Sani-Lav 531FA User Manual

HANDS-FREE FLOOR MOUNTED SCRUB SINKS

AC OR BATTERY POWERED

Operating Manual for Hands-Free Floor Mounted Scrub Sinks

AC Models 531FA, 531FA-1.0 and 531FA-0.5

Battery Models 531FB, 531FB-1.0 and 531FB-0.5

1

Columbia does not recommend use with harsh chemicals.

NSF/ANSI Standard 2 - Food Equipment and NSF/ANSI 372 low-lead.

COLUMBIA SPECIFICATIONS

HANDS-FREE FLOOR MOUNTED SCRUB SINKS

AC OR BATTERY POWERED

2

Parts List

(1) Floor mount sink

(1) Leg assembly set

(4) Washers and nuts for connection sink to leg assembly set

(1) AC or Battery powered sensor faucet assembly

(1) Mixing check valve

(1) Strainer assembly with basket

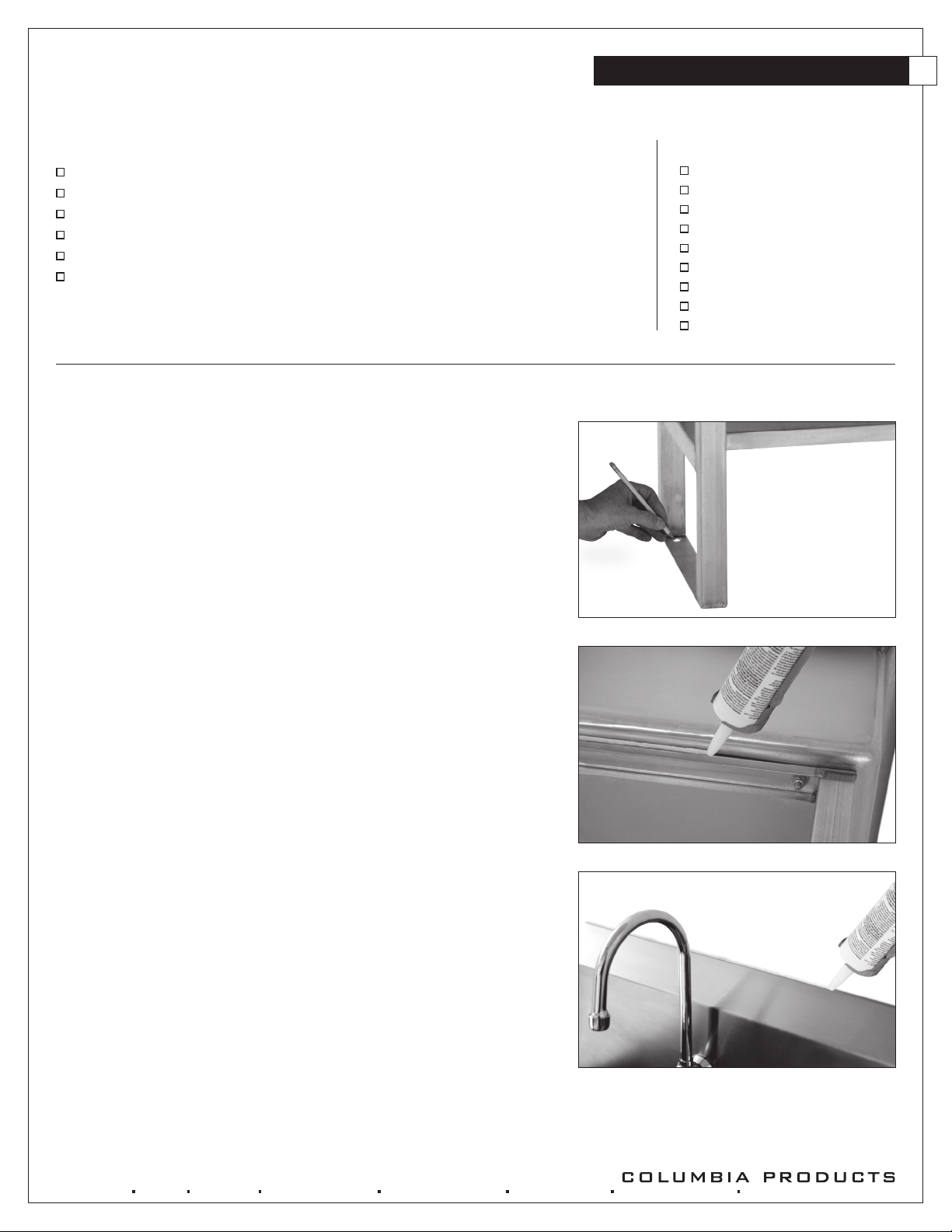

Installation Instructions

Step 1

1. Attach upper and lower leg support brackets to legs with hardware (provided).

2. Place wash station sink on leg assembly and secure with hardware (provided).

3. Establish sink location.

4. Mark the floor where the four holes are at the base as shown in illustration A.

5. Drill holes as required for mounting hardware. (Hardware not included).

Step 2

1. Install strainer assembly.

2. Install faucets to the sink following the instructions provided with sensor unit.

3. Attach supply tube with elbow to back of faucet.

4. Install mixing check valve and compression fitting to control box of each sensor faucet.

Step 3

1. Secure wash station to floor.

2. Connect waste line to strainer assembly (s).

3. Mount sensor control boxes at desired location on wall.

4. Connect power line from sensor to control box.

5. Attach supply tube from faucet to control box.

6. Connect hot and cold water from the source to mixing check valve (s).

7. Remove aerator from the spout assemblies and flush water system. (see step 7 sensor

installation instructions)

8. Check connections for leaks.

9. Replace aerator onto the spout (s).

Step 4

1. Seal gap between bowl and leg assembly as shown in illustration B.

2. We recommend sealing top of backsplash to wall if applicable as shown in illustration C.

Tools Required

Tape Measure

Adjustable Wrench

Drill Motor and Drill Bits

Pipe Wrench

Level

Safety Glasses

Screw Drivers: 1 Phillips & 1 Standard

Pencil

Socket Wrench

Illustration A

Illustration B

Illustration C

1622 Browning Irvine, CA 92606-4809 Phone: 949.474.0777 Toll Free: 800.626.2117 Fax: 949.474.1191 www.columbiasinks.com email: info@columbiasinks.com

©2016 Columbia Products

COLUMBIA SPECIFICATIONS

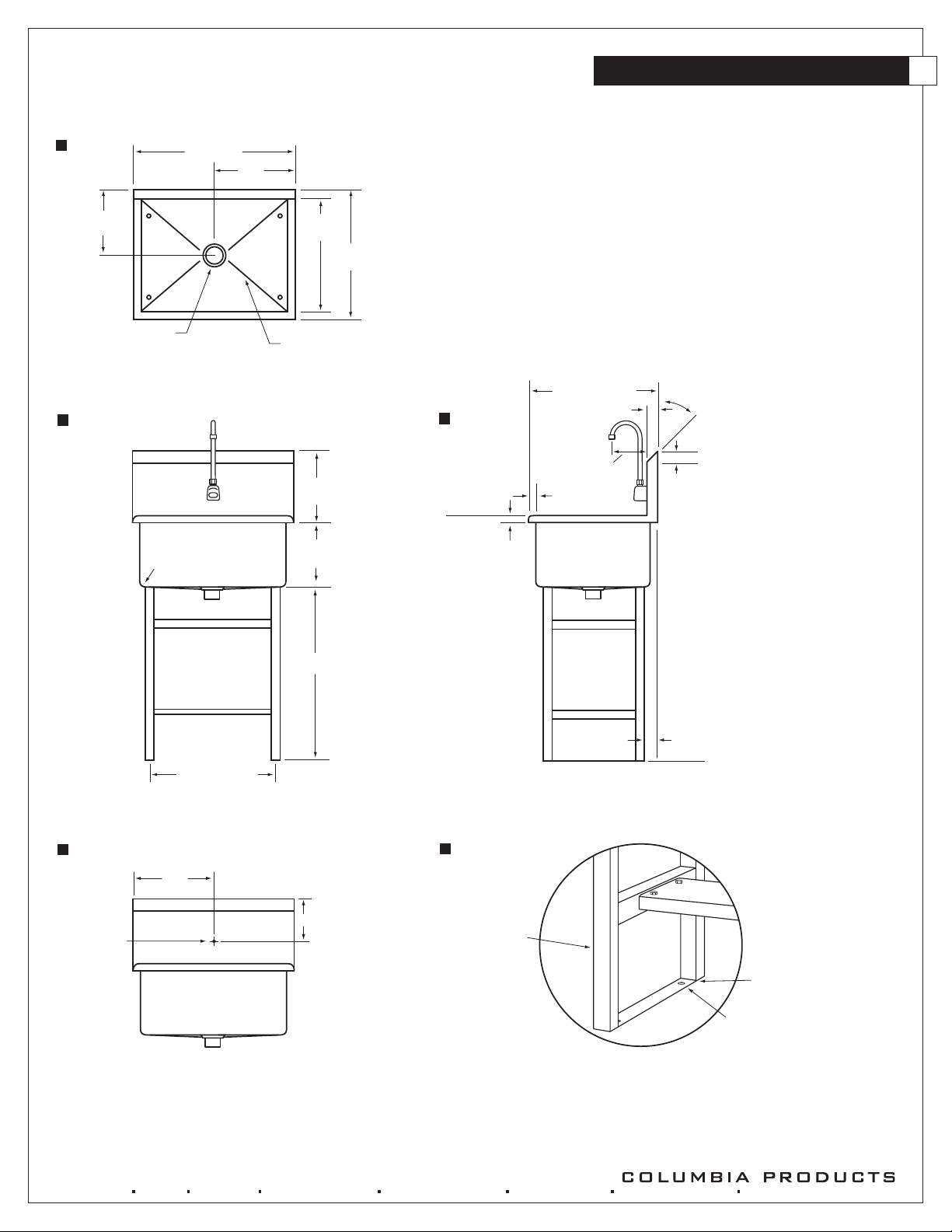

Top

Top

25”(63mm)

12.5”

(137.5mm)

HANDS-FREE FLOOR MOUNTED SCRUB SINKS

AC OR BATTERY POWERED

3

9.75”

(247.65mm)

3.25” drain hole

Front

.25” R

6mm

16”

(406.4mm)

19.5”

(495.3mm)

Cross-breaks

to aid drainage.

9”

(228.6mm)

10.5”

(266.7mm)

27” (686mm)

Side

1.5” (38mm)

19.5” (495.3mm)

2” (51mm)

7.5” (191mm)

45º

.75” (20mm)

Hole Configurations

12.5”

(317.5mm)

.875” (22mm)

dia. holes (1)

22”(558.8mm)

4.5” (114.3mm)

2.875” (73.02mm)

Leg Specifics

1.5” (38mm)

leg thickness

.75” (19mm)

from edge of leg

to first hole

10.5” (267mm)

.5” dia. floor

mounting holes

1622 Browning Irvine, CA 92606-4809 Phone: 949.474.0777 Toll Free: 800.626.2117 Fax: 949.474.1191 www.columbiasinks.com email: info@columbiasinks.com

©2016 Columbia Products

HYDROTEK INTERNATIONAL, INC.

5055 Forsyth Commerce Rd., Ste. 124, Orlando, FL 32807

Phone (800)922

-

9883 / Fax (

866)670

-

5580

www.hydrotekintl.com

OPERATION & MAINTENANCE MANUAL

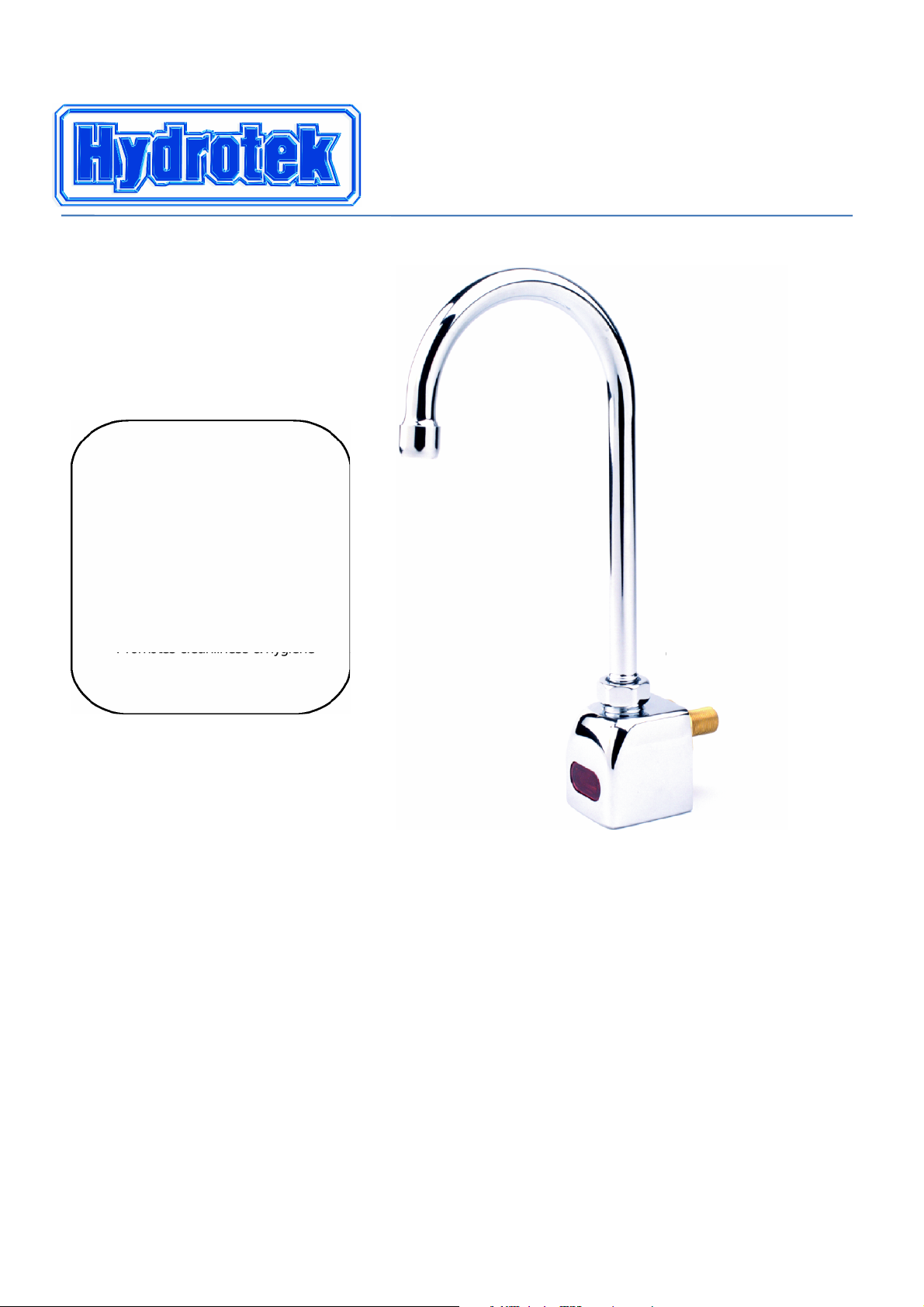

HYDROTEK MODEL #H

-

6700C FAUCET

TECHNICAL SUPPORTTEAM:

Michael

Hu

& Armin

Kharazi

Phone (800) 922

-

9883 ext. 105

Email: mike@hydrotekintl.com or armin@hydrotekintl.com

Solid Brass

AC or

Battery Powered

Automatic Faucet

6700C Series

ISO 9002 Certified

•

ADA Compliant. Meets all barrier

free codes

•

Conserves water and energy

•

Easily installed in new or retrofit

applications

•

Competitively priced for today's

commercial market

High Technology For

No Touch Operation

Features:

•

Promotes cleanliness & hygiene

•

Proven Hydrotek craftsmanship

and reliability

6700C Series

U.S. Patent: 6192530B1

•

ACCU

-

SENSE

adjustable sensor eyes.

•

Chrome plated, solid brass construction.

•

Wall mountable, waterproof control box

with armored, vandal resistant control and

power cables.

•

Preset/adjustable sensor range 6"

-

30" for

various installation requirements.

•

Standard automatic time

-

out feature. Preset

at 0 but adjustable to 15, 30 or 60 seconds.

Prevents accidental sink overflow.

•

Shut

-

off delay is adjustable from 1 second

(preset) to 8 seconds.

•

Includes in

-

line filters with clean

-

out trap to

reduce maintenance costs.

•

Standard 6" gooseneck spout and 2.0 GPM

laminar flow control.

•

Single

-

hole, wall/splash mounting.

•

All parts are field replaceable to ensure quick

and easy repair.

•

Same faucet, field switchable to/from AC

Powered or Battery Powered.

•

Slow closing, piston

-

operated solenoid valve

provides reliable and smooth operation without

water hammer.

•

Superior VSI silicone

elastomer

piston seals

are unaffected by chlorine,

chloromines

or

ammonia.

•

Control module automatically performs a

unique self

-

check of all electrical components.

•

No-touch system enhances hygiene in the

medical, institutional, food service industries,

etc.

Loading...

Loading...