Sanwa Electronic Instrument Co 90408 Users Manual

Page 2

Packaging

The packaging of your Airtronics TM-160 2.4GHz FHSS-1 radio control system has been specially designed for the safe

transportation and storage of the radio control system's components. After unpacking your radio control system, do not discard

the packaging materials. Save the packaging materials for future use if you ever need to send your radio control system to us

for service, or to store your radio control system if you don't plan on using it for an extended period of time.

TaBLE OF cOnTEnTS

Introduction......................................................................................................................................................................... Page 3

Additional Receiver Information ................................................................................................................................. Page 3

Transmitter Signal Range ............................................................................................................................................ Page 3

FCC Compliance Statement ........................................................................................................................................ Page 3

Safety and Usage Precautions.......................................................................................................................................... Page 4

General Safety .............................................................................................................................................................. Page 4

2.4GHz Frequency Band Precautions......................................................................................................................... Page 4

Transmitter Precautions .............................................................................................................................................. Page 4

Receiver Precautions ................................................................................................................................................... Page 5

AMA Information........................................................................................................................................................... Page 5

Features and Specications.............................................................................................................................................. Page 6

General System Features ............................................................................................................................................ Page 6

Aircraft-Specic Features............................................................................................................................................ Page 6

Helicopter-Specic Features ....................................................................................................................................... Page 6

System Specications ................................................................................................................................................. Page 6

Features Familiarization .................................................................................................................................................... Page 7

Transmitter Features Diagrams................................................................................................................................... Page 7

Receiver Features Diagram ......................................................................................................................................... Page 8

Features Descriptions.................................................................................................................................................. Page 8

Servo Connections....................................................................................................................................................... Page 9

Transmitter Alarms....................................................................................................................................................... Page 9

Servo Recommendations .......................................................................................................................................... Page 10

Optional Items............................................................................................................................................................. Page 10

Quick-Start Basic Model Setup ..................................................................................................................................Page 11

Tips and Suggestions .................................................................................................................................................Page 11

System Connections........................................................................................................................................................ Page 13

Transmitter Battery Installation................................................................................................................................. Page 13

Airborne System Connections .................................................................................................................................. Page 13

Transmitter and Receiver Battery Charging ............................................................................................................ Page 14

LCD and Programming Keys........................................................................................................................................... Page 15

Programming Keys Overview and Functions .......................................................................................................... Page 15

Multi-Function LCD Overview.................................................................................................................................... Page 16

System Setup Installation................................................................................................................................................ Page 17

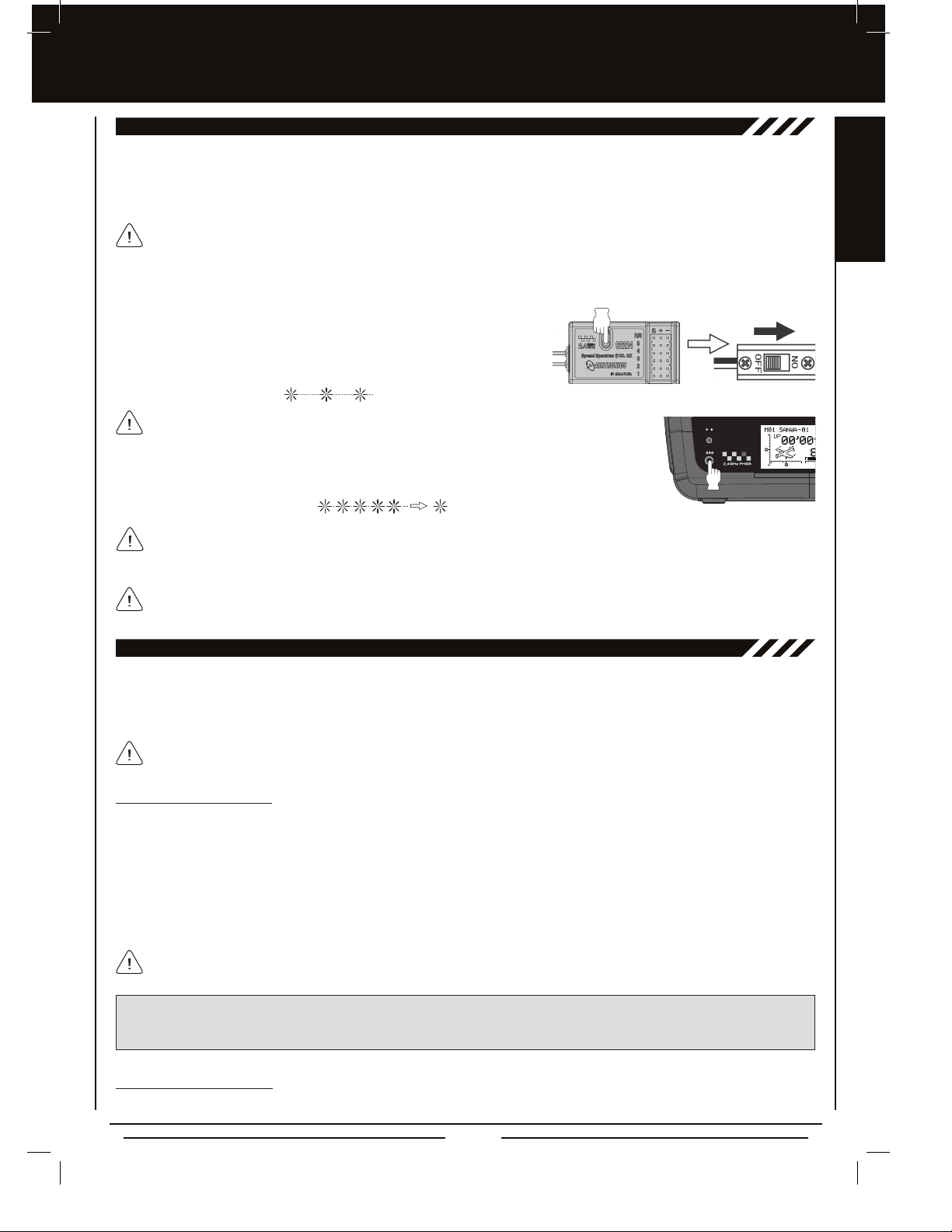

Transmitter and Receiver Binding ............................................................................................................................ Page 17

Fail Safe Programming .............................................................................................................................................. Page 17

Mounting the Receiver ............................................................................................................................................... Page 18

Range Checking - Low-Power Mode......................................................................................................................... Page 19

Control Stick Length Adjustment.............................................................................................................................. Page 19

Flight Modes ..................................................................................................................................................................... Page 20

General Information ................................................................................................................................................... Page 20

Flight Mode Warning Alarm....................................................................................................................................... Page 20

Aero Model Type Contents.............................................................................................................................................. Page 21

Aero Model Type - All Programming............................................................................................................................... Page 22

Heli Model Type Contents................................................................................................................................................ Page 51

Heli Model Type - All Programming................................................................................................................................ Page 52

Reference .......................................................................................................................................................................... Page 81

Troubleshooting Guide .............................................................................................................................................. Page 81

Glossary of Terms ...................................................................................................................................................... Page 82

Index ............................................................................................................................................................................ Page 85

Setup Sheets..................................................................................................................................................................... Page 90

Service Information.................................................................................................................................................... Back Cover

Page 3

Due to differences in the implementation of 2.4GHz technology among different manufacturers, only Airtronics brand

2.4GHz FHSS-1 aircraft receivers are compatible with your radio control system.

inTRODUcTiOn

Fcc cOMPLiancE STaTEMEnT

aDDiTiOnaL REcEivER inFORMaTiOn

Additional Airtronics 2.4GHz FHSS-1 aircraft receivers can be purchased and paired with the TM-160 transmitter through the

Binding procedure. For more information about the current receivers available, please visit your local Airtronics dealer or our

website at http://www.airtronics.net.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the operating

instructions, may cause harmful interference to radio communications, however, there is no guarantee that interference will not

occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

l

Reorient or relocate the receiving antenna.

l

Increase the separation between the equipment and the receiver.

l

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

l

Consult the dealer or an experienced technician for help.

This device complies with Part 15 of the FCC Rules and with RSS-210 of Industry Canada. Operation is subject to the following

two conditions:

1) This device may not cause harmful interference, and....

2) This device must accept any interference received, including interference that may cause undesired operation.

WARNING: Changes or modications made to this equipment not expressly approved by Airtronics may void the FCC authorization

to operate this equipment.

RF Exposure Statement

The TM-160 transmitter has been tested and meets the FCC RF exposure guidelines when used with the Airtronics accessories

supplied or designated for this product, and provided at least 20cm separation between the antenna the user's body is

maintained. Use of other accessories may not ensure compliance with FCC RF exposure guidelines.

We appreciate your purchase of the Airtronics TM-160 2.4GHz FHSS-1 radio control system. This Operating Manual is intended

to acquaint you with the many unique features of your new radio control system. In designing the TM-160 2.4GHz FHSS-1 radio

control system, our engineers listened to input from our test-pilots and feedback from our users to design a radio control system

that will allow you to extract the maximum performance from your model, while at the same time making the programming

process as easy as possible to accomplish.

Because the TM-160 2.4GHz FHSS-1 radio control system is advanced and is packed with many features for aircraft and helicopter

models, this Operating Manual is quite long. Don't be intimidated! This Operating Manual is laid out in such a way as to make it

as easy as possible to nd, understand, and learn to use the features you require. Please read this Operating Manual carefully

so that you may obtain maximum success and enjoyment from the operation of your new radio control system. This radio control

system has been designed for the utmost in comfort and precise control of your aircraft and helicopter models. We wish you the

best of success and fun with your new purchase.

An index is provided in the back of this Operating Manual to make it easy to nd the information that you're looking for.

Keep this Operating Manual in a safe place with your TM-160 transmitter so that you can use it as a reference book for any

questions you might have regarding your radio control system.

This is a high-output full-range radio control system that should well exceed the range needed for any model. For safety, the

user should perform a range check at the area of operation to ensure that the radio control system has complete control of the

model at the farthest reaches of the operational area. A range check can be accomplished using Low-Power Mode. For more

information, see page 19.

TRanSMiTTER SignaL RangE

GENERAL

Page 4

SaFETy anD USagE PREcaUTiOnS

gEnERaL SaFETy

l

Be certain to read this Operating Manual in its entirety.

l

'Safety First' for yourself, for others, and for your equipment.

l

Observe all the rules of the ying site or anywhere you

operate your radio control equipment.

l

If at any time during the operation of your model should

you feel or observe erratic operation or abnormality, end

your operation as quickly and safely as possible. DO NOT

operate your model again until you are certain the problem

has been corrected. TAKE NO CHANCES.

l

Your model can cause serious damage or injury, so please

use caution and courtesy at all times.

l

Do not expose the radio control system to water or excessive

moisture.

l

Please waterproof the receiver and servos by placing them

in a water-tight radio box when operating model boats.

l

If you have little to no experience operating models, we

strongly recommend you seek the assistance of experienced

modelers or your local hobby shop for guidance.

l

The low voltage alarm will sound when the transmitter

battery voltage drops to 6.7 volts. If this occurs, stop

using the transmitter as soon as possible, then replace or

recharge the transmitter batteries.

TRanSMiTTER PREcaUTiOnS

l

Turn the transmitter ON rst, then turn the receiver ON. After using your model, turn the receiver OFF

rst, then turn the transmitter OFF. It can be dangerous if you activate the components in reverse order

as the servos may start up inadvertently.

l

Before use, double-check that the transmitter and receiver batteries have sufcient power and/or are

sufciently charged (if using Ni-Cd/Ni-MH batteries).

l

Never touch the transmitter antenna during use. Doing so may cause loss of transmitter output, making

it impossible to control your model.

l

The transmitter antenna should be rotated and angled so that the antenna is

as close to perpendicular to the ground as

possible during use. After use, to prevent

any chance of damaging the antenna, the

antenna should be rotated and moved into

the horizontal stowed position.

l

Do not expose the transmitter to excessive heat, moisture, fuel, exhaust residue, etc.

l

Do not expose the transmitter to excessive heat or direct sunlight. Leaving the transmitter in direct sunlight can damage the LCD.

l

Do not press the Bind Button during use. The signal is interrupted while the Bind Button is pressed. It may also require a short time

to restore the signal after releasing the Bind Button, which can be dangerous.

ON

OFF

Keep Antenna

Perpendicular

to Ground

Do Not Expose to Moisture

or Direct Sunlight

2.4ghz FREqUEncy BanD PREcaUTiOnS

l

The 2.4GHz frequency band may be used by other devices, and other devices in the immediate area may cause interference

on the same frequency band. Always before use, conduct a bench test to ensure that the servos operate properly. Also,

conduct a range check at the area of operation to ensure that the radio control system has complete control of the model at

the farthest reaches of the operational area.

l

The response speed of the receiver can be affected if used where multiple 2.4GHz transmitters are being used, therefore,

carefully check the area before use. Also, if response seems slow during use, discontinue use as quickly as possible.

l

If the 2.4GHz frequency band is saturated (too many transmitters on at once), as a safety precaution, the radio control system

may not bind. This ensures that your radio control system does not get hit by interference. Once the frequencies have been

cleared, or the saturation level has dropped, your radio control system should be able to bind without any problems.

l

Observe any applicable laws and regulations in place at your ying site when using the 2.4GHz radio control system.

l

Unlike frequency bands used with earlier radio control systems, reception with this 2.4GHz radio control system can be

adversely affected by large obstructions and concrete or steel structures between your model and the transmitter. Also, wire

mesh and similar barriers can adversely affect operation. Keep this mind to ensure the safety of your model.

This radio control system operates on the 2.4GHz frequency band. The 2.4GHz connection is determined by the transmitter

and receiver pair. Unlike ordinary crystal-based systems, your model can be used without frequency control.

Page 5

SaFETy anD USagE PREcaUTiOnS

l

The receiver antenna wires consist of two coaxial cables and two reception wires (the thin tip at the end of the coaxial cables).

When you mount the receiver antenna wires, do not bend the reception wires. Reception performance decreases if the reception

wires are bent.

l

The receiver antenna wires are delicate, therefore, handle with care. Do not pull on the receiver

antenna wires with force. Do not cut or extend the receiver antenna wires.

l

The coaxial cables can be bent into gentle curves, however, do not bend the coaxial cables acutely, or

repeatedly bend them, or the antenna cores can be damaged.

l

When installed in an electric-powered model, keep the receiver antenna wires as far away as possible

from the motor, battery, and electronic speed control (ESC).

l

There is a danger of runaway operation if connectors shake loose during use. Make sure that the receiver, servo(s), and switch

harness connectors are securely tted.

l

The receiver is susceptible to vibration and moisture. Take appropriate measures to

protect against vibration and moisture. The receiver should be wrapped in foam and the

foam should be secured around the receiver to hold it in place. The foam should not be

secured too tightly or the vibration dampening quality will be reduced. Failure to take

appropriate measures could result in damage to the receiver.

l

When installing the receiver, the antenna reception wires (the thin tip at the end of the coaxial cables) should not come into

contact with any carbon or metal components (conductive components). Aircraft fuselages and helicopter frames may contain

conductive components. If mounting the receiver surrounded by conductive materials (for example, a carbon ber fuselage),

mount the receiver so that the antenna reception wires can be extended outside of the model. Reception can be blocked if the

antenna reception wires are shielded inside a carbon ber fuselage.

l

The manufacturer disclaims all responsibility for damages resulting from use of components other than genuine Airtronics

components.

It is extremely important to install the receiver and route the receiver antenna wires correctly in your model. This will ensure

that your model receives control signals no matter what its posture, attitude, or heading. For more information, see page 18.

Wrap Receiver

in Foam to Protect From

Vibration and Damage

REcEivER PREcaUTiOnS

aMa inFORMaTiOn

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

Phone (800) 435-9262

Fax (765) 741-0057

www.modelaircraft.org

The Academy of Model Aeronautics (AMA) is a national organization representing modelers in the United States. We urge you

to examine the benets of membership, including liability protection in the event of certain injuries. The Academy has adopted

simple and sane rules which are especially pertinent for radio controlled ight as the Ofcial AMA National Model Aircraft Safety

Code, which we have partially reprinted below:

l

I will not y my model aircraft in sanctioned events, airshows or model ying demonstrations until it has been proven to be

airworthy by having been previously, successfully ight tested.

l

I will not y my model higher than approximately 400 feet within 3 miles of an airport without notifying the airport operator.

I will give the right-of-way and avoid ying in the proximity of full-scale aircraft. Where necessary, an observer shall be

utilized to supervise ying to avoid having models y in the proximity of full-scale aircraft. Where established, I will abide by

the safety rules for the ying site I use, and I will not willfully and deliberately y my models in a careless, reckless and/or

dangerous manner.

l

I will have completed a successful radio equipment ground range check before the rst ight of a new or repaired model.

l

I will not y my model aircraft in the presence of spectators until I become a qualied yer, unless assisted by an experienced

helper.

l

I will perform my initial turn after takeoff away from the pit or spectator areas, unless beyond my control.

GENERAL

Page 6

l

6-Channel 2.4GHz FHSS-1 Digital Proportional Computer Radio Control System for Aircraft and Helicopters

l

Full-Range 92224 (RX600) 6-Channel 2.4GHz FHSS-1 Receiver

l

6 Cell Battery for Lighter Weight and Better Feel

l

10 Model Memory

l

Direct Model Select (Models 1~3)

l

Easy-to-Read Multi-Function LCD with Digital Voltage Display

l

User-Selectable Model Type Templates

l

Digital Trims

l

Trainer System Compatible with SD-5G and SD-10G Transmitters

l

Model Naming

FEaTURES anD SPEciFicaTiOnS

gEnERaL SySTEM FEaTURES

l

Model Select

l

Audible Low Voltage Alarm

l

Low-Power Range Check Mode

l

Programmable Fail Safe

l

User-Selectable Flight Modes

l

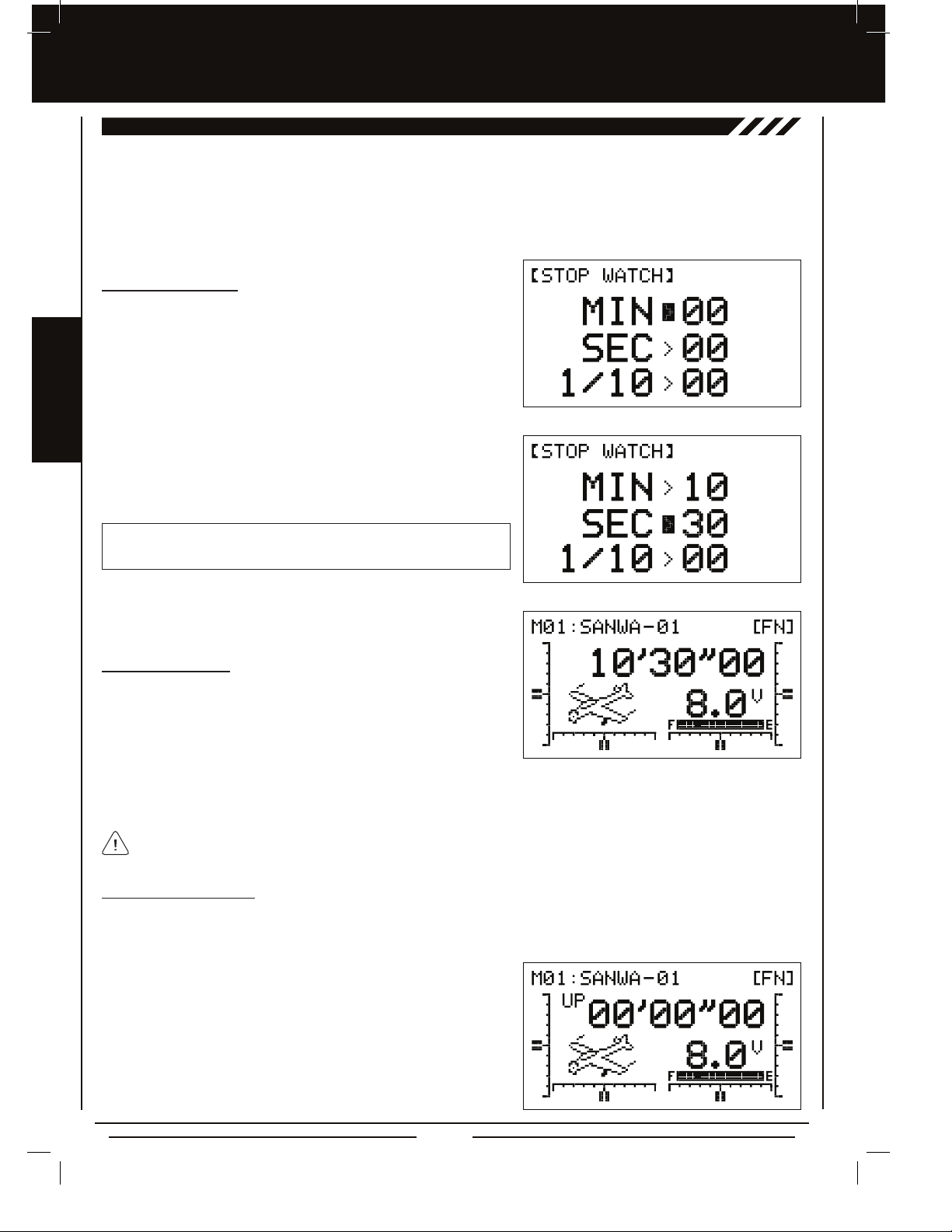

Stop Watch and Count Up Timers

l

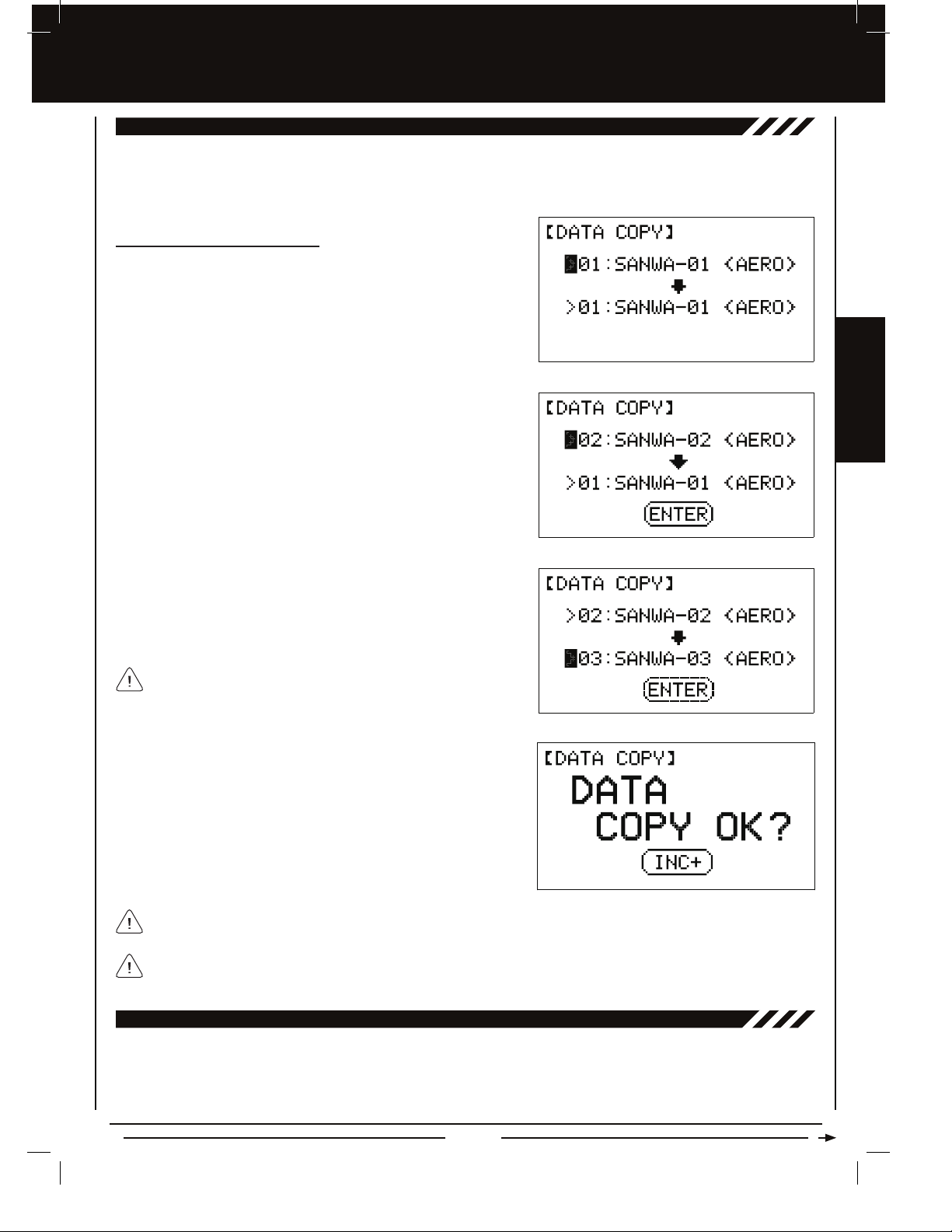

Data Copy and Data Reset

aiRcRaFT-SPEciFic FEaTURES

l

Servo Monitor

l

3 Flight Modes (FN/F1/F2)

l

Aileron, Elevator, and Rudder Dual Rate

l

Aileron, Elevator, and Rudder Exponential

l

Servo Reversing

l

Servo Centering Sub-Trim

l

End Point Adjustment

l

Throttle Cut

l

5-Point Programmable Throttle Curve

l

Aileron Differential

l

Flaperon Mixing

l

Flap to Elevator Mixing

l

Dual Elevator Mixing with End Point Adjustment

l

Ailvator Mixing

l

V-Tail Mixing with End Point Adjustment

l

Delta (Elevon) Mixing with End Point Adjustment

l

2 Programmable Compensation Mixers

l

Common or Flight Mode-Specic Trim with Throttle Trim Lock

hELicOPTER-SPEciFic FEaTURES

l

Servo Monitor

l

3 Flight Modes (FN/F1/F2)

l

9 Preprogrammed Swashplate Templates

l

Aileron, Elevator, and Rudder Dual Rate

l

Aileron, Elevator, and Rudder Exponential

l

Servo Reversing

l

Servo Centering Sub-Trim

l

Advanced Swashplate Adjustment

l

CCPM End Point Adjustment

l

End Point Adjustment

l

Throttle Cut

l

5-Point Programmable Throttle Curve

l

Throttle Hold

l

5-Point Programmable Pitch Curve

l

Revolution Mixing

l

2 Remote Gyro Gains

l

2 Programmable Compensation Mixers

l

Common or Flight Mode-Specic Trim with Throttle Trim Lock

SySTEM SPEciFicaTiOnS

Transmitter

Model: TM-160

Output Power: 100mW

Operating Voltage: 6.7v~9.6v

Current Drain: 130mA~200mA

Temperature Range: 32ºF~122ºF (0ºC~50ºC)

Pulse Width: 0.9msec~2.1msec

Weight with Batteries: 26.45oz (750gr)

Frequency/Modulation Type: 2.4GHz/FHSS-1

Model Memory: 10

Receiver

Model: 92224 (RX600)

Frequency/Modulation Type: 2.4GHz/FHSS-1

Nominal Input Voltage: 4.8v~6.0v

Weight: 0.27oz (7.8gr) with Case

Weight: 0.20oz (5.9gr) without Case

Dimensions: 1.64 x 0.85 x 0.47in (41.7 x 21.5 x 12.0mm)

Fail Safe Support: Yes (CH 1~CH 4)

Connector Type: Universal 'Z'

Page 7

FEaTURES FaMiLiaRizaTiOn

TRanSMiTTER FEaTURES DiagRaMS

Use the diagrams below to familiarize yourself with the basic features of your TM-160 2.4GHz FHSS-1 transmitter. Descriptions

of these features can be found on pages 8 and 9.

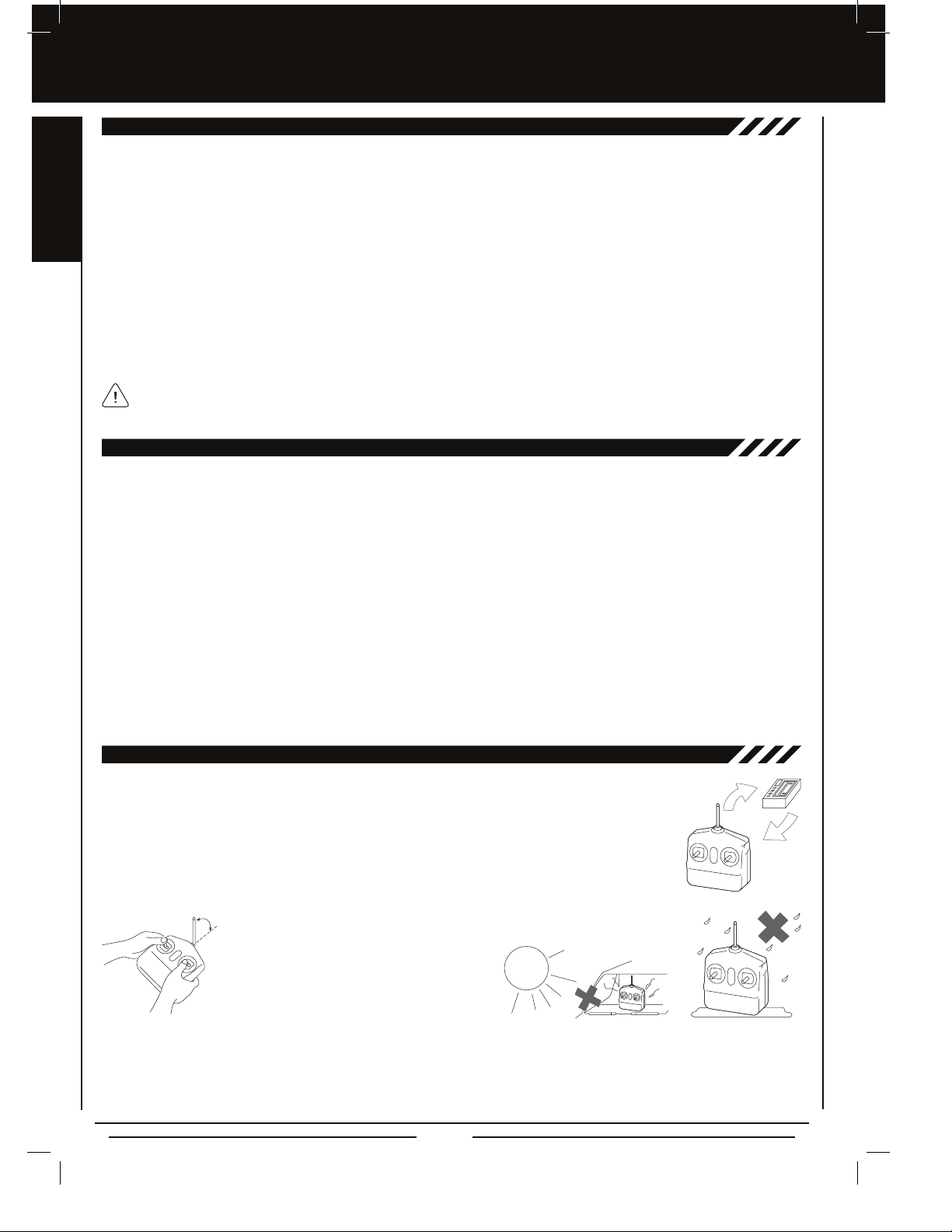

The transmitter antenna is adjustable. It should be adjusted so that when you're holding the transmitter while you're ying,

the antenna is orientated as close to perpendicular to the ground as possible at all times. This provides the best signal

between the transmitter and the receiver. You should never point the antenna directly at your aircraft, as this results in a weakened

signal. For more information, see page 4.

GENERAL

Page 8

FEaTURES FaMiLiaRizaTiOn

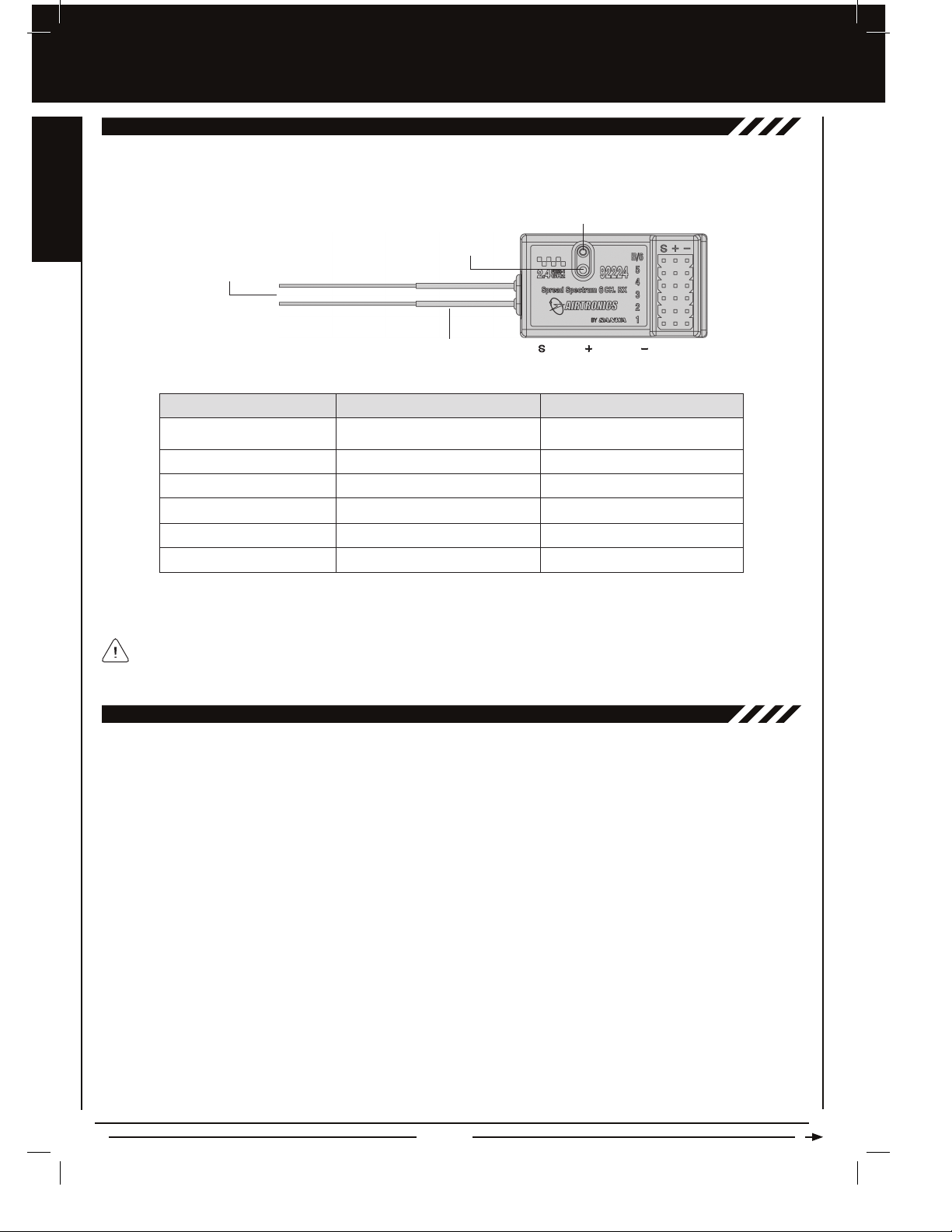

Use the diagram below to familiarize yourself with the 92224 (RX600) 6-Channel receiver included with your TM-160 2.4GHz

FHSS-1 radio control system. Descriptions of these features can be found below and on the next page.

REcEivER FEaTURES DiagRaM

*To utilize this channel and power the receiver at the same time, you must use a Y-Harness (available separately). For more

information, see page 13.

Aileron/Elevator Control Stick: Controls the Aileron and Elevator axes. The Aileron/Elevator Control Stick length is adjustable

to suit your preference. For more information, see page 19.

Aileron Trim Switch: Used to control the Aileron axis Right and Left trim.

Antenna: Transmits the signal from the transmitter to the receiver in the model. The Antenna should be pivoted into the vertical

position during use. When not in use, the Antenna should be collapsed into the horizontal position to prevent damage during

handling and transport.

Antenna Reception Wires: The portion of each of the receiver antenna wires that actually receives the transmitter signal. The

Antenna Reception Wires should never be bent or they could be damaged and limit the range of the receiver.

Battery Compartment: Houses the 6 cells that power the transmitter. The transmitter uses 6 cells for lighter weight and better

feel, while still providing long usage time and high power output.

Bind Button: Used to Bind the transmitter and receiver. Also used to enter Low-Power Range Check mode.

Bind LED: Displays the current status of the transmitter and receiver pair.

Charging Jack: Used for onboard charging of the Ni-Cd or Ni-MH batteries.

Coaxial Cables: The portion of each antenna wire that extends the Antenna Reception Wires. The Coaxial Cables can be bent

into gentle curves, however, do not bend the Coaxial Cables acutely, or repeatedly bend them, or the antenna wire's cores can

be damaged. For information on mounting the receiver and orientating the receiver antenna wires, see page 18.

Elevator Trim Switch: Used to control the Elevator axis Up and Down trim.

FEaTURES DEScRiPTiOnS

Bind Button

Coaxial Cables

Antenna

Reception

Wires

Bind LED

= Signal = Positive = Negative

(Antenna Wires Not to Scale)

The default channel slot assignments shown in the table above will vary based on the Model Type selection options you have

programmed in the TYPE menu. For example, in AERO mode with TAIL>2xEL selected in the TYPE menu, Channel Slot 1

will control the Left Elevator and Channel Slot 5 will control the Right Elevator. For more information, see page 25.

CHANNEL SLOT AERO CHANNEL ASSIGNMENT

Channel Slot 1

Channel Slot 2

Channel Slot 3

Channel Slot 4

Channel Slot 5

Channel Slot 6/BATT*

Elevator

Aileron

Throttle

Rudder

Gear

Flaps

Elevator (Fore/Aft Cyclic)

Aileron (Left/Right Cyclic)

Throttle

Rudder (Tail Rotor)

Gyro

Pitch (Collective)

HELI CHANNEL ASSIGNMENT

Page 9

FEaTURES FaMiLiaRizaTiOn

Multi-Function LCD: The heart of the programming and display features of the transmitter. All programming and transmitter

display functions are shown on the Multi-Function LCD.

Navigation Pad: The Navigation Pad is used in conjunction with the Programming Keys to facilitate transmitter programming.

The Navigation Pad allows you to quickly and easily move the Programming Cursor up and down, and right and left. The ENTER

key in the center of the Navigation Pad is used to open the selected menu or programming option.

Neck Strap Anchor: Used to attach your neck strap (available separately) to the transmitter.

Power Indicator: Indicates that there is power to the transmitter. When the battery voltage drops to 6.7 volts, the audible Low

Voltage Alarm will sound. For more information, see the Transmitter Alarms section below.

Power Switch: Turns the transmitter ON and OFF.

Programming Keys: The Programming Keys are used to facilitate transmitter programming and select models stored in

memory. The four Programming Keys consist of the INC+/M1 (Increase/Model 1) key, the DEC-/M2 (Decrease/Model 2) key, the

END/M3 (End/Model 3) key, and the F-MODE (Flight Mode) key.

Rudder Trim Switch: Used to control the Rudder axis Right and Left trim.

Throttle/Rudder Control Stick: Controls the Throttle and Rudder axes. The Throttle/Rudder Control Stick length is adjustable

to suit your preference. For more information, see page 19.

Throttle Trim Switch: Used to control the Throttle axis Up and Down trim.

Trainer Port: The Trainer Port is where the trainer cable (available separately) is plugged into. An adapter to use the transmitter

with a ight simulator can also be plugged into the Trainer Port.

RF Output Indicator: Illuminates when the transmitter is turned ON and transmitting a signal. If the RF Output Indicator fails

to illuminate, RF output is limited or non-existent. In this case, you should not y. The RF Output Indicator will ash when the

transmitter Trainer mode is set to Slave.

FEaTURES DEScRiPTiOnS, cOnTinUED....

The 92224 (RX600) 6-Channel receiver included with your TM-160 2.4GHz FHSS-1 radio control system uses universal Airtronics

'Z' connectors which are electronically compatible with the servos of other radio control system manufacturers. The connectors

are rugged, but should be handled with care.

When unplugging the servo connector, it's best not to pull on the servo wire itself. This could result in damage to the servo

wire pins in the plastic plug. Always grasp the plastic connector itself.

SERvO cOnnEcTORS

- = Negative (Black)

+ = Positive (Red)

S = Signal (Blue)

The TM-160 transmitter is equipped with several safety alarms to warn you of an abnormal transmitter condition.

TRanSMiTTER aLaRMS

Low Voltage Alarm

The TM-160 transmitter is equipped with a Low Voltage Alarm to warn you when the transmitter batteries need to be replaced or

recharged. The Low Voltage Alarm will sound when the transmitter batteries reach 6.7 volts. If the Low Voltage Alarm sounds

while you are ying, you should land immediately, then replace or recharge the transmitter batteries. If the Low Voltage Alarm

sounds after replacing or recharging the transmitter batteries, there may be a problem with the transmitter. If this occurs, please

contact Airtronics Customer Service using the information on the back cover of this Operating Manual.

Flight Mode Warning Alarm

The TM-160 transmitter is equipped with a safety feature that will not allow you to use the transmitter if the Flight Mode is not set

to FN (Normal) when you turn the transmitter ON. If the Flight Mode is not set to FN when you turn the transmitter ON, the Flight

Mode Warning alarm will sound continuously, the RF Output Indicator will ash, and the LCD will read F-MODE NOT 'N' ! To clear

the Flight Mode Warning, set the Flight Mode to FN using the Flight Mode Switches (move both Flight Mode switches forward).

The LCD will read normally, the Flight Mode Warning alarm will cease, and RF Output Indicator will stop ashing.

GENERAL

Page 10

FEaTURES FaMiLiaRizaTiOn

TRanSMiTTER aLaRMS, cOnTinUED....

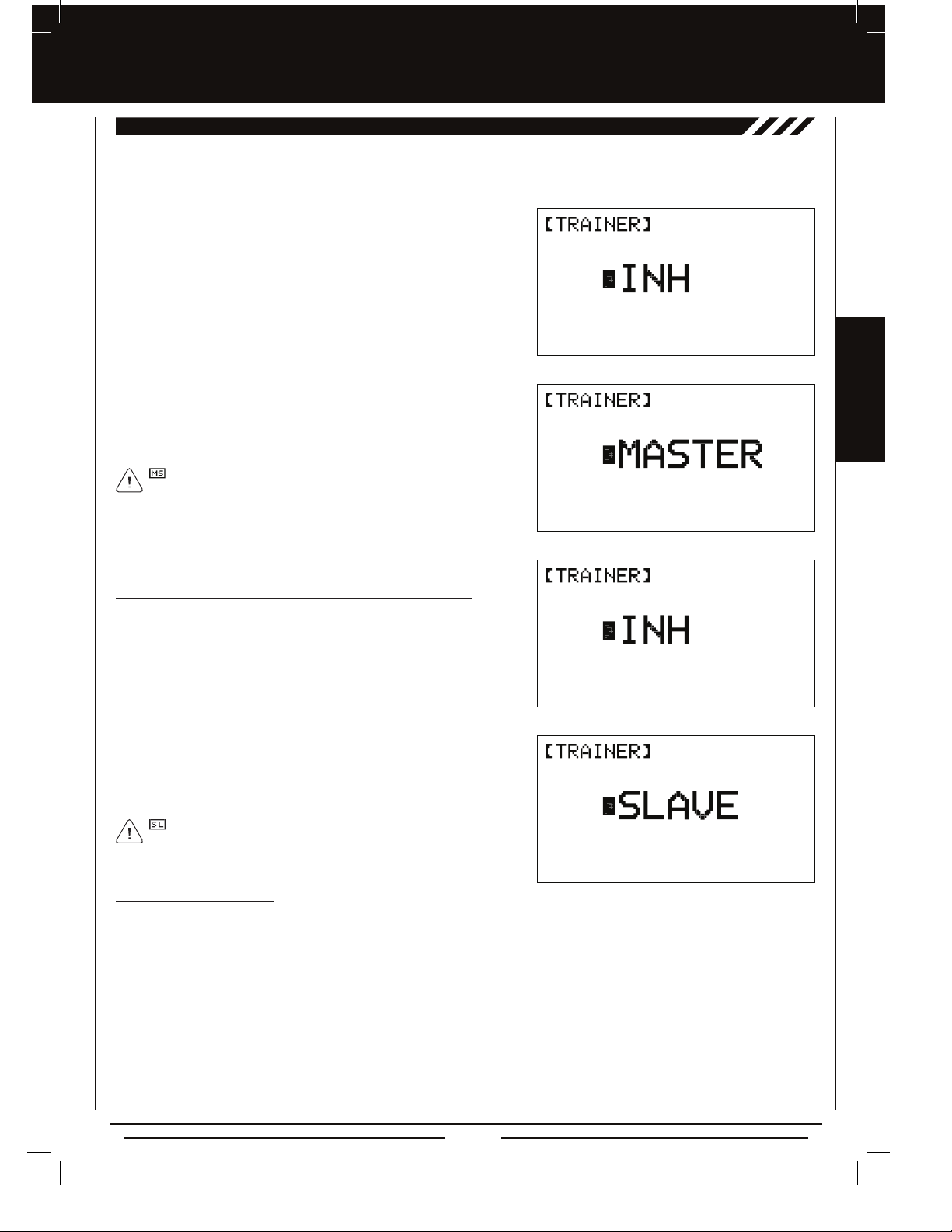

Trainer Mode Warning Alarm

The TM-160 transmitter is equipped with a safety feature that will warn you when the transmitter is set to Trainer>Master or

Trainer>Slave when the transmitter is turned ON. If the transmitter is set to Trainer>Master when you turn the transmitter ON, the

Trainer Mode Warning alarm will sound continuously, the RF Output Indicator will blink, and the LCD will read TRAINER MODE

MASTER ! If the transmitter is set to Trainer>Slave when you turn the transmitter ON, the Trainer Mode Warning alarm will sound

continuously, the RF Output Indicator will blink, and the LCD will read TRAINER MODE SLAVE !

To clear either of the Trainer Mode Warnings, press any of the Programming Keys or the ENTER key. The LCD will read normally,

the Trainer Mode Warning alarm will cease, and the RF Output Indicator will stop ashing (if set to Slave, the RF Output Indicator

will continue to ash).

Clearing the Trainer Mode Warning does not change the Trainer setting of the transmitter. When the Trainer Mode Warning

is cleared, the transmitter will still be in Trainer Mode - either set to Master or set to Slave as indicated on the LCD.

Although most current brand servos will work with your TM-160 2.4GHz FHSS-1radio control system, we recommend using

Airtronics brand servos. For pricing, availability, and more selection, please visit your local Airtronics dealer or our website at

http://www.airtronics.net.

SERvO REcOMMEnDaTiOnS

Both analog and digital servos will work with your TM-160 2.4GHz FHSS-1 radio control system. To get the most out of your

experience though, we recommend the use of digital servos.

Torque: 115oz/in (8.3kg/cm @ 4.8v)

144oz/in (10.4kg/cm @ 6.0v)

Speed: 0.23 sec/60º @ 4.8v

0.18 sec/60º @ 6.0v

Dimensions: 1.54 x 0.79 x 1.61in

(39.1 x 20.0 x 40.9mm)

Weight: 2.36oz (67gr)

Torque: 42oz/in (3.0kg/cm @ 4.8v)

53oz/in (3.8kg/cm @ 6.0v)

Speed: 0.20 sec/60º @ 4.8v

0.16 sec/60º @ 6.0v

Dimensions: 1.54 x 0.79 x 1.42in

(39.1 x 20.0 x 36.0mm)

Weight: 1.59oz (45gr)

94102Z Standard Bushing

94162Z High Torque MG Dual Ball Bearing

94842 Digital Precision Dual Ball Bearing

Torque: 111oz/in (8.0kg/cm @ 4.8v)

132oz/in (9.5kg/cm @ 6.0v)

Speed: 0.16 sec/60º @ 4.8v

0.13 sec/60º @ 6.0v

Dimensions: 1.57 x 0.77 x 1.56in

(40.0 x 19.5 x 39.6mm)

Weight: 1.62oz (45.8gr)

Torque: 18oz/in (1.3kg/cm @ 4.8v)

23oz/in (1.7kg/cm @ 6.0v)

Speed: 0.12 sec/60º @ 4.8v

0.10 sec/60º @ 6.0v

Dimensions: 0.91 x 0.44 x 0.87in

(23.0 x 11.2 x 22.1mm)

Weight: 0.32oz (9gr)

94091Z Super Micro Bushing

94856 Digital High Speed MG Dual Ball Bearing

Torque: 125oz/in (9.0kg/cm @ 4.8v)

150oz/in (10.8kg/cm @ 6.0v)

Speed: 0.14 sec/60º @ 4.8v

0.11 sec/60º @ 6.0v

Dimensions: 1.50 x 0.79 x 1.49in

(38.0 x 20.0 x 37.8mm)

Weight: 2.04oz (58.0gr)

Torque: 22oz/in (1.6kg/cm @ 4.8v)

26oz/in (1.9kg/cm @ 6.0v)

Speed: 0.18 sec/60º @ 4.8v

0.15 sec/60º @ 6.0v

Dimensions: 0.91 x 0.35 x 0.90in

(23.0 x 9.0 x 22.8mm)

Weight: 0.26oz (7.4gr)

94802 Digital Sub-Micro Dual Ball Bearing

OPTiOnaL iTEMS

The following optional items (available separately) can be used with your TM-160 2.4GHz FHSS-1 radio control system. For

pricing and availability, please visit your local Airtronics dealer or our website at http://www.airtronics.net.

233819 Hi-Energy 4.8v 2200mAh Ni-MH Square Receiver Battery*

233808 Hi-Energy 6.0v 2200mAh Ni-MH Flat Receiver Battery*

96750 Stick Tip Extensions

99103 Adjustable Neck Strap

978411 Aluminum Carry Case

97020Z 8" Y-Harness

97011Z 12" Servo Extension

97107 Trainer Cable

96506 Airtronics Baseball Cap

978425 Airtronics Folding Field Chair

*Not an Airtronics brand product, however, this product is available through most Airtronics dealers.

Many more accessories, such as servos, servo extension leads, male and female plugs, receiver battery packs, and more

are available through your local Airtronics dealer or our website at http://www.airtronics.net.

Page 11

qUick-STaRT BaSic MODEL SETUP

The information in this section describes the basic steps that you can use to quickly setup a new model. Regardless of the model

you are fying, using the basic functions of the TM-160transmitter for most applications is easy and will get your model setup

quickly. It's a simple ve-step process.

1) Bind the Receiver to the Transmitter and Install the Receiver:

l

After connecting your airborne components and installing fully-charged transmitter and receiver batteries, turn the transmitter ON.

l

Hold down the Bind Button on the receiver. While holding down the Bind Button on the receiver, turn the receiver ON.

l

Release the Bind Button on the receiver. The Bind LED will slowly ash.

l

Press the transmitter Bind Button. The receiver's Bind LED will ash rapidly, then the receiver's Bind LED will turn solid blue

indicating the system is paired.

l

Install the receiver in your model, making sure that the two receiver antenna wires are mounted 90º to each other.

l

Rotate the transmitter antenna so that it is positioned at a 45º angle toward you.

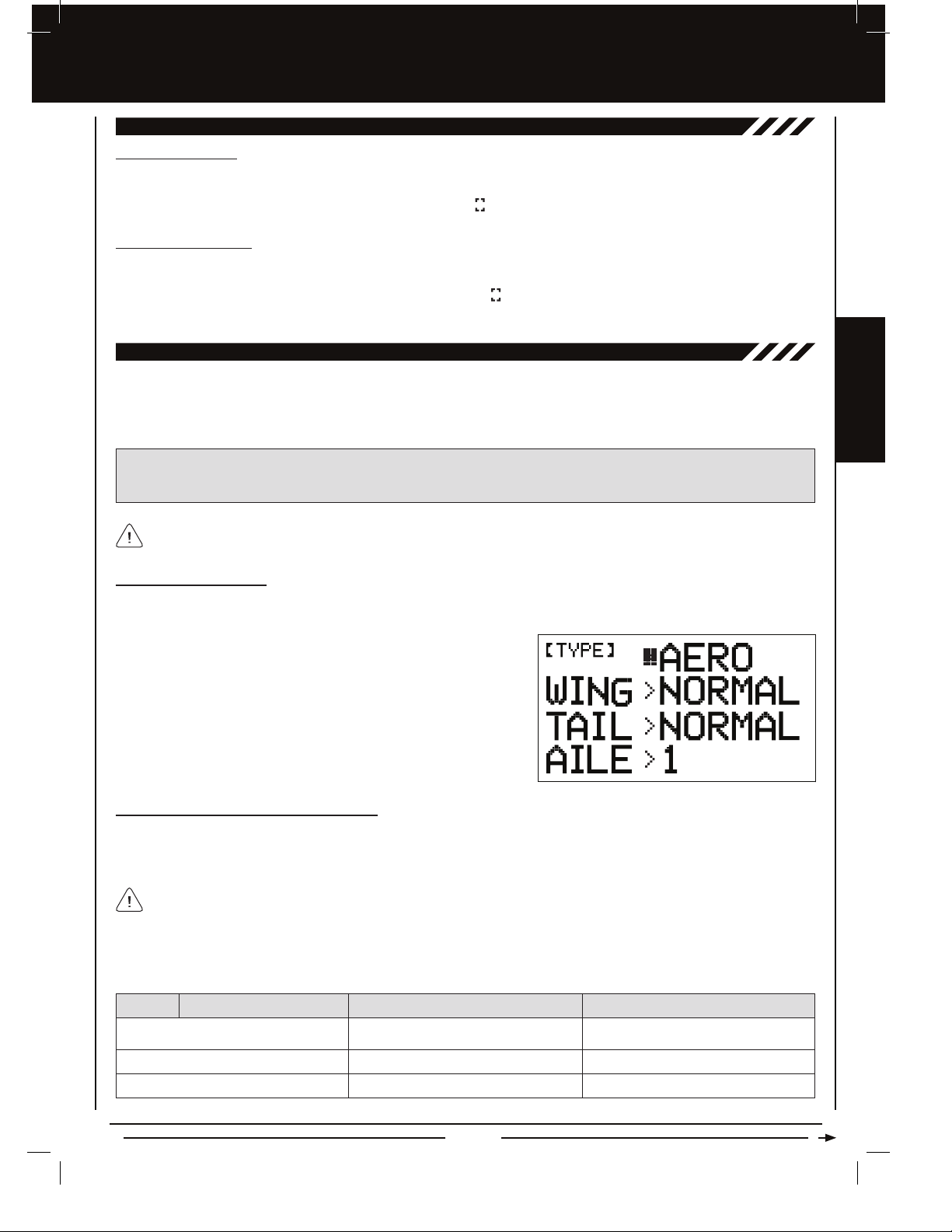

2) Choose a Model Type:

l

Navigate to the TYPE menu, then press the INC+/M1 or DEC-/M2 keys to select the Model Type that matches your

model, either AERO (Aircraft) or HELI (Helicopter).

3) Make Model Type Selection Options:

l

Scroll down to choose the various options related to the Model Type you've chosen.

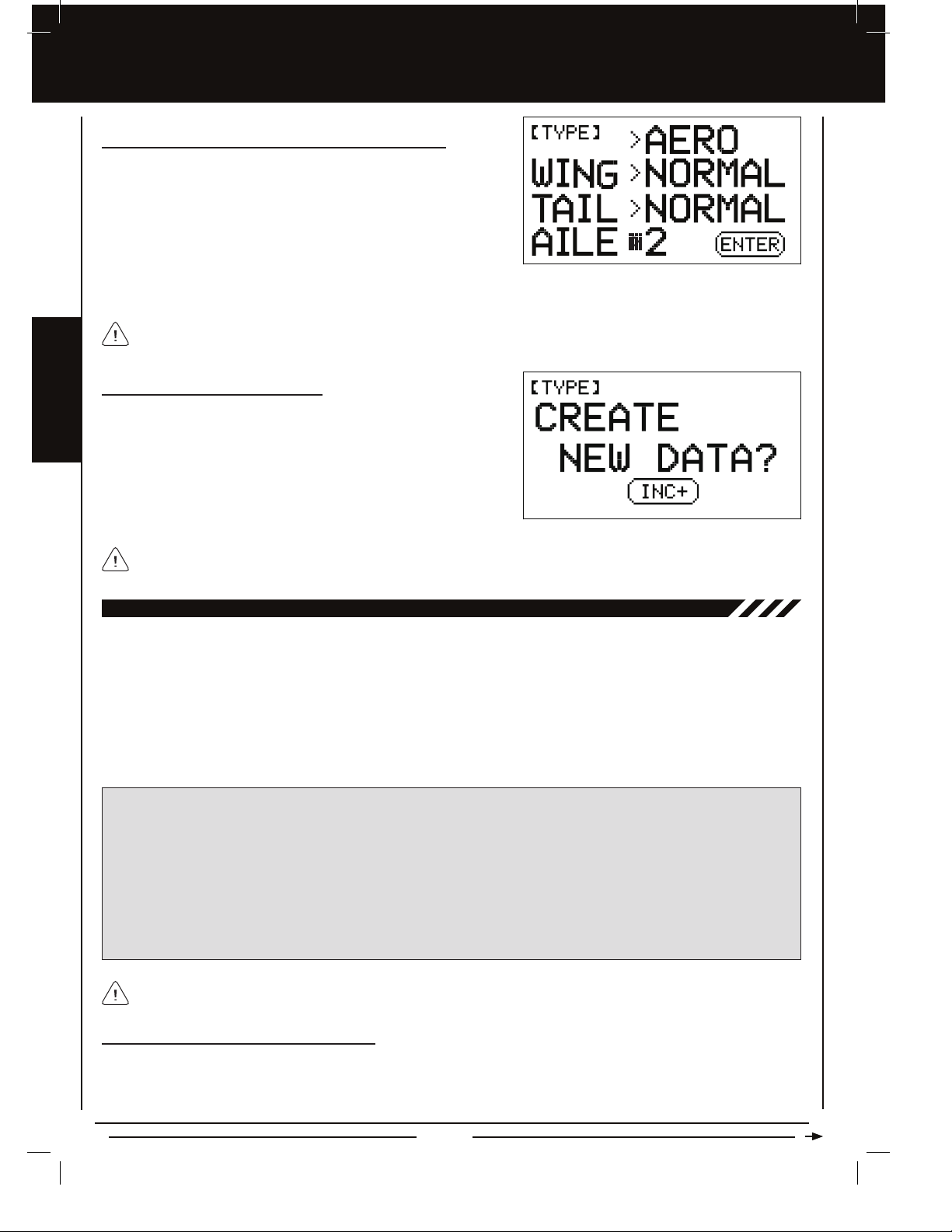

AERO - Select what type of wing (Normal or Delta), the type of tail (Normal, V-Tail, or Dual Elevator servos), and the

number of aileron servos in your wing (1 or 2).

HELI - Select what type of swashplate your model features, either Normal, or a CCPM swashplate. If choosing a CCPM

swashplate option, make sure that the CCPM swashplate type matches your model exactly.

l

After making your selections, press the ENTER key, then the INC+/M1 key. The pre-programmed model template will be

loaded into the transmitter.

4) Name Your Model:

l

Navigate to the MODEL NAME menu and input a name for your model. This will allow you to easily choose this model again

for later use. The Model Name will be displayed on the Display screen so that you know which model is currently in use.

5) Plug In Servos and Setup Control Surfaces:

l

Navigate to the SX MONITOR menu and use the information displayed on the Servo Monitor to plug your servos into the

correct channel slots in the receiver based on the Model Type selection options you chose previously.

l

Navigate to the REVERSE, CENTER, EPA, and D/R & EXPO menus to adjust direction of servo travel (REVERSE), servo

centering sub-trim (CENTER), desired servo travel in both directions (EPA), and if desired, the Dual Rate and Exponential

(D/R & EXPO) percentage values.

Many of the Tips and Suggestions on the following pages can be found throughout this Operating Manual, however, we have

listed what we feel are the more important ones in this section for your convenience.

TiPS anD SUggESTiOnS

FEaTURES FaMiLiaRizaTiOn

The information in this section is general in nature. For more in-depth instructions about the individual steps outlined below,

please make sure to read the pertinent sections of this Operating Manual.

l

When you see in the lower right corner of a page, this indicates that the current section is continued at the top of the

next page.

l

The receiver’s nominal input voltage is 4.8 volts to 6.0 volts. If your receiver battery's nominal voltage rating is greater than

6.0 volts, you must use a voltage regulator plugged between the switch harness and the receiver battery to drop your battery's

voltage to 6.0 volts.

GENERAL

Page 12

FEaTURES FaMiLiaRizaTiOn

TiPS anD SUggESTiOnS, cOnTinUED....

l

An after-market peak-detection charger, cycler, or fast charger should NOT be used to charge Ni-Cd or Ni-MH rechargeable

batteries through the transmitter. The circuitry within the transmitter can interfere with the peak-detection charger's normal

operation, resulting in over-charging and damaging the batteries, and possibly the transmitter itself. In addition, a fast

charger can damage the transmitter's circuitry. These chargers can be used, but ONLY if the batteries are charged outside of

the transmitter.

l

Up to 6 servos can be plugged into the receiver separately. To utilize the Channel 6/BATT slot along with the receiver battery,

you must plug a Y-Harness into the channel slot, then plug the servo into one side of the Y-Harness and the battery switch

harness into the other side of the Y-Harness.

l

It is extremely important that the receiver antenna wires be mounted as described. This will ensure that your model receives

control signals no matter what its posture, altitude, or heading.

l

The radio control system is range checked using the Low-Power Mode function. Do not attempt to y with the transmitter in

Low-Power Mode. You will be unable to control your model once it is a certain distance away from you.

l

The TM-160 transmitter features a Type function which allows you to quickly set up the transmitter's low-level mixing based on

the type of model you're ying. Common templates for AERO (Aircraft) and HELI (Helictopter) model types are provided. For

example, if your model features two aileron servos and dual elevator servos, choosing these options will automatically change

the transmitter's programming to accommodate this setup. This takes the guess-work out of setting up more complex models.

l

The TM-160 transmitter features an audible Flight Mode Warning alarm. If you turn your TM-160transmitter ON and it beeps,

the transmitter is more than likely in Flight Mode F1 or Flight Mode F2. Putting the transmitter in Flight Mode FN (Normal), will

silence the Flight Mode Warning alarm.

l

In the default conguration, the Model Select List contains 5 AERO model types and 5 HELI model types. The Model Type for any

of the 10 models in the Model Select List can be changed using the Type menu.

l

The Direct Model Select function allows you to select one of three of your most-used models from memory without going

through the Model Select menu. This makes it much quicker and easier to load the programming for your three favorite models.

l

Pressing both the INC+/M1 and DEC-/M2 keys together will Reset the highlighted programming selection to the Factory Default

Setting.

l

When the Display screen is displayed, pressing the INC+/M1 key will Start and Stop the Timer. Pressing the INC+/M1 and

DEC-/M2 keys together will Reset the Timer.

l

Unless otherwise noted, all programming changes take effect immediately.

l

An audible double-tone is heard when the trim switches reach the center position. This allows you to know when the trim

switches reach the center position without the need to look at the Trim Indicators on the Display screen.

l

The TM-160 transmitter features Digital Trim Memory. Any amount of control surface trim that you set during fight using the

trim switches is automatically stored in memory for that specic channel and for that specic model. The Digital Trim values for

each model will automatically be loaded when the transmitter is turned ON.

l

There is always one Flight Mode Active at all times. In the default conguration, Flight Mode FN (Normal) is Active.

l

The F-MODE key is used to facilitate programming the individual Flight Modes only and does not turn the Flight Modes ON

or OFF. Flight Modes are turned ON and OFF using the two Flight Mode switches.

l

Prior to takeoff, check the position of the Dual Rate switch to ensure that it is in the position you want.

l

Use the Servo Monitor to determine which receiver channel slots to plug your servos into. The channels displayed on the Servo

Monitor will vary based on the Model Type selection options chosen in the TYPE menu. For example, if you chose TAIL>2xEL

and AILE>2 in the TYPE menu, LE (Left Elevator), RE (Right Elevator), LA (Left Aileron), and RA (Right Aileron) will be

displayed along with the corresponding receiver channel slot numbers.

l

Many menu functions feature Common or Separate choices. When set to COMMON the function settings will be the same

regardless of which Flight Mode the transmitter is operating in. When set to SEPARATE, you can program different function

settings separately for each Flight Mode.

l

When setting up a CCPM swashplate helicopter, you may want to use the CP-EPA function instead of the standard EPA

function. The CCPM End Point Adjustment function allows you to adjust servo travel in each direction for the elevator, aileron,

and pitch servos independently. Unlike the standard End Point Adjustment function, which affects all the cyclic servos, CCPM

End Point Adjustment allows you to adjust each cyclic servo independently without any affect on the other cyclic servos. This

allows you to also quickly and easily level the swashplate.

Page 13

SySTEM cOnnEcTiOnS

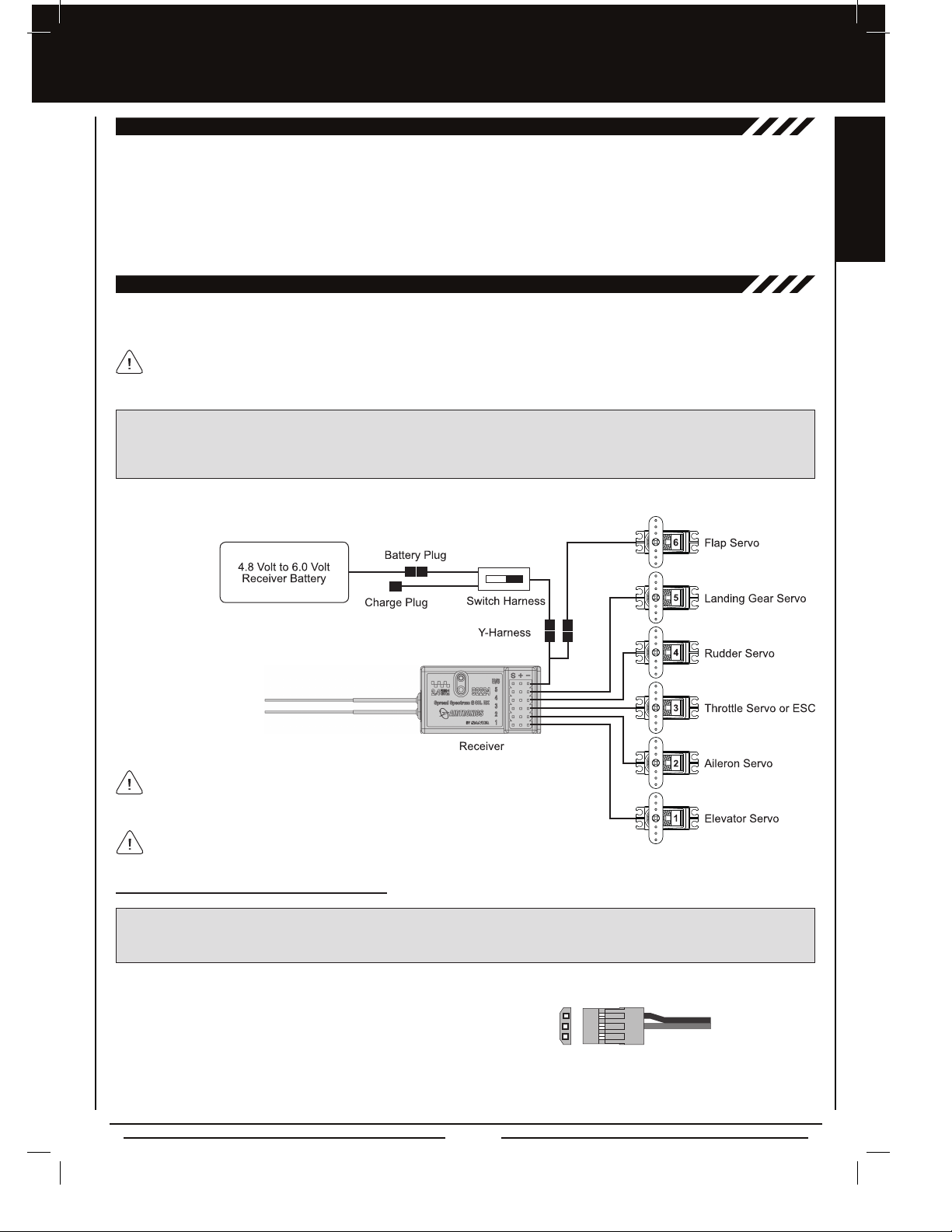

Use the diagram below to familiarize yourself with how to connect the switch harness, servos (available separately), and receiver

battery (available separately) to your 92224 (RX600) 6-Channel receiver.

A receiver battery is not included. The receiver can be powered by a 4.8 volt (4 cell) or a 6.0 volt (5 cell) Ni-Cd or Ni-MH

battery of desired capacity. The receiver can also be powered by a 2 cell Li-Fe/A123 or a 2 cell Li-Po battery of desired

capacity as long as you use a voltage regulator. See WARNING below.

WARNING The receiver’s nominal input voltage is 4.8 volts to 6.0 volts. If your receiver battery's nominal voltage rating is

greater than 6.0 volts, you must use a voltage regulator plugged between the switch harness and the receiver battery to drop

your battery's voltage to 6.0 volts. If you do not use a voltage regulator, damage to the receiver could result. We recommend a

switching type regulator and it must be able to handle the amperage demands of the servos used in your model.

If you decide to power the receiver using a 2 cell Li-Fe/A123 battery or a 2 cell Li-Po battery, please observe the following:

l

Use ONLY a 2 cell Li-Fe or Li-Po battery of desired capacity with a voltage

regulator. You MUST use a voltage regulator.

l

When changing the plug on your battery to be compatible with the switch harness, please observe correct polarity. Connecting

with reverse polarity could damage the switch harness and/or the receiver. See plug polarity diagram above.

l

Observe all safety precautions provided with your battery before use, during use, and during the charging process.

WARNING The nominal voltage rating of a 2 cell Li-Fe/A123 battery or a 2 cell Li-Po battery is greater than 6.0 volts.

Because of the higher voltage, you MUST use a voltage regulator plugged between the switch harness and the receiver

battery to drop the battery voltage to 6.0 volts. If you do not use a voltage regulator, damage to the receiver could result.

- = Negative (Black)

+ = Positive (Red)

TRanSMiTTER BaTTERy inSTaLLaTiOn

1) Remove the battery cover on the back of the transmitter by pushing down rmly on the tab in the top of the battery cover and

pulling the battery cover out.

2) Install six 'AA' batteries into the battery tray, making sure that the polarity is correct. The direction that each battery should be

installed is molded into the battery tray (+ Positive and - Negative).

3) Set the bottom of the battery cover back onto the transmitter and push it rmly until it 'clicks' closed.

aiRBORnE SySTEM cOnnEcTiOnS

Using an Li-Fe/A123 or Li-Po Receiver Battery

If necessary, the receiver battery can be plugged into any of the channel slots and

still power the receiver without causing damage.

*

*To utilize this channel and power the receiver at the same time,

you must use a Y-Harness (available separately).

The receiver channel slots that you plug your servos into will vary based on the

TYPE menu options you choose. After making TYPE menu option selections, use

the Servo Monitor to determine which receiver channel slots to plug your servos into.

GENERAL

Page 14

SySTEM cOnnEcTiOnS

TRanSMiTTER anD REcEivER BaTTERy chaRging

The TM-160 transmitter features a Charging Jack, which can be used with the Airtronics 95034 110v AC Transmitter and Receiver

Dual Charger to recharge the batteries without removing them from the transmitter. In addition, this charger can also be used to

recharge a 4.8v (4 cell) or 6.0v (5 cell) rechargeable Ni-Cd or Ni-MH receiver battery pack at the same time. We recommend

one of the following receiver battery packs:

Hi-Energy 4.8v 2200mAh Ni-MH Rechargeable Flat Battery Pack for Receiver (1 PC.)

Hi-Energy 6.0v 2200mAh Ni-MH Rechargeable Flat Battery Pack for Receiver (1 PC.)

Warnings About Charging the Transmitter and Receiver Batteries

The TM-160 transmitter features a Charging Jack located on the right side of the transmitter, allowing you to recharge the Ni-Cd

or Ni-MH rechargeable batteries without removing them from the transmitter. Use ONLY the recommended optional Airtronics

95034 110v AC Transmitter and Receiver Dual Charger or damage to the transmitter and/or batteries could result.

WARNING Do NOT attempt to recharge Alkaline batteries. Do NOT attempt to charge any type of batteries other than those

recommended and use ONLY the recommended charger. Do not use the Charging Jack with any other after-market fast

charger or Peak-Detection charger or the transmitter could be damaged.

Charging the Transmitter and Receiver Batteries

1) Plug the Airtronics 95034 110V AC Transmitter and Receiver Dual Charger into a 110v AC wall socket.

2) Plug the round connector from the charger into the Charging Jack in the transmitter and plug the female connector from the

charger into the switch harness charge plug. The charger LEDs will illuminate red, indicating that the charger is charging.

3) Both transmitter and receiver charger outputs are 150mAh, therefore, it will take approximately 15 hours to recharge

fully-discharged 2200mAh batteries (2200/150=14.6). Charge time will vary depending on the mAh capacity of the batteries

you're charging. For example, 1200mAh batteries would require an 8 hour charge (1200/150=8).

l

Always follow the charging procedures described below to ensure the safe and correct use of the rechargeable batteries and

charger.

l

Before charging the batteries, double-check that both the transmitter and the receiver are turned OFF.

l

Overcharging reduces the life of the batteries and can result in overheating and bursting. This may cause personal injury

and/or property damage.

l

Do not plug the recommended charger into anything other than an AC 110v power outlet. Plugging the charger into anything

other than AC 110v outlet may result in smoking, sparks, or re.

l

Do not throw the batteries or abuse them in any manner. Do not dispose of the batteries in the re or allow them to overheat.

l

Do not short-circuit the battery terminals with wire or any other object.

WARNING If you're using a Li-Fe or Li-Po receiver battery, do NOT attempt to charge either of these types of batteries with

the optional Airtronics 95034 110v AC Transmitter and Receiver Dual Charger. You MUST use a charger that is specically

designed to charge Li-Fe or Li-Po batteries.

Depending on the region in which your purchase your TM-160 2.4GHz FHSS-1 radio control system, rechargeable

transmitter batteries and an overnight charger may or may not be included. If these items are NOT included, we recommend

using the following:

Hi-Energy 1200mAh Ni-MH 'AA' Rechargeable Batteries (4-Pack) for Transmitter (2 PCS.)

Airtronics 95034 110v AC Transmitter and Receiver Dual Charger (1 PC.)

WARNING An after-market peak-detection charger, cycler, or fast charger should NOT be used to charge Ni-Cd or Ni-MH

rechargeable batteries through the transmitter. The circuitry within the transmitter can interfere with the peak-detection

charger's normal operation, resulting in over-charging and damaging the batteries, and possibly the transmitter itself.

In addition, a fast charger can damage the transmitter's circuitry. These chargers can be used, but ONLY if the batteries are

charged outside of the transmitter.

Instead of using Alkaline batteries to power the transmitter, you can use rechargeable Ni-Cd or Ni-MH batteries. This will provide

longer usage time and reduced cost in the long run, since you won't need to continuously purchase new Alkaline batteries.

Page 15

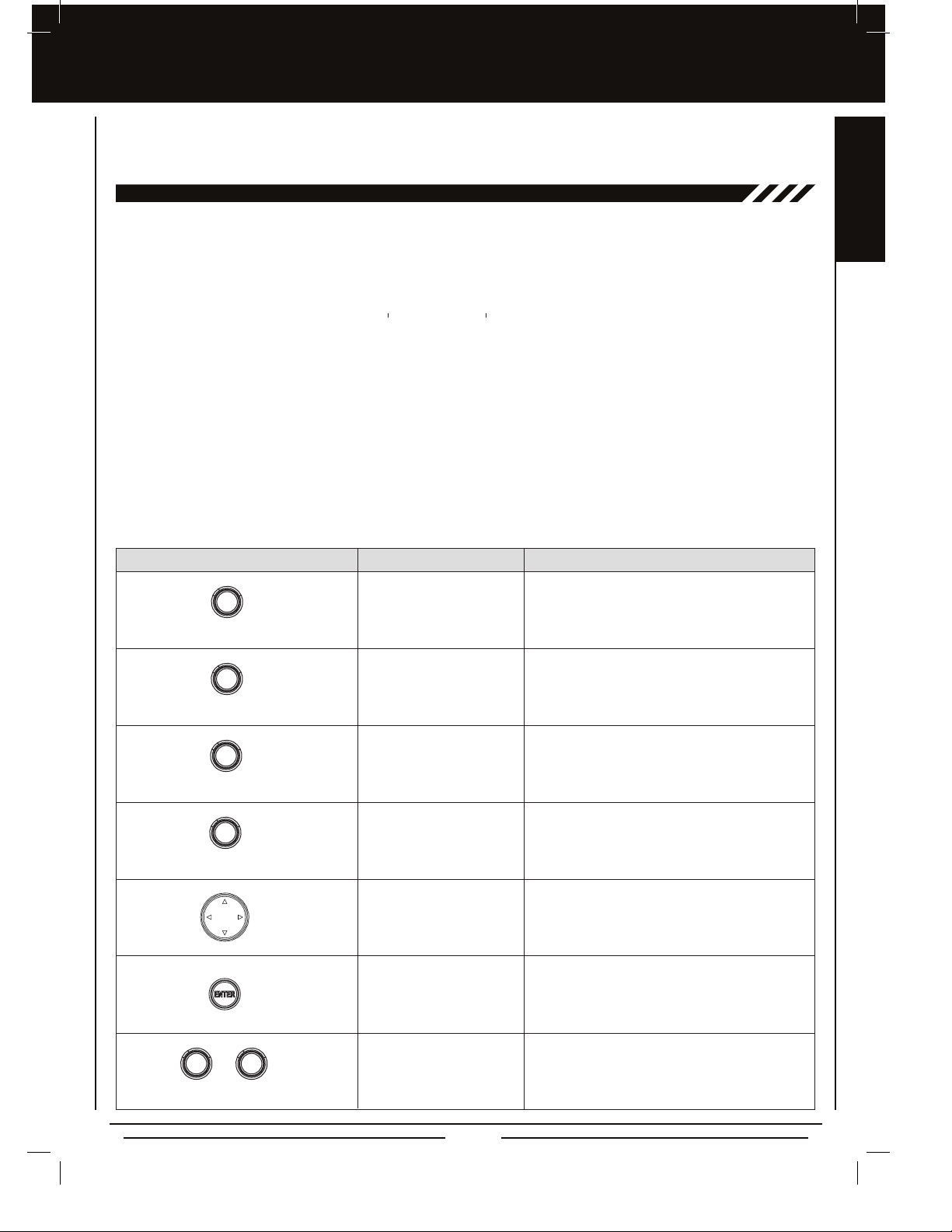

The TM-160 transmitter features four Programming Keys, a Navigation Pad and an ENTER key, all used in conjunction to facilitate

transmitter programming. This section summarizes the functions of these features in addition to detailing the main areas of the

Multi-Function LCD.

PROgRaMMing kEyS OvERviEw anD FUncTiOnS

Increases Programming Values and is used to

select Model 1, using the Direct Model Select

function.

Decreases Programming Values and is used to

select Model 2, using the Direct Model Select

function.

END/M3

(End/Model 3)

Returns to the previous menu. Press several times to

return to the Display screen. Is also used to select

Model 3, using the Direct Model Select function.

F-MODE

(Flight Mode Select)

Cycles through the three Flight Modes during

programming. Does NOT switch between Flight

Modes during use.

INC+/M1

(Increase/Model 1)

DEC-/M2

(Decrease/Model 2)

INC+/M1

DEC-/M2

END/M3

F-MODE

LcD anD PROgRaMMing kEyS

INC+/M1 DEC-/M2

+

Rest Default Shortcut

Pressing both keys at the same time within a

Programming Menu resets the Programming

Value to the Default value.

PROGRAMMING KEY NAME FUNCTION

Moving around the LCD and programming the transmitter is accomplished using the Navigation Pad, the ENTER key, and the

four Programming Keys positioned on the right half of the transmitter.

Navigation Pad

Moves the Programming Cursor Up 5, Down 6,

Right 4, and Left 3.

ENTER Key

Opens the selected menu or programming option.

Advances the cursor in the Model Name menu.

GENERAL

Page 16

LcD anD PROgRaMMing kEyS

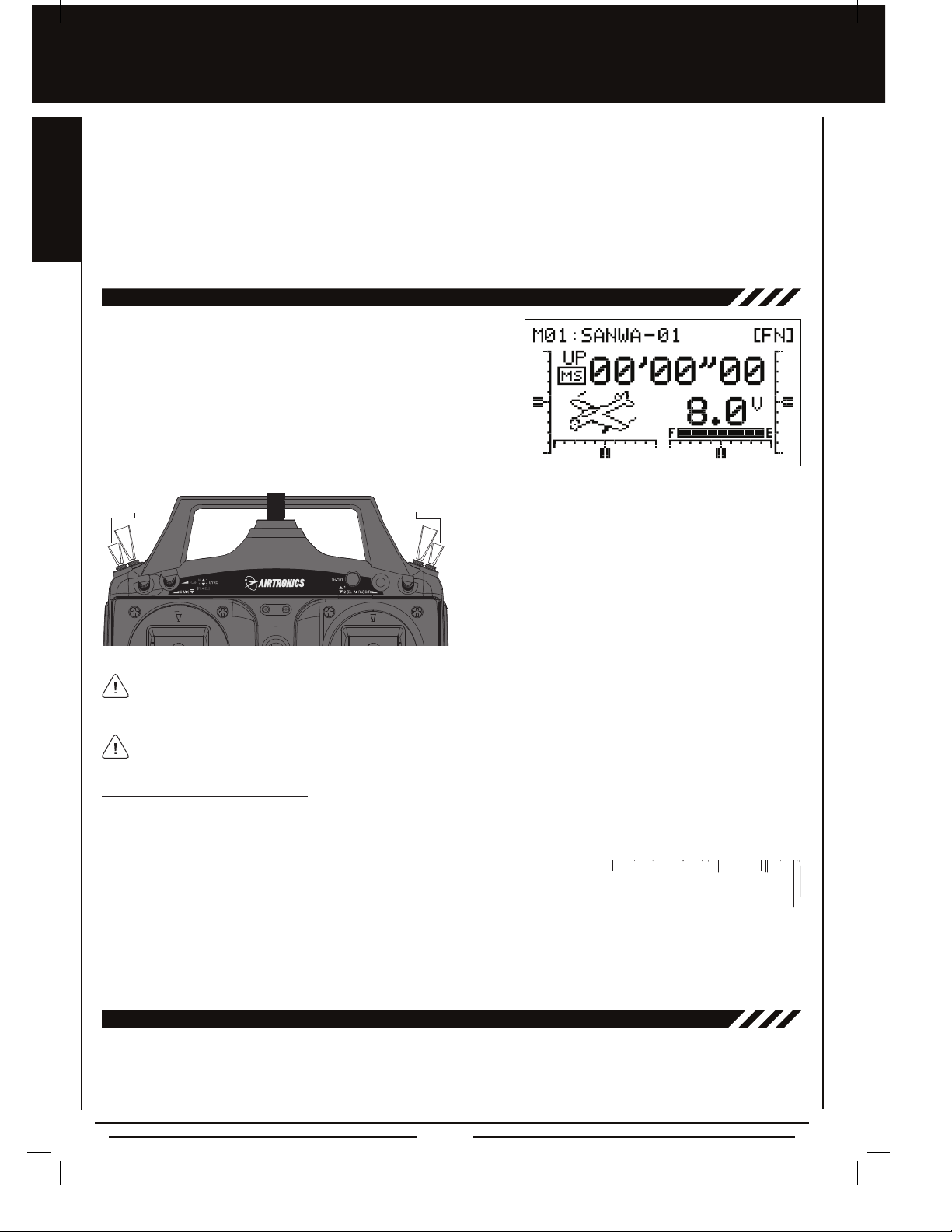

MULTi-FUncTiOn LcD OvERviEw

Use the diagram below to familiarize yourself with the layout and different indicators that make up the Multi-Function LCD.

Model Number

Model Type Icon

Rudder Trim

Elevator Trim

Trainer Status Indicator

Model Name

Timer

Active Flight Mode

Voltage Indicator

Throttle Trim

Aileron Trim

Battery Capacity Indicator

Active Flight Mode: Displays the Flight Mode number that is currently Active.

Aileron Trim: Displays the current position of the Aileron trim switch*.

Battery Capacity Indicator: Indicates the current remaining usable capacity of the transmitter batteries.

Count Up Timer Indicator: Displayed when the Count Up Timer is chosen.

Elevator Trim: Displays the current position of the Elevator trim switch*.

Model Name: Displays the Name of the currently selected Model.

Model Number: Displays the Number of the currently selected Model.

Model Type Icon: Displays the current Active Model Type loaded into memory, either AERO (Aircraft icon) or HELI (Helicopter icon).

Rudder Trim: Displays the current position of the Rudder trim switch*.

Timer: Displays the Stop Watch Timer or the Count Up Timer.

Throttle Trim: Displays the current position of the Throttle trim switch*.

Trainer Status Indicator: Displays when the transmitter Trainer function is Active. If the transmitter is in Master mode, MS will be

displayed. If the transmitter is in Slave mode, SL will be displayed.

Voltage Indicator: Displays the current voltage of the transmitter batteries. When the voltage reaches 6.7 volts, the Low Voltage

Alarm will sound.

Count Up Timer Indicator

*An audible tone will sound each time a trim switch is pressed. When the trim reaches the center, an audible double-tone will

sound. This allows you to know when the trim is centered without needing to look down at the transmitter during ight.

THIS SPACE INTENTIONALLY LEFT BLANK

Page 17

SySTEM SETUP anD inSTaLLaTiOn

TRanSMiTTER anD REcEivER BinDing

The Binding function allows you to Bind the transmitter and receiver pair. When new, it is necessary to pair the transmitter and

receiver to prevent interference from transmitters operated by other users. This operation is referred to as 'binding'. Once the

binding process is complete, the setting is remembered even when the transmitter and receiver are turned OFF. Therefore,

this procedure usually only needs to be done once.

Under some circumstances, the receiver may not operate after turning the transmitter and receiver ON. If this occurs,

perform the binding process again.

Before beginning the binding process, connect the switch harness, servos, and the receiver battery to your 92224 (RX600)

6-Channel receiver, using the diagram on page 13. Make sure that both the transmitter and the receiver are turned OFF.

When the binding procedure is successful, the Bind LED on the receiver will stay solid blue when both the transmitter and

receiver are turned ON. If the Bind LED on the receiver is ashing rapidly or not ON at all, the transmitter and receiver are

not paired. In this case, turn both the transmitter and receiver OFF, then repeat the binding procedure.

1) Ensure that the throttle control stick is in the LOW position (pulled all the way back).

2) Turn the transmitter ON. The Bind LED on the transmitter will illuminate solid green.

Use the tip of a pencil or a 1.5mm hex wrench to press the Bind Button on the receiver.

3) While holding down the Bind Button on the receiver, turn the receiver ON.

The Bind LED on the receiver will ash slowly. After ~2 seconds release

the Bind Button. The Bind LED on the receiver will continue to ash slowly.

4) Quickly press the Bind Button on the transmitter. The Bind LED on the receiver will ash rapidly

for ~3 seconds, go out momentarily, then illuminate solid blue, indicating the Binding process

is complete.

FaiL SaFE PROgRaMMing

The Fail Safe function automatically sets the servos to a predetermined position in the event that the signal between the transmitter and

the receiver is interrupted, whether due to signal degradation or to a low transmitter battery. For example, the Fail Safe function

can be set so that the throttle returns to idle, the elevator moves slightly up, and the ailerons move slightly right or left to result in

a shallow downward decent of your aircraft.

The Fail Safe function is available on channels 1 through 4 only. We suggest programming the Fail Safe function prior to

mounting the receiver into your aircraft if you will be unable to access the receiver's Bind Button after mounting.

Setting Fail Safe Positions

1) Turn the transmitter ON, then turn the receiver ON. Move the transmitter control sticks to verify correct servo movement.

2) Move the transmitter control sticks to the desired Fail Safe positions. While holding the transmitter control sticks in those

positions (generally throttle at idle and a minimal amount of elevator and/or aileron), press and HOLD the Bind Button on the

receiver. After ~2 seconds, the Bind LED will begin to ash slowly. Continue holding the Bind Button until the Bind LED begins

to ash rapidly (~2 more seconds). Once the Bind LED begins to ash rapidly, release the Bind Button.

3) Turn the transmitter OFF to test the Fail Safe operation. The servos should move to the positions that you set in step 2.

The Fail Safe settings will be erased if you re-bind the transmitter and receiver pair. If you bind the same transmitter and

receiver pair you MUST repeat these procedures to setup the Fail Safe function again.

IMPORTANT If you don't program the Fail Safe function, if the signal between the transmitter and receiver is lost, the servos

will stay in the last position they were in when the signal was lost. However, the servos will be free to move under load. They

will NOT be locked in the last position they were in.

Clearing Fail Safe Settings

1) To clear the currently programmed Fail Safe settings, re-bind the transmitter and receiver pair.

GENERAL

Page 18

SySTEM SETUP anD inSTaLLaTiOn

When mounting the receiver into your model, it's important to mount the receiver exactly as described. In addition, the receiver

should be wrapped in foam rubber to protect it from vibration. Failure to mount the receiver antenna wires as described can

result in poor reception, or in some cases, complete loss of reception.

We recommend that you bind the transmitter and receiver, and program the Fail Safe function, prior to mounting the

receiver into your model, otherwise, it may be difcult or impossible to access the Bind Button on the receiver.

The receiver should be mounted securely in your model and the receiver antenna wires installed per the diagram below. The two

receiver antenna wires should be mounted to a wood or plastic non-conductive part of your model and angled so that the antenna

reception wires (thin, silver-colored antenna tips) are positioned 90º apart.

WARNING It is extremely important that the receiver antenna wires be mounted as described. This will ensure that your

model receives control signals no matter what its posture, attitude, or heading.

l

The receiver antenna wires consists of two coaxial cables and two reception wires (the thin tip at the end of the coaxial cables).

When you mount the receiver antenna wires, do not bend the reception wires. Reception performance decreases if the

reception wires are bent.

l

The receiver antenna wires are delicate, therefore, handle with care. Do not pull on the receiver antenna wires with force. Do

not cut or extend the receiver antenna wires.

l

The coaxial cables (the thicker portion of the receiver antenna wires) can be bent into gentle curves, however, do not bend

the coaxial cables acutely, or repeatedly bend them, or the antenna cores can be damaged.

l

When installed in an electric-powered model, keep the receiver antenna wires as far away from the motor, battery, and

electronic speed control (ESC) as possible.

l

When installing the receiver, the antenna reception wires (the thin tip at the end of the coaxial cables) should not come into

contact with any carbon or metal components (conductive components). Aircraft fuselages may contain conductive components.

If mounting the receiver surrounded by conductive materials (for example, a carbon ber fuselage), mount the receiver so that

the antenna reception wires can be extended outside of the model. Reception can be blocked if the antenna reception wires

are shielded inside a carbon ber fuselage.

Tape can be used to secure the antenna reception wires to your model. Alternatively, cut two

short pieces of plastic tube and slide one antenna reception wire into each piece of tube, then

tape or glue the tube to your model. The tubes will protect the antenna reception wires from damage.

If moun ting inside a carbo n fi ber

fus elage, the antenna reception wires

mu s t be run o utsi d e of the m ode l as

de scribed in the notation below.

MOUnTing ThE REcEivER

The Coaxial cables can

be mounted parallel to

each other, b ut un de r no

circumstances should the

antenna reception wires be

mounted parallel to each other.

Reception Wire

Coaxial Cable

Coaxial Cables

Reception Wire

Reception

Wire

Reception Wire

Plastic Tube

OR OR

Page 19

SySTEM SETUP anD inSTaLLaTiOn

RangE chEcking - LOw-POwER MODE

When lengthening the control sticks, we strongly suggest that you leave at least four threads inside the top half of each

control stick. This will ensure that the control sticks maintain optimum mechanical security. If you thread the control sticks

out too far, the control sticks might come loose during use.

cOnTROL STick LEngTh aDjUSTMEnT

The length of the control sticks can be adjusted to best suit the way you hold them. In general, pilots who place their thumbs on

top of the control sticks prefer the control sticks to be shorter, and pilots who grasp the control sticks prefer the control sticks to

be longer. In the default conguration, the control sticks are adjusted as short as possible.

Activating Low-Power Mode

1) Press and HOLD the Bind Button on the transmitter, then turn the

transmitter ON. The Bind LED will ash.

2) Continue to HOLD the Bind Button for approximately 5 seconds. After

approximately 5 seconds, the Bind LED will ash rapidly, then go out.

3) Release the Bind Button and the Bind LED should begin to ash again. The transmitter is now in Low-Power Mode and you

can begin the Range Check process.

IMPORTANT The radio control system should be Range Checked prior to the day's rst ight and prior to the rst ight after

a hard landing or after a repair. This will ensure that the transmitter and receiver are communicating properly prior to ight.

This ensures the safety of your aircraft, yourself, and the people around you.

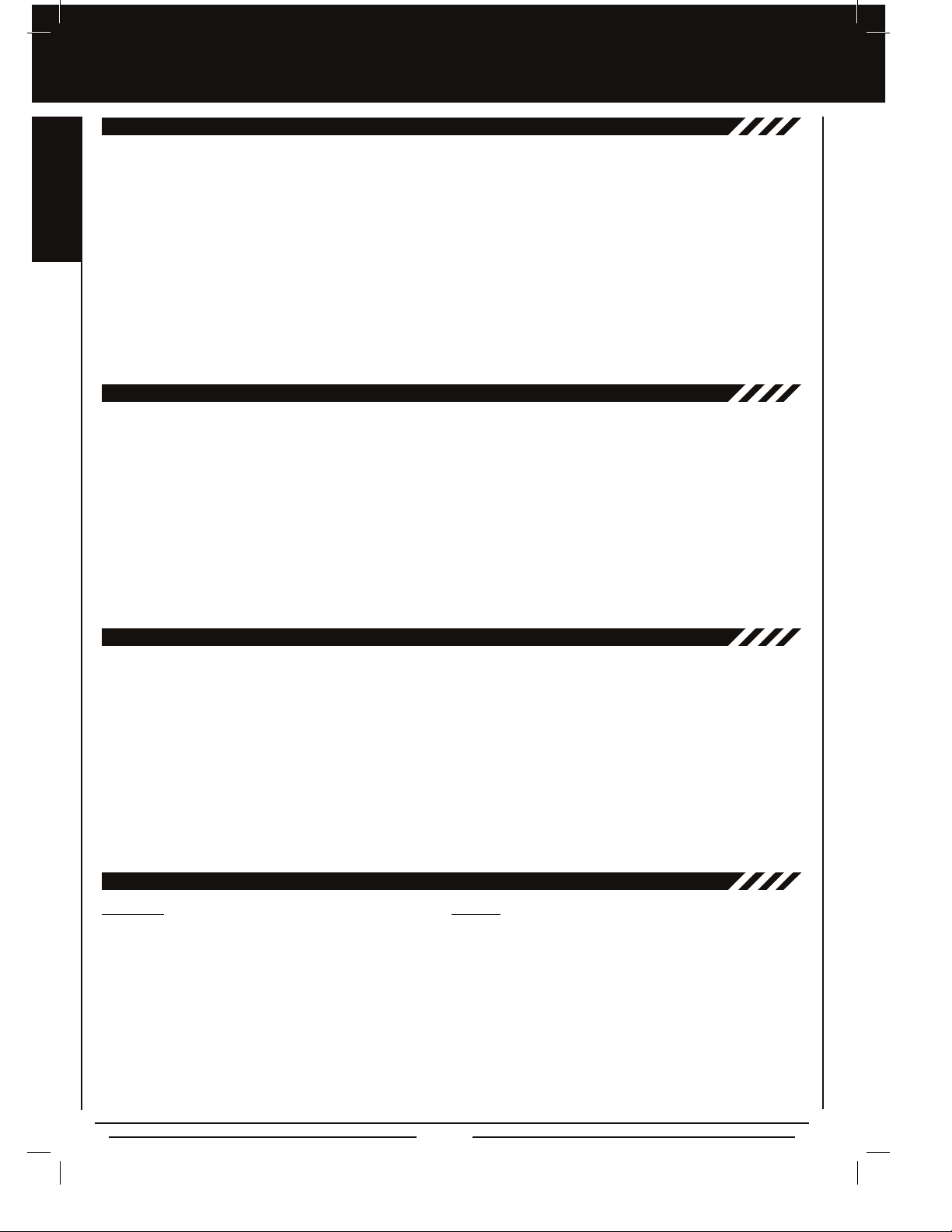

Low-Power Mode

Normal Mode

POWER MODE TRANSMITTER STATUS

Bind LED Flashing

Bind LED Solid

The Low-Power Mode function lowers the transmitter's RF output level to check radio signal reception (Range Check). Use

this function to check radio signal reception on the ground, prior to ight.

Range Checking

1) Turn the receiver in your aircraft ON.

2) With the transmitter in Low-Power Mode (Bind LED ashing), walk approximately 30 paces from your aircraft (approximately

90 feet) and, with the help of another person, check to make sure that the servos move without any problems. If there is a

problem with servo movement, try moving to a different position while still maintaining the same distance from your aircraft,

then check servo movement again. If there is still a problem, DO NOT FLY. Check to make sure that all receiver, servos,

switch, and onboard battery connections are correct and secure. Check to ensure that the receiver antenna wires are correctly

mounted as described previously.

3) When satised that the system is operating correctly, turn the transmitter OFF, then back ON to resume use in Normal Mode.

WARNING Do not attempt to y with the transmitter in Low-Power Mode. You will be unable to control your aircraft once it is

a certain distance away from you. Always verify that the Bind LED is solid prior to ight.

The transmitter will revert to Normal Mode after approximately 3 minutes. If you haven't completed your Range Check

within that time, turn the transmitter OFF, then repeat steps 1 through 3 to re-enter Low-Power Mode.

If after checking all airborne system components and verifying correct antenna wire mounting, your radio control system

still fails the Range Check, DO NOT FLY. Please contact Airtronics Customer Service using the information on the back

cover of this Operating Manual.

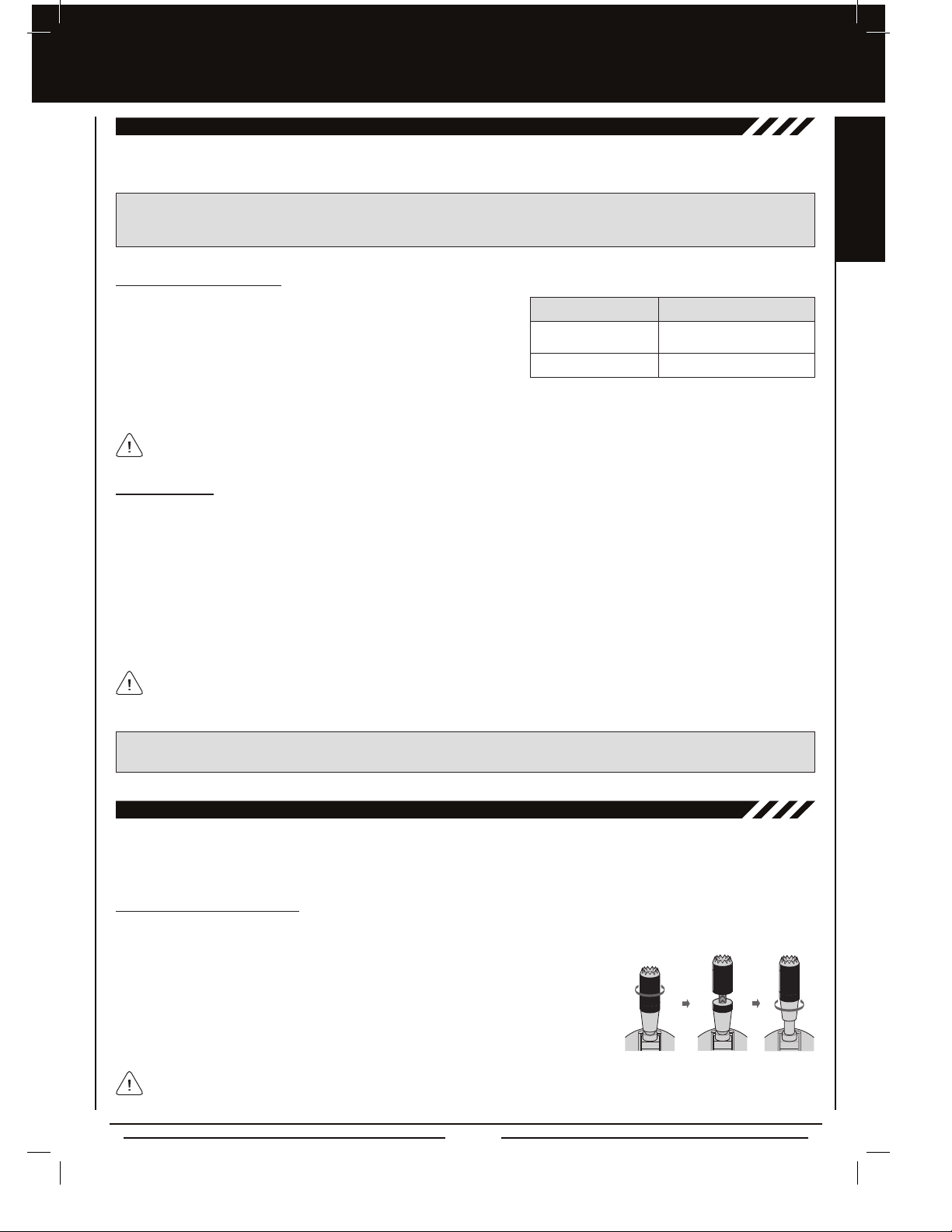

Adjusting Control Stick Length

1) While holding the base of the control stick, turn the top half of the control stick counter-clockwise to loosen it.

2) To lengthen the control stick, turn the top half of the control stick counter-clockwise. To

shorten the control stick, turn the top half of the control stick clockwise.

3) Once your are satised with the length of the control stick, thread the bottom half of the

control stick up and tighten it gently against the top half of the control stick.

GENERAL

Page 20

FLighT MODES

The TM-160 transmitter model programming is based around Flight Modes. Each Model Type (AERO and HELI) feature three

independently programmable Flight Modes. Flight Mode FN (Normal), Flight Mode F1, and Flight Mode F2. Within these Flight

Modes is where the core of the model programming takes place. Features such as Dual Rate, Exponential, Throttle Curve, Pitch

Curve, Mixing, Compensation Mixing, and much more can be individually programmed to each of the three Flight Modes. Each

Flight Mode is controlled by a switch so that they can be turned ON and OFF during ight.

Flight Modes allow you to change the ying characteristics of your model with the ip of a switch. For example, if you y

helicopters, you can have one Flight Mode for normal ying and a second Flight Mode for aerobatic ying. Flip the Flight Mode

switch from FN (Normal) to F1 and your helicopter is now programmed with all of your 'Aerobatic' Flight Mode programming. With

three programmable Flight Modes available for each Model Type, the combinations of model programming is highly-congurable.

FLighT MODE waRning aLaRM

The TM-160 transmitter is equipped with a safety feature that will not allow you to use the transmitter if the Flight Mode is not set

to FN (Normal) when you turn the transmitter ON. If the Flight Mode is not set to FN when you turn the transmitter ON, the Flight

Mode Warning alarm will sound continuously, the RF Output Indicator will ash, and the LCD will read F-MODE NOT 'N' ! To clear

the Flight Mode Warning, set the Flight Mode to FN using the Flight Mode Switches (move both Flight Mode switches forward).

The LCD will read normally, the Flight Mode Warning alarm will cease, and RF Output Indicator will stop ashing.

There are three Flight Modes that can be individually programmed for

each Model Type. The currently Active Flight Mode (FN, F1, or F2) is

displayed in the upper right corner of the Display screen.

There is always one Flight Mode active at all times and will vary based on the positions of the two Flight Mode switches.

When both Flight Mode switches are pushed away from you (OFF), Flight Mode FN (Normal) will be Active.

gEnERaL inFORMaTiOn

The F-MODE key is used to facilitate programming the individual Flight Modes only and

does not turn the Flight Modes ON or OFF or switch between Flight Modes during use.

It's important to note that higher numbered Flight Modes override lower numbered Flight Modes. For example, if you have

Flight Mode F1 and Flight Mode F2 Active at the same time (both Flight Mode switches pulled toward you), Flight Mode F2

will override Flight Mode F1.

Common or Separate Flight Modes

Many Flight Mode programming options can be agged either COMMON or SEPARATE. Options agged as Common are

common across all Flight Modes. Options agged as Separate can be programmed separately for each Flight Mode from the

same Programming Menu.

Flight Modes are turned ON and OFF using the two Flight

Mode switches, as described below:

Flight Mode FN (Normal) - Both Flight Mode switches pushed

forward (OFF).

Flight Mode F1 - Flight Mode F1 Switch pulled toward you

(ON) and Flight Mode F2 switch pushed away from you (OFF).

Flight Mode F2 - Flight Mode F2 switch pulled toward you

(ON).

Flight Mode F1

Switch

Flight Mode F2

Switch

Page 21

aERO MODEL TyPE cOnTEnTS

General Information ......................................................................................................................................................... Page 22

AERO Model Type Menu Flow Chart .............................................................................................................................. Page 22

AERO Model Type Transmitter Layout........................................................................................................................... Page 23

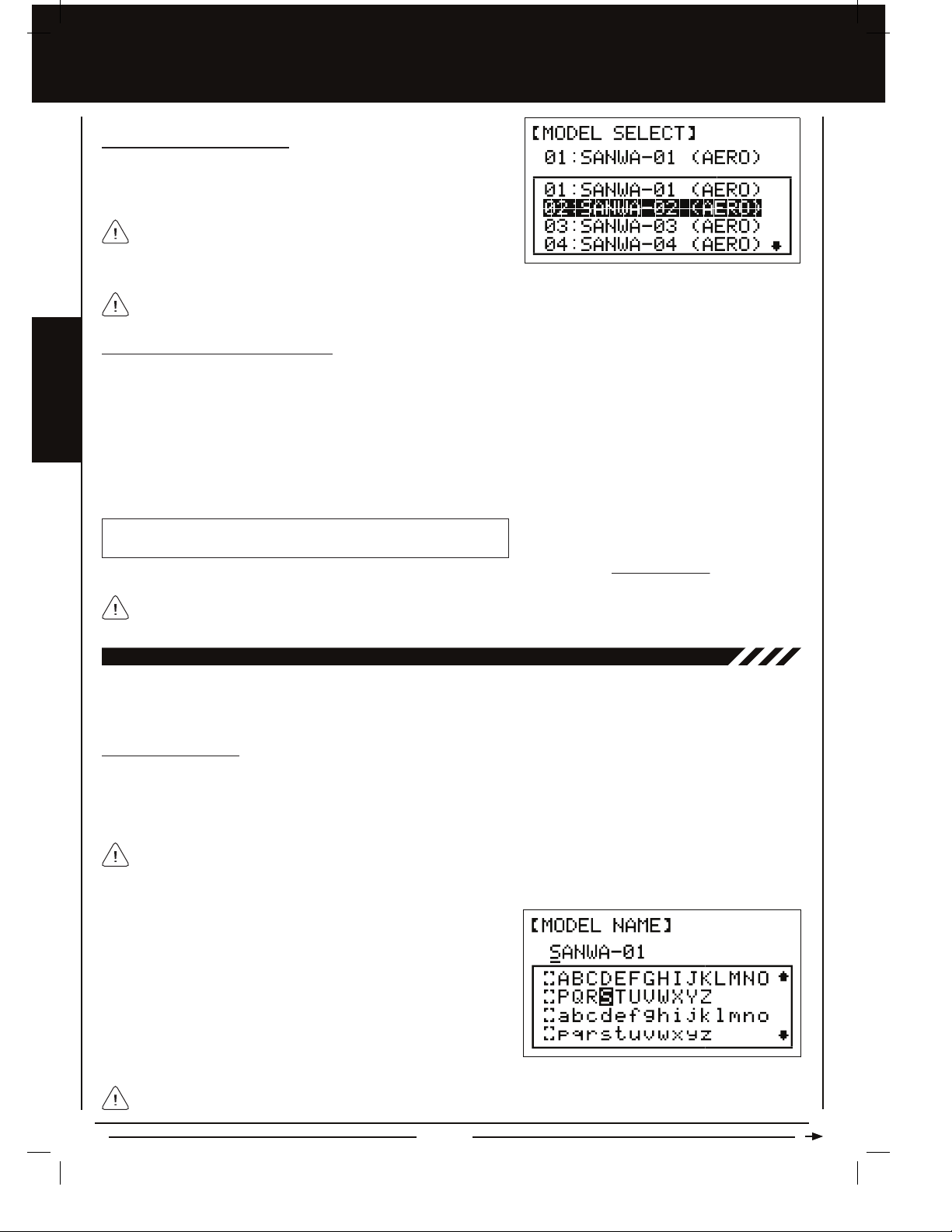

MODEL SELE (Model Select)........................................................................................................................................... Page 23

MODEL NAME (Model Naming)....................................................................................................................................... Page 24

TYPE (Model Type)........................................................................................................................................................... Page 25

TRAINER (Trainer System) .............................................................................................................................................. Page 26

STOP WATCH (Stop Watch and Count Up Timer).......................................................................................................... Page 28

DATA COPY (Model Programming Data Copy) .............................................................................................................. Page 29

DATA RESET (Model Programming Data Reset) ........................................................................................................... Page 29

REVERSE (Servo Reversing)........................................................................................................................................... Page 30

CENTER (Servo Centering Sub-Trim)............................................................................................................................. Page 31

EPA (End Point Adjustment)............................................................................................................................................ Page 32

TH-CUT (Throttle Cut) ...................................................................................................................................................... Page 33

D/R & EXP (Dual Rate and Exponential)......................................................................................................................... Page 34

TRIM (Digital Trim)............................................................................................................................................................ Page 36

TH-CURVE (Throttle Curve)............................................................................................................................................. Page 37