Santec 1770WE User Manual

ETNA COLLECTIONETNA COLLECTION

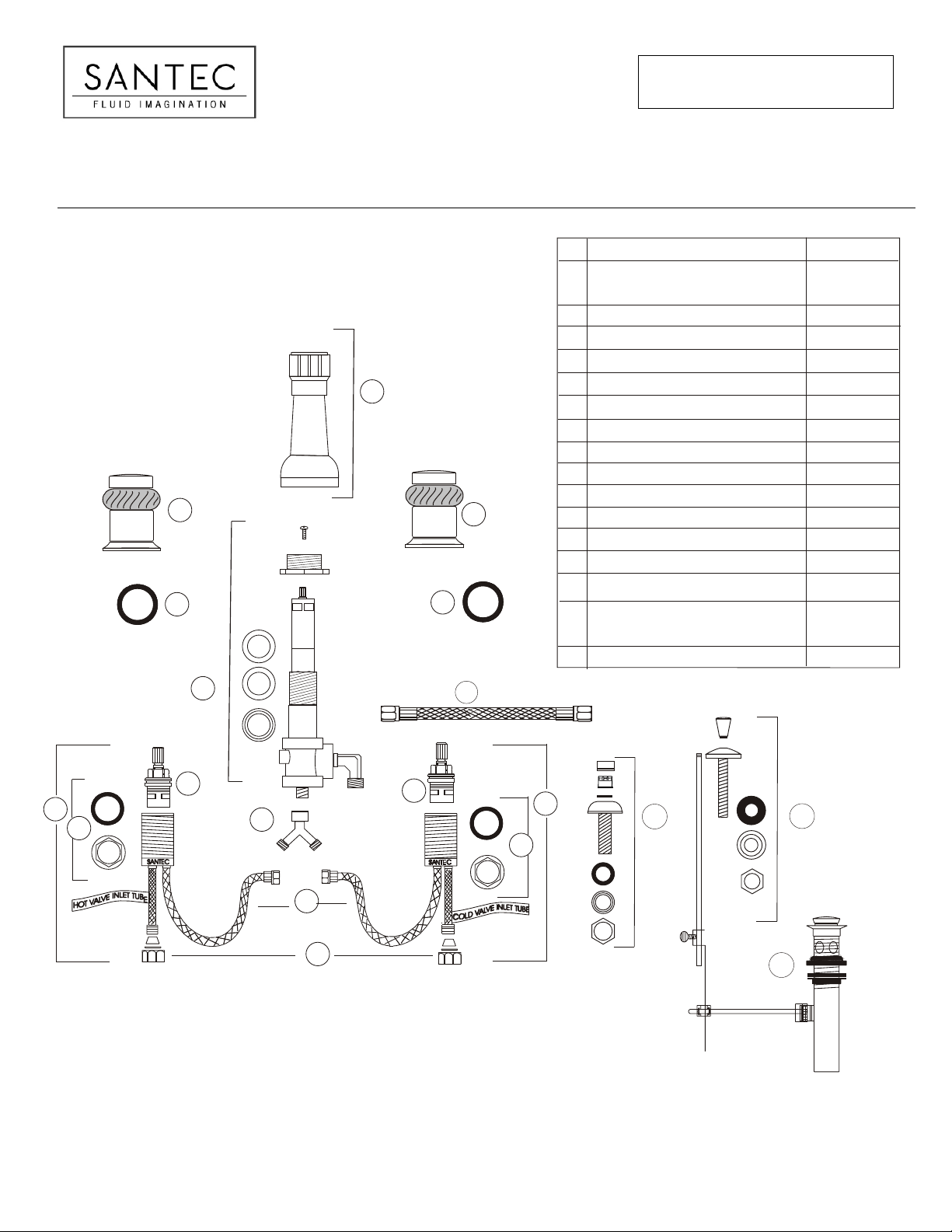

BIDET FITTING WITH “WE” HANDLESBIDET FITTING WITH “WE” HANDLES

ITEM NUMBER

1770WE _ _-_ _

##

11

22

33

44

11

55

66

77

88

99

1010

22

22

1111

1212

1313

1414

33

33

1515

1616

1111

1313

* Please specify the finish when ordering the part.* Please specify the finish when ordering the part.

PARTPART

DESCRIPTIONDESCRIPTION

Complete Vacuum Breaker Trim *Complete Vacuum Breaker Trim *

Complete WE HandleComplete WE Handle

Washers for Spout & HandleWashers for Spout & Handle

Hot Cartridge OnlyHot Cartridge Only

Cold Cartridge OnlyCold Cartridge Only

Complete Hot ValveComplete Hot Valve

Complete Cold ValveComplete Cold Valve

Connecting Hose to the TeeConnecting Hose to the Tee

Connecting Hose to the SupplyConnecting Hose to the Supply

Valve Body Mounting HardwareValve Body Mounting Hardware

Complete Vacuum Breaker CartridgeComplete Vacuum Breaker Cartridge

Y- Connector Y- Connector

Connecting Hose for the Aerator Connecting Hose for the Aerator

Aerator Housing, Insert, Flange & HardwareAerator Housing, Insert, Flange & Hardware

Complete Lift Knob, Rod and Hardware *Complete Lift Knob, Rod and Hardware *

Complete Pop-Up *Complete Pop-Up *

Assembly *Assembly *

FlangesFlanges

LineLine

PART #PART #

BD4200-4cap

BD4200-4cap

BD4200-1cylinder

BD4200-1cylinder

BD4200-3 ring

BD4200-3 ring

00WE00WE

PM-400PM-400

P0408P0408

P0409P0409

P0456P0456

P0457P0457

P0441P0441

P0440P0440

BD4100BD4100

PM-B100KPM-B100K

PM-B100GPM-B100G

BD4600-5 housing

BD4600-5 housing

BD4600-6 Base

BD4600-6 Base

BD4600-8 knob *

BD4600-8 knob *

BD4600-7 flange *

BD4600-7 flange *

BD4600-9 rod *

BD4600-9 rod *

P0202P0202

SANTECSANTEC

44

66

1010

1212

SANTECSANTEC

55

77

1414

1010

88

99

1616

KEEP THIS INSTRUCTION BOOKLET FOR FUTURE REFERENCE

1515

PAGE 01

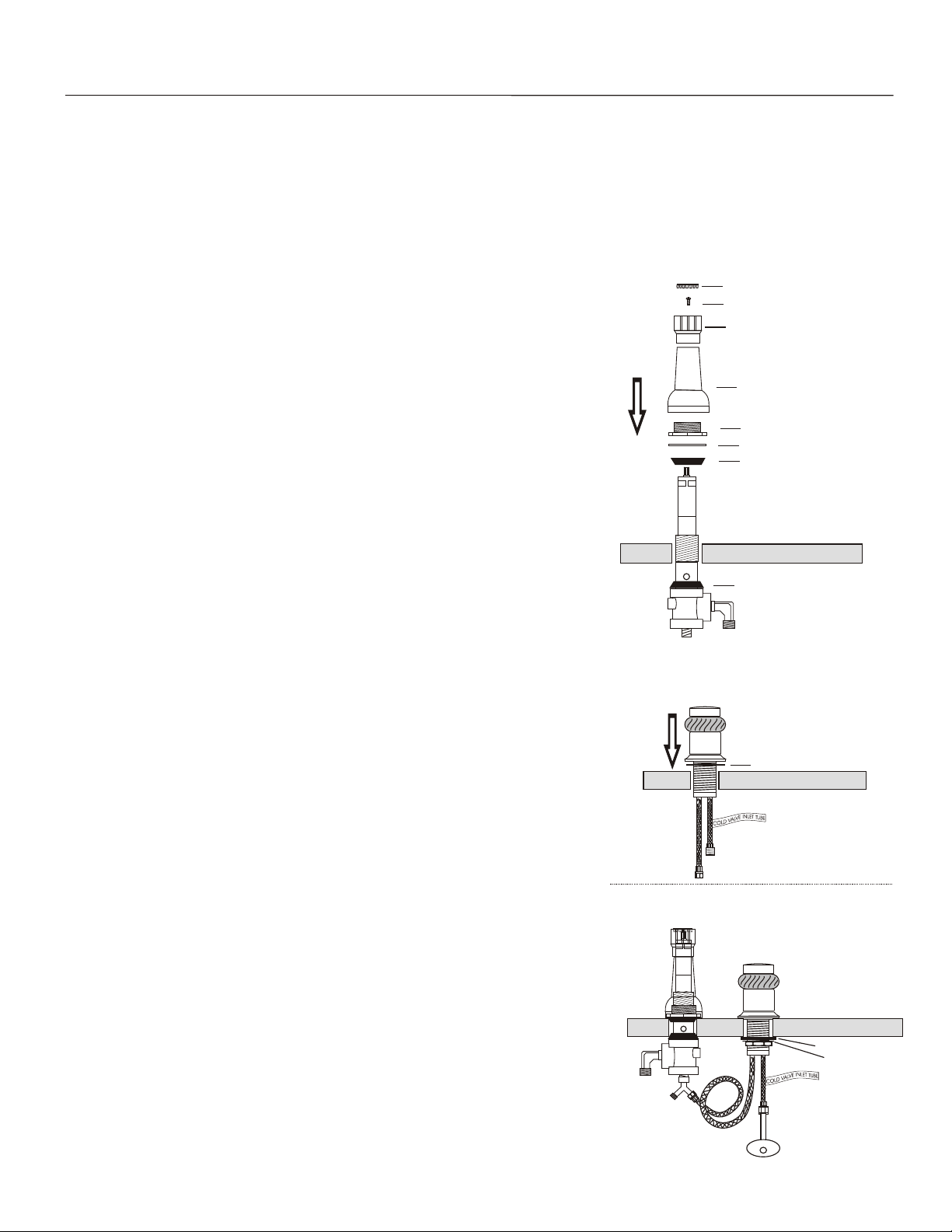

INSTALLATION INSTRUCTIONS

FLUSH BOTH SUPPLY LINES BEFORE INSTALLATION

.

AFTER FLUSHING , SHUT OFF BOTH SUPPLY LINES.

MINIMUM HOLE SIZE FOR THE SPOUT AND HANDLE TRIM IS 1 1/4” AND MAXIMUM OF 1 1/2”

VACUUM BREAKER INSTALLATION

1

- Remove the complete vacuum breaker trim (1) from the cartridge (11).

From the underneath of the sink, insert the vacuum breaker cartridge (11) through the

center hole of the sink with the one of 2 conical black Soft Seating China Seals inserted.

- From the top of the sink, insert the second black Soft Seating China Seal, the White Nylon

Slip Washer, then the black Plastic Inverted Lock Nut onto the Cartridge (11).

Tighten it firmly.

- Screw the Trim Cylinder onto the Cartridge (11). Tighten Firmly.

- Slip the Handle onto the Cartridge stem and secure it with the brass screw.

- Clip the Handle Cap onto the Handle after the installation is complete to check for the

water flow options.

1770WE _ _

Handle Cap

Screw

Handle

Trim Cylinder

Black plastic lock nut

White Nylon Slip Washer

Black Soft Seating China Seals

HANDLE TRIM INSTALLATION

1

- For proper handle turning direction, install the handle with the “cold” blue label (7)

at the right side of the sink (looking from the front) and the handle with the “hot”

red label at the left side of the sink.

- Both hot and cold side handle trims are pre-assmbled for faster installation.

- Remove the valve body mounting hardware (10) from the valve body. Slip the

valve body’s flexible hoses from the top of the sink or counter through the

appropriate hole next to the vacuum breaker. Make sure the handle flange washer (3)

is properly placed underneath of the flange and gently pressed against the sink

top. Aim the tee connecting hoses (8) toward the Y- connector (12).

2

- From beneath of the basin or counter, screw the valve body mounting

hardware (10) back to the valve body. First the fiber washer, then the

brass lock nut.

- Tighten the lock nut until it secures the valve body firmly.

3

- Loop and connect the flexible hoses (8) to the Y-Connector (12). Tighten to avoid

leakage.

- Connect and tighten the Inlet hoses (9) to the supply lines.

Black Soft Seating China Seals

Rubber washer

SANTEC SANTEC

SANTEC SANTEC

Fiber washer

Brass lock nut

INLET HOSEINLET HOSE

PAGE 02

Loading...

Loading...