Santec PB-3600 User Manual

ESTATE SERIES PRESSURE

BALANCE SHOWER VALVE (NEW 2010)

MODEL: PB-3600

Specications

Description

This product is precision engineered to provide satisfactory performance provided it is installed and

operated in accordance with our recommendations contained in this manual. In order to fully enjoy the

comfort, safety and the reliability of your pressure balancing valve, be certain to familiarize yourself with the

contents of this manual.

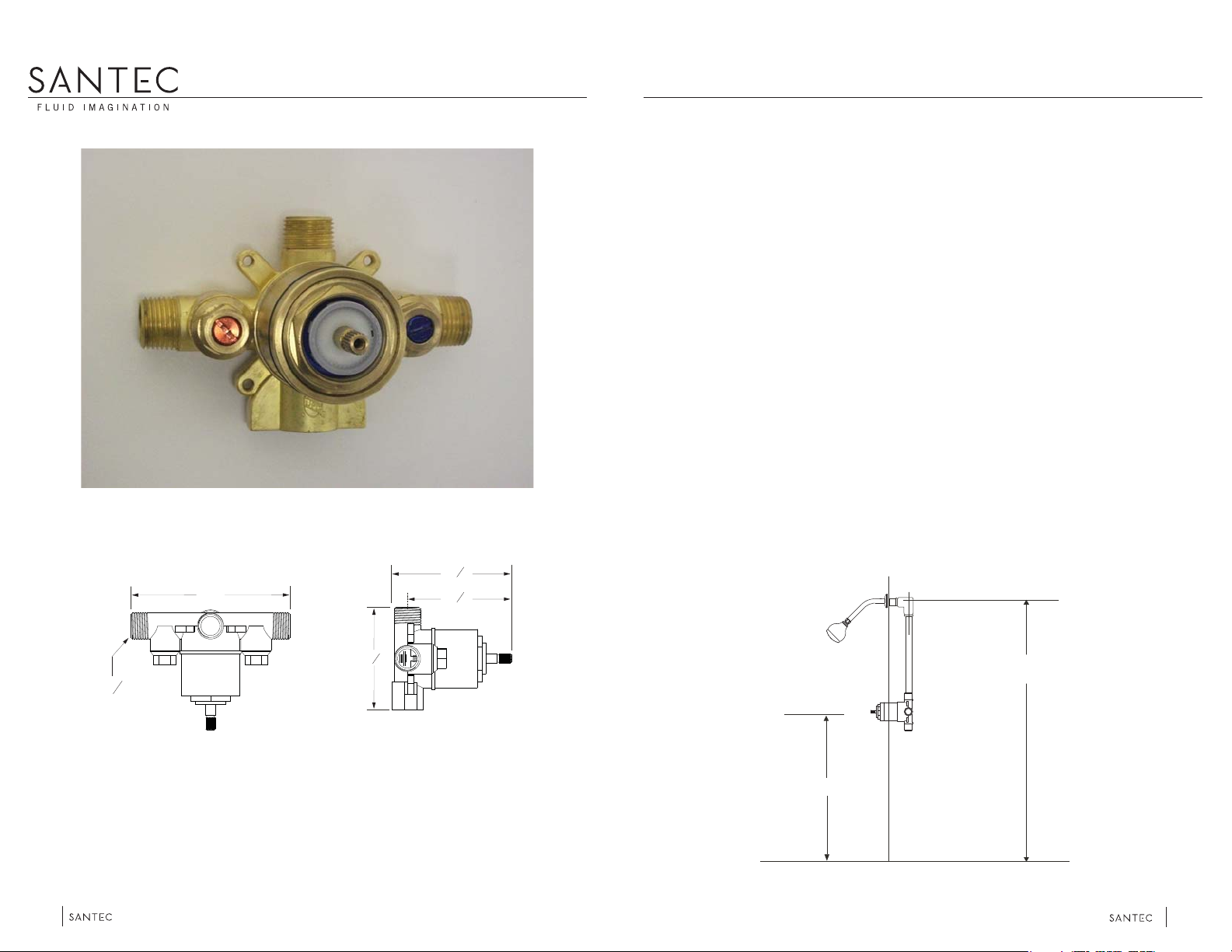

Specication and Dimensions

Minimum operating pressure 20 psi

Maximum operating pressure 145 psi

Maximum test pressure 500 psi

Hot and cold water inlets ½" IPS

Shower outlet ½" IPS

Flow capacity 5 USGPM @ 50 psi

Finished wall adjustment : See Figure 1

3

"

4

3

1

"

3

2

Ø

½”

6

3

"

8

3

1

2

"

KEEP THIS INSTRUCTION BOOKLET FOR FUTURE REFERENCE

Important : Please register your product online at www.santecfaucet.com within

30 days of purchase. Santec reserves the right to request additional documents

before servicing warranty requests.

01

NOTE:

An access panel should be provided to any valve plumbed in the wall for future

maintenance purposes.

WALL LINE

78"

(1981 mm)

46"

FLOOR

LINE

02

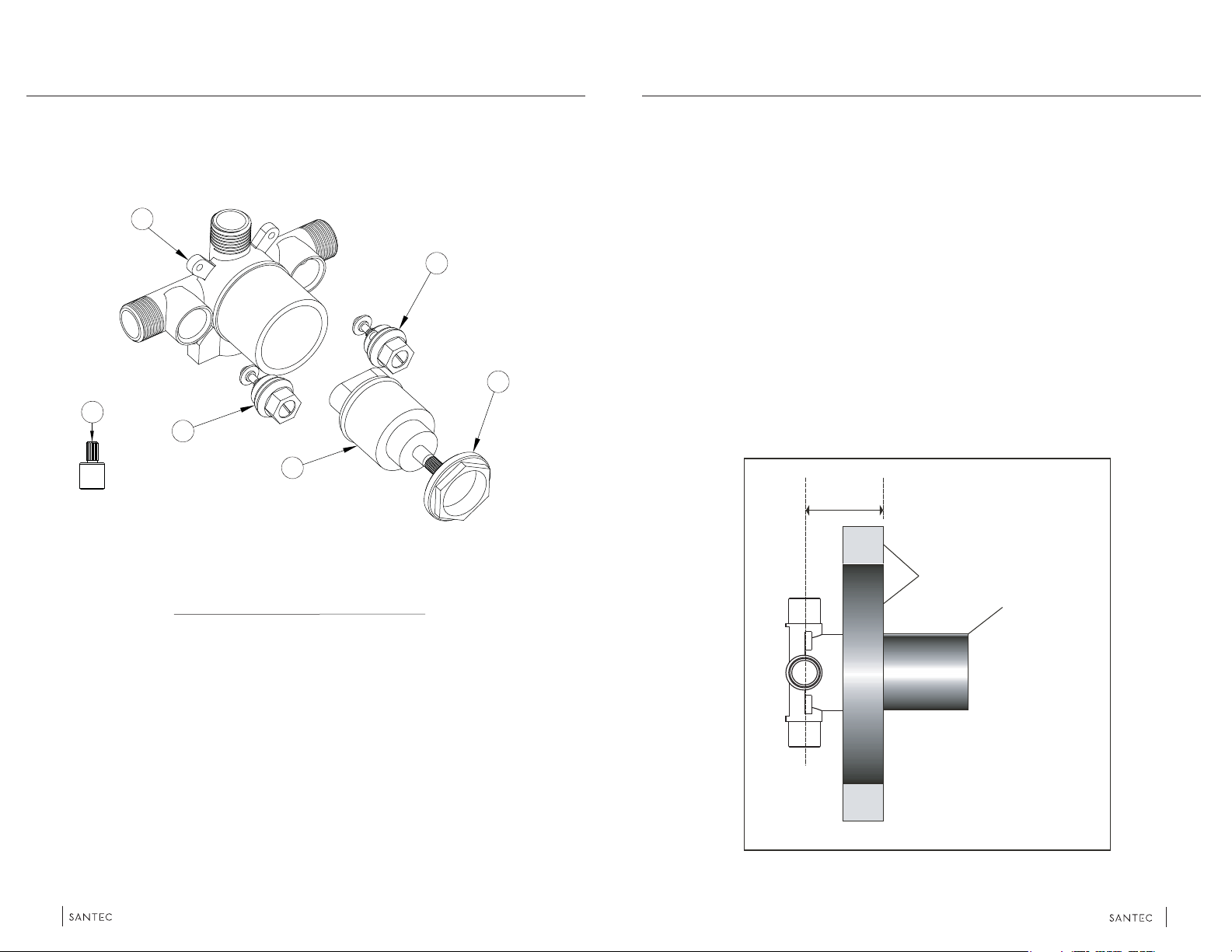

Parts Breakdown

Pressure Balanced Shower Valve

The spare parts list is valid for the valves purchased after February 1, 2010.

*

4

1

6

2

3

#

PART

1

Service Stop

2

Service Stop

PB Cartridge

3

4

Valve Body

5

Valve Lock Nut

6

Extension

DESCRIPTION

PART #

PB-3600-C

PB-3600-H

PB40R

SA200

1. Rough-in & Valve Installation

NOTE: Failure to follow these instructions may cause damage or improper operations and nullify the

warranty.

Make sure the water supplies are off.

1.

Rough valve body into wall, connecting piping to 1/2” female copper sockets or 1/2“ male I.P. nipples.

2.

IMPORTANT: NOTE “UP” & “DOWN” MARKINGS ON BACK OF VALVE.

The depth of rough-in should account for thickness of wall materials to be used (combined thinckness

3.

of wall board and nished wall material). The distance between the center inlet of the valve and

the nished wall should be between 1 5/8” and 2”. Face of plastic guard should be ush with

nished wall (see Figure 1).

Anchor installation to bracing between studs (ears on the valve body can be used for this by removing

4.

the plastic guard) - otherwise, anchor the connecting pipe.

Valve should be pressurized and tested for leaks at the connections.

5.

Plastic guard should be left attached to the valve until the nished wall material is installed and until the

5

6.

trim arrives to be installed.

FIGURE 1

1 5 /8” - 2 .0”

FLUSH

Plastic guard

03

Center

of inlet

Finished wall

04

Loading...

Loading...