SaniServ A7081HEP Operation Manual

SaniServ

An AFFINIS GROUP Company

“Reliability from the team that Serves the Best”

®

Pressurized Frozen Beverage Dispenser

Model A7081HEP

Operation Manual

SaniServ P.O. Box 1089 Mooresville, Indiana 46158

Distributor Name: _____________________________ __________________________

Address: ___________________________________________ ___________________

Phone: ________________________________________________________________

Date of Installation: ________________________________ _____________________

Model Number: _________________________________________________________

Serial Number: _________________________________________________________

Installer/Service Technician: _____________________________________________

SERVICE: Always contact your SaniServ dealer or distributor for service questions or service

agency referral. If your SaniServ dealer or distributor cannot satisfy your service requirements,

he is authorized to contact the factory for resolution.

Note: It is the Owner’s responsibility to maintain the Service Record located on the inside rear

cover of this manual. An accurate record of service performed can greatly expedite

troubleshooting of problems and significantly reduce repair costs.

PARTS: Always order parts from your SaniServ dealer or distributor. When ordering

replacement parts, specify the part numbers, give the description of the part, the model number

and the serial number of the machine.

WARRANTY: Remove the Check Test Start (CTS) form and fill it out in its entirety. Return the

original (white) copy to SaniServ. The Dealer/Distributor retains the second (yellow) copy and

theOwner/Operator retains the third (pink) copy.

The Manufacturer's Limited Warranty is printed on the reverse side of the Owner/Operator copy.

IMPORTANT

TO VALIDATE THE WARRANTY, THE CTS FORM MUST BE COMPLETED AND RETURNED

TO THE FACTORY WITHIN 30 DAYS OF INSTALLATION.

Note: The Check Test Start function must be performed by a qualified technician.

WARRANTY INFORMATION

Introduction

This manual provides a description of the SaniServ Pressurized Frozen Beverage Dispenser. It has been prepared to

assist in the training of personnel on the proper installation, operation, and maintenance of the machin es.

Read and fully understand the instructions in this manual before attempting to install, operate, or perform routine

maintenance on the machines.

Initially, the following sections of the manual must be performed in sequence:

1. Installation 4. Operation

2. Installer's Preoperational Check 5. Disassembly & Cleaning

3. Initial Start-up Preparation 6. Assembly & Lubrication

Installation

1. Install the legs using the instructions on the shipping

carton.

2. Place the machine in the desired location and level

the unit by turning the bottom part of each leg clockwise

or counterclockwise (Fig. 2). The machine MUST be

level to operate properly.

THESE UNITS MUST NOT BE OPERATED WITHOUT

WARNING

THE LEGS INSTALLED UNLESS THE MACHINE IS

SUPPLIED WITH A COUNTERTOP MOUNTING PAD

OR SEALED TO THE COUNTERTOP.

Minimum Clearance

3.

A minimum 6” (152 mm) clearance

must be maintained at

the rear and sides of the machine

for adequate ventilation.

4”(102 mm) for

Counter Top Models

Fig. 2

Leg Installation

IMPORTANT

4. Electrical and refrigeration specifications are located

on the data plate on the rear panel of the machine.

Consult local authorities for information regarding

plumbing and electrical codes in your area.

Insure that the unit is in the off position and plug it into a

115 volt, 15 amp or 20 amp receptacle.

Note: All SaniServ machines should have their own

dedicated circuits to prevent low voltage conditions

caused by other operating equipment.

WARNING

FAILURE TO PROVIDE FOR PROPER EARTH

GROUND ACCORDING TO LOCAL ELECTRICAL

CODES COULD RESULT IN SERIOUS ELECTRICAL

SHOCK OR DEATH. DO NOT USE EXTENSION

CORDS. INSTALL THE PROPER SIZE WIRE FOR

THE REQUIRED MACHINE AMPS. BE CERTAIN TO

OBSERVE LOCAL CODES IN SELECTING WIRE OR

CORD SIZE AND TYPE.

DO NOT TURN MACHINE ON UNTIL THE

INSTALLER’S PRE-OPERATIONAL CHECK

SECTION IS COMPLETE.

PAGE 1

INTRODUCTION and INSTALLATION

Installer’s Preoperational Check

THE FOLLOWING ITEMS MUST BE PERFORMED BEFORE ATTEMPTING TO OPERATE THE EQUIPMENT:

WARNING! HAZARDOUS MOVING PARTS. DO

NOT WEAR LOOSE FITTING CLOTHING. KEEP

HANDS, HAIR, AND CLOTHING AWAY FROM

MOVING INTERNAL PARTS.

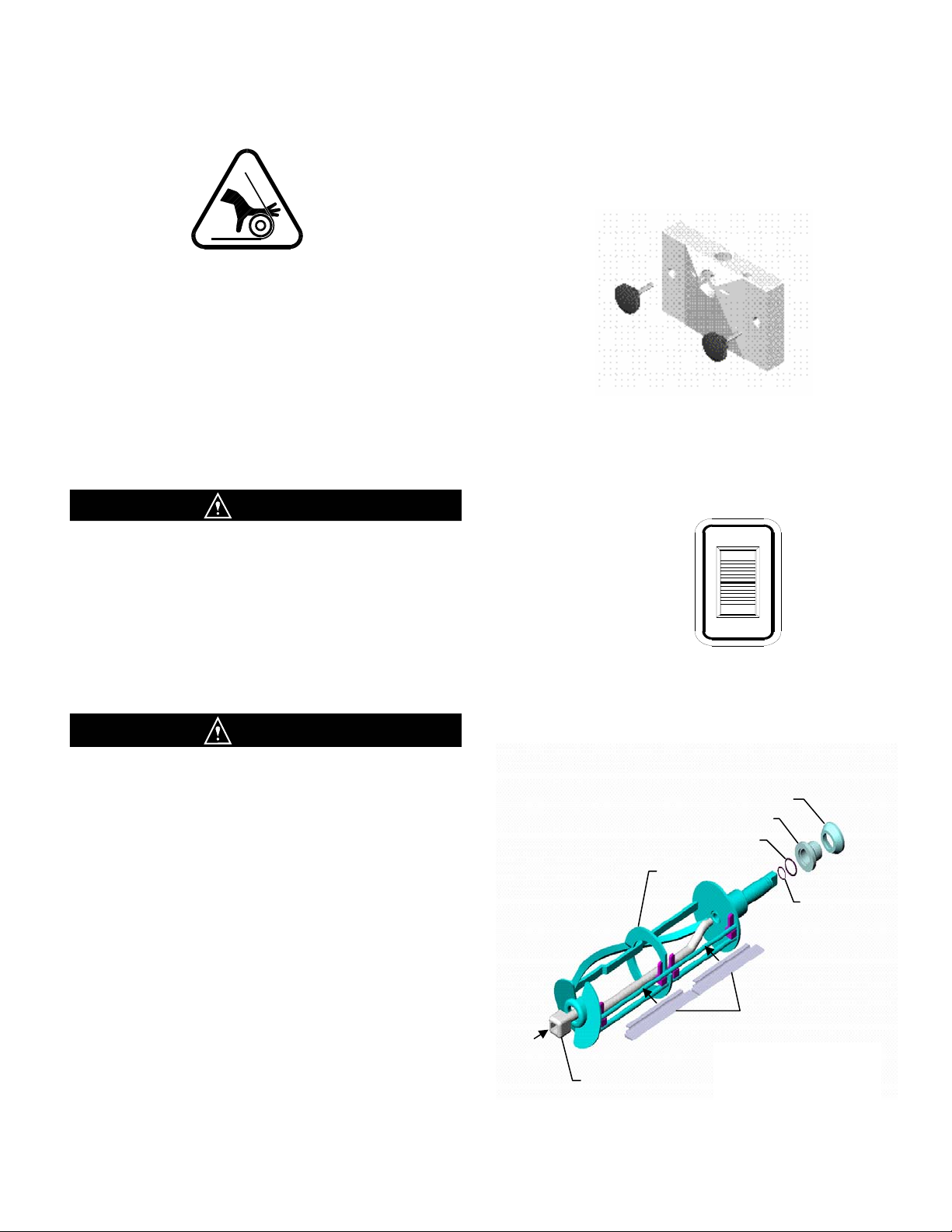

1. Remove the front plate (Fig. 1) by turning the black

plastic knobs in a counterclockwise direction.

After removing the knobs, pull the front plate off the

studs. Then grasp the front of the dasher assembly

(Fig.3) and remove it from the dispenser by pulling

it out slowly and straight so the scraper blades are

not damaged.

WARNING

Fig. 1

Front Plate

BEFORE PROCEEDING TO STEP 2, BE CERTAIN

THAT THE DASHER HAS BEEN REMOVED

2. Set the Auto/Clean switch (Fig. 2) to th e “AUTO”

position. Doing so allows the compressor and

dasher motor to start. Check to see that the

refrigeration system is operating by feeling the

inside of the freezing cylinder. It should turn cold

CAUTION

UNDER NO CIRCUMSTANCES SHOULD THE UNIT

BE OPERATED IN THE “AUTO” POSITION FOR

MORE THAN THREE MINUTES WITH EMPTY

FREEZING CYLINDERS . DOING SO WILL RESULT

IN DAMAGE TO THE MACHINE

within one minute.

3. Set the Auto/Clean switch to the “OFF” position.

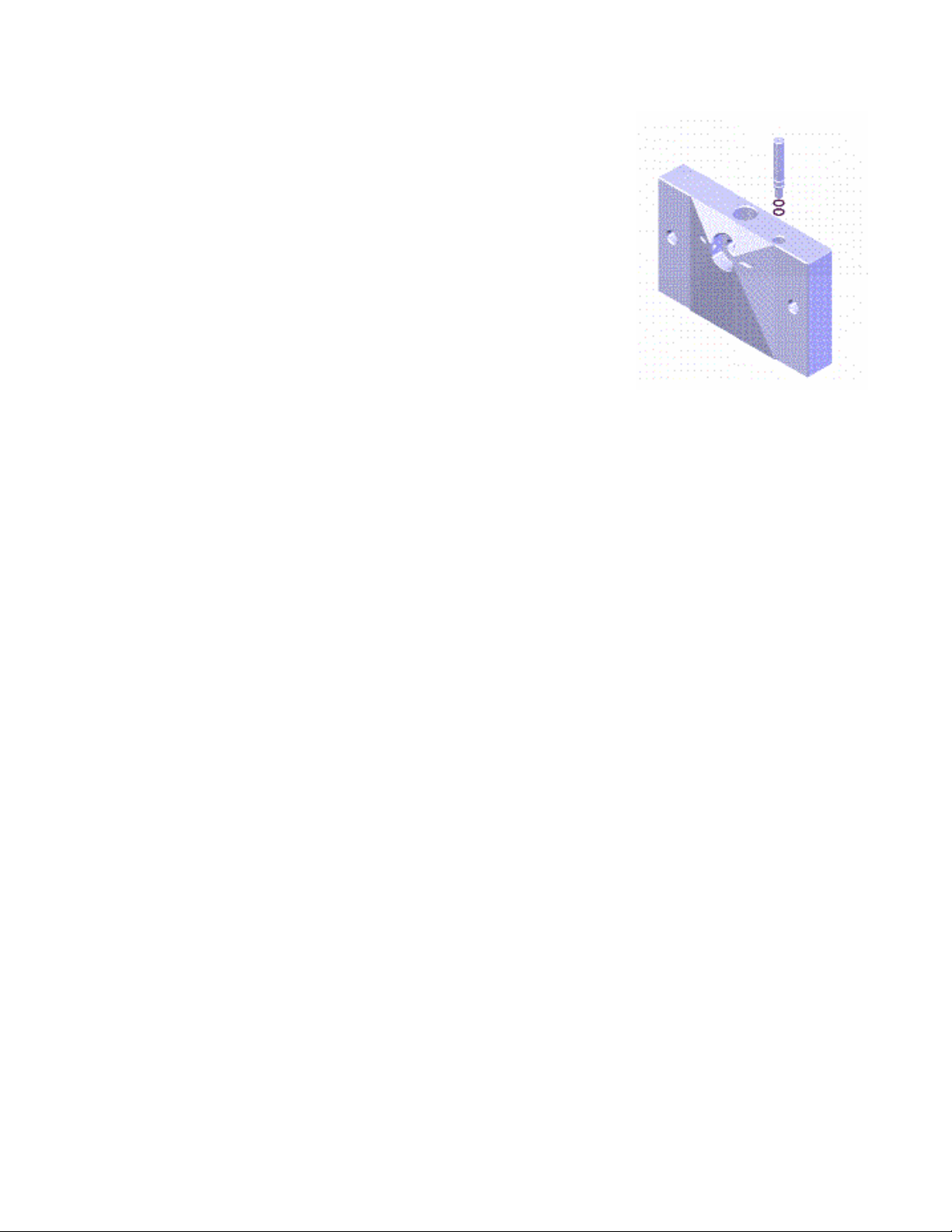

4. Install the Dasher Assembly (Fig. 3) inserting it in

the freezing cylinder and pushing toward the rear of

the cylinder while rotating the assembly until it seats

into the drive at the rear of the cylinder.

5. Install Front Plate Assembly and secure with the

black knobs (Fig. 1).

Rear Bearing O-Ring

Stator Rod

AUTO

OF

F

CLEANOUT

OF

F

Fig. 2

Auto/Clean Switch

Rear Seal

Rear Bearing

Dasher

Scraper

Fig. 3

Dasher Assembly

Dasher O-Ring

INSTALLERS PREOPERATIONAL CHECK

PAGE 2

1. Connect the regulator to an approved CO2 cylinder and

connect to the CO2 port on the "smart coupler".

2. Turn the "smart coupler" to the "OFF" position.

3. Set the CO2 regulator to 12-13 psig.

4. Prepare a 5 gallon container of brewery approved beer line

cleaning solution and connect to the "smart coupler".

5. Turn the coupler lever to the "CLEAN" position.

6. Fill the freezing cylinder until the amber light goes out.

7. Lift up on the Pressure Relief Plug (Fig. 4) to vent air from

the freezing cylinder. When solution discharges from the

bottom of the Pressure Relief Plug, close by pushing

downward on the plug.

8. When the amber light goes out again, turn the "Auto/

Cleanout" switch to the "CLEAN" position and allow the

machine to run for approximately 3 minutes.

9. Turn the machine to "OFF" and drain cleaning solution by

opening spigot and Pressure Relief Plug. Close plunger

and plug when machine is drained.

10. Repeat steps 4 through 9 using fresh potable water and

drain.

Initial Startup Preparation

Operation

Fig. 4

Pressure Relief Plug

1. With machine in "OFF" position, connect keg of product and fill cylinder until amber light goes off.

2. Allow any foam to settle and vent barrel by lifting up on the pressure relief plug. Close Pressure Relief Plug.

3. Turn "Auto/Cleanout" to the "AUTO" position.

4. When the machine cycles off, draw a sample of product and check for proper consistency. Repeat this step two

times.

5. If the product is too soft or two stiff, refer to the section on consistency adjustment.

Disassembly and Cleaning

CONSULT YOUR LOCAL HEALTH AGENCY FOR LOCAL CLEANING AND SANITIZING REQUIREMENTS.

This unit does not come pre-sanitized from the factory. Before serving product, the dispenser must be disassembled,

cleaned, lubricated, and sanitized. Please be aware that these instructions are general guidelines. Cleaning and sanitizing

procedures must conform to local Health Authority requirements.

Emptying Machine

Prior to the disassembly and cleaning of parts, the machine must be emptied of product. Use the following

Procedures. If this is first time operation, disregard these steps.

1. Set the Auto/Clean switch to the “CLEANOUT” position and dispense all product from the freezing cylinder by

pulling downward on the spigot handle to empty the machine.

2. Set the Auto/Clean switch to the “OFF” (center) position. Close the spigot handle before proceeding to cleaning.

DO NOT INSERT ANY OBJECTS OR TOOLS FRONT PLATE DISPENSING HOLE WHILE THE MACHINE IS

RUNNING. DAMAGE TO THE MACHINE OR PERSONAL INJURY MAY RESULT

PAGE 3

DISASSEMBLY and CLEANING

Loading...

Loading...