Page 1

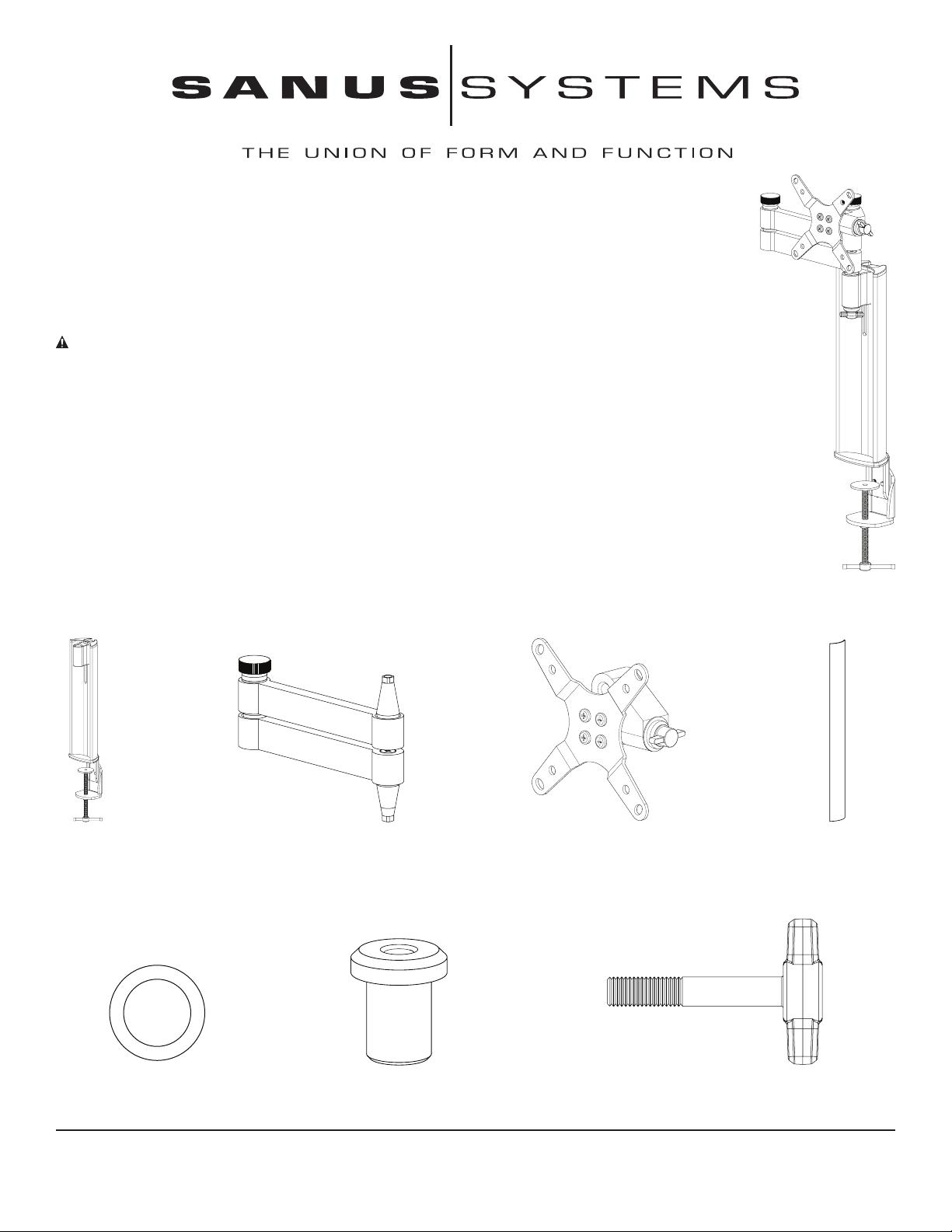

Assembly Instructions for Model: SD115

Thank you for choosing a Sanus Systems desk mount. The SD115 is designed to mount LCD

at panels with a VESA (Video Electronics Standards Association) hole pattern of 75 mm x 75 mm

or 100 mm x 100 mm. It allows you to effortlessly tilt and swivel the monitor up to 15° vertically, and

in almost any direction horizontally.

CAUTION: The weight of the monitor must not exceed 20 lbs (9 kg). Improper installation may cause

property damage or personal injury. Do not use this product for any purpose that is not explicitly specied

by Sanus Systems.

If you do not understand these directions, or have any doubts about the safety of the installation, please

contact Sanus at 800.359.5520 or www.sanus.com. Our customer service representatives can quickly

assist you with installation questions, and missing or damaged parts. Replacement parts for products

purchased through authorized dealers will be shipped directly to you. Check carefully to make sure that

there are no missing or defective parts. Sanus Systems can not be liable for damage or injury caused

by incorrect mounting, incorrect assembly, or incorrect use. Please call Sanus Systems before returning

products to the point of purchase.

Supplied Parts and Hardware

NOTE: Threaded fasteners and washers are shown actual size.

Pillar – A

Qty: 1

Washer – E

Qty: 1

Sanus Systems 2221 Hwy 36 West, Saint Paul, MN 55113 09.07.06 (6901-100122)

Customer Service: 800.359.5520. See complementary Sanus products at www.sanus.com

Arm – B

Qty: 1

Extended Cap – F

Qty: 1

Monitor Mount – C

Qty: 1

Cable Cover – D

Qty: 1

T-Knob – G

Qty: 1

Page 2

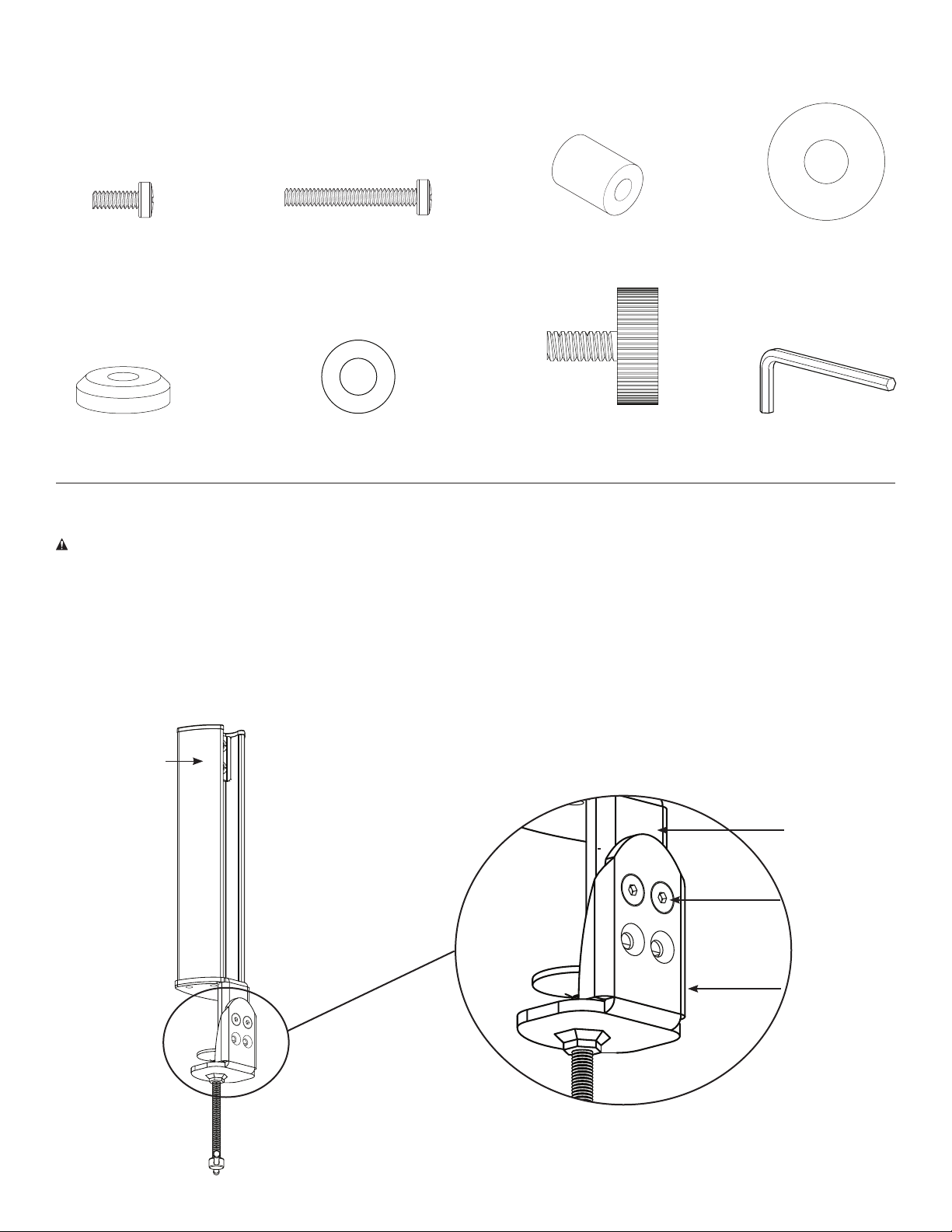

Supplied Parts and Hardware (continued)

NOTE: Threaded fasteners and washers are shown actual size.

M4 x 10 Screw–H

Qty: 4

Small Cap – L

Qty: 1

M4 x 30 Screw – I

Qty: 4

Small Washer – M

Qty: 2

Spacer – J

Qty: 4

Round Knob – N

Qty: 1

Large Washer – K

Qty: 1

Allen Key – O

Qty: 1

Step 1: Adjust the Pillar Clamp Height for Thicker Desk Surfaces (optional)

CAUTION: Do not adjust the height of the pillar with a monitor attached. Sanus Systems is not responsible for property

damage and/or personal injury.

If you have a thick desk surface, you may need to adjust the pillar clamp height. Loosen and remove the two screws on

the pillar stem (A) with the Allen key (O), as shown in Figure 1. Slide the two pieces of the stem apart until the upper holes

on the outside stem align with the holes on the inner stem. Place the screws through the holes and tighten them with the

Allen key.

Figure 1

Pillar (A)

Inner Stem

Screw

Outer Stem

Page 3

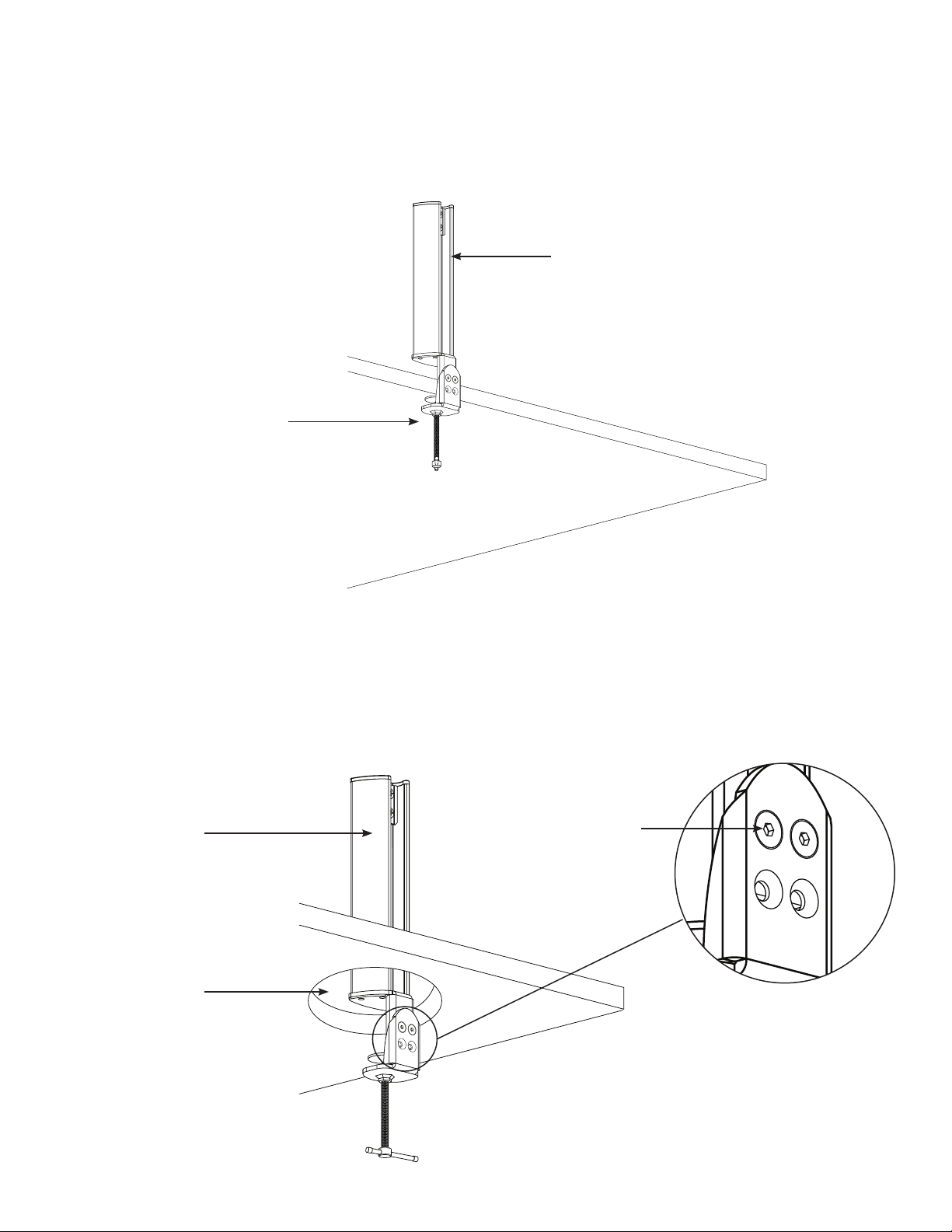

Step 2: Attach the Pillar to the Desk.

To attach the pillar (A) to the edge of the desk as shown in Figure 2a, place the pillar in the desired location. Check that

the pad is resting at on the nished surface of the desk. Secure the pillar (A) by tightening the clamp until the base rests

rmly against the bottom of the desk.

Figure 2a

Pillar (A)

Tighten clamp against

bottom of desk

Desk

To attach the pillar through a wire management hole as shown in Figure 2b, you must rst separate the inner and outer

stems on the pillar. Loosen and remove the two screws on the stem with the Allen key (D), and slide the stems apart.

Place the pillar through the wire management hole, resting the pad at on the nished surface of the desk. Reattach the

outer stem with the two screws and the Allen key. Then secure the pillar by tightening the clamp until the base rests rmly

against the bottom of the desk.

Figure 2b

Pillar (A)

Wire Management

Hole in Desk

Screw on Outer

Stem of Pillar

Page 4

Step 3: Place the Arm into the Pillar

Slide the arm (B) into the pillar (A) by placing the cone-shaped bushing into the opening on the pillar. The knob on the arm

should face up, as shown in Figure 3.

Figure 3

Arm (B)

Pillar (A)

Desk

Step 4: Attach the Arm to the Pillar

Place the washer (E) onto the extended cap (F) and place them onto the bottom cone-shaped bushing on the arm (B), as

shown in Figure 4. Turn the extended cap until it clicks into place, and the square cut ts snugly over the square end of

the arm bushing. Insert the T-knob (G) through a small washer (M) into the extended cap, as shown in Figure 4. Tighten

the T-knob.

CAUTION: Make certain that the arm (B) is rmly attached to the pillar (A). If the arm wobbles, the extended cap (F)

may have slipped off the square end of the arm bushing. Remove the T-knob (G) and turn the extended cap until it clicks

back into place. Then reinsert the T-knob and tighten.

Figure 4

Arm (B)

Pillar (A)

Bushing on

Arm (B)

Pillar (A)

Washer (E)

Extended Cap (F)

Small Washer (M)

T-Knob (G)

Page 5

Step 5: Attach the Monitor Mount to a Monitor with a Flat Back

NOTE: For monitors with curved backs or obstructions, go to Step 6.

Attach the monitor mount (C) to the back of your LCD monitor using the M4 x 10 mm screws (H), as shown in Figure

5. Position the monitor mount so that the large side of the tapered hole faces the bottom of the monitor. Place the four

screws through the monitor mount into the VESA bolt mounting pattern on the back of the monitor. Tighten the screw into

the monitor. Go to Step 7.

Figure 5

M4 x 10 Screw (H)

Tapered hole on Monitor

Mount (C) faces down

M4 x 10 Screw (H)

Step 6: Attach the Monitor Mount to a Monitor with a Curved Back or Obstructions

Attach the monitor mount (C) to the back of your LCD monitor using the M4 x 30 mm screws (I) and the spacers (J), as

shown in Figure 6. Position the monitor mount so that the large side of the tapered hole faces the bottom of the monitor.

Place the four screws through the monitor mount and the spacers, and then into the VESA bolt mounting pattern on the

back of the monitor. Tighten the bolts to the monitor.

Figure 6

Spacer (J)

M4 x 30 Screw (I)

Tapered hole on Monitor

Mount (C) faces down

M4 x 30 Screw (I)

Spacer (J)

Page 6

Step 7: Attach the Monitor Mount and Monitor to the Arm

NOTE: So that all the parts can be seen clearly, this step is shown without the monitor in Figure 7b.

Set the tapered hole in the monitor mount (C) down over the cone-shaped bushing on the arm (B). Make certain the

monitor mount is completely seated onto the arm, as seen in Figures 7a and 7b.

Add the large washer (K). Then add the small cap (L), turning it until the square cut ts over the square top of the coneshaped bushing on the arm. Finally, place the round knob (N) through the small washer (M), the small cap, and the large

washer, and into the cone-shaped bushing on the arm. You can now set the desired level of tension for each of the knobs.

Figure 7a

Monitor Mount (C)

Cone-Shaped Bushing on Arm (B)

Figure 7b

Round Knob (N)

Small Washer (M)

Small Cap (L)

Large Washer (K)

Monitor Mount (C)

Cone-Shaped Bushing

on Arm (B)

Page 7

Step 8: Cable Management

Place the monitor cables into the channel on the back of the pillar (A). Snap the cable cover (D) into the grooves along the

edge of the channel, as shown in Figure 8.

Figure 8

Groove

Cable Cover (D)

Channel on

Pillar (A)

Step 9: Adjust Arm Height (Optional)

Required Tool: Phillips screwdriver

CAUTION: Do not adjust the Arm height if a monitor is attached. Sanus Systems is not responsible for property

damage and/or personal injury.

Remove the Cable Cover (D) from the Pillar (A), and lift the monitor cables out of the channel on the Pillar. See Step

8 for additional information. Remove the Monitor Mount (C) and the attached monitor from the Arm (B). See Step 7 for

additional details about how the Monitor Mount and Arm t together.

Loosen the two screws at the top of the Pillar with a Phillips screwdriver. See Figure 9. Slide the Arm to the desired height,

and tighten the screws with the screwdriver. Replace the Monitor Mount with attached monitor as described in Step 7.

Replace the monitor cables and Cable Cover as described in Step 8.

Figure 9

Bushing on Arm (B)

Screws

CSAV, Inc. and its afliated corporations and subsidiaries (collectively, “CSAV”), intend to make this manual accurate and complete. However, CSAV makes no claim that the information contained herein

covers all details, conditions, or variations. Nor does it provide for every possible contingency in connection with the installation or use of this product. The information contained in this document is subject to

change without notice or obligation of any kind. CSAV makes no representation of warranty, expressed or implied, regarding the information contained herein. CSAV assumes no responsibility for accuracy,

completeness or sufciency of the information contained in this document.

Page 8

SD115 ADDENDUM

This Addendum covers the assembly procedure for the SD115 Monitor Mount.

Supplied Parts and Hardware

Make sure all parts are included and undamaged. Never use defective parts. If hardware is damaged or missing, contact your local

hardware store or Sanus Systems. Before returning products to the point of purchase, contact Sanus Systems. Replacement parts

for products purchased through authorized dealers are shipped directly to you.

[02] x1

[01] x1

Sanus Systems 2221 Hwy 36 West, St Paul, MN 55113 USA • 12.19.06 (6901-100138)

Customer Service 800.359.5520 • www.sanus.com

[03] x1

[06] x1[05] x1[04] x1

Page 9

1

The square surfaces of the shaft on the head [01] and Spacer [04] must nest together.

[02]

[03]

[01]

[04]

[05]

[06]

CSAV, Inc. and its affiliated corporations and subsidiaries (collectively, “CSAV”), intend to make this manual accurate and complete. However, CSAV makes no claim that the information contained herein covers all details,

conditions, or variations. Nor does it provide for every possible contingency in connection with the installation or use of this product. The information contained in this document is subject to change without notice

or obligation of any kind. CSAV makes no representation of warranty, expressed or implied, regarding the information contained herein. CSAV assumes no responsibility for accuracy, completeness or sufficiency of the

information contained in this document.

2

6901-100138

Loading...

Loading...