Santec 4334GL User Manual

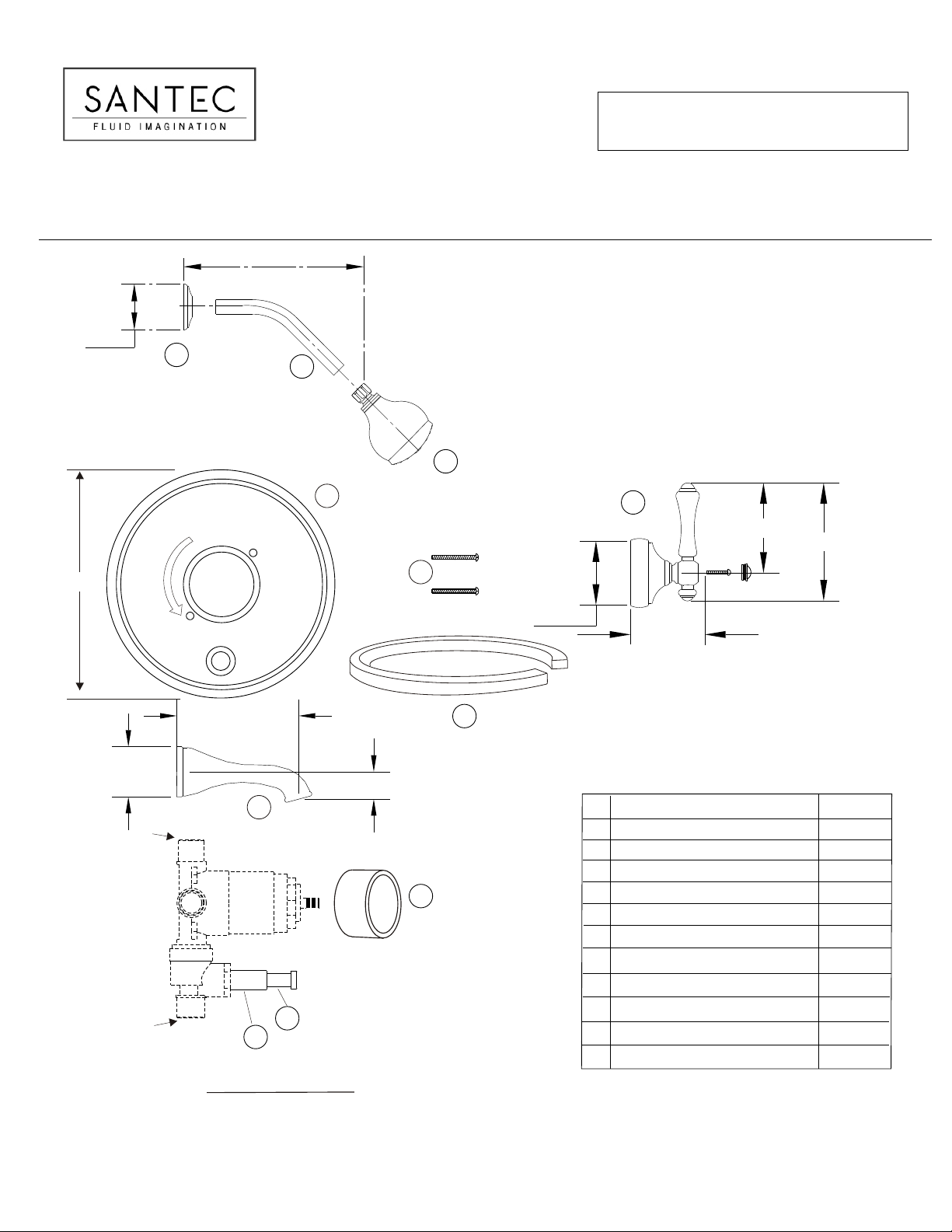

1.246"

5.569"

Ø2.315"

Ø2.250"

4.099"

3.104"

2.200"

Ø2.500"

7.349"

4334GL-10-TM 4334GL-75-TM

4334GL-23-TM 4334GL-41-TM

MODEL NUMBER

4334GL _ _- TM

ESTATE SERIES CHADWICK/ MONTAGE COLLECTION

PRESSURE BALANCED TUB AND SHOWER WITH “GL” HANDLE

33

Off

7”

Cold

Hot

½” NPT

½” NPT

INSPECTED BY

SANTEC

66

1010

99

22

55

11

77

88

1111

44

##

Complete Shower head *

1

8” Shower Arm *

2

Shower Flange *

3

4

Complete GL Handle for Shower *

Tub/shower Trim Plate *

5

Complete Wall Mount Tub Spout *

6

Plate Screws (2) *

7

Valve Sleeve *

8

Diverter Body *

9

Diverter Knob *

10

Shower Plate Sealing Foam Strip

11

* Please specify the finish when ordering the part.

PART

DESCRIPTION

PART #

P0-285

P0-286

P0-2520

00YY-GL

Ph29999

P0-2E81

PM-617

P0-2101

P0-2102

P0-2103

P0-022

KEEP THIS INSTRUCTION BOOKLET FOR FUTURE REFERENCE

PAGE 01

INSTALLATION INSTRUCTIONS

4334GL_ _-TM

DESCRIPTION

This product is precision engineered to provide satisfactory performance provided it is installed and operated in

accordance with our recommendations contained in this manual. In order to fully enjoy the comfort, safety and the

reliability of your pressure balancing valve, be certain to familiarize yourself with the contents of this manual.

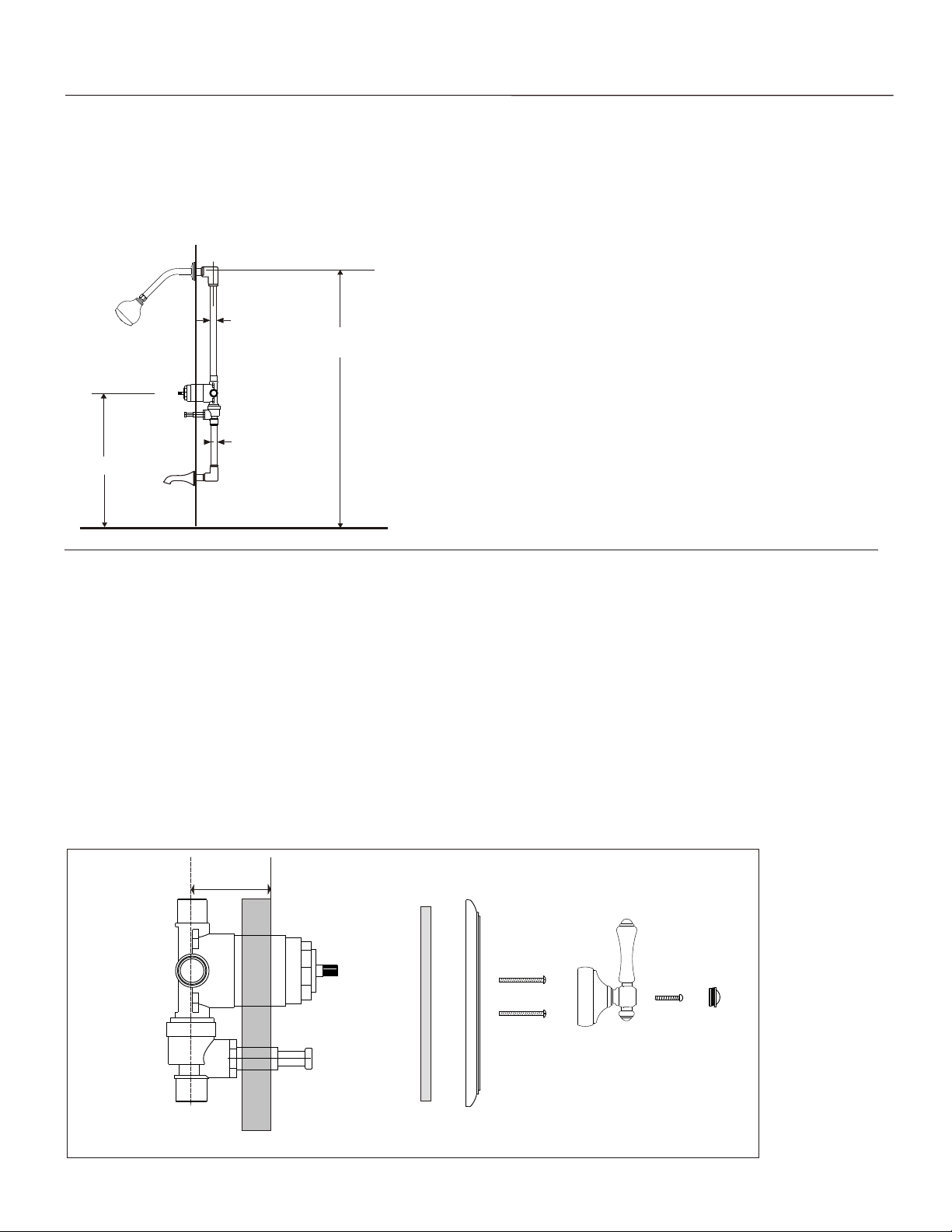

WALL LINE

SPECIFICATIONS AND DIMENSIONS

½”

78"

(1981 mm)

Minimum operating pressure 20 psi

Maximum operating pressure 145 psi

Maximum test pressure 500 psi

Hot and cold water inlets ½" IPS

½”

33"

Shower outlet ½" IPS

Flow capacity 5 USGPM@ 50 psi

Finished wall adjustment : see Illustration B

FLOOR

LINE

INSTALLATION

NOTE: Failure to follow these instructions may cause damage or improper operations and nullify the warranty.

ROUGH IN

- Make sure the water supplies are off.

- Remove all the trim items (plate and flange) before installation.

- Secure the valve firmly against the stud. Make sure the ½" shower outlet is in the up position.

- Make sure to flush or raise grouting on the tiled wall surface.

- Position the valve using the dimension shown in the illustration B.

(The distance between the center inlet of the valve and the finished wall should be between 1 5/8” and 2”).

1 5/8” - 2.0”

Foam Strip

Trim Plate

SCREWS

PLATE

HANDLE

HANDLE

SCREW

CAP

center of inlet

finished wall

ILLUSTRATION B

PAGE 02

Loading...

Loading...