Sankyo SANDEX-Alpha 11AR Operation And Maintenance Manual

11AR

ALPHA SERVO DRIVE INDEX

Optimum Reliability in Motion Control

OPERATION AND MAINTENANCE MANUAL

SERVO DRIVE TYPE

Preface

Thank you for purchasing a SANDEX product. These instructions cover installation procedures, linkage

procedures, and maintenance precautions to be followed to ensure maximum performance from this

product. Please read these instructions carefully before installing or trial operating of this product.

After unpacking, make sure the product delivered fits your ordering specifications.

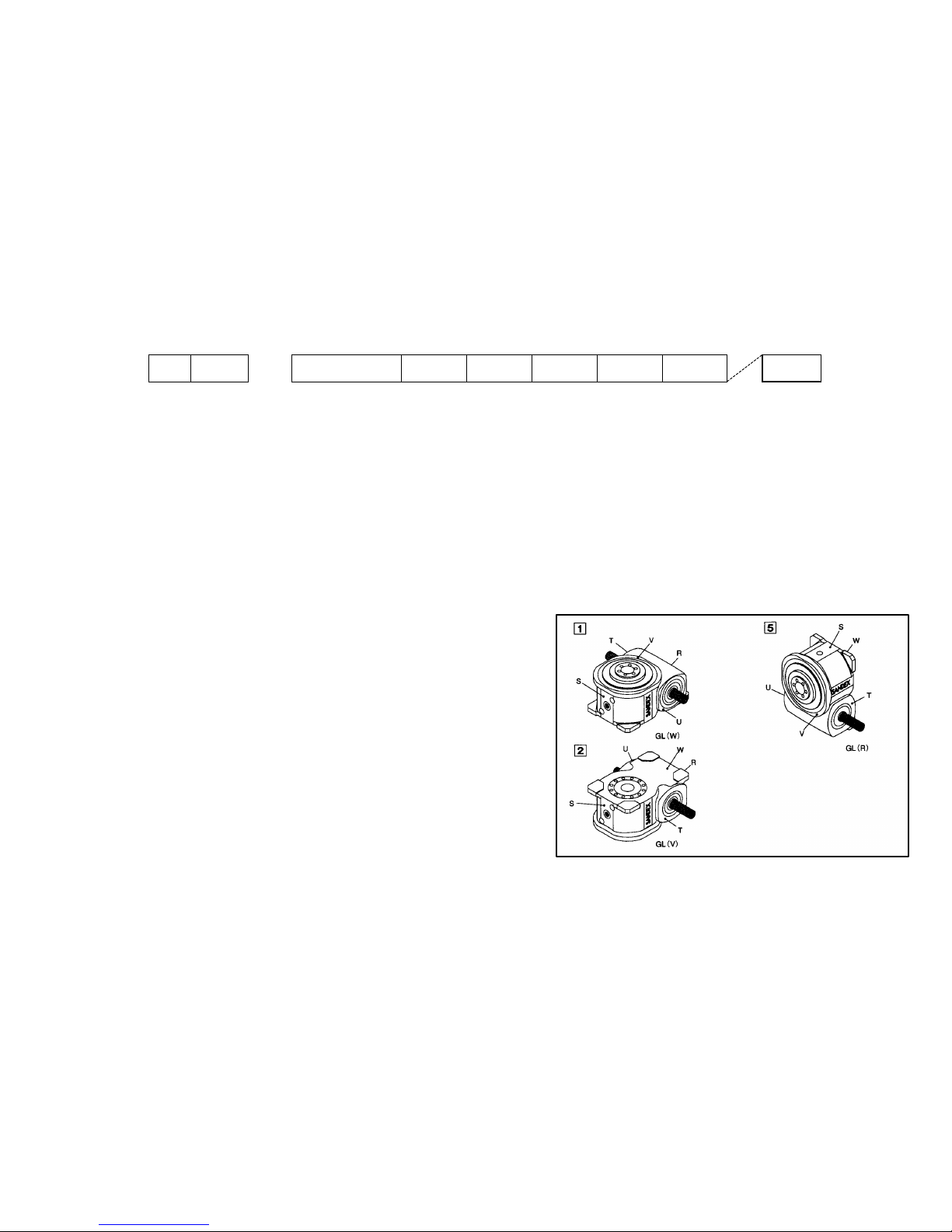

99 ARAR -- S01S01 AA 00 00 00 00 XX

|

aa | bb

|

cc

|

dd

|

ee

|

ff

|

gg

|

hh

|

II

a: Size

Shaft to shaft distance

Availability: 7=70mm, 9=90mm, 11=110mm, and 15=150mm

b: Model

AR=Alpha series Roller drive type

c: Roller Drive

Type of roller drives

Availability:

S01=Roller gear ratio; 1/12, Mounting position; 1

S02=Roller gear ratio; 1/12, Mounting position; 2

S05=Roller gear ratio; 1/12, Mounting position; 5

d: Motor & Bracket

Type of Motor & Bracket

Availability:

A=Standard (Pulley ratio; 7&9AR=1/3, 11&15AR=1/2)

April 2002

e: Motor Driver

Type of Motor Driver

Availability:

11

0=Single phase 200 to 230VAC for 7AR & 9AR

1=Three phase 200 to 230VAC for 11AR & 15AR

2=Three phase 380 to 480VAC for 11AR & 15AR

f: Controller

Type of controller

Availability:

0=Standard

x=Special requirements

g: Cable

Type of cables

Availability:

0=3 meters length, w/o conduit

1=5 meters length, w/o conduit

2=10 meters length, w/o conduit

3=15 meters length, w/o conduit

4=3 meters length, w/ conduit

5=5 meters length, w/ conduit

6=10 meters length, w/ conduit

7=15 meters length, w/ conduit

Y=Connectors Only

h: Control Software

Type of control software

Availability:

0=Standard

x=Special requirements

I: Special Instructions

Include the symbol X in case of special orders

No symbols= Standard

22

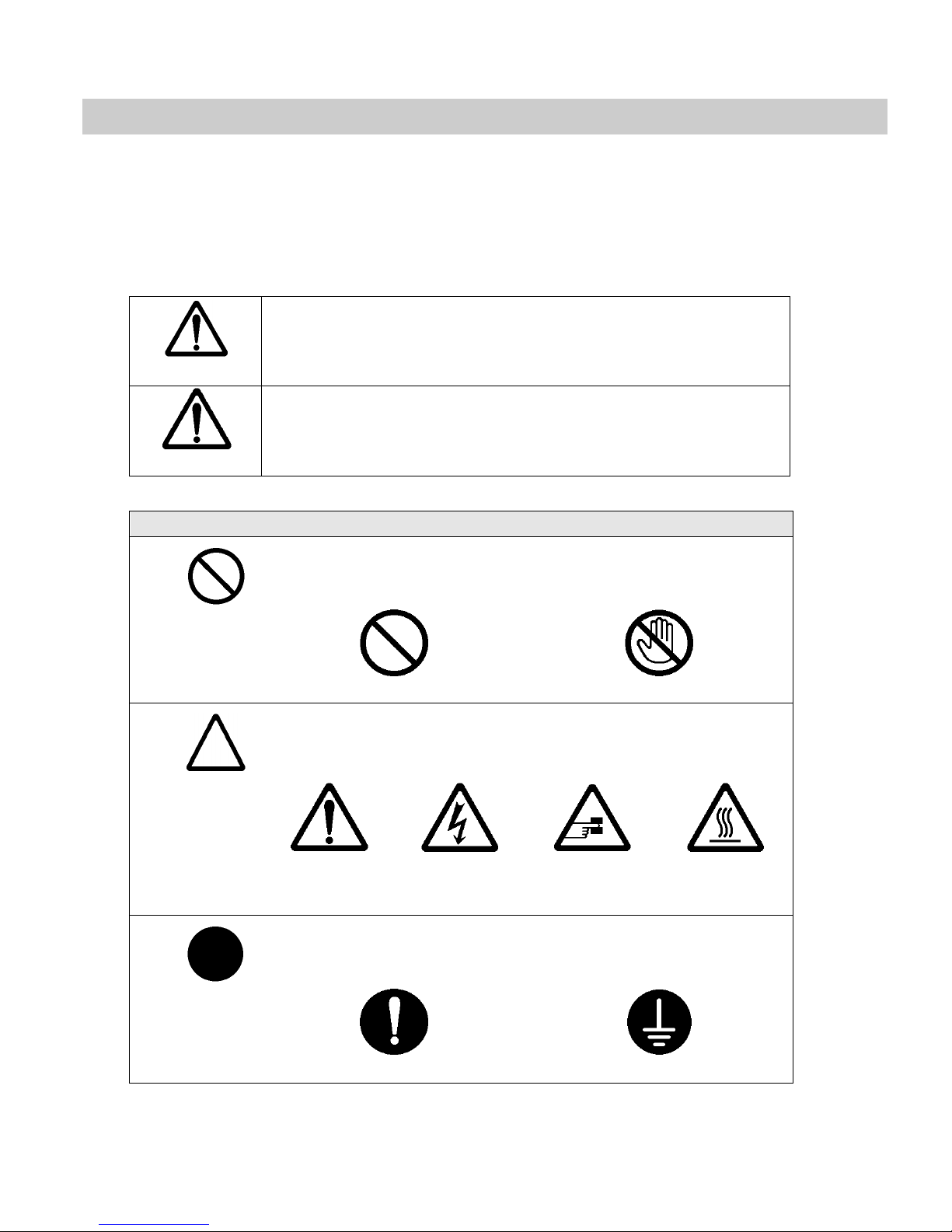

Safety Precautions

Symbols to ensure the safe and proper use of the Variax

The following symbols are used this manual where safety precautions must be observed. Read

and understand the meanings of these symbols to ensure the safe and proper use of Variax.

Failure to obey these precautions can cause machine problems, accidents, or other unexpected

behavior.

Indicates a potentially hazardous situation, which may result

in death or serious injury.

Warning

Indicates a potentially hazardous situation, which may result

in minor or moderate personal injury or damage to the

Caution

equipment.

Meaning of symbols

In general, this symbol alerts you to an action or operation that you

must not do.

General prohibition

Do Not Touch

In general, this symbol alerts you to the possibility of damage

to you or your equipment.

General

Warning

Electrical

Hazard

Pinch Point

Temperature

High

This symbol alerts you to actions that are reserved for

qualified service personnel only

Mandatory Action

Electrical Grounding

33

Contents

PREFACEPREFACE

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

SAFETY PRECAUTIONSSAFETY PRECAUTIONS 33

SSYMBOLS TO ENSURE THEYMBOLS TO ENSURE THE SAFE AND PROPER USE SAFE AND PROPER USE OF THE OF THE VVARIAXARIAX 33

1. OPERATING THEORY1. OPERATING THEORY 66

2. HANDLING YOUR SA2. HANDLING YOUR SANDEXNDEX 77

2.12.1 IIDENTIFYING DENTIFYING AALPHA LPHA SSERVO LAYOUTERVO LAYOUT 77

3. TRANSPORTATION A3. TRANSPORTATION AND ENVIRONMENTND ENVIRONMENT 88

3.13.1 SSHIPPING CONDITIONHIPPING CONDITION 88

3.2 3.2 TTEMPERATURESEMPERATURES 88

3.33.3 MMOISTUREOISTURE 88

3.43.4 DDUSTUST 88

4. INSTALLATION4. INSTALLATION 1010

4.1 CASING MAIN BODY 1010

4.2 DRIVER 1010

4.2.1 STORAGE CONDITIONS 10

4.2.2 INSTALLATION SITE 11

4.2.34.2.3 ORIENTATIONORIENTATION 11

4.2.44.2.4 WIRING THREE PHASE 2WIRING THREE PHASE 200VAC00VAC 12

4.2.54.2.5 WIRING THREE PHASE 4WIRING THREE PHASE 400VAC00VAC 13

4.3 CONTROLLER 1414

4.3.1 MOUNTING THE MP940 14

4.3.24.3.2 CONNECTION OF PERIPHCONNECTION OF PERIPHERAL DEVICESERAL DEVICES 15

4.44.4 WWIRINGIRING 1616

4.4.14.4.1 I/O CIRCUITSI/O CIRCUITS 17

4.4.24.4.2 CONTROLLER I/O CONNECONTROLLER I/O CONNECTIONSCTIONS 18

5.OPERATION5.OPERATION 1919

5.15.1 SSETTING ENCODER ZERO ETTING ENCODER ZERO POSITIONPOSITION 1919

5.25.2 SSETTING ZERO POSITIONETTING ZERO POSITION ((STARTING POSITIONSTARTING POSITION)) 1919

5.35.3 I/O I/O TIMING CHART WHILE ITIMING CHART WHILE IN JOG MODEN JOG MODE 2020

5.45.4 I/O TIMING CHART WHILE IN AUTOMATIC MODE 2121

5.55.5 IINDEXING TIME VSNDEXING TIME VS. . STOPS CHARTSTOPS CHART 2222

44

5.65.6 DDATA SWITCH SETTINGSATA SWITCH SETTINGS 2222

6. HANDLING PROCEDU6. HANDLING PROCEDURES FOR THE RES FOR THE OUTPUT SHAFTOUTPUT SHAFT 2323

6.16.1 TTABLE TYPE OUTPUTABLE TYPE OUTPUT 2323

7. LUBRICATION7. LUBRICATION 2424

4.54.5 PPURPOSE OF LUBRICATIOURPOSE OF LUBRICATIONN 2424

7.27.2 OOIL SELECTION PRECAUTIL SELECTION PRECAUTIONSIONS 2424

7.37.3 LLUBRICATING OIL VISCOUBRICATING OIL VISCOSITYSITY’’SS 2525

7.47.4 RRECOMMENDED LUBRICATIECOMMENDED LUBRICATING OILNG OIL 2525

8. FILLING AND REPL8. FILLING AND REPLACING LUBRICATING OIACING LUBRICATING OILL 2626

8.18.1 RREFILLING LUBRICATINGEFILLING LUBRICATING OILS OILS 2626

8.28.2 OOIL REPLACEMENT SCHEDIL REPLACEMENT SCHEDULEULE 2626

9. LUBRICATION GREA9. LUBRICATION GREASESSES 2727

9.19.1 SSUPPLYING LUBRICATINGUPPLYING LUBRICATING GREASE GREASE 2727

10. REPAIRS AND MAI10. REPAIRS AND MAINTENANCENTENANCE 2828

10.110.1 YYASKAWA ASKAWA DDRIVER AND RIVER AND CCONTROLLERDISPLAY CODONTROLLERDISPLAY CODESES 2929

10.210.2 TTROUBLESHOOTING PROCEROUBLESHOOTING PROCEDURES DURES (1)(1) 3131

10.310.3 TTROUBLESHOOTING PROCEROUBLESHOOTING PROCEDURES DURES (2)(2) 3232

55

Unit 2

Handling your Sandex

1. Operating theory

SANDEX units operate based on the following principal. A globoidal cam is mounted onto the input

shaft. This cam interlocks with the turret portion of the output shaft. The turret has cam followers along

its perimeter, which are in contact with the tapered ribs on the cam. This contact or pressure is called

the preload. Turning the input shaft rolls the cam followers along the rib surfaces thereby rotating the

turret according to the curve of the cam. The turret is motionless when the ribs are parallel with the

edges of the cam although the cam followers stay in motion.

Two of three cam followers are always kept pressed against the tapered ribs to ensure an accurate

transmission of rotation. Any backlash or movement between the tapered rib surfaces and cam

followers can cause vibrations, noise, and also damage the cam and cam follower surfaces. Backlash

can be completely eliminated by rotating the eccentric flange that holds the input shaft, and minimizing

the distance between the input and output shaft.

Explanation of terms used with indexing equipment

TERM DEFINITION

The number of stops determined by the customer’s programming.

Number of stops

A predetermined number of stops have been programmed into the

controller (1-16) CW or CCW.

Index angle The index angle is dependant on the number of stops.

Dynamic Torque output

rating(Top)

The maximum torque that can be applied on the output shaft

during indexing phases. Directly related to machine life.

66

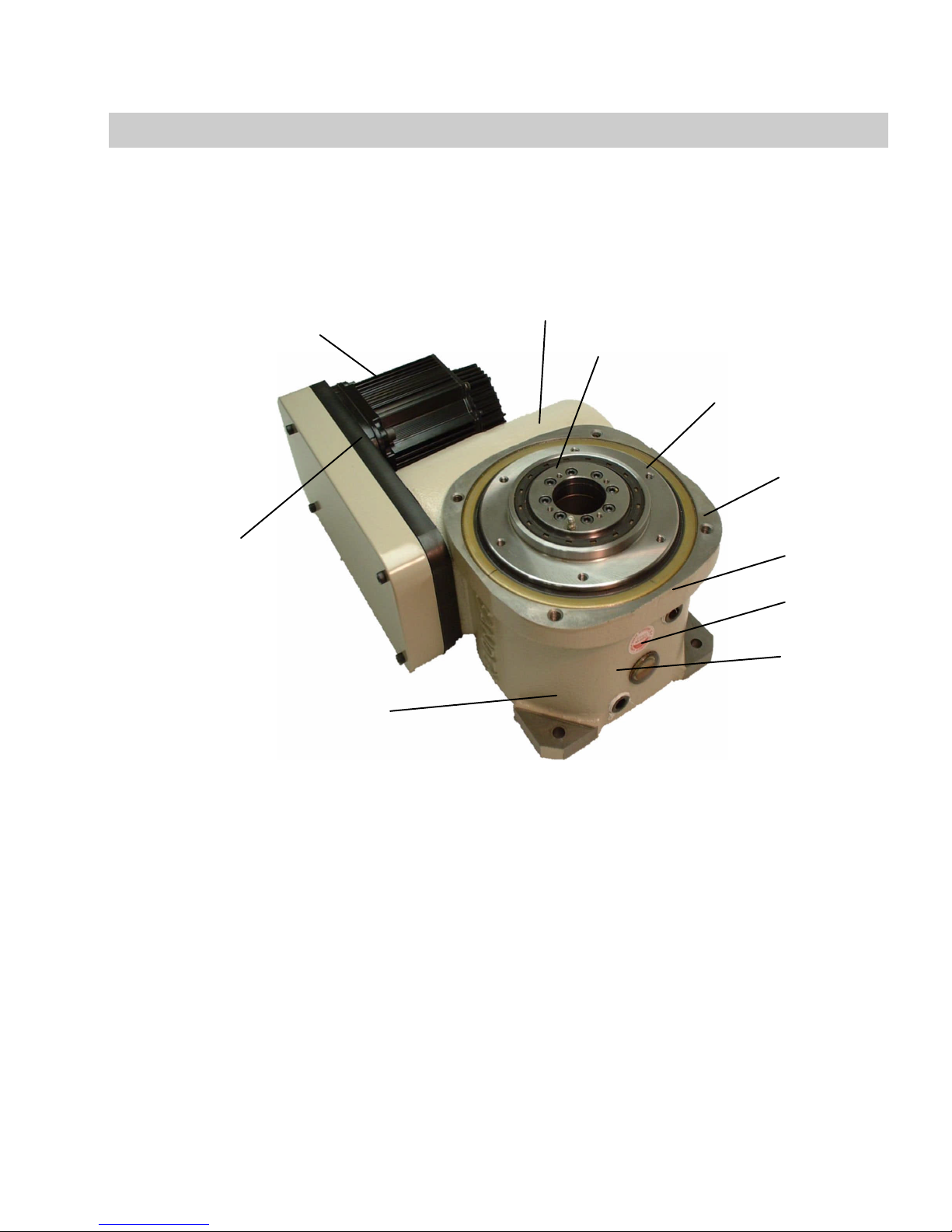

Unit 2

Roller Drive

Mounting hole

Handling your Sandex

2. Handling your SANDEX

Over 90% of the mechanical failures reported with roller gear cam equipment comes from careless

or improper handling. Improper handling not only reduces the life of your SANDEX unit, it can also

affect the performance of both the SANDEX unit and your machine.

2.1 Identifying Alpha Servo layout

Servomotor

Servomotor

mounting bracket

Fixed hollow flange

Installation surface

for indexing table.

Installation for

fixed table.

Oil cap

at W-surface

2.2 Handling your Alpha Servo

(1) Torsion and deflection within the rotation transmission system

(2) Frictional torque within the rotation transmission system

(3) Frequent load charge

(4) Usage under rust stimulant conditions such as water, acid, or alkali

(5) Usage in dusty areas

(6) Electrical currents

(7) Improper maintenance and repairs

(8) Mounting areas with insufficient rigidity

Oil gauge

*Drain

77

Unit 3

Transportation and environment

3. Transportation and Environment

3.1 Shipping condition

(1) All SANDEX products are thoroughly inspected after the final assembly. Only those

products that pass this inspection are shipped.

(2) Before shipped, each SANDEX unit is filled with lubrication oil in accordance to the

customer’s operating speed and environment.

(3) A rust preventative solution is applied to the input /output shafts, key, and mounting

surface. Vinyl tape is also used extensively to protect your SANDEX unit from

scratches while transporting.

Remove the rust preventative solution with a light oil or thinner. Be careful not to let the

light oil or thinner contact the oil seal. Never use thinner on or near the plastic sight gauge.

This may cause severe clouding of the material.

3.2 Temperatures

(1) For use between -20 to 0 degrees Celsius, (-4 to 32°F) use a lubricating oil with a lower

viscosity than the recommended oil. This is because the dynamic viscosity of the

lubricating oil rises in low temperatures and may not allow proper speed acceleration.

(2) For use between 40 to 70 degrees Celsius, (104 to 158°F) use lubricating oil with a

higher viscosity than the recommended oil. This is because the dynamic viscosity of the

lubricating oil lowers in higher temperatures and reduce the life of the equipment.

(3) For use between 70 to 100 degrees Celsius, (158 to 212°F) replace the oil seal and O-ring

with a heat resistant synthetic rubber.

3.3 Moisture

Rust may occur in storage or if the main machine is washed with water. Water does not

have to come directly into contact with the unit to cause rust. Moisture, condensation, and

other sources of humidity can also cause rust.

To use under these conditions, the mounting surfaces and shafts of the unit must be

painted, or otherwise rust proofed. Applying mineral oil or grease to the mounting surfaces

has a rust preventative effect and should always be practiced.

In addition, if the unit is directly subject to water, the sealing devices on the input and

output must be changed to a waterproof construction.

3.4 Dust

SANDEX units are generally built resistant to dust. This is because the roller gear cam

mechanism is enclosed within its own housing, and then sealed off at the input and output

with an oil seal. However, depending on the amount of dust or other foreign particles, the

88

Unit 3

Transportation and environment

oil seal may wear and thereby cause oil leaks. This is particularly evident when chemicals

are used. Chemicals can also cause andor accelerate rust and corrosion. When using

your SANDEX unit in dusty areas, you should consider using protective covers made from

stainless steel or plastic.

If the location for your SANDEX unit is very dusty, the air outlet in the oil

fill port may become an entrance into the housing. Placing an air filter over

this port should prevent dust from entering the housing. Electrical currents

If electricity passes through the SANDEX unit, minute dimples can occur on the cam

followers and roller gear cam, as well as on the rolling surfaces and members of the

bearings.

““Electrolytic corrosion” is where electrical sparks actually melt away the surfaces of

the rolling members. Electrolytic corrosion is a current-based effect. Therefore, it can

occur under less than one volt of electrical power.

If your SANDEX unit may be subject to electrical currents, make sure to insulate it.

Electrolytic corrosion, if allowed to persist, will increase the amount of vibration and noise,

and eventually render your SANDEX unit useless. Always insulate the table and unit from

welding applications or other automated machinery that use large amounts of electrical

current.

When linking the motor with the input system, consider using rubber couplings instead

of metal types. Rubber provides more insulation. Other measures that can prevent

electrolytic corrosion include using V-belts and timing belts.

99

Unit 4

Installation

4. Installation

Another crucial factor to the performance of your SANDEX unit is the operating environment. Make an

early review of the location for your SANDEX unit and take any corrective actions necessary.

4.1 Casing main body

(1) Always use the lifting bolt holes provided on the housing of your SANDEX unit. Do not lift

the unit using the input or output shafts as this can affect the precision of the equipment, or

worse, affect the life of the machine.

(2) Each SANDEX unit has oil fill, drain and sight gauge ports. The unit should be mounted for

easy maintenance access to these ports.

(3) To ensure that your SANDEX unit is mounted accurately in the best possible position, make

sure the housing, shaft dimensions, and mounting holes comply with drawing specifications.

Also check the mounting area for perpendicularity and flatness. If the mounting surface has

any scratches, burrs, debris, or paint, use an oilstone or emery paper to remove it. Next,

clean the mounting surface and apply a light coat of grease or mineral oil to prevent rust

and scratches. You may now mount your SANDEX unit. Never install the unit in a position

not specified for your particular product.

(4) Align your peripheral equipment with the input and output shafts on the SANDEX unit to

ensure the best possible mounting position.

Apply Loctite 242 or equivalent screw locking solution to the mounting bolts, and tighten to

the specified torque with a torque wrench. (Tightening torque: DIN 8.8)

(5) The foundation for your SANDEX unit must be rigid enough to withstand vibrations from

other machines. The foundation is crucial to the precision and life of your SANDEX unit.

To ensure maximum performance mounts your SANDEX unit on a foundation that is

smooth, flat, hard, and free from vibration.

The standard operating temperature range for SANDEX units is between 0 to 40 degrees

Celsius (32 to 104°F). For usage outside of this range, follow the tips below.

4.2 Driver

The SGDH servo amplifiers are base-mounted. Incorrect installation will cause

problems. Follow the installation instructions below.

4.2.1 Storage Conditions

Store the servo amplifier within the following temperature range, as long as it is

stored with the power cable disconnected. -20 to 85°C (-4 to 185°F)

1010

Loading...

Loading...