SANMOTION E-6, E-9 User Manual

Ê-,6"Ê-9-/-

Ver.3

Simplified Setup Process for Optimum

Operating Conditions

Auto-Tuning

A new auto-tuning algorithm improves system response by

providing functions such as inertia identification, 5 autotuning modes, 30 levels of response, and parameter setting

auto-save.

Velocity command

value

Tuning start

Detected velocity value

Test Function (JOG)

On-board JOG operation function is available for testing

servo motor and servo amplifier connection without the

need to connect to host device.

Capable of JOG operation

without connecting

to host device

Setup Software is required.

Conformance to Overseas Standards

Our standard servo amplifier has attained the UL, c-UL and

EN standards. You can also employ servo motors that have

attained the EN standards.

All-in-One Control

Configurable parameters allow you to switch between

control modes for torgue, position or velocity.

Position

Velocity

START

or

Flat

Torque

control

Ascending

GOAL

1

Setup Software

Multiaxial Monitor Function

Functions

Features and

The setup software allows you to set parameters, view

graphical displays of monitored position, velocity or torque

waveforms, and perform system analysis.

Parameter settings Position, velocity,

torque waveforms

*

*Use optional cable

AL-00490833-01 for PC connection

The setup software allows up to 15 servo amplifiers to be

monitored.

Daisy chain up to 15 units

*

DC SERVO SYSTEMS AC SERVO SYSTEMS

*Use optional cable

For PC connection

Maximum

15 units

Nomencalture

Model Number

System

Configuration

Standard

Specifications

Diagram

External Wiring

Dimensions

Setup Software

Protection Code IP43

Protection code is IP43 for all models.

Water

Shaft feedthrough and cable end are excluded.

Dust

IP43

Optional

Equipment

2

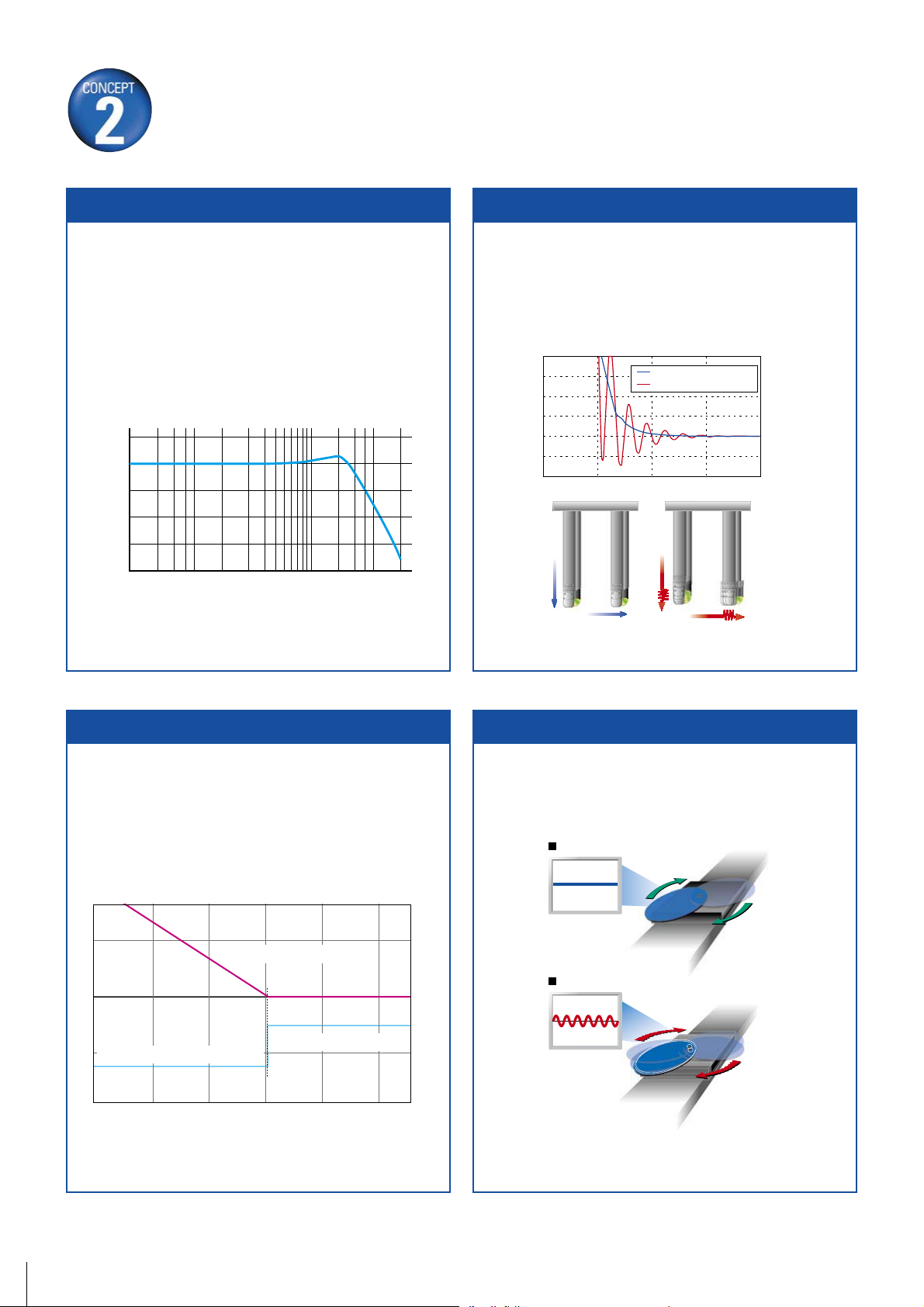

Improved Systems Precision and Shortened Cycle Time

High Response

A 4th-order notch filter reduces phase delay to suppress

mechanical resonance and improve velocity response of

equipment.

10

0

-10

-20

Gain (dB)

-30

-40

1

5 10 50100 500 1000

Frequency (Hz)

Vibration-damping Control

With feed-forward vibration suppression control, vibrations

at the processing point and base of a machine can be

suppressed through simple tuning procedures. Up to 4

types of vibration control frequencies can be selected.

Position deviation during stop

With vibration suppression control

Without vibration suppression control

With vibration

suppression control

17-bit absolute encoder is required.

Without vibration

suppression control

100ms/div

Shorter Position Settling Time

A new algorithm drastically shortens positioning settling

time for equipment.

Position deviation

Position complete signal

Example of positioning settling time

in highly rigid machinery

Settling time (0ms)

5ms/div

Disturbance Suppression

It is possible to control impacts from other axes in case

of multiaxial constitution, by using the new disturbance

observer with extended applicable frequency.

Disturbance observer function ON

Oscillation waveform

of direct drive section

Disturbance

Disturbance observer function OFF

Oscillation waveform

of direct drive section

Disturbance

17-bit encoder is required.

3

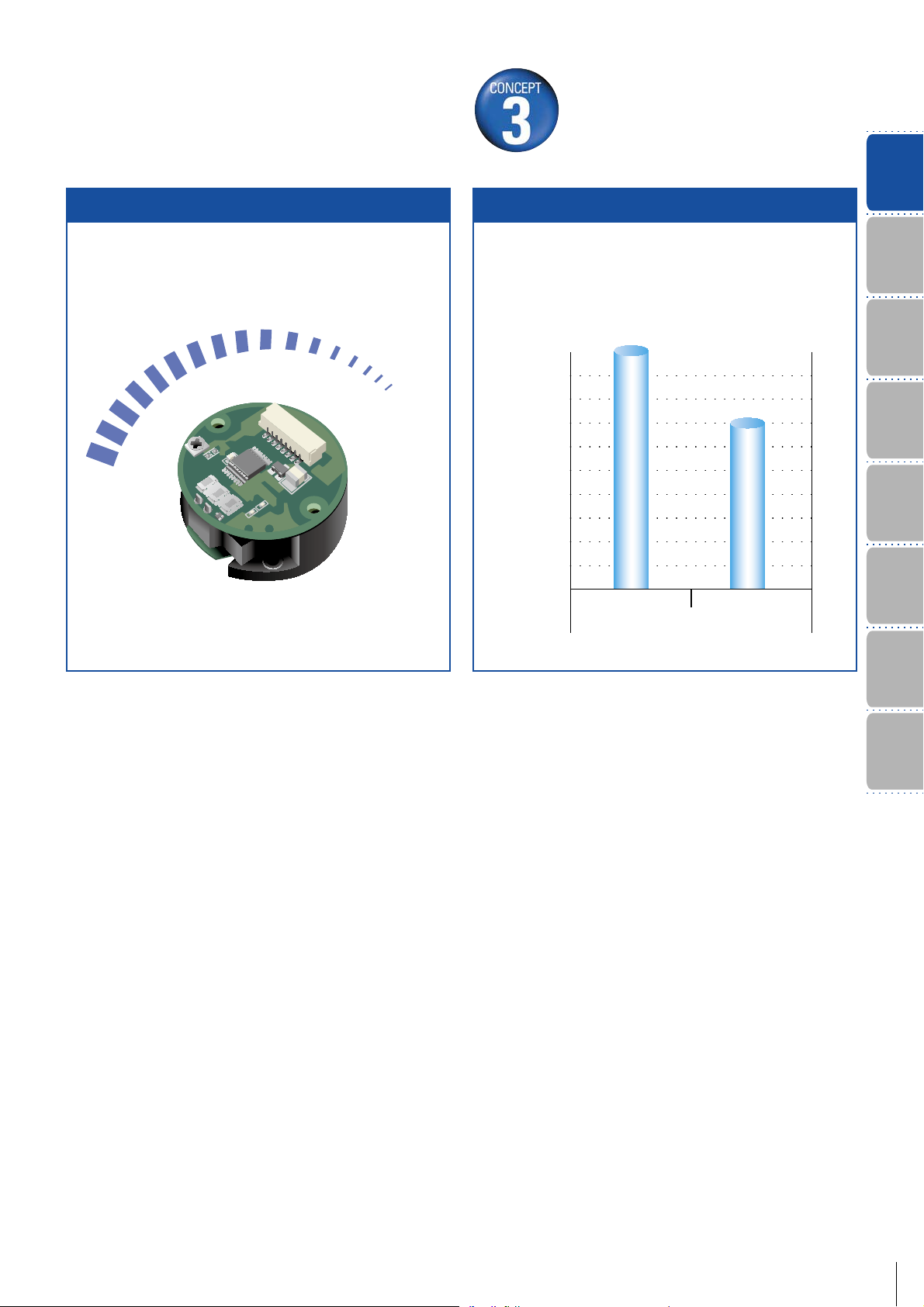

High Resolution

Curtailed Running Cost

30% Reduction in Power Loss

Functions

Features and

Control suitable for the high-resolution incremental

encoder and absolute encoder can be performed.

0

4

1

8

n

o

i

t

u

l

o

s

e

R

m

u

m

i

x

a

5

7

6

d

i

v

i

s

i

o

n

s

M

A low-power loss module has been employed to reduce the

power loss in the main circuit by 30%.

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

Reduction rate of power loss

0%

SANMOTION TCurrent model

Nomencalture

Model Number

System

Configuration

Standard

Specifications

Diagram

External Wiring

Dimensions

Setup Software

Optional

Equipment

4

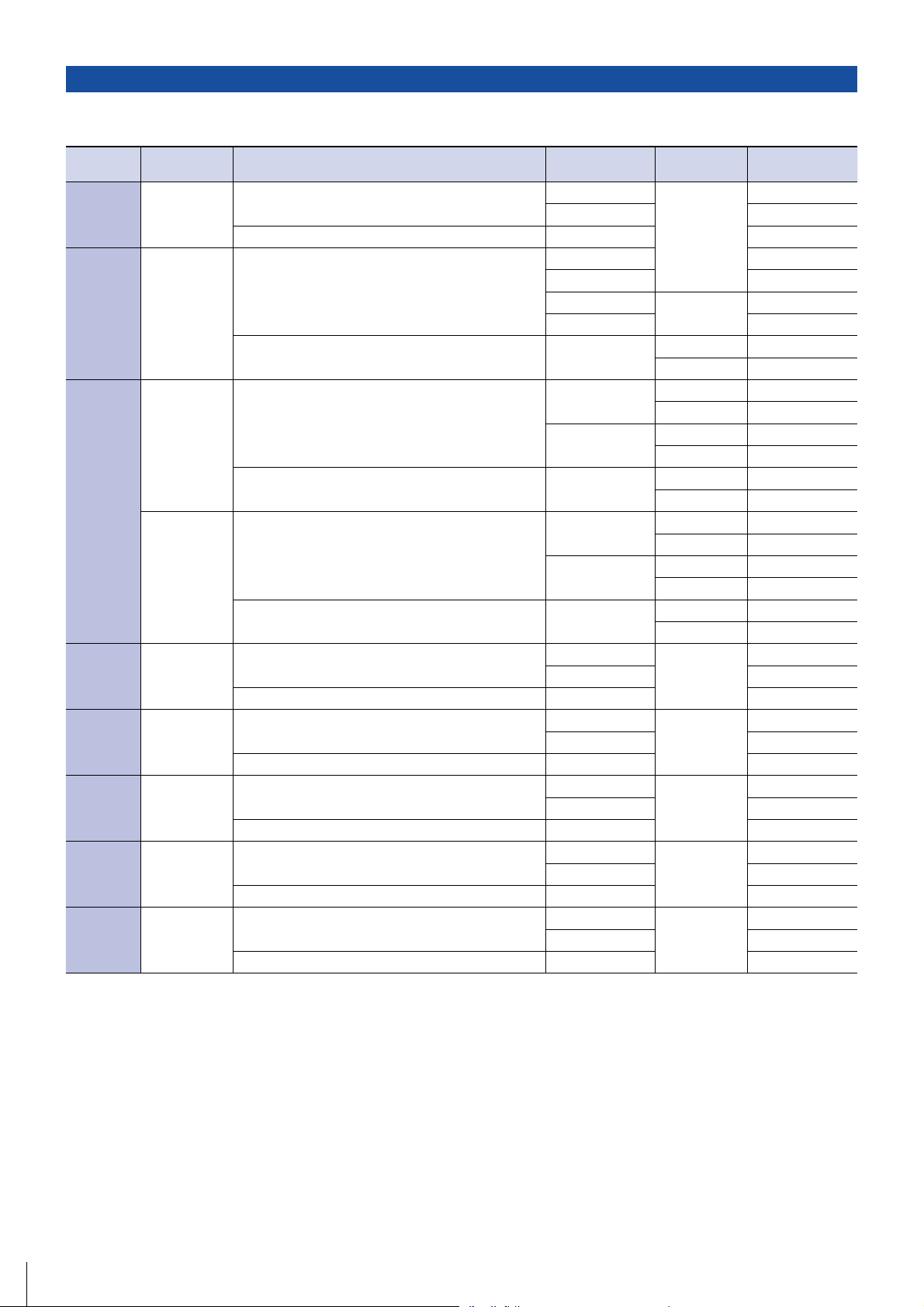

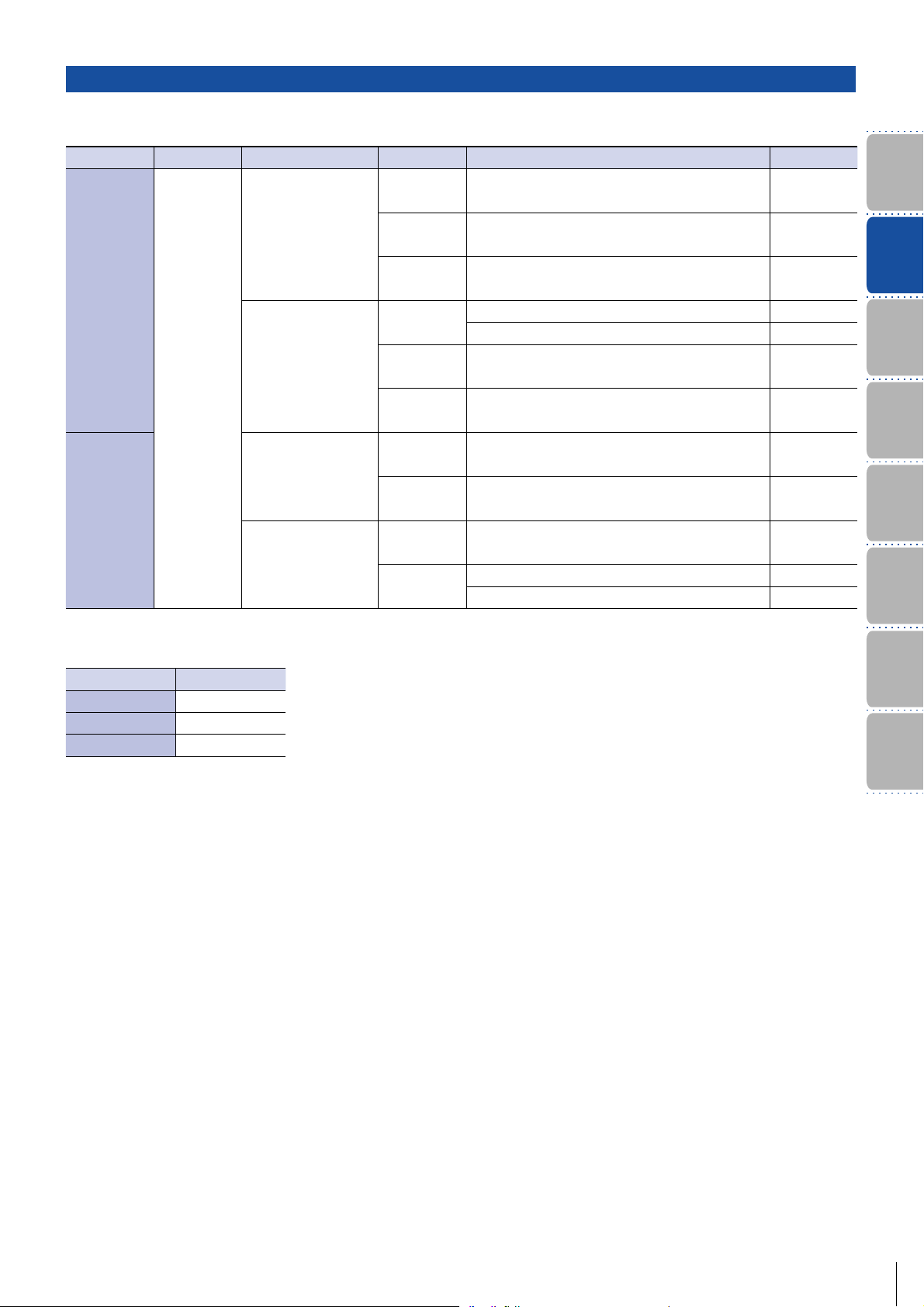

Servo Motor Standard Model Number List

Rated Output

23W

40W

60W

110 W

200W

300W

400W

500W

Outer diameter

of motor

φ

41mm

φ

41mm

φ

41mm

φ

51mm

φ

51mm

φ

76mm

φ

76mm

φ

87.5mm

φ

87.5mm

Encoder

―

Incremental encoder (PP031) 1000P/R

―

Incremental encoder (PP031) 1000P/R

―

Incremental encoder (PP031) 1000P/R

―

Incremental encoder (PP031) 1000P/R

―

Incremental encoder (PP031) 1000P/R

―

Incremental encoder (PP031) 1000P/R

―

Incremental encoder (PP031) 1000P/R

―

Incremental encoder (PP031) 1000P/R

―

Incremental encoder (PP031) 1000P/R

Tachometer

generator

―

Winding

specifications

Model No.

T402- 011

With T402T-011

―

―

24VSystem

T402- 011EL8

T404 - 011

With T404T-011

―

With T404T-012

―

―

With

―

―

With

―

―

With T511T-012

―

―

With T720T-012

―

―

With T730T-012

―

―

With T840T-012

―

―

With T850T-012

―

For specifications on other model, please contact us.

75VSystem

24VSystem T404-011EL8

System T404-012EL8

75V

24VSystem T406-011

System T406-012

75V

System T406T-011

24V

System T406T-012

75V

24VSystem T406-011EL8

System T406-012EL8

75V

24VSystem T506-011

System T506-012

75V

System T506T-011

24V

System T506T-012

75V

24VSystem T506-011EL8

System T506-012EL8

75V

75VSystem

75VSystem

75VSystem

75VSystem

75VSystem

T404 - 012

T511- 012

T511- 012 EL8

T720-012

T720-012EL8

T730-012

T730-012EL8

T840-012

T840-012EL8

T850-012

T850-012EL8

5

Servo Amplifier Standard Model Number List

Main power

DC140V

DC50V

Control power

DC24V

Control system

Pulse train,Speed,

Tor que

Speed,Torque

Pulse train,Speed,

Tor que

Speed,Torque

Amp. capacity

Detector Model No.

20A Incremental encoder TS1A02AA

25A Incremental encoder TS1AA2AA

30A Incremental encoder TS1A03AA

20A

Tachometer generator (Motor model T4) TS1A02AN

Tachometer generator (Motor model T5)TS1A02AP

25A Tachometer generator(Motor model T5,T7) TS1A A2 AP

30A Tachometer generator (Motor model T8) TS1A03AP

20A Incremental encoder TS1B02AA

25A Incremental encoder TS1BA2AA

20A Tachometer generator (Motor model T4) TS1B02AN

25A

Tachometer generator (Motor model T4) TS1BA2AN

Tachometer generator (Motor model T5)TS1BA2AP

For specifications on other model, please contact us.

Functions

Features and

Nomencalture

Model Number

System

Configuration

Standard

Specifications

Diagram

External Wiring

Dimensions

Power unit

Output capacity Model No.

5ATS1PA0500

10A TS1PA1000

15ATS1PA1500

Setup Software

Optional

Equipment

6

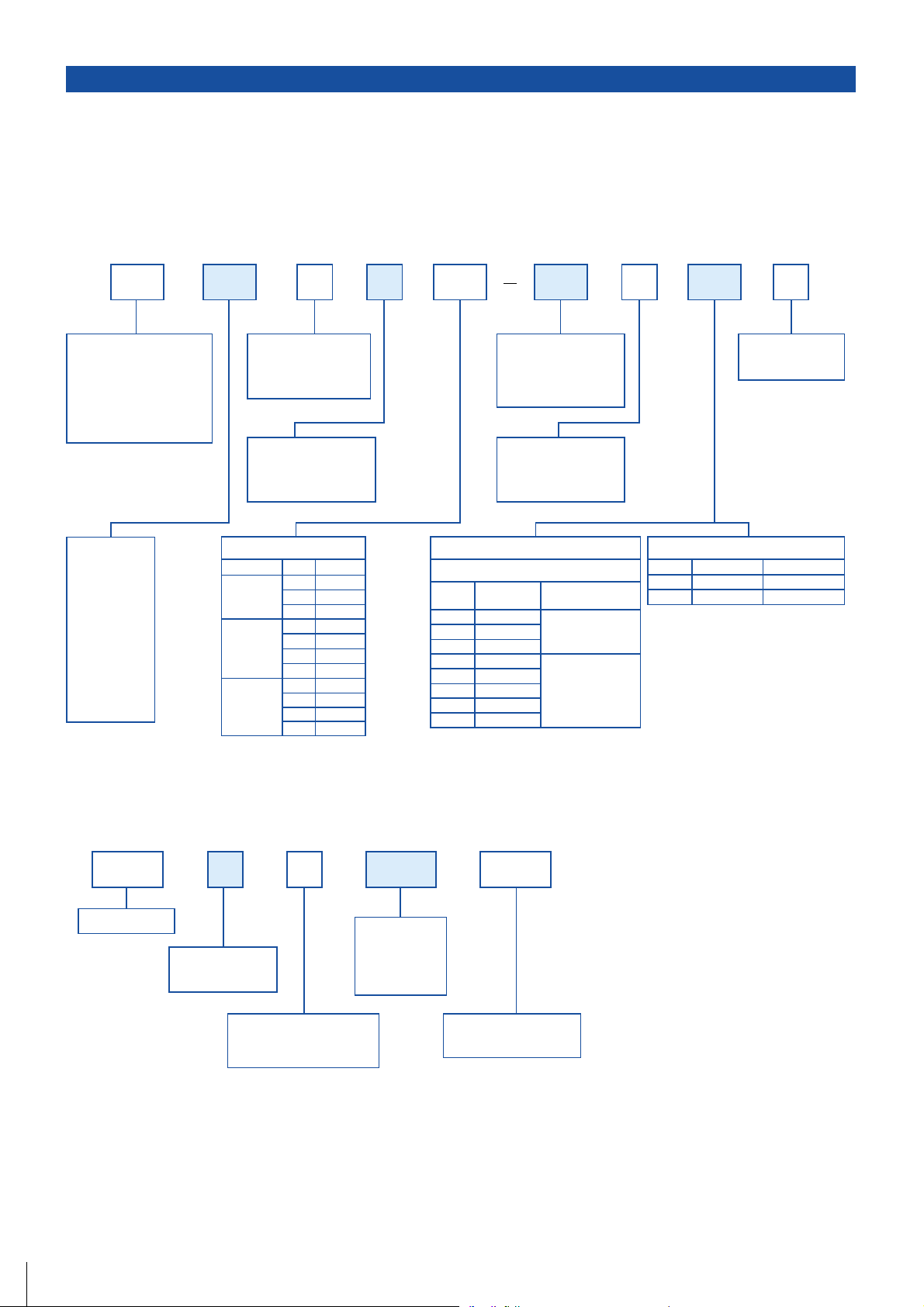

Servo Motor / Power Unit Model Number Nomenclature

Servo Motor

Example : The model number is as follows when 200W rated output, 76mm outer diameter,

incremental encoder (1000P/R), a brake, tachometer generator, gear (1/15 gear ratio),

and 75V series voltage specification are selected for "SANMOTION T" servo motor:

Model

Outer diameter

of motor

T4‥‥‥‥‥ φ41 mm

T5

‥‥‥‥‥ φ51 mm

T7

‥‥‥‥‥ φ76 mm

T8

‥‥‥‥‥ φ87.5 mm

Rated output

02‥‥ 23W

04

‥‥ 40W

06

‥‥ 60W

11

‥‥ 110W

20

‥‥ 200W

30

‥‥ 300W

40

‥‥ 400W

50

‥‥ 500W

20

Brake

B‥‥‥ Equipped

None

‥

Not equipped

Tachometer generator

T‥‥‥ Equipped

None

‥

Not equipped

Gear

Motor model Gear ratio

model

model

model

T4

T5

T7

Model No.

GA

1/12.5

1/25

GB

GC

1/50

G1

1/15

G2

1/30

G3

1/60

G4

1/90

G6

1/15

G7

1/30

G8

1/60

G9 1/90

TB

G6

Specification identification

01‥‥‥‥ Standard

Other

Winding specifications

(W/O oil seal)

‥‥ Option

2T7 01 EL8

U

None‥ Standard

U‥‥‥UL

1‥‥ 24V series

2

‥‥ 75V series

Incremental Encoder

Line driver output

Output

Model No.

pulse number

EL8

EL0

E59

EAL8

EAL0

EA59

EA51

EA53

・No indication: No encoder

※

T4 type can be equipped with either tacho-generator or

encoder only. It cannot be equipped with brake oil seal.

※

Motors with a rated output of 23W, 40W, and 60W support

the 24V winding specification.

1000

2000

2500

1000

2000

2500

5000

10000

Encoder type

PP031

PP031T

Quick response

specifications

Absolute encoder

Number of bits

Model No.

A12

A22

17

20

Baud rate

2.5Mbps

2.5Mbps

Power Unit

7

TS1 series

Unit structure type

Power Unit

‥‥

Input voltage Note)

‥‥

(for common use)

Note) Supply AC100V if the motor

winding specification is 75V

series and supply AC35V if

it is 24V series.

ATS1 10 00P

100V AC or 35V AC

Output capacity

05‥‥ 5A

10

‥‥ 10A

15

‥‥ 15A

Individual specification

‥‥ Standard product

Servo Amplifier Model Number Nomenclature

Servo Amplifier

Example: The model number is as follows when "SANMOTION T "series servo amplifier with input voltage

of DC140V, 20A capacity, and incremental encoder (1000P/R).

A AATS1 02

TS1 series

Input voltage

A…DC 140V

B

…DC 50V

Amp. capacity

02 ‥‥‥‥ 20A

A2

‥‥‥‥ 25A

03

‥‥‥‥ 30A

Motor structure type

‥‥

Rotary motor

Control unit hardware type Note)

A ‥‥‥‥ Incremental encoder (Line driver output only)

F

‥‥‥‥ Absolute Encoder

N ‥‥‥‥ Tacometer generator (Motor model T4)

P

‥‥‥‥ Tacometer generator (Motor model T5,T7,T8)

Note) Tacho-generators have not attained international

standards (UL, c-UL and EN Standards).

Functions

Features and

Nomencalture

Model Number

System

Configuration

Standard

Specifications

Diagram

External Wiring

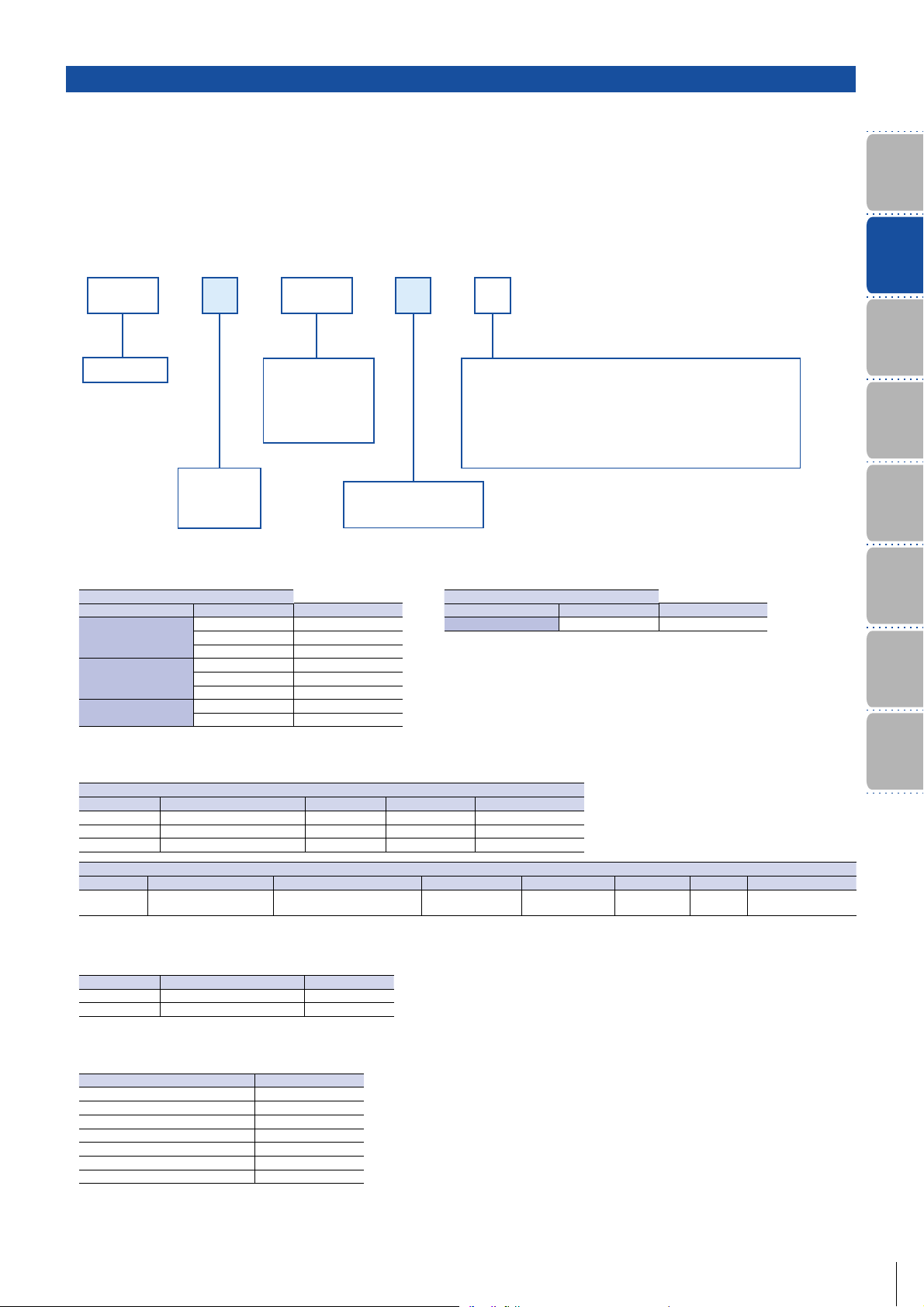

1 )Compatible servo motor type

Input voltage-140V DC

Type of Amplifier. Type of Motor Factory settings

TS1A02 A

TS1AA 2A

TS1A03A

T404-012

T406-012

T506- 012

T511-012

T720-012

T730-012

T840-012

T850-012

2 )Compatible encoder type

Format Divisions per rotation [P/R] Addreviation Hard type. Factory settings

Optical 1000 INC-E

Optical 2000 INC-E

Optical 2500 INC-E

Format Transmission format Divisi ons per rot ation [P/ R] Multiple rotation Addreviation Hard type. Remarks Factory settings

Optical

Half duplex start-stop

synchronization 2.5M

Note)

Note)

Incremental encoder

Input voltage-50V DC

√

√

√

17bit 16bit PA035C-2.5MH

Type of Amplifier. Type of Motor Factory settings

TS1B02A T402-011

A

A

A

Absolute encoder

√

√

F

3 )Compatible tacometer generator

Motor Model Tacometer generator Model Hard type

T4 3V / 1000min

T5, T7, T8 7V / 1000min

-1

-1

N

P

Dimensions

Setup Software

Optional

Equipment

√

4 )Interface for control section

Control type Factory settings

Velocity control type

Torque control type

Position control type

Velocity - Torque switch type

Position - Torque switch type

Positio n - Velocit y switch type

Internal velocity control type

Note)

√

Note)Please change the compatible servo motor, compatible encoder and the interface for control section using the set-up software.

8

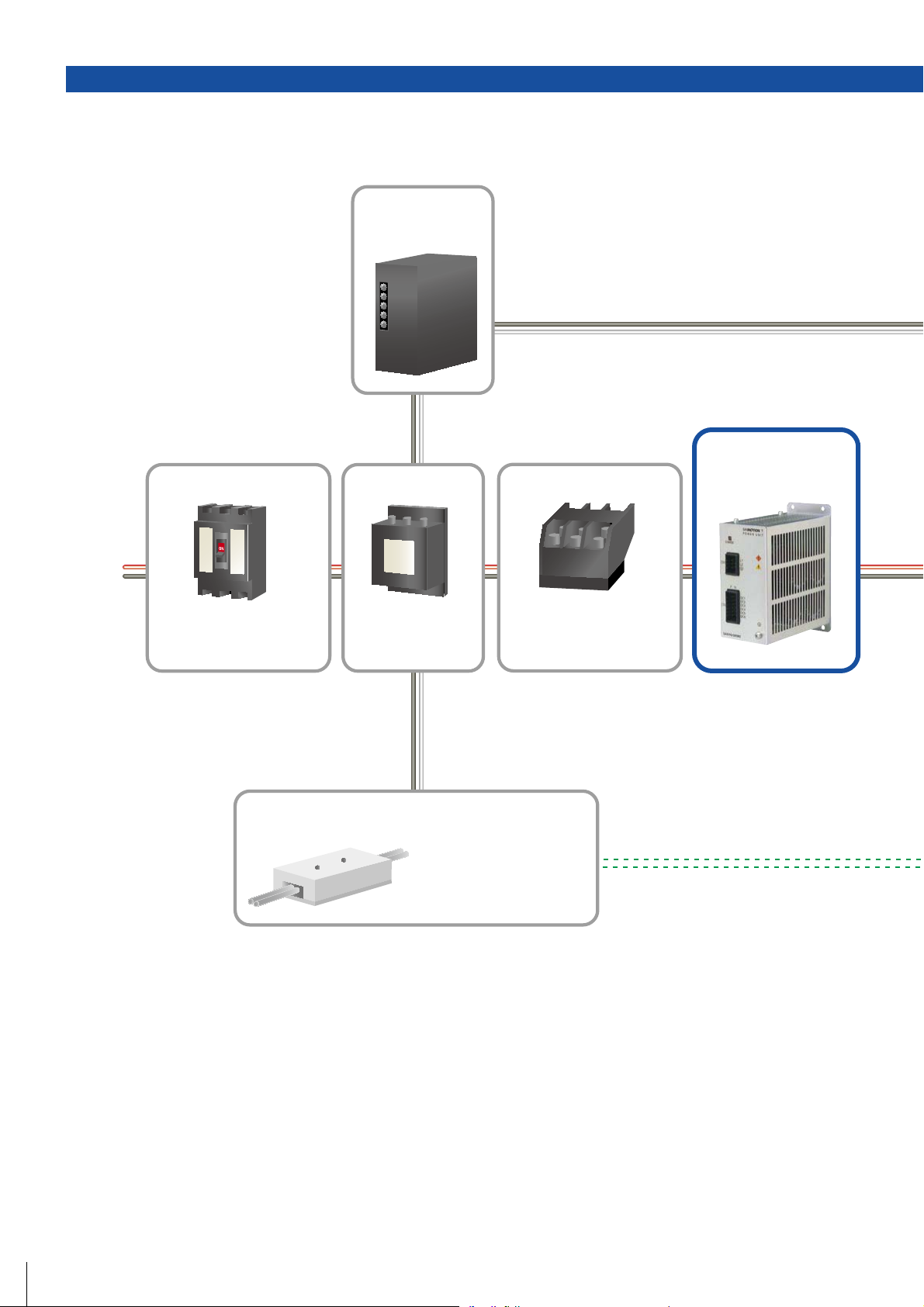

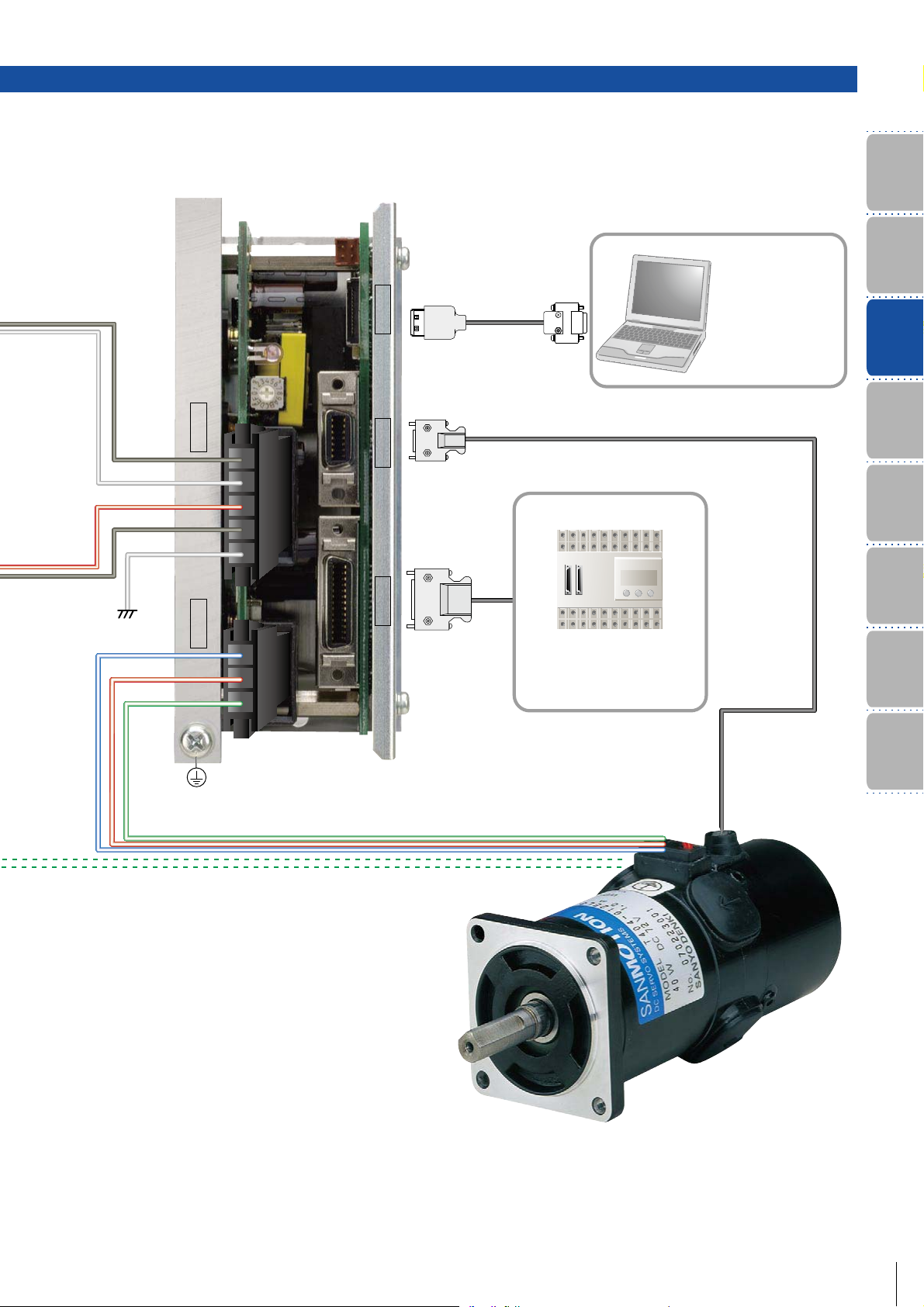

System Configuration

Circuit Breaker (MCCB)

Main

power

supply

AC100V

50/60Hz

Control power supply:

DC24V output

Noise Filter

Electromagnetic Contactor

Power unit:

DC140V output

Cuts off power in the case of

an overload, to protect the

power line.

Brake Power

Protects the power line

from external noise, and

from noise generated

by the servo amplifier.

Required for use when the

servo motor is equipped

with a brake.

Switches servo power on

and off. Requires installation

of a surge protector.

9

Functions

Features and

Setup Software

C

N

5

CN5

AL-00490833-01

Parameter

configuration and

monitoring is possible

via communication

with a PC.

Nomencalture

Model Number

System

Configuration

C

N

3

C

N

2

CN2CN2

Host Devices

Standard

Specifications

Diagram

External Wiring

C

C

N

4

N

1

Dimensions

CN1

SANYO DENKI's host devices

permit communication with

third-party products.

Setup Software

Wiring required for brake.

Optional

Equipment

10

Loading...

Loading...