Santec 6734AR-TM User Manual

ESTATE SERIES ARKO COLLECTION

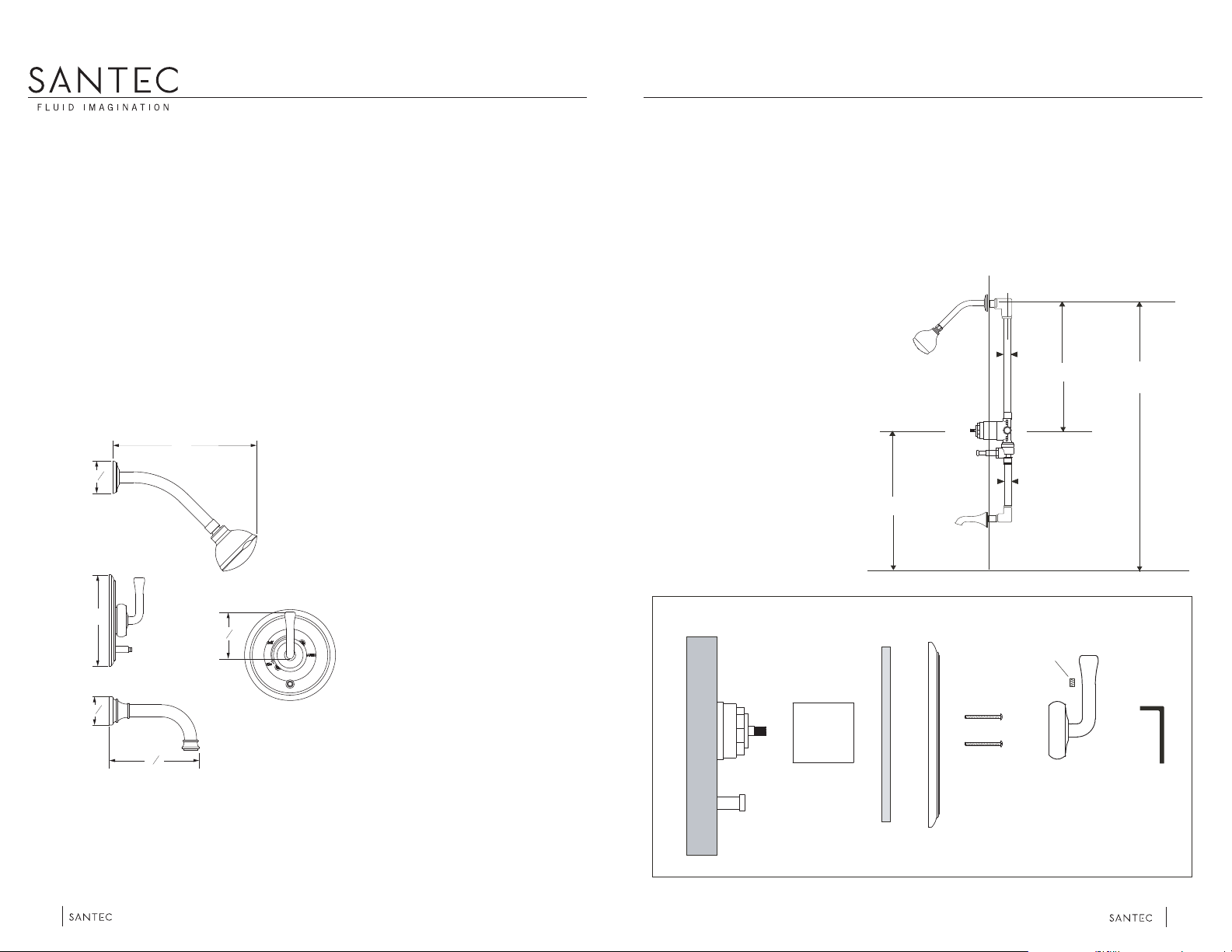

PRESSURE BALANCED TUB/SHOWER

TRIM WITH “AR” HANDLES

MODEL: 6734AR10-TM

6734AR75-TM

Specications

Description

This product is precision engineered to provide satisfactory performance provided it is installed and

operated in accordance with our recommendations contained in this manual. In order to fully enjoy the

comfort, safety and the reliability of your pressure balancing valve, be certain to familiarize yourself with the

contents of this manual.

Ø2

Ø2

Ø7"

1

Specication and Dimensions

WALL LINE

Minimum operating pressure 20 psi

Maximum operating pressure 145 psi

Maximum test pressure 500 psi

Hot and cold water inlets ½" IPS

Shower outlet ½" IPS

Flow capacity 5 USGPM @ 50 psi

11"

1

"

2

33"

FLOOR

LINE

Trim

5

"

3

16

Sleeve

4

"

plate

Plate

screws

½”

½”

Set screw

Min 36"

78"

(1981 mm)

Allen

key

1

"

4

6

KEEP THIS INSTRUCTION BOOKLET FOR FUTURE REFERENCE

Important : Please register your product online at www.santecfaucet.com within

30 days of purchase. Santec reserves the right to request additional documents

before servicing warranty requests.

01

Finished wall

Handle

Foam

strip

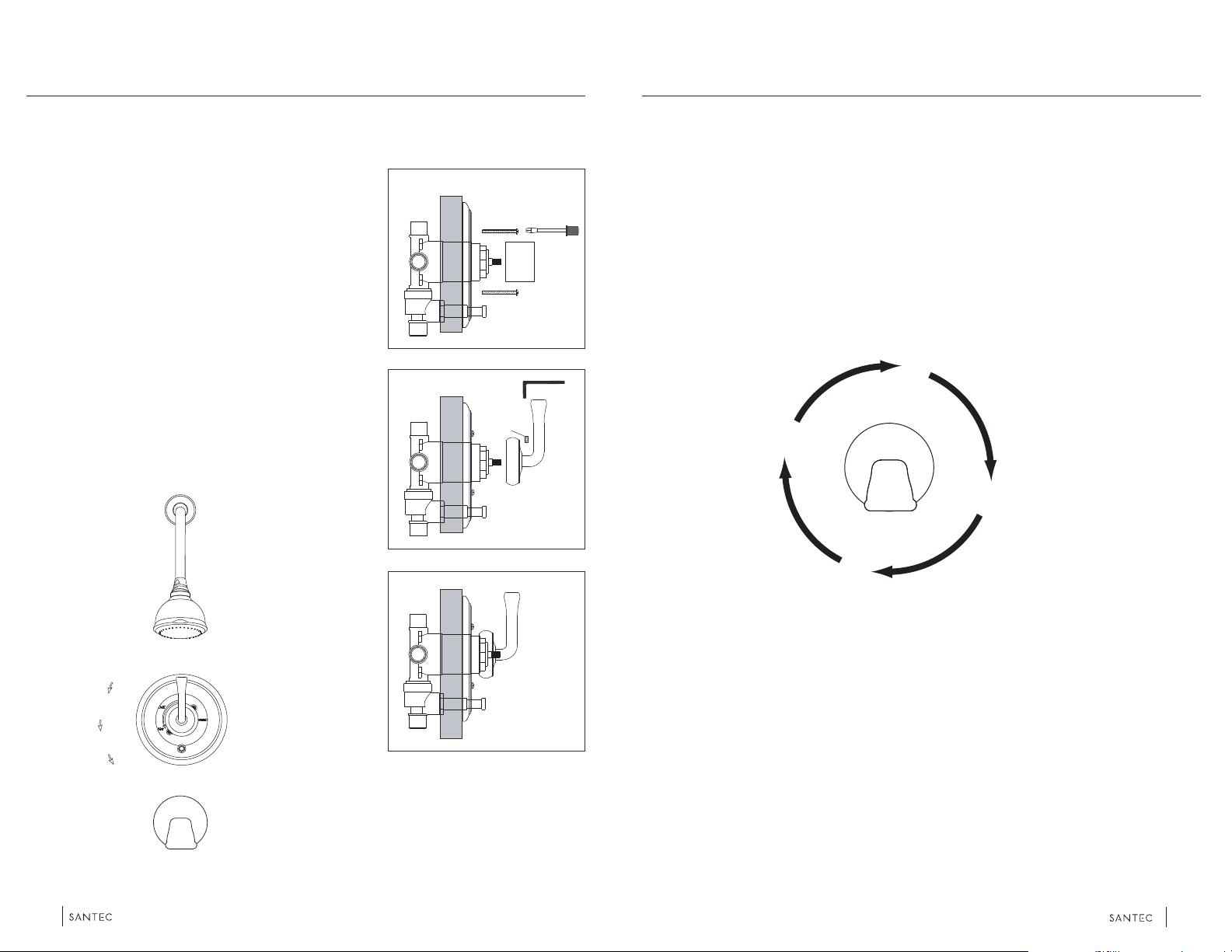

02

Pressure Balanced Shower

Pressure Balanced Shower

1. Trim Plate & Handle Installation

TRIM PLATE

Fit sleeve over valve until it bottoms out.

Place foam strip around the inner edge of the shower plate.

Press the shower plate against the wall.

Screw the 2 plate screws through the plate holes and onto the

valve’s screw holes. Tighten both screws rmly.

HANDLE

Insert the Handle onto the Valve Stem. Turn the handle

clockwise until it reaches the end. Reposition the handle to

the desired position. The handle should be facing up at 12

o’clock position.

Using the provided Allen Key, insert the Handle Set Screw

onto the Handle and press against the valve’s stem. Tighten it

rmly.

Adjust the height of the Handle if it is scraping against the

shower plate.

Finished wall

Trim plate

Plate screws

Trim plate

Handle

set screw

Handle

Sleeve

2. Tub Spout Installation

NOTE: The length of threaded pipe coming out from the nish wall should be no longer than 1/2”.

Wrap the pipe threading for the spout with Teon tape. Then thread the spout onto the pipe until it is

secured with the spout facing downward.

WARNING: Do not use excessive force when threading the spout.

Allen key

03

COLD

WARM

WARM ER

HOT

04

Loading...

Loading...