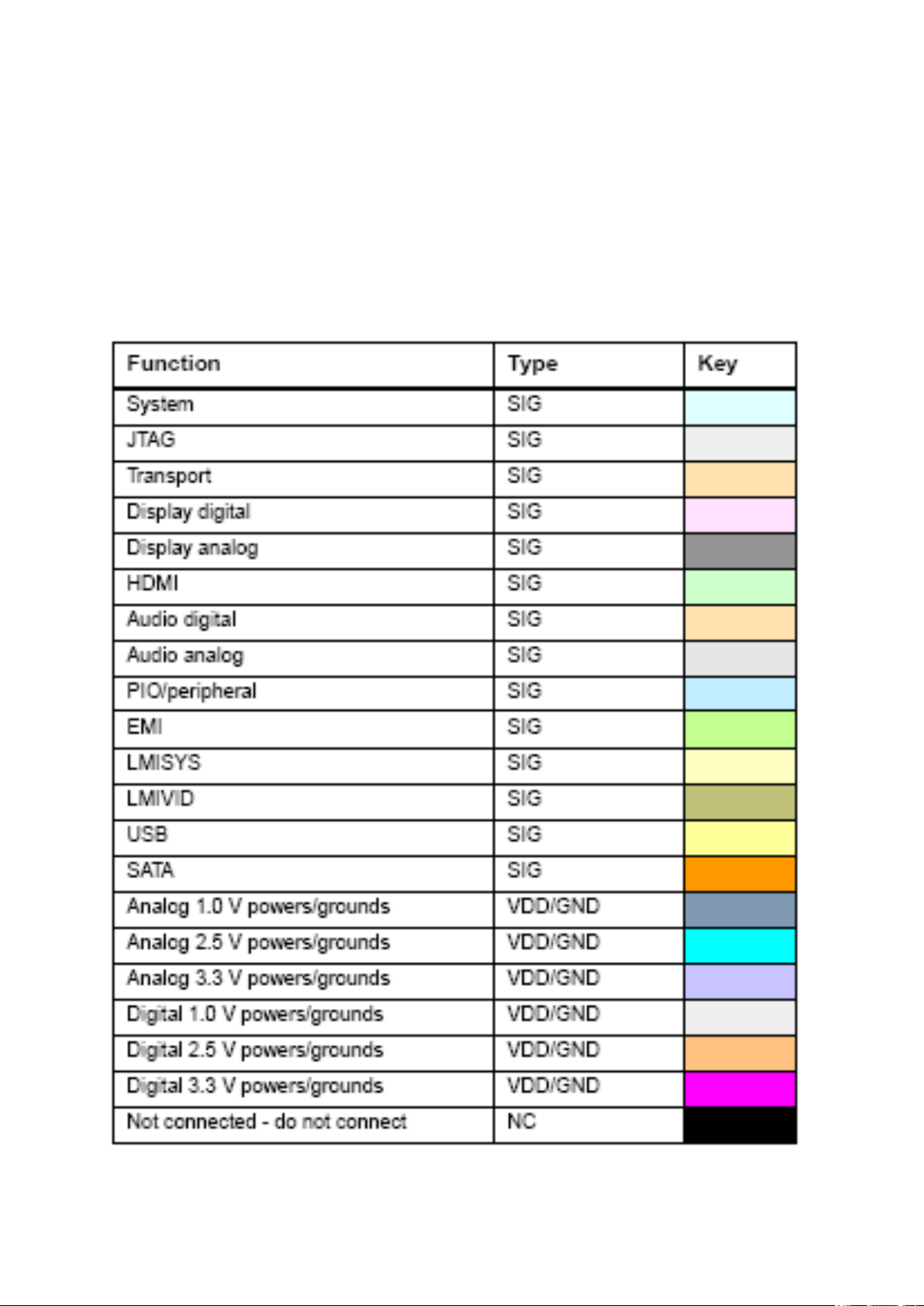

Page 22

Pin Description

Signal names are prefixed by NOT if they are active low; otherwise they are active high.

On the pin-out diagram, black indicates that the pin is reserved and must not be used.

The following pages give the allocation of pins to the package, shown from the top looking down

using the PCB footprint.

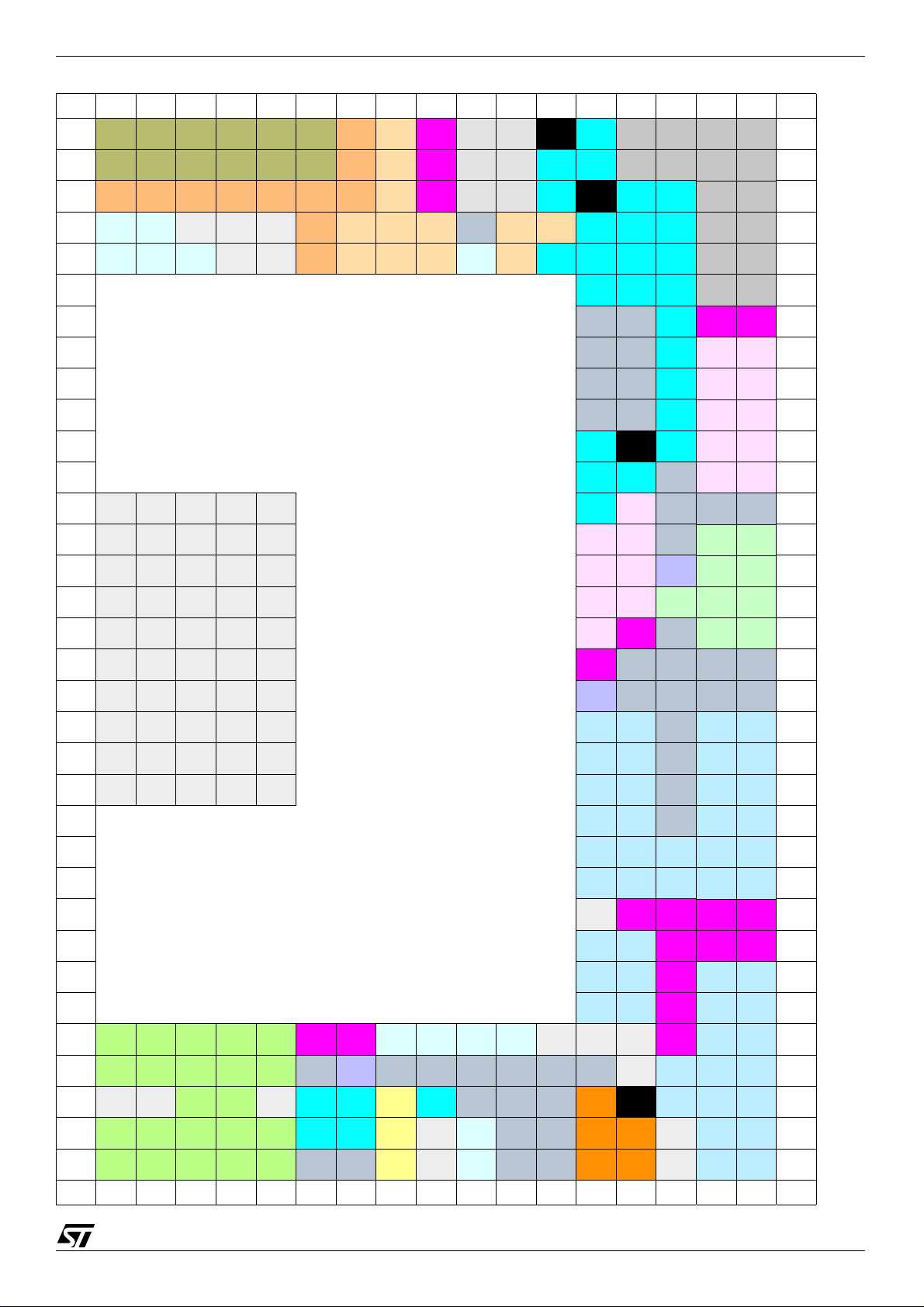

Table : Key to pin-out diagram

Page 23

STx7101 Pin list and alternative functions

18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34

LMIVID

LMIVID

DAT ASTRO

A

BE[0]

LMIVID

DAT A

B

C

D

E

DATASTRO

MASK[0]

GNDE GNDE GNDE GNDE GNDE GNDE GNDE

TRIGGER

OUT

TMUCLK

DATA

MASK[2]

LMIVID

BE[2]

NOT

RESETIN

WDOG

RSTOUT

LMIVID

DATA[16]

LMIVID

DATA[17]

NOT

TRST

NOT

ASEBRK

F

G

Pin-out (R)

H

J

K

L

M

VDD VDD GND GND GND

N

VDD GND GND GND GND

P

VDD GND GND GND VDD

R

GND GND GND VDD VDD

T

GND GND GND VDD VDD

U

GND GND GND VDD VDD

V

GND GND GND VDD VDD

W

VDD GND GND GND VDD PIO5[6] PIO5[7]

Y

Confidential

VDD GND GND GND GND PIO4[7] PIO5[5]

AA

VDD VDD GN D GND GND PIO4[5] PIO4[6]

AB

AC

LMIVID

LMIVID

DATA[18]

DATA[20]

LMIVID

LMIVID

DATA[19]

DATA[21]

TCK TDI GNDE

TMS TDO GNDE

LMIVID

DATA[22]

LMIVID

DATA[23]

GNDE

GNDE

AUDSPDIF

OUT

AUDS

CLKOUT

AUDPCM

OUT0

AUDPCM

OUT1

AUDPCM

OUT2

AUDPCM

OUT3

AUDPCM

OUT4

VDDE

3V3

VDDE

3V3

VDDE

3V3

AUDPCM

CLKOUT

AUDLR

CLKOUT

AUDANA

MLEFT

OUT

AUDANA

PLEFT

OUT

AUDANA

IREF

GND_ANA

SYSBCLK

INALT

AUDANA

MRIGHT

OUT

AUDANA

PRIGHT

OUT

AUDANA

VBGFIL

AUDDIG

STRBIN

AUDDIGLR

CLKIN

NC

AUD_

VCCA

FS0_

VCCA

AUDDIG

DAT AIN

VDDE2V5_

PLL80_

ANA

AUD_

VIDANA

GNDA

REXT[0]

VIDANA

AUD_

GNDAS

REXT[0]

NC

DA_HD_0_

VDDE2V5_

VCCA

AUD_ANA

DA_SD_0_

VDDE2V5_

VCCA

FS0_ANA

GNDE_

DA_SD_0

_GNDA

FS0_

VDDD

CKGB_

CKGB_

4FS1_

VDDD

CKGB_

CKGB_

4FS0_

VDDD

DVDD

PLL80V0

PLL80V0

CKGB_

4FS1_

VCCA

CKGB_

CKGB_

4FS0_

VCCA

AVDD

DIGOUT

PLL80V0

VID

DIGOUT

DIGOUT

YC[14]

VID

DIGOUT

DIGOUT

YC[12]

VID

DIGOUT

DIGOUT

YC[10]

VID

DIGOUT

YC[8]

GNDE

3V3

TMDS

VDDE3V3

VDDC0

PIO4[3] PIO4[4]

GNDA

FS0_

GNDA

4FS_

ANA

FS0_

GNDD

4FS1_

GNDD

4FS0_

GNDD

DGND

NC

4FS0_

GNDA

VID

YC[15]

VID

YC[13]

VID

YC[11]

VID

YC[9]

GNDE

3V3

TMDS

VDD

TMDS

VIDANA

REXT[1]

VIDANA

GNDA

REXT[1]

DA_HD_0_

GNDA

AGNDPLL

80V0

GNDE_

AUD_ANA

GNDE_

FS0_

ANA

VDDE2V5

_4FS_ANA

VDDE2V5

_VID_ANA

GNDE_

VID_ANA

GNDE_

PLL80_

ANA

CKGB_

4FS1_

GNDA

GND_

ANA

TMDS

VSSD

TMDS

VSSP

TMDS

GNDE

TMDS

REF

TMDS

VSSSL

TMDS

VSSCK

TMDS

VDDCK

TMDS

VDDC1

TMDS

VDDSL

TMDS

VDDD

TMDS

VDDP

VIDANAID

VIDANAC1

UMPC1

VIDANAID

VIDANAY1

UMPY1

VIDANAID

VIDANACV

UMPCV1

1OUT

VIDANAID

VIDANAR0

UMPR0

VIDANAID

VIDANAB0

UMPB0

VIDANAID

VIDANAG0

UMPG0

VDDE

VDDE

3V3

VID

DIGOUT

DIGOUT

YC[7]

YC[6]

VID

DIGOUT

DIGOUT

YC[5]

YC[4]

VID

DIGOUT

DIGOUT

YC[3]

YC[2]

VID

DIGOUT

DIGOUT

YC[1]

YC[0]

VID

DIGOUT

DIGOUT

HSYNC

VSYNC

TMDS

TMDS

VSSC1

VSSC0

TMDS

TMDS

TX2P

TX2N

TMDS

TMDS

TX1P

TX1N

TMDS

TMDS

TX0P

TX0N

TMDS

TMDS

TXCP

TXCN

TMDS

TMDS

VSSX

VSSC2

TMDS

TMDS

VDDX

VDDC2

PIO5[4] PIO5[3]

PIO5[2] PIO5[1]

PIO5[0] PIO3[7]

PIO3[6] PIO3[5]

OUT

OUT

OUT

OUT

OUT

3V3

VID

VID

VID

VID

VID

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

U

V

W

Y

AA

AB

AC

AD

AE

AF

AG

AH

AJ

AK

AL

AM

AN

AP

EMIA

DDR[16]

EMI

ADDR[17]

VDD VDD

EMI

DATA[10]

EMI

DATA[2]

EMI

ADDR[18]

EMI

ADDR[19]

EMI

DAT A[9]

EMI

DAT A[1]

EMI

ADDR[20]

EMI

ADDR[21]

EMI

BUSREQ

EMI

DATA[8]

EMI

DATA[0]

EMI

ADDR[22]

EMI

ADDR[23]

EMI

BUSGNT

EMI

FLASHCLK

NOT

EMIBAA

EMIT

READYOR

WAIT

EMIDMA

REQ[1]

GND

EMIDMA

REQ[0]

NOT

EMILBA

VDDE3V3 VDDE3V3

USB

USB

VSSBS

VDDB3V3

USB

USB

VSSP

VDDBC

2V5

2V5

USB

USB

VSSC

VDDP

2V5

2V5

USB

USB

VSSP

VDDP

SYS

ITRQ[0]

ITRQ[1]

USB

VDDBS

VDDOSC

SATAVDD

USBREF

OSC2V5

USBDP GND

USBDM GND

SYS

SATA

SYS

ITRQ[2]

SATA

VSSOSC

SATA

VSSREF

SYSB

CLKOSC

SYSB

CLKIN

SYS

ITRQ[3]

SATA

VDDR[1]

SATA

VSSDLL

SATA

VSSR

SATA

VSST

PIO4[1] PIO4[2] PIO4[0] PIO3[4]

PIO2[7] PIO2[6] PIO3[0] PIO3[2]

VDDE

VDD

3V3

PIO2[4] PIO2[5]

PIO2[2] PIO2[3]

PIO2[0] PIO2[1]

GND GND GND

SATA

VDDDLL

SATA

VDDR[0]

SATA

VDDT[0]

SATA

VDDT[1]

SATAVDDR

GND PIO0[7] PIO1[1]

EF

ATAREF NC PIO0[0] PIO0[5]

ATATXP ATARXP GND PIO0[2]

ATATXN ATARXN GND PIO0[1]

VDDE

GNDE

GNDE

GNDE

GNDE

18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34

7983497A STMicroelectronics Confidential 57/1172

3V3

3V3

3V3

3V3

3V3

VDDE

3V3

GNDE

3V3

PIO1[7]

PIO1[5]

PIO1[3]

PIO3[3]

PIO3[1]

VDDE

3V3

GNDE

3V3

PIO1[6]

PIO1[4]

PIO1[2]

PIO1[0]

PIO0[6]

PIO0[4]

PIO0[3]

AD

AE

AF

AG

AH

AJ

AK

AL

AM

AN

AP

Page 24

Pin list and alternative functions STx7101

7.2 Alternative functions

To impr ove flexibility and to allow the STx7101 to fit into differ ent set-top box application

architectures, the input and output signals from some of the peripherals and functions are not

directly connected to t he pi ns of the device. Instead they are assigned t o t he alternative functi on

inputs and outputs of a PIO port bit, or an I/O pi n. This scheme allows the pins to be configured

with their default function if the associated input or output is not required in that particular

application.

Some pins have several alternative functions, for inputs and/or outputs. In Table 6 to Table 11,

the different alternative functions are listed under the table headings Alt 1, Alt 2, to Alt n.

Inputs connec ted to the alternative function input are permanently connected to the input pin.

The output signa l from a peripheral is only connected when the PIO bit is configured into either

push-pull or open drain driver alternative function mode.

Some alternative function signals are available on more than one PI O port.

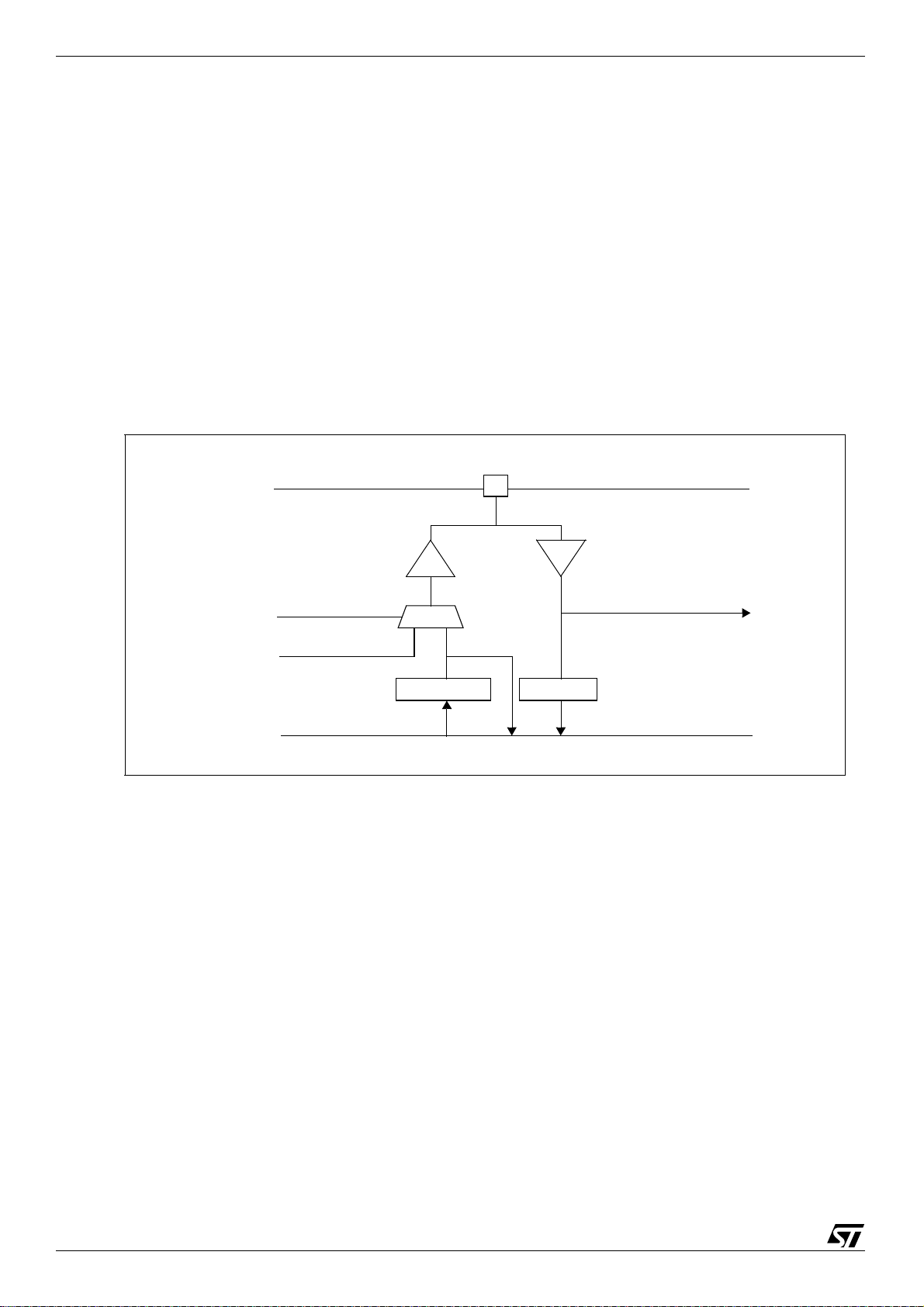

Figure 20: I/O port pins

Pin

Confidential

Push-pull

tri-state

open drain

weak pull-up

Alternative function

Alternative function output

1 0

Output latch

Alternative function input

Input latch

58/1172 STMicroelectroni cs Confide ntial 7983497A

Page 25

TUNER

A horizontal mounted and Digital Half-Nim tuner is used in the product, which covers 3

Bands(From 48MHz to 862MHz for COFDM, from 45.25MHz to 863.25MHz for CCIR CH).

The tuning is available through the digitally controlled I2C bus (PLL). Below you will find

info about the tuner.

1.1. General description of TDTC-G101D:

The Tuner covers 3 Bands(from 48MHz to 862MHz for COFDM, from 45.25MHz to

863.25MHz for CCIR CH). Band selection and Tuning are performed digitally via the I2C

bus.

1.2. Features of TDTC-G101D:

Digital Half-NIM tuner for COFDM

Covers 3 Bands(From 48MHz to 862MHz for COFDM,

From 45.25MHz to 863.25MHz for CCIR CH)

Including IF AGC with SAW Filter

Bandwidth Switching (7/8 MHz) possible

DC/DC Converter built in for Tuning Voltage

Internal(or External) RF AGC, Antenna Power Optional

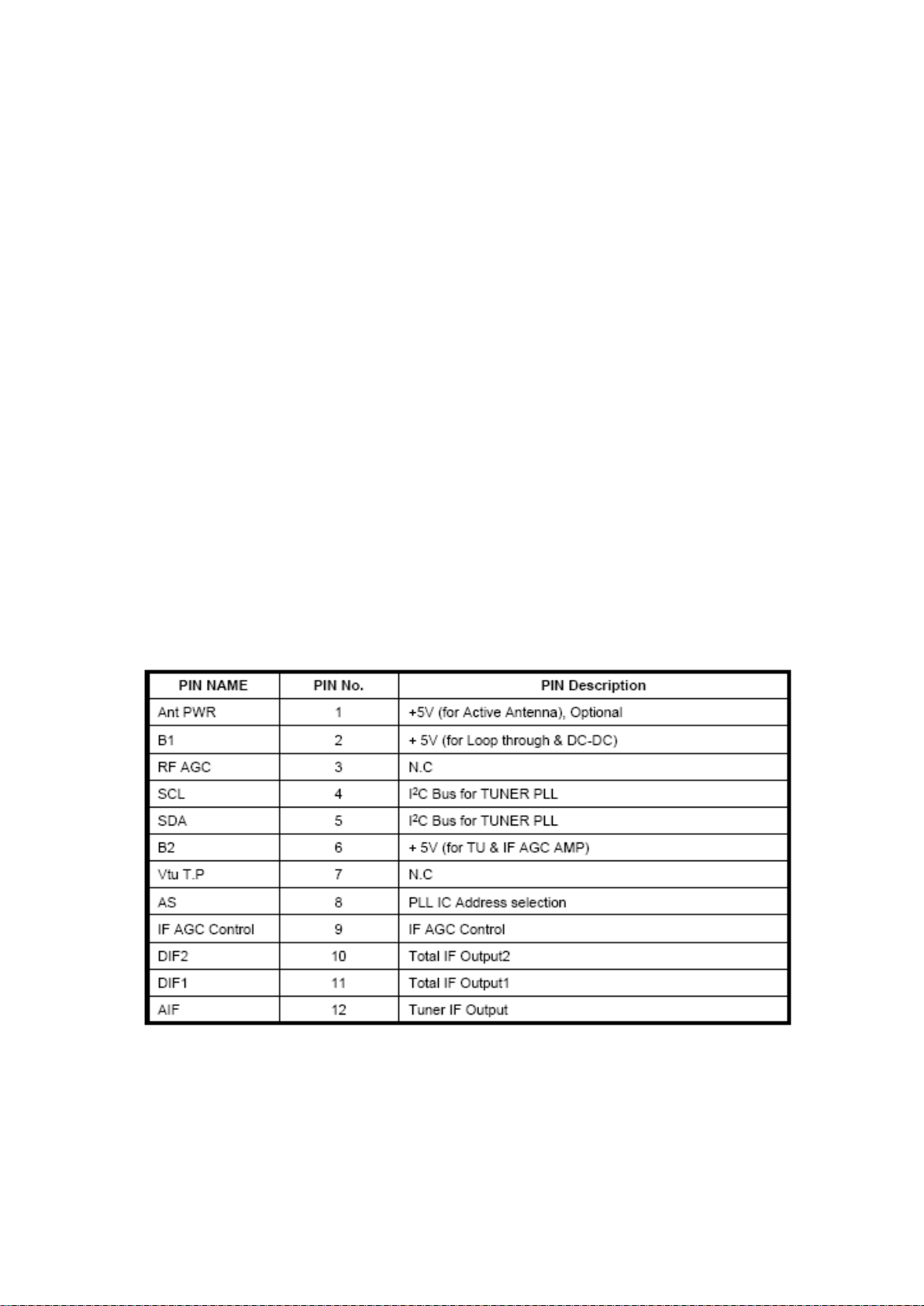

1.3. Pinning:

Page 26

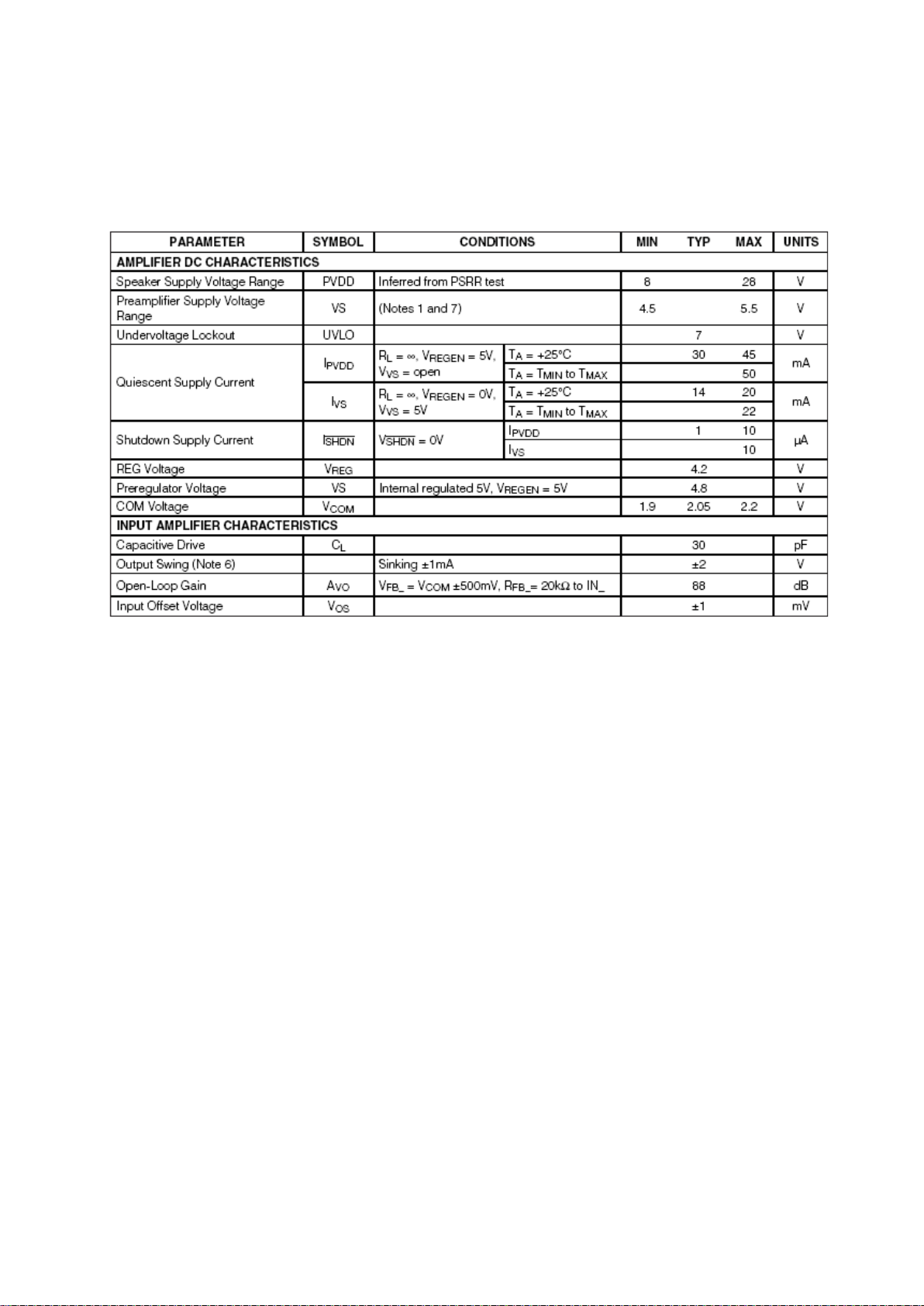

Audio Amplifier

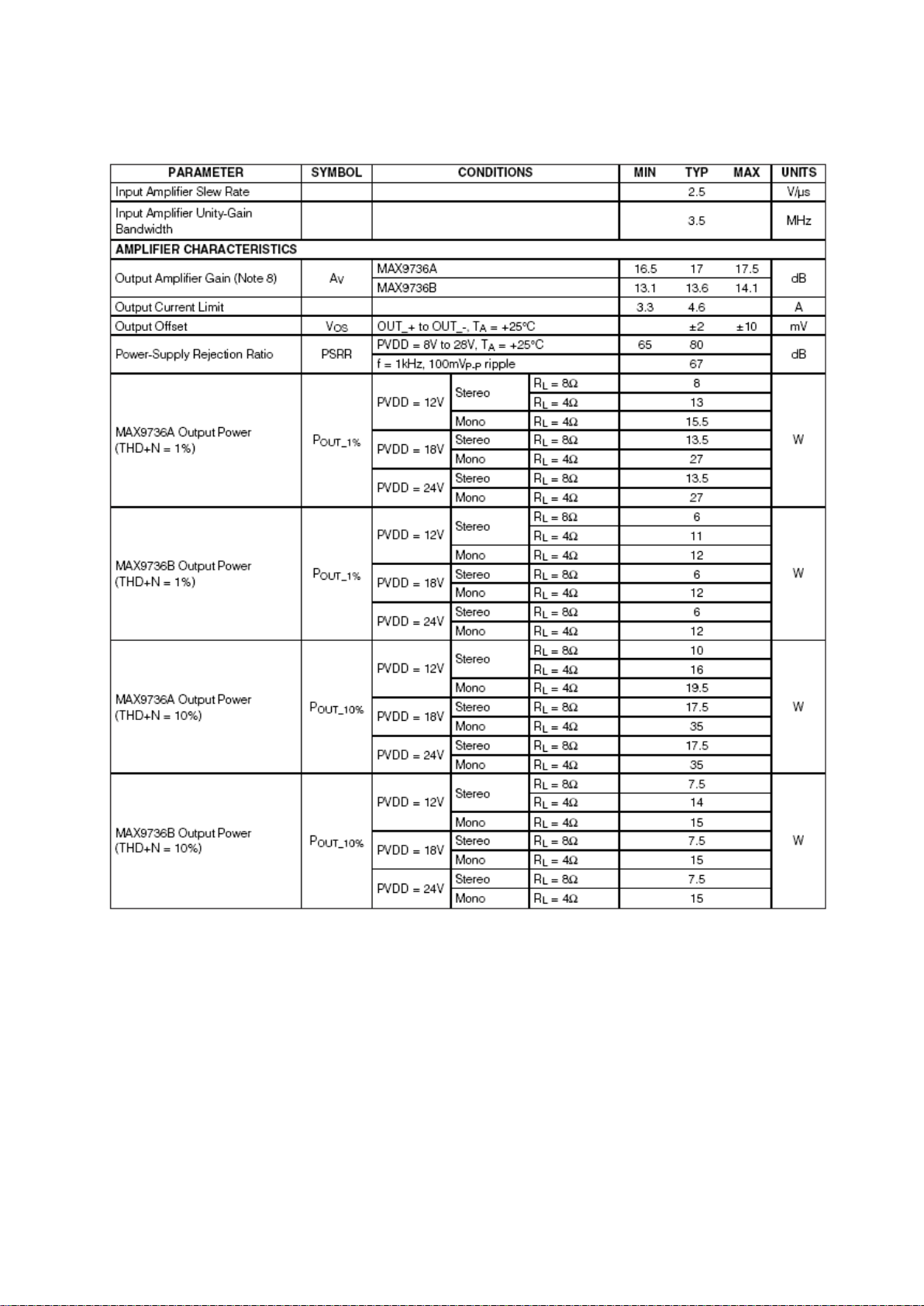

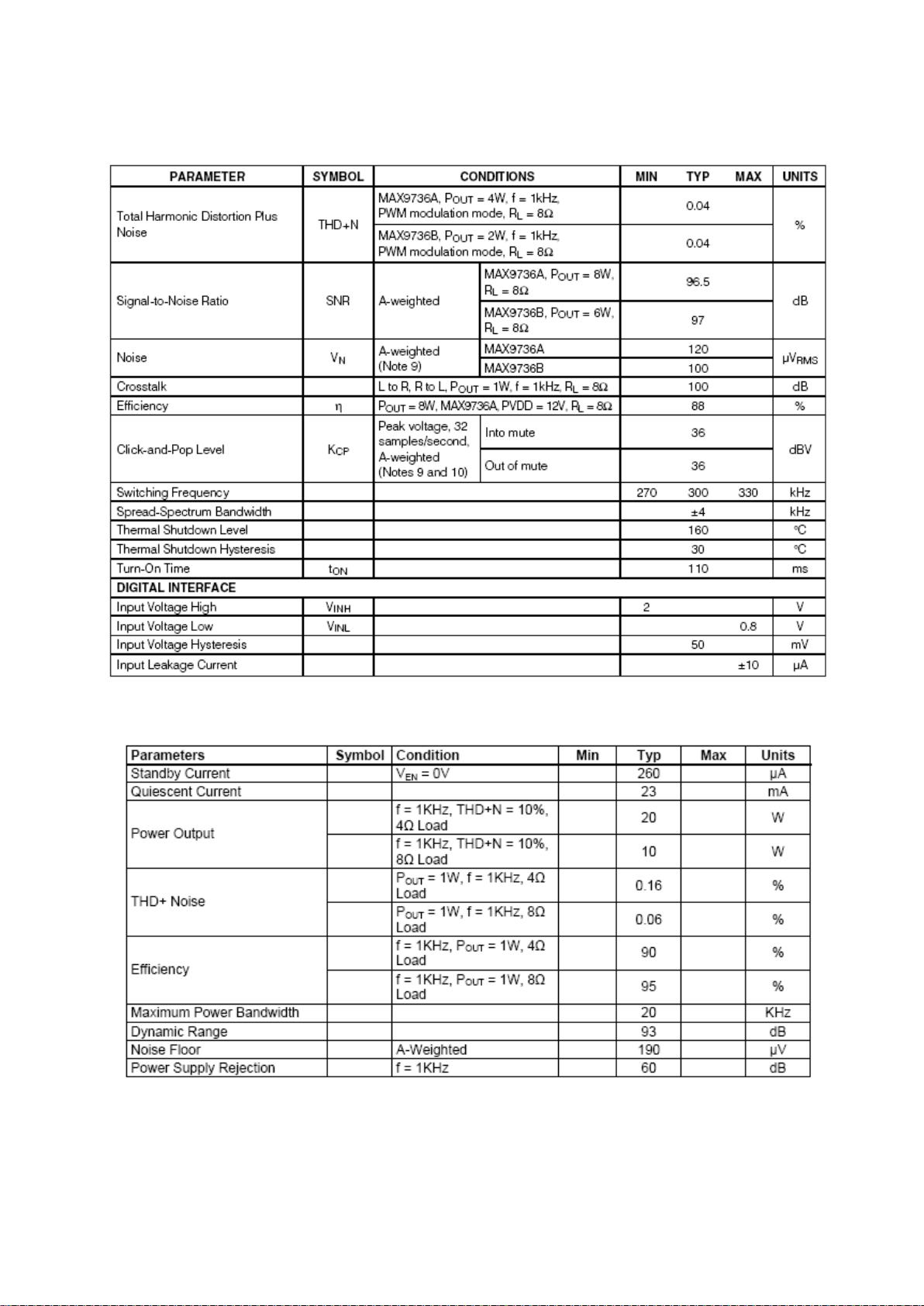

MAX9736(8-10WATT)

General Description

The MAX9736A/B Class D amplifiers provide high-performance,thermally efficient

amplifier solutions. The

into a 4Ω load. The MAX9736B delivers 2 x 6W into 8Ω loads or 1 x 12W into a 4Ω

These devices are pinfor pin compatible, allowing a single audio design to work across a

broad range of platforms, simplifying design efforts, and reducing PCB inventory.

Both devices operate from 8V to 28V and provide a high PSRR, eliminating the need for a

regulated power supply. The MAX9736 offers up to 88% efficiency at 12V supply.

Pin-selectable modulation schemes select between filterless modulation and classic PWM

modulation.

Filterless modulation allows the MAX9736 to pass CE EMI limits with 1m cables using

only a low-cost ferrite bead and capacitor on each output. Classic PWM modulation

is optimized for best audio performance when using a full LC filter.

A pin-selectable stereo/mono mode allows stereo operation

operation into 4Ω loads. In

spare device, allowing flexibility in system design. Comprehensive click-and-pop reduction

circuitry minimizes noise coming into and out of shutdown or mute.

Input op amps allow the user to create summing amplifiers, lowpass or highpass filters,

and select an optimal gain. The MAX9736A/B are available in 32-pin TQFN packages

and specified over the -40°C to +85°C temperature range.

MAX9736A delivers 2 x 15W into 8Ω loads, or 1 x 30W

load.

into 8Ω loads or mono

mono mode, the right input op amp becomes available as a

Features

Wide 8V to 28V Supply Voltage Range

♦ Spread-Spectrum Modulation Enables Low EMI

Solution

♦ Passes CE EMI Limits with Low-Cost Ferrite

Bead/Capacitor Filter

♦ Low BOM Cost, Pin-for-Pin Compatible Family

♦ High 67dB PSRR at 1kHz Reduces Supply Cost

♦ 88% Efficiency Eliminates Heatsink

♦ Therm

♦ < 1μA Shutdown Mode

♦ Mute Function

♦ Space

Package

al and Output Current Protection

-Saving, 7mm x 7mm x 0.8mm, 32-Pin TQFN

Applications

LCD/PDP/CRT Monitors

LCD/PDP/CRT TVs

MP3 Docking Stations

Notebook PCs

PC Speakers

All-in-One PCs

Page 27

Absolute Ratings

Electrical Characteristics

Page 28

Page 29

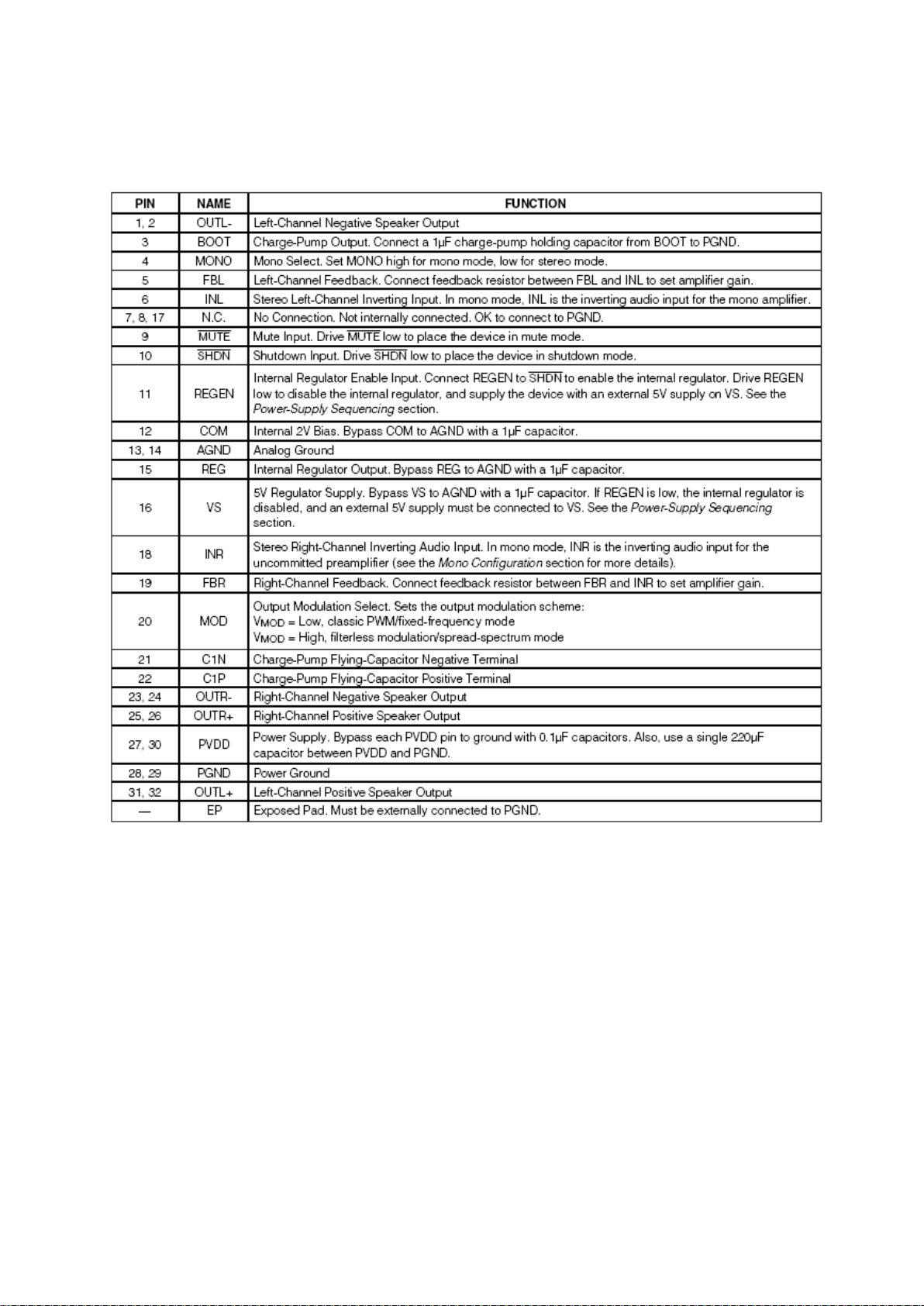

Operating Specifications

Page 30

Pinning

PT2333(2.5 WATT)

Description

The PT2333 is a Class-D power amplifier designed for audio equipments, maximum

output power can reach

composed of exclusively designed Class-D circuitry (patented) by PTC, along with

the most advanced semi-conductor technology. When compared to the traditional

Class-AB amplifiers, the PT2333’s has a much higher efficiency (>80%), low

heat dissipation, and produces superior audio quality. PT2333’s external circuitry is

simple and easily accessible, and consists of flawless self-protection capabilities.

The chip’s packaging is small, thus it occupies an insignificant amount of space on

the circuit board; therefore, making it the predominant choice when it comes to

audio amplifiers.

up to 2.5W (VDD=5V, RL=4Ω, THD=10%). The PT2333

Page 31

Features

CMOS technology

Operating voltage range from 2.7V up to 5.5V

Differential analog input

Maximum output power 2.5W(4Ω) @ THD=10%

Output low-pass LC filter is not required.

Voltage gain determinate by the external resister

Contains shutdown function

POP noises free in shutdown and power ON/OFF

period

Built-in short circuit protection

Built-in overheat protection

High efficiency (8Ω load >85%), low heat

dissipation

Available in MSOP 10-pin and WLCSP 9-pin

miniature packages

Aplications

Cellular phone

Portable media player

GPS

LCD monitor

Small multimedia speakers

Hand-free phone

Laptop

Other audio applications

Block Diagram

Page 32

POWER STAGE

The DC voltages required at various parts of the chassis and inverters are provided by a

main power supply unit. The power supply generates 33V, 24V, 12V, 5V, 3,3V and 5V,

3,3V stand by mode DC voltages. Power stage which is on-chasis generates 1,26V stand

by voltage and 8V, 2.5V, 2,6V, 1,8V and 1V supplies for other different parts of the

chassis.

ADAPTOR USE (Optional)

The DC voltages required at various parts of the chassis and inverters are provided by an

external power supply unit or produced on the chassis if an adapter is used for the supply.

The 12V dc voltage is switched by IRF 7314 power mosfet in TV sets with mechanical

switch to produce the required standby voltage. Also regulators and mosfets generate

1.8V, 3.3V and 5V and 1.26V voltages for other different parts of the chassis.

Page 33

MPEG-2/MPEG-4 DVB Decoder (STi7101)

1.4. General Description

The STi7101 is a new generation, high-definition IDTV / set-top box / DVD decoder chip, and

provides very high performance for low-cost HD systems. STx7101 includes an H.264 video

decoder for new, low bit rate applications. Based on the Omega2 (STBus) architecture, this

system-on-chip is a full back-end processor for digital terrestrial, satellite, cable, DSL and IP

client high-definition set-top boxes, compliant with ATSC, DVB, DIRECTV, DCII,

OpenCable and ARIB BS4 specifications. It includes all processing for DVD applications.

The STx7101 demultiplexes, decrypts and decodes HD or SD video streams with associated

multi-channel audio. Video is output to two independently formatted displays: a full resolution

display intended for a TV monitor, and a downsampled display intended for a VCR or DVD-R.

Connection to a TV or display panel can be analog through the DACs, or digital through a copy

protected DVI/HDMI. Composite outputs are provided for connection to the VCR with

Macrovision protection. Audio is output with optional PCM mixing to an S/PDIF interface,

PCM interface, or through integrated stereo audio DACs. Digitized analog programs can also

be input to the STx7101 for reformatting and display. The STx7101 includes a graphics

rendering and display capability with a 2D graphics accelerator, three graphics planes and a

cursor plane. A dual display compositor provides mixing of graphics and video with

independent composition for each of the TV and VCR/DVD-R outputs. The STx7101 includes

a stream merger to allow seven different transport streams from different sources to be merged

and processed concurrently. Applications include DVR time-shifted viewing of a terrestrial

program, while acquiring an EPG/data stream from a satellite or cable front end.

The flexible descrambling engine is compatible with required standards including DVB, DES,

AES and Multi2. The STx7101 embeds a 266 MHz ST40-202 CPU for applications and device

control. A dual DDR1 SDRAM memory interface is used for higher performance, to allow the

video decoder the required memory bandwidth for HD H.264 and sufficient bandwidth for the

CPU and the rest of the system. A second memory bus is also provided for flash memory,

storing resident software, and for connection of peripherals. This bus also has a high speed

synchronous mode that can be used to exchange data between two STx7101 devices. This can

be used to connect a second STx7101 as a co-decoder for a dual TV STB application. A harddisk drive (HDD) can be connected either to the serial ATA interface, or as an expansion drive

through the USB 2.0 port.

Page 34

The figure below shows the architecture of the Sti7101.

6.2 Features

The STx7101 is a single-chip, high definition video decoder including:

_ H.264 support

_ Linux® and OS21 compatible ST40 CPU core: 266 MHz

_ transport filtering and descrambling

_ video decoder: H.264 (MPEG-4 part 10) and MPEG-2

_ SVP compliant

_ graphics engine and dual display: standard and highdefinition

_ audio decoder

_ DVD data retrieval and decryption

The STx7101 also features the following embedded interfaces:

_ USB 2.0 host controller/PHY interface

_ DVI/HDMI™ output

_ digital audio and video auxiliary inputs

_ low-cost modem

_ 100BT ethernet controller with integrated MAC and MII/ RMII interface for external PHY

_ serial ATA (SATA)

Page 35

Processor subsystem

_ ST40 32-bit superscaler RISC CPU

_ 266 MHz, 2-way set associative 16-Kbyte ICache, 32-Kbyte DCache, MMU

_ 5-stage pipeline, delayed branch support

_ floating point unit, matrix operation support

_ debug port, interrupt controller

Transport subsystem

_ TS merger/router

_ 2 serial/parallel inputs

_ 1 bidirectional interface

_ merging of 3 external transport streams

_ transport streams from memory support

_ NRSS-A module interface

_ TS routing for DVB-CI and CableCARD

modules

_ Programmable transport interfaces (PTIs)

_ two programmable transport interfaces

_ two transport stream demultiplexers: DVB, DIRECTV®, ATSC, ARIB, OpenCable, DCII

_ integrated DES, AES, DVB and Multi2 descramblers

_ NDS random access scrambled stream protocol (RASP) compliant

_ NDS ICAM CA

_ support for VGS, Passage and DVS042 residue handling

Video/graphics subsystem

_ H.264(MPEG-4 part 10) main and high profile level 4.1/MPEG-2 MP@HL video decoder

_ advanced error concealment and trick mode support

_ dual MPEG-2 MP@HL decode

_ SD digital video input

_ Displays

_ one HD display multi format capable (1080I, 720P, 480P/576P, 480I/576I)

analog HD output RGB or YPbPr

HDMI encoded output

_ one standard-definition display

analog SD output: YPbPr or YC and CVBS

_ Gamma 2D/3D graphics processor

_ triple source 2D gamma blitter engine

_ alpha blending and logical operations

_ color space and format conversion

_ fast color fill

_ arbitrary resizing with high quality filters

_ acceleration of direct drawing by CPU

_ Gamma compositor and video processor

_ 7-channel mixer for high definition output

_ independent 2-channel mixer for SD output

_ 3 graphic display planes

_ high-quality video scaler

Page 36

_ motion and detail adaptive deinterlacer

_ linear resizing and format conversions

_ horizontal and vertical filtering

_ Copy protection

_ HDMI /HDCP copy protection hardware

_ SVP compliant

_ Macrovision® copy protection for 480I, 480P, 576I, 576P outputs

_ DTCP-IP

_ AWG-based DCS analog copy protection

Audio subsystem

_ Digital audio decoder

_ support for all the most popular audio standards including MPEG-1 layer I/II, MPEG-2 layer

II, MPEG-2 AAC, MPEG- 4 AAC LC 2-channel/5.1 channel MPEG-4 AAC+SBR 2channel/5.1 channel, Dolby® Digital EX, Pro Logic® II, MLP™ and DTS®

_ PCM mixing with internal or external source and sample rate conversion

_ 6- to 2-channel downmixing

_ PCM audio input

_ independent multichannel PCM output, S/PDIF output and analog output

_ Stereo 24-bit audio DAC for analog output

_ IEC958/IEC1937 digital audio output interface (S/PDIF)

_ CSS/CPxM copy protection hardware Interfaces

_ External memory interface (EMI)

_ 16-bit interface supporting ROM, flash, SFlash, SRAM, peripherals

_ access in 5 banks

_ high speed synchronous mode for interconnecting two STx7101 devices

_ External microprocessor interface (EMPI)

_ 32-bit MPX satellite, target-only interface,

_ synchronous operation at MPX clock speed, capable of 100 MHz,

_ Dual local memory interface (LMI)

_ dual interface (2 x 32-bit) for DDR1 200-MHz (DDR400) memories,

supports 128-, 256- and 512-Mbit devices

_ USB 2.0 host controller/PHY interface

_ Serial ATA hard-disk drive support

_ record and playback with trick modes

_ pause and time shifting, watch and record

_ 100BT Ethernet controller, MAC and MII/RMII

_ On-chip peripherals

_ 4 ASCs (UARTs) with Tx and Rx FIFOS, two of which can be used in smartcard interfaces

_ 2 smartcard interfaces and clock generators (improved to reduce external circuitry)

_ 3 SSCs for I²C/SPI master slaves interfaces

_ serial communications interface (SCIF)

_ 2 PWM outputs

_ teletext serializer and DMA module

_ 6 banks of general purpose I/O, 3.3 V tolerant

_ SiLabs line-side (DAA) interface

_ modem analog front end (MAFE) interface

_ infrared transmitter/receiver supporting RC5, RC6 and RECS80 codes

Page 37

_ UHF remote receiver input interface

_ interrupt level controller and external interrupts, 3.3 V tolerant

_ low power/RTC/watchdog controller

_ integrated VCXO

_ DiSEqC 2.0 interface

_ PWM capture/compare functions

_ Flexible multi-channel DMA Services and package

_ JTAG/TAP interface, ST40 toolset support, ST231 toolset support

_ Package

_ 35 x 35 PBGA, 580 + 100 balls (standard version)

6.3 Absolute Maximum Ratings

I/O specifications 3.3 volt pads

Page 38

I/O specifications 2.5 volt pads

DVB-T DEMODULATOR – STV0362

8.1 General Description

The STv0362 is a single-chip demodulator using coded orthogonal frequency division

multiplexing (COFDM) and is intended for digital terrestrial receivers using compressed

video, sound and data services. It converts IF or baseband differential signals to MPEG-2

format by processing OFDM carriers.

The STv0362 is fully compliant with the DVB-T specification (ETS 300 744) and NorDig

Unified specification. The chip implements all the functions to convert the signals from the

IF or direct conversion tuner, to produce the MPEG-2 transport stream output; in terms of

IF tuner configuration, the chip is compatible with the popular STV0360/STV0361. The

STv0362 offers improved performance over the STV0360 with respect to:

channel estimation and correction,

an extended CRL frequency and TRL timing offset,

additional features such as:

o synchronization for echo outside GI,

o impulse noise rejection,

o PLL allowing 4 MHz quartz usage.

The STv0362 processes 2, 4 and 8 K modes and integrates two A/D converters capable

of handling up to 64 QAM carriers in a direct IF or zero IF sampling architecture. This

eliminates the need for an external downconverter. A 12-bit ADC, intended for RF signal

strength indication, eliminates the need for external components when using wide-band

AGC tuners. In addition to the demodulation and forward error correction (FEC) functions

required for recovery of the QAM modulated bit streams with very low BER, the chip also

includes several features that give easy and immediate access to various quality

monitoring parameters or lock status. The STv0362 also provides delayed AGC and a

noise-free I2C bus dedicated to tuner control, which facilitate the design of high quality

integrated receiver decoders. The STv0362 outputs an error-corrected MPEG-2 transport

stream that complies with the DVB common interface format with programmable data

clock frequency.

Page 39

The STv0362 features the full DVB-T and DVB-H standards framing structure, channel

coding and modulation. The symbol, timing and carrier recovery loops are fully digital and

sized with regard to the state-of-the-art RF down-converting devices.

The STv0362 is compatible with direct conversion tuners featuring two differential ADC for

I and Q channels. The tuner baseband power is controlled by a classic AGC loop, and the

radio frequency level is monitored by a dedicated single-ended 8-bit ADC. It is

recommended the RF power is left under the tuner’s control, but it can be derived from

baseband power by a dedicated power split algorithm. If required, the tuner serial I2C bus

can be isolated by the STv0362 I2C bus repeater.

The terrestrial DVB-T network can be subjected to several interference sources which are

the neighboring digital and analog channels, as well as the in-band analog channels. The

STv0362 cancels these interference sources as well removing the effects of impulse

noise. The channel equalization is capable of static and dynamic echo cancelling even in

severe urban environments. The embedded algorithms are enhanced to cope with out-ofguard interval echoes; specific channel quality monitoring is available for acquisition and

survey. The specific power handling constraints are primarily addressed by both

technology and clock rate management. The efficiency of channel acquisition and reacquisition, minimizes power consumption.

Page 40

8.2 Features

Compatible with direct conversion (ZIF) and IF tuners

o Wide range carrier tracking loop for offset recovery

o Dual analog to digital conversion for IQ baseband interface

o Signal strength indicator dedicated ADC

o Dual ΣΔ digital split AGC for RF and BB

o Flexible clock generation to operate with 4 MHz to 27 MHz external reference

Channel management

o NorDig Unified Specification (v1.0.2) capable

o Dynamic fading compatible

o Urban environment compatible

o Channel reception quality indicator

o Out of guard interval echoes compatible

o Impulsive noise rejection capable

o Outstanding adjacent and co-channel rejection capability with integrated

channel filters

Digital carrier, timing and symbol recovery loops

Decoding

o 2K, 4K, 8K FFT length

o 6, 7 and 8 MHz channels bandwidth

o 1/4, 1/8, 1/16, 1/32 guard interval length

o QPSK - 16 QAM - 64 QAM modulations

o Hierarchical capability

o TPS decoding

o Viterbi soft decoder rate 1/2

o Puncture rates are 1/2, 2/3, 3/4, 5/6, 7/8

o Outer Reed-Solomon decoder as per DVB-T system

o Energy dispersal descrambler

Technology

o Low power CMOS process (90nm)

o Multi supply: 1.0 V core, 2.5 V analog, 3.3 V digital interface

o TQFP64 7x7x1.0 mm

o Power consumption: 350 mW (typ),

o Standby < 80 mW

Page 41

Data to transport decoder

o DVB common interface compliant

o 12-bit parallel and 5-bit serial data interface with data on D7

(packet error private line)

o Automatic regulation of the transport bit

o rate with regard to transport clock

o Up to 33 Mbit/s payload data rate

I2C serial bus interface

o Fast I2C up to 400 kHz slave interface

o Four possible slave addresses

o Up to 400 kbit/s private repeater for tuner isolation

GPIOs and interruption line

o Lock indicators: AGC, symbol, TPS, VITERBI-decoder and transport

synchronization

o ΣΔ analog and logical levels generation

Monitoring through I2C serial interface

o C/N estimator

o Constellation and frequency response display

o BER and PER estimator

8.3 Absolute Maximum Rating

Page 42

Page 43

8.4 Pinning

Page 44

DVB-C DEMODULATOR – STV0297E

7.1 General Desription

The STV0297E is a complete single-chip QAM (quadrature amplitude modulation)

demodulation and FEC (forward error correction) solution that performs sampled IF to

transport stream (MPEG-2 or MPEG-4) block processing of QAM signals. It is intended for

the digital transmission of compressed television, sound, and data services over cable. It

is fully compliant with ITU-T J83 Annexes A/C or DVB-C specification bitstreams (ETS

300 429, “Digital broadcasting systems for television, sound and data services – Framing

structure, channel coding and modulation - Cable Systems”). It can handle square (16,

64, 256-QAM) and non-square (32, 128-QAM) constellations. Japanese DBS systems

require a transport stream multiplex frame (TSMF) layer to carry digital signals over cable

systems. When the recovered transport stream is a multiplex frame, the STV0297E postprocesses it to extract a single transport stream. Automatic detection of the TSMF layer is

provided. The chip integrates an analog-to-digital converter that delivers the required

performance to handle up to 256-QAM signals in a direct IF sampling architecture, thus

eliminating the need for external downconversion.

7.2 Features

Decodes ITU-T J.83-Annexes A/C and DVB-C bit streams

Processes Japanese transport stream multiplex frame (TSMF)

High-performance integrated A/D converter suitable for direct IF architecture in all

QAM (quadrature amplitude modulation) modes

Supports 16, 32, 64, 128 and 256 point constellations

Small footprint package: (10 x 10 mm²)

Very low power consumption

Full digital demodulation

Variable symbol rates

Front derotator for better low symbol rate performance and relaxed tuner

constraints

Integrated matched filtering

Robust integrated adaptive pre and post equalizer

On-chip FEC A/C with ability to bypass individual blocks

10 programmable GPIO

Two AGC outputs suitable for delayed AGC applications (sigma-delta outputs)

Integrated signal quality monitors, plus lock indicator and interrupt function mapped

to GPIO pin

Improved signal acquisition

System clock generated on-chip from quartz crystal

Low frequency crystal operations 4, 16, 25 - 30 MHz

4 I2C addresses

Easy control and monitoring via 2-wire fast I2C bus

Page 45

7.3 Absolute Maximum Ratings

7.4 Pinning

Page 46

STE100P Ethernet PHY

7.5 General Description

The STE100P, also referred to as STEPHY1, is a high performance Fast Ethernet

physical layer interface for 10Base-T and 100Base-TX applications. It was designed with

advanced CMOS technology to provide a Media Independent Interface (MII) for easy

attachment to 10/100 Media Access Controllers (MAC) and a physical media interface for

100Base-TX of IEEE802.3u and 10Base-T of IEEE802.3.

The STEPHY1 supports both half-duplex and fullduplex operation, at 10 and 100 Mbps

operation. Its operating mode can be set using auto-negotiation, parallel detection or

manual control. It also allows for the support of auto-negotiation functions for speed and

duplex detection.

7.6 Features

- IEEE802.3u 100Base-TX and IEEE802.3 10Base-T compliant

- Support for IEEE802.3x flow control

- IEEE802.3u Auto-Negotiation support for 10Base-T and 100Base-TX

- MII interface

- Standard CSMA/CD or full duplex operation supported

- Integrates the whole Physical layer functions of 100Base-TX and 10Base-T

Page 47

- Provides Full-duplex operation on both 100Mbps and 10Mbps modes

- Provides Auto-negotiation(NWAY) function of full/half duplex operation for both 10 and 100

Mbps

- Provides MLT-3 transceiver with DC restoration for Base-line wander compensation

- Provides transmit wave-shaper, receive filters, and adaptive equalizer

- Provides loop-back modes for diagnostic

- Builds in Stream Cipher Scrambler/ De-scrambler and 4B/5B encoder/decoder

- Supports external transmit transformer with turn ratio 1:1

- Supports external receive transformer with turn ratio 1:1

- Standard 64-pin QFP package pinout

7.7 Absolute Maximum Ratings

12.4 Pinning

Page 48

Page 49

Page 50

8 SAW FILTER

8.1 IF Filter for Audio Applications – Epcos K9656M

8.1.1 Standart:

B/G

D/K

I

L/L’

8.1.2 Features:

TV IF audio filter with two channels

Channel 1 (L’) with one pass band for sound carriers at 40,40 MHz (L’) and 39,75

MHz (L’- NICAM)

Page 51

Channel 2 (B/G,D/K,L,I) with one pass band for sound carriers between 32,35 MHz

and 33,40 MHz

8.1.3 Pin configuration:

1 Input

2 Switching input

3 Chip carrier - ground

4 Output

5 Output

8.1.4 Frequency response:

Page 52

8.2 IF Filter for Video Applications – Epcos K3958M

8.2.1 Standart:

B/G

D/K

I

L/L’

8.2.2 Features:

TV IF filter with Nyquist slopes at 33.90 MHz and 38.90 MHz

Constant group delay

Pin configuration:

1 Input

2 Input - ground

3 Chip - carrier ground

4 Output

5 Output

Page 53

8.2.3 Frequency response:

Page 54

IC DESCRIPTIONS

8.3 LM1117

8.3.1 General Description

The LM1117 is a series of low dropout voltage regulators with a dropout of 1.2V at 800mA

of load current. It has the same pin-out as National Semiconductor’s industry standard

LM317. The LM1117 is available in an adjustable version, which can set the output

voltage from 1.25V to 13.8V with only two external resistors. In addition, it is also

available in five fixed voltages, 1.8V, 2.5V, 2.85V, 3.3V, and 5V. The LM1117 offers

current limiting and thermal shutdown. Its circuit includes a zener trimmed bandgap

reference to as-sure output voltage accuracy to within ±1%. The LM1117 series is

available in SOT- 223, TO-220, and TO-252 Dtantalum capacitor is required at the output to improve the transient response and

stability.

8.3.2 Features

Available in 1.8V, 2.5V, 2.85V, 3.3V, 5V, and Adjustable Versions

Space Saving SOT-223 Package

Current Limiting and Thermal Protection

Output Current 800mA

Line Regulation 0.2% (Max)

Load Regulation 0.4% (Max)

Temperature Range

LM1117 0°C to 125°C

LM1117I -40°C to 125°C

PAK packages. A minimum of 10μF

8.3.3 Applications

2.85V Model for SCSI-2 Active Termination

Post Regulator for Switching DC/DC Converter

High Efficiency Linear Regulators 15

32” TFT TV Service Manual 10/01/2005

Battery Charger

Battery Powered Instrumentation

8.3.4 Absolute Maximum Ratings

Page 55

8.3.5 Pinning

8.4 74HCT4053

8.4.1 General Description

The 74HC4053; 74HCT4053 is a high-speed Si-gate CMOS device and is pin compatible

with the HEF4053B. It is specified in compliance with JEDEC standard no. 7A. The

74HC4053; 74HCT4053 is triple 2-channel analog multiplexer/demultiplexer with a

common enable input (E). Each multiplexer/demultiplexer has two independent

inputs/outputs (nY0 and nY1), a common input/output (nZ) and three digital select inputs

(Sn). With E LOW, one of the two switches is selected (low-impedance ON-state) by S1 to

S3. With E HIGH, all switches are in the high-impedance OFF-state, independent of S1 to

S3. VCC and GND are the supply voltage pins for the digital control inputs (S1 to S3 and

E). The VCC to GND ranges are 2.0 V to 10.0 V for 74HC4053 and 4.5 V to 5.5 V for

74HCT4053. The analog inputs/outputs (nY0 and nY1, and nZ) can swing between VCC

as a positive limit and VEE as a negative limit. VCC - VEE may not exceed 10.0 V.

For operation as a digital multiplexer/demultiplexer, VEE is connected to GND (typically

ground).

8.4.2 Features

Low ON resistance:

80 W (typical) at VCC - VEE = 4.5 V

70 W (typical) at VCC - VEE = 6.0 V

60 W (typical) at VCC - VEE = 9.0 V

Logic level translation:

To enable 5 V logic to communicate with ±5 V analog signals

Typical ‘break before make’ built in

Complies with JEDEC standard no. 7A

ESD protection: HBM EIA/JESD22-A114-C exceeds 2000 V, MM EIA/JESD22-

A115-A exceeds 200 V

Multiple package options

Specified from -40 °C to +85 °C and from -40 °C to +125 °C

8.4.3 Applications

Analog multiplexing and demultiplexing

Digital multiplexing and demultiplexing

Signal gating

Page 56

8.4.4 Absolute Maximum Ratings

8.4.5 Pinning

8.5 NUP4004M5

8.5.1 General Description

This 5-Pin bi-directional transient suppressor array is designed for applications requiring

transient overvoltage protection capability. It is intended for use in transient voltage and

Page 57

ESD sensitive equipment such as computers, printers, cell phones, medical equipment,

and other applications. Its integrated design provides bi-directional protection for four

separate lines using a single TSOP-5 package. This device is ideal for situations where

board space is a premium.

8.5.2 Features

Bi-directional Protection for Four Lines in a Single TSOP-5 Package

Low Leakage Current

Low Capacitance

Provides ESD Protection for JEDEC Standards JESD22

Machine Model = Class C

Human Body Model = Class 3B

Provides ESD Protection for IEC 61000-4-2, 15 kV (Air), 8 kV (Contact)

This is a Pb-Free Device

8.5.3 Absolute Maximum Ratings

8.5.4 Pinning

Page 58

8.6 FDN336P

8.6.1 General Description

The ST24LC21 is a 1K bit electrically erasable programmable memory (EEPROM),

organized by 8 bits.This device can operate in two modes: Transmit Only mode and I2C

bidirectional mode. When powered, the device is in Transmit Only mode with EEPROM

data clocked out from the rising edge of the signal applied on VCLK. The device will

switch to the I2C bidirectional mode upon the falling edge of the signal applied on SCL

pin. The ST24LC21 cannot switch from the I2C bidirectional mode to the Transmit Only

mode (except when the power supply is removed). The device operates with a power

supply value as low as 2.5V. Both Plastic Dual-in-Line and Plastic Small Outline packages

are available.

8.6.2 Features

1 MILLION ERASE/WRITE CYCLES

40 YEARS DATA RETENTION

2.5V to 5.5V SINGLE SUPPLY VOLTAGE

400k Hz COMPATIBILITY OVER the FULL RANGE of SUPPLY VOLTAGE

TWO WIRE SERIAL INTERFACE I2C BUS COMPATIBLE

PAGE WRITE (up to 8 BYTES)

BYTE, RANDOM and SEQUENTIAL READ MODES

SELF TIMED PROGRAMMING CYCLE

AUTOMATIC ADDRESS INCREMENTING

ENHANCED ESD/LATCH UP PERFORMANCES

8.6.3 Absolute Maximum Ratings

8.6.4 Pinning

Page 59

8.7 TL062 -

8.7.1 General Description

Low-power JFET-input operational amplifier

8.7.2 Features

Very Low Power Consumption

Typical Supply Current . . . 200 µA (Per Amplifier)

Wide Common-Mode and Differential Voltage Ranges

Low Input Bias and Offset Currents

Common-Mode Input Voltage Range Includes VCC+

Output Short-Circuit Protection

High Input Impedance . . . JFET-Input Stage

Internal Frequency Compensation

Latch-Up-Free Operation

High Slew Rate . . . 3.5 V/µs Typ

8.7.3 Absolute Maximum Ratings

Page 60

8.7.4 Pinning

8.8 PI5V330

8.8.1 General Description

Pericom Semiconductor.s PI5V series of mixed signal video circuits are produced in the

Company.s advanced CMOS low-power technology, achieving industry leading

performance. The PI5V330 is a true bidirectional Quad 2-channel

multiplexer/demultiplexer that is recommended for both RGB and composite video

switching applications. The VideoSwitch. can be driven from a current output RAMDAC or

voltage output composite video source. Low ON-resistance and wide bandwidth make it

ideal for video and other applications. Also this device has exceptionally high current

capability which is far greater than most analog switches offered today. A single 5V

supply is all that is required for operation. The PI5V330 offers a high-performance, lowcost solution to switch between video sources. The application section describes the

PI5V330 replacing the HC4053 multiplier and buffer/amplifier.

8.8.2 Features

High-performance, low-cost solution to switch between video sources

Wide bandwidth: 200 MHz

Low ON-resistance: 3Ω

Low crosstalk at 10 MHz: .58 dB

Ultra-low quiescent power (0.1 µA typical)

Single supply operation: +5.0V

Fast switching: 10 ns

High-current output: 100 mA

Packages available:

16-pin 300-mil wide plastic SOIC (S)

16-pin 150-mil wide plastic SOIC (W)

16-pin 150-mil wide plastic QSOP (Q)

8.8.3 Absolute Maximum Ratings

Page 61

8.8.4 Pinning

8.9 AZC099-04S

8.9.1 General Description

AZC099-04S is a high performance and low cost design which includes surge rated diode

arrays to protect high speed data interfaces. The AZC099-04S family has been

specifically designed to protect sensitive components, which are connected to data and

transmission lines, from over-voltage caused by Electrostatic Discharging (ESD),

Electrical Fast Transients (EFT), and Lightning.

AZC099-04S is a unique design which includes surge rated, low capacitance steering

diodes and a unique design of clamping cell which is an equivalent TVS diode in a single

package. During transient conditions, the steering diodes direct the transient to either the

power supply line or to the ground line. The internal unique design of clamping cell

prevents over-voltage on the power line, protecting any downstream components.

AZC099-04S may be used to meet the ESD immunity requirements of IEC 61000-4-2,

Level 4 (± 15kV air, ±8kV contact discharge).

8.9.2 Features

ESD Protect for 4 high-speed I/O channels

Provide ESD protection for each channel to IEC 61000-4-2 (ESD) ±15kV (air),

±8kV (contact) IEC 61000-4-4 (EFT) (5/50ns) Level-3, 20A for I/O, 40A for Power

IEC 61000-4-5 (Lightning) 4A (8/20

5V operating voltage Low capacitance : 1.0pF typical

Fast turn-on and Low clamping voltage

Array of surge rated diodes with internal equivalent TVS diode

Small package saves board space

Solid-state silicon-avalanche and active circuit triggering technology

μs)

Page 62

8.9.3 Absolute Maximum Ratings

8.9.4 Pinning

8.10 TDA1308

8.10.1 General Description

The TDA1308; TDA1308A is an integrated class-AB stereo headphone driver contained in

an SO8, DIP8 or a TSSOP8 plastic package. The TDA1308AUK is available in an 8 bump

wafer level chip-size package (WLCSP8). The device is fabricated in a 1 mm

Complementary Metal Oxide Semiconductor (CMOS) process and has been primarily

developed for portable digital audio applications. The difference between the TDA1308

and the TDA1308A is that the TDA1308A can be used at low supply voltages.

8.10.2 Features

Wide temperature range

No switch ON/OFF clicks

Excellent power supply ripple rejection

Low power consumption

Short-circuit resistant

High performance

High signal-to-noise ratio

Page 63

High slew rate

Low distortion

Large output voltage swing

8.10.3 Absolute Maximum Ratings

8.10.4 Pinning

8.11 LM358D

8.11.1 General Description

The LM158 series consists of two independent, high gain, internally frequency

compensated operational amplifiers which were designed specifically to operate from a

single power supply over a wide range of voltages. Operation from split power supplies is

also possible and the low power supply current drain is independent of the magnitude of

the power supply voltage. Application areas include transducer amplifiers, dc gain blocks

and all the conventional op amp circuits which now can be more easily implemented in

single power supply systems. For example, the LM158 series can be directly operated off

of the standard +5V power supply voltage which is used in digital systems and will easily

provide the required interface electronics without requiring the additional ±15V power

supplies. The LM358 and LM2904 are available in a chip sized package (8-Bump micro

SMD) using National’s micro SMD package technology.

8.11.2 Features

Available in 8-Bump micro SMD chip sized package,

Internally frequency compensated for unity gain

Large dc voltage gain: 100 dB

Wide bandwidth (unity gain): 1 MHz (temperature compensated)

Wide power supply: Single supply: 3V to 32V or dual supplies: ±1.5V to ±16V

Page 64

Low supply current drain (500 µA)—essentially independent of supply voltage

Low input offset voltage: 2 mV

Input common-mode voltage range includes ground

Differential input voltage range equal to the power supply voltage

Large output voltage swing

8.11.3 Absolute Maximum Ratings

8.11.4 Pinning

8.12 74LCX244

8.12.1 General Description

The LCX244 contains eight non-inverting buffers with 3-STATE outputs. The device may

be employed as a memory address driver, clock driver and bus-oriented

Page 65

transmitter/receiver. The LCX244 is designed for low voltage (2.5V or 3.3V) VCC

applications with capability of interfacing to a 5V signal environment. The LCX244 is

fabricated with an advanced CMOS technology to achieve high speed operation while

maintaining CMOS low power dissipation.

8.12.2 Features

5V tolerant inputs and outputs

2.3V to 3.6V VCC specifications provided

6.5ns Tpd max. (VCC=3.3V), 10µA ICCmax.

Power down high impedance inputs and outputs

Supports live insertion/withdrawal

±24mA output drive (VCC=3.0V)

Implements patented noise/EMI reduction circuitry

Latch-up performance exceeds 500mA

ESD performance:Human body model>2000V, Machine model>200V

Leadless DQFN package

8.12.3 Absolute Maximum Ratings

Page 66

8.12.4 Pinning

8.13 74LCX245

8.13.1 General Description

The LCX245 contains eight non-inverting bidirectional buffers with 3-STATE outputs and

is intended for bus oriented applications. The device is designed for low voltage (2.5V and

3.3V) VCC applications with capability of interfacing to a 5V signal environment. The T/R

input determines the direction of data flow through the device. The OE input disables both

the A and B ports by placing them in a high impedance state.

The LCX245 is fabricated with an advanced CMOS technology to achieve high speed

operation while maintaining CMOS low power dissipation.

8.13.2 Features

5V tolerant inputs and outputs

2.3V to 3.6V VCC specifications provided

7.0ns tPDmax. (VCC=3.3V), 10µA ICCmax.

Power down high impedance inputs and outputs

Supports live insertion/withdrawal

±24mA output drive (VCC=3.0V)

Implements patented noise/EMI reduction circuitry

Latch-up performance exceeds 500mA

ESD performance: Human body model>2000V, Machine model>200V

Leadless DQFN package

Page 67

8.13.3 Absolute Maximum Ratings

8.13.4 Pinning

8.14 FSA3157

8.14.1 General Description

The NC7SB3157 / FSA3157 is a high-performance, single- pole / double-throw (SPDT)

analog switch or 2:1 multiplexer/ de-multiplexer bus switch. The device is fabricated with

advanced sub-micron CMOS technology to achieve high-speed enable and disable times

and low on resistance. The break-beforemake select circuitry prevents disruption of

signals on the B Port due to both switches temporarily being enabled during select pin

Page 68

switching. The device is specified to operate over the 1.65 to 5.5V VCC operating range.

The control input tolerates voltages up to 5.5V, independent of the VCC operating range.

8.14.2 Features

Useful in both analog and digital applications

Space-saving, SC70 6-lead surface mount package

Ultra-small, MicroPak™ Pb-free leadless package

Low On Resistance: <10Ω on typical at 3.3V VCC

Broad VCC operating range: 1.65V to 5.5V

Rail-to-rail signal handling

Power-down, high-impedance control input

Over-voltage tolerance of control input to 7.0V

Break-before-make enable circuitry

250 MHz, 3dB bandwidth

8.14.3 Absolute Maximum Ratings

8.14.4 Pinning

Page 69

8.15 TSH343

8.15.1 General Description

The TSH343 is a triple single-supply video buffer featuring an internal gain of 6dB and a

large bandwidth of 280MHz. The main advantage of this circuit is that its input DC level

shifter allows for video signals on 75

tip of the video signal, while using a single 5V power supply with no input capacitor. The

DC level shifter is internally fixed and optimized to keep the output video signals between

low and high output rails in the best position for the greatest linearity. Chapter 4 of this

datasheet gives technical support when using the TSH343 as Y-Pb-Pr driver for video

DAC output on a video line (see TSH344 for RGB signals). The TSH343 is available in

the compact SO8 plastic package for optimum space-saving.

Ω video lines without damage to the synchronization

8.15.2 Features

Bandwidth: 280MHz

5V single-supply operation

Internal input DC level shifter

No input capacitor required

Internal gain of 6dB for a matching between 3 channels

AC or DC output-coupled

Very low harmonic distortion

Slew rate: 780V/μs

Specified for 150Ω and 100Ω loads

Tested on 5V power supply

Data min. and max. are tested during production

8.15.3 Absolute Maximum Ratings

Page 70

8.15.4 Pinning

8.16 MT48LC4M16A2TG8E

8.16.1 General Description

The 64Mb SDRAM is a high-speed CMOS, dynamic random-access memory containing

67,108,864 bits. It is internally configured as a quad-bank DRAM with a synchronous

interface (all signals are registered on the positive edge of the clock signal, CLK). Each of

the x4’s 16,777,216-bit banks is organized as 4,096 rows by 1,024 columns by 4 bits.

Each of the x8’s 16,777,216-bit banks is organized as 4,096 rows by 512 columns by 8

bits. Each of the x16’s 16,777,216-bit banks is organized as 4,096 rows by 256 columns

by 16 bits. Read and write accesses to the SDRAM are burst oriented; accesses start at a

selected location and continue for a programmed number of locations in a programmed

sequence. Accesses begin with the registration of an ACTIVE command, which is then

ollowed by a READ or WRITE command. The address bits registered coincident with the

ACTIVE command are used to select the bank and row to be accessed (BA0, BA1 select

the bank; A0-A11 select the row).

8.16.2 Features

PC66-, PC100- and PC133-compliant

143 MHz, graphical 4 Meg x 16 option