CLOSED LOOP STEPPING SYSTEMS

English

Model No.PB

Ver.3

1

CLOSED LOOP STEPPING SYSTEMS

Model No.PB

Hybrid system combining the ease-of-use of stepping motors with the reliability of servomotors.

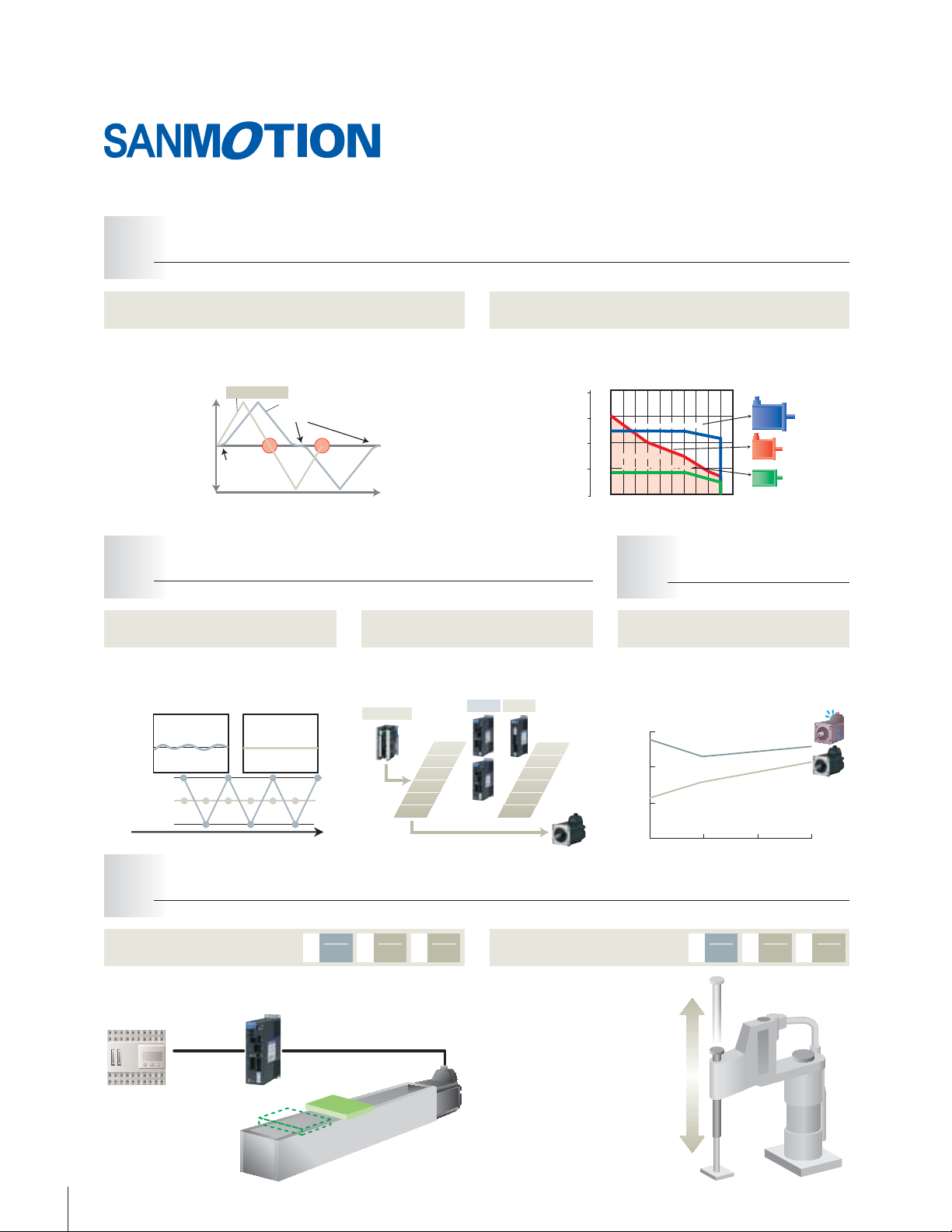

Increased System Speed and Smaller System Size

MERIT

1

Stable Stand-Still

MERIT

2

Simplified Control

MERIT

4

High Speed Positioning Smaller System Size

Stable Stand-Still

General Purpose I/O Input Support For Various Operations

High Resolution

Improved Efficiency from Current Control

A

C

Ty p e

R

D

C

Ty p e

M

D

C

Ty p e

R

A

C

Ty p e

R

D

C

Ty p e

M

D

C

MERIT

3

High torque performance in the low speed range delivers shorter positioning

time for short stoke/high hit rate applications.

Smaller system size is achievable for low speed applications due to the availablity

of higher torque performance in the low speed range as compared to conventional

servomotors.

Complete stand-still motion is possible due

to the availability of holding torque, a typical

characteristic of stepping motors.

The position resolution can be subdivided for

higher positioning precision.

Higher efficiency from low heat generation is

achieved by controlling the current flow to motor

according to motor load.

ACmodel DCmodel

DC Multi-axis Model

System can be easily controlled by using the general purpose I/O to designate

preset point or program numbers (up to 256 points).

Comprehensive built-in amplifier

functionality includes thrust control,

point designation, programming,

homing, holding brake control and

sensor limit input.

Point 1 output

Upper-level PLC

Point 1

Point 0

Energy-Saving

Ty p e

R

Multi

Axis

Ty p e

R

Multi

Axis

Model No. PB

CW

Speed 0

Droop pulse

CCW

SERVO MOTOR

Settling time

Time

200

150

100

Torque(oz・in)

50

0

Torque・Speed Curve

1.6

1.2

Servo motor (AC input)

0.8

Model No. PB (AC input)Model No. PB (AC input)

Torque(N・m)

Servo motor (AC input) – 100WServo motor (AC input) – 100W

0.4

0

0 1000 2000 3000 4000 5000

–300WServo motor (AC input) –300W

Speed(min-1)

Flange size

76mm

60mm

54mm

CW

Motor

Speed

Servo system

0

CCW

+1 pulse

Target

position

-1 pulse

Model No. PB system

0

Tim e

800

200

4000

5000

10000

1000

2000

500

6400

12800

1600

3200

Motor temperature rise

60

40

20

Temp increase (K)

0

500 1000

Competing products

Model No.PB

1500 2000

Speed (min

-

1

)

AC Power Input DC Power Input

Ty p e

A

General Purpose I/O Input Type (RS-485 + PIO)

C

R

Ty p e

A

Pulse-Train Input Type

C

P

MERIT

Reduced System Design Cost and Time

5

Ty p e

D

Multiple Input Type

C

M

Ty p e

D

Multi

General Purpose I/O Input Type (RS-485 + PIO)

C

Axis

R

(General Purpose I/O Input + Pulse-Train Input)

Wide Availability of Optional Cables and Connectors

Cables and connectors for controller/amplifier and amplifier/motor connection

are available for hassle-free setup.

Built-in Pulse Generation Function

A built-in pulse generation function is included in the Model No. PB Types R

and M. The amplifier receives speed, acceleration/deceleration and distance

as numeric data from the upper-level device, and automatically generates an

optimal speed pattern according to the commands internally.Since no separate

pulse generator is required, this contributes to lower system cost.

4000

)

-1

3000

2000

1000

Rotations(min

0

→

-1000

-2000

-3000

-4000

PC Interface Multi-Axis Type (DC Power Input)

Parameter setting, data editing and monitoring of position and speed can be

done on a PC using the bundled setup software.

PC

PC Software

for Windows

TM

Multi-axis systems can be reduced in size and weight using the PB-R 4-axis

type.

1,2,3A can be selected using software switches.

※

PB-R(4-axismodel)

Ty p e

A

C

R

Speed pattern

example

D

C

→Time

Ty p e

M

Ty p e

D

Multi

C

Axis

R

Functions

Features and

Ty p e

D

Multi

C

Axis

R

Typ e RTyp e PTyp e MType R Multi-Axis

Converter

MERIT

Complies with International Safety Standards

6

Encoder Cable

Motor(1A)Motor(2A)Motor(3A)Motor(3A

Motor

Cable

)

Compliant

General

Specifications

Drawings

Motor Dimensional

Options

2

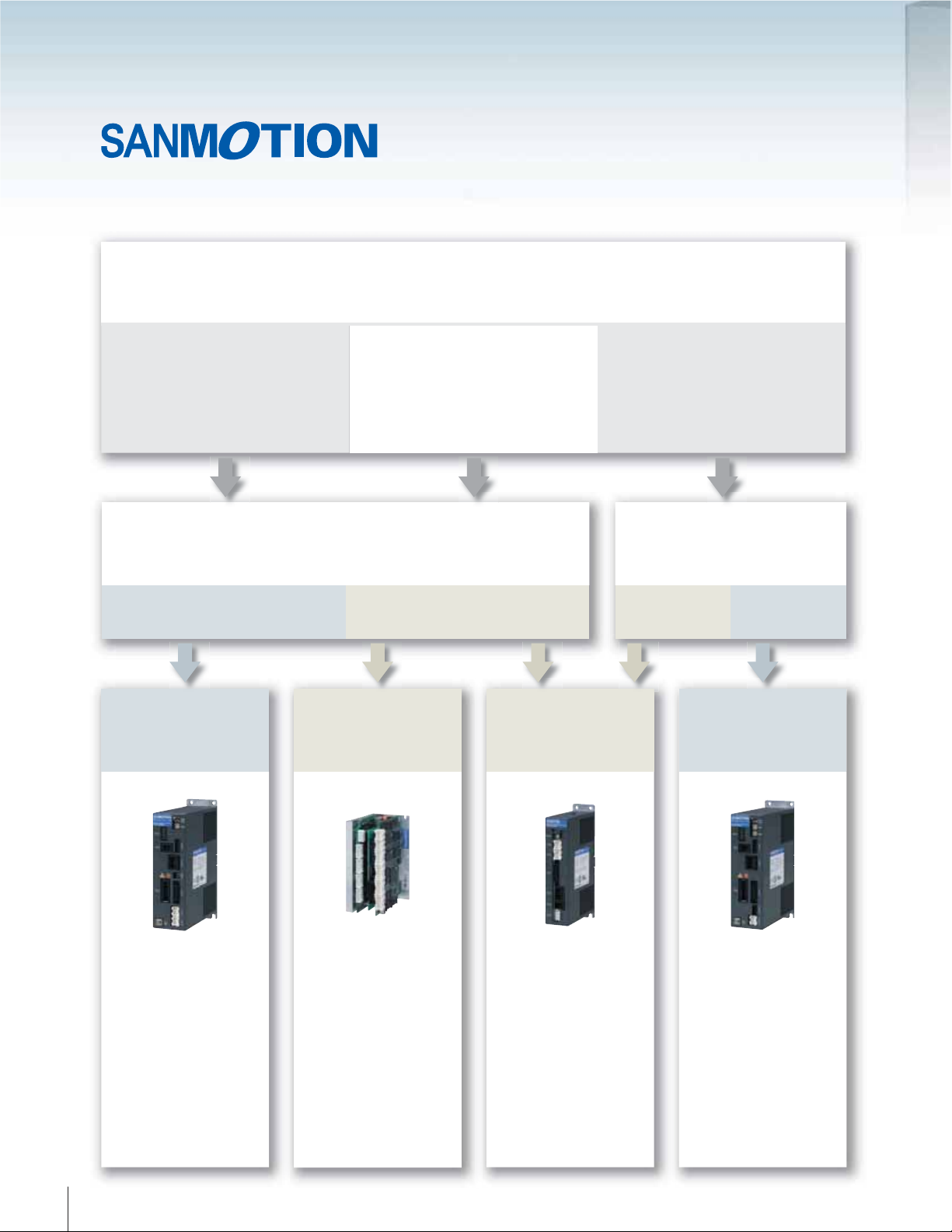

Extensive Closed-Loop Stepping System Lineup

CLOSED LOOP STEPPING SYSTEMS

How do you want to control the equipment?

The Model No. PB Series offers 3 types of control methods.

Point Command

Control using PLC I/O

Network Control using Serial

Communication (RS-485)

Power Source

AC Power Source DC Power Source

Model No.PB

Control using a Pulse

Generator

Power Source

DC Power

Source

AC Power

Source

AC Power Source

Type R

Startup via I/O

●

Startup preset points or programs

in the amplifier me mory using

the I/O.

Startup via Serial

●

Communication

Control by transmitting speed,

acceleration/deceleration and

distance data via serial

communication.

DC Power Source

Type R Multi-Axis

Startup via I/O

●

Startup preset points or programs

in the amplifier me mory using

the I/O.

Startup via Serial

●

Communication

Control by transmitting speed,

acceleration/deceleration and

distance data via serial

communication.

DC Power Source

Ty p e M

Startup via I/O

●

Startup preset points or programs

in the amplifier me mory using

the I/O.

Startup via Serial

●

Communication

Control by transmitting speed,

acceleration/deceleration and

distance data via serial

communication.

Motion is generated

●

by responding to pulse

input commands from an

upper-level controller.

AC Power Source

Type P

Motion is generated

●

by responding to pulse

input commands from an

upper-level controller.

3

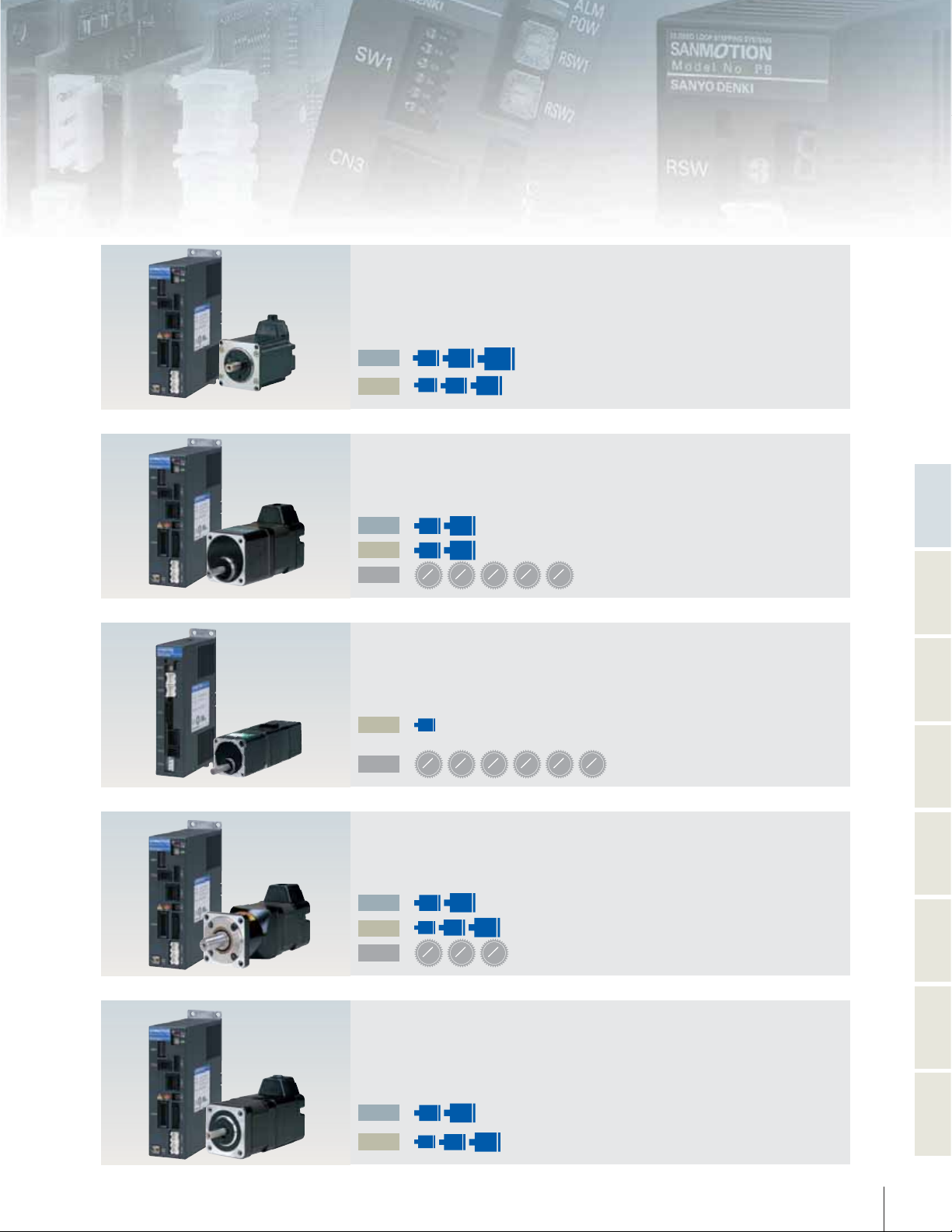

Standard Model

The standard model includes an amplifier and a motor

Motor Flange Size

□

AC

DC

□

42

(1.65in)

□

28

(1.10in)

□

60

86

(2.36in)

(3.39in)

R

□

(1.65in)

□

42

60

(2.36in)

P23

Low-backlash Gear Model

This model includes a low-backlash gear that engages the final stage with a tapered gear.

Motor Flange Size

□

□

42

AC

DC

REDUCTION

GEAR

RATIO

(1.65in)

□

(1.65in)

1

42

3.6

60

(2.36in)

R

□

(2.36in)

P25

60

1

1

1

7. 2

10

1

20

30

Spur Gear Model

This model utilizes a spur gear design for gear reduction.

Functions

Features and

Typ e RTyp e PTyp e MType R Multi-Axis

Motor Flange Size

DC

REDUCTION

GEAR

RATIO

R

P29

1

1

1

1

1

3.6

7. 2

10

20

1

30

50

□

28

(1.10in)

Harmonic Gear Model

The harmonic gear provides high torque and eliminates backlash.

Motor Flange Size

□

□

42

AC

DC

REDUCTION

GEAR

RATIO

60

in

)

(1.65

(2.36in)

□

□

28

42

in

)

(1.10

(1.65in)

1

1

30

R

P31

□

60

in

(2.36

)

1

50

100

Electromagnetic Brake Model

This model uses a non-excitation electromagnetic brake, capable of maintaining

positionand supporting a load in vertical operation, even when power is off

Motor Flange Size

AC

DC

□

(1.65

□

(1.10in)

□

42

60

in

)

in

)

(2.36

□

28

42

(1.65in)

R

□

(2.36

P33

60

in

)

General

Specifications

Drawings

Motor Dimensional

Options

4

5

Model Nomenclature

`

System Model Nomenclature

Note 1: No symbol indicates no options.

Note 2: Power(39.37inch) and I/O (39.37inch) cables are included in the set models.

Motor Option 3: Holding Brake (B: included)

Note

1

Motor Option 2: Gear Ratio

Note

1

Motor Option 1: Gear Specifications

Note

1

Motor Length

Motor Flange Size (in mm)

Interface Type R: RS-485+PIO P: Pulse Stream M: Multi

Power Input A: AC Power Source D: DC Power Source

System Name PB: Model No.PB System

PB A R 60 3-C 3.6 B

`

Amplifier Model Nomenclature

Specification Identification 00: Standard

Encoder Type 1: 200P/R INC 2:500P/R INC

Interface Type R: RS-485+PIO P: Pulse Stream M: Multi

Motor Excitation Current 001: 1A 002: 2A 003: 3A

Power Input A: AC Power Source D: DC Power Source

Series Name PB□: Model No.PB Amplifier

PB3 D 003 R 1 00

`

Motor Model Nomenclature

PBM 42 3 F X E 20

DC (Multi-axis)

only

Specification Identification 20: Standard

Encoder Type

E

: 500P/R with C-phase output

A

: 200P/R No C-phase output

C

: 200P/R with C-phase output

Options

*

Contact us for assistance

X : without option

C : 24V DC Break

GA to GL : with Gear

HJ to HM : with Harmonic Gear

Power Input F: AC Power Source

,

DC Power Source

(Single-axis)

D: DC Power Source (Multi-axis)

Motor Length

Motor Flange Size (in mm)

Series Name PBM: Model No.PB Motor

Please enquire separately for the sizes of PBM503 and PBM565.

*

Motor Option CombinationTable

Motor Option Combination Table

Motor No. Gear Box Harmonic Gear

PBM

PBM

PBM

PBM

PBM

282

F□E20/PBM

284

F□E20/PBM

423

F□E20/PBM

603

F□E20/PBM

604

F□E20/PBM

282

284

423

603

604

D□A

D□A

D□A

D□A

D□A

20

20

20

20

20

○○△

××△

○○○

○○○

××○

Electromagnetic Brake

Motor Standard Specifications (common to all models)

Motor No.

Insulation

class

Withstand

Voltage

Insulation

resistance

Degrees of

protection

Vibration

resistance

Impact

resistance

Ambient

temperature

Ambient

humidity

*

*

*

The user should not test the insulation resistance or insulation withstand voltage, because a

capacitor has been inserted between the encoder output groundline and the frame to prevent noise.

PBM

423

603

F, P B M

AC1500V 50/60Hz 1minute AC500V 50/60Hz 1minute

604

F, P B M

15G(Frequency range 10 to 70Hz amplitude 0.060inch 70 to 2000 acceleration 15G)

The x, y and z are each tested three times for each direction for a total of 18 tests.

F, P B M

861

862

F, PBM

-10℃ to+ 40℃(Harmonic Gear Model 0℃to+ 40

FPBM

30G(half sine wave with 11 ms duration)

20 to 90%RH(No Condensation

282

D, PBM

Class B(130

DC500V 100M1MIN.

40

IP

℃)

282

F, P B M

Functions

Features and

284

)

D, PBM

℃)

284

F, P B M

423

D, PBM

603

D, PBM

604

D

Type RType PType MType R Multi-Axis

General

Specifications

6

Drawings

Motor Dimensional

Options

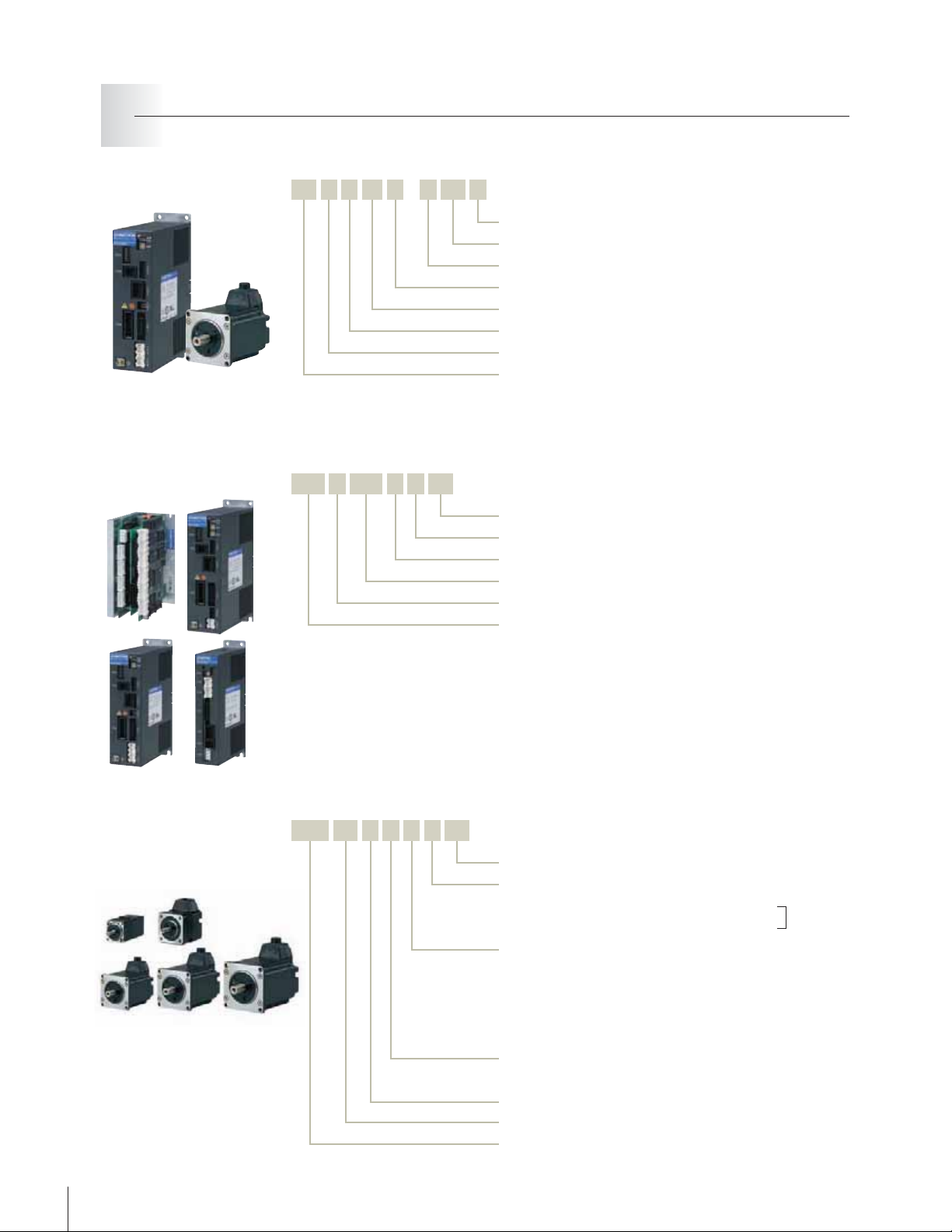

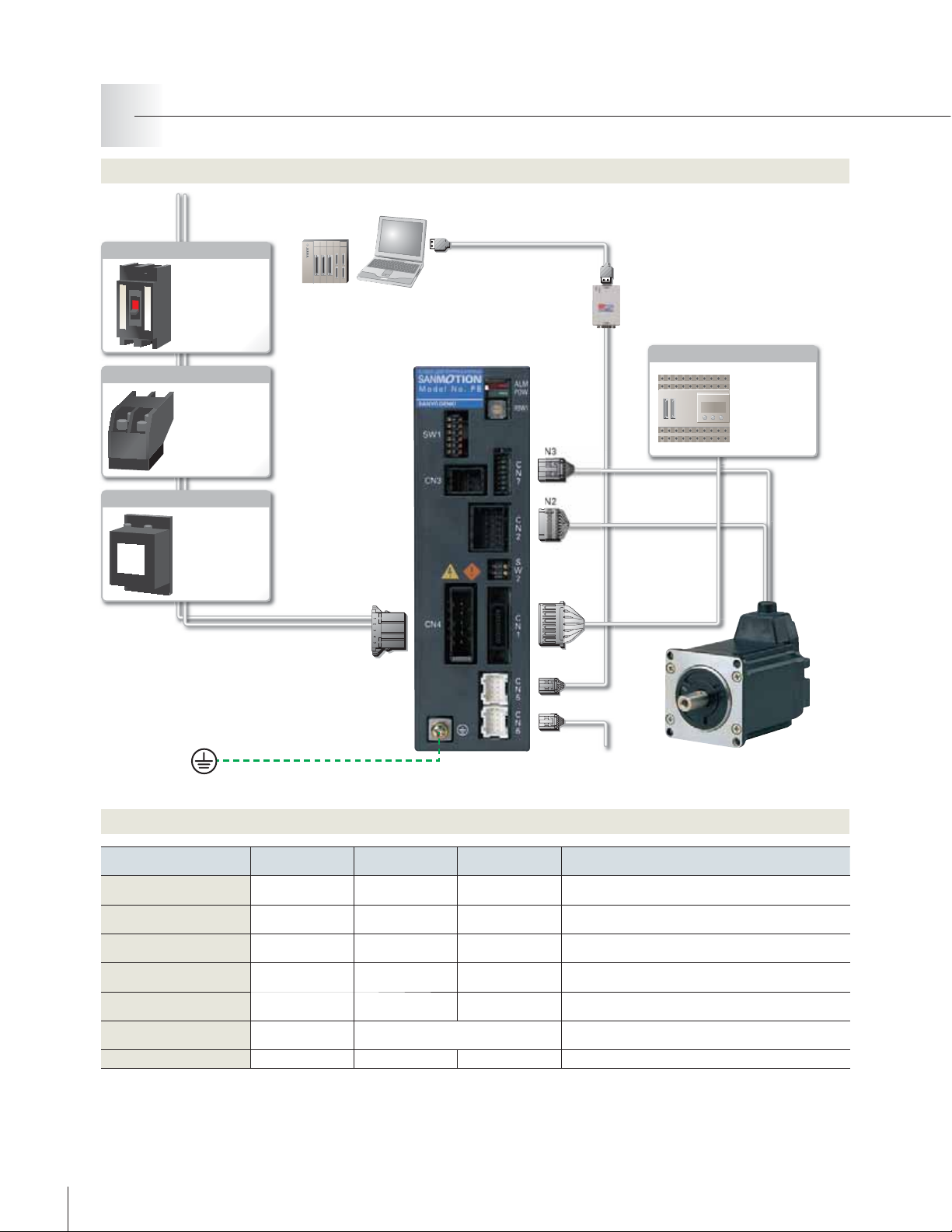

Model No. PBType R Single-Axis Type

AC Power Input Type

System Configuration

Serial communication control

Single-phase AC100V to 230V

Circuit Breaker

parameter editing

Protects the power

line; shuts off circuit

during an overflow

of electric current.

Electromagnetic Contactor

Switches amplifier

power on and off.

Installation of a

surge protector is

required.

Noise Filter

Protects the power

line from external

noise, and from

noise generated by

the servo amplifie

Power Cable

①

Controller

PC

PC I/F Software

⑦

CN4

Communication

⑥

Converter Unit

CN3

CN2

CN1

CN5

CN6

A converter unit is required for

*

RS-232C/RS-485 conversion.

Motor Ext. Cable

②

Encoder Ext. Cable

③

I/O Cable

④

Communication Cable

⑤

Control Device

PLC

SANYO DENKI's

high level

devices permit

communication

with third-party

products

Options

Cable Type

Power Cable

①

Motor Ext. Cable

②

Encoder Ext. Cable

③

I/O Cable (unshielded)

④

Communication Cable

⑤

Communication Converter Unit

⑥

PC I/F Software

⑦

7

Standard Model

Number(Length

PBC7P0010A

1m(39.37in

PBC6M0030A

3m(118.11in

PBC6E0030A

3m(118.11in

PBC1S0010A

1m(39.37in

PBC6C0003A

30cm(11.81in

PBFM-U5

SPBA1W-01

Connector Set Model

)

)

)

)

)

)

Number

PBC7P0000A

PBC6M0000A

PBC6E0000A

PBC1S0000A

PBC6C0000A

Main Body Model.No:232485CFP01-01

Cable Model.No:PBC4T0005A

−−

To other slaves

Maximum Length Remarks

2m(78.74 in

20m(787.40 in

20m(787.40 in

2m(78.74 in

100m(3937.01 in

)−

Use when an extension of 50cm(19.69in) or more is required.

)

Use when an extension of 50cm(19.69in) or more is required.

)

)−

Use when multiple axes are connected in a daisy-chain

)

configuration for communication.

RS-232C/RS-485 Converter Unit

Converter unit and cable set model

Software for operational check and parameter setting

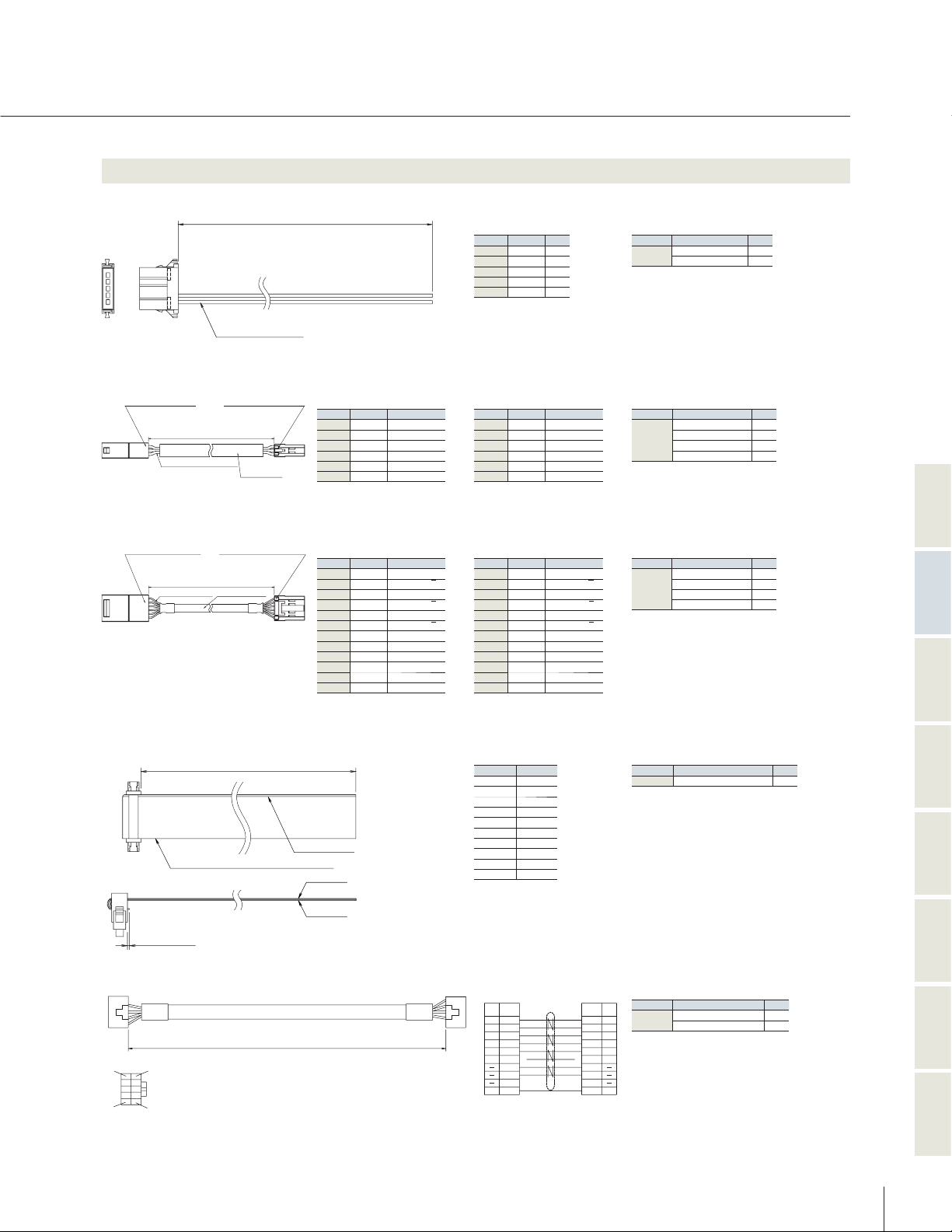

Optional Cable

①

Power Cable

Amp.side

12 34 5

②

Motor Ext. Cable

MOTOR SIDE CONNECTOR

③

Encoder Ext. Cable

MOTOR SIDE CONNECTOR

1318115-3

HOUSING:1-

1318109-1

TERMINAL:

MANUFACTURER: AMP

3000±50

LEADWIRE UL

1318115-6

HOUSING:1-

1318110-1

TERMINAL:

MANUFACTURER:AMP

3000±50

LEADWIRE AWG

AWG16 Black UL1015

AMPLIFIER SIDE CONNECTOR

HOUSING:1TERMINAL:

MANUFACTURER: AMP

118.11±1.97

mm (

1430

22

AWG

ULVINYL TUBE

AMPLIFIER SIDE CONNECTOR

HOUSING:1-

TERMINAL:

MANUFACTURER:AMP

118.11±1.97

mm (

in)

28

ENCODER CABLE

20276

UL

in)

1318106-1

±

L

1318119-3

1318105-1

1318118-6

±

50

1.97

mm (L

Connector Connection Of Motor Side

PIN No.

A1Blue

B1Orange

A2Red

B2Yellow

A3White Brake Lead Wire

B3Black Brake Lead Wire

Connector Connection Of Motor Side

PIN No.

A1Blue CHANNEL A

B1Brown

A2Green CHANNEL B

B2Purple

A3White CHANNEL C

B3Yellow

A4Red +5V

B4Black

A5N.C.

B5Orange OVER HEAT

A6Black Shield

B6N.C.

in)

LEAD COLR

LEAD COLR

Motor Lead Wire

Motor Lead Wire

Motor Lead Wire

Motor Lead Wire

CHANNEL A

CHANNEL B

CHANNEL C

0

V

―

―

PIN No.

LEAD COLR

1

2

3

4

Power

Supply

5

Connector Connection Of Amplifier Side

PIN No.

LEAD COLR

1(A1

) Blue

2(B1

) Orange

3(A2

)Red

4(B2

)Yellow

5(A3

) White Brake LeadWire

6(B3

) Black Brake Lead Wire

Connector Connection Of Amplifier Side

PIN No.

LEAD COLR

1(A1

) Blue CHANNEL A

2(B1

)Brown

3(A2

) Green CHANNEL B

4(B2

) Purple

5(A3

) White CHANNEL C

6(B3

)Yellow

7(A4

)Red +5V

8(B4

)Black0V

9(A5

) N.C.

10(B5

) Orange OVER HEAT

11(A6

)Black Shield

12(B6

) N.C.

1

Black AC

2

Black AC

――

――

――

Motor Lead Wire

Motor Lead Wire

Motor Lead Wire

Motor Lead Wire

CHANNEL A

CHANNEL B

CHANNEL C

Connector Set : PBC7P

Manufacturer

AMP

Connector Set : PBC6M

Manufacturer

AMP

Connector Set : PBC6E

Manufacturer

AMP

―

―

0000

Typ e Qt y.

Housing :1-

175218-55

Contact :1-

0000

Typ e Qt y

Housing :1-

:

1318109-16

Ter m i na l

Housing :1-

:

1318105-16

Ter m i na l

0000

Typ e Qt y

Housing :1-

:

1318110-110

Ter m i na l

Housing :1Ter m i na l :1-

A

178288-51

A

1318115-31

1318119-31

A

1318115-61

1318118-61

1318106-110

Functions

Features and

Typ e RTyp e PTyp e MType R Multi-Axis

④

I/O Cable (unshielded)

1

B

E

1

A

10

A

10

B

Flat cable UL

1

mm MAX.

039

.

inch MAX.

⑤

Communication Cable

9

1

10

9

2

1

2962

±

L

L

AWG

30

28

mm (L

Cable Mark

Cable

Cable

±

1.18

in)

CONNECTOR

0000

A

Typ e Qt y

:

8822E-020-171D1

Cable Connection

Cable1Cable

A1-No.1B1-No.

A2-No.2B2-No.

A3-No.3B3-No.

A4-No.4B4-No.

A5-No.5B5-No.

A6-No.6B6-No.

A7-No.7B7-No.

A8-No.8B8-No.

A9-No.9B9-No.

1

A10-No.10B10-No.

2

11

12

13

14

15

16

17

18

19

20

Connector Set : PBC1S

Manufacturer

KEL

2

General

Specifications

Housing

Contact

0000

A

Typ e Q ty

:

PAD P-10V-1-S

:

SPH-OO2T- P0.5L

2

20

Drawings

Motor Dimensional

Connector relay cable

1

CNA

Signal

Name

Pin.No.

A

1

9

B

2

(Y)

3

)

(

Z

4

GND

5

Vcc

6

7

8

9

FG

10

Yellow

White

Brown

Blue

Black

Purple

Green

Drain

Connector Set : PBC6C

CNB

Pin.No.

Yellow

White

Brown

Blue

Black

Red

Red

Purple

Green

Drain

Manufacturer

Signal

Name

A

1

2

3

4

5

6

7

8

9

10

(Y)

(

GND

JST

B

)

Z

Vcc

FG

Options

8

9

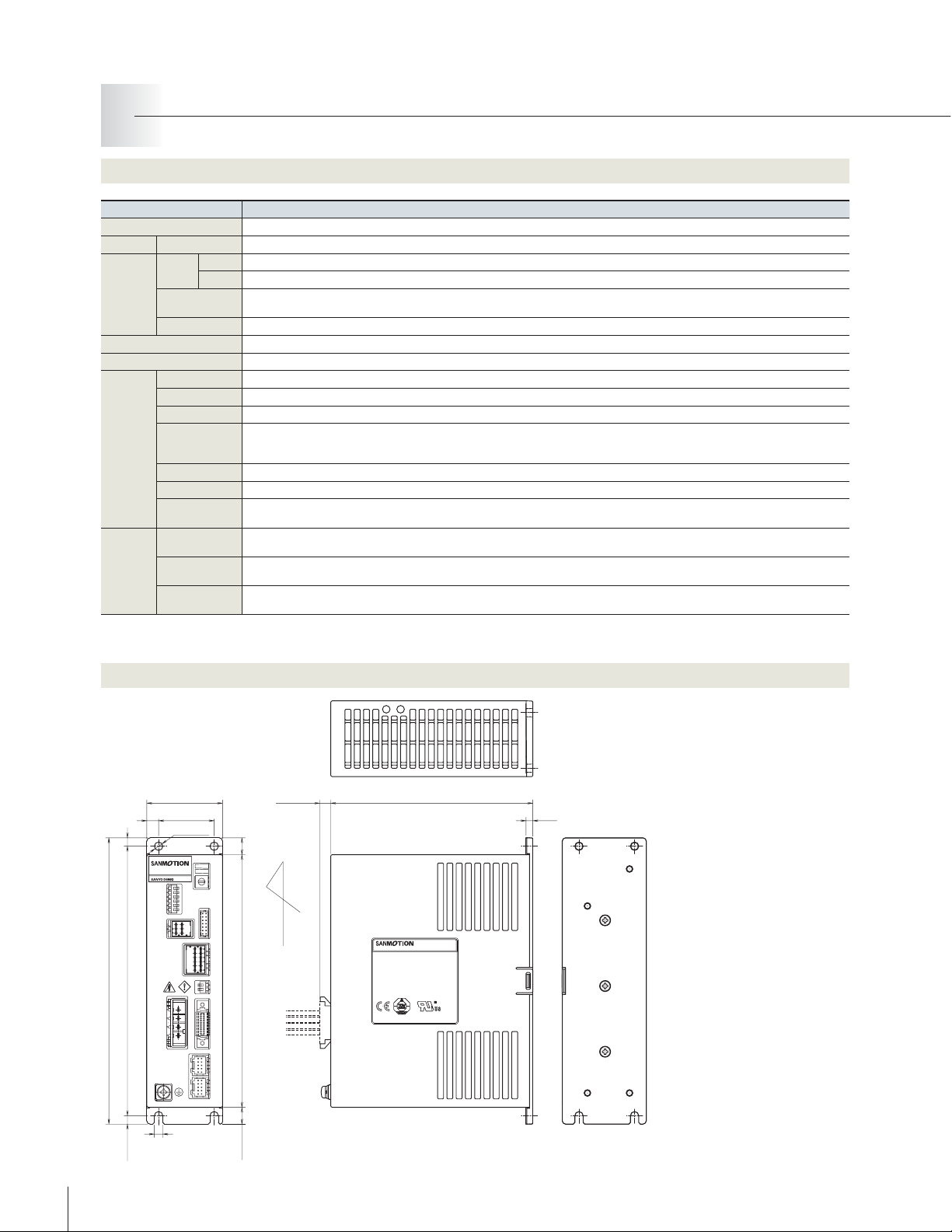

General Specifications

Model No. PBType R Single-Axis Type

AC Power Input Type

Amplifier Model

PB3A

003R200

Control Mode PWM Control SIN drive method

Power Supply

Single Power AC100V to 230V −15% +10% 50/60Hz

Environment

Ambient

temp.

Operating

0 to 55

℃

Storage −20 to 70

℃

Operating/

Storage Humidity

Maximum 90% RH(non-condensing

)

Vibration Resistance

0.5G(tested with frequency range 10 to 55 Hz, X, Y, Z each direction 2H

)

Structure Tray structure Rear mounting type

Mass

(

Weight)/ Dimensions Approx. 0.8kg(28.22oz

)

/

W45×H150×D120mm(W1.77×H5.91×D4.72inch

)

Functions

Rotation Speed 0 to 4500min

-1

(

4000min

-1

is used for an 86mm-square motor

)

Resolution

(

P/R)500, 1000, 2000, 4000, 5000, 10000

Regeneration Process

Internal(external regeneration available

)

Protective Functions

Encoder Disconnection, Encoder Counter Error, Power Voltage Error, Initialization Error, Position Deviation Error, Over-speed,

Regeneration Voltage Error, Zero-return Error, Absolute position sign reversal, Deviation Counter Overflow, Motor Overheat,

Amplifier Overheat, Internal voltage Error, Over-current, CPU Error

LED Display Power status, Alarm(flashing indicator

)

Operation Functions

Normal Drive(incremental move command, absolute move command), Zero-return, Module Operation, Push Operation

Switch

DIP SW1: Transmission Speed Setting(9600, 38400,115200,128000bps) DIP SW2: Terminating Resistor Setting

RSW:Node Adress Setting(0 to F

)

Input/

Output

Signals

Input Signals

Fixed function(2): EXE

,

Point,ALMCLR,STOP

Selectable(5): Point

,

Pause,Interlock,SELECT,Generic Input,HOME,Hard Limit

Output Signals

CN1 Fixed function(2): ALM, In-Position, Ack

Selectable(5): ZONE, END, Busy, HEND, SON MON, Generic Input, Input Monitor

Communication

Specifications

RS-485 Standard Start-Stop Synchronization, Full Duplex

Trans. Speed

:

9600,38400,115200,128000bps

Amplifier Dimensional Drawing[Unit : mm (inch

)]

Mounting Direction

10(.39)

150(5.91)

6.5(.26)

CLOSED LOOP STEPPING SYSTEMS

MADE IN JAPAN

170(6.69)

5(.20)

160(6.30)

7(.28)

CLOSED LOOP STEPPING SYSTEMS

ModelNo.PB

SW1

CN3

CN4

45(1.77)

33(1.30)

2-φ5(2-φ.20)

ALM

POW

D

E

C

F

0

B

1

A

9

2

RSW1

8

3

7

4

5

6

C

N

7

C

N

2

S

W

2

C

N

1

C

N

5

C

N

6

120(4.72)

4(.16)

ModelNo.PB

00563491

5(.20)

5(.20)

10(.39)

External Wiring Diagram

Input Power

100

AC

+COM(DC

4

IN

or SDN(Point6)

OUT

User Device

230

Vto

GND

N.C

N.C

N.C

N.C

5

Vto24V)

Point

Point

IN1(Point3)

2

IN

(Point4)

3

IN

(Point5)

ALMCLR

5

IN

(Point7)

In-Position

1

OUT

(ZONE)

2

OUT

(END)

3

(SON MON)

−

V

Exe

STOP

ACK

ALM

OUT

OUT

COM

Amplifier

003R200

PB3A

4

CN

5

1

2

N.C

N.C

1

2

4

5

3

4

6

CN5,

1

2

Vcc

3

4

5

GND

5

V

+

6

7

8

9

10

1

CN

1

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2

P. E ( M4)

CN

CN

BRK+

BRK-

CN

N.C

O.H

N.C

2

1

A

2

A

3

B

4

B

5

C

6

C

7

5

V

8

5

G

9

10

11

FG

12

3

1

A

2

A

3

B

4

B

5

6

7

Holding Brake

24VDC

(

)

)

*

OPTICAL

ENCORDER

TH

Motor

Twisted Pair

Cable With External Shield

Functions

Features and

Typ e RTyp e PType MType R Multi-Axis

Input / Output Signals Circuit

Generic Input

■

Input Voltage Specifications : DC5V to 24V±10

+COM

1

DC Power Source

+5Vto24V

Note 1: The CN1 general-purpose input / output signal function is selected through communication.

Please see the basic specifications for details.

Generic Output

■

%

Output Current : 30mA MAX.

MAX.

30

V

2

−

COM

-COM

MAX.

General

30

mA

Specifications

Drawings

SG

Motor Dimensional

Options

10

Model No. PBType P

AC Power Input Type

System Configuration

Single-phase AC100V to 230V

Circuit Breaker

Protects the power

line; shuts off circuit

during an overflow

of electric current.

Electromagnetic Contactor

Switches amplifier

power on and off.

Installation of a

surge protector is

required.

Noise Filter

Protects the power

line from external

noise, and from

noise generated by

the servo amplifier.

Power Cable

①

parameter editing

PC I/F Software

⑦

4

CN

PC

3

CN

CN

CN

2

1

Motor Ext. Cable

②

Encoder Ext. Cable

③

I/O Cable

④

Control Device

PLC/Pulse board Controller

SANYO DENKI's high level devices permit

communication with third-party products.

Options

Cable Type

Power Cable

①

Motor Ext. Cable

②

Encoder Ext. Cable

③

I/O Cable (shielded)

④

Communication Cable

⑤

(Dsub9pin)

Communication

⑥

Converter Unit

PC I/F Software

⑦

Standard Model

Number(Length

PBC7P0010A

1m(39.37in

PBC6M0030A

3m(118.11in

PBC6E0030A

3m(118.11in

PBC1S0010C

1m(39.37in

PBC5C0010A

1m(39.37in

Not required

SPBA1W-01

)

)

)

)

)

)

5

CN

Communication Cable

⑤

Connector Set

Model Number

PBC7P0000A

PBC6M0000A

PBC6E0000A

PBC1S0000A

−−

−− −

−−

Maximum Length Remarks

2m(78.74 in

20m(787.40 in

20m(787.40 in

2m(78.74 in

)−

Use when an extension of 50cm(19.69in

)

or more is required.

Use when an extension of 50cm(19.69in

)

or more is required.

)−

Dedicated cable for RS-232C

communications

Software for operational check and

parameter setting

)

)

11

Optional Cable

①

Power Cable

Amp.side

12 34 5

②

Motor Ext. Cable

MOTOR SIDE CONNECTOR

③

Encoder Ext. Cable

MOTOR SIDE CONNECTOR

1318115-3

HOUSING:1-

1318109-1

TERMINAL:

MANUFACTURER: AMP

3000±50

LEADWIRE UL

1318115-6

HOUSING:1-

1318110-1

TERMINAL:

MANUFACTURER:AMP

3000±50

LEADWIRE AWG

AWG16

AMPLIFIER SIDE CONNECTOR

HOUSING:1TERMINAL:

MANUFACTURER: AMP

118.11±1.97

mm (

1430

22

AWG

AMPLIFIER SIDE CONNECTOR

HOUSING:1-

TERMINAL:

MANUFACTURER:AMP

118.11±1.97

mm (

28

ENCODER CABLE

20276

UL

±

L

Black

1318119-3

1318105-1

in)

ULVINYL TUBE

1318118-6

1318106-1

in)

50

mm (L

UL1015

±

1.97

in)

Connector Connection Of Motor Side

PIN No.

LEAD COLR

Blue Motor Lead Wire

1

A

Orange Motor Lead Wire

1

B

Red Motor Lead Wire

2

A

Yellow Motor Lead Wire

2

B

White Brake Lead Wire

3

A

Black Brake Lead Wire

3

B

Connector Connection Of Motor Side

LEAD COLR

PIN No.

A1Blue CHANNEL A

B1Brown

A2Green CHANNEL B

B2Purple

A3White CHANNEL C

B3Yellow

A4Red +5V

B4Black

A5N.C.

B5Orange OVER HEAT

A6Black Shield

B6N.C.

Power

Supply

CHANNEL A

CHANNEL B

CHANNEL C

0

V

―

―

PIN No.

LEAD COLR

1

2

3

4

5

Connector Connection Of Amplifier Side

PIN No.

LEAD COLR

1(A1

)Blue

2(B1

) Orange

3(A2

)Red

4(B2

)Yellow

5(A3

)WhiteBrakeLeadWire

6(B3

)BlackBrakeLeadWire

Connector Connection Of Amplifier Side

PIN No.

LEAD COLR

1(A1

) Blue CHANNEL A

2(B1

)Brown

3(A2

)Green CHANNELB

4(B2

) Purple

5(A3

)White CHANNELC

6(B3

)Yellow

7(A4

)Red +5V

8(B4

)Black0V

9(A5

) N.C.

10(B5

) Orange OVER HEAT

11(A6

) Black Shield

12(B6

) N.C.

1

Black AC

2

Black AC

――

――

――

Motor Lead Wire

Motor Lead Wire

Motor Lead Wire

Motor Lead Wire

CHANNEL A

CHANNEL B

CHANNEL C

―

―

Connector Set : PBC7P

Manufacturer

Housing

AMP

Contact

Connector Set : PBC6M

Manufacturer

Housing :1Ter m i na l

AMP

Housing :1Ter m i na l

Connector Set : PBC6E

Manufacturer

Housing

Ter m i na l

AMP

Housing

Ter m i na l :1-

0000

A

Typ e Q t y.

:

1-178288-51

:

1-175218-55

0000

A

Typ e Qt y.

1318115-31

:

1318109-16

1318119-31

:

1318105-16

0000

A

Typ e Qty .

:

1-1318115-61

:

1318110-110

:

1-1318118-61

1318106-110

Functions

Features and

Typ e RTyp e PType MType R Multi-Axis

④

I/O Cable (shielded)

±

L

1

B

A1g

10

B

10

A

⑤

Communication Cable (Dsub 9Pin)

mm

10

±

150

in)

39

.

±

91

.

5

(

PC side

95

61

50

mm (L

±

1.97

±

50

L

in)

mm (L

CN1 Wiring

CN1 PIN No.

1

A

2

A

3

A

4

A

5

A

6

A

7

A

8

A

9

A

10

A

Mark

Display

|

Mark

Red

Black

Red

Black

Red

Black

Red

Black

Red

Black

LINE

COLR

Orange

Gray

White

Yel lo w

Pink

CN1 PIN No.

1

B

2

B

3

B

4

B

5

B

6

B

7

B

8

B

9

B

10

B

Mark

Display

|

|

Mark

Red

Black

Red

Black

Red

Black

Red

Black

Red

Black

LINE

COLR

Orange

Gray

White

Yel lo w

Pink

Connector Set : PBC1S

Manufacturer

KEL

0000

:

Connector

Crimp Contact

Drain Wire:UL

20276-28

Cable:UL

A

Typ e Qt y.

8822E-020-171D1

:

4

V1.25-M

1007 20

AWG

AWG

―

―

―

General

±

1.97

in)

Amp.side

192

Connector relay cable

PC Side

Signal

Pin.No.

Name

N.C

1

RXD

2

TXD

3

N.C

4

GND

5

N.C

6

N.C

7

N.C

8

N.C

9

(RS-232C D-Sub 9Pin)

Amp.Side

Pin.No

Signal

Name

RXD

1

TXD

2

N.C

3

N.C

4

GND

5

N.C

6

N.C

7

N.C

8

N.C

9

Shield

10

Without connector set

*

Specifications

Drawings

Motor Dimensional

Options

12

13

Model No. PBType P

AC Power Input Type

General Specifications

Amplifier Dimensional Drawing[Unit : mm (inch

)]

Amplifier Model

PB3A

003P201

,PB3A

003P202

Control Mode PWM Control SIN drive method

Power Supply

Single Power AC100V to 230V −15% +10% 50/60Hz

Environment

Ambient temp.

Operating

0 to 55

℃

Storage −20 to 70

℃

Operating/

Storage Humidity

Maximum 90% RH(non-condensing

)

Vibration Resistance 0.5G(tested with frequency range 10 to 55 Hz, X, Y, Z each direction 2H

)

Structure Tray structure Rear mounting type

Mass

(

Weight)/ Dimensions Approx. 0.8kg(28.22oz

)

/

W45×H150×D120mm(W1.77×H5.91×D4.72inch

)

Functions

Rotation Speed 0 to 4500min

-1

(

4000min

-1

is used for an 86mm-square motor

)

Resolution (P/R) 500, 1000, 2000, 4000, 5000, 10000

Regeneration Process Internal(external regeneration available

)

Protective Functions

Encoder Disconnection, Encoder Counter Error, Power Voltage Error, Initialization Error, Position Deviation Error,

Over-speed,Regeneration Voltage Error, Zero-return Error, Absolute position sign reversal, Deviation Counter Overflow,

Motor Overheat, Amplifier Overheat, Internal voltage Error, Over-current, CPU Error

LED Display Power status, Alarm (flashing indicator

)

Functions Normal Drive, Zero-return, S-shape Acceleration / Deceleration Drive

Switch

DIP SW1: Pulse Input Type Select (ON: 2 Input OFF: 1 Input

)

DIP SW2, 3: Resolution Selection(500, 1000, 5000, 10000P/R

)

※

2000 and 4000 division resolution modes are selected via communication

DIP SW 4 to 6: Motor Select

RSW1: Normalize velocity loop gain setting

RSW2: S-Shape filter potentiometer setting

Input/ Output

Signals

Input Signals Pulse, Deviation Clear, HOME, Hard.Limit, STOP, ALMCLR

Output Signals SON Monitor, ALM, Zero-return completion,In-Position, Encoder Signal Output

Communication

Specifications

RS-232C(For parameter setting

)

Trans. Speed:9600bps

170(6.69)

5(.20)

160(6.30)

7(.28)

CLOSED LOOP STEPPING SYSTEMS

ModelNo.PB

SW1

CN3

CN4

45(1.77)

33(1.30)

2-φ5(2-φ.20)

10(.39)

ALM

POW

D

C

E

B

F

A

0

9

1

8

RSW1

2

7

3

6

4

5

D

C

E

B

F

A

0

9

1

8

RSW2

2

7

3

6

4

5

C

N

7

C

N

2

150(5.91)

C

N

1

C

N

6

C

N

5

6.5(.26)

Mounting Direction

CLOSED LOOP STEPPING SYSTEMS

120(4.72)

4(.16)

ModelNo.PB

MADE IN JAPAN 00563491

5(.20)

5(.20)

10(.39)

External Wiring Diagram

User Device

Input Power

100

230

AC

Vto

N.C

TXD

RXD

NC

NC

GND

NC

NC

NC

NC

CCW Pulse+ /Pulse+

CCW Pulse- /Pulse-

CW Pulse+ /DIR+

CW Pulse- /DIR-

-COM

5

Vto24V)

+COM(DC

STOP

ALMCLR

(Deviation Clear)

1

IN

IN2(Gain Select)

Im-Position

SON Monitor

ENA+

ENA-

ENB+

ENBENC+

ENC-

-COM

Amplifier

3A003P201

PB

4

CN

N.C

V

5

1

1

AC

2

2

AC

3

P

4

N

5

CN

1

2

3

4

5

GND

Vcc

6

7

8

9

10

1

CN

3

4

5

6

14

1

7

8

9

10

11

12

13

15

16

17

18

19

20

2

P.E(M4)

2

CN

1

A

2

A

3

B

4

B

5

C

6

C

7

5

V

8

5

G

10

OH

11

FG

3

CN

1

A

2

A

3

B

4

B

5

BRK+

6

BRK-

Holding

Brake

24VDC

(

)

)

*

7

CN

6

CN

1

2

Positive direction Limit (SDN)

3

4

Negative direction Limit(SDN)

5

Without allocation function

6

7

Without allocation function

8

9

NC

10

NC

OPTICAL

ENCORDER

EN

MO

BRK

Motor

Twisted Pair Cable

With External Shield

Note 1: The CN1 general-purpose input/output signal function is

selected through communication. Please see the basic

specifications for details.

Note 2: Pulse input and encoder output signal circuitry are line

receiver type.Linedriver type is also available as amplifier

model PB3A003P202.

Functions

Features and

Typ e RType PType MType R Multi-Axis

Input / Output Signals Circuit

,

3,5

6

MAX.

30

V

-COM

)/(

MAX.

270

30

mA

+R)≒

003P201

PB3A

Pulse Input

■

Input Voltage Specifications : DC5V±10

DC Power Source

4

In case the voltage is at 5V MIN.

Insert a resistor "R" which satisfies "

Input Voltage−1V

(

Line driver input permitted

Encoder Signal Output

■

Collector Voltage: DC30V MAX.

Output Current : 30mA MAX.

15、17、19

2、14、16、18、20

10 mA

003P201/202

003P202

PB3A

Pulse Input

■

%

Pulse Input : 250kpps MAX.

3,5

4

6

,

14

SG

SG

+5V+5V

SG

PB3A

Generic Input/Limit Input

■

Input Voltage Specifications : DC5V to 24V±10

DC Power Source

+5Vto24V

%

General

Encoder Signal Output

■

15,17,19

20

16

,18,

14

SG

Generic Output

■

Collector Voltage: DC30V MAX.

Output Current : 30mA MAX.

30

MAX.

MAX.

30

V

2

-COM

mA

-COM

Specifications

Drawings

Motor Dimensional

Options

14

Model No. PBType M

DC Power Input Type

System Configuration

Circuit Breaker

Protects the power

line; shuts off circuit

during an overflow

of electric current.

Electromagnetic Contactor

Switches amplifier

power on and off.

Installation of a

surge protector is

required.

Noise Filter

Protects the

power line from

external noise,

and from noise

generated by the

servo amplifier.

Power Supply Switch

Converts power

supply from AC

to DC power.

Serial communication control

parameter editing

Controller PC

PC I/F Software

⑦

4

CN

Communication

⑥

Converter Unit

6

CN

5

CN

1

CN

④

2

CN

③

3

CN

②

*

RS-232C/RS-485 conversion.

⑤

I/O Cable

Encoder Ext. Cable

Motor Ext. Cable

A converter unit is required for

Communication Cable

Control Device

PLC I/O

To other slaves

SANYO DENKI's

high level

devices permit

communication

with third-party

products

Options

Cable Type

Power Cable

①

Motor Ext. Cable

②

Encoder Ext. Cable

③

I/O Cable (unshielded)

④

I/O Cable (shielded)

④

Communication Cable (to

⑤

Communication Converter Unit

⑥

PC I/F Software

⑦

Amp.

Power Cable

①

Standard Model

Number(Length

PBC6P0010A

1m(39.37in

PBC6M0030A

3m(118.11in

PBC6E0030A

3m(118.11in

PBC5S0010A

1m(39.37in

PBC5S0010C

1m(39.37in

PBC6C0003A

)

30cm(11.81in

PBFM-U5

SPBAIW01

Connector Set Model

)

)

)

)

)

)

)

Number

PBC6P0000A

PBC6M0000A

PBC6E0000A

PBC5S0000A

PBC5S0000A

PBC6C0000A

Main Body Model.No:232485CFP01-01

Cable Model.No:PBC4T0005A

−−

Maximum Length Remarks

2m(78.74 in

20m(787.40 in

20m(787.40 in

2m(78.74 in

2m(78.74 in

100m(3937.01 in

)−

Use when an extension of 50cm(19.69in) or more is required.

)

Use when an extension of 50cm(19.69in) or more is required.

)

)−

Use for pulse input

)

Use when multiple axes are connected in a daisy-chain

)

configuration for communication.

RS-232C/RS-485 Converter Unit

Converter unit and cable set model

Software for operational check and parameter setting

15

Optional Cable

①

Power Cable

±

L

50

mm (L

±

1.97

in)

1234

②

Motor Ext. Cable

MOTOR SIDE CONNECTOR

③

Encoder Ext. Cable

MOTOR SIDE CONNECTOR

④

I/O Cable (unshielded)

1318115-3

HOUSING:1-

1318109-1

TERMINAL:

MANUFACTURER: AMP

3000

LEADWIRE UL

1318115-6

HOUSING:1-

1318110-1

TERMINAL:

MANUFACTURER:AMP

3000±50

LEADWIRE AWG

±

50

118.11±1.97

mm (

1430

AWG

118.11±1.97

mm (

28

AMPLIFIER SIDE CONNECTOR

1318119-3

HOUSING:1-

1318105-1

TERMINAL:

MANUFACTURER: AMP

in)

22

ULVINYL TUBE

AMPLIFIER SIDE CONNECTOR

1318118-6

HOUSING:1-

1318106-1

TERMINAL:

MANUFACTURER:AMP

in)

ENCODER CABLE

20276

UL

L

1

B

E

1

A

13

A

13

B

Flat cable UL

1

mm MAX.

039

.

inch MAX.

④

I/O Cable (shielded)

1

B

E

1

A

13

B

13

A

mm

10

±

150

⑤

Communication Cable (Dsub 9 Pin)

2962

AWG

±

L

in)

39

.

±

91

.

5

(

50

mm (L

±

1.97

9

1

±

30

mm (L

L

10

9

2

1

1430

UL

300V,105

Cable Mark

28

in)

±

AWG18(21/0.18)

℃

Connector Connection Of Motor Side

PIN No.

1

A

1

B

2

A

2

B

3

A

3

B

Connector Connection Of Motor Side

PIN No.

1

A

1

B

2

A

2

B

3

A

3

B

4

A

4

B

A5N.C.

5

B

6

A

B6N.C.

1

Cable

2

Cable

1.18

in)

LEAD COLR

Blue Motor Lead Wire

Orange Motor Lead Wire

Red Motor Lead Wire

Yellow Motor Lead Wire

White Brake Lead Wire

Black Brake Lead Wire

LEAD COLR

Blue

CHANNEL A

Brown

CHANNEL A

Green

CHANNEL B

Purple

CHANNEL B

White

CHANNEL C

Yellow

CHANNEL C

Red

Black

Orange

OVER HEAT

Black

CN Wiring

CN1 Pin.No.

Signal Name

1

A

2

A

3

A

4

A

5

A

6

A

7

A

8

A

9

A

10

A

11

A

12

A

13

A

+5V

0

―

Shield

―

|

|

|

Connector Connection Of Amplifier Side

PIN No.

LEAD COLR Signal Name

Red

1

2

3

4

Connector Connection Of Amplifier Side

PIN No.

1(A1

)

2(B1

)

3(A2

)

4(B2

)

5(A3

)

6(B3

)

Connector Connection Of Amplifier Side

PIN No.

1(A1

)

2(B1

)

3(A2

)

4(B2

)

5(A3

)

6(B3

)

7(A4

)

Red

Red

Red

Red

Red

Red

Red

8(B4

)

9(A5

)N.C.

10(B5

)

11(A6

)

12(B6

)N.C.

Cable Connection

Cable

A1-No.1B1-No.

A2-No.2B2-No.

A3-No.3B3-No.

A4-No.4B4-No.

A5-No.5B5-No.

A6-No.6B6-No.

A7-No.7B7-No.

A8-No.8B8-No.

A9-No.9B9-No.

A10-No.10B10-No.

A11-No.11B11-No.

A12-No.12B12-No.

A13-No.13B13-No.

LINE

CN1 Pin.No.

COLR

Orange

Gray

White

Yellow

Pink

Orange

B

B

Gray

Connector relay cable

CNA

Signal

Name

Pin.No.

A

1

B

2

(Y)

3

)

(

Z

4

GND

5

Vcc

6

7

8

9

FG

10

V

Mark

Black

Black

Black

Black

Black

Black

1

9

DC+24/48V

Blue

GND

Yellow

Green

LEAD COLR

Orange Motor Lead Wire

Yellow Motor Lead Wire

LEAD COLR

Brown

Yellow

Orange

1

1

B

2

B

3

B

4

B

5

B

6

B

7

B

8

B

9

B

10

B

11

B

12

13

Yellow

White

Brown

Blue

Black

Red

Purple

Green

Drain

―

FG

Blue Motor Lead Wire

Red Motor Lead Wire

White Brake Lead Wire

Black Brake Lead Wire

Blue

CHANNEL A

CHANNEL A

Green

CHANNEL B

Purple

CHANNEL B

White

CHANNEL C

CHANNEL C

Red

Black

OVER HEAT

Black

Cable

Signal Name

|

|

|

|

|

Yellow

White

Brown

Blue

Black

Red

Purple

Green

Drain

+5V

Shield

2

14

15

16

17

18

19

20

21

22

23

24

25

26

Pin.No.

0

―

―

CNB

V

Mark

Black

Red

Black

Red

Black

Red

Black

Red

Black

Red

Black

Red

Black

1

2

3

4

5

6

7

8

9

10

Signal

Name

(Y)

(

GND

Vcc

A

B

)

Z

FG

LINE

COLR

Gray

White

Yellow

Pink

Orange

Gray

White

Connector Set : PBC6P

Manufacturer

JST

Connector Set : PBC6M

Manufacturer

AMP

Connector Set : PBC6E

Manufacturer

AMP

Connector Set : PBC5S

Manufacturer

KEL

Connector Set : PBC5S

Manufacturer

KEL

Connector Set : PBC6C

Manufacturer

JST

0000

A

Typ e Qt y.

:

Connector

VHR-4N

:

Contact

Appropriate electric wire:AWG#22-18

Housing :1Ter m i na l

Housing :1Ter m i na l

Housing

Ter m i na l

Housing

Ter m i na l :

Connector

Connector

Crimp Contact:V1.25-M

Drain Wire:UL

Cable:UL

Housing

Contact

14

SVH-21T- P1.

0000

A

Typ e Qty .

1318115-31

:

1318109-16

1318119-31

:

1318105-16

0000

A

Typ e Qt y.

:

1-1318115-61

:

1318110-110

:

1-1318118-61

1318106-1

0000

A

Typ e Qt y.

:

8822E-026-171D1

0000

A

Typ e Qt y.

:

8822E-026-171D1

1007 20

20276-28

AWG

0000

A

Typ e Qt y.

:

PAD P-10V-1-S

:

SPH-OO2T- P0.5L

4

AWG

1

―

10

Functions

Features and

Typ e RTyp e PTyp e MType R Multi-Axis

―

―

―

General

Specifications

Drawings

2

20

Motor Dimensional

Options

16

17

Model No. PBType M

DC Power Input Type

External Wiring Diagram

Positive direction Pulse+ /Pulse+

Positive direction

Pulse- /Pulse-

-COM

+COM(+

5

Vto24VDC)

Positive direction Limit

Negative direction Limit

IN

1

(HOME)

IN

2

(

Deviation CLR

)

IN

3

(Gain SEL1)

IN

4

(Gain SEL2)

IN

5

(

Current limit

)

STOP

ALMCLR

ALM

HEND

SON MON

STOP MON

Reserved

Reserved

In-Position

ENC / Phase origin

ENA

ENB

-COM

1

2

3

4

14

25

5

6

7

8

9

10

11

12

13

15

16

17

18

19

20

21

22

23

24

26

Note 1: The CN1 general-purpose input / output signal function is selected through communication. Please see the basic specifications for details.

Holding Brake

(

24VDC

)

Motor

Twisted Pair Cable

With External Shield

CN

1

CN

3

A

A

B

B

BRK+

BRK-

1

2

3

4

5

6

CN

2

A

A

B

B

C

C

5

V

5

G

NC

NC

FG

NC

1

2

3

4

5

6

7

8

9

10

11

12

OPTICAL

ENCORDER

1

2

3

4

CN

4

Amplifier

PB3D

003M200

CN5,

6

1

2

6

5

7

10

DIP SW-

2

Vcc

User Device

Input Power

DC24V/48V

N.C

CTXD

RTXD

NC

GND

STOP

Pow

GND

GND

Terminating

resistance

CTXD

CRXD

■

Pulse Stream Input DIP Switch SW1:OFF

■

Generic Input DIP Switch SW1:ON

-COM

+COM(+

5

Vto24V)

IN

1

(EXE)/PWR

IN

2

(Point0)/Point

0

IN3(Point1)/Point

1

IN4(Point2)/Point

2

IN5(Point3)/Point

3

IN6(Point4)/Point

4

IN7(HOME)/Jog+

IN

8

(STOP)/STOP

ALMCLR/Jog-

ALM/ALM

OUT

1

(PEND0)/PEND

0

OUT2(PEND1)/PEND

1

OUT3(PEND2)/PEND

2

OUT4(PEND3)/PEND

3

OUT5(PEND4)/PEND

4

OUT6(HEND)/HEND

OUT

7

(In-Position)/In-Position

OUT

8

(MODE MON)/MODE MON

OUT

9

(SON MON)/SON MON

-COM

1

2

3

4

14

25

5

6

7

8

9

10

11

12

13

15

16

17

18

19

20

21

22

23

24

26

Holding Brake

(

24VDC

)

Motor

Twisted Pair Cable

With External Shield

CN

1

CN

3

A

A

B

B

BRK+

BRK-

1

2

3

4

5

6

CN

2

A

A

B

B

C

C

5

V

5

G

NC

NC

FG

NC

1

2

3

4

5

6

7

8

9

10

11

12

OPTICAL

ENCORDER

1

2

3

4

CN

4

Amplifier

PB3D

003M200

CN5,

6

1

2

6

5

7

10

DIP SW-

2

Vcc

User Device

Input Power

DC24V/48V

N.C

CTXD

RTXD

NC

GND

STOP

Pow

GND

GND

Terminating

resistance

CTXD

CRXD

Nomal (initial value)/ Teaching

Preliminary

Preliminary

General Specifications

Amplifier Model

PB3D

003M200

Interface Generic Input (SW1=ON

)

Pulse Train Input (SW1=OFF

)

Control Mode PWM Control SIN drive method

Power

Supply

Single Power DC24V/48V ±10%

(

□

28mm [□1.10inch] Motor is only available as 24V.

)

Ambient

temp.

Operating

0 to 55

℃

Storage

−20 to 70

℃

Operating/

Storage Humidity

Maximum 90% RH (non-condensing)

Vibration Resistance

0.5G(tested with frequency range 10 to 55 Hz, X, Y, Z each direction 2H

)

Mass(Weight)/ Dimensions

Approx. 0.36kg (12.70oz

)

/

W32×H160×D95mm(W1.26×H6.30×D3.74inch

)

Rotation Speed 0 to 4500min

-1

Resolution (P/R) 500, 1000, 2000, 4000, 5000, 10000

Regeneration Process

Built-in

Protective Functions

Power Voltage Error, Regeneration Voltage Error, Over-speed, Encoder Disconnection, CPU Error, Overload Stop, Excessive Position Deviation,

Zero-return Error, Nonvolatile Memory Error, Initialization Error (Power Line Disconnection

)

Display 7SEG LED Display

Functions

Normal Drive (incremental move , absolute move), Zero-return, Module Operation, Push

Operation, Teaching Functions

Point Functions: 128Point

Program Functions: 1PRG×1024Line 32PRG×32Line 128PRG×8Line

Normal Drive, Zero-return

Rotary Switch Node Adress Setting(0 to F

)

Normalize velocity loop gain setting

DIP-Switches SW1:Interface Selection(On: RS-485

,

OFF: Pulse) SW2:Ter minating Resistor Setting (On: with terminating resistance

)

Input Signals

(Normal Mode) STOP, EXE, POINT, HOME, JOG, SELECT, Pause, Interlock, Generic Input,

MODE SELECT, Hard Limit, ALM CLR

(Teaching Mode) STOP, JOG, Point, PWR

Pulse, STOP, ALMCLR, Gain Setting,

Deviation Clear, HOME

Output Signals

(

Normal Mode)Ack, PEND, END, Busy, Zone, Mode MON, STOP MON,

In-Position, Homing complete, Generic Output, Encoder Output, Input Monitor(Teaching

Mode)PEND, HEND, In-Position, Mode MON

,

SON MON

ALM, STOP MON, In-Position, Homing complete,

Encoder Output, SON MON, STOP MON

Communication Specifications

Trans. Speed

RS-485 Standard Start-Stop Synchronization, Full Duplex

9600, 38400, 115200, 128000bps 9600bps

Environment

FunctionsInput/ Output Signals

Negative direction Pulse+/ Rotation direction +

Negative direction Pulse+/ Rotation direction -

)

*

)

*

Amplifier Dimensional Drawing[Unit : mm (inch

)]

32(1.26)

20(.79)

6(.24)

5(.20)

150(6.30)

160(6.69)

5(.20)

CLOSED LOOP STEPPING SYSTEMS

ModelNo.PB

RSW

CN6

CN5

CN1

CN2

CN3

CN4

(.20)

2-ø5(2-ø.20)

10

(.39)

Mounting Direction

140(5.51)

5

Input/ Output Signals Circuit

CN1- Pin. No.1

■

Input Voltage Specifications : DC3V to 5V±10

Pulse Input : 250kpps MAX.

2 / No.3,4

,

30MAX.

(1.18MAX.)

%

95(3.74)

4(.16)

Generic Input (CN1- Pin.5 to No.13)

■

Input Voltage Specifications : DC5V to 24V±10

Functions

Features and

Typ e RType PType MType R Multi-Axis

%

DC Power Source

In case the voltage is at 5V MIN.

Insert a resistor "R" which satisfies "(Input Voltage−1V

Generic Output

■

Collector Voltage : DC30V MAX.

Output Current : 30mA MAX.

30

mA

MAX.

MAX.

30

V

26

-COM

-COM

+COM

25

DC Power Source

+5Vto24V

270

(

)

/

+R)≒

10 mA

General

Specifications

Drawings

Motor Dimensional

Options

18

Model No. PBType R Multi-Axis Type

DC Power Input Type

System Configuration

Single-phase AC100V to 230V

Circuit Breaker

Protects the

power line; shuts

off circuit during

an overflow of

electric current.

Electromagnetic Contactor

Switches amplifier

power on and off.

Installation of a

surge protector is

required.

Noise Filter

Protects the

power line from

external noise,

and from noise

generated by the

servo amplifier.

Power Supply Switch

①

Power Cable

Controller PC

PC I/F Software

⑦

Communication

⑥

Converter Unit

A converter unit is required for

*

RS-232C/RS-485 conversion.

Control Device

SANYO DENKI's

high level

devices permit

communication

with third-party

PLC I/O

products

Options

Converts power

supply from AC

to DC power.

Communication Cable

⑤

I/O Cable

④

Encoder Ext. Cable

③

Motor Ext. Cable

②

To other slaves

Cable Type

Power Cable

①

Motor Cable

②

Encoder Cable

③

Encoder Cable

③

I/O Cable

④

Communication Cable

⑤

Communication Converter Unit

⑥

PC I/F Software

⑦

Regenerative Unit

⑧

19

(with limit sensor input)

Standard Model

Number(Length

PBC6P0010A 1m (39.37in)PBC6P0000A

PBC4M0030A 3m (118.11in)PBC4M0000A

PBC5E0030A 3m (118.11in)PBC5E0000A

PBC5E0030C 3m (118.11in)PBC5E0000A

PBC4S0010A 1m (39.37in)PBC4S0000A

PBC4C0003A 30cm (11.81in)PBC4C0000A

PBFM-U5

SPBR1W-01

PBFE-01

Connector Set

Model Number

)

Main Body Model.No:232485CFP01-01

Cable Model.No:PBC4T0005A

−−

−−

Maximum

Length

2m(78.74 in

20m(787.40 in

20m(787.40 in

20m(787.40 in

2m(78.74 in

100m (3937.01 in

)

)

)

)

)

)

Remarks

−

An extension cable is required.

An extension cable is required.

Please specify when using an external limit sensor.

−

Use when multiple axes are connected in a daisy-chain configuration for communication.

RS-232C/RS-485 Converter Unit

Converter unit and cable set model

Software for operational check and parameter setting

Required if regeneration voltage is more than 40V

Optional Cable

①

Power Cable

UL

±

L

50

mm (L

±

1.97

300V,105

in)

1234

②

Motor Cable

MOTOR SIDE CONNECTOR

5111 2-0610

HOUSING:

TERMINAL:

MANUFACTURER: MOLEX

LEADWIRE UL

③

Encoder Cable

MOTOR SIDE CONNECTOR

HOUSING:

TERMINAL:

MANUFACTURER: MOLEX

LEADWIRE AWG

③

Encoder Cable (with limit sensor input)

MOTOR SIDE CONNECTOR

HOUSING:

TERMINAL:

MANUFACTURER: MOLEX

④

I/O Cable (unshielded)

1

B

E

1

A

16

A

16

B

1

mm MAX.

039

.

inchMAX.

⑤

Communication Cable

50398-8000

±

3000

50

51029-0910

50087-8030

±

3000

50

51029-0910

50087-8030

±

3000

LEADWIRE AWG

LEADWIRE UL

Flat cable UL

AMPLIFIER SIDE CONNECTOR

51103-0600

HOUSING:

50351-8000

TERMINAL:

MANUFACTURER: MOLEX

118.11±1.97

mm (

in)

1430

22

AWG

ULVINYL TUBE

AMPLIFIER SIDE CONNECTOR

HOUSING: PADP-16V-1-S

TERMINAL: SPHMANUFACTURER: JST

118.11±1.97

mm (

in)

ENCODER CABLE

24

20276

UL

AMPLIFIER SIDE CONNECTOR

HOUSING: PADP-16V-1-S

TERMINAL: SPHMANUFACTURER: JST

50

118.11±1.97

mm (

in)

ENCODER CABLE

24

20276

UL

1430

24

AWG

±

30

mm (L

L

2962

Cable

Cable

002

002

1

2

GW-P0.5S

GW-P0.5S

±

AWG

1.18

in)

28

9

1

±

30

mm (L

L

10

9

2

1

1430

AWG18(21/0.18)

℃

Connector Connection Of Motor Side

PIN No.

1

A

1

B

2

A

2

B

3

A

3

B

Connector Connection Of Motor Side

PIN No.

1

2

3

4

5

6

7

8

9

Connector Connection Of Motor Side

PIN No.

1

2

3

4

5

6

7

8

9

Cable Mark

±

1.18

in)

LEAD COLR

Blue Motor Lead Wire

Orange Motor Lead Wire

Red Motor Lead Wire

Yellow Motor Lead Wire

White Brake Lead Wire

Black Brake Lead Wire

LEAD COLR

Blue

CHANNEL A

Brown

CHANNEL A

Green

CHANNEL B

Purple

CHANNEL B

White

CHANNEL C

Yellow

CHANNEL C

Red

Black

Black

LEAD COLR

Brown

Green

Purple

White

Yellow

Black

Black

Blue

Red

+5V

0

Shield

CHANNEL A

CHANNEL A

CHANNEL B

CHANNEL B

CHANNEL C

CHANNEL C

+5V

Shield

Connector Connection Of Amplifier Side

PIN No.

LEAD COLR

Signal Name

Red

1

2

3

4

*Connect only for amplifiers with

part numbers ending with "1"or"2"

Connector Connection Of Amplifier Side

PIN No.

1(A1

)

2(B1

)

3(A2

)

4(B2

)

5(A3

)

6(B3

)

Connector Connection Of Amplifier Side

PIN No.

1

2

3

4

5

6

V

0

V

7

8

9

10

11

12

13

14

15

16

Connector Connection Of Amplifier Side

PIN No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Cable Connection

Cable

A1-No.

A2-No.

A3-No.

A4-No.

A5-No.

・・

・・

・・

・・

A13-No.

A14-No.

A15-No.

A16-No.

DC+24/48V

Blue

Yellow

Green

LEAD COLR

Blue Motor Lead Wire

Orange Motor Lead Wire

Red Motor Lead Wire

Yellow Motor Lead Wire

White Brake Lead Wire

Black Brake Lead Wire

LEAD COLR

Blue

Brown

Green

Purple

White

Yellow

Red

Black

Black

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

LEAD COLR

Blue

Brown

Green

Purple

White

Yellow

Red

Black

Black

N.C.

Blue

Black

Yellow

Black

Red

Red

1

1

2

3

4

5

13B13

14B14

15B15

16B16

GND

DC+24V *

CHANNEL A

CHANNEL A

CHANNEL B

CHANNEL B

CHANNEL C

CHANNEL C

Shield

CHANNEL A

CHANNEL A

CHANNEL B

CHANNEL B

CHANNEL C

CHANNEL C

Shield

SDN

GND

LIMIT

GND

Cable

B1-No.

B2-No.

B3-No.

B4-No.

B5-No.

-No.

-No.

-No.

-No.

+5V

+5V

Vcc

Vcc

17

18

19

20

21

FG

0

V

―

―

―

―

―

―

―

0

V

―

2

29

30

31

32

1

Connector Set : PBC6P

Manufacturer

JST

Connector Set :PBC4M

Manufacturer

MOLEX

Connector Set :PBC5E

Manufacturer

MOLEX

JST

Connector Set :PBC4S

Manufacturer

KEL

0000

A

Typ e Qt y.

Connector:VHR-4N

Contact:SVH-21T-P1.1

Appropriate electric wire:AWG#22-18

0000

A

Typ e Qt y.

:

51112-0610 1

Housing

:

50398-8000 6

Terminal

:

51103-0600 1

Housing

:

50351-8000 6

Terminal

0000

A

Typ e Qt y.

:

51029-0910 1

Housing

:

50087-8030 9

Ter m i na l

:

Housing

PADP-16V-1-S

002

Ter m i na l:SPH-

Connector

GW-P0.5S

0000

A

Typ e Qty.

:

8822E-032-171D1

1

4

―

1

15

Functions

Features and

Typ e RType PType MType R Multi-Axis

General

Specifications

Drawings

1

9

Connector relay cable

CNA

Signal

Name

Pin.No.

Yellow

A

1

White

B

2

Brown

(Y)

3

Blue

)

(

Z

4

Black

GND

5

Red

Vcc

6

Purple

(

)

STOP

7

Green

FG

8

Drain

9

10

Connector Set :PBC4C

CNB

Signal

Name

Pin.No.

Yellow

1

White

2

Brown

(Y)

3

Blue

(

4

Black

GND

5

Red

Vcc

6

Purple

(

STOP

7

Green

FG

8

Drain

9

10

Manufacturer

A

B

)

Z

)

JST

Housing

Contact

:

0000

A

Typ e Qt y.

:

PADP-10V-1-S

SPH-OO2T- P0.5L

Motor Dimensional

2

20

Options

20

21

General Specifications

Model No. PBType R Multi-Axis Type

DC Power Input Type

Amplifier Dimensional Drawing [Unit : mm (inch

)]

Amplifier Model PB2D003R1U

△

Control Mode PWM Control Trapezoidal drive method

Power

Supply

Main Power Supply

Control Power Supply

DC24V/36V±10

%

DC24V±10%(only for part numbers ending with "1" or "3"

)

Ambient

temp.

Operating

0to55

℃

Storage −20 to 70

℃

Operating/

Storage Humidity

Maximum 90% RH (non-condensing

)

Vibration Resistance

0.5G(tested with frequency range 10 to 55 Hz, X, Y, Z each direction 2H

)

Structure Open Frame

Mass (Weight) / Dimensions Approx. 0.8kg (28.22oz

)

/

W120×H55×D80(W1.77×H5.91×D4.72inch

)

Rotation Speed 0 to 4500min

-1

Resolution (P/R) 200, 800, 1600, 3200, 6400, 12800

Regeneration Process Not available(External regenerative unit is optional

)

Protective Functions

Over-voltage, Regenerated voltage overload, Over-speed, Encoder disconnection, Reset error, CPU error, Overload stop,

Soft Servo Error, Amplifier Overheat

Display Power status, Alarm (flashing indicator

)

Functions

Operation Functions:Normal Drive(incremental move , absolute move ), Zero-return, push operation

Point Function:256Point

Program Function:256PRG×16Line 8PRG×512LINE

Switch

DIP SW1,2:Transmission Speed Setting

DIP SW3 to 6:Axis valid / invalid (On: Activate

)

DIP SW7 to 10:Ter minating Resistor Setting (On: with terminating resistance

)

Rotary SW:Node Adress Setting(0 to E

)

Input Signals

CN1 Fixed function(4): EXE, Point, SELECT, STOP, ALMCLR

CN1 Selectable(4): Generic Input, Point, Pause, Interlock

CN4 to CN7 Allocation Function (2 X 4-axis

)

Hard.Limit(SDN)Signal

Output Signals

CN1 Fixed function

In-Position, Ack, Busy, ALM

CN1Selectable(8

)

Generic Output, Motor Stop, H.Limit Monitor, ZONE, Zero-return completion, END, STOP Monitor, SDN Monitor

Communication Specifications

RS-485 Standard Start-Stop Synchronization, Half Duplex (Part numbers ending with "0" or "1"

)

RS-485 Standard Start-Stop Synchronization, Full Duplex (Part numbers ending with "2" or "3"

)

Amplifier Model Number Nomenclature

△

Communication

Specifications

Power Input

0

Start-Stop Synchronization,

Half Duplex

Single Pwr.

1

Separate

2

Start-Stop Synchronization,

Full Duplex

Single Pwr.

3

Separate

PB2D

003R1

U

△

Environment

Input/ Output Signals Functions

4.5(.18)

RSW

80(3.15)

DSW1

CN9CN8

70(2.76)

22(.87)

49(1.93)

3.5(.14)

3.5(.14)

113(4.45)

4.5(.18)

CN7CN6CN5CN4CN3CN2

LED1

LED2

2-ø4

(2-ø.16)

4.5(.18)

55(2.17)

120(4.72)

External Wiring Diagram

Main Power Supply

1

*

Control Power Supply

DC24V/36V

DC24V

2

*

±

±

CTXD

RTXD

EXE

SELECT

ALMCLR

IN-POS

IN-POS

IN-POS

IN-POS

10

10

FG

GND

N.C

FG

N.C

N.C

+COM

-COM

EXE

Point

Point

Point

Point

STOP

BUSY

ALM

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

+COM

-COM

%

%

ACK

△

003R1

PB2D

GND

Vcc

U

Vcc

GND

Vcc

1

Limit

Vcc

GND

2

Limit

GND

Vcc

GND

Vcc

CN

FG

11to14

BRK+

BRK-

CN

A

B

C

A

B

C

A

B

C

A

B

C

A

A

B

B

C

C

A

A

B

B

9

1

1

1

2

2

2

3

3

3

4

4

4

4to7

CN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

(Axis1to4)

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

(Axis1to4)

N.C

Ach(Axis1)

Bch(Axis

Cch(Axis

Ach(Axis

Bch(Axis

Cch(Axis

Ach(Axis

Bch(Axis

Cch(Axis

Ach(Axis

Bch(Axis

Cch(Axis

Vcc

GND

×

4

OPTICAL

ENCORDER

×

4

MOTOR

BRAKE

1

)

1

)

2

)

2

)

2

)

3

)

3

)

3

)

4

)

4

)

4

)

1

Connect control circuit to power source only for models with part

*

numbers ending with "

2

Please check individual specifications for each part number, as

*

communication specifications differ according to amplifier model.

1

Note

:The CN1general-purpose input/output signal function is selected

through communication. Please see the basic specifications for

details.

1

"or"3".

Functions

Features and

Typ e RTyp e PType MType R Multi-Axis

10

CN

1

Pow

2

GND

3

4

FG

2,3

CN

1

A

2

B

3

Y

4

Z

5

Vcc

6

2

EXE

2

1

1

2

3

4

1

IN

2

IN

3

IN

4

IN

1

2

3

4

1

2

3

4

5

6

7

8

N.C

7

8

9

10

1

CN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

N.C

31

32

Input/ Output Signals Circuit

Generic Input

■

Input Voltage Specifications:DC5V to 24V±10

1,31

DC Power Source

+5Vto24V

+COM

7

Generic Output

■

%

Generic Output

2、32

−

COM

MAX.

30

V

30mA MAX.

30

mA

MAX.

Hard Limit (SDN)

■

Not insulated

CN4to

*

General

5

V

16

15

,

5

V

11

13

,

Specifications

Drawings

12

14

-COM

SG

,

Motor Dimensional

Options

22

23

General Specifications

Standard Model

□

42

□

60

□

86

Motor Flange Size

DC

AC

□

28

□

42

□

60

Size

Motor Flange

Size

□

28

mm

(□

1.10

in

)

□

42

mm

(□